Patents

Literature

131results about How to "Prevent stuck situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

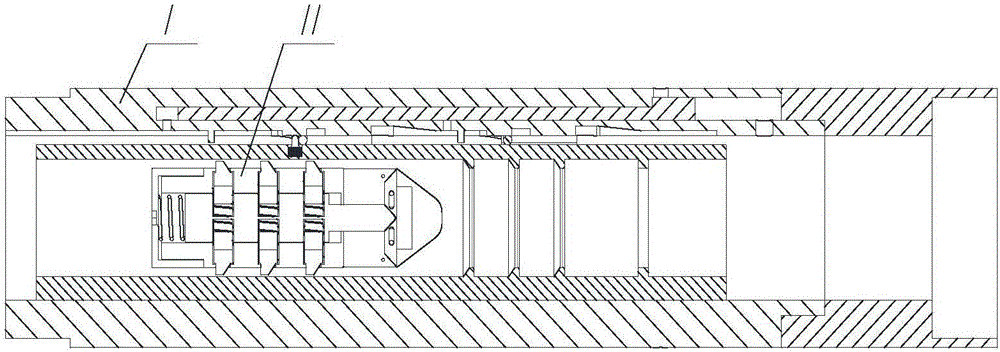

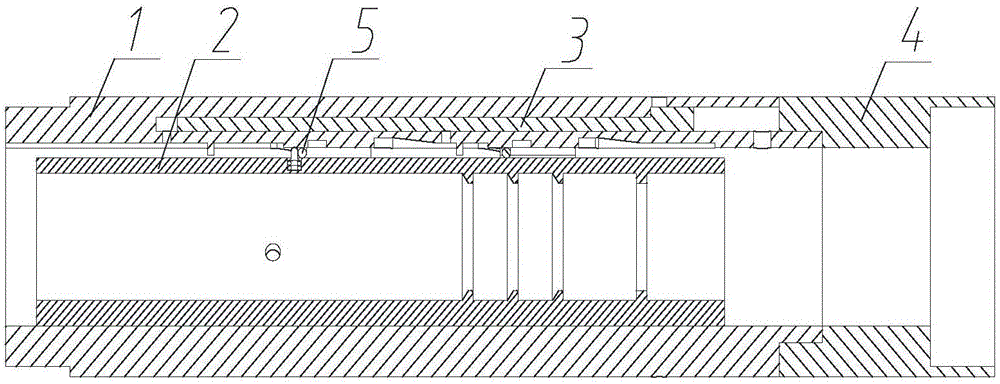

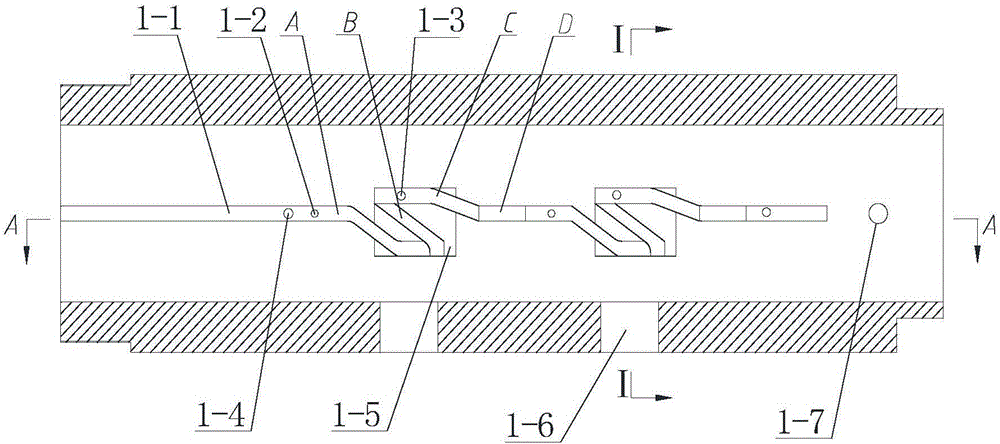

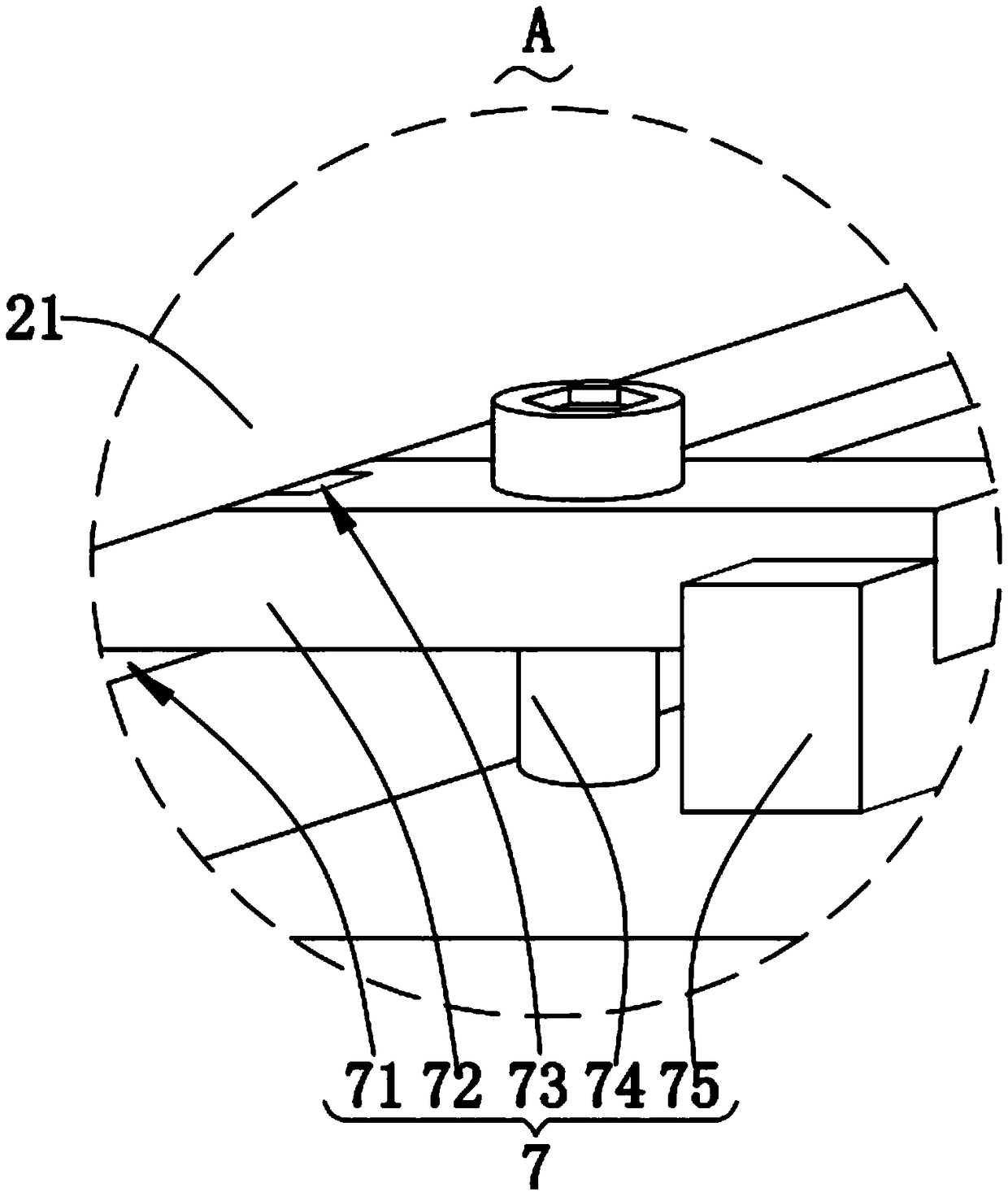

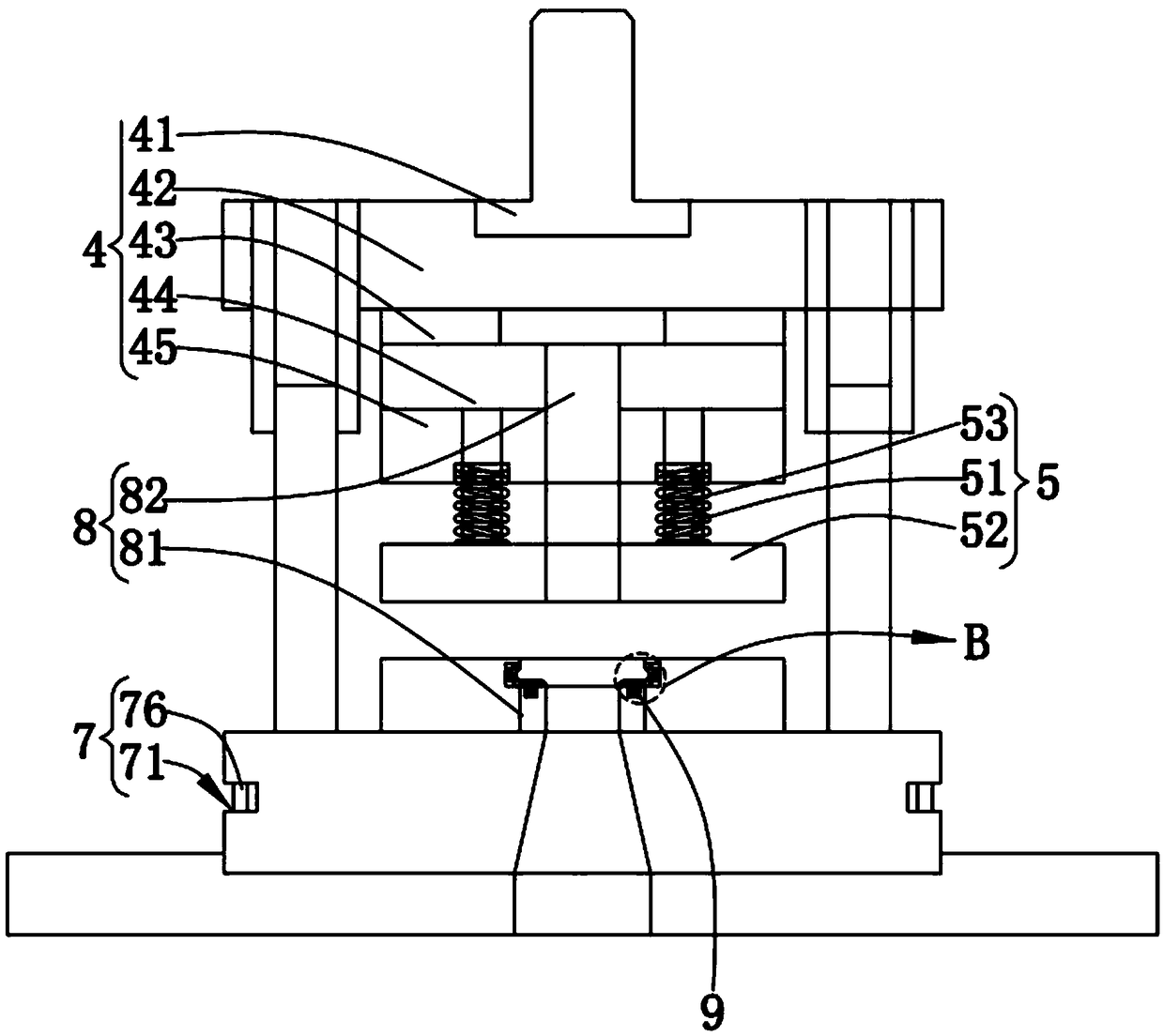

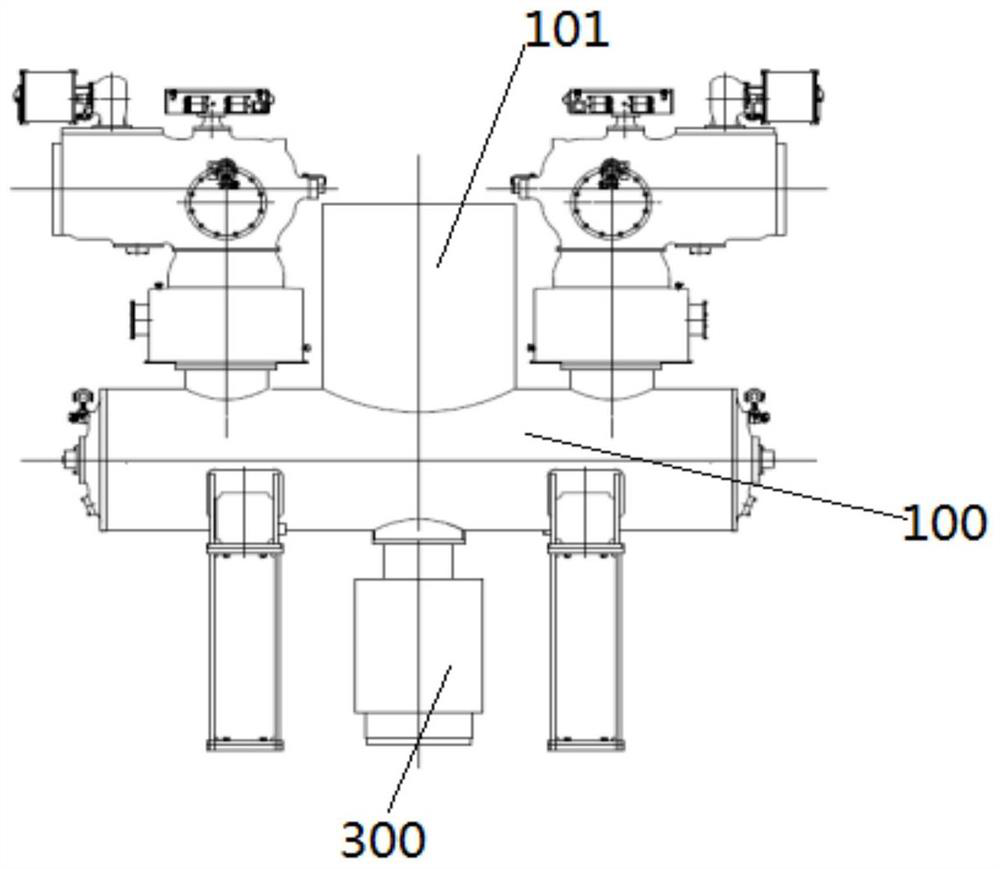

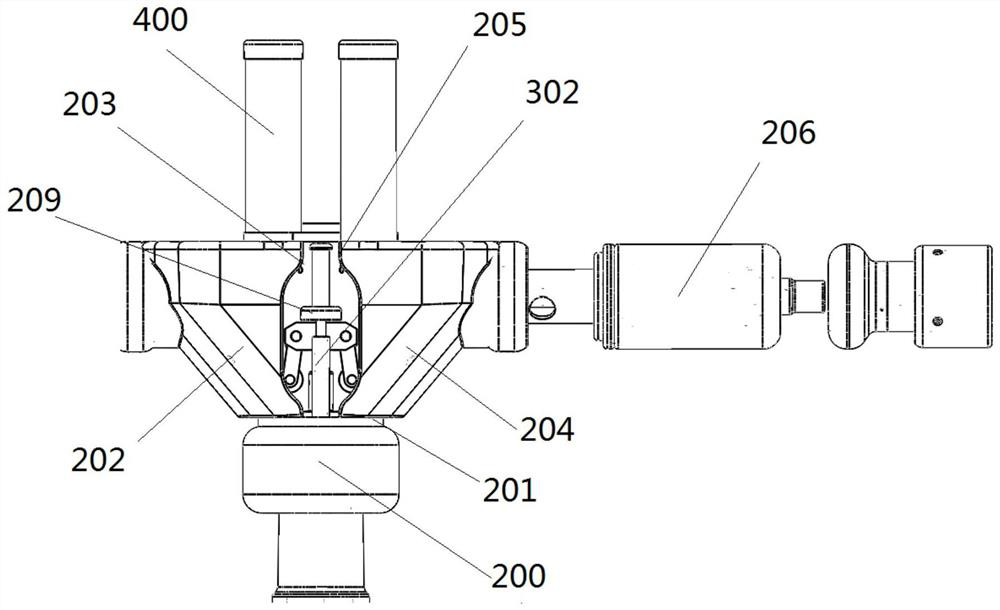

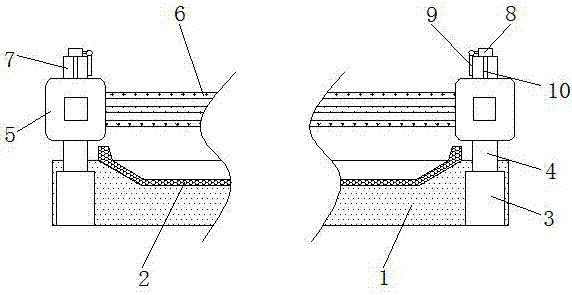

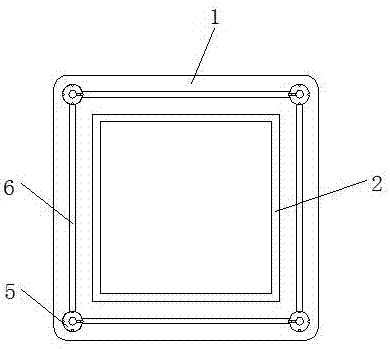

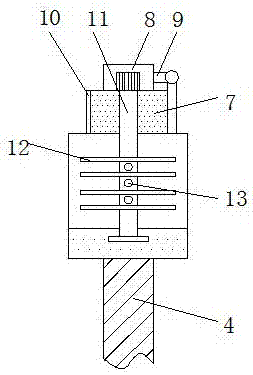

Full-bore multistage-key switch type fracturing slide sleeve

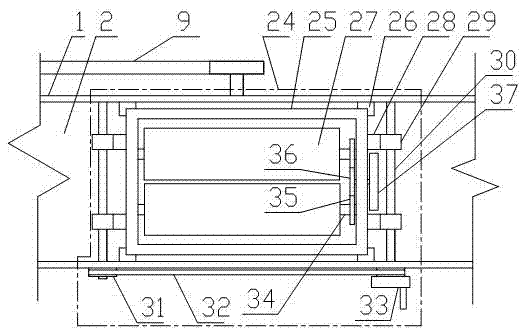

InactiveCN106677755AEasy to open and closeGood recognition effectFluid removalWell/borehole valve arrangementsPistonKey switch

The invention discloses a full-bore multistage-key switch type fracturing slide sleeve. By adoption of the full-bore multistage-key switch type fracturing slide sleeve, the problems that existing slide sleeves are complex in structure and low in working reliability are solved. The full-bore multistage-key switch type fracturing slide sleeve specifically comprises a slide sleeve actuator and a slide sleeve switch mechanism. The slide sleeve actuator comprises a slide sleeve main body, an inner drum, a pressure adjustment piston, a base and a pulling rod. The slide sleeve switch mechanism comprises a throwing block body, a switch body, a clamping block, an outer slide block, an inner slide block, a slide block spring, a switch spring and an upper cap. According to the full-bore multistage-key switch type fracturing slide sleeve, the circumferential rotating angle of the inner drum is small in the opening process of the slide sleeve, the total rotating angle of the inner drum in the circumferential direction is zero degree after the slide sleeve is opened and closed each time, error superposition in the rotating process is avoided, the working reliability is improved, the recognition effect is good, opening and closing of slide sleeves in different stratums can be controlled by different switch mechanisms, multiple times of opening and closing of sleeves in one single stratum can be achieved, and the comprehensive performance of the slide sleeve is good.

Owner:NORTHEAST GASOLINEEUM UNIV

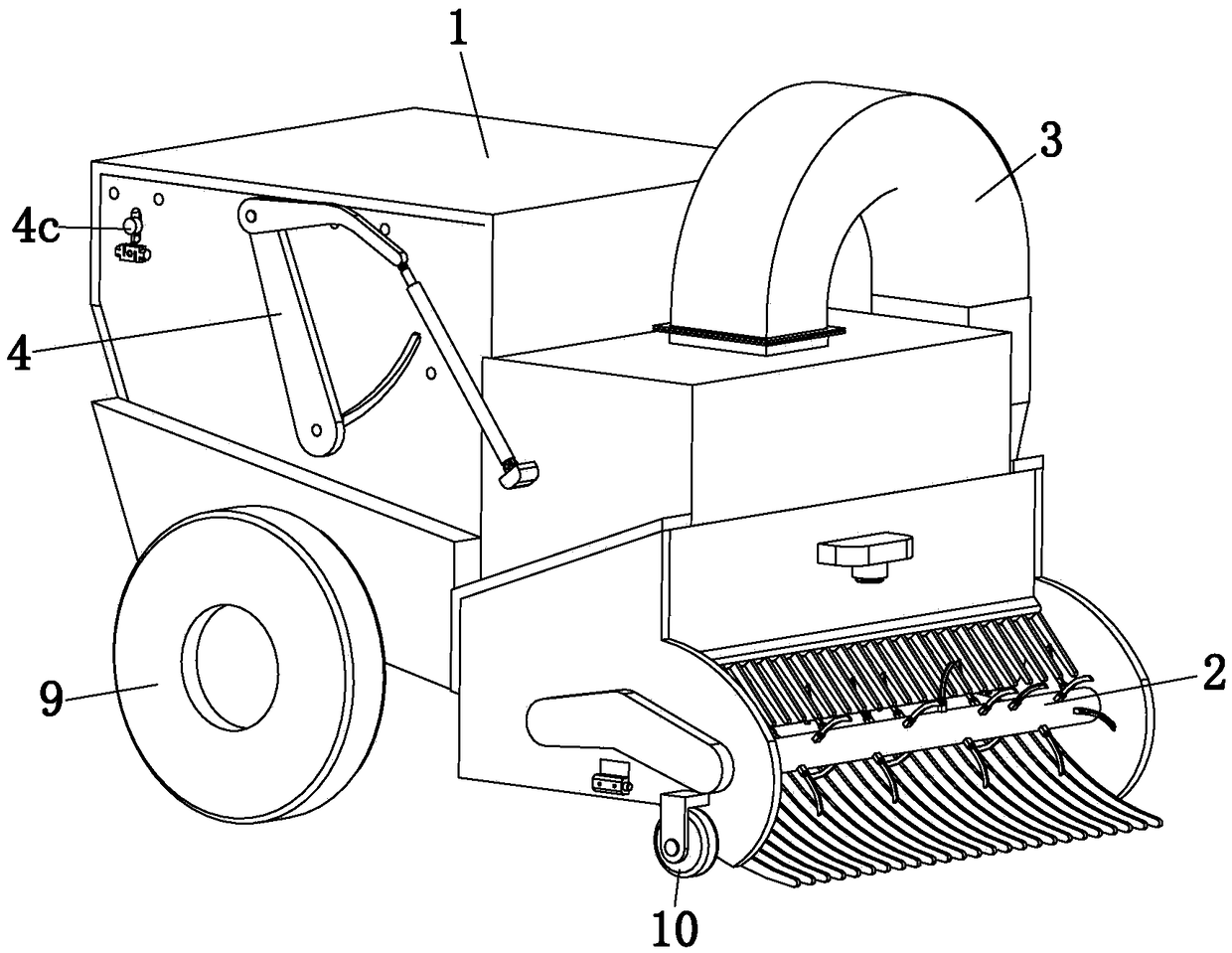

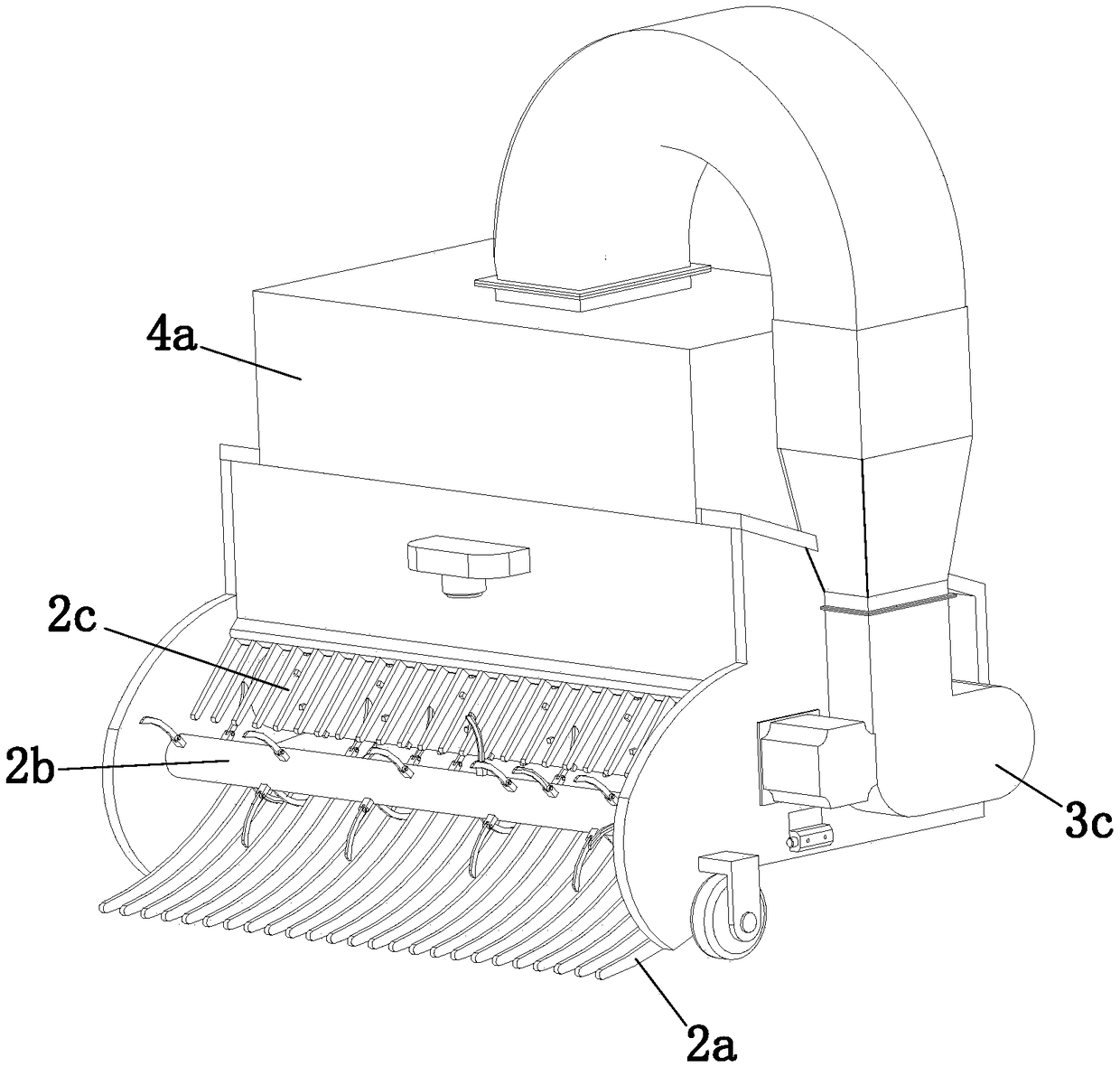

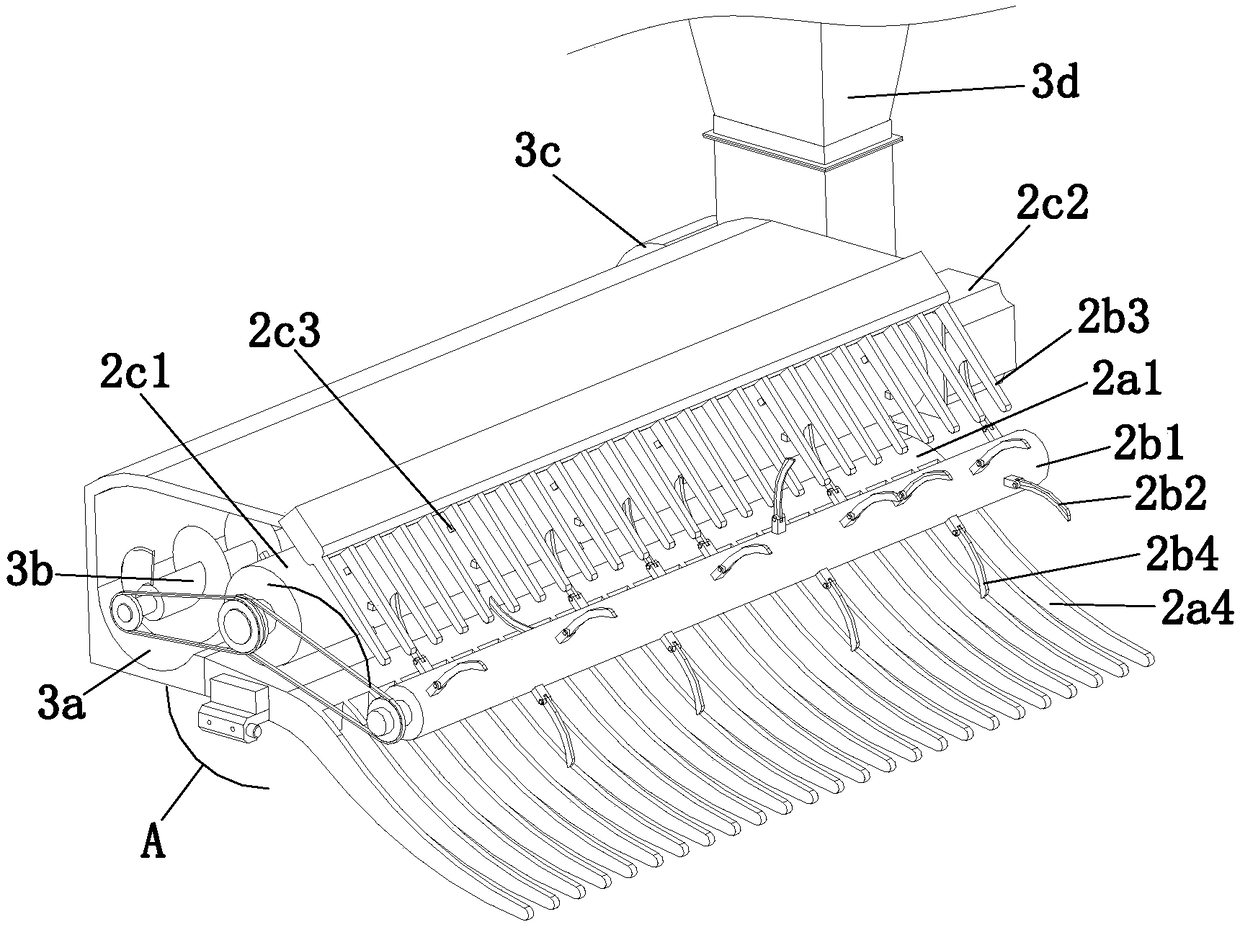

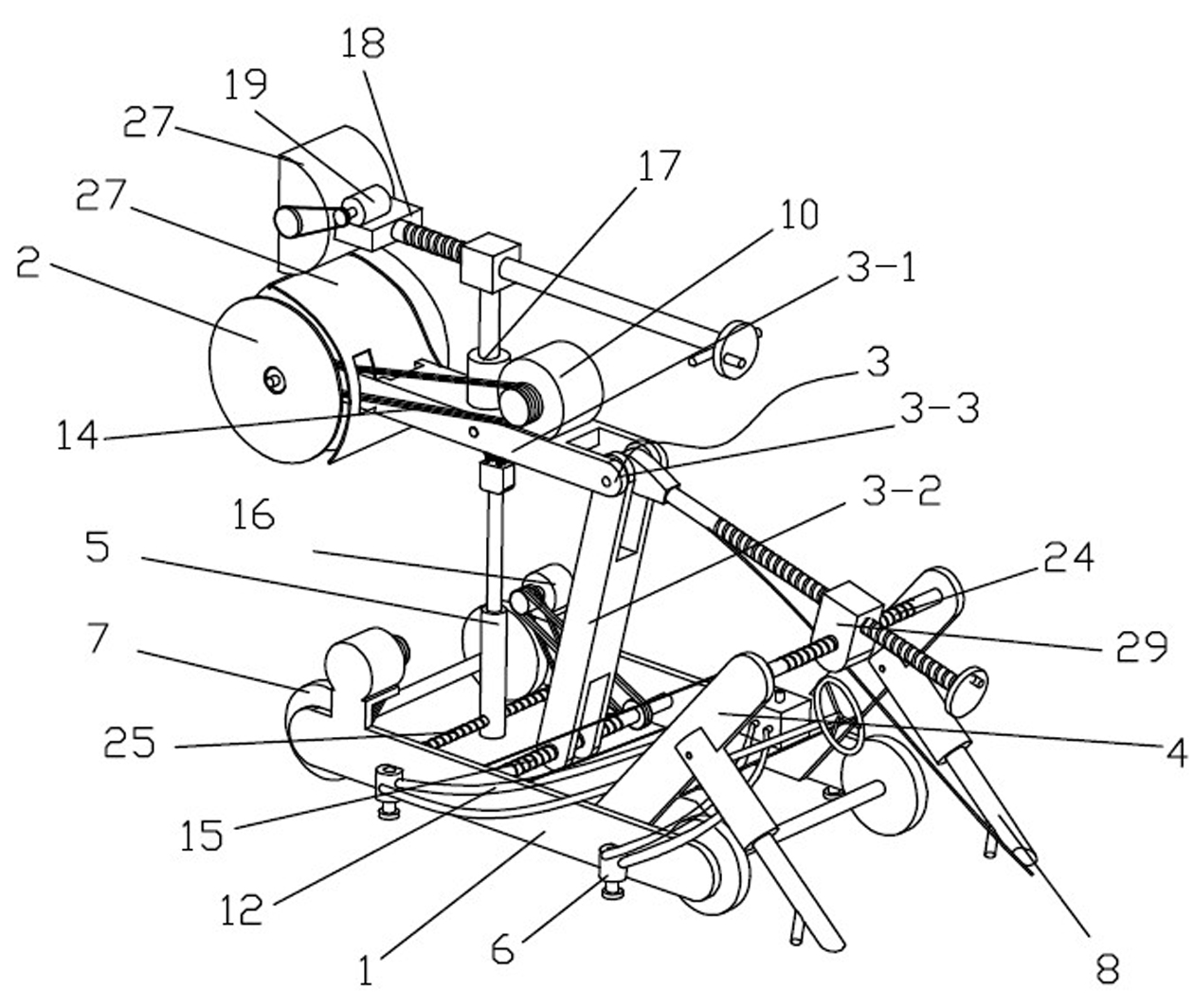

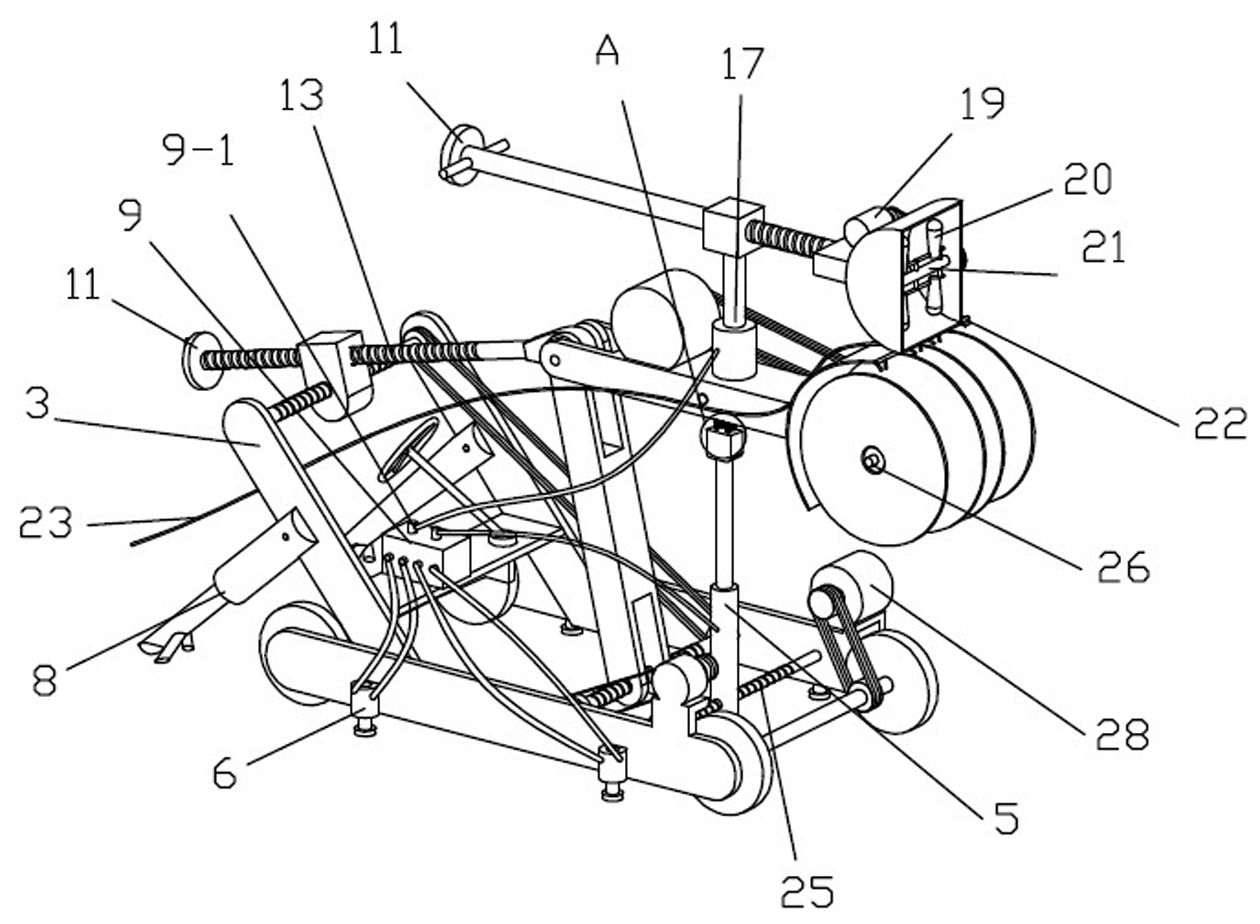

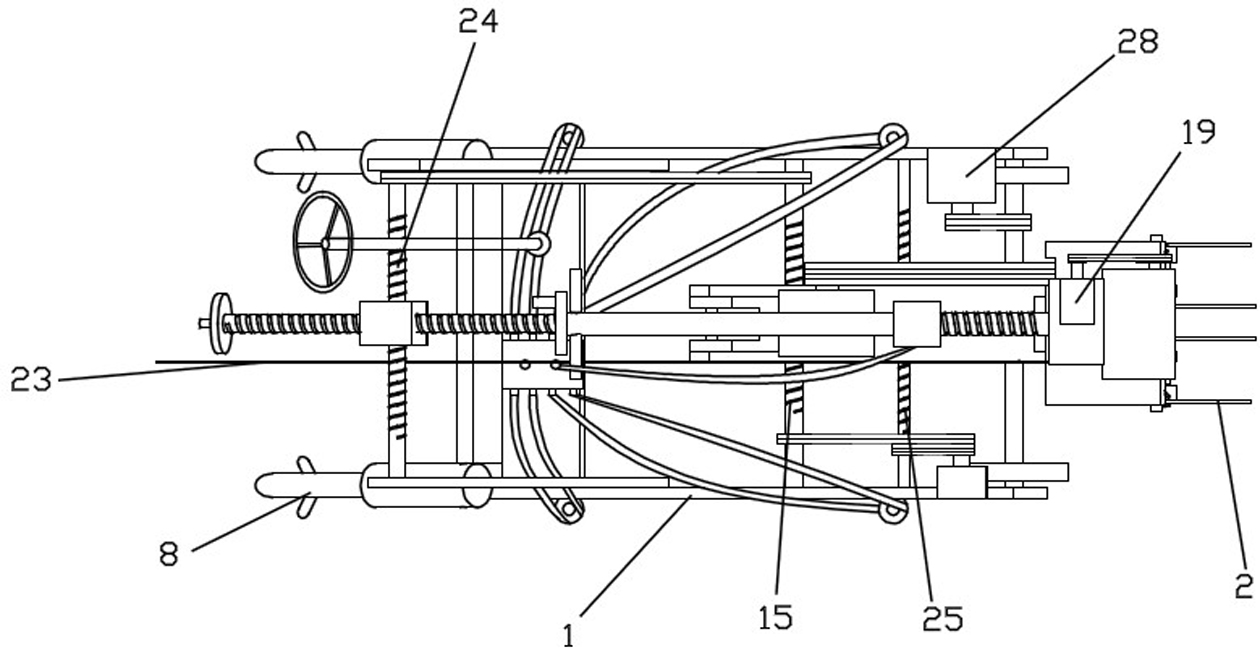

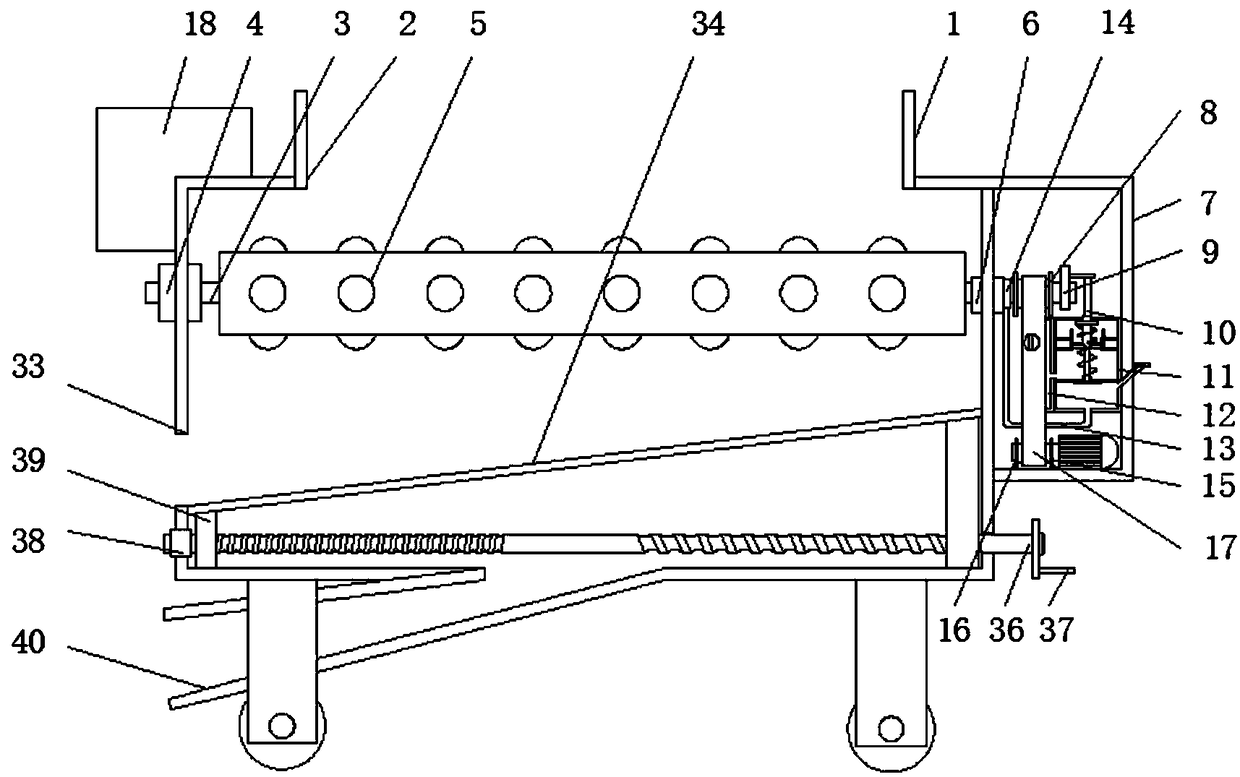

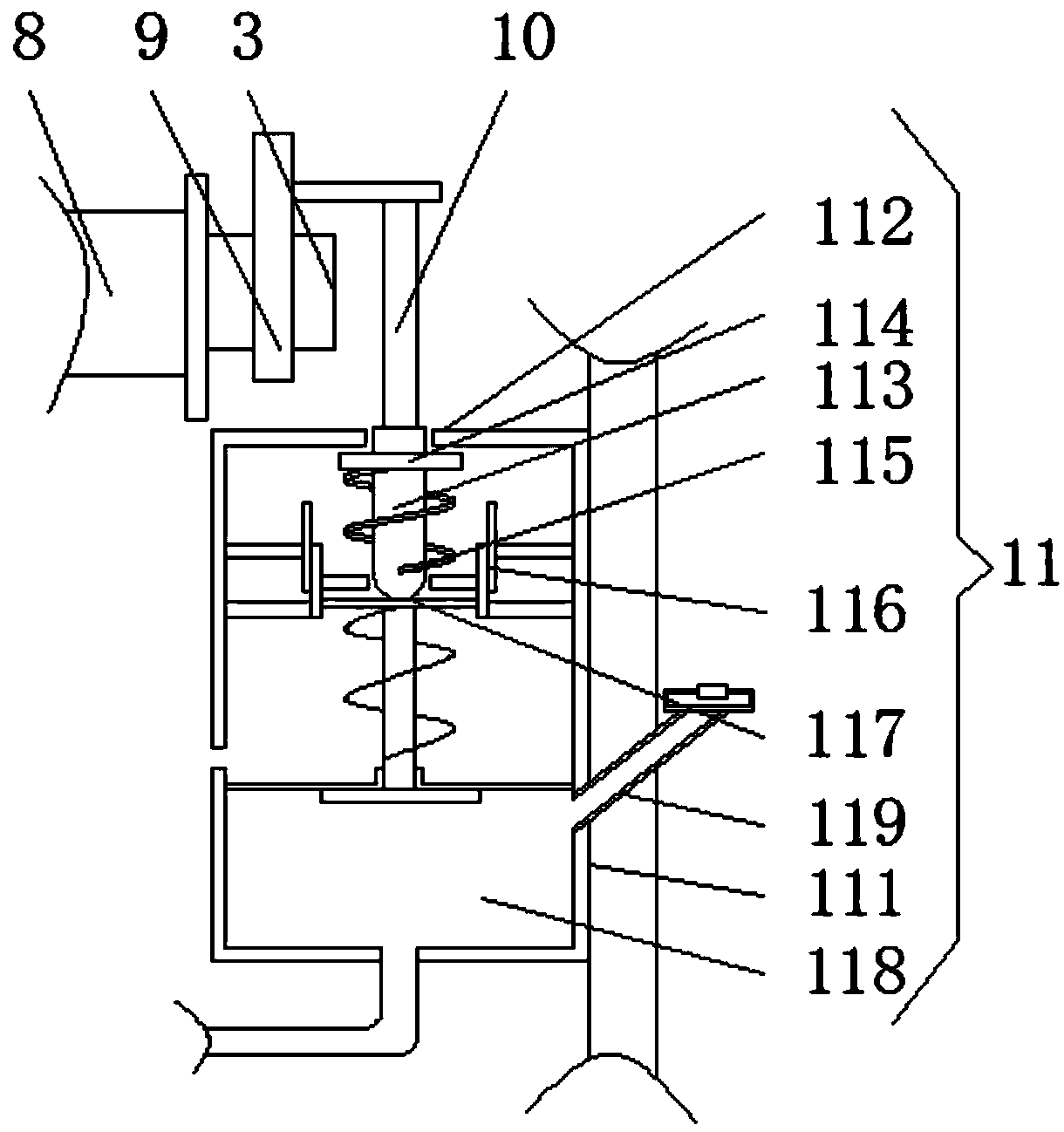

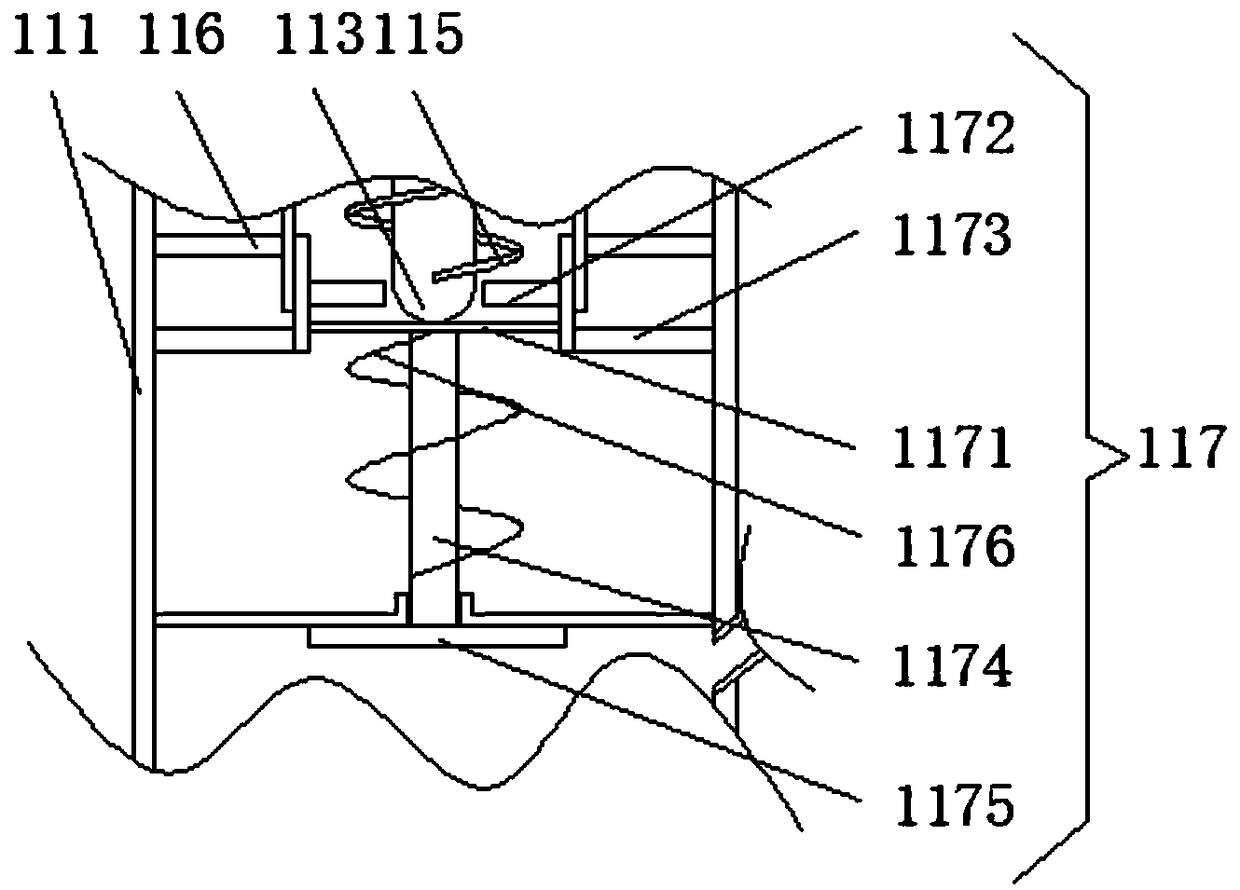

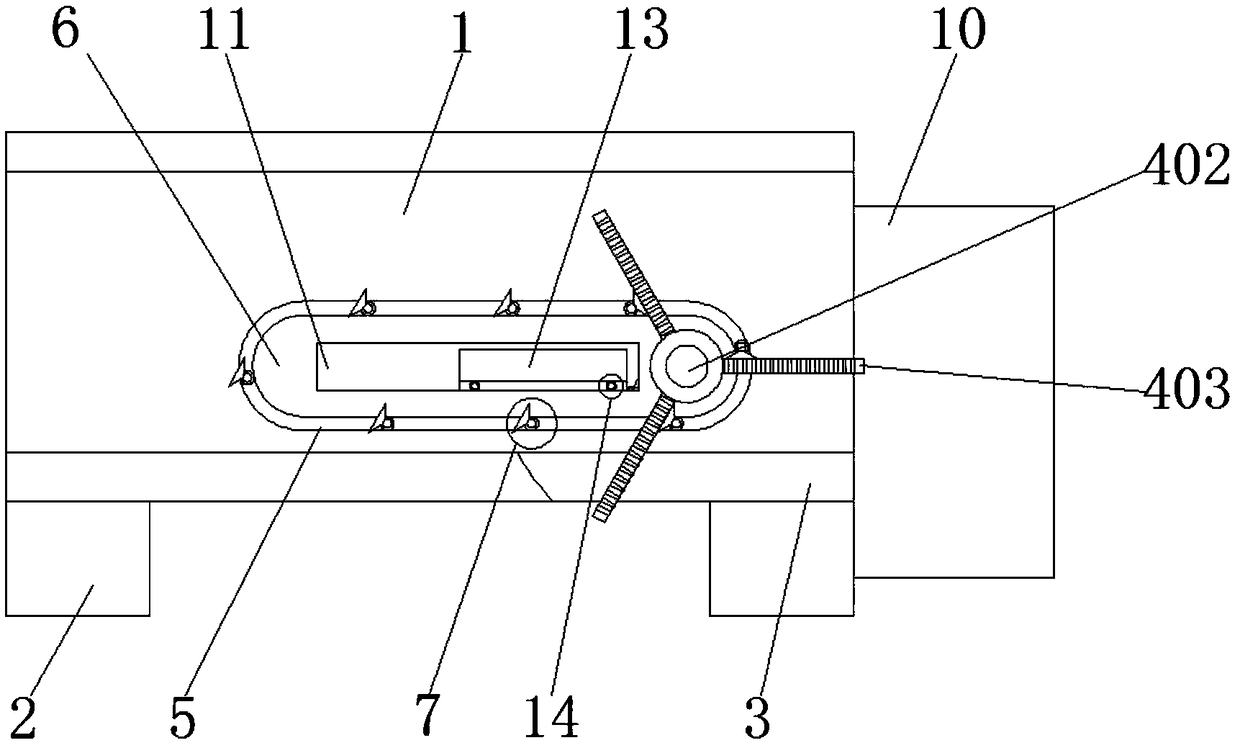

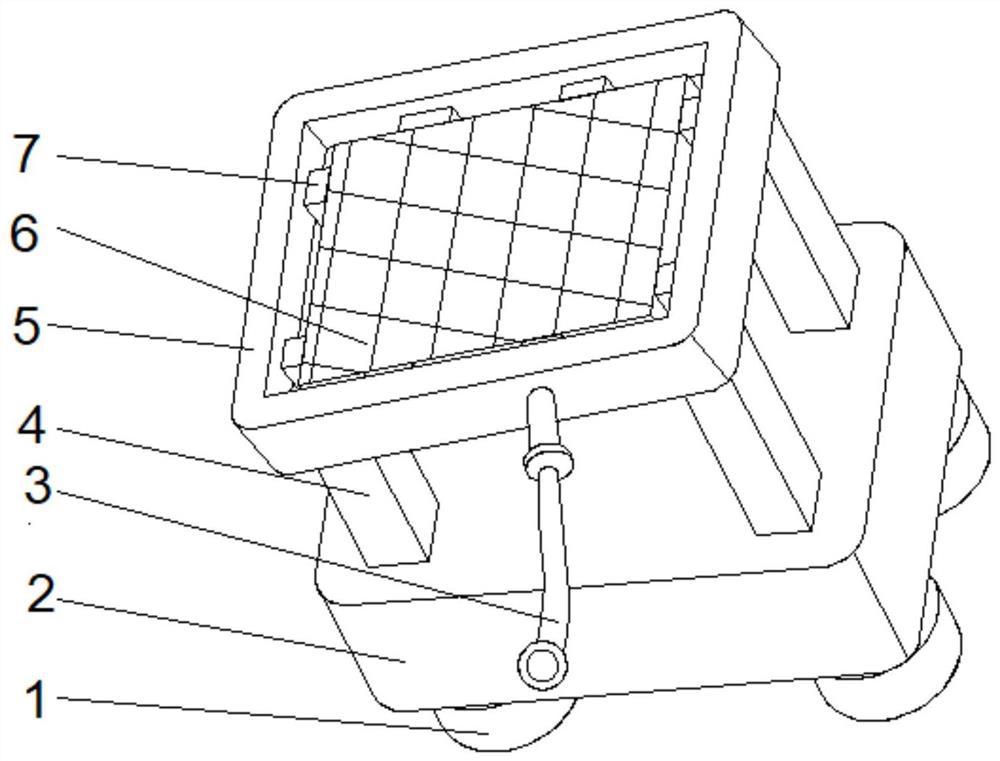

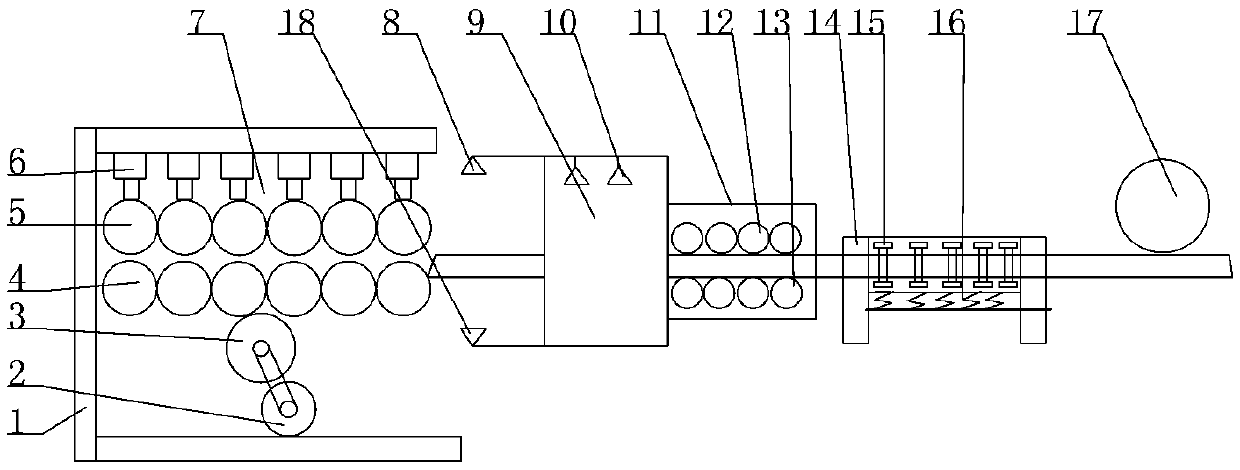

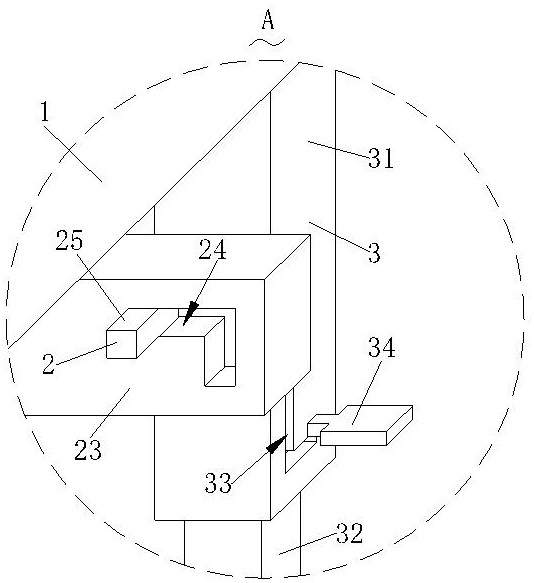

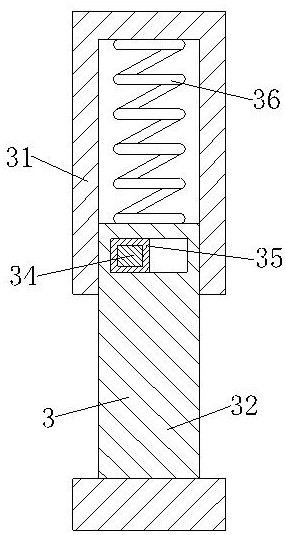

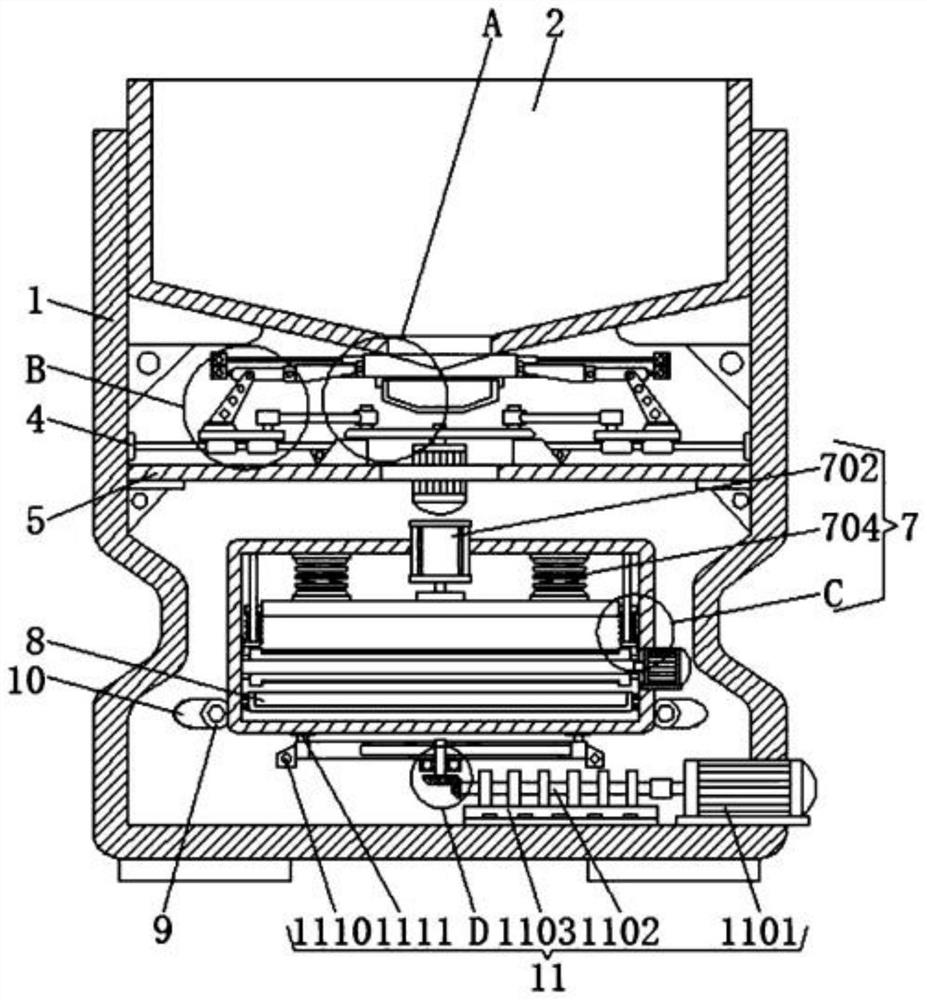

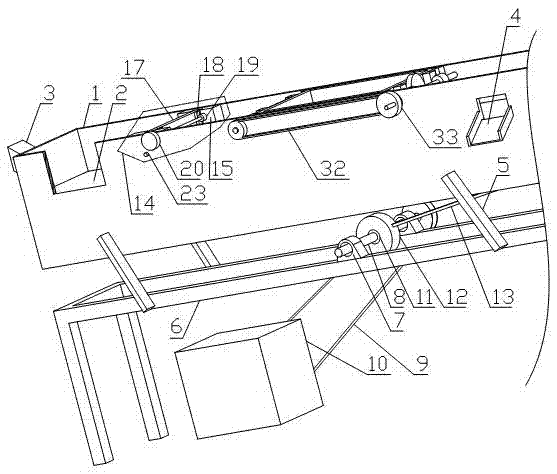

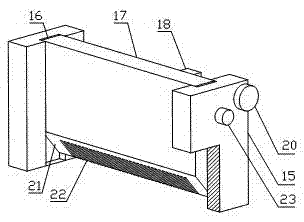

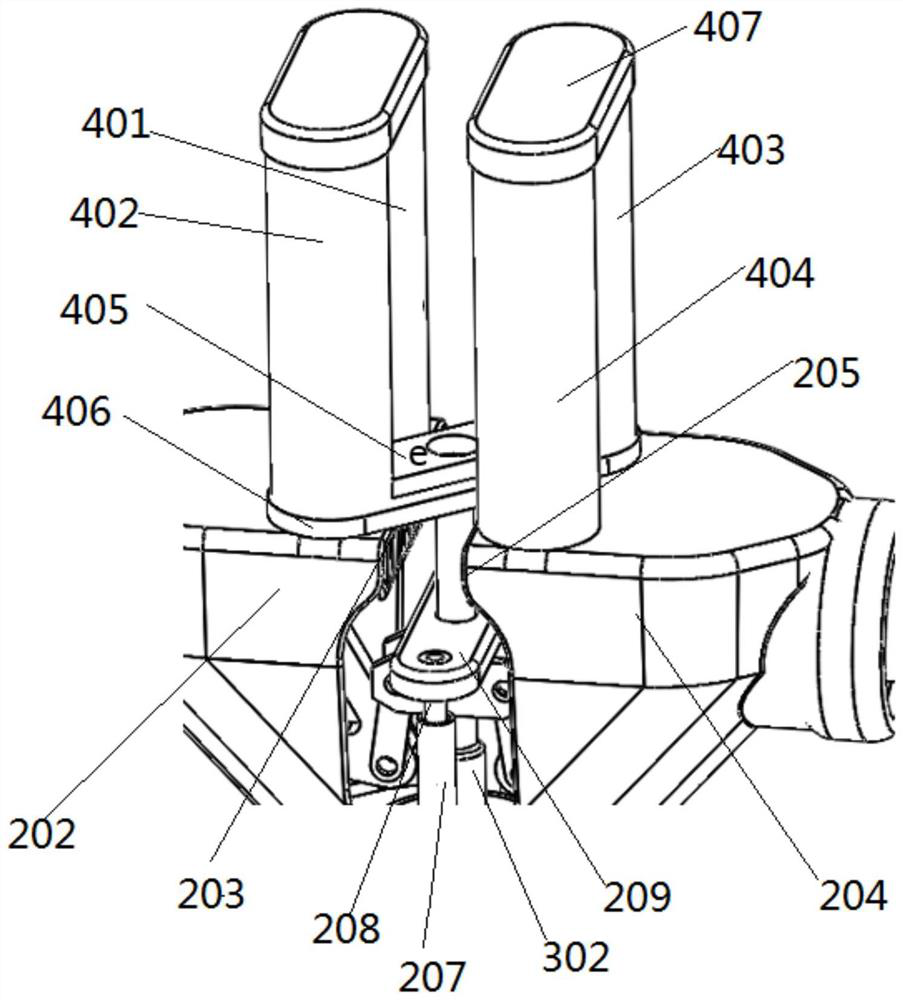

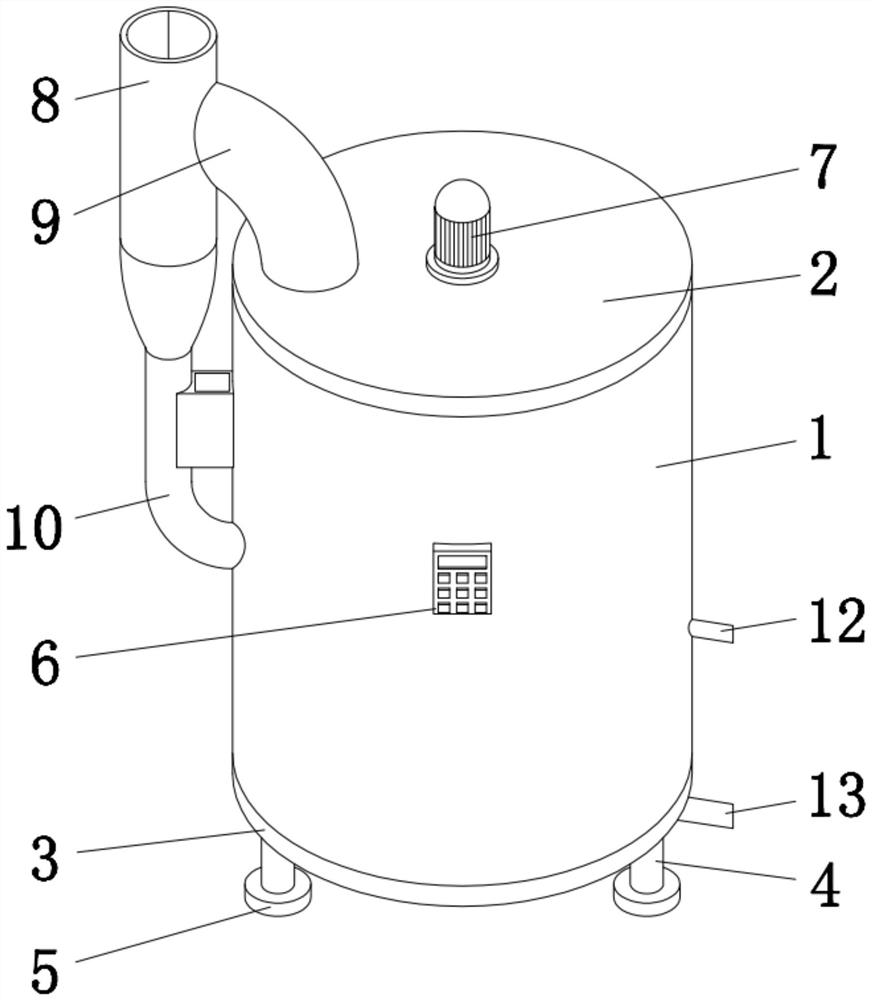

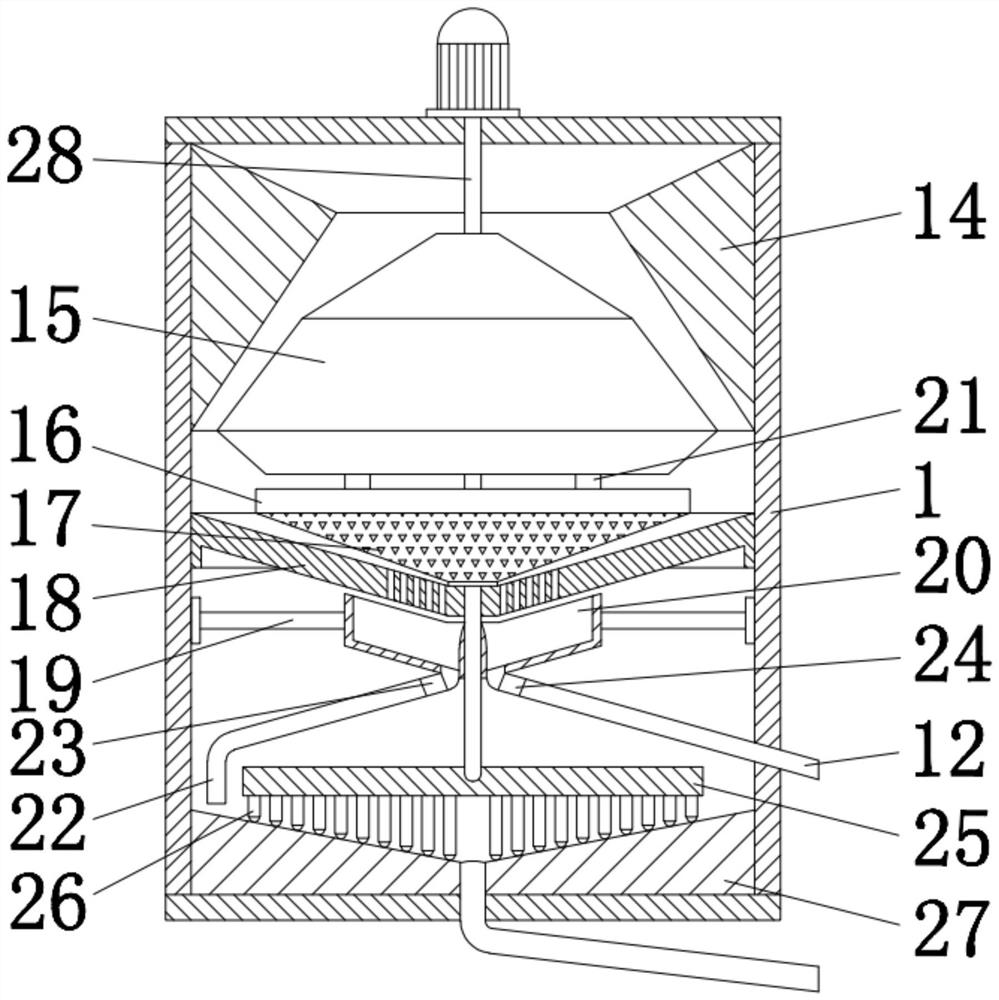

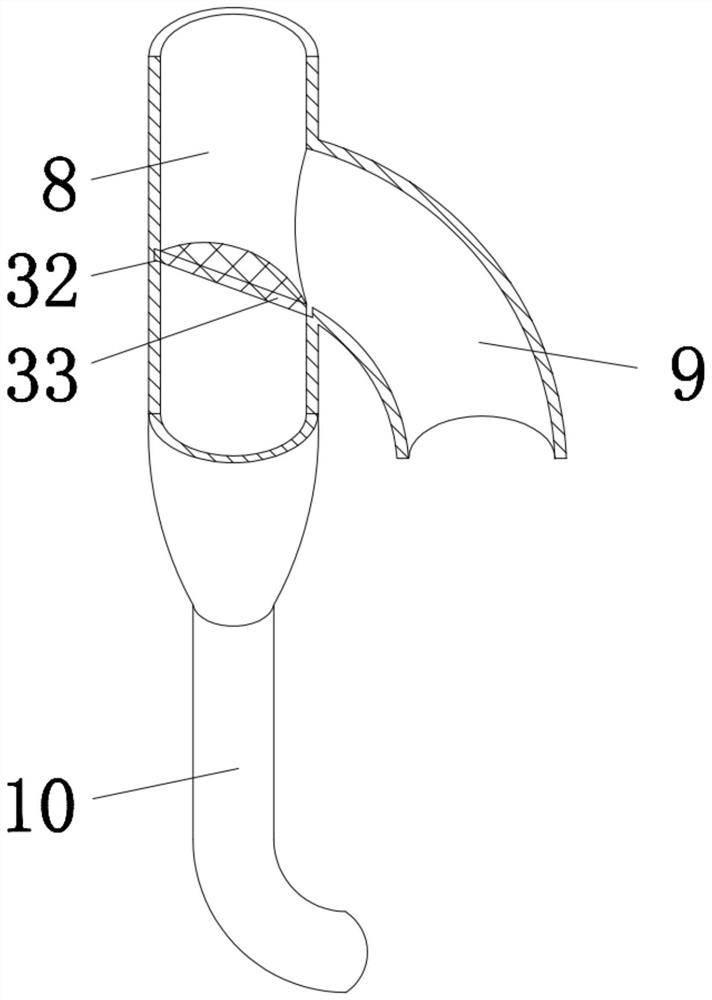

Straw baler capable of realizing automatic monitoring

PendingCN109275427APrevent stuck situationsStuck situation avoidanceBalingGratingAgricultural engineering

The invention discloses a straw baler capable of realizing automatic monitoring, and belongs to the technical field of agricultural machinery equipment. The straw baler comprises a frame, a collectingmechanism, a conveying mechanism, a bundling mechanism and a rope feeding mechanism, the collecting mechanism comprises a collecting assembly, a cutting assembly and a compacting assembly, the cutting assembly is located above the collecting assembly, the compacting assembly is located at the rear of the cutting assembly, the bundling mechanism comprises a material limiting assembly, a bundling assembly and a tension detecting assembly, the material limiting assembly is connected with the conveying mechanism, the bundling assembly is installed nearby the material limiting assembly, and the tension detecting assembly is fixedly connected the bundling assembly. According to the invention, a user can conveniently grasp the equipment working state in time by a camera, a tension sensor, a grating sensor and a pressure sensor, and the setting of the collecting mechanism and the conveying mechanism can effectively avoid occurrence of material jamming.

Owner:ANHUI SCI & TECH UNIV

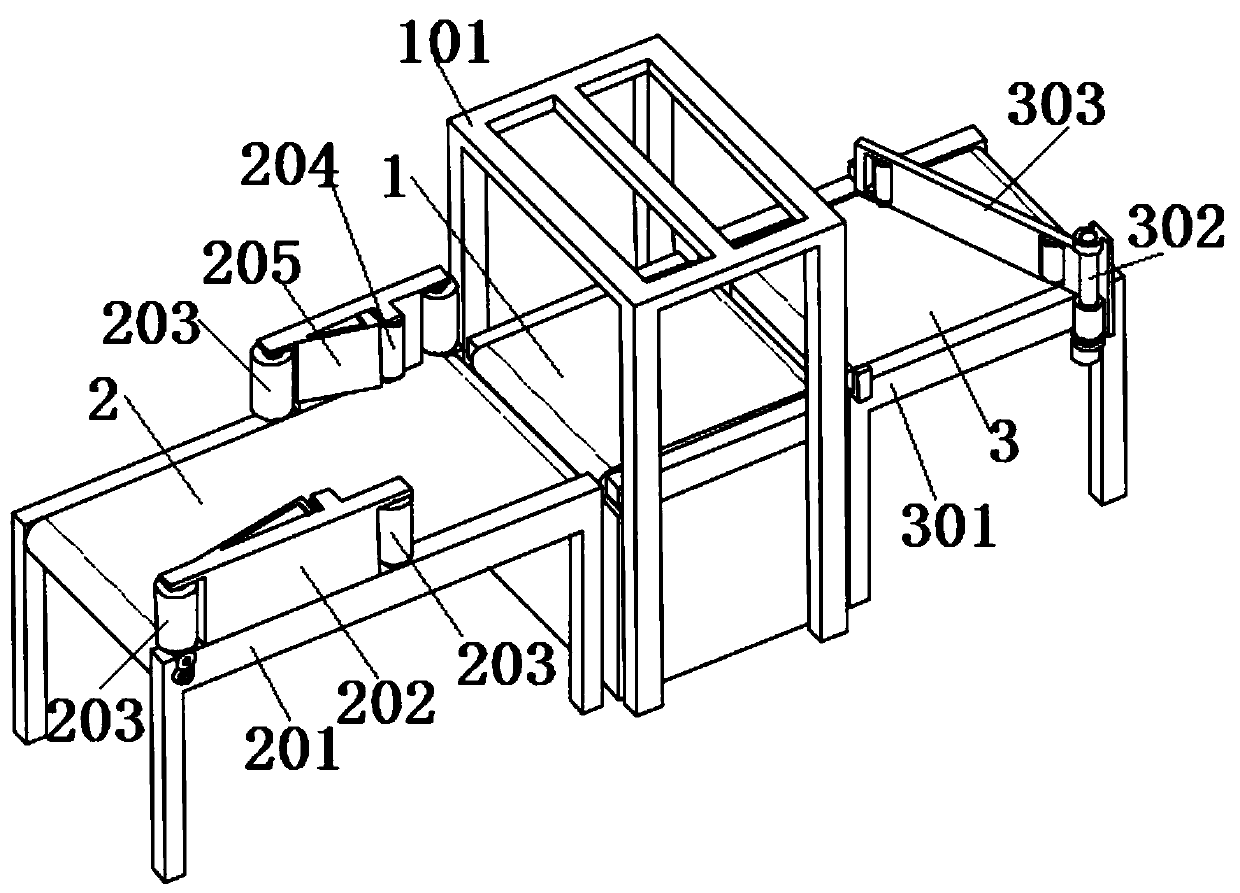

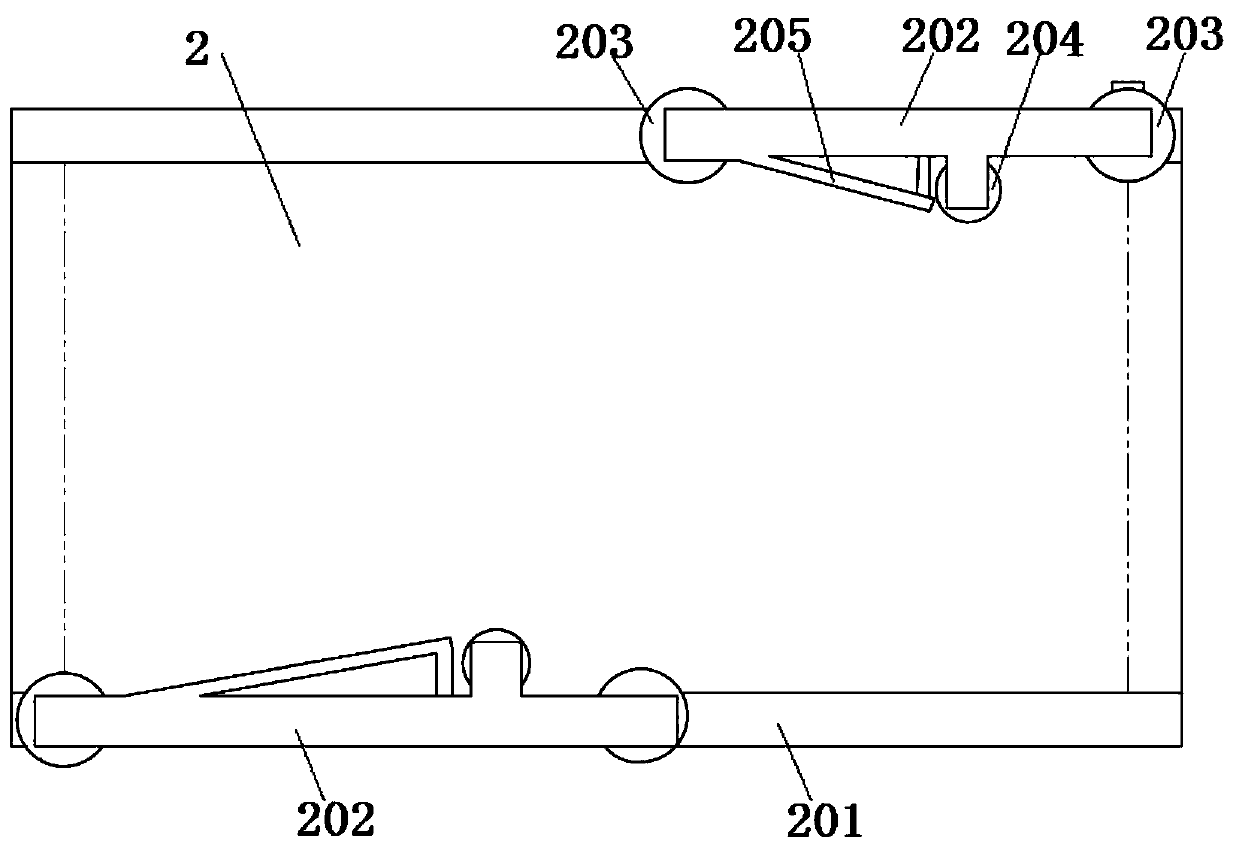

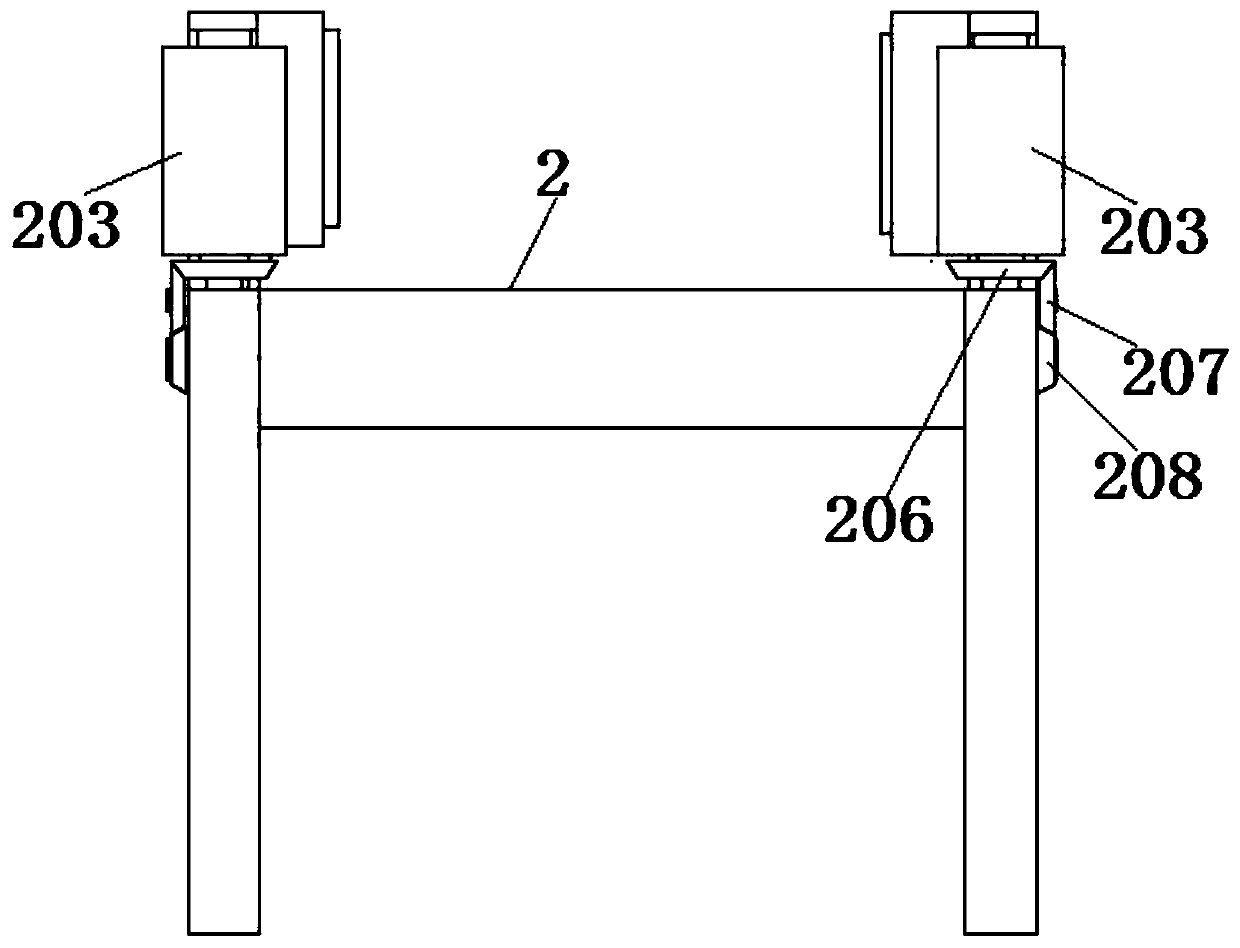

Large-size parcel weighing and code scanning device and system

PendingCN110052419APrevent stuck situationsImprove the efficiency of weighing and scanningSortingEngineeringLarge size

The invention discloses a large-sized parcel weighing and code scanning device and system and relates to the technical field of logistic sorting devices. The large-sized parcel weighing and code scanning device comprises a dynamic scale, a scale feeding conveyer belt and a scale discharging conveyer belt. The upper surfaces of the two sides of the scale feeding machine frame of the scale feeding conveyer belt are both fixedly connected with fixing plates. The two sides of each fixing plate are both rotationally connected with supporting rollers. One side of each fixing plate is rotationally connected with a side roller. The supporting rollers and the side rollers are connected through a conveying belt. One side of the scale discharging machine frame of the scale discharging conveyer belt is rotationally connected with a rotating shaft. The circumferential side face of the rotating shaft is fixedly connected with a baffle. According to the large-size parcel weighing and code scanning device and system, the supporting rollers and the side rollers are connected through the conveying belt, position correcting is conducted on an inclined box parcel on the scale feeding conveyer belt, and the situation that the inclined box parcel gets stuck when passing by the supporting rollers is avoided; through the arrangement of the baffle, when weighing or code scanning of the parcel is abnormal, the baffle can rotate to block the parcel, abnormal parcels are collected, and halt is not needed; and in this way, the weighing and code scanning efficiency are greatly improved.

Owner:HEFEI HAIMING SCI & TECH CO LTD

Saw blade type cave development machine

InactiveCN102003179AProtection securityProtection from damageDriving meansCutting machinesElectric machineryMachine

The invention discloses a saw blade type cave development machine, which comprises a machine body, wherein the machine body is provided with wheels, a movable frame and a supporting frame; the movable frame comprises an upper bracket and a lower bracket, the front end of the upper bracket is provided with a rotating shaft, a saw blade is fixed on the rotating shaft, and a motor is connected on the rotating shaft; the rear end of the upper bracket is coupled at the top of the lower bracket, and the bottom of the lower bracket is supported on the machine body; the saw blade supporting frame is supported at the bottom of the upper bracket, and the bottom of the saw blade supporting frame is supported on the machine body; and a push rod is connected at the joint of the brackets, the front end of the push rod is coupled at the joint of the brackets, and the rear end of the push rod is connected on the supporting frame by screw threads. The saw blade type cave development machine has the advantages of simple structure, low production cost, low operating vibration and low damage; a saw blade and a hammering machine of the development machine can be adjusted up and down, left and right, so the development machine is flexible, simple and convenient to operate and can be used on different terrains; and the development machine does not need to use explosive, and can control the size of the crushed ores during excavating so as to improve the value of the ores and reduce environmental pollution.

Owner:郑家富

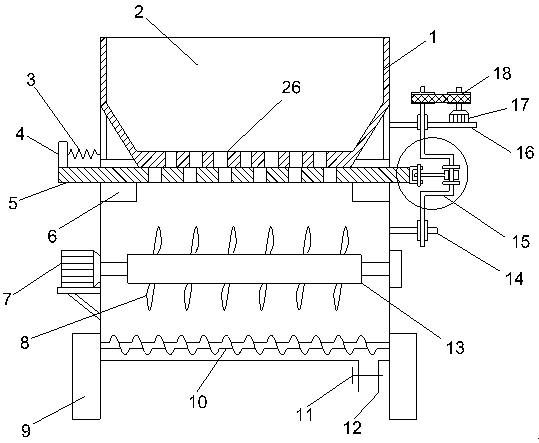

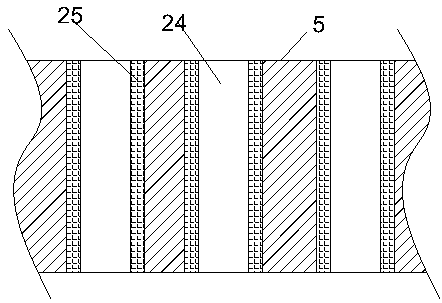

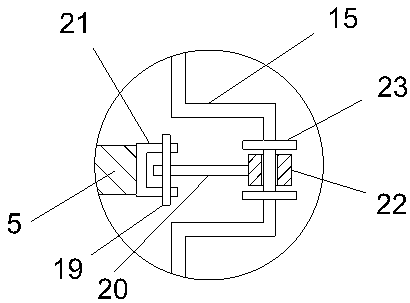

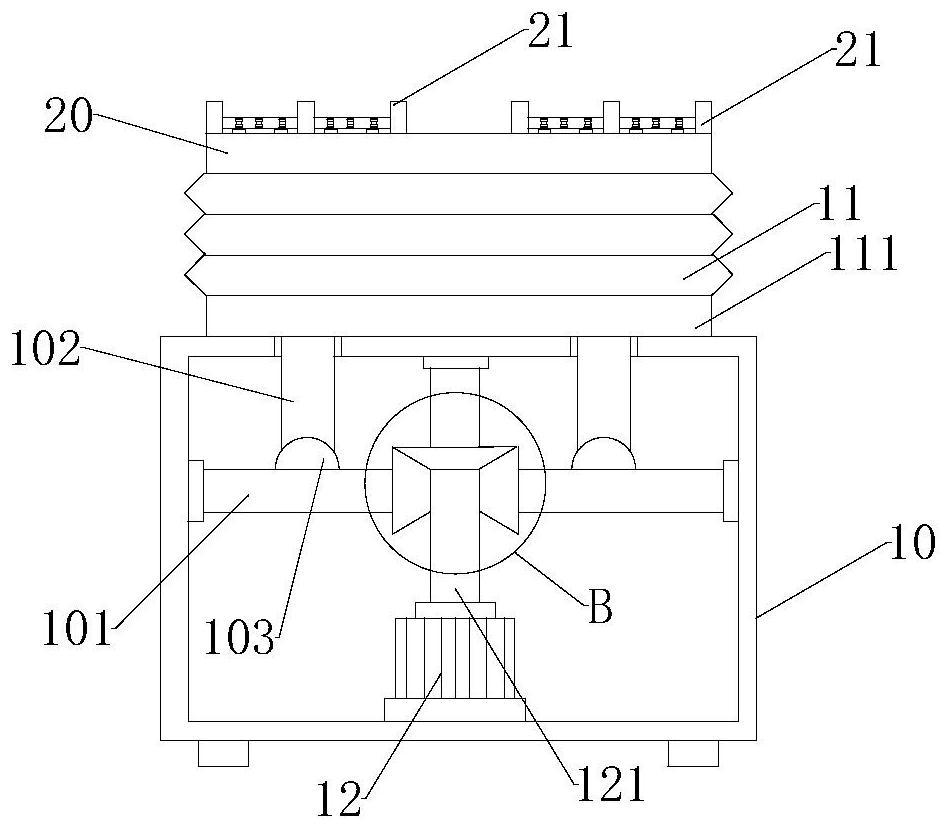

Novel corn thresher

ActiveCN108781775ATo achieve superchargingIncrease profitSaving energy measuresBearing componentsEngineeringPiston

The invention relates to the technical field of modern agricultural equipment, and discloses a novel corn thresher. The novel corn thresher comprises a corn thresher, the top end of the corn thresheris provided with a feeding port, and the middle part of the feeding port is slidably sleeved with a first rotating shaft, one end of the first rotating shaft passes through the inside of a first bearing and extends to the outside of one side of the corn thresher, and the outer wall of the first bearing is fixedly mounted inside one side of the corn thresher, the outer wall of the first rotating shaft is fixedly fitted with a threshing piece, and the other end of the first rotating shaft passes through the inside of a second bearing and extends to the outside of the other side, and the outer wall of the second bearing is fixedly mounted inside the other side of the corn thresher. The novel corn thresher can utilize the force generated by the first rotating shaft by setting a disc, a connecting rod, a booster box, a piston port, a piston rod, a baffle, a tension spring and a T-shaped plate, so as to play the role of pressurizing the down pressure mechanism, improve the utilization rate of energy and achieve the purpose of saving energy.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

Lake surface floating algae removing and fishing device

The invention provides a lake surface floating algae removing and fishing device, and relates to the field of fresh water purification. The lake surface floating algae removing and fishing device comprises a rectangular frame body, foam floating blocks are fixedly connected to the bottom of the rectangular frame body, and the bottom of the rectangular frame body is provided with a fishing groove;the back portion of the rectangular frame body is provided with an elliptical slot, and the elliptical slot is internally provided with an elliptical block; a fishing mechanism is fixedly connected tothe back portion of the rectangular frame body, and scraping devices are arranged between the elliptical slot and the elliptical block; a transmission device is connected to the fishing mechanism, and a centrifugal mechanism is arranged at the back portion of the rectangular frame body. According to the lake surface floating algae removing and fishing device, fishing and filtering plates can fishalgae in water and have a water filtering function, the water can be discharged while the algae is collected, the problem of excessive water content of fished algae is effectively solved, and the fishing effect is improved.

Owner:浙江仙峰鞋业有限公司

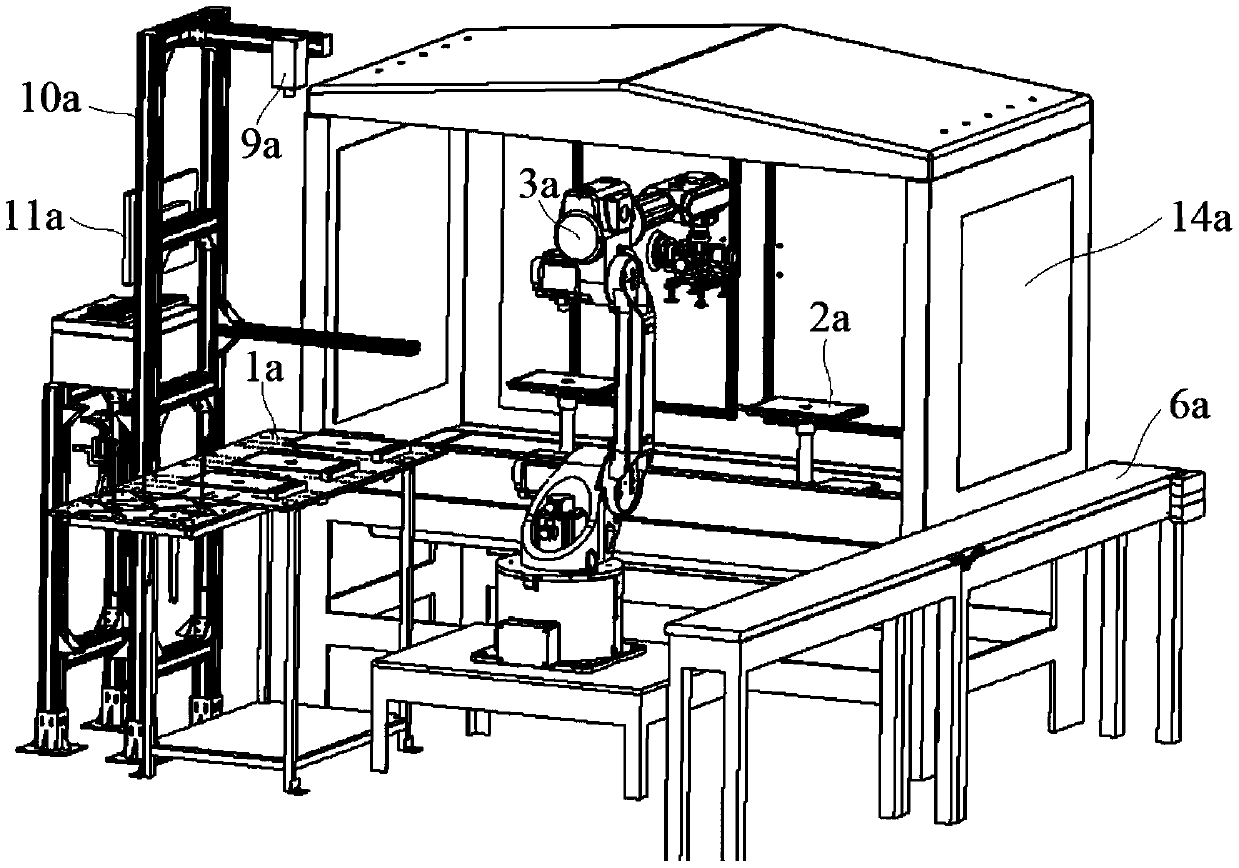

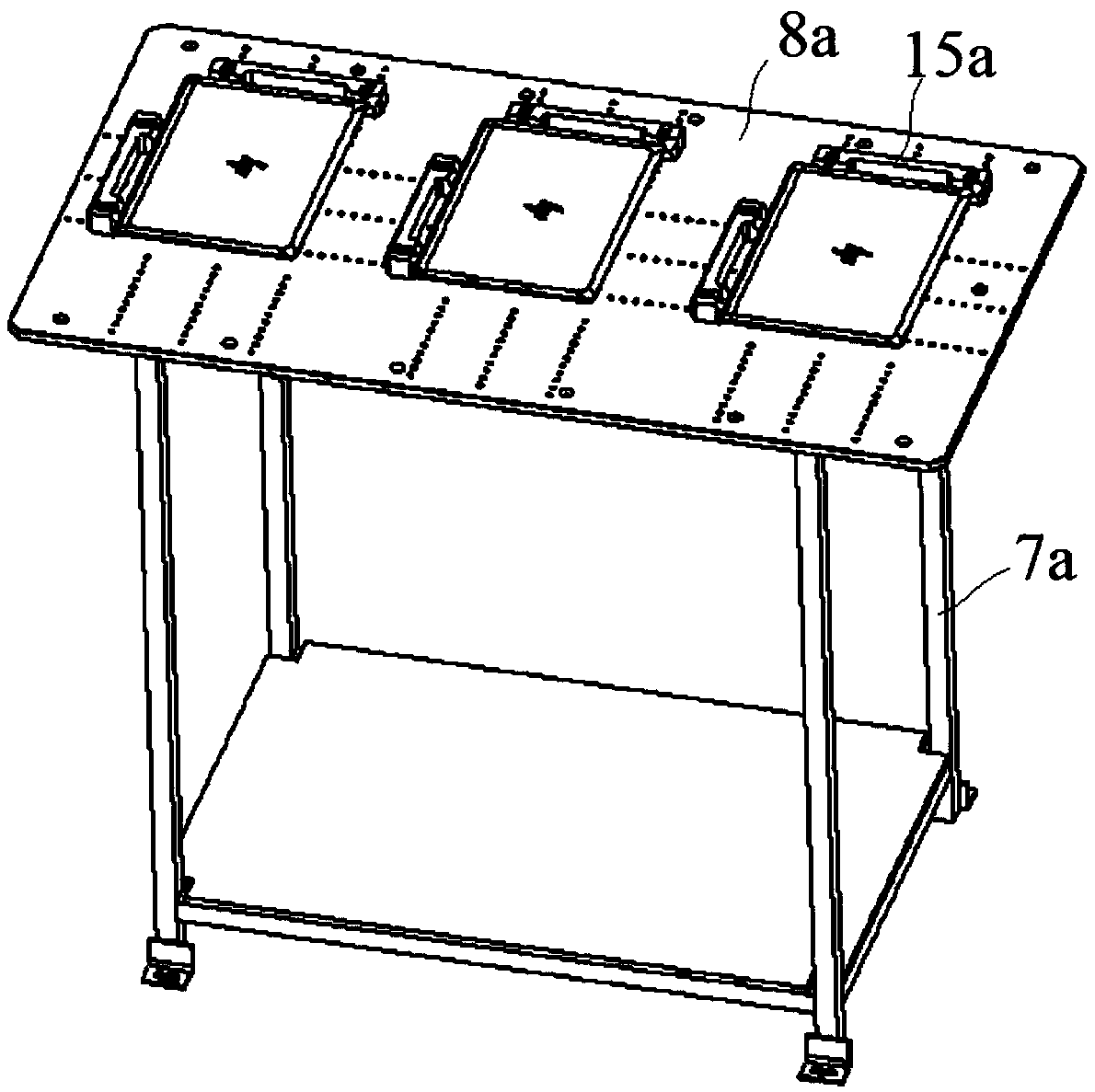

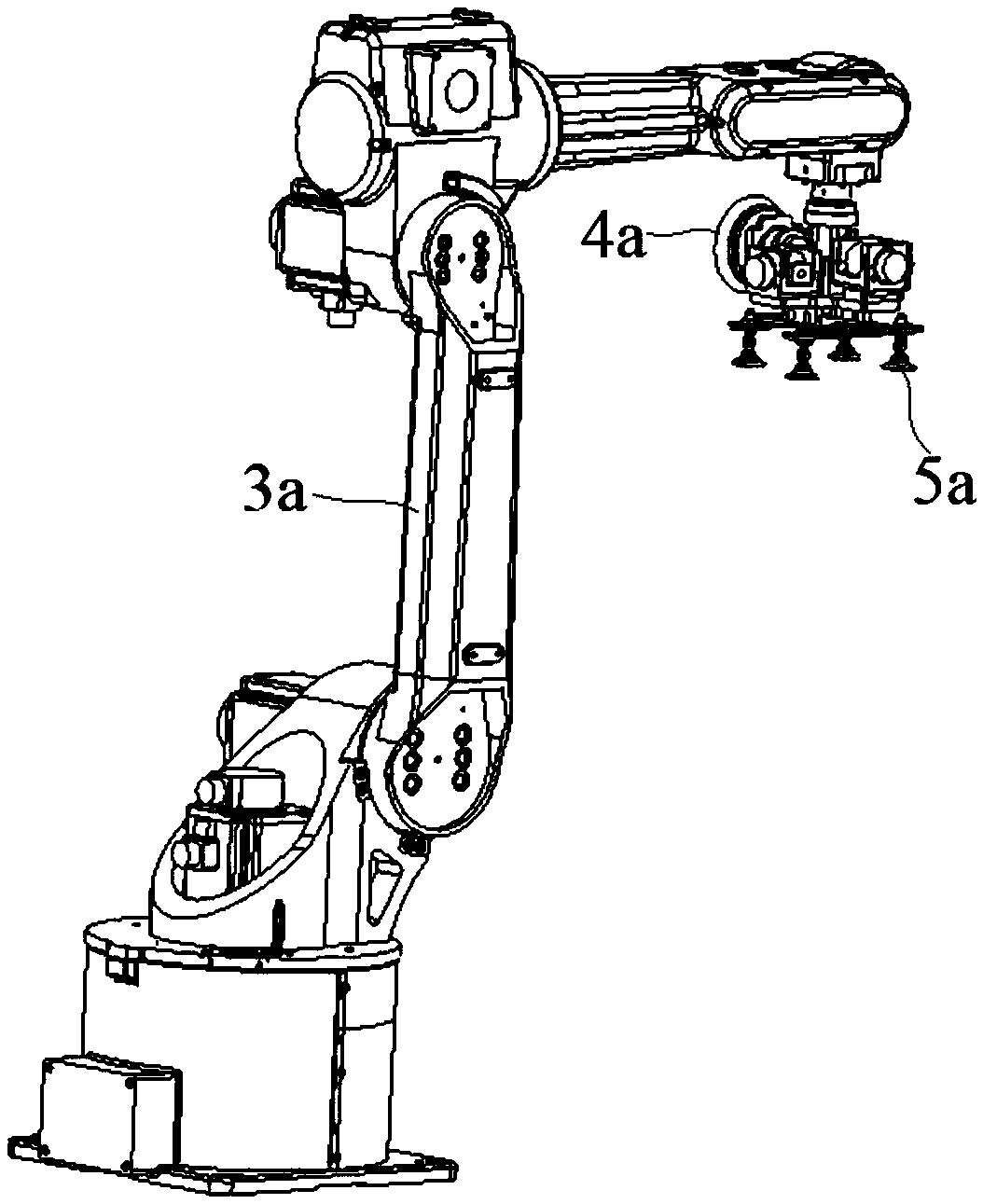

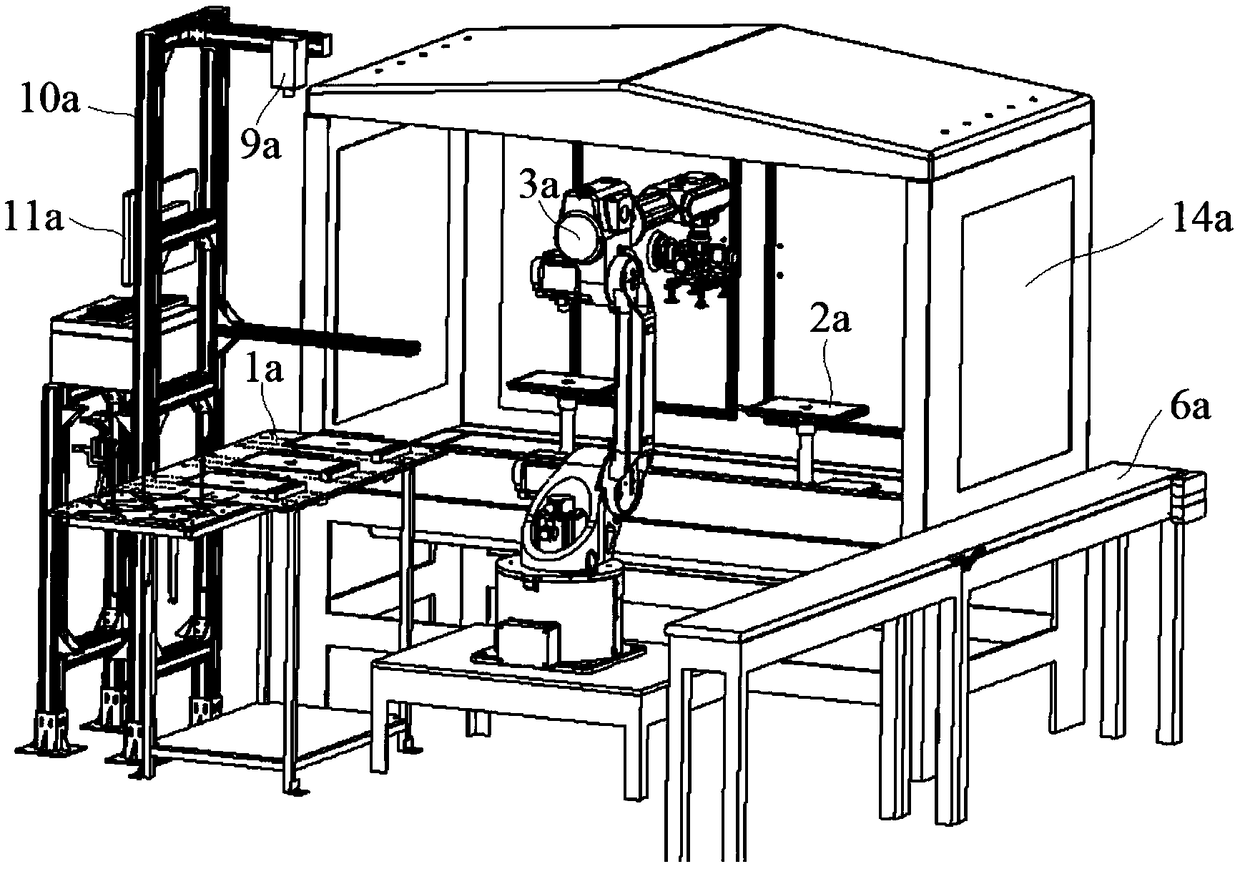

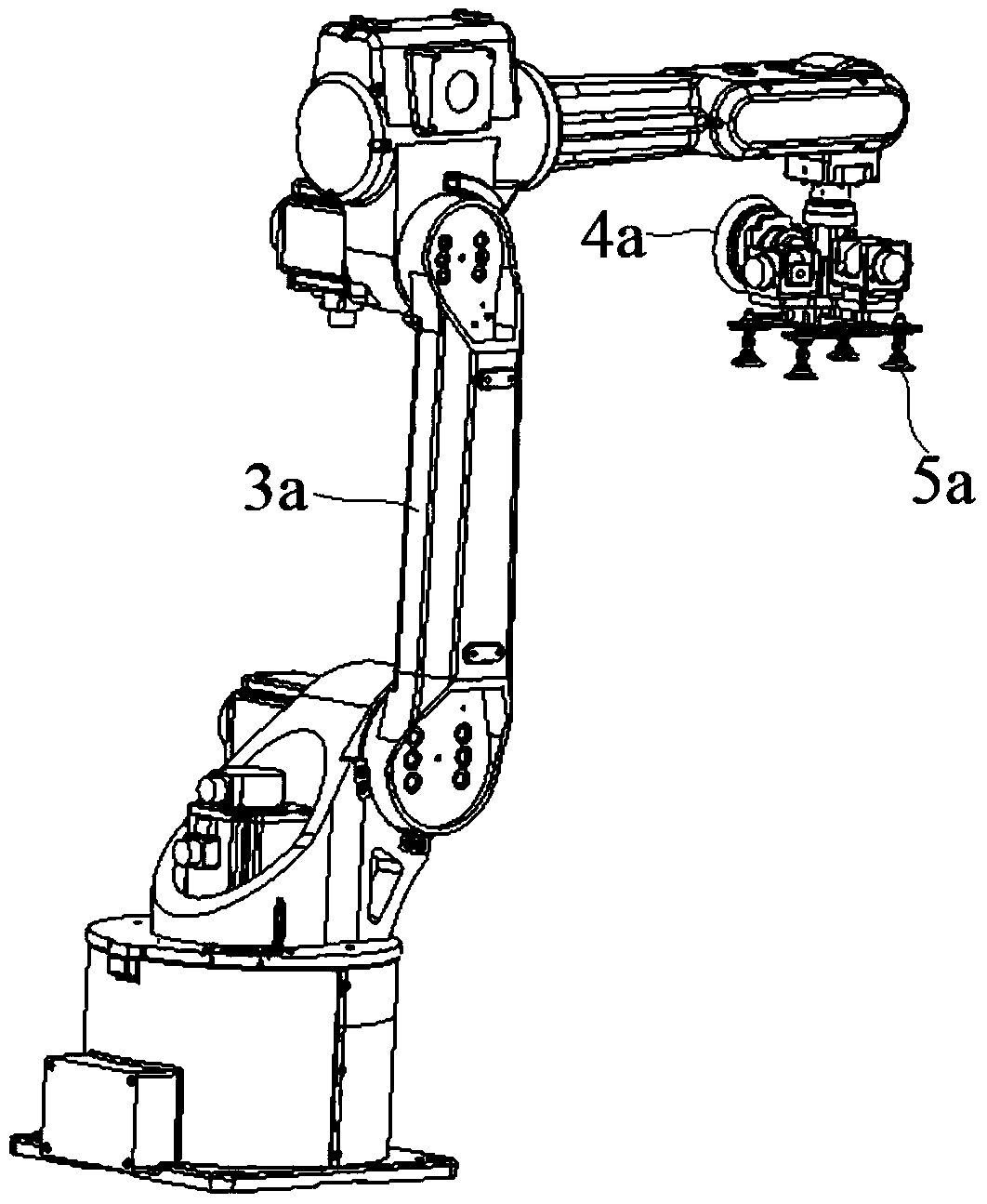

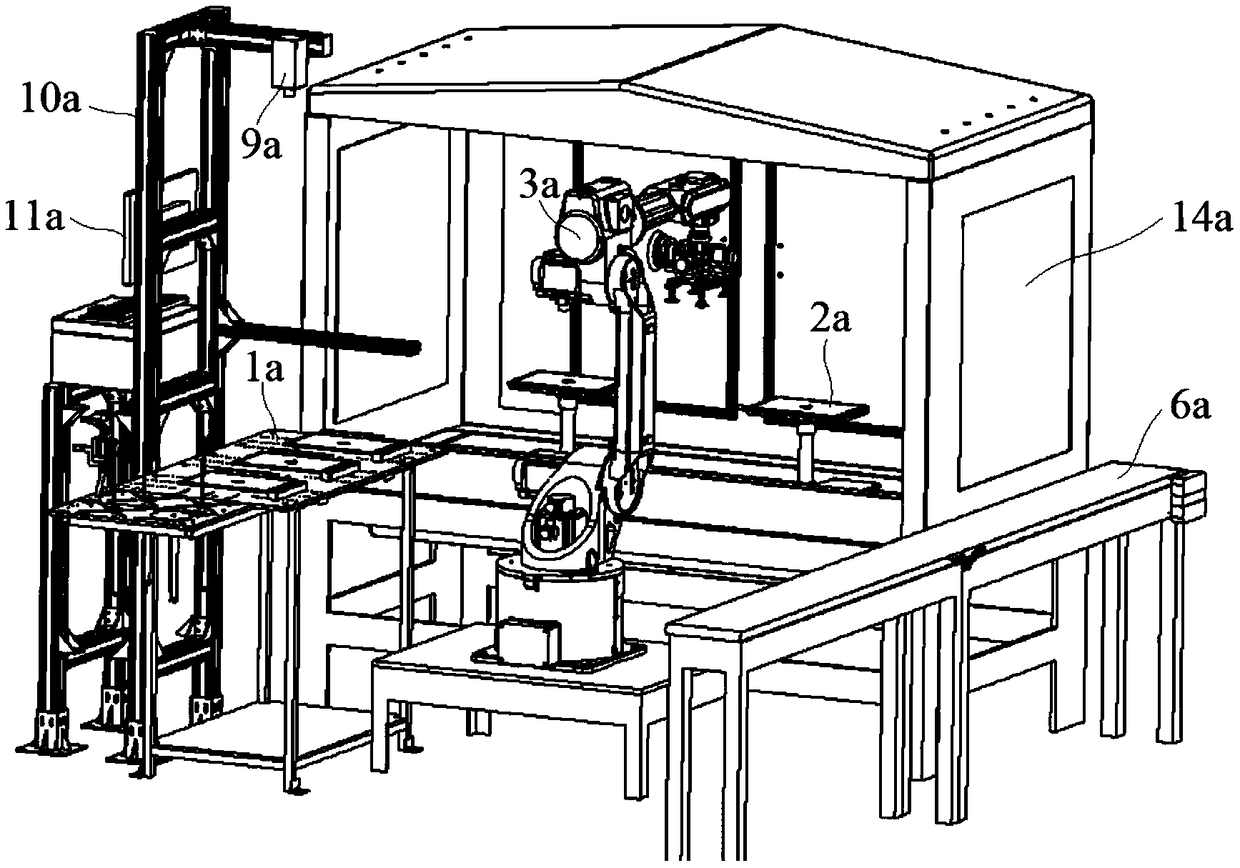

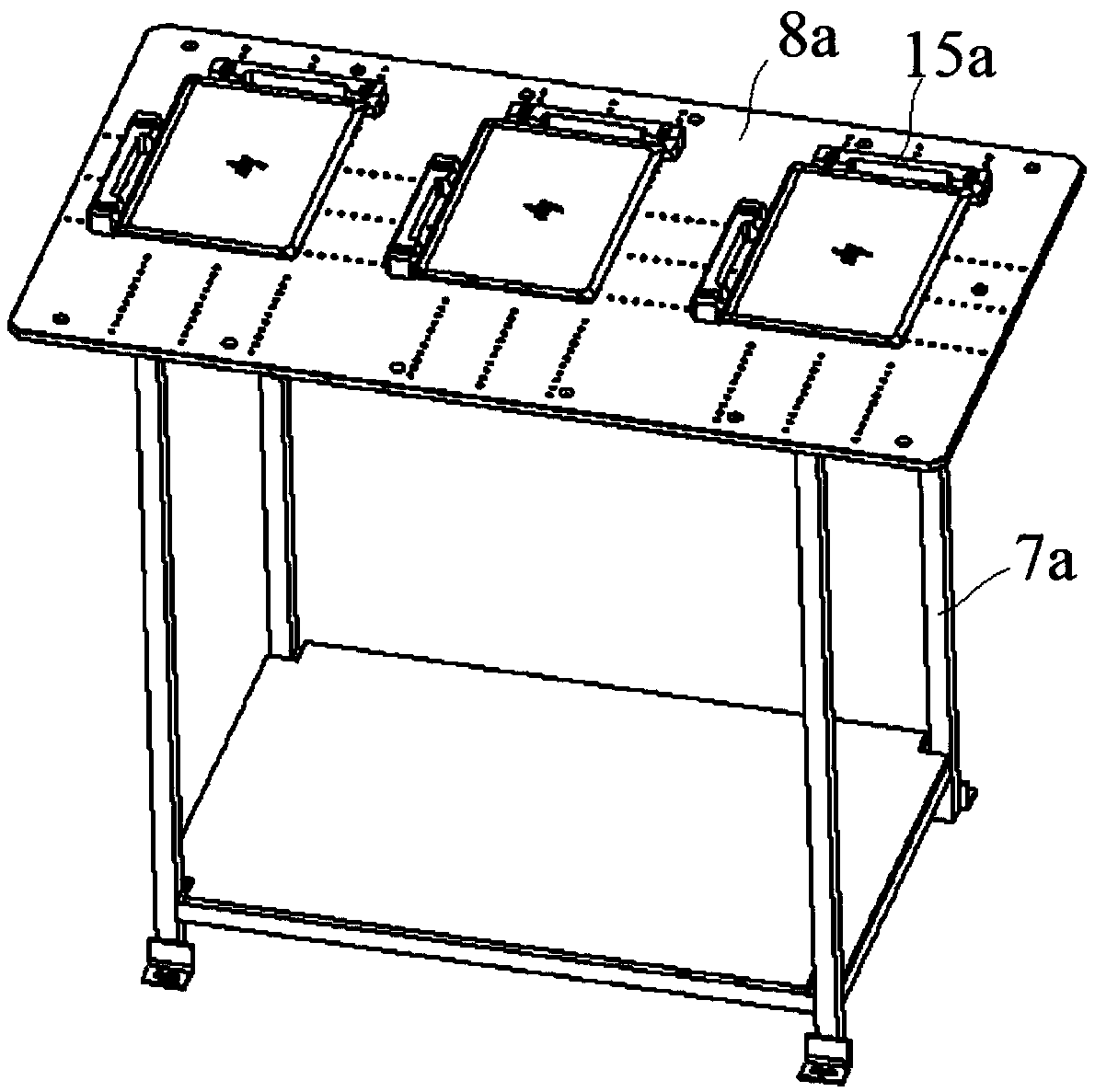

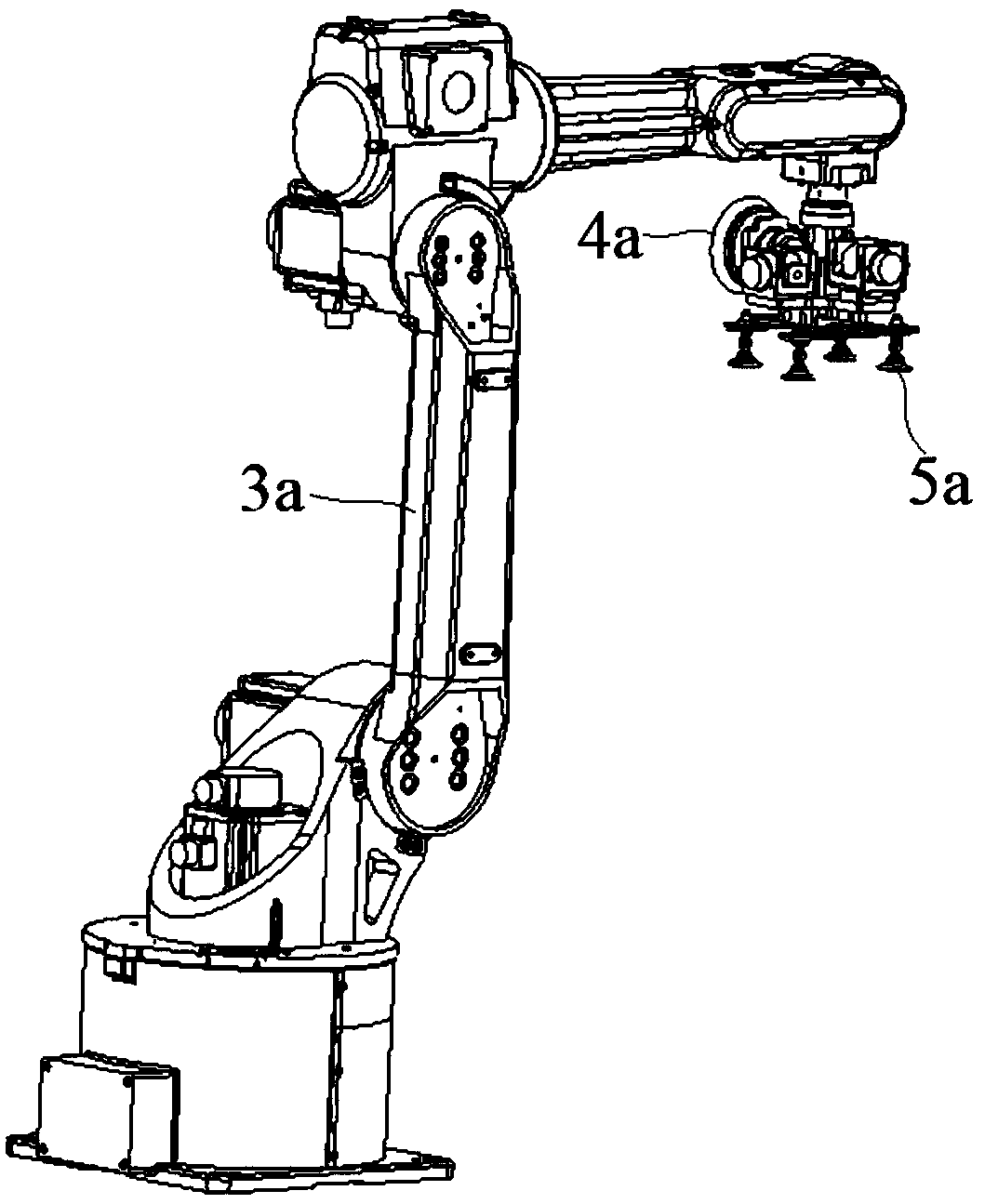

Automatic machining mechanism for notebook computer shell

InactiveCN109623567ASave materialReduce grinding time and processProgramme-controlled manipulatorGrinding carriagesEngineeringRubber ring

The invention discloses an automatic machining mechanism for a notebook computer shell. The automatic machining mechanism comprises feeding supports, polishing supports, a plurality of mechanical arms, a polishing head and a material-conveying clamp, the polishing head and the material-conveying clamp are mounted at and connected with end joints of the mechanical arms correspondingly, and the feeding supports and the polishing supports are arranged in the circumferential directions of the mechanical arms correspondingly; and a rubber ring is mounted at the tail end of a lower shaft part in a sleeving mode, a bearing is arranged in a shell part of a rotating shell, a sealing washer is arranged on the lower part of the bearing, an annular gasket is arranged on the lower part of the sealing washer, a washer is mounted on a lower shaft part of a core body in a sleeving mode and embedded into a through hole in the upper surface of a lower bearing seat, and the upper surface of the washer ishigher than the upper surface of the lower bearing seat. According to the automatic machining mechanism for the notebook computer shell, the situation that a rotating head is stuck when downward-pressing force is excessively large can be prevented, flexible rotation of the rotating head is ensured, through eccentric arrangement that the rotating head and the core body for driving the rotating head to rotate have different axes, a polishing trajectory is not left in the polishing process, and the elaborate degree of polishing is increased.

Owner:苏州丰川电子科技有限公司

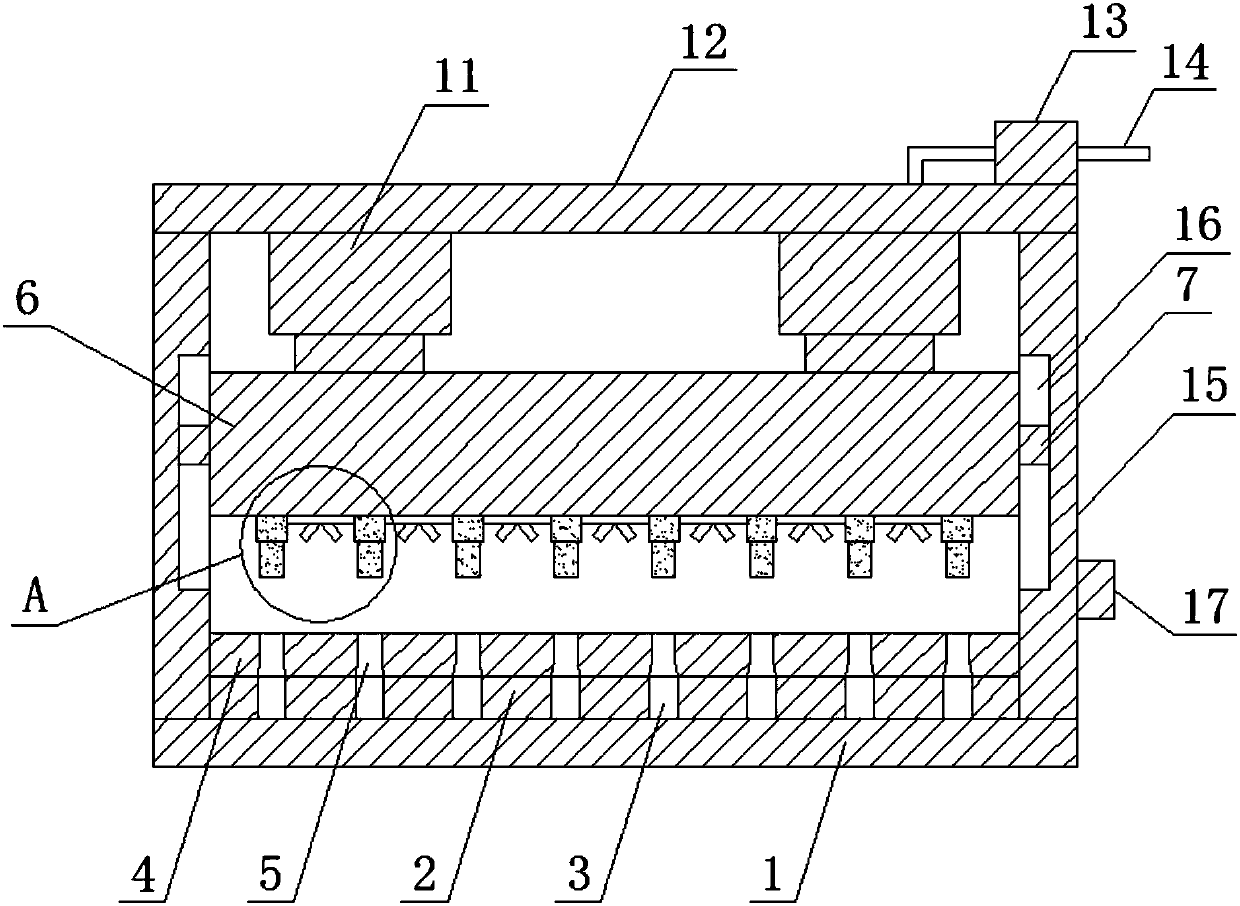

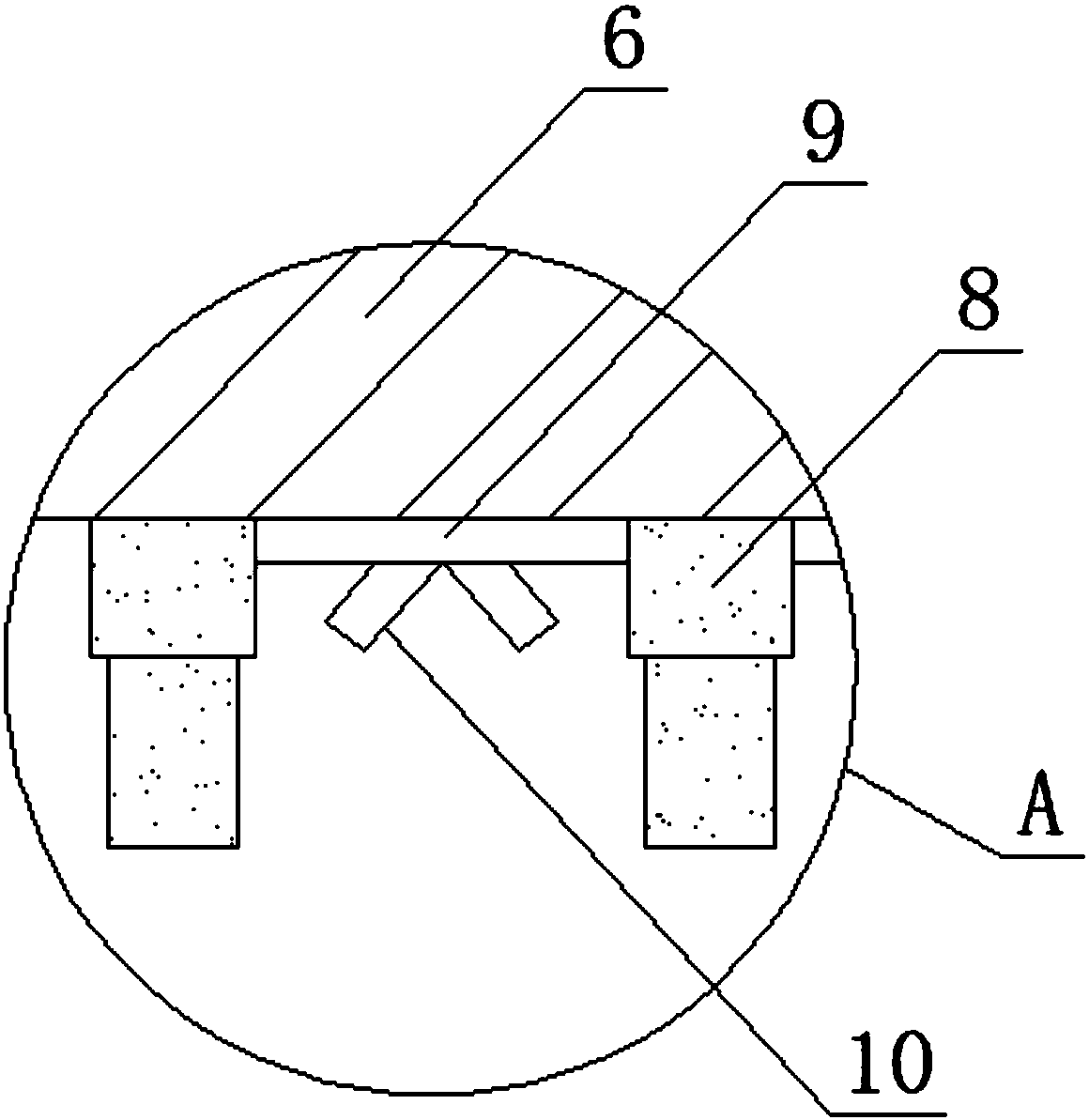

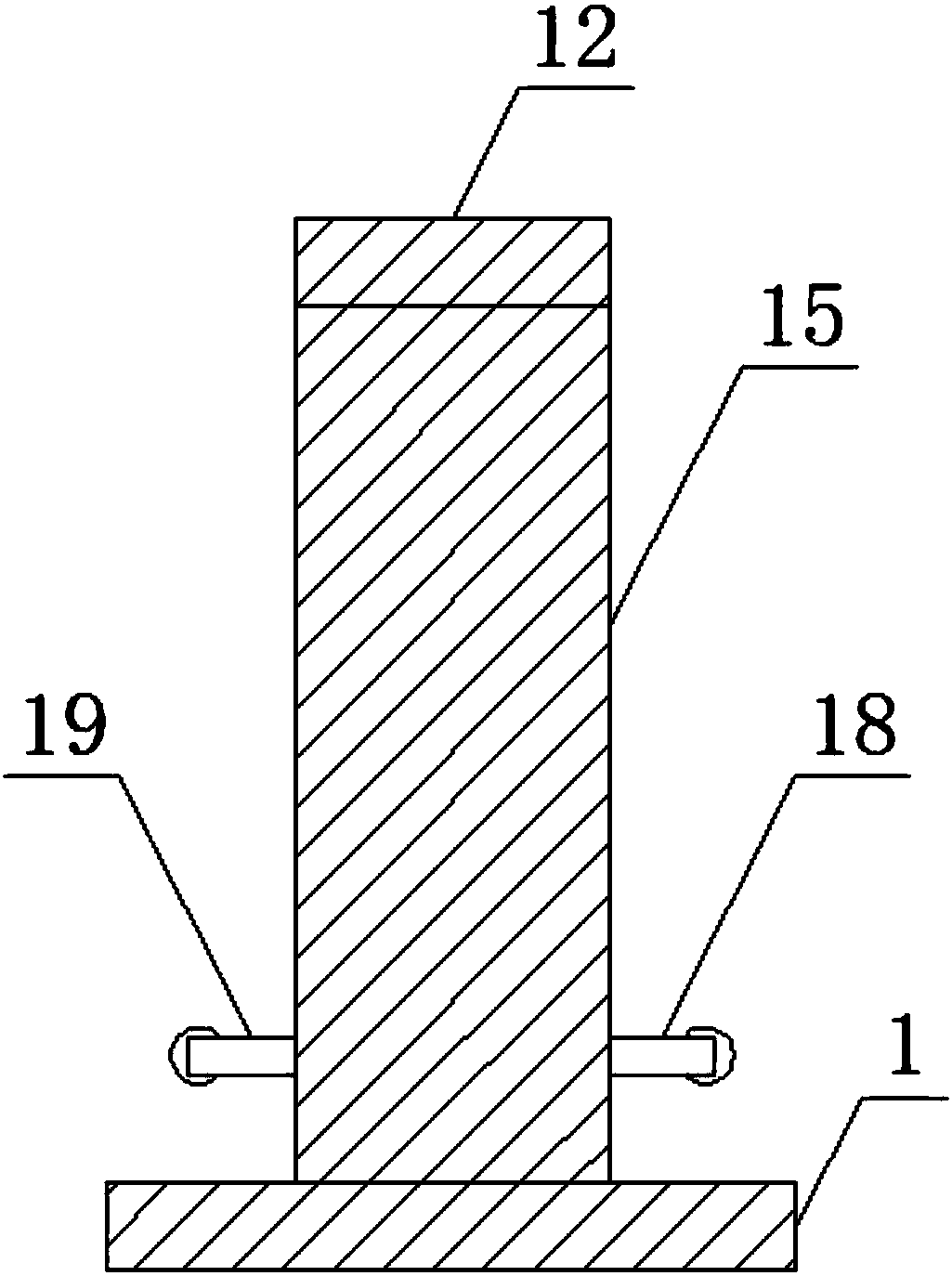

Continuous steel plate punching device

ActiveCN107745035AReduce the burden onPrevent stuck situationsShaping toolsPerforating toolsSteel platesWater pipe

The invention discloses a continuous steel plate punching device comprising a base plate. Fixing blocks are arranged on the top of the base plate. Material discharging grooves are formed between the fixing blocks. A lower die is arranged on the tops of the fixing blocks. The lower die is provided with punching holes in a penetrated manner. An upper die is arranged on the top of the lower die. Thetwo sides of the upper die are provided with sliding blocks. The bottom of the upper die is provided with punch pins. Cooling water pipes are arranged between the punch pins. The bottoms of the cooling water pipes are provided with sprayers. The top of the upper die is provided with air cylinders. The tops of the air cylinders are provided with a top plate. One end of the top of the top plate is provided with a booster pump. The booster pump is provided with a water source connection pipe. The two ends of the bottom of the top plate are both provided with side plates. According to the continuous steel plate punching device, an auxiliary feeding device, a cross rod and separating blocks are arranged, so that labor is greatly saved, the burden on operation personnel is lowered, high practicability is achieved, the work efficiency is effectively improved, a steel plate can be prevented from getting stuck in the discharging process, and the fault rate is lowered.

Owner:YUEXI COUNTY YONGTAI MACHINERY MFG

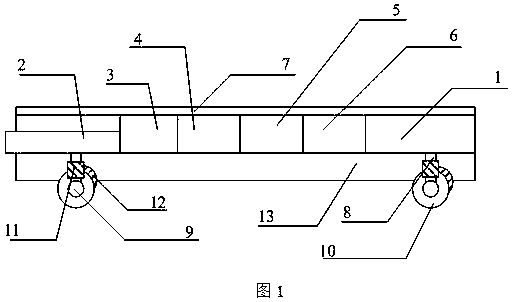

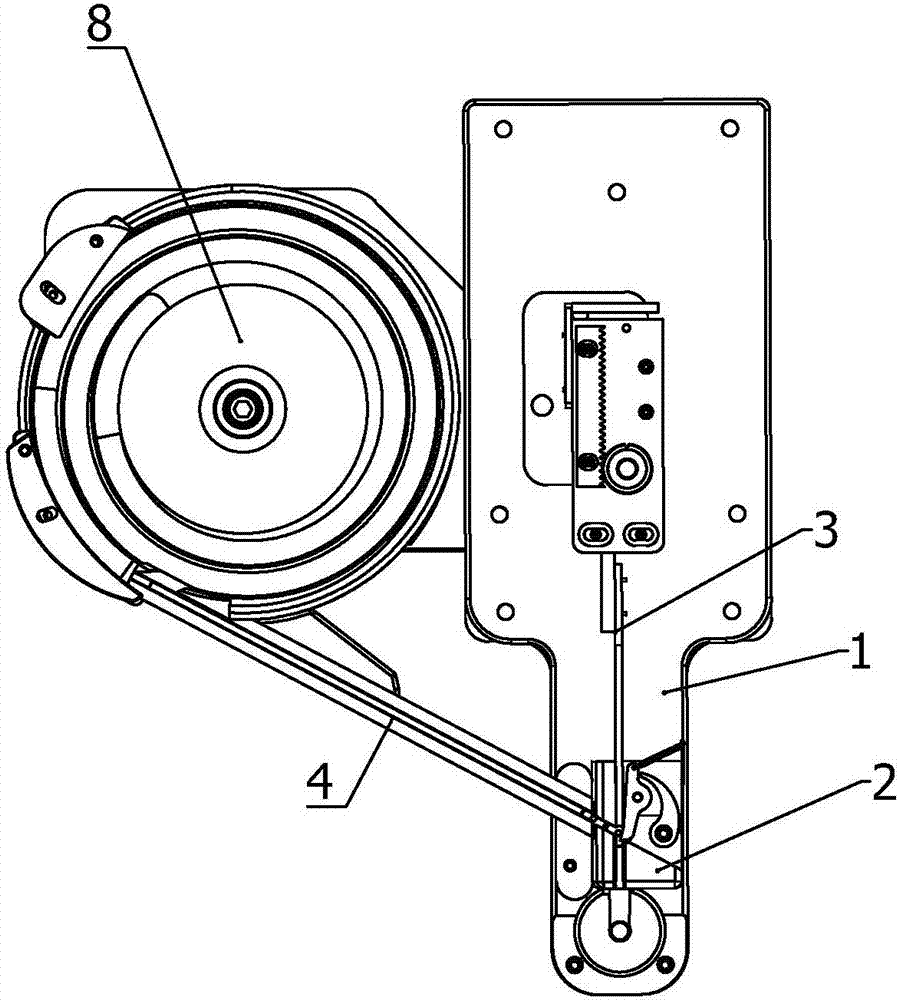

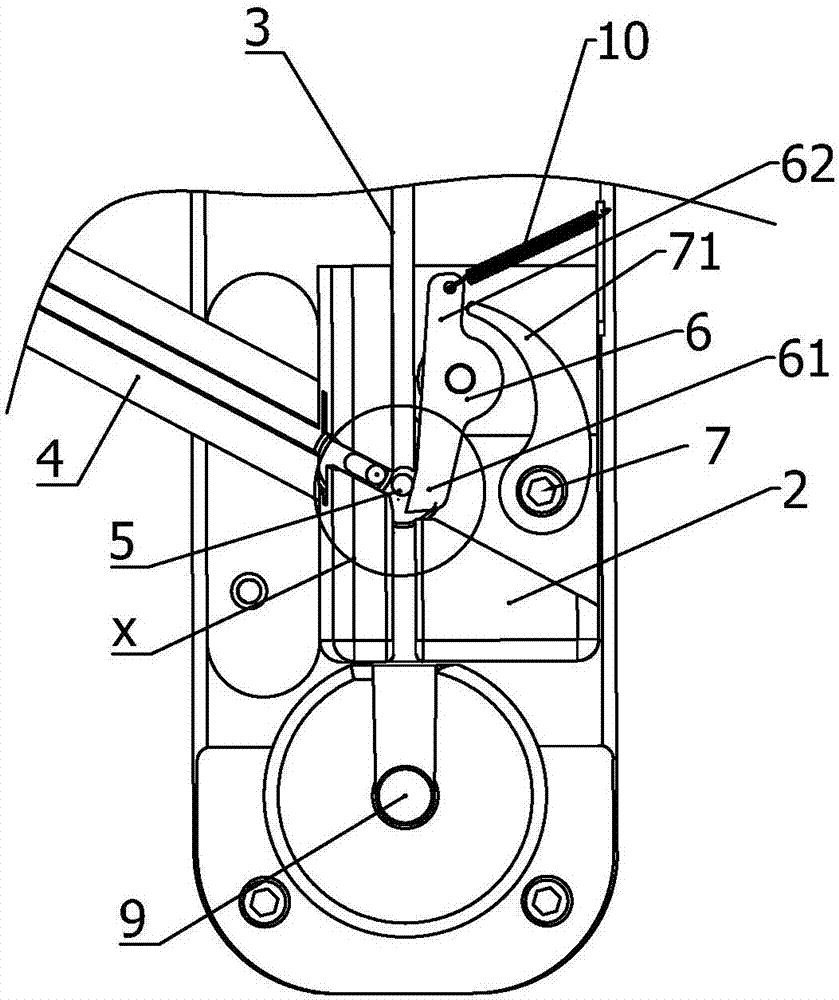

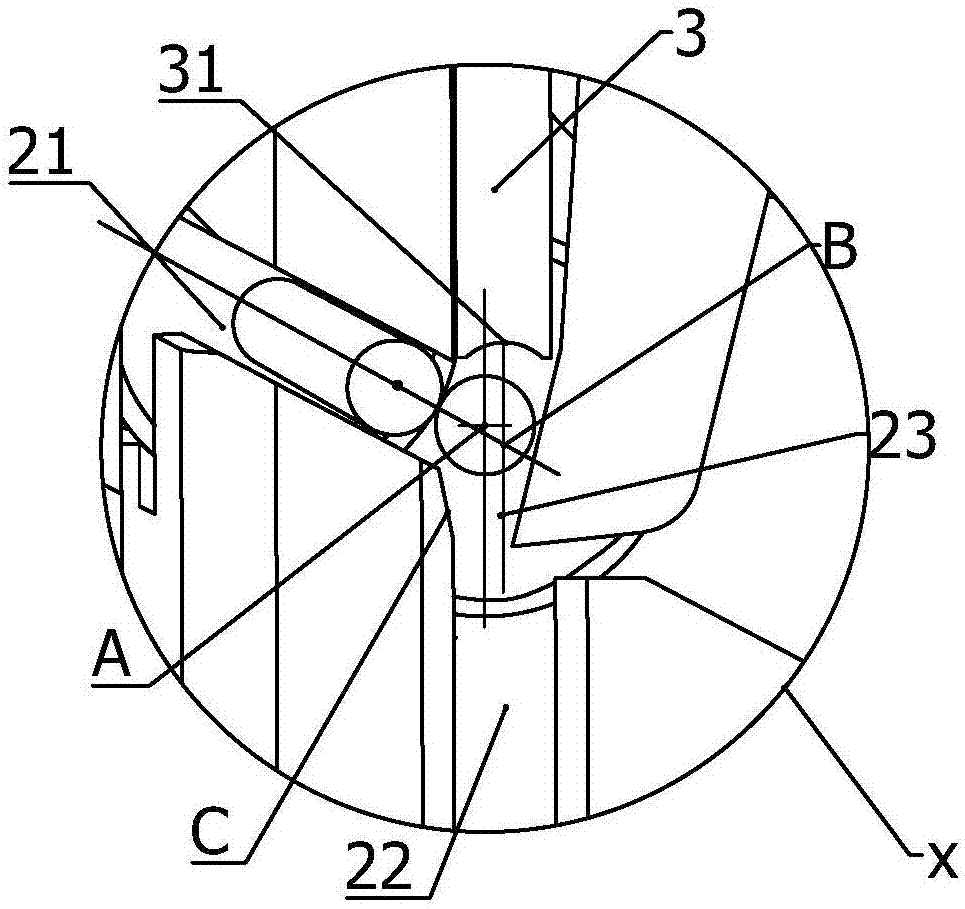

Infrared induction type rail flat car

InactiveCN108382409AEnsure safetyPrevent stuck situationsCarriagesBrake arrangement with braking memberWireless controlDrive shaft

The invention discloses an infrared induction type rail flat car. The infrared induction type rail flat car is characterized in that an infrared induction mechanism is mounted in a main body and connected with a distance detecting unit on the right side, the distance detecting unit is connected with a deceleration control unit on the right side, the deceleration control unit is connected with a wireless control unit on the right side, the wireless control unit is connected with a storage battery on the right side, a carrying plate is mounted on the upper portion of the main body, the main bodyis connected with a transmission shaft through a connecting shaft, and wheels are mounted on the transmission shaft and located on the two sides of the lower portion of the main body. According to the infrared induction type rail flat car, the distance between the rail flat car and an object in front of the rail flat car can be inducted through the infrared induction mechanism, when the distancedetecting unit calculates that the distance is too small, the rail flat car is decelerated through a deceleration device, and it is ensured that the rail flat car does not collide with other objects.

Owner:太仓圣广仁自动化设备有限公司

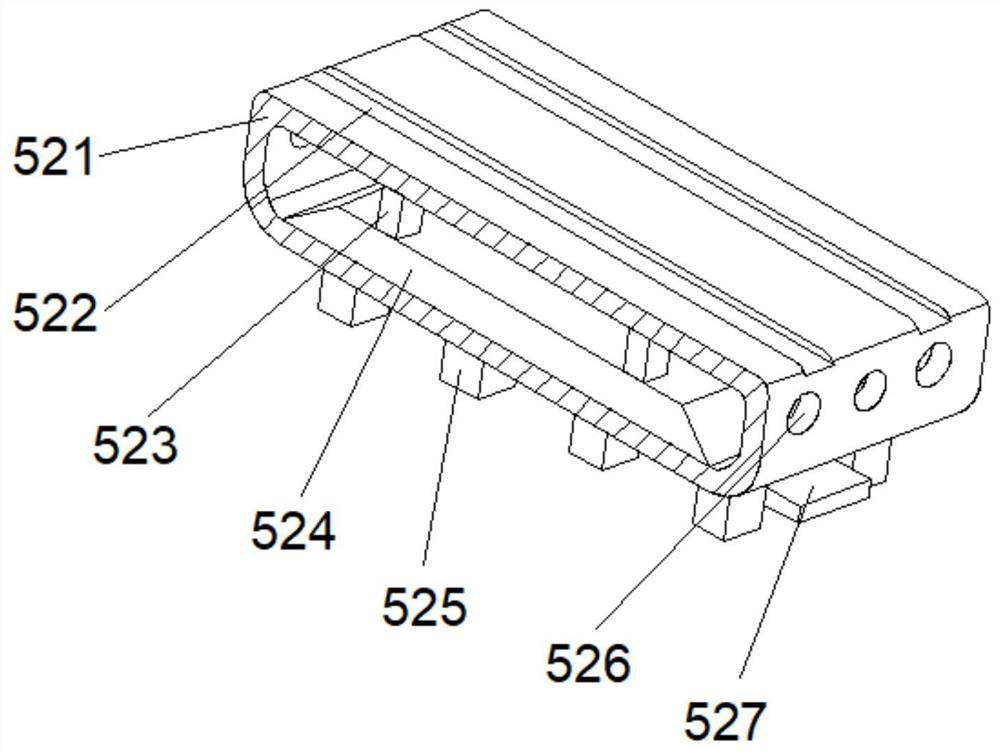

Lower rivet feed mechanism for automatic button-riveting machines

ActiveCN106942814AAvoid interferencePrevent stuck situationsClothes making applicancesRiveting machinesEngineering

The invention provides a lower rivet feed mechanism for automatic button-riveting machines, which comprises a rack, a feed base, a feed track, and a push rod, wherein the feed track carries out feeding for the feed base, the push rod is located in the rear section of the feed base to push a lower rivet supplied by the feed track into a die, the feed base is provided with a push guideway corresponding to the push rod and a feed channel corresponding to the feed track, a workpiece-positioning channel is formed at a position, which corresponds to the feed channel, on the push guideway, and the feed direction of the feed channel approximately forms an angle of 90 degrees with a lower rivet discharge direction in the push guideway. The lower rivet feed mechanism for automatic button-riveting machines further comprises a blocking part which can block the lower rivet before the push rod feeds the lower rivet and can release blocking when the push rod feeds the lower rivet, the blocking part abuts against the lower rivet upon the push guideway, so that the lower rivet is eccentric from the workpiece-positioning channel and is deviated toward the rear end of the feed channel, the blocking part abuts against the lower rivet, so that the distance by which the lower rivet is deviated toward the rear end of the feed channel is adjustable, and thereby the circumstance that the push rod is jammed in the process of push due to the stacking of bottom plates of neighboring lower rivets can be prevented.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

Solar power generation equipment

ActiveCN112583349AImprove power generation efficiencyProtectivePhotovoltaic supportsPhotovoltaic energy generationWater storage tankWater flow

The invention discloses solar power generation equipment which comprises a water storage tank, supporting bases are fixedly connected to the two sides of the bottom of the water storage tank, linkageframes are fixedly connected to the two sides of the top of the water storage tank, cleaning devices are arranged at the tops of the linkage frames, and fixing blocks are fixedly connected to the inner walls of the two sides of each cleaning device. A power generation plate is fixedly connected to the side, away from the cleaning devices, of the fixing block, a pipeline communicates with the middle of the front face of the water storage tank, and the end, away from the water storage tank, of the pipeline is fixedly connected with the cleaning devices. The invention relates to the technical field of solar power generation equipment. According to the solar power generation equipment, a water pump in the water storage tank is started, so that water flow enters the cleaning devices through a pipeline, the power generation efficiency of the equipment can be effectively improved after cleaning, the angle is adjusted through a self-adaptive block, the illumination receiving time of the equipment is prolonged, and the cleaning devices have a certain protection effect; and the situation that the device is damaged in daily life is avoided.

Owner:浙江浦江裕恒五金制品有限公司

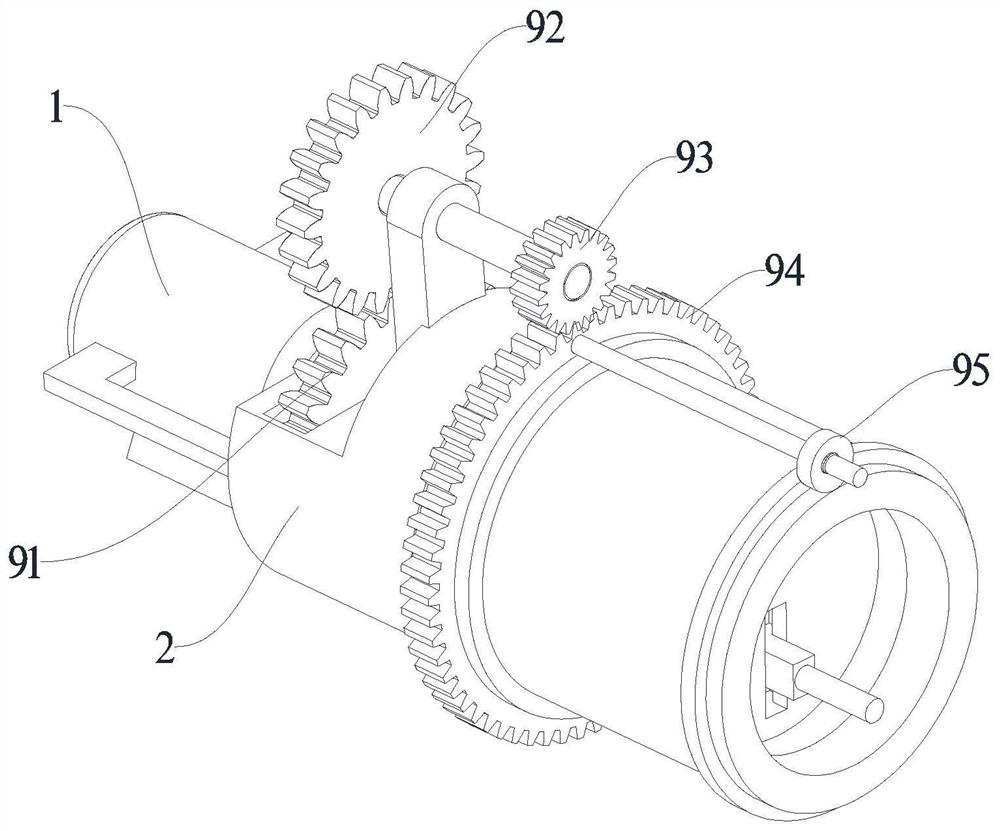

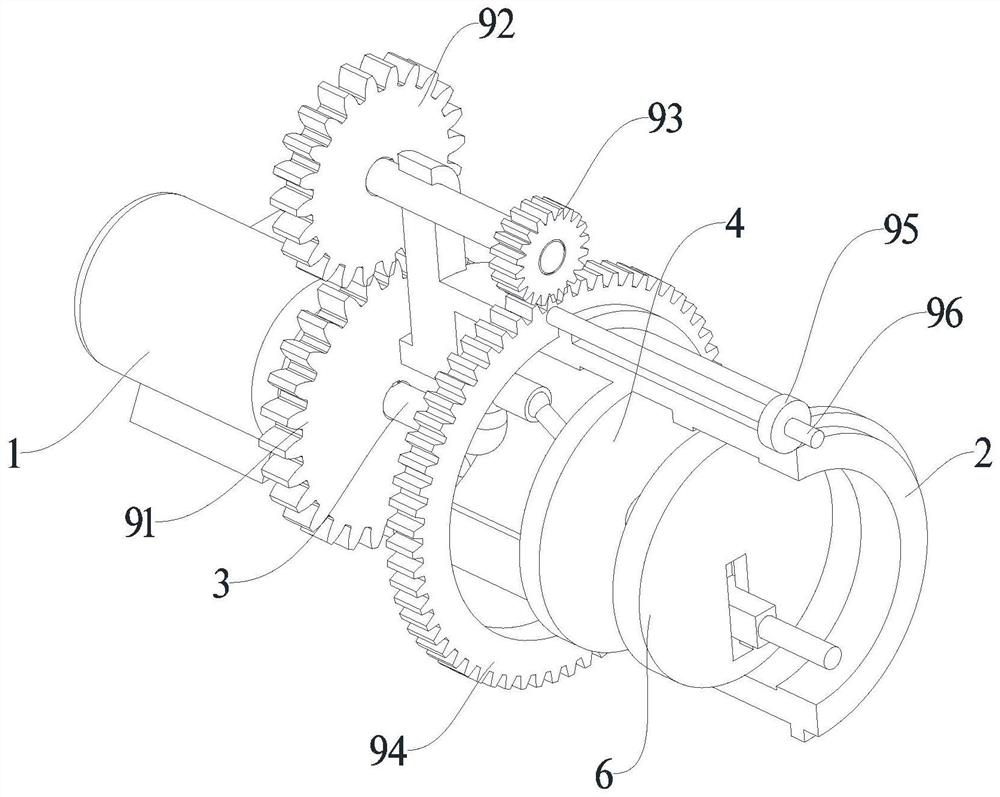

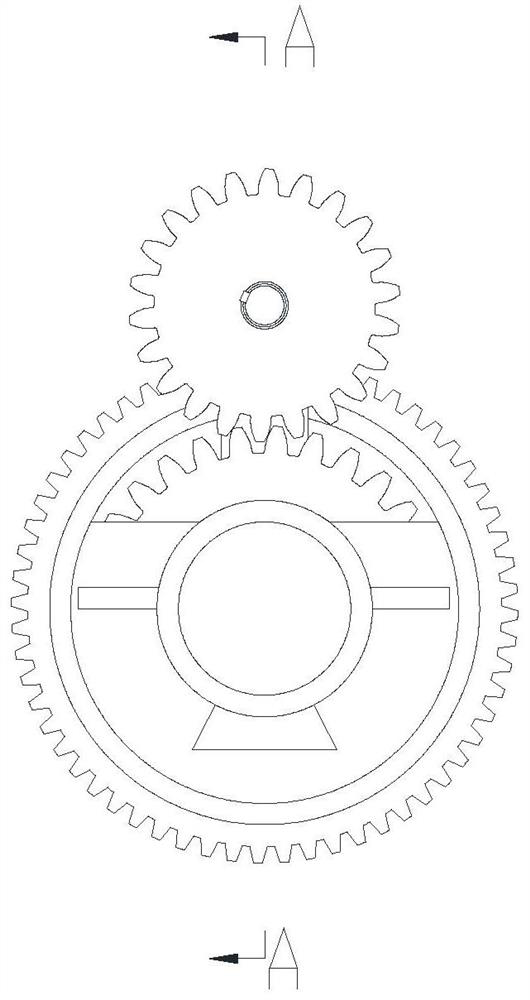

Motor mechanism with ball head shaft

ActiveCN112619527AChange driving forcePrevent stuck situationsTransportation and packagingRotary stirring mixersCrankElectric machinery

The invention relates to a motor mechanism with a ball head shaft. The motor mechanism with the ball head shaft comprises a driving motor, a mounting cylinder, a crank, a first movable disc, a connecting shaft, a second movable disc, a first stirring rod, an electric pole and an output assembly. The motor mechanism has the advantages that the crank and the connecting shaft are arranged, so that the driving motor can drive the first stirring rod to do circular motion for stirring processing; by moving the first movable disc, the diameter of the first stirring rod in circular motion can be adjusted, and the supporting point of the connecting shaft is adjusted, so that the driving force of the driving motor to the first stirring rod is changed, and the situation that the first stirring rod is stuck is prevented; and by arranging the output assembly, the driving motor can drive the second stirring rod to do circular motion at the same time, and the driving force distribution of the driving motor to the first stirring rod and the second stirring rod can be adjusted by adjusting the supporting point of the connecting shaft.

Owner:NINGBO XIASHA GEARS

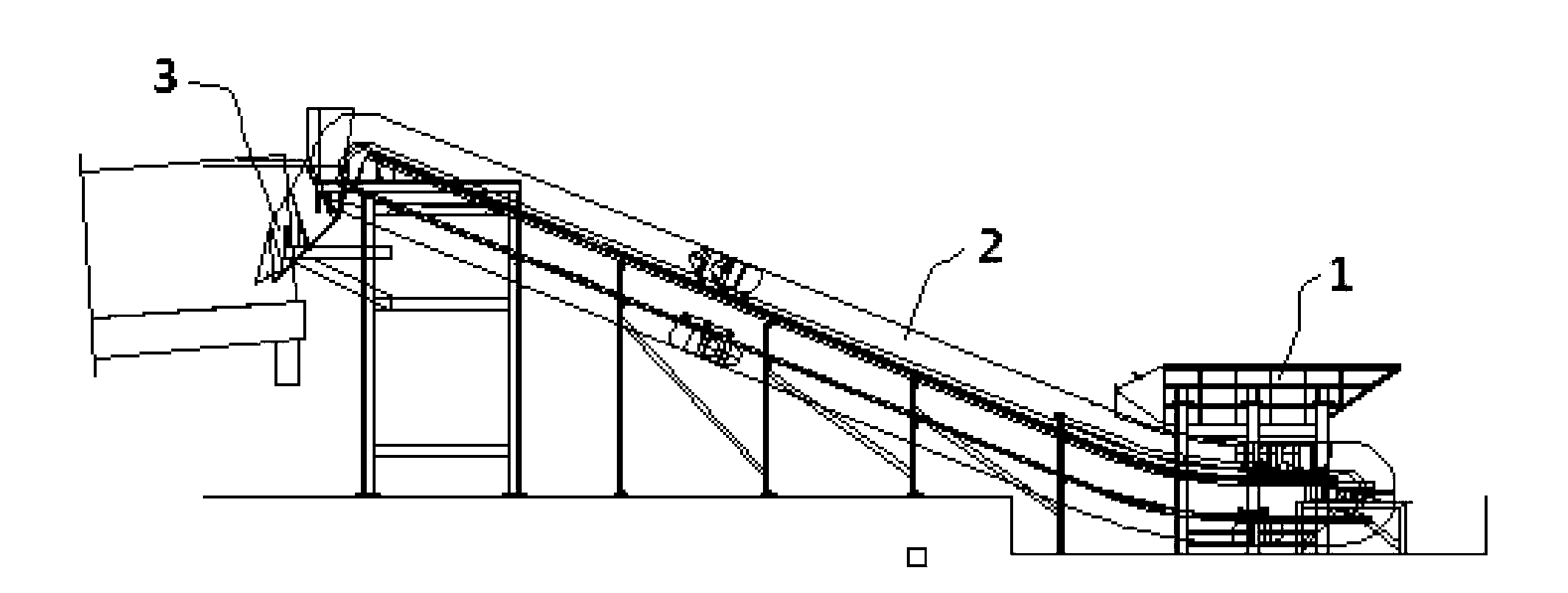

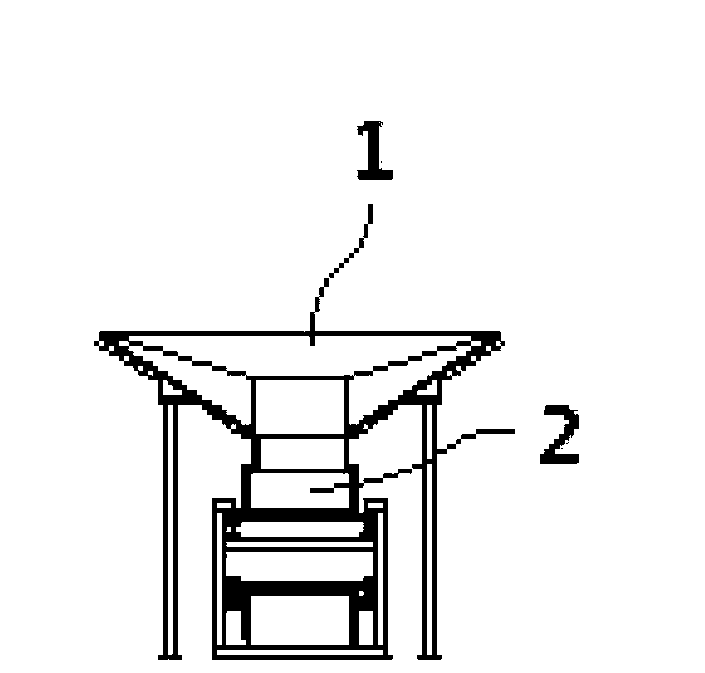

Chain scraper conveyor system for conveying waste purple impure copper

InactiveCN103010664APrevent stuck situationsPrevent embeddingConveyorsControl devices for conveyorsLowering plantsEngineering

The invention relates to a chain scraper conveyor system for conveying waste purple impure copper. The chain scraper conveyor system comprises a feeding hopper, a chain scraper conveyor, a discharging chute and a blanking hopper; a material supporting chain scraper and a chain hopper lateral chain scraper both have a series of chain plates; in each series of chain plates, a tail part of a front chain plate is covered on a hinge part of a rear chain plate along a conveying direction; the feeding hopper has a shape of truncated rectangular pyramid; a lower opening of the truncated rectangular pyramid platform is of rectangular shape; the length along the conveying direction at least spans three chain plates; the width along the direction vertical to the conveying direction is at least 0.1m less than the width of the chain plates; the discharging chute is covered between a position of an end chain plate of the chain scraper conveyor and the blanking hopper; the chain plate width of the chain scraper conveyor is at least 1m less than the width of the discharging chute; and the width of the discharging chute is at least 1m less than the upper width of the blanking hopper. The chain scraper conveyor system for conveying the waste purple impure copper can continuously and efficiently work in a lower plant and can prevent the chain scraper conveyor from being tightly blocked by the wound or embedded materials.

Owner:GANZHOU JIANGWU NEW TYPE ALLOY MATERIAL

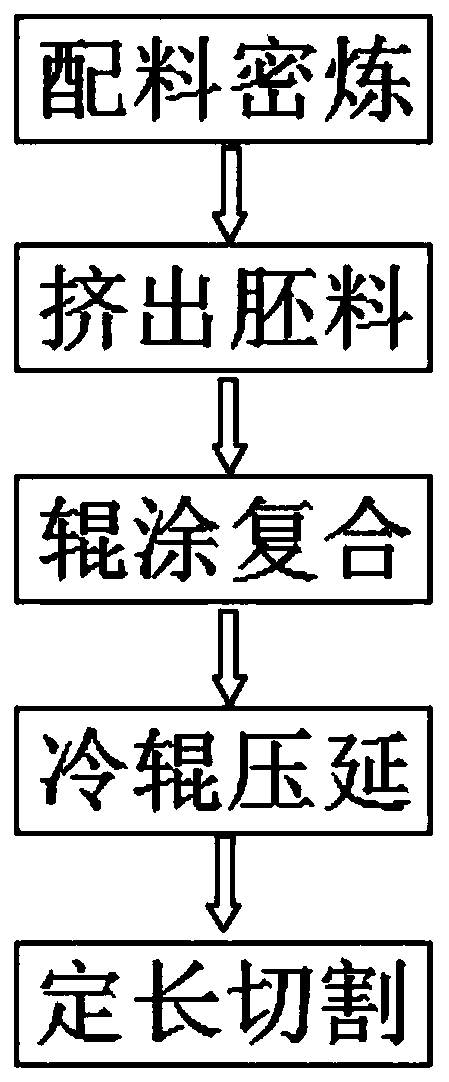

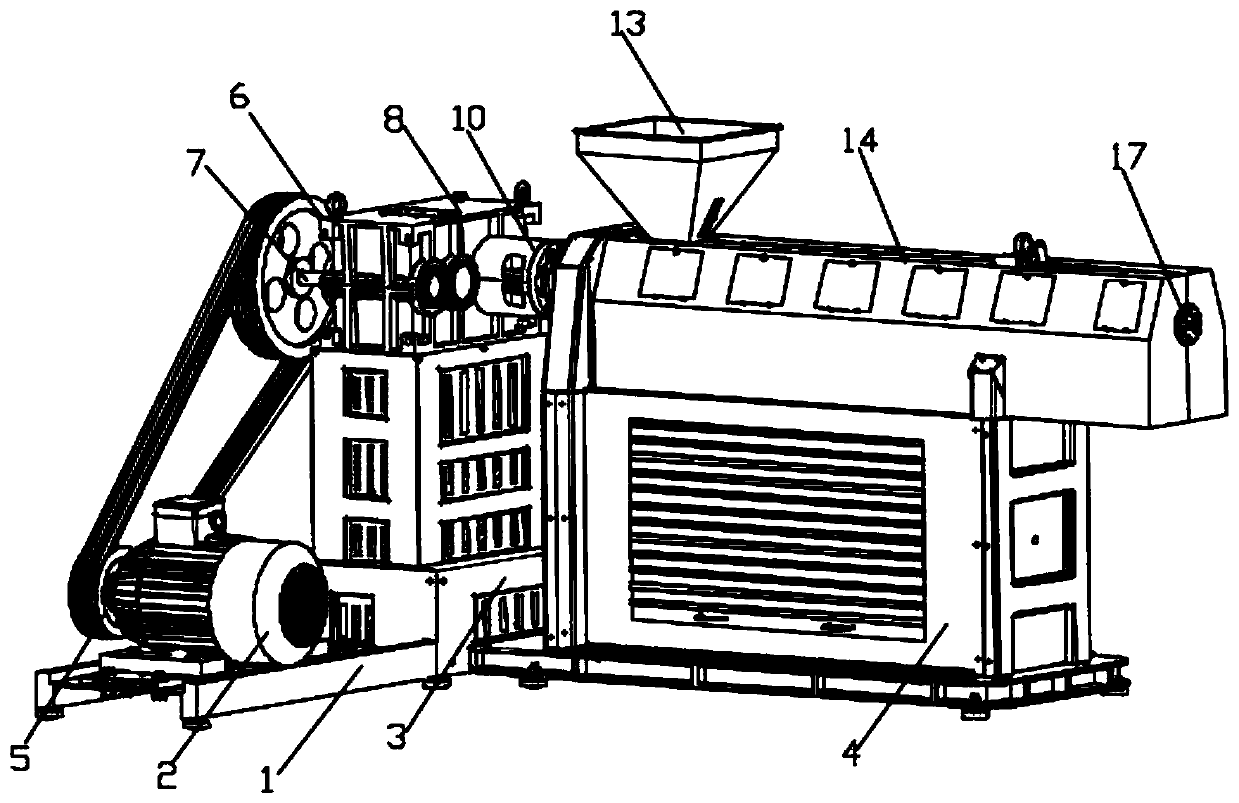

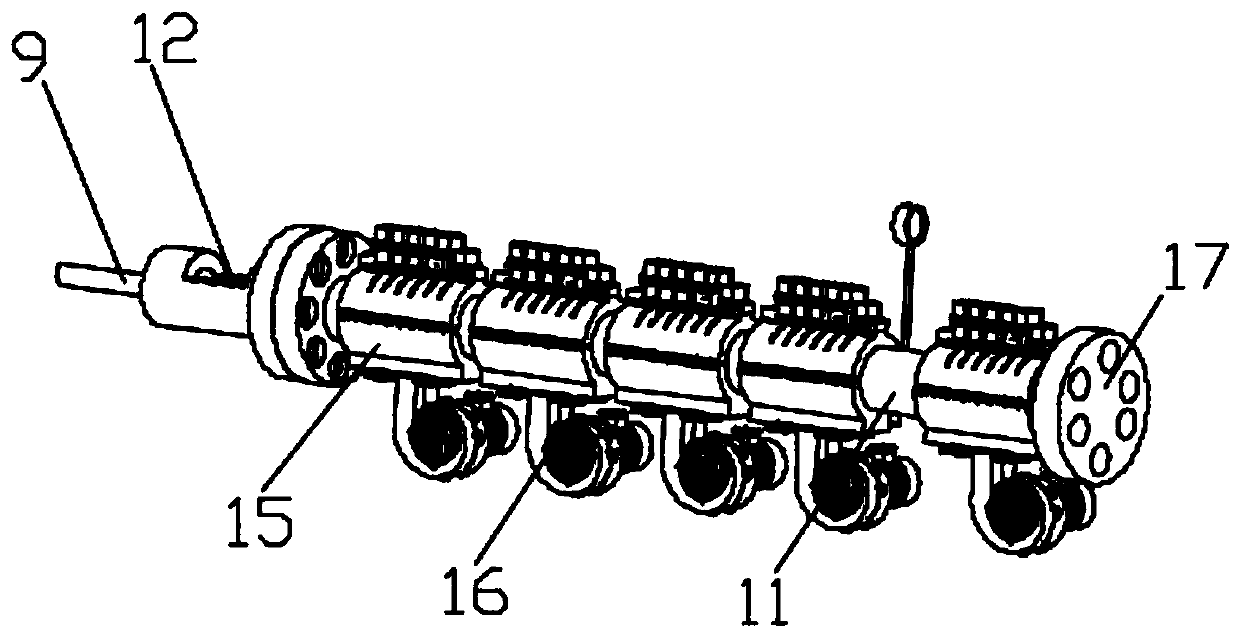

Processing method of fireproof aluminum-plastic plate

InactiveCN110370690AHigh tensile strengthImprove bending strengthFlat articlesSurface finishingFlexural strength

The invention discloses a processing method of a fireproof aluminum-plastic plate. The processing method of the fireproof aluminum-plastic plate comprises the steps of perform banburying on materials,extruding blanks, roller-coating and compounding, performing cold roller calendaring as well as performing fixed-length cutting. Through addition of a foaming agent aluminum hydroxide, a flame retardant synergist, a surface treating agent, an antioxidant, a lubricating agent, an interface modifier and a light stabilizing agent, the technical problems in the prior art of insufficient tensile strength, bending strength and heat-conducting coefficient of the fireproof aluminum-plastic plate are solved; through design of transmission between a belt and a transmission rod and a stop block arrangedon the outer circumferential surface of a conical screw rod, large particles in the mixture are effectively extruded and the technical problems in the prior art that noise generated in the equipmentworking process is big and the extruding screw rod is liable to jam are solved; and through cooperative design of a condensing pump, a condensing pipe and an air blower, the mixture in the extruding process is subjected sectional type cooling, so that the problem in the prior art that the purity of the blanks after extrusion is insufficient caused by too high temperature in the extruding process is solved.

Owner:安徽英标新材料科技有限公司

Device for cutting and crushing wheat straw

InactiveCN107801500APromote fragmentationFully crushed and refinedCuttersReciprocating motionEngineering

A wheat straw cutting and crushing device, comprising a main body, a feeding port is provided on the top of the main body, a grid plate is provided at the bottom of the feeding port, several square through holes are provided in the cutting board, and cutting blades are provided on the left and right inner walls of the through holes A bow-shaped rod is rotatably installed between the first shaft support and the second shaft support, and two limit rings are fixedly installed in the middle of the bow-shaped rod. A movable sleeve is installed on the bow-shaped rod in a rotating manner, and a connection is fixedly installed at the left end of the movable sleeve A connecting block is fixedly installed on the right end of the cutting plate, the connecting rod is hinged on the connecting block through a hinge shaft, a crushing shaft is arranged horizontally in the body, and a rotating blade is evenly arranged on the outer surface of the crushing shaft; the present invention can reciprocate left and right The moving cutting blade performs a preliminary cutting and truncating treatment on the wheat straw, which prevents the rotating blade from being stuck due to the excessive length of the wheat straw, and improves the work efficiency; the wheat straw is cut and broken after the second time, and the crushing effect is good.

Owner:郦莉萍

Surface treatment device for notebook-computer shell

PendingCN109382728AGuaranteed imaging accuracyGuaranteed accuracyGrinding carriagesGrinding machinesL-shellClosed state

The invention discloses a surface treatment device for a notebook-computer shell. The surface treatment device comprises a feeding support, a polishing support, multiple mechanical arms, a polishing head and a transporting clamp, wherein the polishing head and the transporting clamp are connected with tail end nodes of the mechanical arms respectively, and the feeding support and the polishing support are circumferentially arranged along the mechanical arms; the feeding support comprises a supporting frame and a feeding table installed on the supporting frame, multiple blade grooves are formedin a core body at equal intervals in the circumferential direction, and driving blades are embedded into the blade grooves respectively; an air inlet and an air outlet are formed in an outer shell, the air inlet is communicated with a first cavity, and the air outlet is communicated with the second cavity. As an air pipe installing base and an air pipe are arranged on the surface treatment devicefor the notebook-computer shell, the air inlet and an air outlet in the outer shell can be in the closed state, it is completely isolated that liquid used in the polishing process enters a shell fromthe air inlet or the air outlet, the service life of the polishing head is prolonged, the cost is saved, and the production efficiency is improved.

Owner:苏州丰川电子科技有限公司

Efficient plant fiber separator

InactiveCN107937987AReduce labor intensityEasy to separateMechanical fibre separationPlant fibrePulp and paper industry

The invention discloses an efficient plant fiber separator and belongs to the technical field of plant fiber treatment. The efficient plant fiber separator sequentially comprises, in order of processing sequence, a grinding separation device, a softening device, a steam heating device, a secondary grinding device, a vibration separation device and a discharge device. The grinding separation devicecomprises a roller bracket, a plurality of roller wheel sets are arranged on the roller bracket, and each roller wheel set is composed of a top roller wheel set and a bottom roller wheel set which are correspondingly arranged up and down. The lower end of the bottom roller wheel set is in transmission connection with a transmission gear. The efficient plant fiber separator has the advantages of simple structure, good separation effect, high efficiency and high yield.

Owner:绵阳市吉富精密机械有限公司

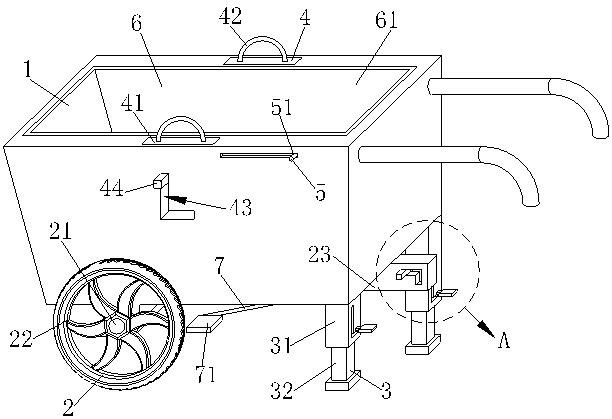

Material lifting device for building construction

InactiveCN112937648AEasy ground movementEasy to transportHand carts with one axisBuilding material handlingBrakeArchitectural engineering

The invention relates to the field of material lifting devices, and in particular relates to a material lifting device for building construction. The device comprises a vehicle body, a brake structure, a support structure, a lifting structure, a shielding structure, a mounting structure and a jacking structure. The brake structure is mounted at the bottom end of the vehicle body, so that the vehicle body for lifting materials can conveniently move on the ground, the vehicle body can be fixed, automatic sliding is avoided, operation is convenient and fast, the vehicle body can be supported when the vehicle body needs to be placed through the arrangement of the support structure, a support assembly can be retracted in the process of pushing the vehicle body, so that the situation that the support assembly scrapes the ground in the process of pushing the vehicle body can be avoided, the lifting structure is arranged at one end of the vehicle body, the hanging effect can be achieved when the materials need to be lifted, the lifting structure can be hidden when the materials do not need to be lifted, and the materials are prevented from adhering to the lifting structure to influence the lifting stability.

Owner:齐嘉蕾

Anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device and method

ActiveCN113142602AImprove processing efficiencyConvenient for picking meatHuskingHullingHydraulic cylinderProcess engineering

The invention discloses an anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device and method, and relates to the technical field of Yang-tonifying fruits. The anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device comprises a machine body; the top of the machine body is sleeved with a material collecting cylinder; a discharging port is formed in the middle of the bottom in the material collecting cylinder and penetrates through the bottom of the material collecting cylinder; an intermittent discharging mechanism is arranged below the discharging port; the left side and the right side of the inner wall of the machine body are fixedly connected with the left side and the right side of a fixing plate correspondingly; and a material guide plate is arranged below the discharging port. According to the anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device, by arranging a hydraulic cylinder and the pressing plate, the hydraulic cylinder operates to drive the pressing plate to be attached to Yang-tonifying fruits on a conveying belt and extrude hulls to break the hulls, and a traditional hulling method consuming a large amount of time and manpower is replaced; and the problem that in the prior art, a hull breaking treatment device for the Yang-tonifying fruits is lacked is solved.

Owner:人民非物质文化传播有限公司

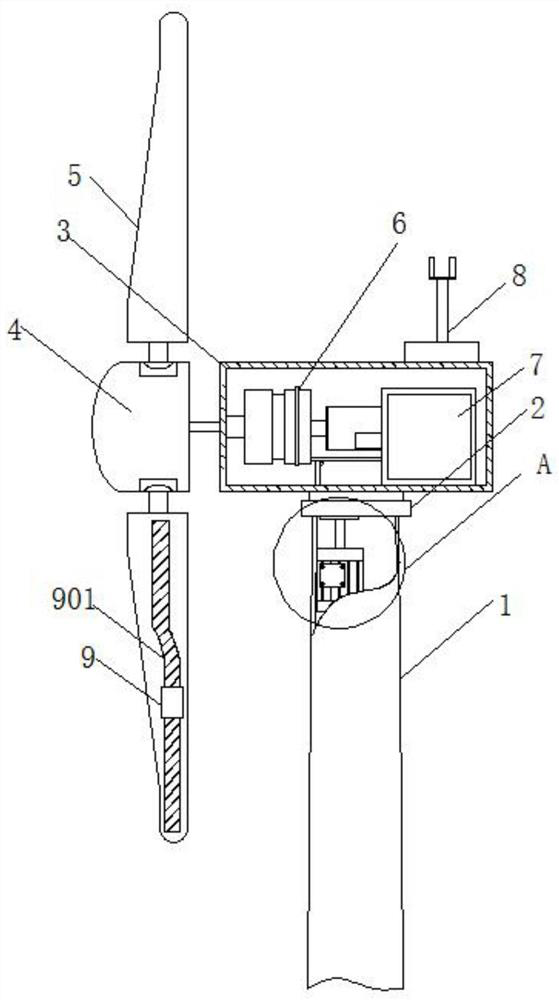

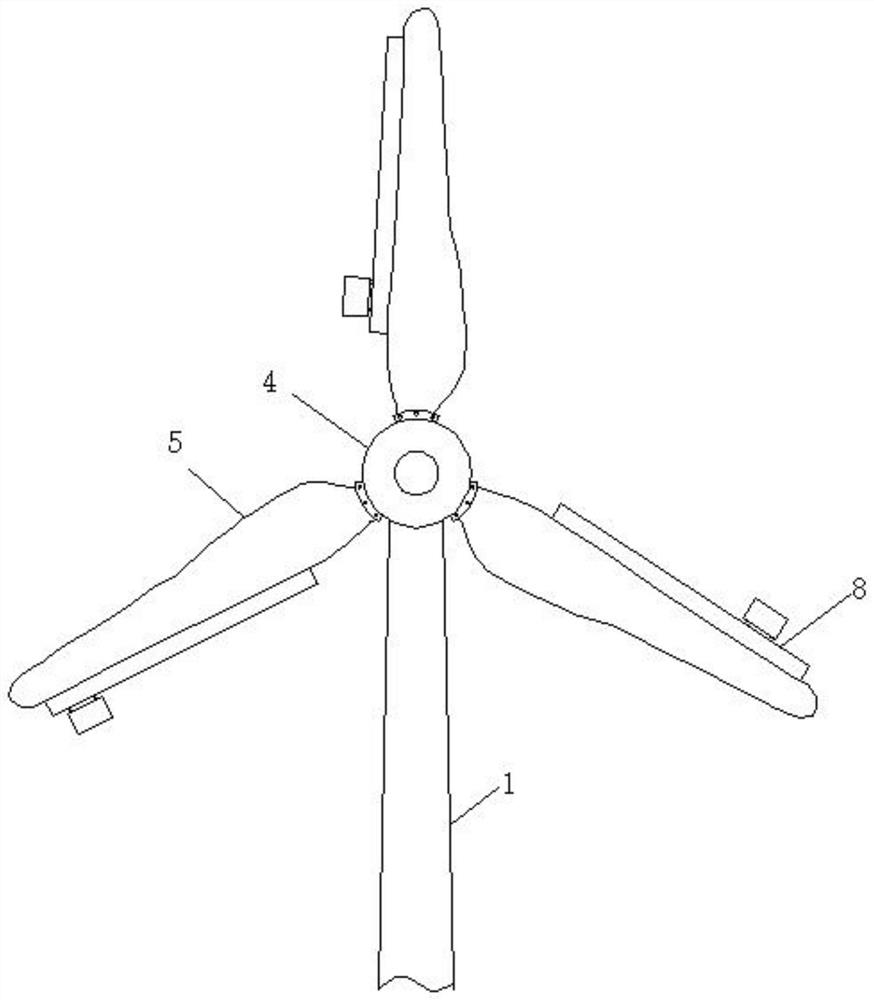

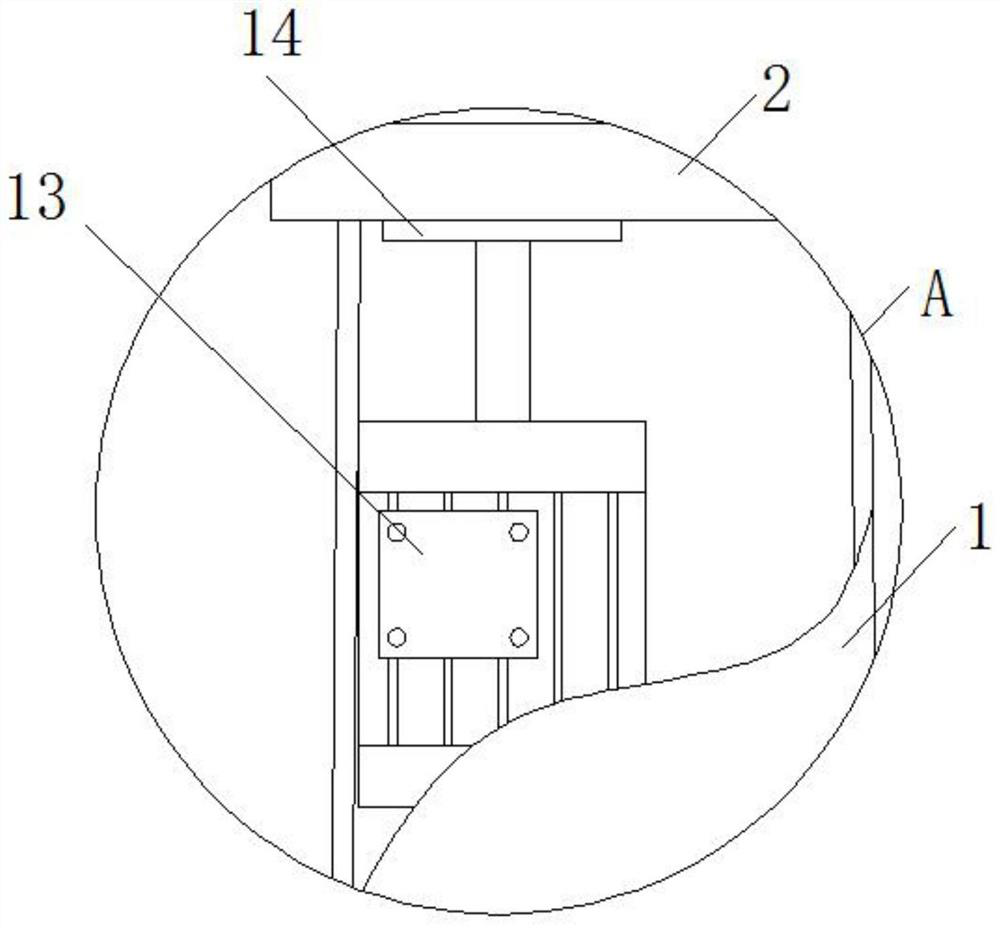

Wind power generation direction correcting and assisting system

InactiveCN112196736AIncrease the weight of the outer endEase the momentumWind motor controlWind energy with garvitational potential energyWind drivenNacelle

The invention discloses a wind power generation direction correcting and assisting system. The wind power generation direction correcting and assisting system comprises a supporting tower barrel, wherein the top end of the supporting tower barrel is fixedly connected with a bearing, and the top end of the bearing is rotationally connected with a cabin body; and a hub is fixedly arranged on one side of the cabin body, and the surface of the hub is fixedly connected with three rotation blades. In the wind power generation direction correcting and assisting system, when the rotation blades rotateat the low speed, rollers in a sliding rail drive a material storage groove with a plurality of balancing weights to move, the rotation blade balancing weights at the upper end slide towards the outer ends of the rotation blades, the weight of the outer ends of the rotation blades can be increased, the downward rotation speed of the rotation blades at the upper end is increased, and accordingly aplurality of rotation blades are driven through inertia to rotate in an accelerated manner. Compared with a traditional wind driven generator, the device can be used for generating power through rapid rotation of the rotation blades when wind power is small, and the wind energy utilization rate is increased; and through abutting plates and compression springs, the impact force of the rollers to the two ends of the sliding rail can be relieved, and damage caused by excessive force impacting to the rollers or the sliding rail is prevented.

Owner:安徽稳行智能装备科技有限公司

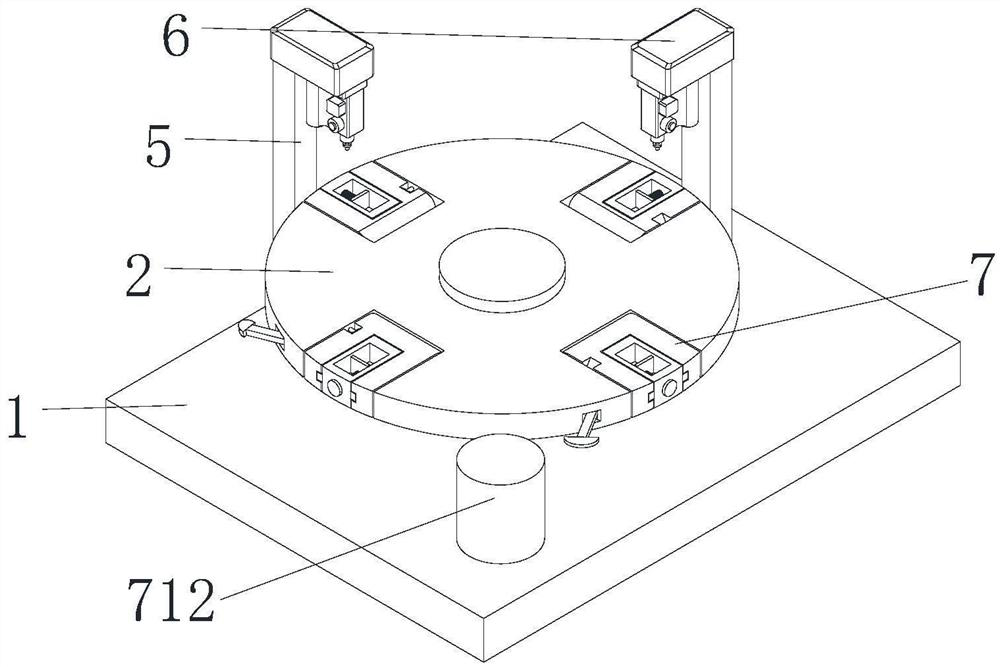

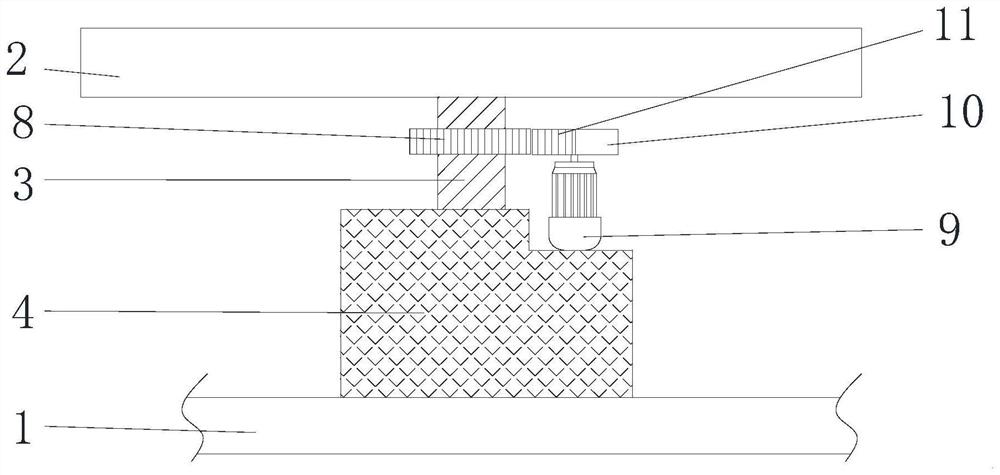

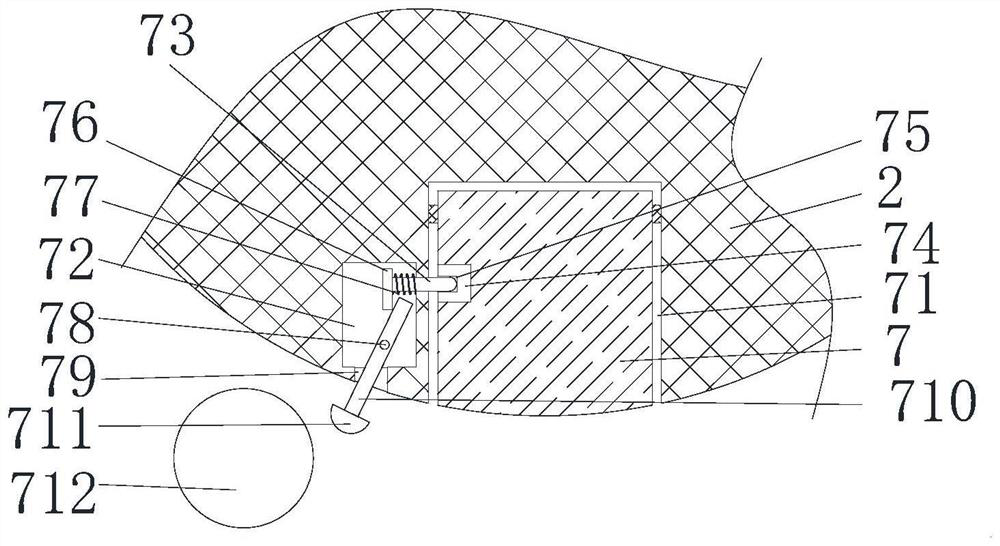

Punching and grinding equipment for electronic products

InactiveCN114310322AFast processingImproved drilling processOther manufacturing equipments/toolsRotational axisGear wheel

The invention discloses punching and grinding equipment for electronic products, and relates to the technical field of electronic product machining. The punching and grinding equipment for the electronic products comprises a mounting bottom plate, a mounting rotating disc is arranged on the upper side surface of the mounting bottom plate, a rotating shaft is fixedly connected to the lower side surface of the mounting rotating disc, a bearing seat is rotatably connected to the lower end of the rotating shaft, and a driving gear fixedly sleeves the outer surface of the rotating shaft; the upper side surface of the bearing seat is fixedly connected with a driving motor, an output shaft of the driving motor is fixedly connected with a rotating disc, and teeth are arranged on the outer surface of the rotating disc. According to the punching and grinding equipment for the electronic products, the punched electronic products are rotated to the position below the grinding mechanism to be ground, the punching mechanism punches the electronic products which are not punched, the efficiency of the two procedures of punching and grinding the electronic products is effectively improved, the machining speed of the electronic products is increased, and the machining efficiency of the electronic products is improved. And meanwhile, the working intensity of workers is also reduced.

Owner:江西宏均光电有限公司

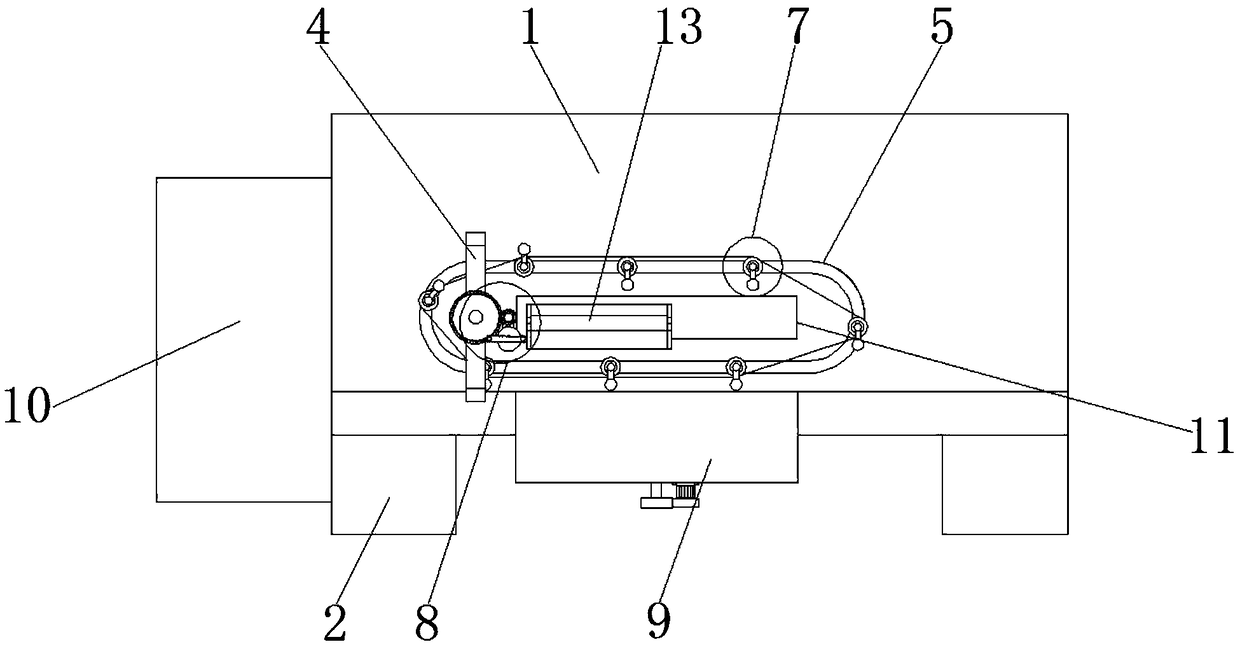

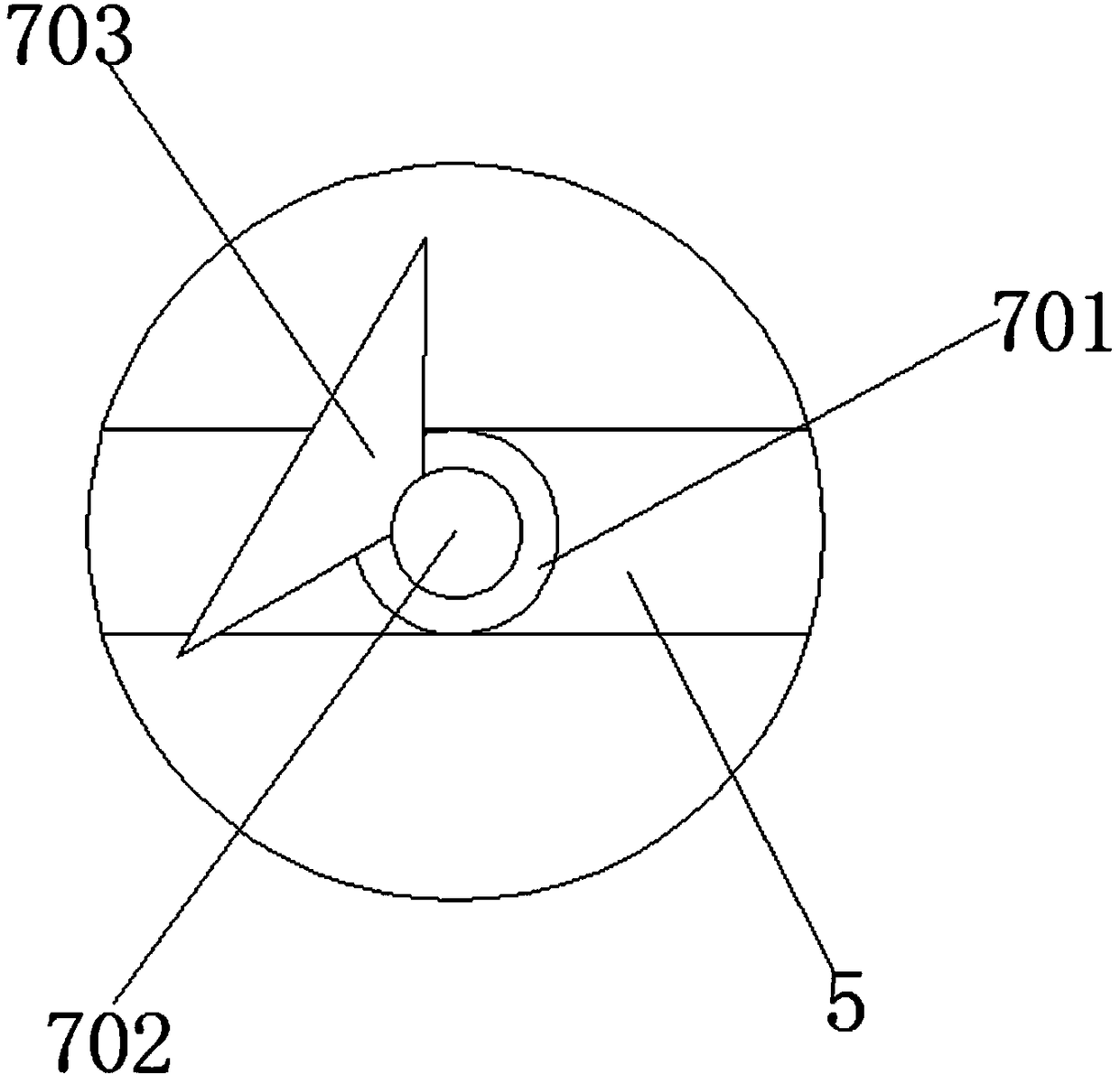

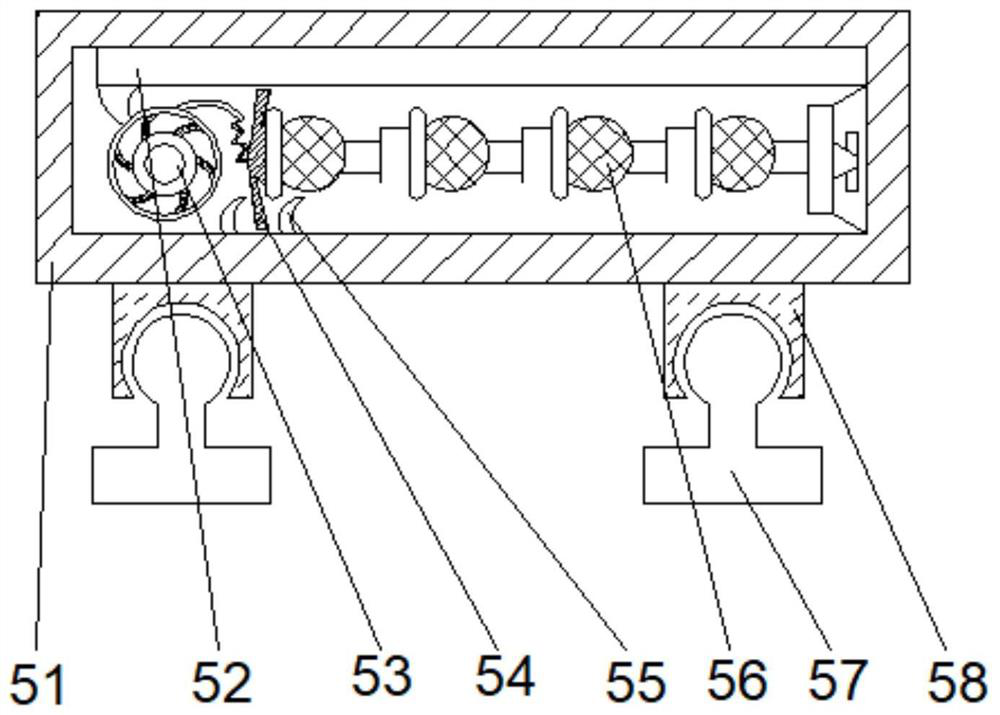

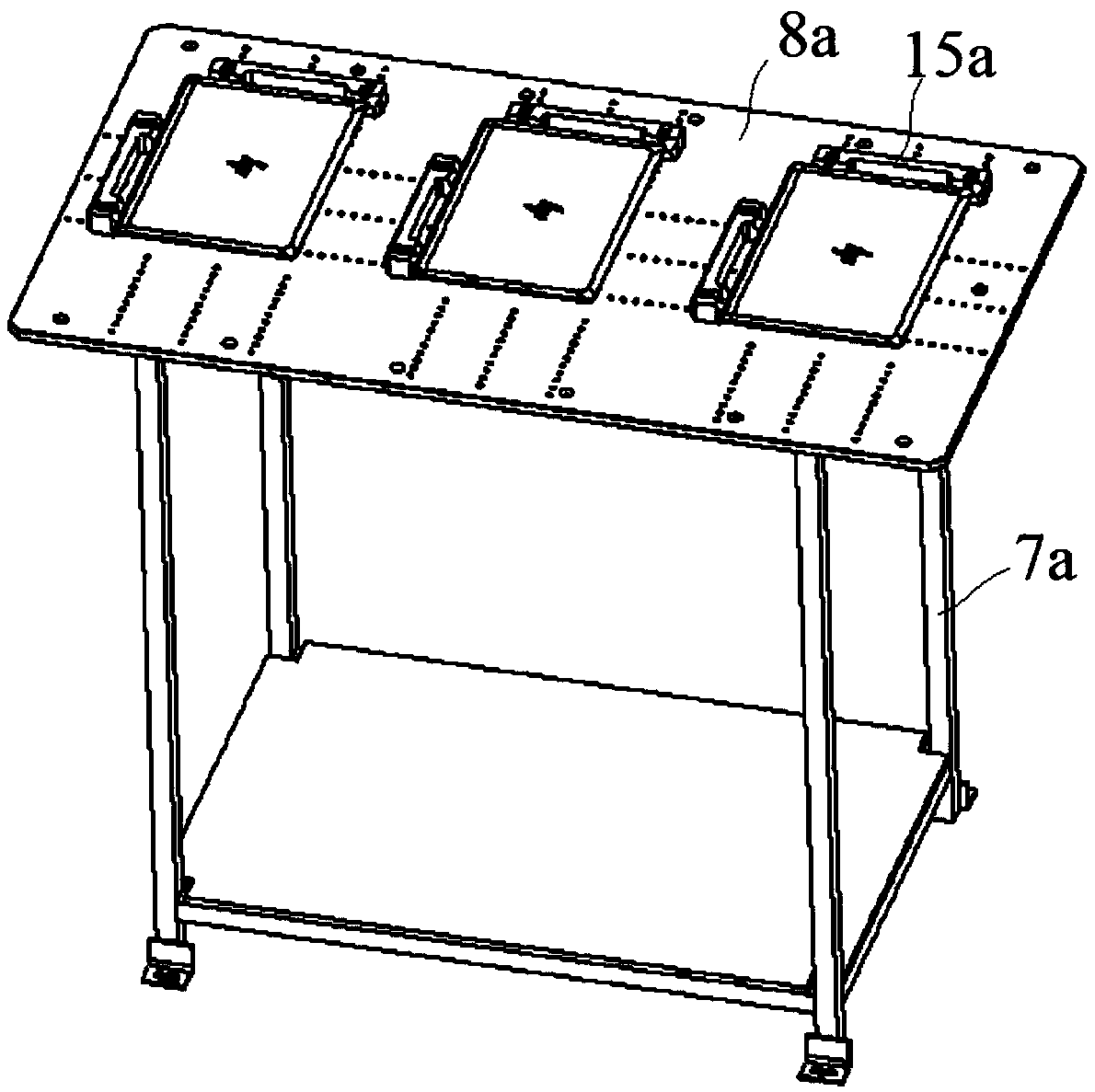

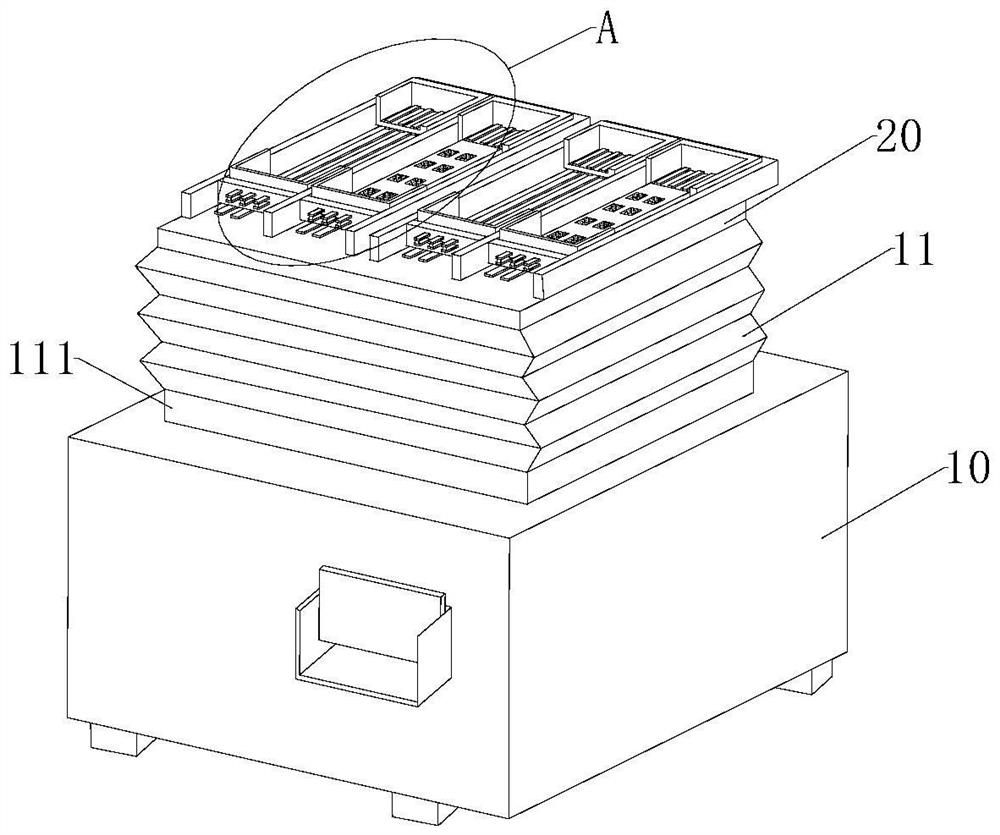

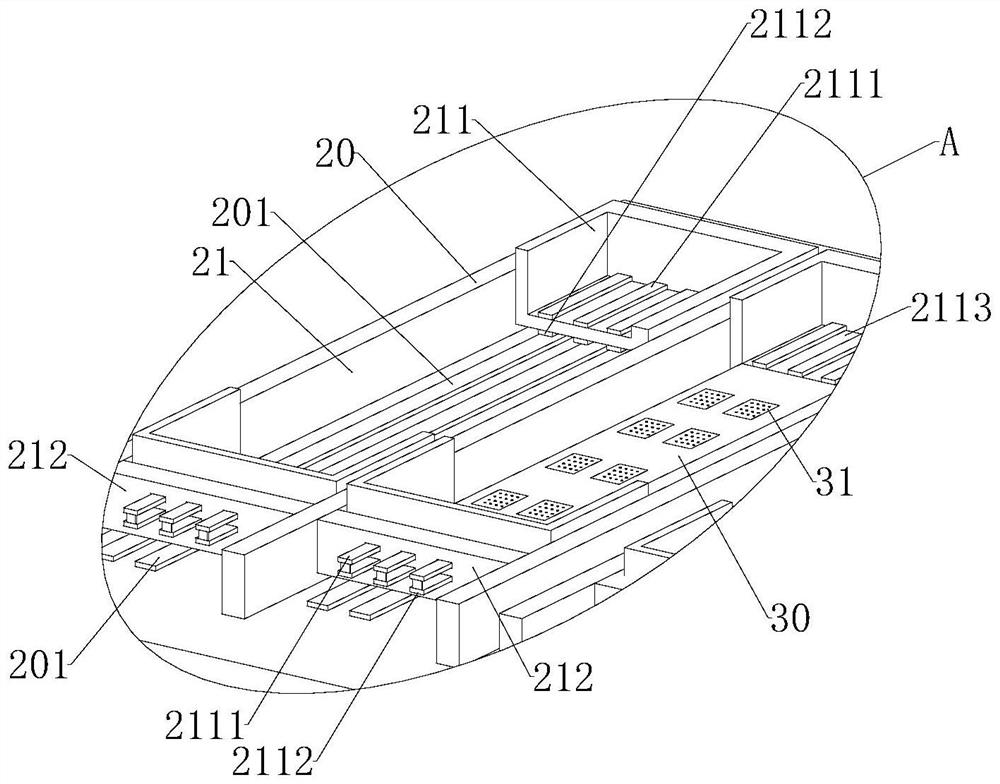

Efficient full-automatic sheet arranging machine and sheet arranging assembly and sheet arranging method thereof

PendingCN114420615ARealize limit operationImplement the fetch operationSemiconductor/solid-state device manufacturingConveyor partsEngineeringMachining

The invention discloses an efficient full-automatic sheet arranging machine and a sheet arranging assembly and method thereof, and belongs to the technical field of sheet arranging machining, the efficient full-automatic sheet arranging machine comprises a sheet arranging mechanism, a sheet arranging piece is arranged on the sheet arranging mechanism, a plurality of limiting cavities are formed in the sheet arranging piece, the multiple limiting cavities are arranged on the sheet arranging piece at equal intervals, and two rows of limiting cavities are arranged on the sheet arranging piece; a plurality of sheet arranging plates are installed on the sheet arranging piece, a plurality of sheet arranging holes arranged at equal intervals are formed in the sheet arranging plates, the sheet arranging plates are connected with the sheet arranging piece in a clamped mode through corresponding limiting cavities, sensors are installed at the inner bottom ends of the limiting cavities, limiting mechanisms are arranged in the limiting cavities, the number of the limiting mechanisms is two, and the limiting mechanisms are arranged in the limiting cavities. The clamping grooves are formed in the two sides of the sheet arranging plate, the first pushing plate and the second pushing plate are arranged in the limiting cavity, and limiting operation of the limiting mechanism on the sheet arranging plate is achieved through the angle formed by the first pushing plate and the second pushing plate.

Owner:广东台进半导体科技有限公司

Overturn clearing-up type tartarian buckwheat conveying mechanism

InactiveCN106927196ALarge spreading areaGood synchronizationMagnetic separationLoading/unloadingPolygonum fagopyrumGear wheel

The invention discloses a turning and cleaning type tartary buckwheat transportation mechanism. Including the conveying box, the conveying box is equipped with a conveying plate; the conveying box is also equipped with a leveling device, and an adsorption device is arranged next to the leveling device; the leveling device includes a scraper frame, which is connected with the scraper, and the scraper There is a rack, the rack is connected with the gear, and the gear is connected with the adjustment knob; the slope structure is arranged under the scraper, and the scraping teeth are arranged on the slope structure; the adsorption device includes a positioning frame, which is connected with the delivery box, and the positioning frame is also set. There is an adjustment rack, the adjustment rack is connected to the adjustment gear, the adjustment gear is connected to the capstan through the connecting shaft, and the two capstans are connected through the twist belt; two magnets are symmetrically arranged in the positioning frame, and each magnet is equipped with a flip on the axis. The two turning shafts are provided with turning gears, the two turning gears are connected with the common gear, and the common gear is connected with the turning knob. The invention has the characteristics of filtering product impurities, improving product purity, flexible use and convenient cleaning.

Owner:FUJIAN FLAVOR FOOD

High-precision automatic polishing machine

ActiveCN109500718ASave materialShorten the timeGrinding carriagesPolishing machinesRubber ringWater vapor

The invention discloses a high-precision automatic polishing machine. The high-precision automatic polishing machine comprises a material loading support seat, polishing support seats, a plurality ofmechanical arms, polishing heads and material conveying fixtures, wherein the polishing heads and the material conveying fixtures are installed and connected to tail end joint points of the mechanicalarms correspondingly, the material loading support seat and the polishing support seats are arranged in the circumferential direction of the mechanical arms correspondingly, the material conveying fixtures are suction cup mechanisms, the suction cup mechanisms comprise installation plates and a plurality of suction cups connected to the corresponding installation plates, each polishing head comprises an outer shell body, an inner shell body, a core body and a rotating head, the inner shell body is located inside the corresponding outer shell body, the core body is rotatably arranged inside the corresponding inner shell body, the rotating head is installed and connected to the corresponding core body, each polishing head is further provided with an air pipe installation seat installed to the corresponding outer shell body, and each air pipe installation seat comprises an air inlet portion and an air outlet portion. According to the high-precision automatic polishing machine, by means of the arrangements of rubber rings, sealing pad rings and pad pieces, the sealing effect of the lower portions of the polishing heads is enhanced layer by layer, water vapor and liquid can be effectively prevented from entering the shell bodies, components inside the shell bodies are protected, and the service life of the high-precision automatic polishing machine is prolonged.

Owner:苏州丰川电子科技有限公司

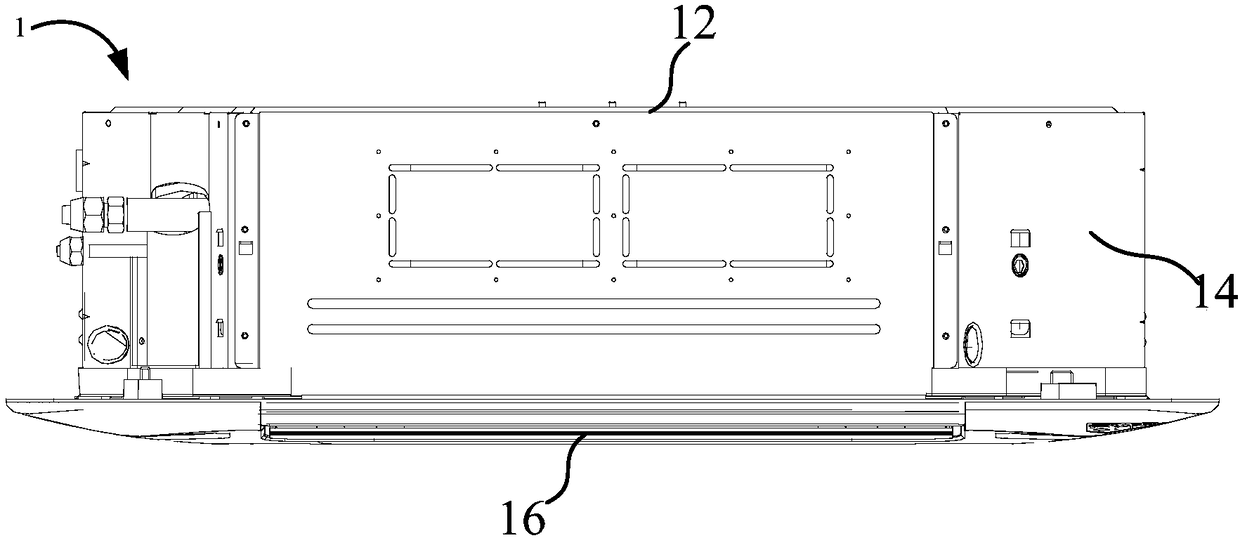

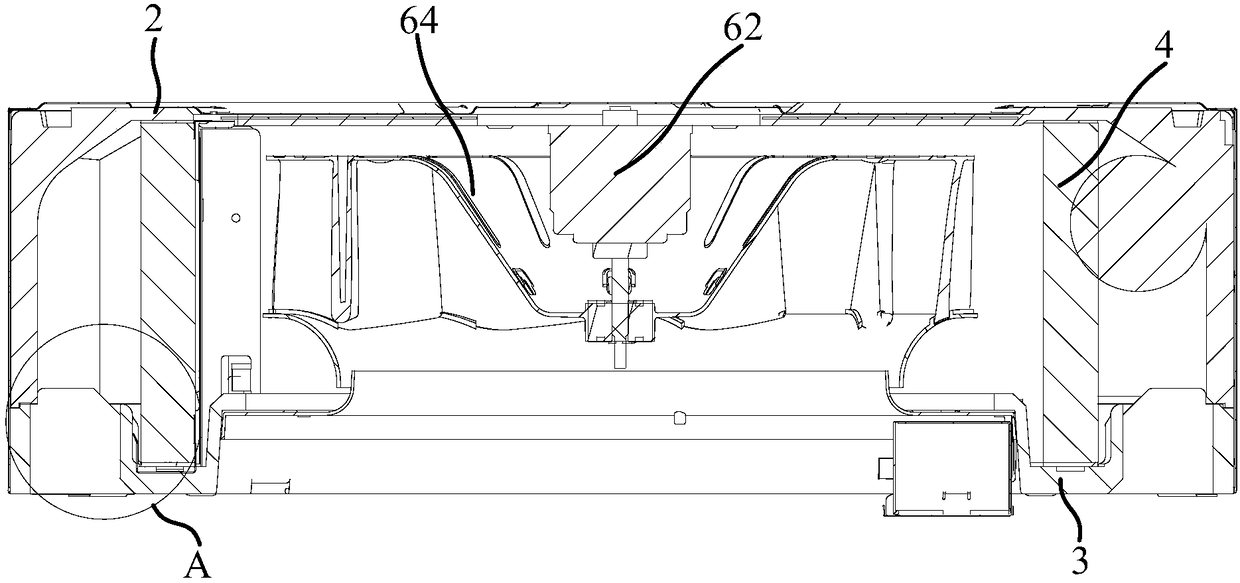

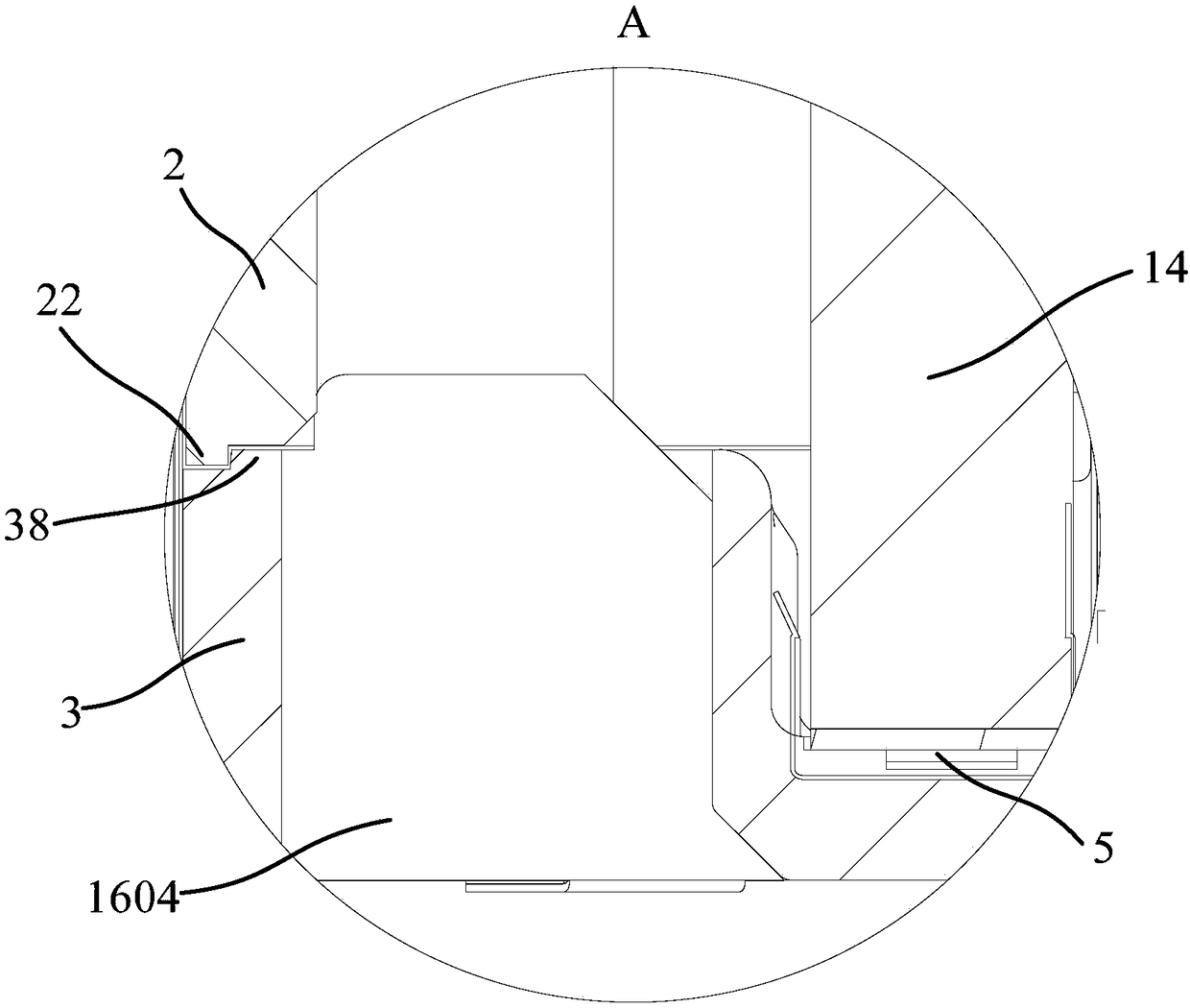

Air conditioner equipment

PendingCN108507023AAvoid prolonged soakingImprove condensation phenomenonCondensate preventionLighting and heating apparatusEngineeringMicro heat exchanger

The invention provides air conditioner equipment. The air conditioner equipment comprises a shell, an insulation board, a water receiving tray, a heat exchanger and a heat preservation pad. The shellis defined by a base plate, a coaming assembly and a panel assembly. An air inlet and air outlets are formed in the panel assembly. The insulation board is installed on the base plate. The water receiving tray is installed on the side, away from the base plate, of the insulation board, and the water receiving tray and the insulation board form an air duct communicated with the air inlet and the air outlets. The heat exchanger is installed in the air duct. The heat preservation pad is arranged between the heat exchanger and the insulation board and / or between the heat exchanger and the water receiving tray. According to the scheme, the heat preservation performance of the end, close to the insulation board, of the heat exchanger can be improved by installing the heat preservation pad between the heat exchanger and the insulation board, and the temperature of the end, close to the insulation board, of the heat exchanger can be increased, so that the phenomenon of condensation at the end,close to the insulation board, of the heat exchanger can be alleviated; and by installing the heat preservation pad between the heat exchanger and the water receiving tray, the heat preservation performance of the end, close to the water receiving tray, of the heat exchanger can be improved, and the temperature of the end, close to the water receiving tray, of the heat exchanger can be increased,so that the phenomenon of condensation at the end, close to the water receiving tray, of the heat exchanger can be effectively alleviated.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

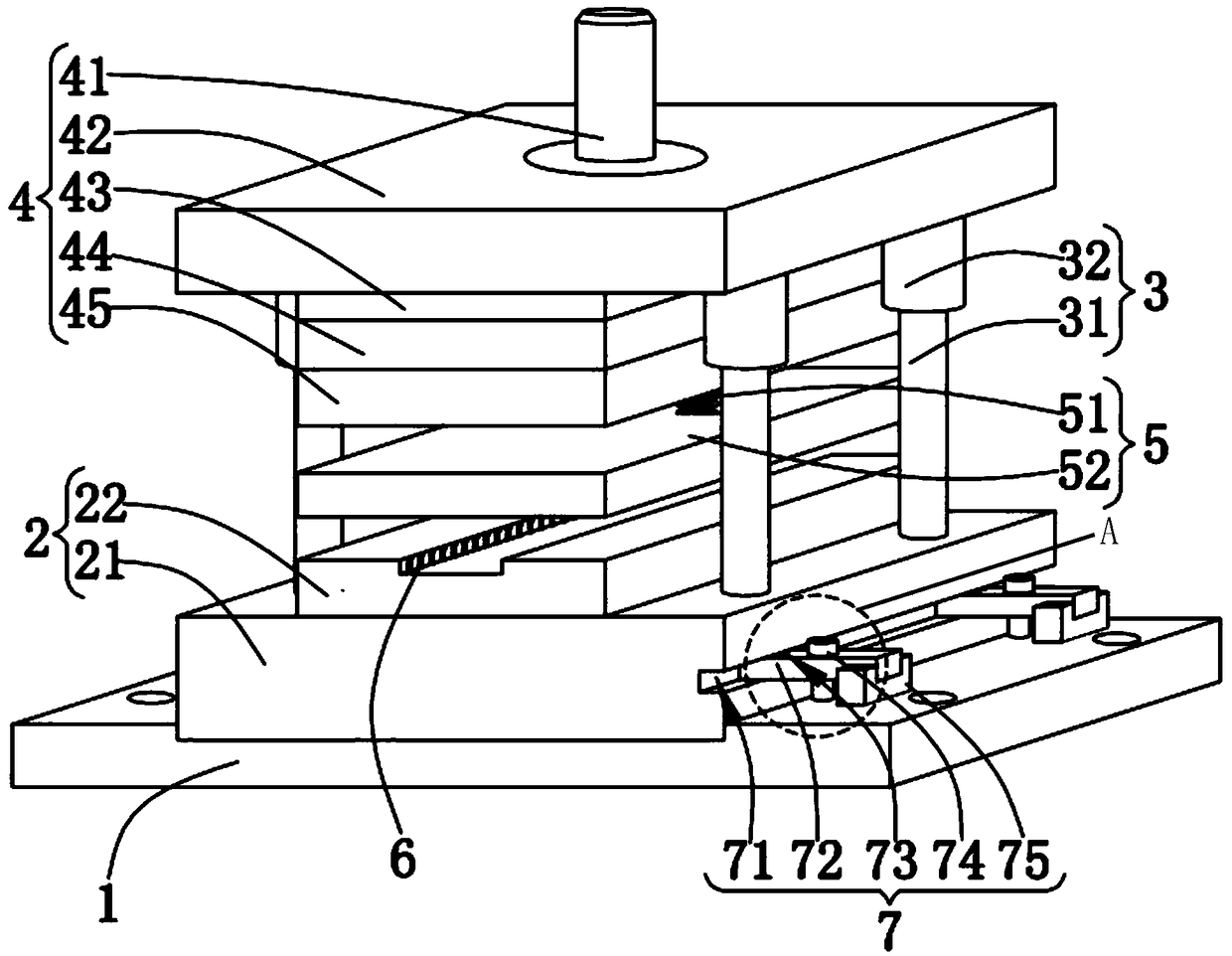

Single drive punch side cutting stamping die

InactiveCN109500206AStamping work in orderPrevent stuck situationsEjection devicesEngineeringMechanical engineering

The invention relates to the technical field of cold stamping, in particular to a single drive punch side cutting stamping die. The single drive punch side cutting stamping die comprises a base, a lower die structure, a guiding structure, an upper die structure, a discharging structure, a limiting structure, a fixed structure, a stamping structure and a jacking structure; the limiting structure isarranged inside the lower die structure, the limiting structure can limit and guide stamping materials, and the stamping materials are prevented from being stuck. The jacking structure is arranged atthe top end of the stamping structure. The jacking structure is arranged so that the stamping materials can be jacked up in time after the stamping is completed, the phenomenon that the stamping materials are stuck is prevented, the stamping work of the die can be performed orderly, and the work efficiency is improved.

Owner:周焱春

Circuit breaker

PendingCN114783816AAchieve compactnessGood elasticity and conductivityHigh-tension/heavy-dress switchesAir-break switchesPhysicsEngineering

The invention relates to a circuit breaker which comprises an arc extinguish chamber barrel fixedly provided with an arc extinguish chamber and an operating mechanism arranged on one side of the arc extinguish chamber barrel, and a supporting structure supported on a movable support is arranged in the arc extinguish chamber barrel. The supporting structure comprises two electric conductors, the upper ends of the two electric conductors are connected through a closing resistor, and the circuit breaker comprises a closing resistor containing cavity used for covering the closing resistor. The circuit breaker further comprises a closing resistor static contact and a closing resistor moving contact, the closing resistor static contact comprises static contact split bodies arranged on the two electric conductors respectively, and the closing resistor moving contact is used for stretching into and being clamped between the two static contact split bodies so as to short-circuit the closing resistor. According to the embodiment of the invention, the arc extinguish chamber cylinder only needs to be provided with the closing resistor accommodating chamber with the corresponding size at the position, corresponding to the closing resistor, of the upper side of the arc extinguish chamber cylinder, and the overall size of the arc extinguish chamber cylinder in the radial direction and the axial direction cannot be affected.

Owner:PINGGAO GRP +1

Ore grinding equipment and method for mineral exploitation

ActiveCN113941390AVolume averagePrevent stuck situationsProcess efficiency improvementGrain treatmentsMining engineeringMineralogy

The invention relates to the technical field of mining equipment, in particular to ore grinding equipment and method for mineral exploitation. The ore grinding equipment comprises a shell body and a feeding pipe, wherein a top cover is installed on the outer wall of the top of the shell body through a bolt, a bottom cover is installed on the outer wall of the bottom of the shell body through a bolt, a motor is installed on the outer wall of the top of the top cover through a bolt, the output end of the motor is fixedly connected with a rotating shaft through a coupler, and the exterior of the rotating shaft is in key connection with a crushing wheel and a smashing wheel. The ore grinding equipment has the beneficial effects that through the arrangement of a crushing wall, the crushing wheel, the smashing wheel, a smashing supporting plate, grinding rods and a grinding disc, the equipment is provided with a three-stage structure, and ore can be subjected to three-stage treatment of primary crushing, fine crushing and grinding, so that the size of ore entering grinding treatment is average, the situation that a grinding mechanism is stuck by ore can be effectively prevented, and meanwhile, the service life of the equipment is prolonged, and the powder discharging quality of the equipment is improved.

Owner:滁州方大矿业发展有限公司

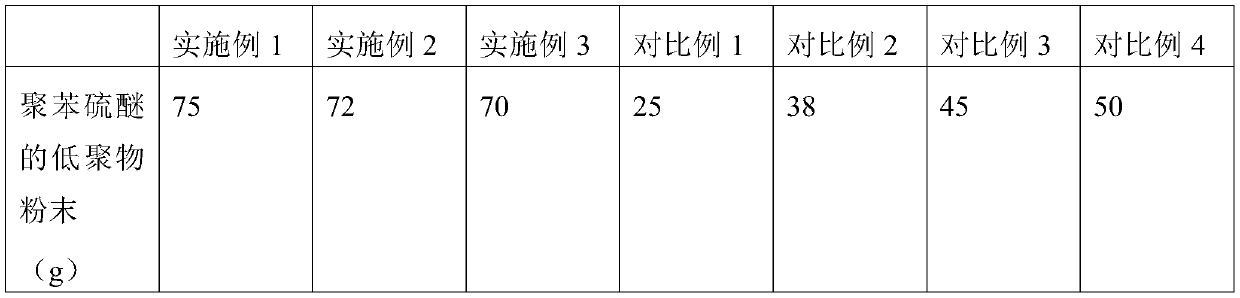

Process for separating and purifying polyphenylene sulfide

The invention discloses a process for separating and purifying polyphenylene sulfide. The process includes (1), separating the granular polyphenylene sulfide from mixtures with the polyphenylene sulfide by centrifugal machines, and mixing the remaining mixtures and diatomaceous earth with one another in mixing kettles to obtain mixtures A; (2), connecting outlets of the mixing kettles with pumps,connecting outlets of the pumps with regulating valves, connecting the regulating valves with plate hermetic filters, conveying the mixtures A to the plate hermetic filters by the pumps and filteringthe mixtures A to obtain solid materials and filter liquor B; (3), delivering the filter liquor B into rectification systems and rectifying the filter liquor B. The process has the advantages that theself-operated regulating valves and the plate hermetic filters are used with one another, the diatomaceous earth is applied to procedures for separating and purifying the polyphenylene sulfide, accordingly, the problems of pump and rectification tower blockage due to materials, the requirement on detaching tower equipment for clearing or washing the tower equipment and material leakage can be effectively solved by the aid of the process, product loss further can be reduced, environmental pollution can be abated, and the productivity can be improved.

Owner:ZHUHAI CHANGXIAN CHEM TECH

Collision-proof artificial intelligence robot testing site

PendingCN107363865AExtended service lifeChange heightManipulatorCircular discAgricultural engineering

The invention discloses a collision-proof artificial intelligence robot testing site which comprises a base and fixing seats. A damping plate is arranged on the base, air cylinders are mounted around the inner side of the base, a telescopic rod is connected to the upper portion of each air cylinder, elastic ropes are connected between every two adjacent fixing seats, a limiting block is arranged on each fixing seat, an operating rod is connected to the lateral side of a wrench mounted on each limiting block, each limiting block is provided with limiting grooves all around, a disc is mounted on a moving rod arranged on the inner side of each fixing seat, and each moving rod in the middle of corresponding disc is provided with fixing holes. The collision-proof artificial intelligence robot testing site has advantages that by the elastic ropes around the site, a robot about to fall down can be intercepted and buffered so as to prevent robot damages.

Owner:王月娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com