Solar power generation equipment

A technology for power generation equipment and solar energy, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problems of not being able to clean up automatically at regular intervals, easily damaging solar panels, affecting the power generation efficiency of equipment, etc., to achieve convenient control, easy interception, The effect of increasing the open range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

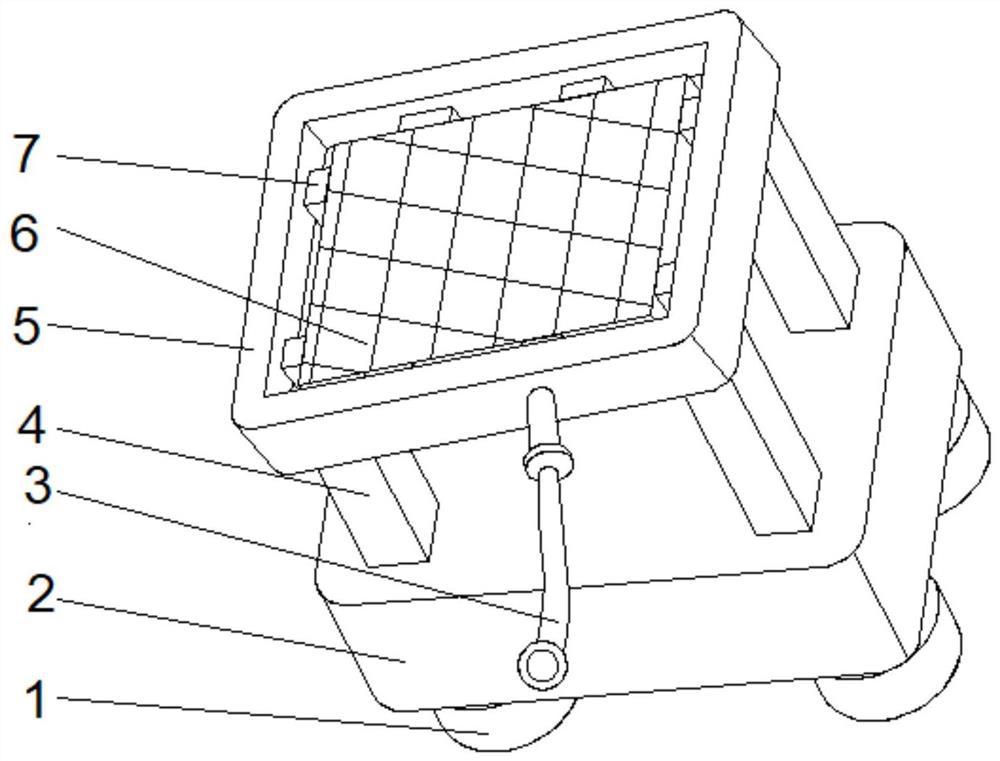

[0034] see Figure 1-2 , the present invention provides a technical solution: a solar power generation device, including a water storage tank 2, a support seat 1 is fixedly connected to both sides of the bottom of the water storage tank 2, and a linkage frame is fixedly connected to both sides of the top of the water storage tank 2 4. The top of the linkage frame 4 is provided with a cleaning device 5, the inner walls of both sides of the cleaning device 5 are fixedly connected with a fixed block 6, and the side of the fixed block 6 away from the cleaning device 5 is fixedly connected with a power generation board 7, and the water storage tank 2 The middle part of the front is communicated with a pipeline 3, and the end of the pipeline 3 away from the water storage tank 2 is fixedly connected with the cleaning device 5.

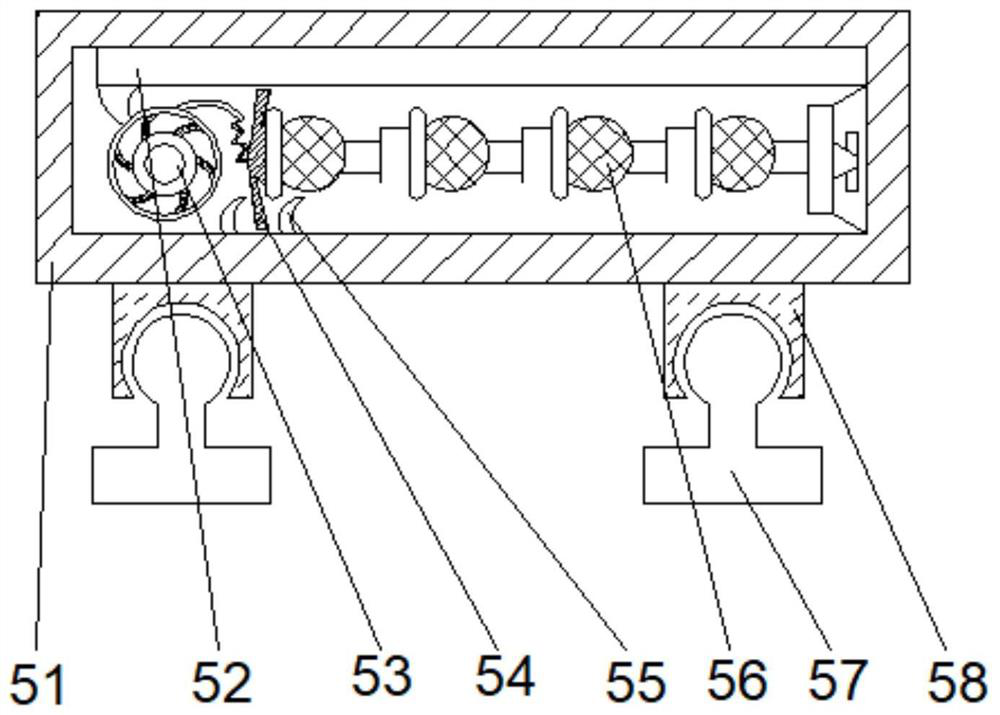

[0035]Wherein, cleaning device 5 comprises frame 51, and the bottom both sides of frame 51 is fixedly connected with recessed block 58, and the inner chamber...

Embodiment 2

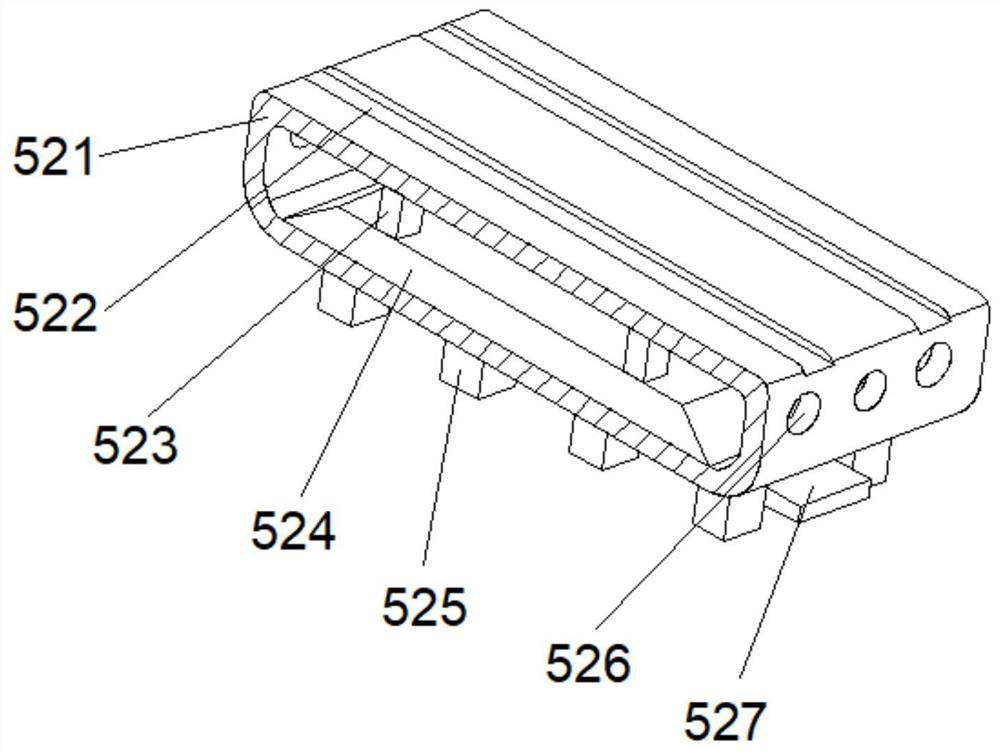

[0038] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the cleaning mechanism 52 includes a baffle 521, a nozzle 527 is arranged at the middle of the bottom of the baffle 521, and the bottom of the baffle 521 is fixedly connected to both sides of the nozzle 527 There is a scraping mechanism 525, the top of the baffle 521 is provided with a chute 522, the bottom of the inner cavity of the baffle 521 is provided with a circulation box 524, and both sides of the top of the circulation box 524 are fixedly connected with fixed rods 523, and the two sides of the baffle 521 The side outer wall defines a through hole 526 .

[0039] Wherein, the scraping mechanism 525 includes an upper block d1, an adjustment block d2 is arranged at the middle position of the inner cavity bottom of the upper block d1, the bottom of the adjustment block d2 is fixedly connected with a bottom block d3, and the top two sides of the bottom block d3 are arra...

Embodiment 3

[0042] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the auxiliary mechanism d5 includes a swing plate d51, the bottom of the swing plate d51 is provided with a blocking plate d52, and the top of the swing plate d51 is fixedly connected with a joint plate d53, the bottom of the inner cavity of the combination plate d53 is provided with a lower swing plate d54, and the right side of the top of the lower swing plate d54 is fixedly connected with a rebound piece d55.

[0043] Wherein, the lower swing plate d54 includes a bearing plate t1, the top of the bearing plate t1 is fixedly connected with a plate surface t2, the top of the bearing plate t1 is fixedly connected with a guide rod t4, and the bottom of the guide rod t4 is provided with a protruding ball t3.

[0044] When in use, the device reduces the impact force during the lifting process, and the plate surface t2 has the effect of increasing friction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com