Patents

Literature

184results about How to "Large spreading area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

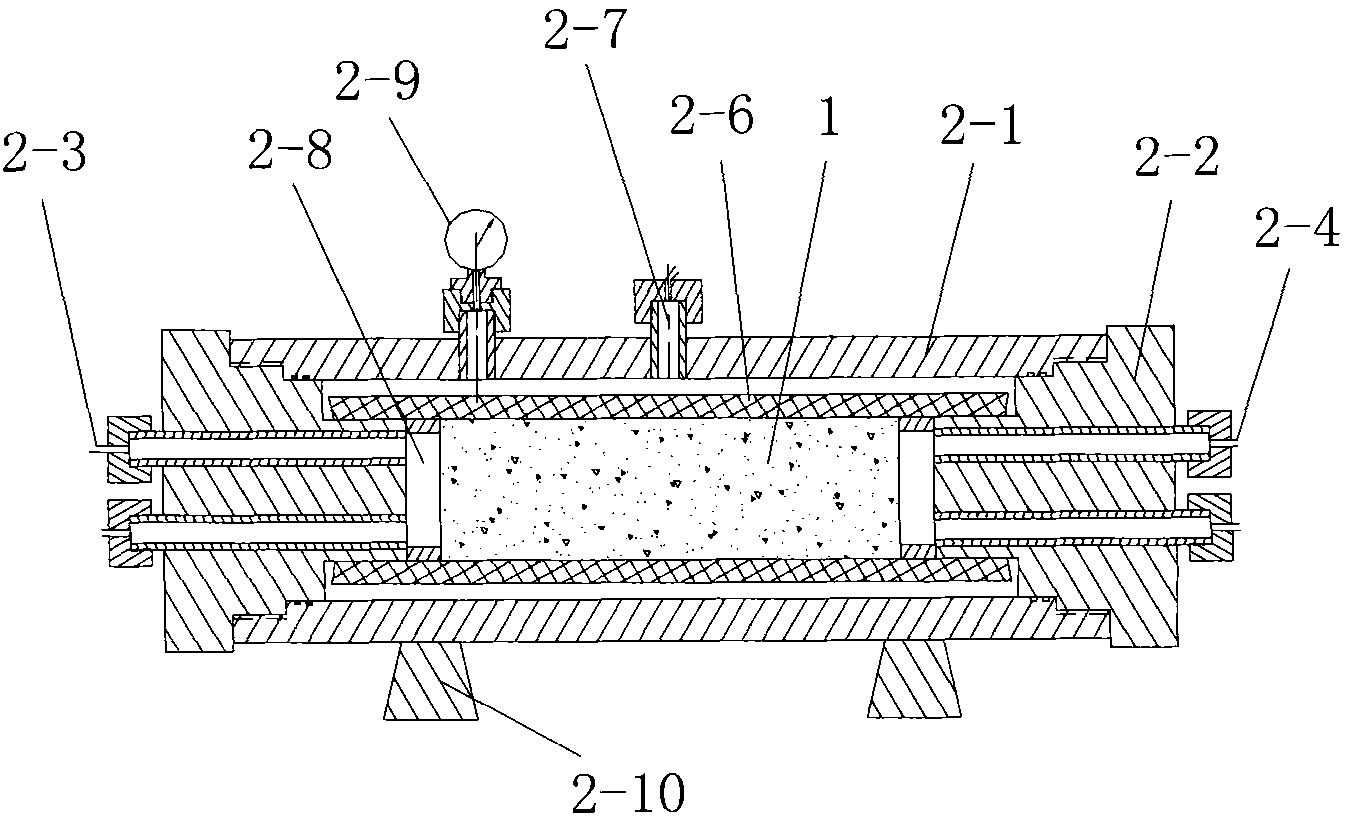

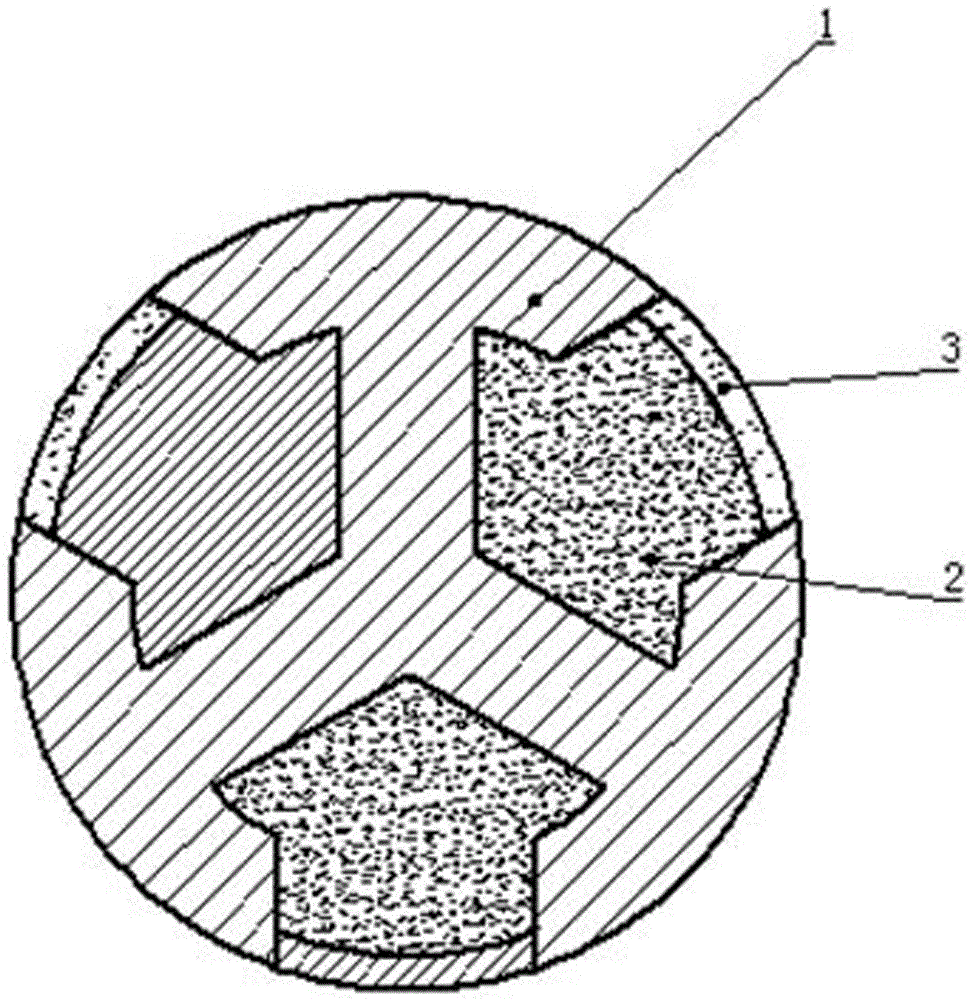

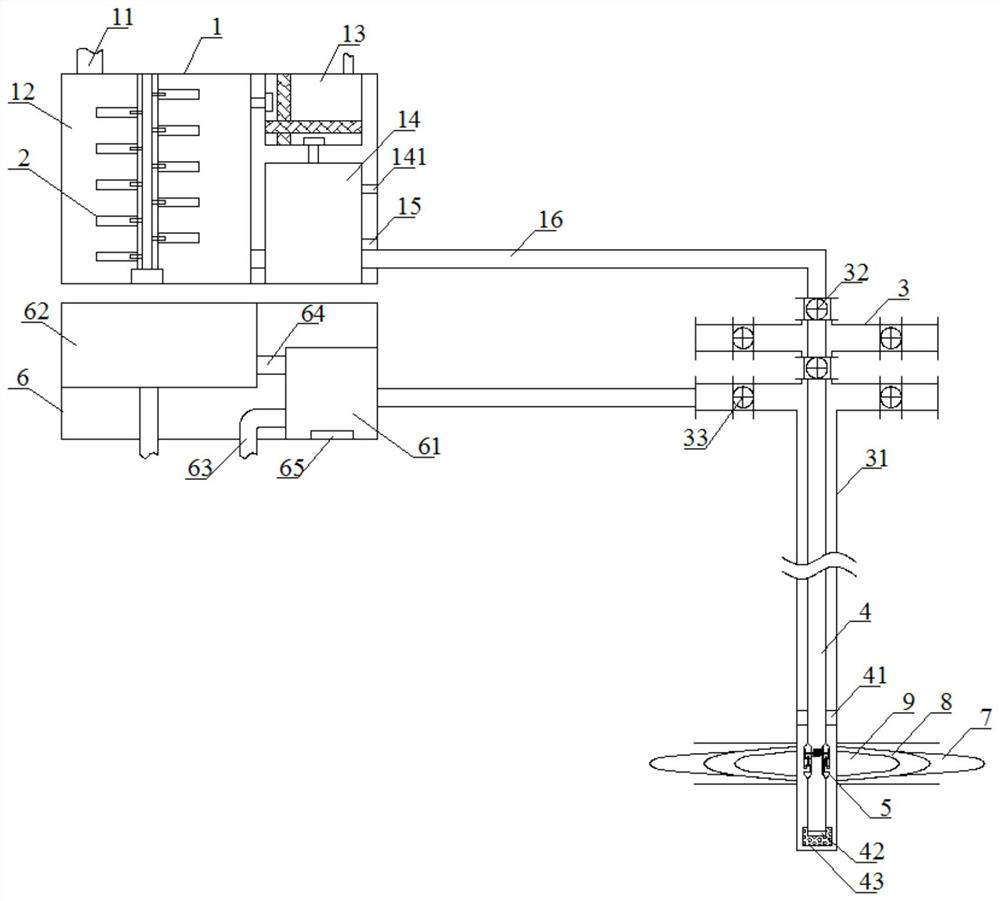

Hydraulic power pulse oil displacement experimental facility and experimental method thereof

ActiveCN101975053AImprove work efficiencyEnhanced overall recoveryFluid removalVibration devicesExperimental methodsWater storage tank

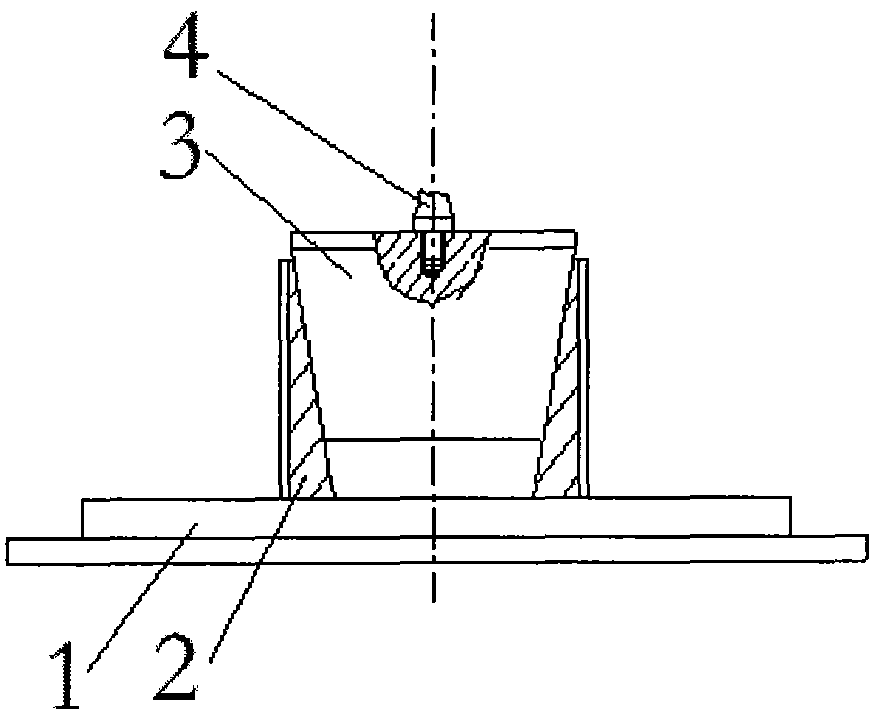

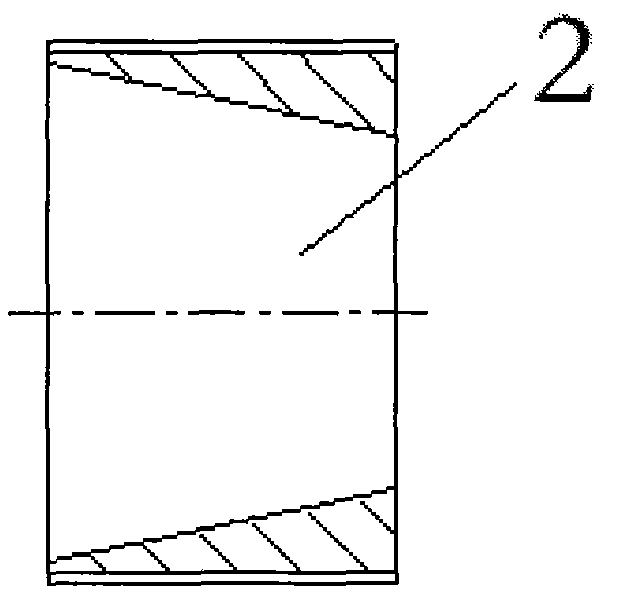

The invention discloses a hydraulic power pulse oil displacement experimental facility and an experimental method thereof. The experimental facility comprises a core clamping device, an annular pressure supply device, a hydraulic power pulse wave generating device, a water storage tank and an oil storage tank which are connected with the liquid inlet of the core clamping device by virtue of a water pipeline and an oil pipeline as well as a liquid container which is connected with the liquid outlet of the core clamping device; wherein the water pipeline and the oil pipeline are all provided with an intermediate container, a pumping device used for generating high pressure liquid flow and an energy storage tank. The experimental method includes the following steps: firstly, oil displacementexperiment is carried out under the condition that no hydraulic power pulse is added; secondly, oil displacement experiment is carried out while frequency and amplitude hydraulic power pulse wave of core are replaced, and meanwhile hydraulic power pulse auxiliary chemical oil displacement experiment is completed; thirdly, data processing is carried out. The invention has reasonable design, mounting convenience, simple operation and good simulation effect, can improve efficiency of oil displacement by water and crude oil recovery ratio, and experiment of hydraulic pulse wave oil displacement and hydraulic pulse wave auxiliary reservoir core oil displacement by water can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

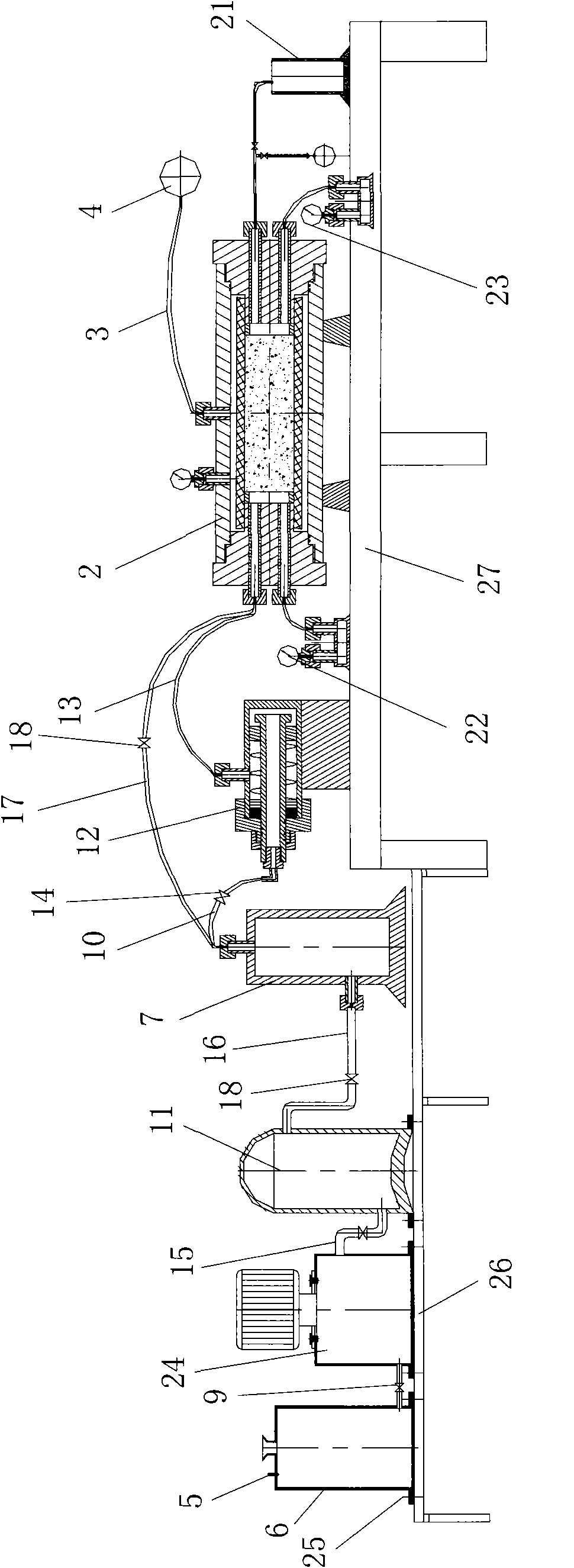

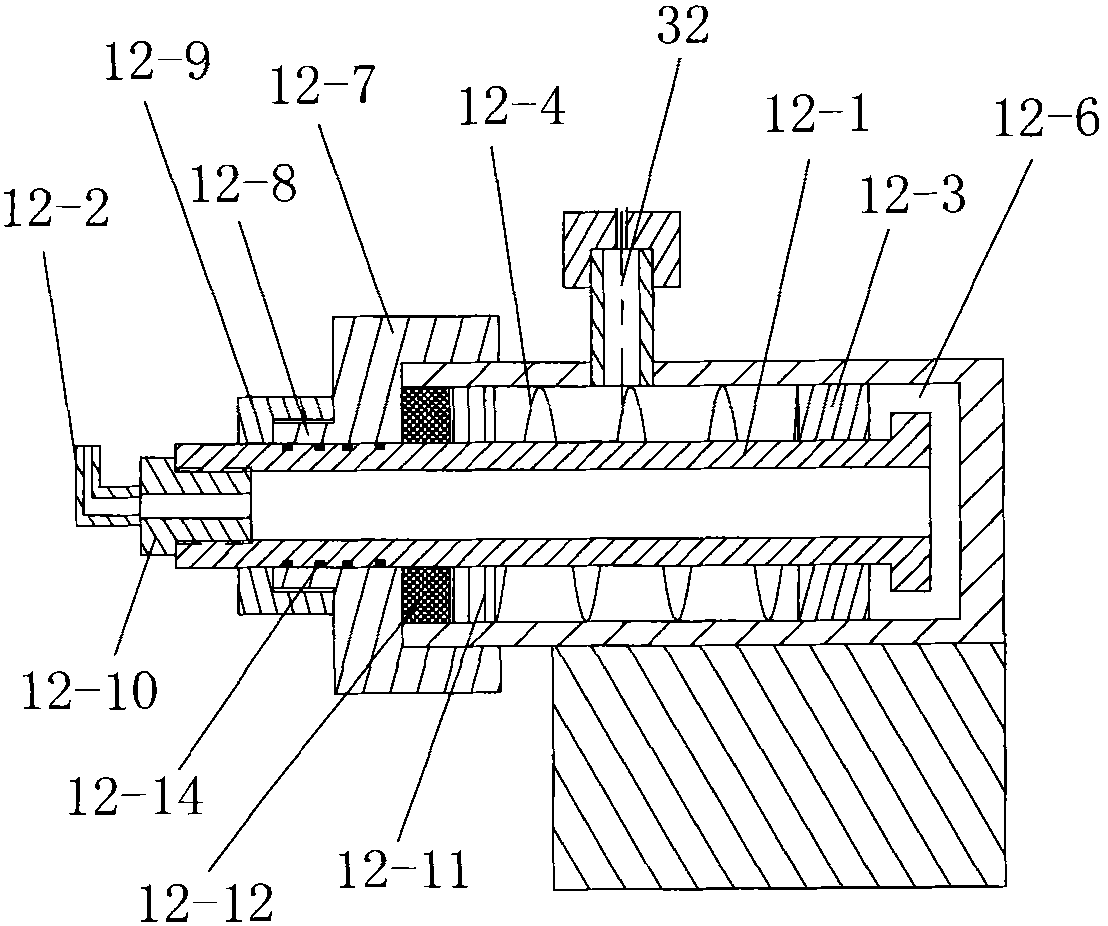

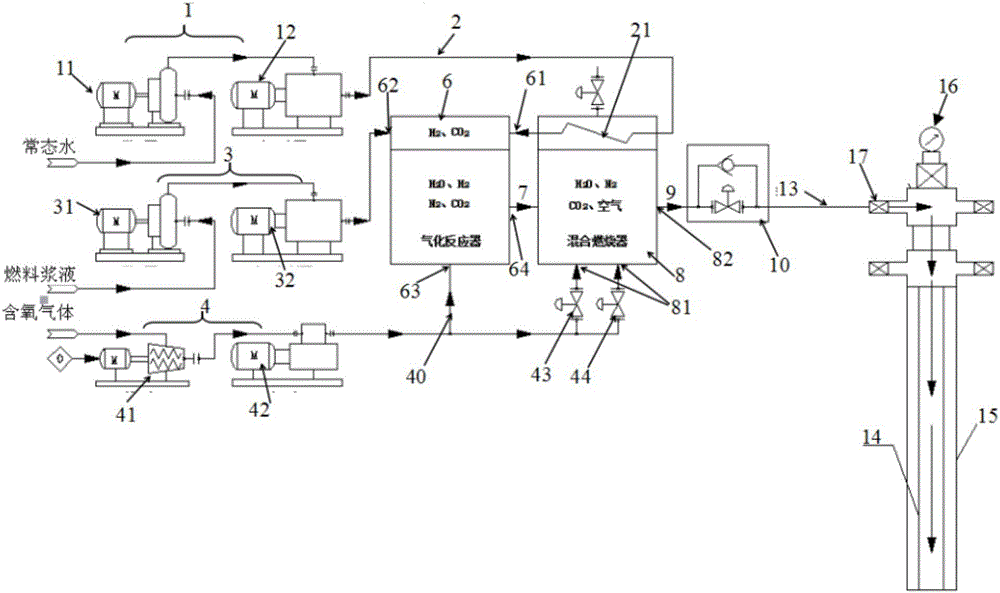

Supercritical multisource multielement thermal fluid injection-production system and injection-production method

InactiveCN106640008AImprove insulation effectLow thermal conductivityLiquid fuel feeder/distributionFluid removalCombustionProduct gas

The invention discloses a supercritical multisource multielement thermal fluid injection-production system and injection-production method. The system comprises a supercritical multisource multielement thermal fluid generating system and an oil tube. The oil tube is arranged in an exploiting shaft; the supercritical multisource multielement thermal fluid generating system comprises a supercritical gasification reactor and a supercritical mixed combustion reactor; in the presence of supercritical water, a gasification reaction is performed on fuel slurry in the supercritical gasification reactor, and the gasification product of the reaction and oxygen-containing gas dissolved in the supercritical water combust in the supercritical mixed combustion reactor to form a supercritical multisource multielement thermal fluid containing supercritical water and carbon dioxide; the supercritical mixed combustion reactor is connected to the oil tube. The supercritical multisource multielement thermal fluid injection-production system provided by the invention has the effects that thermal efficiency is high, the viscosity of thickened oil is reduced, the flowability of the thickened oil is improved and the recovery efficiency is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

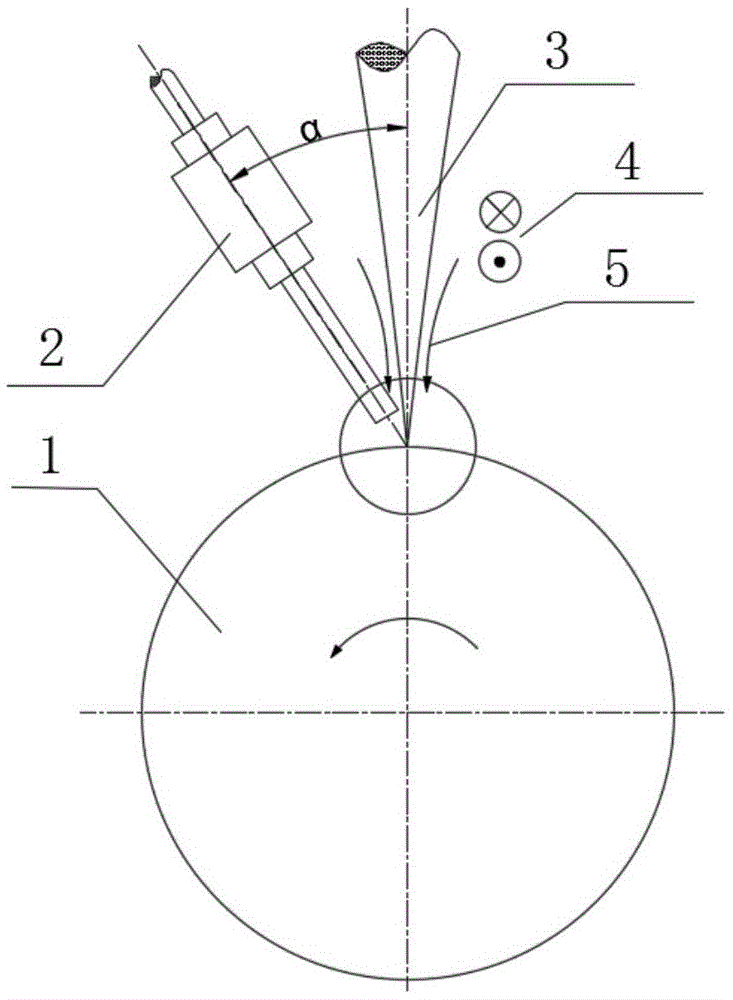

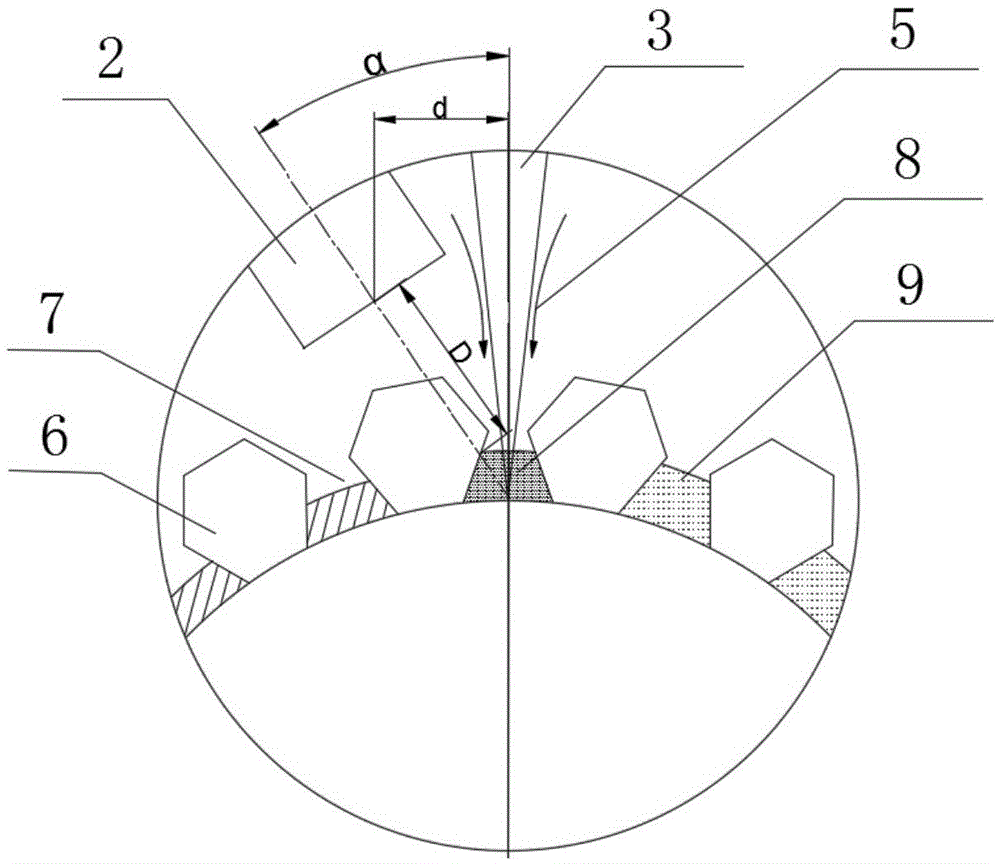

Method for brazing diamond tool through lasers with assistance of ultrasonic waves

ActiveCN105479025AControl the amount of thermal deformationShort manufacturing cycleOther manufacturing equipments/toolsMetal working apparatusHeating furnaceLaser beams

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

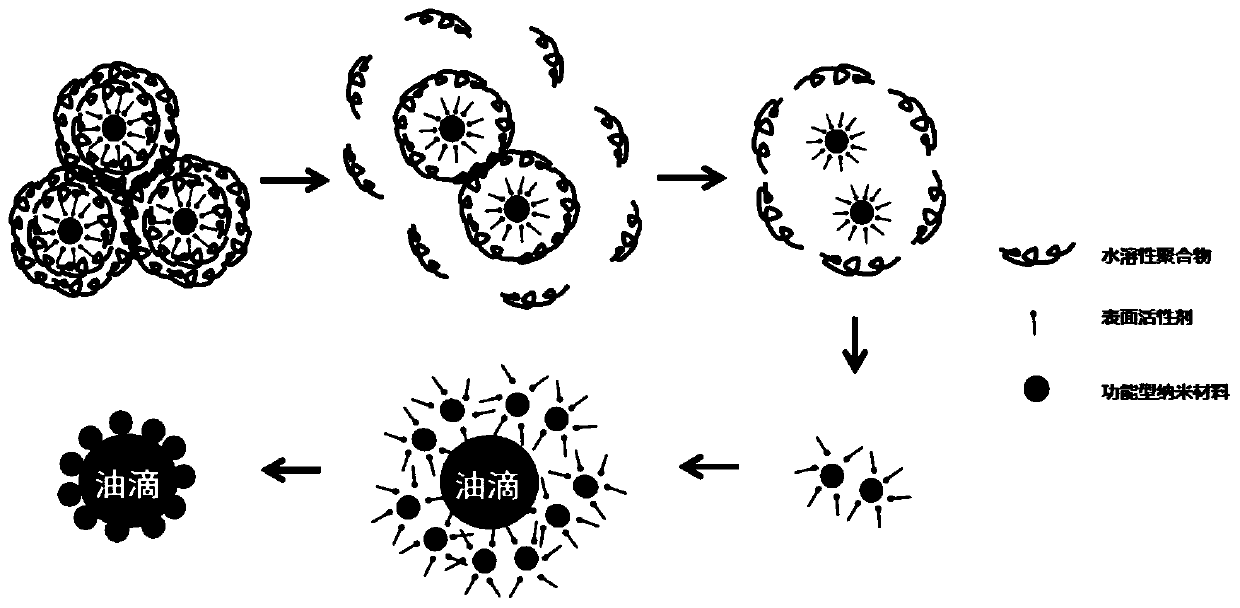

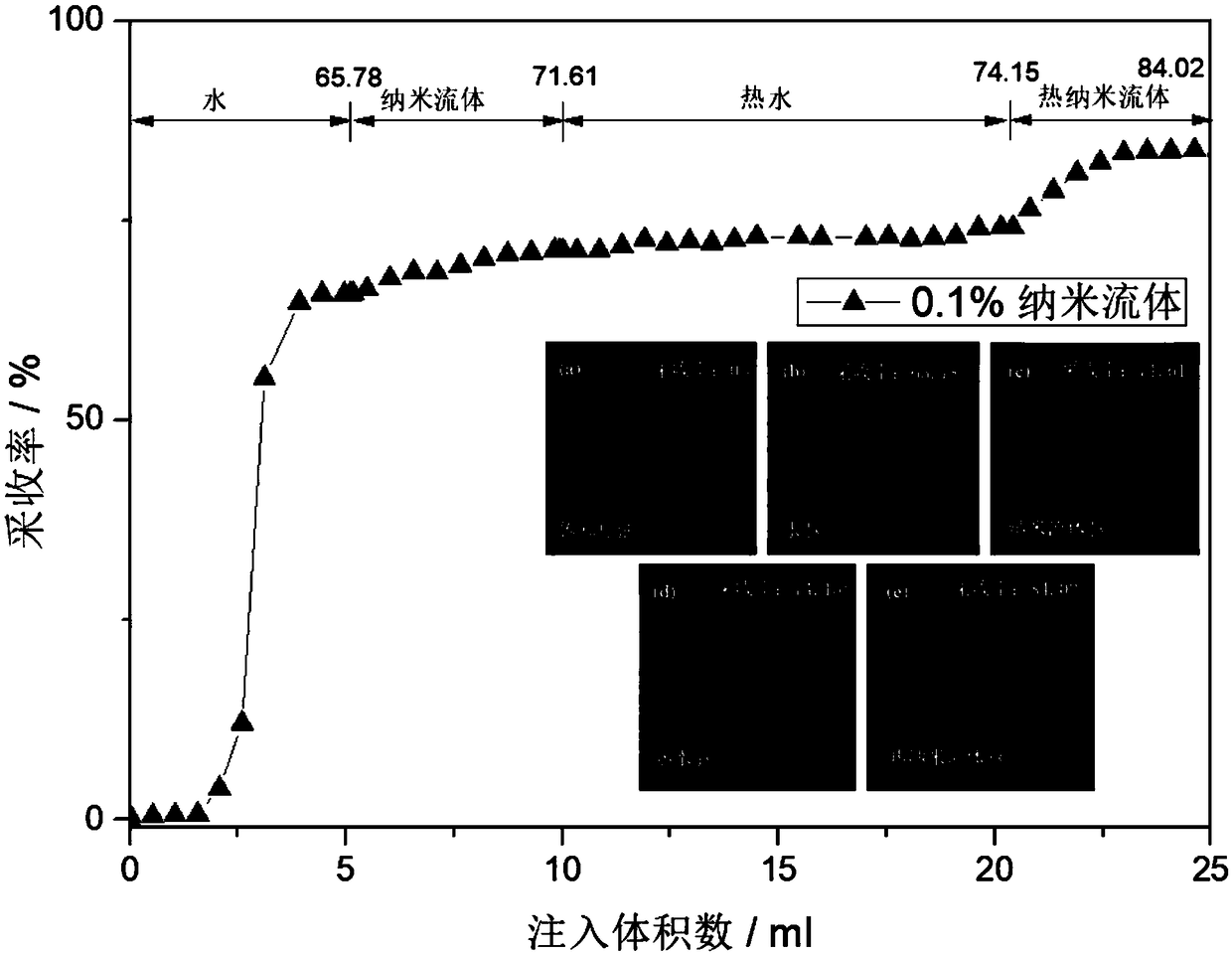

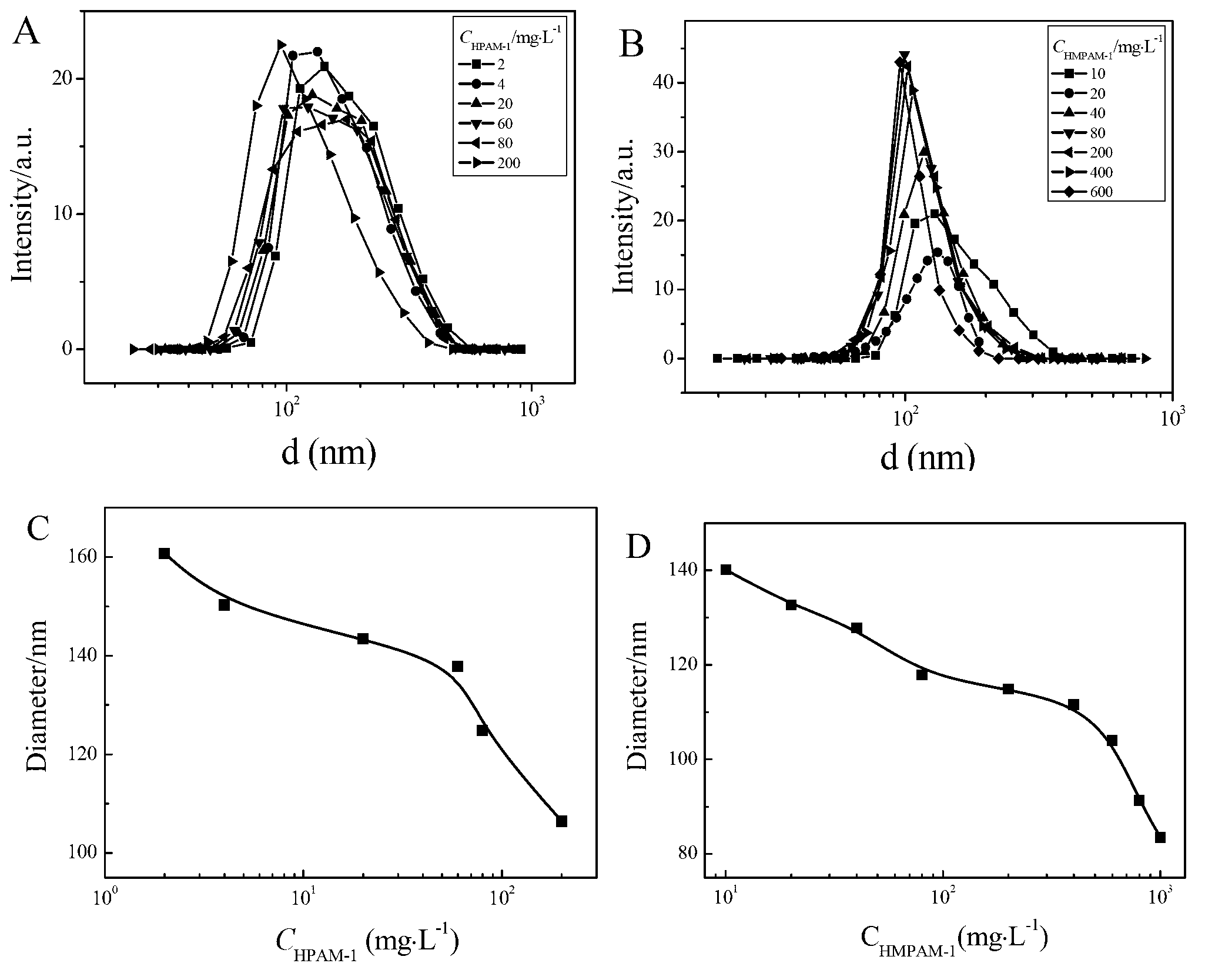

Nano oil displacement agent and preparation method and application thereof

InactiveCN111423866AGuaranteed no flocculationPrevent flocculationFluid removalDrilling compositionActive agentSoluble polymer

The invention discloses a nano oil displacement agent and a preparation method and application thereof. The nano oil displacement agent is characterized by comprising a nanometer material, a surfactant, a water-soluble polymer and water, and the water-soluble polymer is coated at the periphery of the nano material. The nano oil displacement agent is a temperature-resistant and salt-resistant oil-displacing agent, and ensures that a functional nano dispersion liquid does not flocculate or precipitate within a certain temperature and salinity range, the water-soluble polymer can be slowly decomposed under the conditions of high temperature and high salt, and meanwhile, the nano material is released, so that the functional nano material plays a role.

Owner:NINGBO FENGCHENG NANOTECHNOLOGY CO LTD

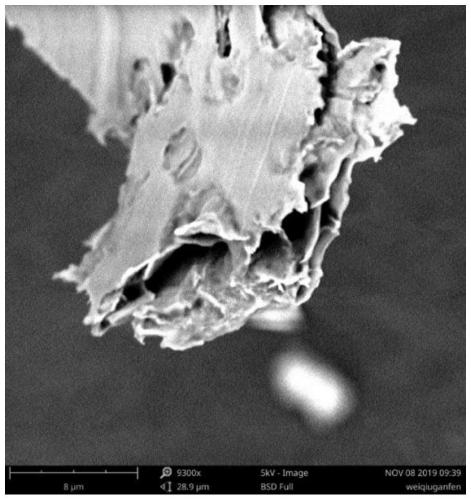

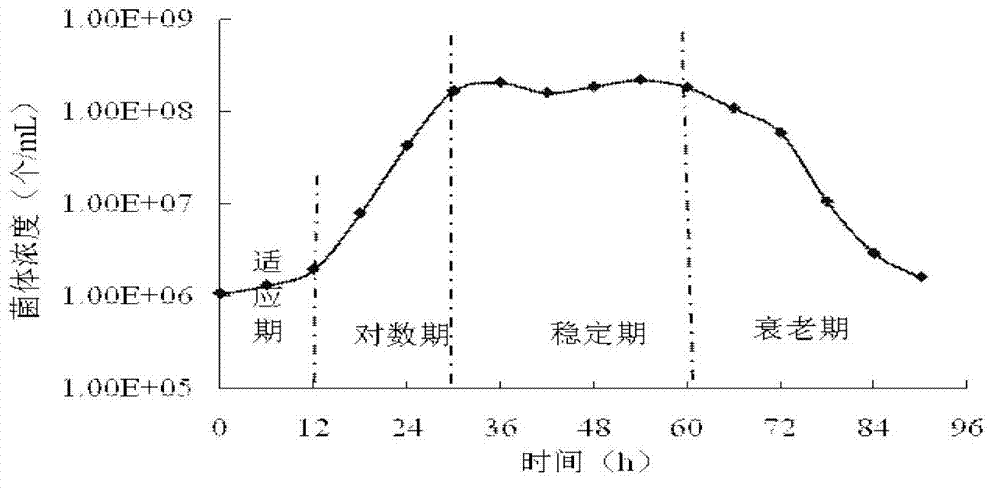

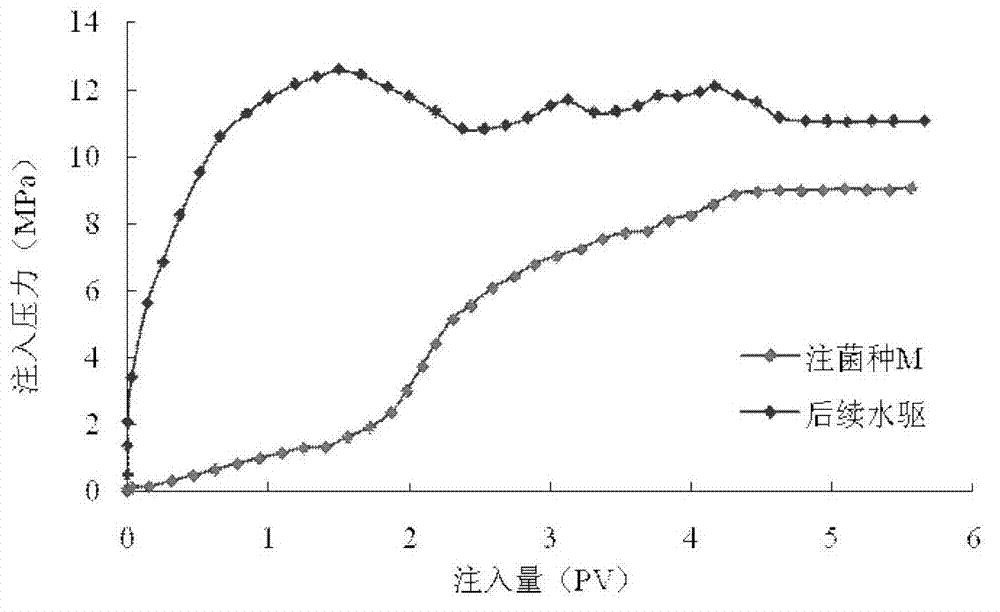

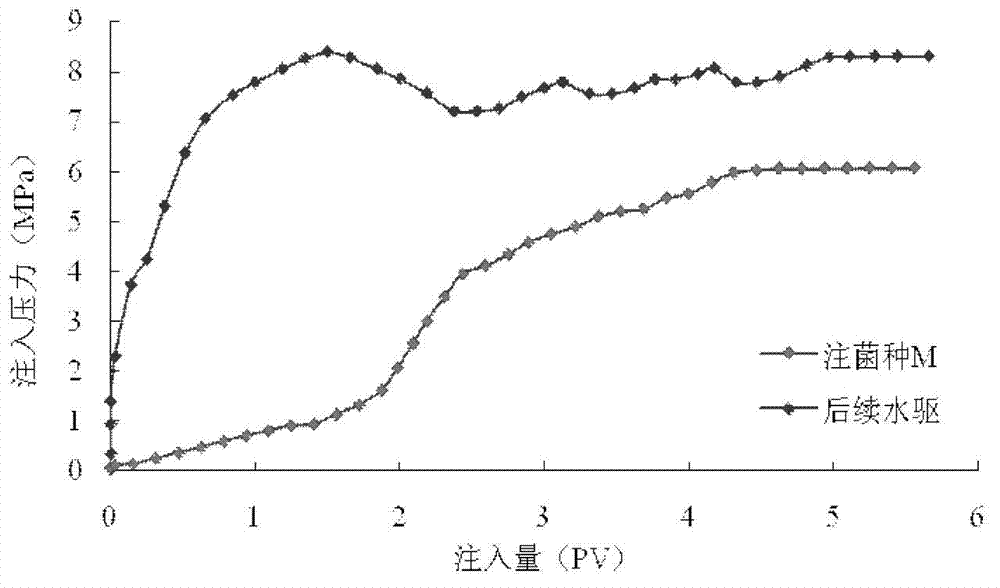

Compound microorganism oil extraction method for low permeability oilfield

InactiveCN102852497AImprove mobility ratioIncrease the spread areaFluid removalSurface-active agentsAnaerobic microorganisms

The invention discloses a compound microorganism oil extraction method for a low permeability oilfield. The compound microorganism oil extraction method comprises the following steps of (1) cultivating pseudomonas aeruginosa YM4 strains and pseudomonas stutzeri DP1 strains in an indoor shaking flask respectively, and obtaining fermentation broth of high-activity pseudomonas aeruginosa YM4 strains and fermentation broth of polymer produced strains through first-stage and second-stage seeding tank amplification and fermentation production of a production tank; (2) mixing surface active agent produced strains and the pseudomonas stutzeri DP1 strains fermented and produced in the step (1) according to volume ratio of 1:1; and (3) enabling compound microorganism bacterium liquid obtained in the step (2) to serve as an oil-displacing agent to inject in an oil layer directly through a water injection well, and obtaining crude oil from a producing well. The YM4 strains and the DP1 strains are both facultative anaerobic microorganisms and can both grow and breed in a ground layer, polymers produced by the DP1 strains can improve mobility ratio, increases water injection affecting area, and the product surface active agent of the YM4 strains can reduce oil-water interfacial tension and improve oil recovery.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

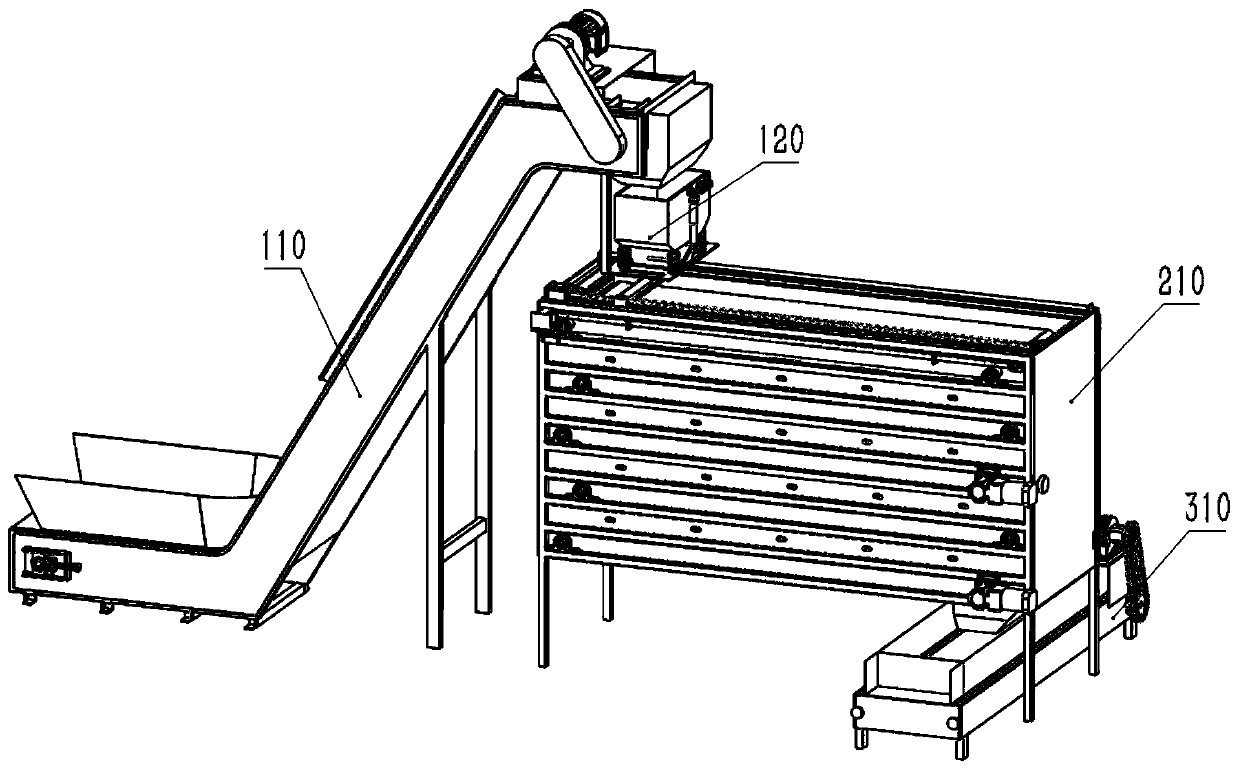

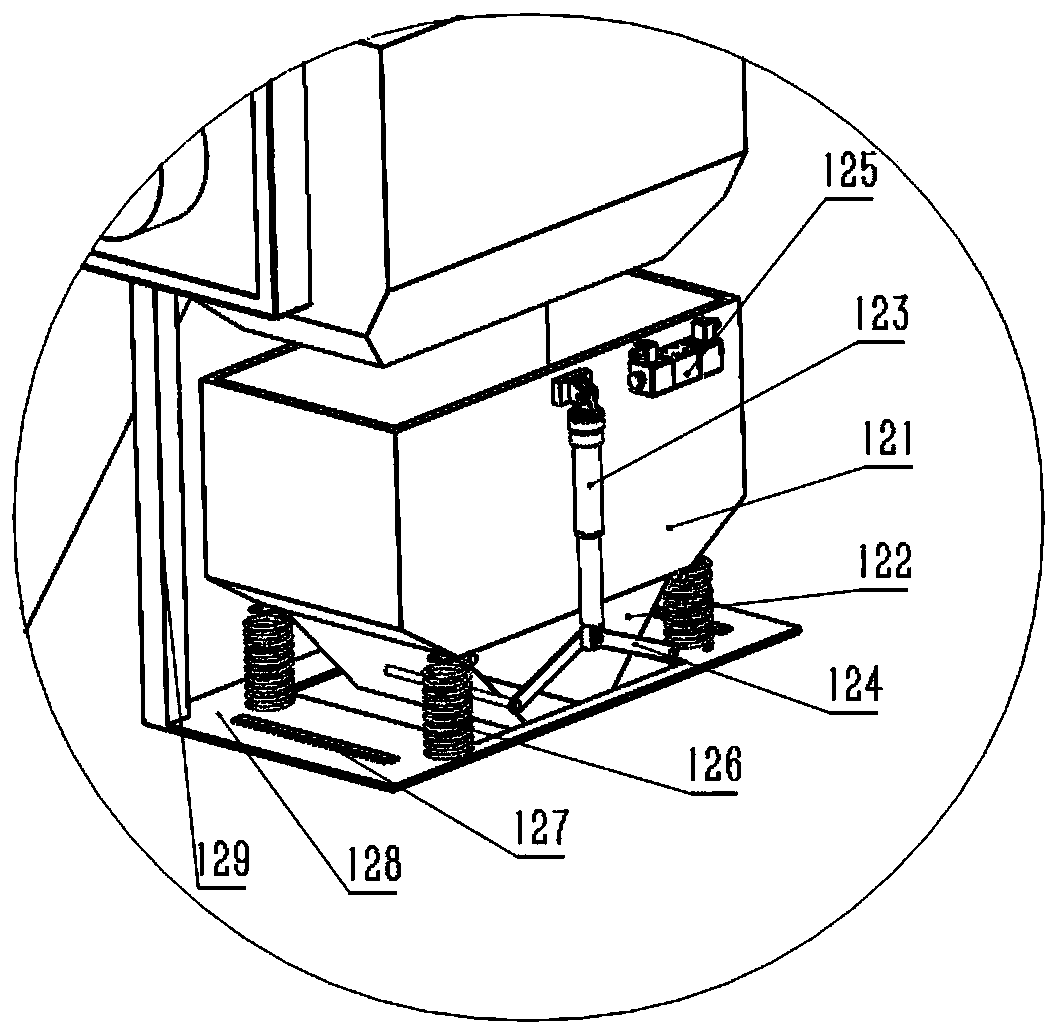

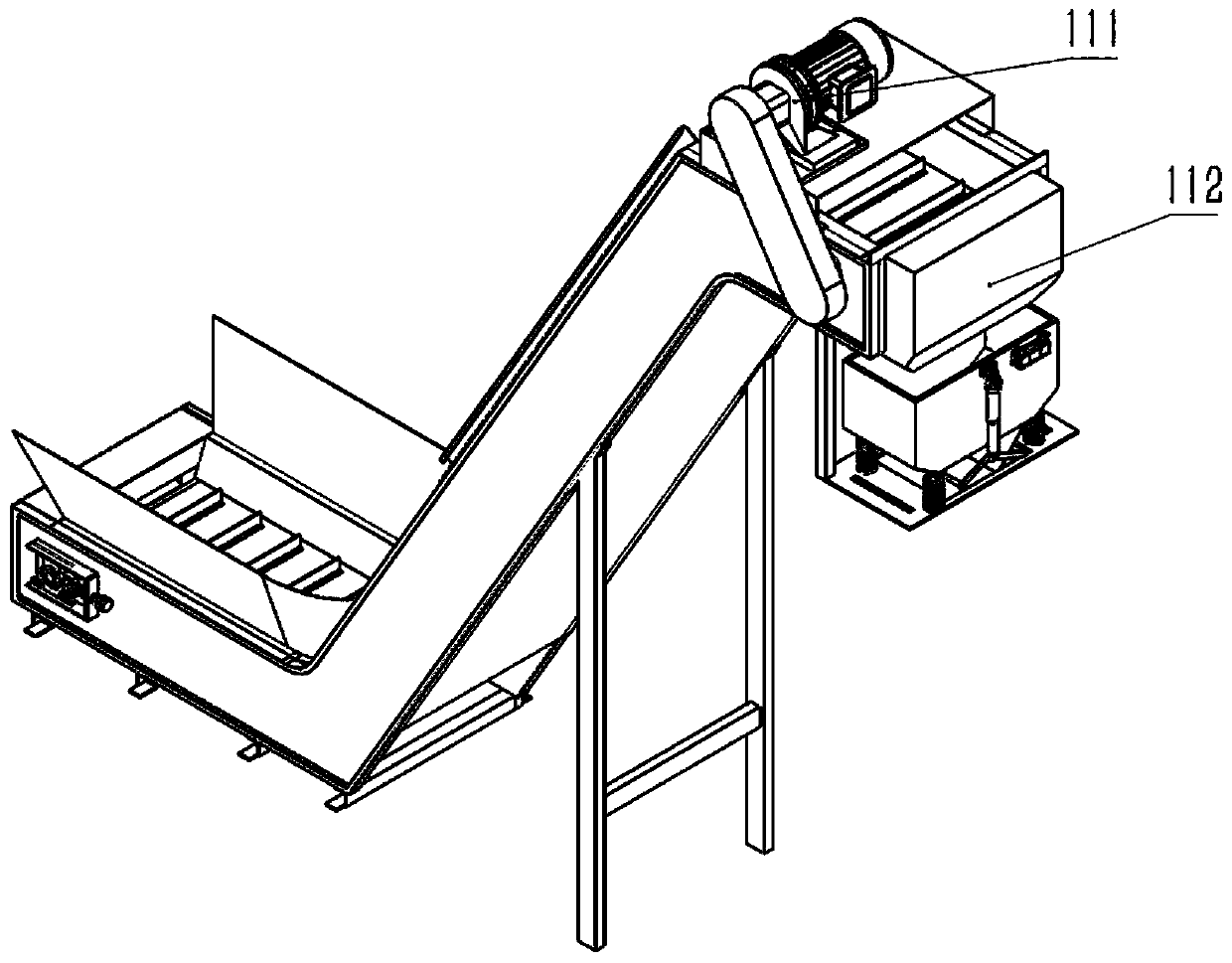

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

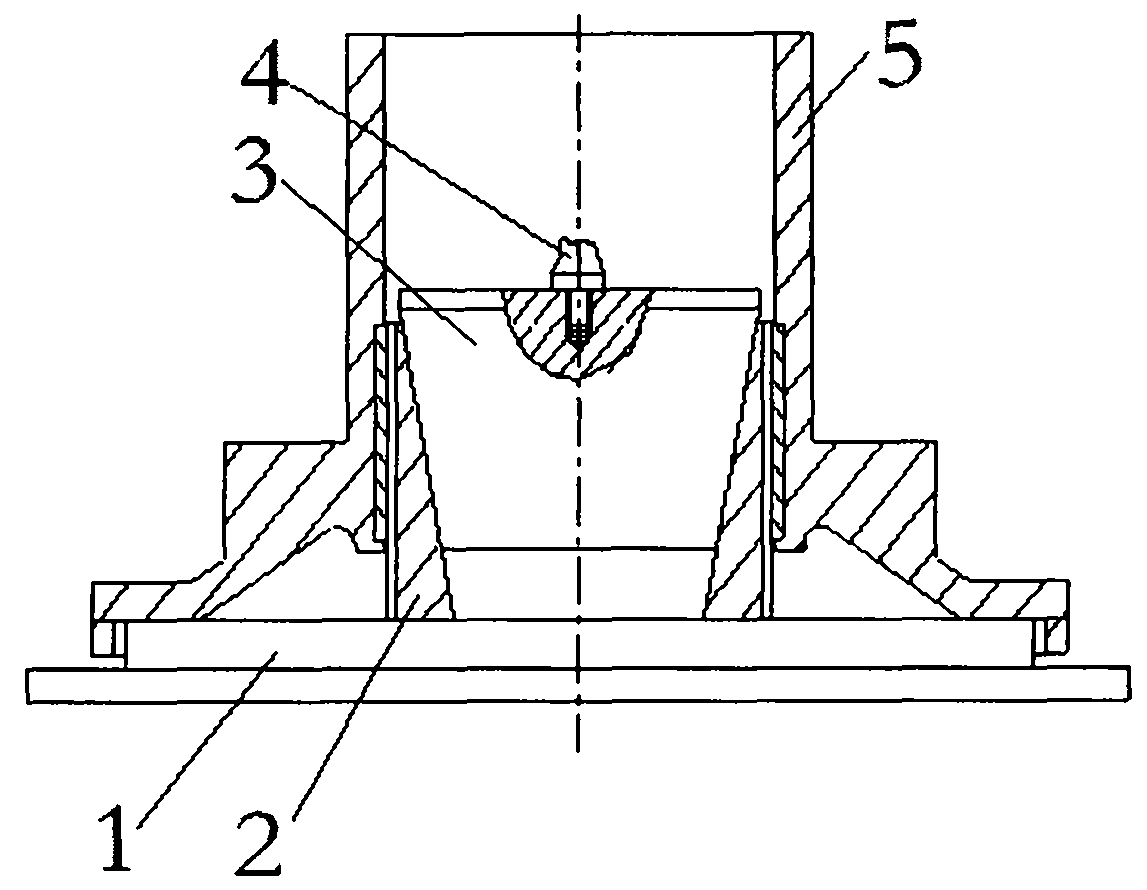

Method and fixture for welding high temperature alloy and cupronickel

ActiveCN101983819AHigh strengthImprove corrosion resistanceSoldering auxillary devicesCupronickelManganese

The invention discloses a method and fixture for welding high temperature alloy and cupronickel. A brazing filler metal consisting of powdery gold 20, nickel, chromium, iron, silicon and boron, or consisting of platinoid copper, manganese, cobalt and nickel is used for welding. The brazing filler metal is coated or arranged between a cupronickel piece and high temperature alloy, and the peripheryof the bonding surface of the cupronickel piece and the high temperature alloy is coated with a red stop-off agent and is pressed tightly by a fixture. A brazing filler metal welding piece which is pressed tightly by the fixture is put in a vacuum furnace, and then the processes of vacuumizing, heating and brazing are performed. Since the brazing filler metal consisting of copper, manganese, cobalt and nickel has the characteristics of high strength, good corrosion resistance, low price and high weld joint quality, and the brazing filler metal consisting of gold 20, nickel, chromium, iron, silicon and boron has the characteristics of good ductility and strong wetting function, respective pressing is omitted the process of brazing, thereby achieving good molding quality of the weld joint. Since the brazing elements of the two brazing filler metals used in the brazing process have the alloying effect on the two materials to be connected, the brazing joint has large spreading area, the joint is high in strength, and the quality of the brazing joint meets the requirement.

Owner:AECC AVIATION POWER CO LTD

Continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and preparation method of continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide

InactiveCN105834609AImprove toughnessImprove plasticityWelding/cutting media/materialsWelding/soldering/cutting articlesTrioxideFiller metal

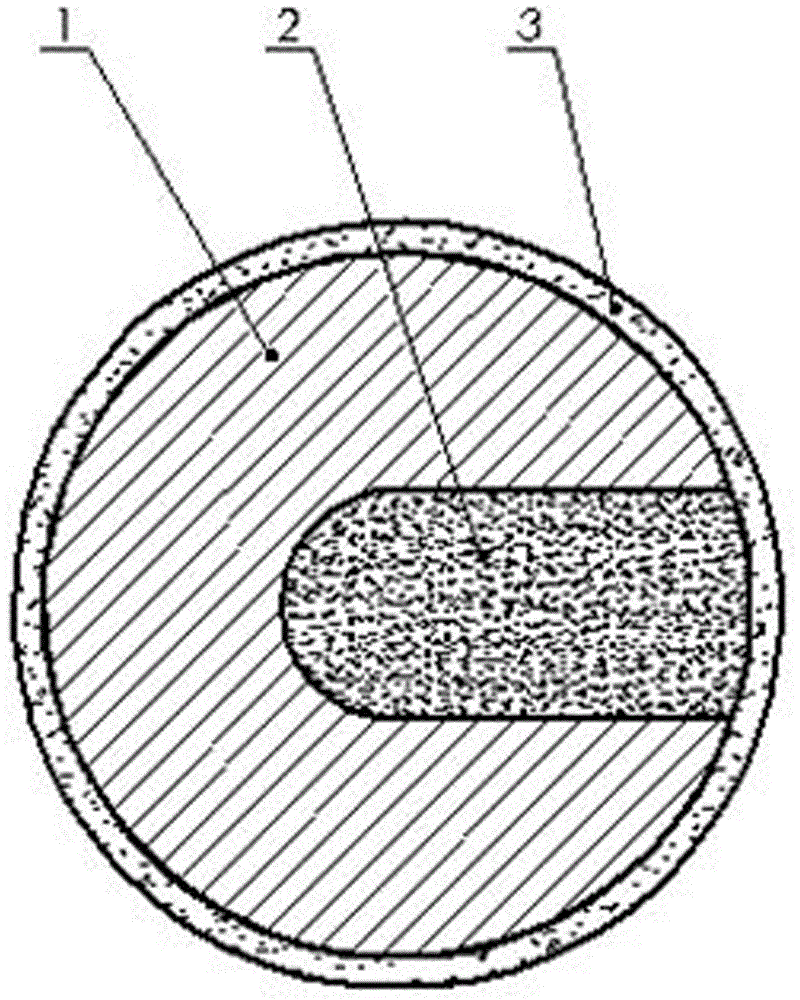

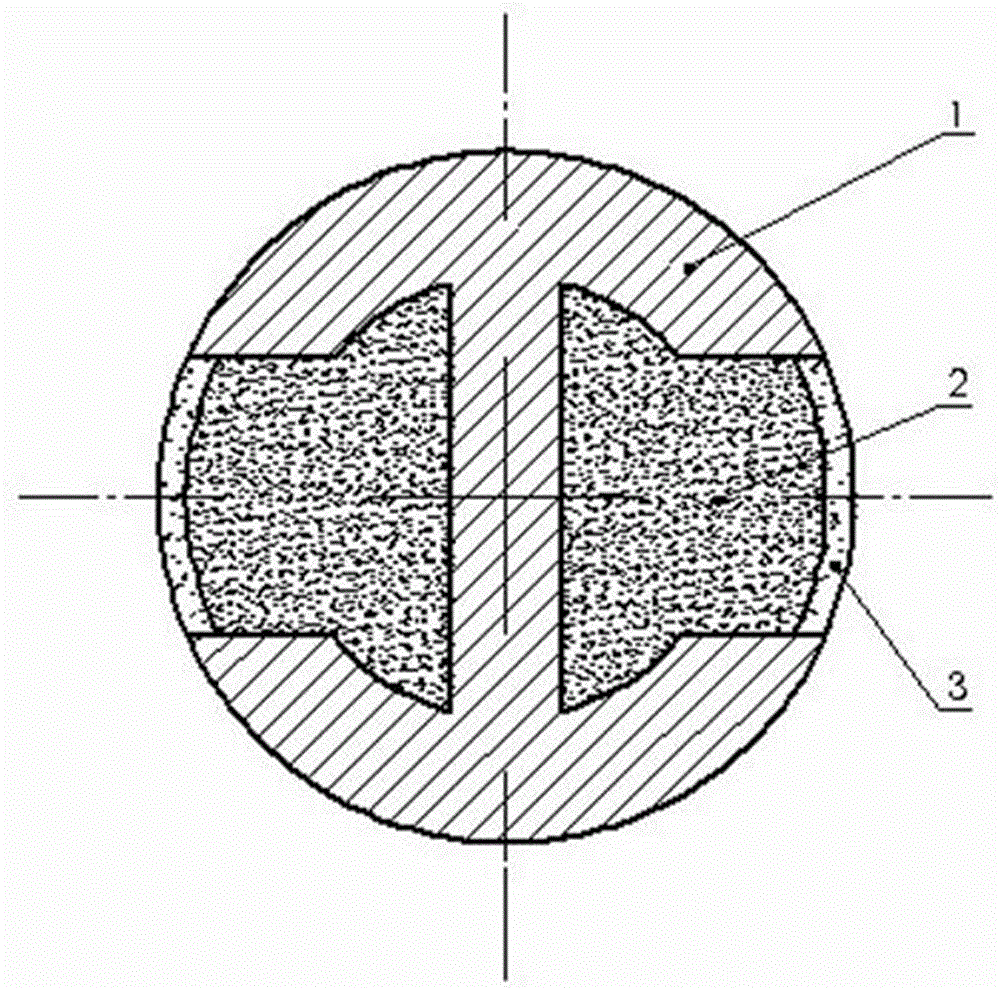

The invention discloses a continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and a preparation method of the continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide. The continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide is composed of an aluminum-based brazing filler metal core material with a groove formed in the outer surface, a no-corrosive flux used for aluminum and applied in the peripheral groove of the core material in a wrapping manner, and a coating layer sprayed on the surface of the composite brazing flux. The obtained product is excellent in material performance, easy to machine and form, good in brazing process performance, capable of fully adapting to efficient and continuous brazing and excellent in brazing connector performance.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Method for mining coal seam gas

InactiveCN102587958ABreakthrough drainage is affected by the complex constraints of geological structureImprove the extraction effectGas removalCoal matrixCoal

The invention discloses a method for mining coal seam gas, belonging to the field of coal seam gas mining. The method comprises the steps of: drilling a gas injection hole downwards from the ground; injecting gas into the gas injection hole; displacing the coal seam gas by the injected gas; drilling an underground pumping hole; and pumping the coal seam gas from the underground pumping hole. Through the method provided by the invention, the gas injection has a large influence range, effects are exerted on adjacent and non-adjacent drilled holes, and the coal seam gas in coal seams can be displaced to ensure that the coal seam gas adsorbed on the inner surfaces of coal matrix holes are changed from an adsorbed state to a detached state, so that the pumping effect of the coal seam gas is improved.

Owner:山西蓝焰煤层气工程研究有限责任公司

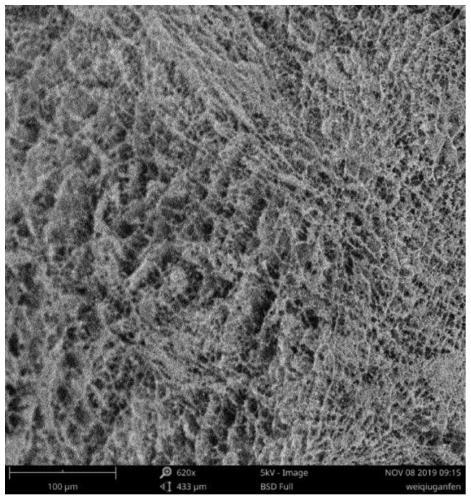

Preparation method of intelligent nano-foam oil-displacing agent

ActiveCN108659807AReduced stabilityIncrease the spread areaDrilling compositionNanoparticleOil water

The invention discloses a preparation method of an intelligent nano-foam oil-displacing agent. By grafting a temperature-sensitive polymer onto magnetic nano particle surfaces, compound nano particleswith the temperature-sensitive property and magnetic response are prepared, and the nano particles have the property of stabilizing foam. The oil-displacing agent has the characteristics that the hydrophilia and lipophilicity of the oil-displacing agent can be adjusted and controlled; when the formation temperature is high, the nano particles show the lipophilicity, and when the foam meets crudeoil, the foam bursts, which is beneficial to peeling the crude oil off a rock stratum surface and improving the recovery ratio; when the temperature is low, the nano particles show the hydrophilia, which is beneficial to separation of oil and water, and through an applied magnetic field, recovery of the nano particles can be fast achieved; moreover, the foam-displacing liquid can respond to the magnetic field, so that through the applied magnetic field, flow of the displacing liquid can be controlled.

Owner:XI AN JIAOTONG UNIV

Soldering flux for brazing diamond cemented carbide sand and preparation method for soldering flux

ActiveCN102814601AImprove solubilityImprove rigidityWelding/cutting media/materialsWelding/soldering/cutting articlesCemented carbideSoldering

The invention provides a soldering flux for brazing a diamond cement carbide. The soldering flux comprises the following components in percentage by weight: 12 to 33% of Na2B4O7, one or two of 5 to 14.8% of KBF4 and 2 to 12% of MF, wherein M is alkali metal, one or two of 0.5 to 10% of CoWO4 and 1 to 15% of CoCl2, one or two of 0.5 to 9% of an oxide of Mo, 0.5 to 5% of the oxide of Ni and 0.5 to 10% of the oxide of W, and the balance of H3BO3. The soldering flux for brazing the diamond cement carbide has a wide scope of application, and can be applied to brazing a cemented carbide such as Co, Mo and Ni and a diamond. Compared with conventional soldering flux, the soldering flux disclosed by the invention can increase an expanding area; a weld joint has a better appearance and high shearing strength, so that a brazing performance is improved.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

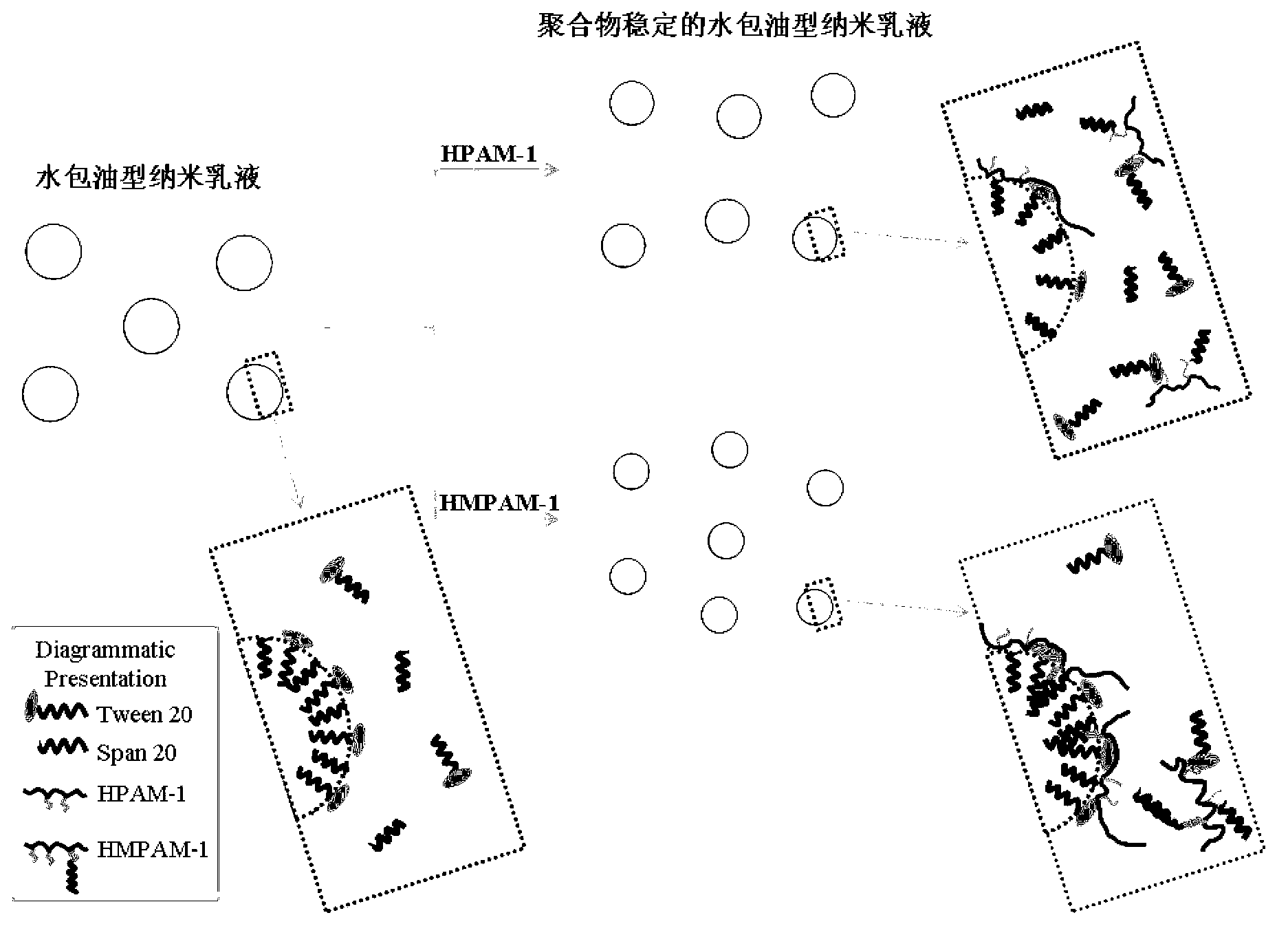

Preparation method for nano-emulsion with stable polymers

ActiveCN103191670ANarrow particle size distributionImprove long-term stabilityTransportation and packagingMixingOil phaseNanometre

The invention relates to a preparation method for nano-emulsion with stable polymers. The nano-emulsion comprises the following components in 100 parts by weight: 20-60 parts of oil phases, 5-10 parts of nonionic surfactants, 7*10<-5>-7*10<-2> parts of polymers and the balance of water. The preparation method comprises the following steps of: proportioning the nonionic surfactants into mixed emulgators by adopting a constant-temperature invert emulsion method, mixing the mixed emulgators with the oil phases, and dripping the mixture into aqueous phase containing the polymers under a high-speed stirring condition, so as to form the stable nano-emulsion. The preparation method has the characteristics that the components are simple, the operation is easy, the particle diameter of the prepared oil-in-water nano-emulsion is fine, the kinetic stability is durable, the energy consumption is small, and the cost is low.

Owner:SHANDONG UNIV

Plant-growth promoter capable of promoting balanced growth and preparation method thereof

ActiveCN104126597AReduce surface tensionImprove efficacyBiocidePlant growth regulatorsBiotechnologyGrowth plant

The invention provides a plant-growth promoter capable of promoting balanced growth. The plant-growth promoter contains a growth promoter in a plant-growth regulator, further contains trace elements, an adhesive agent, a diffusion agent and a powder matrix and is in the form of wettable powder. Moreover, the plant-growth promoter contains a chelating agent. Furthermore, the plant-growth promoter also contains DPPA. The plant-growth promoter capable of promoting balanced growth is a directly usable, scientific, reasonable and formulated variety, is beneficial for reducing waste and cost, makes full use of its excellent performance and produces an expected effect. The plant-growth promoter can rapidly penetrate and diffuse, substantially promotes fluidity and diffusivity of forchlorfenuron in a plant, gives full play to excellent growth-promotion performance of forchlorfenuron, ensures balanced growth of the plant and fruit, overcomes disadvantages of fruit deformity and slow coloring of fruit due to improper usage of forchlorfenuron, improves sweetness of fruit, changes fruit quality, has a high utilization rate of effective components and is applicable to a variety of crops, especially to fruit and vegetable crops.

Owner:GUILIN GUIKAI BIOLOGICAL SCI & TECH

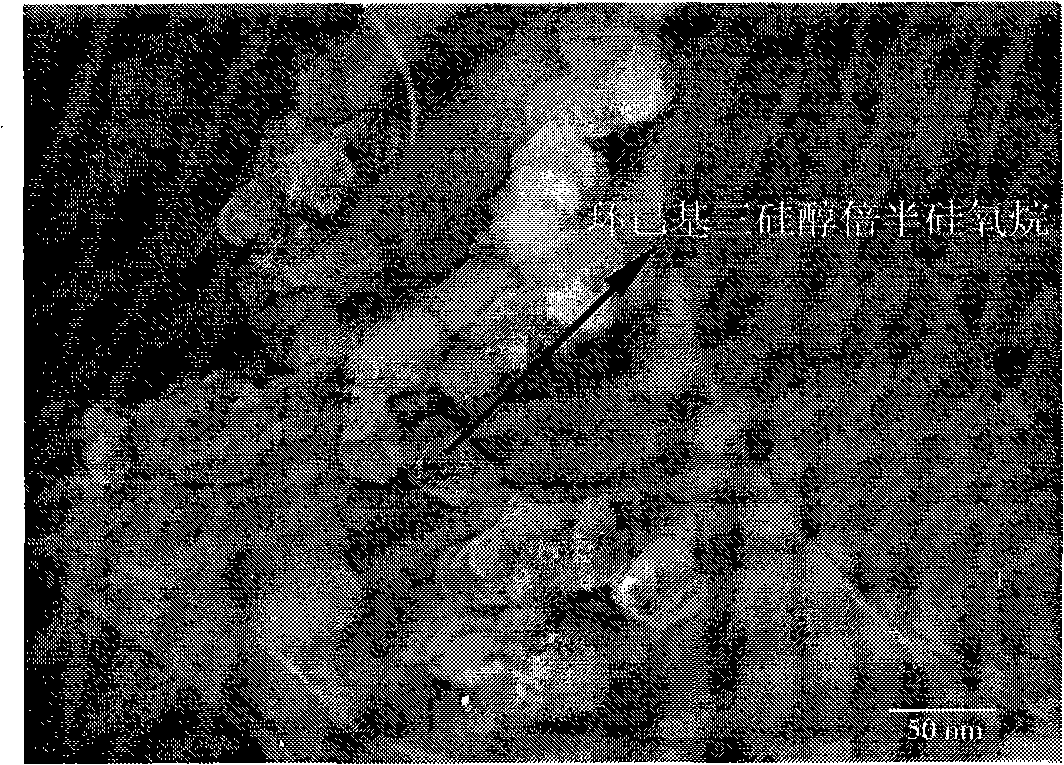

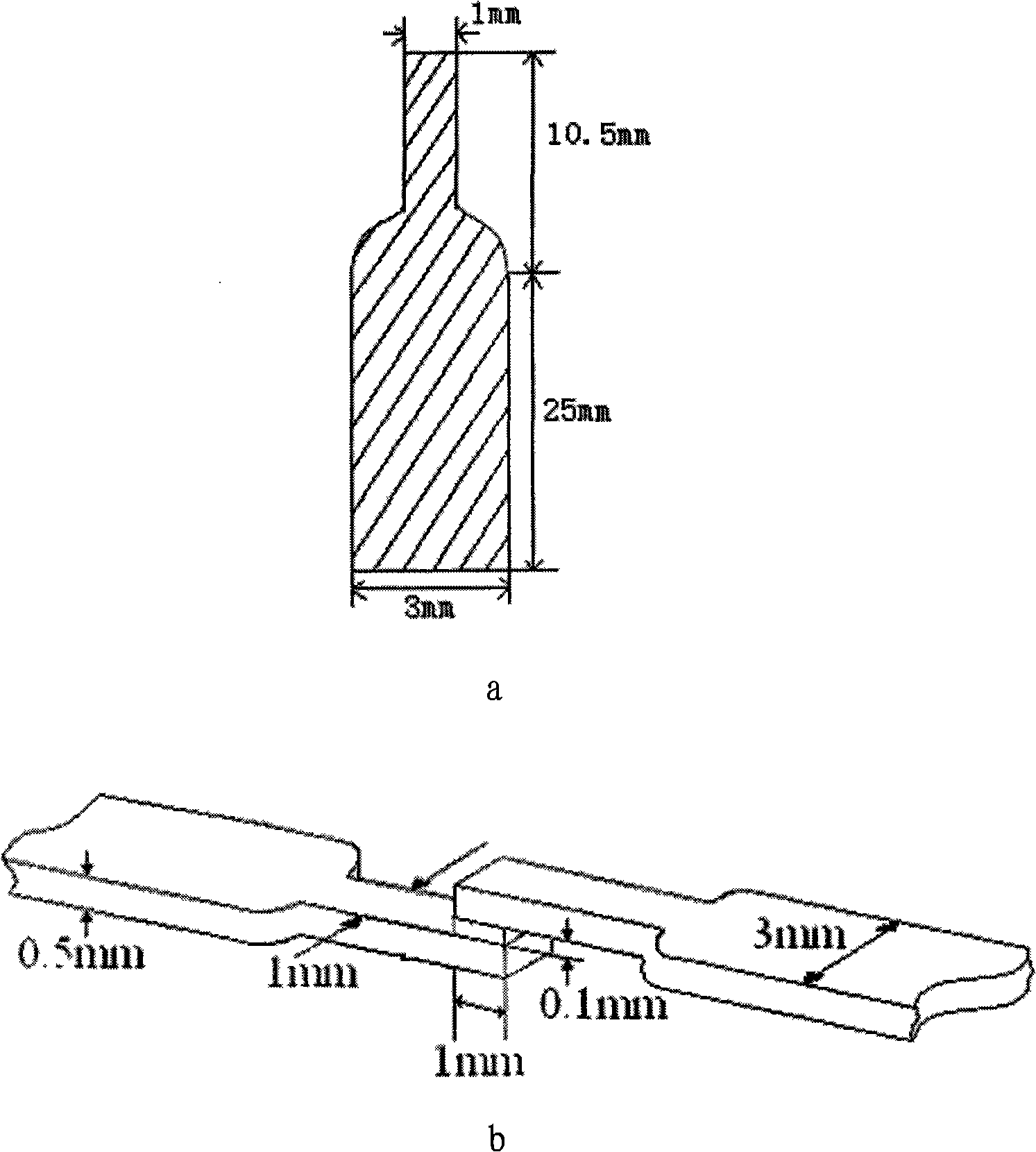

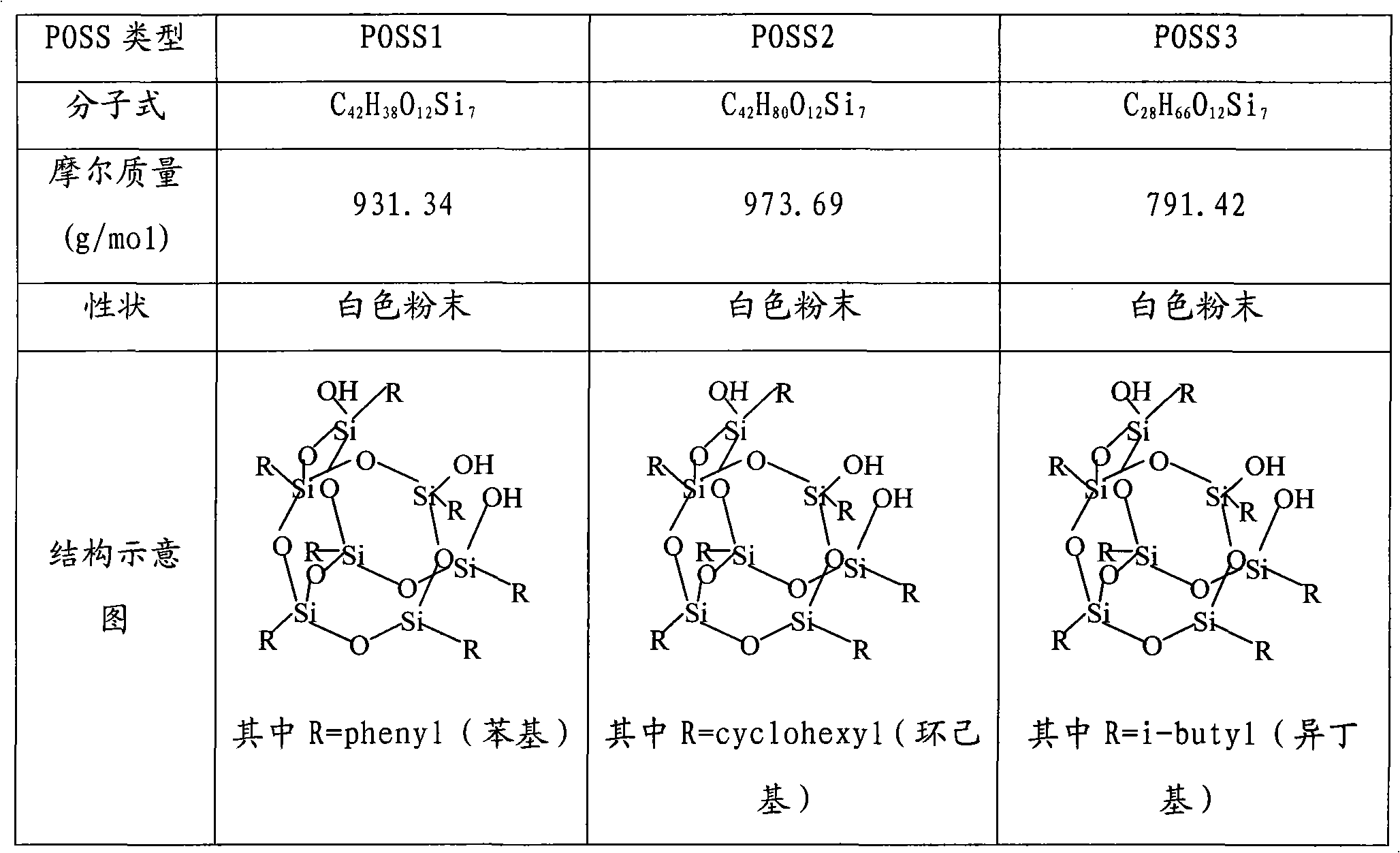

Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

InactiveCN101279405AImprove mechanical propertiesImprove reliabilityWelding/cutting media/materialsSoldering mediaManufacturing technologyTin-silver-copper

The invention relates to a tin, silver and copper based lead-free composite solder with enhanced nanometer-structure and a preparation method thereof, which belong to the technical field of the manufacturing of metal-based lead-free composite solders. The existing spreading process for SnSn-Ag-Cu series lead-free solder is characterized by poor processing performance, short creep rupture service life and high cost. The composite solder of the invention consists of 97 wt percent to 99 wt percent of commercial Sn-3.0Ag-0.5Cu solder paste and 1 wt % to 3 wt % of enhanced particles (POSS1, POSS2 or POSS3). The solder paste consists of 85 wt percent of Sn-3.0Ag-0.5Cu solder and 15 wt % of flux. The tin, silver and copper based lead-free composite solder with enhanced nanometer-structure is prepared by stirring and mixing the solder paste and enhanced particles according to the component concentration for 15 to 30 minutes. The composite solder of the invention has the advantages of good wettability and good creep rupture resistance, high shearing strength, excellent mechanical property, long creep rupture service life of the soldered joint and simple preparation process, etc.

Owner:BEIJING UNIV OF TECH

Modified polycarboxylate powder superplasticizer dedicated to flowable mortar

The present invention discloses a modified polycarboxylate powder superplasticizer dedicated to flowable mortar. The superplasticizer comprises the following components by weight: 90.0-98.0% of a polycarboxylate original powder, 0.5-5.0% of superfine talc, 0.25-1.0% of an anti-adsorbent, 0.03-0.08% of high-viscosity biosynthesis collagen, 0.3-0.5% of fibril synthesized pulp, and 0.5-2.0% of retarder with high degree of polymerization. Through the above-described manner, the modified polycarboxylate powder superplasticizer dedicated to flowable mortar provided by the present invention with the help of physical complex and efficient, low-dosage additive improves the flowability of polycarboxylate superplasticizer, improves the spreading area of flowable mortar, extends the release time of the polycarboxylate force, maintains good degree of construction work, improves work efficiency, and improves the quality of construction.

Owner:SUZHOU XINGBANG CHEM BUILDING MATERIALS

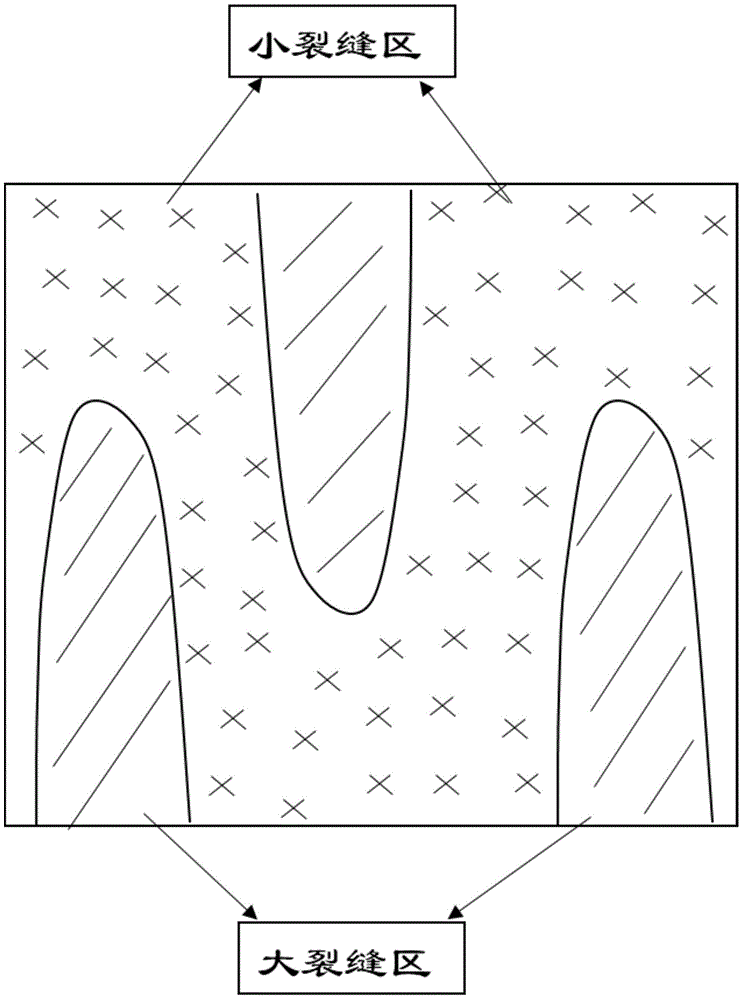

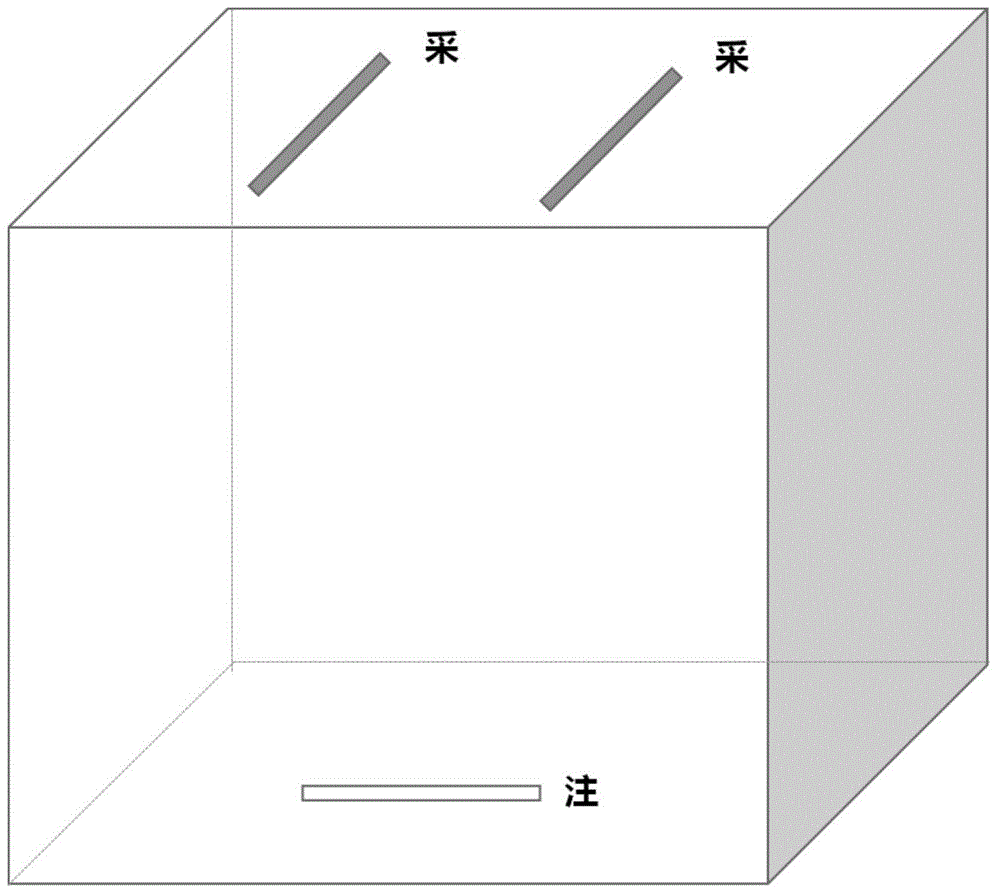

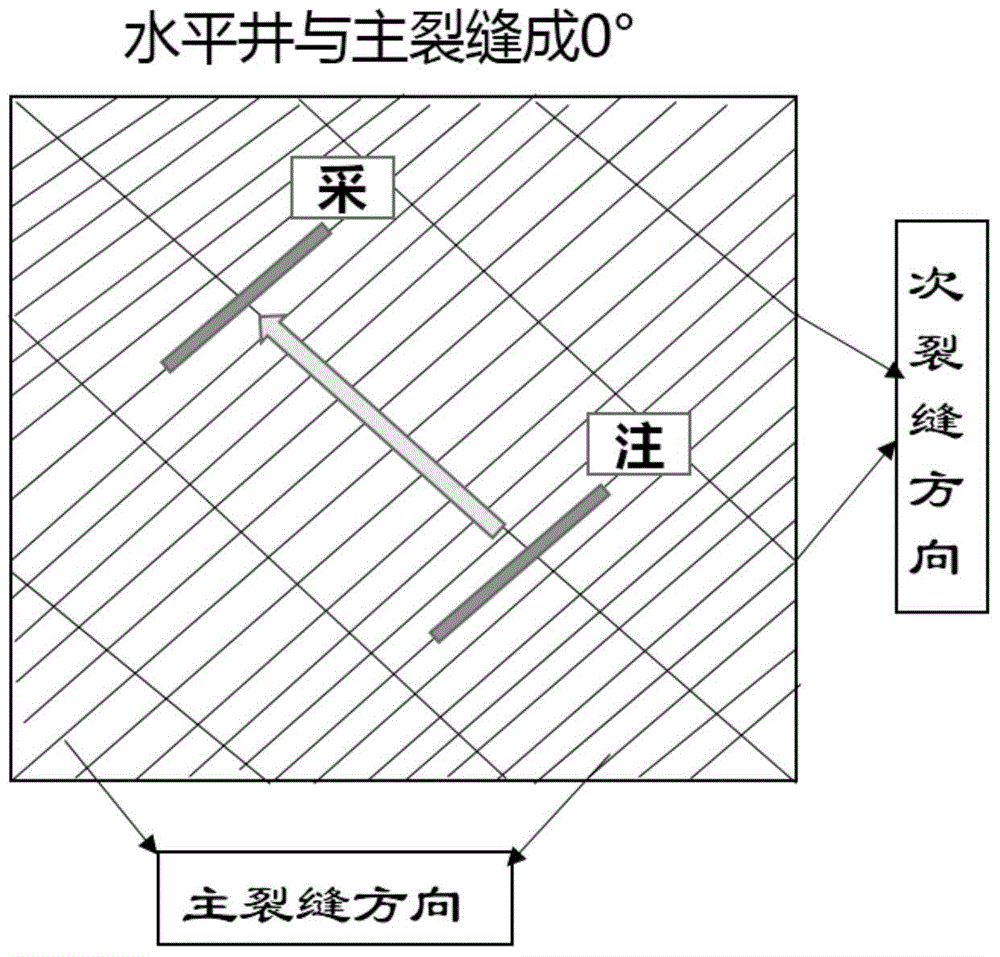

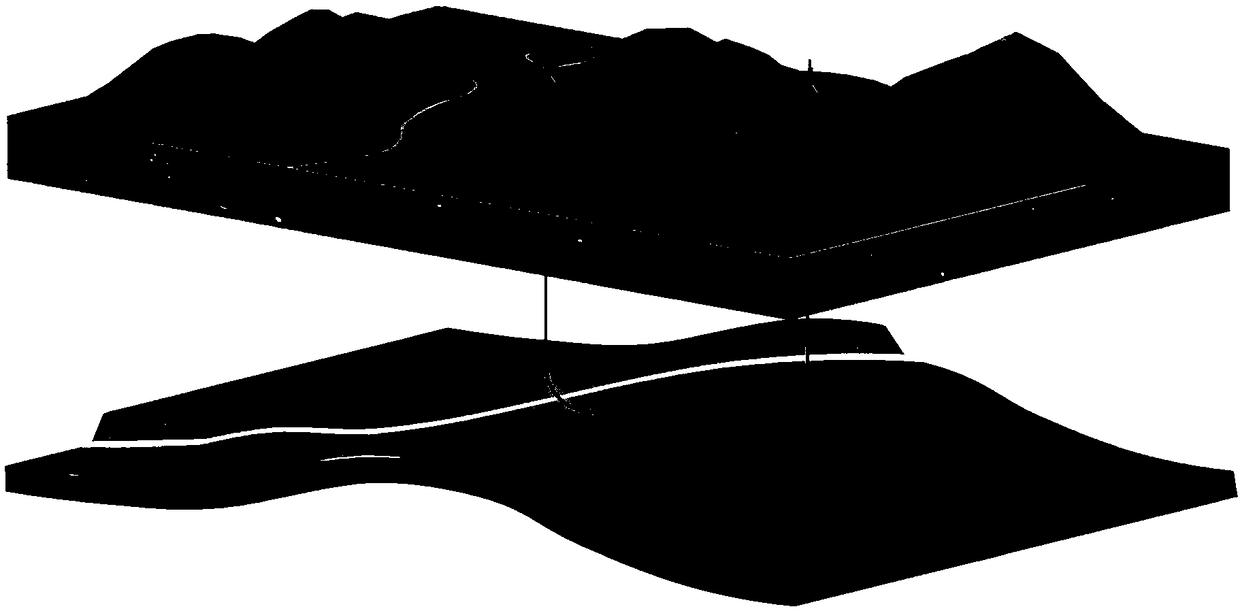

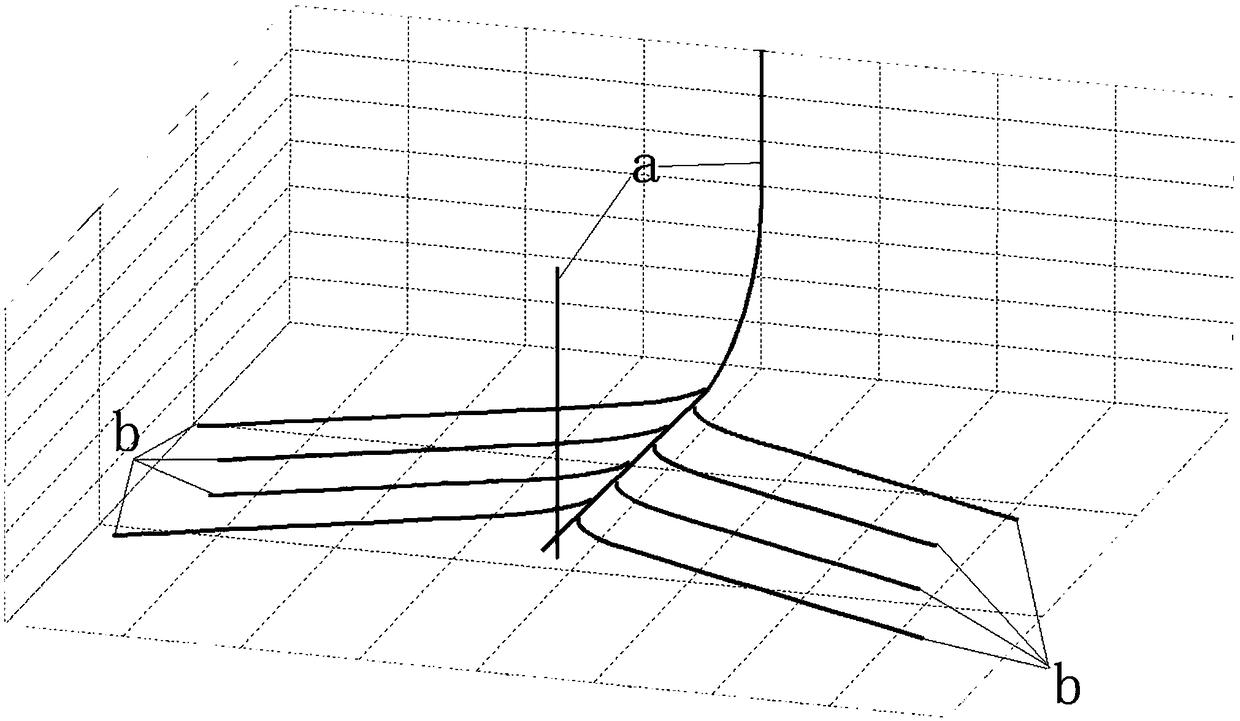

Well network deployment method of giant thick fractured and buried hill reservoir

ActiveCN104912537AGuaranteed encounterReduce production differential pressureFluid removalNetwork deploymentDistribution method

The invention relates to a well network deployment method of a giant thick fractured and buried hill reservoir. The method is characterized in that a set of large-fracture-injection small-fracture-production plane-staggering longitudinal-three-dimension bottom-injection and top-production horizontal well injection-production well network is deployed in the giant thick fractured and buried hill reservoir, wherein for the large-fracture injection, an injection well is deployed at a large fracture region of the giant thick fractured and buried hill reservoir; for the small-fracture production, a production well is deployed in a small fracture region of the giant thick fractured and buried hill reservoir; for the plane staggering, the projection of the injection well and the projection of the production well on the plane are mutually parallel but not rightly aligned; for the longitudinal three-dimension, the horizontal wells are in parallel arrangement at different depths in the giant thick fractured and buried hill reservoir, and a three-dimensional well network is formed in a direction parallel to the gravity and in a cross section perpendicular to a main shaft; and for the bottom injection and top production, a water injection well is arranged at the bottom of the giant thick fractured and buried hill reservoir, and a production well is arranged on the top of the giant thick fractured and buried hill reservoir. The well network deployment method can effectively solve the problem of well distribution difficulty of the giant thick buried hill reservoir, and belongs to an effective well distribution method of the giant thick fractured and buried hill reservoir.

Owner:CHINA NAT OFFSHORE OIL CORP +1

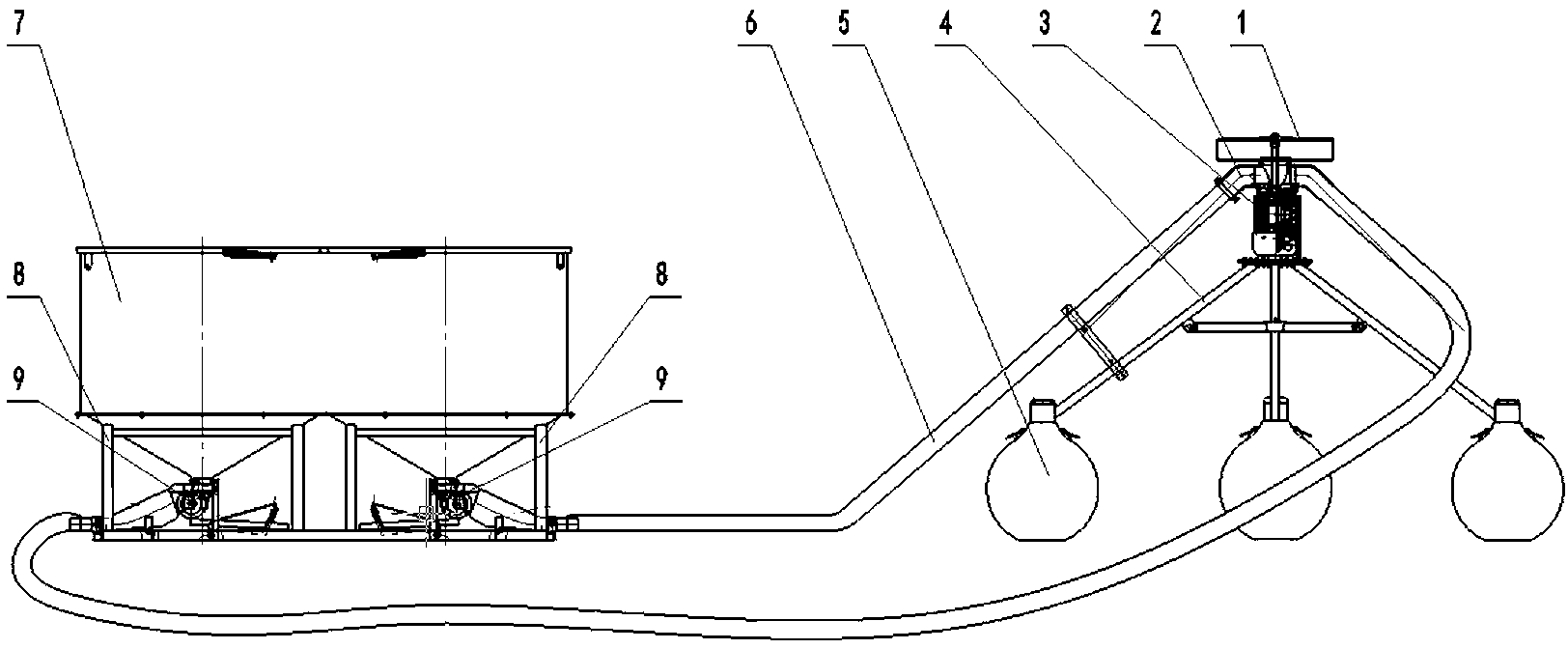

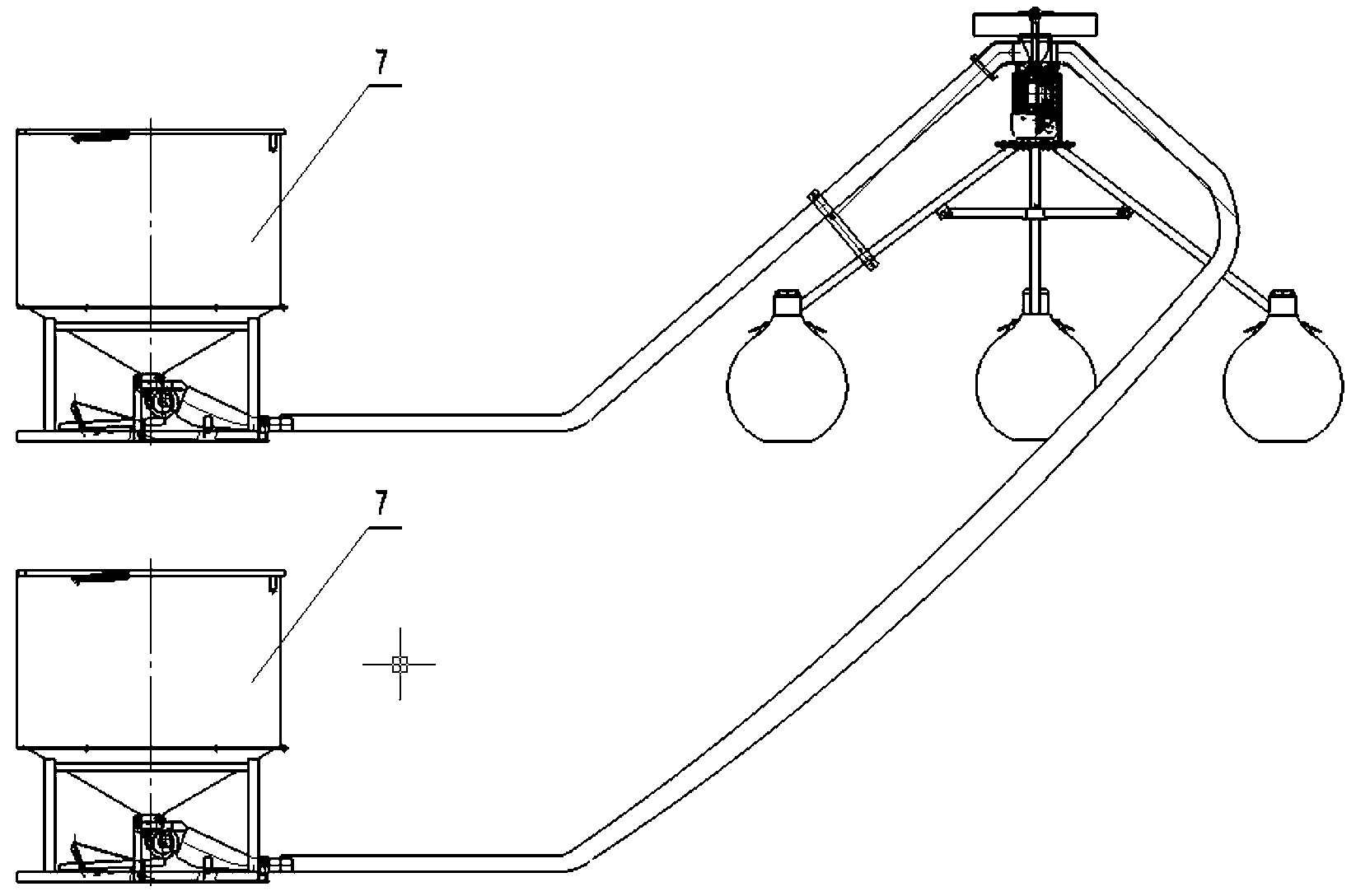

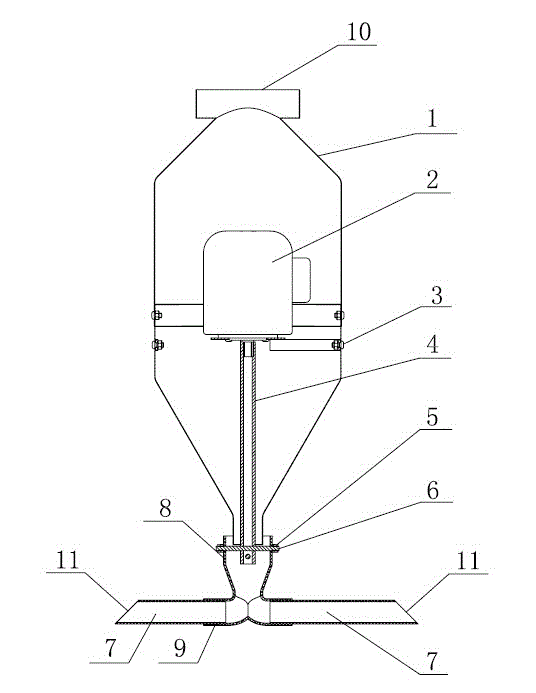

Multi-pipe wind conveying feeder for fishponds

InactiveCN103283663ALarge amount of throwingLarge spreading areaPisciculture and aquariaElectric machineryEngineering

The invention discloses a multi-pipe wind conveying feeder for fishponds. Feed bins (7), feed receiving hoppers (9), vibration hoppers (13) and vibration motors (14) are mounted on bases (8), one vibration hopper (13) is mounted below each discharge hole of each feed bin (7), a discharge port of each vibration hopper (13) is aligned to each feed receiving hopper (9), the vibration hoppers (13) are connected with the vibration motors (14), floating bodies (5) are mounted at the bottom of a support rod assembly (4), a long-axis motor (3) is mounted on the support rod assembly (4), a multi-head windmill screen (2) is mounted on a base of the long-axis motor (3), the bottom plane of a wind-suction feed-throwing wind wheel (1) is sleeved above the multi-head windmill screen (2), an inner hole of the top plane of the wind-suction feed-throwing wind wheel (1) is connected with the long-axis motor (3), each feed port of the multi-head windmill screen (2) is connected to one end of a conveying pipe (6), and the other end of each conveying pipe (6) is connected with the corresponding feed receiving hopper (9), so that the feeder is formed integrally. The multi-pipe wind conveying feeder is capable of achieving multi-pipe feeding, large in throwing quantity, wide in throwing area and high in working efficiency.

Owner:金湖小青青机电设备有限公司

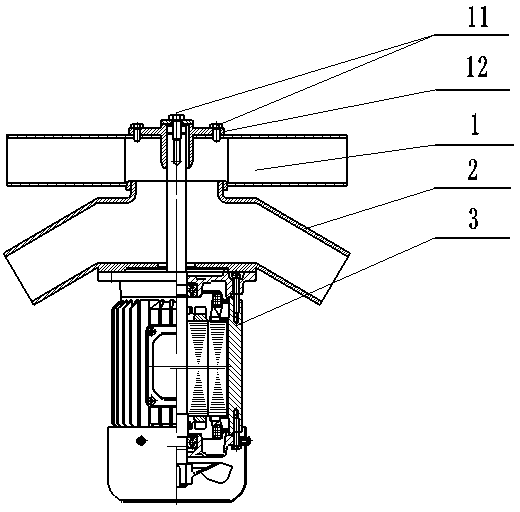

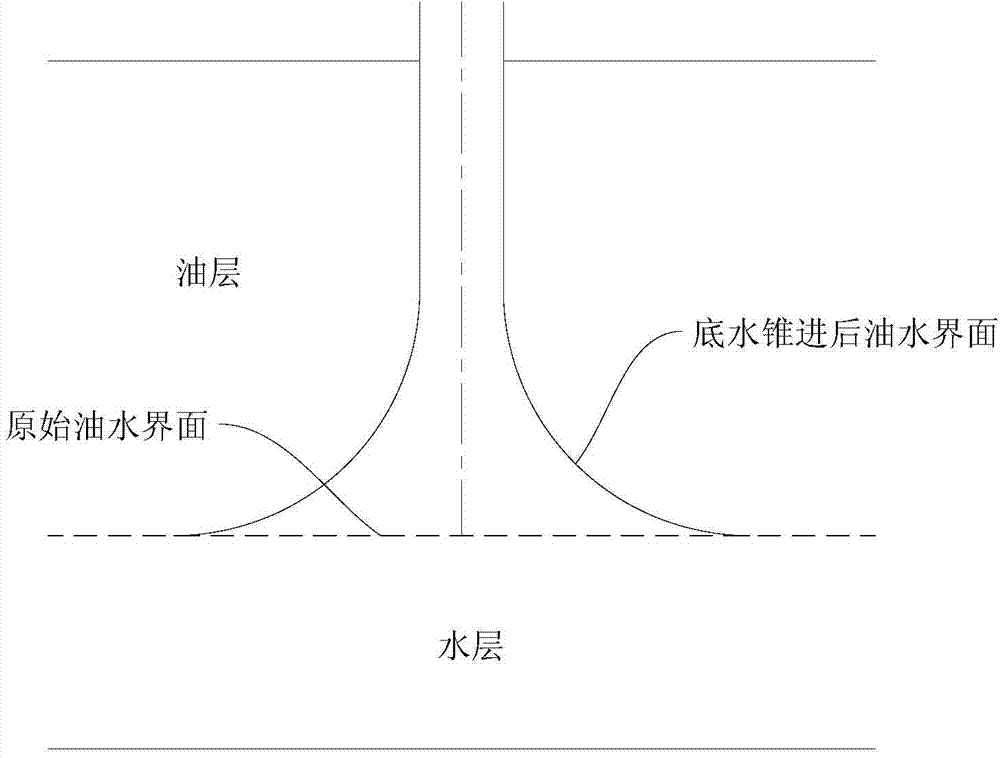

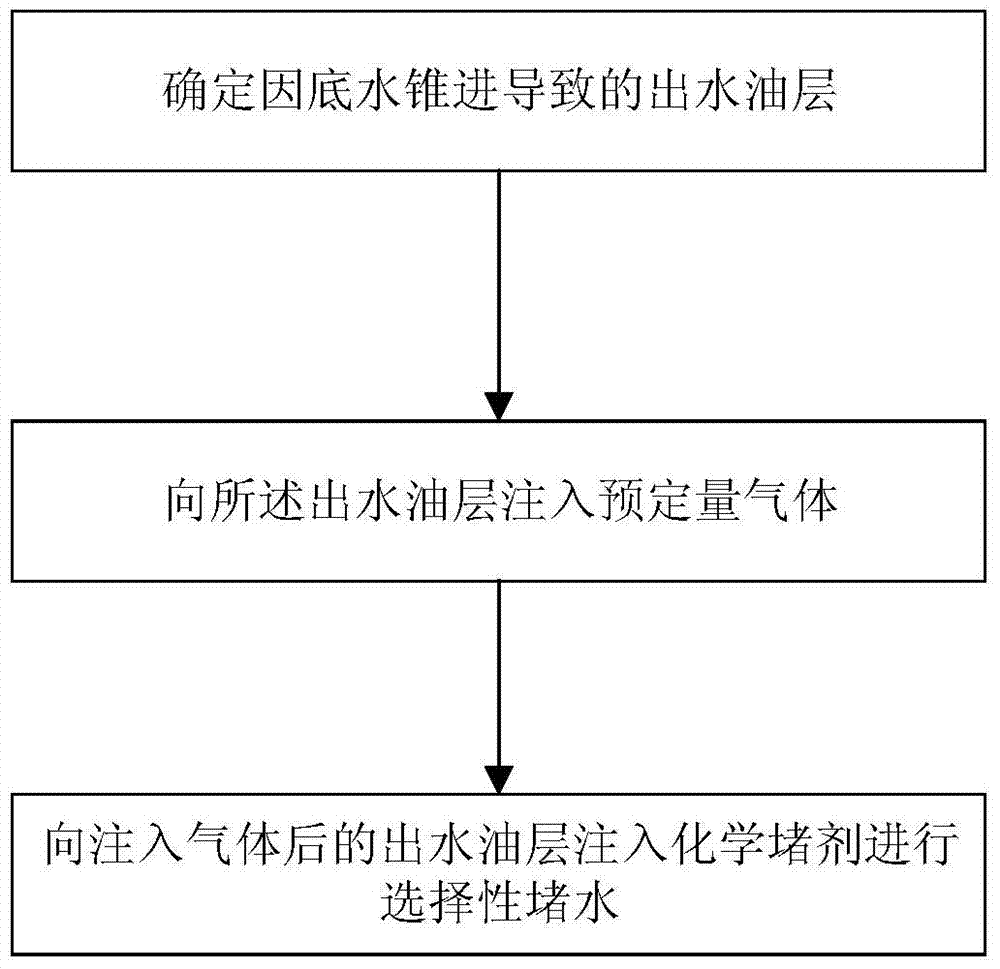

Heavy oil reservoir water-coning-control water plugging method

InactiveCN104847302AIncrease blockage radiusImprove the heating effectFluid removalSealing/packingEnvironmental engineeringProduct gas

The invention provides a heavy oil reservoir water-coning-control water plugging method. The method comprises the following steps: determining a water-outlet oil layer caused by bottom water coning; injecting gas with predetermined quantity into the water-outlet oil layer; and injecting a chemical water plugging agent into the water-outlet oil layer injected with the gas for selective water plugging. Wherein the chemical water plugging agent is composed of a first slug and a second slug; and according to the mass percent concentration, the first slug comprises 0.4-0.5% polyacrylamide, 2-3% rubber particles and 1-3% tanning extract powder, and the second slug is an aqueous solution prepared from 15-25% resin and fly ash. According to the heavy oil reservoir water-coning-control water plugging method provided by the invention, before the chemical water plugging agent is injected into the water-outlet oil layer caused by bottom water coning for selective water plugging, the gas with a certain pressure is injected into the water-outlet oil layer in advance, and the injected gas preferentially occupies the top space of the water-outlet oil layer to drive heavy oil at the top of the oil layer to move downwards, so that rapid water coning control is realized.

Owner:PETROCHINA CO LTD

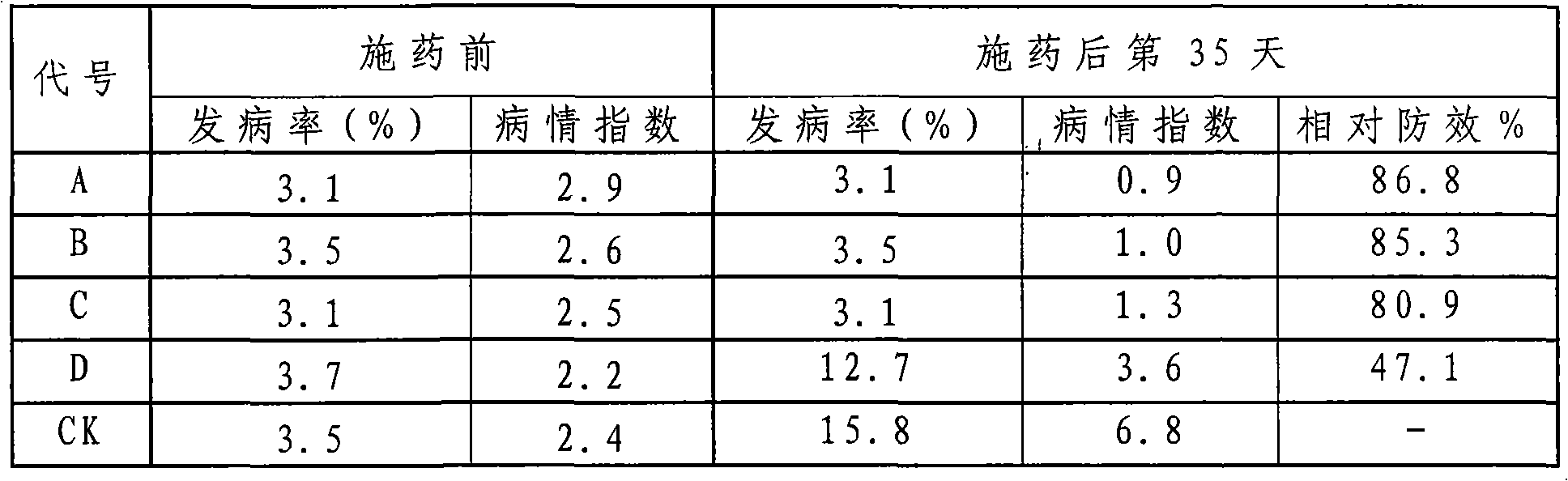

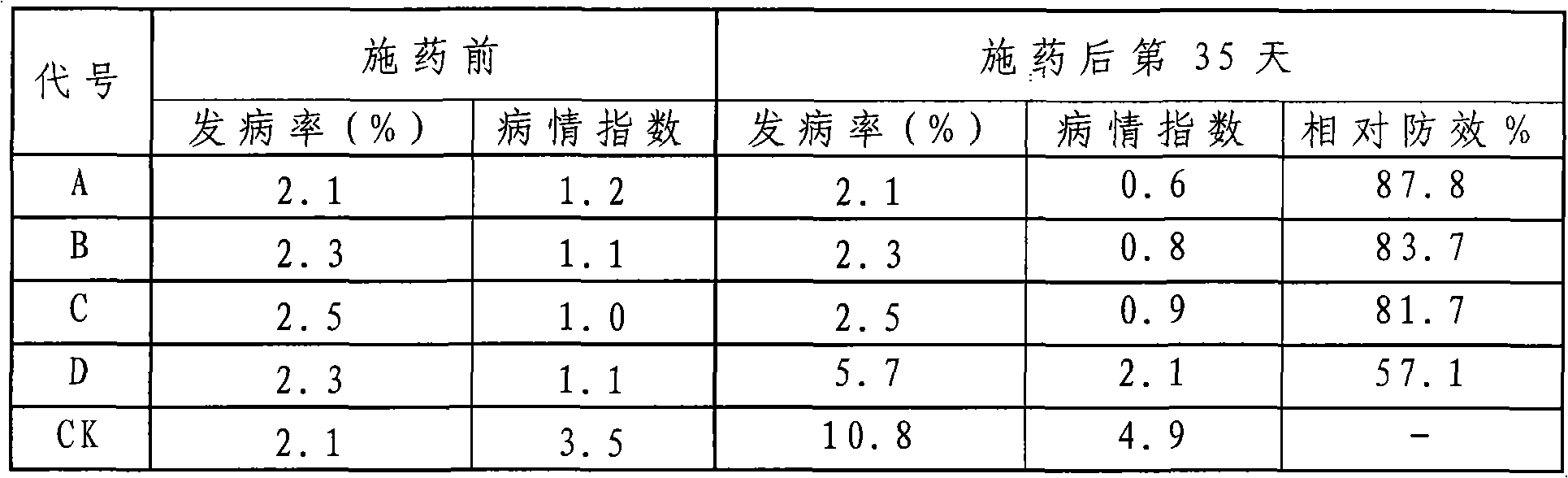

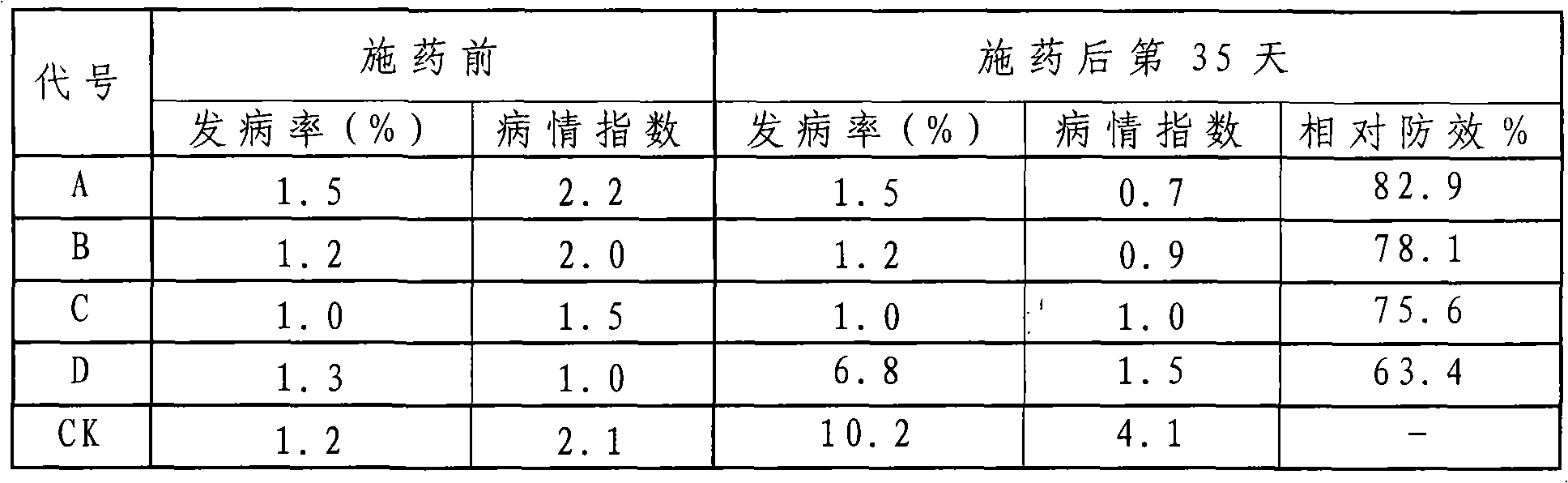

Anti-plant virus agent and preparation method and application thereof

InactiveCN101766187AImprove biological activityStrong insecticidal functionBiocidePlant growth regulatorsDiseaseMode of action

The invention discloses an anti-plant virus agent and a preparation method and application thereof. The anti-plant virus agent of the invention comprises the following components in parts by weight: 10-50 parts of jatropha curcas seed oil cake extract, 10-50 parts of alkaloid, 10-50 parts of fulvic acid salt, 5-50 parts of plant growth regulator, 10-60 parts of surfactant and 20-75 parts of solvent. The preparation method mainly comprises the following steps: respectively heating and dissolving the alkaloid, the plant growth regulator, the solvent, the jatropha curcas seed oil cake extract and the surfactant; adding, heating and dispersing the fulvic acid salt; and obtaining the anti-plant virus agent after cooling. The invention can solve the defects of single mode of action on the plant virus and low controlling effect of the current products. The product of the invention has the advantages of reduction of virus diseases transmitted by aphids, good therapeutic effect on plant virus diseases, obviously improvement of the disease-resisting capacity of plants, and good wettability, spreading property and permeability, low use cost and simple production processes.

Owner:罗波

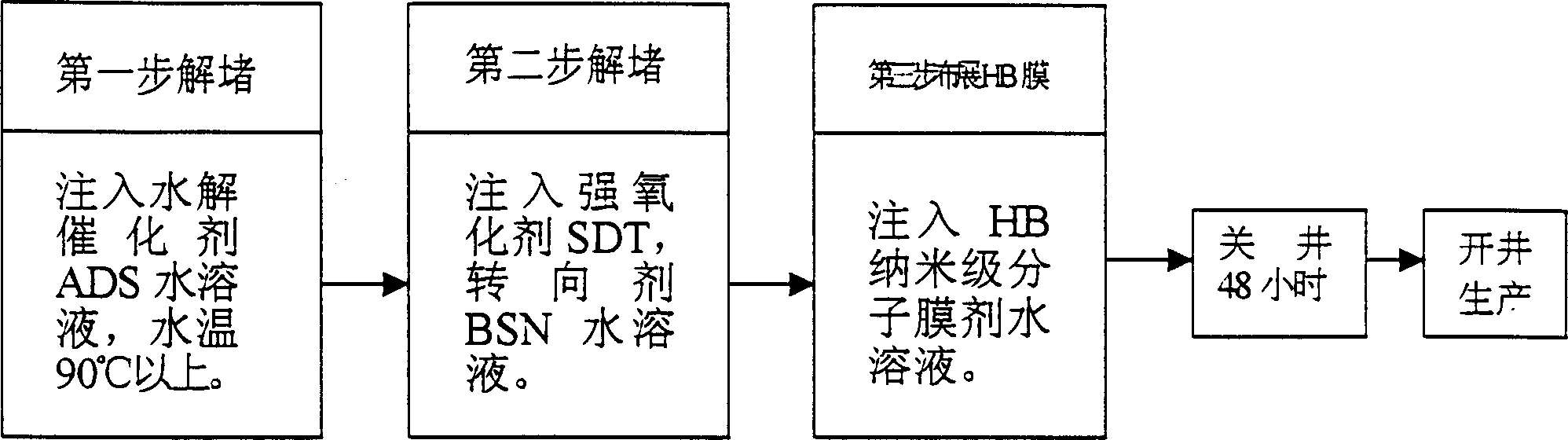

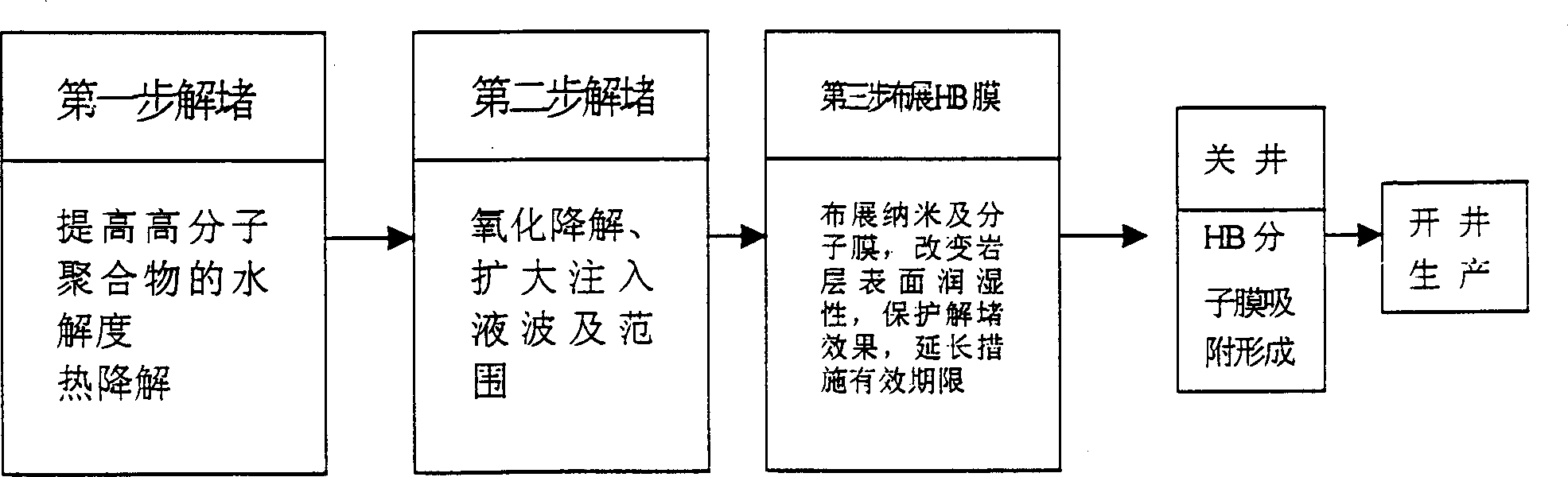

Method for releasing oil field from blockage caused by high molecular polymer

A method for removing the plug of high-molecular polymer in oil field includes injecting high-temp aqueous solution of ADS as hydrolyzing catalyst for promoting the hydrolyzing and thermodecomposing reaction of high-molecular polymer, adding the aqueous solution of SDT as strong oxidant for oxidizing degradation, reaction to lower the molecular weight of said polymer, using BSN as pilotting agent for forcing the injected liquid to come in low-osmosis region, and injection nano molecular filming agent HB for improving the lubrication of stratum.

Owner:胡新锁

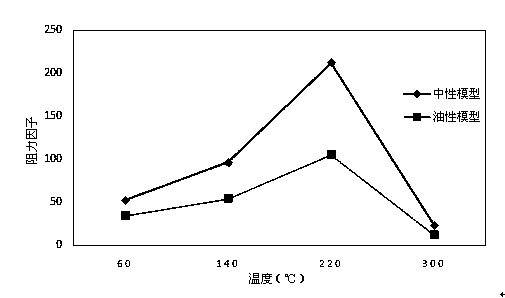

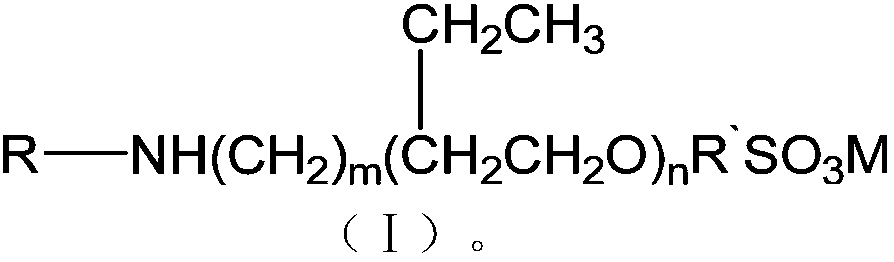

High-temperature resistant assistant steam expelling foaming agent

ActiveCN107903886AImprove high temperature stabilityImprove stabilityDrilling compositionSulfonateFoaming agent

The invention belongs to the technical field of oil recovery and in particular relates to a high-temperature resistant assistant steam expelling foaming agent which comprises the following componentsin parts by weight: 5-10 parts of a foaming agent, 10-30 parts of a foam stabilizer and 60-85 parts of water, wherein the foaming agent is amino-containing polyether sulfonate. The high-temperature resistant assistant steam expelling foaming agent provided by the invention is high in foaming property and high in stability, and 300-DEG C temperature resistant tests show that the foaming agent is stable in chemical property, in addition, the foaming agent is high in sealing profile control property, and under a condition of residual oil, a sealing profile control function can be still achieved,the expelling area can be effectively increased, sweeping areas can be increased, the oil reservoir exploration effect is improved, and the oil recovery rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil well acidification process and device for increasing oil-gas well yield

ActiveCN112523737AReduce acid contentAvoid cloggingFluid removalDrilling compositionLiquid tankPre treatment

The invention discloses an oil well acidification process and device for increasing oil-gas well yield. The oil well acidification device comprises an acid liquid tank and a waste liquid tank, whereina stirring tank is arranged in the acid liquid tank, a stirring device is arranged in the stirring tank, an acidification pipe column penetrates through a wellhead device and then extends into the bottom of a casing pipe, a nozzle is arranged at the bottom of the acidification pipe column, and pulse supercharging devices are arranged on the two sides of the acidification pipe column above the nozzle; and the waste liquid tank is connected with a liquid outlet of the wellhead device. The acidification process comprises the following steps that S1, acidification pretreatment is conducted; S2, preposed acid liquid is injected; S3, reaction acid liquid is injected; and S4, a neutralizer is injected in a pulse pressurization mode, so that the acid liquid enters an oil layer in a fluctuation mode, the swept area is enlarged, the injection effect of the acid liquid is effectively enhanced, residual acid liquid is neutralized in sections at the bottom of a well, the content of the acid liquidin flowback fluid is reduced, components of preposed acid liquid, reaction acid liquid and the neutralizer are optimized, the problem of oil layer blockage can be effectively solved, and the purposeof increasing the yield is achieved.

Owner:西安石油大油气科技有限公司

Method for improving CO2 miscible flooding recovery efficiency

ActiveCN111058816AReduce gas channelingEORFluid removalDrilling compositionApparent viscositySoil science

The invention provides a method for improving CO2 miscible flooding recovery efficiency. The method comprises the following steps that a chemical agent capable of improving the macroscopic apparent viscosity of a supercritical CO2 miscible flooding system is added in the CO2 miscible flooding process, the chemical agent is partially or completely dissolved in supercritical CO2, the viscosity of supercritical CO2 can be improved, the chemical agent can be dissolved in formation water, and an aqueous solution and supercritical CO2 can form a stable dispersion. According to the method, the macroscopic apparent viscosity of the supercritical CO2 system is improved, so that the swept area of supercritical CO2 is further increased, and the CO2 miscible-phase displacement recovery ratio of the low-permeability reservoir is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite brazing flux suitable for copper and aluminum dissimilar metal brazing

ActiveCN104708232AReduced active temperature rangeHigh activityWelding/cutting media/materialsSoldering mediaCorrosionDissimilar metal

The invention discloses a composite brazing flux suitable for copper and aluminum dissimilar metal brazing. The composite brazing flux comprises 50-55% of cesium fluoride, 30-35% of aluminum fluoride, 3-5% of potassium fluoride, 10-12% of rubidium fluoride, 0.1-1% of potassium fluorogermanate, 0.1-0.5% of zinc difluoro and 0.1-0.5% of potassium fluoborate. The composite brazing flux is formed by preparing seven kinds of fluoride in proportion, and has the advantages of being non-hygroscopic and free of corrosion compared with a traditional chloride brazing flux; compared with a traditional fluoride brazing flux, the composite brazing flux obviously narrows the activity temperature range and further improves the activity; compared with a traditional fluoride brazing flux, the spreading area of ZN-15AL brazing filler metal on an aluminum alloy plate at 500 DEGC is improved by about 40%, and the spreading area of the ZN-15AL brazing filler metal on the aluminum alloy plate at 520 DEG C is improved by about 25%.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Multiple thermal fluid composite system oil displacing method

InactiveCN104632161AEnhanced overall recoveryReduce pollutionFluid removalDrilling compositionPollutionHeavy oil reservoir

The invention discloses a multiple thermal fluid composite system oil displacing method and particularly relates to a method for economically and effectively improving the oil recovery rate for the later period of water displacing normal heavy oil reservoir exploitation. The method comprises the steps of a, injecting mixtures, which is 0.15-0.2 time the formation pore volume, of hot water and flue gases; b, injecting a foaming agent solution into a water injection well for 25-30 d; c, injecting a viscosity reducer solution into the water injection well for 5-10 d; d, injecting the mixtures of hot water and flue gases for 60-80 d; e, repeating the steps b, c and d. The method displaces a great amount of residual oil which cannot be extracted through common water displacing in an oil reservoir, the heavy oil reservoir recovery rate after water displacing is improved greatly by 26.4%, and the final reservoir recovery rate can reach 48.8%. Meanwhile, flue gases generated by combustion are directly injected underground, the thermal efficiency can be improved by more than 10%, and environment pollution is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

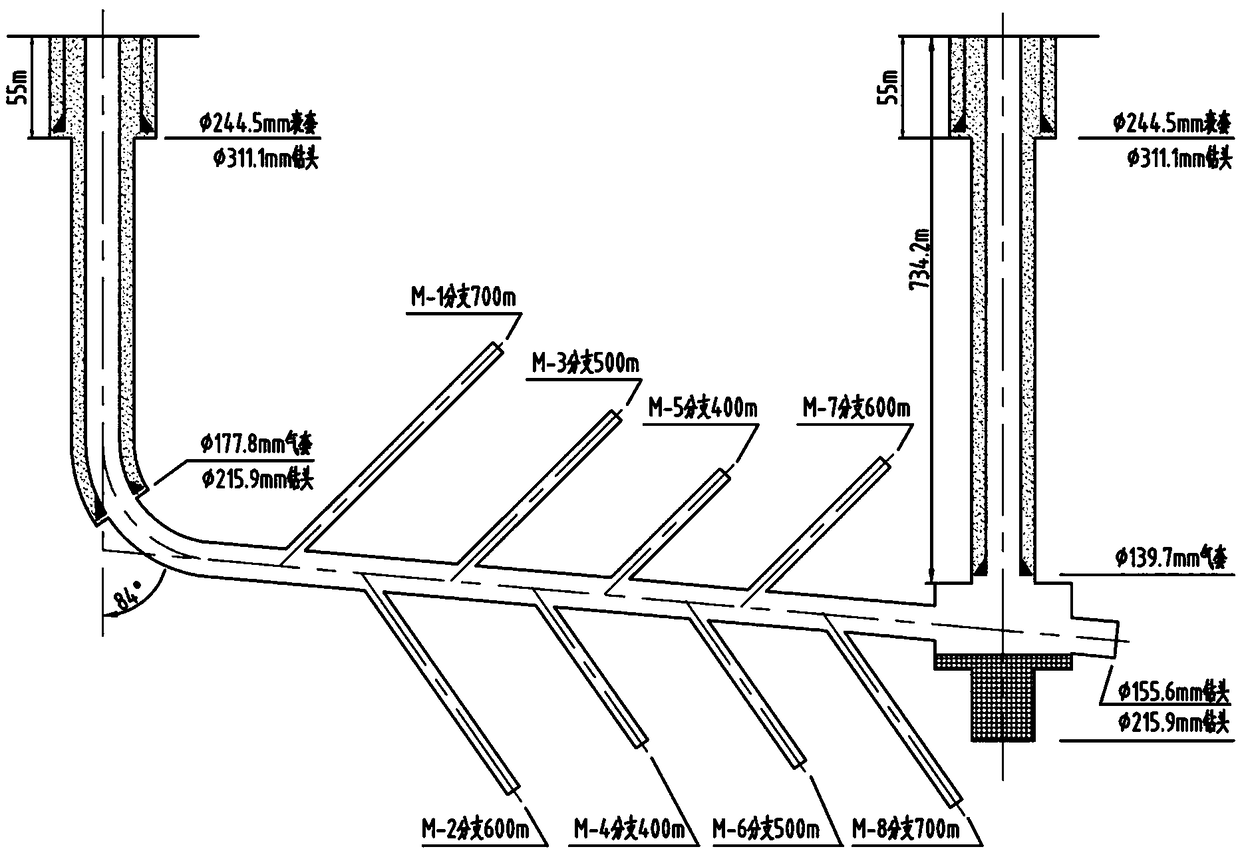

Exploitation method for coalbed methane multibranch remote-end communicated well

InactiveCN108716396AIncrease productionImprove diversion capacitySurveyConstructionsWell drillingWell cementing

The invention relates to the technical field of coalbed methane exploitation, and relates to an exploitation method for a coalbed methane multibranch remote-end communicated well. The method concretely includes the following steps: 1) using a drill bit with the phi being 311.1 mm to drill to the depth of a designed surface casing during first exploitation, and placing a casing with the phi being 244.5 mm to seal an upper layer section which is unstable and prone to leakage and collapse; 2) using a drill bit with the phi being 215.9 mm to drill to a designed target point during secondary exploitation, wherein the inclination angle of the well reaches 84 degree, and placing a technical casing with the phi being 177.8 mm to enhance the well and seal a stratum which is prone to leakage; 3) using a drill bit with the phi being 155.6 mm to drill to a designed target point in an inclined section during third exploitation; and 4) using drill bits with the phi being 155.69 mm to drill to designed target points in branch well sections. Compared with a vertical well and a horizontal well, the multibranch horizontal well is improved in conductivity increased in sweep area and greatly improvedin single well output. The method adopts drilling along the downdip direction of a reservoir stratum, which is beneficial to the well trajectory control, can help water in a coal seam flow into the bottom of the production well under the action of gravity, and can improve the efficiency of drainage and gas recovery of the production well.

Owner:LANZHOU CITY UNIV

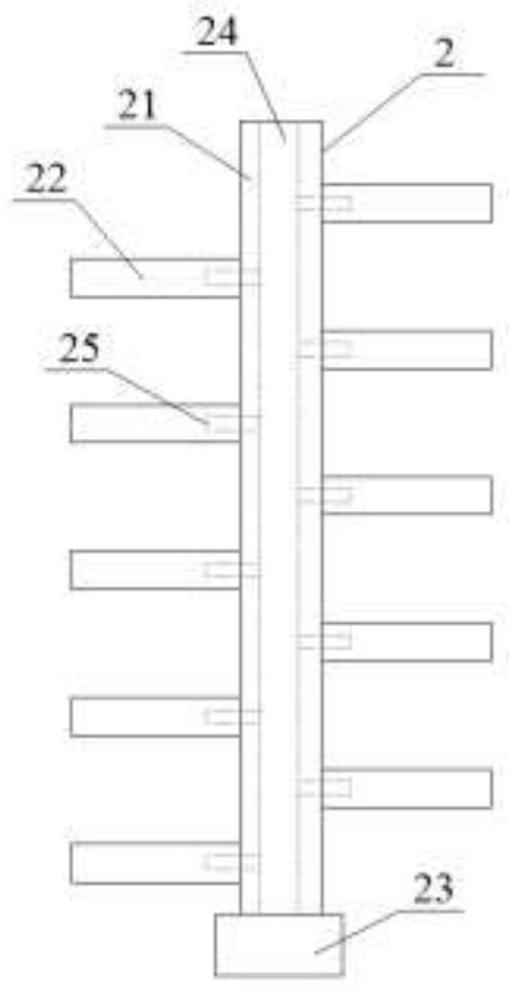

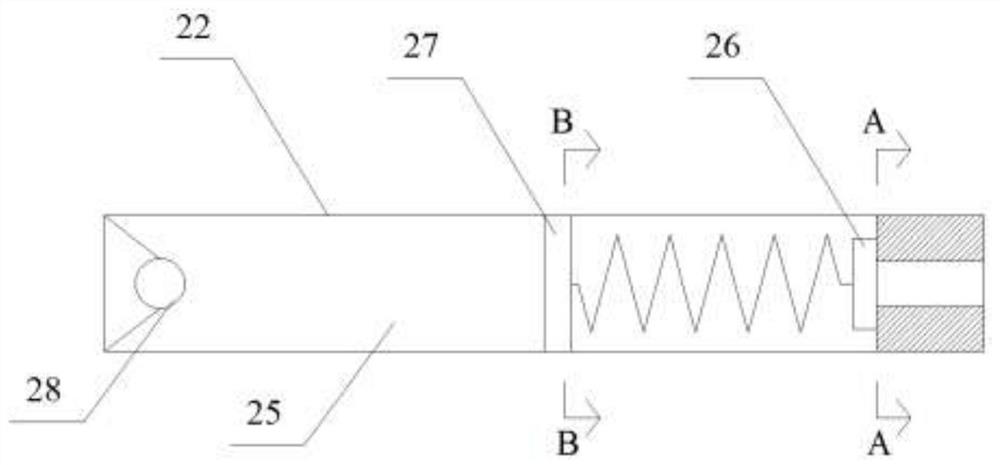

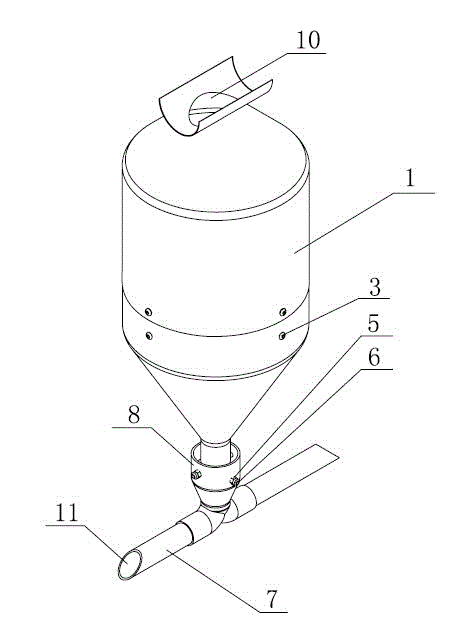

Feed scattering and charging device

InactiveCN102742533AIntegrity guaranteedReduce powder ratePisciculture and aquariaDrive shaftElectric machinery

The invention relates to a feeding device, in particular to a feed scattering and charging device. The feed scattering and charging device comprises a feed measuring barrel, a motor and a scattering assembly, wherein the motor is arranged in the feed measuring barrel; the scattering assembly is arranged at the bottom of the feed measuring barrel and is connected with the motor by a transmission shaft; the scattering assembly comprises two scattering barrels and a three-way pipe piece; one end of the three-way pipe piece is a joint and is sleeved at the outer part of the transmission shaft and connected with the transmission shaft by a screw and a nut, and the other two ends of the three-way pipe piece are sleeve joints which are respectively connected with the scattering barrels in a sheathing manner; the scattering assembly does rotary motion along with rotation of the motor and transmission of the transmission shaft; and the transmission shaft is adopted as the central shaft for the rotary motion. The feed scattering and charging device has the advantages that the feed is uniformly scattered towards the periphery taking the transmission shaft as the center by the linear-shaped scattering barrels; due to design with two scattering barrels with different lengths and inclined-plane outlets, the scattering area is expanded, and the scattering is uniform; due to the whole structure, the pulverization rate of the feed in the scattering process can be greatly reduced, further the pollution to a feeding environment can be reduced and the feed can be saved; and due to adoption of automatic feeding, the labor cost is reduced.

Owner:CHENGDU TONGWEI AUTOMATION EQUIP

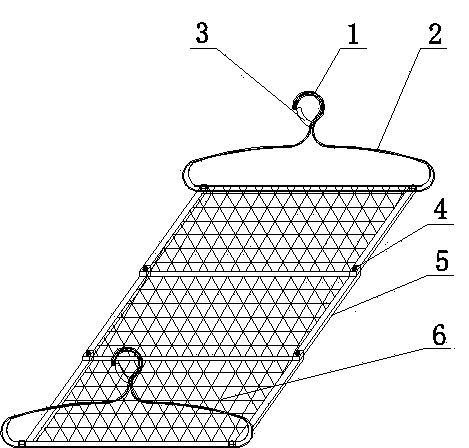

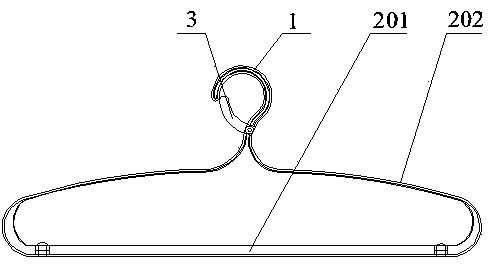

Telescopic clothes rack

The invention relates to a telescopic clothes rack. The telescopic clothes rack comprises two clothes rack bodies, wherein each clothes rack body comprises a pothook and a clothes rack body part connected to one end of the pothook, the other end of the pothook is a free end, a connecting sheet which can be in sealing connection with the free end of the pothook is articulated at a connecting end between the pothook and the clothes rack body part, two expansion links arranged in parallel are fixedly connected between the two clothes rack bodies, each expansion link comprises multiple fixed links which are sequentially arranged from top to bottom in a lap joint manner, a sliding chute matched with the fixed link at the upper part is formed in the fixed link at the lower part, the two adjacent fixed links are fixed together through elastic positioning screws arranged at the lap joint ends of the fixed links, and a flexible supporting net is formed between the two expansion links. When the telescopic clothes rack is used, clothes can be spread out on the supporting net so as to avoid the defect that when the clothes are vertically hung, the clothes deform; when the telescopic clothes rack is not in use, the extension links can be folded, and the telescopic clothes rack is easy to store and place; and when the telescopic clothes rack is hung on a clothesline or a clothesline pole, the telescopic clothes rack does not fall off, so that the clothes is prevented from being polluted.

Owner:LUOYANG INST OF SCI & TECH

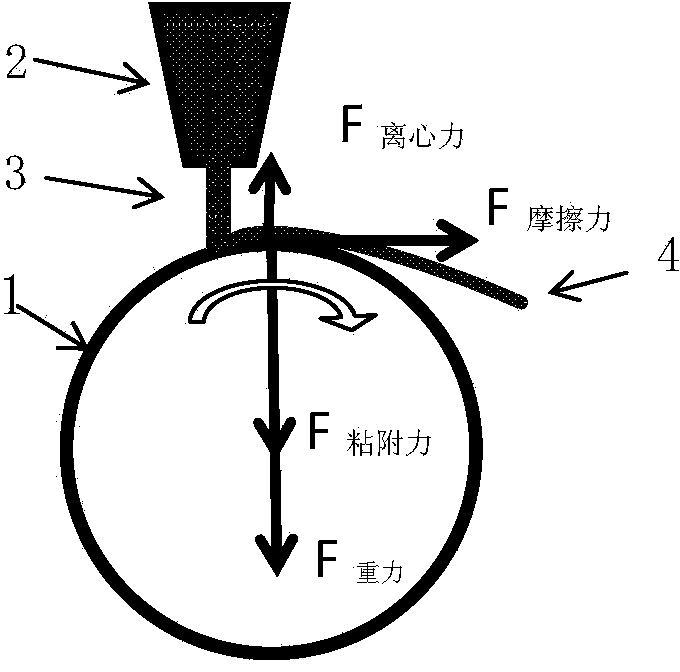

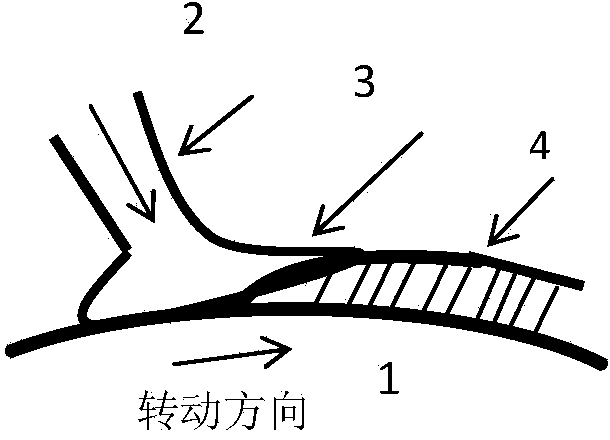

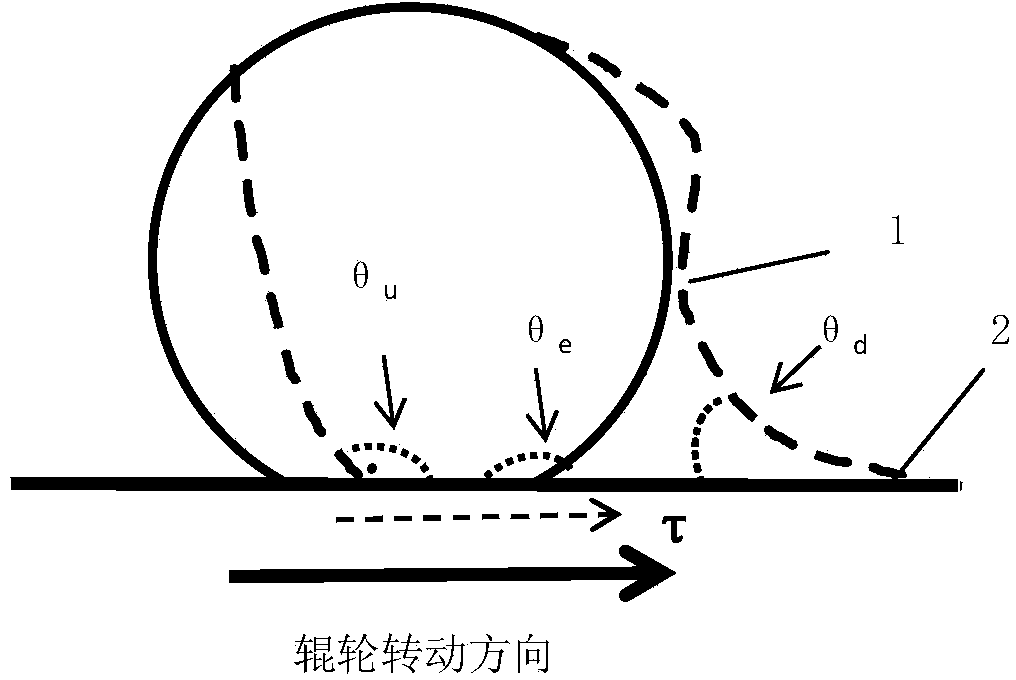

Method for adopting belt spinning of disc-type single roller to prepare amorphous alloy thin belt

ActiveCN103706770ALarge melt spreading areaGood belt forming performanceAmorphous metalSurface smoothness

The invention belongs to the technical field of alloy thin belt preparation and discloses a method for adopting belt spinning of a disc-type single roller to prepare an amorphous alloy thin belt. The method includes adopting the disc-type roller, spraying melt on the surface of a disc rotating around a disc central shaft, enabling a direction in which a centrifugal force is applied on the melt to be parallel to a contact face, namely the surface of the disc, and forming the amorphous alloy thin belt after an amorphous thin belt at the edge of the disc automatically breaks away from the roller under the action of cooling contraction and the centrifugal force. The amorphous alloy thin belt prepared by the method is thinner in size, higher in surface smoothness and better in performance.

Owner:TONGZHOU XINGCHEN MACHINERY

Efficient urea-formaldehyde resin plugging agent and application thereof

InactiveCN102585787AIncrease the spread areaReduce investmentDrilling compositionUltimate tensile strengthPetroleum

The invention relates to a plugging agent for plugging petroleum wells, and particularly relates to an efficient urea-formaldehyde resin plugging agent and application thereof. The efficient urea-formaldehyde resin plugging agent comprises the following raw materials in parts by weight: 55-75 parts of urea-formaldehyde resin, 0.01-2 parts of sodium persulfate, 0.1-5 parts of sodium polyacrylate and 5-35 parts of medical stone powder. The plugging agent is used for plugging petroleum wells at a temperature of 30-120 DEG C. When the plugging agent is used, the plugging agent is prepared into mixed liquid according to the weight parts above, the mixed liquid is uniformly stirred and is injected into the stratum, a petroleum well is closed, and reaction is carried out for more than 24 hours. When a production well is plugged by using the plugging agent disclosed by the invention, the later maintenance workload and capital investment of the production well can be greatly reduced; and meanwhile, the plugging agent achieves a uniform, integrated and efficient plugging effect, and is long in period of validity, high in strength and wide in applicable temperature range.

Owner:李良川

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com