Preparation method for nano-emulsion with stable polymers

A technology of nanoemulsions and polymers, which is applied in the direction of drilling compositions, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor stability of nanoemulsions, easy to pollute preparations, high cost, etc., and achieve simple and easy preparation methods Operation, low energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of partially hydrolyzed polyacrylamide (HPAM-1) stabilized nanoemulsion

[0044] The nanoemulsion is based on 100 parts by weight, and the components are as follows: 20 parts of liquid paraffin, 5.12 parts of nonionic surfactant Tween20, 4.88 parts of nonionic surfactant Span20, partially hydrolyzed polyacrylamide (average molecular weight is 12 million, degree of hydrolysis 18 %, abbreviated HPAM-1) 7×10 -5 ~1.4×10 -2 portion, the balance is water.

[0045] The preparation steps are as follows:

[0046] (1) Weigh 1.25g HPAM-1 and dissolve it in 250ml tertiary water to obtain 0.5wt% HPAM-1 mother liquor.

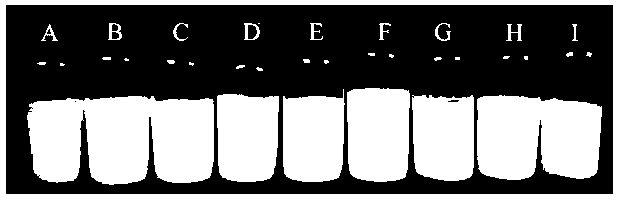

[0047] (2) Weigh 1.28g of nonionic surfactant Tween20 and 1.22g of Span20 into a 30ml bottle, then add 5g of oil-phase liquid paraffin respectively, and stir at a high speed of 15-20°C and 1000-2000rpm for 5-10min. A total of 9 bottles (marked as A-I) of nanoemulsion mixture were prepared.

[0048] (3) Dilute an appropriate amount of 0.5wt%...

Embodiment 2

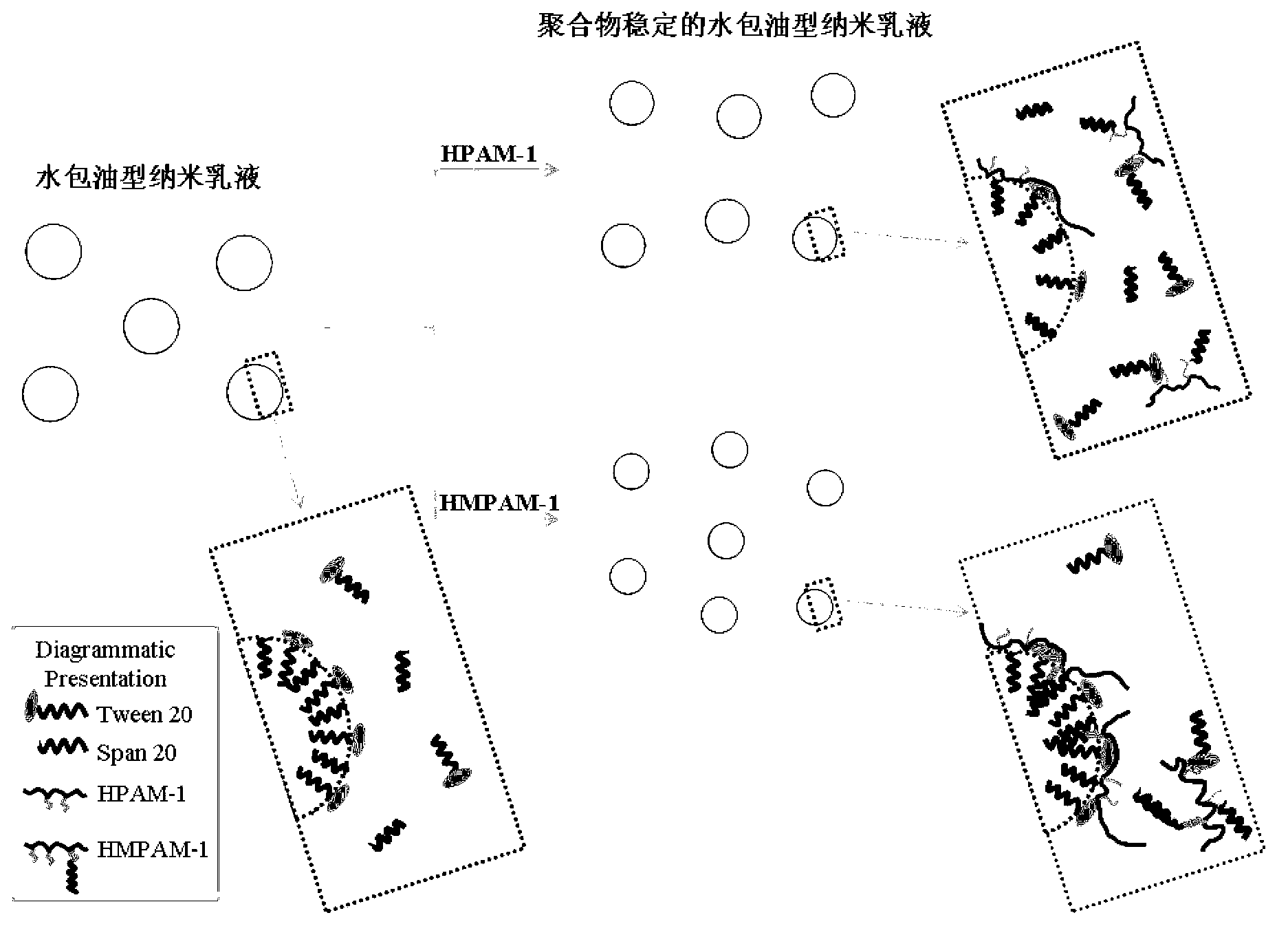

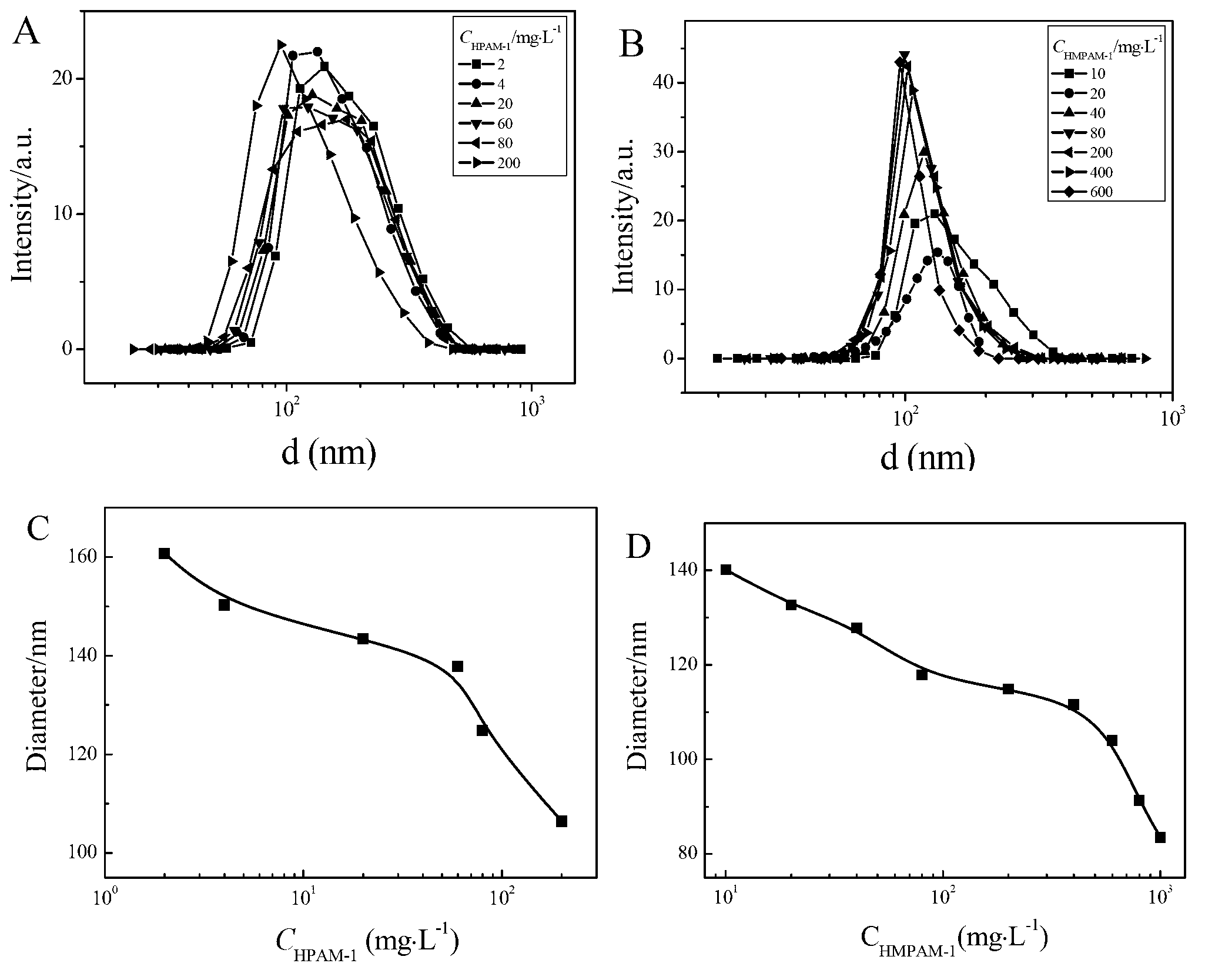

[0050] The particle size variation trend diagram and particle size distribution of the obtained HPAM-1O / W emulsion with the change of polymer concentration are as follows: image 3 As shown in (A, C), the surface tension and oil-water interfacial tension of pure HPAM-1 aqueous solution and O / W emulsion at the same concentration are as follows Figure 4 As shown in (A,C), the zeta potential of the emulsion with polymer concentration is as follows Figure 5 As shown in (A), the viscosity changes of the emulsions with different polymer concentrations as a function of shear rate are as follows: Image 6 As shown in (A), the zero-shear viscosity change of the emulsion at different polymer concentrations is as follows: Figure 7 shown in (A). Example 2: Preparation of Hydrophobically Modified Polyacrylamide (HMPAM-1) Stabilized Nanoemulsion

[0051] The nanoemulsion is based on 100 parts by weight, and the components are as follows: 20 parts of liquid paraffin, 5.12 parts of noni...

Embodiment 3

[0056] The particle size variation trend diagram and particle size distribution of HMPAM-1O / W emulsion with the change of polymer concentration are as follows: image 3 As shown in (B, D), the surface tension and oil-water interfacial tension of pure HMPAM-1 aqueous solution and O / W emulsion at the same concentration are as follows Figure 4 As shown in (B,D), the zeta potential of the emulsion with polymer concentration is as follows Figure 5 As shown in (B), the viscosity changes of the emulsions with different polymer concentrations as a function of shear rate are as follows: Image 6 As shown in (B), the zero-shear viscosity change of the emulsion at different polymer concentrations is as follows Figure 7 (B). Example 3: Preparation of partially hydrolyzed polyacrylamide (HPAM-2) stabilized nanoemulsion

[0057] The nanoemulsion is based on 100 parts by weight, and the components are as follows: 20 parts of n-heptane, 5.12 parts of nonionic surfactant Tween 60, 4.88 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com