Spherical silver powder and preparation method thereof

A silver powder and spherical technology, applied in the field of metal powder and its preparation, can solve the difficult application requirements of product purity, particle size, shape and other performance characteristics, long preparation cycle, heavy environmental pollution and other problems, and achieve particle size distribution The effect of narrow range, short preparation cycle and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

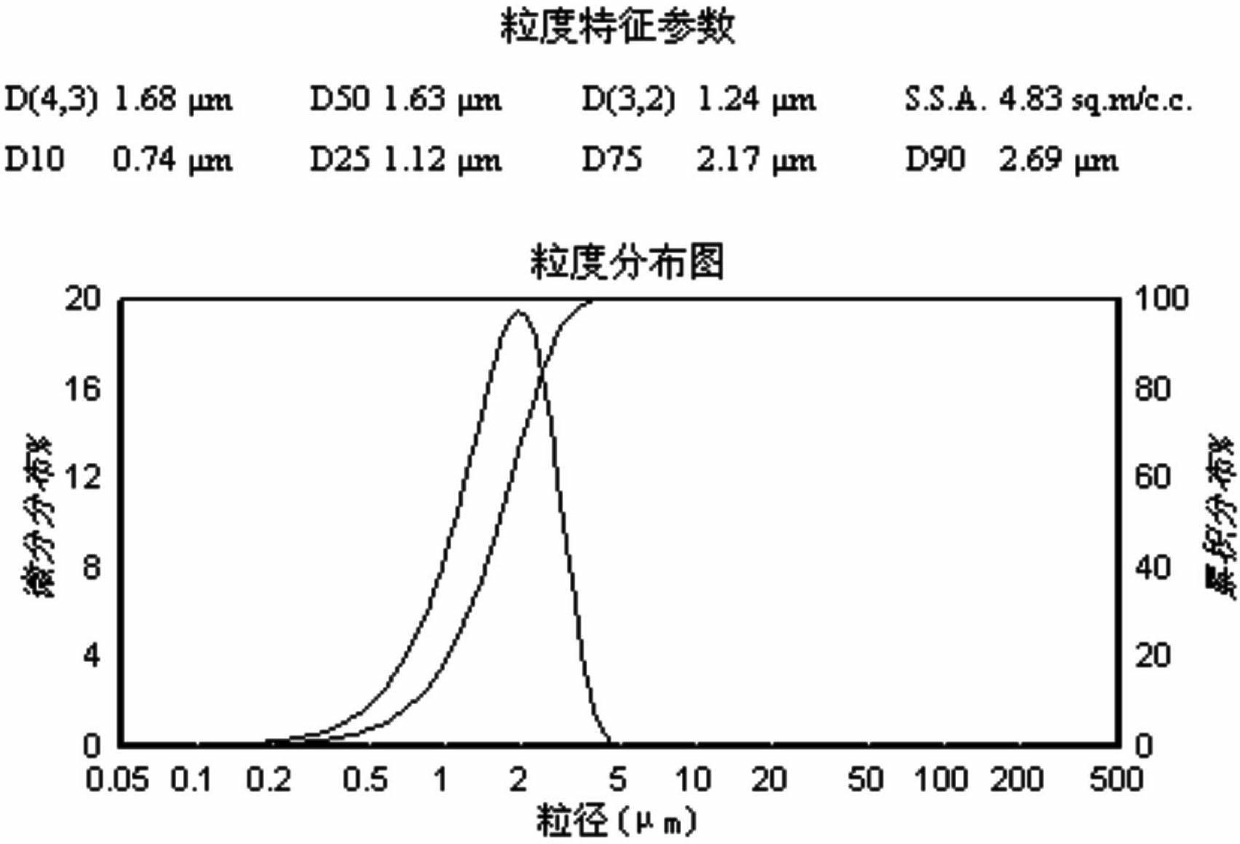

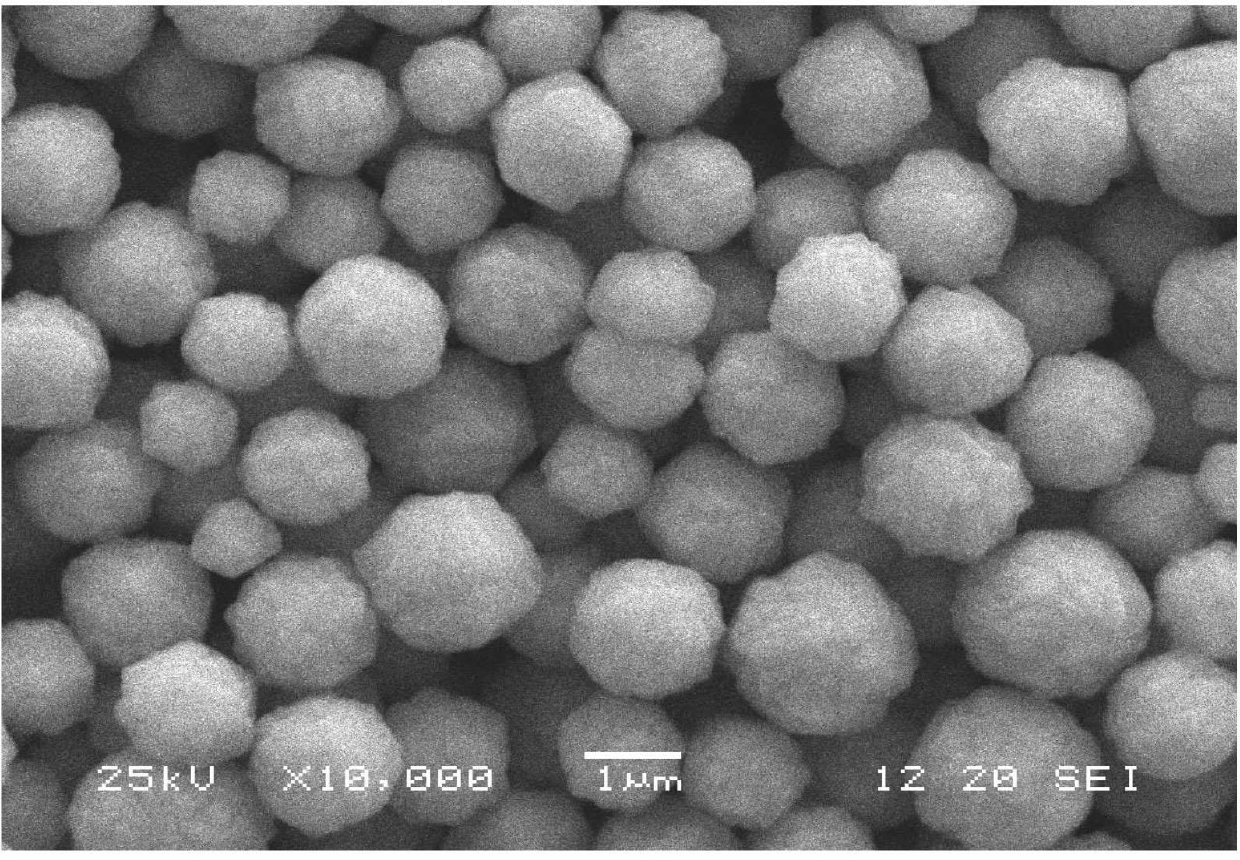

[0034] a kind of like figure 1 and figure 2 As shown in the spherical silver powder of the present invention, the particle size distribution range of the spherical silver powder is 0.2 μm to 5 μm, the particle size distribution is concentrated, and D 50 The particle size is 1.63μm; the tap density of the spherical silver powder is 4.12g / cm 3 , the specific surface area of the spherical silver powder is 0.46m 2 / g.

[0035] The spherical silver powder of the present embodiment is mainly prepared through the following steps:

[0036] (1) Weigh 20.0g of L-ascorbic acid, dissolve it in 500mL deionized water, and make 40g / L reducing agent solution A; weigh 7.0g of PVP, dissolve it in 200mL of distilled water at 40℃~60℃, Heat-promoting and forming protective agent solution B; then adding protective agent solution B dropwise into reducing agent solution A, and stirring evenly; adding 24wt% ammonia water to adjust the pH value so that the pH value is about 4.0 to prepare the re...

Embodiment 2

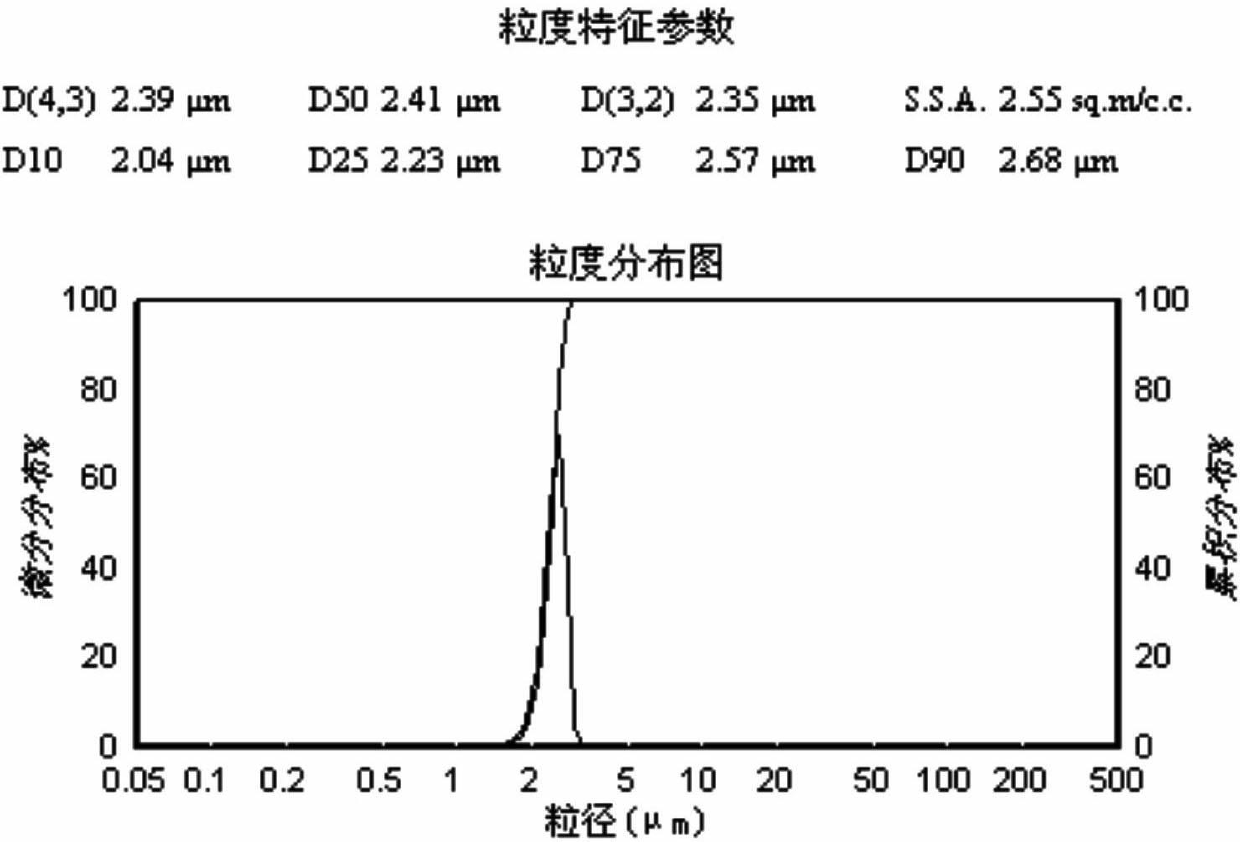

[0041] a kind of like image 3 and Figure 4 As shown in the spherical silver powder of the present invention, the particle size distribution range of the spherical silver powder is 1.5 μm to 4 μm, the particle size distribution is concentrated, D 50 The particle size is 2.41μm; the tap density of the spherical silver powder is 3.64g / cm 3 , the specific surface area of the spherical silver powder is 0.24m 2 / g.

[0042] The spherical silver powder of the present embodiment is mainly prepared through the following steps:

[0043] (1) Weigh 20.0g of L-ascorbic acid, dissolve it in 1L of deionized water, and make 20g / L reducing agent solution A; heat 400mL of deionized water to 50°C, add 16.4g of PVP, stir and dissolve to make a protective agent Solution B; then add the protective agent solution B dropwise into the reducing agent solution A, and stir evenly to obtain the reaction bottom liquid;

[0044] (2) Take an appropriate amount of 24 wt% ammonia water, add deionized ...

Embodiment 3

[0048] a kind of like Figure 5 and Figure 6 As shown in the spherical silver powder of the present invention, the particle size distribution range of the spherical silver powder is 1.5 μm to 5 μm, the particle size distribution is concentrated, D 50 The particle size is 2.95μm; the tap density of the spherical silver powder is 3.71g / cm 3 , the specific surface area of the spherical silver powder is 0.2m 2 / g.

[0049] The spherical silver powder of the present embodiment is mainly prepared through the following steps:

[0050] (1) Weigh 300.0g of L-ascorbic acid, dissolve it in 7.5L of deionized water, make 40g / L reducing agent solution A, and then add it to the reaction kettle; heat 3L of deionized water to 50°C and add 170g of PVP, Stir and dissolve for 30 minutes to make protective agent solution B; then add protective agent solution B into the reaction kettle, stir evenly with reducing agent solution A, and prepare the reaction bottom liquid;

[0051] (2) Take an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com