Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

A technology of epoxy resin curing and microcapsule curing agent, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of high material preparation cost, slow polymerization reaction speed, complicated reaction equipment, etc., and achieve tensile shear strength. The effect of improved performance, narrow particle size distribution and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

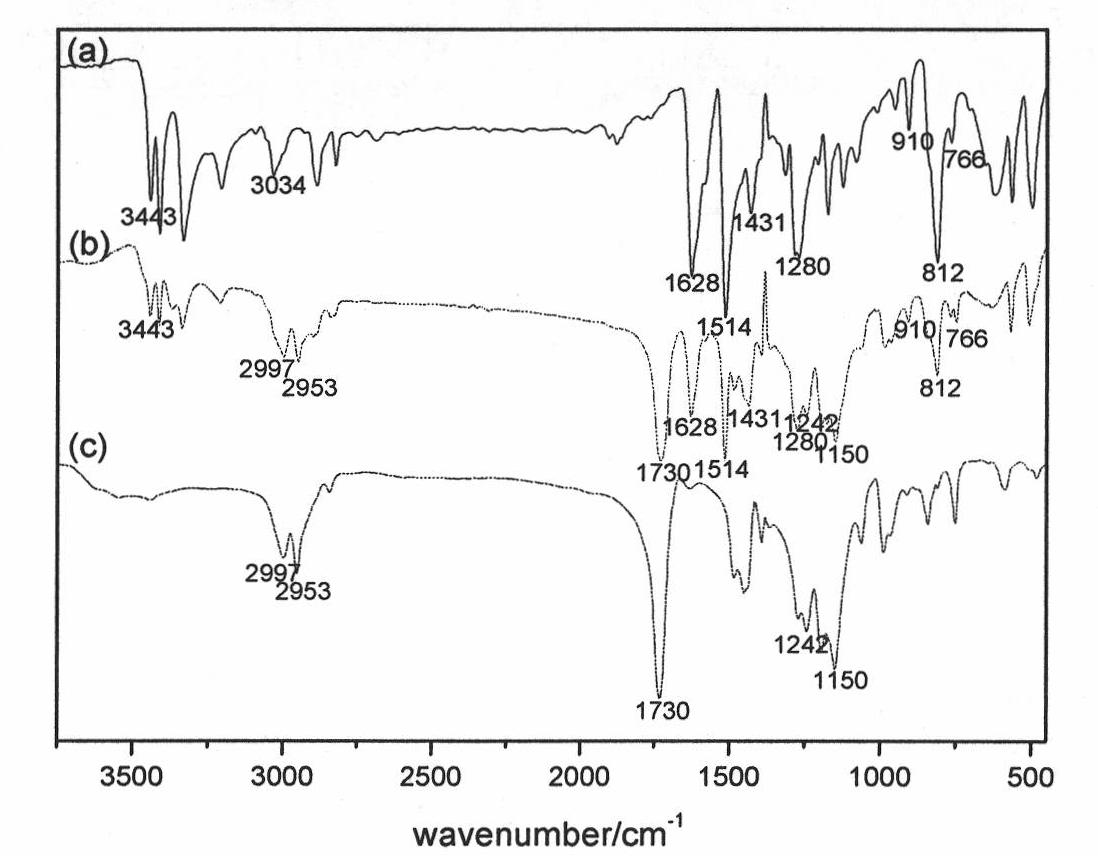

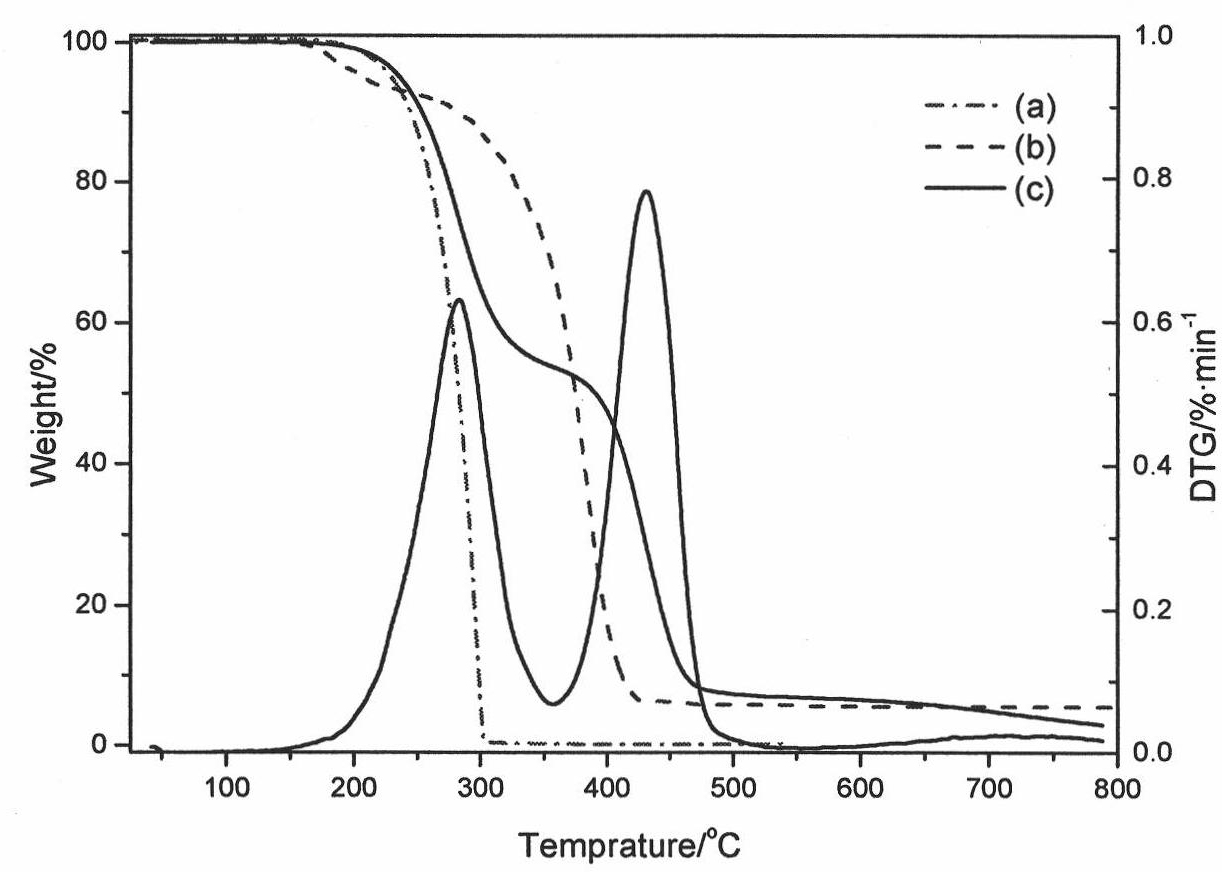

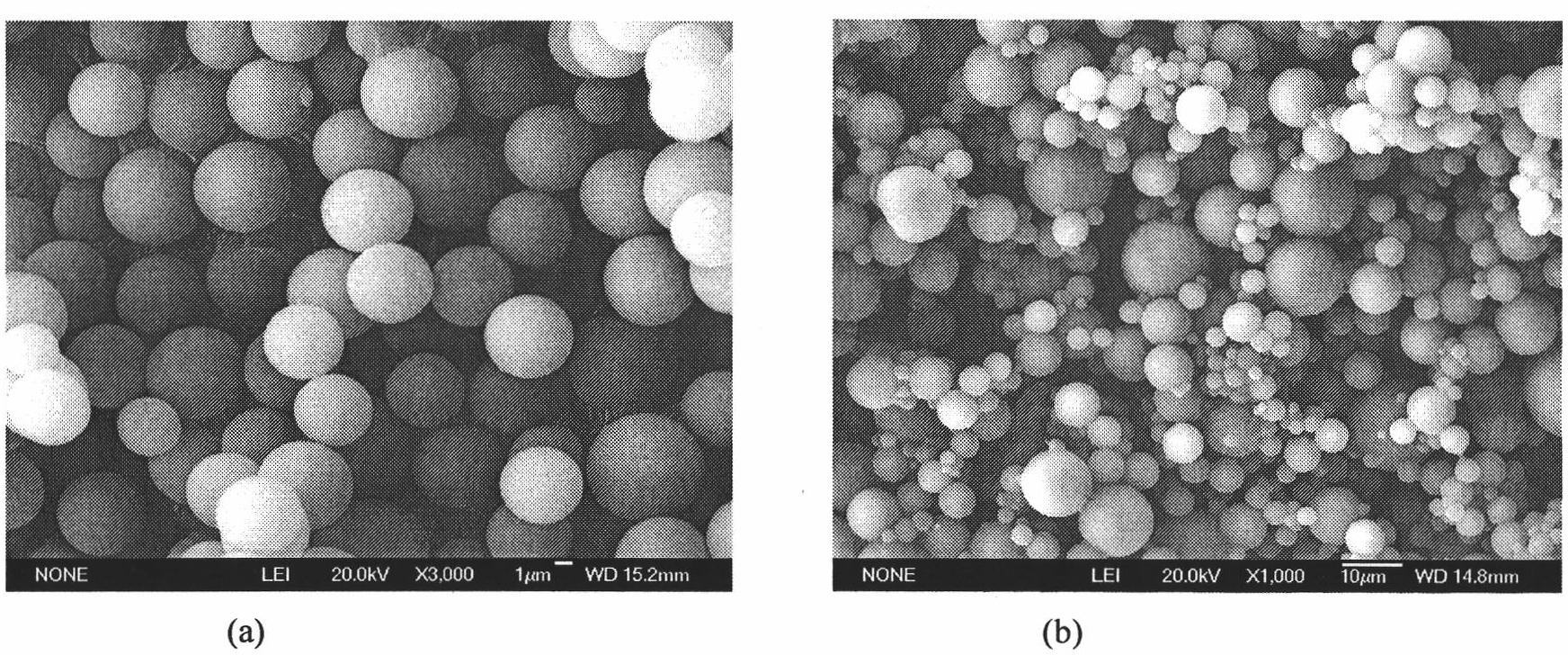

[0052] Embodiment 1: Take gelatin as a dispersant, sodium dodecylbenzenesulfonate as an emulsifier, and dichloromethane as a solvent

[0053] In a fume hood, directly add 50mL of 0.5wt% gelatin aqueous solution and 100mL of 0.2wt% sodium dodecylbenzenesulfonate aqueous solution into a 500ml three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer. Stir and disperse for 30 minutes to obtain a stable and uniform water phase; respectively add 1 g of diaminodiphenylmethane and 1 g of polymethyl methacrylate to two beakers filled with 20 mL of dichloromethane, and disperse evenly in an ultrasonic instrument until they dissolve The oily phase was obtained, and the oily phase was gradually added dropwise to the three-necked flask within 5 minutes. Stir for about 30 minutes to make the oil phase and water phase form a uniform and stable emulsion. Slowly raise the reaction temperature to 30°C and stir for 3 hours, then raise the temperature to 38°C and ...

Embodiment 2

[0055] Embodiment 2: Take polyvinyl alcohol as a dispersant, sodium dodecylbenzenesulfonate as an emulsifier, and dichloromethane as a solvent

[0056] In a fume hood, directly add 40mL of 0.2wt% polyvinyl alcohol aqueous solution and 80mL of 0.2wt% sodium dodecylbenzenesulfonate aqueous solution into a 500ml three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer. Disperse under mechanical stirring for 30min to obtain a stable and uniform aqueous phase; add 1g N-aminoethylpiperazine and 2g polystyrene to two beakers containing 20mL of dichloromethane respectively, and disperse evenly in an ultrasonic instrument until the The oil phase was obtained by dissolving, and the oil phase was gradually added dropwise into the three-necked flask within 5 minutes. Stir for about 30 minutes to make the oil phase and water phase form a uniform and stable emulsion. Slowly raise the reaction temperature to 30°C and stir for 3 hours, then raise the temperatu...

Embodiment 3

[0058] Embodiment 3: Take gelatin as dispersant, Tween and Span as emulsifier, and dichloromethane as solvent

[0059] In a fume hood, directly add 50mL of 0.3wt% gelatin aqueous solution, 90mL of 0.1wt% Tween and Sipan (1:1) aqueous solution into a 500ml three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer, at 700r / min disperse under mechanical stirring for 30min to obtain a stable and uniform aqueous phase; add 2g m-phenylenediamine and 1g styrene-methyl methacrylate copolymer to two beakers containing 20mL dichloromethane respectively, and Disperse until it dissolves to obtain an oil phase, and gradually add the oil phase to the three-necked flask within 5 minutes. Stir for about 30 minutes to make the oil phase and water phase form a uniform and stable emulsion. Slowly raise the reaction temperature to 30°C and stir for 3 hours, then raise the temperature to 40°C and stir for more than 3 hours until the dichloromethane volatilizes compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com