Patents

Literature

538results about How to "Achieve solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

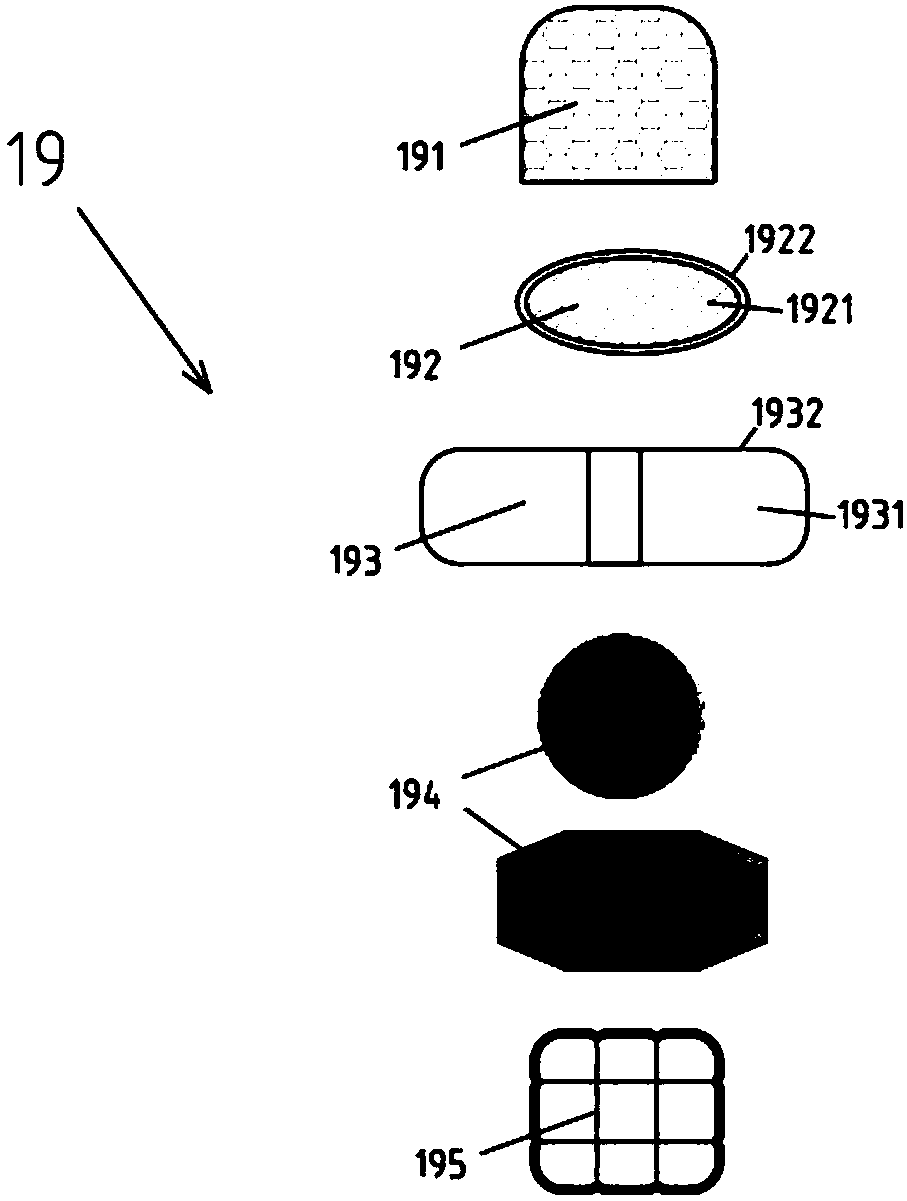

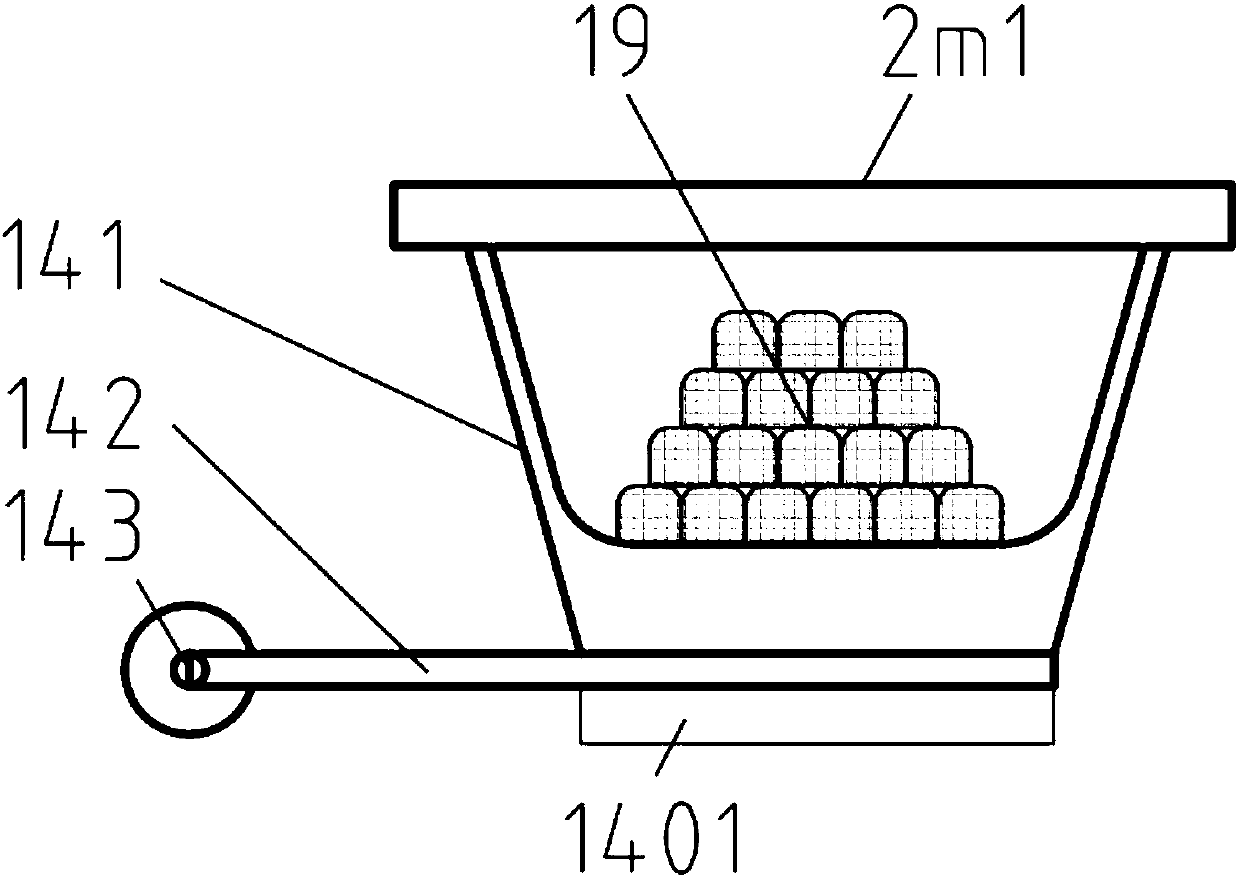

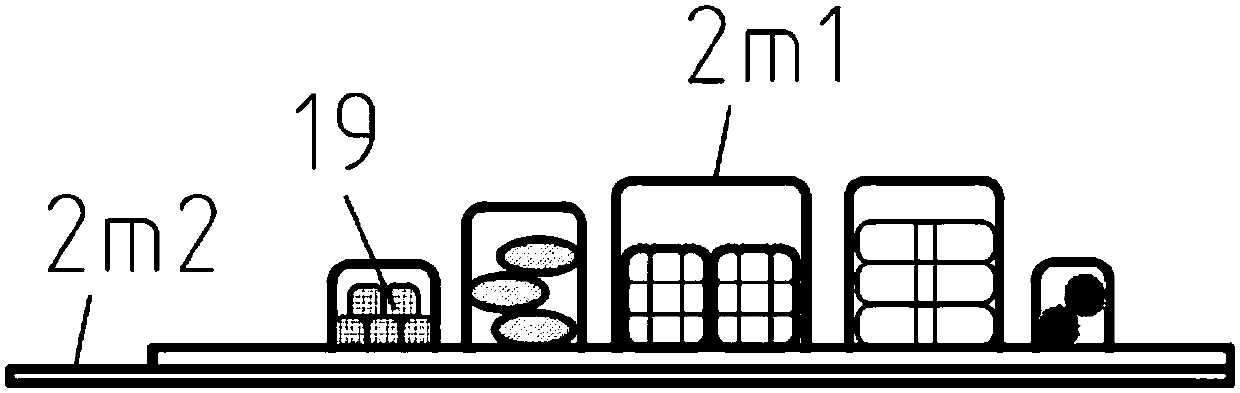

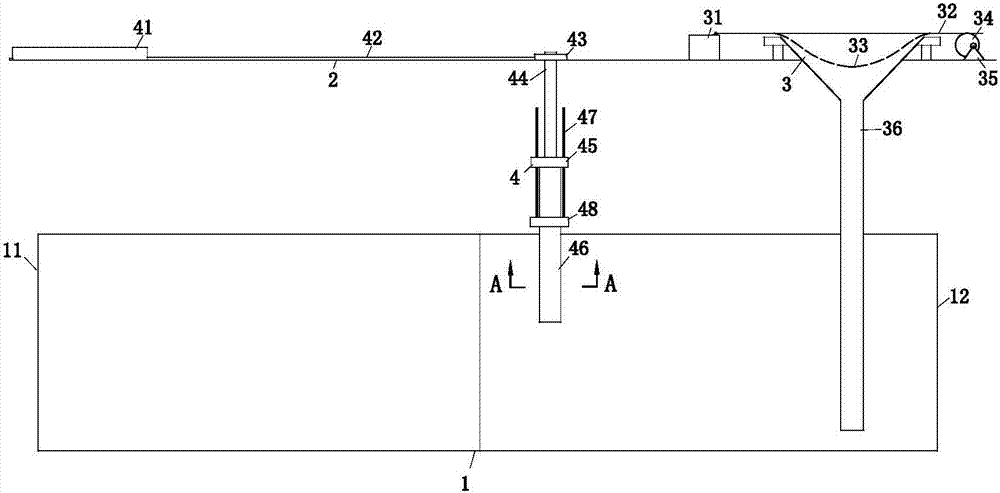

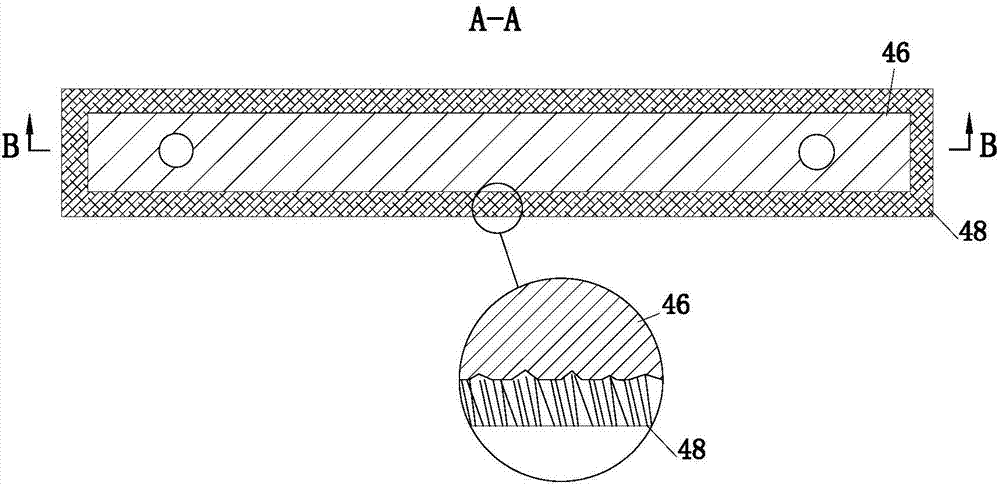

Bundling treating method for cooking raw materials, cooking raw materials and intelligent cooking machine

PendingCN110051228AAchieve solidificationNot easy to stickCooking-vessel lids/coversFood scienceLiquid stateFood material

The invention relates to the technical field of intelligent home equipment, and discloses a bundling treating method for cooking raw materials, the cooking raw materials and an intelligent cooking machine. The bundling treating method includes the steps that liquid-state or powdery or fine-granular or pasty or dispersed cooking raw materials are subjected to solidifying or large-granular or blocking treatment, or small-sheet cooking raw materials are packaged / bundled so that the cooking raw materials cannot be easily stuck on a feeding box of the intelligent cooking machine, or the cooking rawmaterials with fluffy size are dense, and the cooking raw materials are matched with the feeding device, and are fed into a pot body of the cooking machine. According to the bundling treating methodfor the cooking raw materials, the cooking raw materials and the intelligent cooking machine, the liquid-state or powdery or granular or pasty or sheet-shape or disperse or fluffy cooking raw materials are solidified or made into large-granular materials or blocky materials or buckled / packaged, and the food materials are not easily stuck on the feeding box when being used in the intelligent cooking machine accordingly.

Owner:李亚锐

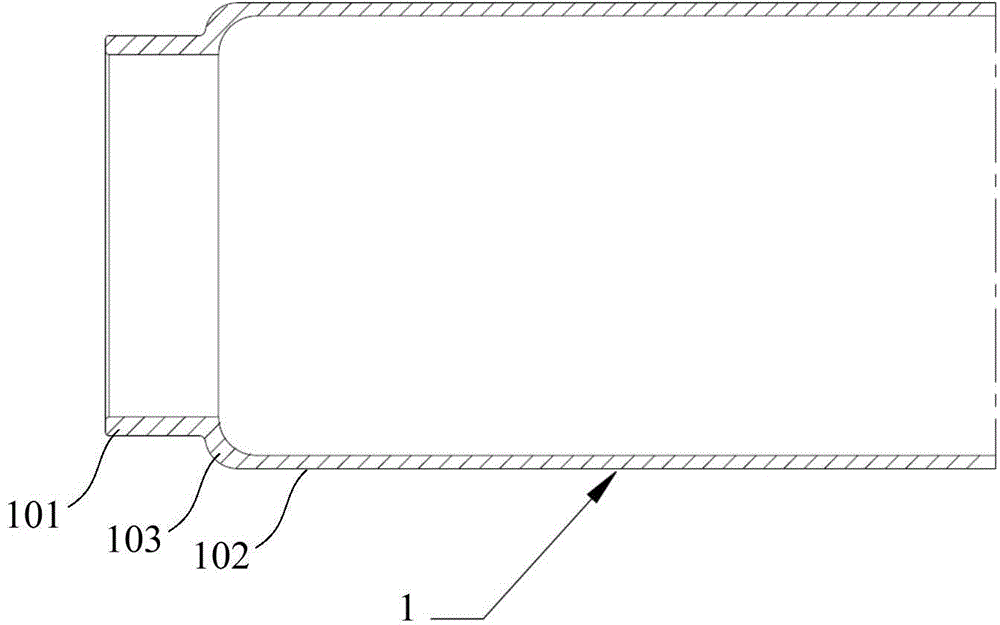

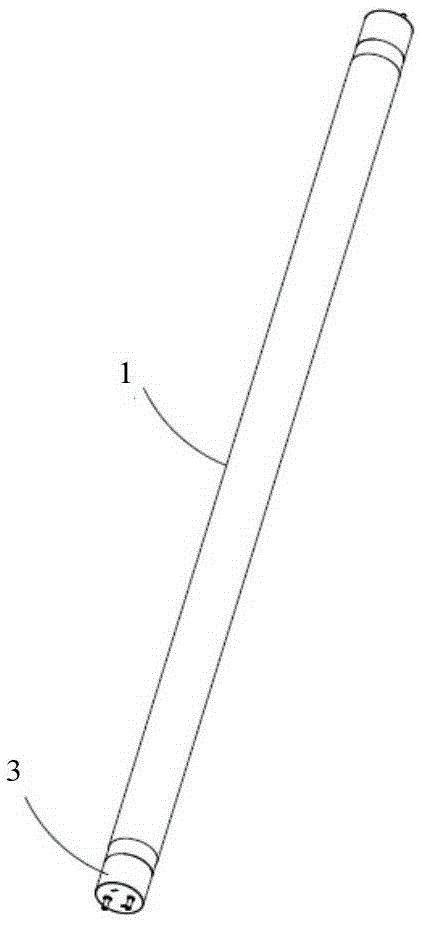

LED (light emitting diode) fluorescent lamp

ActiveCN104832813AAchieve solidificationGood adhesionPoint-like light sourceElongate light sourcesEngineeringLight-emitting diode

The invention provides an LED (light emitting diode) fluorescent lamp, which comprises a lamp tube and a lamp head arranged outside the end part of the lamp tube, wherein the lamp head comprises an insulation tube and magnetic conducting materials; the insulation tube is used for being arranged outside the end part of the lamp tube in a sleeving way; the material conducting material is arranged between the inner peripheral surface of the insulation tube and the end part of the lamp tube. The magnetic conduction materials are arranged on the lamp head; when the lamp head is bonded with the lamp tube, the bonding agent curing can be realized through an electromagnetic induction technology; the bonding is convenient; the efficiency is high.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

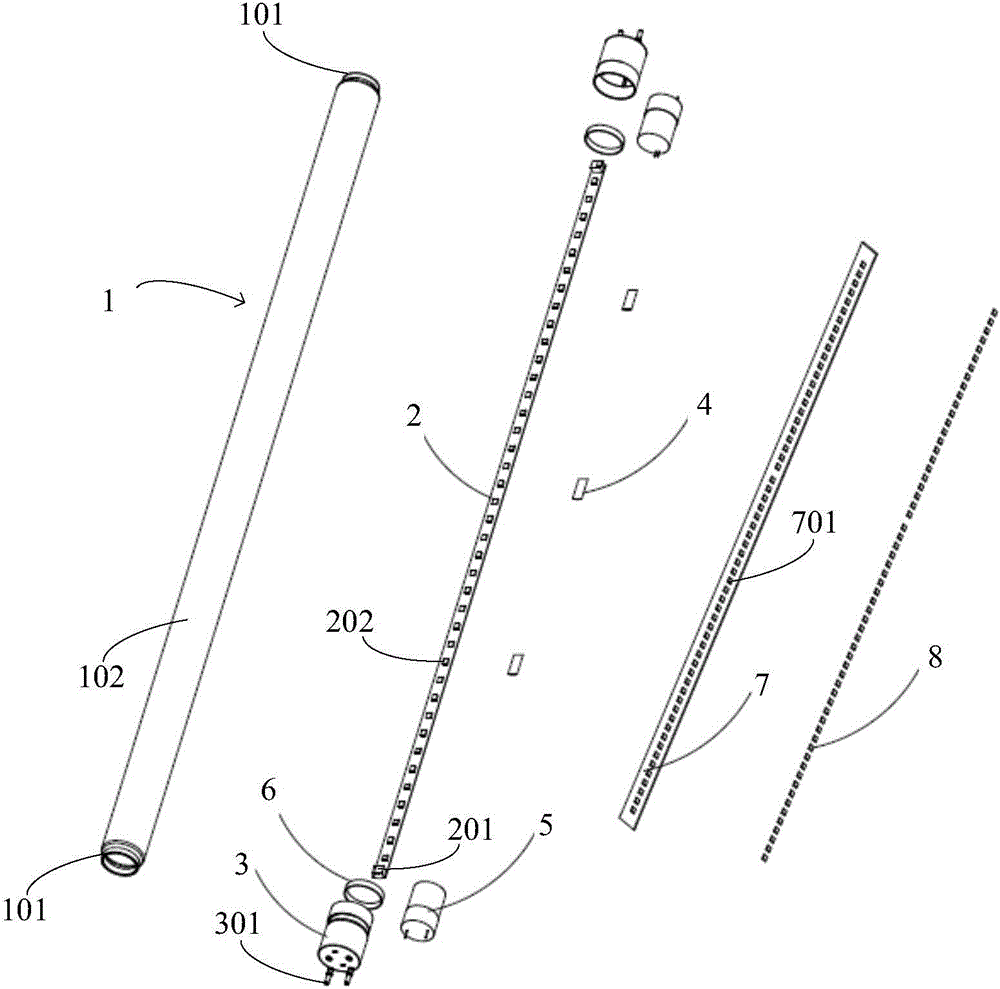

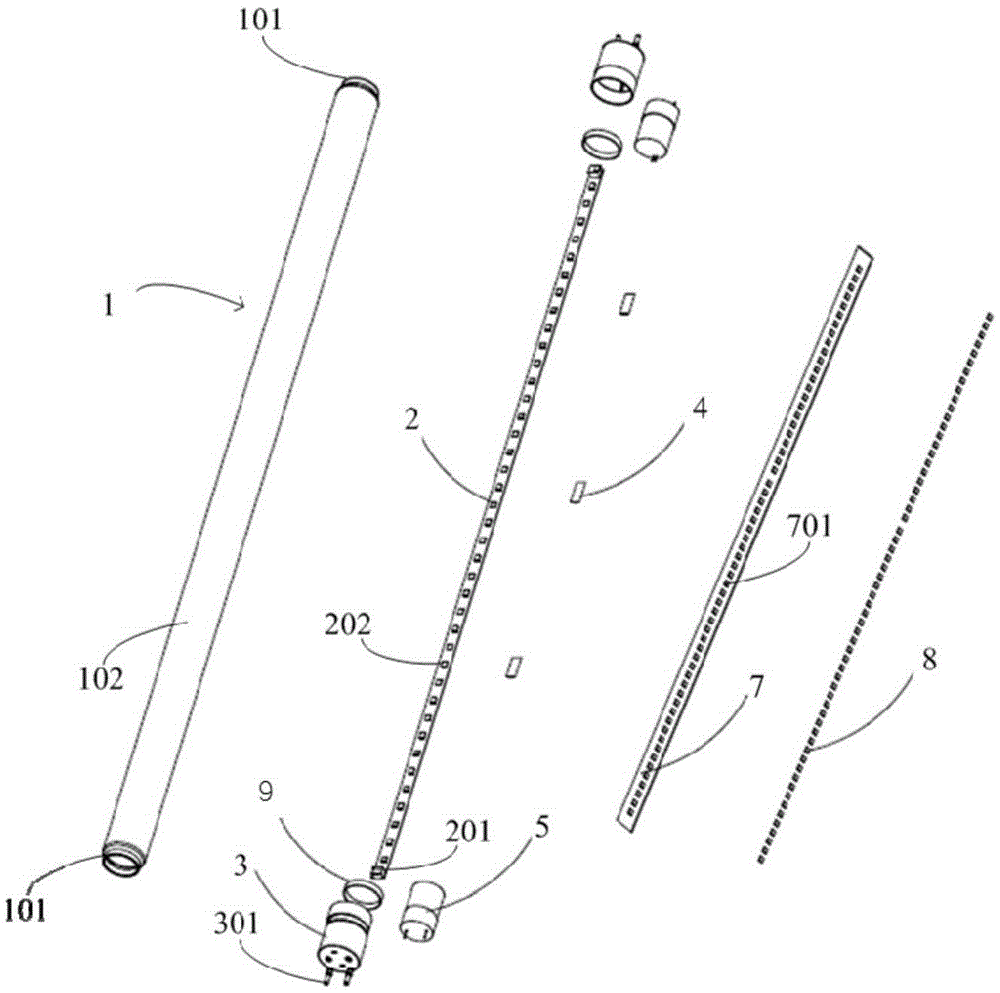

LED straight-tube lamp

PendingCN105465640AAvoid Electric Shock AccidentsAvoid breakingElongate light sourcesElectric circuit arrangementsFlexible circuitsStraight tube

The invention discloses an LED straight-tube lamp comprising a lamp tube, a lamp cap, a power source and a lamp panel, wherein the lamp cap is arranged at one end of the lamp tube; the power source is arranged in the lamp cap; the lamp panel is arranged in the lamp tube and is provided with a light source; the light source is electrically communicated with the power source through the lamp panel; and the lamp panel is a flexible circuit board of which the end part is provided with a light source pad, and holes are formed in the light source pad. The flexible circuit board is directly welded at the power output end of the lamp cap, so that the quality problem caused by conducting wire migration breakage generated by a wire bonding way in the production, transportation and use processes can be avoided.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

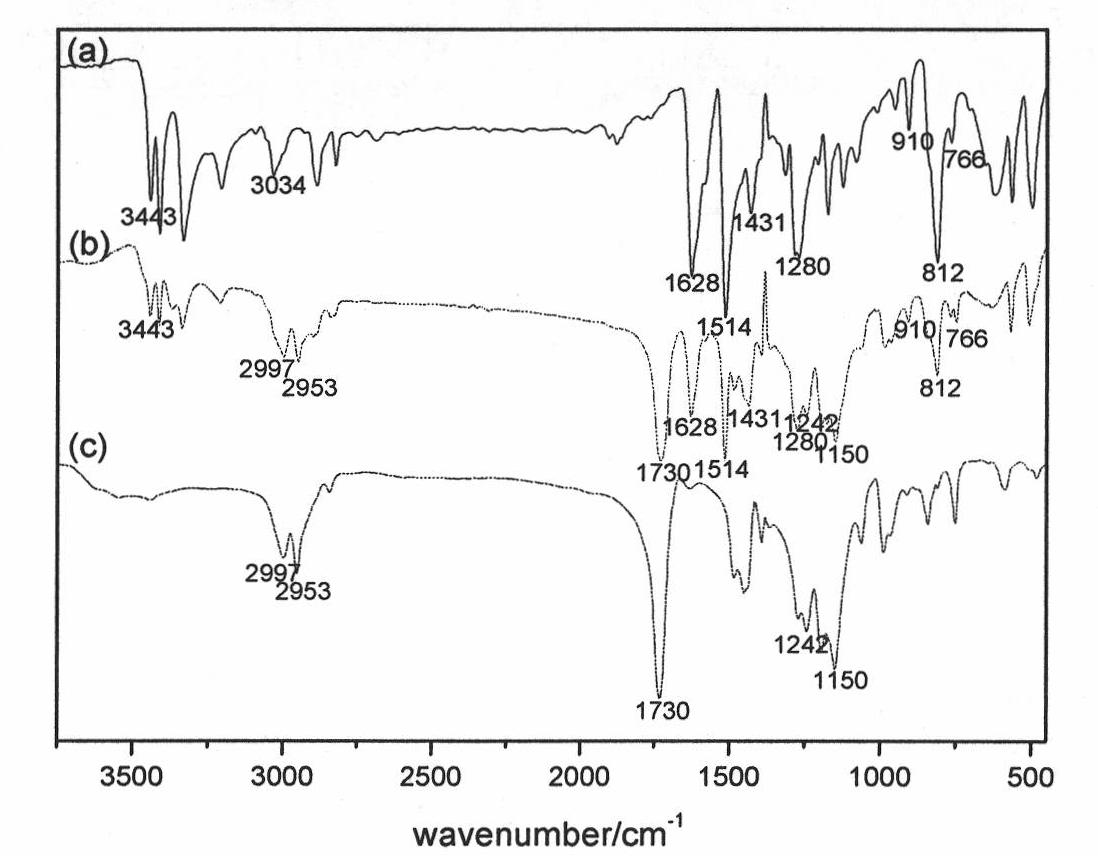

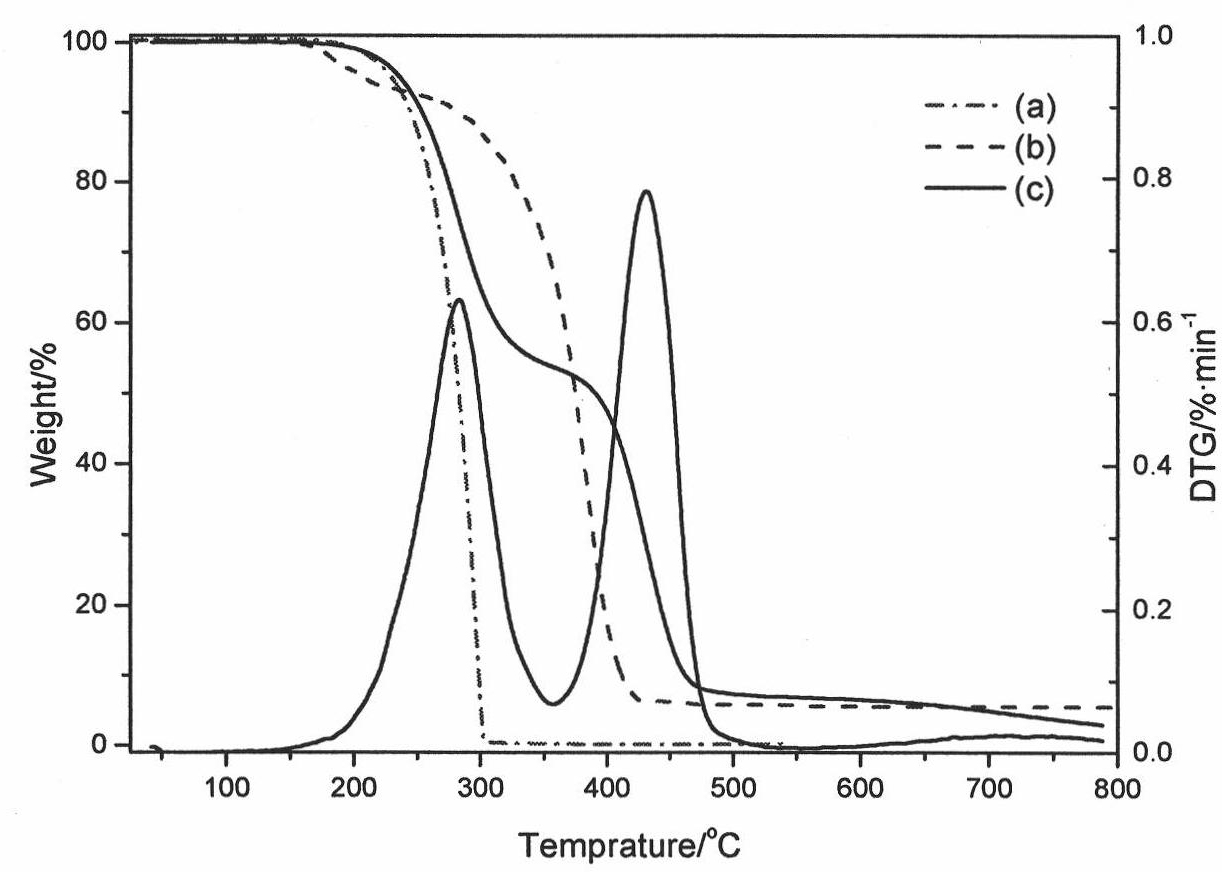

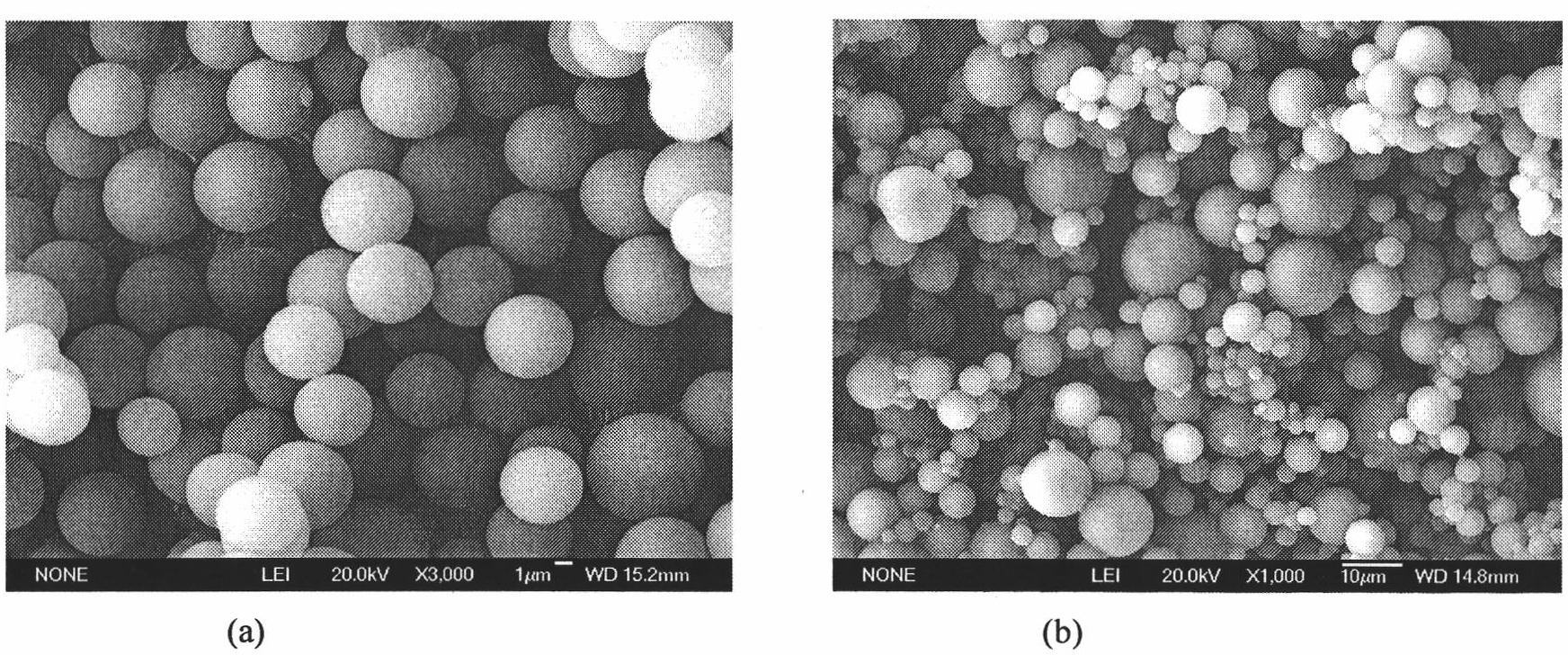

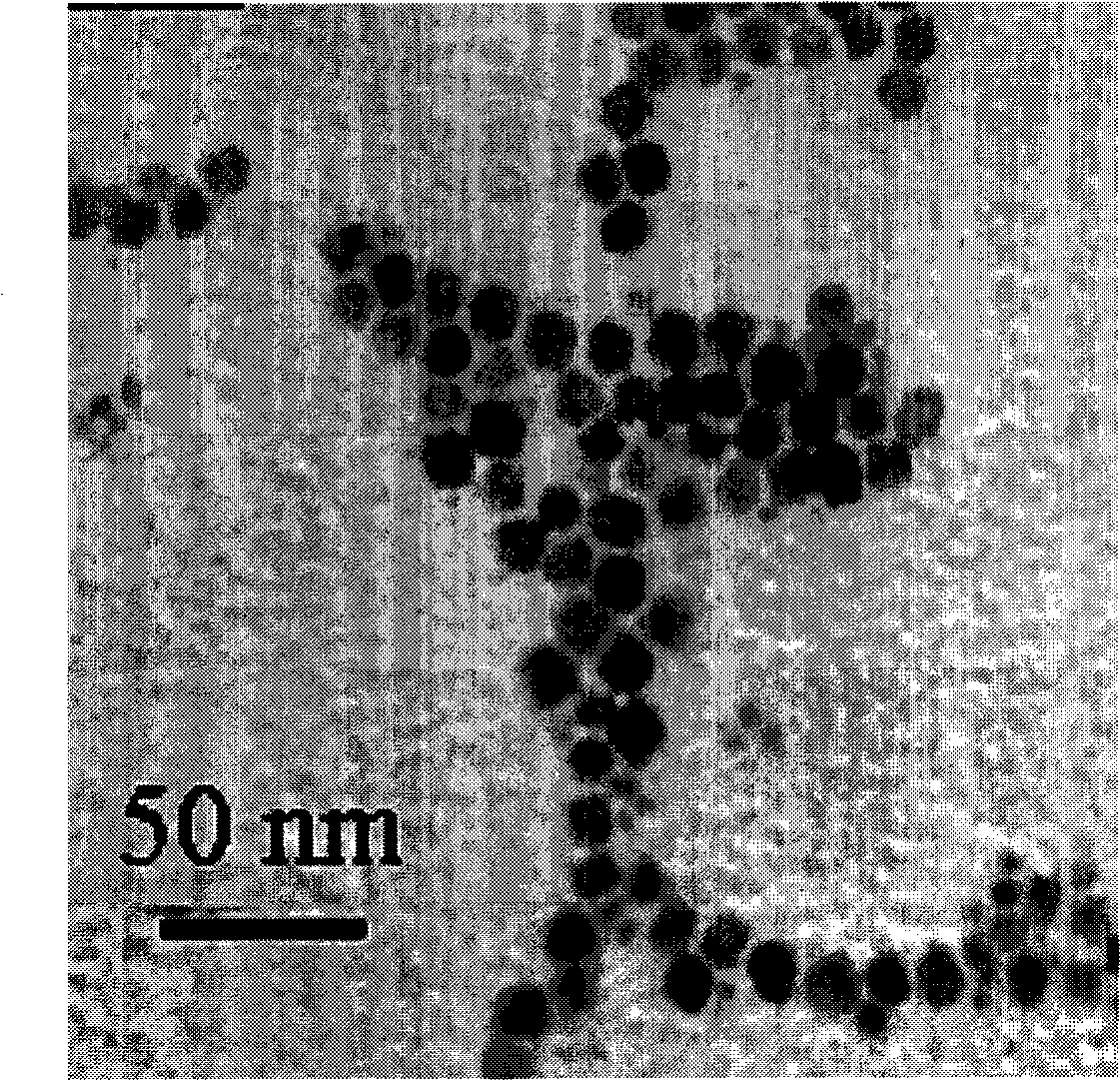

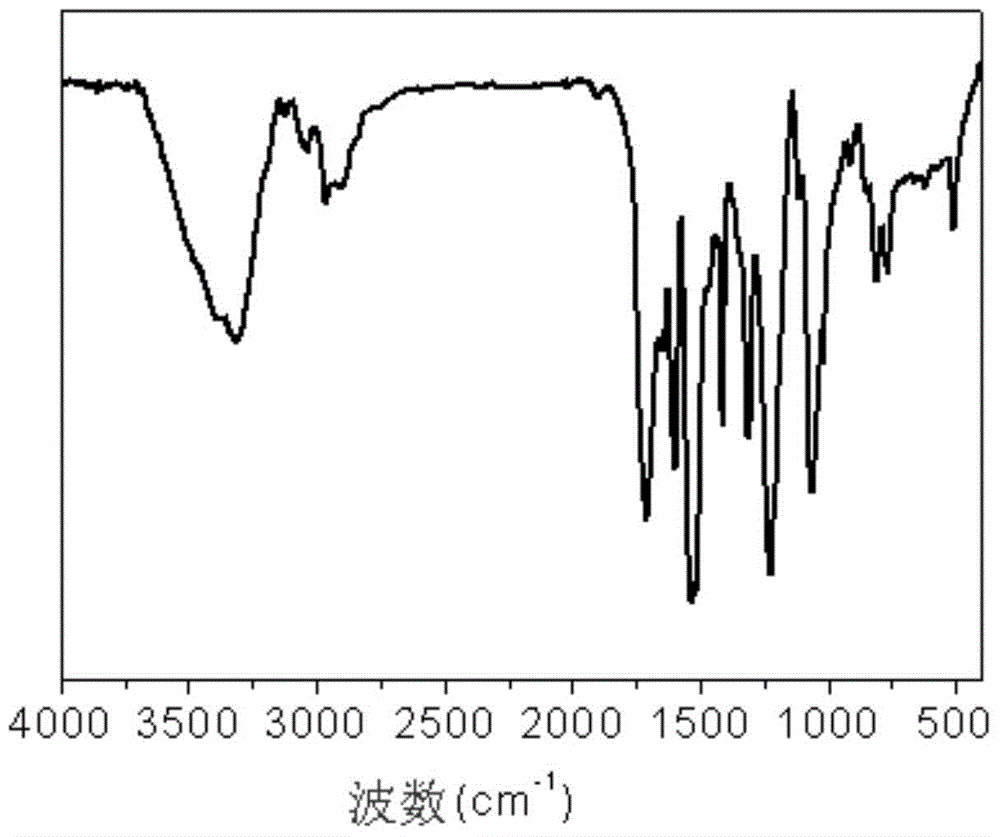

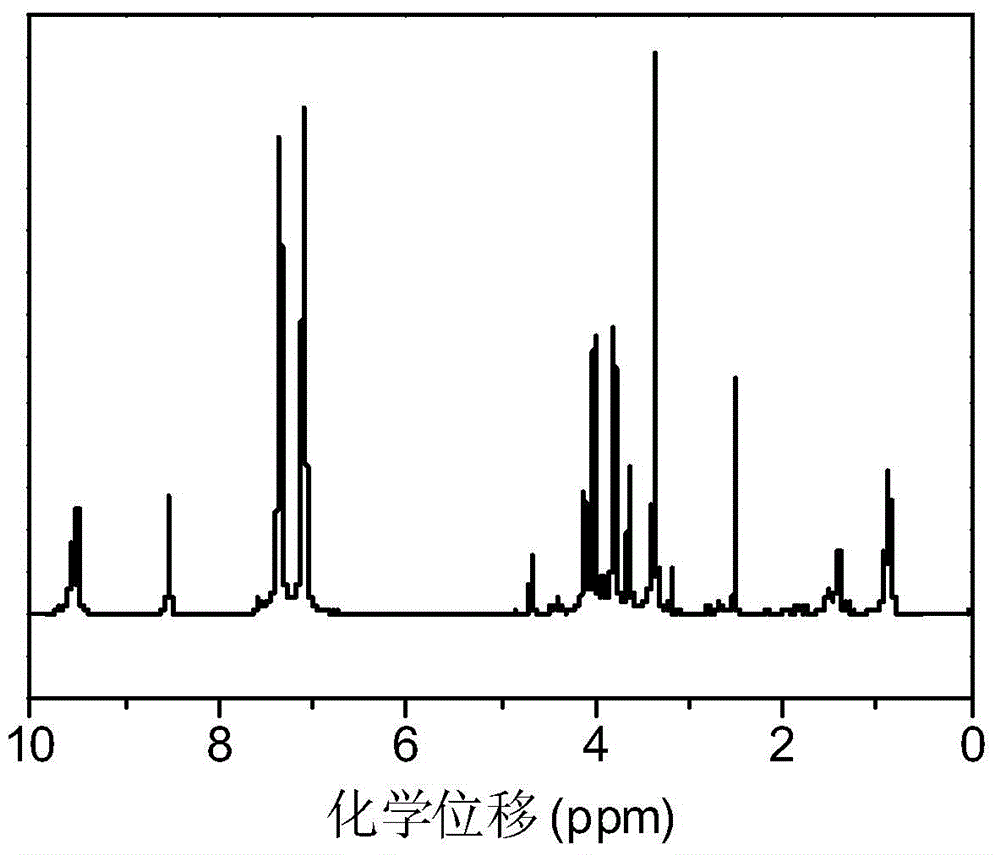

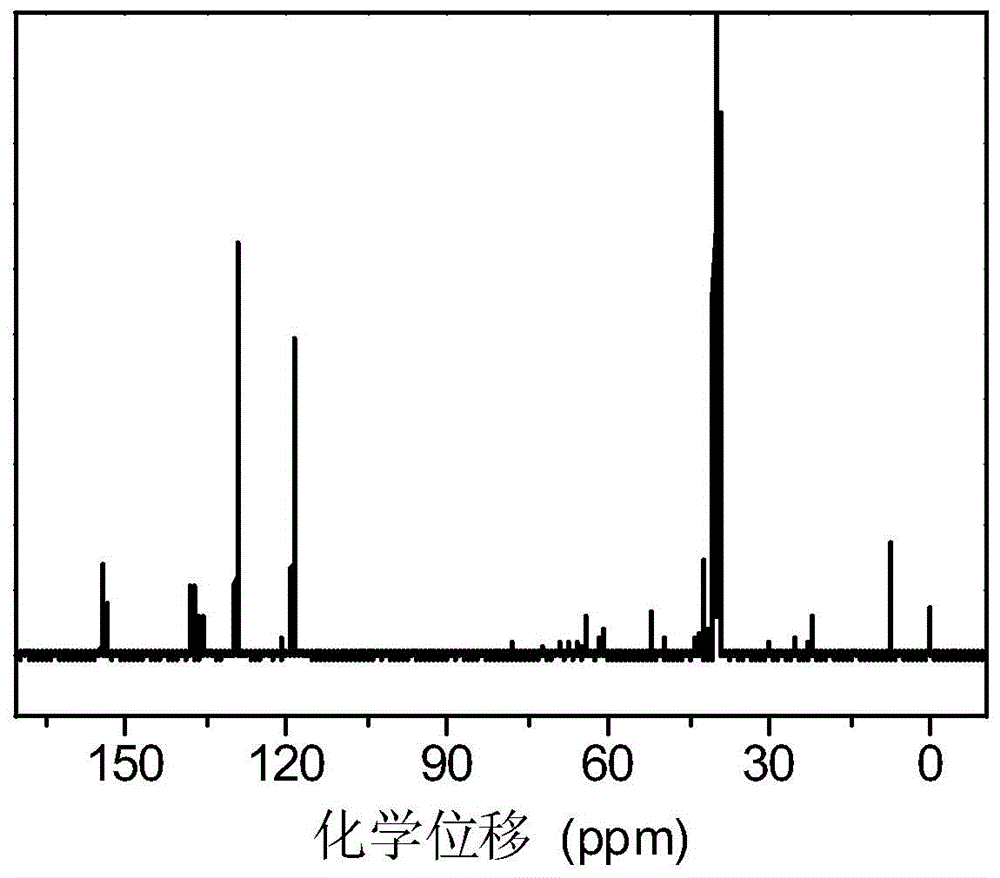

Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

InactiveCN102423673AHigh core contentFlat surfaceMicroballoon preparationMicrocapsule preparationEpoxyMicrosphere

The invention relates to a latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and a preparation method of an adhesive thereof. The latent microcapsule curing agent is technically characterized in that the high-activity medium temperature curing agent is taken as a core material, thermoplastic high polymer microspheres are taken as a wall material, the solvent evaporation technology is adopted for preparing the latent microcapsule curing agent with better curing performance and latent performance, and the latent microcapsule curing agent can be applied to an epoxy resin system for preparing the single-component medium temperature curing epoxy resin adhesive. Microcapsules prepared by the method are high in capsule core content, smooth in surfaces, narrow in particle size distribution and good in compatibility with matrix epoxy resin and can be better dispersed in the epoxy resin; and the prepared single component adhesive can realize curing at the medium temperature, the storage period at room temperature is longer and the tensile shear strength performance can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Amido complex compound and preparation method and usage

InactiveCN101182006AFast separationImprove conversion efficiencyAmmonia compoundsTransformation efficiencyAmmonia

The invention discloses an amino complex compound and a preparation method and application thereof. The components of the amino complex compound are MX (NH3)n, wherein, M is one or a plurality of Li, Mg, Al, Ca, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Sr, Ba, Sn; X is one or a plurality of F, Cl, Br, NO3, SO4; m is determined according to chemical valence, which is less than or equal to 5 and more than or equal to 1; n is determined according to coordination number, which is less than or equal to 15 and more than or equal to 1. The amino complex compound is used as an absorbent of amino after deamination and realizes separation, purification, storage and transporting of ammonia gas through low-temperature ammonia absorption and high-temperature ammonia discharge. The ammonia in circulating gas used in a synthetic ammonia technique of the invention has fast separation speed and the ammonia content entering into a tower can be reduced below 0.1 percent, thus remarkably promoting the ammonia net value and improving the transformation efficiency of the synthetic ammonia technique; furthermore, the invention can be suitable for different ammonia synthesis systems, in particular to a low-pressure ammonia synthesis system and realize the solidification of the ammonia gas during storage and transporting processes; the ammonia storage quantity can reach 40 to 70wt percent with safety and high efficiency.

Owner:ZHEJIANG UNIV

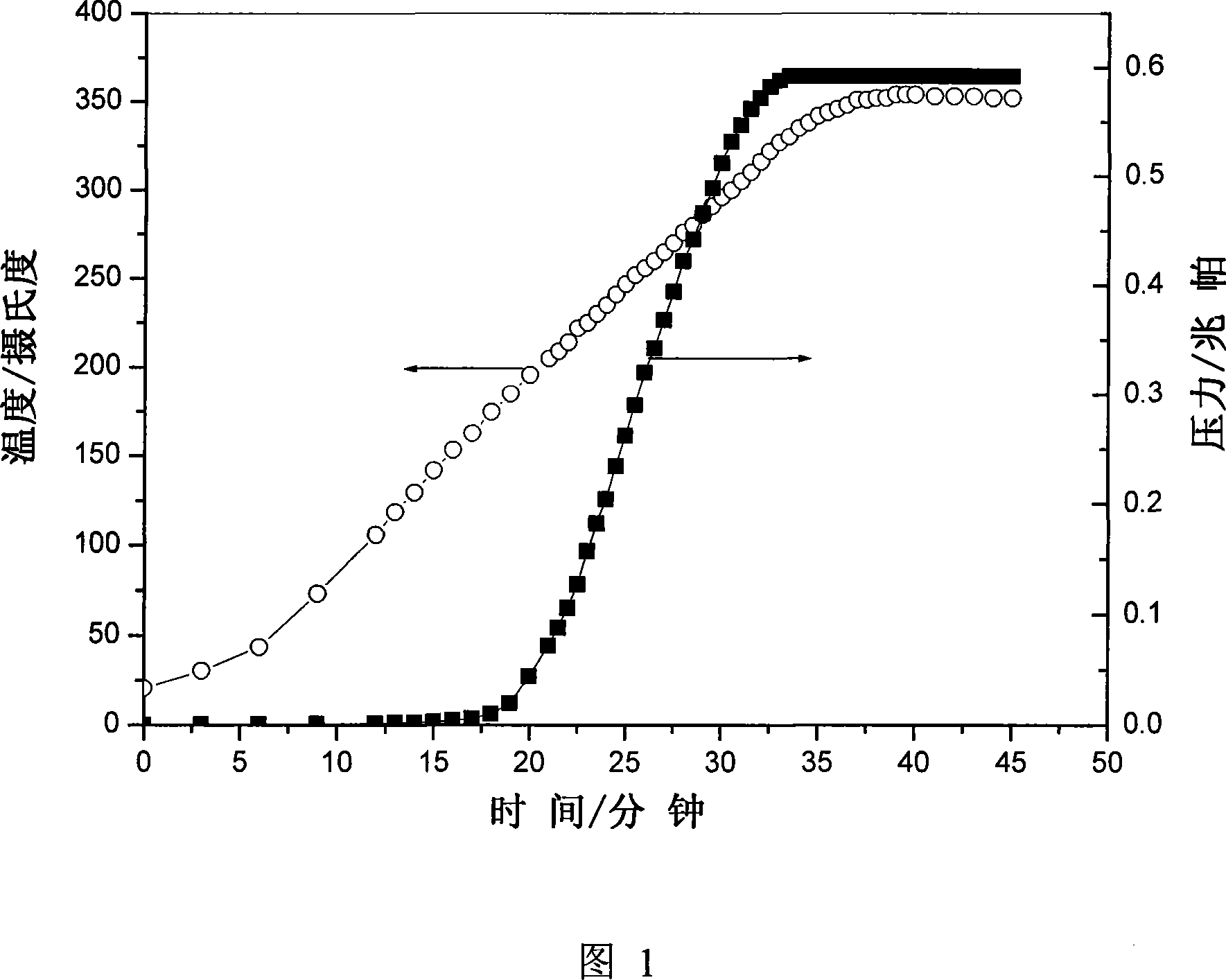

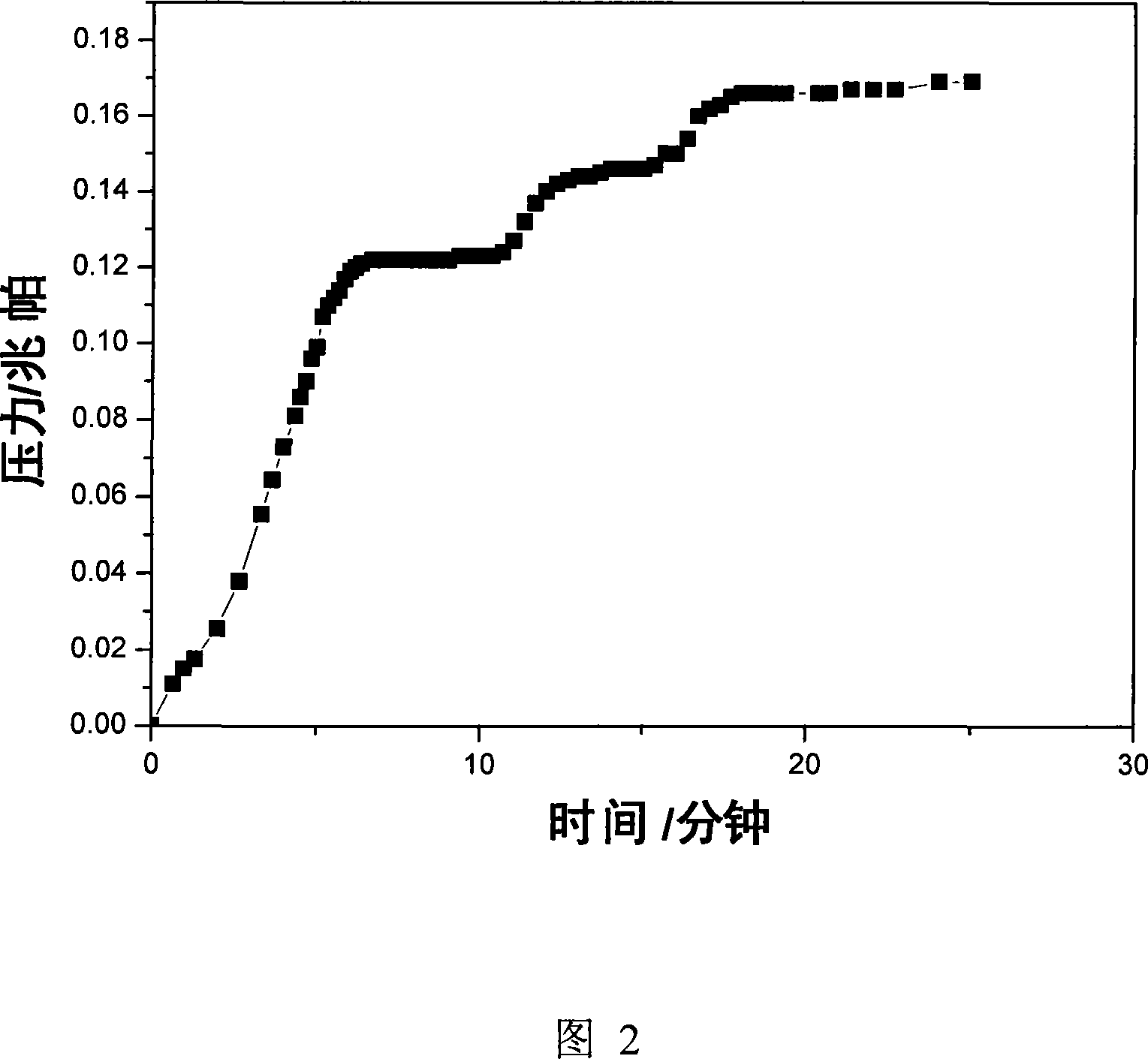

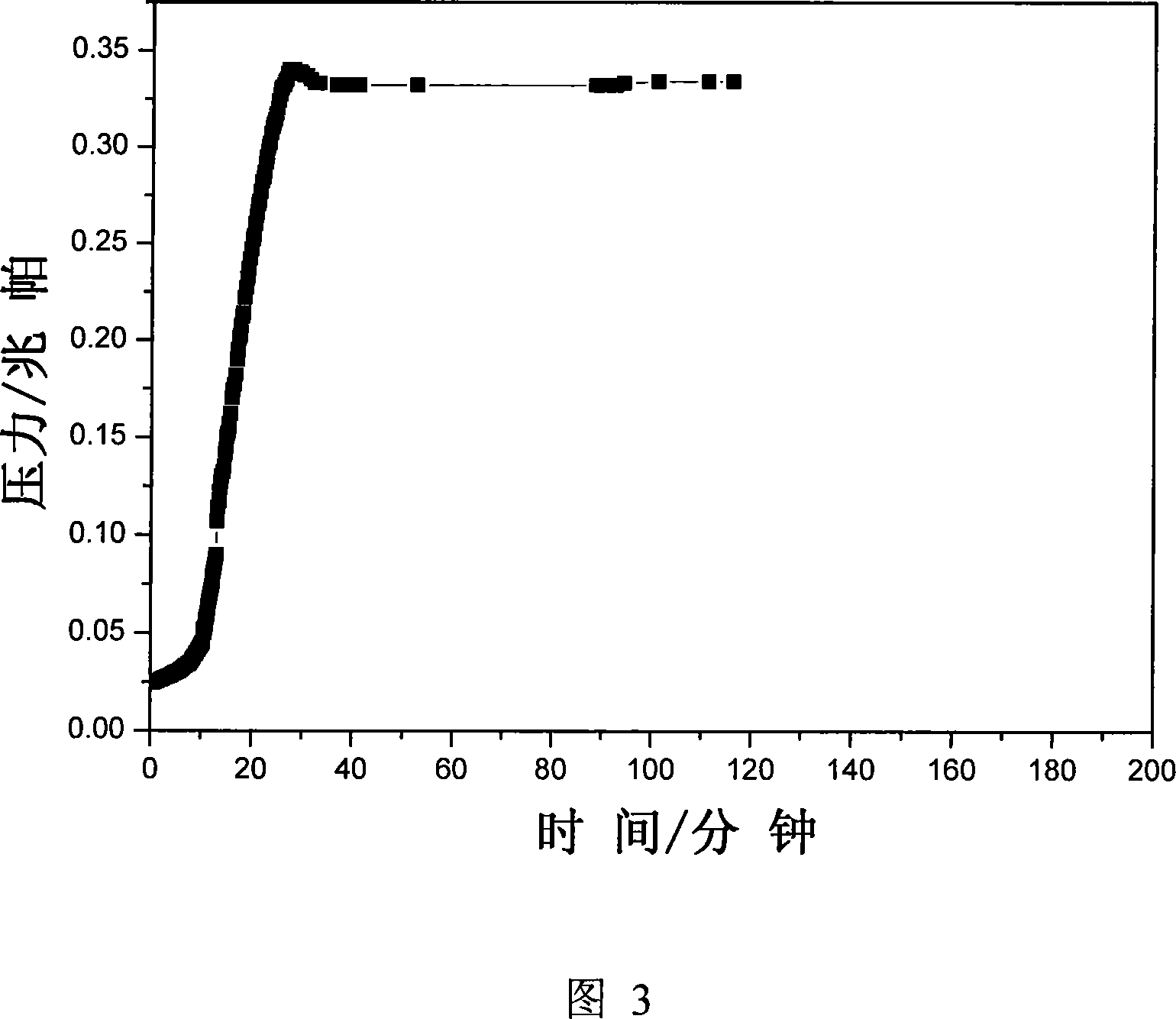

Ultraviolet-curing liquid optical silica gel used for reworkable gluing as well as preparation method and application thereof

InactiveCN106497505AReduce scrap rateAnti-yellowing and agingNon-macromolecular adhesive additivesAdhesiveOptical transmittance

The invention belongs to the technical field of preparation of adhesives and specifically discloses an ultraviolet-curing liquid optical silica gel used for reworkable gluing. The ultraviolet-curing liquid optical silica gel used for reworkable gluing comprises the following ingredients in parts by weight: 100 parts of methacryloyloxyethyl modified polysiloxane; 0-90 parts of MQ silicon resin, 0.1-10 parts of a photoinitiator, 0.01-5 parts of a coupling agent, 0.01-5 parts of a stabilizer and 0.01-5 parts of a polymerization inhibitor. The liquid optical silica gel provided by the invention has high light transmittance, small shrinking percentage, small yellowing index and good reworkable performance; the liquid optical silica gel can be repeatedly used for gluing an optical element and a screen; meanwhile, the rejection rate of materials can be effectively controlled, the production cost of enterprises is greatly reduced, and the application prospect is wide.

Owner:矽时代材料科技股份有限公司

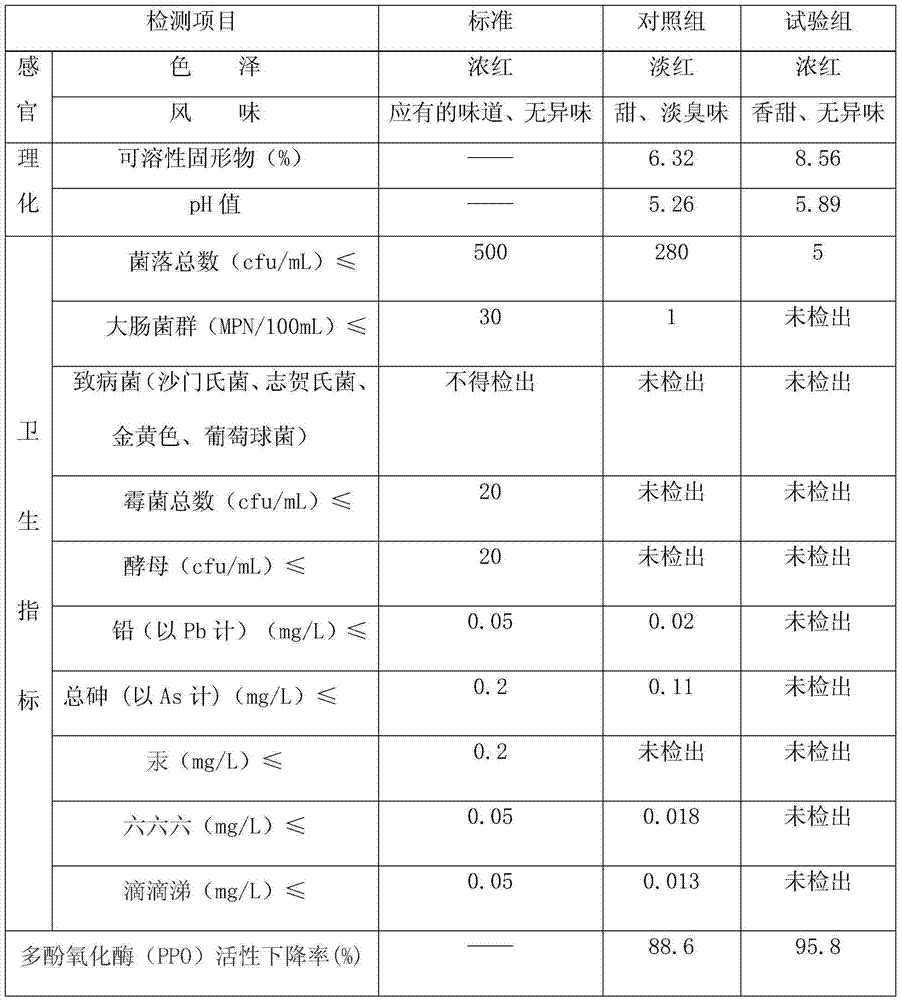

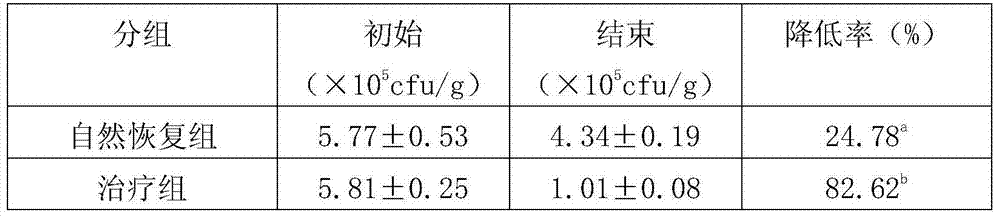

Watermelon juice probiotic fermented beverage and preparation method thereof

InactiveCN104770816AEnhanced abiotic and biotic stabilityReduce the introductionFood preparationHigh pressure pulseChemistry

The present invention discloses a watermelon juice probiotic fermented beverage and a preparation method thereof. The beverage preparation method uses watermelons as raw materials, scientifically blends prebiotic factors, does not add any essences and coloring matters, mainly uses low-temperature processing technology such as ultrasonic wave cleaning, high-pressure pulsed electric field treatment, biological enzymolysis, vacuum degassing, etc. in the whole process, replaces the existing heat sterilization and enzyme blunting technology, maintains the color and luster, flavor and mouth feel of the natural watermelon juice to a maximum degree, enhances the non-biological stability and biological stability of the watermelon juice, reduces the addition of chemical additives, increases the juice squeezing rate and food safety of the watermelon juice, and has a probiotic live bacteria content of 7 multiplied by 10^11 to 8 multiplied by 10^11 cfu / ml. The watermelon juice probiotic fermented beverage is environmentally friendly, can be processed into probiotic solid beverage and quantitatively packaged beverage which have natural taste, are nutritious and health-care, are convenient to drink, and have longer shelf lives, opens up a new way for watermelon deep processing and industrial development, and can achieve better economic and social benefits.

Owner:NINGXIA HENGRUI BIOLOGICAL FOOD TECH CO LTD

Preparation method of high-transmittance self-healing ionic liquid gel with good mechanical properties

A preparation method of high-transmittance self-healing ionic liquid gel with good mechanical properties comprises: adding a monomer and a photoinitiator into ionic liquid, mixing well, removing oxygen, adding to a light-transmitting container, and exposing to an ultraviolet lamp to obtain the ionic liquid gel; or comprises: adding a monomer and a thermal initiator into ionic liquid, mixing well, removing oxygen, adding to a mold, mixing well under stirring, and curing to obtain ionic liquid gel. By modifying ionic liquid gel synthetic process parameters, such as the monomer for reaction, molar ratio of the monomer, reaction time, and initiating mode, self-healing property can be introduced to the field of ionic liquid gels successfully, and certain stress tolerance is imparted; the mechanical properties of the gel are significantly improved, the yellowing problem common in ionic gels is solved, and the gel has good light transmittance; the gel has a promising application prospect in the crossing field of gels.

Owner:XI AN JIAOTONG UNIV

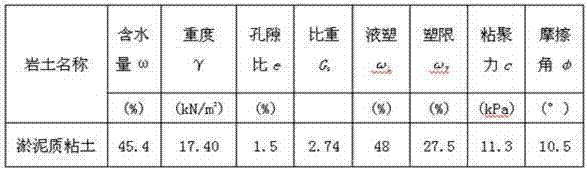

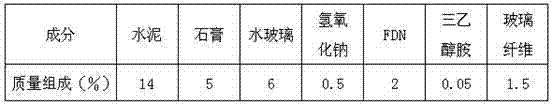

Muck soil composite curing agent

InactiveCN101081981AImprove early strengthStable late strengthBuilding constructionsOrganic fertilisersHigh resistanceSludge

The composite sludge curing agent consists of Portland cement as cementing material; alkaline exciting component selected from lime, water glass and sodium hydroxide; expanding component of gypsum; and surfactant selected from triethanolamine and superplasticizer FDN. It has the advantages of high early strength, stable long-term strength, high water stability, high frost resistance, etc. It may be used in curing waste sludge into stable building material for road bed, composite foundation, etc.

Owner:ZHEJIANG UNIV

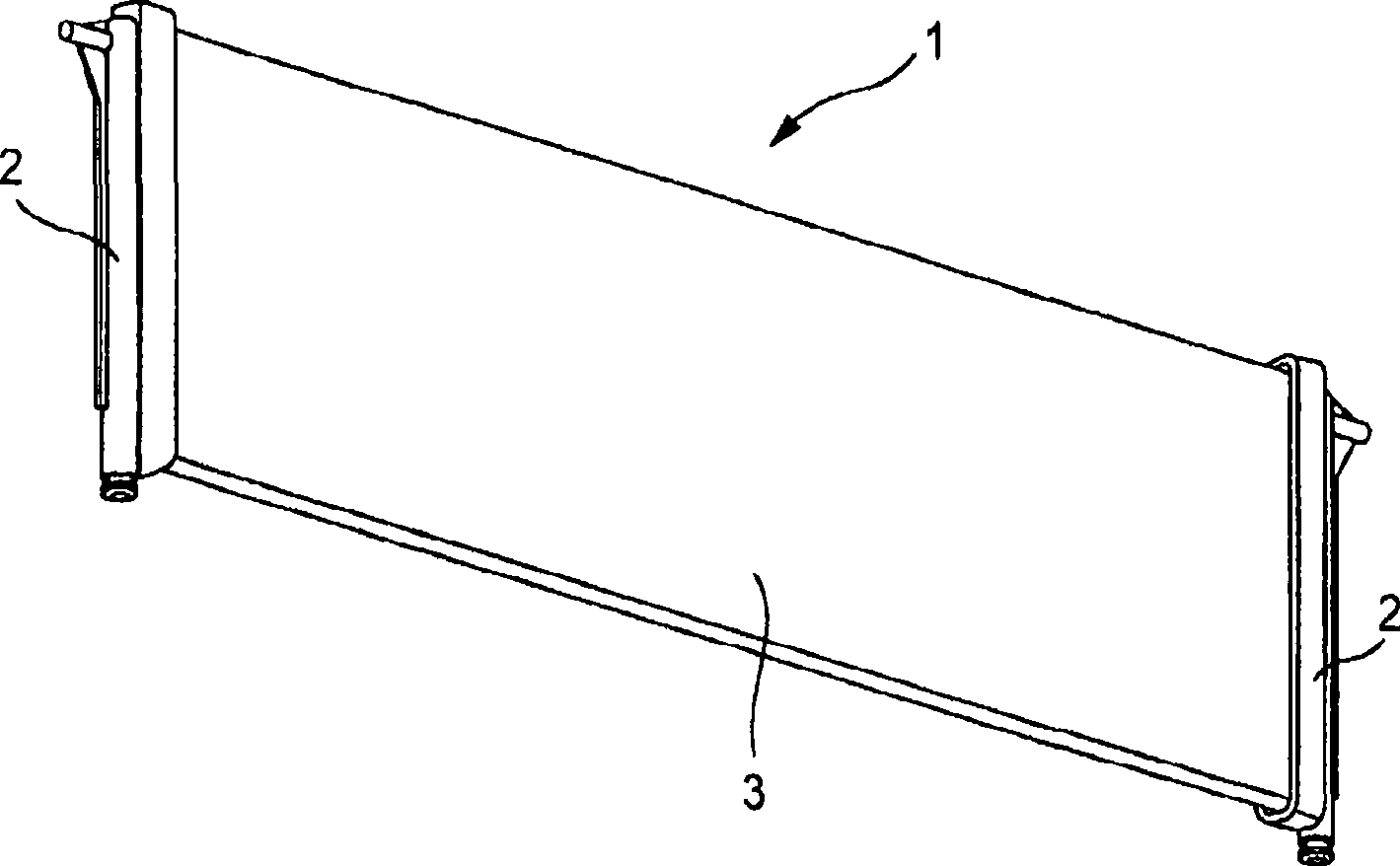

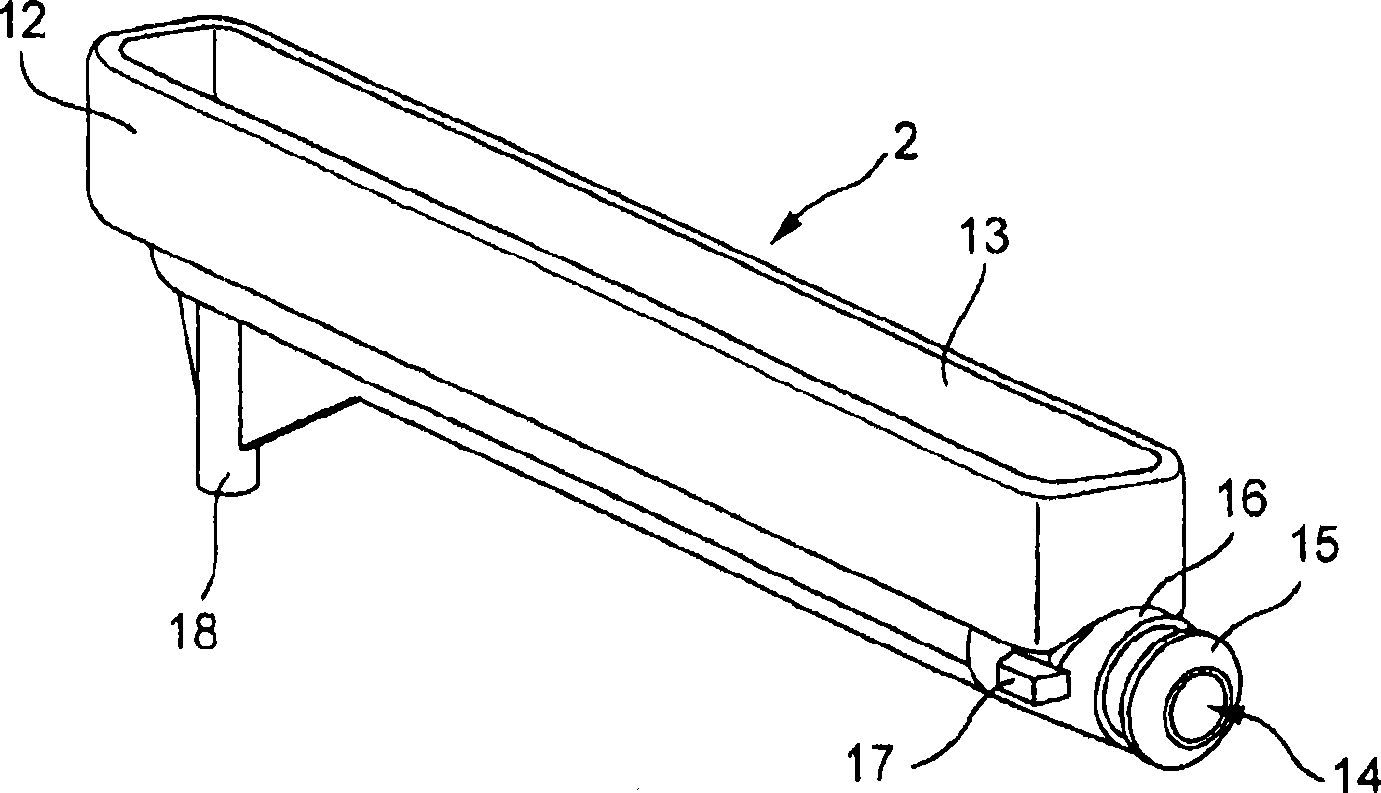

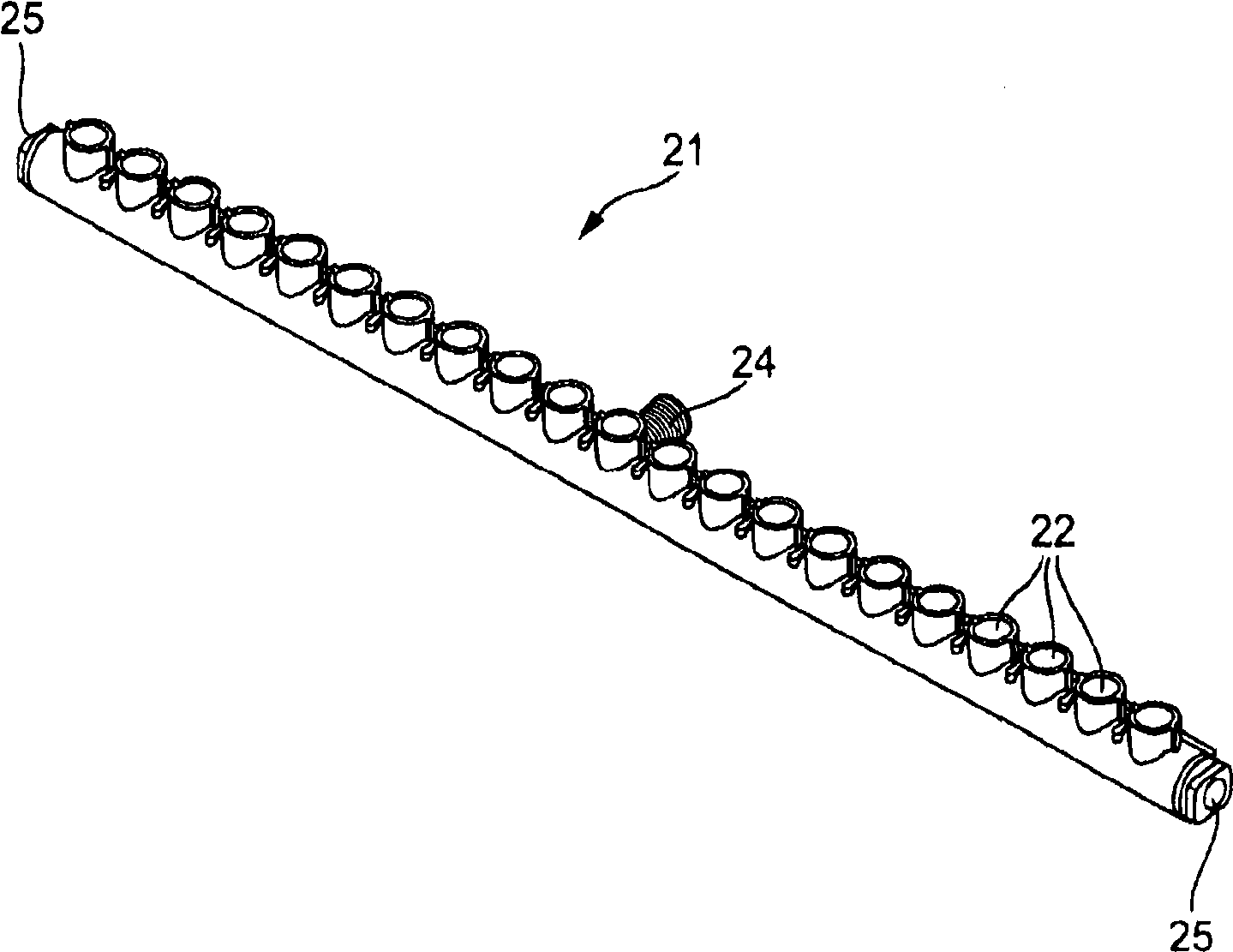

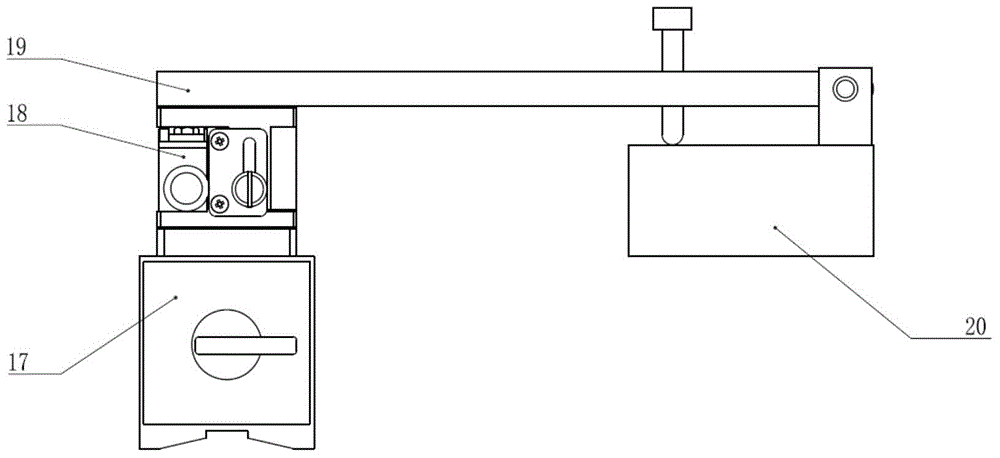

Filter unit for wastewater treatment and production of drinking water

InactiveCN101489653AIncrease productionHigh filter actionMembranesUltrafiltrationFilter systemRetrofitting

A filter unit for sewage treatment and drinking water provision and components which are suitable for the production and the use of such filter units are described. The filter unit has at least one ceramic filter(3) and at least one holder for liquid-tight fixing of the filter in the holder(2), the filter being fixed in the holder by adhesive bonding with the aid of an adhesive. At the same time, the holder is adjusted to the design of the filter, especially to its design as a flat filter. A separate filtrate collecting channel (21)and a holding device (18)for the filter units or other components allow the provision of a finished filter system which is also suitable for retrofitting of already existing plants.

Owner:ITN NANOVATION AG

Absorbable operating suture line and preparation method thereof

InactiveCN102406961AImprove toughnessGuaranteed absorbencySuture equipmentsFibre chemical featuresSurgical sutureSuture line

The invention discloses an absorbable operating suture line and a preparation method thereof, and mainly relates to a chitosan operating suture line. The preparation process comprises the following steps of: preparing a chitosan spinning solution, spinning, solidifying, performing subsequent treatment, and the like. By the process, chitosan is subjected to wet spinning, so that the roundness of the cross section of the chitosan operating suture line is increased, and the operability of the suture line is improved; and the suture line prepared by the process has high tensile strength and elasticity and meets the clinical requirement.

Owner:司忠

No-solvent ultraviolet curing glass printing ink and preparation method thereof

InactiveCN101709179AAdjustable viscosityComply with packaging and printing requirementsInksPolyesterScreen printing

The invention relates to a no-solvent ultraviolet curing glass printing ink and a preparation method thereof; the ink takes high-tractility photochemical active polyester acrylic ester as main ingredient, takes initiator and assistant initiator as curing agents and takes defoamer and flatting agents as auxiliary materials, and then inorganic or organic pigment is mixed, and a functional acrylic ester activated monomer is used as a viscosity regulator; the proportion of the ingredients of the no-solvent ultraviolet curing glass printing ink is as follows: 20-60 parts of multi-functional polyester acrylic ester, 3-8 parts of initiators, 2-5 parts of assistant initiator, 1-3 parts of defoamers, 0-1 part of flatting agent, 8-50 parts of inorganic pigments, 8-15 parts of organic pigments and 10-30 parts of functional acrylic ester activated monomers; the preparation method comprises batching, rolling dispersion and tempering steps; the no-solvent ultraviolet curing glass printing ink has the advantages that: 1. the ink is a 100-percent curing system, has no solvent volatilization and is harm to human body. 2. the curing performance is good, two mercury high pressure lamps with 80-120w / cm are adopted, and complete curing can be realized within 3-6 seconds. 3. the activated monomer is used to regulate the system viscosity, the ink is applied to pad transferring or silk-screen printing, and the universality is strong.

Owner:杭华油墨股份有限公司

Curing agent special for Bayer process red mud roadbeds and preparation method and application method thereof

ActiveCN105693127AAchieve solidificationNo secondary pollutionSolid waste managementGypsumBayer process

The invention discloses a curing agent special for Bayer process red mud roadbeds and a preparation method and application method thereof, and belongs to the field of road engineering. The curing agent is formed by mixing industrial residue ardealite, modifier and stabilizer according to a certain ratio, curing of red mud is achieved through the chemical characteristic that solid wastes supplement one another and through stimulation of active materials, and therefore red mud is used for highway roadbed filling projects. The curing agent has the advantages of being free of secondary pollution, low in cost, simple in preparation method and high in resource utilization rate.

Owner:山东海逸生态环境保护有限公司

High toughness 70DEG C curable epoxy resin prepreg and preparation method thereof

Belonging to the technical field of materials, the invention relates to a high toughness 70DEG C curable epoxy resin prepreg and a preparation method thereof. In order to solve the problems of poor toughness, high curing temperature and short room temperature storage period in existing epoxy resin prepregs, the prepreg is prepared from a high toughness 70DEG C curable epoxy resin system soaking reinforced material, wherein the high toughness 70DEG C curable epoxy resin system is prepared from an epoxy resin mixture and a curing agent system mixture. The epoxy resin mixture is formed by copolymerization of epoxy resin, thermoplastic resin and an addition type curing agent, and the curing agent system mixture is formed by mixing of a catalytic curing agent and an accelerant. The preparation method includes: 1. preparation of the high toughness epoxy resin mixture; 2. preparation of the curing agent system mixture; and 3. preparation of the prepreg. A composite material prepared from the prepreg has high toughness and compression strength after impact greater than 220MPa, can realize complete curing at 70DEG C, and has a room temperature storage period over 30 days.

Owner:广联航宇(哈尔滨)新材料科技有限公司

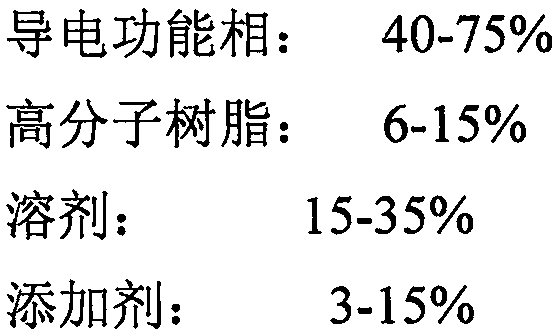

Special ultralow temperature cured laser etching conductive silver paste for mobile phone touch screen

ActiveCN108022669AAchieve solidificationStable storageNon-conductive material with dispersed conductive materialMetal/alloy conductorsSilver pasteLaser etching

The invention relates to a special ultralow temperature cured laser etching conductive silver paste for a mobile phone touch screen. The conductive silver paste mainly comprises the following components: 40%-75% of a conductive function phase, 6-15% of macromolecule resin, 15-35% of a solvent and 3-15% of an additive. The preparation of the silver paste comprises the steps of macromolecule regioncarrier preparation, conductive silver paste preparation and conductive silver paste post-processing. The conductive silver paste can be completely cured under the condition of an ultralow temperatureof 80-110 DEG C, the temperature is reduced by 20-50 DEG C compared with a curing condition of 130 DEG C of the existing conductive silver paste, and shrinkage, folding and deformation of a substratemembrane material during high-temperature curing are reduced. The paste has excellent laser etching performance, and a clear pattern with the line width / line spacing being 30 microns / 30 microns can be etched; the paste has good adhesion on PET, an ITO film, a silver nanowire conductive film, TIO glass and ordinary glass, the pencil hardness is above 2H, and the square resistance can reach up to 20m[Omega] / square@1mil. In addition, the conductive silver paste is sintered and molded at an ultralow temperature, low in production cost, energy-saving and free of halogen, thereby being an environment-friendly product.

Owner:NANO TOP ELECTRONICS TECH

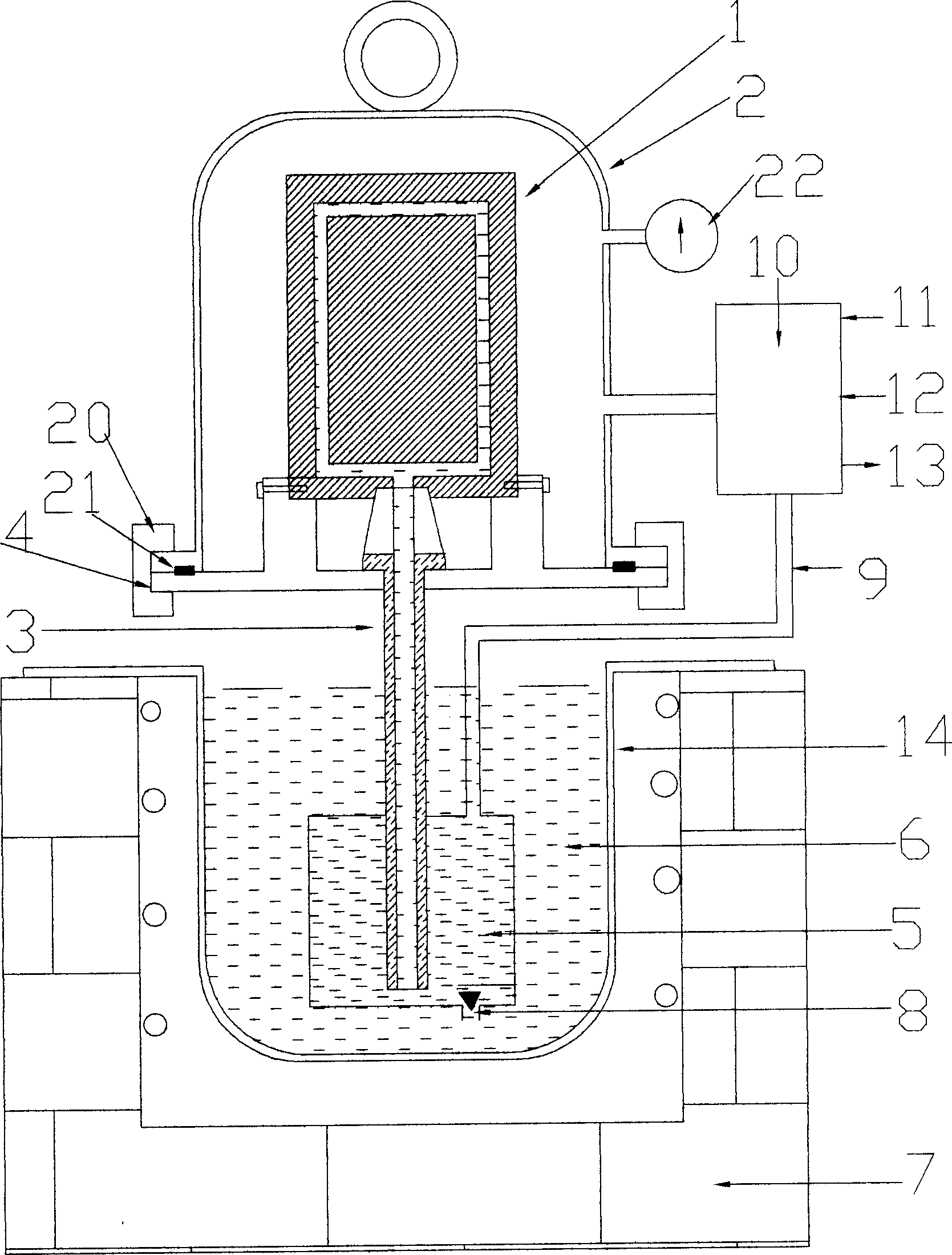

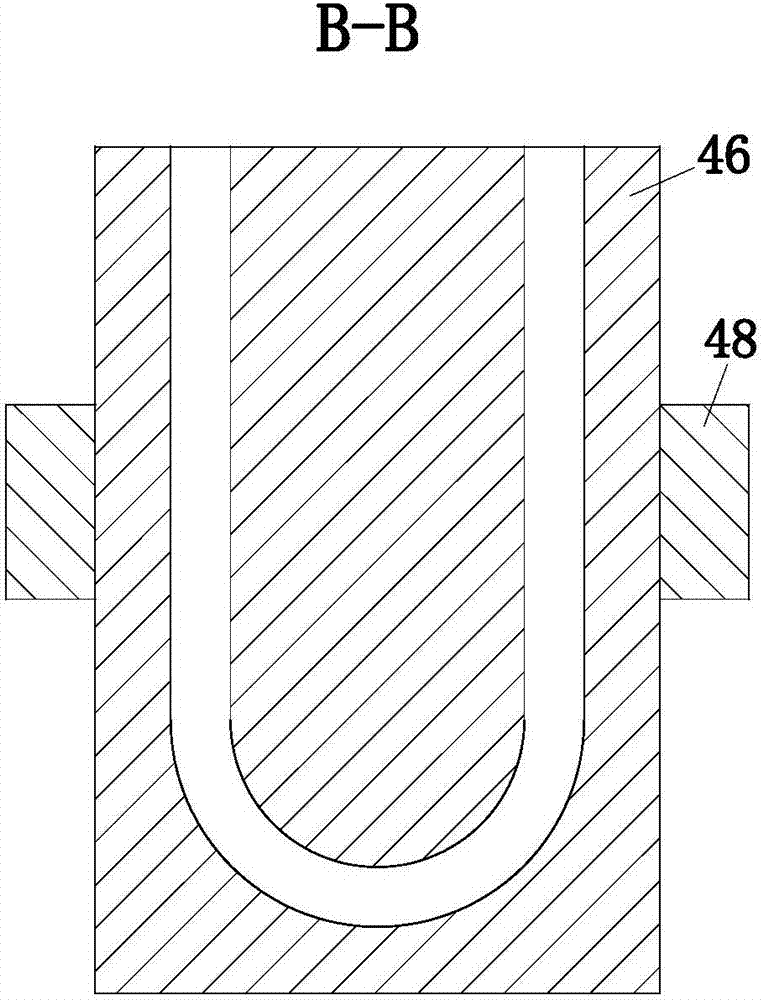

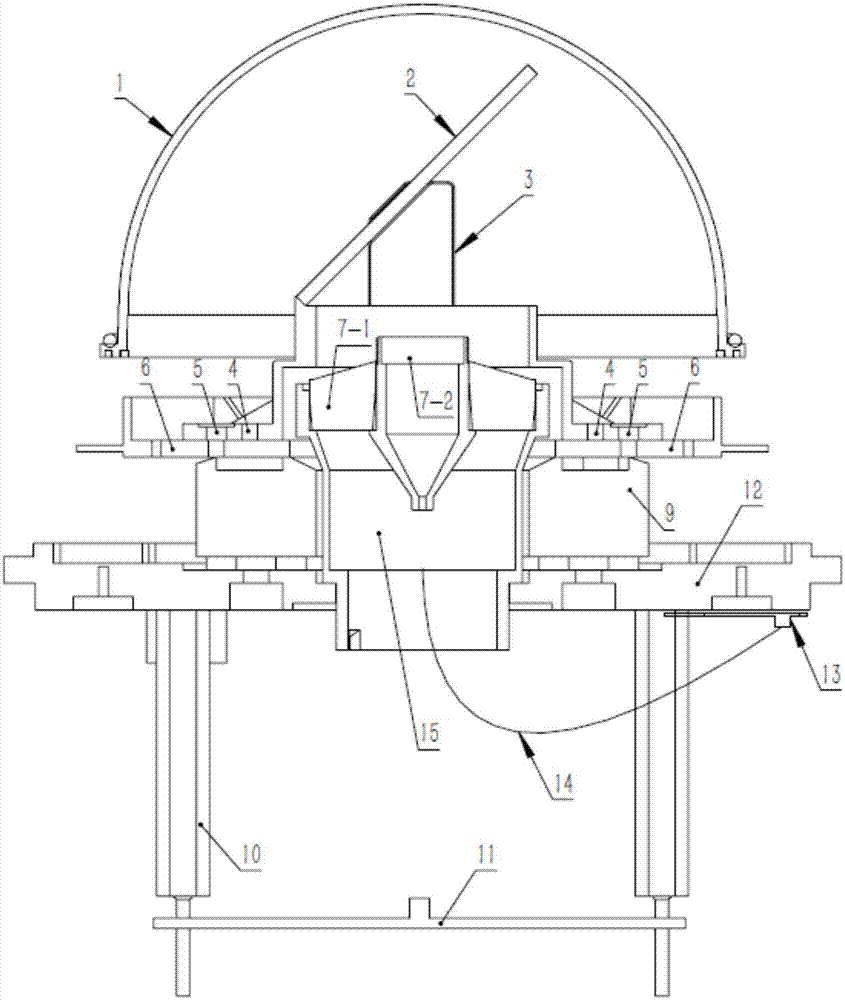

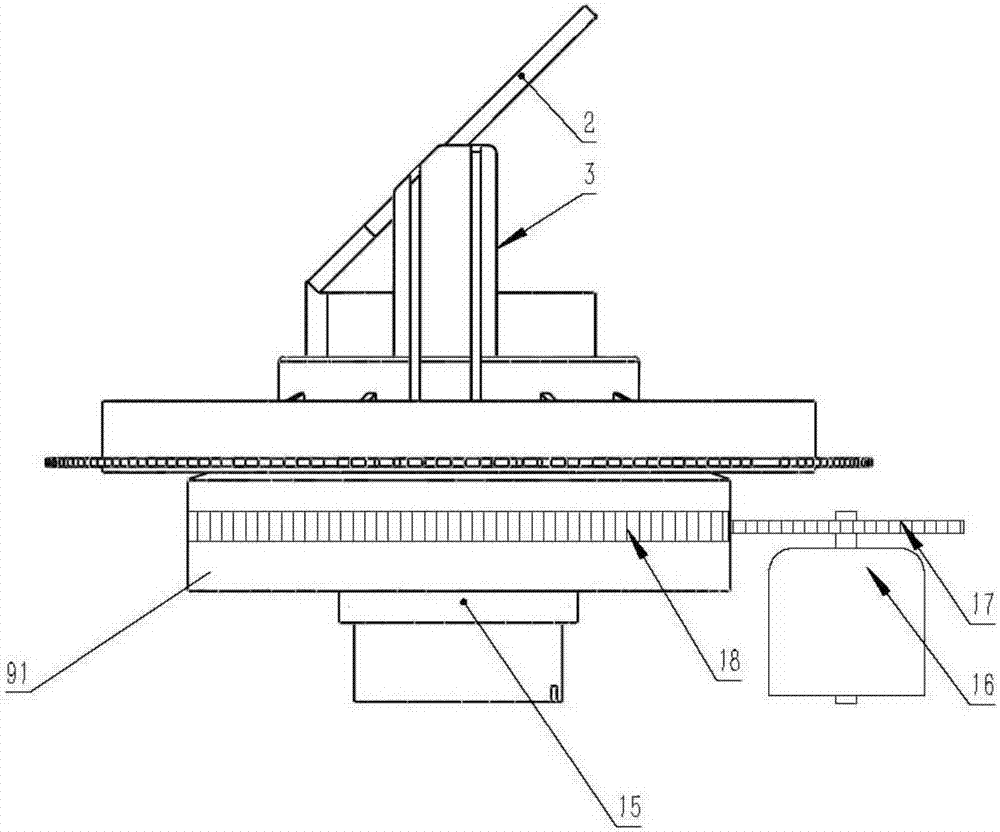

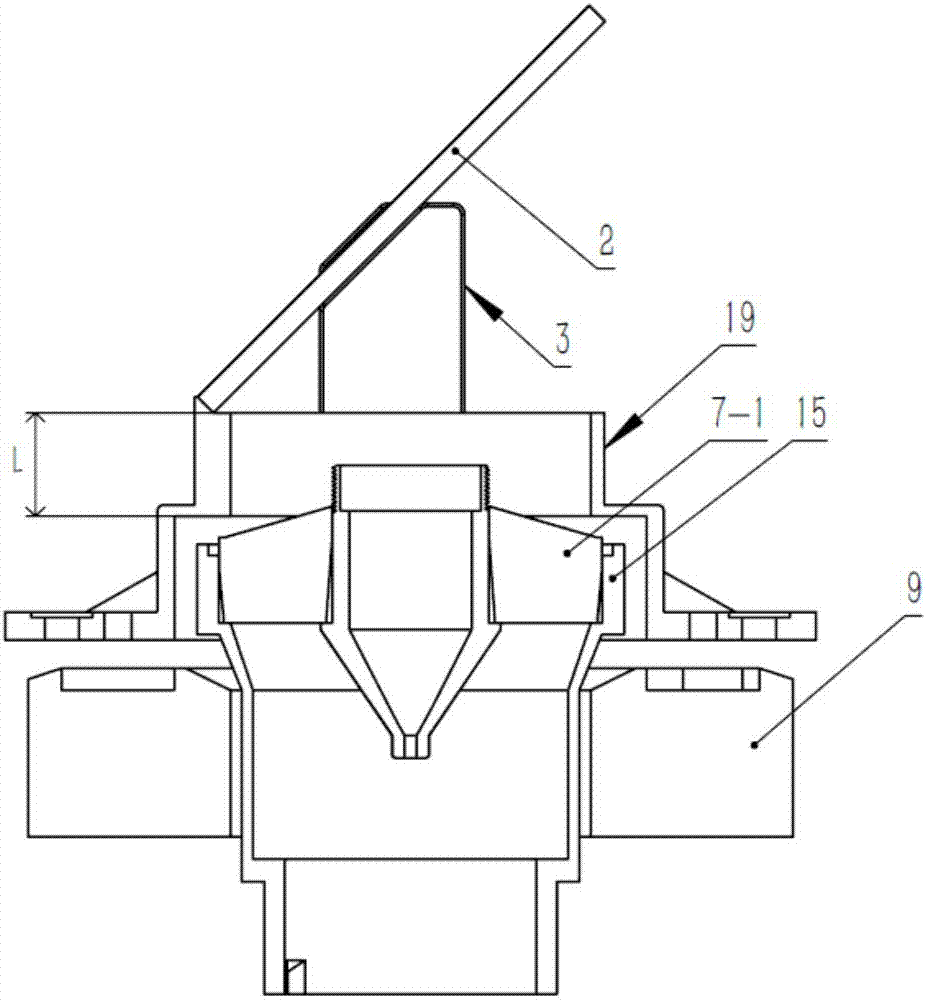

Vacuum pressure casting machine for magnesium alloy

The invention belongs to metal casting device. The magnesium alloy cast is complex, and the performance is bad. The invention is a magnesium alloy casting device which fills shape in vacuum state and solidifies them in various pressure state. It can realize the optimized casting process condition, it can be applied to produce each kind of large, complex, thin magnesium alloy casting piece with precise size and high thickness.

Owner:李书伟 +2

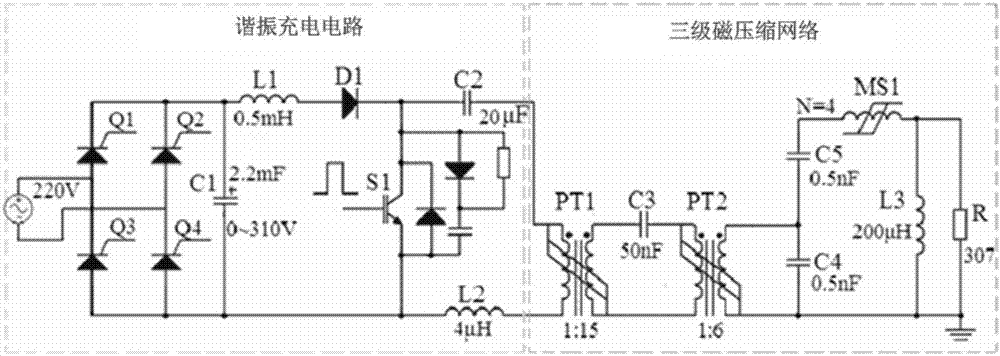

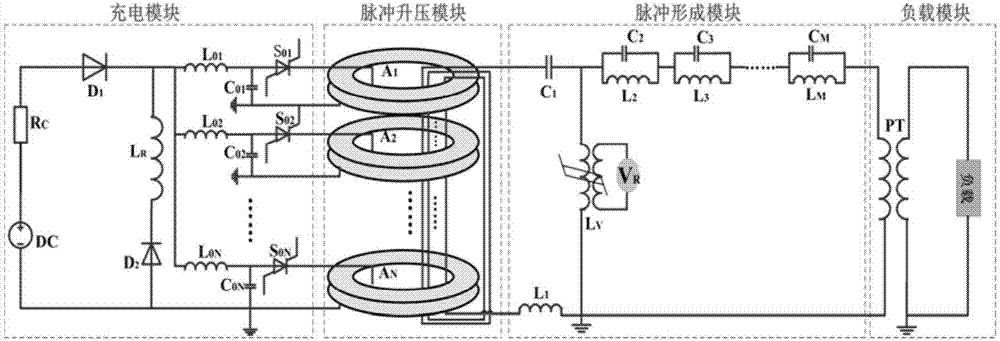

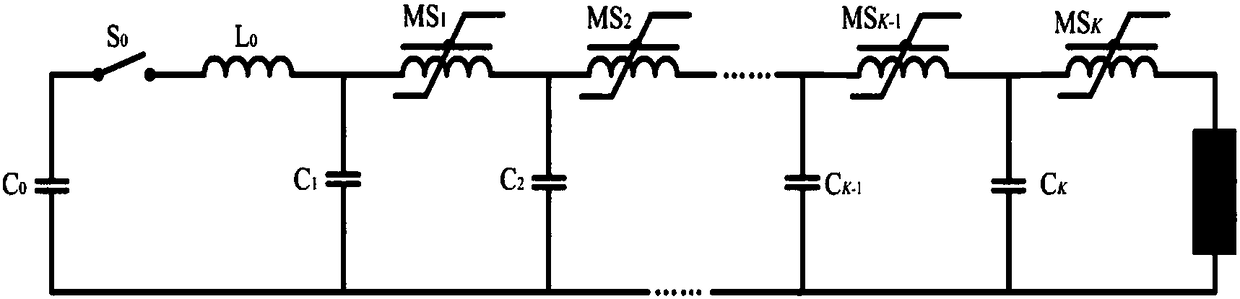

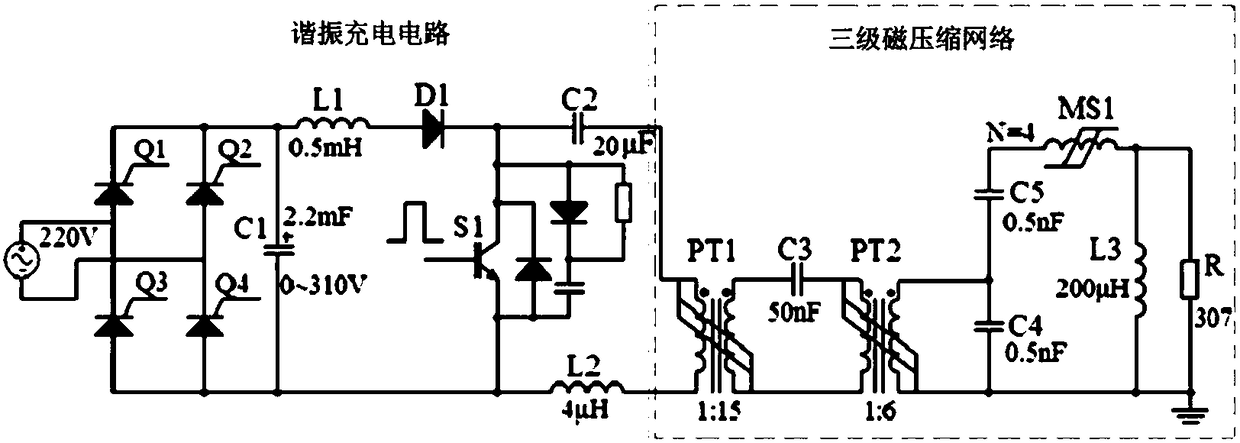

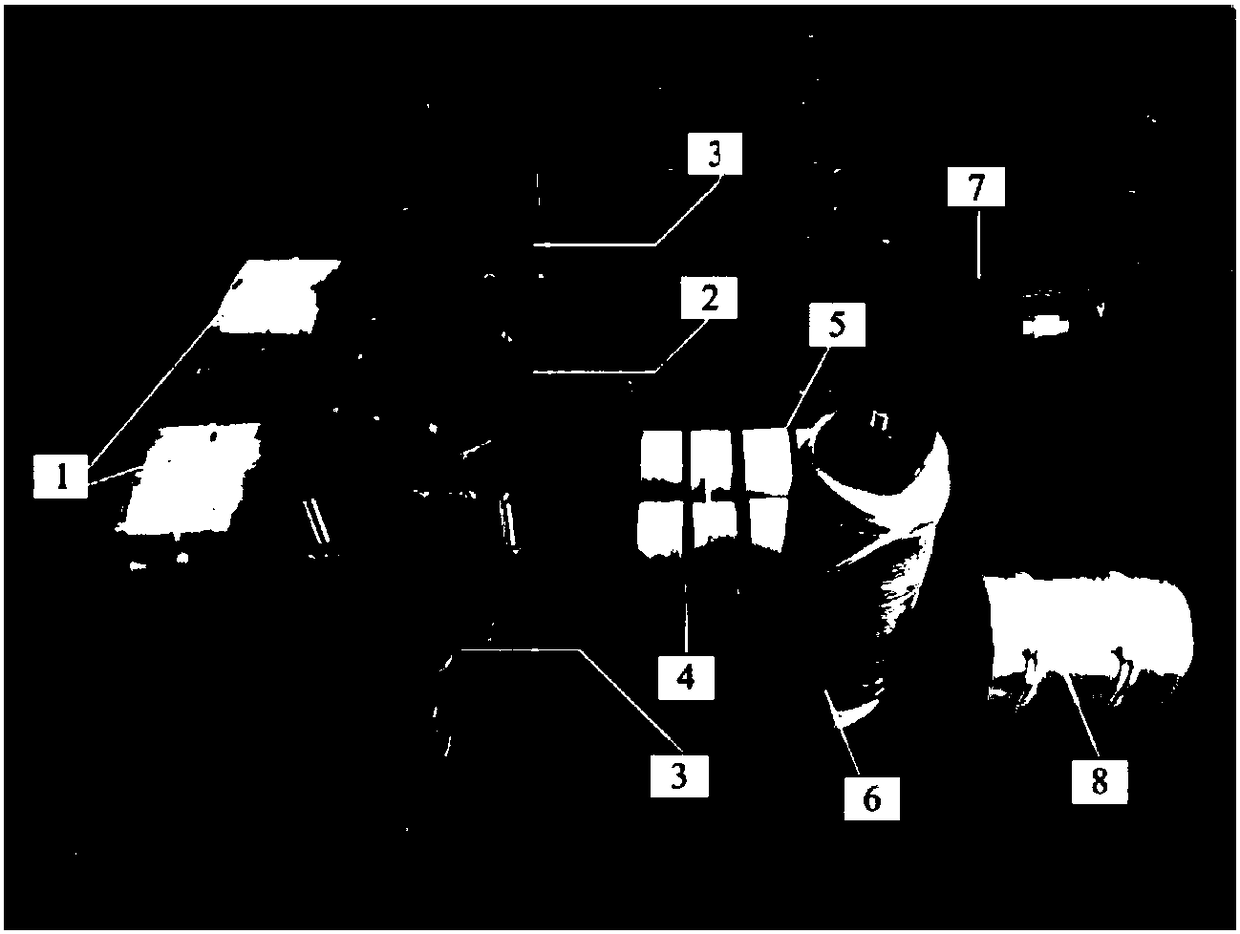

All-solid-state high-voltage microsecond pulse generator based on FRSPT (Fractional-turn Ratio Saturable Pulse Transformer) and anti-resonance network

ActiveCN107040244ACompact integrationAvoid the voltage equalization problem of the working voltagePulse generation by bulk negative resistance devicesAll solid stateMicrowave

The invention relates to a microsecond pulse generator, particularly relates to an all-solid-state high-voltage microsecond pulse generator based on a FRSPT (Fractional-turn Ratio Saturable Pulse Transformer) and an anti-resonance network, and belongs to the field of pulse power. The pulse generator consists of a charging module, a pulse boosting module, a pulse forming module and a load. The charging module is mainly used for charging the pulse generator, and charges the pulse forming module by the pulse boosting module; the pulse boosting module is the FRSPT; in one aspect, the FRSPT is used as a transformer of the pulse boosting module, and in the other aspect, the FRSPT is used as a switch of the pulse forming module; and the pulse forming module is used for forming a quasi-square wave pulse which is reasonable in leading and lagging edge time and good in flat top degree. The pulse generator is long in service life and stable to operate; all-solid-state compact integration of the pulse generator is implemented; an output square wave is high in quality; and the all-solid-state high-voltage microsecond pulse generator can be used for the fields of a high-power microwave source, foods, sterilization and disinfection, wastewater treatment and the like.

Owner:NAT UNIV OF DEFENSE TECH

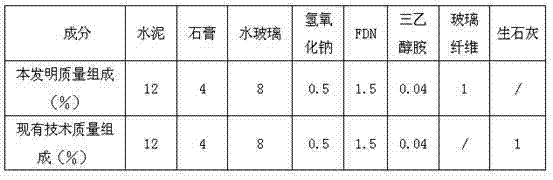

Novel mucky soil composite curing agent

InactiveCN102517031AAchieve solidificationLow priceBuilding constructionsOrganic fertilisersGlass fiberSuperplasticizer

The invention discloses a novel mucky soil composite curing agent, which is formed by mixing cement as gelatinous materials and alkaline stimulation component, expansion component and surface active agent as ingredients. The alkaline stimulation component adopts sodium silicate and sodium hydroxide; the expansion component adopts gypsum, and the surface active agent adopts triethanolamine and high efficiency slushing agent. The novel mucky soil composite curing agent is characterized by also comprising an anti-crack component which adopts glass fiber. The mass percentage of the components are as followed:12-16 percent of cement, 2-5 percent of gypsum, 4-8 percent of sodium silicate, 0.4-0.8 percent of sodium hydroxide, 0.02-0.1 percent of triethanolamine, 1.5-2.5 percent of high efficiency slushing agent, and 0.4-2 percent of glass fiber. The novel mucky soil composite curing agent has the advantages of good tensile strength and fracture resistance, high shearing strength, stable long-term strength, good water stability and the like, and can be used for generating a composite foundation on a mucky soil field through a deep mixing method.

Owner:NINGBO UNIV

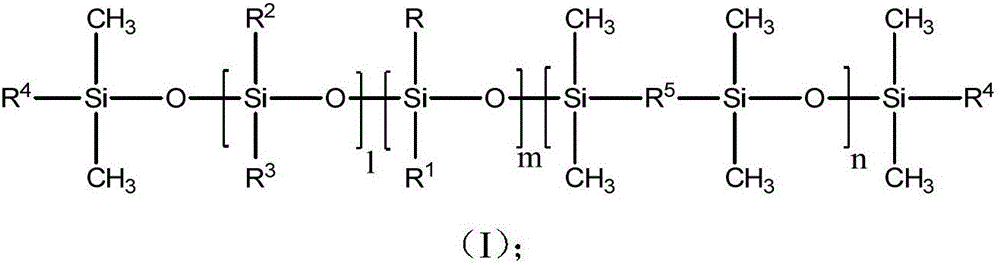

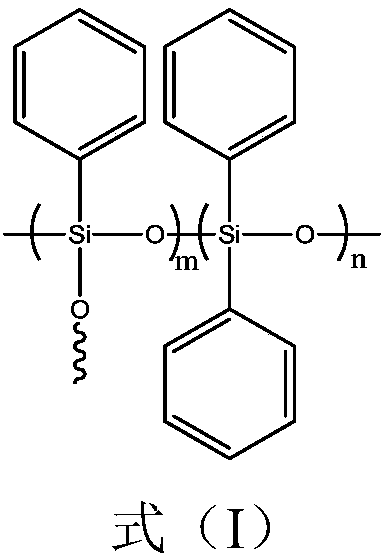

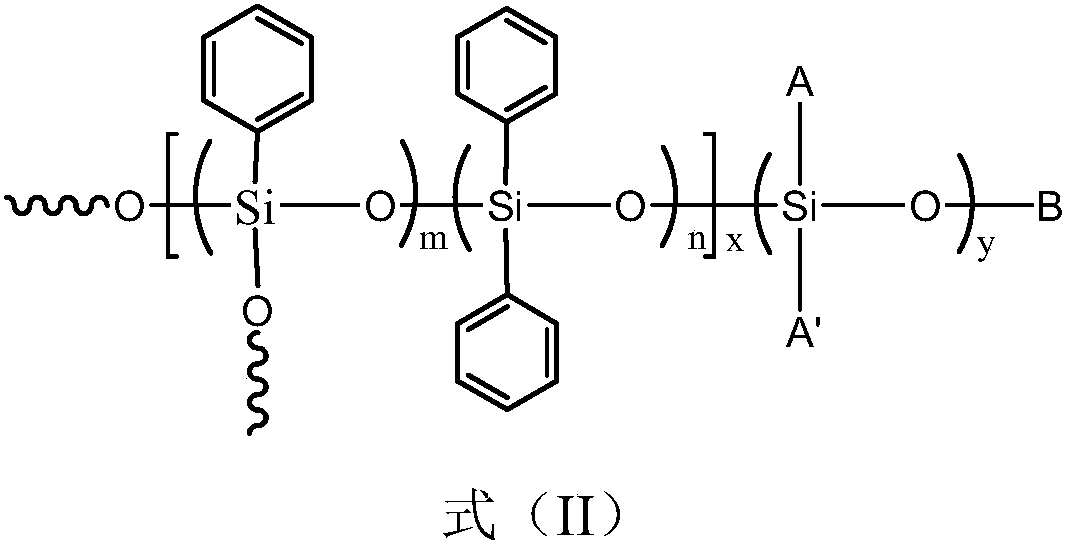

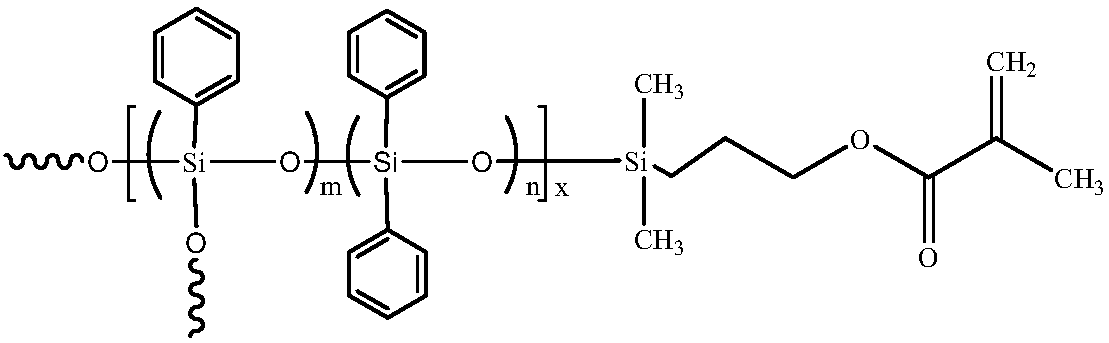

Composition containing high-phenyl-group polysiloxane, and packaging material or optical thin film comprising the composition

ActiveCN108329473AEasy to prepareAchieve solidificationSemiconductor devicesUltraviolet lightsRefractive index

The invention provides high-phenyl-group polysiloxane, a polysiloxane composition containing the high-phenyl-group polysiloxane, and a packaging material or an optical thin film, comprising the composition, and preparation methods and applications thereof. In the high-phenyl-group polysiloxane, molar percentage of phenyl group in organic groups, connected to silicon, in a main chain can reach morethan 50 mol%. The high-phenyl-group polysiloxane can be used for preparing a polysiloxane composition used for the packaging material or optical thin film, especially ultraviolet curing. The preparation method of the polysiloxane composition is simple and can achieve ultraviolet curing. The packaging material or optical thin film can be cured under ultraviolet light, wherein the obtained materialhas excellent optical property, can reach up to 1.64 in refractive index, is equal to or larger than 90% in transmittance within wavelength range of visible light, and has excellent heat resistance.According to thermogravimetic analysis, in a nitrogen atmosphere, temperature can optimally reach up to 480 DEG C when weightlessness is 5%.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing solid bee honey

The invention discloses a method for preparing solid honey and relates to a method for preparing food, in particular to a preparation method for hardening honey. The method mainly comprises the steps of material selection, mixing and crystallization. The steps in detail are as follows: a. a material is selected, in which exquisite honey with small crystallization nucleus is selected as a crystallization revulsant; b. at a temperature of between 50 and 55 DEG C, honey is condensed till Be is between 39 and 45 degrees or the water content is between 14 and 25 percent and is cooled; c. when the temperature is cooled to 40 DEG C, the exquisite honey selected in the step a is added into the honey obtained in the step b; and d. the honey is stirred and is continuously cooled to a temperature of between 10 and 14 DEG C; the humidity of air is controlled less than or equal to 58 percent; and the honey is recrystallized to obtain the solid honey. The method has a simple process, easy control of the process course and low crystallization temperature, well protects the effective nutritive compositions of the honey, does not need to add minor ingredients additionally to realize the solidification of the liquid honey, ensures the original flavor and nutrition of the honey to the maximum and brings great convenience for people to store, carry and eat the honey.

Owner:陈建祥

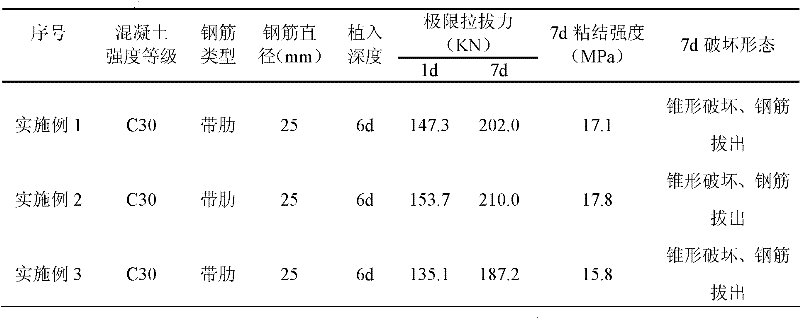

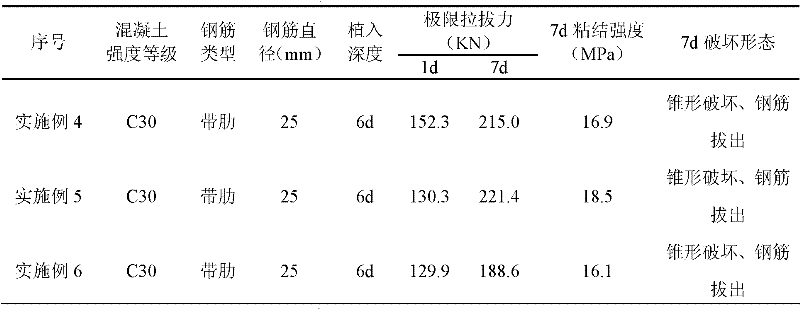

Non-cement-based inorganic anchoring bonded bar adhesive and preparation method thereof

The invention discloses a non-cement-based inorganic anchoring bonded bar adhesive and a preparation method thereof. The preparation method of the non-cement-based inorganic anchoring bonded bar adhesive disclosed by the invention comprises the following steps of: uniformly mixing one or several kinds of powder of slag powder, metakaolin powder, coal ash, coarse calcium powder, quartz sand, a swelling agent and the like; mixing a sodium silicate solution, a sodium phosphate solution, a sodium hydroxide solution, water and the like into emulsion; and weighing threes parts of bonded bar adhesive powder and one part of the emulsion in terms of weight part, and uniformly mixing to prepare the non-cement-based inorganic anchoring bonded bar adhesive. The non-cement-based inorganic anchoring bonded bar adhesive disclosed by the invention has the advantages of early strength, high strength, stable volume, good durability, high-temperature resistance, large bond stress to reinforcing steel bars, high anchoring strength, seismic resistance, impact resistance and favorable fatigue resistance, and can be widely applied to surrounding rock anchoring for engineering, equipment foundation bar bonding, building structure bar bonding, reinforcing steel bar anchoring for water conservancy, hydropower, roads, bridges, tunnels and other projects, and the like.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

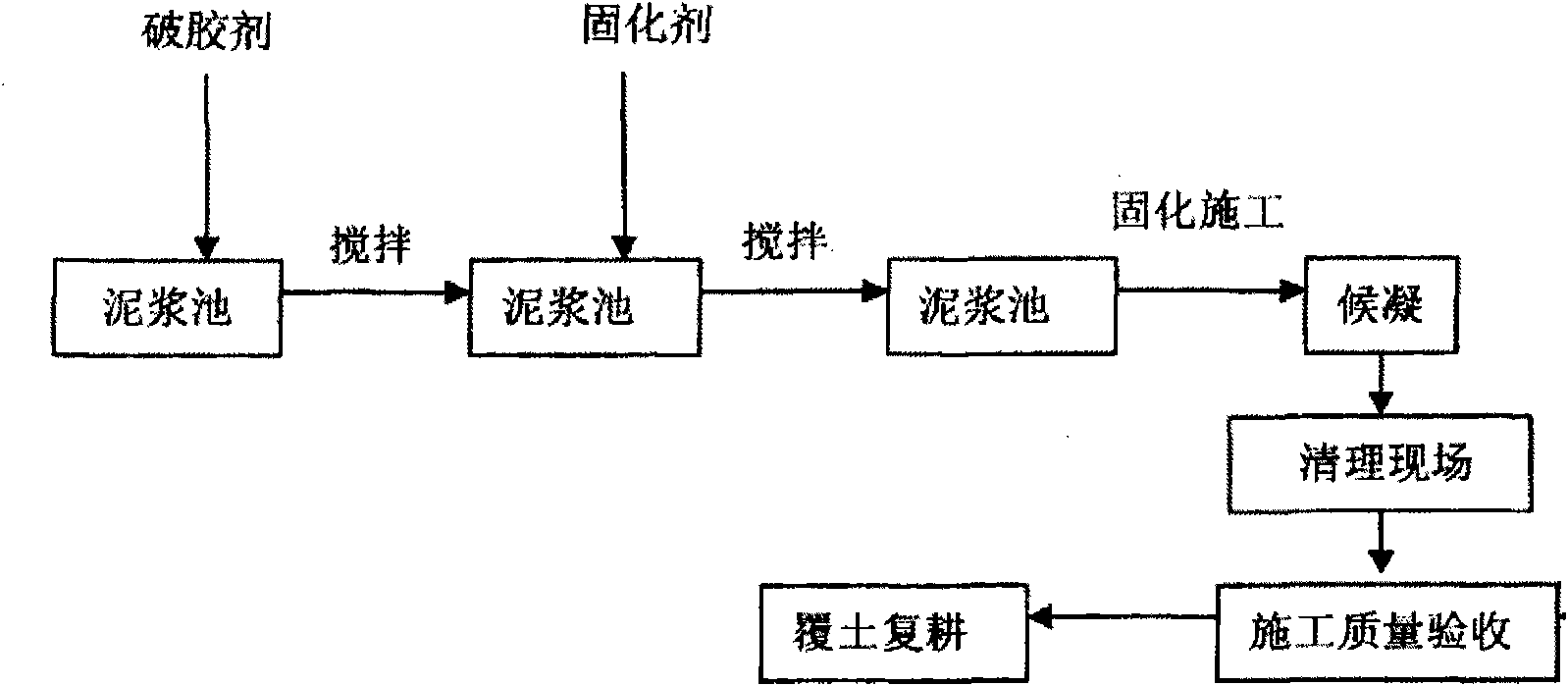

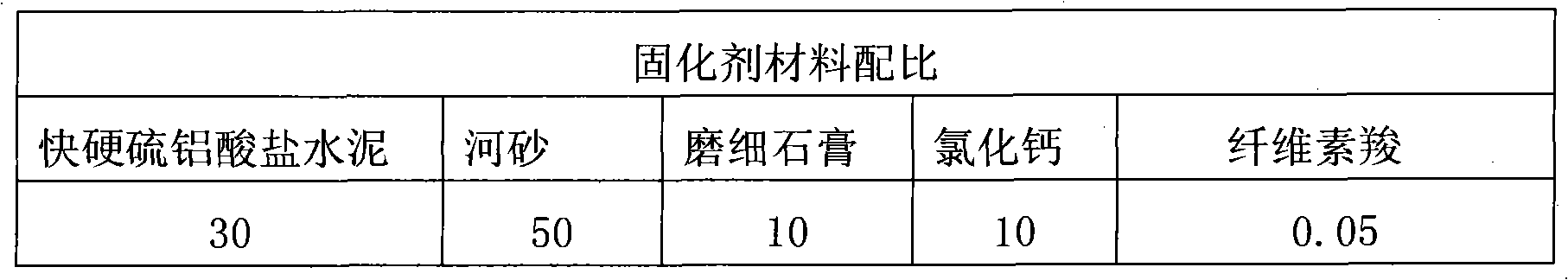

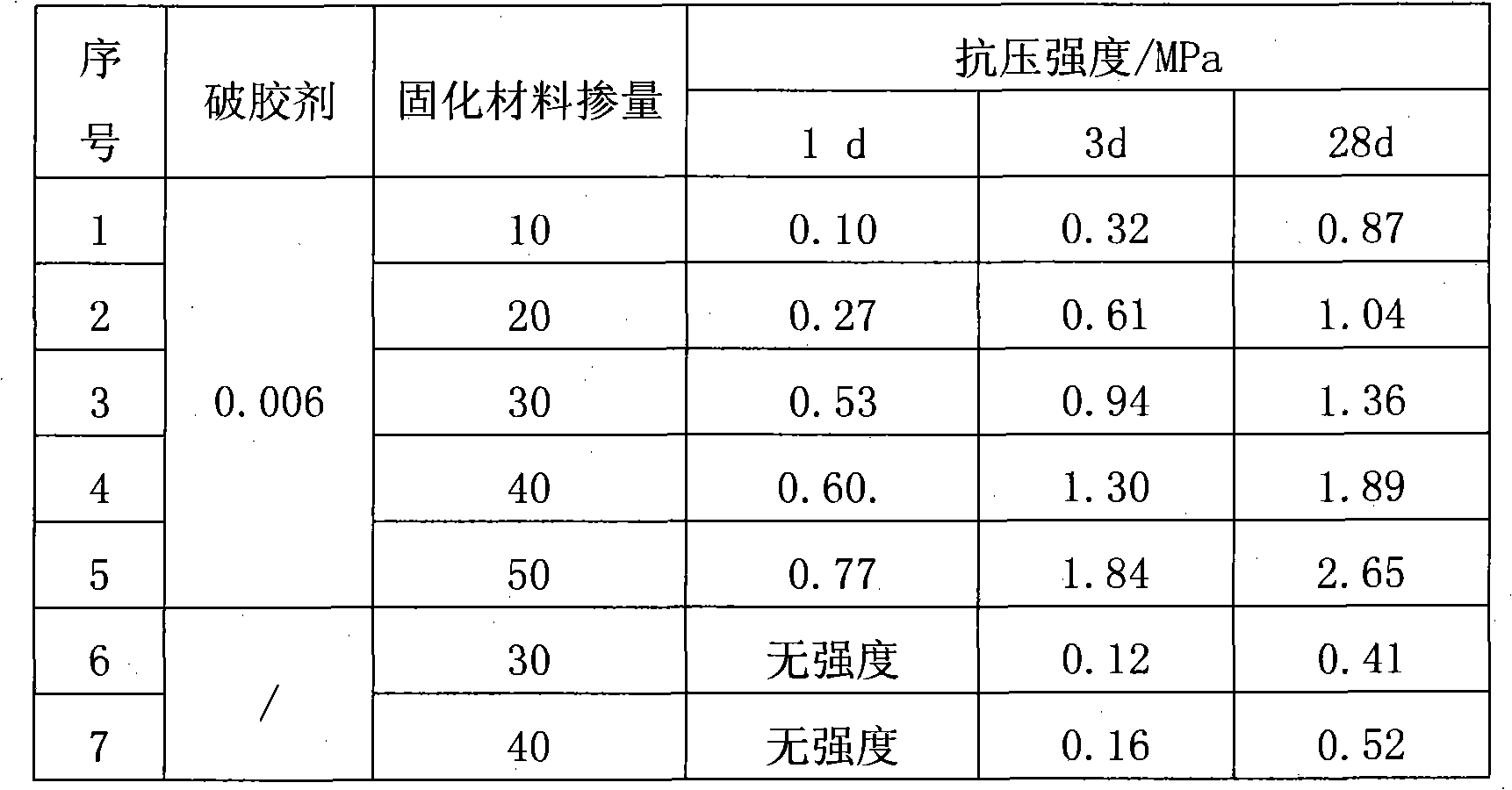

Mud curing agent

The invention discloses a mud curing agent. The mud curing agent comprises the following raw materials in part by weight: 30 to 50 parts of rapid-hardening sulfoaluminate cement, 40 to 50 parts of river sand, 5 to 15 parts of ground plaster, 5 to 15 parts of calcium chloride and 0.025 to 0.075 part of cellulose carboxyl material. A using method for the mud curing agent comprises that: the colloid system of the mud must be subjected to colloid breaking treatment by adopting a colloid breaker before the mud is cured, and the mud curing agent is added into the mud after colloid breakage according to a certain proportion, so the mud can be well cured. By effective curing treatment for the mud, the original lacking land resource of China is saved, and the curing of the mud is realized, so that other constructions can be performed after soil is covered for returning tillage or certain curing strength is met, and the mud curing agent has good economic and social benefits.

Owner:CHINA TIESIJU CIVIL ENG GROUP

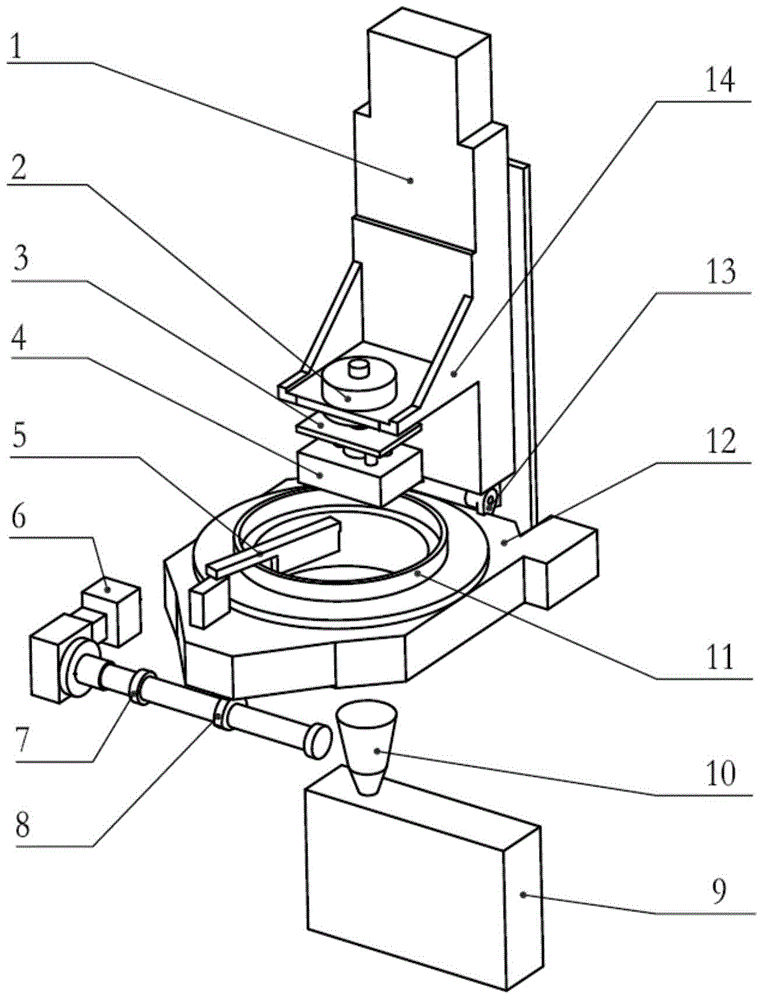

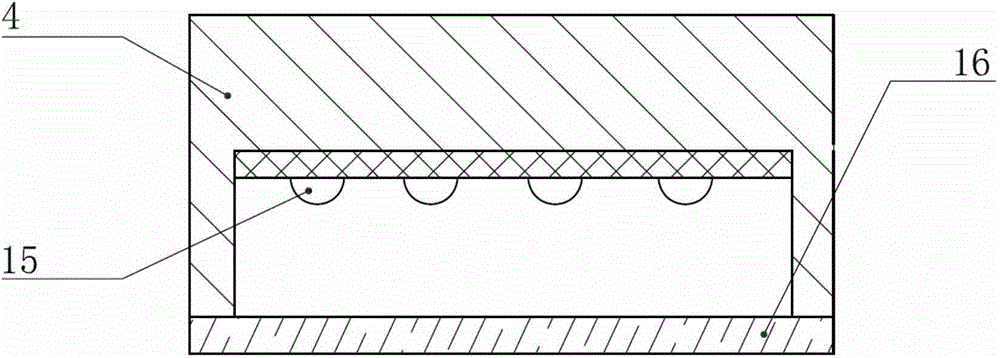

Surface exposure forming device of high viscosity material

ActiveCN104924621AAchieve solidificationSmooth forming materialAdditive manufacturing apparatusHinge angleCam

The invention discloses a surface exposure forming device of a high viscosity material, which comprises a processing system, an exposure system and a control system, wherein the processing system is a mechanism part of the surface exposure forming device; a working table support is fixed on a Z-axis translation table fixed on a rack; a tension and pressure sensor, a precise inclinator and a working table are fixed on the worktable support; the rack is articulated with a material groove rotating table; the rotating table can allow a material groove to do quick complete cycle rotating movement; by matching with a material recoating mechanism fixed on the rotating table, a material in the material groove can be recoated and slicked; by matching with the exposure system and the control system, the material in the material groove can be solidified; and after each material layer is solidified, a cam mechanism allows the whole rotating table to incline downward by a certain angle around a hinge of the rotating table, to allow the solidified material layer to be delaminated from the bottom of the material groove. The surface exposure forming device can solve the problems that the forming of the high viscosity material is difficult in a forming material light solidification process and the precision of the formed high viscosity material is poor at present.

Owner:XI AN JIAOTONG UNIV

Kitchen waste oil recovery device

ActiveCN107215921AAchieve separationReduce pollutionFatty/oily/floating substances removal devicesFatty-oils/fats refiningTemperature controlOil water

The invention relates to a kitchen sewage treatment field, and in particular relates to a kitchen waste oil recovery device including a containing module, a top plate, a filter module, a freezing separation module and a controller, the top plate is located above the containing module, and is used for supporting the filter module and the freezing separation module, the filter module is used for filtering impurities in oil water and introducing the filtered oil water into the containing module, the freezing separation module is used for freezing separation of the oil water in the containing module and separated collection of different types of oil in the oil water, the controller is used to control the coordination work of all the modules. Kitchen waste oil is condensed and collected by a condensation plate in the freezing separation module, environment pollution of the kitchen waste oil is reduced, and by a temperature controller on the condensation plate in the freezing separation module, different types of kitchen waste oil can be recovered, resources are saved, and the use scope is expanded.

Owner:绿桥(泰州)生态修复有限公司

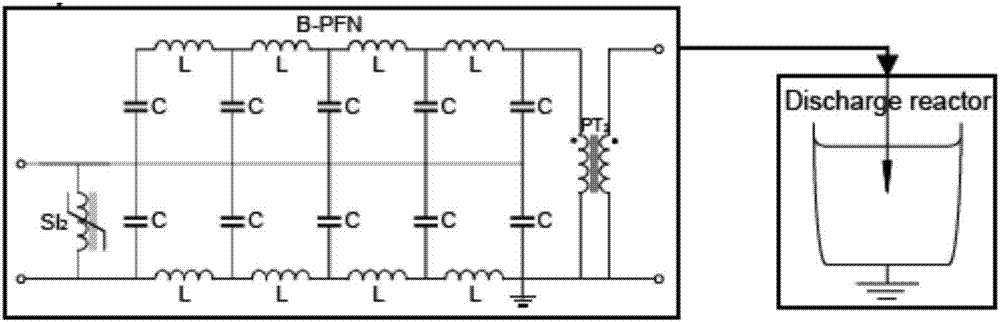

All-solid-state square-wave pulse generator

ActiveCN108390665ACompact integrationAvoid the voltage equalization problem of the working voltageElectric pulse generator circuitsHigh pressurePhysics

The invention relates to a square-wave pulse generator, and in particular relates to an all-solid-state square-wave pulse generator based on a fractional ratio saturable pulse transformer and a Marx generator, and belongs to the field of pulse power. The pulse generator is composed of a charging module, a pulse boosting module and a load module. According to the pulse generator provided by the invention, the primary working voltage and an auxiliary side saturable inductor of the pulse transformer can be reduced, and compact integration of the pulse transformer and the magnetic switch can be achieved; the magnetic switch is used for replacing an air switch in the traditional Marx generator, so that the service life of the whole system and the repeat frequency are greatly enhanced; a high voltage silicon rectifier stack is used for replacing an isolated inductor in the Marx generator, and the pre-pulse problem is effectively eliminated; meanwhile quasi-square-wave pulse with relatively high quality and good flattening degree can be output via an anti-resonant network, the system is all solidified and miniaturized, and is small in volume, light in weight, convenient in transport and practicability, avoids a multi-switch serial structure of the high voltage pulse generator, and can improve the service life.

Owner:NAT UNIV OF DEFENSE TECH

Liposome calcium sulphate composite nano artificial bone, preparation method and use thereof

ActiveCN101507840AImprove mechanical strengthExtend the usable timeProsthesisLiposomeBiocompatibility Testing

The invention relates to a liposome calcium sulfate composite nanometer artificial boneware, as well as a preparation method and application thereof. The preparation method comprises the steps of well mixing liposome (1 to 40 percent), calcium sulfate powder (40 to 80 percent) and diluent (10 to 50 percent), curing the materials and then preparing a bone graft substitute containing nanometer liposome. The liposome can carry medicine and can modify surface, has two forms, namely solution and powder, and comprises traditional micromolecule liposome and macromolecule liposome having macromolecule characteristics. The invention can provide an artificial bone material which has nanometer reinforcing effects, function of sustaining and controlling medicine release, controllable degradation time, good biocompatibility and mechanical strength, can induce bone growth in vivo, and is beneficial to the healing of defective areas of bones.

Owner:SHANGHAI INST OF ONCOLOGY

Hyperbranched polyurethane containing epoxy groups as well as preparation method and application thereof

The invention discloses hyperbranched polyurethane containing epoxy groups as well as a preparation method and application thereof. According to the invention, by controlling the mole ratio of diisocyanate and trihydric alcohol, a reaction medium, adding amount of a matter containing epoxy groups, reaction temperature and reaction time, the hyperbranched polyurethane with the weight-average molecular weight of 25,000-10,0000 and 8-40 epoxy groups is obtained. The prepared hyperbranched polyurethane containing epoxy groups is wide in raw material source, and commercialized; a polymerization method is mature and the preparation process is simple; the hyperbranched polyurethane containing epoxy groups is easy to store. In addition, the hyperbranched polyurethane containing epoxy groups can be used as an active modifier for a thermosetting resin prepolymer.

Owner:XI AN JIAOTONG UNIV

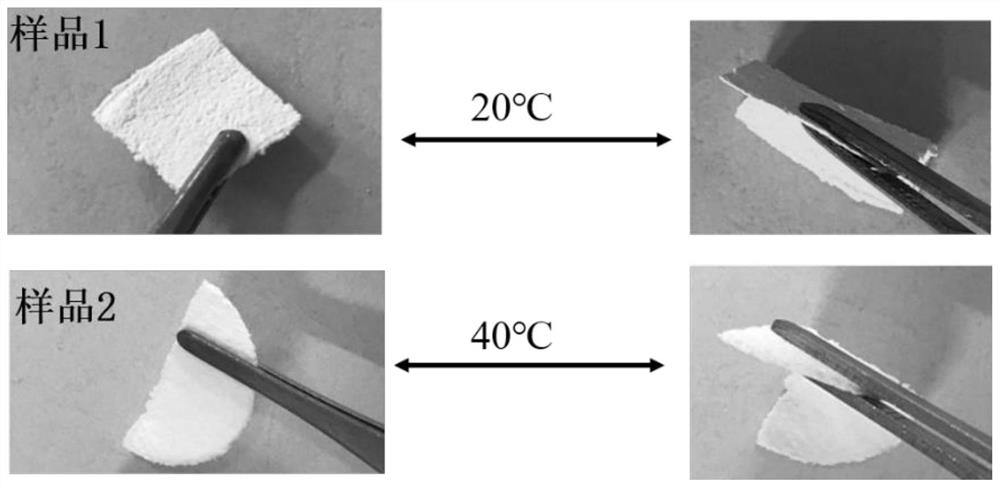

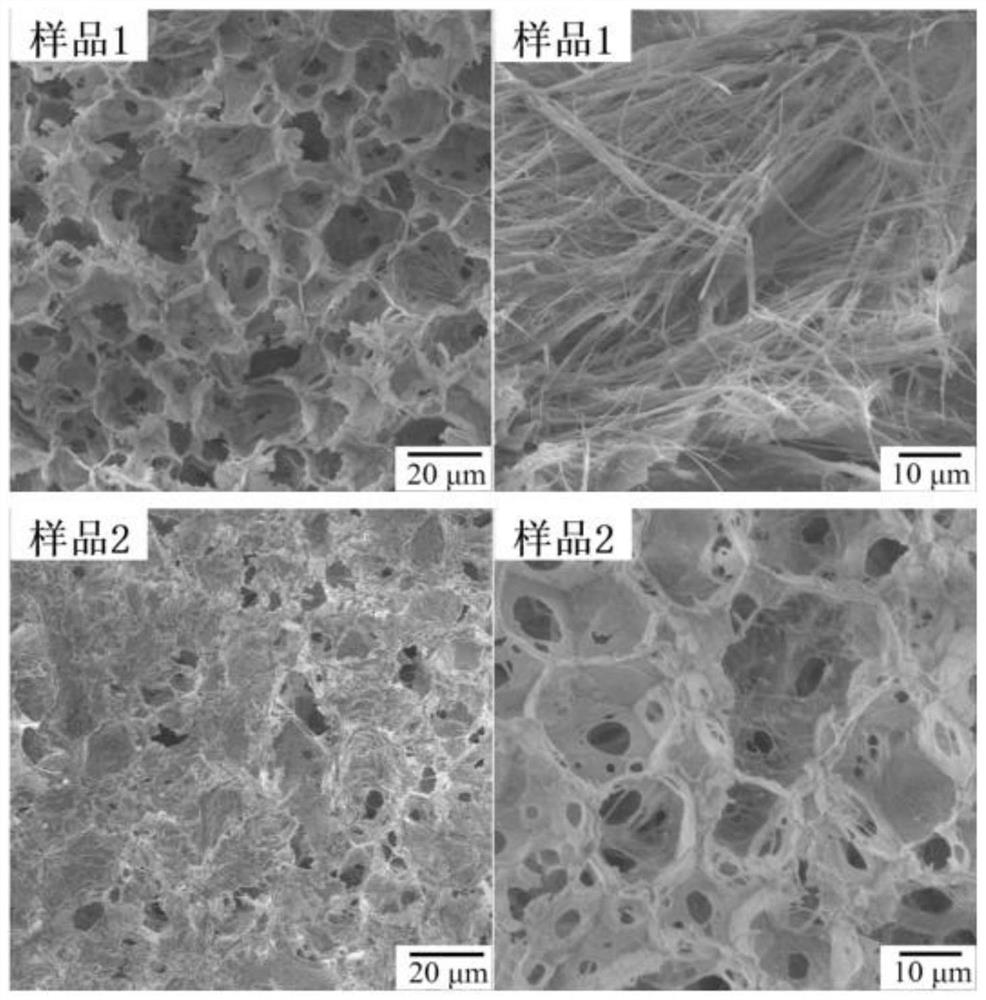

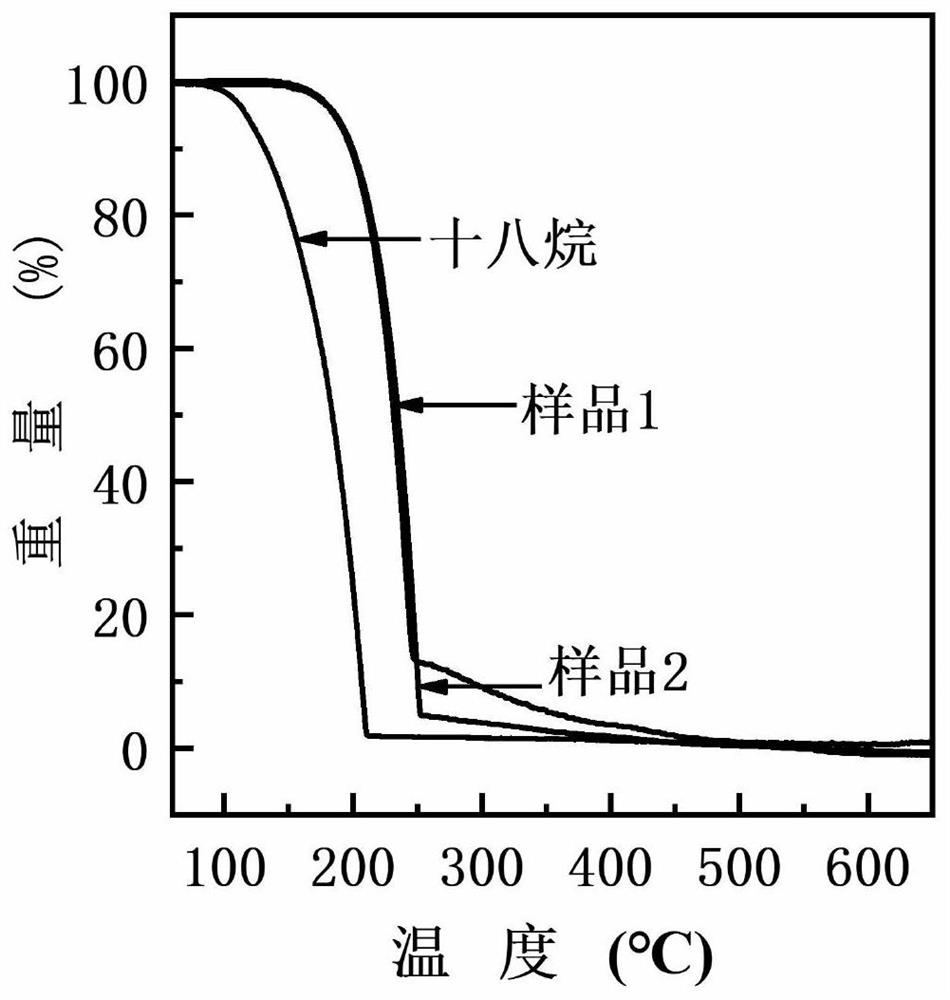

Cellulose-based flexible heat storage composite material and preparation method thereof

ActiveCN113337252AStabilize cross-linking defectsLess cross-linking defectsHeat-exchange elementsCellulosePtru catalyst

The invention provides a cellulose-based flexible heat storage composite material and a preparation method thereof, and the preparation method comprises the following steps: uniformly mixing an oil phase and a water phase to obtain an oil-in-water type high internal phase emulsion, wherein the oil phase is an organic phase change material, the water phase comprises a water-soluble emulsifier, a cellulose suspension and water; adding a cross-linking agent and a catalyst into the oil-in-water type high internal phase emulsion, realizing interfacial polymerization of the cellulose emulsion through heating, forming a cross-linked polymer at an interface, and obtaining the heat storage composite material through heating drying and freeze drying. The appearance of the heat storage composite material can be controlled through a mold for containing the high internal phase emulsion during polymerization, a nanofiber structure is arranged in the heat storage composite material, the heat storage density of the material after heating and drying can reach 200 J / g, the heat storage density of the material after freeze drying can reach 250 J / g, and the heat storage composite material has flexibility, can be curled and folded at the room temperature and the temperature of 40 DEG C or above and is good in heat conduction performance.

Owner:SUZHOU UNIV

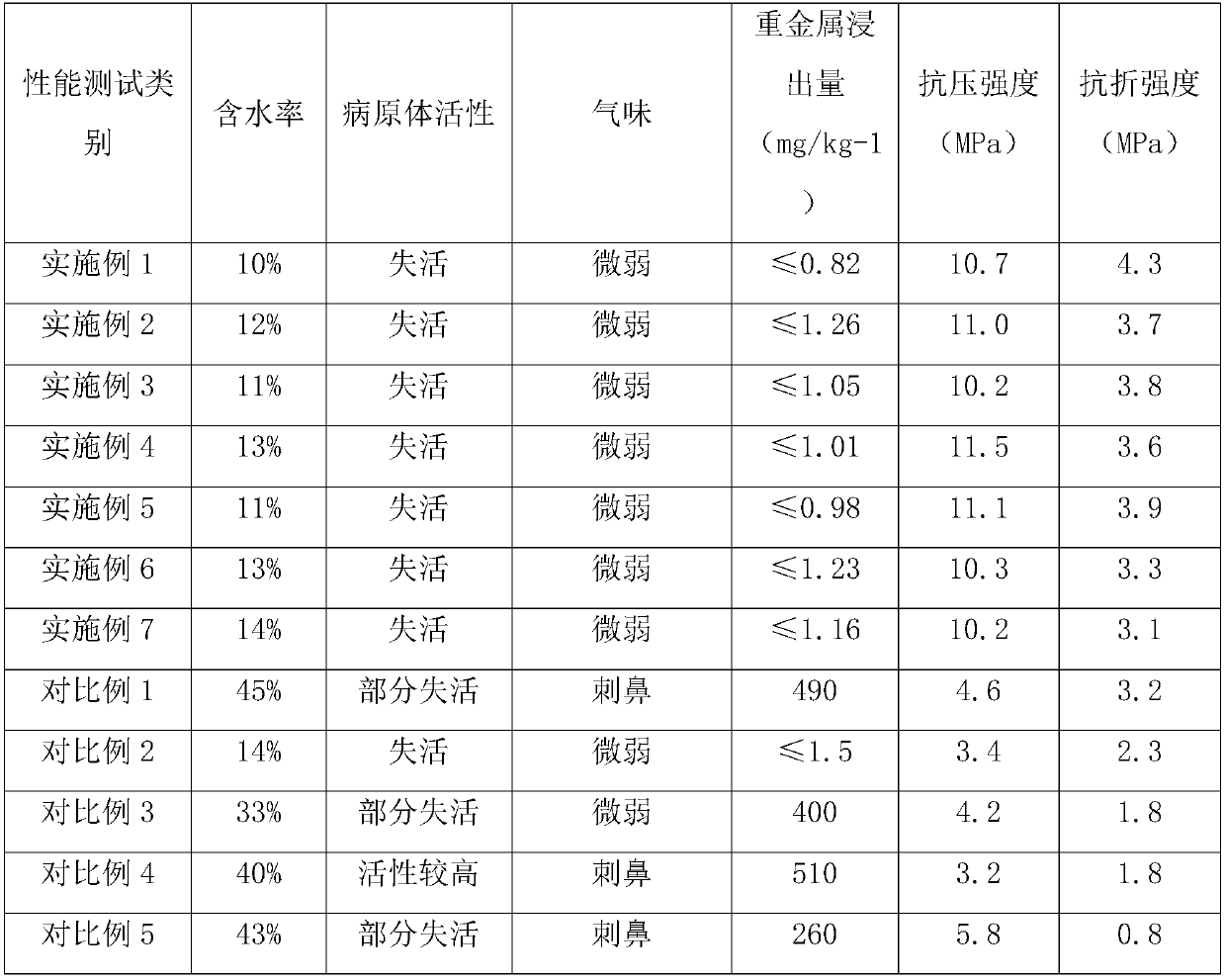

Sludge curing agent and application thereof

ActiveCN107673572AAchieve reuseAchieve solidificationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeFlexural strength

The invention discloses a sludge curing agent and application thereof. The sludge curing agent is suitable for curing treatment on high-water-content sludge in town sewage treatment plants, rivers andlakes. The sludge curing agent comprises the following raw materials in percentage by weight: 26 to 44 percent of silicon aluminum iron calcium oxide, 19 to 37 percent of calcium oxide, 13 to 30 percent of special cement, 5 to 25 percent of polyacrylamide and 0.2 to 3 percent of chitosan. The sludge curing agent realizes sludge curing and stabilization through the chemical property of the industrial waste and the mutual activity excitation; the water content of the sludge is effectively reduced, the early-stage compressive strength and the flexural strength of the sludge are improved, and mechanical operation during backfilling is facilitated; heavy metal in the sludge is adsorbed by the chitosan, organic matters are degraded, the pathogene is deactivated, pollution is reduced and stink can be eliminated; and the sludge curing agent is low in price and simple in curing process, and the cured sludge does not cause secondary pollution.

Owner:武汉鹏森环境科技有限公司

Optical scanning sensor

InactiveCN107490792AStrong converging effectIncrease the effective light-receiving areaElectromagnetic wave reradiationDriven elementLight source

The invention provides an optical scanning sensor, which comprises a light source, a light casting unit, a light receiving unit, a light receiver, a deflection unit, a curved light transmission cover, a rotation unit, and an angle encoder, wherein the deflection unit comprises a reflector and a reflector support; the rotation unit comprises a hollow part and a driving element; the light casting unit comprises a basic light casting unit, and the basic light casting unit and the light receiving unit are a transmitting-receiving coaxial optical system and are located at the same side of the reflector, and light reflected by a target area and deflected by the reflector enters the light receiver through a through hole in the hollow part; and the reflector is fixed above the rotation unit through the reflector support and rotates for 360 DEG under driving of the driving element.

Owner:BEIJING FREEMEASURE OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com