Non-cement-based inorganic anchoring bonded bar adhesive and preparation method thereof

A reinforced rubber, non-cement technology, applied in the field of anchoring materials, can solve the problems of poor moisture and heat resistance, easy to become brittle, easy to change, etc., and achieve the effect of excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

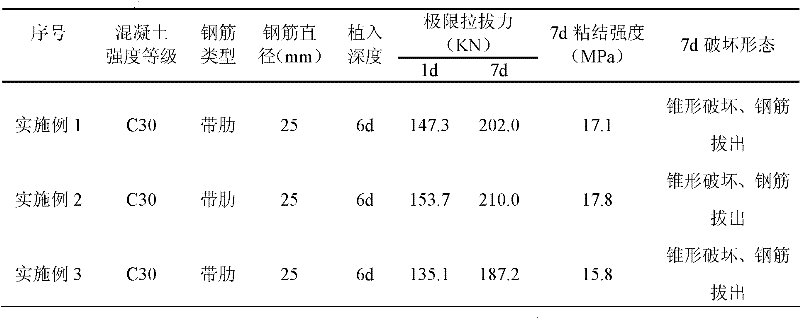

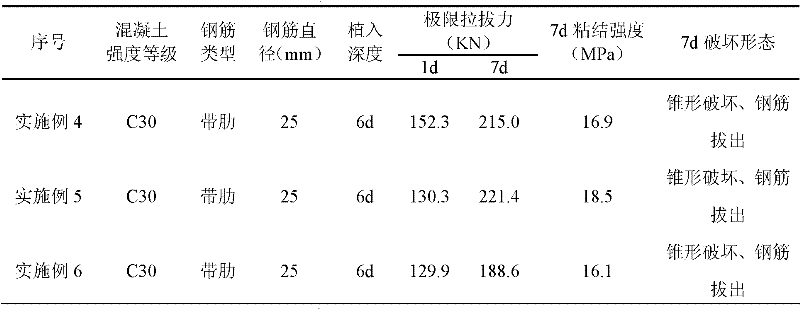

Examples

Embodiment 1

[0026] Mix 10 parts of metakaolin, 3 parts of slag powder, 5 parts of fly ash, 15 parts of heavy calcium carbonate, 50 parts of quartz sand, and 2 parts of expansion agent in a mixer for 15 minutes, and pack them for use; 60 parts of sodium silicate solution , 2 parts of industrial caustic soda, 20 parts of water, 1 part of high-efficiency superplasticizer, mix well and let stand until the emulsion is clear, pack for use; add the packaged emulsion to the powder, stir with a hand-held mixer for 5 minutes, until the glue is planted The powder and emulsion are evenly mixed to form a fluid viscous slurry, which can be used for construction.

Embodiment 2

[0028] 20 parts of metakaolin, 8 parts of slag powder, 5 parts of heavy calcium carbonate, 80 parts of quartz sand, and 1 part of expansion agent were mixed in a mixer for 30 minutes, and packed for use; 60 parts of industrial sodium silicate, 10 parts of industrial caustic soda, Mix 10 parts of water evenly and let it stand until the emulsion is clear, pack it for use; add the packaged emulsion to the powder, and stir with a hand-held mixer for 5 minutes until the planting rubber powder and emulsion are evenly mixed to form a fluid viscous slurry The body can be constructed.

Embodiment 3

[0030] Mix 15 parts of metakaolin, 3 parts of slag fine powder, 2 parts of fly ash, 10 parts of heavy calcium carbonate, and 70 parts of quartz sand in a mixer for 30 minutes, and pack them for use; mix 40 parts of sodium silicate solution, 8 parts of phosphoric acid Sodium solution, 8 parts of industrial caustic soda, 11 parts of water, and 1 part of admixture (superplasticizer) are mixed evenly and packaged for use; add the packaged emulsion to the powder, and stir for 5 minutes with a hand-held mixer until the glue is planted Mix the powder and emulsion evenly to form a fluid viscous slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com