Preparation method of high-transmittance self-healing ionic liquid gel with good mechanical properties

An ionic liquid, self-healing technology, applied in the field of preparation of ionic liquid gel, can solve the problems of low tensile strength and elongation at break, insufficient light transmittance of ionic gel, insufficient mechanical properties, etc., and achieve high fracture Elongation, excellent self-healing function, the effect of accelerating the rate of initiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

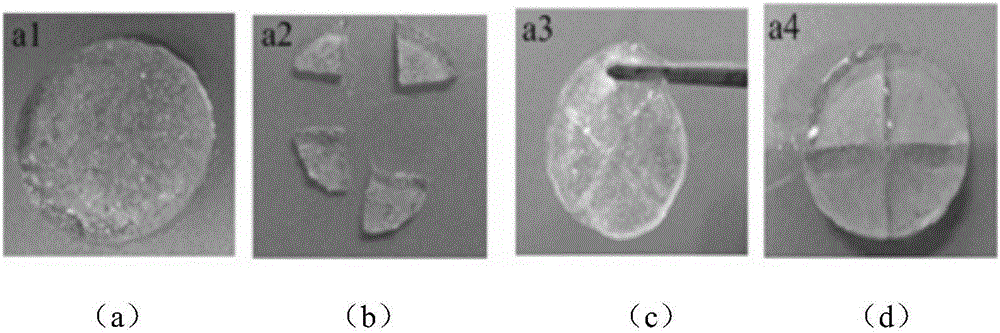

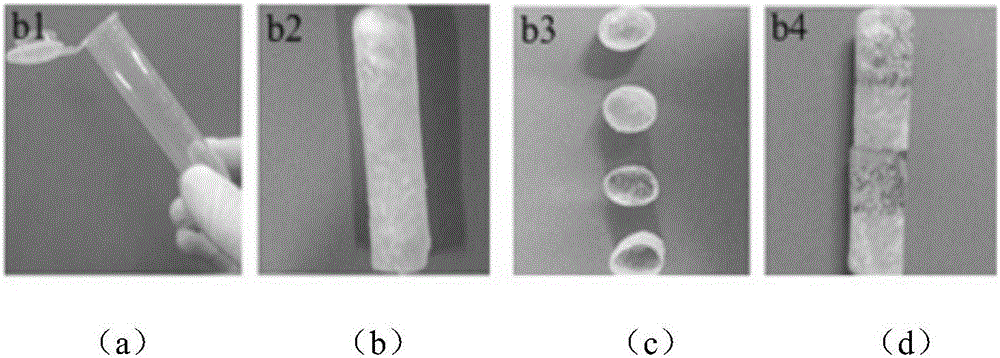

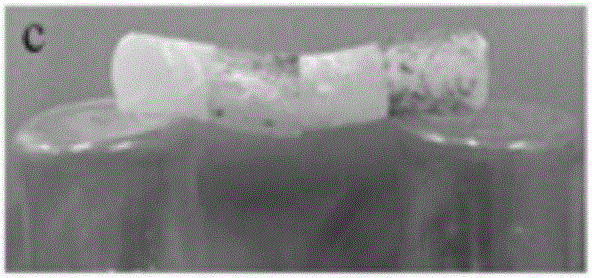

Examples

Embodiment 1

[0041] Using 1-ethyl-3-methylimidazolium ethyl sulfate as the ionic liquid filling solution, add N,N-dimethylacrylamide (DMAA) and α-ketoglutaric acid to it, stir and mix well, Put it into a small flask connected with a nitrogen bottle and an exhaust tube, alternately perform the pumping and inflation process to eliminate the oxygen in the system, then put it into a glass mold or a transparent plastic mold, and irradiate it under an ultraviolet lamp for 2 hours to initiate free radical gathering After the reaction, the ionic liquid gel with a tensile strength of 0.35 MPa, an elongation at break of 3000% and a light transmittance of 94% can be obtained. Wherein, DMAA is 33% of the total mass of 1-ethyl-3-methylimidazole ethyl sulfate, DMAA and α-ketoglutaric acid, and the amount of α-ketoglutaric acid is 0.5% of the amount of DMAA substance.

Embodiment 2

[0043] Use 1-ethyl-3-methylimidazolium ethyl sulfate as the ionic liquid filling solution, add N-hydroxyethylacrylamide (HEAA) and 2-hydroxy-methyl phenylacetone to it, and stir and mix thoroughly, Put it into a small flask connected with a nitrogen bottle and an exhaust tube, alternately perform the process of pumping and inflating to eliminate the oxygen in the system, then put it into a glass mold or a transparent plastic mold, and irradiate it under an ultraviolet lamp for 4 hours to obtain The tensile strength is 0.38MPa, the elongation at break is 2800%, and the light transmittance is 93% of the ionic liquid gel. Wherein, the amount of HEAA is 36% of the total mass of 1-ethyl-3-methylimidazolium ethyl sulfate, HEAA and 2-hydroxy-methyl phenylacetone. The amount of 2-hydroxy-methylpropiophenone was 1% of the amount of substance of HEAA.

Embodiment 3

[0045] With 1-ethyl-3-methylimidazolium ethyl sulfate salt as the ionic liquid filling liquid, add monomer and 2-methyl-2-(4-morpholinyl)-1-[4-(methylsulfide) Base) phenyl]-1-acetone, after fully stirring and mixing, put it into a small flask connected with a nitrogen bottle and an exhaust tube, and alternately perform the process of exhausting and inflating to eliminate the oxygen in the system, and then add a glass mold or Put it in a transparent plastic mold and irradiate it under an ultraviolet lamp for 2 hours to obtain an ionic liquid gel with a tensile strength of 0.65 MPa, an elongation at break of 2000%, and a light transmittance of 95%. Among them, the quality of the monomer is 1-ethyl-3-methylimidazole ethyl sulfate salt, monomer, 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio) 45% of the total mass of phenyl]-1-propanone.

[0046] The monomer is a mixture of N,N-dimethylacrylamide (DMAA), N-methylolacrylamide (HMAA) and N-hydroxyethylacrylamide (HEAA) in any proporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com