Sludge curing agent and application thereof

A curing agent and sludge technology, which is applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of landfill engineering geological disasters, high pollutant content and high treatment costs , to achieve the effect of reducing stacking area, reducing pollution and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

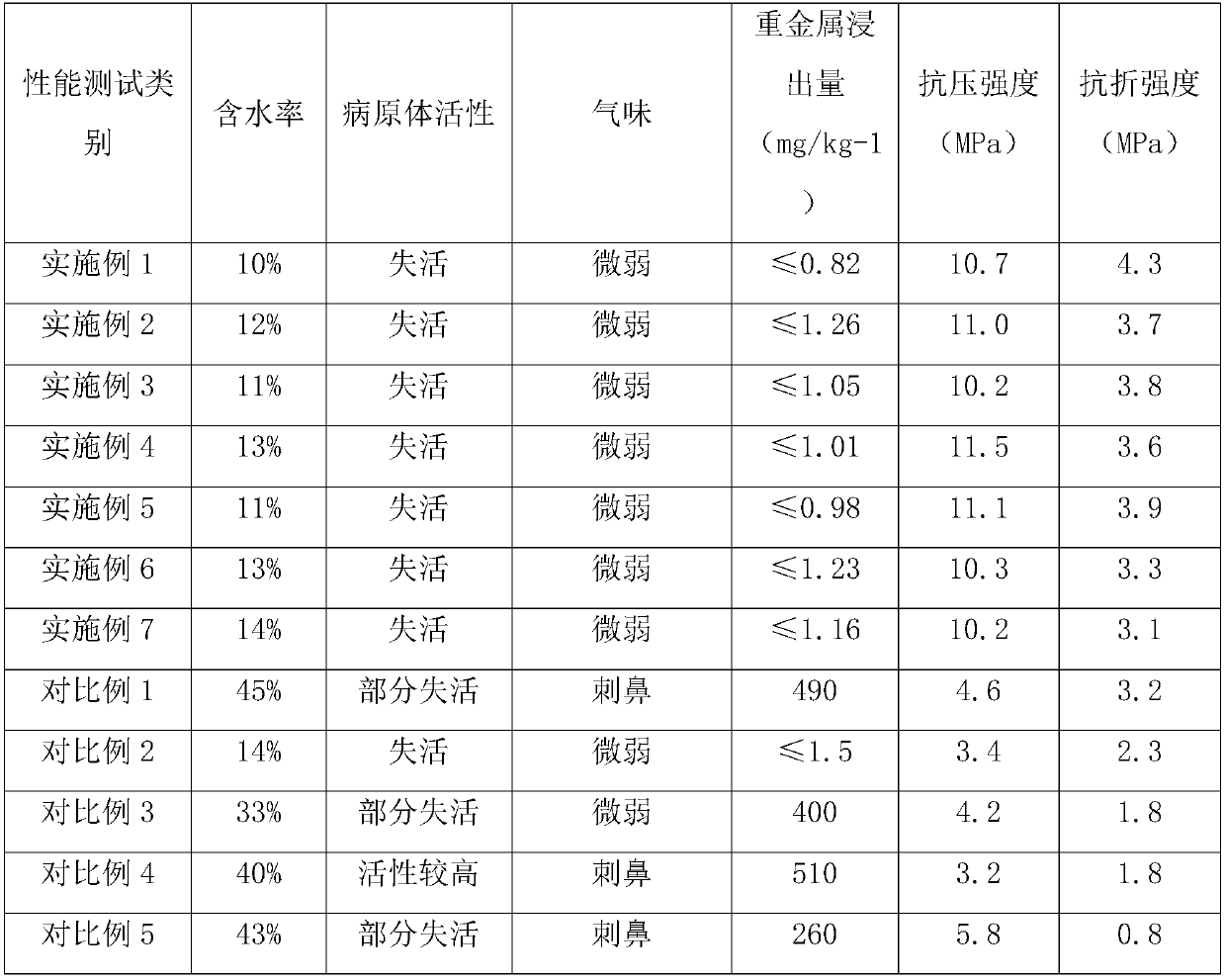

Examples

Embodiment 1

[0038] A sewage sludge curing agent comprises the following raw materials in weight percentage: 35.4% of silicon-aluminum-iron-calcium oxide; 28.3% of calcium oxide; 21.3% of special cement; 14.2% of polyacrylamide;

[0039] Wherein, the silicon-aluminum-iron-calcium oxide is formed by mixing fly ash and fine coal slag at a mass ratio of 1:1.

[0040] The particle size of the polyacrylamide is 0.6-1mm, the particle size of the silicon-aluminum-iron-calcium oxide is ≤1mm, and the specific surface area of the special cement is ≧350m 2 / kg.

[0041] The application of the sludge solidifying agent comprises the following steps: adding 14.1% by mass percentage of the sludge solidifying agent to the water-containing sludge and stirring evenly; extruding with a plate and frame filter press under a pressure of 30 MPa to realize solid-liquid separation.

Embodiment 2

[0043] A kind of sewage sludge curing agent and application thereof, compared with Example 1, the difference is that the addition ratio of the sewage sludge curing agent accounts for 11% of the total weight of the water-containing sludge, and the silicon-aluminum-iron-calcium oxide is powder Coal ash and fine coal cinder are mixed in a mass ratio of 1:1.5.

Embodiment 3

[0045] A kind of sewage sludge curing agent and application thereof, compared with Example 1, the difference is that the addition ratio of the sewage sludge curing agent accounts for 20% of the total weight of the water-containing sludge, and the silicon-aluminum-iron-calcium oxide is coal gangue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com