Mud curing agent

A technology of mud curing agent and curing agent, which is applied in the field of construction materials, can solve problems such as unsatisfactory requirements, and achieve good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

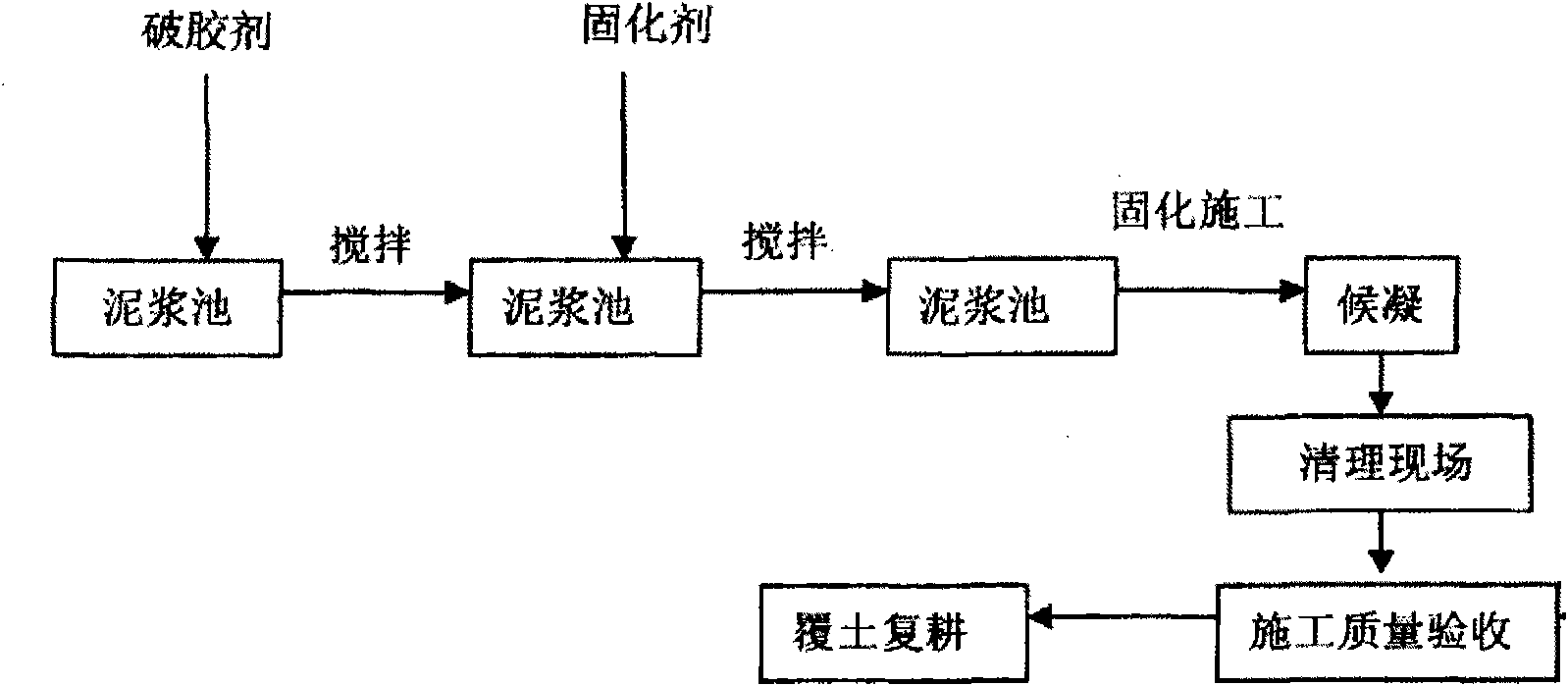

Method used

Image

Examples

Embodiment Construction

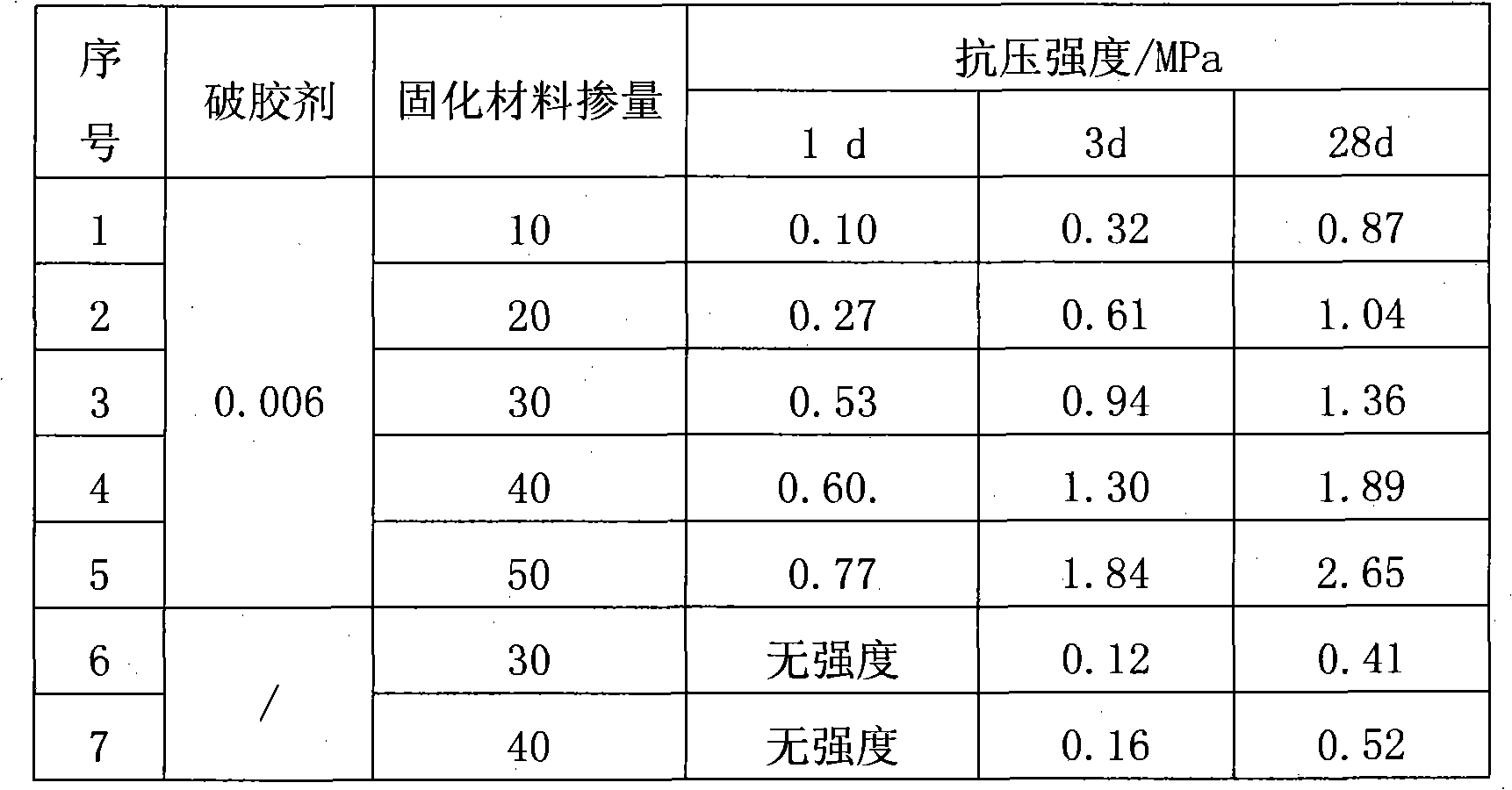

[0020] On-site mud specific gravity is 1.2g / cm 3 , the water content is 217%, and the breaker Al is added before the mud is solidified 2 (SO4) 3 , its concentration is 10%, and the dosage is 6 / 1000 (mass ratio of mud). Use a mechanical stirring device to stir the mud after adding the gel breaker evenly. After the mud colloidal system is destroyed (the solid and liquid in the mud have been separated), add the mud curing material for curing treatment. The amount of the mud curing material is 20% ~ 50% (mud Mass ratio), and then use a mechanical stirring device to stir the mud after adding the solidified material evenly, and after solidification, cover the soil and plow it or carry out other construction operations such as bracket erection.

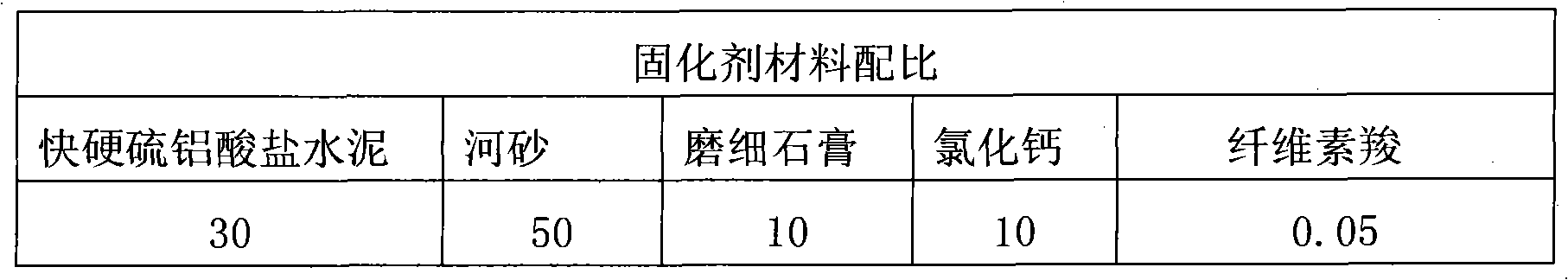

[0021] Table 1 is the ratio of mud curing materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com