Surface exposure forming device of high viscosity material

A molding device and high-viscosity technology, applied in the direction of additive processing, etc., can solve the problems of application limitation of light-curing molding technology, difficult to precisely control layer thickness, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

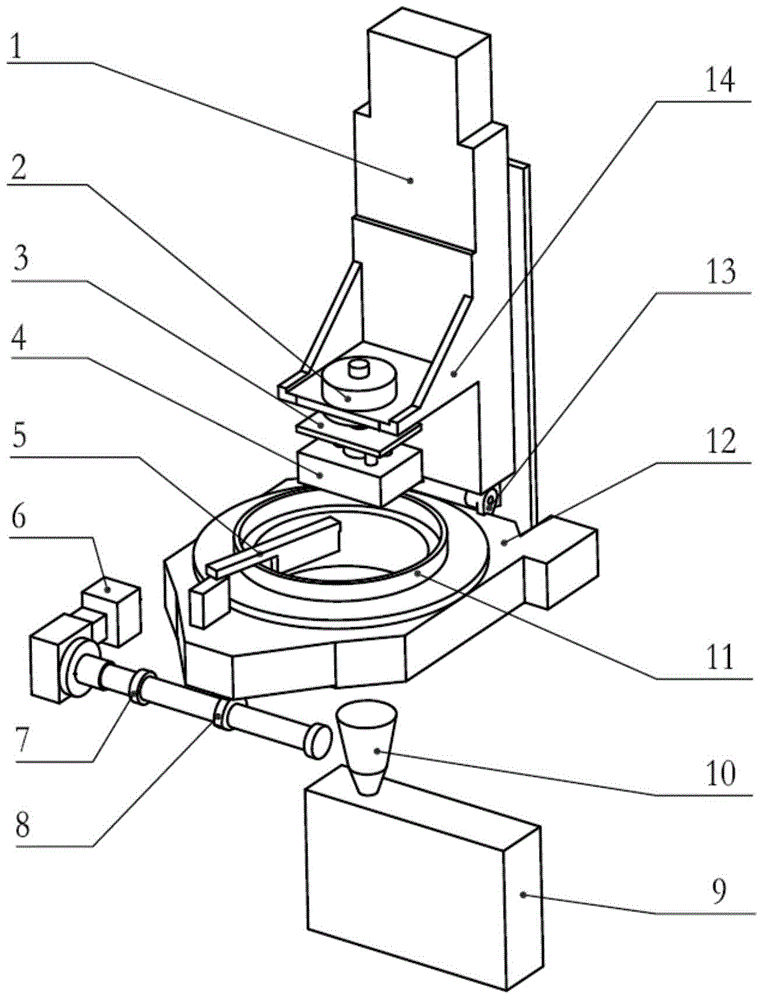

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

[0021] The overall axonometric view of the present invention is as figure 1 As shown, the surface exposure molding device for this high-viscosity material has a Z-axis translation table 1, which is fixed on the frame and is perpendicular to the frame reference plane. A workbench support 14 is fixed on the Z-axis translation platform 1 . 14 on the workbench support is connected with pull pressure sensor 2, precision tilter 3, workbench 4. Among them, the function of the tension pressure sensor 2 is to monitor the pulling force on the workbench 4 generated during delamination during the molding process, and to prevent the workbench 4 or the formed parts on it from colliding with the material during the descending process of the Z-axis translation platform 1 The function of groove 11. The high viscosity is 3000 mPas - 20000 mPas.

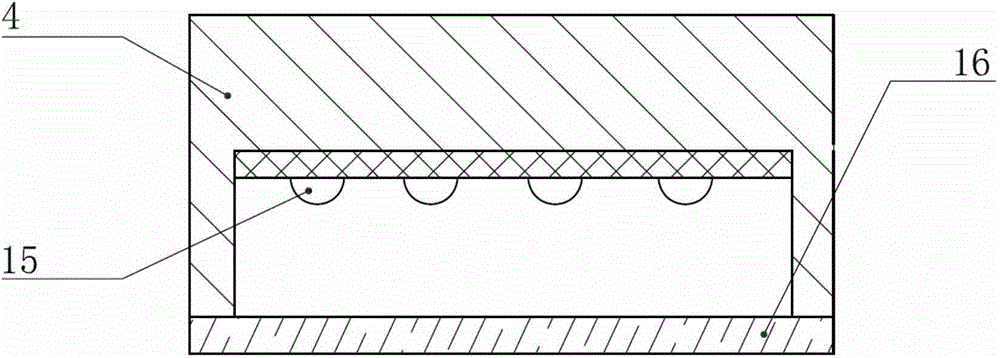

[0022] like figure 2 , the workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com