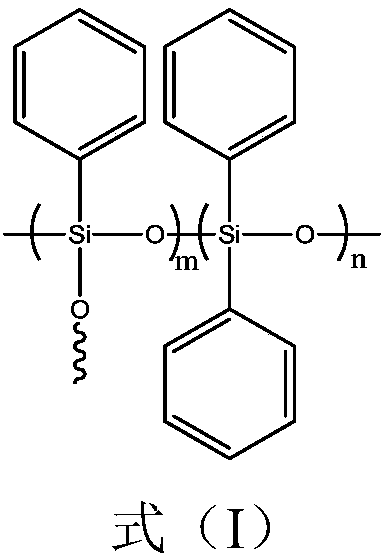

Composition containing high-phenyl-group polysiloxane, and packaging material or optical thin film comprising the composition

A high phenyl polysiloxane, polysiloxane technology, used in electrical components, circuits, semiconductor devices and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

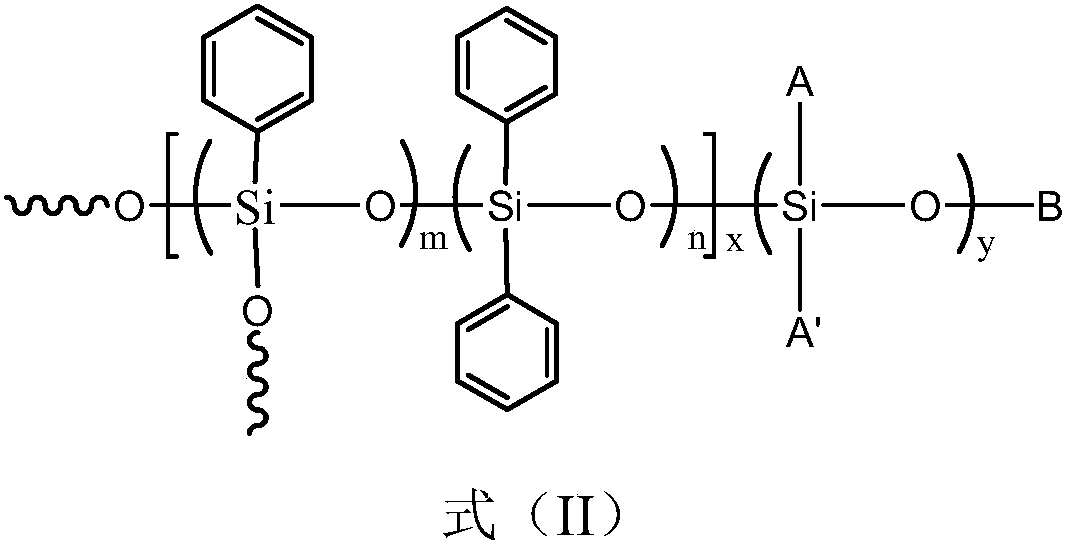

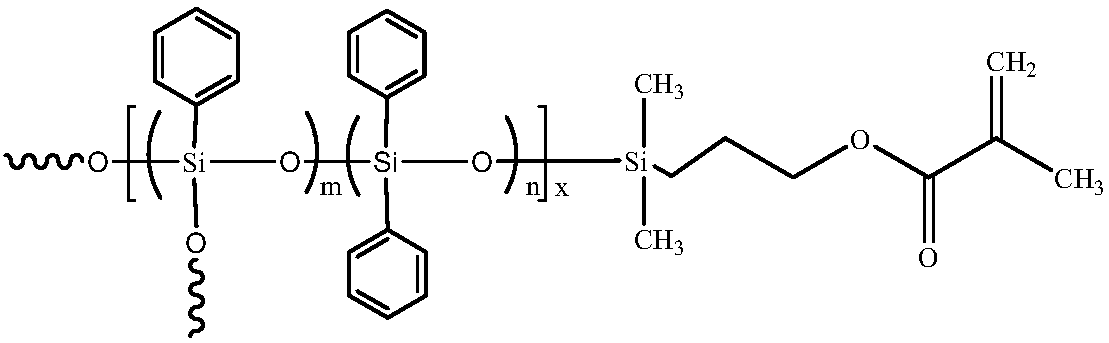

[0099] High phenylpolysiloxane (II-1) was prepared from diphenylsilanediol, phenyltrimethoxysilane, methacryloxypropyldimethylmethoxysilane.

[0100] (1) Under the protection of dry nitrogen, put 50ml of phenyltrimethoxysilane in a multi-necked flask equipped with a condenser tube and a dropping funnel, and mix 10 grams of diphenylsilanediol and 80 The mixed solution of 1.5 grams of tetrahydrofuran was added in batches to a multi-neck bottle, and ammonia gas was introduced at the same time; the reaction was stopped for 3 hours, and the ammonia gas was stopped, and the temperature was gradually raised to remove ammonia; after the reaction was stopped, distillation was concentrated and purified to obtain 20wt% siloxane intermediate solution;

[0101] (2) Add 10 grams (0.56 moles) of water to the siloxane intermediate solution in step (1), adjust the pH value of the system with ammonia water to 8; stir at 25°C to 80°C for 24 hours; remove the water from the reaction mixture , pu...

Embodiment 2

[0112] The high phenylpolysiloxane (II-1) obtained in Example 1 is added to methylphenyl silicone oil (methacryloyloxy terminated), photoinitiator 2-hydroxyl-2-methyl-1- Phenylacetone, antioxidant Irganox-1076, antioxidant Irgafos-168, and UV curing to prepare films.

[0113] 1 gram of high phenyl polysiloxane (II-1), 0.25 gram of methyl phenyl silicone oil (methacryloxy-terminated), 0.0125 g of initiator 2-hydroxyl-2-methyl-1 -Phenylacetone, 0.05g of antioxidant Irganox-1076, and 0.0125g of antioxidant Irgafos-168 were mixed evenly. The homogeneously mixed composition was placed at room temperature, and vacuumized in a vacuum drying oven for 30 minutes to remove air bubbles. After vacuum defoaming, it is placed in a mold. Under a high-pressure mercury lamp with a dominant wavelength of 365 nm and a nitrogen atmosphere, irradiate for 15 minutes to cure, and prepare a transparent film material with a thickness of 1 mm.

[0114] By FT-IR spectrogram, different from the high p...

Embodiment 3

[0120] Preparation of materials for LED chip packaging.

[0121] Add the phosphor powder (YGG-530, China Minmetals Corporation) of 10wt% (0.1325g) to the composition described in Example 2, drop it on the dried LED chip after defoaming, and the main wavelength is 365nm Irradiate under a high-pressure mercury lamp for 15 minutes to cure, and prepare the material for LED chip packaging.

[0122] According to the characterization result of the light extraction efficiency, the light extraction efficiency is 142lm / W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com