Novel mucky soil composite curing agent

A composite curing agent and silty soil technology, applied in fertilizer mixtures, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of insignificant increase in shear strength, low tensile strength and low flexural strength of soil , to achieve superior flexural performance, high shear strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

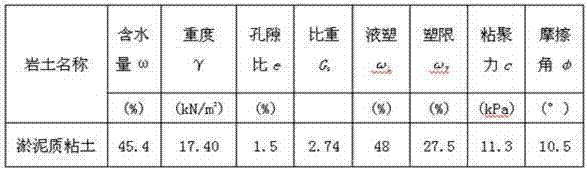

[0021] The soil is silty clay, and its performance indicators are shown in Table 1

[0022] Table 1 Physical and mechanical indexes of muddy soil samples

[0023]

[0024] Before the test, pass the soil sample through a 2mm sieve to remove impurities, weigh part of the sieved soil sample, and add 5% humic acid of the soil sample mass (humic acid is a main indicator that distinguishes organic soil from inorganic soil, adding humic acid The purpose of uric acid is to prepare different organic matter soils) into the sieved residual soil samples, and stir evenly to make organic matter soils for testing.

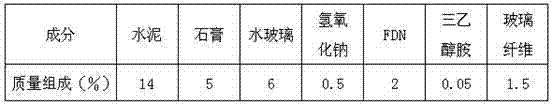

[0025] Table 2 Components of the new muddy soil composite curing agent

[0026]

[0027] Weigh 500g of the prepared organic matter soil sample, add curing agent according to the ratio in Table 2, stir the mixture evenly to make 3 cylinder parallel samples with a diameter of 39.1mm and a height of 80mm, standard curing, the average non-side The ultimate compressive strengt...

Embodiment 2

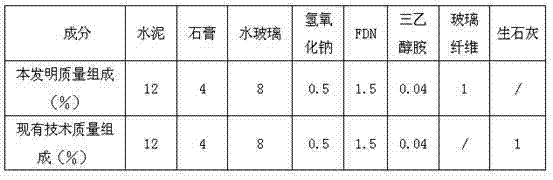

[0029] Table 3 Components of the new muddy soil composite curing agent

[0030]

[0031] Weigh 500g of the prepared organic matter soil sample, add curing agent according to the ratio in Table 3, stir the mixture evenly to make three parallel cylinder samples with a diameter of 39.1mm and a height of 80mm, standard curing, the average sideless The ultimate compressive strength can reach 0.932MPa, and the average unconfined compressive strength of 60 days can reach 1.734MPa.

Embodiment 3

[0033] Table 4 Components of new muddy soil composite curing agent

[0034]

[0035] Weigh 500g of the prepared organic matter soil sample, add curing agent according to the ratio in Table 4, stir the mixture evenly to make 3 cylindrical parallel samples with a diameter of 39.1mm and a height of 80mm, standard curing, and the average no-side The limited compressive strength can reach 1.052MPa, and the average unconfined compressive strength for 60 days can reach 1.950 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com