Patents

Literature

1447results about How to "Small water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

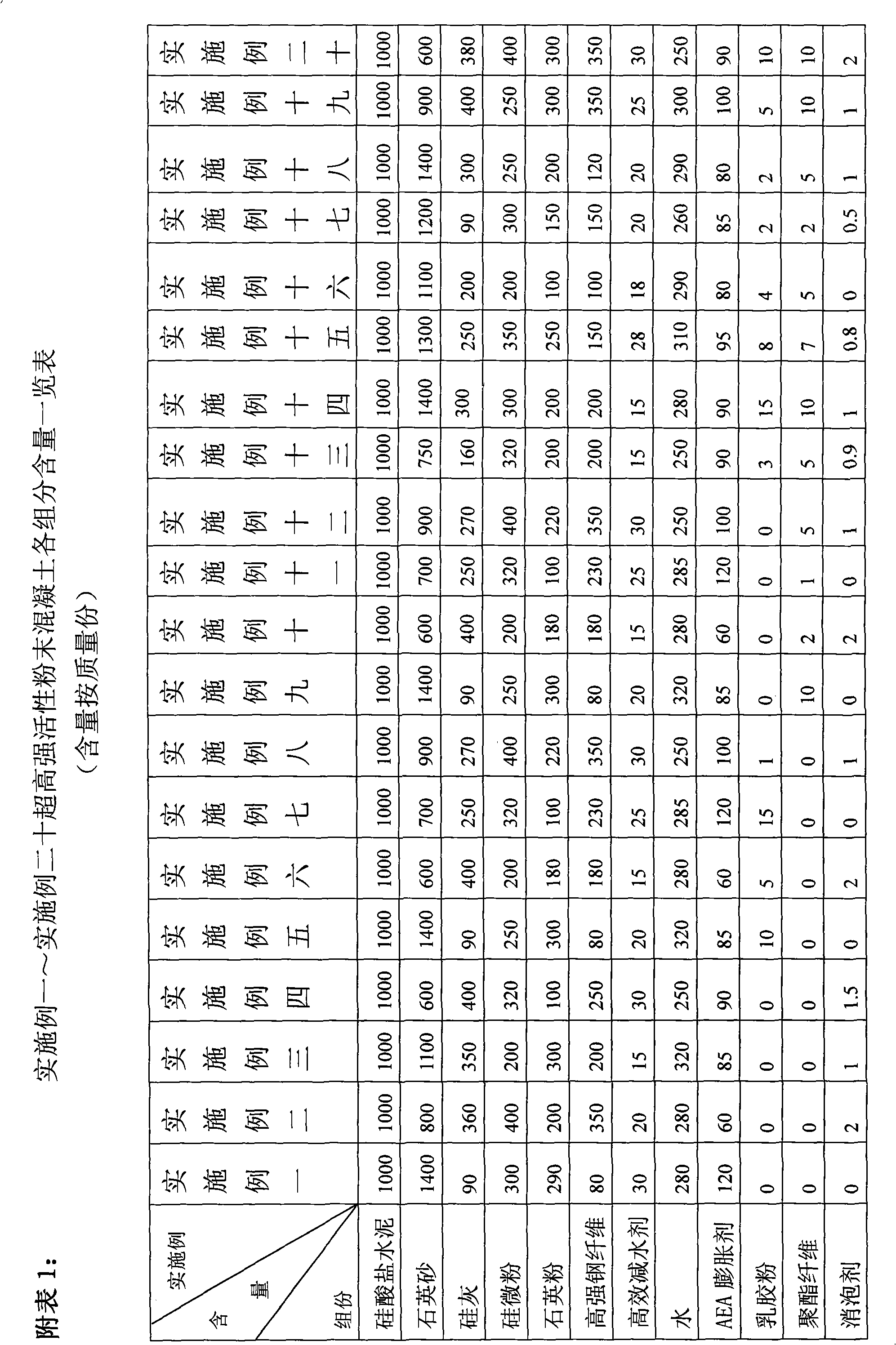

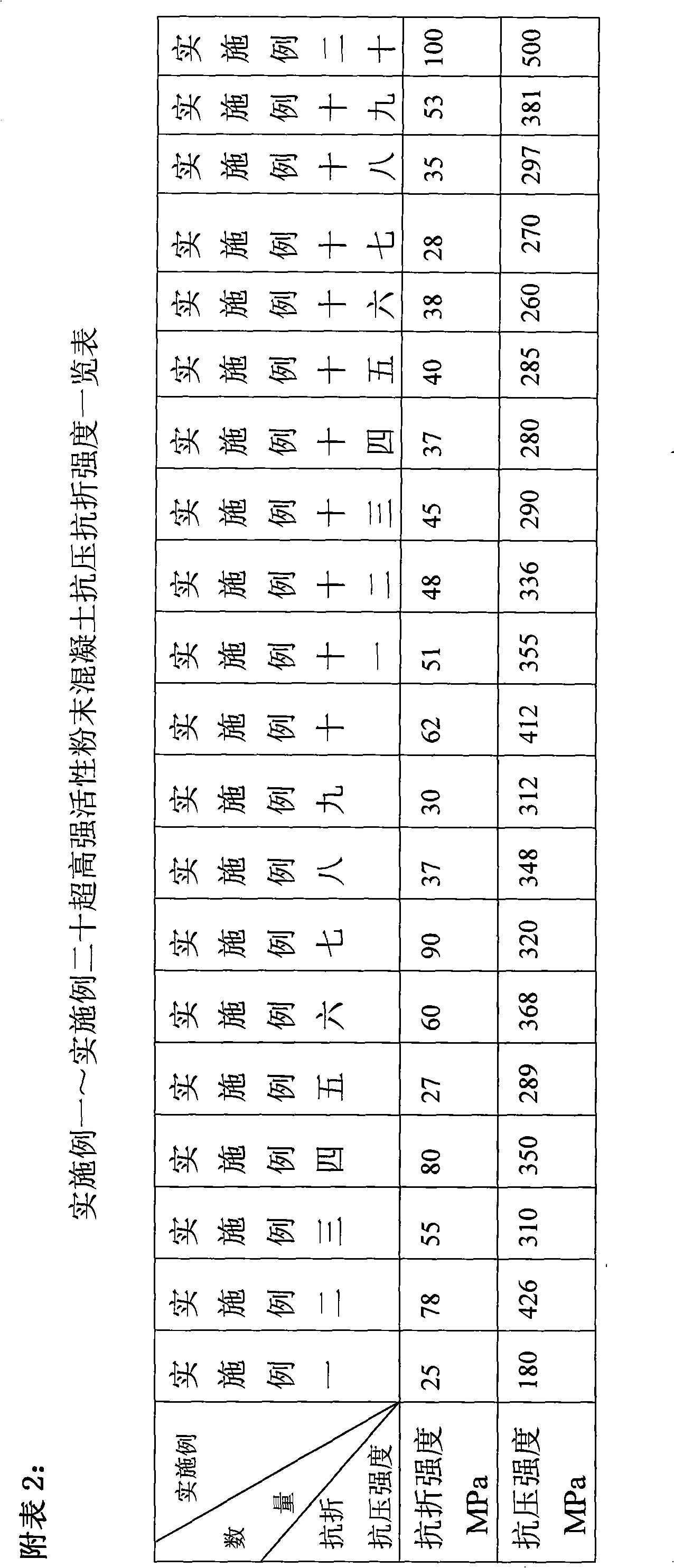

Ultrahigh-strength active powder concrete and preparation method thereof

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

Halogen-less high frequency resin composition, and prepreg and laminate manufacturing by using same

ActiveCN101684191ALow heat resistanceImprove heat resistanceSynthetic resin layered productsWoven fabricsStyrene maleic anhydrideAbsorbance

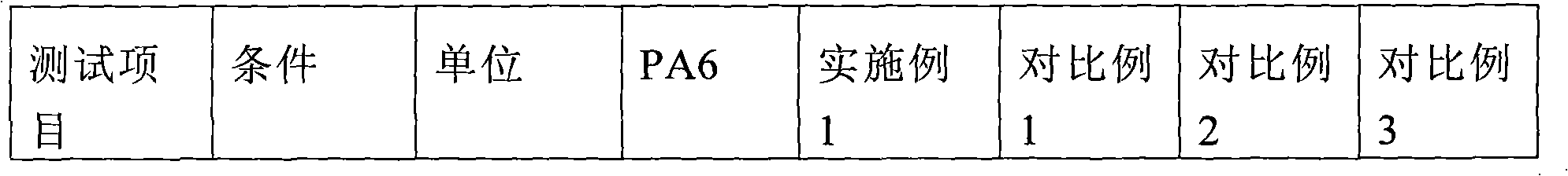

The invention relates to a halogen-less high frequency resin composition, and a prepreg and a laminate manufactured by using the same. The halogen-less high frequency resin composition comprises the following components based on weight part of the organic solids: (A) 10 to 50 parts of styrene-maleic anhydride oligomer; (B) 10 to 50 parts of at least one compound containing dihydro-benzoxazine ring; (C) 10 to 50 parts of at least one polyepoxide; and (D) 5 to 30 parts of at least one phosphorus-containing flame retardant. The prepreg and the laminate manufactured by using the halogen-less highfrequency resin composition has low dielectric constant, low dielectric loss factor, high glass transition temperature, good heat resistance, low water absorbance, and simple and convenient technological operation.

Owner:GUANGDONG SHENGYI SCI TECH

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

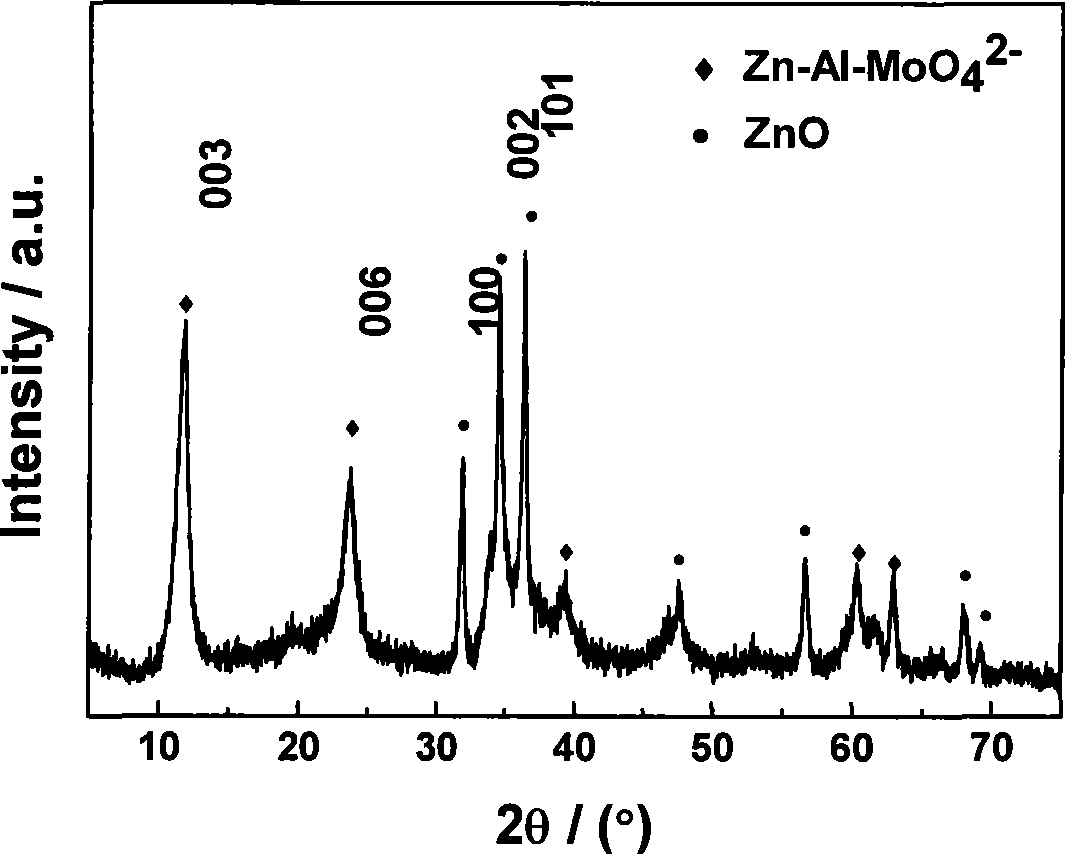

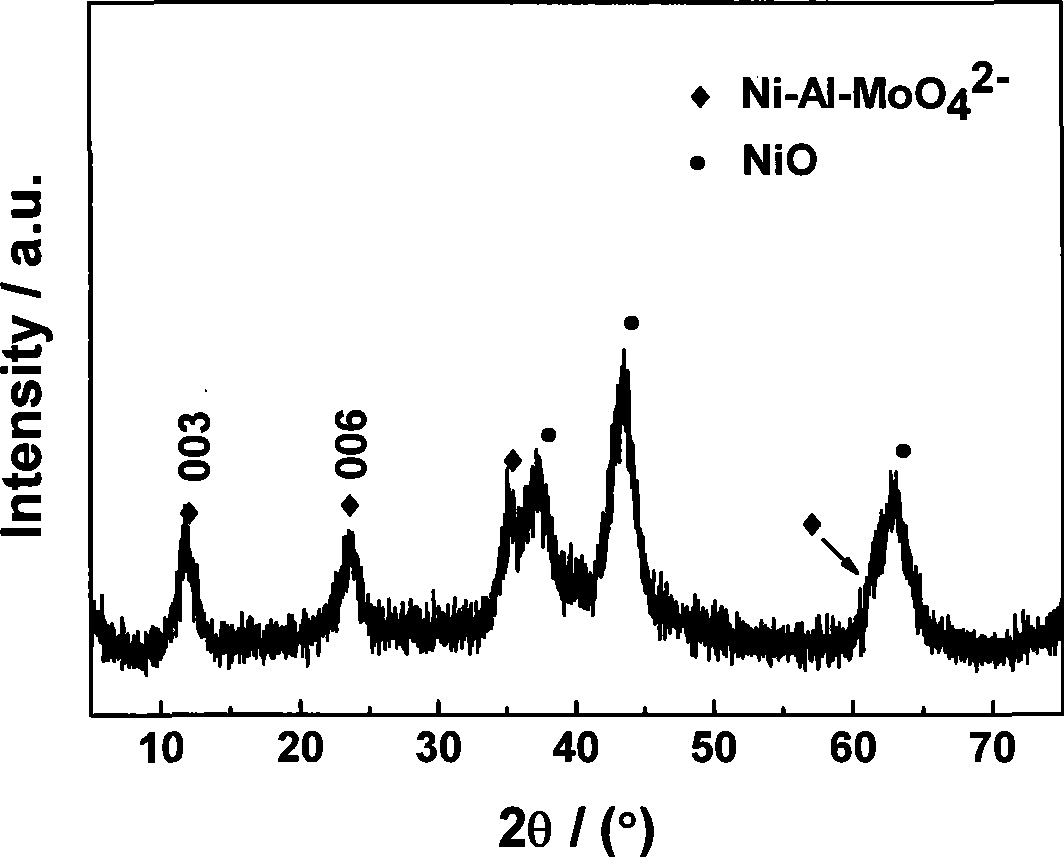

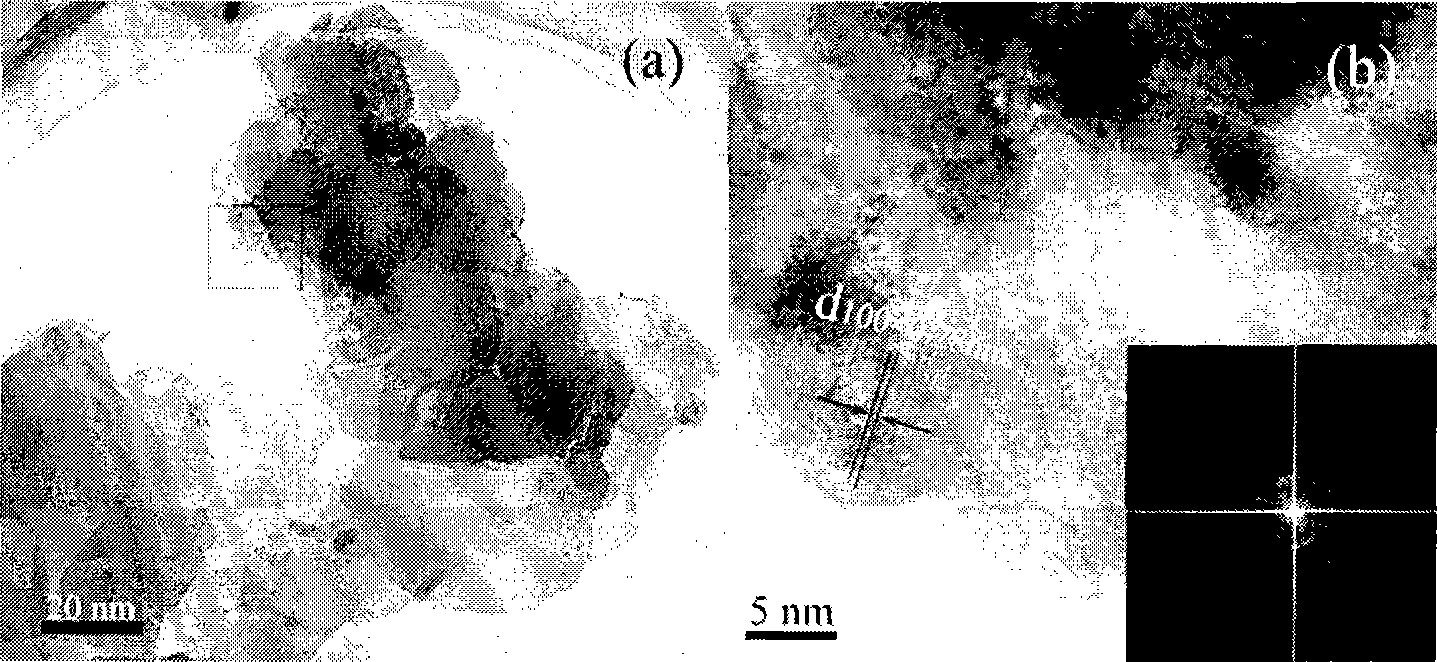

Method for preparing corrosion inhibition anion intercalated layered double hydroxides/oxide composite material and application

InactiveCN101418154AFacilitated releaseImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOxide compositeReaction temperature

The invention provides a corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material, a preparation method thereof and application of the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material. The preparation method is as follows: corrosion-inhibiting anions are directly inserted between hydrotalcite layers by the one-step coprecipitation method and the roasting restoring method; the nano oxide is generated by means of in situ synchronization during the process of generation of hydrotalcite crystals by controlling the mixture ratio of divalent metal ions to trivalent metal ions, the pH value of a reaction solution and the reaction temperature; and the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material with the anti-corrosive function is prepared. The invention is mainly characterized in that the in situ preparation method for the hydrotalcite / oxide composite material provided with a nano lamellar structure improves the release amount of a corrosion inhibitor and reduces the water absorption of a coating by leading into the corrosion inhibitor with the anti-corrosive function and the nano oxide which is generated in situ during the reaction process. The composite material can be used to be pigment of an anti-corrosive metallic coating system, and particularly has potential application value in improving the anti-corrosive performance of a magnesium alloy anti-corrosive coating.

Owner:HARBIN ENG UNIV

Thermo-setting acrylic-acid emulsion, its preparing method and paint containing same

This invention discloses a thermoset crylic acid latex and its preparation method and a corrosion resistant bottom coat containing such latex and used in the Al fins of the heat converter of air conditioners, in which, said latex includes a crylic acid kind monomers, an ionic vinyl monomers, an ethene monomers, a vinyl silane coupler, a crosslink monomers, a surface active agent and an initiator to be got by seed latex and semi-continuous drop technology. Said bottom coat includes said thermoset crylic acid latex, water-base coating resin, water-base cross-linker, booster solvent, neutralization agent, a water-base adhesive force accelerant, a catalyst and water.

Owner:GUANGZHOU HUMAN CHEM

Solvent-free polyurethane adhesive for compound film

ActiveCN101503611ANo pollution in the processImprove securityPolyureas/polyurethane adhesivesPolyesterComposite film

The invention discloses a solvent-free polyurethane adhesive for a composite film, which consists of an A component and a B component, wherein the A component is end-OH polyester polyol, and the B component is end NCO-polyurethane prepolymer; and the A component and the B component are mixed in the molar ratio of functional groups of NCO to OH being 1.2-1.9:1.0. The polyurethane adhesive for the composite film does not need to adopt solvent and has high safety. The adhesive shows low hydroscopic property as well as low hydrolysis and high shock strength due to introducing dimeric dibasic acid, and shows good adhesive property for some substrates which are particularly difficult to adhere and attach. The invention improves the adhesive strength of the composite film through the design of compositions and a molecular structure of the adhesive, the T peeling strength reaches more than 3.8N / 15mm after the plastic films are compounded for 3 to 5 days, and the T peeling strength between the plastic and an aluminum-plating film reaches more than 4.2N / 15mm.

Owner:黄山万丽美油墨科技有限公司

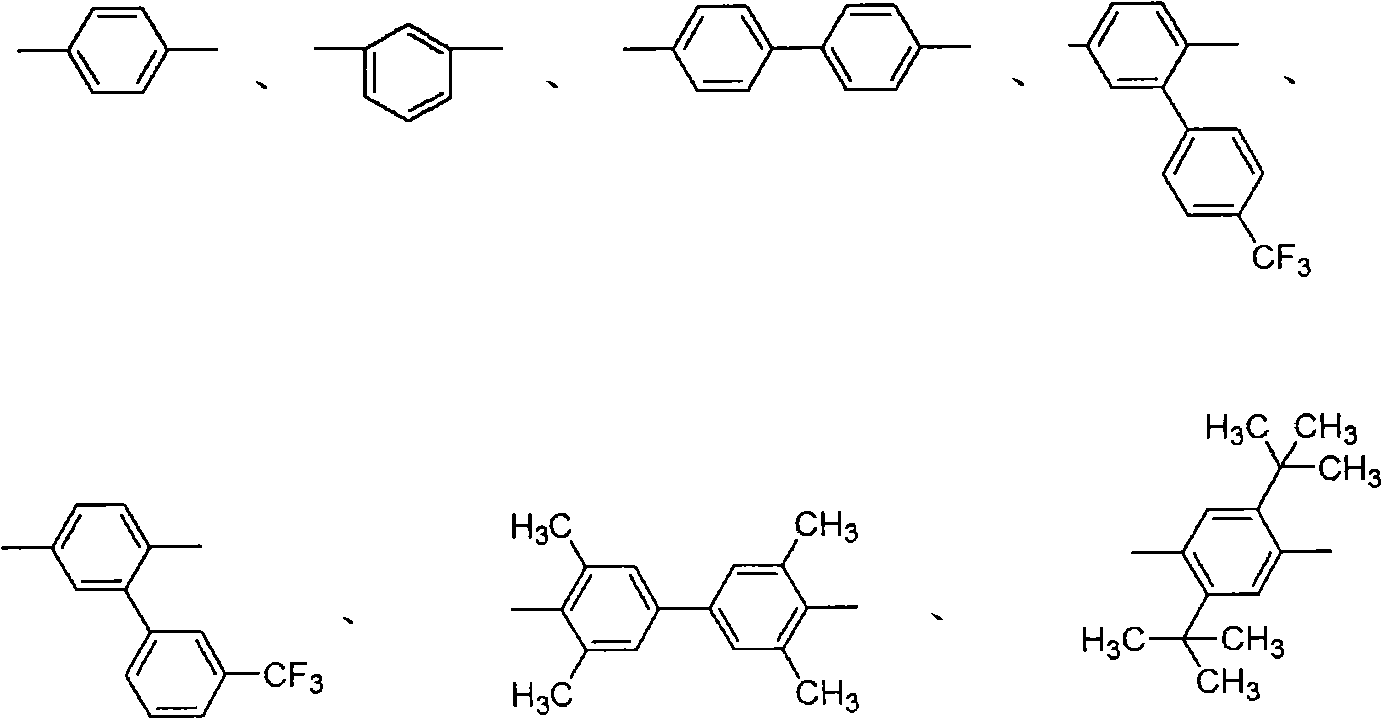

Epoxy resin composition and high-frequency circuit board manufactured thereby

InactiveCN102504201AExcellent dielectric propertiesLow dielectric propertiesCircuit susbtrate materialsSolid componentCopper foil

The invention relates to an epoxy resin composition and a high-frequency circuit board manufactured thereby. The epoxy resin composition comprises the following solid components: (A) cyanate compound or prepolymer thereof, wherein the molecule of the cyanate compound contains at least two cyanato groups; (B) active ester; and (C) epoxy resin containing a naphthol structure; calculated in solid component in parts by weight, the total amount of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, and the component (B), i.e. active ester, is 10-70 parts by weight, and the amount of the component (C), i.e. epoxy resin containing naphthol structure, is 30-90 parts by weight, wherein the weight ratio of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, to the component (B), i.e. active ester, is (0.2-5):1. The high-frequency circuit board manufactured by using the epoxy resin composition of the invention comprises a plurality of layers of prepregs which are overlapped mutually, and copper foils which are compressed on the two sides respectively; and each of the plurality of layers of prepregs comprises a base material and the epoxy resin composition which is adhered to the base material through impregnation and drying.

Owner:GUANGDONG SHENGYI SCI TECH

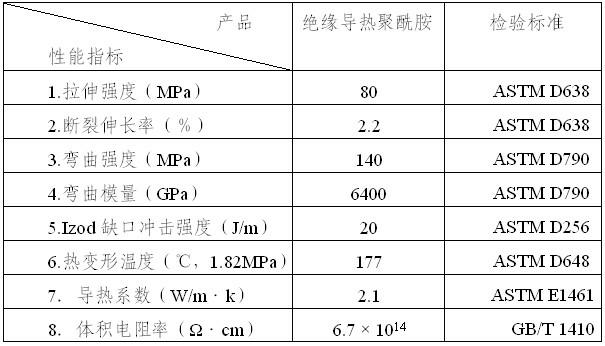

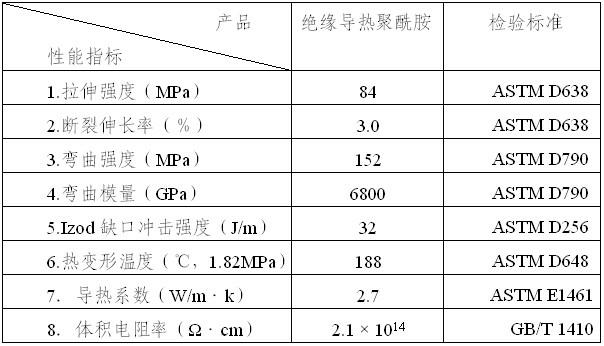

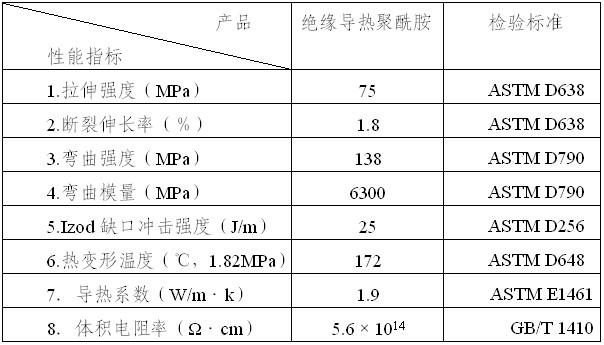

Insulating and heat-conducting polyamide composite material and preparation method thereof

The invention relates to an insulating and heat-conducting polyamide composite material, which is prepared from the following components in part by weight: 60 to 90 parts of polyamide (PA) resin, 10 to 40 parts of polyphenylene sulfide (PPS) resin, 30 to 100 parts of lamellar heat-conducting filler, 10 to 80 parts of whisker-like heat-conducting filler, 1 to 10 parts of nanometer heat-conducing filler, 10 to 20 parts of glass fiber, 1 to 3 parts of coupling agent, 0.2 to 0.5 part of antioxidant and 0.5 to 2 parts of processing aid. The polyamide composite material prepared according to the formula has high heat-conducting property and thermalphysical and mechanical properties.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

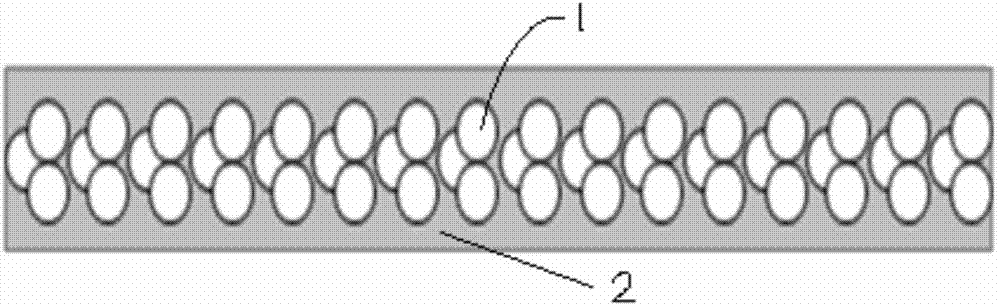

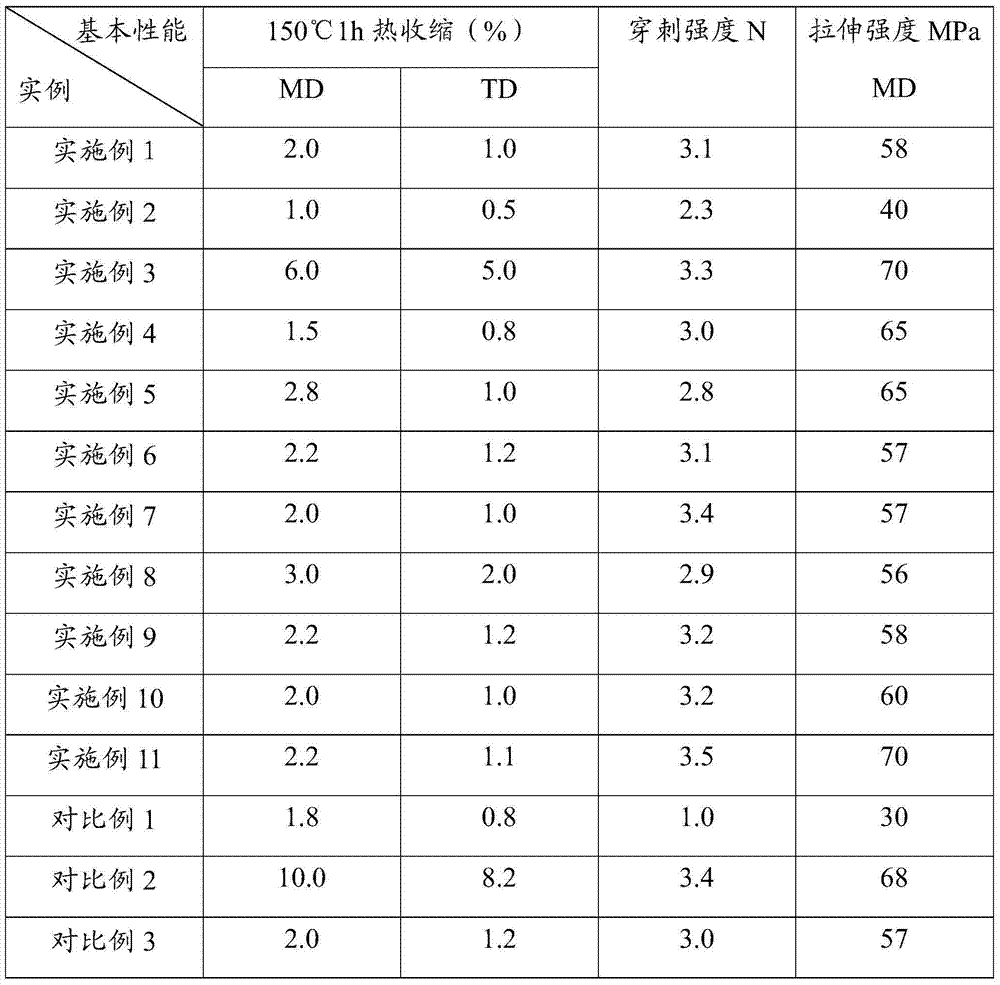

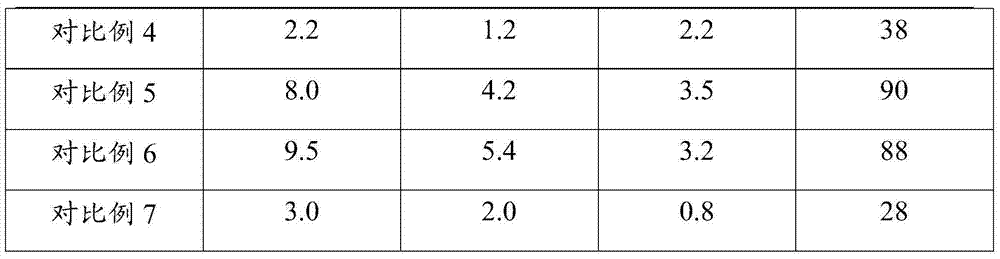

Novel modified non-woven fabric lithium-ion battery diaphragm and preparation method thereof

ActiveCN103928649AEnsuring Winding ProcessabilityEnsuring satisfactory winding processabilityFinal product manufactureSecondary cellsElectrical batteryPhysical chemistry

The invention relates to a novel modified non-woven fabric lithium-ion battery diaphragm. The diaphragm comprises a modified non-woven fabric base material and a filling agent compounded on the modified non-woven fabric base material, wherein the modified non-woven fabric base material comprises a low-smelting-point material and a high-smelting-point material; the low-smelting-point material is subjected to melt crystallization treatment and the weight of the high-smelting point material accounts for 85-99.9% of the total weight of the base material; the residual amount is the low-smelting point material; the filling agent compounded on the modified non-woven fabric base material comprises organic polymer, a first filling material and / or a second filling material. The invention further relates to a preparation method of the battery diaphragm. The preparation method sequentially comprises the following steps: manufacturing a non-woven fabric fiber layer; manufacturing the modified non-woven fabric base material; preparing filling agent slurry; filling; removing a solvent; and carrying out post-treatment. The method is simple in operation and low in cost; a prepared product is low in water content, good in chemical stability and high in mechanical strength; the finished product rate of a battery is increased, the service life is prolonged and the safety is improved.

Owner:河南惠强新能源材料科技股份有限公司

High temperature water heat processing method for timber

ActiveCN1876343AImprove water absorptionSmall water absorptionWood treatment detailsWood dampingMetallurgyIncrease size

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

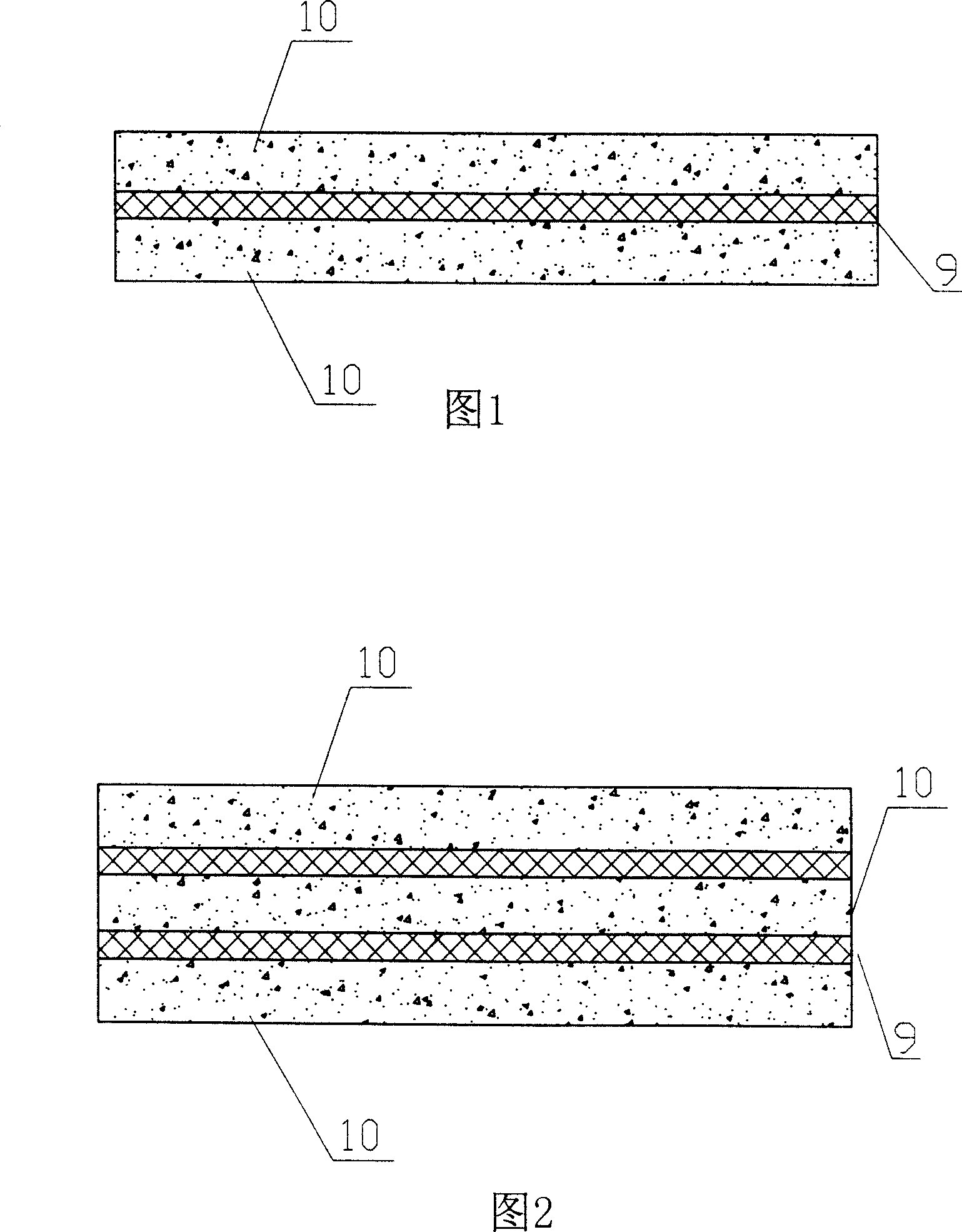

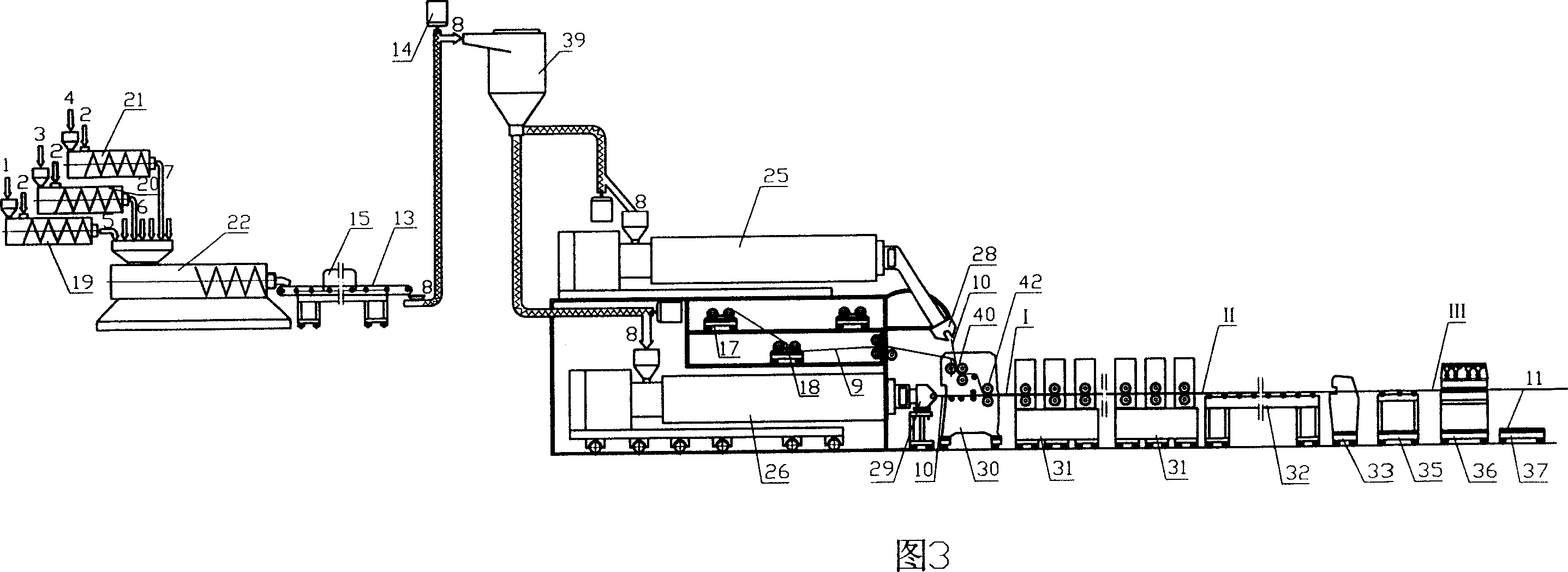

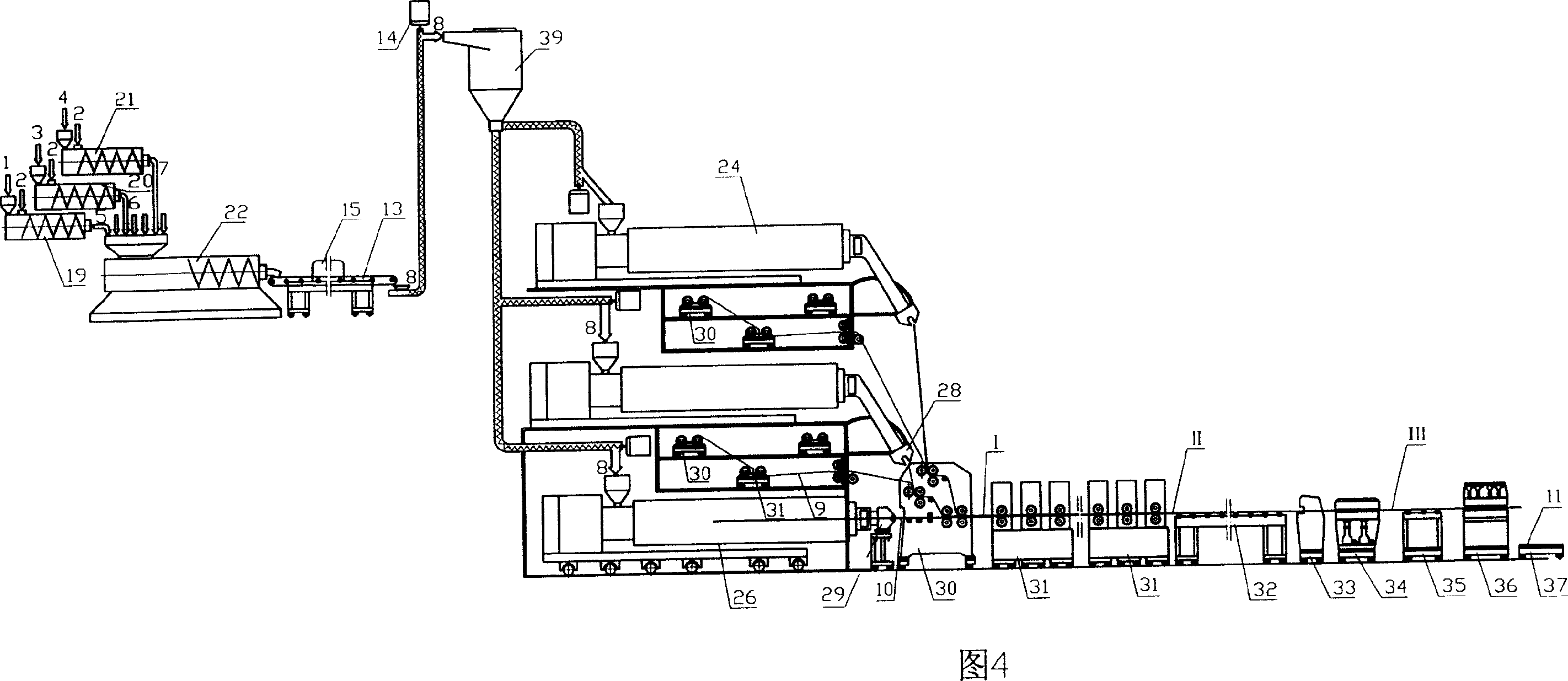

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

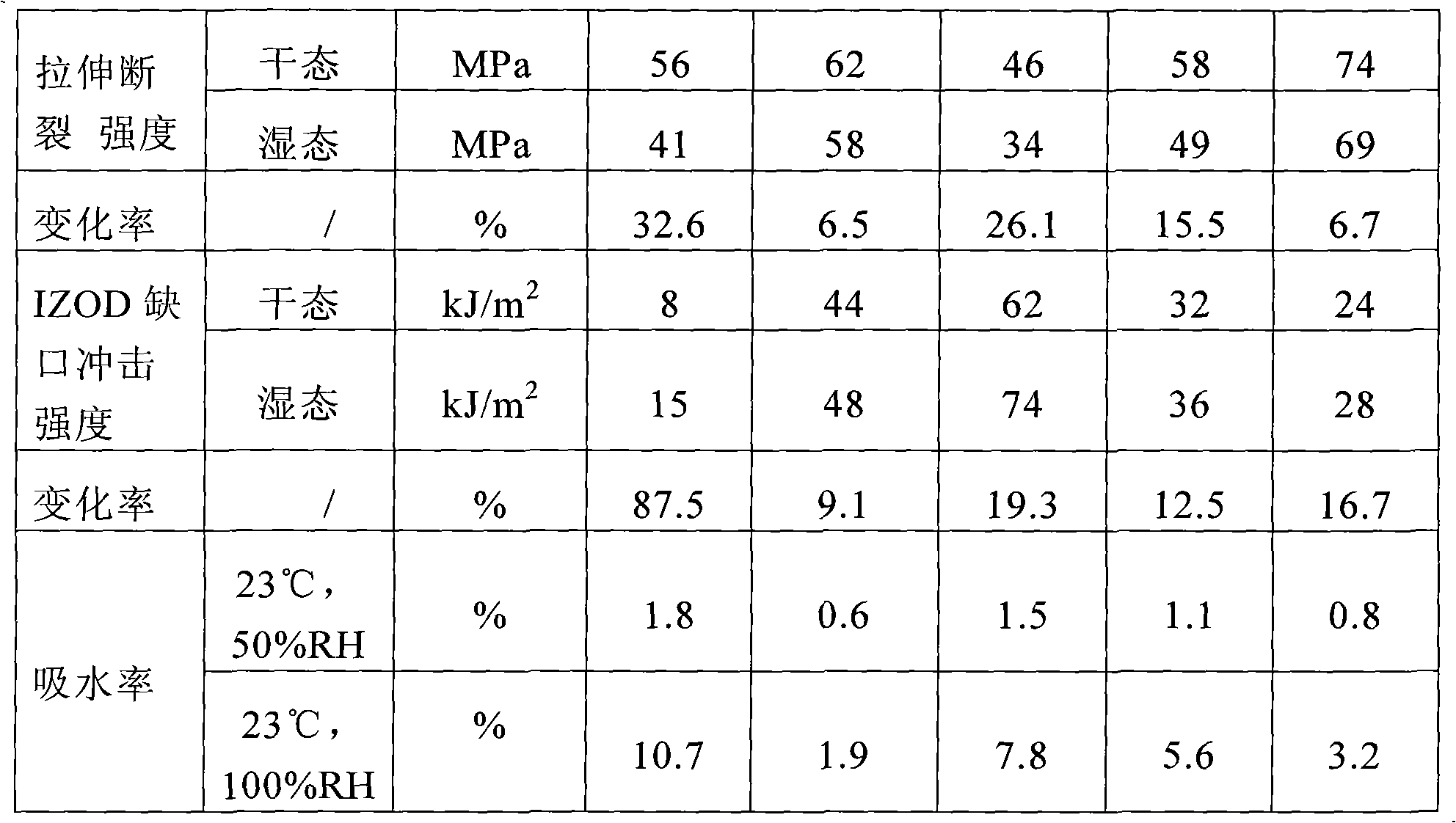

Low water absorption polyamide composite and preparation method thereof

The invention relates to a low water absorption polyamide composite and preparation method thereof. 10-90 parts by weight of polyamide and 3-10 parts by weight of phyllo-silicate clay and less than 2 parts by weight of additive are placed into a high speed mixer to be premixed for 20min and then are added into a double screw extrusion machine, and conveying, melting, cutting, extrusion, cooling and granulation are carried out, thus obtaining polyamide / phyllo-silicate master batch, then the polyamide / phyllo-silicate master batch, 10-60 parts by weight of styrene resin, 2-10 parts by weight of compatilizer and 5-20 parts by weight of short glass fiber are placed into the high speed mixer to be premixed for 20min, temperature is controlled to be 40-60 DEG C, and finally extrusion granulationis carried out in the double screw extrusion machine, thus obtaining the low water absorption polyamide composite. Compared with prior art, the invention has the advantages of solvent resistance, high tenacity and easy processability of polyamide and the advantage of low water absorption of ABS resin; besides, phyllo-silicate clay speeds up crystallization of nylon, degree of crystallization and mechanical strength are improved, extremely low water absorption is obtained, and size stability is greatly improved while impact toughness is maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

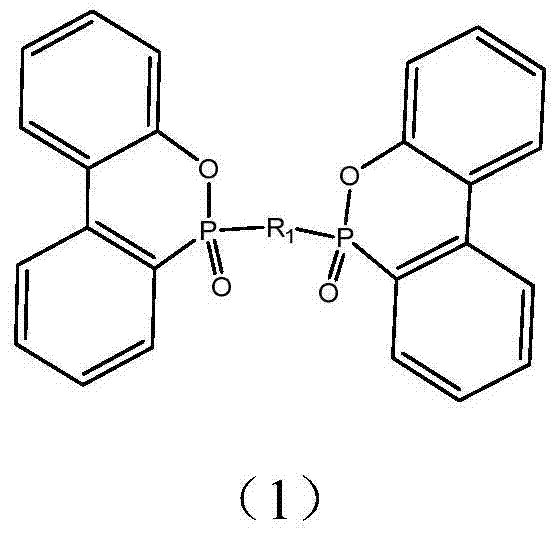

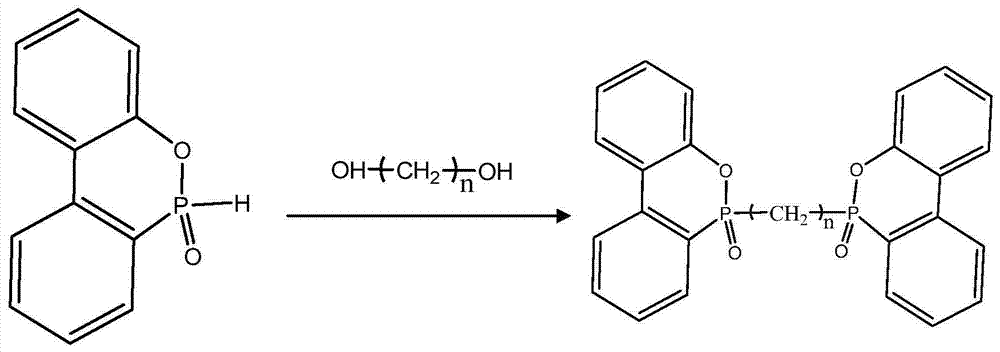

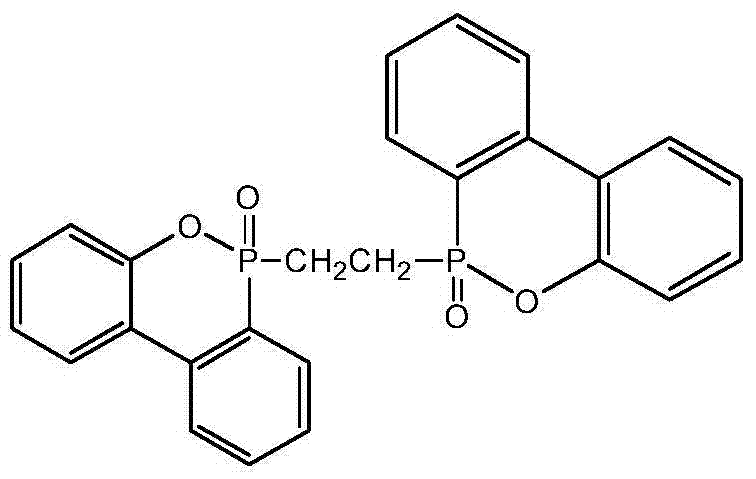

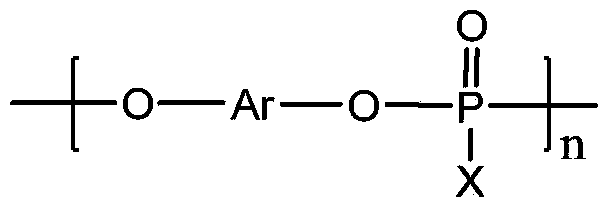

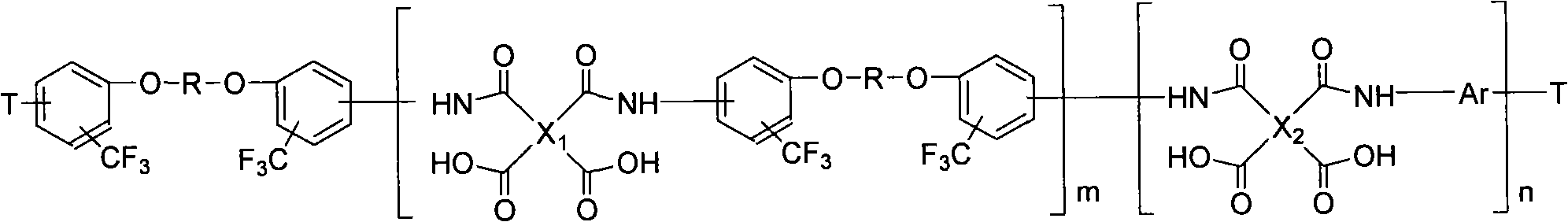

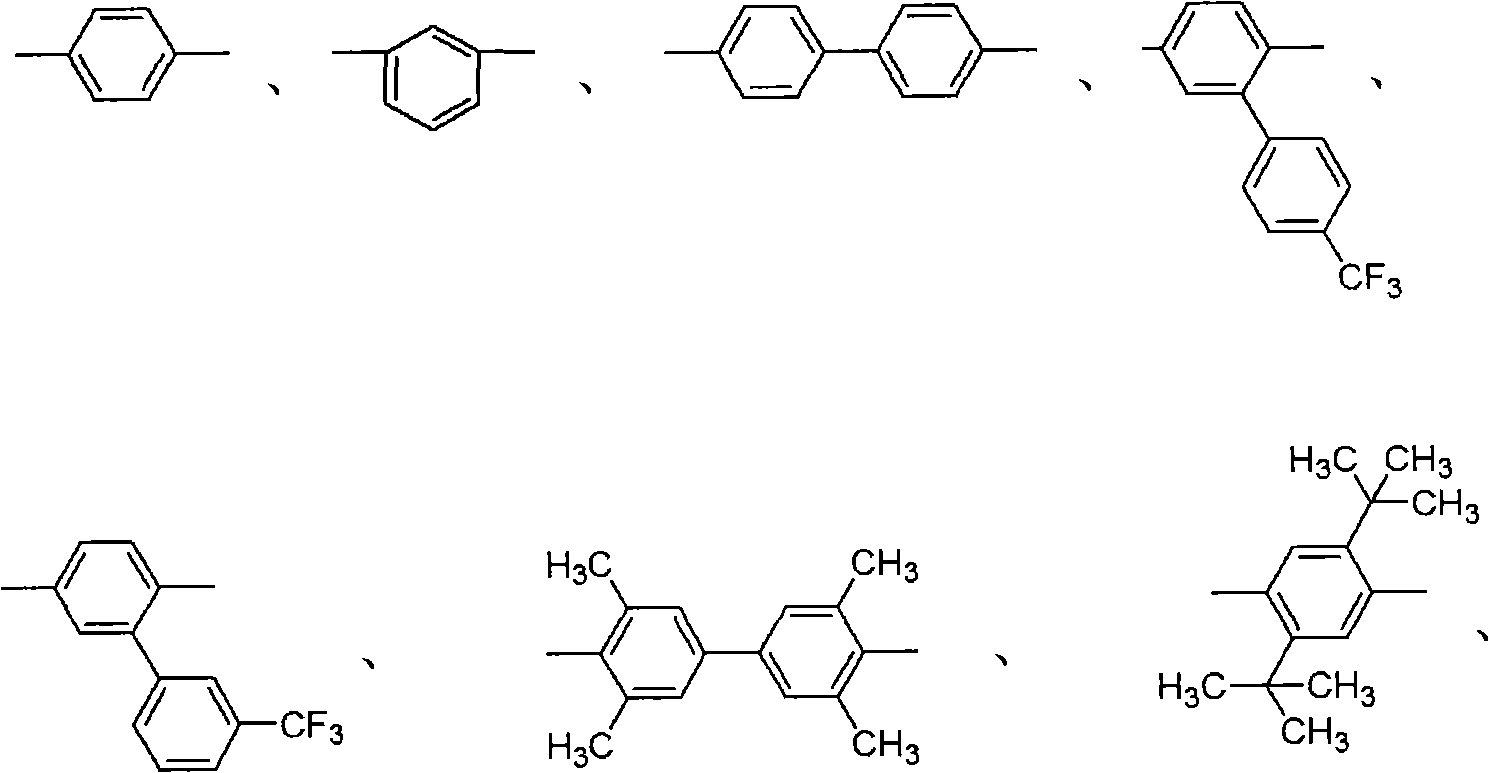

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

High-starch full biodegradable composition and preparation method thereof

ActiveCN104119647AHigh in starchGood compatibilityMechanical properties of carbon nanotubesHigh polymer

The invention belongs to the technical field of high molecular materials, and relates to a high-starch full biodegradable composition and a preparation method thereof. The high-starch full biodegradable composition comprises the following components in parts by weight: 10-80 parts of full biodegradable thermoplastic starch masterbatches, 20-90 parts of biodegradable polyester and 0.3-5 parts of compatilizers. The full biodegradable composition provided by the invention has the advantages of high starch content and good compatibility of starch and a substrate and ensures the mechanical property the material in a long-time storage process; a film product prepared by using the composition can be greatly reduced in cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

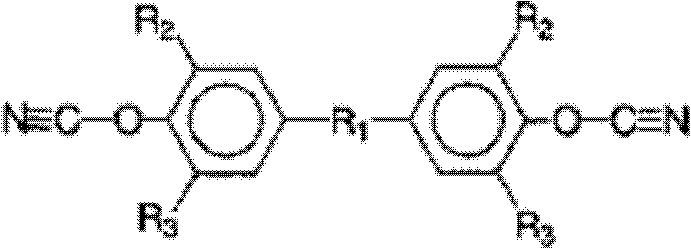

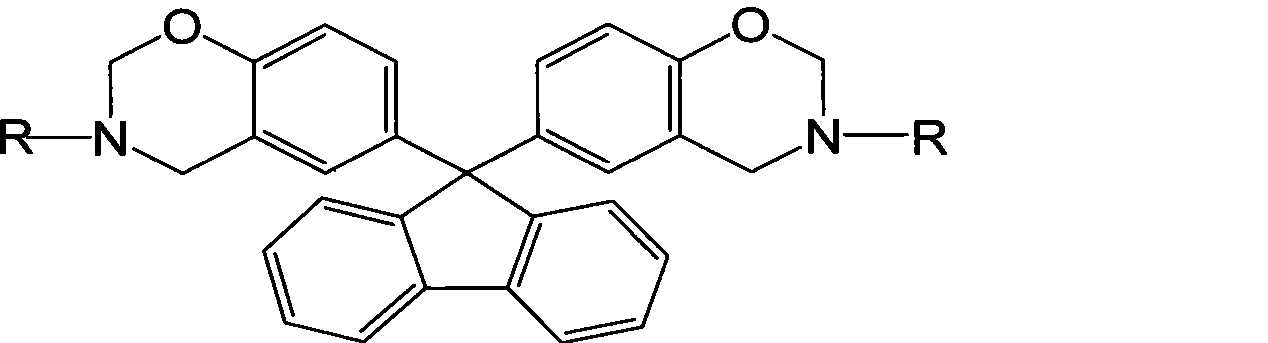

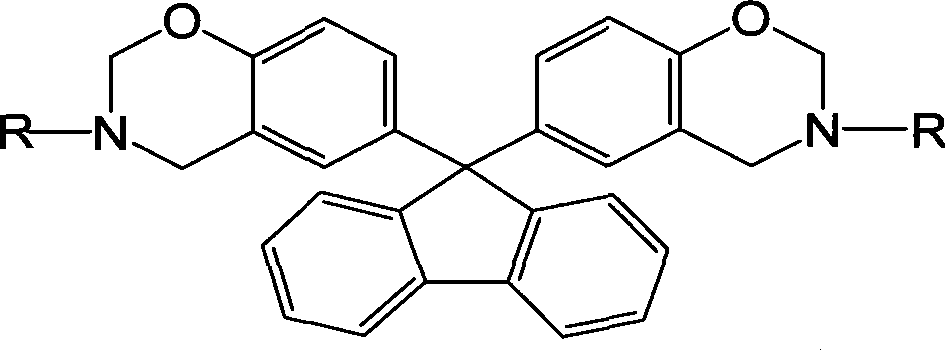

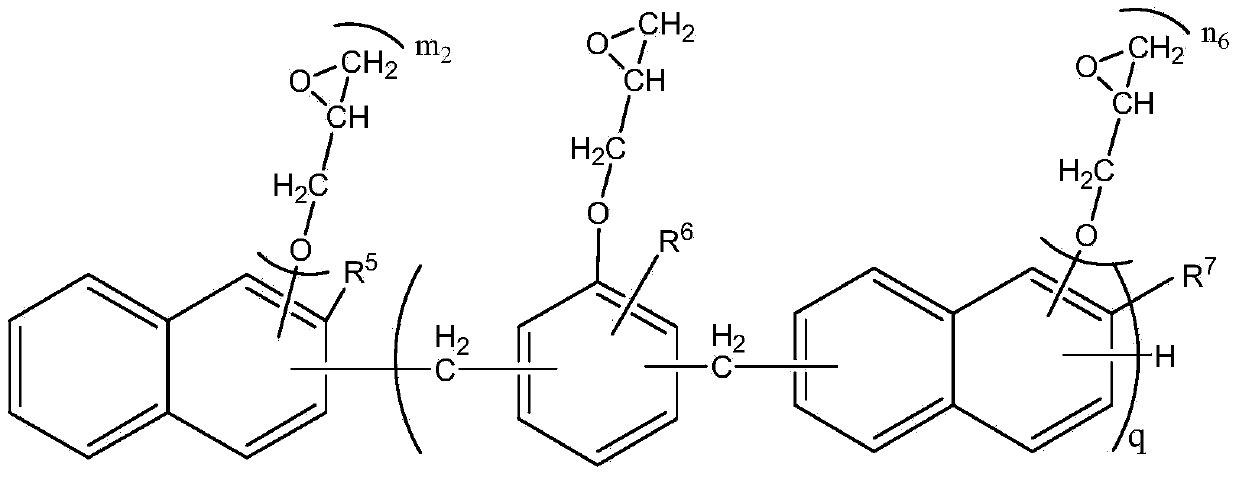

Fluorenyl bi-benzoxazine monomer and method of preparing the same

InactiveCN101367774AHigh glass transition temperatureSmall water absorptionOrganic chemistryOrganic solventGlass transition

The present invention provides a fluorylbis-benzoxazoly monomer and a preparation method thereof. In a container with a mixer, a cooling pipe and a thermometer, formaldehyde solution of 37 percent and an organic solvent are added according to a weight ratio of (1 to 4) to 1, primary amine is added into the formaldehyde solution at the temperature between 5 DEG C and 10 DEG C, the reaction solution is continuously mixed for reaction for 1 to 4 hours and heated to be between 70 DEG C and 120 DEG C, an organic solvent with dissolved bisphenol fluorine is added, weight percentage of the bisphenol fluorine in the organic solvent is 20 percent to 50 percent, the molar ratio of the bisphenol fluorine and the primary amine is (1 to 2) to 3; the reaction continues to last for 4 to 10 hours at the temperature between 70 DEG C and 120 DEG C, and ultimately the fluorylbis-benzoxazoly monomer can be acquired through post processing. Because of the fluorine structure, the rigidity of molecular chains of the product can be enhanced, and the glass-transition temperature of resin can be improved; because of the enhanced nonpolarity of molecules, the hygroscopicity of the resin is lowered, thereby improving the wet-hot aging performance of the resin is greatly improved.

Owner:HARBIN ENG UNIV

Traditional Chinese medicine health-care tipping paper and production method thereof

InactiveCN103741553AImprove toughnessImprove water resistanceSpecial paperNon-macromolecular organic additionSodium sulfatePaper sheet

Traditional Chinese medicine health-care tipping paper is prepared from the following raw materials in parts by weight: 90-100 parts of softwood pulp, 40-50 parts of hardwood pulp, 2-3 parts of methyltriethoxysilane, 1-2 parts of sodium lignosulfonate, 1-2 parts of aerosol-OT, 2-3 parts of ?, 1-2 parts of sodium tripolyphosphate, 4-7 parts of bentonite, 1-2 parts of ascorbic acid, 1-2 parts of chitosan, 4-6 parts of kaolin powder, 1-2 parts of bamboo charcoal powder, 2-3 parts of carboxymethyl starch, 1-2 parts of sodium persulfate, 1-2 parts of soybean oil, 1-2 parts of green tea powder, 1-2 parts of pseudo-ginseng powder, 1-2 parts of gynostemma pentaphyllum powder and 1-2 parts of castanea mollissima leaf powder. The technological effects comprise that by adding traditional Chinese medicine health-care compositions such as pseudo-ginseng, gynostemma pentaphyllum and the like, the health-care performance is increased; also when a smoker keeps a cigarette holder in mouth, harm of smoking is reduced; and also, by adding ester materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance and reduced in water absorbing property, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

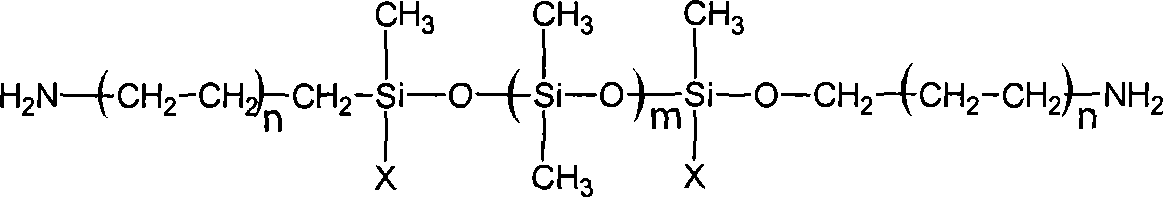

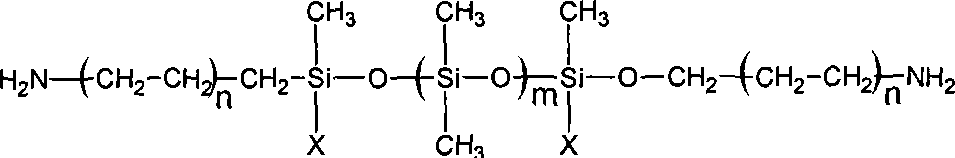

Method for synthesizing water-dispersion organosilicon-polyurethane block copolymer

InactiveCN101225150AEvenly dispersedImprove stabilityNon-fibrous pulp additionLiquid surface applicatorsVegetable oilSynthesis methods

The invention discloses a synthesis method for waterborne organocilicon-polyurethane block copolymer, comprising steps as follows: reaction is carried out between polyisocyanate and polyol (the polyol comprises the one from the castor oil and carboxyl polyol) to generate isocyanate-terminated polyurethane prepolymer; then chain extension is carried out via amino alkyl polysiloxane; eventually alkaline aqueous solution is adopted for neutralization and dispersion, to prepare aqueous dispersion with excellent dispersion and stability. In addition, the aqueous dispersion is applied as coating for the wood and paper, as finishing agent for leathers and textiles, or as adhesives. Since natural vegetable oil from castor beans is selected and amino alkyl polysiloxane is adopted as the chain extender. The synthesis method for waterborne organocilicon-polyurethane block copolymer has the advantages of remarkably improved hydrophobic property, heat resistance and surface smoothness for the polymer films, simple preparation technique, and easy operation.

Owner:ZHEJIANG UNIV

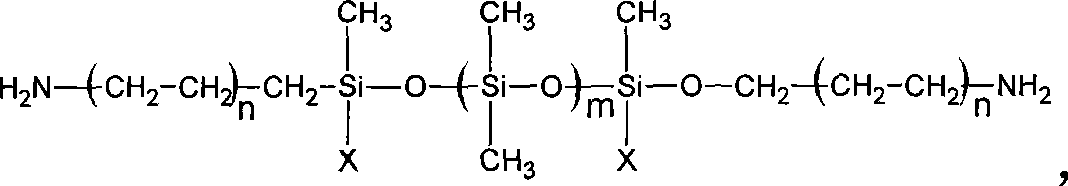

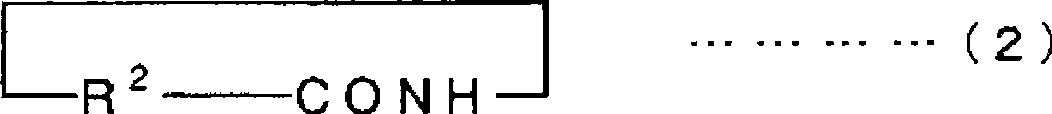

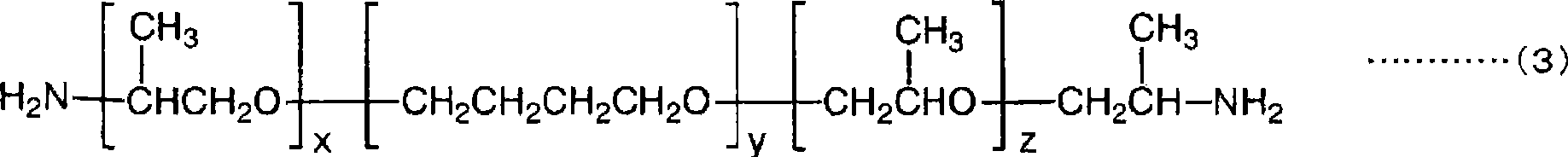

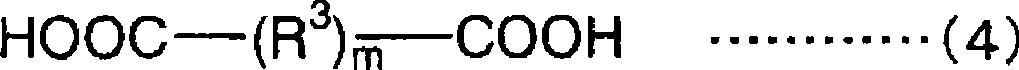

Polyether polyamide elastomer

InactiveCN101472975ASmall water absorptionSatisfactory physical propertiesSynthetic resin layered productsClothingsElastomerPolyamide

Disclosed is a polyether polyamide elastomer particularly excellent in transparency while retaining properties such as dynamic physical properties, stiffness and resistance to fatigue from flexing. The polyether polyamide elastomer can be produced by polymerizing (A) a polyamide-forming monomer selected from (A1) an aminocarboxylic acid compound represented by the formula (1) and (A2) a lactam compound represented by the formula (2), (B) a diamine compound comprising (B1) a triblock polyether diamine compound represented by the formula (3) and (B2) at least one diamine compound selected from a branched saturated diamine having 6 to 22 carbon atoms, a branched alicyclic diamine having 6 to 16 carbon atoms and norbornanediamine, and (C) a dicarboxylic acid compound represented by the formula (4) with one another. H2N-R-COOH (1) wherein R represents a linking group having a hydrocarbon chain. (2) wherein R represents a linking group having a hydrocarbon chain. (3) wherein x represents a number ranging from 1 to 20, y represents a number ranging from 4 to 50, and z represents a number ranging from 1 to 20. HOOC-(R)m-COOH (4) wherein R represents a linking group having a hydrocarbon chain, and m represents 0 or 1.

Owner:UBE IND LTD

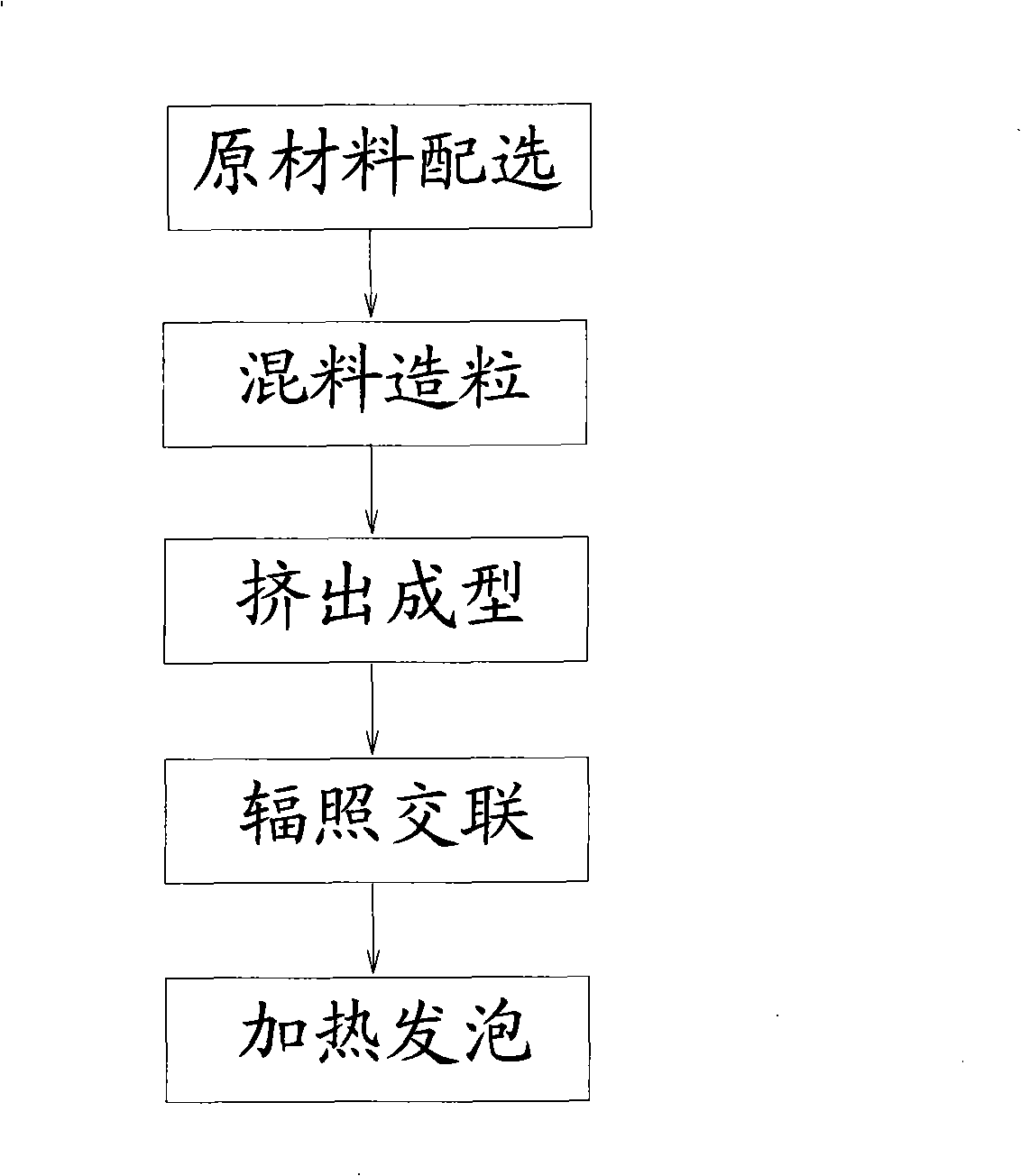

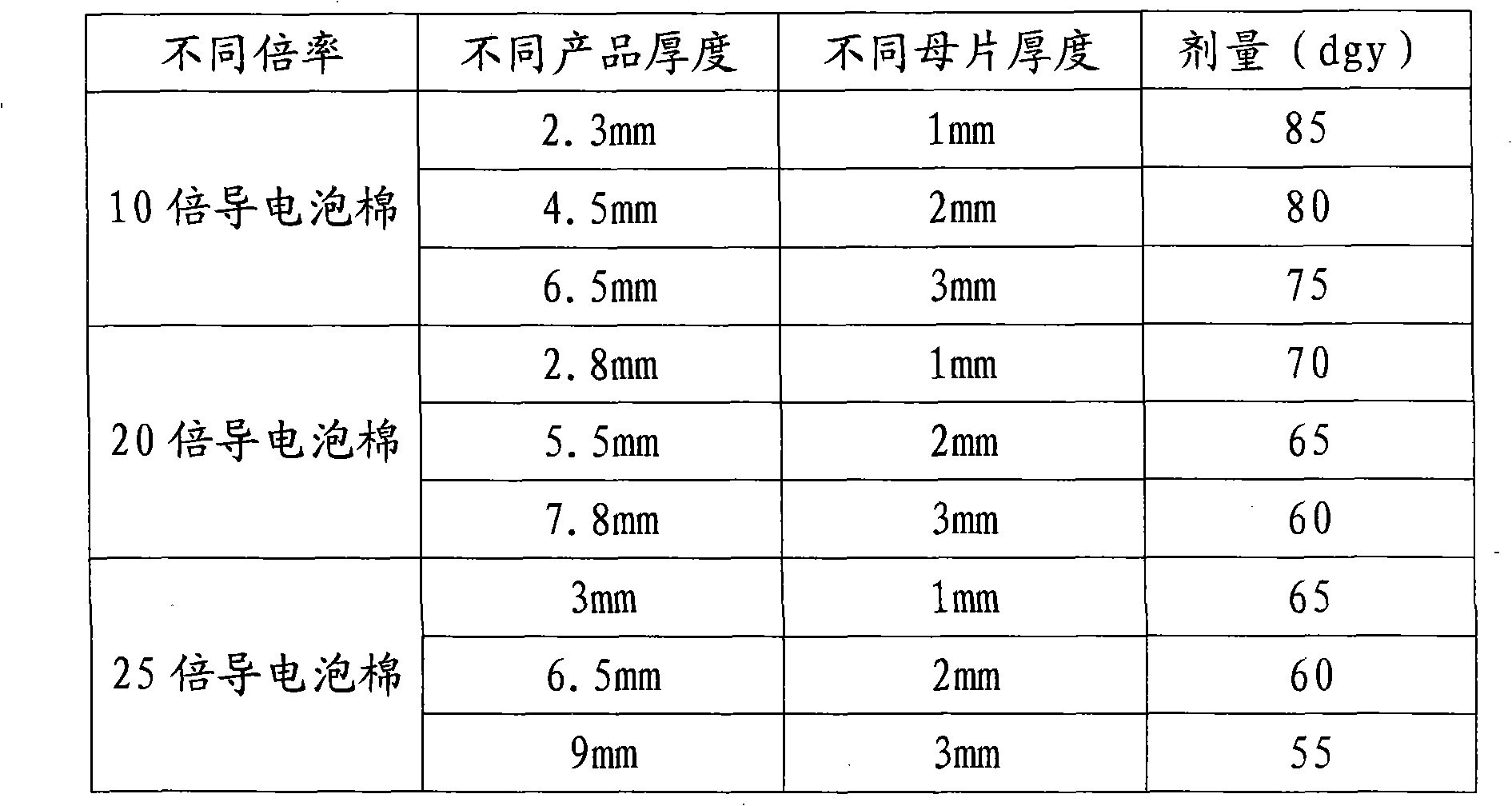

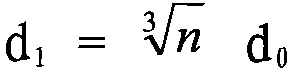

IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

The invention relates to an IXPE electronic radiation crosslinked polyethylene conductive foam and a preparation method thereof. The IXPE electronic radiation crosslinked polyethylene conductive foam mainly contains the mother batch: low density polyethylene; accessories: ethylene-vinyl acetate copolymer, azodicarbonamide blowing agent, polyethylene wax lubrication additive, titanate ester coupling agent and conductive carbon black which are mixed for processing, extruded for molding, radiated for crosslinking, heated for foaming, and treated by secondary processing, etc, to produce the IXPE electronic radiation crosslinked polyethylene conductive foam. The crosslinking of the product of the invention can be easily controlled, the foaming process is stable, the foam pores are fine and even, the quality of the surface is high without unpleasant odor, the foam pores are obstructed, the production can be carried out continually, the electrical conductivity is stable, the product is lightweight, non-toxic, extremely less absorbent; the thermal conductivity is slow, aging resistant, chemical corrosion resistant, pulverization resistant, and a plurality of porous foam materials can be easily achieved; in addition, the product has good properties to be treated by the secondary processing procedures, such as bonding, machining, hot forming, etc.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

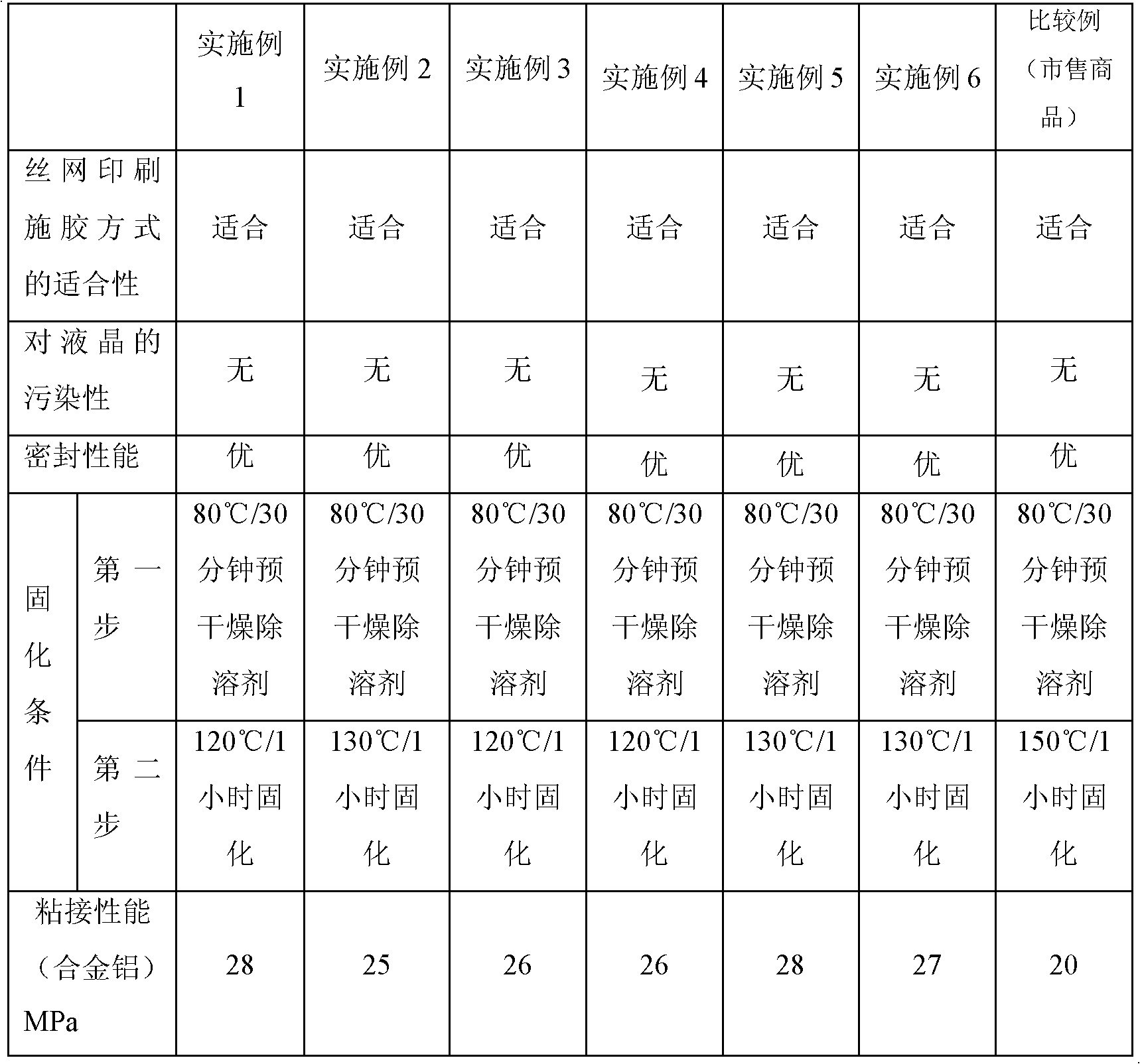

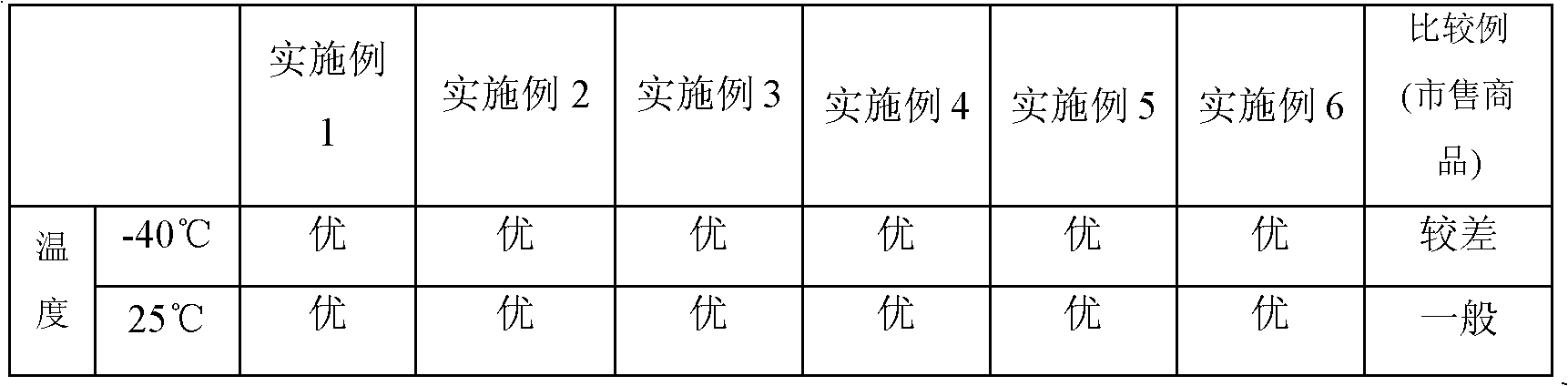

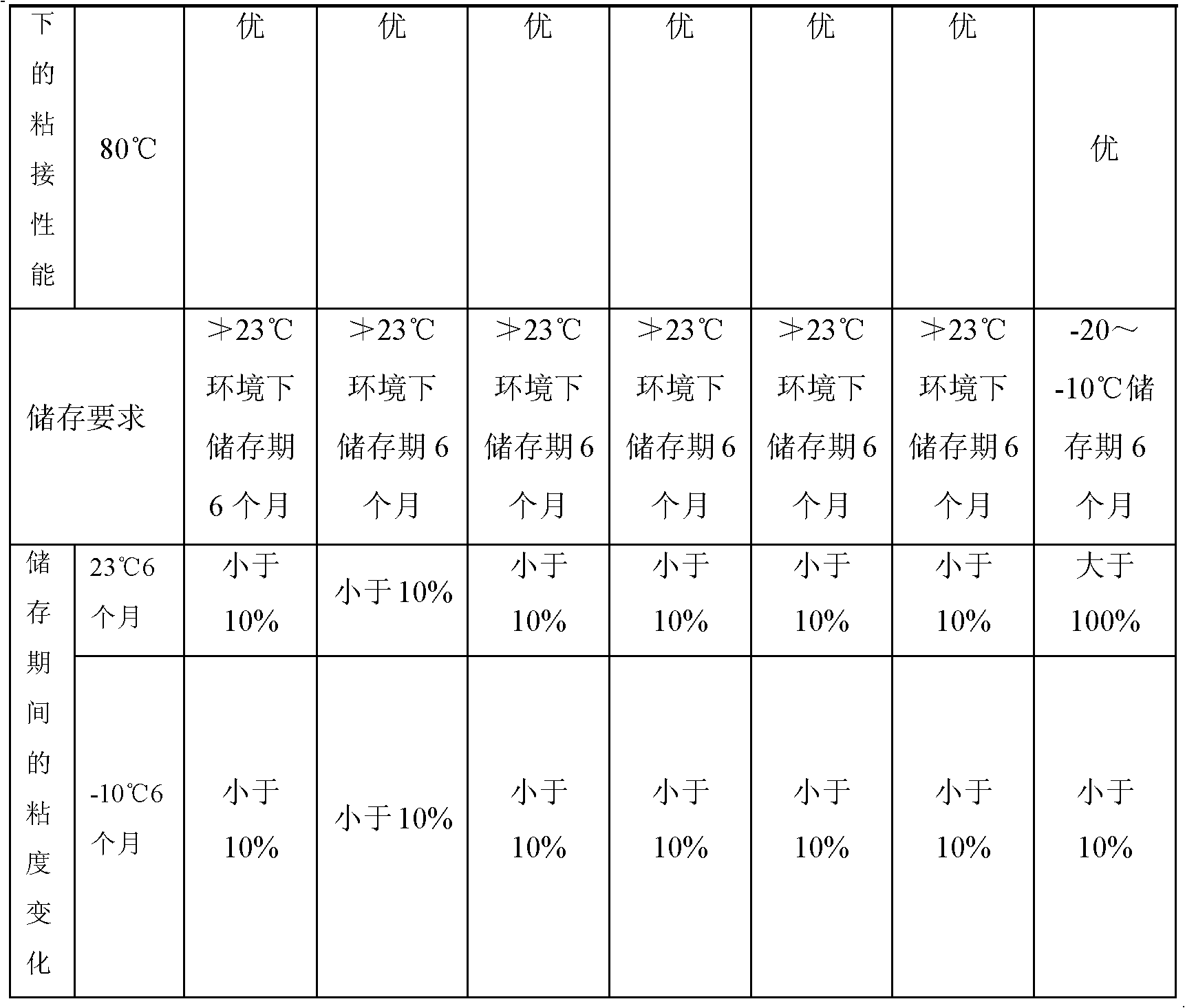

Frame sealing adhesive, and preparation method and application thereof

InactiveCN102585745AEasy to storeSmall water absorptionNon-macromolecular adhesive additivesOther chemical processesScreen printingEpoxy

The invention discloses a frame sealing adhesive and a preparation method and application thereof. The frame sealing adhesive comprises the following component: epoxy resin, a curing agent, a rubber powder, an organic filler, a thixotropic agent, a silane coupling agent and a solvent. The frame sealing adhesive has excellent storage performance and an adhesive applying manner suitable for screen printing and is used for sealing a side frame of a TN (twisted nematic) (STN-super twisted nematic) liquid crystal box; in addition, the solidified frame sealing adhesive has the advantages of low hydroscopic property, long-lasting and excellent sealing performance, excellent heat resistance and electric insulation performance, no pollution to liquid crystal, high rigidity, high toughness and high size stability, and important application value.

Owner:绵阳艾萨斯电子材料有限公司

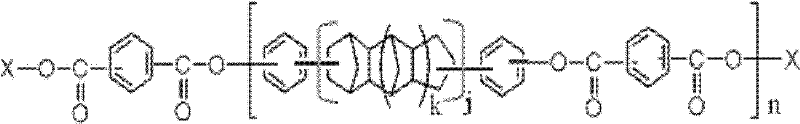

Thermosetting resin composition and application thereof

ActiveCN103694642ALow dielectric constantExcellent dielectric propertiesSynthetic resin layered productsElectrical equipmentDielectric lossCopper foil

The invention relates to a thermosetting resin composition which comprises (A) epoxy resin with a naphthol structure on a molecular main chain; (B) cyanate ester compound or / and cyanate ester prepolymer; and (C) phosphonate or / and phosphonate-carbonic ester copolymer. The thermosetting resin composition provided by the invention is low in dielectric constant and dielectric loss tangent, a prepreg and a copper clad laminate prepared by using the above thermosetting resin composition has excellent dielectrical property, humidity resistant property and craft processability, and the fire resistance is up to the UL94 V-0 level.

Owner:GUANGDONG SHENGYI SCI TECH

Semi-aromatic polyamide resin

ActiveCN101175791AImprove hot water resistanceGood chemical resistanceSynthetic resin layered productsThin material handlingResidenceAramides

The present invention provides a semi-aromatic polyamide resin having high residence stability, hot water resistance and chemical resistance and also having excellent adhesion property to and compatibility with other resin or the like. [MEANS FOR SOLVING PROBLEMS] The semi-aromatic polyamide resin has dicarboxylate units in which aromatic dicarboxylate units comprise 50 to 100 mol% of the dicarboxylate units and diamine units in which aliphatic diamine units having 9 to 13 carbon atoms comprises 60 to 100 mol% of the diamine units. In the resin, at least 10% of the terminal groups present in the molecular chain are end-capped with an end-capping agent, and the amount of the terminal amino groups present in the molecular chain falls within the range from 60 [mu]-equivalents / g to 120 [mu]-equivalents / g inclusive and satisfies the equation: [NH2] / [COOH]=6 wherein [NH2] ([mu]-equivalent / g) represents the amount of the terminal amino groups and [COOH] ([mu]-equivalent / g) represents the amount of the terminal carboxyl groups.

Owner:KURARAY CO LTD

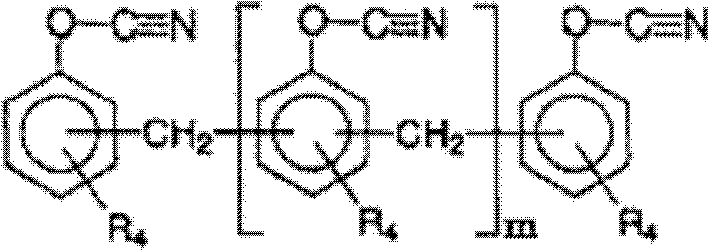

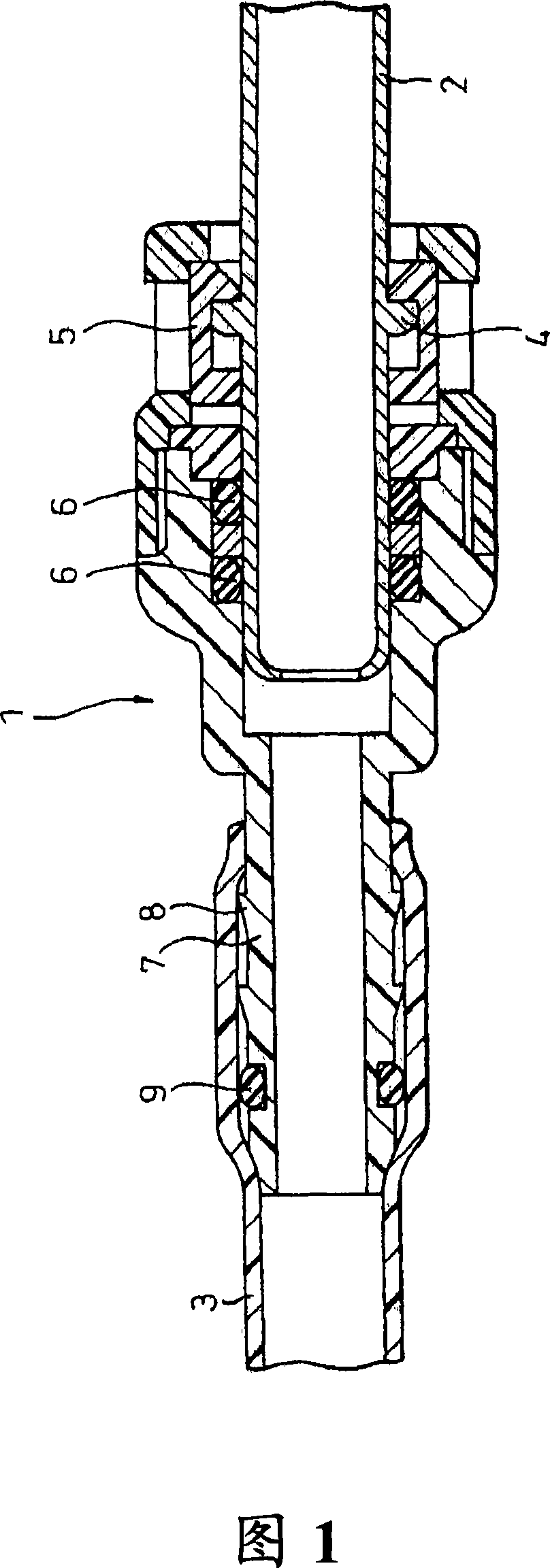

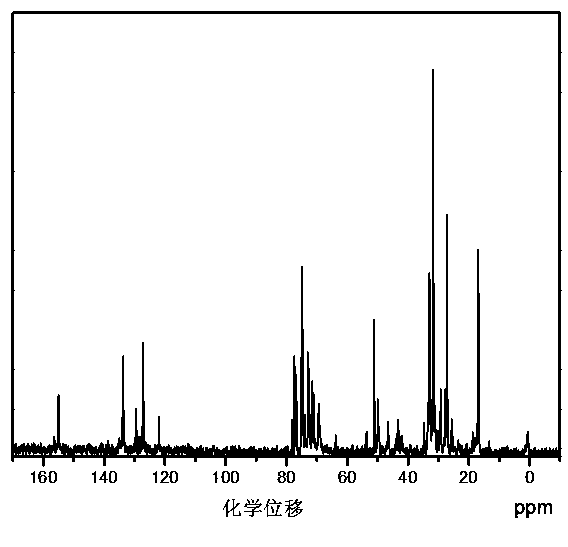

Polyimide resin, its midbody, preparation method and application thereof

ActiveCN101343362AImprove heat resistanceImprove mechanical propertiesLamination ancillary operationsSynthetic resin layered productsChemical structureMetal foil

The invention discloses polyamide resin and intermediate compound thereof as well as the preparation method and the application. The polyamide resin is provided with the chemical structure shown in formula II, wherein, X1 and X2 can be identical or different, representing quadrivalent aryl; Ar represents bivalent aryl, and T represents end capping reagent. The polyamide resin is obtained by polyamic acid shown in formula I structure general formula through chemical imidization or thermal imidization. The polyamide resin is dipped through prosomatic polyamic acid solution or polyamic acid solution being obtained after being dissolved with solvent with a low-boiling point, the basal body is strengthened, and the prepreg is obtained. After the heat-press forming operation is performed, a metal foil layer is covered, and a metal foil layer pressing plate is obtained. The polyamide resin provided by the invention has the advantages of excellent heat resisting property, high mechanical property, low dielectric constant and dissipation, high electrical insulation property and low water absorbing capacity, thereby being especially suitable for manufacturing core plates of packaging subsctrates for packaging super large-scale integrated circuits.

Owner:INST OF CHEM CHINESE ACAD OF SCI

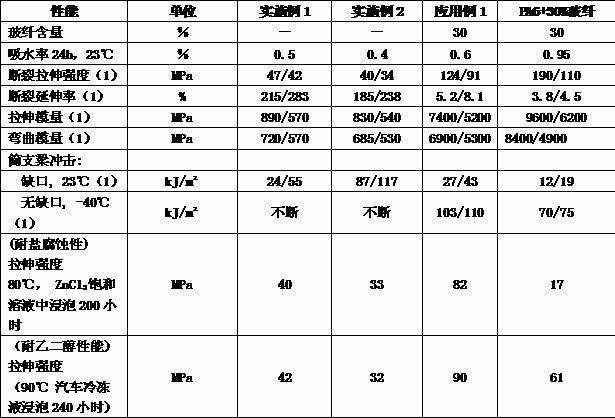

Chemical corrosion resistant high impact long carbon chain nylon master batch and preparation method and application thereof

InactiveCN102643534AGood chemical resistanceImprove low temperature impact resistanceMasterbatchEngineering plastic

The invention relates to a chemical corrosion resistant high impact long carbon chain nylon master batch, which contains long carbon chain nylon, compatible toughening agents and heat stabilizers. The invention further relates to a preparation method and an application of the nylon master batch. The nylon master batch has good impact resistance, chemical corrosion resistance and low humidity absorption, and is good in compatibility with other engineering plastics and capable of improving chemical corrosion resistance, low-temperature impact resistance and dimensional stabilities of composite materials, wherein the chemical corrosion resistance includes corrosion from zinc halide, calcium halide and ethylene glycol.

Owner:苏州隆阁新材料有限公司

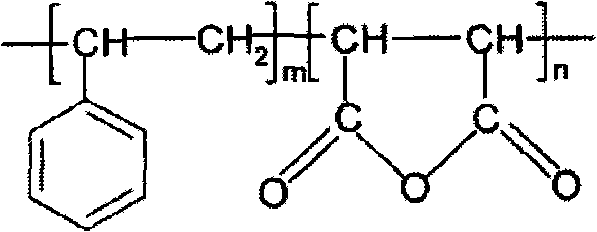

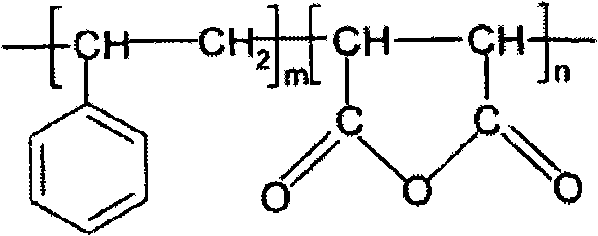

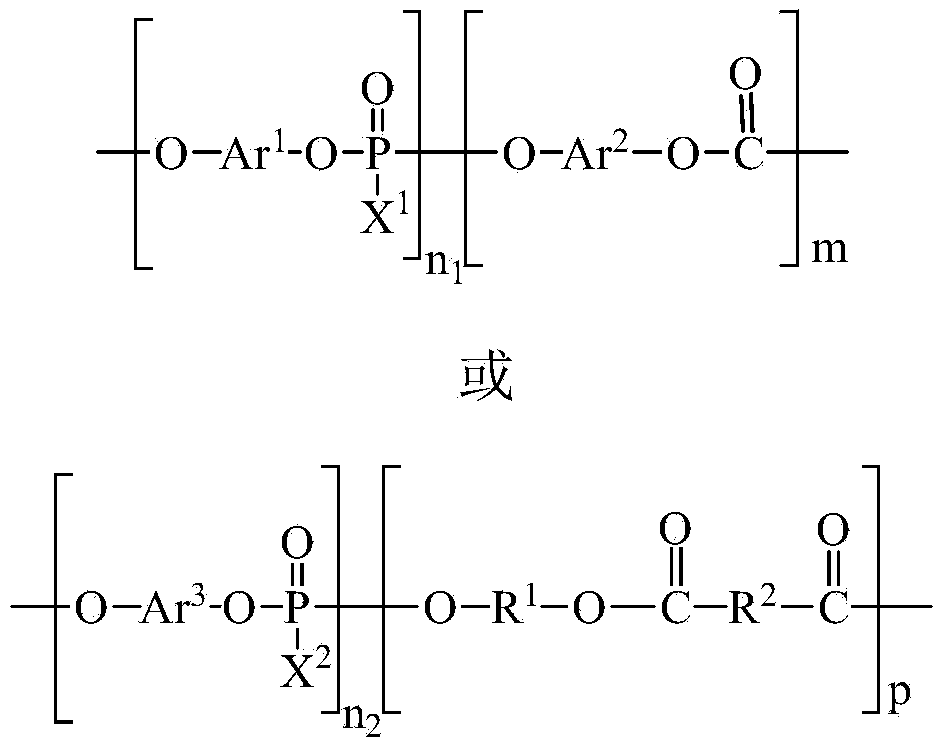

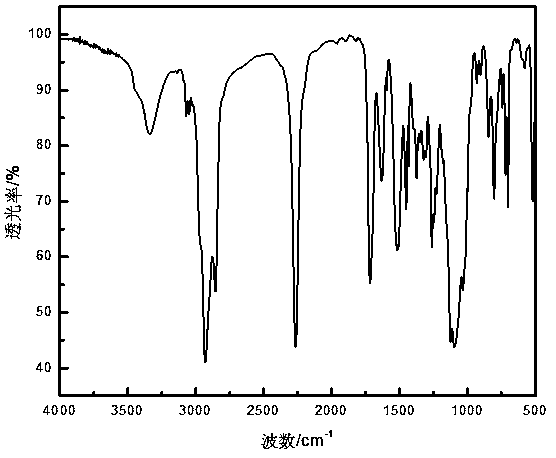

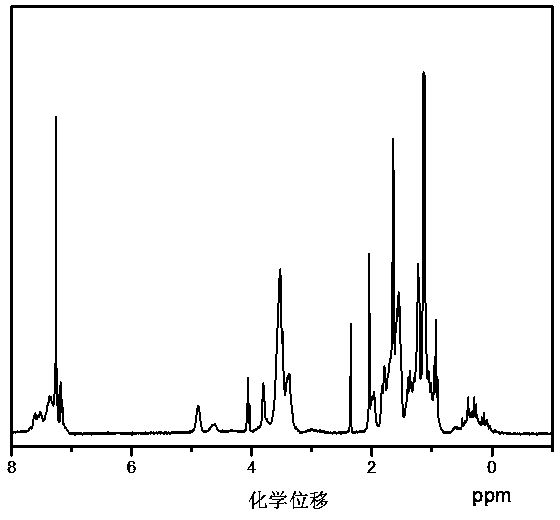

Phenyl organic silicon modified polyurethane resin, preparation method and application thereof

ActiveCN104387546AImprove surface propertiesSmall water absorptionPolyethylene glycolMethyl phenyl polysiloxane

The invention discloses a phenyl organic silicon modified polyurethane resin, a preparation method and application thereof, and belongs to the field of polyurethane resin. The structural formula of the phenyl organic silicon modified polyurethane resin is as shown in the description; the preparation method of the phenyl organic silicon modified polyurethane resin comprises the following steps: dissolving phenylsilanediol into an organic solvent, taking a reaction with chlorosilane (R<2>SiCH3Cl2) to prepare hydroxyl-terminated methyphenyl polysiloxane, under the action of a catalyst, mixing the hydroxyl-terminated methyphenyl polysiloxane with a silane compound to obtain amino or imino terminated methyphenyl polysiloxane, then in the atmosphere of argon, mixing diisocyanate, amino or imino terminated methyphenyl polysiloxane, polyethylene glycol or polyol with a mixed solvent, and taking a reaction to obtain the phenyl organic silicon modified polyurethane resin. The phenyl organic silicon modified polyurethane resin has the advantages of being capable of reducing the water absorption, improving the hydrophobicity, and improving the compatibility of organic silicon and polyurethane, and can be prepared to thin film with good properties; the preparation method is simple and feasible.

Owner:WUHAN UNIV

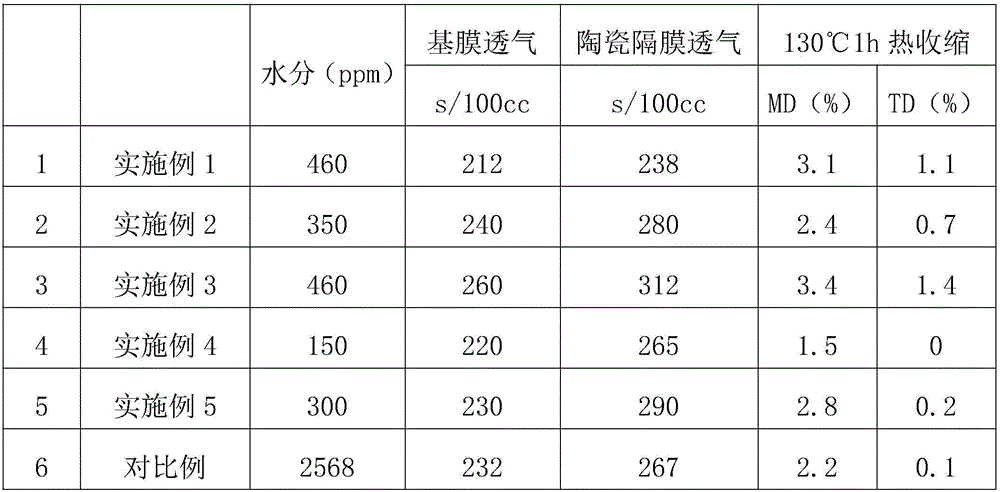

Manufacturing method for ceramic diaphragm with low water absorbency

InactiveCN105957994ASmall water absorptionGuaranteed electricityCell component detailsElectricityOrganic solvent

The invention provides a manufacturing method for a ceramic diaphragm with low water absorbency. The manufacturing method comprises the following steps of 1) surface modification of a ceramic powder: enabling the ceramic powder to be mixed into an organic solvent of a coupling agent, reacting for 2-8h at a temperature of 40-80 DEG C to enable the surface of the ceramic powder to be crosslinked with a hydrophobic functional group; and then carrying out vacuum drying to obtain a solid material; 2) preparing the solid material obtained in the step 1) into aqueous paste, wherein the aqueous paste comprises 10-50mass% of the solid material, 1-20mass% of a binder and 50-80mass% of deionized water; and 3) coating the surface of the lithium ion battery diaphragm with the aqueous paste prepared in the step 2), and removing moisture through a baking process to obtain the product. The manufacturing method has the beneficial effects that the water absorbency of the surface of the ceramic diaphragm is lowered; meanwhile, it is ensured that the ceramic diaphragm does not adsorb moisture and impurity in the production, transport and use processes; and therefore, the electrical property and the safety performance of the lithium battery are ensured.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

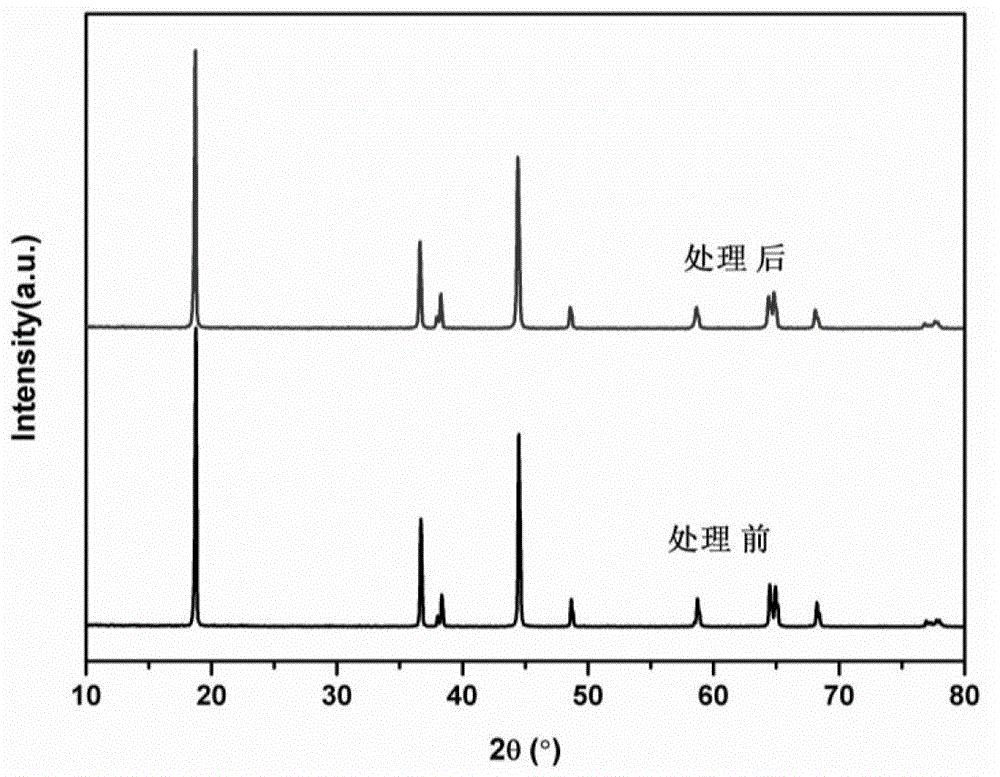

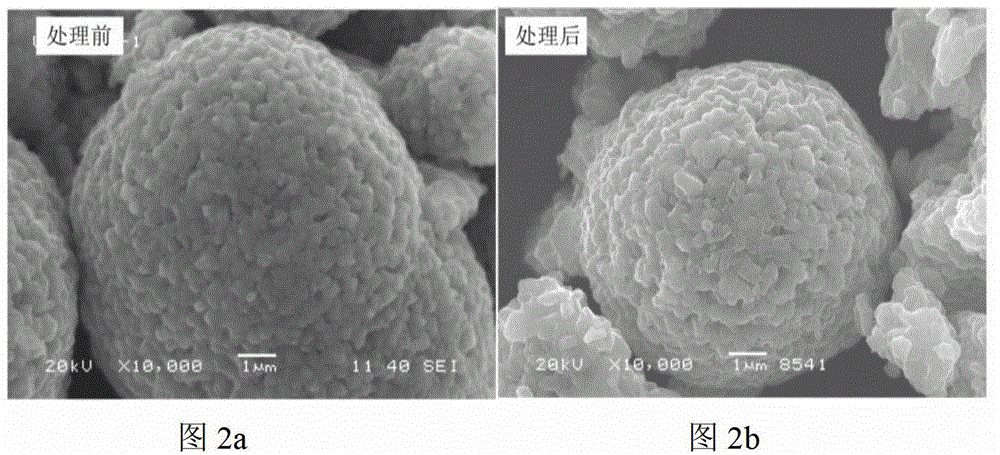

Method for removing lithium ion battery nickel-rich material surface lithium residues by liquid phase precipitation method

ActiveCN102881911ALow hygroscopicityGood hygroscopicityCell electrodesMoisture absorptionMaterial physics

The invention discloses a method for removing lithium ion battery nickel-rich material surface lithium residues by a liquid phase precipitation method. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method includes the steps: dispersing lithium ion battery nickel-rich materials into phosphate solution, combining the nickel-rich material surface lithium residues with phosphate radical ions so as to form precipitation, nucleating on the material surface, and calcining so that a material with the surface wrapped with a compact Li3PO4 layer is obtained. The wrapping layer prepared by the method is more uniform and compact than a traditional wrapping layer, and storage performance of the material in air is obviously improved; and the moisture absorption performance of the nickel-rich materials can be improved while water brought into electrolyte by electrode materials is reduced, and structural stability of the material is enhanced. Moreover, Li3PO4 is better in stability in the electrolyte than in the battery materials, so that the comprehensive electrochemical performance of a positive electrode material can be effectively improved. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method is simple in preparation process, short in flow path and low in production cost, and the prepared positive electrode material is excellent in physical performance and electrochemical performance.

Owner:CENT SOUTH UNIV

Compressed wood and preparation method thereof

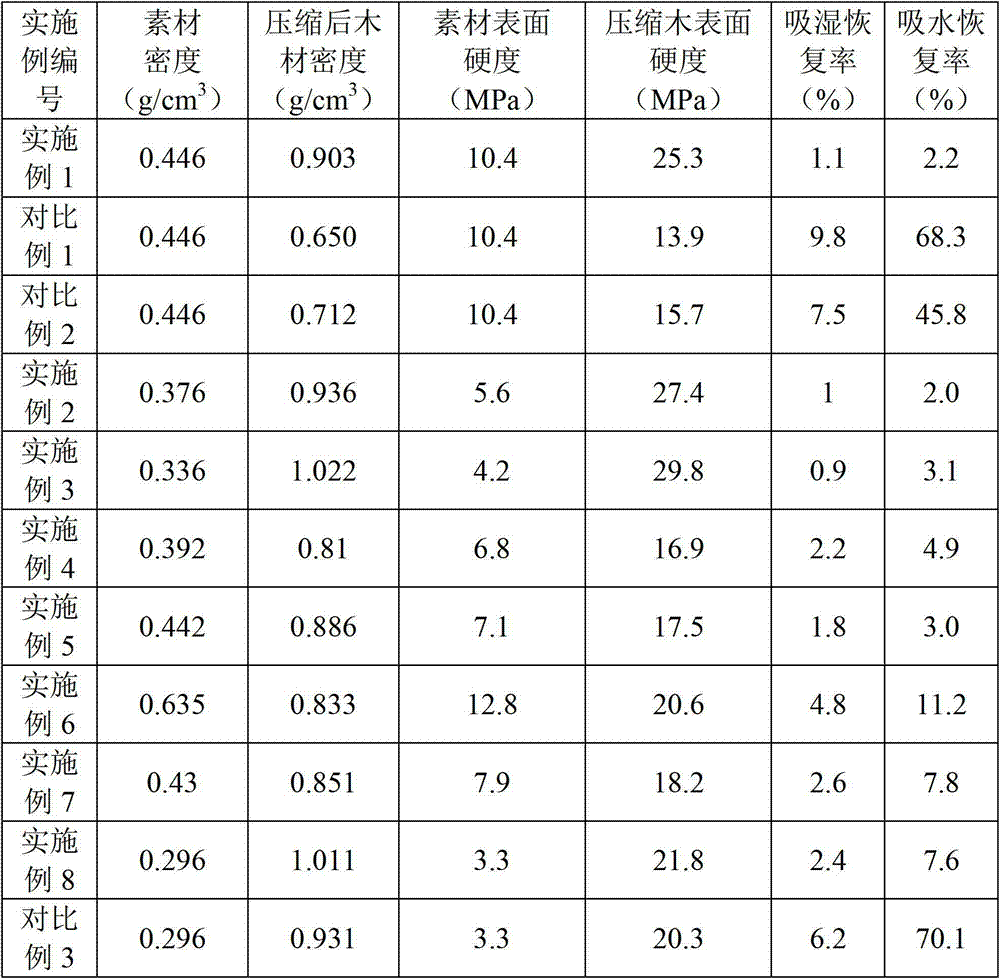

ActiveCN103753664ARebound phenomenon is not easy to occurOvercome serious pollution problemsWood treatment detailsMoisture absorptionCore temperature

The present invention discloses a compressed wood preparation method and compressed wood prepared through the method. The method comprises: (1) carrying out first high-frequency heating on wood with a water content of 12-30 wt%, such that the wood material core temperature achieves 80-120 DEG C; (2) carrying out hot pressing on the wood obtained in the step (1); and (3) carrying out second high-frequency heating on the wood obtained in the step (2), such that the wood material core temperature achieves 180-220 DEG C. The compressed wood prepared by using the preparation method has characteristics of resilience resistance, simple steps, short required time, substantially-increased density, substantially-increased surface hardness, substantially-increased wear resistance, low water absorption recovery rate, and low moisture absorption recovery rate.

Owner:JIUSHENG WOOD

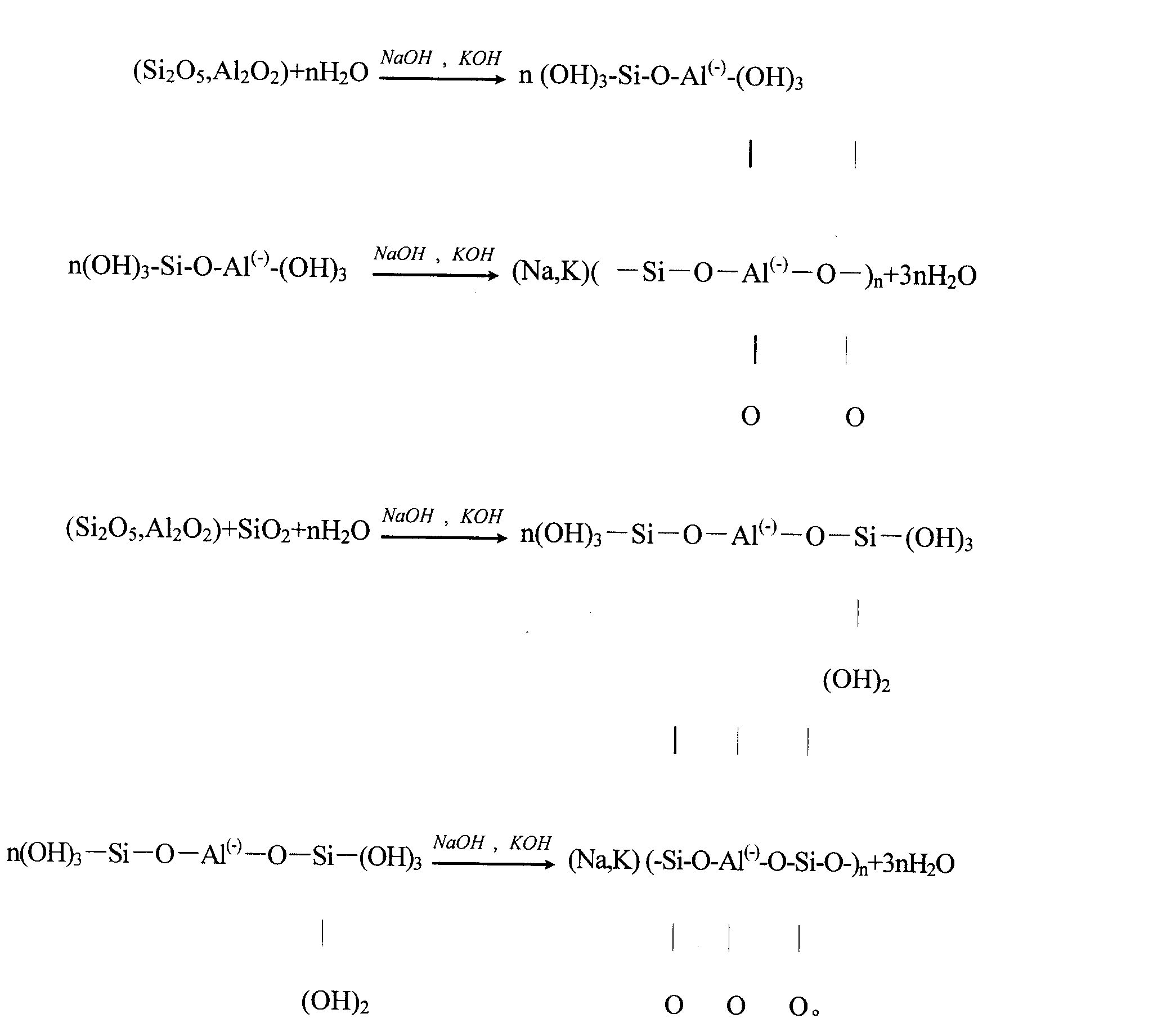

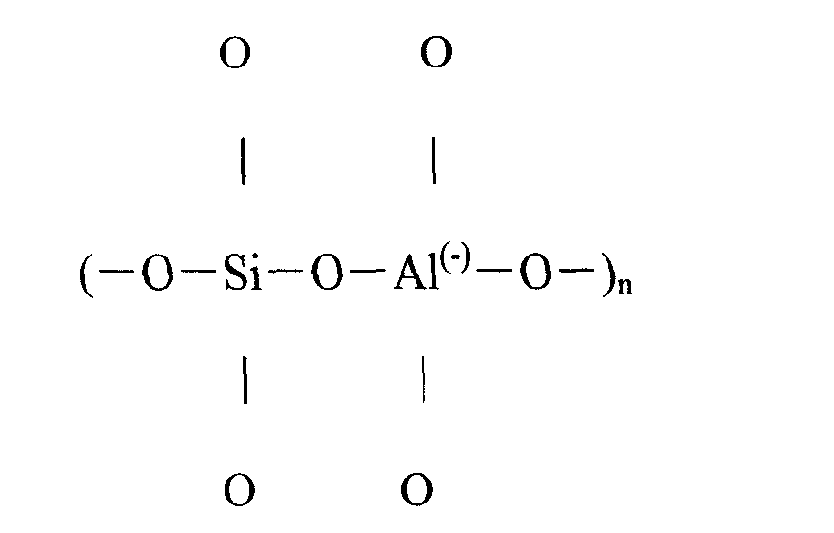

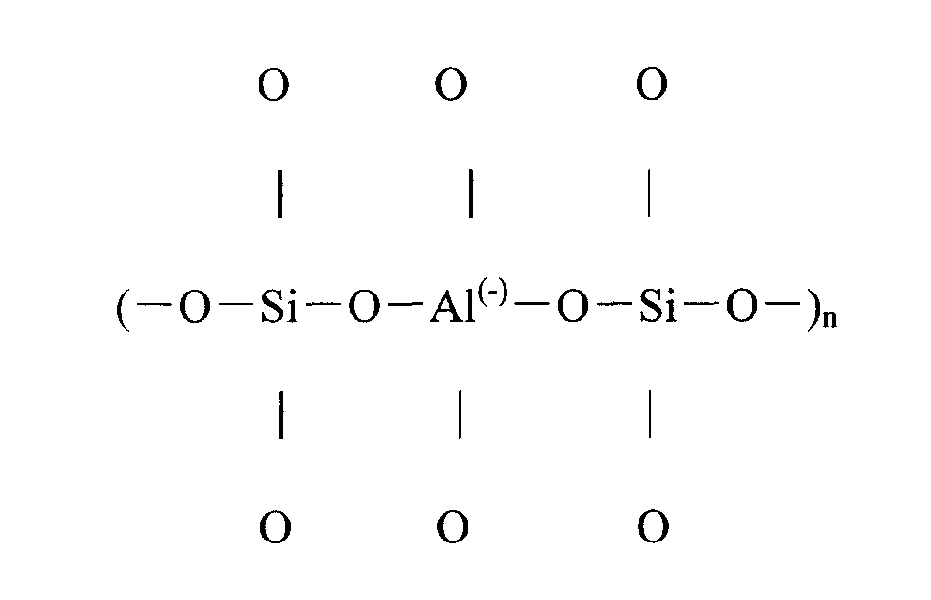

Polymeric aluminium-silica fireproof heat insulation material and preparation method thereof

The invention discloses an insulating refractory material of polymerized silicon and aluminum and the preparation method, applied in construction and industrial facilities, which is characterized in that: excitation, gas evolution and polymerization are carried out for industrial wastes abundant in aluminum oxide, silicon dioxide, and the complex of the silicon dioxide and aluminum oxide, so as to obtain a three-dimensional aluminum silicate minerals with an internal structure made of a plurality of phases from amorphous to semi-crystalline inside, and an internal form in silica tetrahedron and alumina tetrahedron; a plurality of molecules are linked mainly through ionic or covalent bonds, the mechanical properties of the inorganic concretion are externally presented. The raw materials are composed of silicon and aluminum materials as kaolin, fly ashes, coal gangue, cinder, and red mud; without adding any gelled materials, a high temperature and corrosion resistant porous long-chain structure is formed with an intensity over 0.8MPa and a thermal conductivity coefficient of 0.087 (kilocalorie / meter x hour x centigrade). The insulating refractory material is applied not only for the heat insulation wallboards in the building but also for the heat insulation and preservation of the industrial thermal pipelines and facilities.

Owner:中国安华(集团)总公司

Method for preparing wood-plastic composite by blending heat-treated plant fiber with plastic

The invention relates to a method for preparing a wood-plastic composite, in particular to a method for preparing a wood-plastic composite by blending heat-treated plant fibers with plastics. The method comprises the following steps of: crushing the plant fiber, screening the crushed plant fiber by a sieve of 20-120 meshes to prepare the plant fiber powders; carrying out heat treatment on the crushed plant fiber under an oxygen deficient condition, wherein the heat treatment time is 0.5-24h, the temperature is 140-350 DEG C and the preferably selected temperature range is 180-250 DEG C; uniformly mixing the plastic, a lubricant, a plasticizer, a stabilizer, a compatibilizer and the plant fiber modified by heat treatment to prepare the mixture under the high-speed mixing condition with the rotation speed of 800-1000r / min; and extruding the mixture out of a twin-screw extruder after reaction; and granulating and obtaining granules or directly extruding and obtaining the product by a die. The heat-treated plant fiber powder reduces the amount of hydroxy groups, the hydrophilicity and the water absorption of the final product and improves the dimension stability.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com