Chemical corrosion resistant high impact long carbon chain nylon master batch and preparation method and application thereof

A chemical-resistant, long-carbon chain technology, applied in chemical-resistant, high-impact, long-carbon-chain nylon masterbatch and its preparation and application fields to achieve good chemical corrosion resistance, good compatibility, and low low-temperature impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

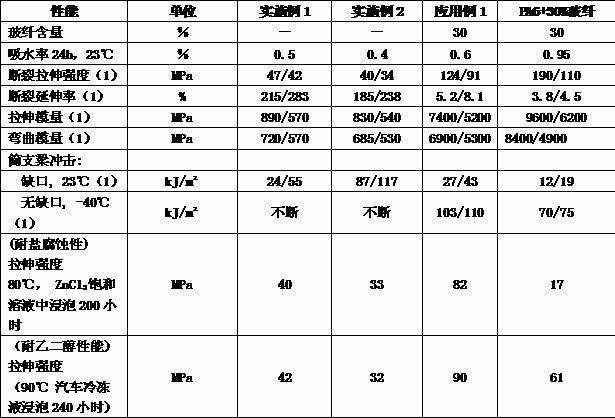

Examples

preparation example Construction

[0021] According to the preparation method of the long carbon chain nylon masterbatch provided by the present invention, preferably, based on the total weight of the nylon masterbatch, the amount of the long carbon chain nylon is 60-90 parts by weight, and the phase The amount of the volume-type toughening agent is 1-30 parts by weight, and the amount of the thermal stabilizer is 0.1-10 parts by weight.

[0022] According to the preparation method of the long carbon chain nylon masterbatch provided by the present invention, the main equipment for producing the product includes a high-speed mixer, an automatic weighing scale, and a screw extruder.

[0023] According to the long carbon chain nylon masterbatch provided by the present invention, its application comprises, the long carbon chain nylon masterbatch and nylon 6, nylon 66, polycarbonate, polyester, polyphenylene ether and acrylonitrile-butadiene-styrene One or more of the terpolymers are heated, melted and mixed to obta...

Embodiment 1

[0025] Premix 84.2 kg of PA610, 15 kg of SEBS-g-MA graft copolymer, and 0.8 kg of H3336 in a high-mixer, then add to a screw extruder, heat and melt, extrude, and then pelletize after water cooling , obtain the long carbon chain nylon masterbatch of the present invention.

Embodiment 2

[0027] 68.7 kg of PA610, 30 kg of SEBS-g-MA graft copolymer, 0.8 kg of H3336, and 0.5 kg of calcium stearate were premixed in a high mixer, then added to a screw extruder, heated and melted, extruded Pelletizing after water-cooling to obtain the long carbon chain nylon masterbatch of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com