Patents

Literature

218results about How to "Improve low temperature impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

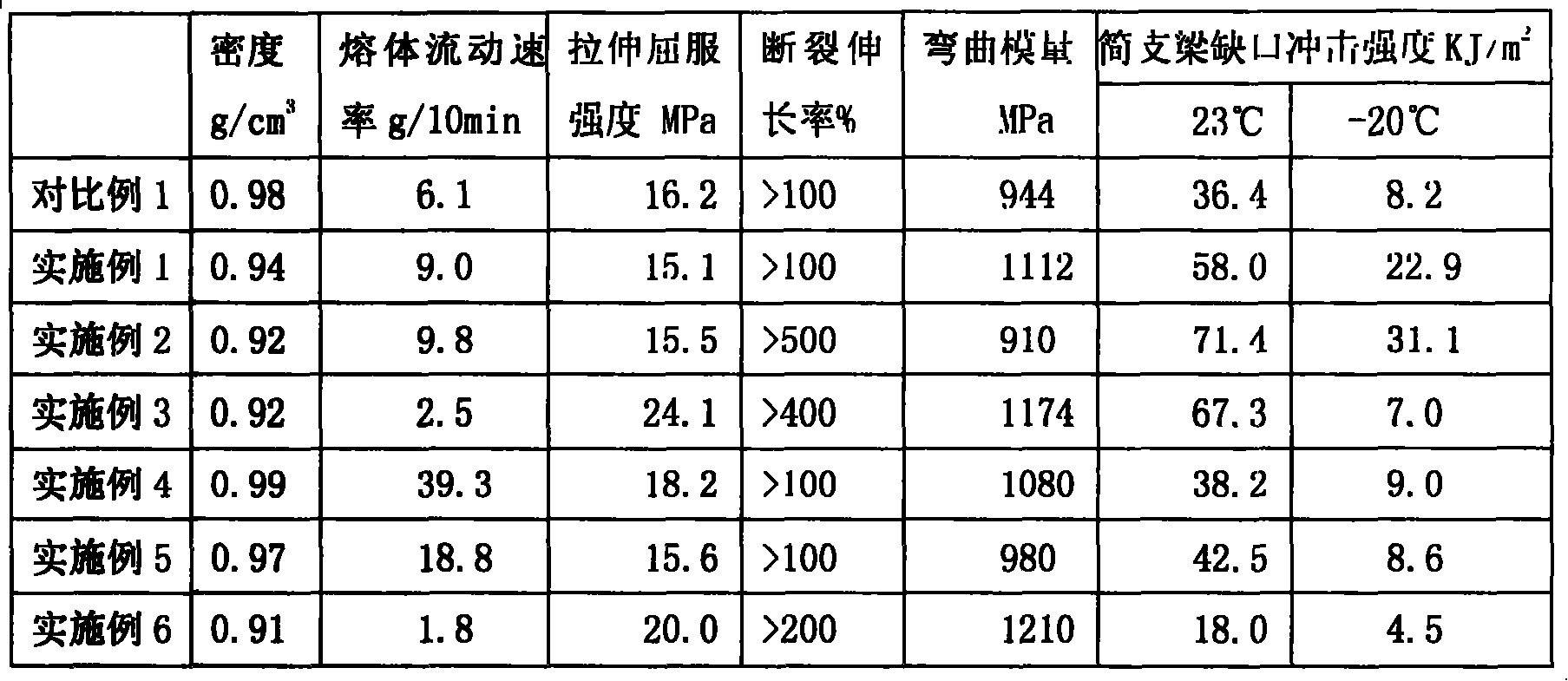

Nanometer calcium carbonate polypropylene composite material

The invention discloses nano calcium carbonate polypropylene composite material. The composite material comprises 100 portions of polypropylene resin, 1 to 15 portions of nano calcium carbonate, 1 to 20 portions of elastomer, and 0.1 to 1 portion of stabilizing agent. The composite material is prepared by method of melt compounding by adopting an internal mixer or double screw extruder. Good rigidity is kept when the toughness of the composite is obviously improved; the composite has good cold impact resistance performance, and is applicable to injection moulding production of automobile parts, i.e. bumper, mudguard, etc.

Owner:CHINA PETROLEUM & CHEM CORP

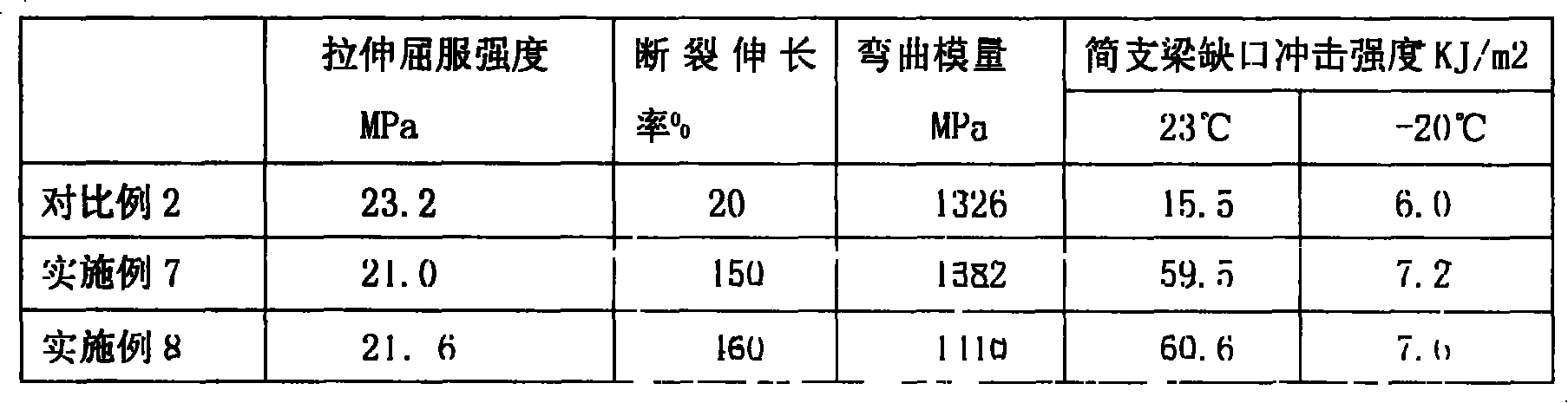

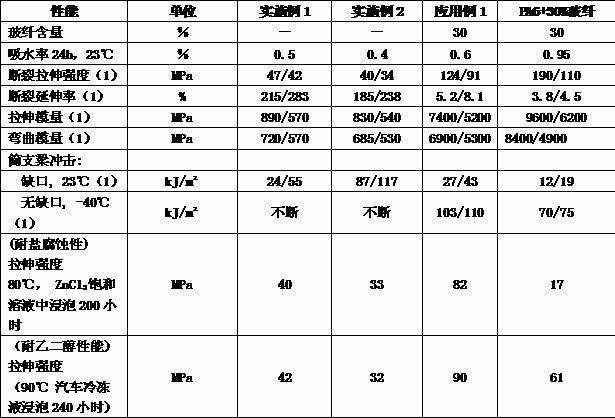

Cold-resistance super tough nylon polyolefin alloy and preparation method thereof

Owner:SHENZHEN KEJU NEW MATERIAL

Chemical corrosion resistant high impact long carbon chain nylon master batch and preparation method and application thereof

InactiveCN102643534AGood chemical resistanceImprove low temperature impact resistanceMasterbatchEngineering plastic

The invention relates to a chemical corrosion resistant high impact long carbon chain nylon master batch, which contains long carbon chain nylon, compatible toughening agents and heat stabilizers. The invention further relates to a preparation method and an application of the nylon master batch. The nylon master batch has good impact resistance, chemical corrosion resistance and low humidity absorption, and is good in compatibility with other engineering plastics and capable of improving chemical corrosion resistance, low-temperature impact resistance and dimensional stabilities of composite materials, wherein the chemical corrosion resistance includes corrosion from zinc halide, calcium halide and ethylene glycol.

Owner:苏州隆阁新材料有限公司

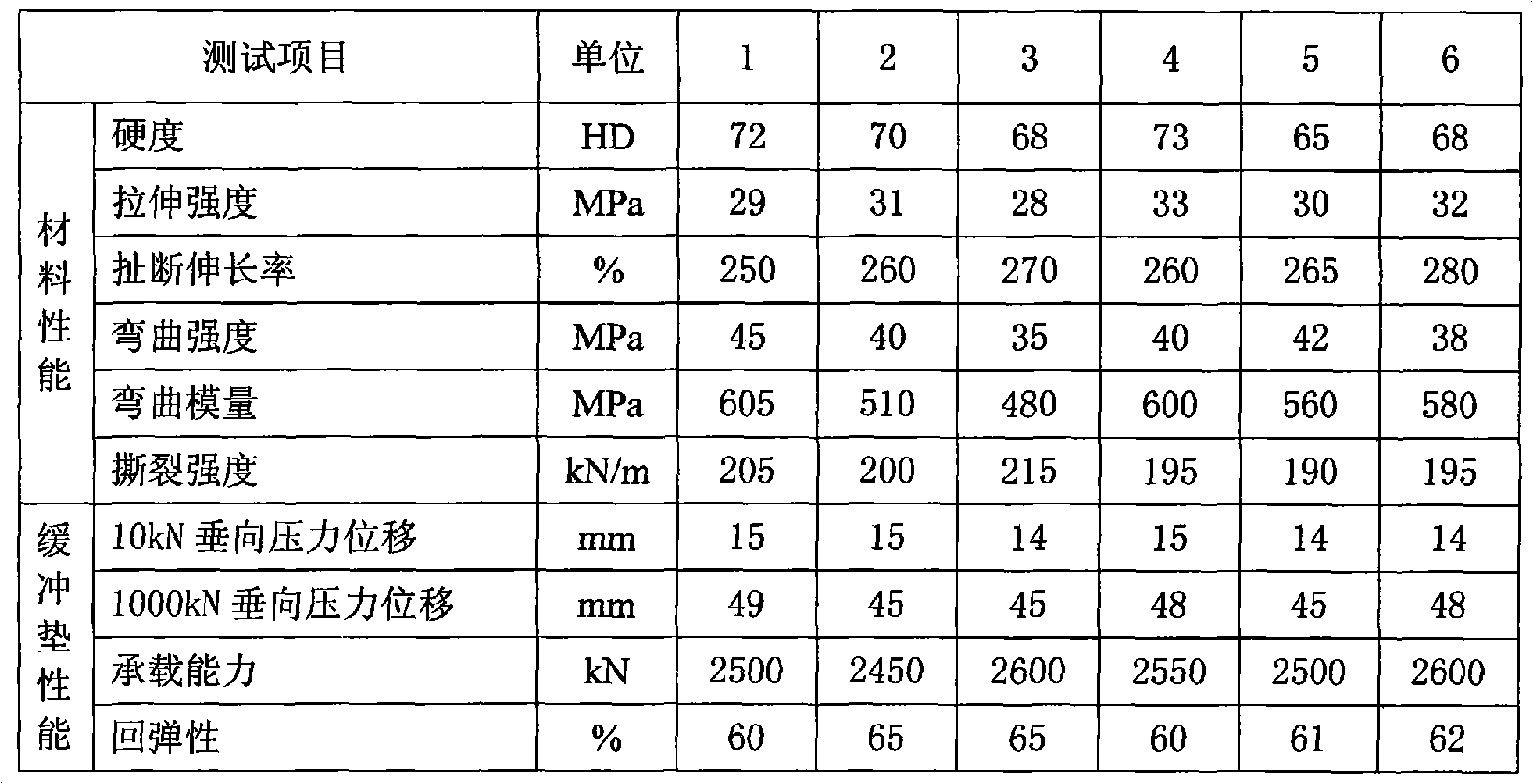

Modified polypropylene resin composition and solar energy rear panel made of the same

ActiveCN103066141AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesSurface layerWater vapor permeability

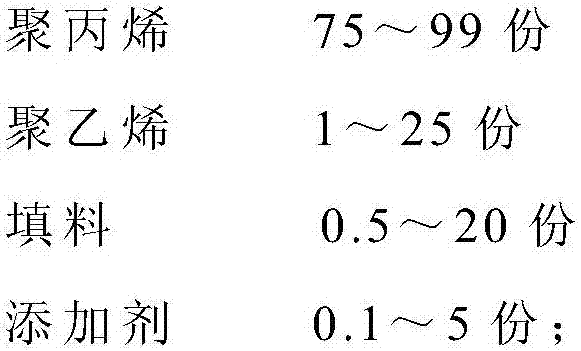

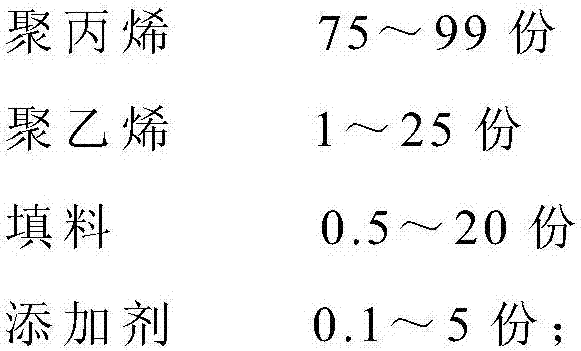

The invention discloses a solar energy rear panel and a preparation method of the solar energy rear panel. The solar energy rear panel comprises an inner surface layer, a core layer and an outer surface layer from inside to outside. By a mass rate, the inner surface layer is 10%-20%, the core layer is 20%-40%, and the outer surface layer is 40%-60%. The inner surface layer and the outer surface layer are made of polyamide resin, fillings and additive, and the core layer is made of the modified polypropylene resin composition. The modified polypropylene resin composition comprises the following components: 100 parts of polypropylene resin, 5-50 parts of graft polyethylene, 0-2.5 parts of additive and 0-100 parts of fillings. Meanwhile, the invention discloses the novel modified polypropylene resin composition used for the solar energy rear panel. Due to the novel modified polypropylene resin composition, a final product obtained has good low temperature resistance and impact resistance, meanwhile anti-aging performance and especially has performance of humidity resistance and resistance to aging. The solar energy rear panel prepared by the novel modified polypropylene resin composition is better than other rear panels in terms of water absorption, water vapor permeability, and interlaminar peeling and has excellent electrical insulating property. A shrinking rate, hot air aging and insulation property required by the solar energy rear panel are met, and the novel modified polypropylene resin composition can be used for solar energy battery components manufacturing .

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

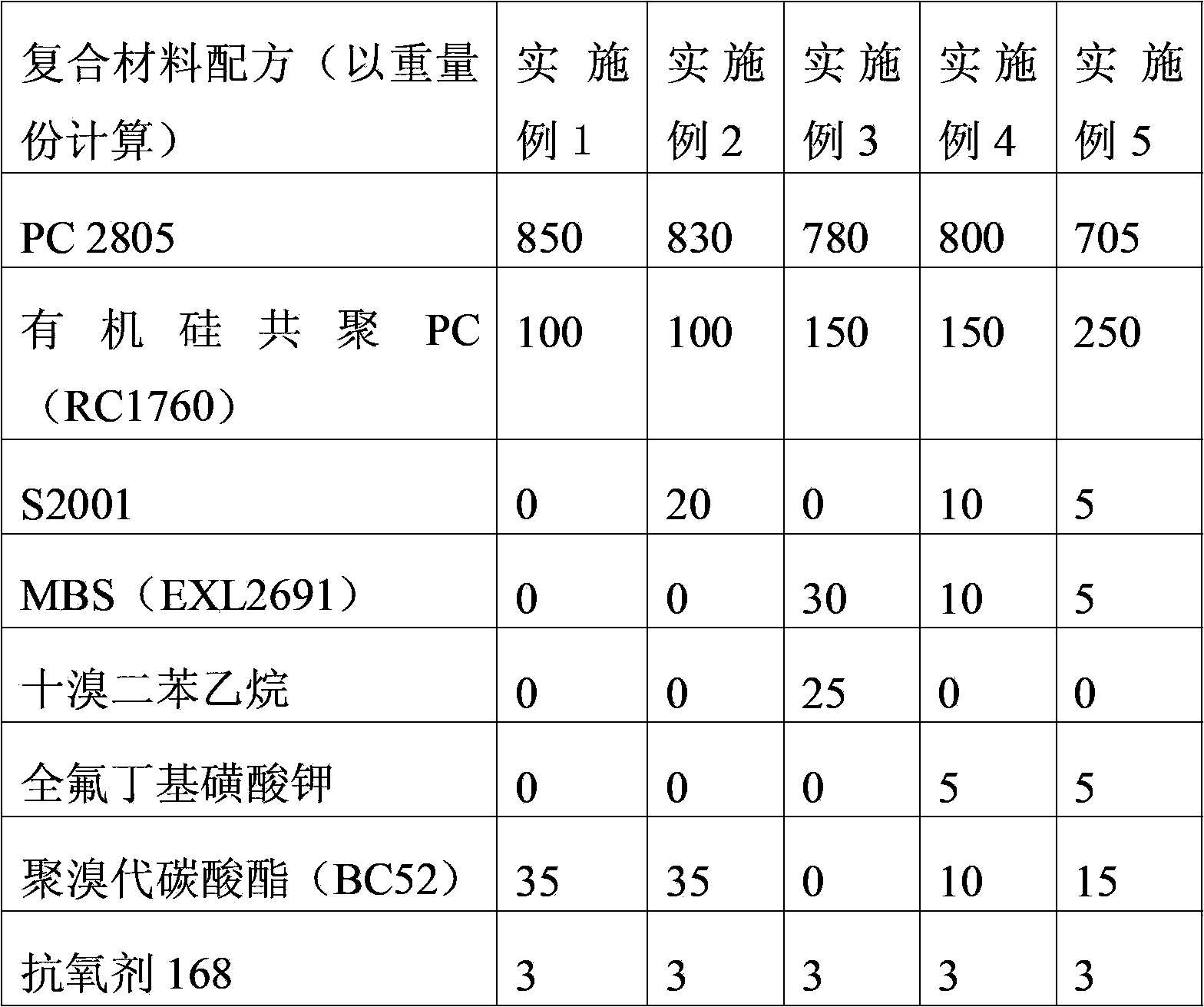

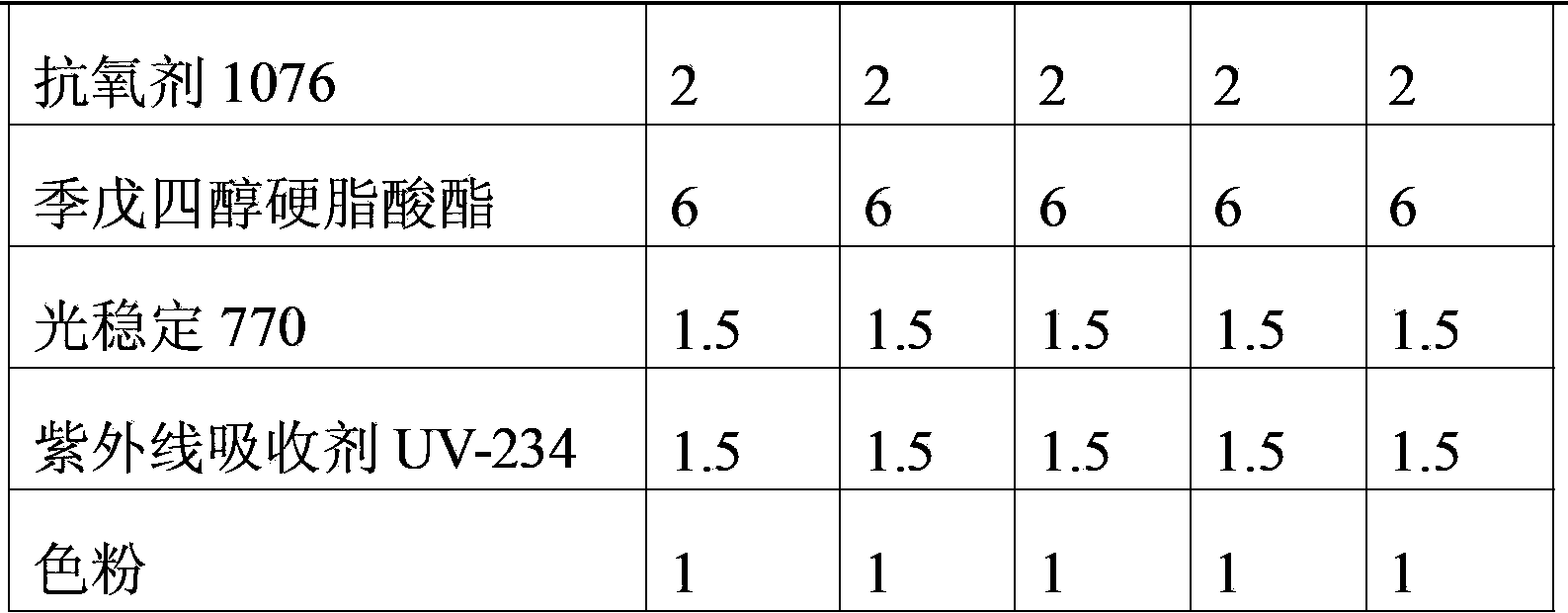

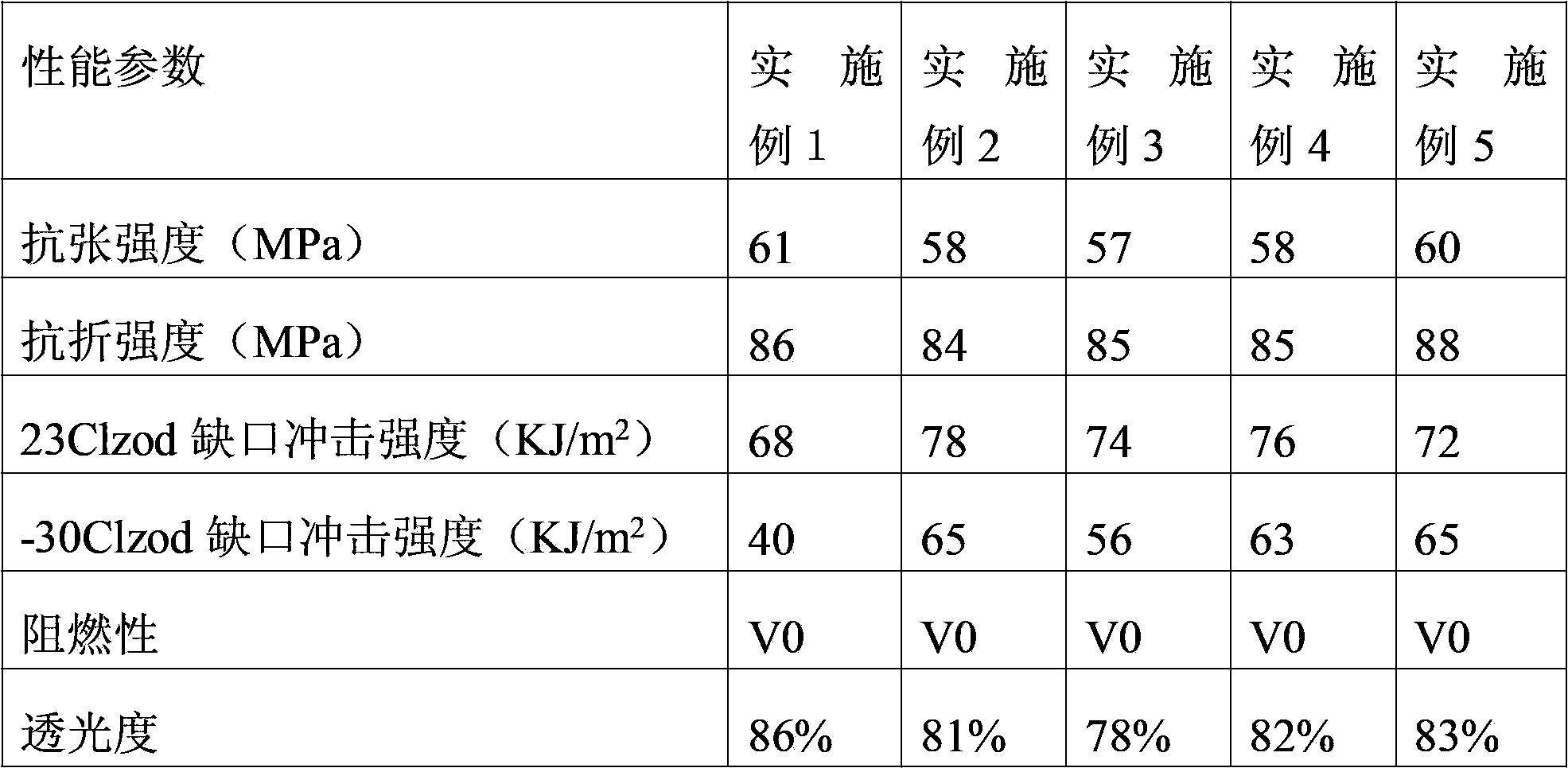

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Hard polychloroethylene tube and its prodn. method

InactiveCN1831041AImprove stabilityWith high temperature sound absorptionTubular articlesPolyvinyl chlorideWhiskers

Owner:上海正鸣塑胶管业有限公司

Extrusion type solar energy backboard and manufacturing method thereof

InactiveCN107275429AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentEngineeringSilica gel

The invention discloses an extrusion type solar energy backboard. The extrusion type solar energy backboard sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, wherein mass ratios of the inner layer, the middle layer and the outer layer are respectively 10-40:40-80:10-40, and total thickness of the extrusion type solar energy backboard is 0.1-0.6mm. The extrusion type solar energy backboard is advantaged in that polypropylene having relatively large rigidity is added to the inner layer, not only can adhesion stress between the backboard and a glue film be guaranteed, but also interlayer adhesion force between the inner layer and the middle-layer polypropylene material is further improved, moreover, polyethylene or copolymer of the polyethylene is added between the middle layer and the outer layer material, excellent adhesion with polyethylene of the inner-layer material can be realized, and interlayer adhesion force and low temperature impact strength of the backboard are further improved; the grafting material is added, uniformity and interlayer adhesion stress of products can be improved, surface tension of the backboard after corona processing can be improved, adhesion force between the backboard and sealing silica gel employed during solar energy cell frame sealing can be enhanced, and sealing performance is better.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

High-weather-resistance acrylate resin composition and preparation method thereof

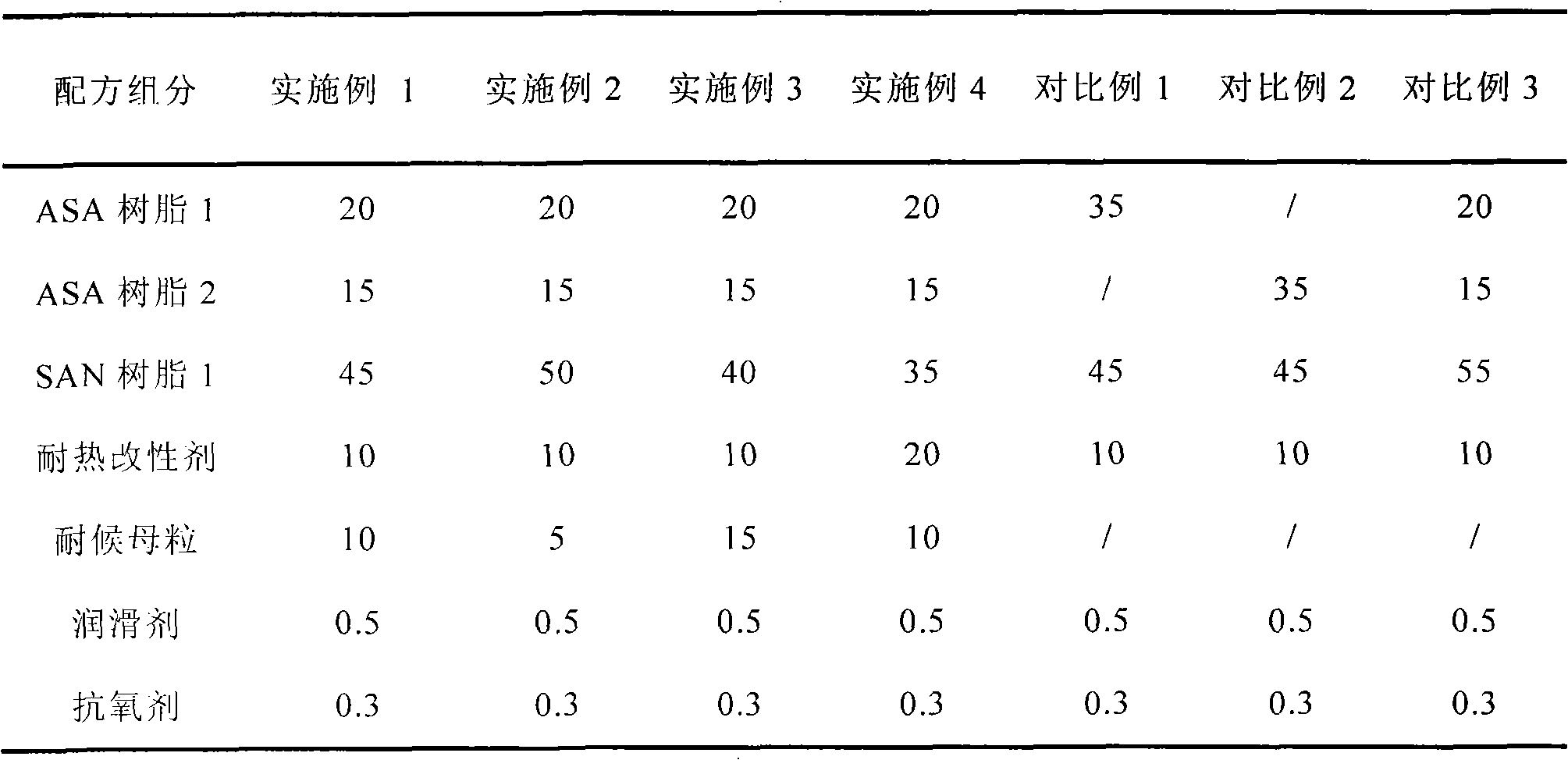

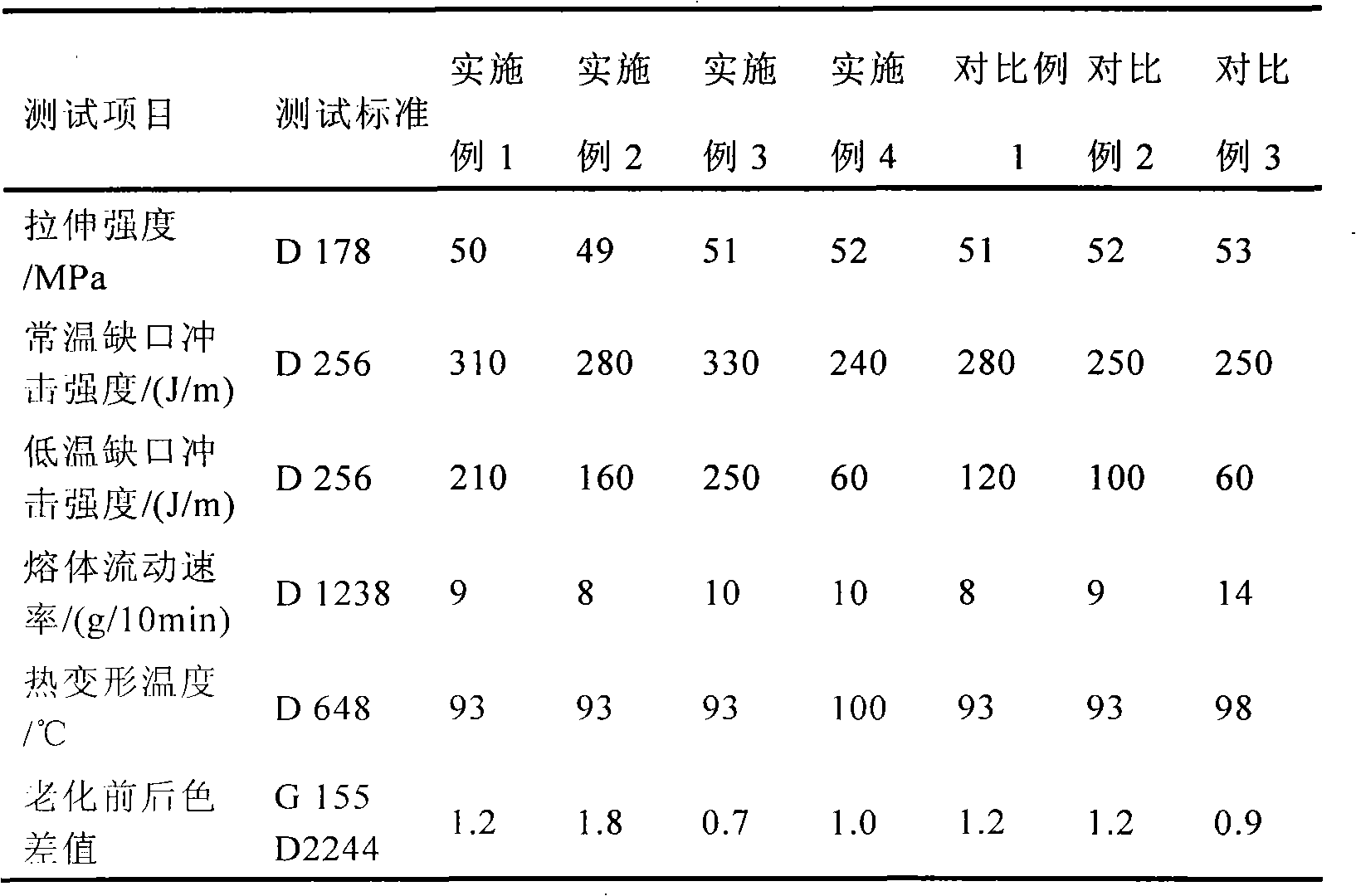

The invention relates to a high-weather-resistance acrylate resin composition and a preparation method thereof. The raw materials of the high-weather-resistance acrylate resin composition comprise the following components in part by weight: 10 to 30 parts of acrylate rubber powder 1, 10 to 30 parts of acrylate rubber powder 2, 30 to 60 parts of SAN resin 1, 5 to 20 parts of heat-resistant modifier, 5 to 15 parts of weather-resistant master batch, 0.3 to 3 parts of lubricant and 0.05 to 0.5 part of antioxidant. The preparation method comprises the following steps of: stirring the raw materials except the weather-resistant master batch to obtain a mixture; adding the mixture from a main feed inlet of a double-screw extruder, and adding the weather-resistant master batch from a side feed inlet; and extruding and pelleting the raw materials by the double-screw extruder to obtain a sample. The high-weather-resistance acrylate resin composition prepared by the method has higher heat resistance, low-temperature impact resistance, weather resistance, excellent size stability and processing property, and is particularly suitable for automobile exterior trim parts, such as radiator grilles, rear-view mirrors, license plates, central pillar plates, outdoor triangular blocks and the like, with high requirements on weather resistance, heat resistance and low-temperature impact resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

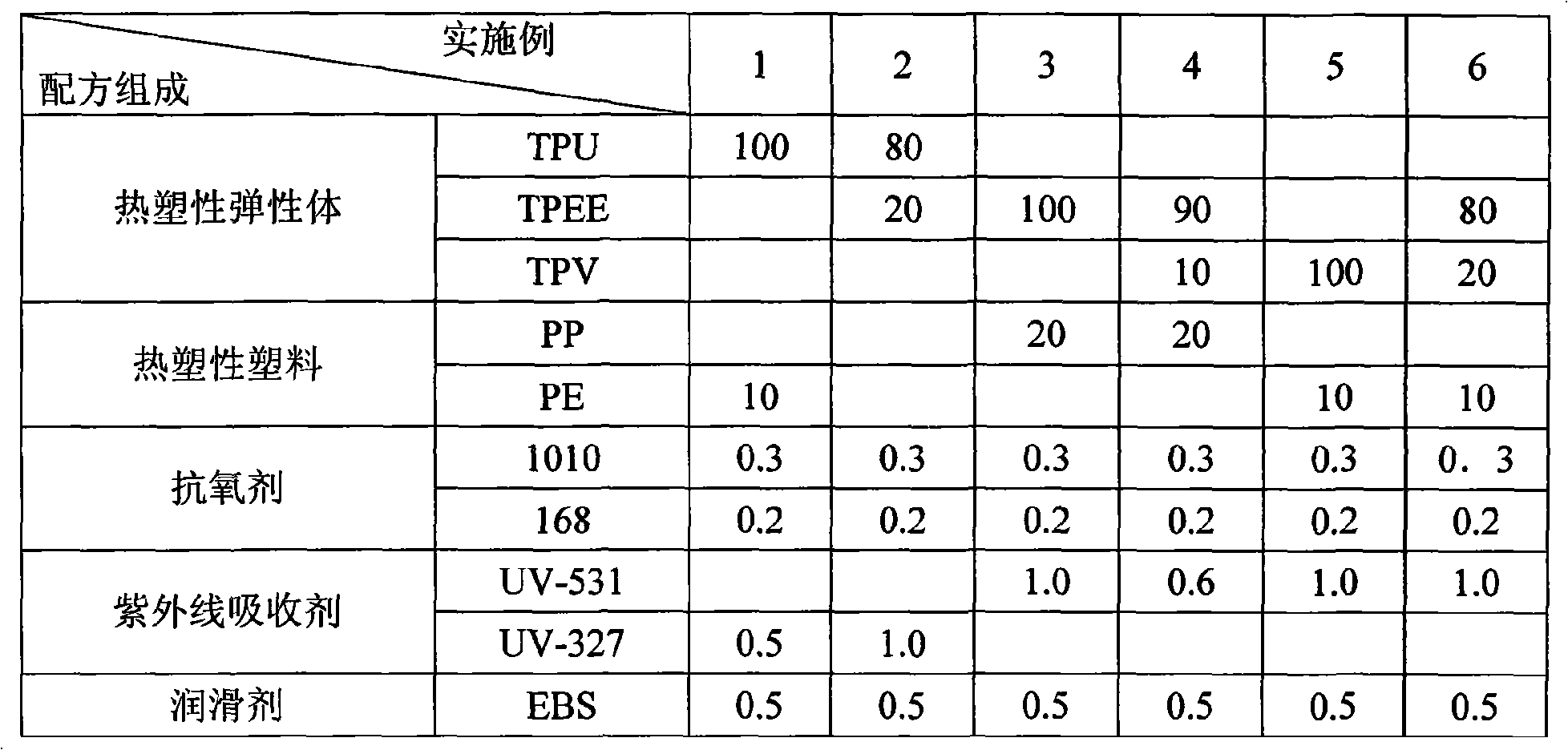

Method of preparing thermoplastic elastomer compound material and product thereof

InactiveCN101550281AGood high pressure resilienceSmall permanent deformationThermoplasticInjection molding machine

Method of preparing thermoplastic elastomer compound material and product thereof, applying post forming technics. The post forming technics is: first prepare the mold core by the method of injection molding or compression molding; then put the mold core into the mould and produce product with mold core by the compression molding method, taking the mold core out of the product by mechanical crushing, getting the product of hollow thermoplastic elastomer compound material. The post forming method includes following steps: 1) preparing the mold core by the injection molding of the compression molding method; 2) putting the mold core into the mould and producing product with the mold core by the injection molding method; 3) taking the mold core out of the product by mechanical crushing to get the hollow product. 4) the crushed mold core can be reclaimed for recreating use. The thermoplastic elastomer product prepared by the invention provided moulding preparation method is in formula (in mass parts proportioning): thermoplastic elastomer 100parts; thermoplastic plastics 1-50 parts; anti-oxidant 0.5-10 parts; ultraviolet absorbent 0.5-10 parts; lubricants 0.1-5.0 parts.

Owner:株洲时代工程塑料制品有限责任公司

Extrusion type solar backboard and preparing method thereof

InactiveCN106279904AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentMass ratioEngineering

The invention discloses an extrusion type solar backboard. The extrusion type solar backboard comprises an inner layer, a middle layer and an outer layer from inside to outside in sequence, wherein the mass ratio of the inner layer to the middle layer to the outer layer is (10-40):(40-80):(10-40). The total thickness of the extrusion type solar backboard is 0.1-0.6 mm. By adding high-rigidity polypropylene to the inner layer, cohesive force between the backboard and an adhesive film is guaranteed, and interlayer cohesive force between the backboard and a polypropylene material of the middle layer is improved; meanwhile, by adding polyethylene or copolymers thereof to the material of the middle layer and the outer layer to enable the middle layer and the outer layer to be well bonded with polyethylene in the material of the inner layer, interlayer cohesive force and low-temperature impact resistance of the backboard are improved.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Environment-friendly vehicle natural fiber composite material and preparation method as well as application thereof

ActiveCN102717558AReduce formaldehyde contentImprove low temperature impact resistanceSynthetic resin layered productsCellulosic plastic layered productsSlurryVolumetric Mass Density

The invention relates to an environment-friendly vehicle natural fiber composite material and a preparation method as well as application thereof. The preparation method of the vehicle natural fiber composite material comprises the following steps of: treating a continuous natural fiber fabric with water content of less than 0.2 percent by using a silane coupling agent; immersing the treated continuous natural fiber fabric in mixed slurry; drying the immersed continuous natural fiber fabric until the water content is less than 0.2 percent; soaking in molten polylactic acid with density of 1.22 g / cm<3>; performing hot pressing on the soaked fabric at 170-190 DEG C to obtain a natural fiber polylactic acid composite felt; and slicing the natural fiber polylactic acid composite felt, laminating and performing hot forming at 170-190 DEG C to obtain the vehicle natural fiber composite material. According to the vehicle natural fiber composite material, the natural fiber and the polylactic acid are used as raw materials, and the raw materials have environment-friendly sources, are renewable and can be completely degraded.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

Low temperature impact-resistant polypropylene composition

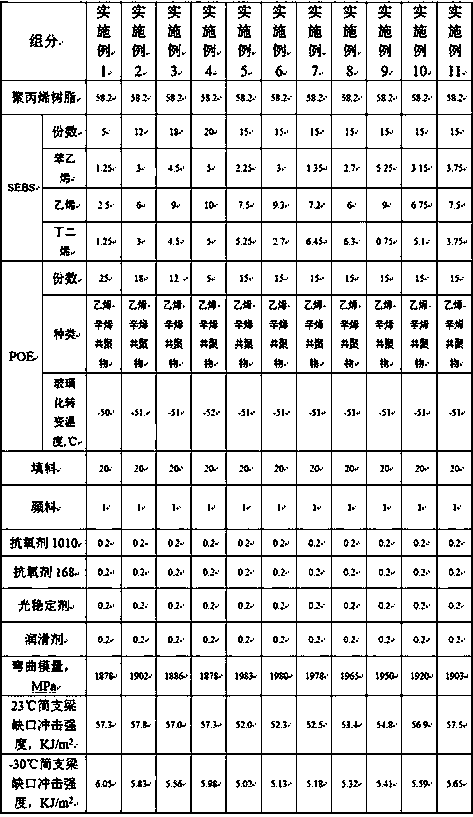

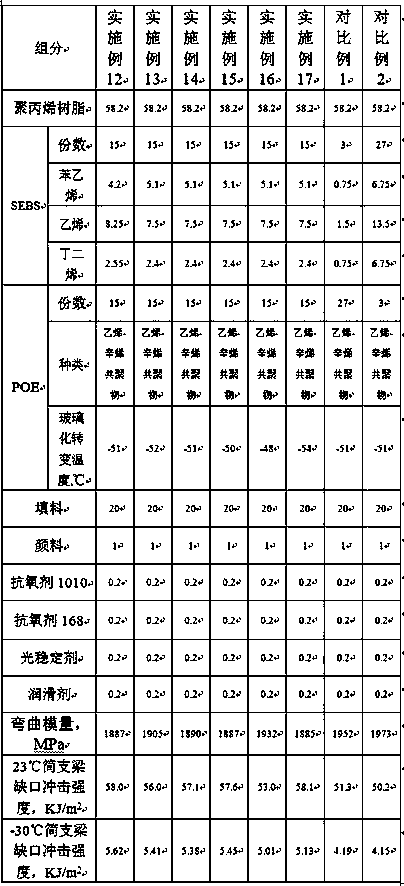

The invention discloses a low temperature impact-resistant polypropylene composition. The low temperature-resistant impact-resistant polypropylene composition comprises, by weight, 40 to 75 parts of polypropylene resin, 5 to 20 parts of a hydrogenated styrene-butadiene block copolymer SEBS and 5 to 25 parts of a polyolefin elastomer POE. Through use of the hydrogenated styrene-butadiene block copolymer SEBS and the polyolefin elastomer POE in specific weight contents in the low temperature-resistant impact-resistant polypropylene composition, the impact resistance and low temperature impact resistance of the composition are improved. A sample prepared from the composition has Charpy notched impact strength of greater than 5.0 KJ / m<2> after standing at -30 DEG C for 4h and has good rigidity.

Owner:KINGFA SCI & TECH CO LTD

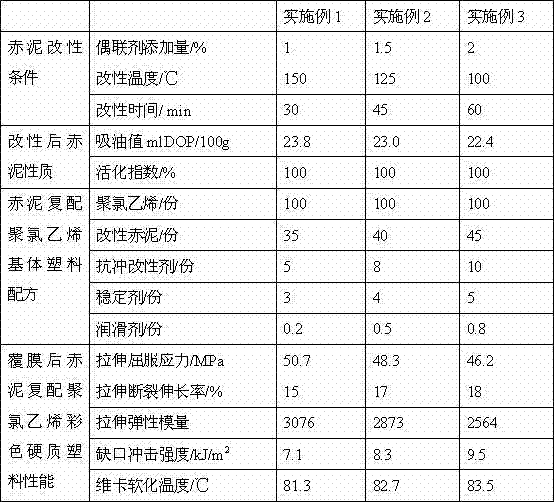

Production method of red mud complexed polyvinyl chloride colorized rigid plastic

ActiveCN102492234ALow alkali contentRealize comprehensive utilizationSynthetic resin layered productsLaminationRed mudPolyvinyl chloride

The invention relates to a production method of modified red mud complexed polyvinyl chloride colorized rigid plastic. The method is characterized in that: graded red mud with a specification of -800 meshes is modified by using a titanate coupling agent; 35-45 parts of the modified red mud, 100 parts of polyvinyl chloride, 5-10 parts of an impact modifier, 3-5 parts of a stabilizing agent, and 0.2-0.8 parts of a lubricating agent are subject to high-speed mixing, melt extrusion and filming, such that the colorized rigid plastic is obtained. According to the invention, red mud is subject to a modification treatment, such that the compatibility of the red mud and polyvinyl chloride is substantially improved. When the plastic is subject to the filming treatment, a monotonic brownish red color of the red mud complexed polyvinyl chloride substrate plastic is changed, a woody pattern is provided, the color is diversified, and the plastic is provided with a good appearance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

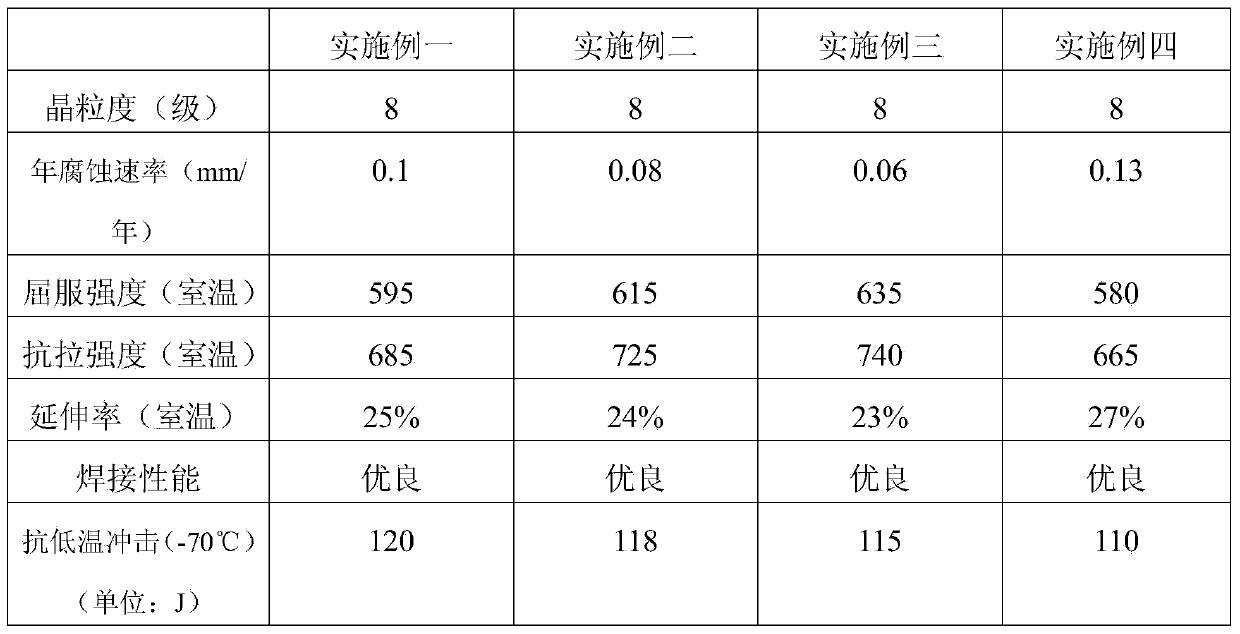

Preparation method of boron-containing seamless pipeline for marine petroleum and natural gas exploitation

The invention discloses a preparation method of a boron-containing seamless pipeline for marine petroleum and natural gas exploitation, which comprises the following steps: a) adopting, smelting and casting waste steel, pig iron and ingredients to obtain a pipe blank, wherein the pipe blank surely comprises the following chemical elements by weight percentage: 0.09-0.19 percent of C, 0.23-0.38 percent of Si, 0.9-1.7 percent of Mn, 0.0015-0.0025 percent of B, 0.01-0.07 percent of Nb, not greater than 0.012 percent of P, not greater than 0.007 percent of S, and Fe and other unavoidable impurities in balancing amount; b) performing heat treatment of the pipe blank; c) then rolling; d) finally obtaining the boron-containing seamless pipeline for the marine petroleum and natural gas exploitation via the heat treatment and detection. The pipeline prepared by the preparation method is high in tensile strength, good in welding performance, excellent in resistance to corrosion of brine and an acid environment and good in low-temperature impact resistance, and has the characteristic of high toughness, and the low-temperature impact resistance can reach 100 J at 70 DEG C below zero.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

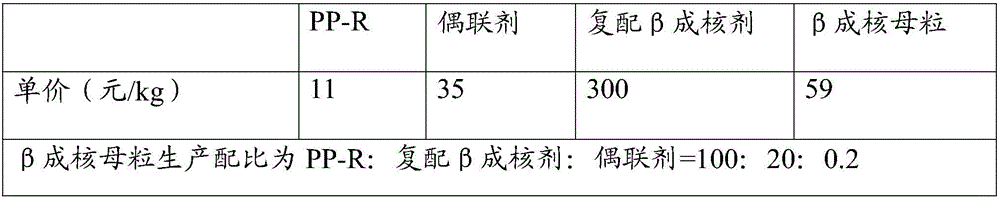

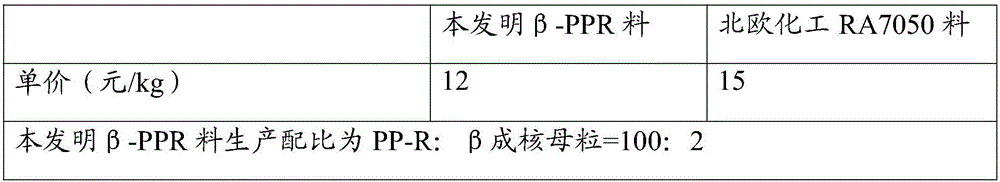

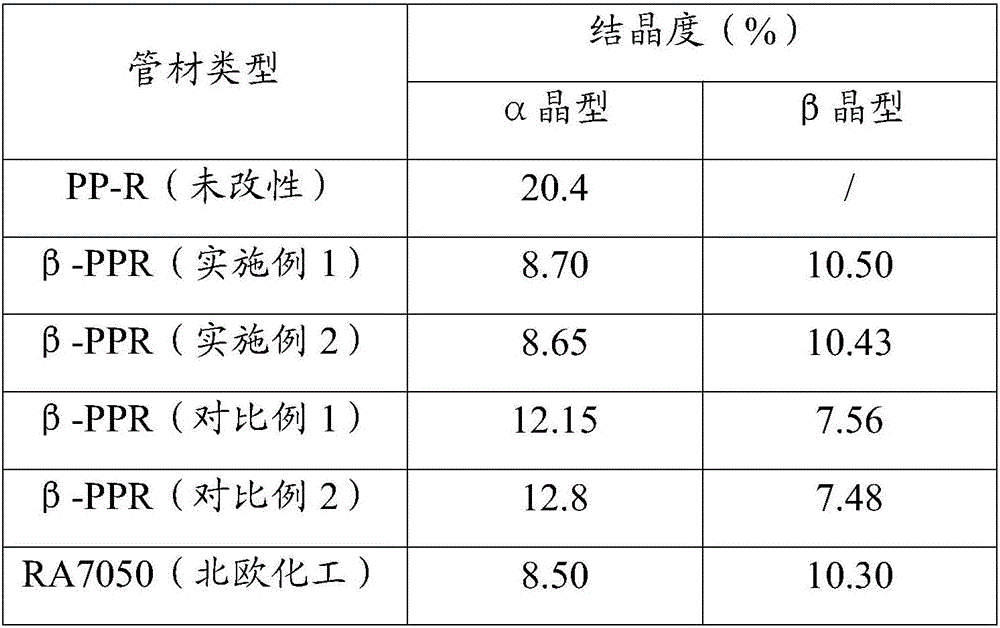

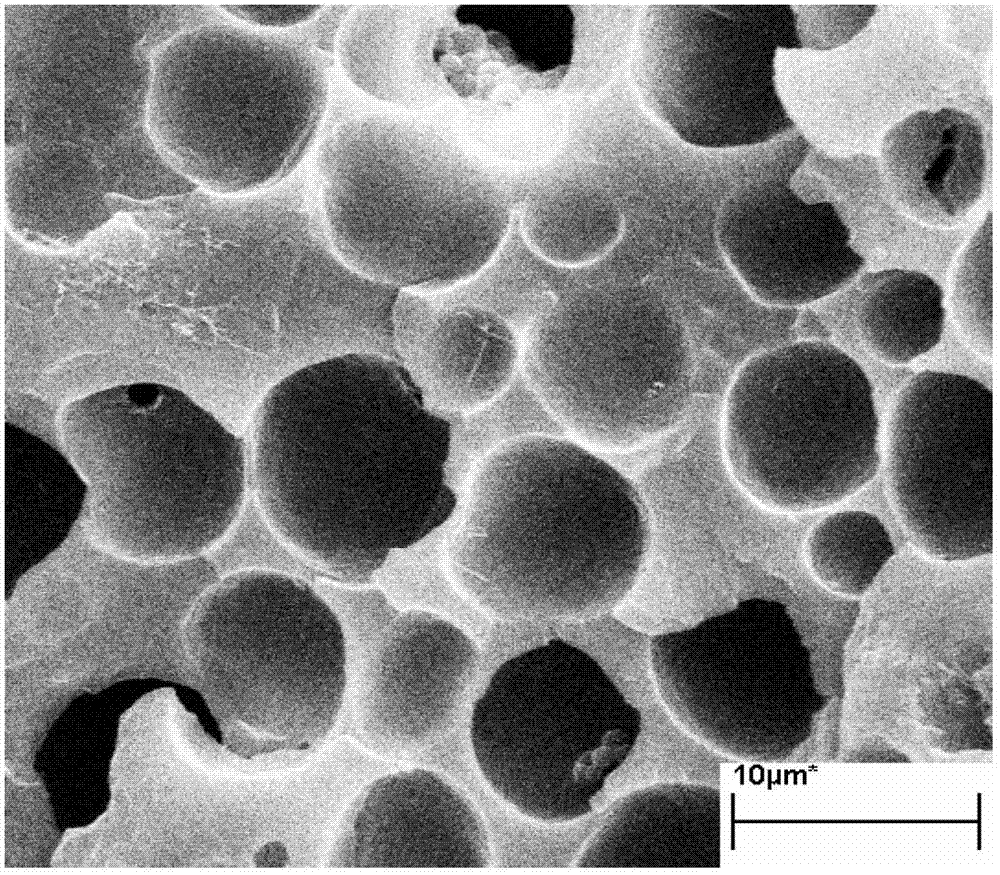

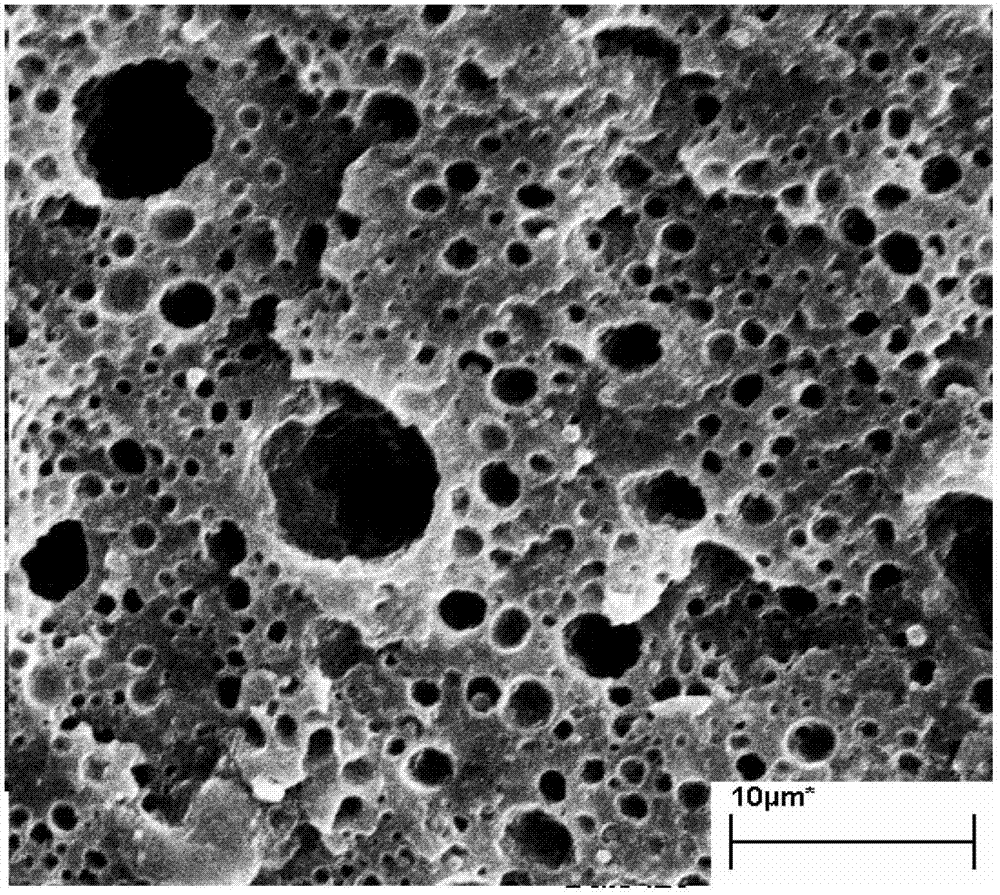

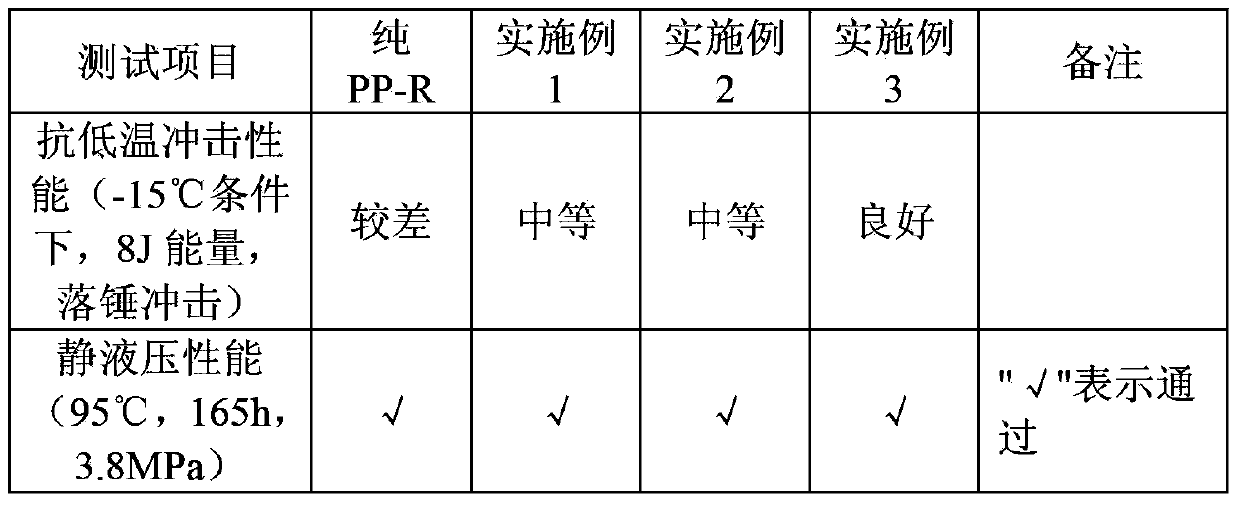

Beta-PPR tube and preparation method thereof

ActiveCN105860275AHigh low temperature impact resistanceReduce brittle crackingShock resistanceMaterials science

The invention relates to a beta-PPR tube and a preparation method thereof. The beta-PPR tube is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin and 1-5 parts of beta nucleated master batch, wherein the beta nucleated master batch is prepared from the following raw materials in parts by mass: 100 parts of PP-R resin, 0.1-1 part of coupling agent and 10-30 parts of beta nucleator. The beta-PPR tube improves the low-temperature shock resistance of the tube and greatly reduces the problem of brittle cracking of the tube, and the preparation method has simple technique, reduces the raw material cost and is favorable for ordinary popularization and use.

Owner:RIFENG TECH CO LTD +1

Supernylon 6 alloy and method for prearing supernylon 6 alloy by means of in-situ reaction compatibilization

The invention discloses a supernylon 6 alloy and a method for preparing supernylon 6 alloy by means of in-situ reaction compatibilization. The method includes mixing nylon 6 and ethylene with octylene copolymer, trigger and maleic anhydride and preparing supernylon 6 alloy high in tenacity, resistant to low temperature and low water absorption in a double-parallel-screw extruder. The raw materials of the supernylon 6 alloy includes, by weight, 55-95 parts of nylon 6, 5-45 parts of POE (polyolefin elastomer), 0.01-1 part of trigger, 0.1-4 parts of maleic anhydride and 0.1-4 parts of HDPE-g-MAH (high-density polyethylene-g-maleic anhydride), wherein the trigger is organic peroxide including hydroperoxide, alkyl peroxide, dibenzoyl peroxide, lipoperoxide and peroxide carbonate. The supernylon 6 alloy is excellent in comprehensive performance, high in impact strength of notches, resistant to low temperature and impact, low in water absorption and easy to popularize and apply, technique process is shortened, and production efficiency is improved.

Owner:SINOPLAST NEW MATERIAL

Heat resistance reinforced polyethylene pipe and its preparation method

InactiveCN101148524AReduced service life impactLower requirementTubular articlesLow-density polyethyleneLinear low-density polyethylene

The present invention relates to one kind of heat resistant reinforced polyethylene pipe and its making process. The materials for the polyethylene pipe includes ultralow density polyethylene 100 weight portions, nanometer silica 20 weight portions and antioxidant 0.1 weight portion. The polyethylene pipe is made through the steps of stoving the materials, feeding, extruding, molding, vacuum sizing, cooling, drawing, ink jetting printing, winding and product packing. It is made in an automatically controlled production line in high production speed and high product quality.

Owner:戴恩晞 +3

Hydroxyl type water-borne cationic polyurethane-acrylic acid resin and preparation method thereof

The invention provides a preparation method of hydroxyl type water-borne cationic polyurethane-acrylic acid resin. The method comprises the following steps that 1, hydroxyl telechelic polyester containing an unsaturated double bond is obtained through a reaction; 2, a product obtained in the first step serves as the raw material, dihydric alcohol, isocyanate, a hydrophilic monomer, a catalyst, an end-capped reagent, neutralizer and the like are added according to the ratio of a designed formula, and the unsaturated water-borne cationic polyurethane is obtained; 3, a product obtained in the second step serves as the raw material to be reacted with an acrylate monomer according to the ratio of a designed formula, and the hydroxyl type water-borne cationic polyurethane-acrylic acid resin is obtained. The end-capped reagent is added in the second step, double bond monomer end-capping is conducted on a water-borne cationic polyurethane resin prepolymer, and the grafting rate of acrylic acid resin is further increased; the reaction condition is mild, water-borne cationic polyurethane-hydroxyl type acrylic acid resin with improved performance is obtained without adding emulsifier, and the application field of the resin is greatly enlarged.

Owner:武汉仕全兴聚氨酯科技有限公司 +1

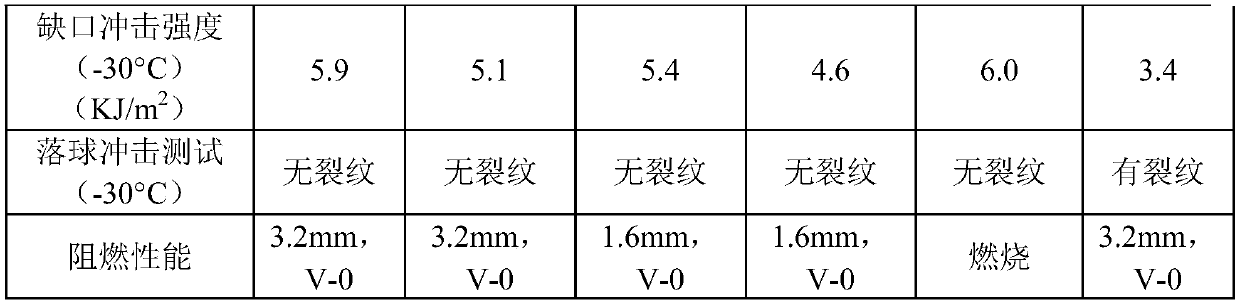

Low-temperature impact resistant, cracking resistant and flame-retardant polypropylene material, and preparation method and applications thereof

InactiveCN109651749AImprove flame retardant performanceImprove toughnessCrack resistancePolypropylene

The invention provides a low-temperature impact retardant, cracking retardant and flame-retardant polypropylene material, and a preparation method and applications thereof. The polypropylene materialincludes, by weight, 40-75 parts of polypropylene resin, 2-20 parts of ethylene-octene copolymer (POE), 0-30 parts of a mineral filler, 5-30 parts of a brominated flame retardant, 5-15 parts of a synergistic flame retardant, 0.3-3.5 parts of a stabilizing agent, and 0.5-2 parts of toner. Through the addition of the brominated flame retardant and the synergistic flame retardant, the material can have good flame retardant properties; and through the selection of the specific copolymerized polypropylene resin and the ethylene-octene copolymer (POE) which is taken as a flexibilizer to perform compounding, the material can have good low-temperature impact resistance and cracking resistance, and therefore, the material can be applied to external decorative parts and functional parts of large vehicles such as trucks and engineering trucks.

Owner:TIANJIN KINGFA NEW MATERIAL

Low-temperature impact resistance PP-R tubing and preparation method thereof

ActiveCN103360686AImprove low temperature impact resistanceGood internal pressure resistanceInternal pressurePolymer science

The invention discloses a low-temperature impact resistance PP-R tubing and a preparation method thereof. The tubing is composed of following components in percentage by weight: 69 to 94.9% of random copolymerized polypropylene, 5 to 30% of polypropylene block copolymer (PPB), and 0.1 to 1.0% of beta-crystal nucleating agent. The preparation method comprises following steps: mixing random copolymerized polypropylene, block copolymerized polypropylene and beta-crystal nucleating agent according to the ratio mentioned above in a mixer for 2 to 5 minutes; subjecting the mixture to an extrusion granulation treatment by using a double screw extruder at the temperature of 170 to 220 DEG C, thus obtaining a composite material of PP-R / PP-B; then subjecting the composite material to an extrusion molding treatment, and obtaining the low-temperature impact resistance PP-R tubing. The PP-R tubing, which is prepared through mixing PP-R powder material and PP-B powder material and adding a certain amount of beta-crystal nucleating agent, has a prominent improved low-temperature impact resistance ability and good internal pressure resistance performance.

Owner:杭州鸿雁管道系统科技有限公司

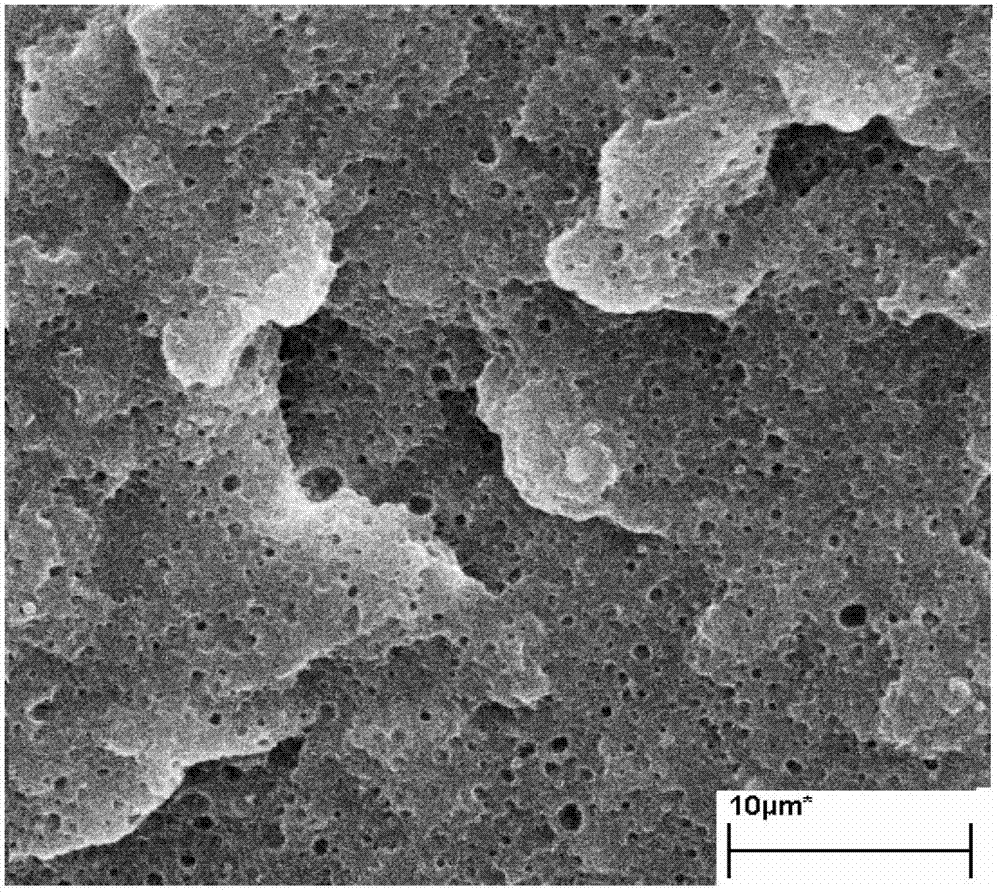

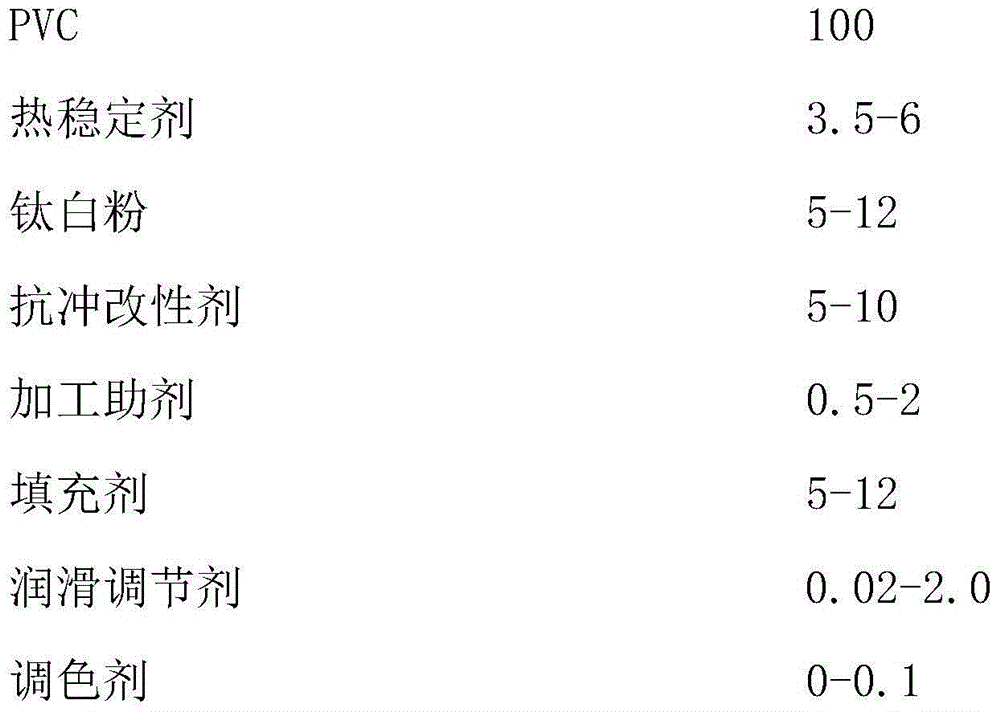

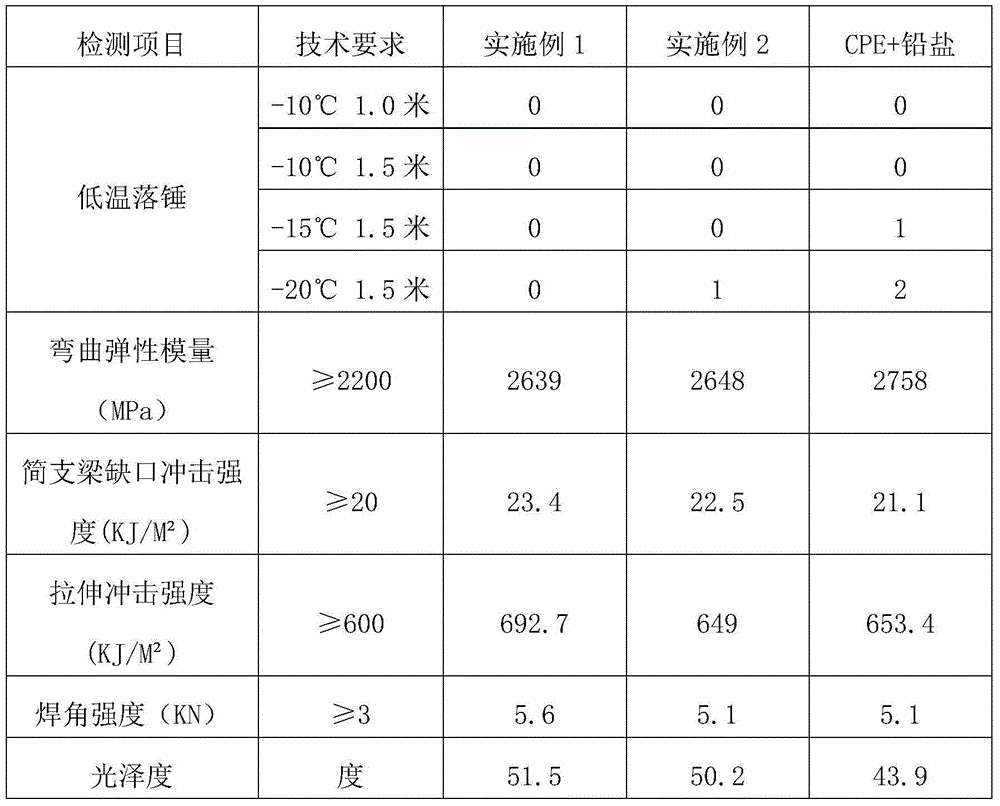

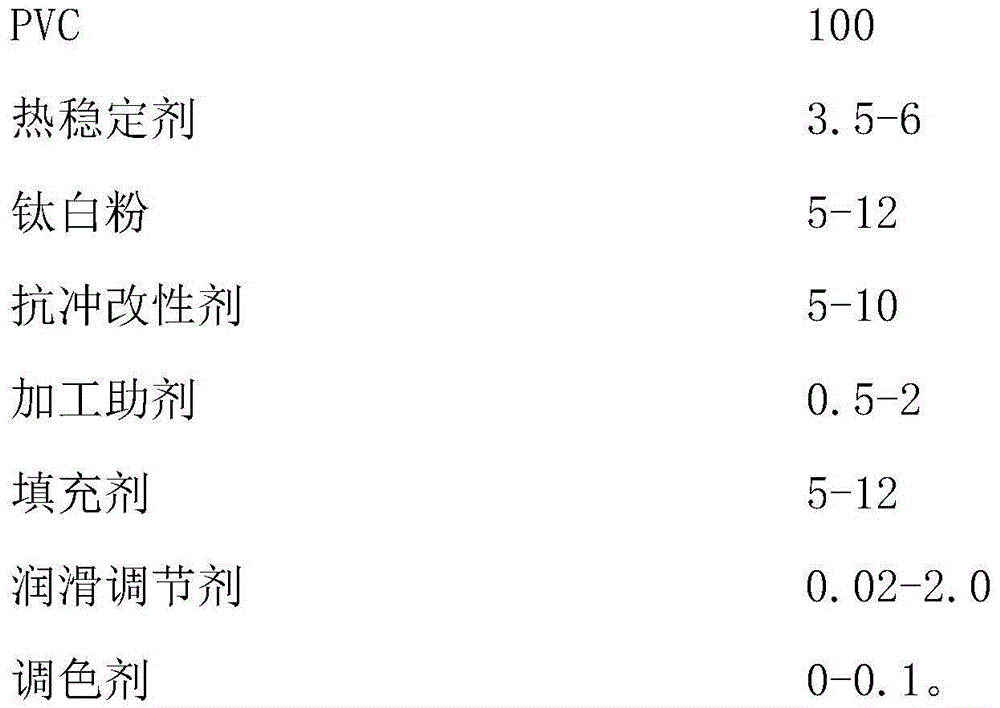

High-impact-resistance PVC profile meeting high-speed extrusion requirement and preparing method thereof

The invention discloses a high-impact-resistance PVC profile meeting the high-speed extrusion requirement and a preparing method of the PVC profile. The PVC profile comprises 100 parts of PVC, 3.5 parts to 6 parts of heat stabilizers, 5 parts to 12 parts of titanium dioxide, 5 parts to 10 parts of impact-resistant modifiers, 0.5 part to 2 parts of processing auxiliaries, 5 parts to 12 parts of filling agents, 0.02 part to 2.0 parts of lubricating regulators and 0 part to 0.1 part of color matching agents. Compared with the prior art, the PVC profile prepared with the method is suitable for high-speed extrusion of a parallel double-screw extruder, low temperature impact resistance is excellent, the appearance quality of the profile is remarkably improved, and the surface is smooth and fine, composition does not include the heavy metal such as Ba, Cd and Pb, the PVC profile is free of poison and environmentally friendly and sulfide pollution cannot happen to the PVC profile easily; a processing range is wide and an existing CPE formula system does not need to be adjusted substantially.

Owner:海螺(安徽)节能环保新材料股份有限公司

Boron-containing seamless pipe line pipe for ocean oil and gas exploitation

The invention discloses a boron-containing seamless pipe line pipe for ocean oil and gas exploitation. The boron-containing seamless pipe line pipe is characterized by comprising the following chemical elements by weight percent: 0.09 to 0.19 percent of C, 0.23 to 0.38 percent of Si, 0.9 to 1.7 percent of Mn, 0.0015 to 0.0025 percent of B, 0.01 to 0.07 percent of Nb, less than or equal to 0.012 percent of P, less than or equal to 0.007 percent of S and the balance of Fe and unavoidable impurities. The boron-containing seamless pipe line pipe is high in tensile strength, good in welding property, excellent in salt water and acid environmental corrosion resistance and good in low-temperature impact resistance, the low-temperature impact resistance can reach 100J under the condition of minus 70 DEG C, and the boron-containing seamless pipe line pipe has the characteristic of high flexibility; by adopting the way for combining hot rolling and tempering heat treatment, the strength can reach the grade of more than 80ksi.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

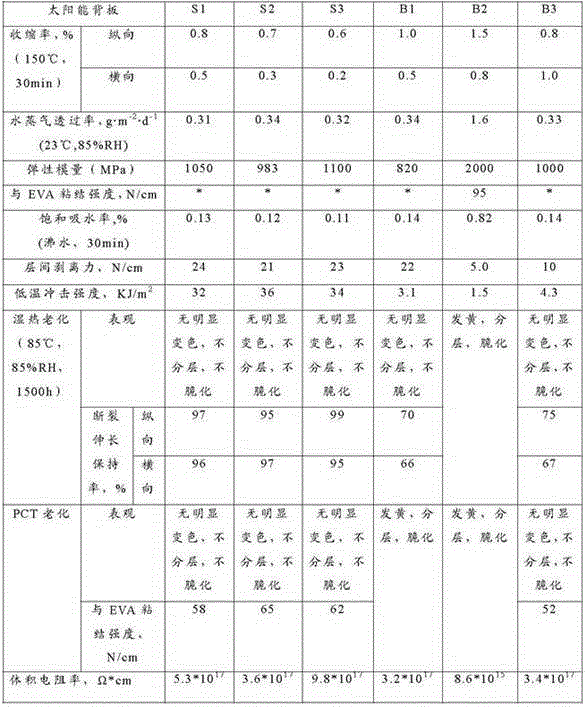

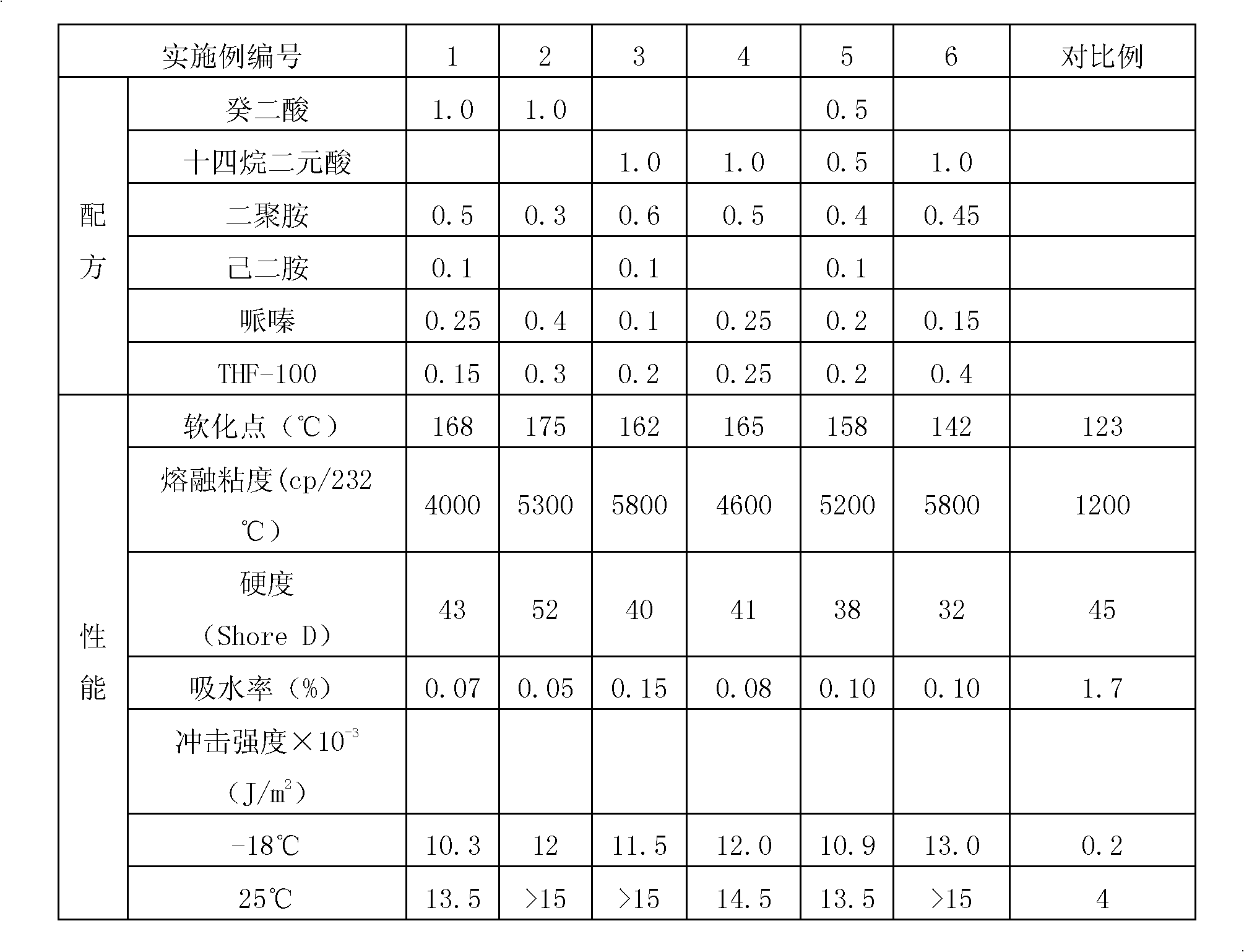

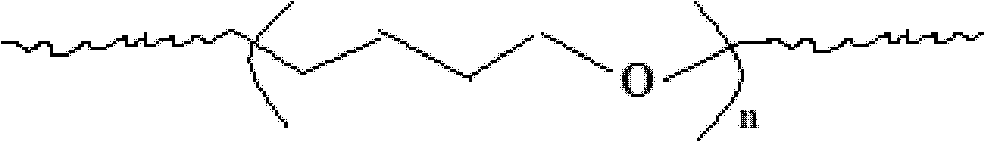

Novel polyamide adhesive

ActiveCN103184030ALow water absorptionImprove low temperature resistanceOther chemical processesAdhesivesPolymer sciencePolyamide

The invention relates to a polyamide hot melt adhesive and a preparation method thereof. The polyamide hot melt adhesive comprises: (1) a C5-C18 aliphatic dicarboxylic acid copolymerization unit; and (2) a diamine copolymerization unit, which is composed of, based on its total mole number: (a) 20-70 mole% of a C24-C48 dipolyamine copolymerization unit; (b) 0-30 mole% of a C2-C10 aliphatic diamine copolymerization unit; (c) 0-50 mole% of a C4-C8 heterocyclic diamine copolymerization unit; and (d) 5-50 mole% of a poly C1-4 alkylidene ether diamine copolymerization unit. The number average molecular weight Mn of the polyamide hot melt adhesive ranges from 2000 to 30000. The polyamide hot melt adhesive has a moderate softening point, extremely low water absorption and low temperature impact resistance, thus being suitable to serve as a hot melt adhesive.

Owner:SHANGHAI LIGHT IND RES INST +1

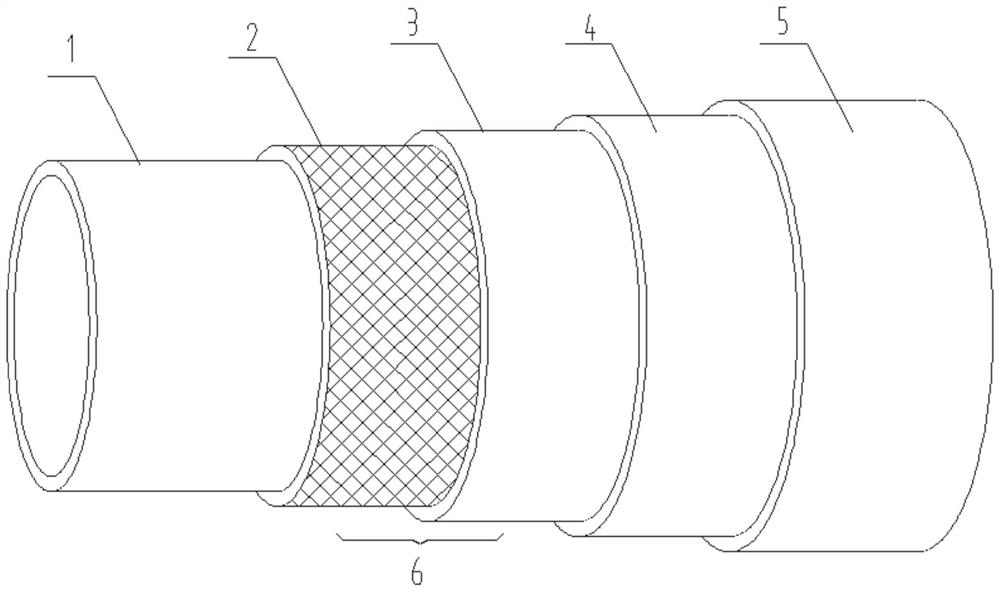

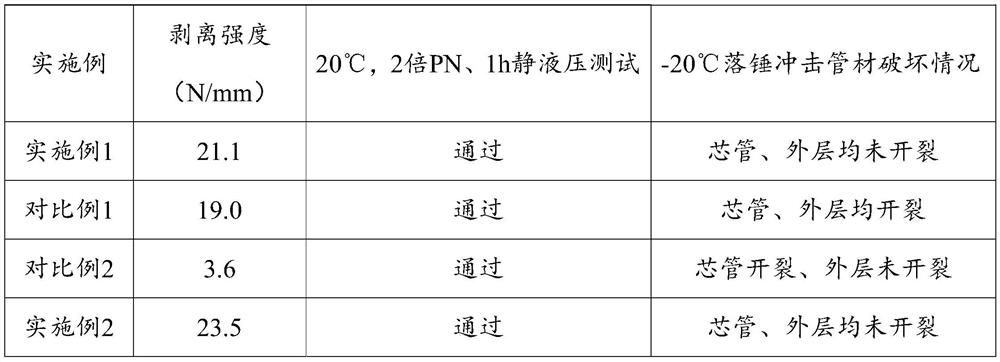

Steel wire mesh framework reinforced polypropylene composite pipe and preparation method and application of steel wire mesh framework reinforced polypropylene composite pipe

ActiveCN112096973AImprove low temperature impact resistanceSolve the problem of low temperature brittlenessCoatingsRigid pipesPolypropylene compositesElastomer

The invention relates to a steel wire mesh framework reinforced polypropylene composite pipe and a preparation method and application of the steel wire mesh framework reinforced polypropylene composite pipe. A polypropylene core pipe, a steel wire reinforced layer, a first adhesive resin layer, a second adhesive resin layer and a polyethylene outer layer are sequentially arranged from inside to outside. The first adhesive resin layer is composed of maleic anhydride grafted polypropylene, polypropylene, a flexibilizer, an adhesive force regulator and an anti-aging auxiliary agent. The second adhesive resin is composed of an elastomer, polypropylene, polyethylene and an anti-aging auxiliary agent. The problems that the low-temperature brittleness is large when polypropylene is independentlyused as a base body pipe and the heat resistance is poor when polyethylene is independently used as a base body are solved, the using temperature of a conveying medium is increased, and the technicalrisk that lantern damage is caused by bulging and wire drawing when an existing polypropylene steel wire mesh framework composite pipe conveys a medium at the temperature of 40 DEG C or above is reduced.

Owner:SHANDONG DONGHONG PIPE IND

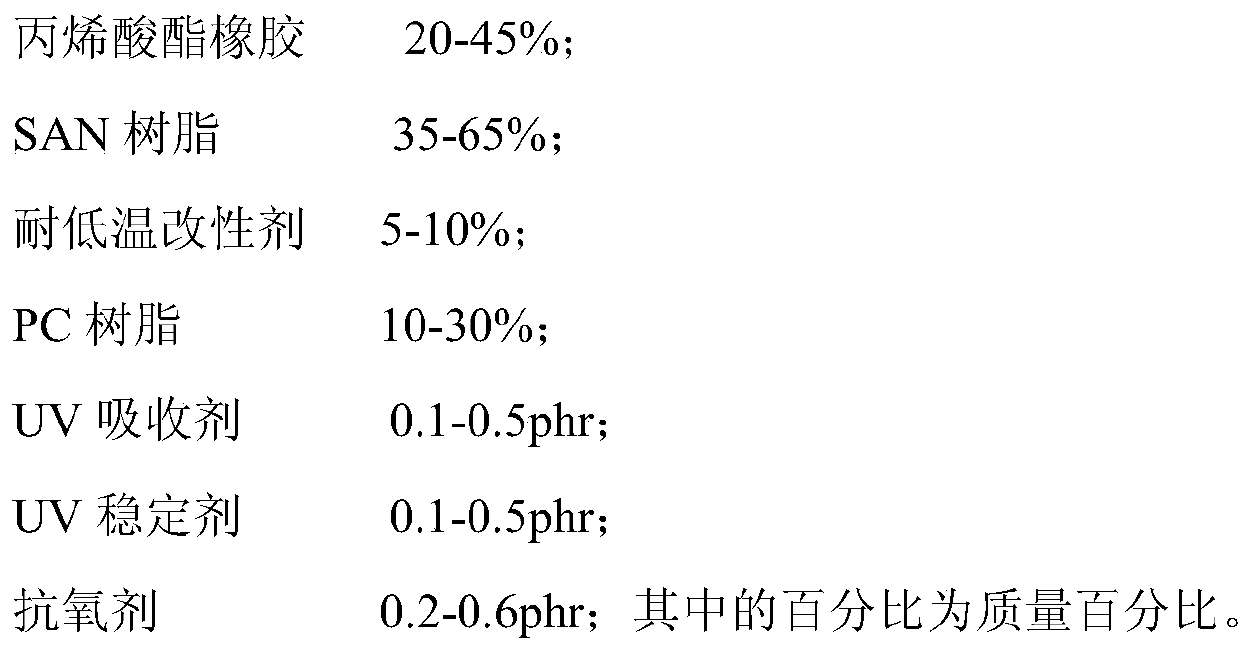

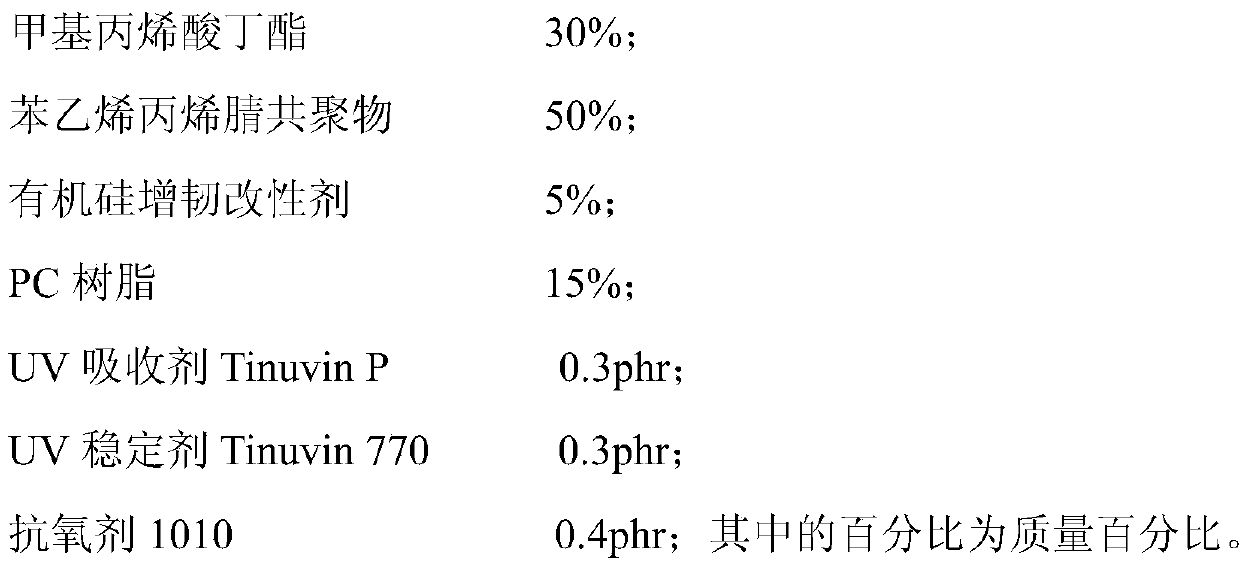

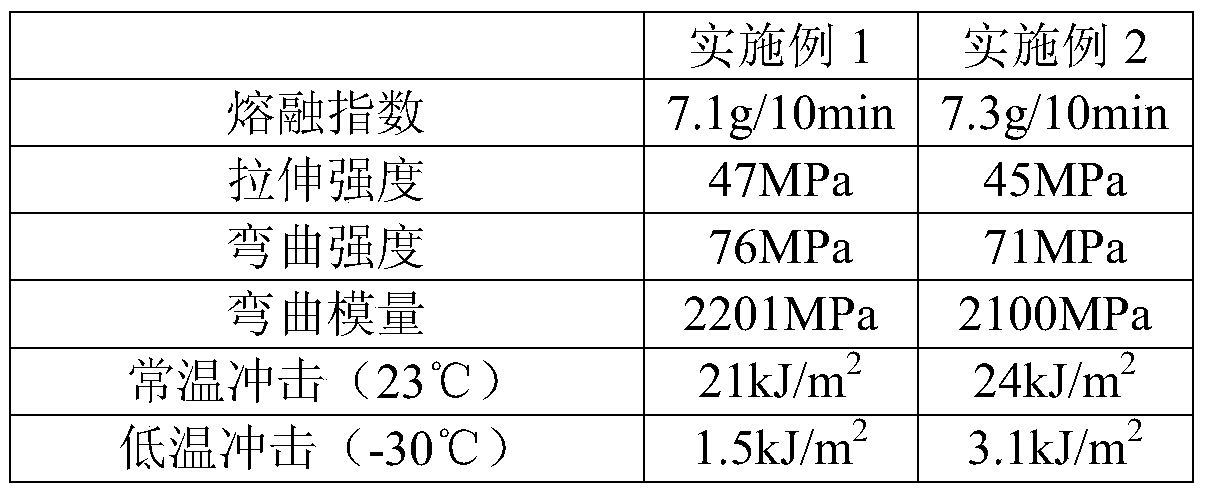

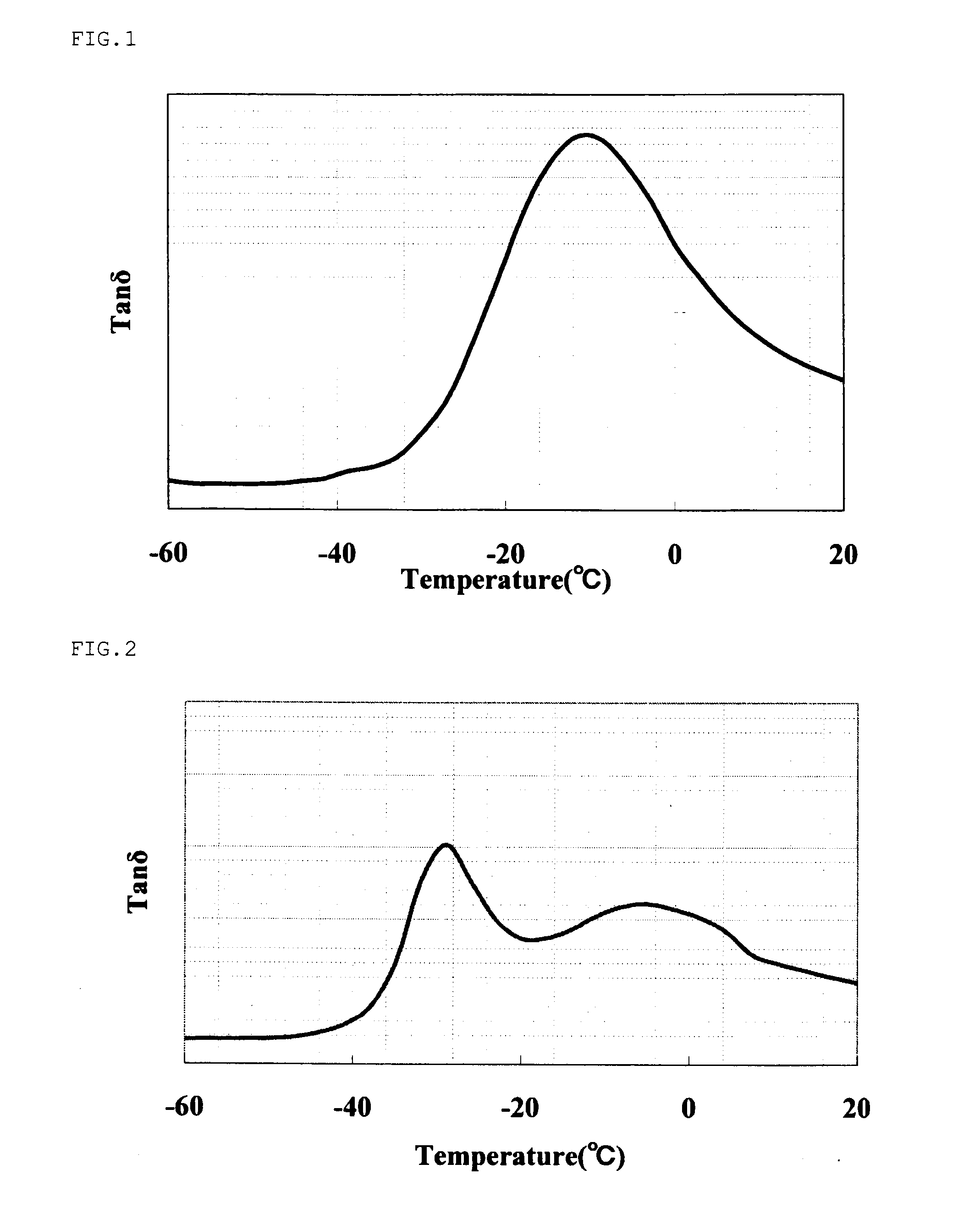

Low temperature resistant and weather-proof ASA (acrylonitrile styrene acrylate copolymer) material and preparation method thereof

The invention relates to a low temperature resistant and weather-proof ASA (acrylonitrile styrene acrylate copolymer) material and a preparation method thereof. The ASA material comprises the following components: acrylate rubber, SAN (styrene-acrylonitrile copolymer) resin, a low temperature resistant modifier, PC (polycarbonate) resin, a UV (ultraviolet) absorbent, a UV stabilizer and antioxidants. The low-temperature impact resistance of the ASA material is obviously improved; the preparation process is simple, is low in cost, has high efficiency and has good application prospect.

Owner:浙江科普特新材料有限公司

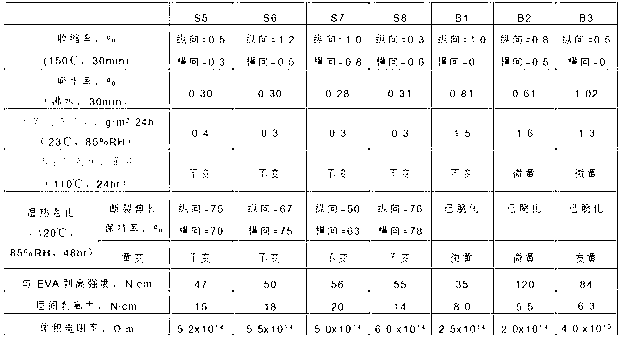

Propylene resin sheet and heat processing packaging body using same

InactiveUS20130177721A1Increase flexibilityIncrease resistanceSynthetic resin layered productsBagsPolymer scienceCopolymer

The invention discloses a propylene resin sheet and a heat-treatable packaging material which have an excellent transparency, flexibility and very-low-temperature impact resistance, and which reduce the thickness variation during lamination, suppress appearance defects such as interfacial roughness. A propylene resin sheet composed of at least one layer, the main layer being made up of a resin composition containing: (1) 50 to 90 wt % of a propylene resin composition (A) which includes from 30 to 70 wt % of a propylene-α-olefin random copolymer component (A1) having a melting peak temperature of 120 to 150° C., and from 70 to 30 wt % of a propylene-α-olefin random copolymer component (A2) having a C2 or C4-8 α-olefin content of at least 10 wt % but less than 20 wt %; and (2) 10 to 50 wt % of a specific ethylene-α-olefin copolymer (B).

Owner:JAPAN POLYPROPYLENE CORP

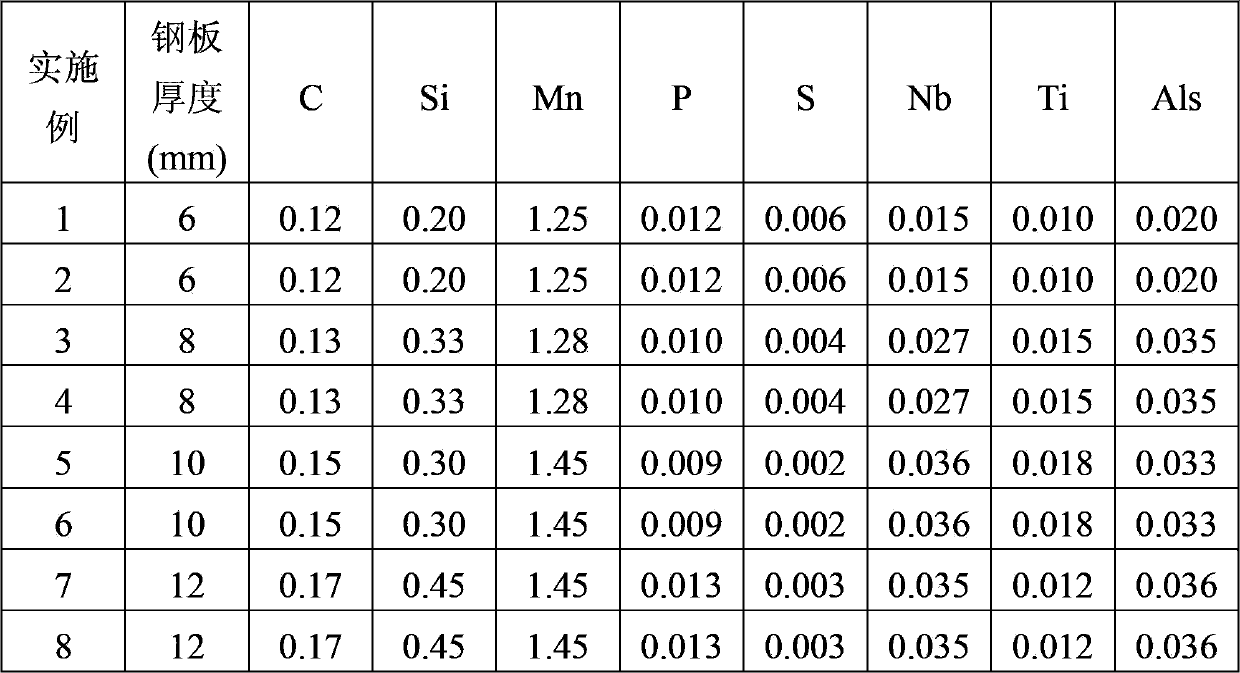

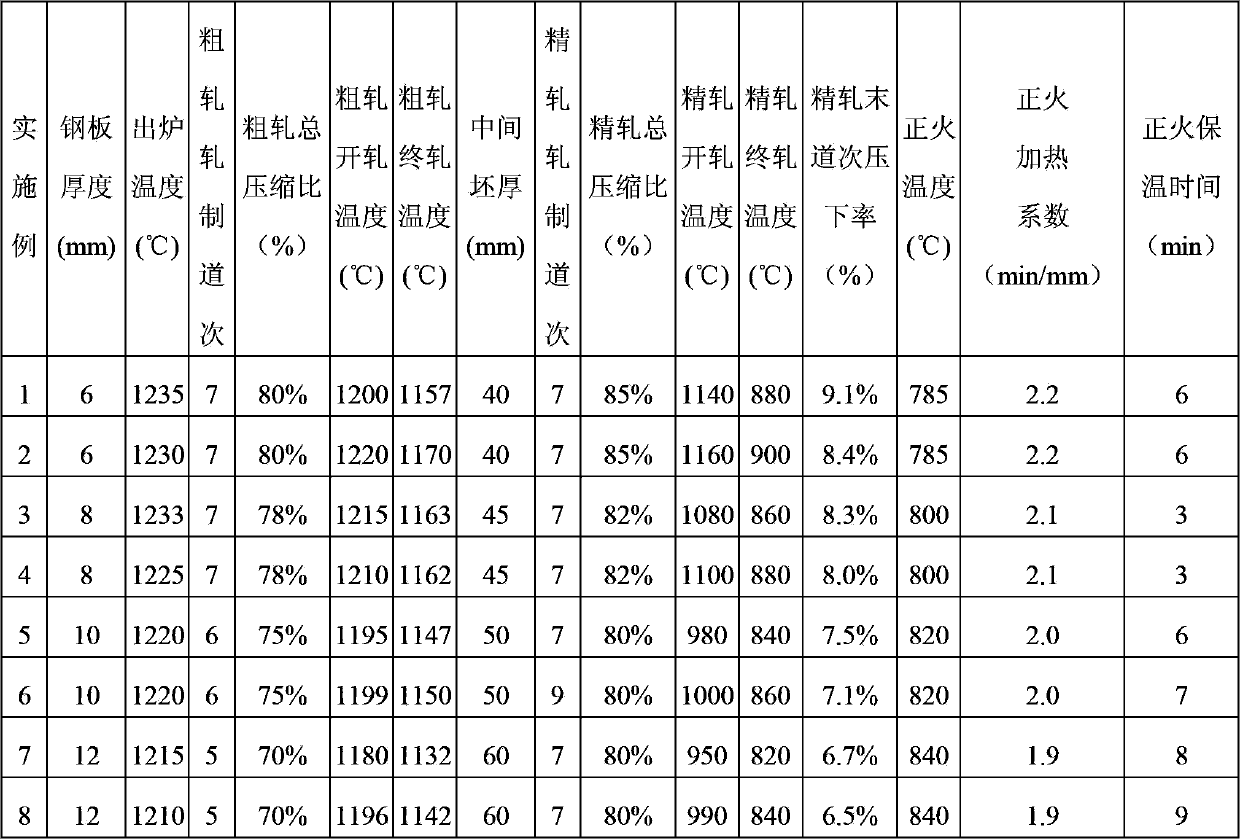

Ultrawide and ultrafine gauge structural steel plate for bridges and production method thereof

ActiveCN102766806BImprove low temperature impact resistanceMeet manufacturing requirementsChemical compositionSheet steel

The invention provides an ultrawide and ultrafine gauge structural steel plate for bridges and a production method thereof. The ultrawide and ultrafine gauge structural steel plate for bridges consists of the following chemical components by weight: C: 0.12 to 0.17 percent; Si: 0.20 to 0.45 percent; Mn: 1.25 to 1.50 percent; S: 0.010 percent or less; P: 0.020 percent or less; Nb: 0.010 to 0.040 percent; Ti: 0.008 to 0.030 percent; Als (standing for acid-soluble aluminium): 0.015 to 0.050 percent; N: 40 multiplied by 10 negative 6 or less; O: 20 multiplied by 10 negative 6 or less; H: 2 multiplied by 10 negative 6 or less; and the balance of iron and inevitable impurities. According to the invention, the ultrawide and ultrafine gauge structural steel plate for bridges has excellent low-temperature impact resistance, can meet the construction requirements of high-speed multi-track railways and wide highway bridges, and also can be widely used in engineering structures such as buildings, traffic and ocean platforms.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

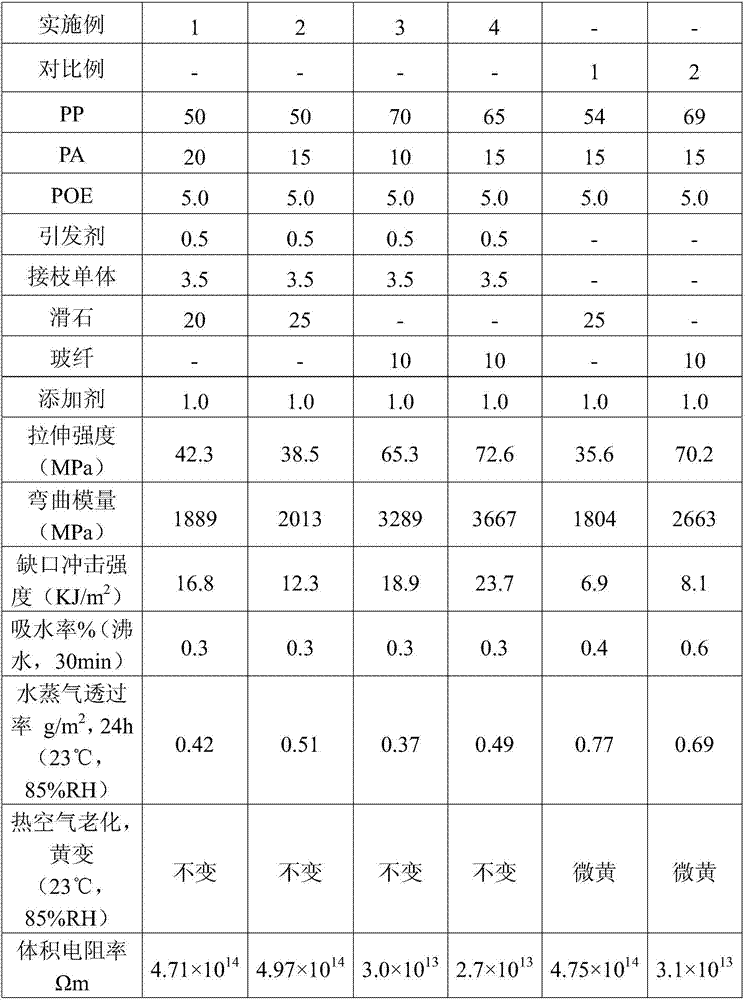

Modified polypropylene composition for solar cell back panel and preparation method thereof

InactiveCN107151384AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesElastomerPolyolefin

The invention discloses a modified polypropylene composition for a solar cell back panel. The modified polypropylene composition comprises the following components in percentage by weight: 40 to 80 percent of polypropylene, 5 to 30 percent of polyamide, 2 to 15 percent of polyolefin elastomer, 0.1 to 1.0 percent of an initiator, 0.5 to 5.0 percent of a grafting monomer, 0 to 30 percent of reinforcing filler, and 0 to 5 percent of an additive. The composition provided by the invention has excellent low-temperature impact resistance and aging resistance, has low saturated water absorptivity, low water vapor permeability and excellent electrical insulating property, and can be used for manufacturing a solar back panel.

Owner:HUAZHONG AGRI UNIV

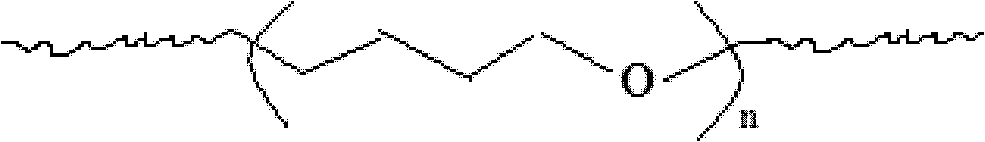

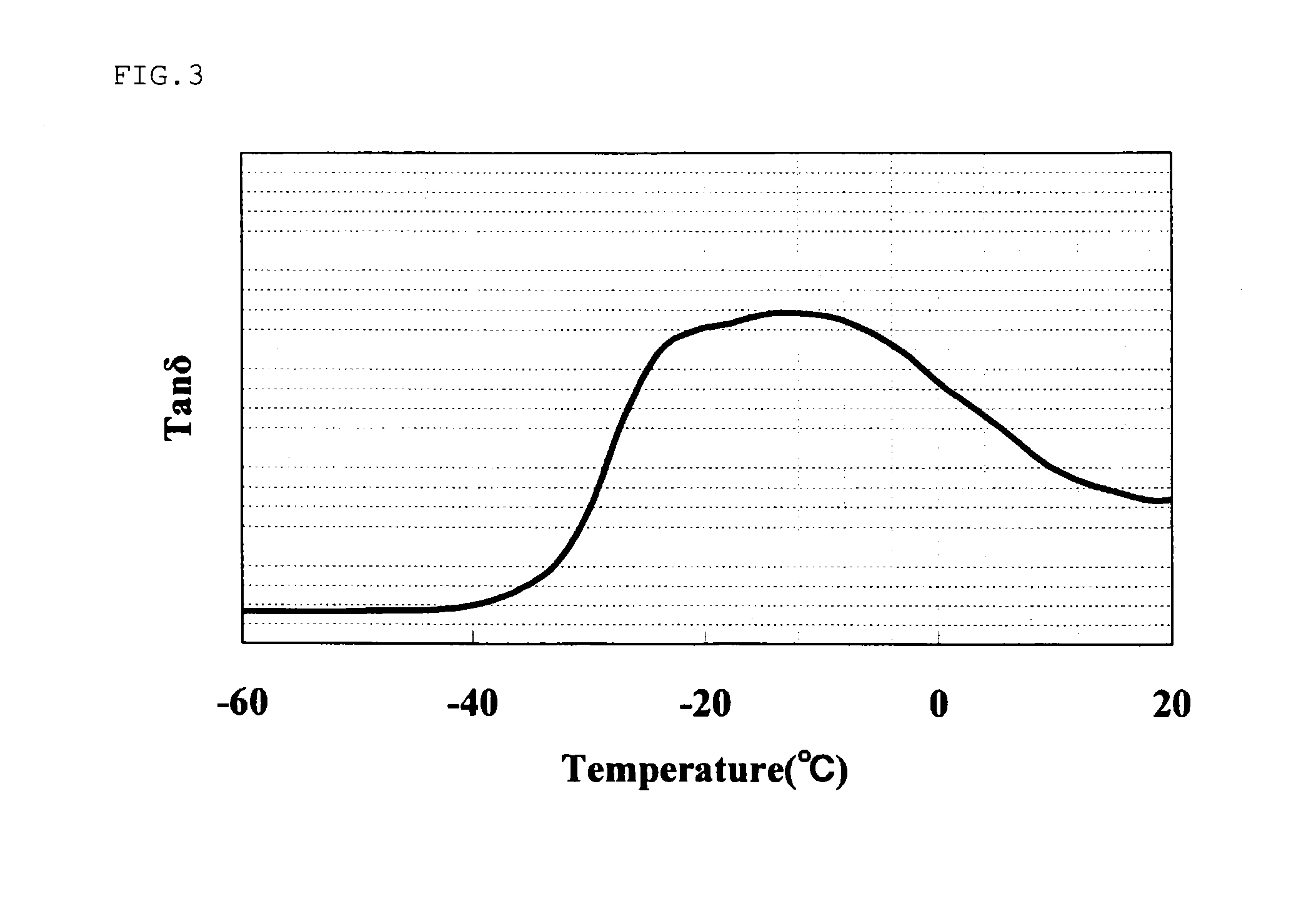

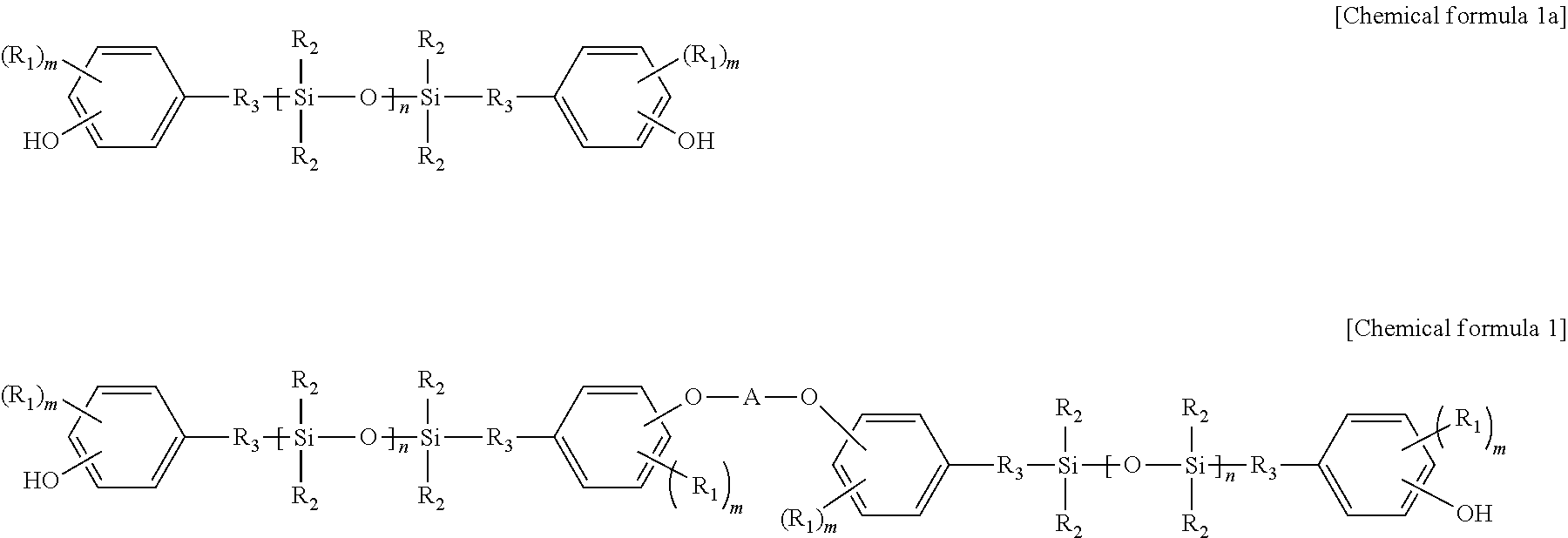

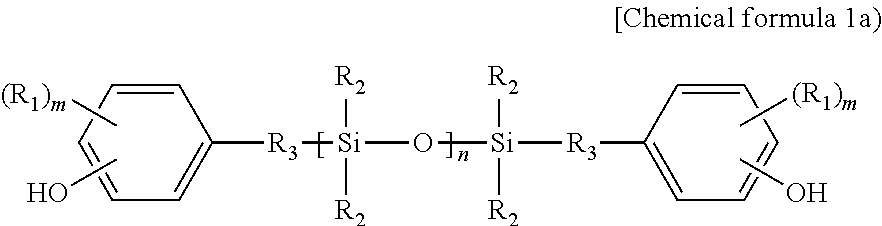

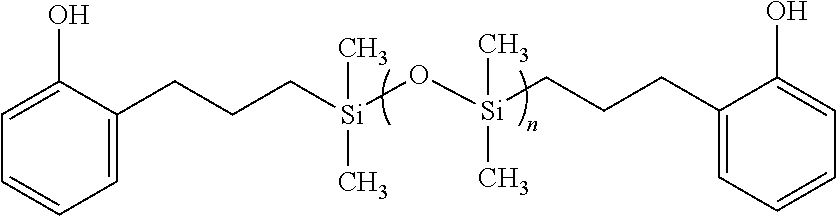

Polysiloxane-polycarbonate copolymer and method of manufacturing the same

ActiveUS20140249280A1Improve liquidityViscosity molecular weight of decreasePolycarbonatePolysiloxane polycarbonate copolymer

The present invention relates to a polysiloxane-polycarbonate copolymer and a method of manufacturing the same. More specifically, the present invention relates to a polysiloxane-polycarbonate copolymer in which the molecular weight of the siloxane monomer constituting the copolymer is maintained in a specifically high level and thus excellent low-temperature impact resistance can be achieved even with low siloxane content, and the viscosity of the copolymer is maintained in a low level and thus flowability and moldability can be improved; and a method of manufacturing the same.

Owner:SAMSANG CORP

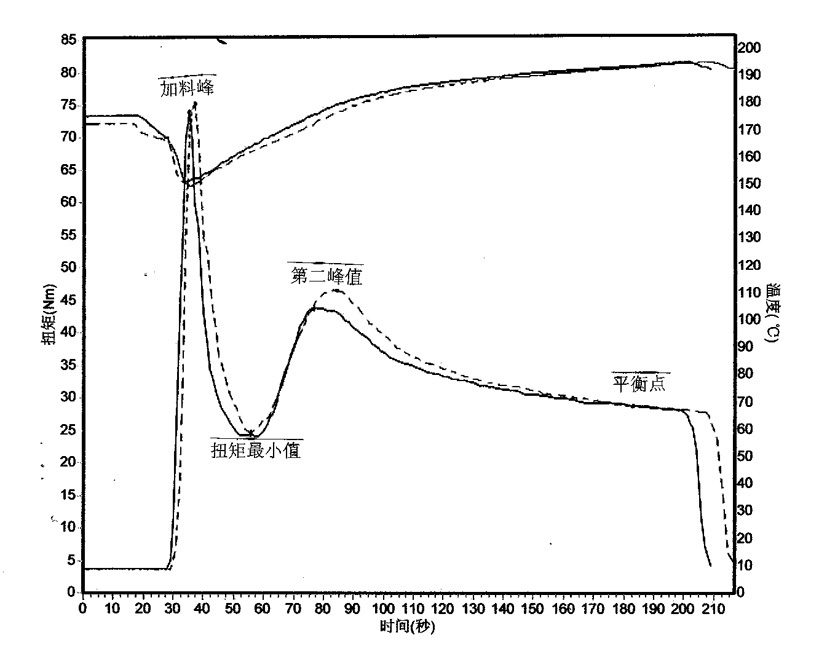

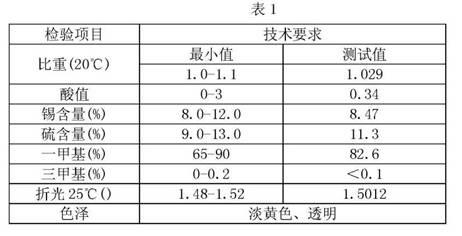

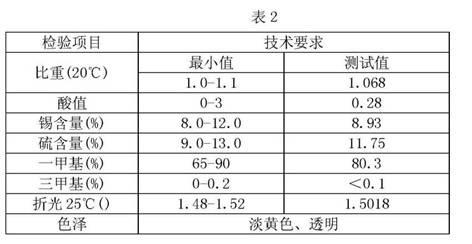

Preparation method of methyl tin heat stabilizer

ActiveCN102079755AGood thermal stabilityAdd lessTin organic compoundsAqueous solutionMethyl palmoxirate

The invention belongs to the technical field of organic chemistry and relates to a preparation method of a methyl tin heat stabilizer. The method comprises the following two steps: a) preparation of a methyl tin chloride intermediate: using tin, chloromethane and stannic chloride to perform alkane halogenation reaction so as to obtain the methyl tin chloride intermediate, and adding water for absorption so as to obtain a methyl tin chloride aqueous solution; and b) esterification-condensation reaction: adding MEO, sodium sulfide and ammonia water in the aqueous solution of methyl tin chloride to perform esterification-condensation reaction, and dewatering after fully reacting to obtain a methyl tin heat stabilizer product. The whole process of the preparation method is easy to control, and the cost is low; the methyl tin heat stabilizer product obtained by the method provided by the invention has an excellent heat stabilizing effect and can completely displace lead salt and cadmium heat stabilizers; and the product has the advantages of linear dosage control performance, low dosage and obviously lowered formula cost, and can be widely used in the manufacturing and processing fields of the PVC (polyvinyl chloride) plastic products.

Owner:杭州天道实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com