Nanometer calcium carbonate polypropylene composite material

A technology of calcium carbonate polypropylene and nano-calcium carbonate, which is applied in the field of polypropylene composite materials, can solve the problems of low temperature resistance that cannot be ignored, and does not mention improving the low temperature impact resistance of composite materials, and achieves the effect of improving low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

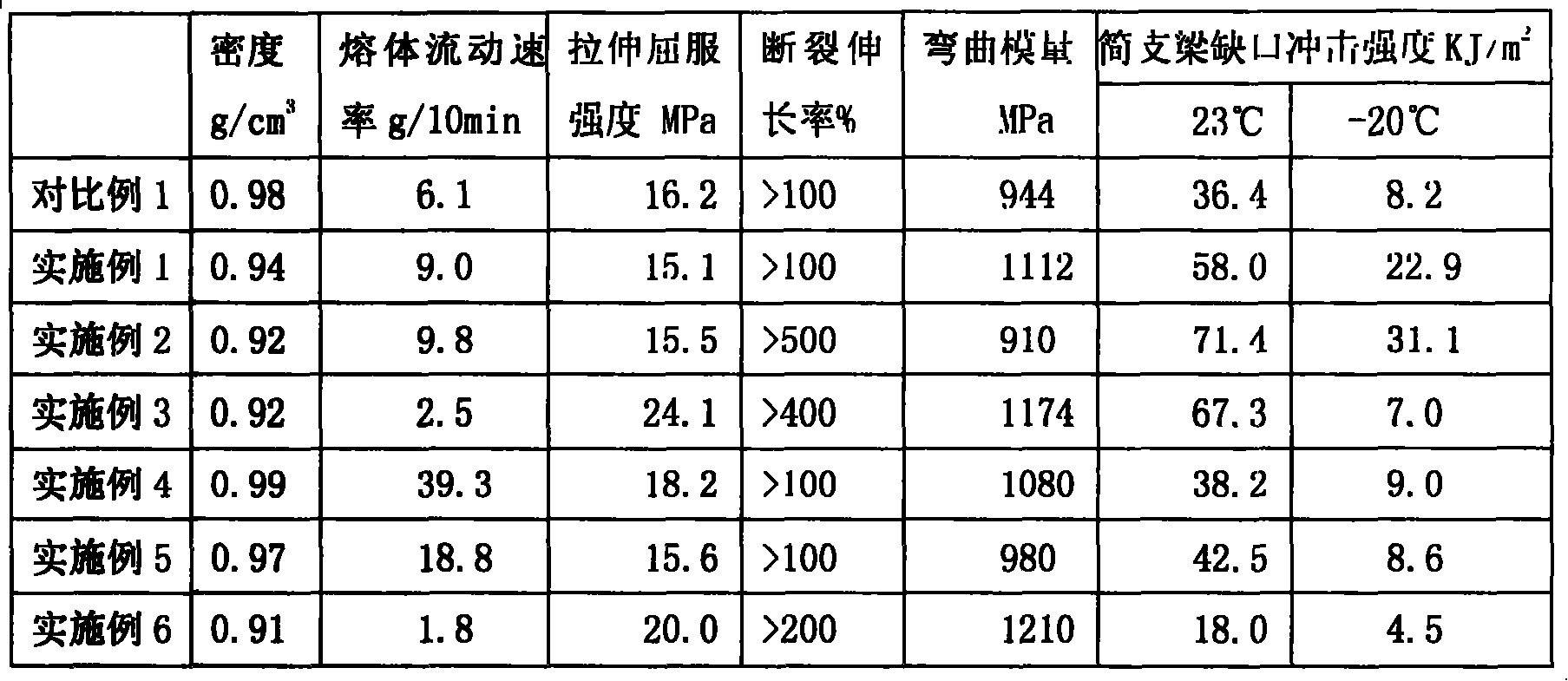

[0027] Example 1: 100 parts of impact copolymer polypropylene with a melt flow rate of 20g / 10min, adding 18 parts of EPDM, 14 parts of n-CaCO 3 Masterbatch (n-CaCO 3 Content 60wt%), 0.2 part of 1010, 0.15 part of 168, 0.3 part of UV-326, 0.1 part of calcium stearate, melt blending, extruding and granulating through a twin-screw extruder. The properties are shown in Table 1.

Embodiment 2

[0028] Example 2: Add 15 parts of EPDM, 10 parts of n-CaCO to 100 parts of impact copolymer polypropylene with a melt flow rate of 15g / 10min 3 Masterbatch, 0.2 part of 1010, 0.15 part of 168, 0.3 part of UV-326, 0.1 part of calcium stearate, melted, mixed, extruded and granulated by twin-screw extruder. The properties are shown in Table 1.

Embodiment 3

[0029] Example 3: Add 6 parts of n-CaCO3 powder, 1 part of SBS, 0.2 part of 1010, 0.15 part of 168, 0.3 part of 622, 0.1 part of hard Calcium fatty acid, melted and blended in internal mixer, extruded, pelletized. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com