Patents

Literature

70results about How to "Balance rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer calcium carbonate polypropylene composite material

The invention discloses nano calcium carbonate polypropylene composite material. The composite material comprises 100 portions of polypropylene resin, 1 to 15 portions of nano calcium carbonate, 1 to 20 portions of elastomer, and 0.1 to 1 portion of stabilizing agent. The composite material is prepared by method of melt compounding by adopting an internal mixer or double screw extruder. Good rigidity is kept when the toughness of the composite is obviously improved; the composite has good cold impact resistance performance, and is applicable to injection moulding production of automobile parts, i.e. bumper, mudguard, etc.

Owner:CHINA PETROLEUM & CHEM CORP

Nylon 66 nano composite material and preparation method thereof

The invention discloses a composite nanometer material and making method of polyhexamethylene adipamide (nylon 66), which comprises the following parts: 100wt% nylon 66, 5-20wt% elastic body and 5-30wt% inorganic nanometer particle, wherein these materials are blended to fuse and squeeze under 260-280 deg. c. The invention balances the rigidity, flexibility and fire resistance and size stability, which expands the applying domain of nylon 66.

Owner:EAST CHINA UNIV OF SCI & TECH

Polyphenyl ether polypropylene resin composition and preparation method thereof

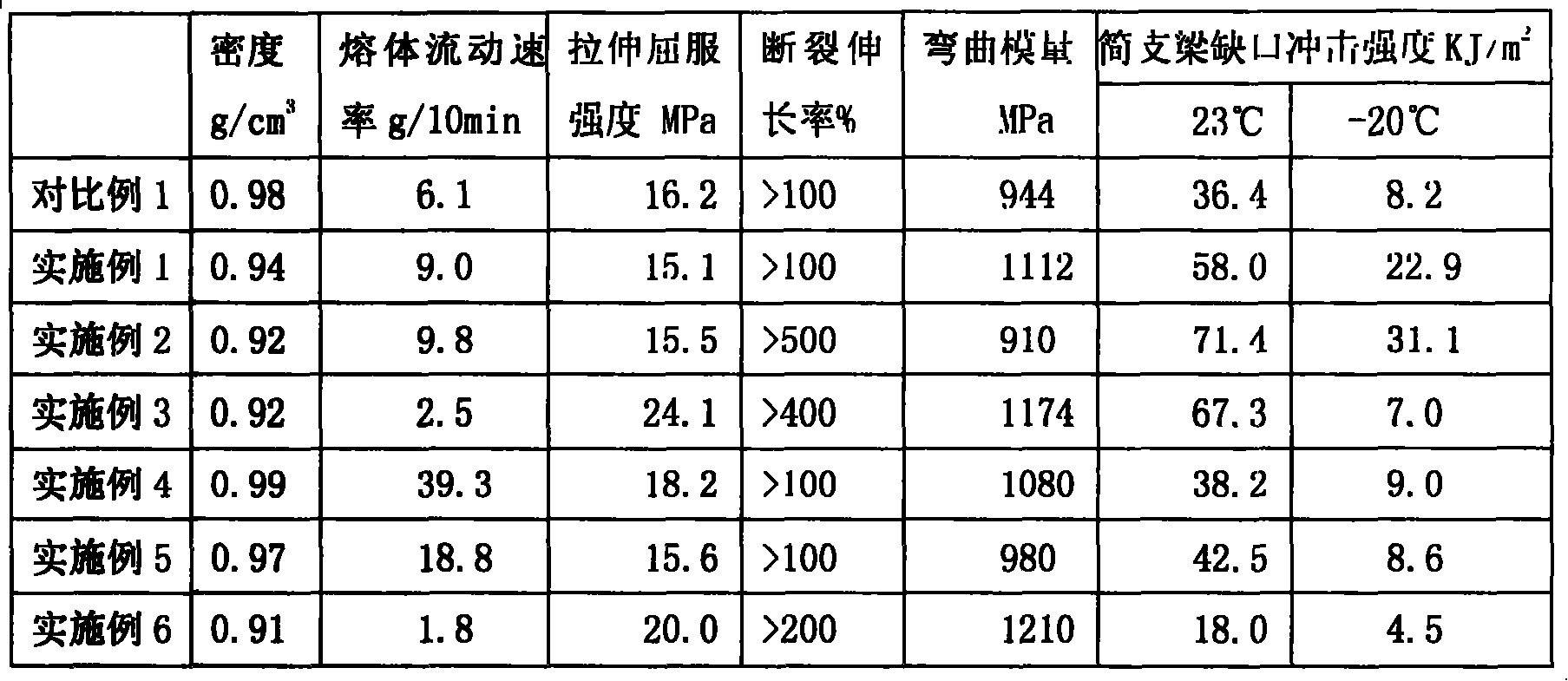

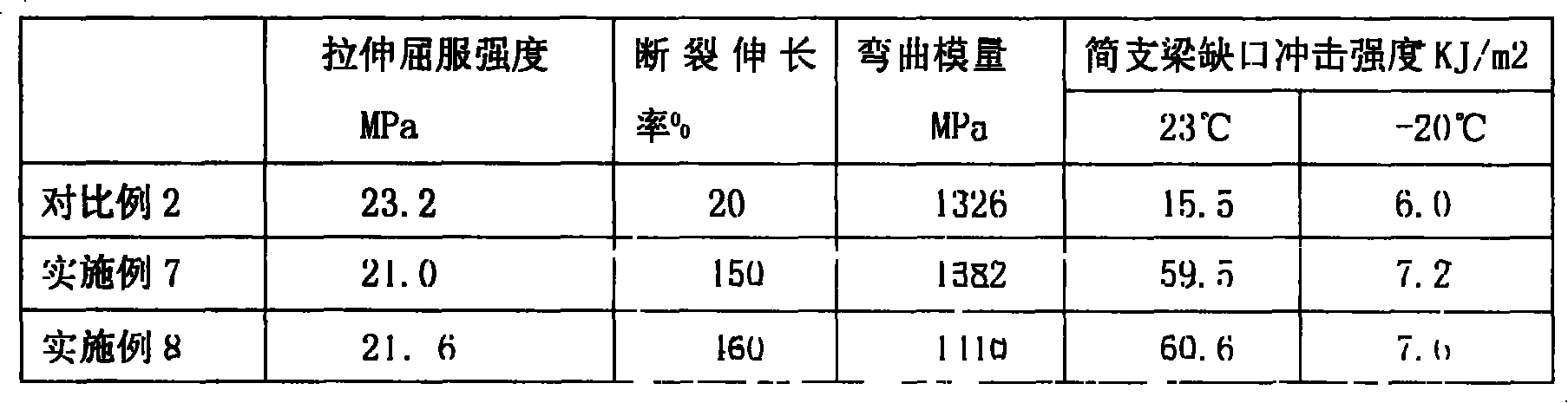

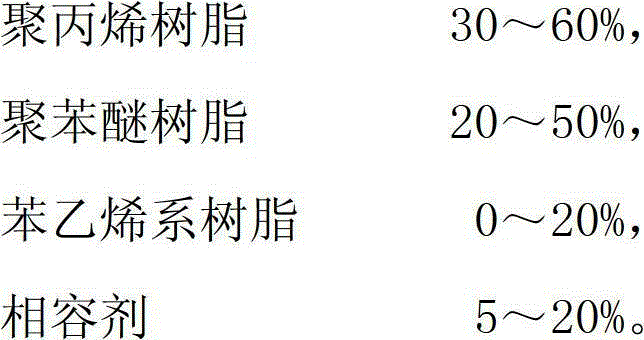

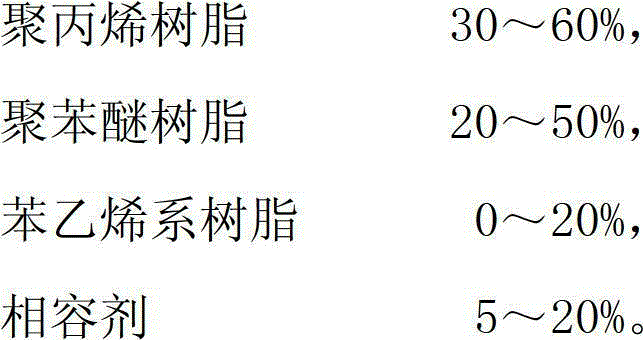

The invention relates to a polyphenyl ether polypropylene resin composition and a preparation method thereof. The composition comprises, by mass, 30% to 60% of polypropylene resins, 20% to 50% of polyphenyl ether resins, 0% to 20% of styrene resins and 5% to 20% of compatilizers. The preparation method includes the following steps of uniformly mixing the polyphenyl ether resins, the styrene resins and the compatilizers to obtain a premix, placing the premix in a double-screw extruder, simultaneously adding the polypropylene resins in a side-feed mode, performing a melt extrusion and granulating. The polyphenyl ether polypropylene resin composition and the preparation method thereof have the advantages that the property of the polyphenyl ether polypropylene resin composition is between those of thermoplastic polyolefin and engineering plastics, a good balance among the rigidity, toughness, heat resistance and processing performance of the material is achieved, the polyphenyl ether polypropylene resin composition can be applied to various fields such as automobile dashboards, automobile seat base plates, electric tool shells, fluid engineering components and food utensils, and the polyphenyl ether polypropylene resin composition and the preparation method thereof have a good application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

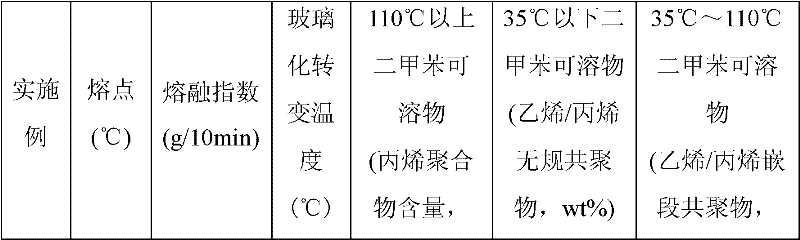

Multi-phase copolymer polypropylene in-reactor alloy and preparation method thereof

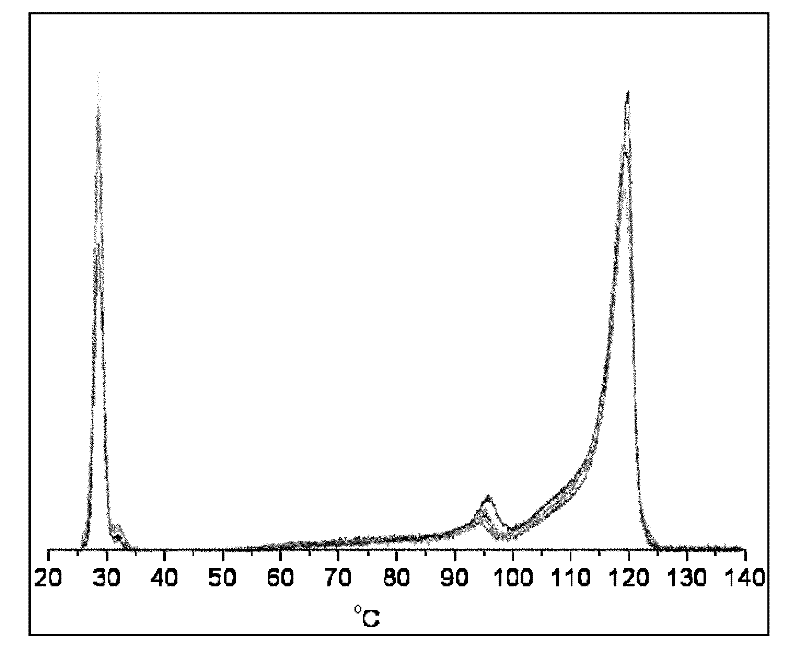

The invention discloses a multi-phase copolymer polypropylene in-reactor alloy and a preparation method thereof. In the method, a compound catalyst which is prepared by combining a Ziegler-Natta catalyst and a metallocene catalyst is adopted; propylene polymerization and ethylene / alpha-olefin copolymerization which are sequentially performed are catalyzed by the components of the two catalysts together; thus a polypropylene resin phase which is mainly prepared under the action of the Ziegler-Natta catalyst is uniformly mixed with an ethylene / alpha-olefin random copolymer rubber phase which is mainly prepared under the action of the metallocene catalyst in a polymerizer; and in the method, the ethylene / alpha-olefin block copolymer which is generated under the action of the Ziegler-Natta catalyst can be utilized as a compatilizer between the resin phase and the rubber phase, so that dispersion stability of the two phases (the resin phase and the rubber phase) is guaranteed, and balance between rigidity and toughness of the material is effectively realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

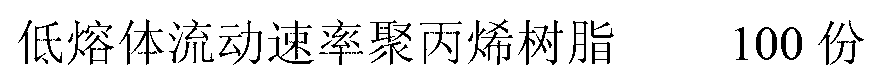

Environment-friendly modified polypropylene profiled bar base station antenna casing and preparation method

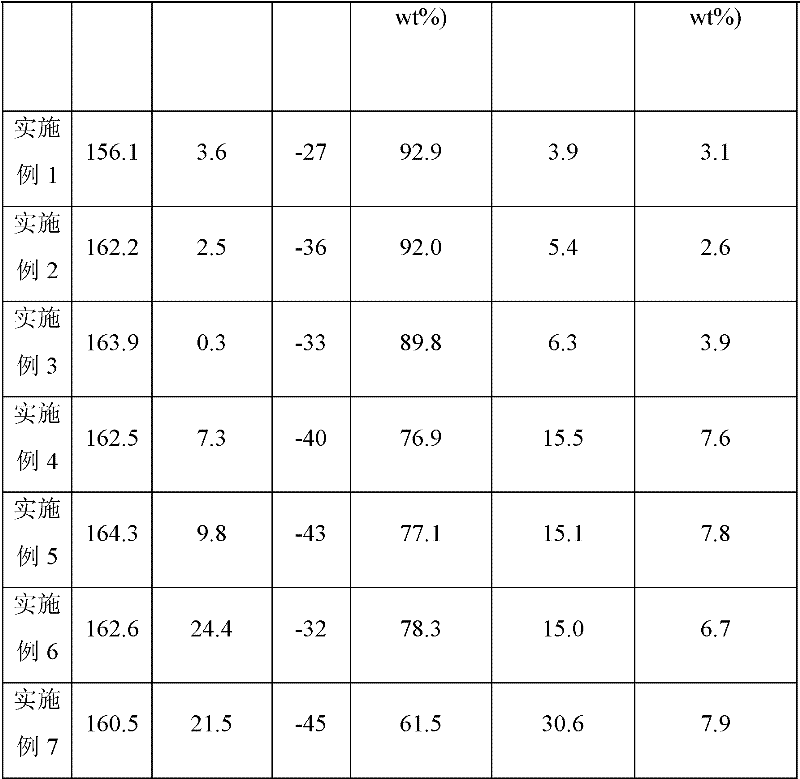

The invention discloses an environment-friendly modified polypropylene profiled bar base station antenna casing, which satisfies the required strength, modulus and hear resistance requirements of the base station antenna housing profiled bar, and more importantly, the melt-strength improvement can reach extrusion moulding treatment requirement of the complex section structural profile bar. The PP profile bar base station antenna casing has good machinery performance and greatly enhances the ultraviolet light resistant performance. The modified polypropylene profiled bar base station antenna casing comprises the following raw materials by mass: 100 parts of low melt flow rate polypropylene resin, 0.2-2 parts of lubricant, 0.1-1.0 parts of ultraviolet light absorbent, 0.2-0.5 parts of anti-oxidant, 0-0.8 parts of hindered amine light stabilizer, 5-20 parts of surface modified titanium dioxide, 5-30 parts of surface modified inorganic filling material and 0.1-0.5 parts of rigid nucleating agent.

Owner:NANJING UNIV OF TECH +1

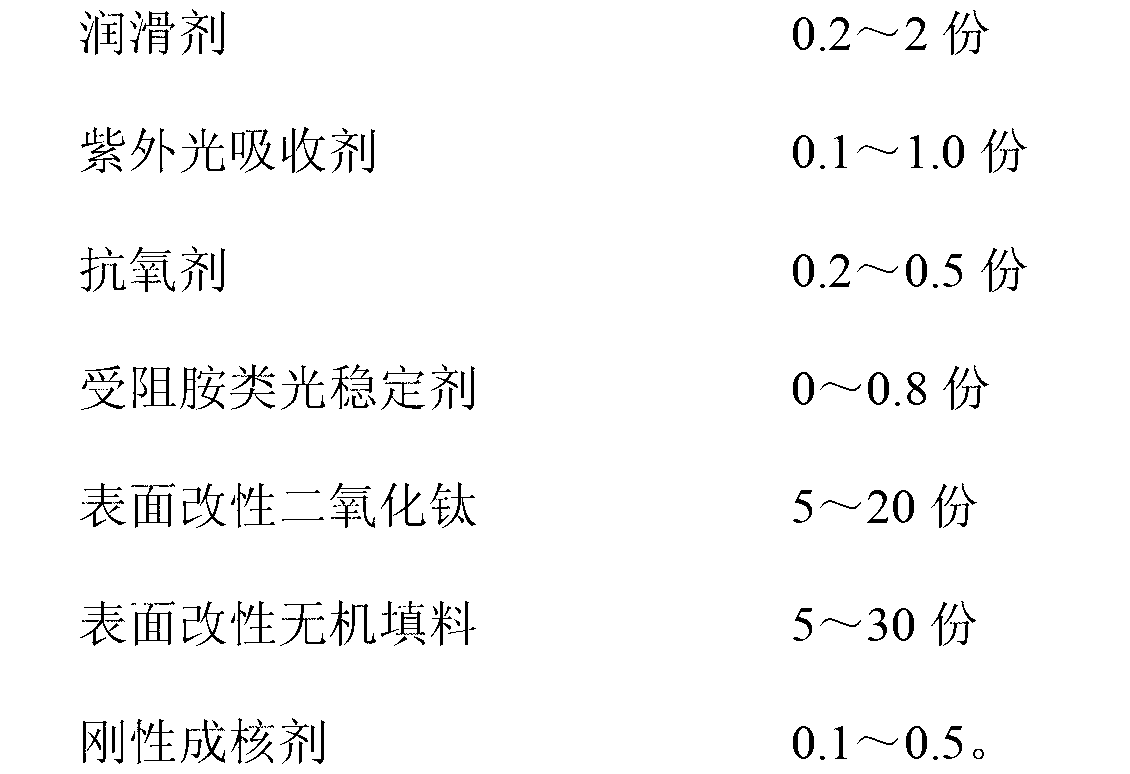

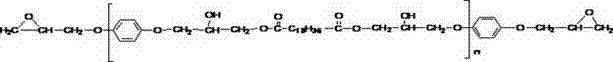

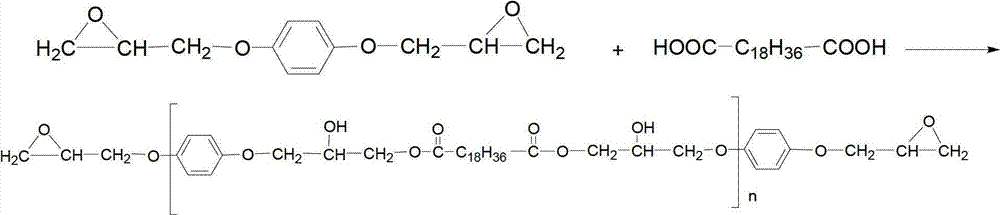

Modified bisphenol A-type epoxy resin and preparation method thereof

InactiveCN102827105ALow reaction temperatureFast responseOrganic chemistryEpoxy resin coatingsBisphenol SAddition reaction

The invention relates to modified bisphenol A-type epoxy resin and a preparation method thereof; the modified bisphenol A-type epoxy resin disclosed by the invention is a product obtained by reacting bisphenol epoxy resin and octadecanedicarboxylic acid under the effect of special catalyst; a carbon chain in a special structure is led into an epoxy resin molecule structure through the addition reaction of the modified bisphenol A-type epoxy resin and an epoxy group; the preparation method comprises the following steps: mixing epoxy resin and the octadecanedicarboxylic acid evenly; then, stirring a mixture under the protection of nitrogen while heating the mixture to 95-100 degrees centigrade; adding catalyst; keeping the reaction time of a reactant within 1.5-5 hours at a temperature when the temperature of the reactant reaches to 130-170 degrees centigrade; cooling the reactant; and discharging the reactant. According to the invention, the modified bisphenol A-type epoxy resin and the preparation method thereof have advantages of low reaction temperature, fast reaction speed, high yield, light color of the modified bisphenol A-type epoxy resin and good rigidity, toughness and chemistry resistance of modified curing epoxy resin.

Owner:SUZHOU SIRGEL RESINS SPECIALTIES CO LTD

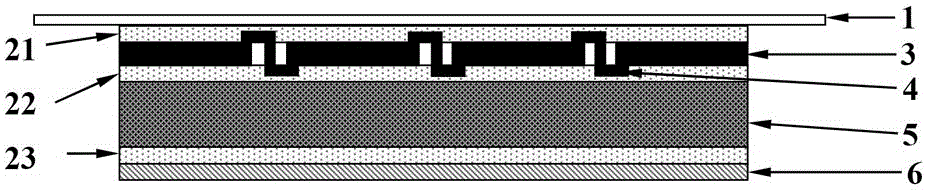

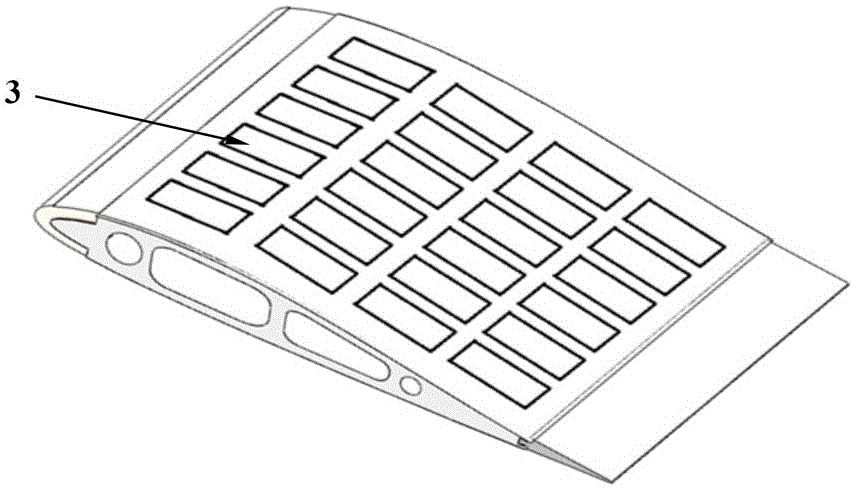

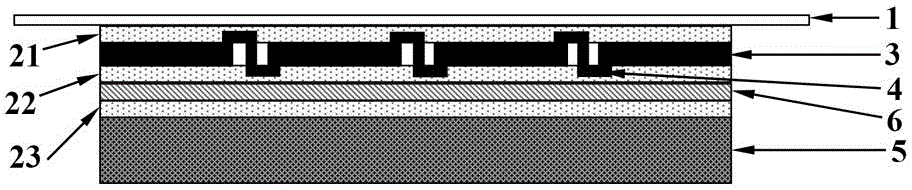

Flexible solar cell module and preparation method and application thereof

ActiveCN106299002AAvoid problems such as poor reliabilityBrittle solar cells and poor reliability problems are avoidedFinal product manufacturePhotovoltaicsEngineeringSolar cell

The invention discloses a flexible solar cell module and a preparation method and application thereof. The flexible solar cell module comprises upper skin, a first packaging adhesive film, a flexible solar cell array, a second packaging adhesive film, a supporting member, a third packaging adhesive film, and lower skin in a hot-pressing packaging in order from up to down, and the supporting member is a polymethacrylimide foam board. The preparation method comprises the steps of stacking the upper skin, the first packaging adhesive film, the flexible solar cell array, the second packaging adhesive film, the supporting member, the third packaging adhesive film, and the lower skin in order from up to down, and performing lamination. The flexible solar cell module is advantaged by low surface density, good bending and flexibility, suitability for being attached to airfoil curved surface, good reliability, no packaging problems such as warping, fragmentation, etc., and wide application in spacecrafts such as solar unmanned aerial vehicles, etc.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Strengthened and toughened polypropylene composite and its preparing process

A three-element composition is prepared from polypropene (PP) (72-91 wt%), POE or MPOE (1-13) and BaSO4 (7-20) through mixing, stirring, kneading and extruding out. Its advantages are high impact strength, high toughness, high P / C ratio, high resistance to thermal or ultraviolet ageing, and low cost.

Owner:SUN YAT SEN UNIV

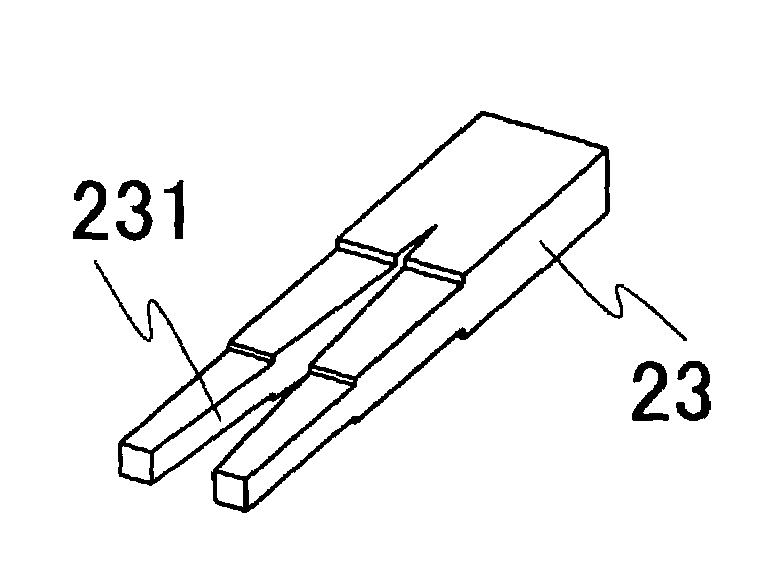

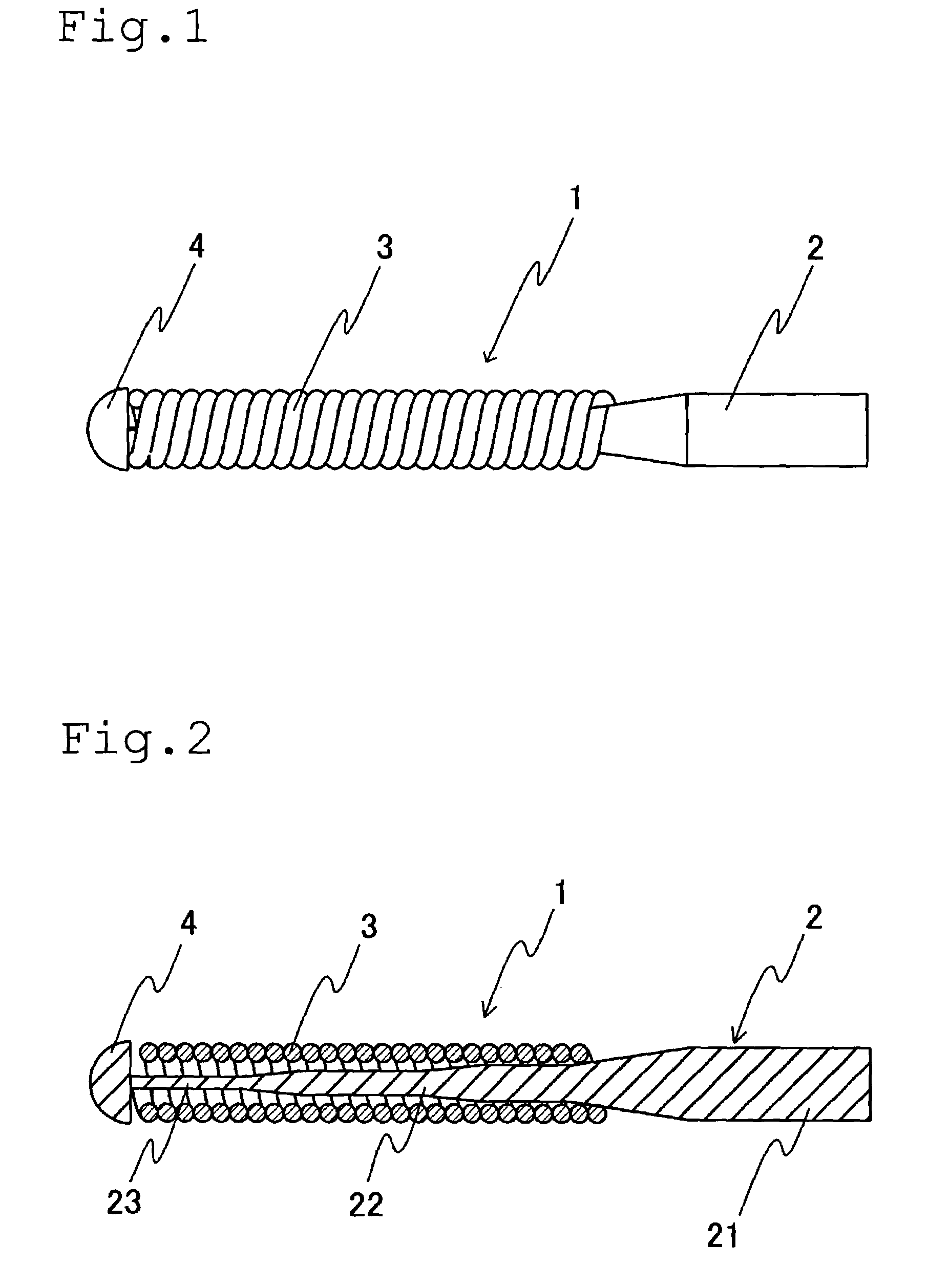

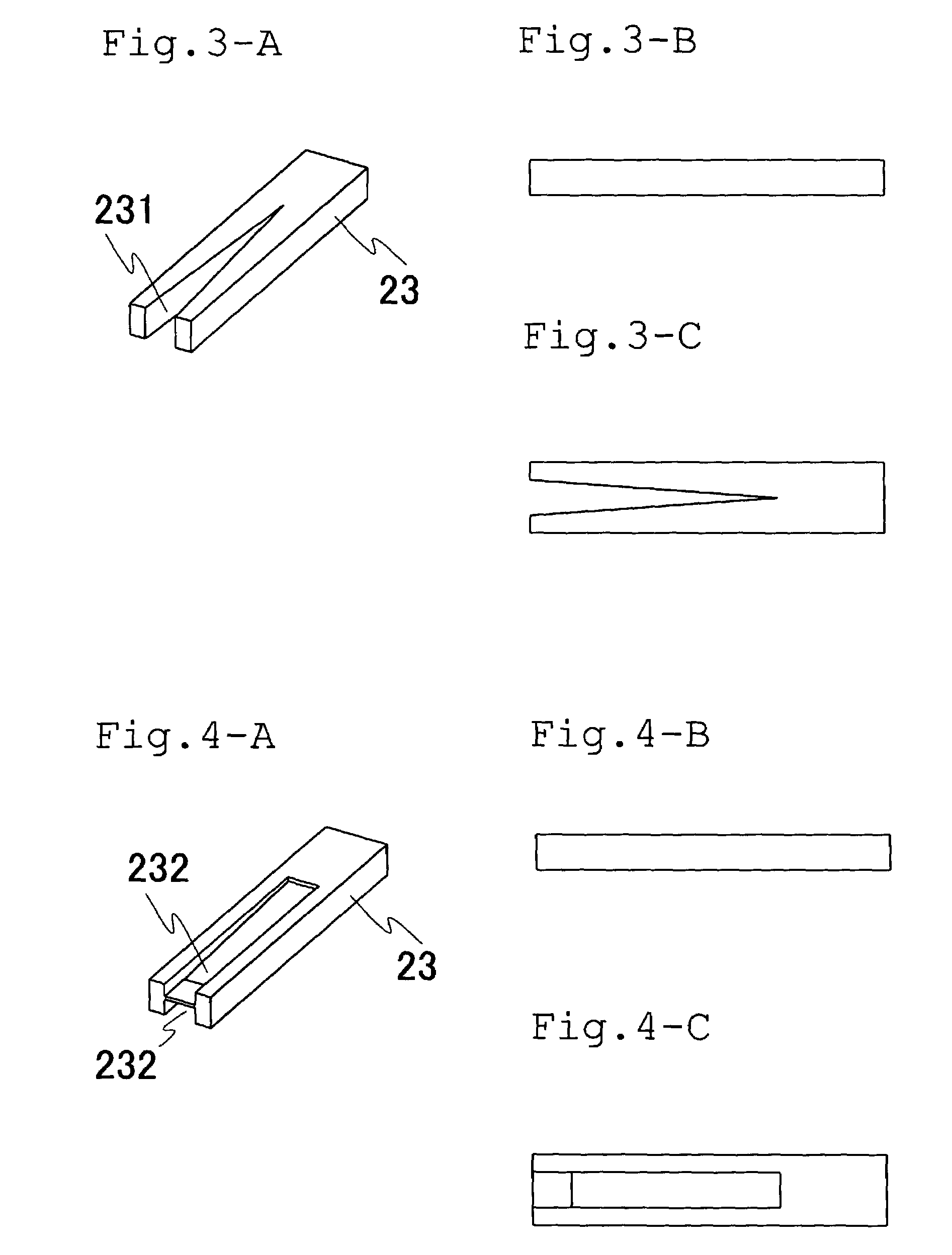

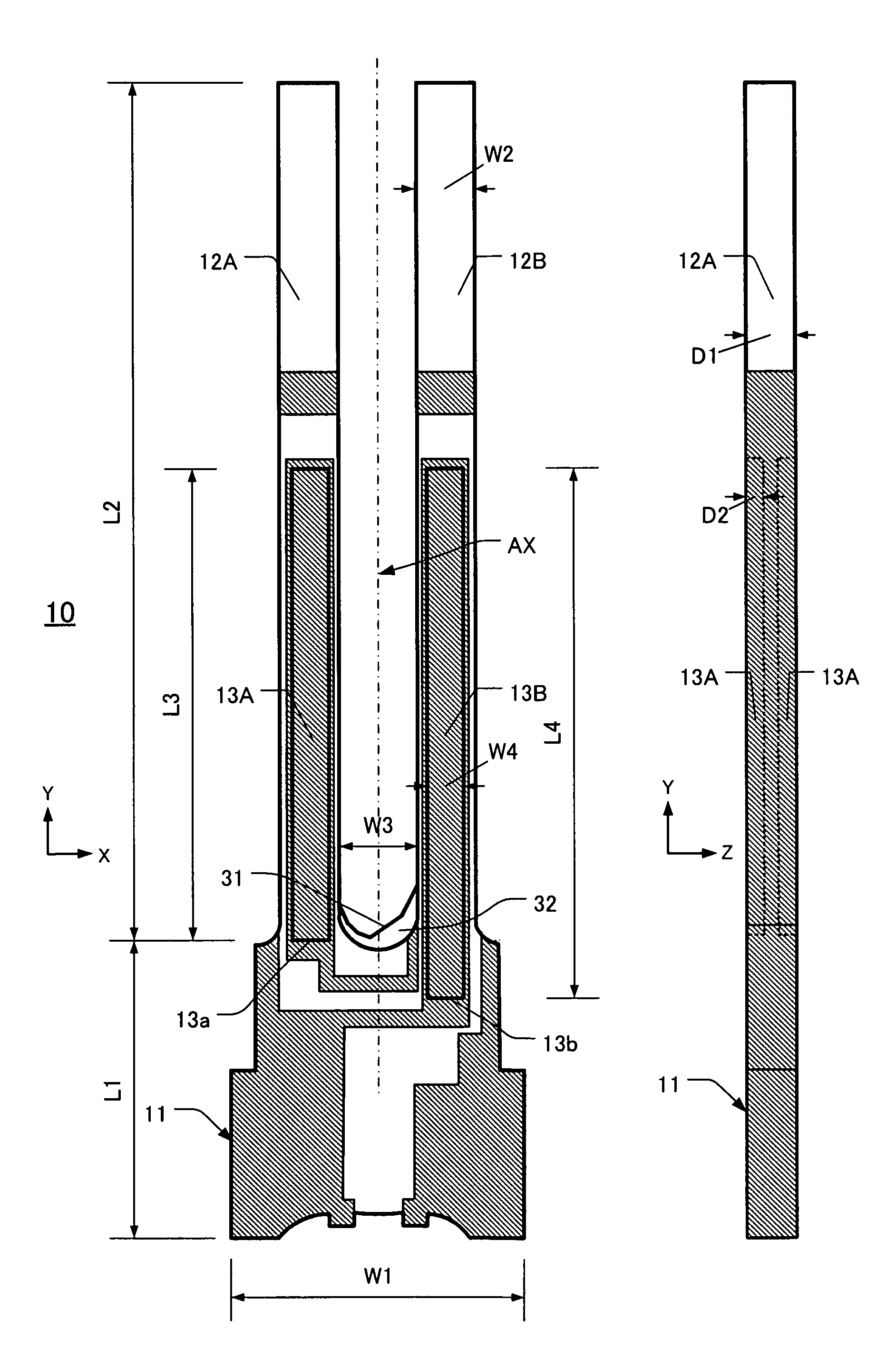

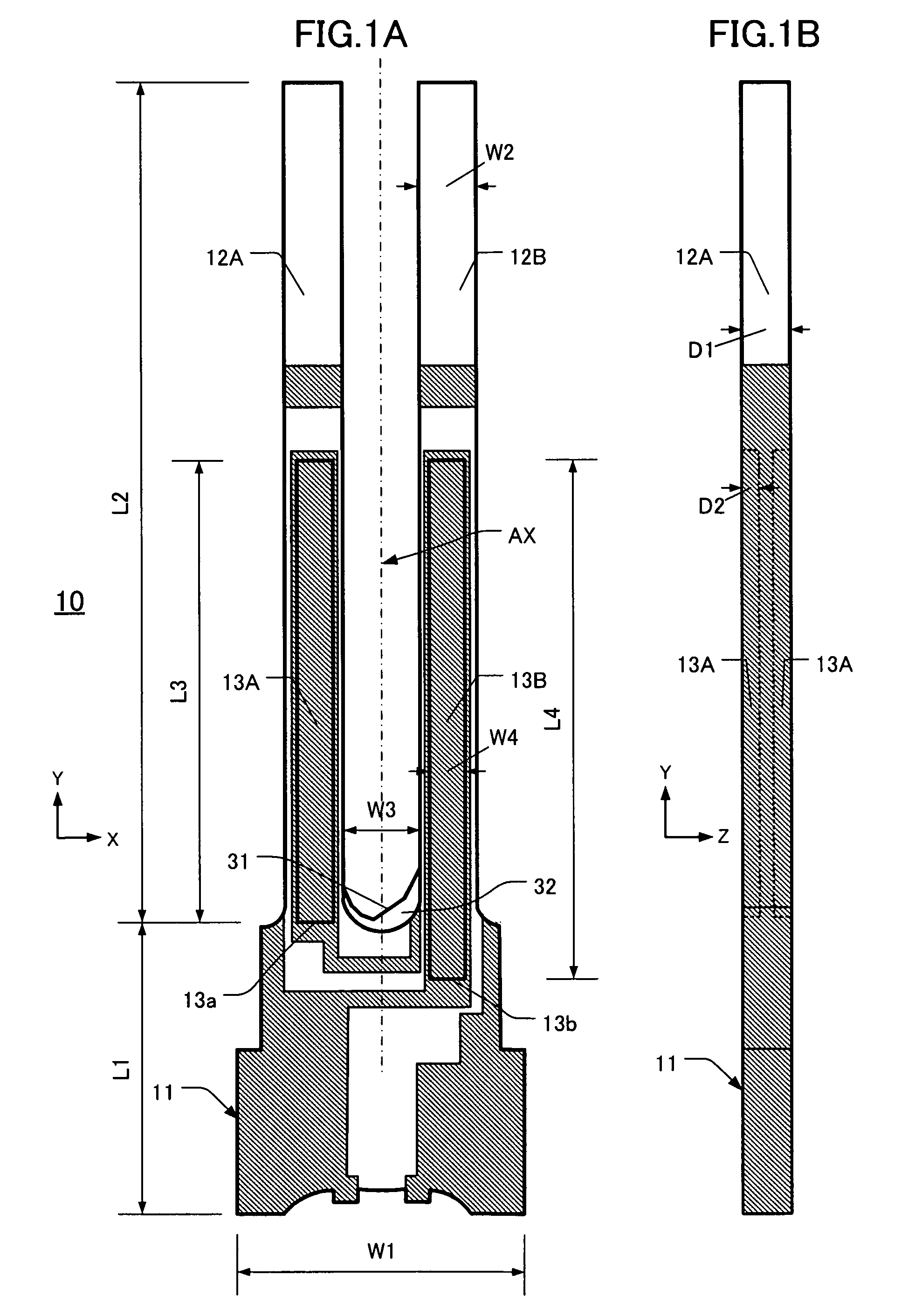

Guide wire

InactiveUS7083577B2Balanced flexibilityBalance rigidityGuide wiresInfusion syringesEngineeringGuide wires

Owner:NIPRO CORP

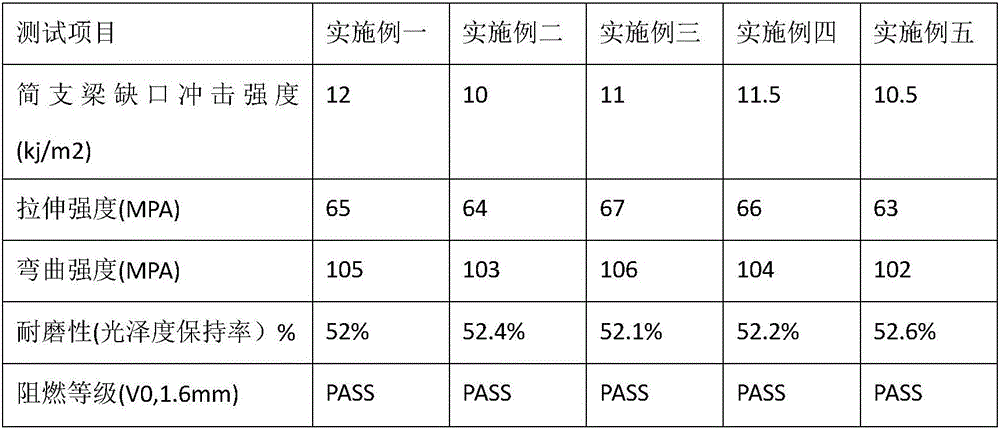

Abrasion-resistant high-flame-retardance PC material and preparation method thereof

The invention provides an abrasion-resistant high-flame-retardance PC material. The abrasion-resistant high-flame-retardance PC material is prepared from, by weight, 70-80 parts of PC, 5-12 parts of glass fibers, 1-5 parts of flexibilizer, 5-8 parts of compatilizer, 3-5 parts of abrasion-resistant agent, 0.1-1 part of coupling agent, 0.1-1 part of anti-dripping agent, 0.1-1 part of flame retardant, 0.2-2 parts of antioxygen, 0.2-2 parts of ultraviolet light absorber and 0.2-2 parts of lubricant. The invention further provides a preparation method of the abrasion-resistant high-flame-retardance PC material. The PC material has good abrasion resistance, high flame retardance and excellent mechanical performance; the PC material is low in cost, high in cost performance, simple in production technological process, easy to implement, free of environmental pollution and small in harm to human health.

Owner:太仓市华鼎塑料有限公司

PP (propylene) composite material capable of replacing ABS (Acrylonitrile Ethylene Styrene) and preparation method of PP composite material

The invention belongs to the technical field of plastics modification, and particularly relates to a PP (propylene) composite material capable of replacing ABS (Acrylonitrile Ethylene Styrene) and a preparation method of the PP composite material. The PP composite material mainly comprises the following components in percentage by weight: 60-80 percent of PP resin, 5-25 percent of talc powder, 5-15 percent of crystal whisker, 0.5-2 percent of a sensitizer and 0.1-0.3 percent of a nucleating agent. The preparation method comprises the steps of mixing, extruding and pelleting. The composite material provided by the invention has the characteristics of high flow, high rigidity, high modulus, low shrinkage, low buckling deformation and the like, and is capable of effectively reducing the material cost and generating larger economic benefit.

Owner:QINGDAO DADU NEW MATERIAL TECH

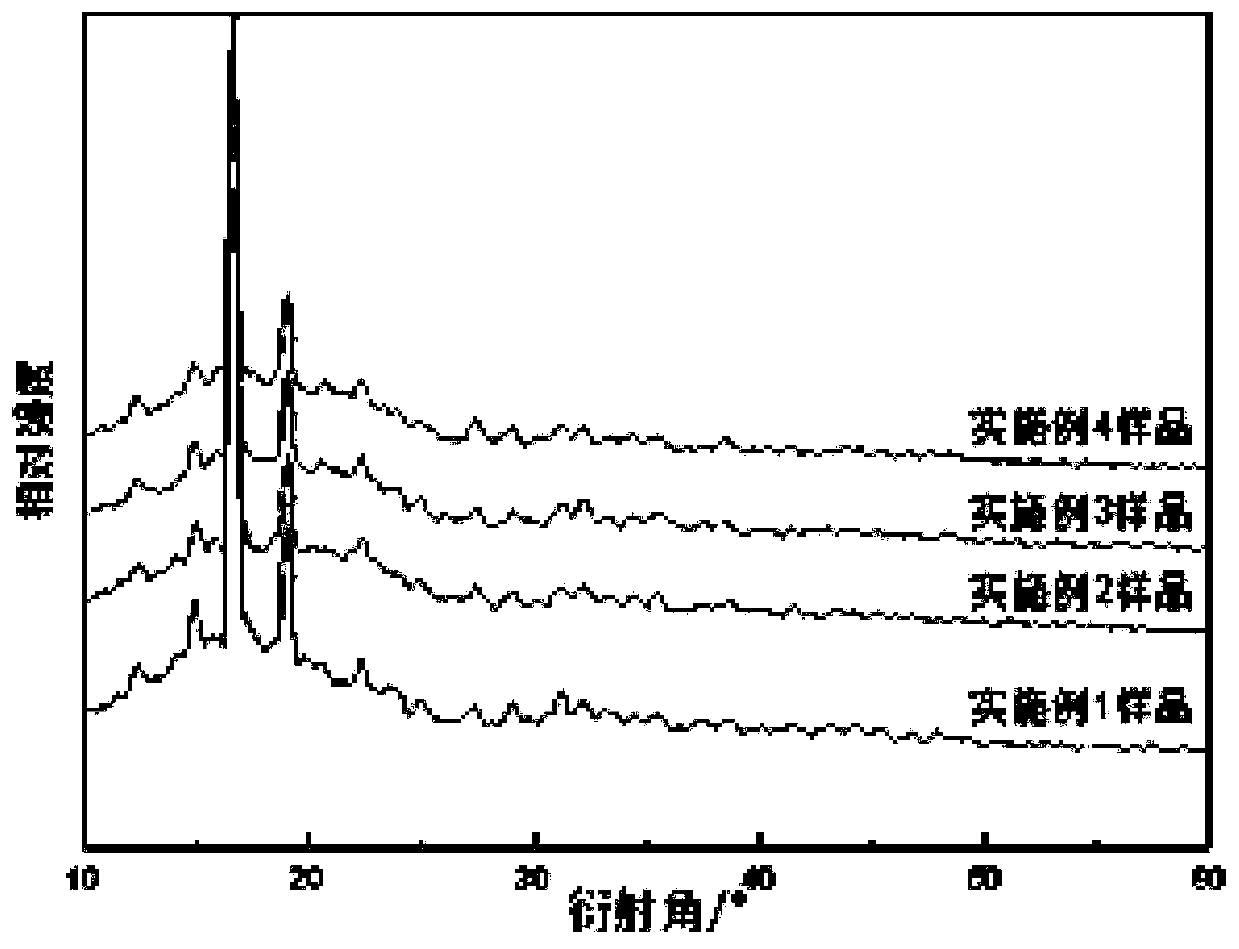

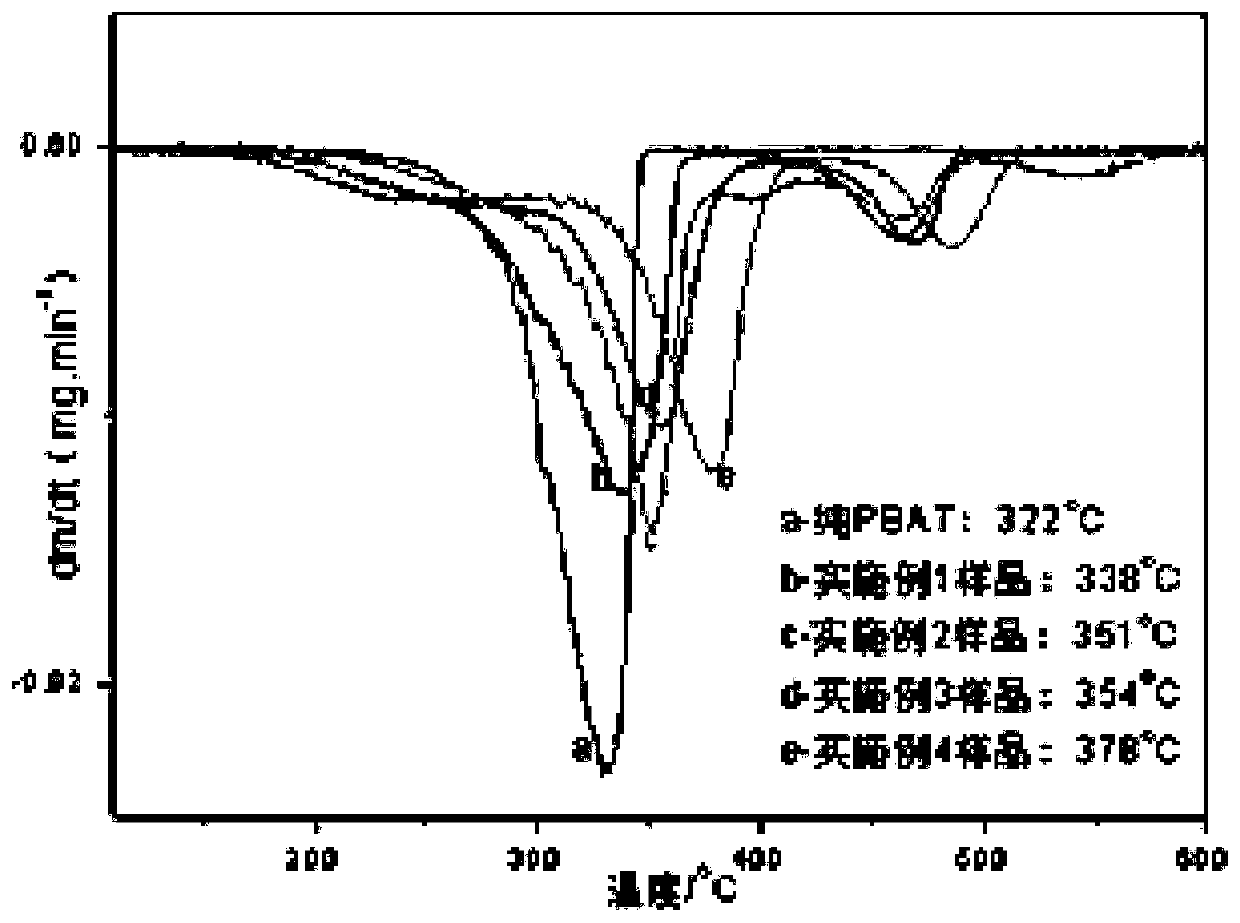

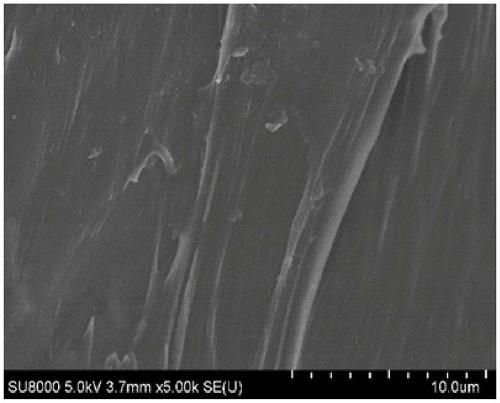

High-content-rice husk fiber-filled PBAT-based composite material and preparation method and application thereof

The invention relates to the technical field of degradable materials, in particular to a high-content-rice husk fiber-filled PBAT-based composite material. The composite material comprises the following components: in parts by weight, 90-110 parts of rice husk powder, 35-90 parts of PBAT, 10-25 parts of PLA, 2-5 parts of a super dispersant, 5-20 parts of a compatibilizer, 1-4 parts of a heat stabilizer and 2-4 parts of a lubricant. The raw materials are mixed and stirred in a high-speed mixer at 120 DEG C, and then crushing, extrusion and injection moulding are performed. The rice husk powderas agricultural processing waste has rich raw material sources, low price and biodegradability at the same time, the rice husk powder is adopted as filler of the degradable polymer PBAT, and the rigidity and toughness of the composite material can be balanced well under the action of the processing aids; and the method has simple operation and low production cost, and is beneficial to industrial production of PBAT degradable composite materials.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

Thermoplastic resin compsn. having excellent chemical resistance and easy vacuum formability

InactiveCN1481420AWell balanced physical propertiesBalanced Physical PropertiesDomestic articlesCyanide compoundPolymer science

The resin composition according to the present invention comprises(A)a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of diene rubber,(B)a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30%by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of acrylic rubber,(C)a linear copolymer prepared by polymerizing 40-50% by weight of vinyl cyanide compound and 50-60% by weight of vinyl aromatic compound, and (D) a branched copolymer prepared by 30-35% by weight of vinyl cyanide compound and 65-70% by weight of vinyl aromatic compound.

Owner:LOTTE ADVANCED MATERIALS CO LTD

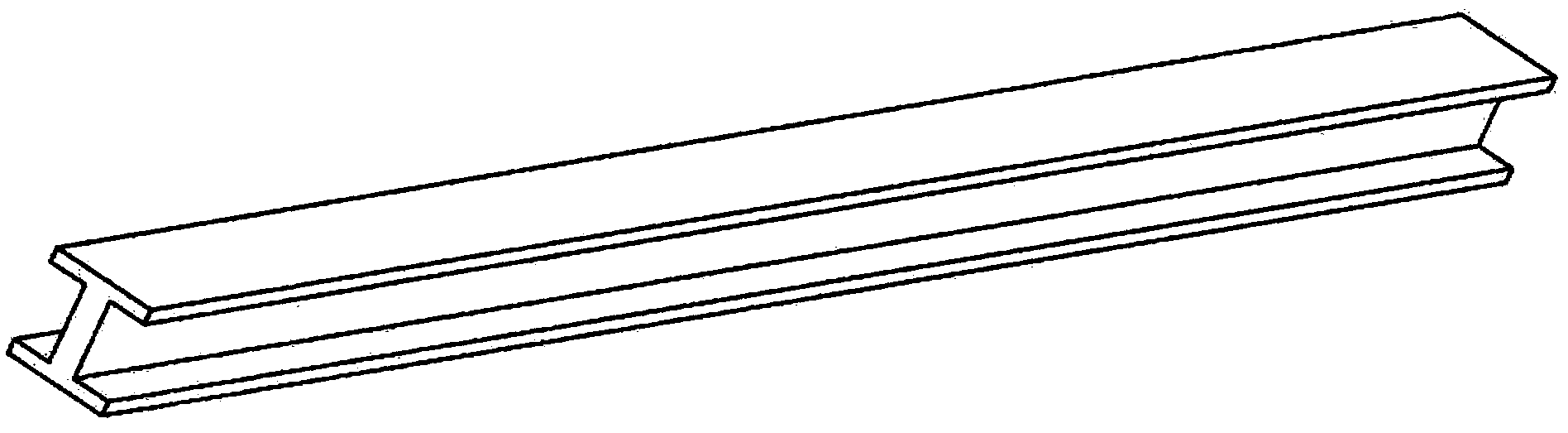

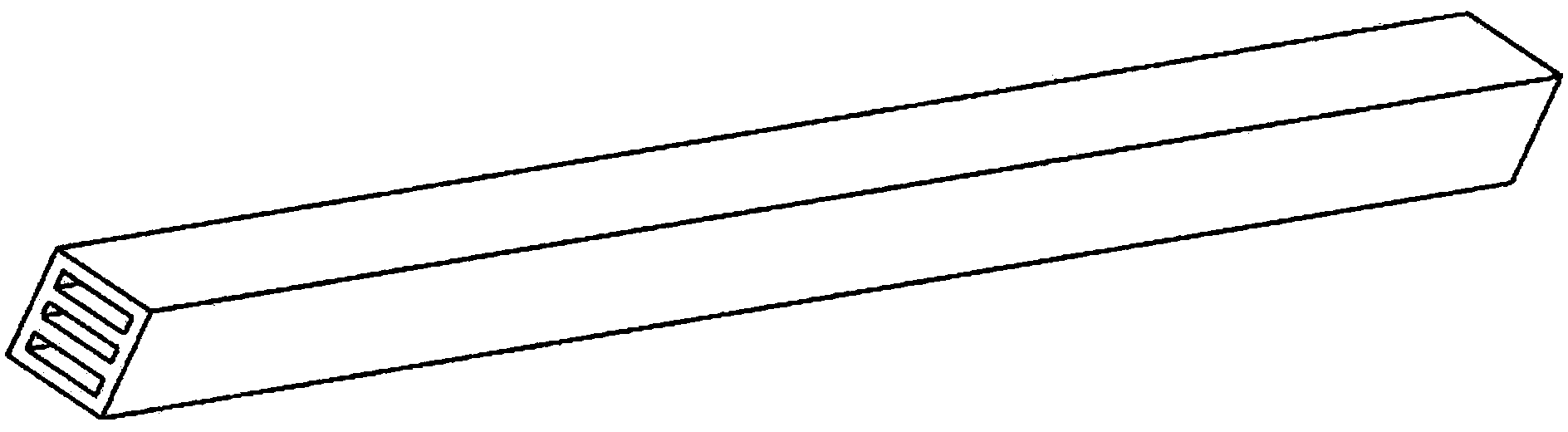

Railway freight transport open wagon vertical column and preparation method thereof

The invention discloses a railway freight transport open wagon vertical column and a preparation method thereof. The wagon vertical column is prepared by composite material, flexibilizer, filler and bulking agent in the mass ratio of 100:(3 to 15):(0.1 to 10):(0.1 to 5), wherein the composite material is prepared from the following constituents in part by weight: 60 to 80 parts of nylon resin, 20 to 40 parts of reinforced fiber, 0.1 to 5 parts of coupling agent, 0.5 to 3 parts of nucleating agent, 0.2 to 3 parts of heat stabilizer, 0.3 to 1.5 parts of antioxygen, and 0.5 to 1.5 parts of lubricant. The novel wagon vertical column is in a square matrix shape (rounded) according to strength calculation, ANSYS software analysis, isotropy requirements and convenience in use: the section size is 45*45mm, the wall thickness is 6mm, and the outer fillet is 10 mm. The wagon vertical column has sufficient impact strength and bending strength, good weather resistance, balanced blasting stress, good comprehensive performance indexes of rigidity, flexibility and balance, and has the advantages of capability of recycling and the like.

Owner:SHAANXI UNIV OF SCI & TECH

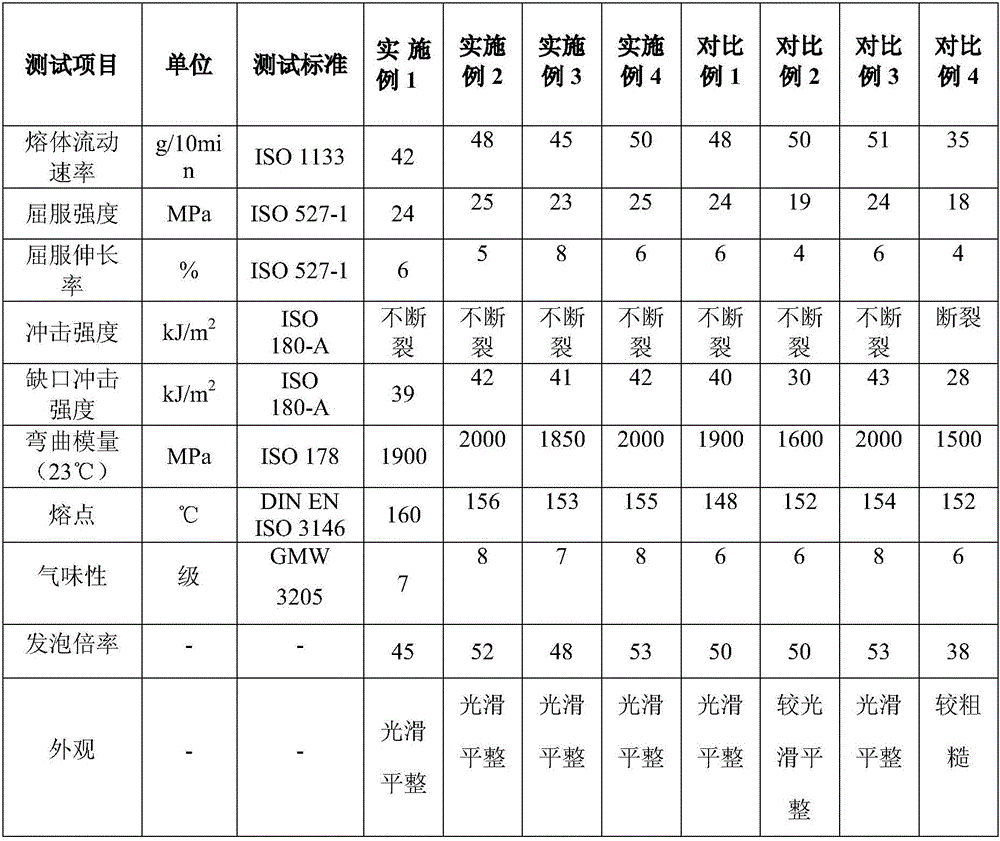

Microcellular-foamed high-strength polypropylene composite material

The invention discloses a microcellular-foamed high-strength polypropylene composite material. The composite material is prepared from, by weight, 100 parts of polypropylene, 0.001-0.01 part of organic peroxide, 10-15 parts of K resin, 1-5 parts of an inorganic foaming agent coated with organic macromolecules, 5-15 parts of talcum powder and 1-5 parts of auxiliaries, wherein the auxiliaries comprise a surfactant, a foaming stabilizing agent and a thermal stabilizing agent, and the particle size of the talcum powder ranges from 100 mesh to 5,000 mesh. According to the microcellular-foamed high-strength polypropylene composite material, the raw materials adopted in the formula are easy to obtain and low in cost, especially the foaming agent NaHCO3 is economical and environmentally friendly, and the microcellular-foamed polypropylene material which is used for an automobile, has injection molding grade closed holes and is uniform in foam hole distribution, high in foaming rate and excellent in physical and mechanical properties can be prepared through cooperation of the foaming agent NaHCO3 and other components.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

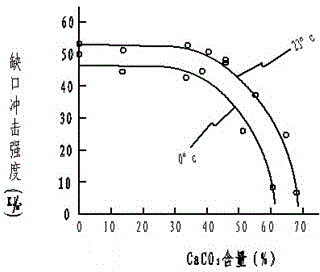

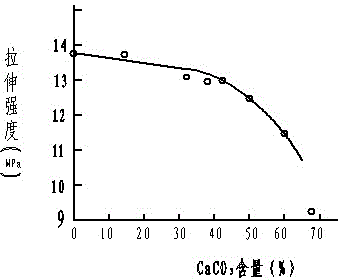

High-impact low-cost PP (Propene Polymer)-SBS (styrene-butadiene-styrene block copolymer)-CaCO3 ternary composite material and preparation method thereof

The invention discloses a high-impact low-cost PP (Propene Polymer)-SBS (styrene-butadiene-styrene block copolymer)-CaCO3 ternary composite material and a preparation method thereof. The high-impact low-cost PP-SBS-CaCO3 ternary composite material comprises the following components in percent by weight: 33.3-56.4 percent of PP, 6.7-11.8 percent of SBS and 31.8-60.0 percent of CaCO3. The preparation method of the high-impact low-cost PP-SBS-CaCO3 ternary composite material comprises the following steps of: 1, mixing and extruding partial PP and SBS for pelleting to prepare a PP-SBS blending master batch material; and 2, mixing and extruding the PP-SBS blending master batch material prepared by the step 1 and left PP and CaCO3 for pelleting to prepare the high-impact low-cost PP-SBS-CaCO3 ternary composite material. The high-impact low-cost PP-SBS-CaCO3 ternary composite material has the characteristics of balance of impact property and rigidity, excellent comprehensive mechanical property and low cost, is suitable for manufacturing a dual-wall corrugated pipe and a large-diameter steel and plastic composite pipe, or is used as a toughening modifying agent of common PP (such as PPH (Propene Polymer Homopolymer) and PPR (propylene random copolymer)).

Owner:重庆顾地塑胶电器有限公司 +1

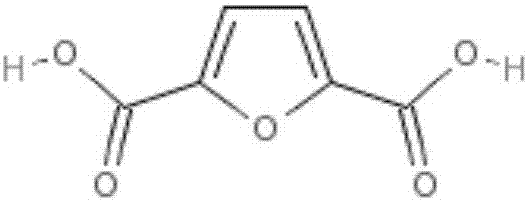

High-weather-resistant high-tenacity reinforced polypropylene material for post insulator and preparation method of reinforced polypropylene material

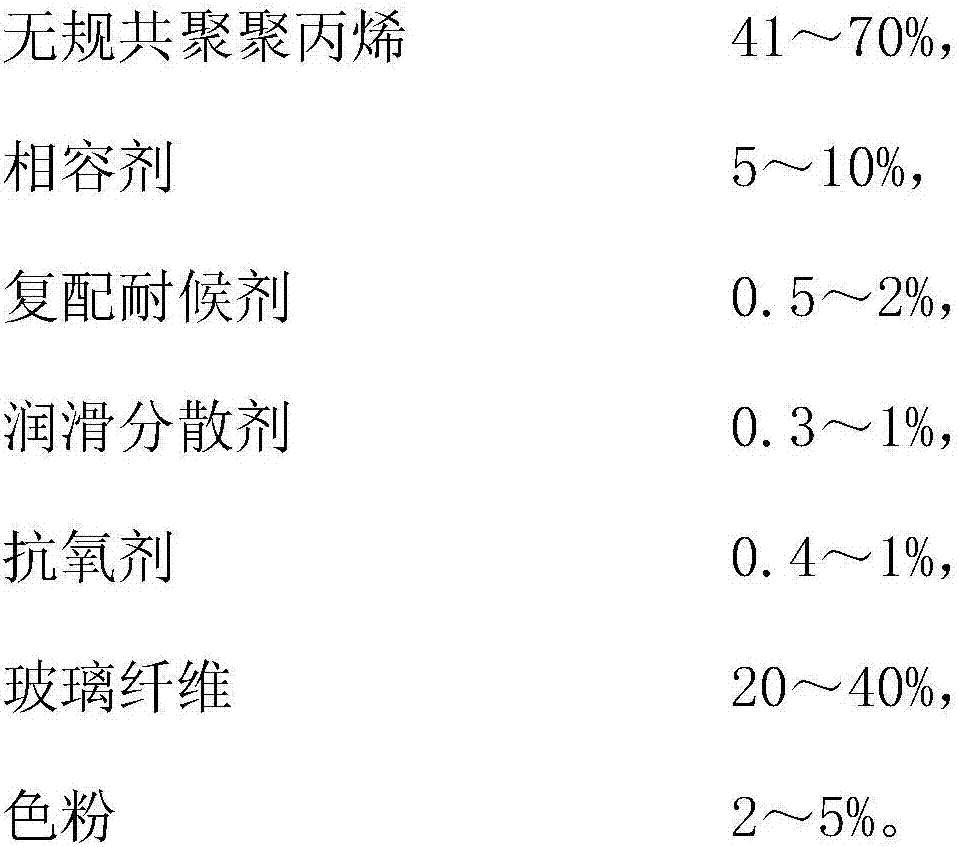

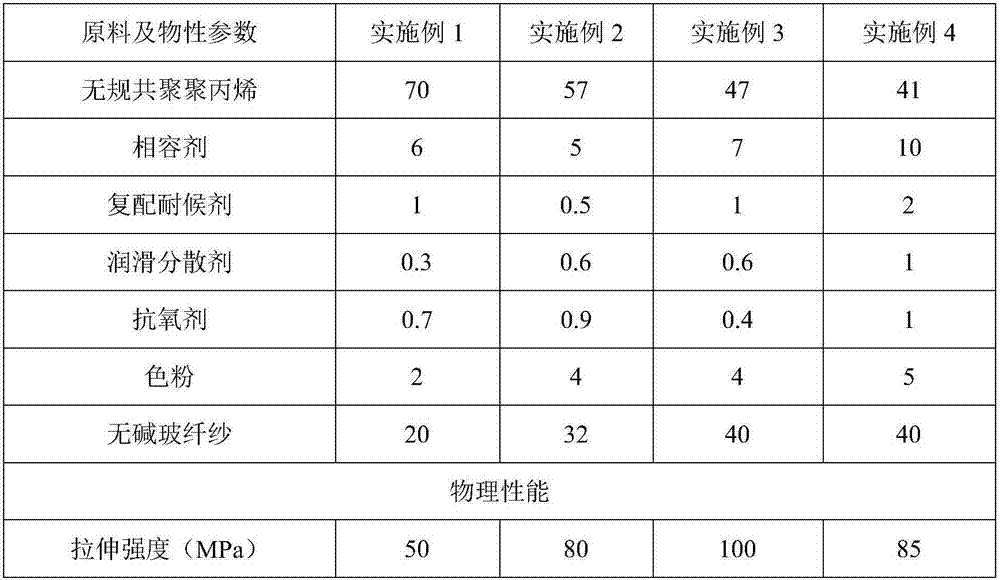

InactiveCN107987398AHigh retention rate of mechanical propertiesGood color stabilityLubricationPolypropylene

The invention discloses a high-weather-resistant high-tenacity reinforced polypropylene material for a post insulator and a preparation method of the reinforced polypropylene material. According to the key point of the technical scheme, the reinforced polypropylene material contains the following components in percentage by weight: 41%-70% of random copolymerization polypropylene, 5%-10% of a compatilizer, 0.5%-2% of a compound weather-resistant agent, 0.3%-1% of a lubrication dispersing agent, 0.4%-1% of an antioxidant, 20%-40% of glass fibers and 2%-5% of a toner. The high-weather-resistanthigh-tenacity reinforced polypropylene material for the post insulator has the advantages that the weather resistance and the tenacity are high, the retention rate of mechanical performance under a photothermal oxygen aging condition is high, the color stability is good, and the like.

Owner:GUANGDONG WAYLAM ENG PLASTICS

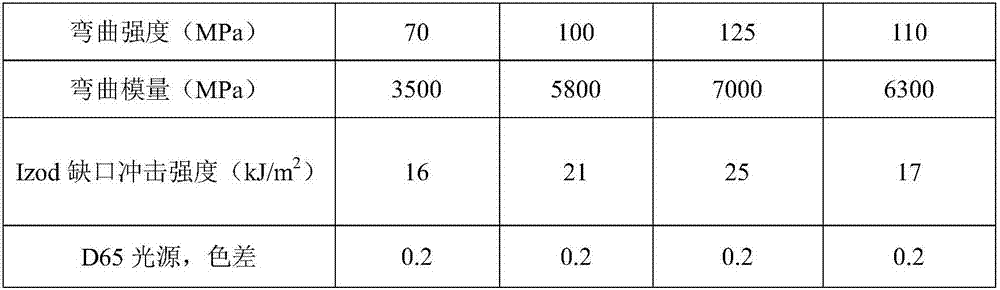

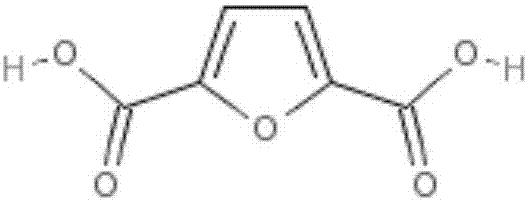

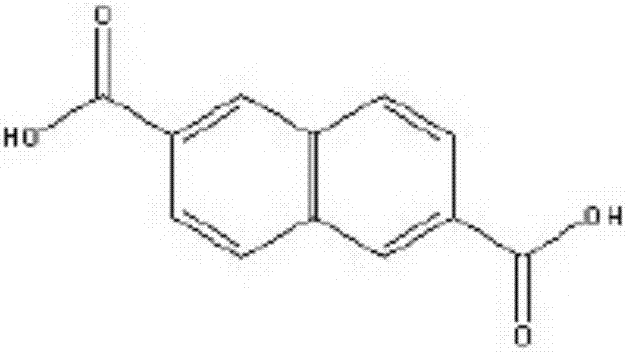

Polyester resin for epoxy resin-cured precoated anticorrosive powder coating and preparation method thereof

ActiveCN107200833AImprove resistance to damageBalance rigidityAnti-corrosive paintsPowdery paintsEpoxyCyclic ether

The invention discloses polyester resin for epoxy resin-cured precoated anticorrosive powder coating. The polyester resin comprises the following components in percent by mass: 30-50% of polyalcohol, 5-35% of furan dicarboxylic acid, 5-25% of naphthalic acid, 5-40% of polyacid, 5-20% of an acidolysis agent, 0.04-0.15% of a catalyst and 0.01-1.0% of a curing accelerant; melt polymerization is performed on the components to obtain the polyester resin with the acid value of 65-100mgKOH / g, the viscosity of 2500-5000mPa.s, the number average molecular weight of 2000-4000 and the glass transition temperature of 55-75 DEGC. The invention further discloses a preparation method of the polyester resin. The polyester resin contains cyclic ether and naphthalene ring structures, and has excellent corrosion resistance, bending resistance and other properties; after being cured by epoxy resin E-12, the polyester resin is particularly suitable for the precoated anticorrosive powder coating; the prepared powder coating is fully applicable to a process flow of an anti-corrosive component which is coated first and then moulded, and other requirements; the conventional processing efficiency can be greatly improved; a coating film is high in hardness and outstanding in toughness.

Owner:蔚复来(浙江)科技股份有限公司

High-tenacity transparent PS plastic cement material and preparation method therefor

The invention discloses a high-tenacity transparent PS plastic cement material. The high-tenacity transparent PS plastic cement material consists of the following raw materials in parts by weight: 70-85 parts of polystyrene (PS), 5-8 parts of polyether sulfone resin (PES), 7-12 parts of polyvinylidene fluoride (PVF) and 3-10 parts of a composite modifier. The invention further discloses a preparation method of the high-tenacity transparent PS plastic cement material. According to the preparation method disclosed by the invention, the PES, the PVF and the PS are blended so as to obtain the plastic cement material, a shock resistant modifier and a flexibilizer in the composite modifier are used for composite modification for the plastic cement material, so that the rigidity and the tenacity of PS products are effectively balanced, and the PS plastic cement material with high tenacity, high impact strength and favorable transparency is obtained.

Owner:JIN BAOLI TECH SUZHOU

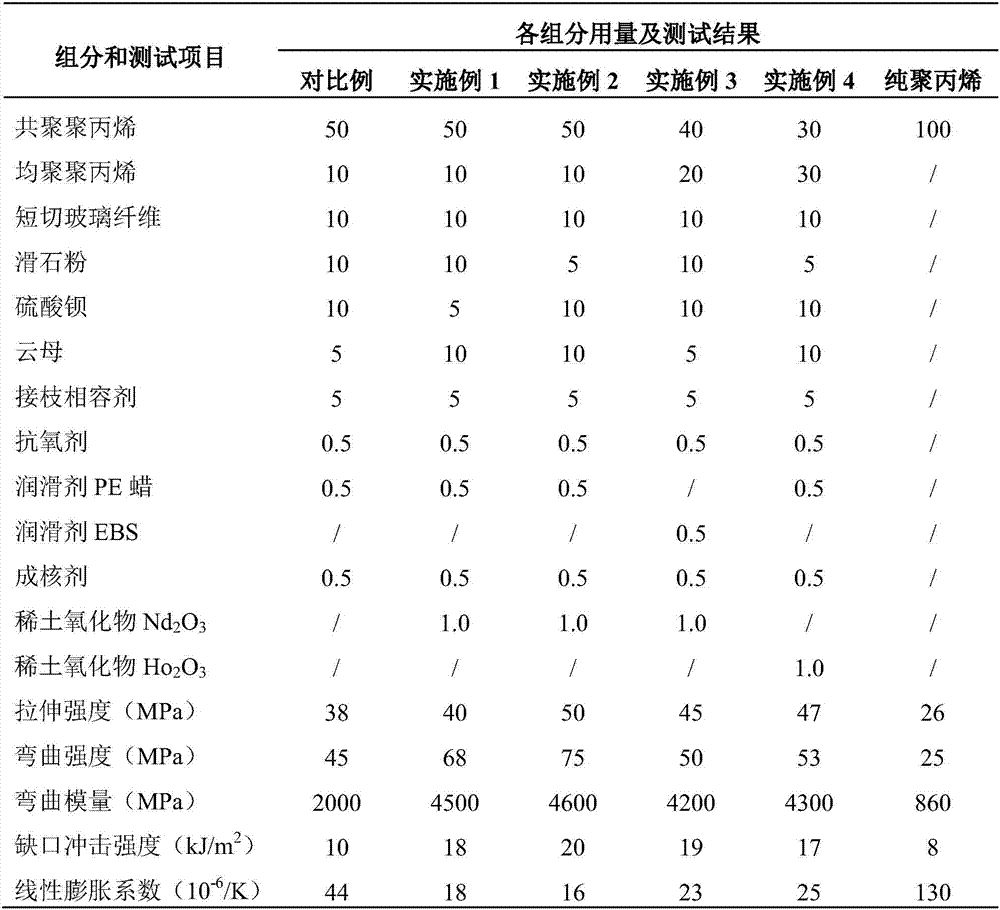

Composite material, preparation method thereof and air conditioner workpieces

The invention discloses a composite material, a preparation method thereof and air conditioner workpieces. The composite material comprises the following materials, in parts by weight: 50-70 parts of polypropylene, 10-20 parts of chopped glass fibers, 20-30 parts of an inorganic filler, 5-10 parts of a graft compatilizer, 0.2-0.8 part of an antioxidant, 0.5-2.0 parts of a lubricant, 0.1-1.0 part of a nucleating agent, and 0.5-2.0 parts of a rare earth oxide. The composite material has a low linear expansion coefficient and excellent dimensional stability, when the air conditioner workpieces are prepared by adopting the composite material, noise caused by thermal expansion and cold contraction in an air conditioner usage process can be effectively avoided.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

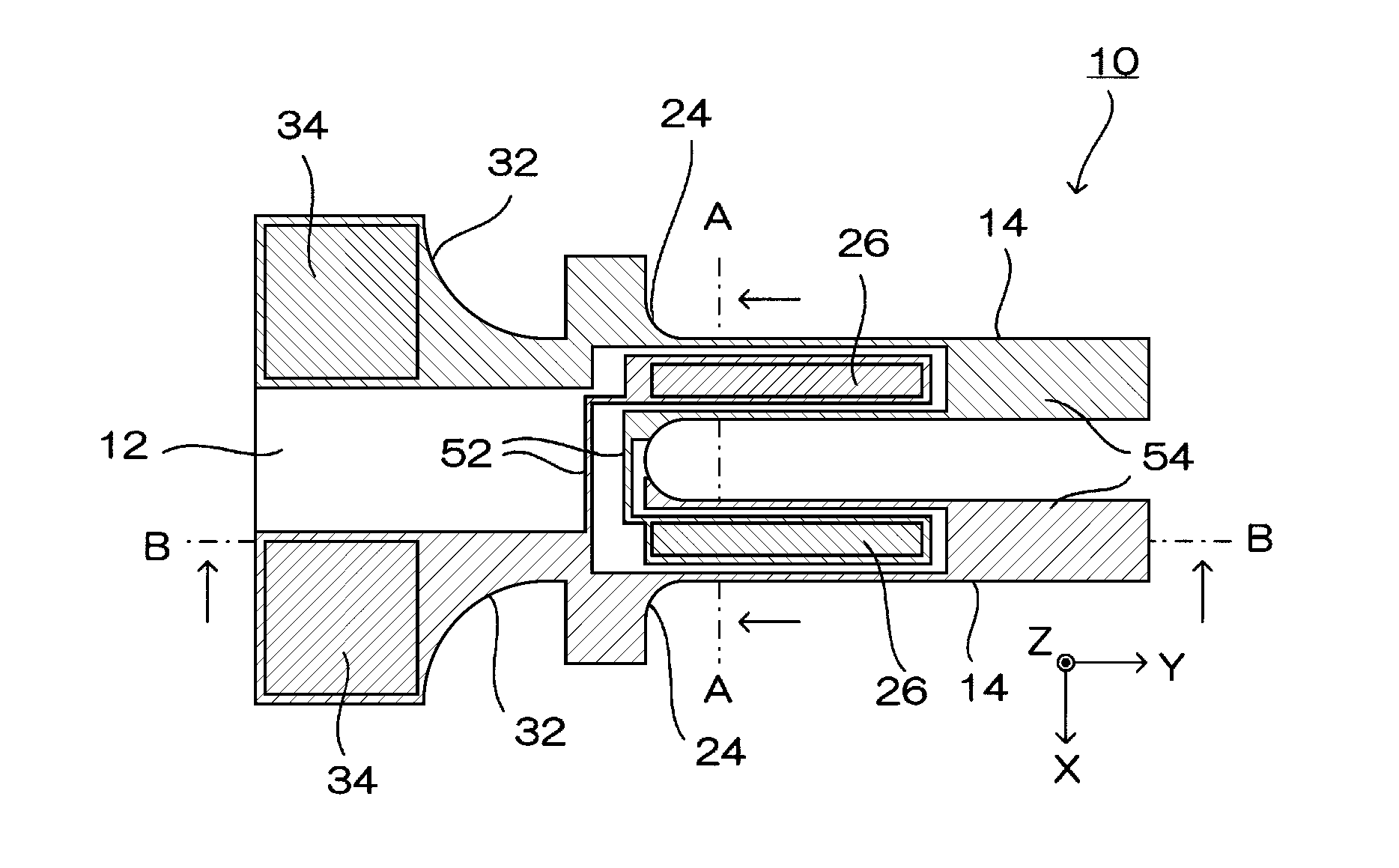

Piezoelectric resonator element, piezoelectric resonator, and acceleration sensor

InactiveUS20110089788A1Reduce sensitivityBalance rigidityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksClassical mechanicsCantilever

A piezoelectric resonator element includes: a resonating arm extending in a first direction and cantilever-supported; a base portion cantilever-supporting the resonating arm; and an excitation electrode allowing the resonating arm to perform flexural vibration in a second direction that is orthogonal to the first direction. In the piezoelectric resonator element, the resonating arm includes an adjusting part adjusting rigidity with respect to a bend in a third direction that is orthogonal to the first and second directions.

Owner:SEIKO EPSON CORP

Wear-resisting and high-rigidity polycarbonate lens

The invention discloses a wear-resisting and high-rigidity polycarbonate lens. The wear-resisting and high-rigidity polycarbonate lens comprises a polycarbonate substrate and a coating which covers the surface of the polycarbonate substrate, wherein the coating is prepared from the following raw materials: a silicon resin pre-polymer, polyurethane, epoxy resin, hydroxyethyl methylacrylate, polyester polyol, aluminum acetylacetonate, dibutyltin dilaurate, tetrabutylammonium hydroxide, methylhexahydrophthalic anhydride, 2-methylimidazole, bicyclic amidine, a solvent, a silane coupling agent andan auxiliary agent. The wear-resisting and high-rigidity polycarbonate lens provided by the invention has good wear resistance, high surface rigidity, excellent heat-resisting performance and long service life.

Owner:望江县天长光学仪器有限公司

Reinforcing material for PVC plastic panel and preparation for reinforcing material for PVC plastic panel

The invention provides a reinforcing material for a PVC plastic panel and a preparation for the reinforcing material for the PVC plastic panel. The reinforcing material for the PVC plastic panel is prepared from the following raw materials in parts by weight: 10-30 parts of ethylene propylene rubber, 20-40 parts of nitrile rubber, 1.5-3 parts of a vulcanizing agent, 1.2-3 parts of an accelerant, 10-20 parts of silicone rubber, 1-2 parts of acrylic acid, 10-15 parts of methyl methacrylate, 10-20 parts of ethyl acrylate, 5-15 parts of butyl acrylate, 5-8 parts of styrene, 0.8-1 part of an antioxidant and 0.5-1 part of an ultraviolet absorber. The reinforcing material for the PVC plastic panel can be applied to PVC panels for furniture and PVC panels for decoration as well as PVC plastic building templates. By adding the reinforcing material into the PVC panel, the strength of the PVC panel can be improved, so that the PVC panel is good in dimensional stability and high in mechanical property. In addition, aging resistance and wear resistance of the PVC panel can be further improved, and the recycling number of times can be increased.

Owner:XIAN HAORUI ELECTRONICS TECH

Strengthened and toughened polypropylene composite and its preparing process

A three-element composition is prepared from polypropene (PP) (72-91 wt%), POE or MPOE (1-13) and BaSO4 (7-20) through mixing, stirring, kneading and extruding out. Its advantages are high impact strength, high toughness, high P / C ratio, high resistance to thermal or ultraviolet ageing, and low cost.

Owner:SUN YAT SEN UNIV

High-toughness formaldehyde removing bamboo-plastic foamed composite door and window material and preparation method thereof

The invention discloses a high-toughness formaldehyde removing bamboo-plastic foamed composite door and window material and a preparation method thereof. The material is characterized by being prepared from, by weight, 2-5 parts of high-elasticity polypropylene fibers, 60-70 parts of isotactic polypropylene, 1-2 parts of SiO2, 10-15 parts of high-melt-strength polypropylene, 30-40 parts of bamboo powder, 10-15 parts of activated carbon, 1-2 parts of polyethylene, 1-2 parts of corundum powder, 20-25 parts of Cu(NO3)2, 1-3 parts of stearic acid, 1-3 parts of calcium stearate, 1-3 parts of a foaming agent AC1601, 10-15 parts of zinc stearate, 50-60 parts of NaOH solution and 1-3 parts of polyacrylate emulsion. The activated carbon and diamond are modified by polyacrylate and the Cu(NO3)2, and loading of the Cu(NO3)2 in pore passages and surfaces of the activated carbon and the diamond is promoted; due to addition of the high-elasticity polypropylene fibers and the like, elasticity of the material is improved.

Owner:安徽三乐节能科技有限公司

A nylon 66 nanometer composite material and a preparation method thereof

The invention discloses a composite nanometer material and making method of polyhexamethylene adipamide (nylon 66), which comprises the following parts: 100wt% nylon 66, 5-20wt% elastic body and 5-30wt% inorganic nanometer particle, wherein these materials are blended to fuse and squeeze under 260-280 deg. c. The invention balances the rigidity, flexibility and fire resistance and size stability, which expands the applying domain of nylon 66.

Owner:EAST CHINA UNIV OF SCI & TECH

High rigidity polycarbonate composition with infrared transmission and preparation method thereof

The invention relates to a high rigidity polycarbonate composition with infrared transmission and a preparation method thereof. The composition is prepared by using the following components and raw materials in parts by weight: 81-95 parts of silicon-containing PC resin, 5-15 parts of glass fiber, 2-6 parts of a zinc sulfide dispersion solution, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant, and 0.01-0.1 part of a color powder. The preparation method is as follows: dispersing deionized water and zinc sulfide according to a ratio of 8:2 by an agitator to obtain the dispersion solution, adding silicon-containing PC resin, the antioxidant, the lubricant, and the color powder into a mixing mixer to perform mixing, feeding the mixture into an extruder from a main material-feeding portof the extruder, feeding the zinc sulfide dispersion solution into the extruder from a side material-feeding port of the extruder using a liquid pump, feeding glass fiber into the extruder from a side material-feeding port of the extruder, and carrying out blend granulation to obtain the high rigidity polycarbonate composition with infrared transmission. The infrared transmission performance of silicon-containing PC is improved by using zinc sulfide, the excellent dispersion of zinc sulfide can be obtained because the zinc sulfide dispersion solution is added, and the balance of toughness andrigidity is obtained by using silicon-containing PC and glass fiber, so that the high rigidity polycarbonate composition with infrared transmission is obtained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Imitation stone paint color granule, imitation stone paint and preparation method and application thereof

ActiveCN109796824APlay a complex roleRealistic effectMulticolor effect coatingsCross-linkWeather resistance

The invention provides an imitation stone paint color granule, an imitation stone paint and a preparation method and application thereof. The imitation stone paint color granule comprises 68.0-74.0% of imitation stone paint color phase paint, 23.8-30.2% of a glue solution and 1.8-2.2% of a cross-linking agent. The imitation stone paint can show a vivid texture only by spraying with a gun, a colorpoint is not easy to break in the spraying process, the color point is easy to spread, the consumption is reduced, meanwhile, the imitation stone paint has excellent weather resistance and water resistance, various natural marble effects can be made, and the imitation stone paint also has storage stability, weather resistance and water resistance and can completely meet the requirements of national standards.

Owner:ASIA PAINT SHANGHAI

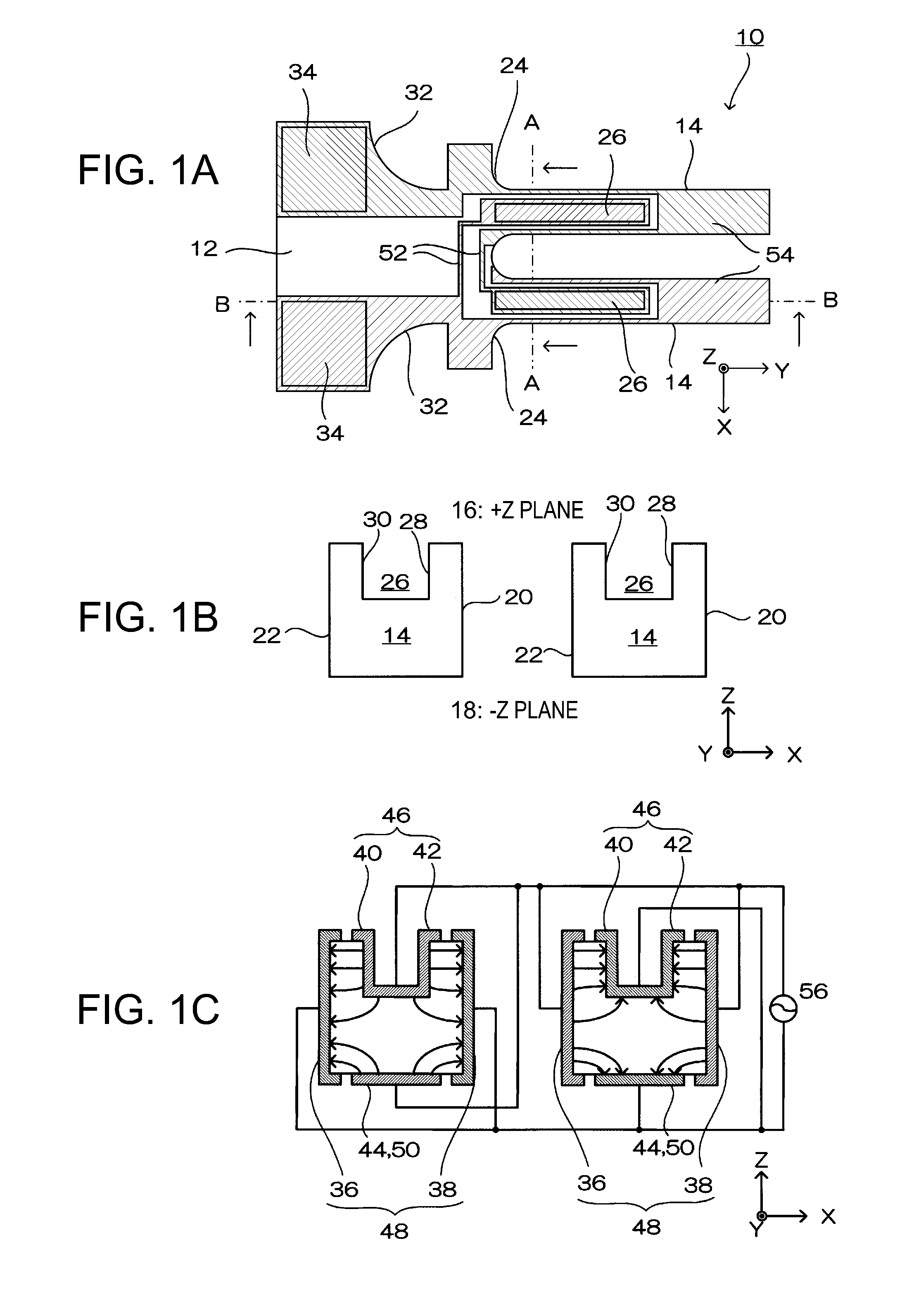

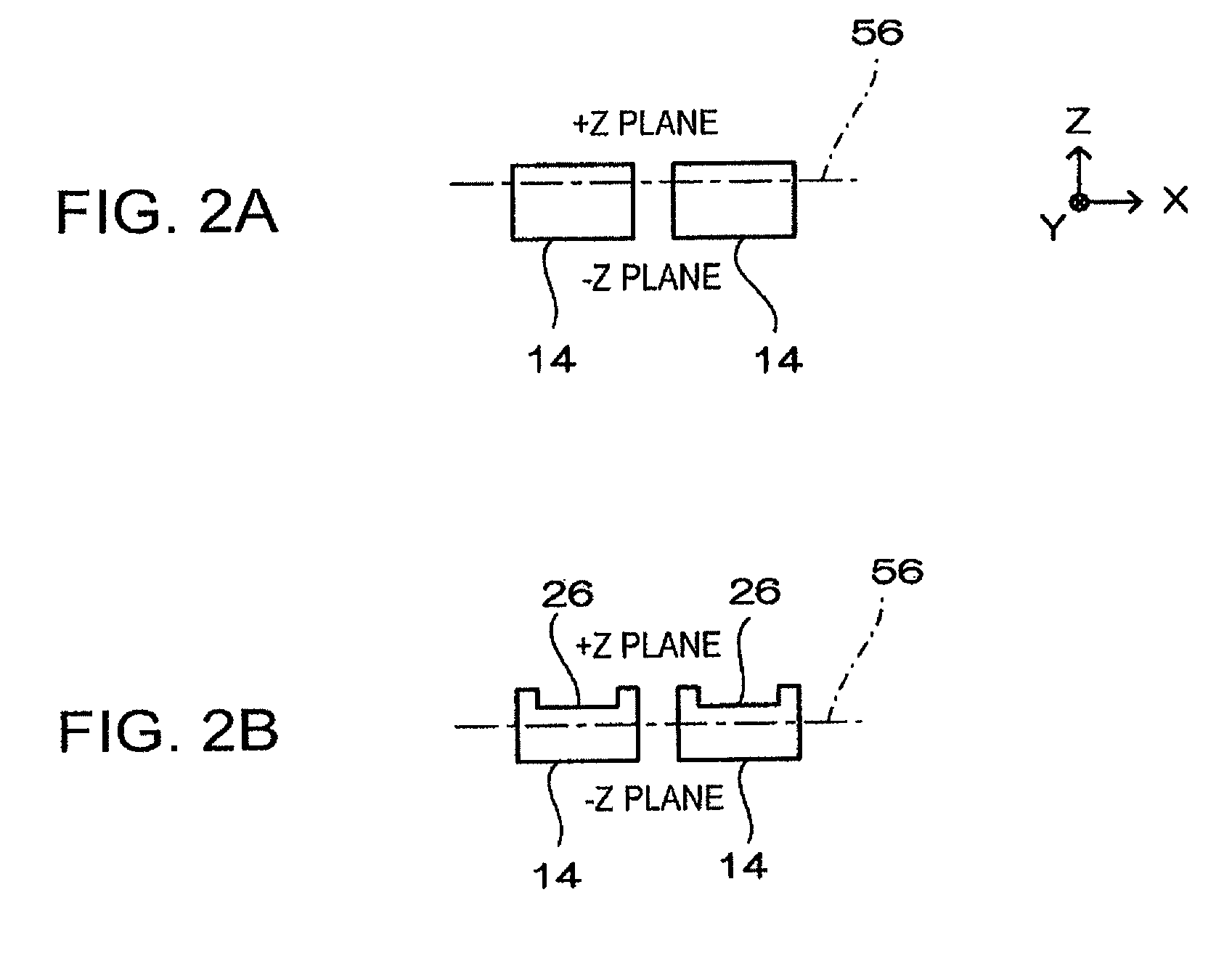

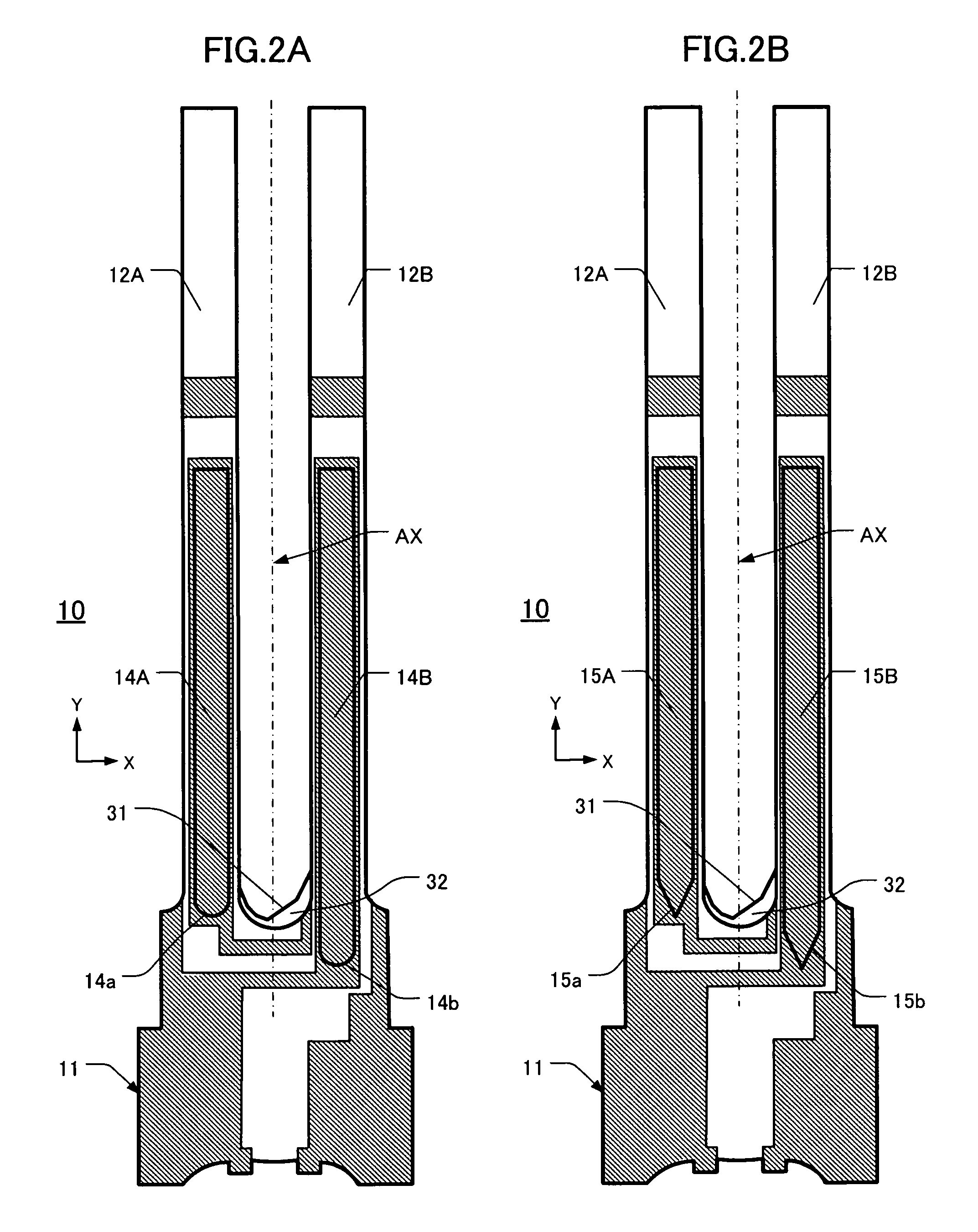

Piezoelectric vibrating pieces, and piezoelectric vibrators and oscillators comprising same

InactiveUS8076830B2Excess rigidityWith balanceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEtchingPiezoelectric actuators

Piezoelectric vibrating pieces are disclosed that include a base portion and first and second vibrating arms extending in a longitudinal direction from the base portion. Each vibrating arm has first and second main surfaces, a first groove on the first main surface, and a second groove on the second main surface. The grooves extend in the longitudinal. By adjusting the length and shapes of at least the first grooves relative to each other, the rigidity of the vibrating arms can be balanced and adverse effects of deformed regions between the vibrating arms caused by anomalous etching can be reduced.

Owner:NIHON DEMPA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com