Flexible solar cell module and preparation method and application thereof

A technology of flexible solar cells and solar cells, which is applied in the field of solar cells and can solve problems such as low surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

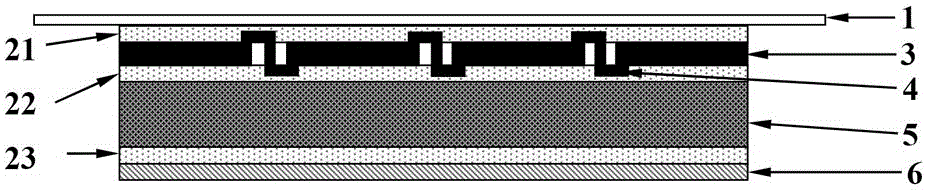

[0034] like figure 1 As shown, a flexible solar cell module of the present invention includes an upper skin 1, a first packaging adhesive film 21, a flexible solar cell array, a second packaging adhesive film 22, a support member, The third packaging adhesive film 23 and the lower skin 6 are supported by polymethacrylimide foam board 5 .

[0035] The thickness of polymethacrylimide foam board 5 is preferably 0.5mm~3mm, and the density is preferably 30 Kg / m 3 ~100Kg / m 3 , compressive strength 0.3MPa~7.5MPa, compressive modulus 20MPa~200MPa, tensile strength 0.8MPa~8MPa, tensile modulus 40MPa~400MPa, torsional shear strength 0.4MPa~7MPa, torsional shear modulus 10MPa~200MPa.

[0036] In the present embodiment, the thickness of polymethacrylimide foam board 5 is 0.5mm, and density 50 Kg / m 3 ~100Kg / m 3 , Compressive strength 1.0MPa, compressive modulus 44MPa, tensile strength 1.7MPa, tensile modulus 74MPa, torsional shear strength 0.92MPa, torsional shear modulus 23MPa.

[00...

Embodiment 2

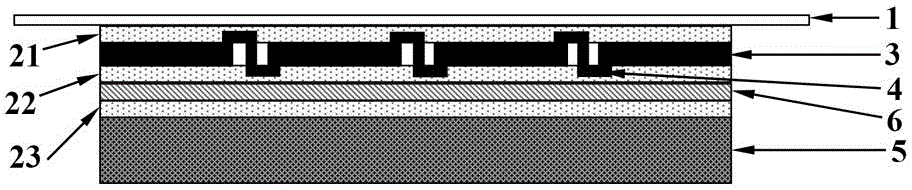

[0048] like image 3 As shown, a flexible solar cell assembly of the present invention includes an upper skin 1, a first packaging film 21, a flexible solar cell array, a second packaging film 22, a lower skin 6. The third encapsulation film 23 and a supporting member, the supporting member is a polymethacrylimide foam board 5 .

[0049] In the present embodiment, the thickness of polymethacrylimide foam board 5 is 0.5mm, and density 50 Kg / m 3 ~100Kg / m 3 , Compressive strength 32MPa, compressive modulus 0.44MPa, tensile strength 23MPa, tensile modulus 0.88MPa, torsional shear strength 0.48MPa, torsional shear modulus 13MPa.

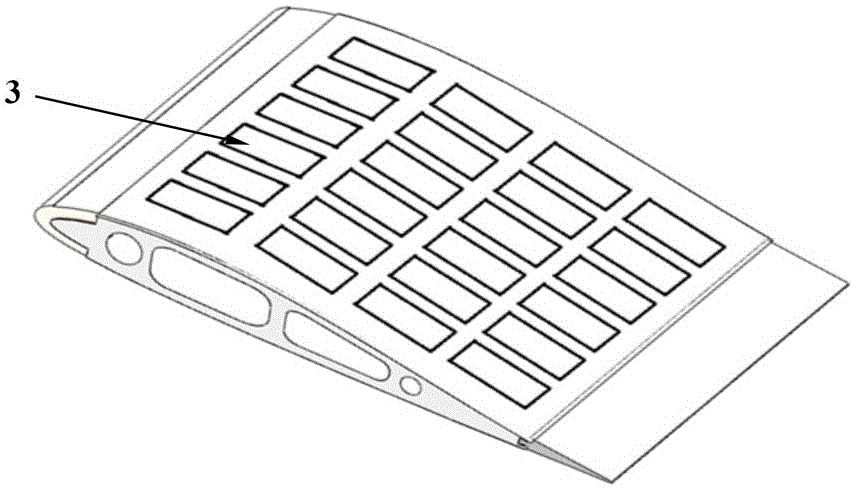

[0050] In this embodiment, the flexible solar cell array includes a plurality of crystalline silicon solar cell sheets 3 and photovoltaic ribbons 4 , and adjacent crystalline silicon solar cell sheets 3 are connected by photovoltaic ribbons 4 , finally forming a flexible solar cell array.

[0051] In this embodiment, the thickness of the crystalline si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com