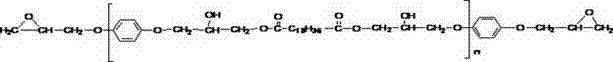

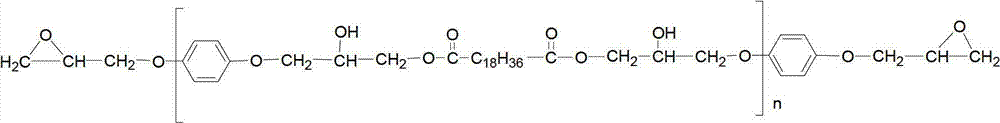

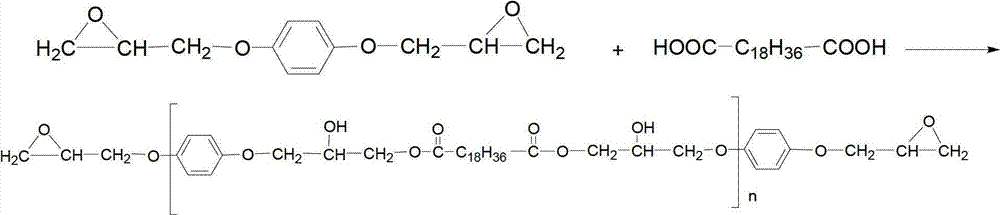

Modified bisphenol A-type epoxy resin and preparation method thereof

A technology of epoxy resin and bisphenol, which is applied in the field of epoxy resin and its preparation, can solve the problems of low yield, general rigidity and flexibility, and high reaction temperature of modified bisphenol A epoxy resin, and achieve high reaction speed Fast, flexible, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: a kind of modified bisphenol A type epoxy resin and preparation method thereof

[0036] Accurately weigh 500 grams (g) of E-51 liquid epoxy resin and 445 grams (g) of eicosadioic acid, stir and heat to 98°C under nitrogen protection, then add 0.6 grams (g) of triphenylethyl ether Phosphonium bromide, when the temperature of the reactant rises to 140-150°C; keep the reactant at this temperature for 1.8 hours; after cooling, discharge the material to obtain the modified bisphenol A epoxy resin. The epoxy equivalent weight of the product was 805 g / eq.

Embodiment 2

[0037] Embodiment two: a kind of modified bisphenol A type epoxy resin and preparation method thereof

[0038] Accurately weigh 500 grams (g) of D.E.R 383 epoxy resin and 405 grams (g) of eicosadioic acid, stir and heat to 96°C under nitrogen protection, then add 0.5 grams (g) of triethanolammonium chloride, when The temperature of the reactant rises to 140-150°C; the reactant is kept at this temperature for 3.5 hours; after cooling, the material is discharged to obtain the modified bisphenol A epoxy resin. The epoxy equivalent weight of the product was 785 g / eq.

Embodiment 3

[0039] Embodiment three: a kind of modified bisphenol A type epoxy resin and preparation method thereof

[0040]Accurately weigh 500 grams (g) of EPIKOTE 828EL epoxy resin and 415 grams (g) of eicosadioic acid, stir and heat to 98°C under nitrogen protection, then add 0.8 grams (g) of triphenylethyl iodide Phosphonium, when the temperature of the reactant rises to 140-150°C; keep the reactant at this temperature for 2 hours; after cooling, discharge the material to obtain the modified bisphenol A epoxy resin. The epoxy equivalent weight of the product was 780 g / eq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com