High-impact low-cost PP (Propene Polymer)-SBS (styrene-butadiene-styrene block copolymer)-CaCO3 ternary composite material and preparation method thereof

A technology of PP-SBS and composite materials, which is applied in the field of polypropylene composite materials, can solve problems such as rigidity reduction, and achieve the effects of impact performance balance, rigidity balance, and comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

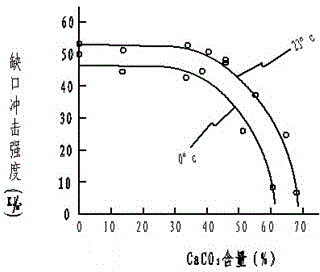

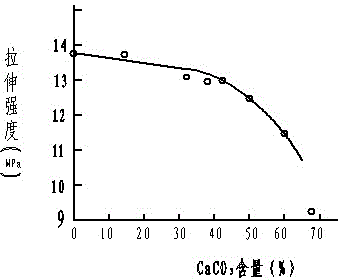

Image

Examples

Embodiment 1

[0026] The high-impact low-cost PP-SBS-CaCO of embodiment 1 3 In the ternary composite material, the weight percentage of PP is 56.4%, the weight percentage of SBS is 11.8%, CaCO 3 The weight percentage is 31.8%.

[0027] The high-impact low-cost PP-SBS-CaCO of this embodiment 3 The preparation method of ternary composite material, comprises the following steps:

[0028] 1) Mix and extrude part of PP and SBS to obtain PP-SBS blend masterbatch;

[0029] 2) Then the remaining PP, CaCO 3 and the PP-SBS blending master batch prepared in step 1) were mixed, extruded and granulated to obtain the ternary composite material.

[0030] In the PP-SBS blending master batch prepared in the step 1), the weight percentages of PP and SBS are 50% respectively; in the step 1) and step 2), reverse parallel twin-screw extruders are used , the extrusion temperature is 188~192℃, and the screw torque is 2500~3000Gm.

[0031] The normal temperature notched impact strength of the obtained ternar...

Embodiment 2

[0033] The high-impact low-cost PP-SBS-CaCO of embodiment 2 3 In the ternary composite material, the weight percentage of PP is 52.1%, the weight percentage of SBS is 10.4%, CaCO 3 The weight percentage is 37.5%.

[0034] The high-impact low-cost PP-SBS-CaCO of this embodiment 3 The preparation method of ternary composite material, comprises the following steps:

[0035] 1) Mix and extrude part of PP and SBS to obtain PP-SBS blend masterbatch;

[0036] 2) Then the remaining PP, CaCO 3 and the PP-SBS blending master batch prepared in step 1) were mixed, extruded and granulated to obtain the ternary composite material.

[0037] In the PP-SBS blending master batch prepared in the step 1), the weight percentages of PP and SBS are 50% respectively; in the step 1) and step 2), reverse parallel twin-screw extruders are used , the extrusion temperature is 188~192℃, and the screw torque is 2500~3000Gm.

[0038] The normal temperature notched impact strength of the obtained ternar...

Embodiment 3

[0040] The high-impact low-cost PP-SBS-CaCO of embodiment 3 3 In the ternary composite material, the weight percentage of PP is 47.6%, the weight percentage of SBS is 9.5%, CaCO 3 The weight percentage is 42.9%.

[0041] The high-impact low-cost PP-SBS-CaCO of this embodiment 3 The preparation method of ternary composite material, comprises the following steps:

[0042] 1) Mix and extrude part of PP and SBS to obtain PP-SBS blend masterbatch;

[0043] 2) Then the remaining PP, CaCO 3 and the PP-SBS blending master batch prepared in step 1) were mixed, extruded and granulated to obtain the ternary composite material.

[0044] In the PP-SBS blending master batch prepared in the step 1), the weight percentages of PP and SBS are 50% respectively; in the step 1) and step 2), reverse parallel twin-screw extruders are used , the extrusion temperature is 188~192℃, and the screw torque is 2500~3000Gm.

[0045] The room temperature notched impact strength of the obtained ternary c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com