Imitation stone paint color granule, imitation stone paint and preparation method and application thereof

A technology of imitating stone and colored particles, applied in the field of coatings, can solve the problems of insufficient toughness, high construction cost, poor stain resistance, etc., and achieve the effect of not easy to agglomerate or crack, easy to use, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

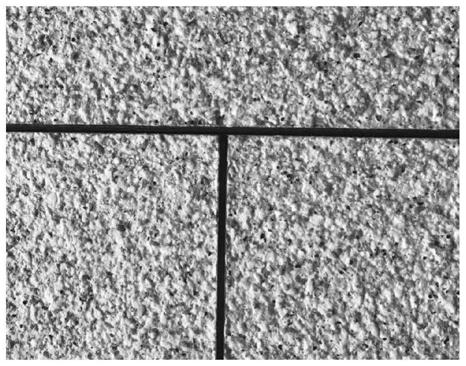

Image

Examples

Embodiment 1

[0118] A formula for preparing artificial stone paint:

[0119] (1) The simulated stone paint includes the following components according to the mass percentage:

[0120]

[0121] (2) The artificial stone paint color particles include the following components according to the mass percentage:

[0122] Imitation stone paint color phase paint 74%

[0123] Glue 24%

[0124] Alkylphenol sulfur salt with octahedral structure 2%;

[0125] (3) The glue solution comprises the following components according to mass percentage:

[0126] Modified lithium magnesium organosilicate 4.4%

[0127] Organic modified bentonite 0.6%

[0128] Deionized water 95%

[0129] (4) The imitation stone varnish color phase paint includes the following components according to the mass percentage:

[0130]

[0131] The preparation method of above-mentioned artificial stone paint:

[0132] (1) Start the machine, add organically modified bentonite and modified organic magnesium lithium silicate t...

Embodiment 2

[0139] The difference from Example 1 is that the modified lithium magnesium silicate is replaced by unmodified lithium magnesium silicate.

Embodiment 3

[0141] The difference from Example 1 is that the silicon-acrylic emulsion is replaced by pure acrylic emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com