Acid activated bentonite and application thereof

A technology of bentonite and acid activation, which is applied in the field of deep processing of bentonite, and can solve the problems of modified bentonite alkali content, low activity index, short thermal stability time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

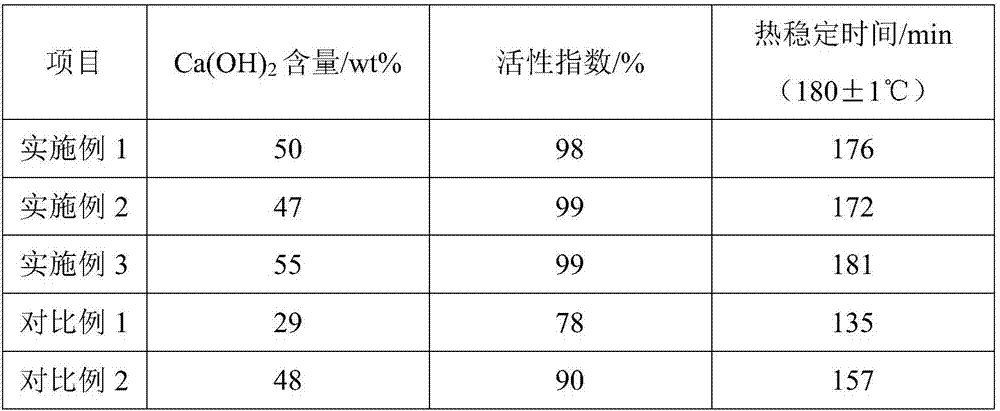

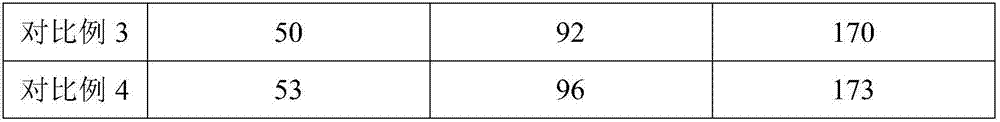

Examples

Embodiment 1

[0035] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0036] S1: Mix bentonite and activated clay wastewater with a concentration of 2.4% at a weight ratio of 1:2.51, and stir evenly at a rotating speed of 300r / min to obtain slurry material A;

[0037] S2: The slurry material A prepared in step S1 is added to a mixed acid with a concentration of 7.2%, and the mixed acid is oxalic acid with a concentration of 14.3wt%, tartaric acid with a concentration of 30-36.2wt%, and citrate with a concentration of 21.7wt%. A mixed acid composed of rafter acid in a volume ratio of 1.8:2.5:1.2, the weight ratio of the slurry material A to the mixed acid is 1:3.6, adding ferrous ammonium sulfate, molecular sieve catalyst and diethylene triethylene oxide under the condition of 300r / min at a rotating speed Sodium amine pentacarboxylate is stirred, and the weight ratio of described ferrous ammonium sulfate, molecular sieve catalyst, sodium diet...

Embodiment 2

[0048] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0049] S1: Mix bentonite and activated clay wastewater with a concentration of 12.2% in a weight ratio of 1.8:9.3, and stir evenly at a rotating speed of 400r / min to obtain slurry material A;

[0050] S2: the slurry material A that step S1 makes is joined in the mixed acid that concentration is 15%, and described mixed acid is the oxalic acid of concentration 17.2wt%, the tartaric acid of concentration 34.5wt%, the citrate of concentration 22wt%. A mixed acid composed of a volume ratio of 4.1:3.6:1.8, the weight ratio of the slurry material A to the mixed acid is 1.9:10, adding ferrous ammonium sulfate, molecular sieve catalyst and diethylene triamine pentacarboxylate under the condition of 400r / min Sodium acid is stirred, and the weight ratio of described ferrous ammonium sulfate, molecular sieve catalyst, sodium diethylenetriamine pentacarboxylate and slurry material A i...

Embodiment 3

[0061] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0062] S1: Mix bentonite and activated clay wastewater with a concentration of 20.2% in a weight ratio of 2.6:16, and stir evenly at a rotating speed of 500r / min to obtain a slurry material A;

[0063] S2: the slurry material A that step S1 makes is joined in the mixed acid that concentration is 22.4%, and described mixed acid is the oxalic acid of concentration 19.6wt%, the tartaric acid of concentration 36.2wt%, the citrate of concentration 22.3wt% A mixed acid composed of a volume ratio of 6.3:5.2:2.6, the weight ratio of the slurry material A to the mixed acid is 2.8:17, and the ferrous ammonium sulfate, molecular sieve catalyst and diethylenetriaminepenta Sodium carboxylate is stirred, and the weight ratio of described ferrous ammonium sulfate, molecular sieve catalyst, sodium diethylenetriamine pentacarboxylate and slurry material A is 1.5-4.2:1-2.4:0.7-1.5:49-158.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com