Alkaline clay prepared from activated clay wastewater and application of alkaline clay

A technology of alkaline clay and activated clay, applied in the direction of inorganic chemistry, non-metal elements, silicon compounds, etc., can solve the problems of modified bentonite alkali content, low activity index, short thermal stability time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

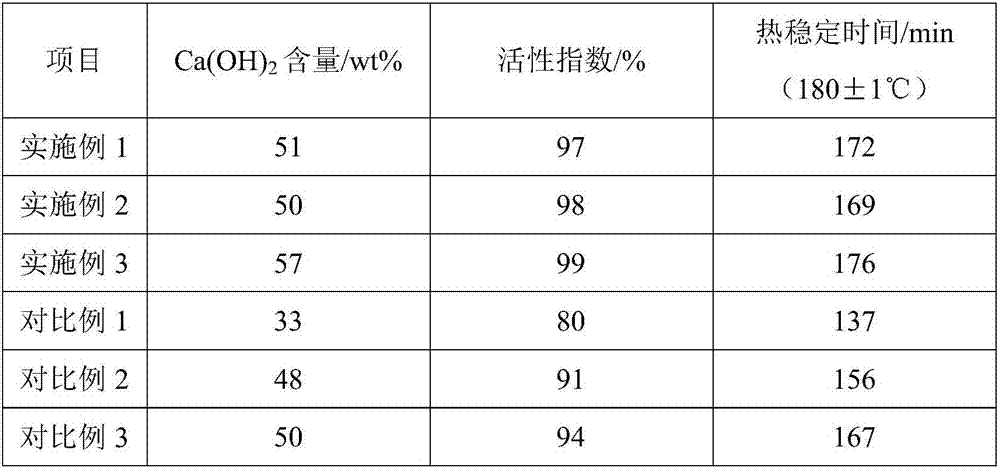

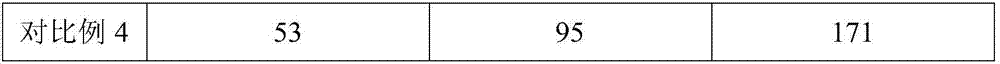

Examples

Embodiment 1

[0035] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0036] S1: Mix bentonite and activated clay wastewater with a concentration of 2.4% at a weight ratio of 1:2.51, and stir evenly at a rotating speed of 300r / min to obtain slurry material A;

[0037] S2: The slurry material A prepared in step S1 is added to a mixed acid with a concentration of 7.2%, and the mixed acid is oxalic acid with a concentration of 14.3wt%, tartaric acid with a concentration of 30-36.2wt%, and citrate with a concentration of 21.7wt%. Acid mixed acid by volume ratio 1.8:2.5:1.2 composition, the weight ratio of slurry material A and mixed acid is 1:3.6, add ascorbic acid, molecular sieve catalyst and sodium gluconate stirring under the condition of 300r / min at rotating speed, ascorbic acid The weight ratio of , molecular sieve catalyst, sodium gluconate and slurry material A is 2.6-5.5:0.8-1.6:0.9-2:46.8-152, the microwave power is 125-180W, heated to...

Embodiment 2

[0048] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0049] S1: Mix bentonite and activated clay wastewater with a concentration of 12.2% in a weight ratio of 1.8:9.3, and stir evenly at a rotating speed of 400r / min to obtain slurry material A;

[0050] S2: the slurry material A that step S1 makes is joined in the mixed acid that concentration is 15%, and described mixed acid is the oxalic acid of concentration 17.2wt%, the tartaric acid of concentration 34.5wt%, the citrate of concentration 22wt%. Mixed acid with a volume ratio of 4.1:3.6:1.8, the weight ratio of slurry material A to mixed acid is 1.9:10, add ascorbic acid, molecular sieve catalyst and sodium gluconate under the condition of rotating speed of 400r / min and stir, ascorbic acid, molecular sieve catalyst 1. The weight ratio of sodium gluconate to slurry material A is 2.6-5.5:0.8-1.6:0.9-2:46.8-152, and the microwave power is 125-180W, heated to 83-95°C and kept...

Embodiment 3

[0061] A preparation method of modified bentonite heat-resistant agent, comprising the following steps:

[0062] S1: Mix bentonite and activated clay wastewater with a concentration of 20.2% in a weight ratio of 2.6:16, and stir evenly at a rotating speed of 500r / min to obtain a slurry material A;

[0063] S2: the slurry material A that step S1 makes is joined in the mixed acid that concentration is 22.4%, and described mixed acid is the oxalic acid of concentration 19.6wt%, the tartaric acid of concentration 36.2wt%, the citrate of concentration 22.3wt% Mixed acid composed of 6.3:5.2:2.6 by volume, the weight ratio of slurry material A to mixed acid is 2.8:17, add ascorbic acid, molecular sieve catalyst and sodium gluconate under the condition of 500r / min and stir, ascorbic acid, molecular sieve The weight ratio of catalyst, sodium gluconate and slurry material A is 2.6-5.5:0.8-1.6:0.9-2:46.8-152, and the microwave power is 125-180W, heated to 83-95°C, and kept at 83-95 Reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com