Patents

Literature

219 results about "Polymer metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A polymer is a macromolecular material having a large number of repeating units linked to each other via covalent chemical bonds while metals are either pure elements or alloys. Therefore, they have different chemical and physical properties. The key difference between polymers and metals is that the polymers are lightweight than the metals.

Nano-sized polymer-metal composites

A polymer nanoparticle is provided. The nanoparticle includes an inner layer having alkenylbenzene monomer units. The nanoparticle further includes an outer layer having monomer units selected from conjugated dienes, alkylenes, alkenylbenzenes, and mixtures thereof. The nanoparticle has at least one functional group associated with the outer layer. The nanoparticle further has at least one metal complexed with said functional group. The nanoparticles can be used as a templates for preparation of nano-sized metal crystals and polymer-metal nanocomposite.

Owner:BRIDGESTONE CORP

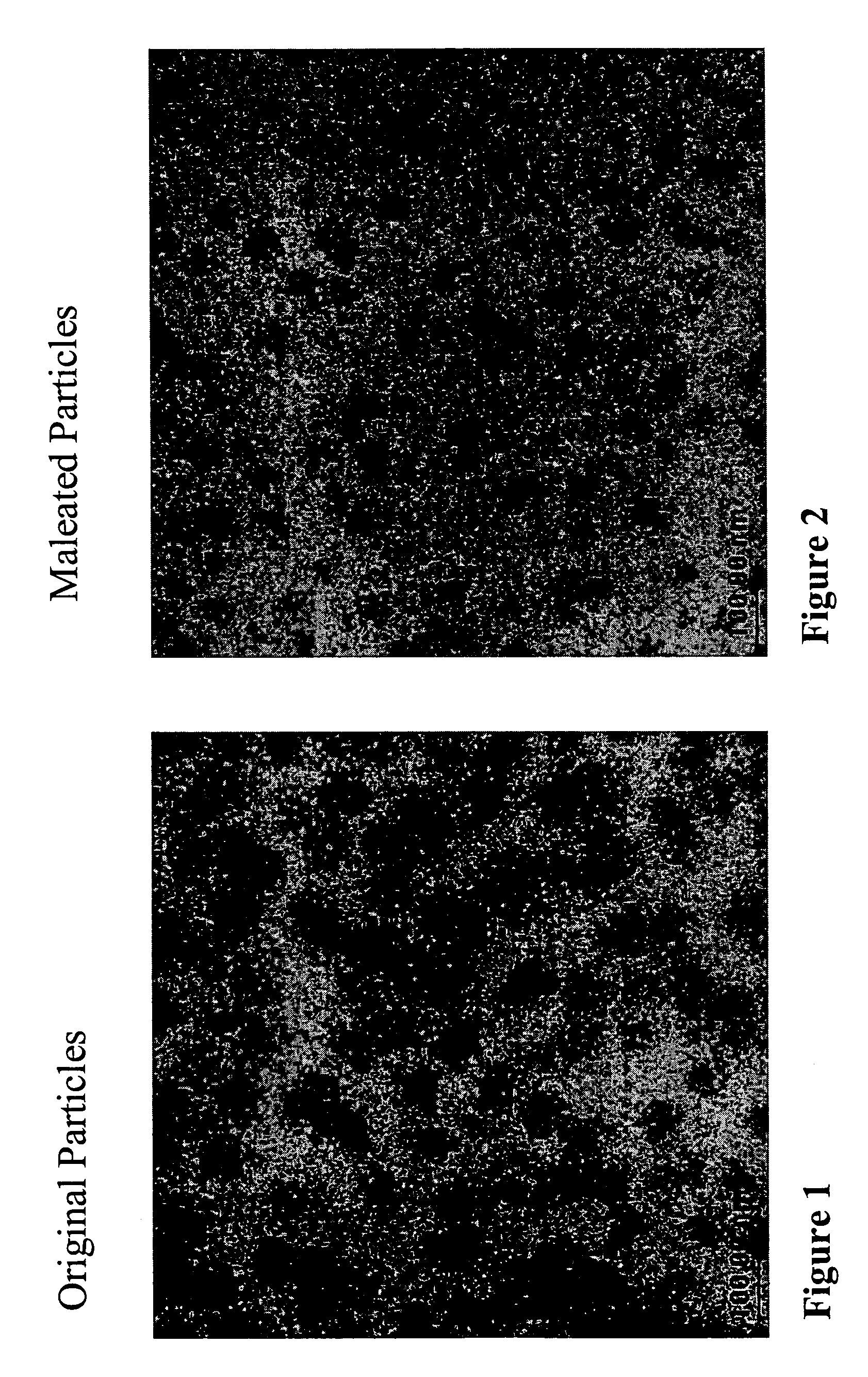

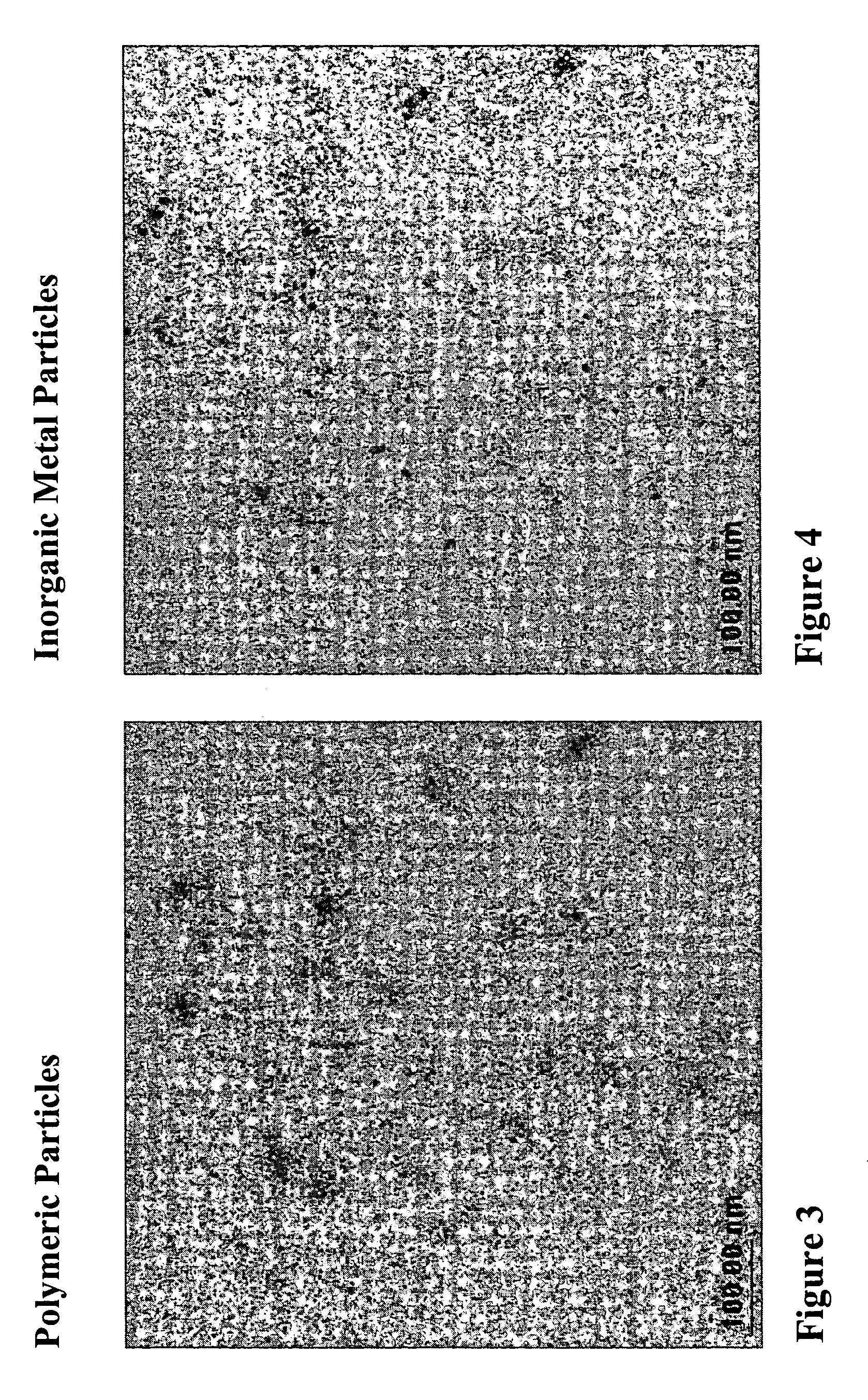

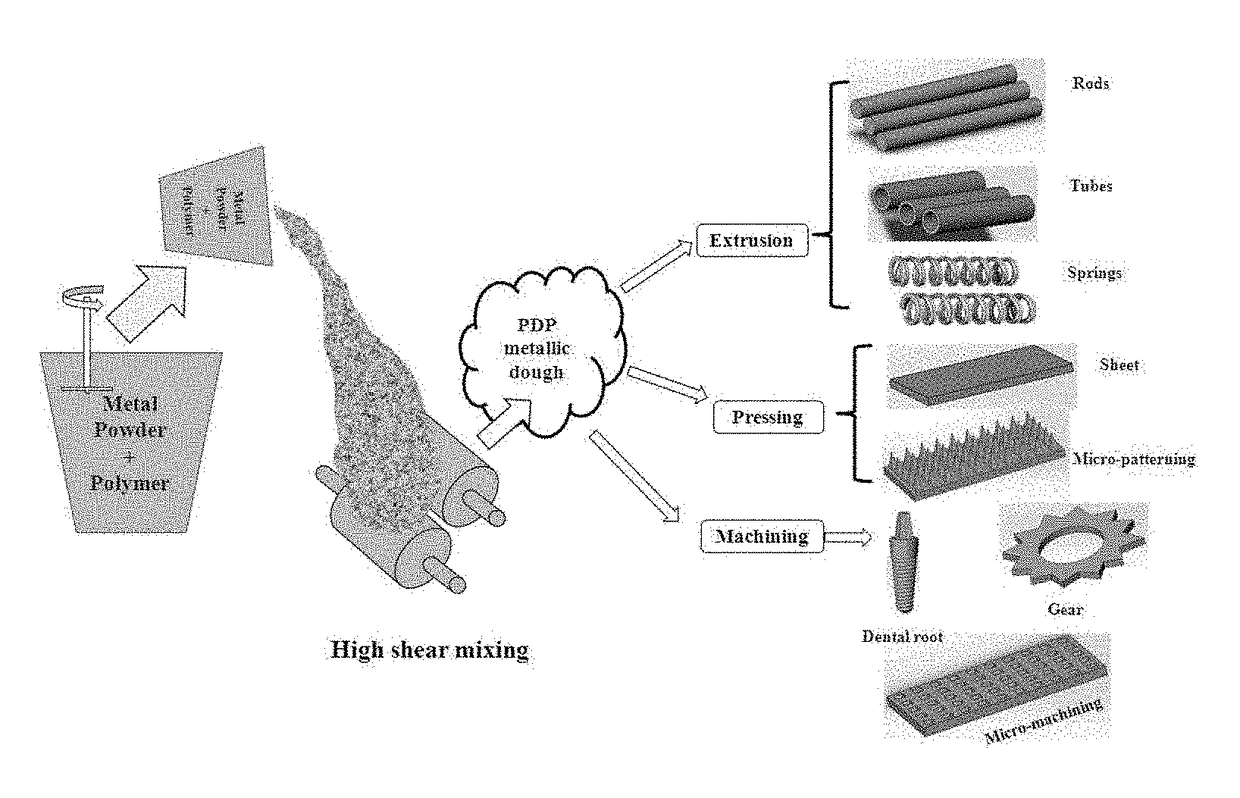

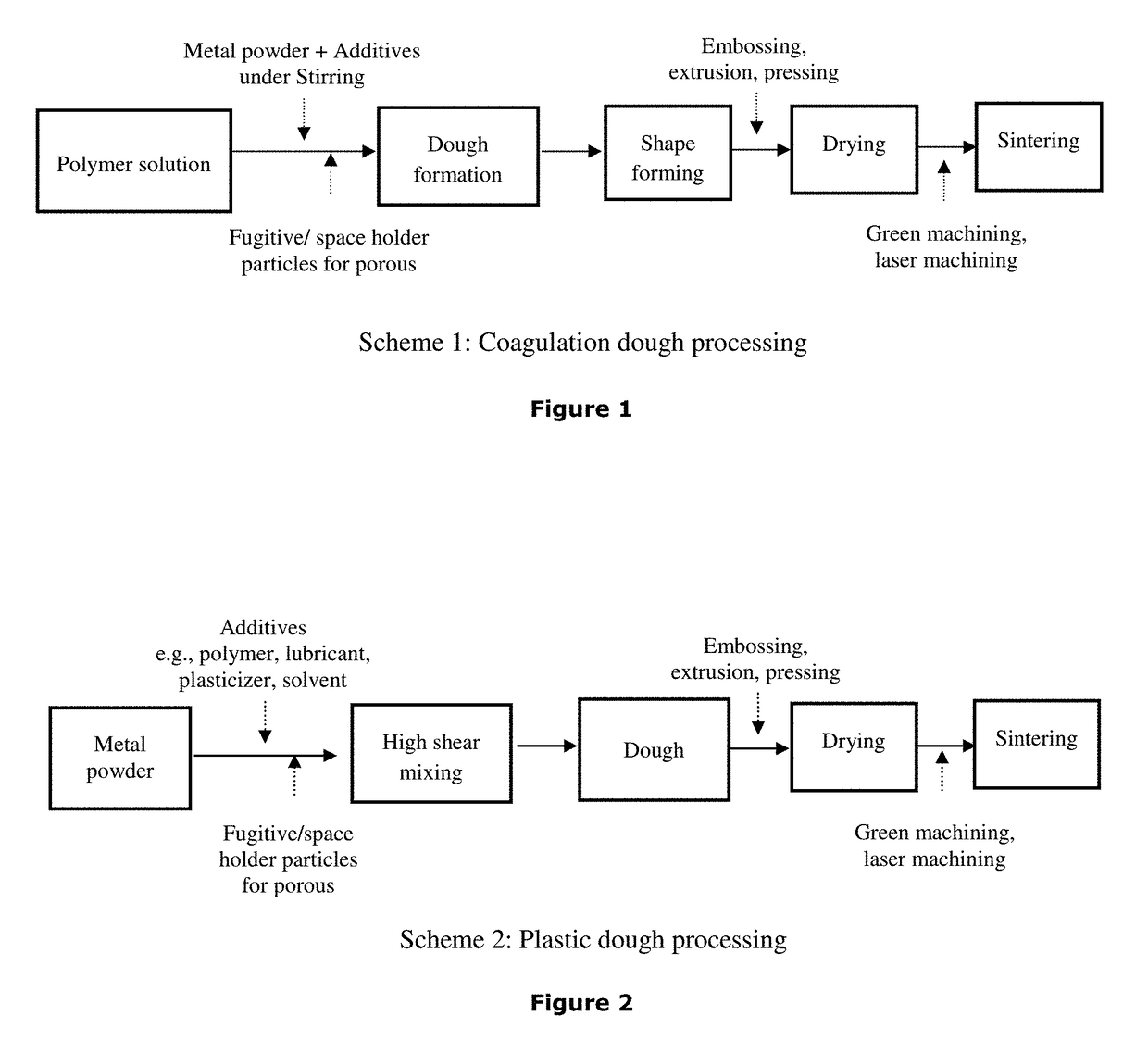

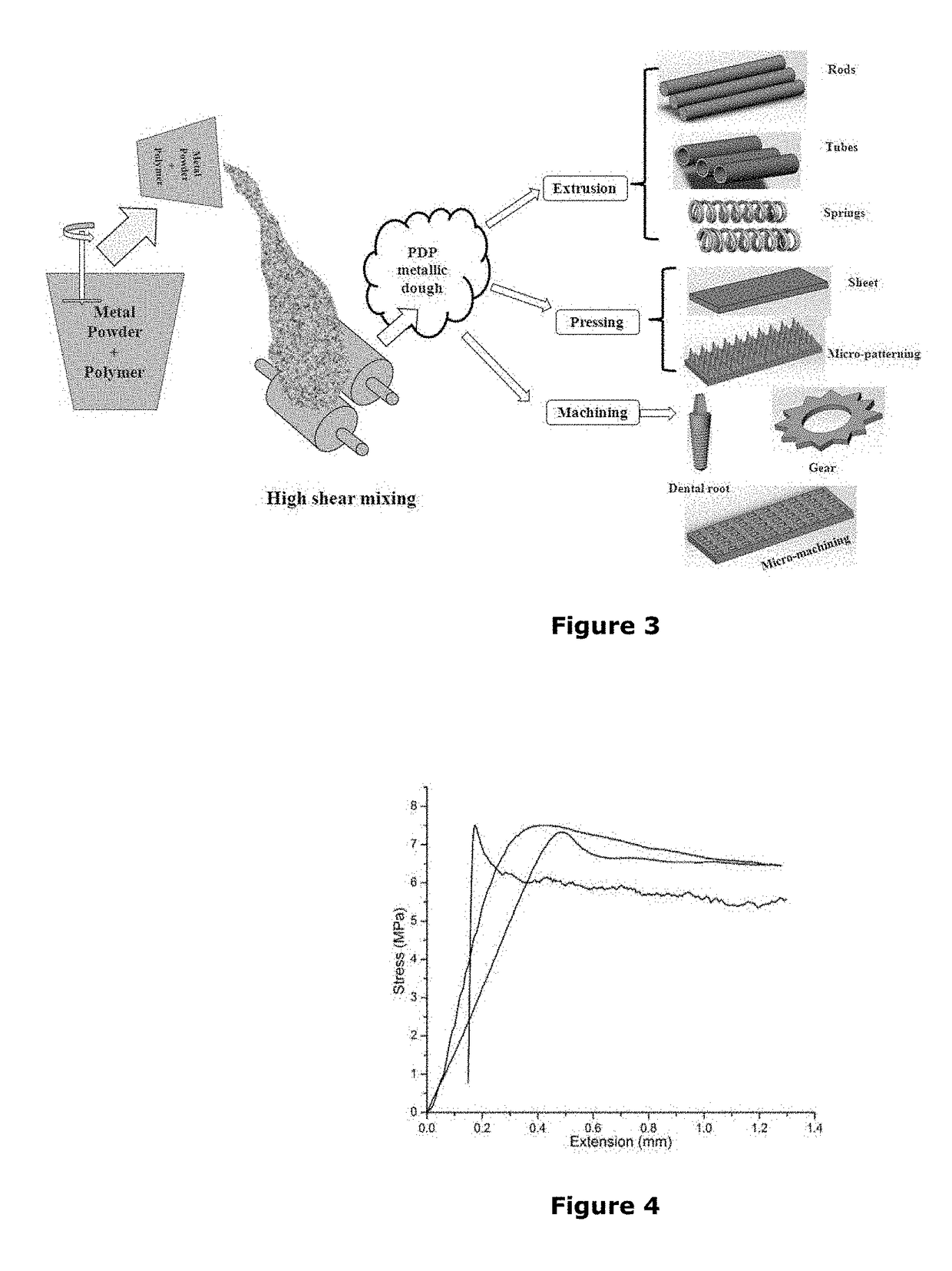

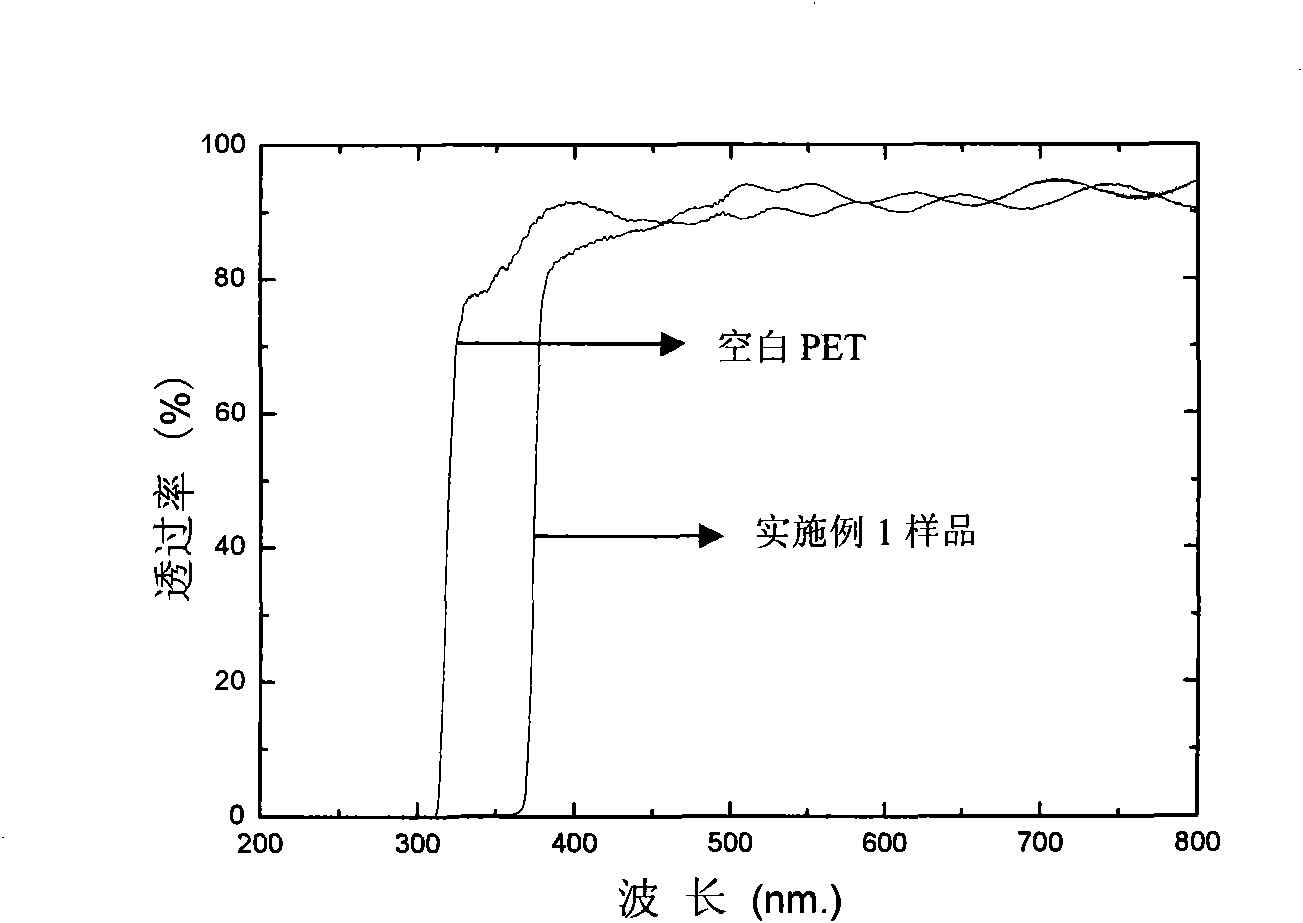

Process of dough forming of polymer-metal blend suitable for shape forming

InactiveUS10022792B2Easy to handleSimplify processing efficiencyTransportation and packagingMetal-working apparatusPolymer metalEngineering

Processing of polymer-metal blend composition involving viscosity control under ambient conditions suitable for shape forming and homogeneous green body preparation. The advancement involves effective controlling of the rate of settling of the metal particles in polymer-metal blend under ambient conditions to generate a cost effective and simple process for producing shape formable dough. Advantageously, the present invention provides a rapid, energy saving process involving minimum material loss and utilizing non hazardous solvent system such as water.

Owner:INDIAN INSTITUTE OF TECHNOLOGYKHARAGPUR

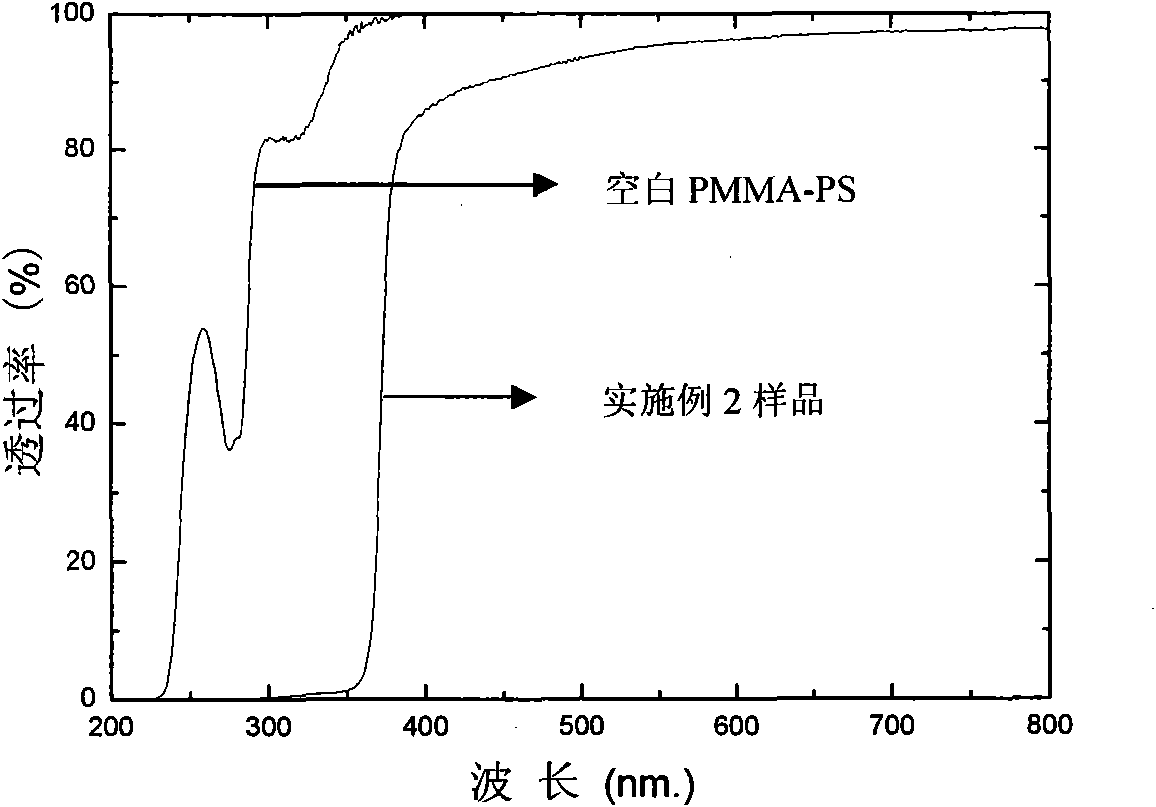

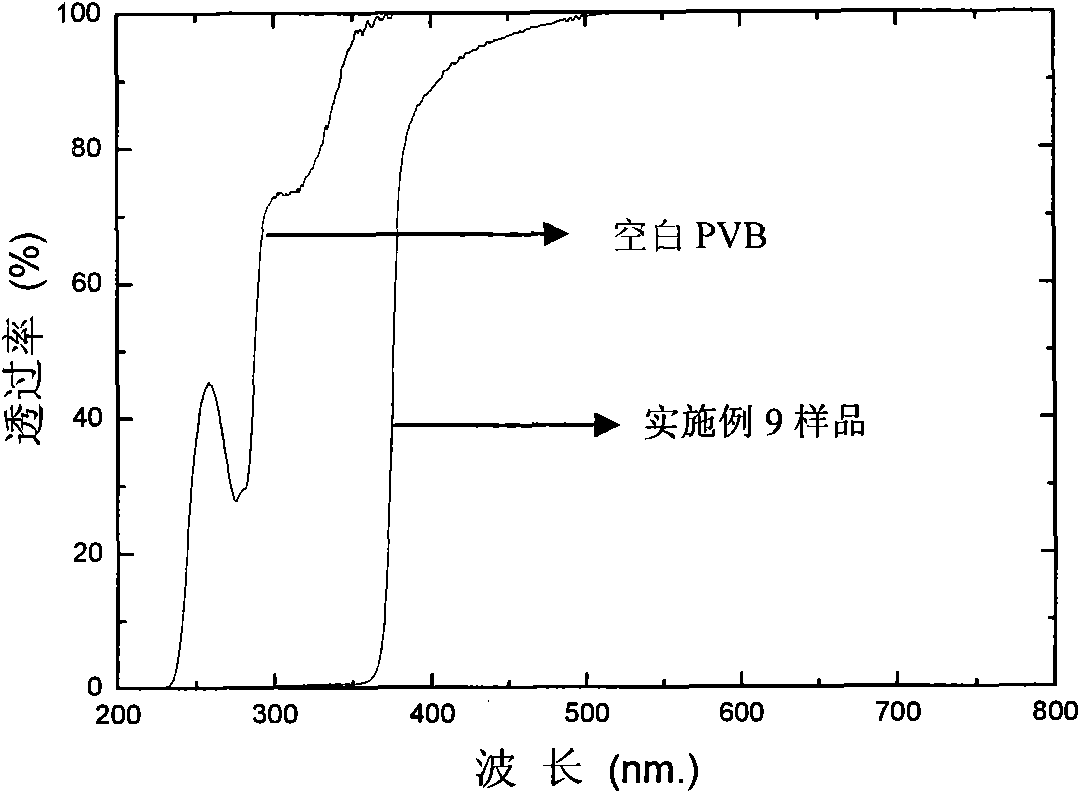

Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

The invention relates to a highly-transparent ultraviolet-resistant energy-saving film and a preparation method thereof, belonging to the field of composite films synthesized by compounding polymer and inorganic nano-particles and aiming at overcoming the defects that the prior film has low visible light transmission and high production cost. The highly-transparent ultraviolet-resistant energy-saving film comprises the following components by the weight percent: 50-99.8 of organic polymer, 0.2-50 of metal-oxide nano-particles and 0-39.9 of polymer auxiliary agent. The highly-transparent ultraviolet-resistant energy-saving film is prepared by a solution mixing method or a solution-melting mixing method; with the solution mixing method, the organic polymer and the metal-oxide nano-particles are dispersed in dispersing medium to prepare film preparing stock solution, and the film preparing stock solution is used for preparing the energy-saving film on a substrate; with the solution-melting mixing method, the mixture of the organic polymer and the metal-oxide nano-particles is dried to prepare master batch, and the master bath is mixed with the organic polymer and the polymer auxiliary agent to prepare the energy-saving film. The highly-transparent ultraviolet-resistant energy-saving film has high visible light transmission, good ultraviolet resistance and energy-saving effect, simple preparation process and low cost, thereby being suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

Detection of implant functionality

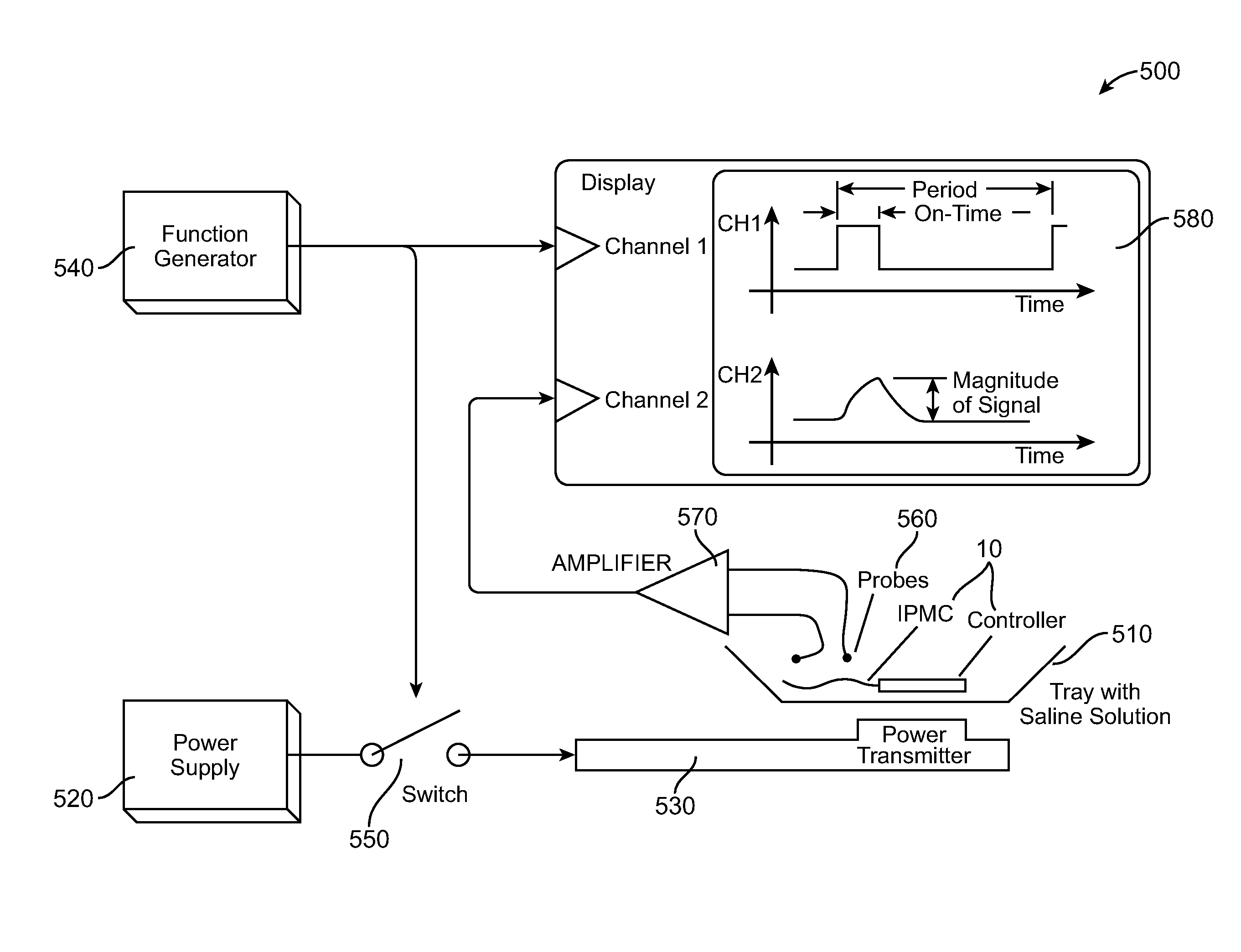

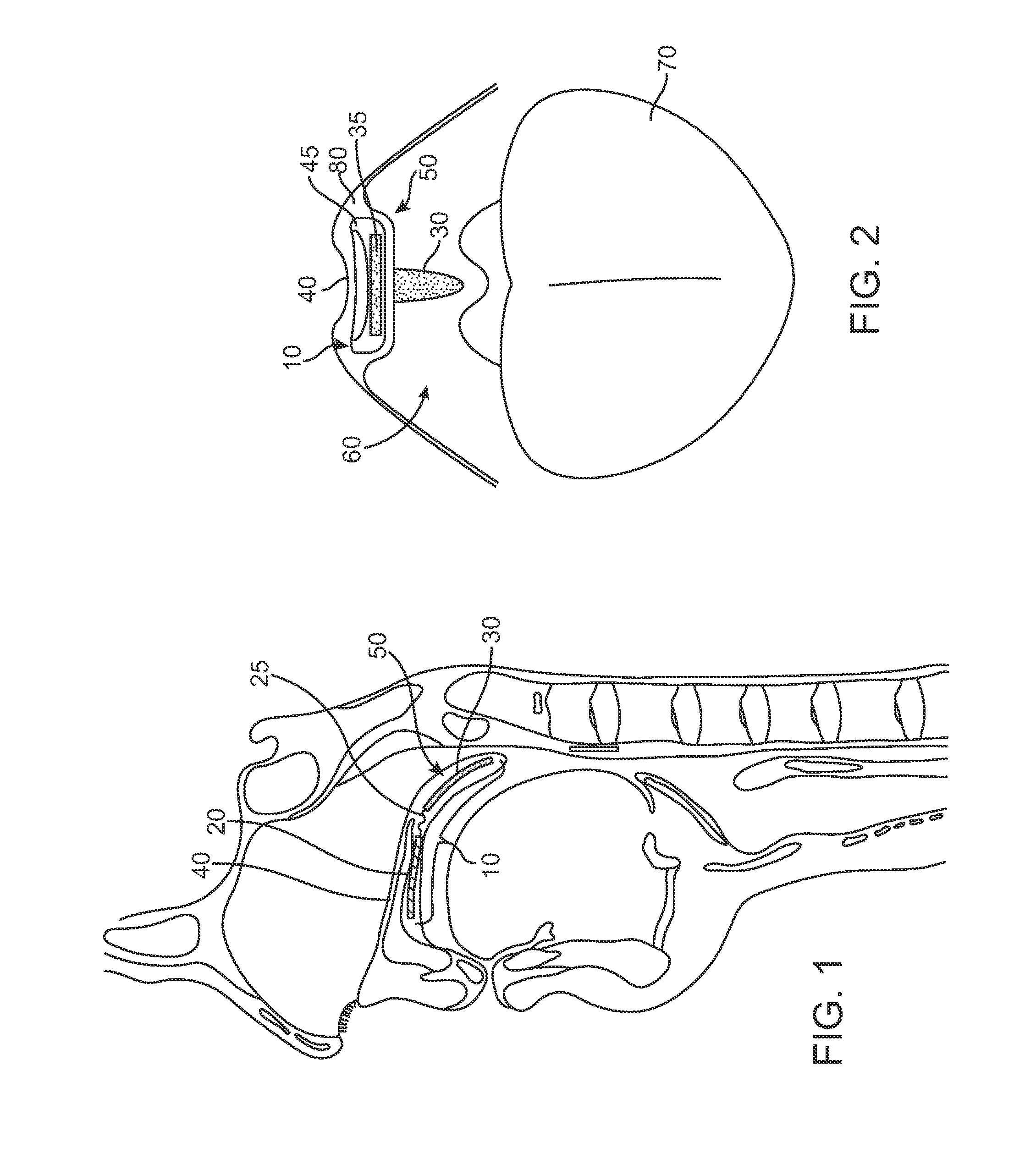

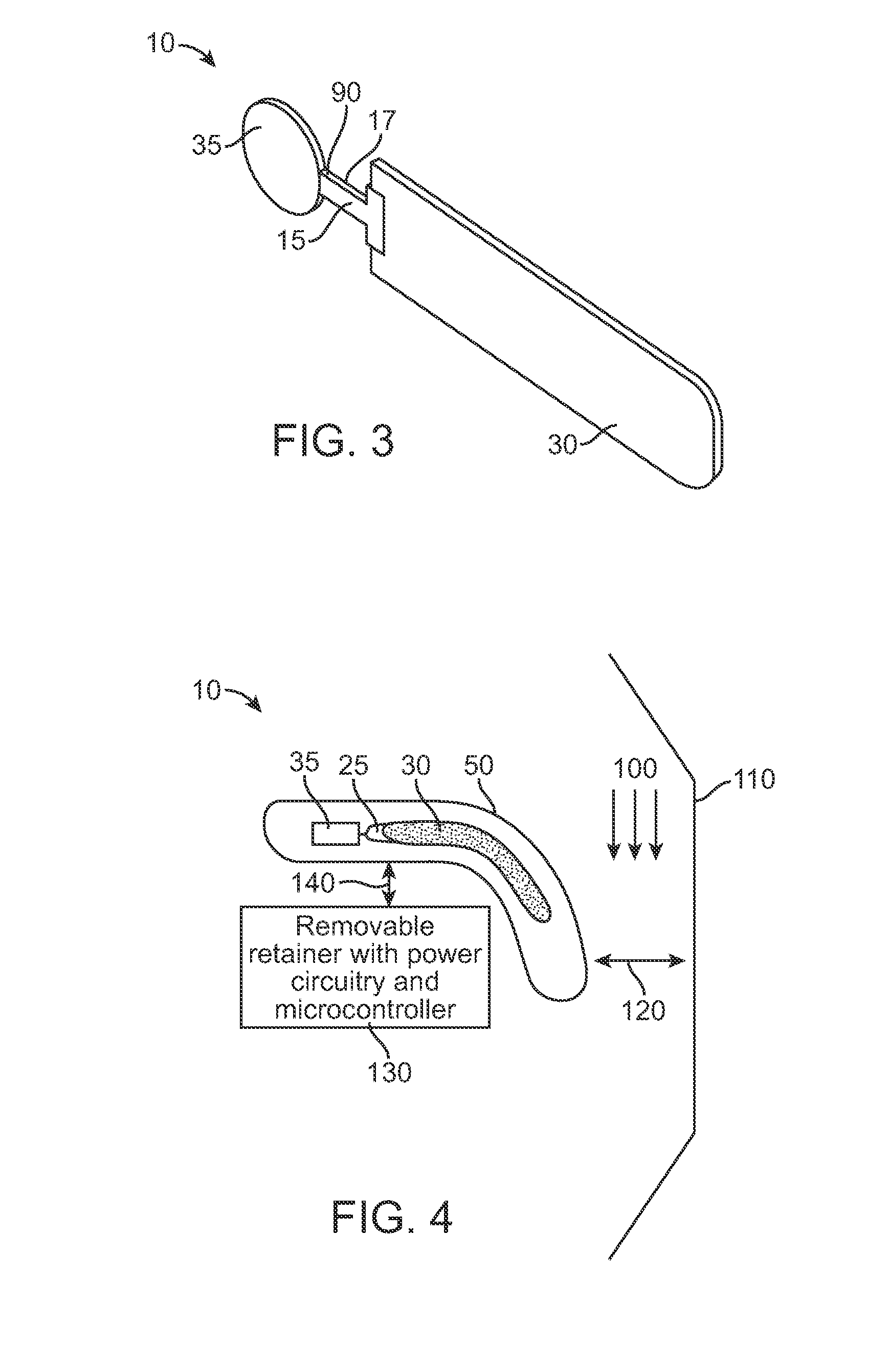

Techniques are disclosed for detecting a functionality of a medical device implanted within the human body. A testing method includes delivering power to and measuring an electrical response of ion exchange polymer metal composite (IPMC) material that is part of the implant device in a first testing interval. Power can be transmitted at radio frequencies which penetrate tissue such that direct contact with the implant device is not required. Following the first testing interval, the implant can be powered continuously for a predetermined time. The implant can be powered in a second testing interval and the electrical response can again be measured. A functionality of the implant device can be detected based on the electrical response in the first and second testing intervals. The testing method can be practiced in connection with a handheld device, a retainer, or other suitable apparatus.

Owner:PAVAD MEDICAL

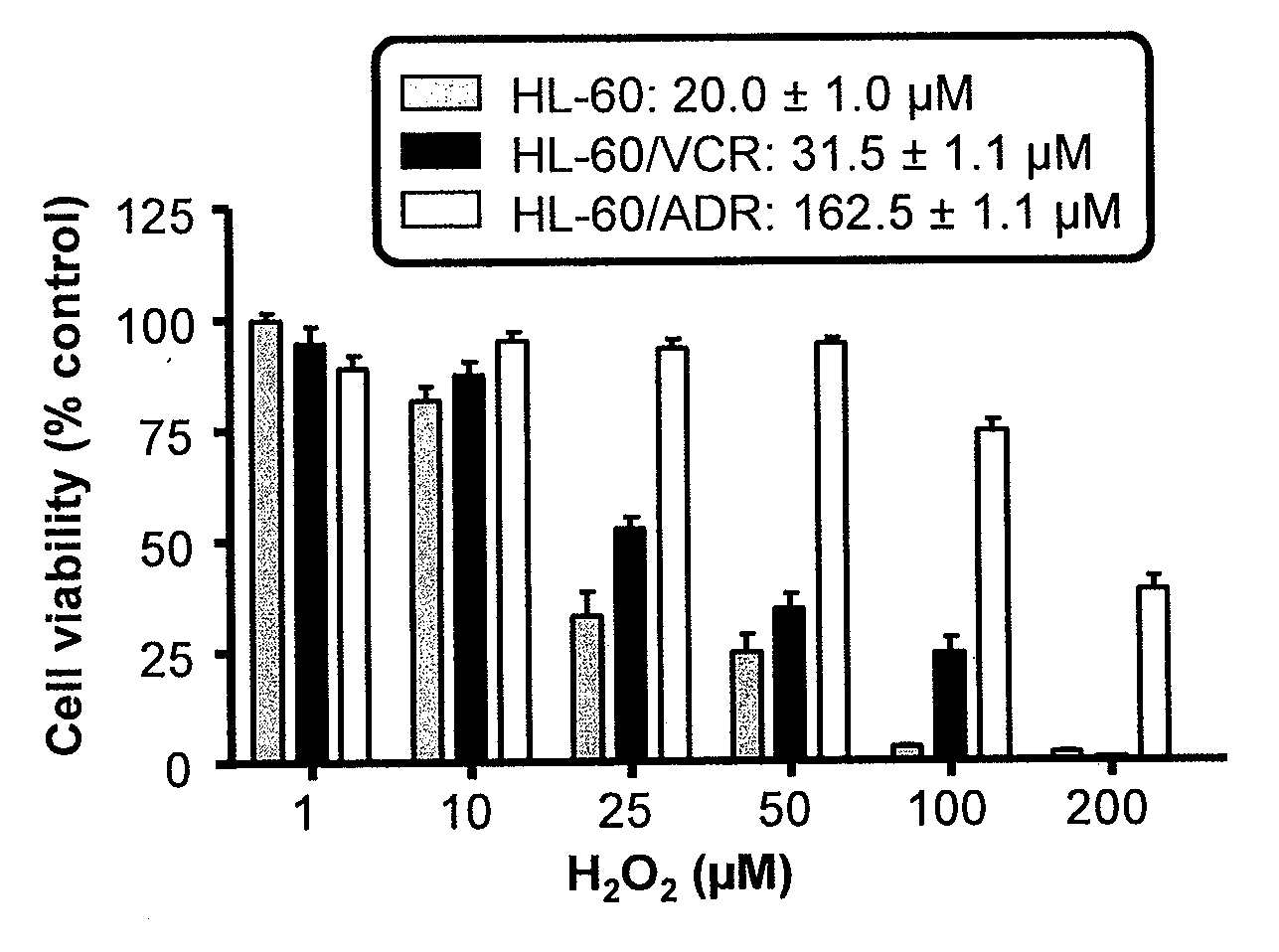

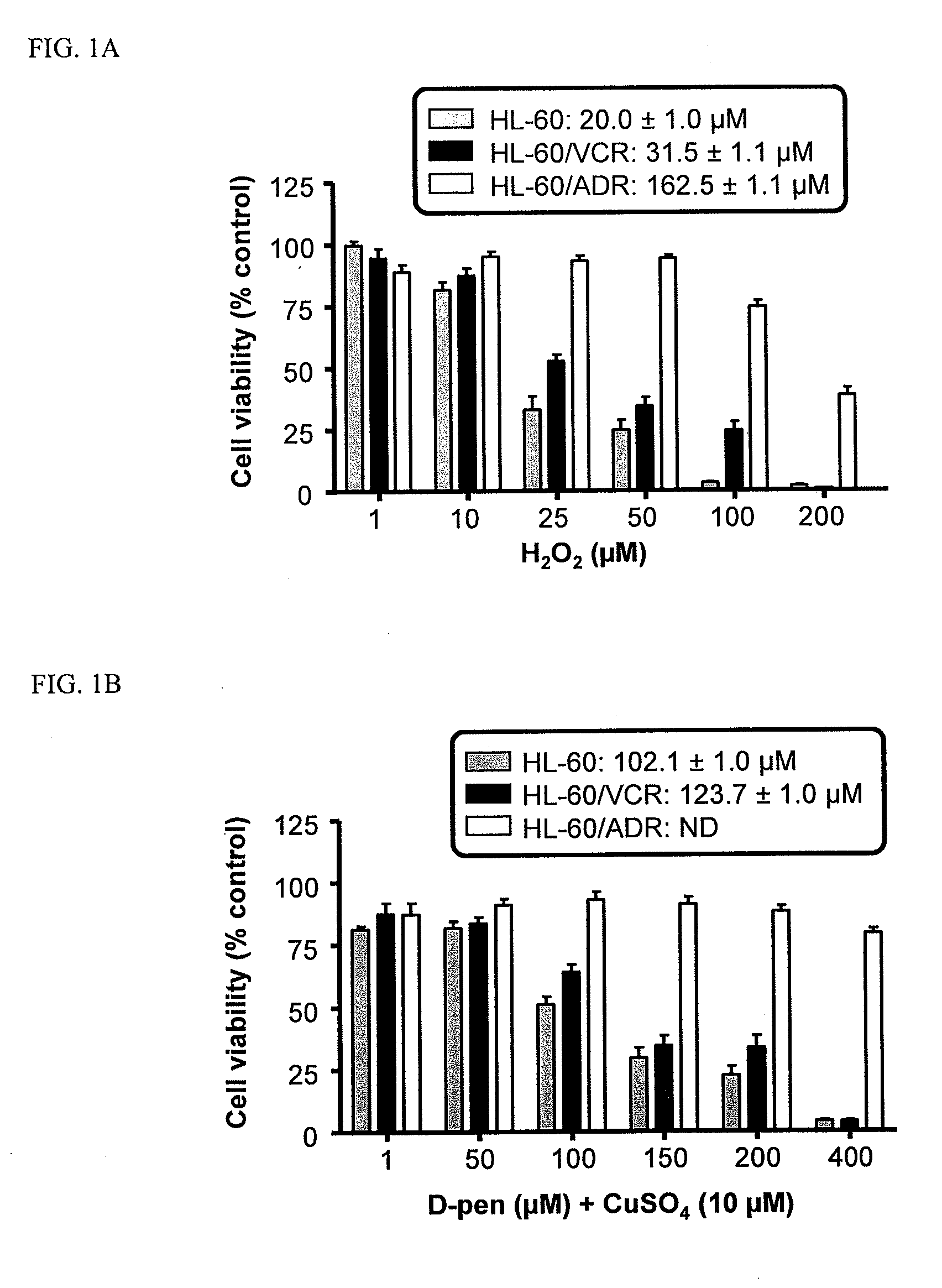

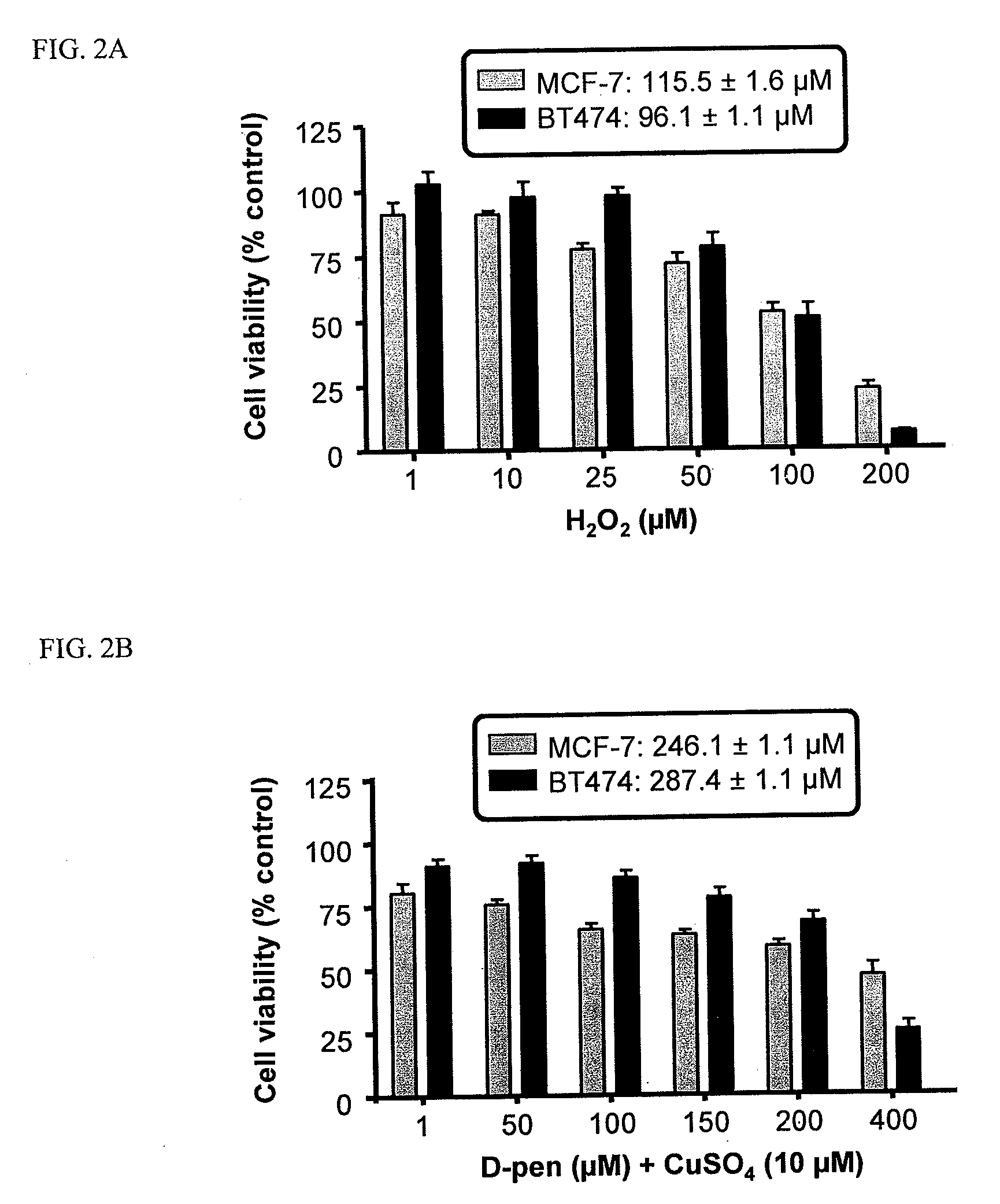

Polymer-metal chelator conjugates and uses thereof

InactiveUS20090092664A1Stability of disulfide bondPrevent oxidationOrganic active ingredientsPeptide/protein ingredientsPenicillamineGelatin product

The present invention provides prodrugs comprising a polymer conjugated to a metal chelator via a disulfide bond. For example, D-penicillamine may be conjugated to a polymer (e.g., gelatin, chitosan, polyglutamic acid) via a linker, such as SPDP. Thus, the cellular delivery and pharmacokinetics of D-penicillamine can be substantially improved. Methods for the treatment of cancer using compositions of the present invention are also disclosed.

Owner:UNIV OF KENTUCKY RES FOUND

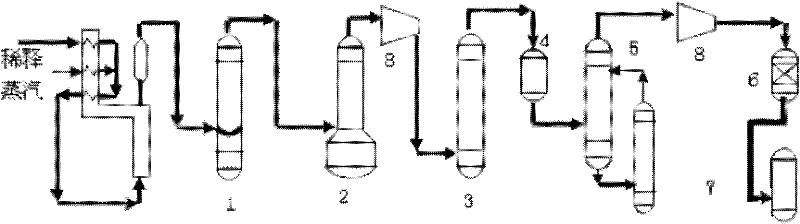

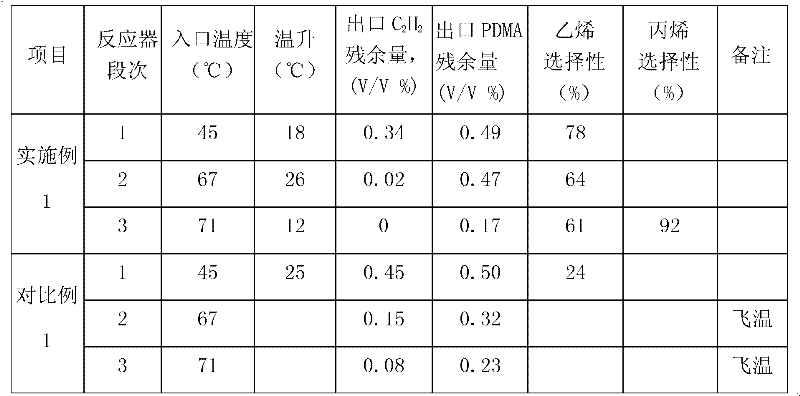

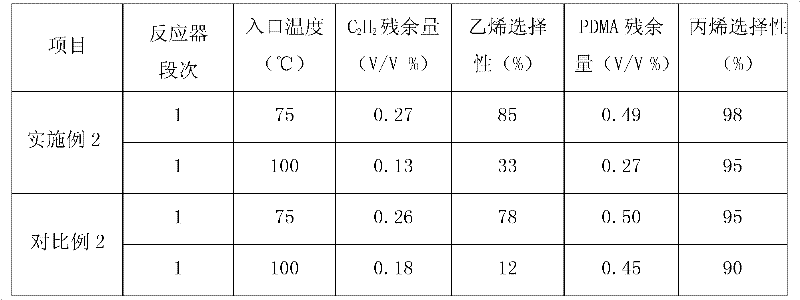

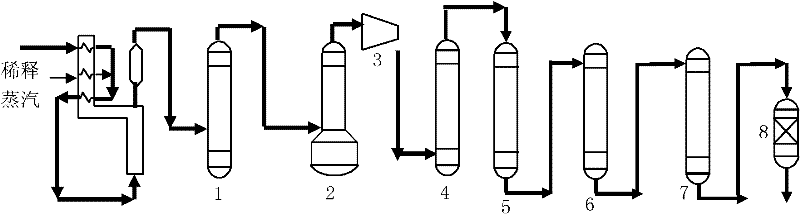

Selective hydrogenation method for C2 fraction

ActiveCN102199067ASelective distinctionGuaranteed hydrogenation qualifiedHydrocarbon purification/separationHydrocarbonsPolymer metalHydrogenation reaction

The invention relates to a selective hydrogenation method for C2 fraction, which employs a front-end hydrogenation process method of front-end depropanization. The selective hydrogenation method is characterized in that a Pd-Ag catalyst is loaded in a heat-insulation bed reactor, wherein the Pd-Ag catalyst contains Al2O3 used as a carrier, and the contents of Pd and Ag are 0.010-0.4% and 0.02-0.2% respectively if assumed that the weight percentage of the catalyst is 100%, and the Pd-Ag catalyst has a specific surface area of 1-20 m<2> / g and a pore volume of 0.1-0.35 mL / g; during the preparation process of the catalyst, an organic polymer metal complex is formed; and the reaction conditions are as follows: the inlet temperature of the used heat-insulation bed reactor is 45-100 DEG C, the reaction pressure is 3.5-4.5 MPa, and the volume airspeed of gas is 3500-25000 h<-1>. Using the method provided by the invention, the improvement of selectivity facilitates the operation of hydrogenation reaction and excessive hydrogenation is not easy to occur; moreover, at high reaction temperature, the catalyst has good activity, and alkyne leakage is not easy to occur.

Owner:PETROCHINA CO LTD

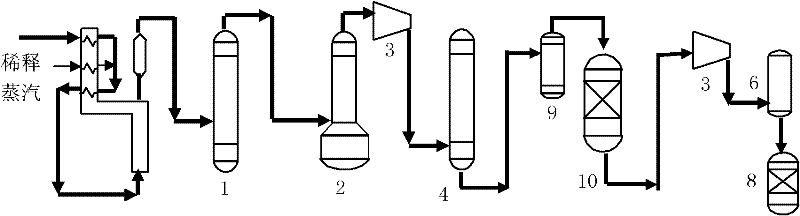

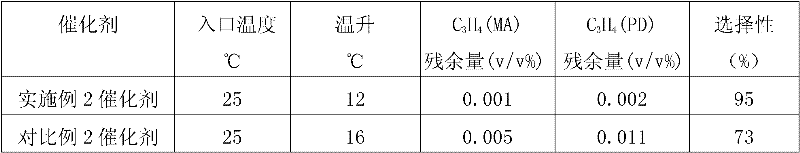

Selective hydrogenation method for C3 fraction

ActiveCN102206132ALower trend for deep hydrogenationEnhanced catalytic reaction selectivityHydrocarbon purification/separationHydrocarbonsPolymer metalFixed bed

The invention relates to a selective hydrogenation method for a C3 fraction. The method is characterized in that: an adiabatic bed reactor is provided with a Pd-Ag catalyst, the Pd-Ag catalyst contains Al2O3 used as a carrier, 0.2-0.4% of Pd and preferable 0.05-0.2% of Ag based on 100wt% of the catalyst, the specific surface area of the catalyst is 15-100 m<2> / g, the pore volume of the catalyst is 0.3-0.6 mL / g, and the catalyst forms an organic polymer metal complex during preparation process; and the hydrogenation process conditions are as follows: the inlet temperature of the fixed bed reactor is 10-50 DEG C, the reaction pressure is 2.5-3.5 MPa, the liquid phase volume space velocity is 5-100 h<-1> and the mol ratio of hydrogen to propyne and propadiene is (1-5):1. The selective hydrogenation method provided by the invention improves the hydrogenation activity and selectivity, greatly broadens the reaction space velocity range, greatly improves the running safety and efficiency of an apparatus and greatly improves economical benefits of the apparatus.

Owner:PETROCHINA CO LTD

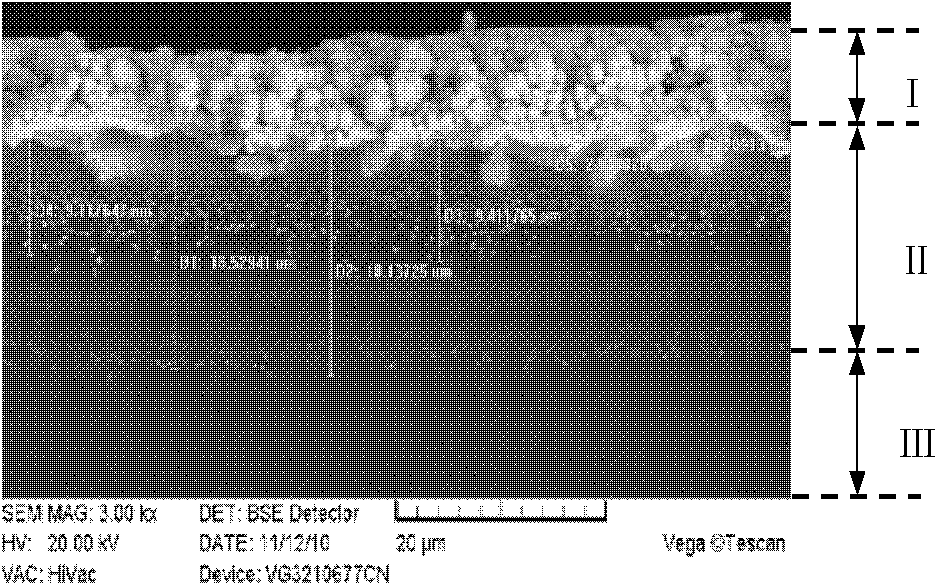

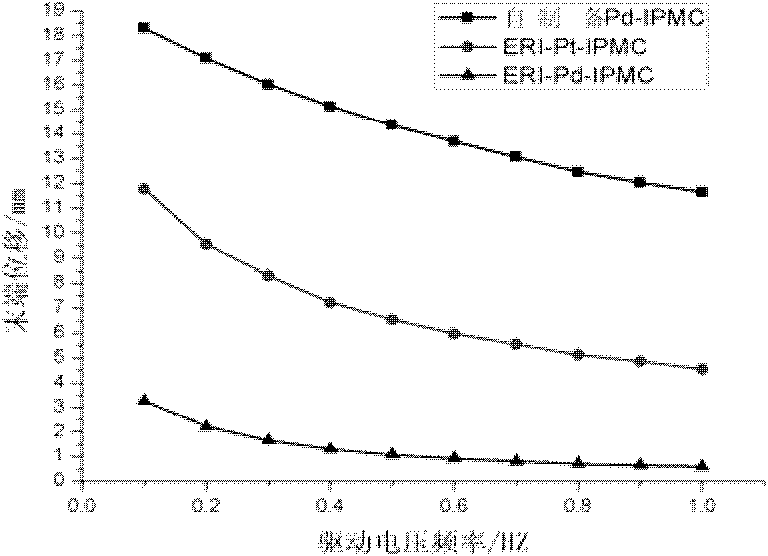

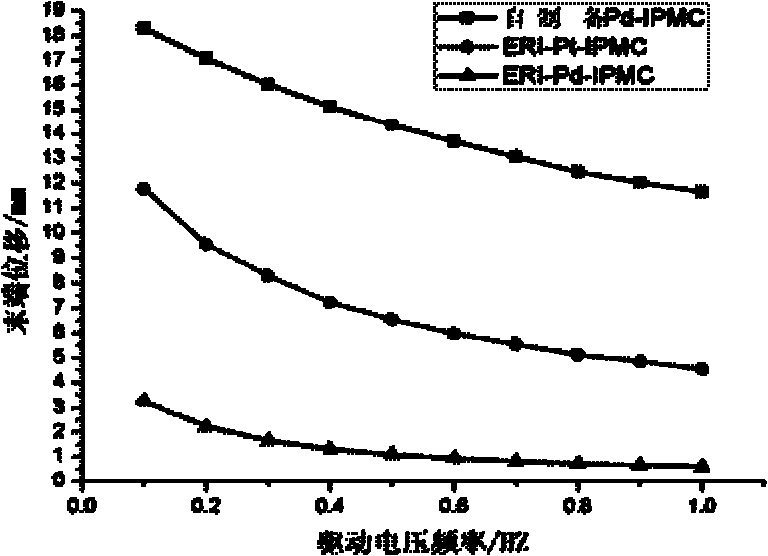

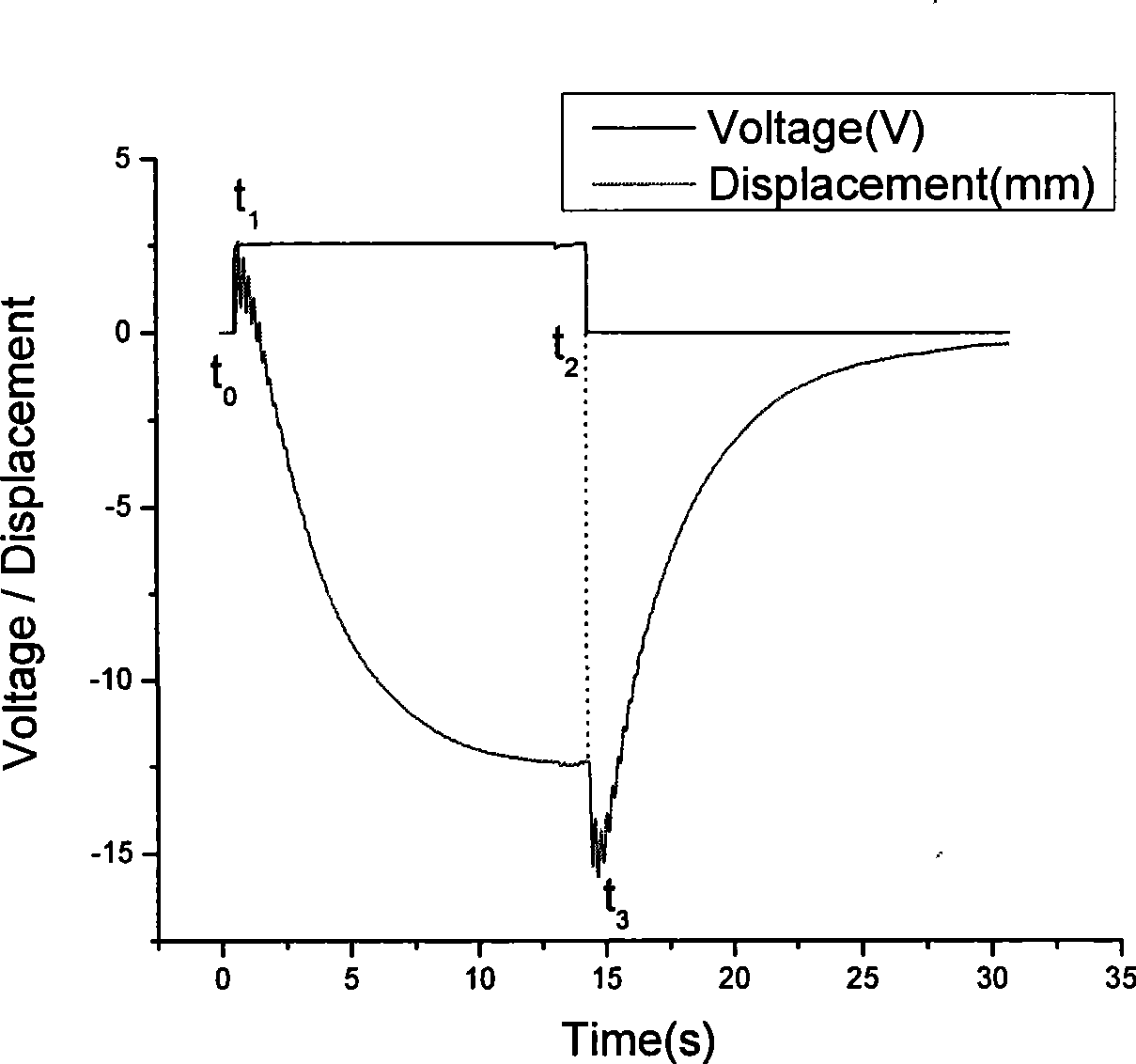

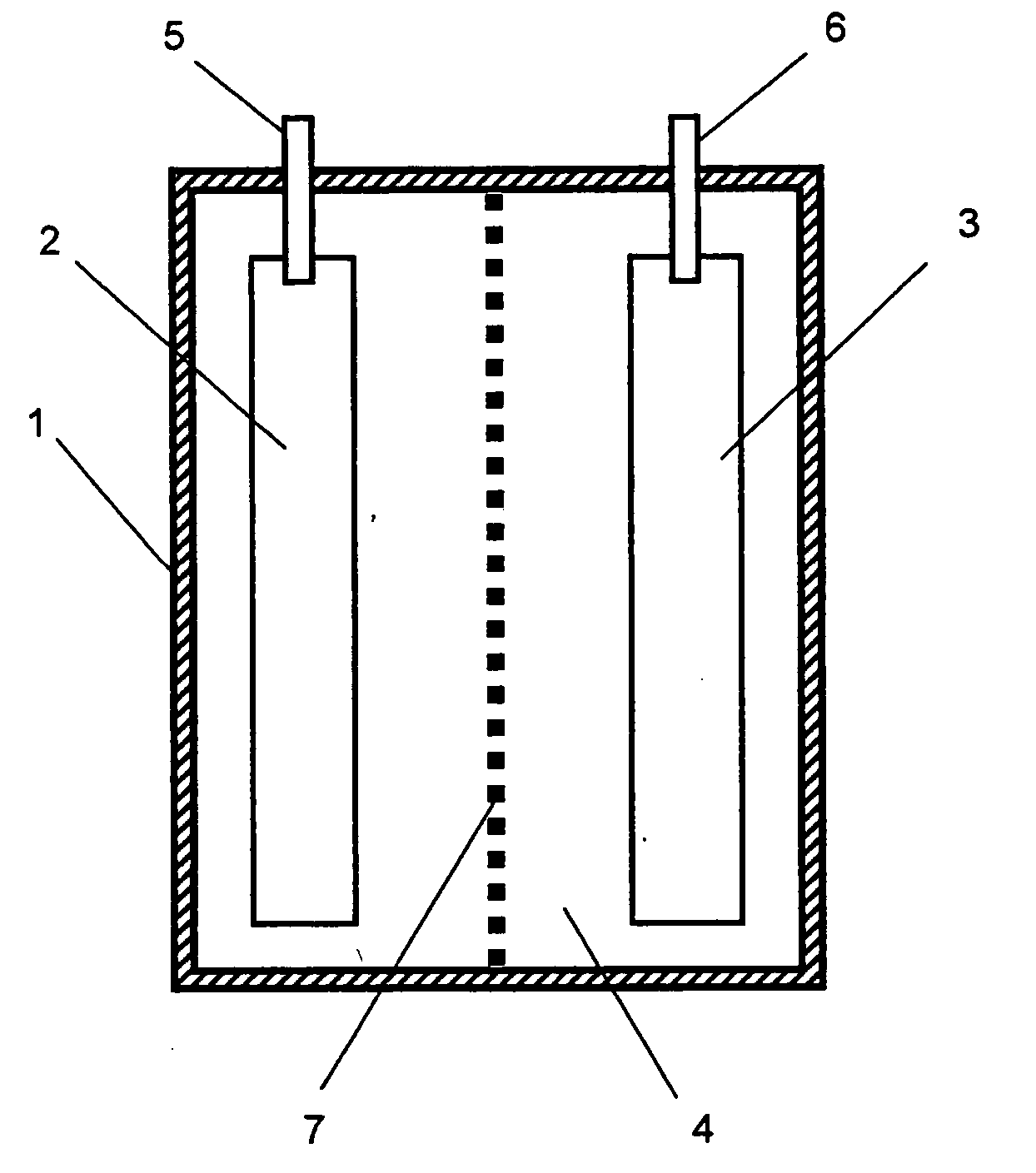

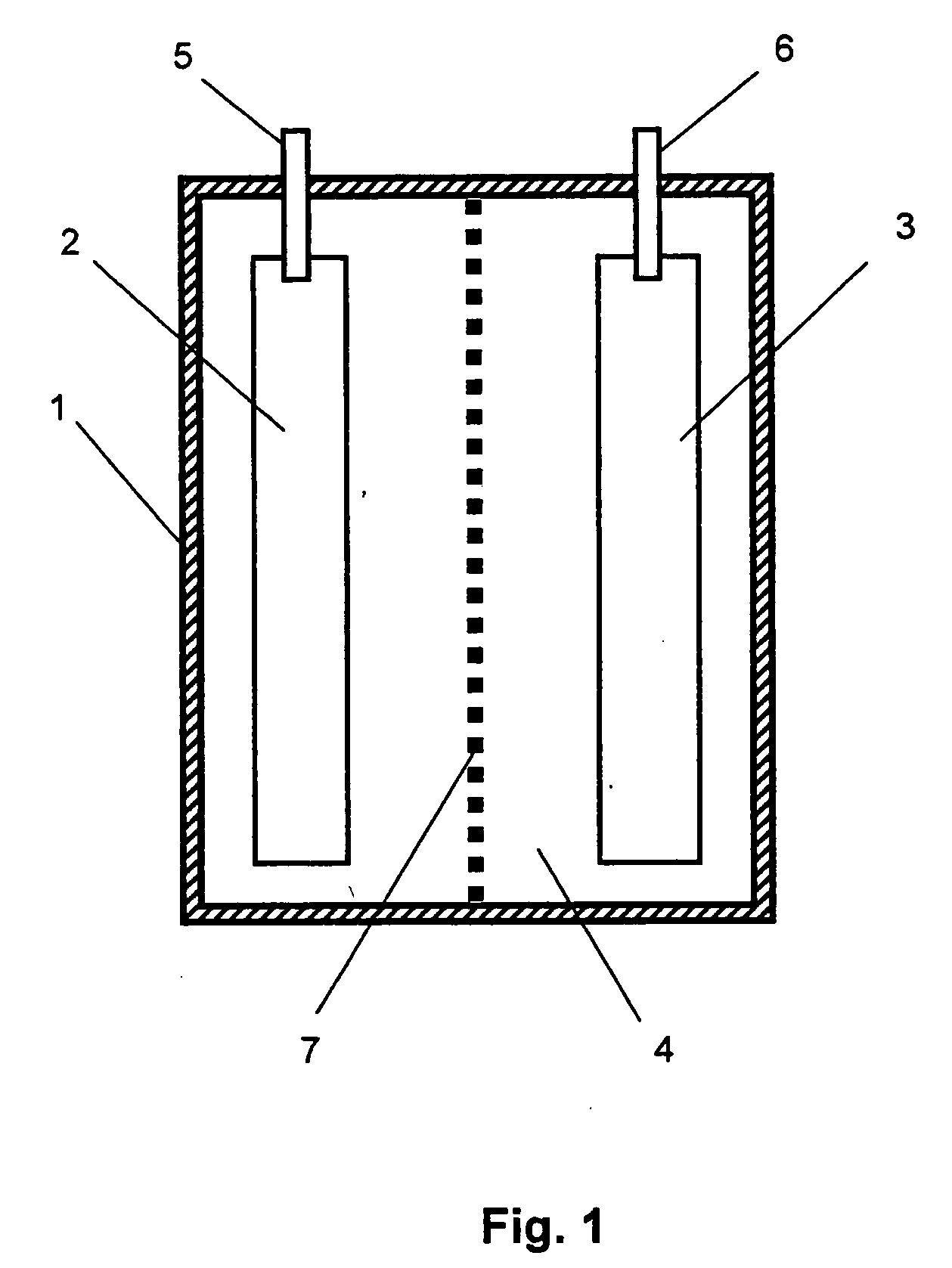

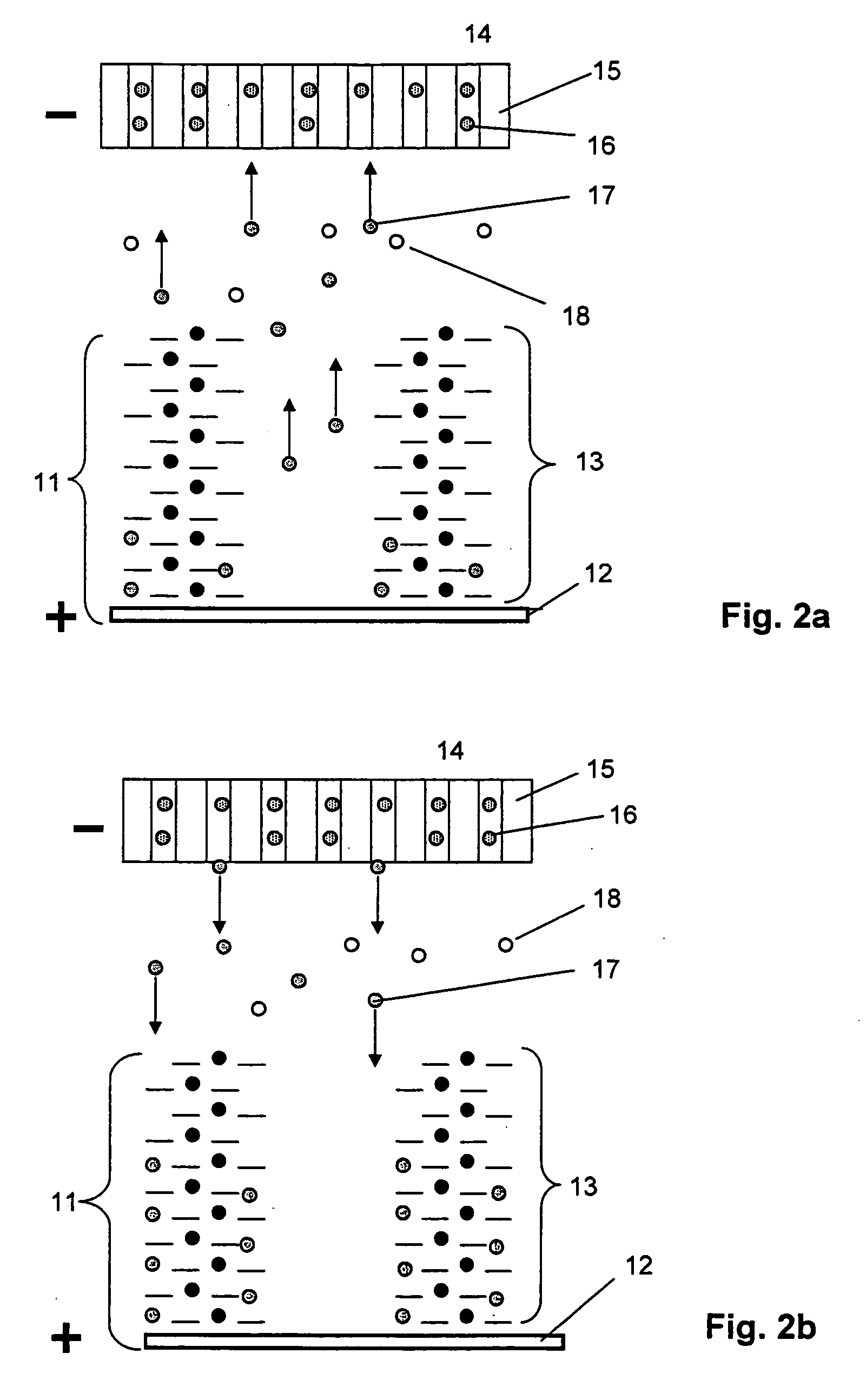

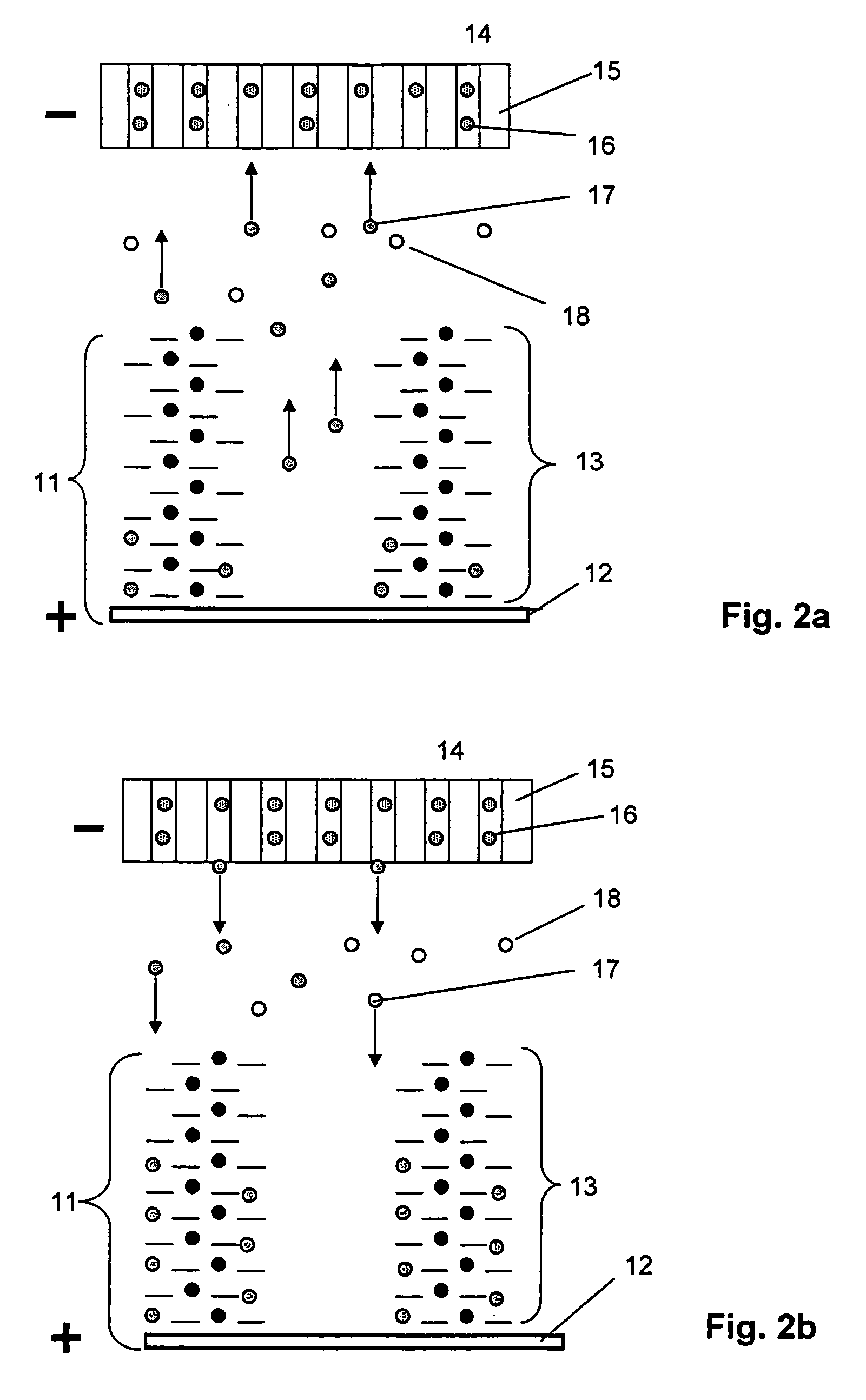

Preparation process of palladium electrode ion polymer and metal composite

InactiveCN102168260AIncrease profitImprove electrical actuation performanceLiquid/solution decomposition chemical coatingIonic polymer–metal compositesChemical plating

The invention discloses a preparation process of a palladium electrode ion polymer and metal composite, which is used for preparing a palladium metal electrode IPMC (Ion Polymer Metal Composite) by using immersion reduction plating and chemical plating methods in which an ion exchange membrane is used as a matrix material and [Pd (NH3)4] C12 is used as a main salt. The preparation process comprises the following four main steps of: (1) pretreatment of the matrix membrane: carrying out roughening, surface cleaning, foreign ion removal and full swelling on the matrix membrane; (2) immersion reduction plating including two processes, i.e., ion exchange and ion reduction: subjecting a pretreated Nafion membrane to repeated palladium ion immersion and exchange, and reducing the pretreated Nafion membrane with NaBH4 by adopting ultrasonic waves to form palladium metals on the surface and the internal surface of the ion exchange membrane; (3) chemical plating: wherein the thickening electrodes on the outer surface of a core material to compact internal surface electrodes by using an improved chemical plating method; and (4) postprocessing of the composite. The preparation process has a higher popularization value due to relatively improved efficiency, relatively lower cost and excellent actuation response.

Owner:XI AN JIAOTONG UNIV

Method for preparing ion polymer-metal composite material

InactiveCN101381866AReduce wasteLow costLiquid/solution decomposition chemical coatingIonomerChemical plating

The invention discloses a method for preparing an ionomer-metallic composite material, which adopts a Nafion-117 type ion-exchange film as a matrix material, uses [Pd(NH3) 2]Cl2 as a main salt, and adopts the chemical plating method to prepare a Pb metal type IPMC material. The process flow is divided into four parts: (1) the surface contact areas for ions to penetrate and reduction reaction are increased through sanding and roughening the ion-exchange film; (2) a pretreated Nafion film is impregnated for Pb ion exchange, a strong reducing agent reduces Pb ions, and a Pb metal layer is formed on the surface of the ion-exchange film; (3) secondary reduction is carried out by the improved chemical Pb plating method to thicken electrodes on the surface of a sandwich layer material; and (4) the material is subjected to post-treatment. The method has low cost, and experiments show that the IPMC material prepared has good performance, so that the ionomer-metallic composite material has high promotion value.

Owner:XI AN JIAOTONG UNIV

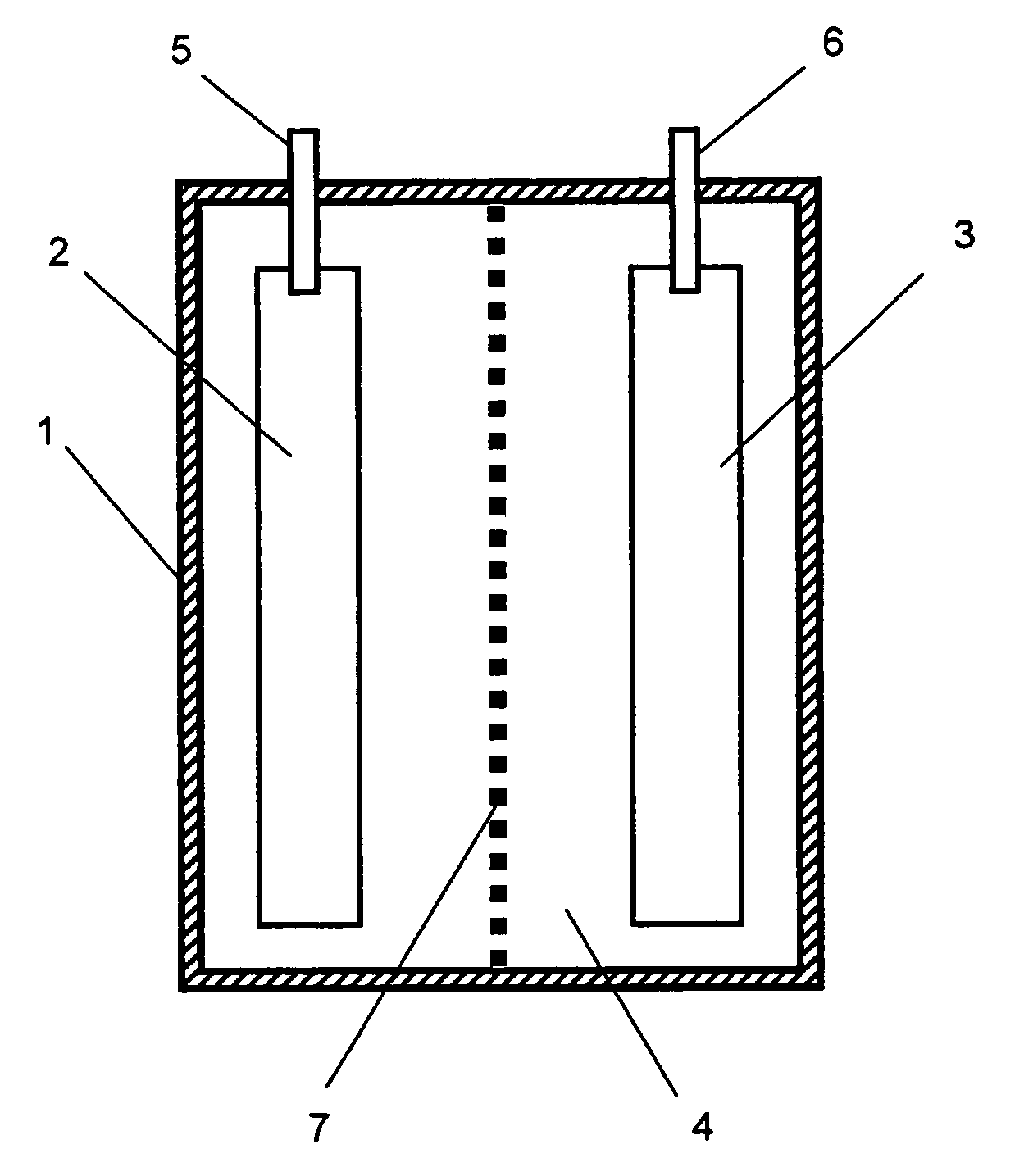

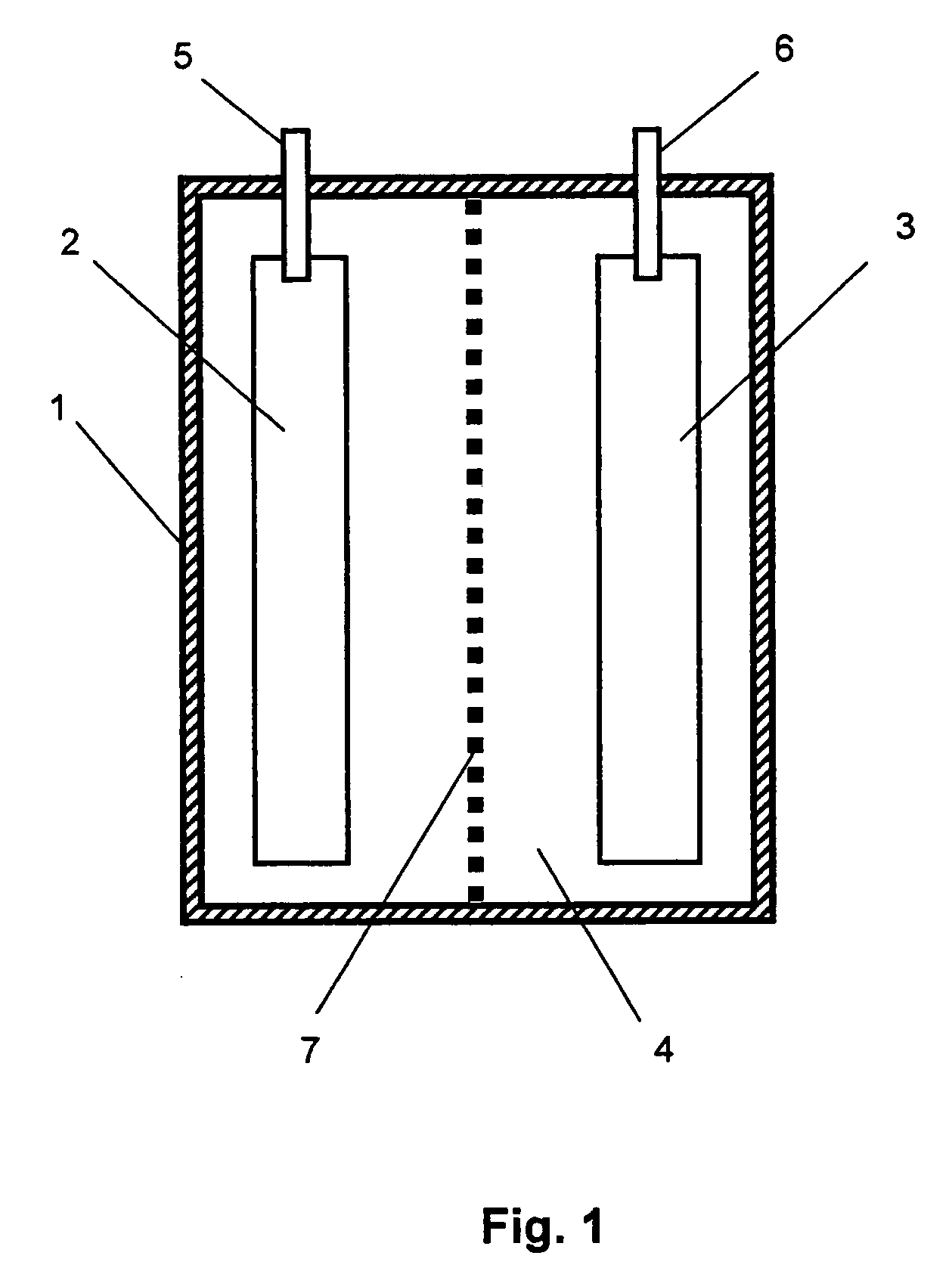

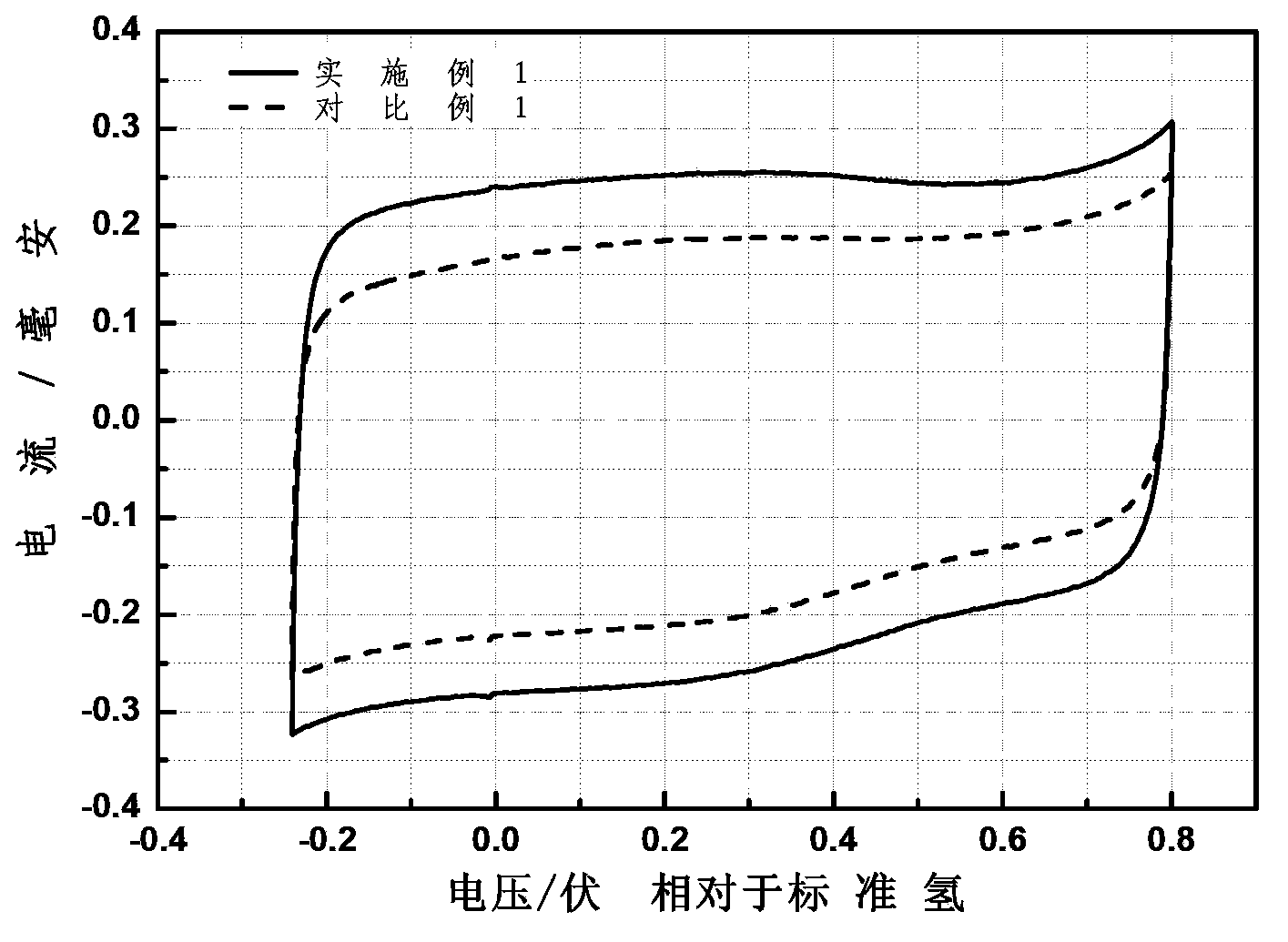

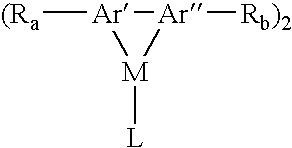

Electrode for energy storage devices and electrochemical supercapacitor based on said electrode

ActiveUS20070065719A1Extended service lifeImprove reliabilityHybrid capacitor electrodesLiquid electrolytic capacitorsPolymer scienceRedox polymers

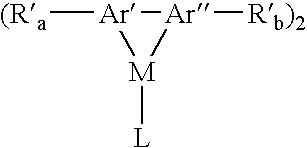

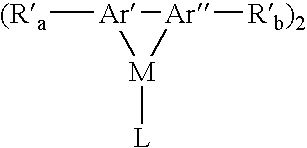

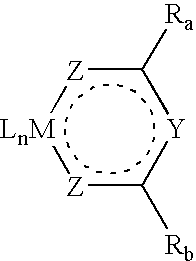

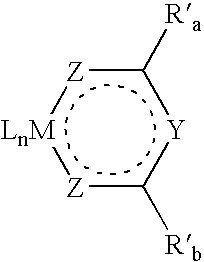

An electrode comprises an electrically conductive substrate, a layer of energy accumulating redox polymer deposited onto the substrate, the redox polymer comprising a polymer metal complex with a substituted tetra-dentate Schiff's base selected from the group: poly-[Me(R, R′—Y)], wherein Me is a transition metal; Y is a bridge group binding the atoms of Nitrogen in the Schiff's base; R is an electron-donating substituent comprising a functional group (X)O—, —COO(X), where (X) is an alkali metal; R′ is Hydrogen or Halogen; and wherein the polymer metal complex has the following structure: The electrochemical capacitor comprises a case housing the above-described positive electrode and a negative electrode disposed inside the case, and an electrolyte filling the space between the electrodes.

Owner:POWERMERS

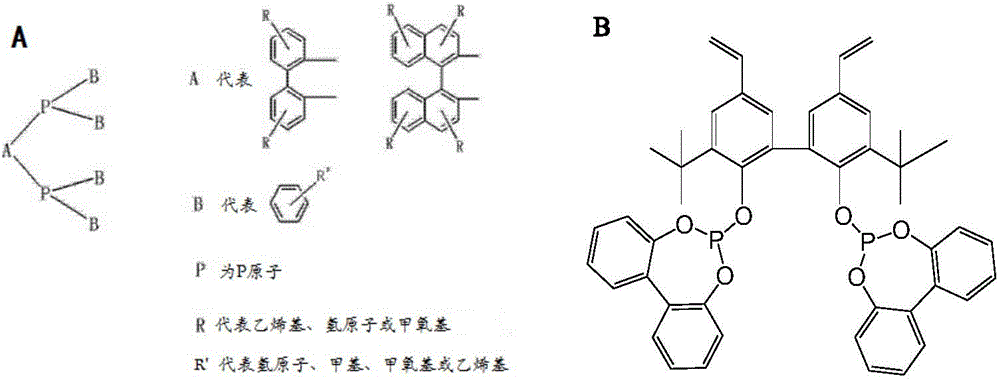

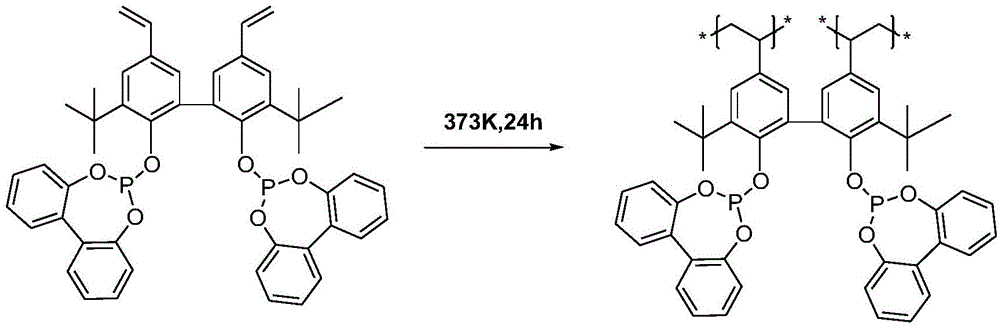

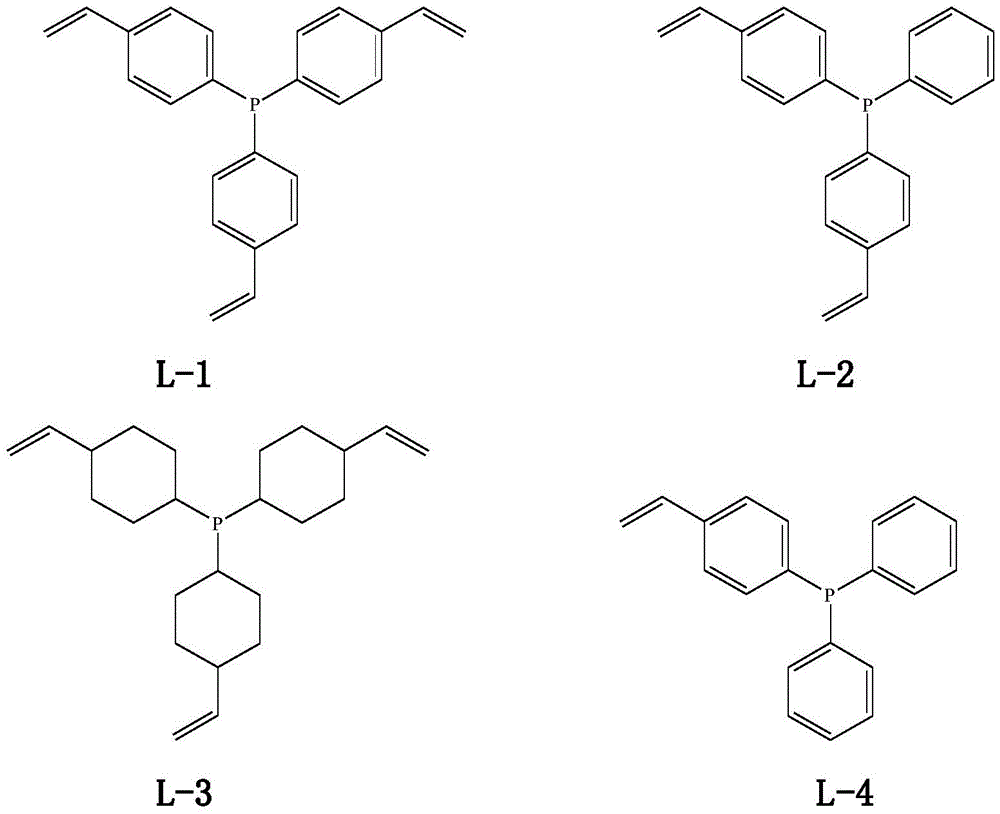

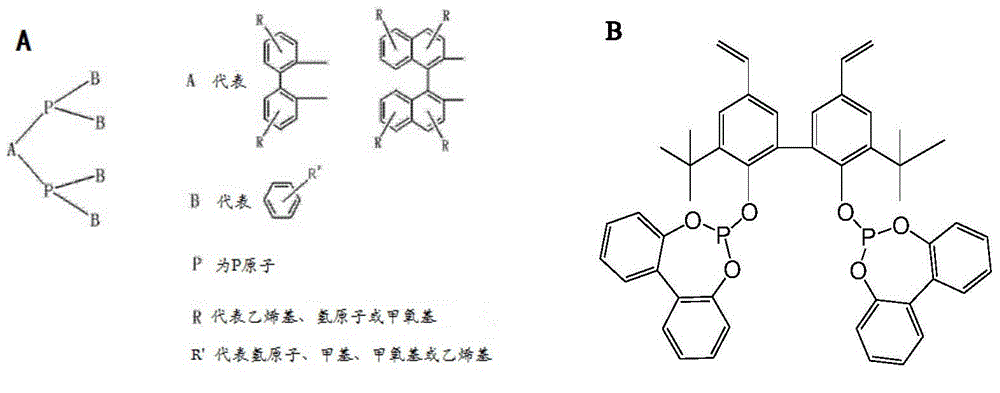

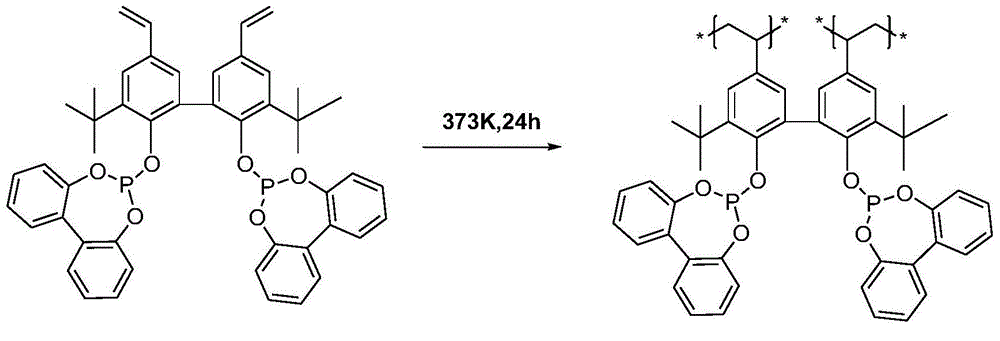

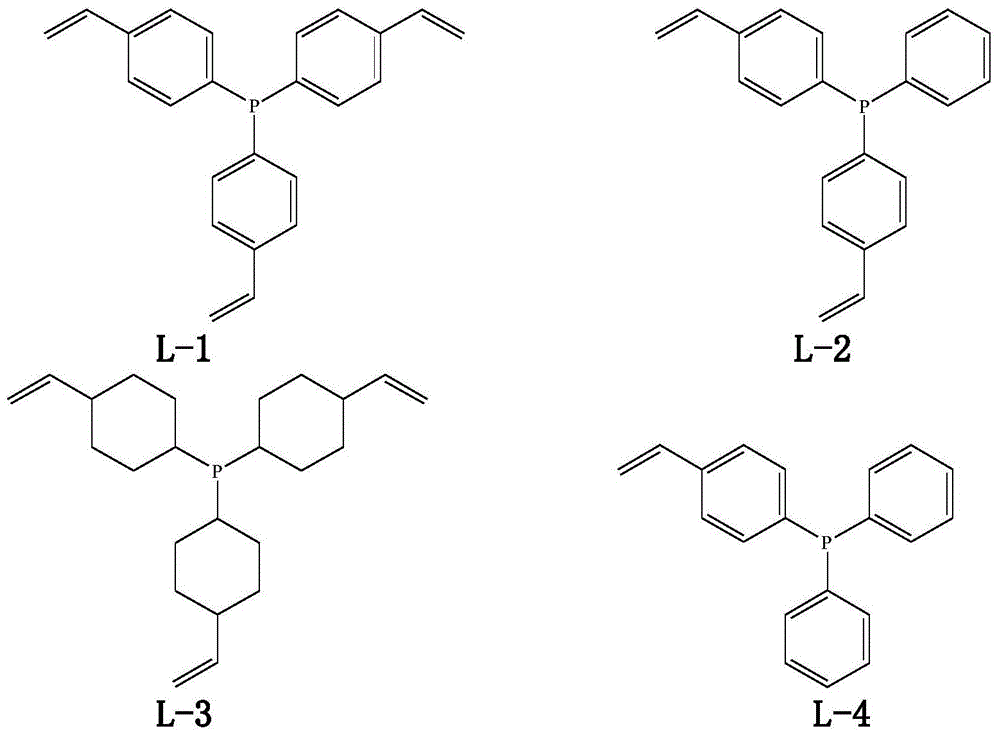

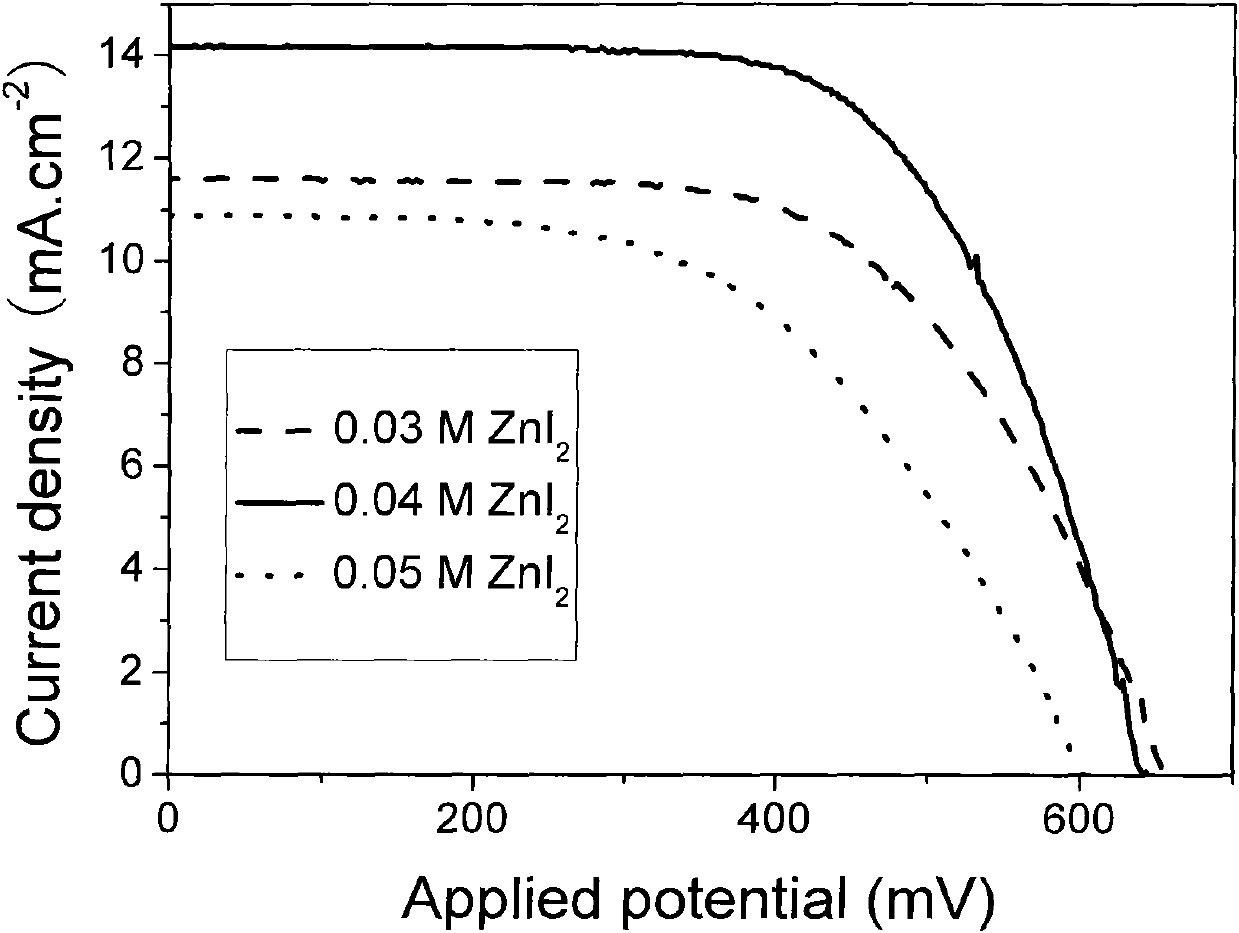

Heterogeneous catalyst adopting phosphine-containing organic mixed polymer-metal as well as preparation and application of heterogeneous catalyst

ActiveCN106140303ASolution to short lifeImprove utilization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryAlkaneFormylation reaction

The invention discloses a heterogeneous catalyst adopting a hierarchical pore structure and adopting phosphine-containing organic mixed polymer-metal as well as preparation and an application of the heterogeneous catalyst in production of aldehyde with a high normal / isomeric ratio through internal olefin hydroformylation. In the heterogeneous catalyst, one, two or three of metal Rh, Co and Ir are taken as active components, and a phosphine-containing organic mixed polymer adopting the hierarchical pore structure is taken as a carrier and is prepared from multidentate organic phosphine ligands containing alkylene and monodentate organic phosphine ligands through copolymerization. The coordinate bond type heterogeneous catalyst is applicable to a fixed bed reactor, a slurry bed reactor, a bubble column reactor, a trickle-bed reactor and other reactors. The provided heterogeneous catalyst has good presentation in the internal olefin hydroformylation reaction, internal olefins are firstly isomerized to be terminal-group olefins under the action of the catalyst, a hydroformylation reaction is performed, corresponding normal aldehyde is selectively generated, accordingly, the normal / isomeric ratio of the product aldehyde is high and can be higher than 15, and the content of alkane in the obtained product is lower than 1%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

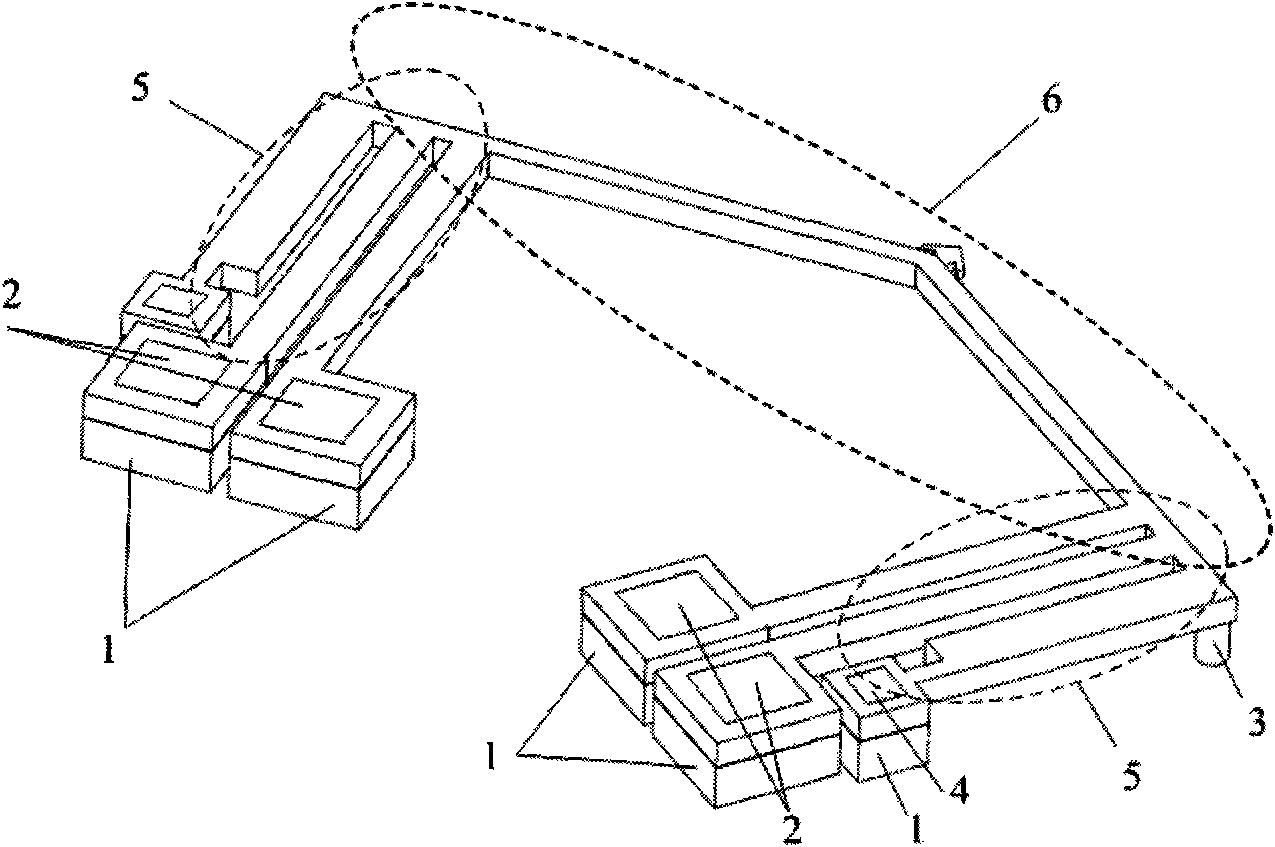

Flexible composite beam electric heating microdriver based on U+V shape

InactiveCN101621261AStructural restoration straightIncrease stiffnessTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceShaped beam

The invention relates to a flexible composite beam electric heating microdriver based on a U+V shape, which belongs to the technical field of microelectromechanical systems. The flexible composite beam electric heating microdriver based on a U+V shape comprises a U-shaped beam base, a U-shaped beam pole, a V-shaped beam base, a V-shaped beam pole, a U-shaped double-hot arm composite beam electric heating driver and a V-shaped composite beam electric heating driver, wherein the U-shaped double-hot arm composite beam electric heating driver comprises a U-shaped double-hot arm metal resistance wire, a U-shaped metal cold arm, a U-shaped double-hot arm polymer drive layer and a U-shaped cold arm polymer layer; and the V-shaped composite beam electric heating driver comprises a V-shaped metal resistance wire, a metal contact point and a V-shaped polymer drive layer. The U-shaped double-hot arm metal resistance wire, the U-shaped metal cold arm and the V-shaped metal resistance wire are completely coated by the U-shaped double-hot arm polymer drive layer, the U-shaped cold arm polymer layer and the V-shaped polymer drive layer to form a polymer-metal-polymer sandwich structure. The electric heating microdriver has larger drive displacement, higher drive rigidity, low power consumption and high energy utilization ratio.

Owner:SHANGHAI JIAO TONG UNIV

Electrode for energy storage devices and electrochemical supercapacitor based on said electrode

ActiveUS7382603B2Increasing specific energy capacity of energyImprove stability and reliabilityElectrolytic capacitorsHybrid capacitor electrodesPolymer scienceRedox polymers

An electrode comprises an electrically conductive substrate, a layer of energy accumulating redox polymer deposited onto the substrate, the redox polymer comprising a polymer metal complex with a substituted tetra-dentate Schiff's base selected from the group: poly-[Me(R, R′-Schiff-Y)], wherein Me is a transition metal; Y is a bridge group binding the atoms of Nitrogen in the Schiff's base; R is an electron-donating substituent comprising a functional group (X)O—, —COO(X), where (X) is an alkali metal; R′ is Hydrogen or Halogen; and wherein the polymer metal complex has the following structure:The electrochemical capacitor comprises a case housing the above-described positive electrode and a negative electrode disposed inside the case, and an electrolyte filling the space between the electrodes.

Owner:POWERMERS

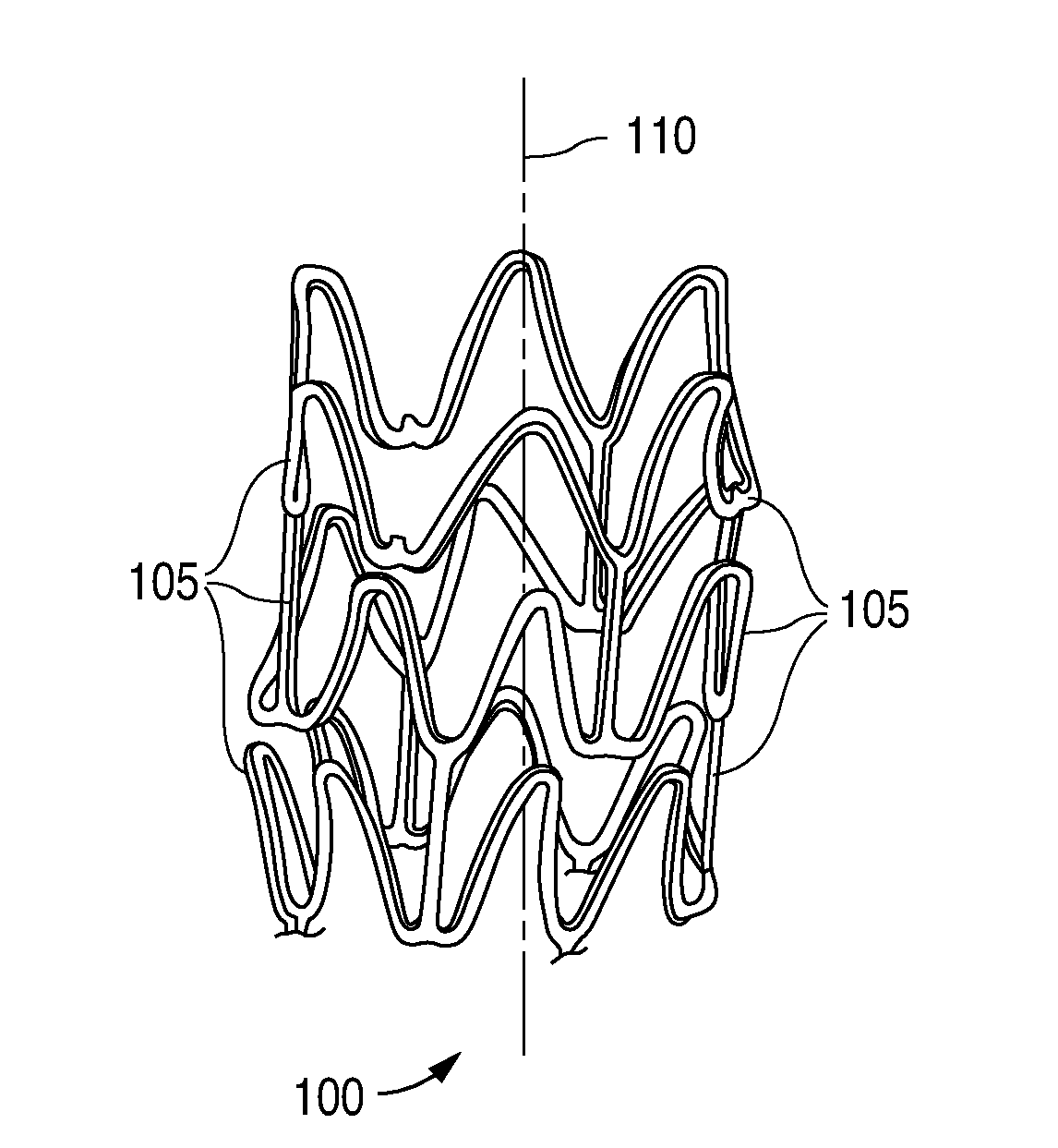

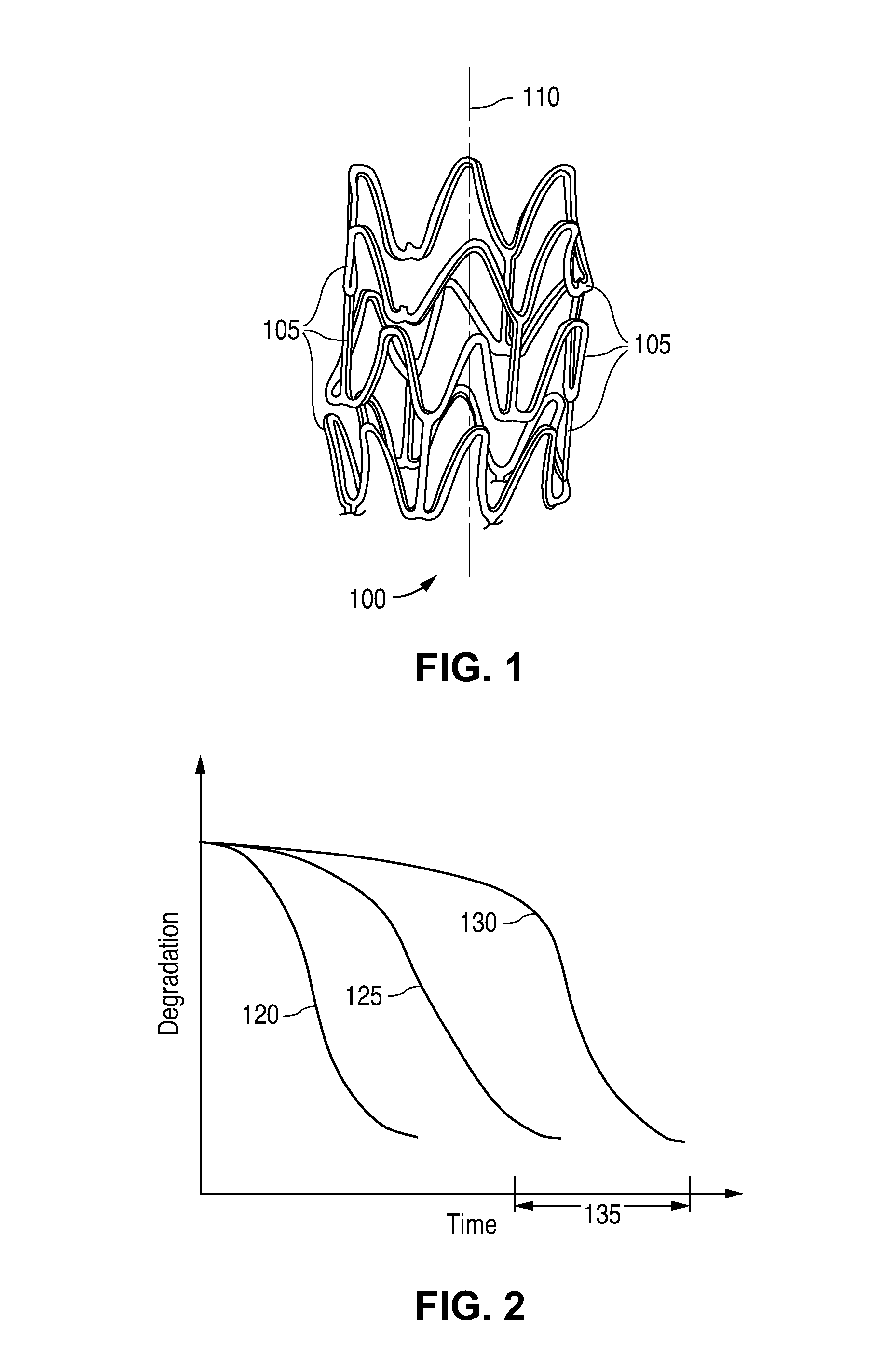

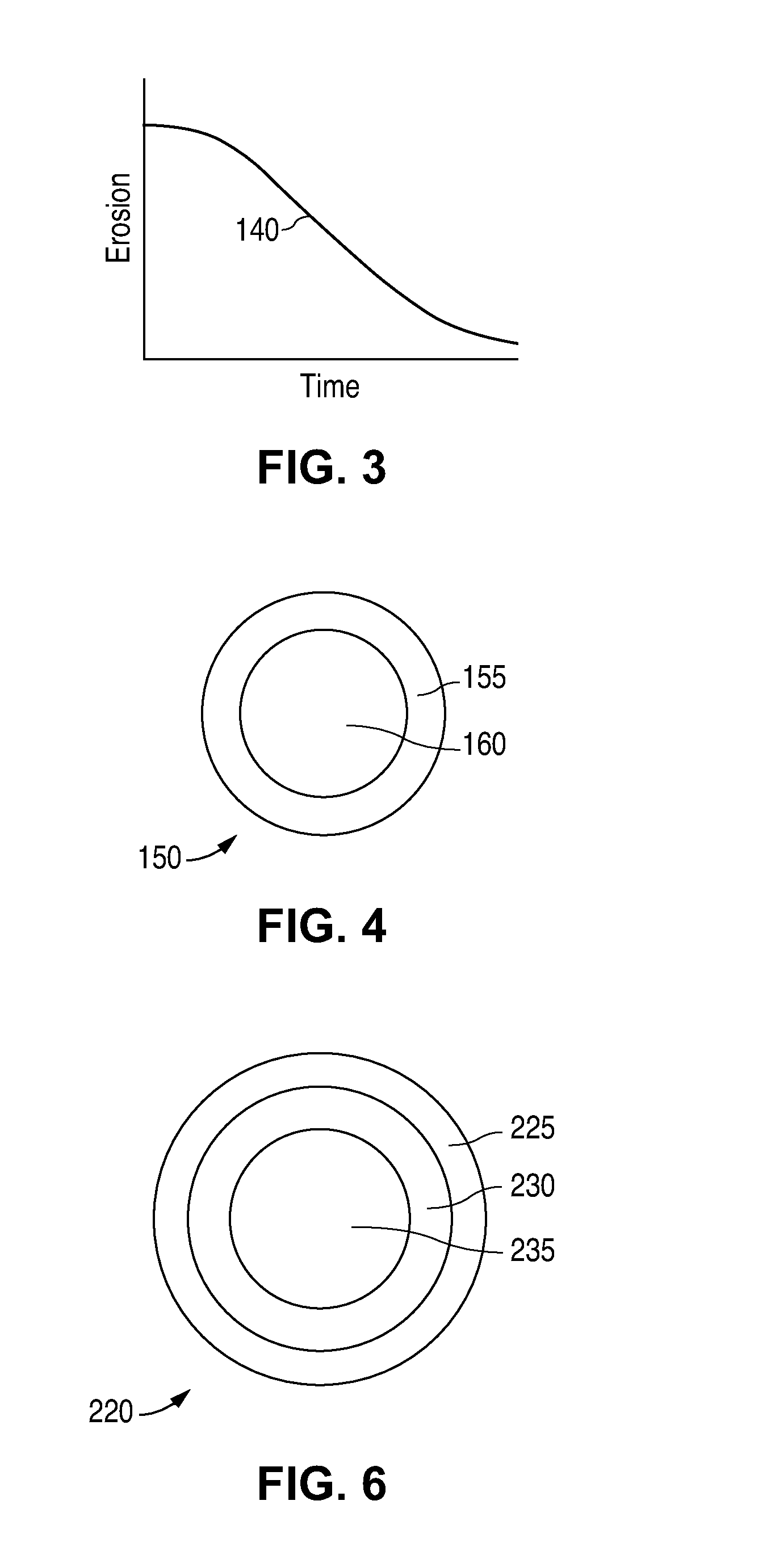

Polymer metal and composite implantable medical devices

A device and a method of manufacturing an implantable medical device, such as a stent, are described herein. The device includes a metallic region composed of a bioerodable metal and a polymer region composed of a biodegradable polymer contacting the metallic region. The metallic region may erode at a different rate when exposed to bodily fluids than the polymer region when exposed to bodily fluids. In certain embodiments, the polymer region is an outer layer and the metallic region is an inner layer of the device.

Owner:ABBOTT CARDIOVASCULAR

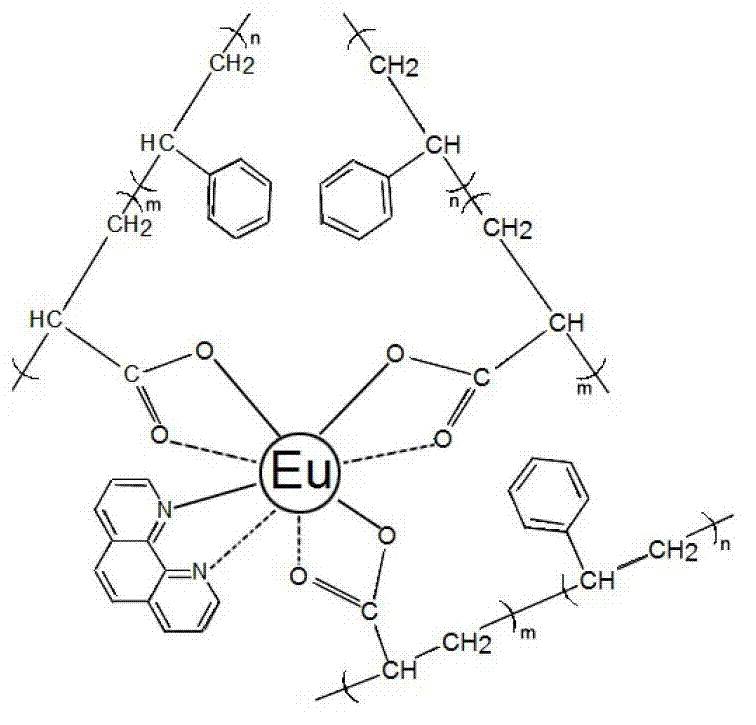

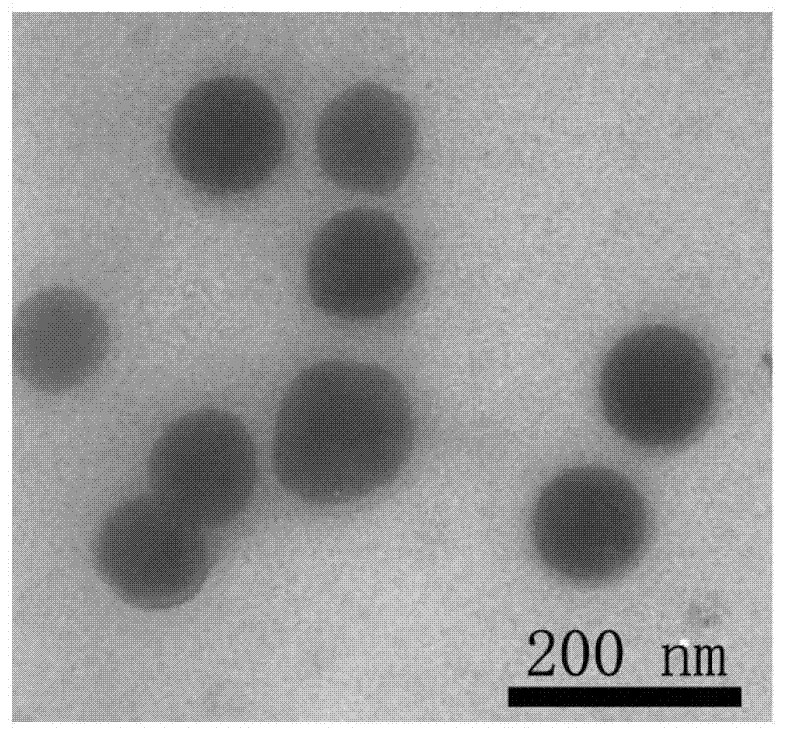

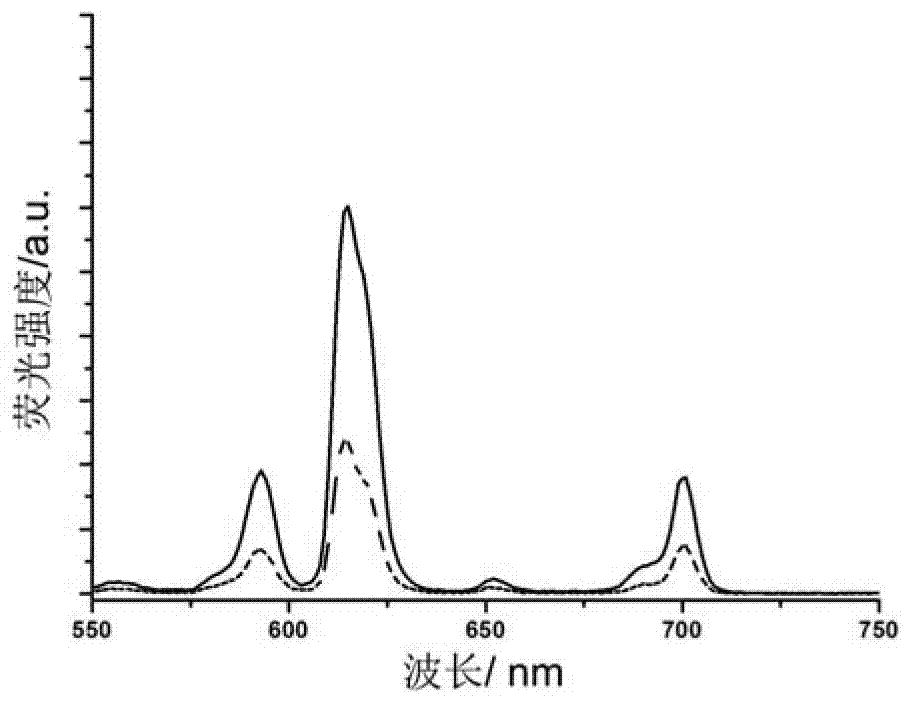

Preparation method of polymer-rare earth ion luminous micelles

ActiveCN102875750AStable structureGood dispersionLuminescent compositionsRare-earth elementWater baths

The invention belongs to the technical field of polymer-metal functional composite material preparation, and relates to a preparation method of polymer-rare earth ion luminous micelles. An amphipathy two-block AB type copolymer or a three-block ABA type copolymer is selected to serve as a first ligand, and molecular weight of each block and total molecular weight of a segmented copolymer are respectively determined through a testing method of nuclear magnetic resonance spectra and a gel permeation chromatography; oxide of rare earth element is contained in a beaker, excessive hydrochloric acid is added for stirring until the oxide is completely dissolved; then the beaker is placed in a water bath until liquid in the beaker is dried to obtain trivalent rare earth chloride crystals; and a polymer solution and a rare earth ion solution are mixed in proportion, organic conjugation micromolecules are added to serve as a second ligand, the polymer solution, the rare earth ion solution and the organic conjugation micromolecules are evenly mixed to be placed in a reaction vessel, and condensation backflow is carried out at a constant temperature to enable the copolymer and rare earth ions to conduct a complexing reaction to obtain the polymer-rare earth ion luminous micelles. The preparation method is simple in process, reliable in principle, strong in operability and stable in product structure.

Owner:QINGDAO UNIV

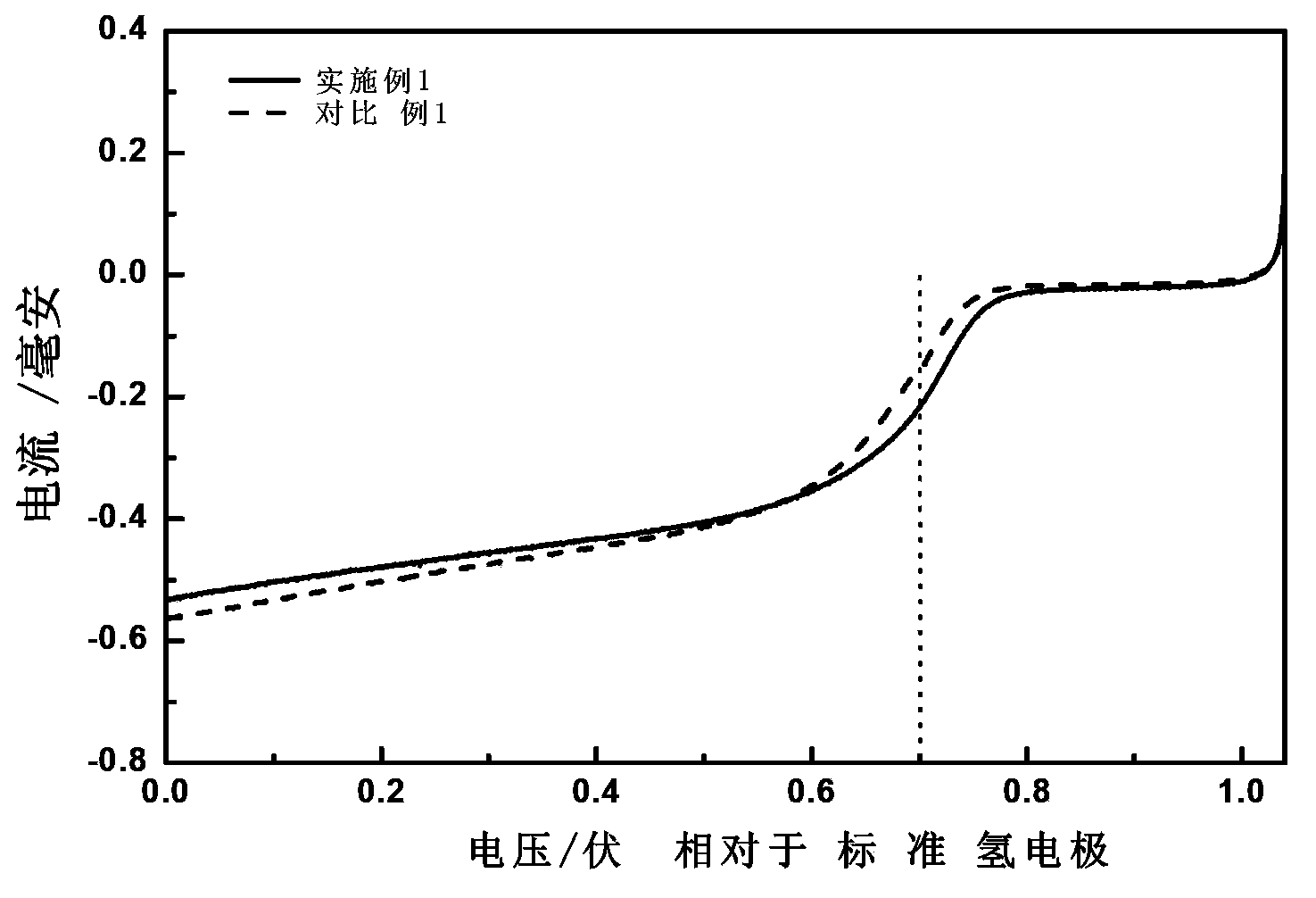

Metal-doped nitrogen-containing carbon-based catalyst of fuel cell and application thereof

ActiveCN103682379AStructurally effective regulationEffective control of morphologyCell electrodesFuel cellsReduction ActivitySurface-active agents

The invention relates to a metal-doped nitrogen-containing carbon-based catalyst of a fuel cell and application of the catalyst. The catalyst adopts organic surface active agents as a protection agent and a structural guide agent and adopts an aromatic compound and aldehyde as reaction monomers, metal elements are added in the reaction process to obtain a polymer-metal compound, and the polymer-metal compound is dried and then is subjected to high-temperature processing with inert gas or / and ammonia gas to finally obtain the metal-doped nitrogen-containing carbon-based catalyst. When the metal-doped nitrogen-containing carbon-based catalyst is used as a cathode catalyst of a proton exchange membrane fuel cell and a direct-methanol fuel cell, the oxide reduction activity, stability and toxicity resistance are excellent; moreover, the catalyst has an environment-friendly effect, is low in cost, controllable in aperture, high in specific surface area and rich in resource and can substitute for platinum to serve as an electric catalyst of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

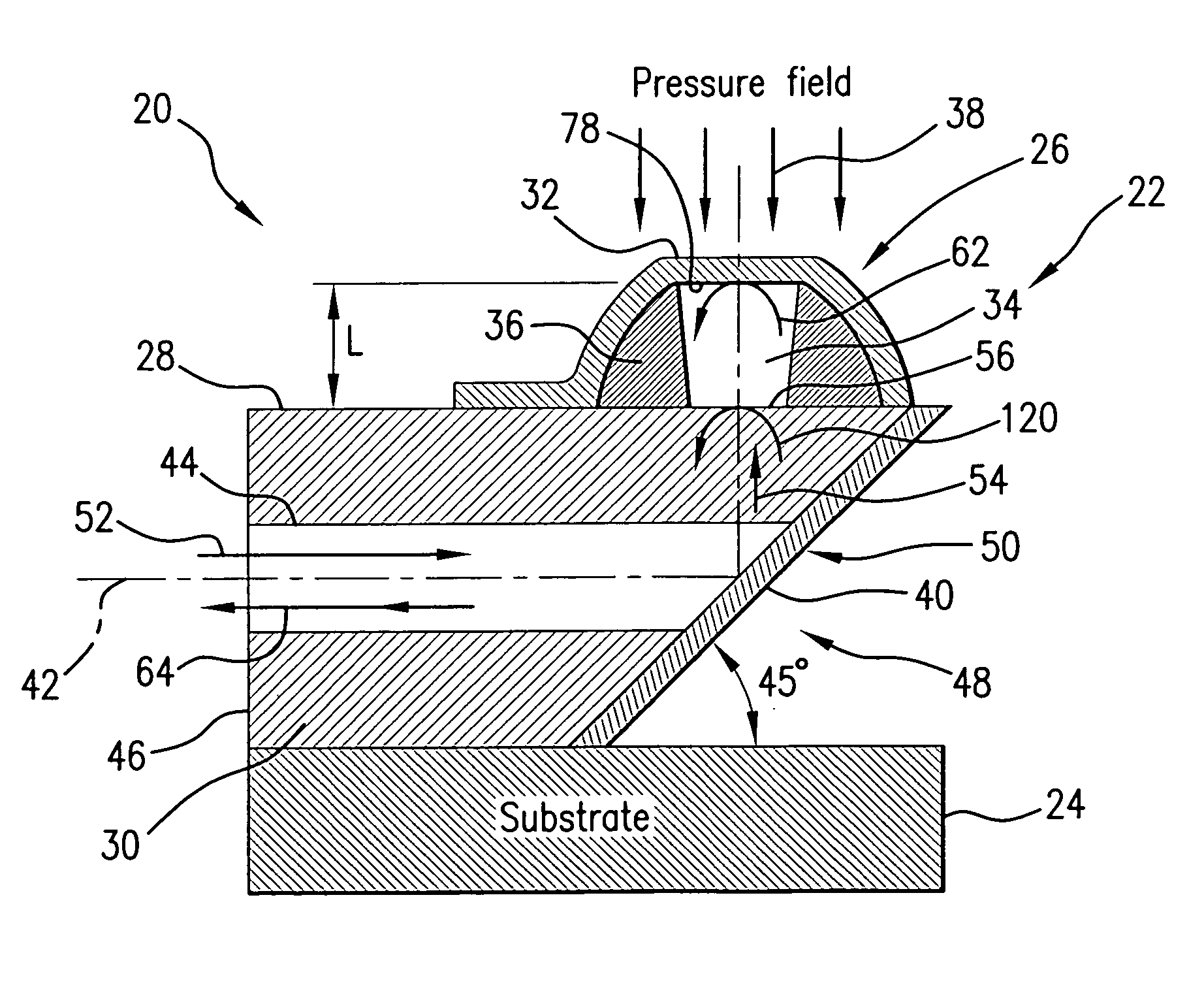

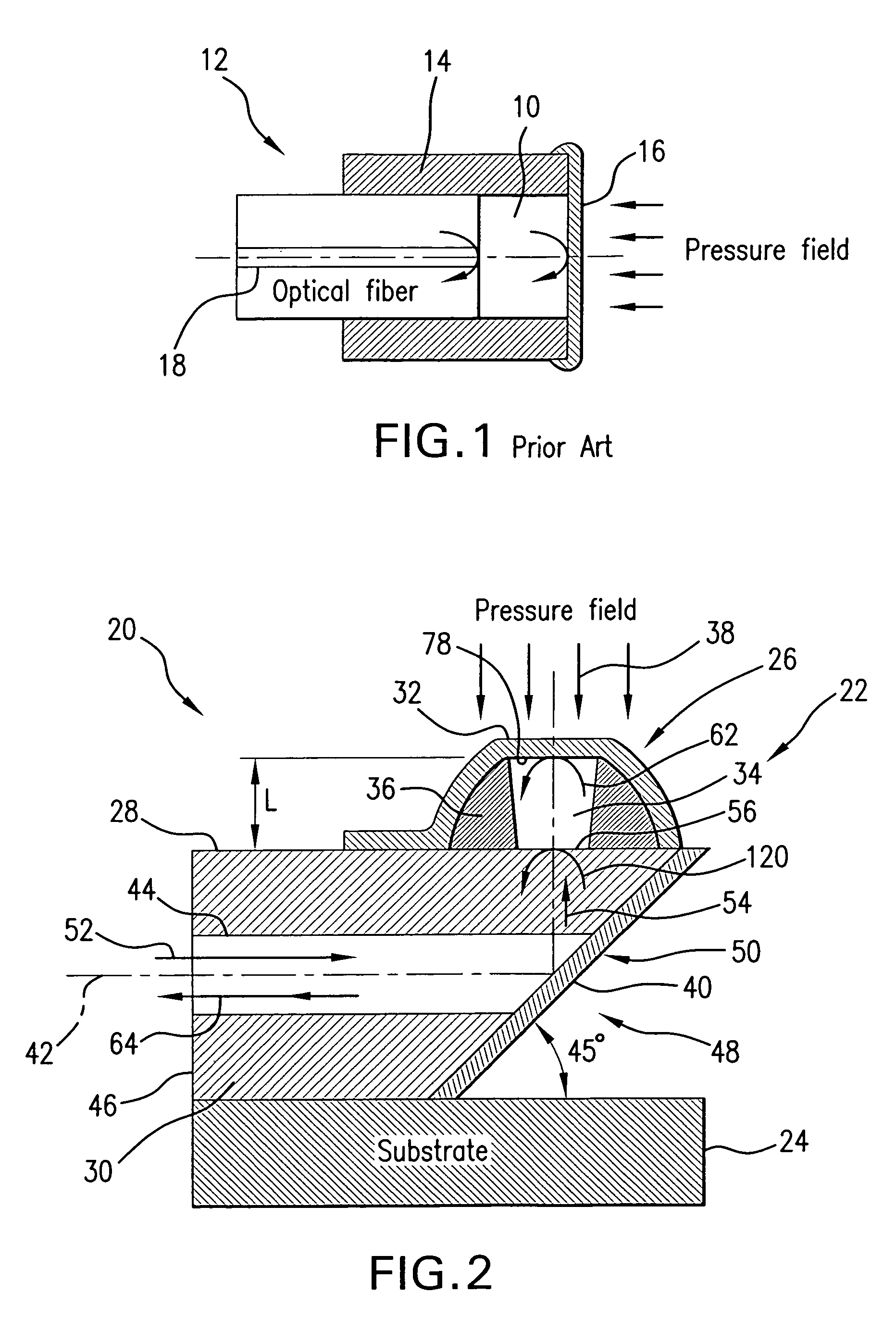

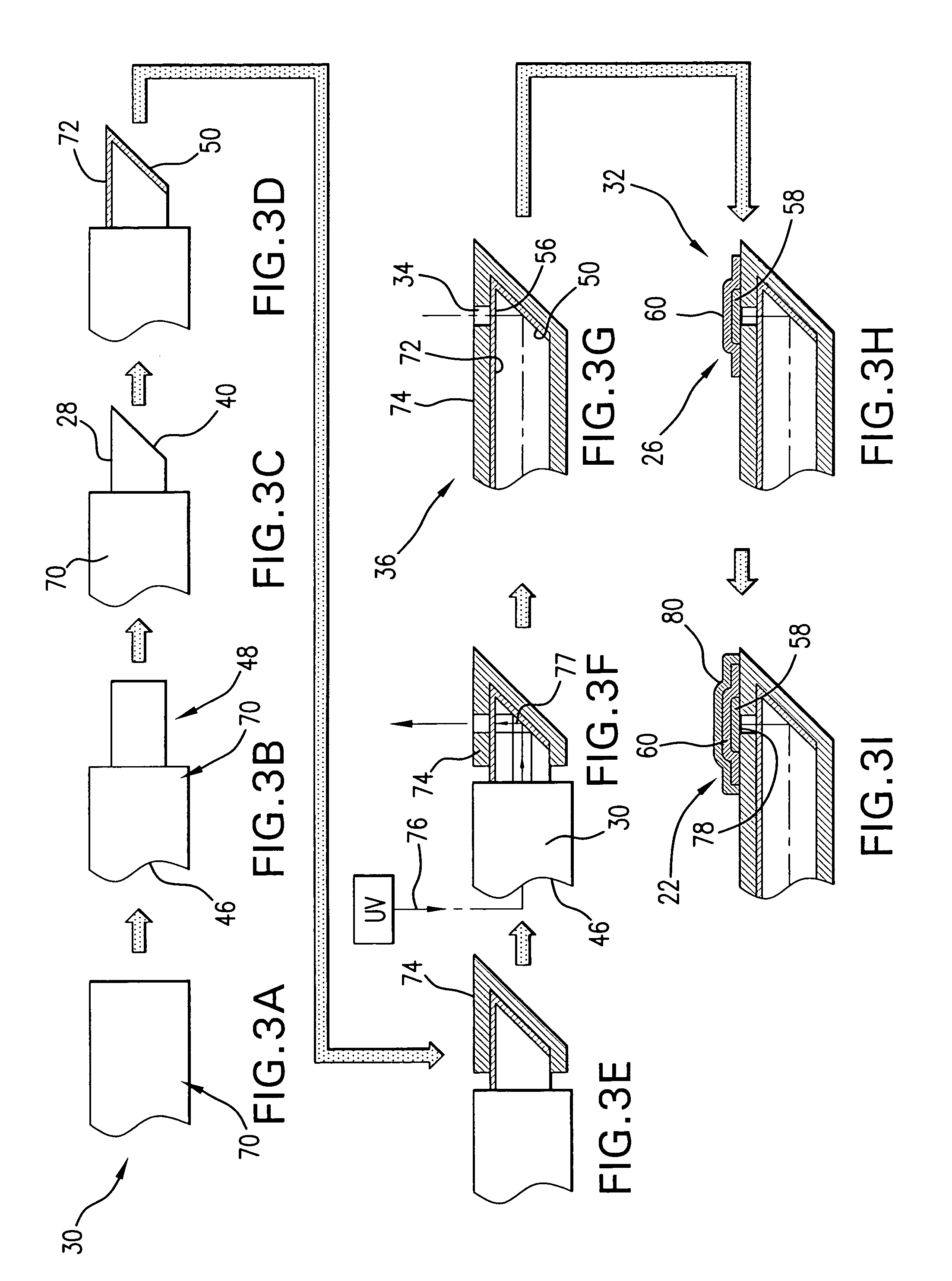

Ultra-miniature fiber-optic pressure sensor system and method of fabrication

ActiveUS8151648B2Improve uniformityImprove performanceFluid pressure measurement by electric/magnetic elementsOptical articlesFiberLinearity

Ultra-miniature surface-mountable Fabry-Perot pressure sensor is constructed on an optical fiber which utilizes a 45° angled fiber tip covered with a reflective layer which steers the optical axis of the fiber by 90°. The Fabry-Perot cavity is formed on the sidewall of the fiber and a polymer-metal composite diaphragm is formed on the top of the Fabry-Perot cavity to operate as a pressure transducer. The sensor exhibits a sufficient linearity over the broad pressure range with a high sensitivity. The sensitivity of the sensor may be tuned by controlling the thickness of the diaphragm. The sensor may be used in a wide range of applications, including reliable in vivo low invasive pressure measurements of biological fluids, single sensor systems, as well as integral spatial-division-multiplexing sensor networks. Methods of batch production of uniform device-to-device Fabry-Perot pressure sensors of co-axial and cross-axial configurations are presented.

Owner:MARYLAND UNIV OF

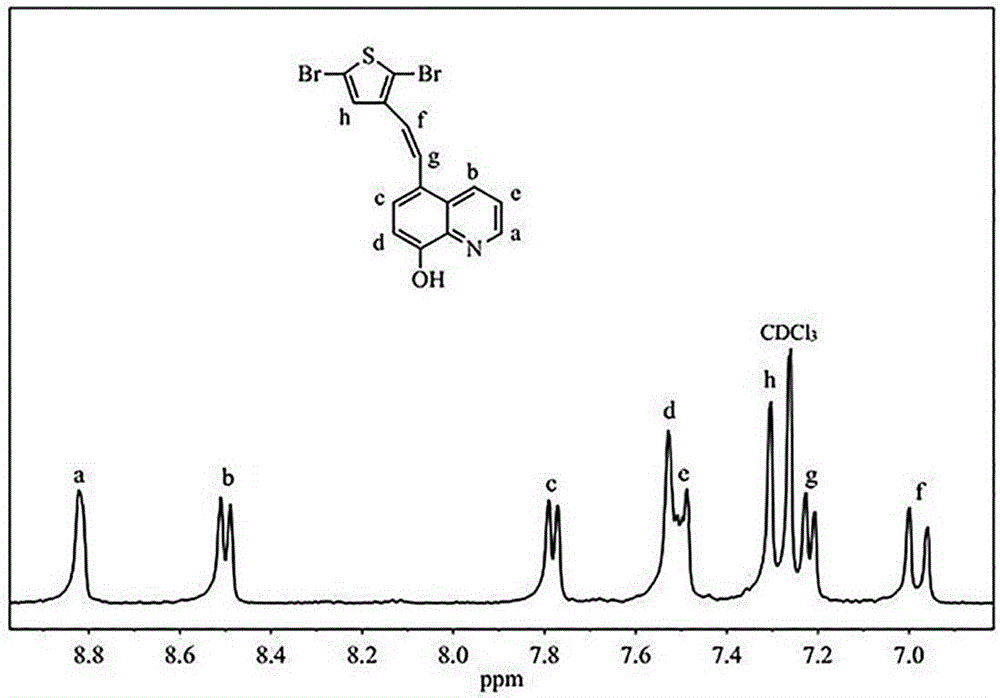

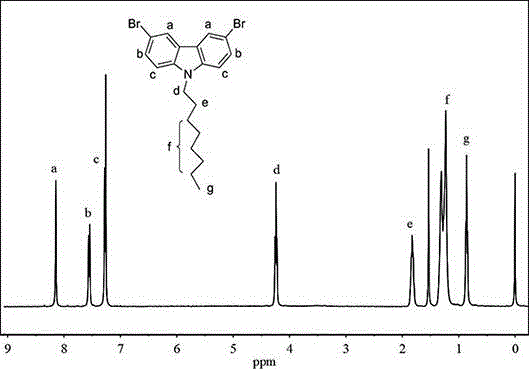

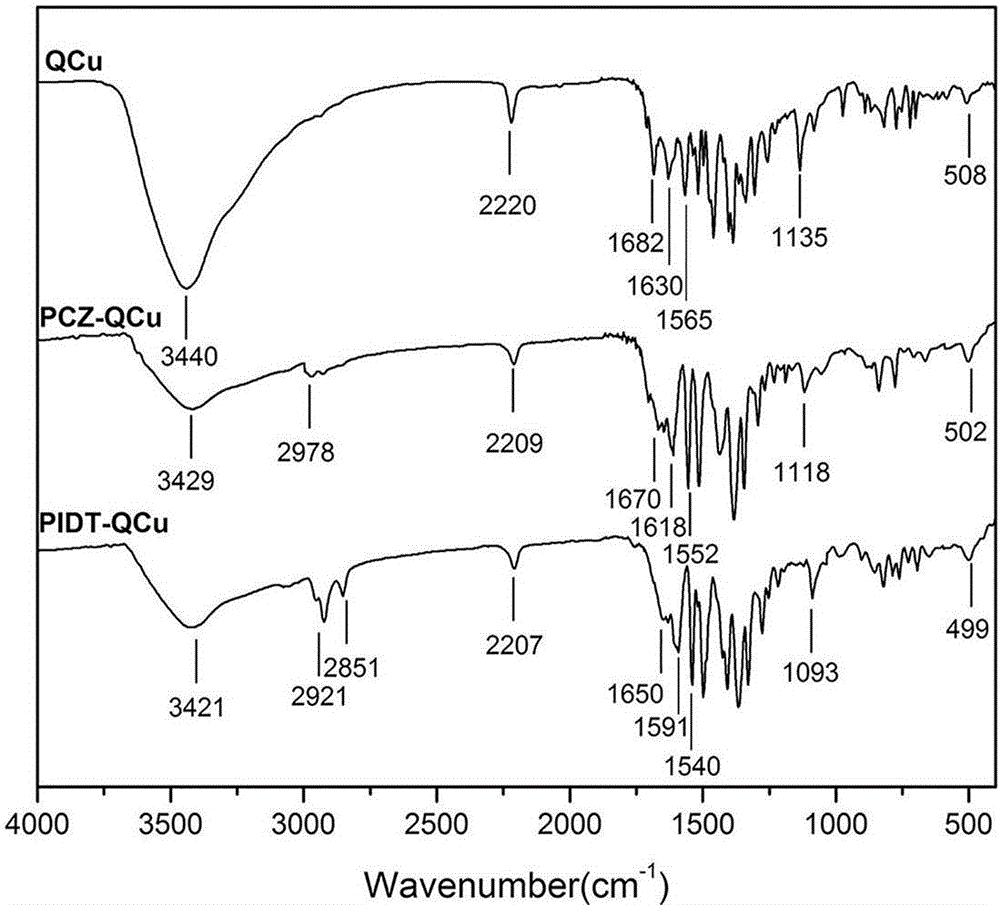

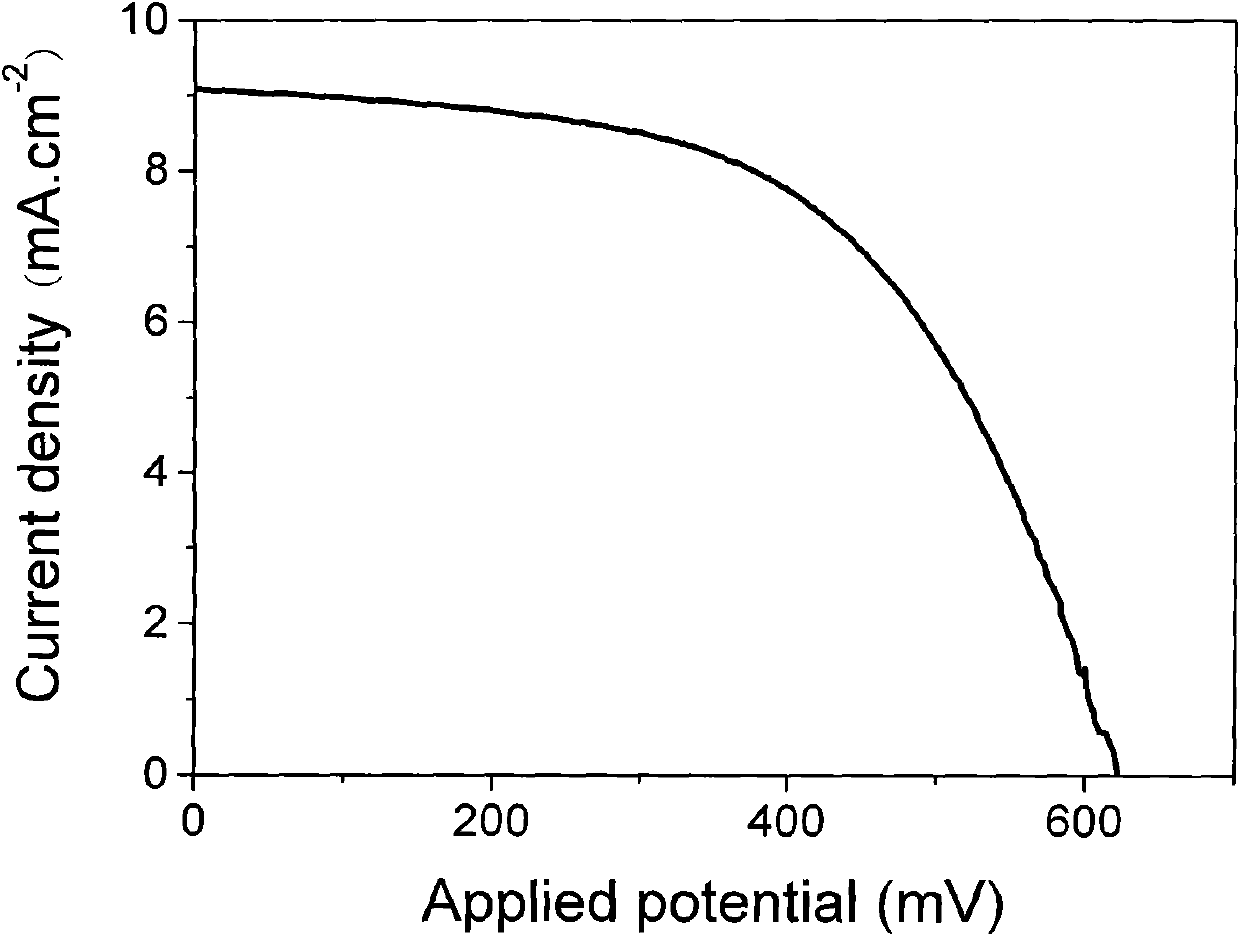

8-hydroxyquinoline derivative cu (II) polymer metal complex containing dye sensitizer and preparation method thereof

ActiveCN106188506AExtended conjugated π systemLow costLight-sensitive devicesOrganic dyesElectron donorQuinoline

The invention relates to a novel D-A'-PI-A polymer metal complex sensitizer (as shown in a formula I) taking 8-hydroxyquinoline derivative Cu (II) as an auxiliary electron acceptor, a preparation method of the sensitizer and application of the sensitizer to dye-sensitized solar cells. The sensitizer takes derivates of IDT (indacenodithiophene) or CZ (carbazole) as electron donors (D), 8-hydroxyquinoline derivative Cu (II) complexes serve as A' and pi bridges respectively, cyanoacrylate serves as an electron acceptor (A) and an anchor group, and Yamamoto polymerization is performed to obtain sensitizers PIDT-QCu and PCZ-QCu. The D-A'-PI-A sensitizer taking high-electrophilicity 8-hydroxyquinoline derivative Cu (II) complexes as the auxiliary electron acceptor A' is synthesized successfully. According to photovoltaic performance tests, the sensitizer is excellent in photovoltaic performance and thermal stability and has a promising application prospect.

Owner:XIANGTAN UNIV

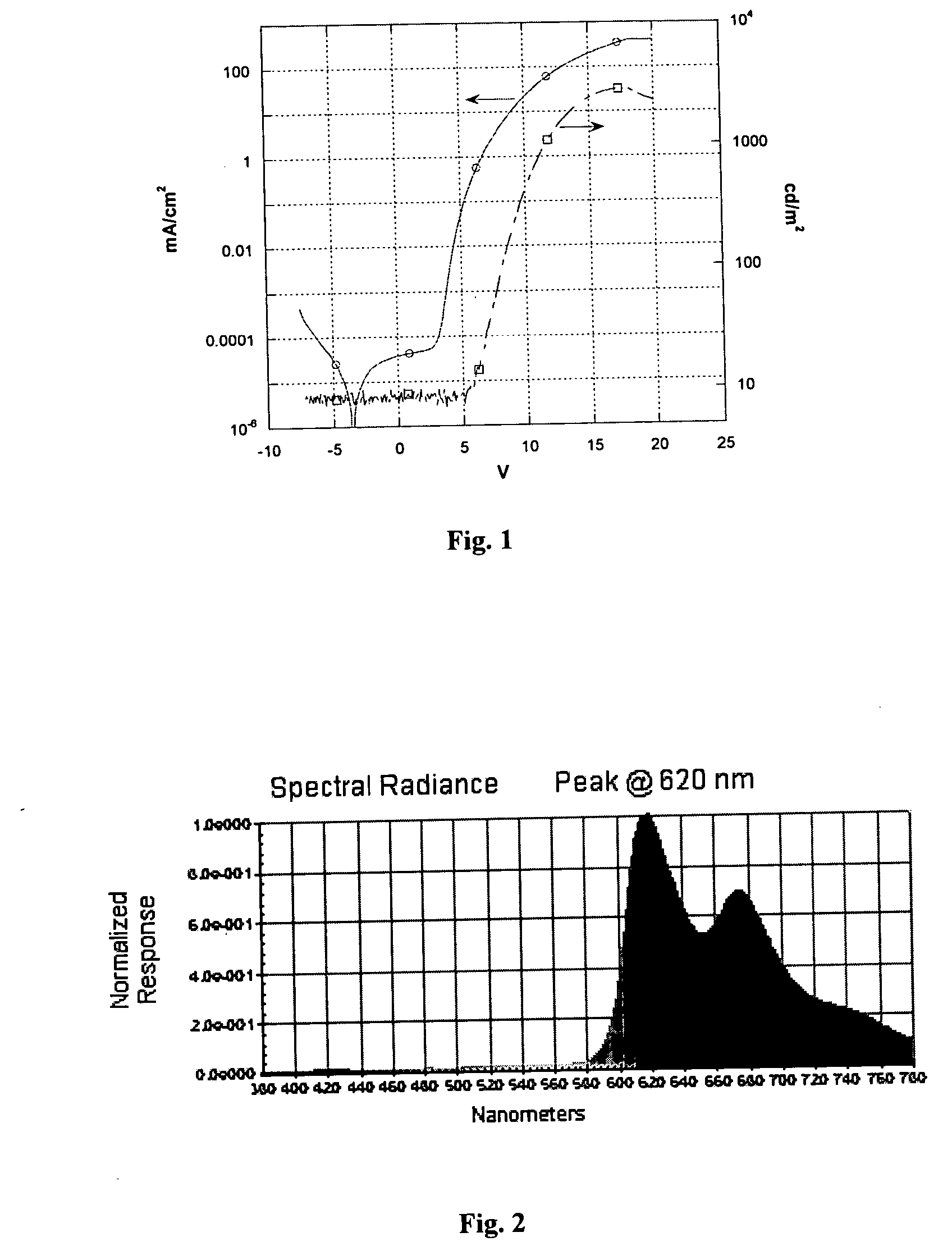

Aromatic monomer-and conjugated polymer-metal complexes

InactiveUS20050031900A1Simple preparation processIndium organic compoundsDischarge tube luminescnet screensElectron delocalizationBackbone chain

A halogenated aromatic monomer-metal complex useful for preparing a polymer for electronic devices such as a light-emitting diode (LED) device is described. The aromatic monomer-metal complex is designed to include a linking group that disrupts conjugation, thereby advantageously reducing or preventing electron delocalization between the aromatic monomer fragment and the metal complex fragment. Disruption of conjugation is often desirable to preserve the phosphorescent emission properties of the metal complex in a polymer formed from the aromatic monomer-metal complex. The resultant conjugated electroluminescent polymer has precisely controlled metal complexation and electronic properties that are substantially or completely independent of those of the polymer backbone.

Owner:SUMITOMO CHEM CO LTD

Method for preparing ionic polymer-metal smart electric driving composite material

InactiveCN102167837AHigh solubility of metal ionsLow initial deformation stressLiquid/solution decomposition chemical coatingDC - Direct currentSpin coating

The invention belongs to the technical field of preparation of macromolecular metal composite materials, and relates to a method for preparing an electroactive ionic polymer-metal smart electric driving composite material. The material prepared by the method has the characteristic of smart deformation under low direct current voltage driving. The method comprises process steps of: preparing ternary ionic copolymer; preparing an ionic polymer and metal composite film; and preparing surface electrodes on two sides, wherein emulsion polymerization monomer is distilled under reduced pressure by using an emulsion polymerization method, a polymerization inhibitor is removed, and the monomer is placed in a refrigerator for later use during the preparation of the ternary ionic copolymer; the ionic polymer-metal composite film is obtained by pouring nano latex in a shallow glass channel type flat bottomed mould under atmospheric environment during the preparation of the ionic polymer-metal composite film; and a micron-thick metal plating is prepared through a chemical reduction method or a conductive filler-containing conductive coating is coated by using a physical spin coating method during the preparation of the surface electrodes on the two sides. The method has the advantages of simple preparation process, high toughness of prepared products, low cost and no environmental pollution.

Owner:QINGDAO UNIV

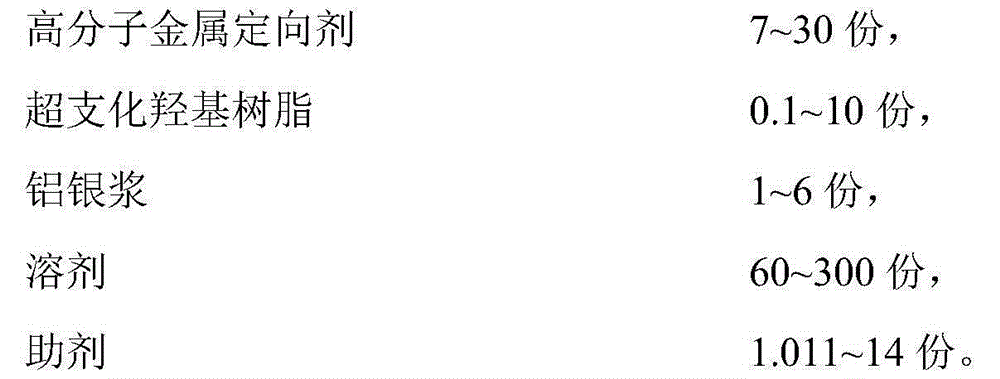

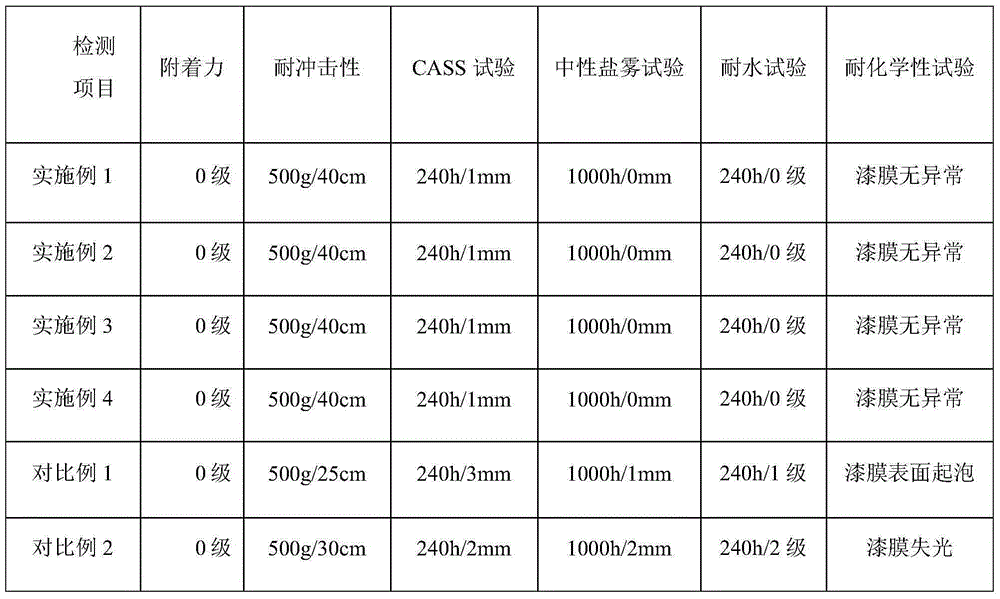

Silver electroplating coating composition, preparation method and application thereof

ActiveCN106243838AConvenient ArrangementEvenly arrangedCellulose coatingsPretreated surfacesSilver pastePolymer metal

The invention discloses a silver electroplating coating composition. The composition comprises the following components in parts by weight: 7-30 parts of a high-molecular metal aligning agent, 0.1-10 parts of hyperbranched hydroxyl resin, 1-6 parts of aluminium silver paste, 60-300 parts of a solvent, and 1.011-14 parts of an auxiliary agent. The invention also discloses a preparation method of the silver electroplating coating combination. The method comprises the following steps: 15-90 parts of the solvent is added into 0.1-10 parts of hyperbranched hydroxyl resin in a first container; 20-60 parts of the solvent is added into 1-6 parts of the aluminium silver paste in a second container, 1.011-14 parts of the auxiliary agent is added with uniform stirring, and uniform stirring is carried out continuously; a mixture in the second container is added into the first container with uniform stirring; finally, 7-30 parts of the high-molecular metal aligning agent and 25-150 parts of the solvent are added with uniform stirring, and the silver electroplating coating composition is obtained. The silver electroplating coating composition has the characteristics of high performance as well as good appearance and brightness.

Owner:LANGFANG NIPPON PAINT +2

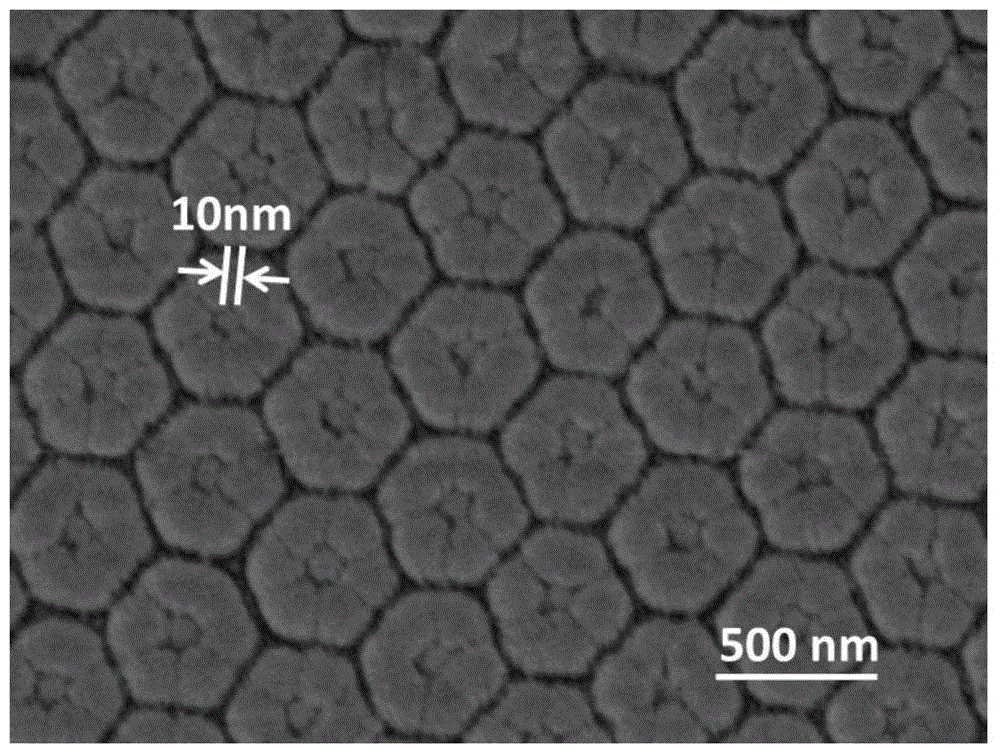

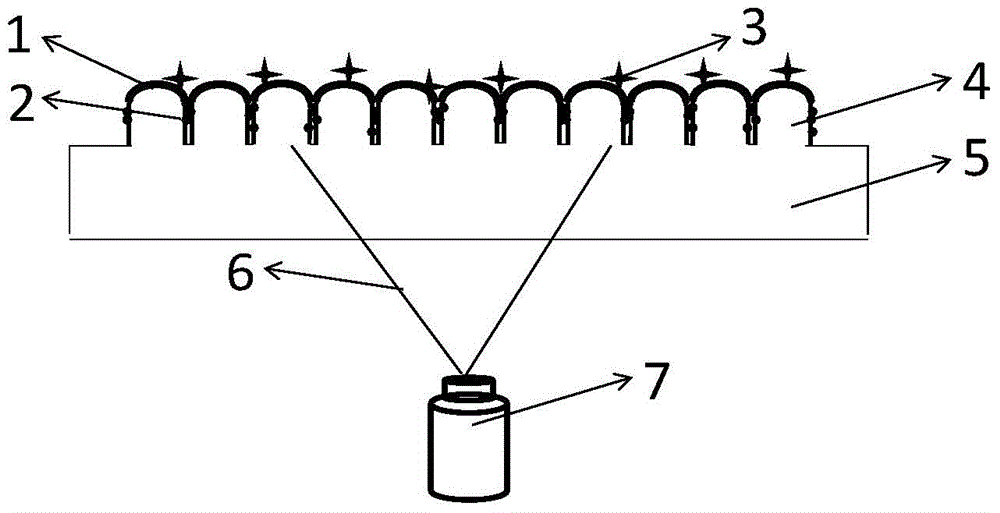

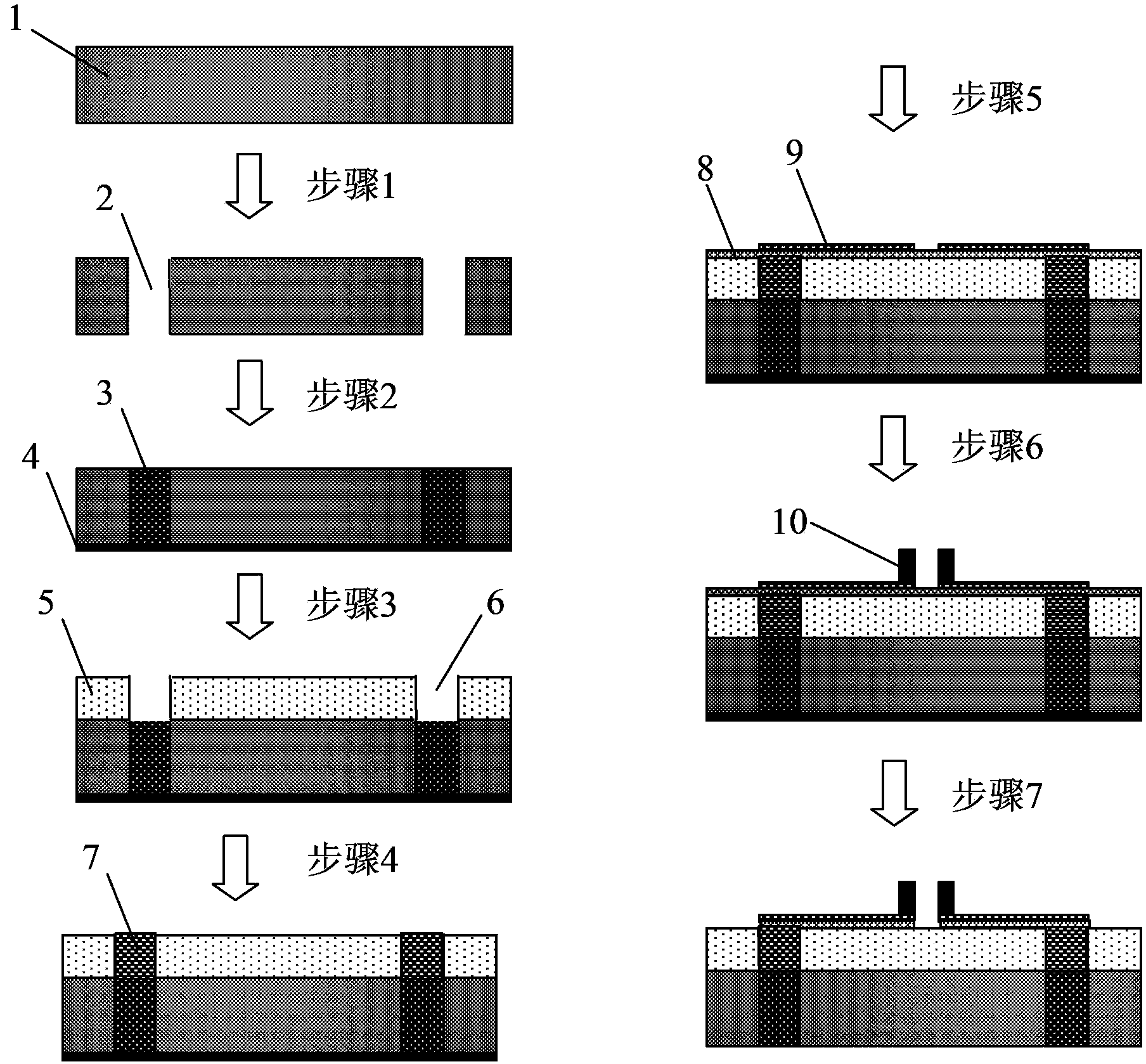

Back surface detection type SERS (surface-enhanced Raman scattering) chip and preparation method thereof

InactiveCN105044076AAccurate detectionImprove detection limitRaman scatteringManufacturing technologyPolymer metal

The invention relates to a back surface detection type SERS (surface-enhanced Raman scattering) chip and a preparation method thereof, and belongs to the technical field of SERS. The SERS chip is a polymer-metal composite material. The preparation method of the SERS chip comprises the following steps: copying an AAO (Anode Alumina Oxide) template structure by using a polymer, so as to obtain a polymer coronary array with the surface structure complementary to the AAO surface structure; further constructing a noble metal layer with SERS activity on the surface of the polymer coronary array, so as to obtain the SERS chip. Through the adoption of the manufacturing technology and the selected chip material, the two sides of the chip are different in medium material and surface roughness; experiments and theoretic simulation prove that surface plasma can be more effectively excited and coupling can be realized on the premise that the back surface detection manner is adopted for the chip, so as to obtain stronger SERS signals.

Owner:JILIN UNIV

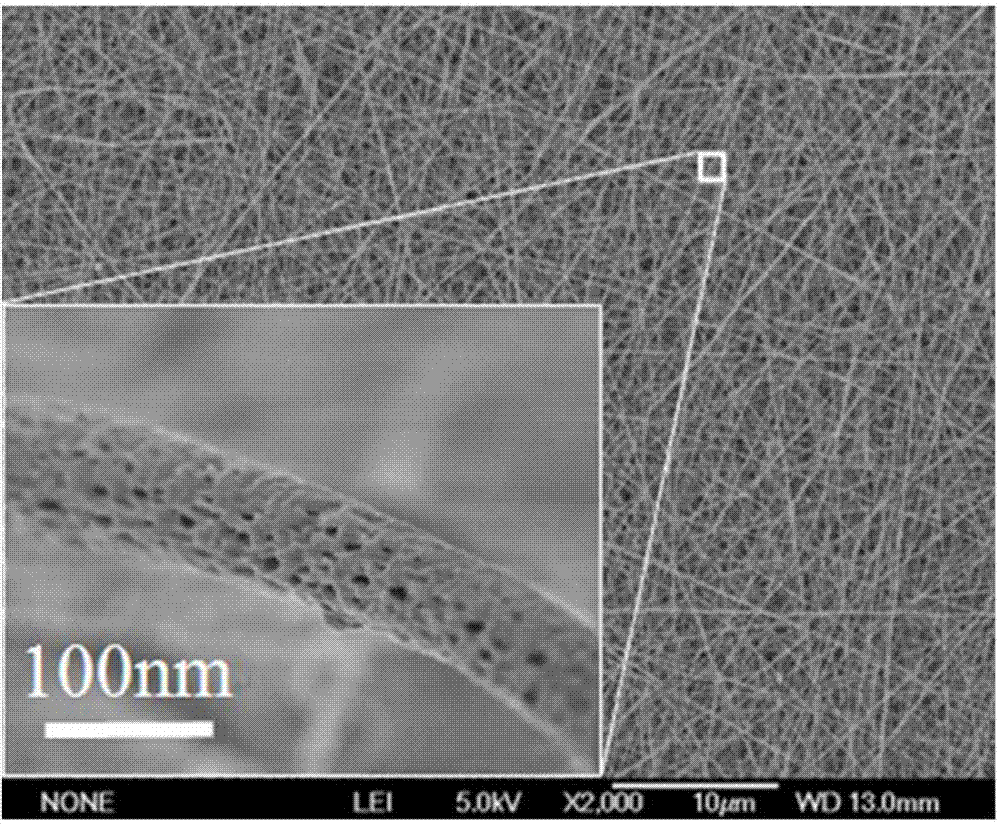

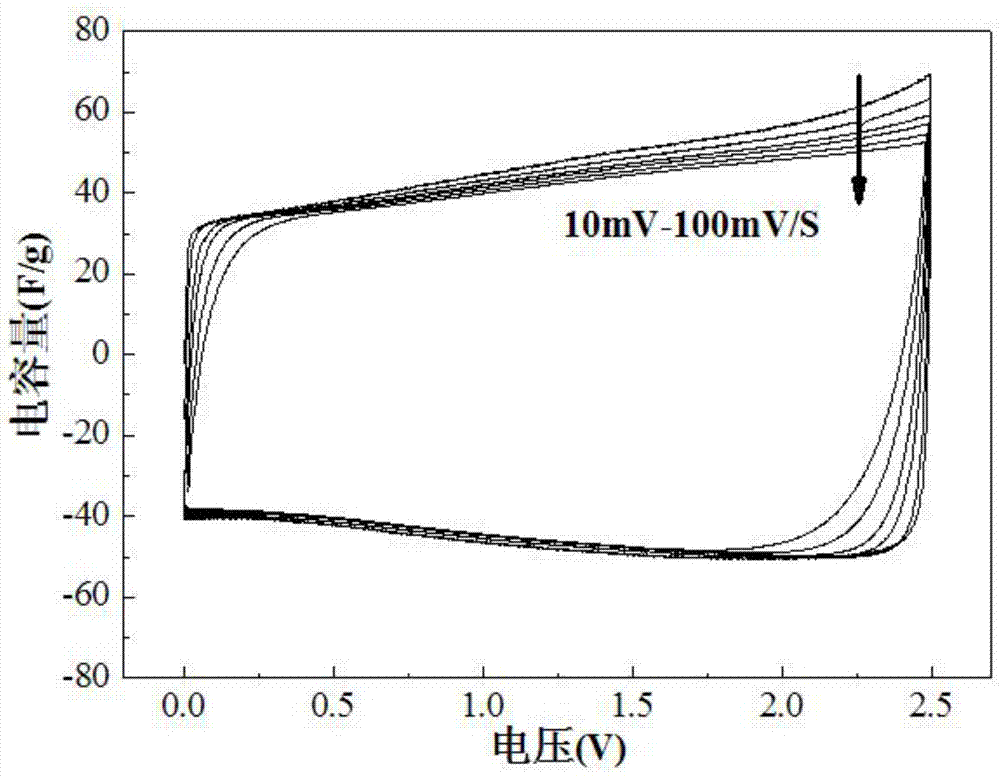

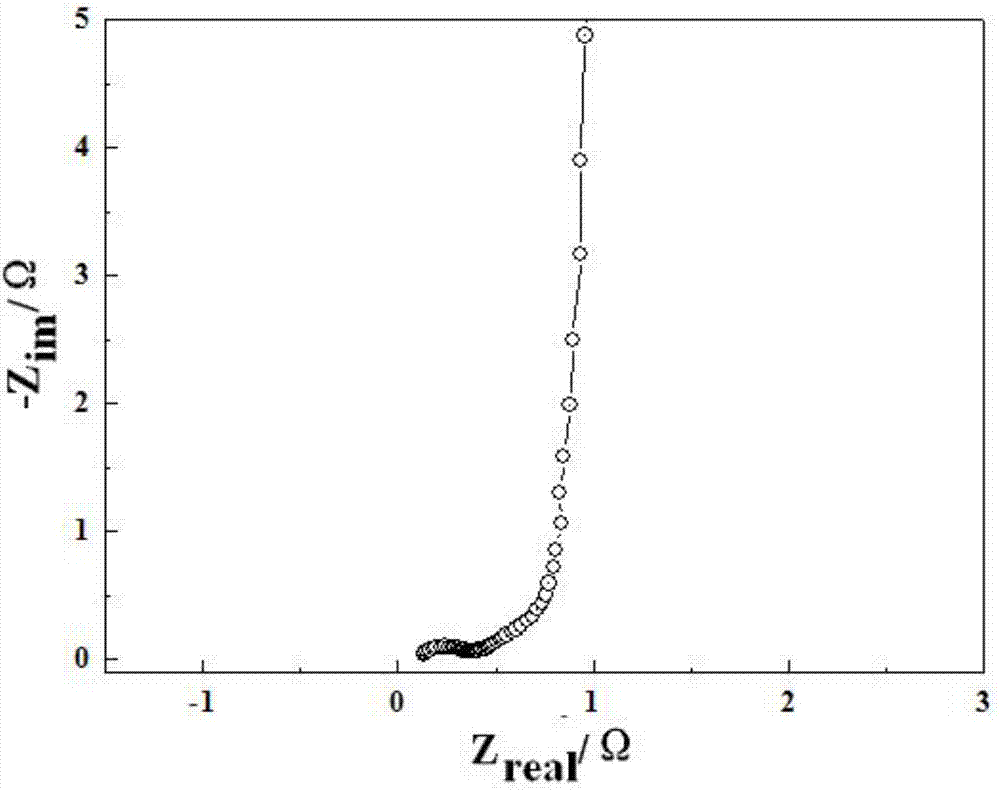

Preparation method of fluorine-containing polymer porous nano-micron fibre electrode diaphragm

ActiveCN104752663AImprove thermal stabilityGood acid and alkali resistanceCell component detailsFiberMetal oxide nanoparticles

The invention relates to a preparation method of a fluorine-containing polymer porous nano-micron fibre electrode diaphragm. The preparation method comprises the following steps: dissolving a fluorine-containing polymer and soluble metal salt in an organic solvent to prepare a spinning precursor, then, preparing a fluorine-containing polymer-metal salt electrostatic spinning fibrous membrane through high-pressure electrostatic spinning, adding a mineralizing agent to carry out hydrothermal reaction so as to obtain a fluorine-containing polymer-metal oxide nano-micron fibrous membrane, carrying out acid treatment by using dilute acid aqueous solution to convert metal oxide nanoparticles in the fluorine-containing polymer-metal oxide nano-micron fibrous membrane into soluble metal salt which is dissolved in inorganic acid aqueous solution, thus obtaining the fluorine-containing polymer porous nano-micron fibre electrode diaphragm. The preparation method disclosed by the invention has the advantages that the liquid holdup, the infiltrating property and the conductive ion migration rate of the diaphragm can be effectively increased; the resistance among the diaphragm, an electrode and electrolyte is reduced; the electrochemical performances of a supercapacitor, such as the power density and the cycle service life, can be increased; and therefore, the supercapacitor having high power density can be obtained.

Owner:锦州凯美能源有限公司

Phosphine-containing organic mixed polymer-metal heterogeneous catalyst and its preparation method and use

ActiveCN106140301ASolution to short lifeImprove utilization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFixed bedSlurry

The invention discloses a phosphine-containing organic mixed polymer-metal heterogeneous catalyst and its use in butyraldehyde production. The heterogeneous catalyst comprises one, two or three of Rh, Co and Ir as active ingredients and utilizes a multistage pore-structure phosphine-containing organic mixed polymer as a carrier. The phosphine-containing organic mixed polymer is prepared from an alkylene-containing polydentate organic phosphine ligand and a single dentate organic phosphine ligand through copolymerization. The coordination bond-type heterogeneous catalyst is suitable for a fixed bed reactor, a slurry bed reactor, a bubbling bed reactor and a trickle-bed reactor. The heterogeneous catalyst has good effects in hydrogen-propene formylation preparation of butyraldehyde, can produce high-normal / isomeric ratio butyraldehyde with a normal / isomeric ratio of 25 or more and realizes product propane content less than 0.1%. The heterogeneous catalyst has good stability and can be simply and efficiently separated from reactants and products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

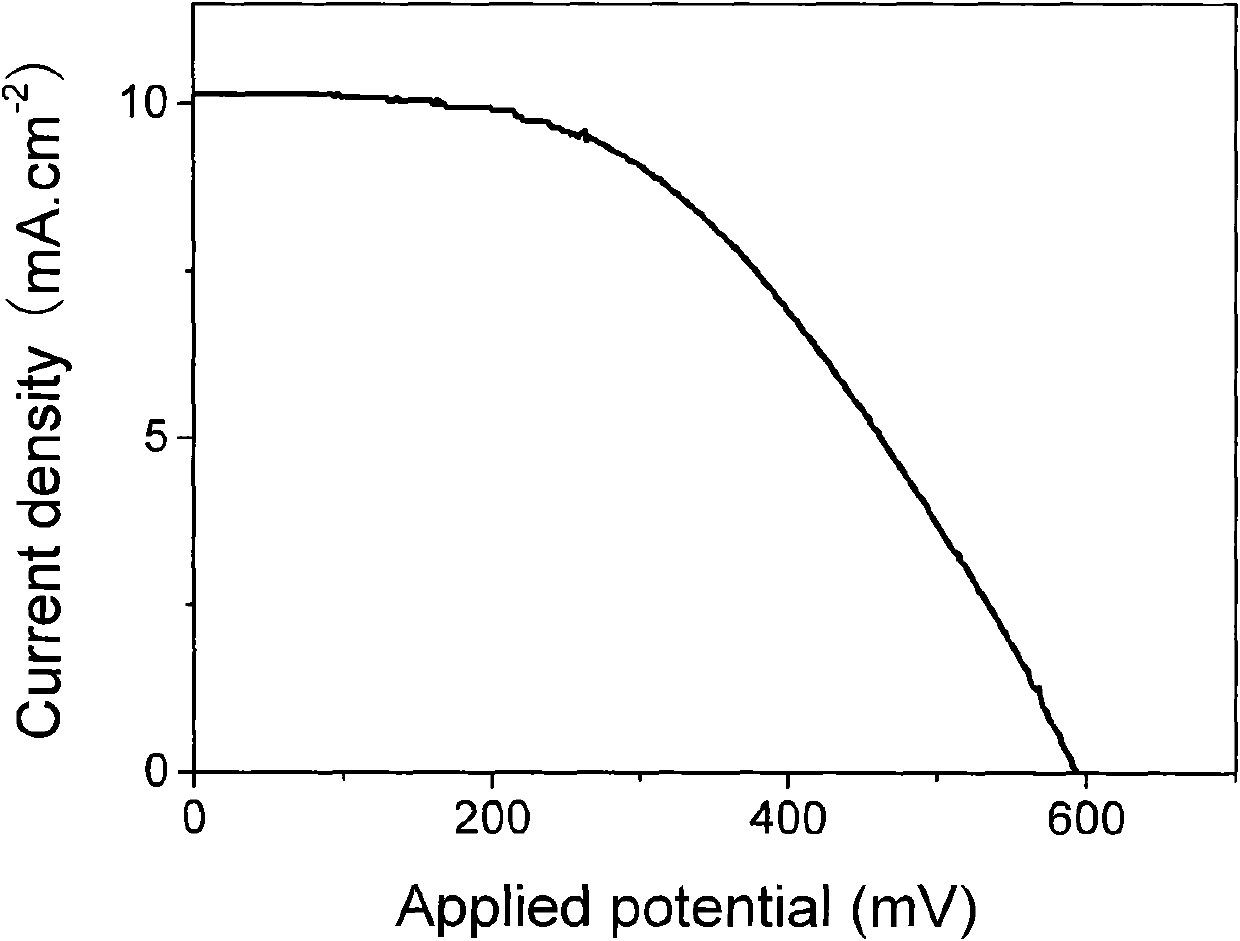

Polymer-metal ion complex gel electrolyte and preparation method and application thereof

InactiveCN102020748AImprove machinabilityOvercome the defects of poor preparation operability and poor interface contactLight-sensitive devicesSolid-state devicesPolymer metalPlasticizer

The present invention discloses a polymer-metal ion complex gel electrolyte and preparation method and application thereof. The polymer-metal ion complex provided by the present invention is prepared by the complexation of polymers and polyvalent metal salts. The polymer gel electrolyte prepared by the polymer-metal ion complex comprises polymers, polar small molecular plasticizers, polyvalent metal salts, monovalent metal salts, and iodine. The present invention also discloses a preparation method of the metal ion complex gel electrolyte. The polymer-metal ion complex gel electrolyte provided by the present invention overcomes the defects of poor maneuverability of electrolyte preparations and poor contact between interfaces in the prior art. The gel electrolyte is especially applicable to prepare dye-sensitized solar cells, which allows the photoelectric conversion efficiency of dye-sensitized solar cells to be above 5%.

Owner:INST OF CHEM CHINESE ACAD OF SCI

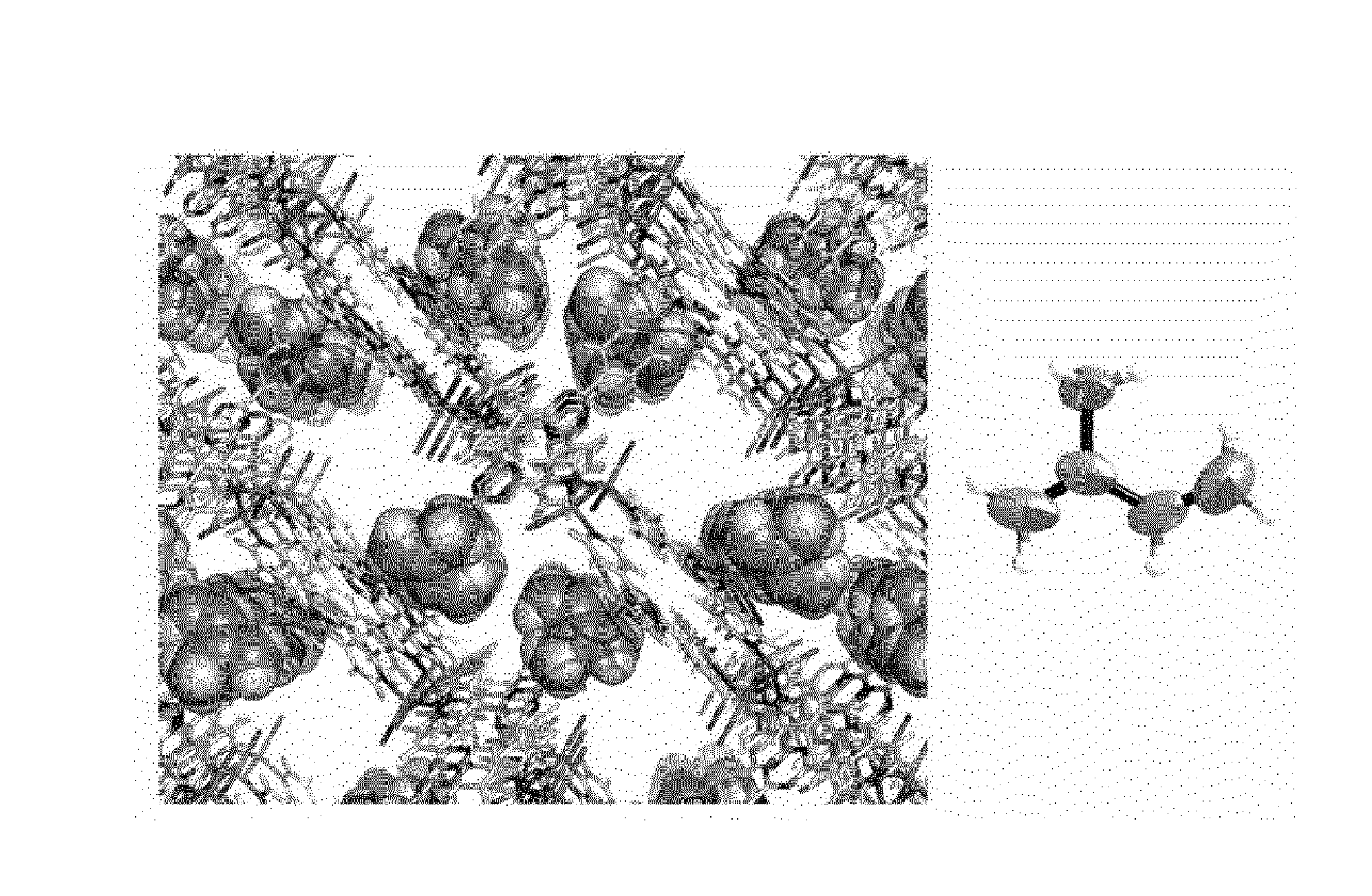

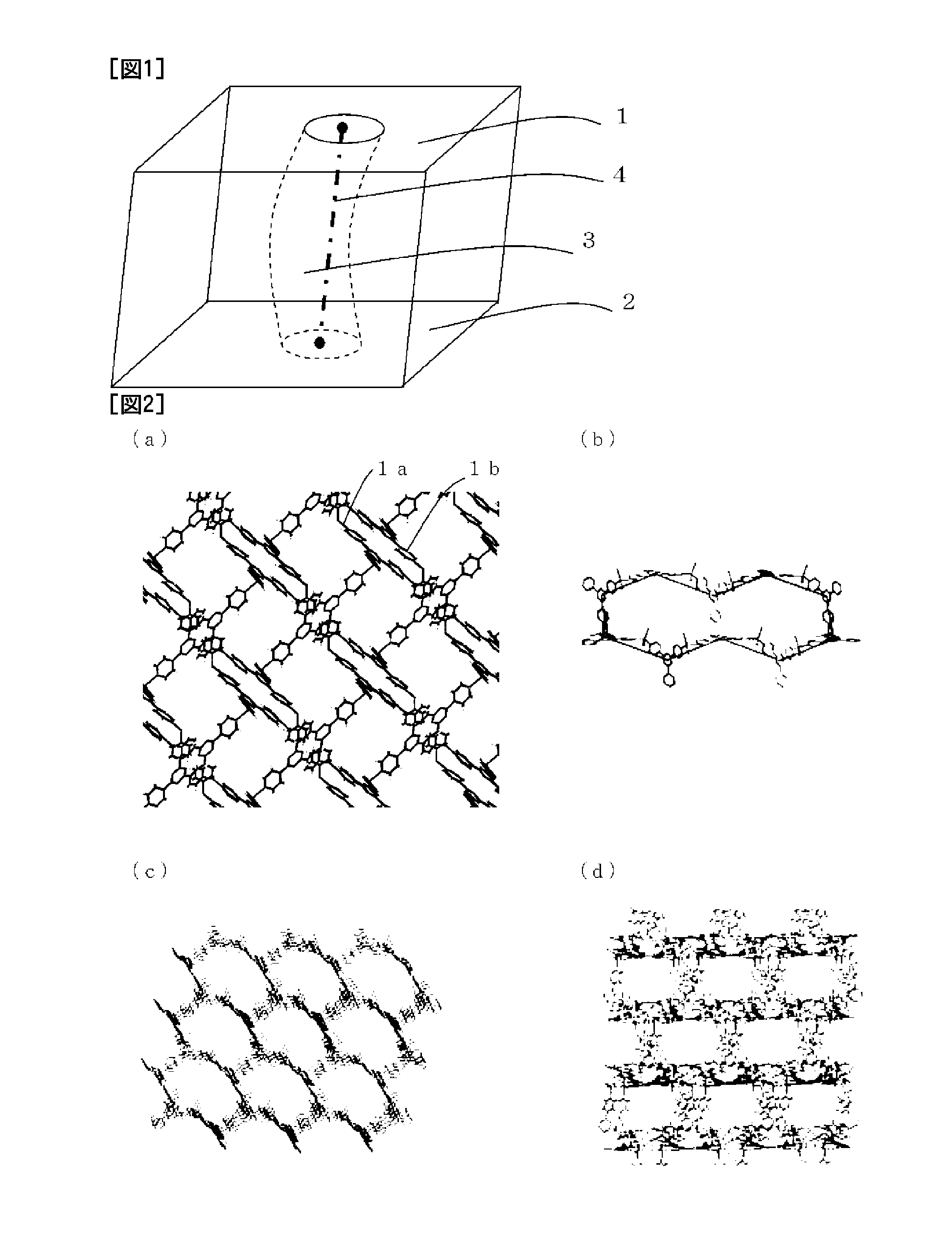

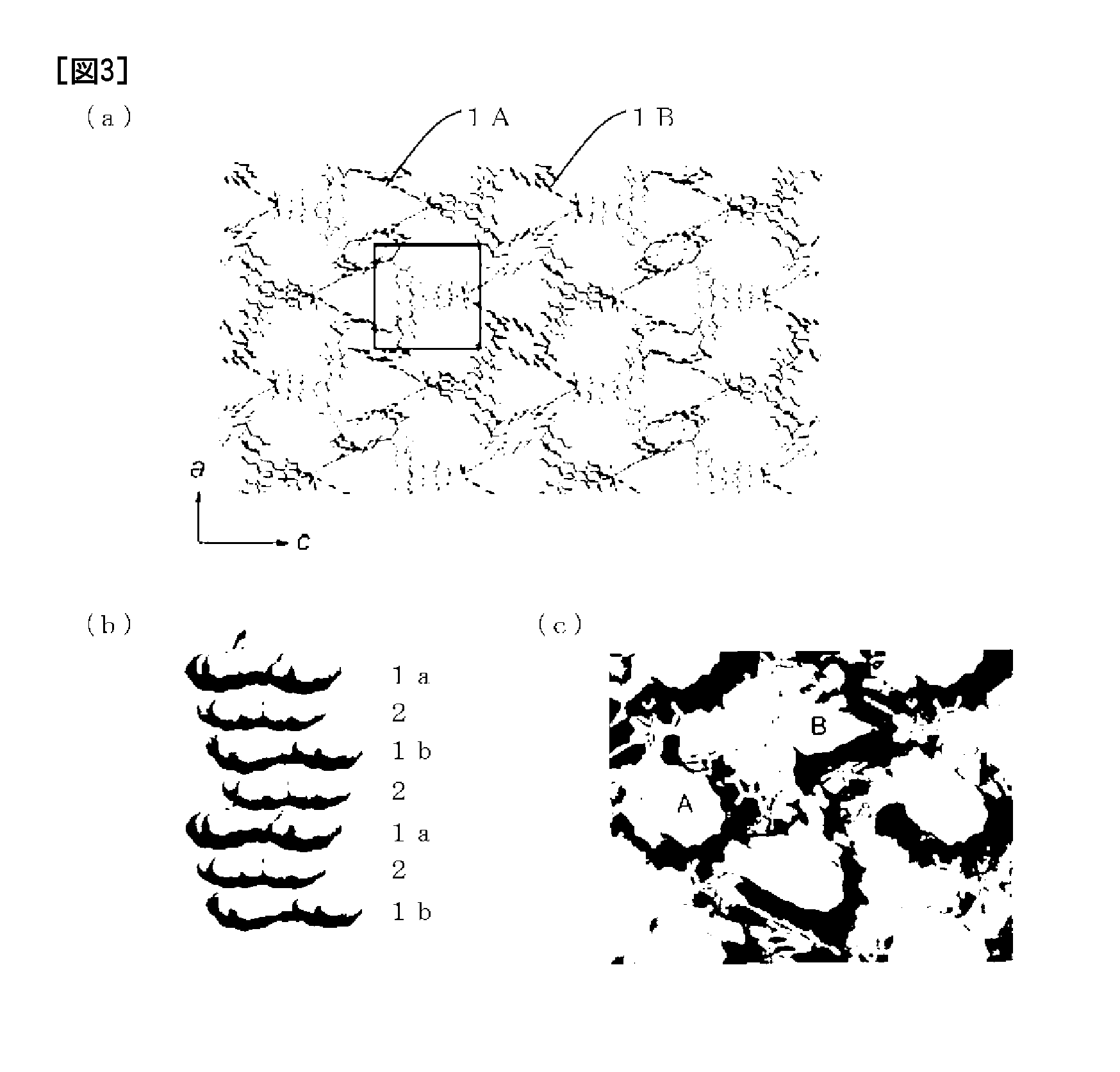

Guest-compound-enveloping polymer-metal-complex crystal, method for producing same, method for preparing crystal structure analysis sample, and method for determining molecular structure of organic compound

ActiveUS20150219533A1Efficient productionEasy and efficient to preparePolycrystalline material growthAnalysis using chemical indicatorsAlicyclic HydrocarbonsOrganic compound

The present invention is: a guest-compound-enveloping polymer-metal-complex crystal characterized by at least one selected from an aliphatic hydrocarbon, an alicyclic hydrocarbon, an ether, an ester, an aromatic hydrocarbon, a halogenated hydrocarbon, and a nitrile being enveloped as a guest compound (A) in the minute pores or the like of a polymer-metal complex that contains a metal ion as a central metal and a ligand having at least two ligating sites, has a 3D network structure formed by the ligand being ligated to the metal ion, and has the minute pores or the like regularly arranged three-dimensionally within the 3D network structure, the amount of the guest compound (A) present within the minute pores or the like being at least 60 mol % of all the guest compounds enveloped in the minute pores or the like; a method for producing the guest-compound-enveloping polymer-metal-complex crystal; a method for preparing a crystal structure analysis sample using the crystal; and a method for determining the molecular structure of an organic compound using the sample obtained by said method.

Owner:JAPAN SCI & TECH CORP

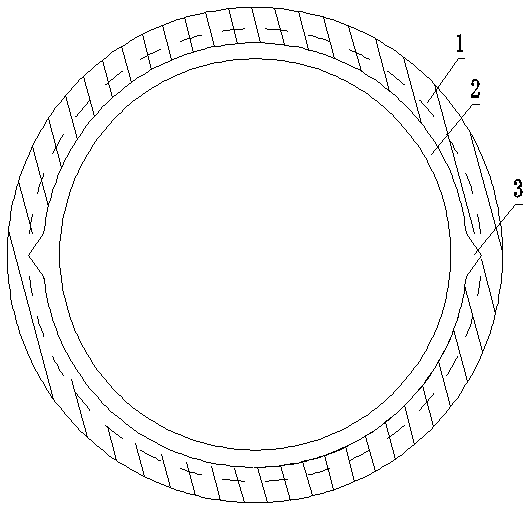

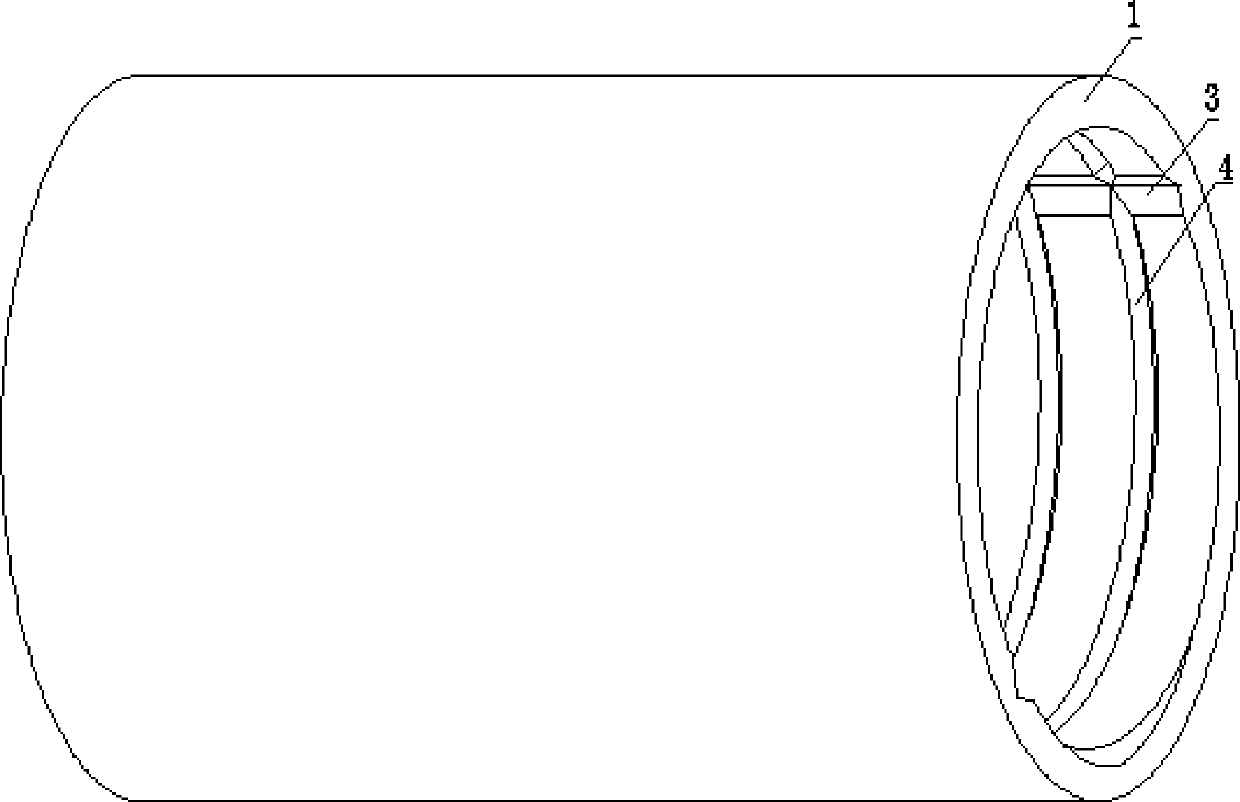

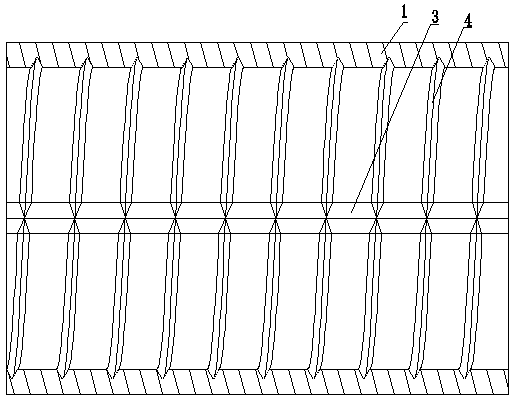

Polymer metal wear-resistant self-lubricating composite material, production method thereof, and guide bearing

ActiveCN103497483AWear-resistant and self-lubricatingHigh strengthLaminationLamination apparatusPolymer metalPotassium titanate

The invention relates to a polymer metal wear-resistant self-lubricating composite material, a production method thereof, and a manufactured guide bearing. The product comprises a metal layer and a polymer layer. The polymer layer comprises, by weight: 50-80 parts of a polymer, 10-30 parts of potassium hexatitanate whisker treated by using a coupling agent, 10-20 parts of a solid lubricant, and processing auxiliary agents. A bonding surface between the metal layer and the polymer layer has at least one straight groove on a first direction, and at least one transverse groove, inclined groove or spiral-shaped groove on a direction crossing the first direction. The production method comprises the steps that: the 50-80 parts by weight of the polymer, 10-30 parts by weight of potassium hexatitanate whisker treated by using the coupling agent, 10-20 parts by weight of solid lubricant, and processing auxiliary agents are uniformly mixed; the mixture is base-dried, extruded, and cut into particles; the particles are bake-dried; the metal layer is processed into metal parts satisfying size and structural requirements; the metal parts are preheated; the metal parts are loaded into a mold; and injection molding processing or mold pressing processing is carried out.

Owner:长沙精达高分子材料有限公司

Aromatic monomer- and conjugated polymer-metal complexes

InactiveUS20050014023A1Minimally affectSimple preparation processDischarge tube luminescnet screensGroup 8/9/10/18 element organic compoundsPolymer metalElectron delocalization

A halogenated or boronated aromatic monomer-metal complex useful for preparing a polymer for light-emitting diode (LED) device is described. The aromatic monomer-metal complex is designed to include a linking group that disrupts conjugation, thereby advantageously reducing or preventing electron delocalization between the aromatic monomer fragment and the metal complex fragment. Disruption of conjugation is often desirable to preserve the phosphorescent emission properties of the metal complex in a polymer formed from the aromatic monomer-metal complex. The resultant conjugated electroluminescent polymer has precisely controlled metal complexation and electronic properties that are substantially or completely independent of those of the polymer backbone.

Owner:SUMITOMO CHEM CO LTD

Elastic base/back surface line leading-based micro-electromechanical systems probe card and preparation method thereof

InactiveCN103412164AShorten the lengthImprove yieldElectrical measurement instrument detailsElectrical testingElectricityPolymer metal

The invention provides an elastic base / back surface line leading-based micro-electromechanical system probe card and a preparation method thereof. The preparation method comprises the following steps that: a substrate through hole is slotted on a substrate; a substrate metal structure is by electroformed the substrate through hole, and a first metal seed layer is sputtered on the back surface of the substrate; an elastic polymer layer is in coated on the substrate, and an elastic polymer through hole structure is prepared on the elastic polymer layer; an elastic polymer metal structure is electroformed in the elastic polymer through hole structure; a second metal seed layer is sputtered on the elastic polymer layer, and a metal circuit layer is prepared on the second metal seed layer; a metal probe structure is prepared on the metal circuit layer; the first and second metal seed layers are removed, and the substrate is arranged on a printed circuit board in a surface mounting manner, such that the elastic base / back surface lead line-based micro-electromechanical systems probe card can be obtained. According to the elastic base / back surface line leading-based micro-electromechanical system probe card and the preparation method thereof provided by the invention, a back surface line leading method is adopted so as to directly connect the prepared probe card with a testing machine stage change-over card; and the elastic base / back surface line leading-based micro-electromechanical system probe card and the preparation method thereof are advantageous in omission of spot welding procedures, simplification of process and improvement of rate of finished products.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com