Metal-doped nitrogen-containing carbon-based catalyst of fuel cell and application thereof

A metal doping and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., to achieve the effects of increased dispersion, low price, and large active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

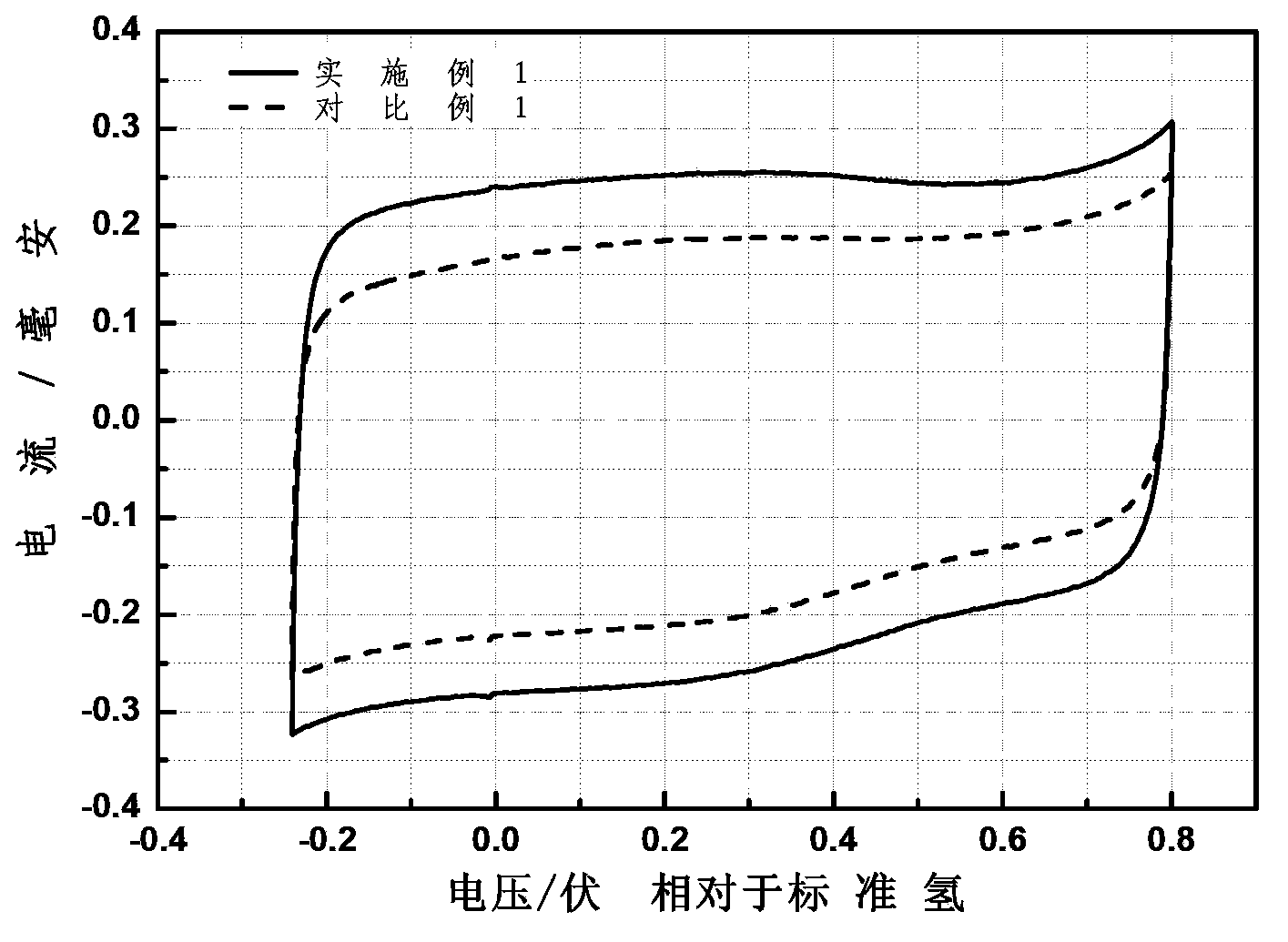

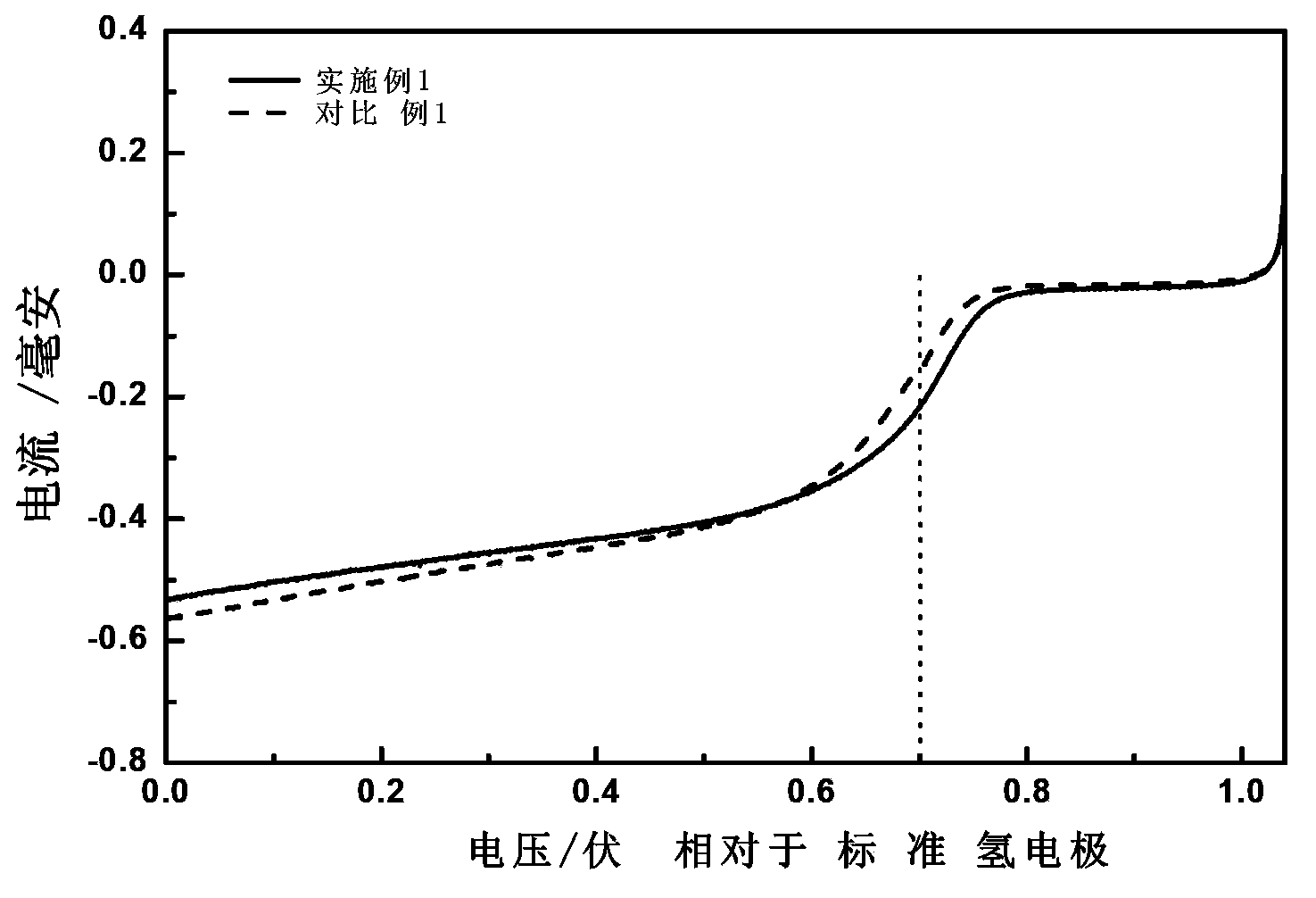

Embodiment 1

[0054] Dissolve 6.16 resorcinol in 7mL deionized water to form solution A; then add dropwise 8.4ml of formaldehyde solution with a mass concentration of 37% to form transparent solution B, stir evenly and add lye dropwise to B to adjust The pH value is about 8, then add 0.815g cobalt nitrate to it, stir evenly, add 0.4g CTAB / ethanol, stir further until the reaction forms gel C; transfer gel C to a vacuum drying oven for vacuum drying at 80°C Aging treatment for 6d, crushing and grinding after taking out to obtain solid powder D; 3 Nitriding treatment in the atmosphere for 2h to obtain a solid powder product.

[0055] The electrode preparation is as follows: Measure 5 mg of catalyst, 1 ml of absolute ethanol, and 50 μl of 5% Nafion solution. After mixing, ultrasonically oscillate evenly, and transfer 10 μl to an area of 0.1256 cm 2 On the glassy carbon disk electrode, it becomes a thin film electrode after drying. The specific electrode is a saturated KCl calomel electrode ...

Embodiment 2

[0059] Dissolve 6.16 resorcinol in 7mL deionized water to form solution A; then add dropwise 8.4ml of formaldehyde solution with a mass concentration of 37% to form transparent solution B, stir evenly and add lye dropwise to B to adjust The pH value is about 8, then add 0.815g cobalt nitrate to it, stir evenly, add 0.4g CTAC / ethanol, stir further until the reaction forms gel C; transfer gel C to a vacuum drying oven for vacuum drying at 80°C Aging treatment for 6d, crushing and grinding after taking out to obtain solid powder D; 3 Nitriding treatment in the atmosphere for 2h, to obtain solid powder E.

Embodiment 3

[0061] Dissolve 7.06g of melamine in 10mL of deionized water to form solution A; add dropwise 12.3ml of formaldehyde solution with a mass concentration of 37% to the stirring solution A, stir at 60°C to form a transparent solution B, and adjust the pH value to about 8, keep stirring to obtain solution C, take 0.4074g cobalt nitrate solid and add it to the above transparent solution C, mix well to obtain solution D; after stirring evenly, add ethanol solution containing 0.4g CTAB, and stir further until the reaction forms a gel E; transfer the gel E to a vacuum drying oven for 3 days of vacuum drying and aging treatment at 80°C, take it out and grind it to obtain a solid powder F; put the solid powder F in NH 3 Carbonization treatment at 800°C for 2 hours in the atmosphere to obtain solid powder G, which was treated with 2M HNO 3 The solution was washed to remove the metal to obtain H as a solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com