A method for refining mesophase pitch by hydrogenation and chain transfer modification

A mesophase asphalt and modified asphalt technology, which is applied in the direction of processing tar asphalt/petroleum asphalt/natural asphalt by distillation, and processing tar asphalt/petroleum asphalt/natural asphalt by chemical methods, which can solve the problem of difficult to improve the quality of mesophase asphalt, etc. problems, to achieve the effect of low cost, guaranteed uniformity, and high structural controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

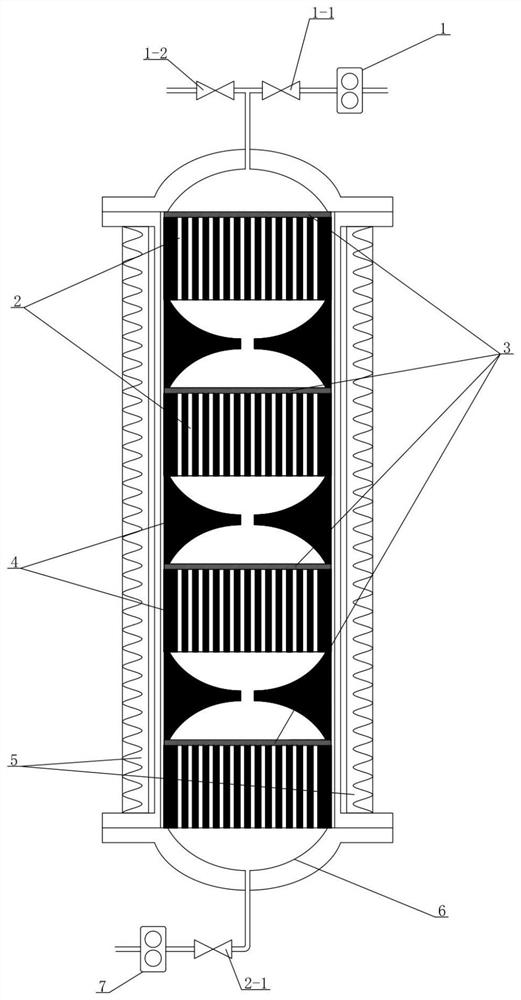

Image

Examples

Embodiment 1

[0035] A new method for hydrogenation and chain transfer modification to refine mesophase pitch raw materials and a special reactor for pressurized polymerization, characterized in that it includes the following steps:

[0036] (1) Heat 500kg / h precursor pitch to 60°C through a heat exchanger, and pump it into the first-stage molecular still to separate the 240°C fraction by a gear pump. The operating temperature is 25°C, the operating pressure is 0.1mbar, and the rotation speed is 380r / min 25kg / h of light components and 475kg / h of heavy components were obtained, and the obtained heavy components were pumped into the second stage molecular still to cut fractions again. The operating temperature was 210°C, the operating pressure was 0.1mbar, and the rotating speed was 380r / min to obtain the A1 fraction 295kg / h, B1 fraction 180kg / h;

[0037] (2) Heat the obtained A1 fraction to 280°C and pump it into a three-stage hydrotreating reactor with a weighted average bed temperature of ...

Embodiment 2

[0044] A new method for hydrogenation and chain transfer modification to refine mesophase pitch raw materials and a special reactor for pressurized polymerization, characterized in that it includes the following steps:

[0045] (1) Heat 500kg / h precursor pitch to 60°C through a heat exchanger, and pump it into the first-stage molecular still to separate the 240°C fraction by a gear pump. The operating temperature is 25°C, the operating pressure is 0.1mbar, and the rotation speed is 380r / min 27kg / h of light components and 473kg / h of heavy components were obtained, and the obtained heavy components were pumped into the second-stage molecular still to cut fractions again. The operating temperature was 210°C, the operating pressure was 0.1mbar, and the rotating speed was 380r / min to obtain the A1 fraction 292kg / h, B1 fraction 181kg / h;

[0046] (2) Heat the obtained A1 fraction to 280°C and pump it into a three-stage hydrotreating reactor with a weighted average bed temperature of ...

Embodiment 3

[0053] A new method for hydrogenation and chain transfer modification to refine mesophase pitch raw materials and a special reactor for pressurized polymerization, characterized in that it includes the following steps:

[0054] (1) Heat 500kg / h precursor pitch to 60°C through a heat exchanger, and pump it into the first-stage molecular still to separate the 240°C fraction by a gear pump. The operating temperature is 25°C, the operating pressure is 0.1mbar, and the rotation speed is 380r / min 23kg / h of light components and 477kg / h of heavy components were obtained, and the resulting heavy components were pumped into the second-stage molecular still to cut fractions again. The operating temperature was 210°C, the operating pressure was 0.1mbar, and the rotating speed was 380r / min to obtain the A1 fraction 293kg / h, B1 fraction 184kg / h;

[0055] (2) Heat the obtained A1 fraction to 280°C and pump it into a three-stage hydrotreating reactor with a weighted average bed temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com