Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

An energy-saving film and transparent violet technology, which is applied in the field of high-transparency UV-blocking energy-saving film and its preparation, can solve the problems of not mentioning industrialization data and application prospects, unable to truly realize mass production, and unsuitable for large-scale industrial production. , to achieve the effect of increasing anti-ultraviolet energy-saving performance, excellent ultraviolet shielding performance, and overcoming poor storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) The coarse dispersion system of ZnO nanoparticle methanol solution was centrifuged and washed, then added to absolute ethanol, and the uniformly dispersed zinc oxide nanoparticle ethanol dispersion was made by ultrasonication. The concentration of zinc oxide nanoparticles in the dispersion was 5.88 wt%, in the shape of a long rod with a diameter of about 50nm;

[0042] 2) Take 16ml of the dispersion in step 1), add 4ml of absolute ethanol, and mix evenly with magnetic stirring. After ultrasonic treatment for 4 hours, add 0.8g PVB powder, mix evenly with magnetic stirring, and ultrasonically disperse for 0.5h to prepare the film-making stock solution , the parameters of the obtained film-making stock solution system are shown in Table 1-1;

[0043] Concentration of ZnO in EtOH (g / ml)

[0044] Table 1-1

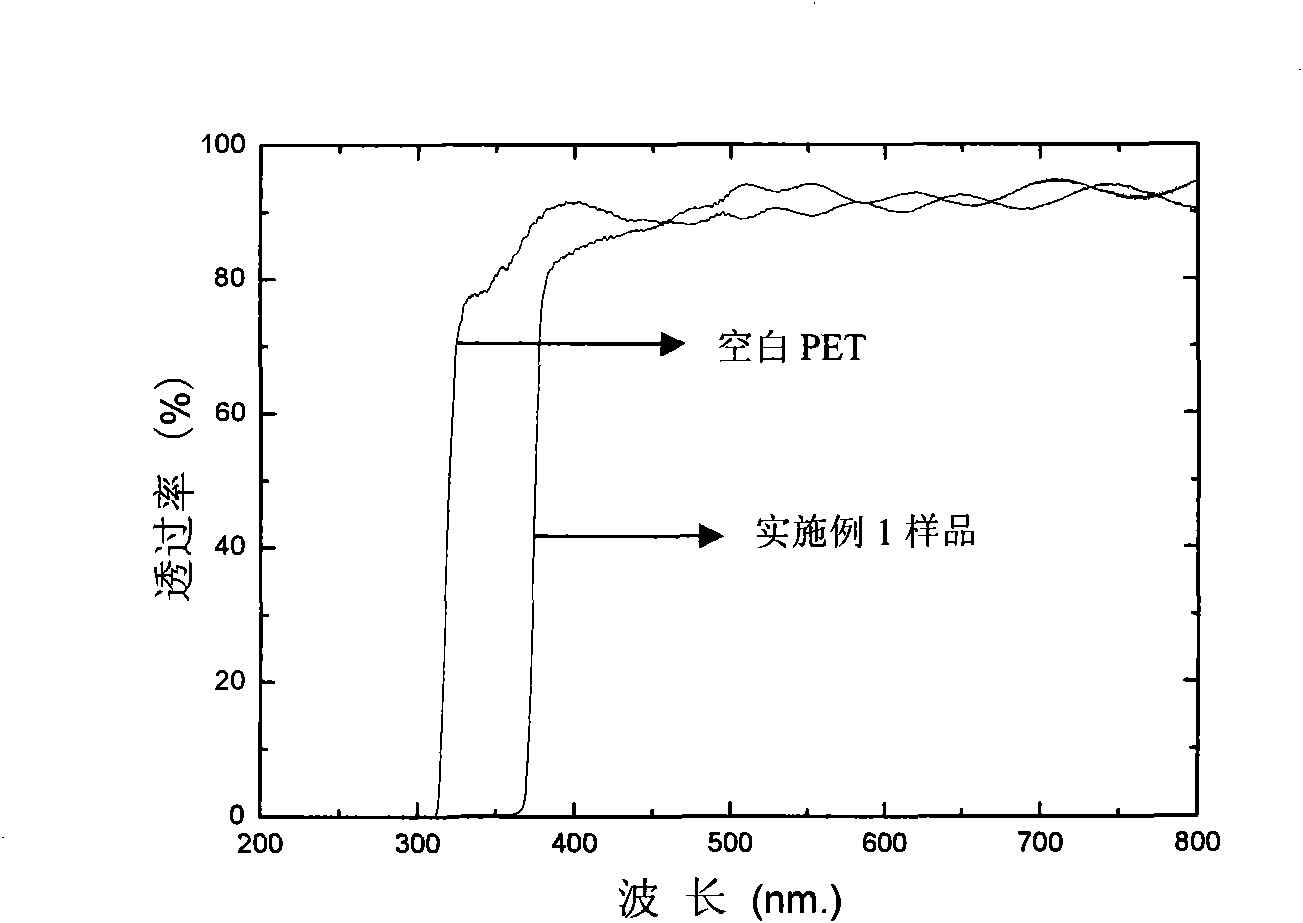

[0045] 3) Select the PET substrate for film formation: after the PET substrate is pretreated with deionized water and alcohol, it is fixed on the clip of t...

Embodiment 2

[0049] 1) The ZnO nanoparticle n-hexane coarse dispersion system is centrifuged and washed, then added to the toluene solution, and ultrasonically dispersed to make a zinc oxide nanoparticle toluene dispersion, and the concentration of the zinc oxide nanoparticle in the dispersion is 5wt%. Spherical shape, particle size 10-20nm;

[0050] 2) Measure the toluene solution, PMMA-PS (polymethyl methacrylate PMMA and polystyrene PS copolymer) and the zinc oxide nanoparticle toluene dispersion liquid in step 1) respectively by the ratio of Table 2-1, Mix evenly with magnetic stirring to obtain the film-making stock solution;

[0051] Concentration of ZnO in toluene (g / ml)

[0052] table 2-1

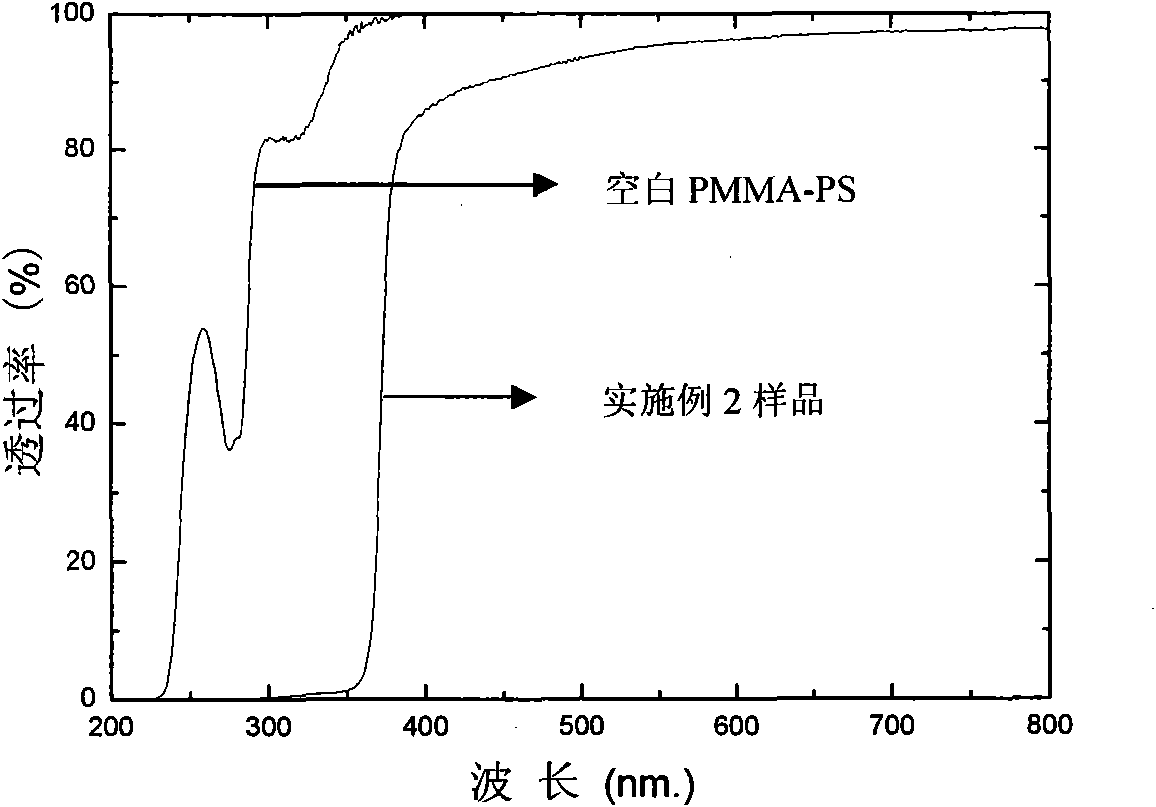

[0053] 3) Cast the film-making stock solution obtained in step 2) into a mold for direct molding, and the thickness of the obtained film is 300 μm. The optical performance test results are shown in Table 2-2.

[0054] Visible light transmittance (%) (550nm)

[0055] Table 2...

Embodiment 3

[0057] 1) Add the ZnO nanoparticle n-hexane coarse dispersion system to the butanone solution after centrifugation and washing, and ultrasonically disperse to make a zinc oxide nanoparticle butanone dispersion with a concentration of 5wt%. The zinc oxide nanoparticle in the dispersion is Spherical shape, particle size 10-20nm;

[0058] 2) Measure the butanone solution, the polymer PMMA-PS, and the zinc oxide nanoparticle butanone dispersion in step 1) according to the ratios in Table 3-1, and stir and mix evenly to obtain the film-forming stock solution;

[0059] Concentration of ZnO in butanone (g / ml)

[0060] Table 3-1

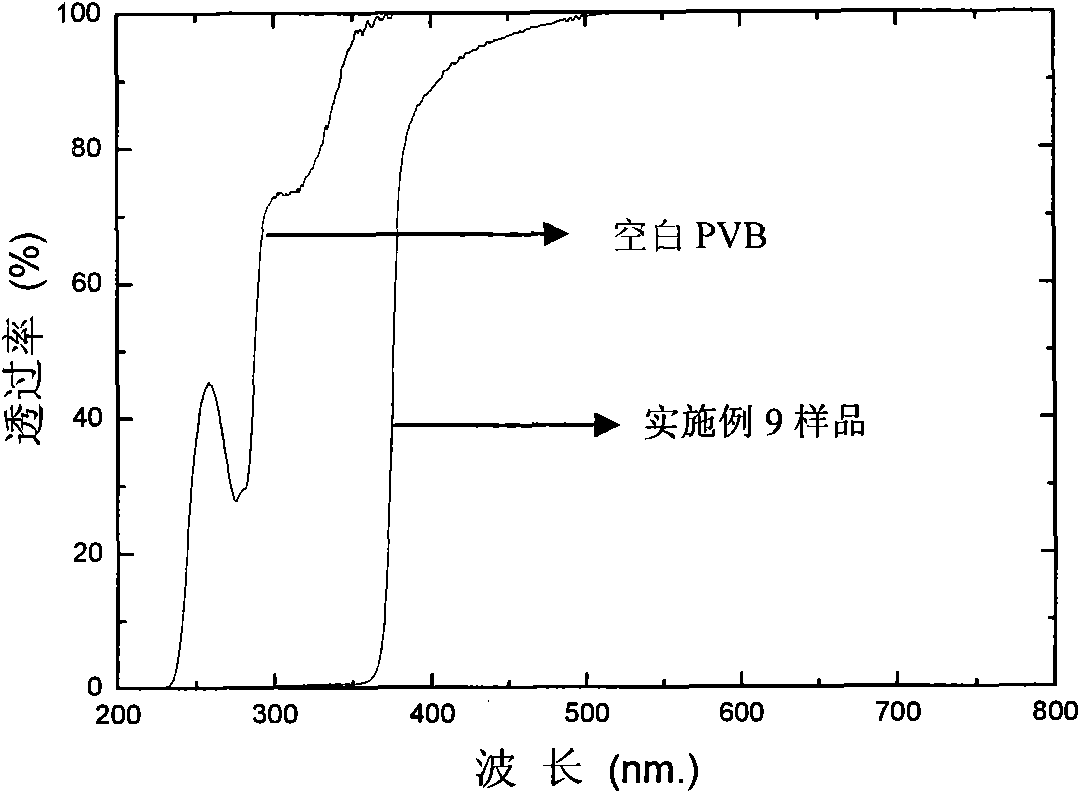

[0061] 3) Cast the film-making stock solution obtained in step 2) into a mold for direct molding, and the thickness of the obtained film is 300 μm. The optical performance test results are shown in Table 3-2.

[0062] Visible light transmittance (%) (550nm)

[0063] Table 3-2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com