Patents

Literature

1266results about "Preparation by carbon monoxide reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing hydrocarbons and oxygen-containing compounds from biomass

InactiveUS20050112739A1Improve direct utilizationImprove utilizationOrganic compound preparationHydrocarbon by hydrogenationChemical industryChemical reaction

The present invention generally relates to biochemical and chemical industry, and more particularly to a method which can be used in fermenting carbohydrate substrates of plant origin for producing C1-C5 alcohols, and for synthesis of higher alcohols, other oxygen-containing compounds and hydrocarbons as well as for the production of motor fuel components from biomass. Since C6 and higher alcohols, ethers, acetals, and higher hydrocarbons are not obtainable by a direct biochemical route, it is proposed to synthesize these using known chemical reactions, wherein by-products of fermentation are as raw materials for said synthesis.

Owner:SWEDISH BIOFUELS AB

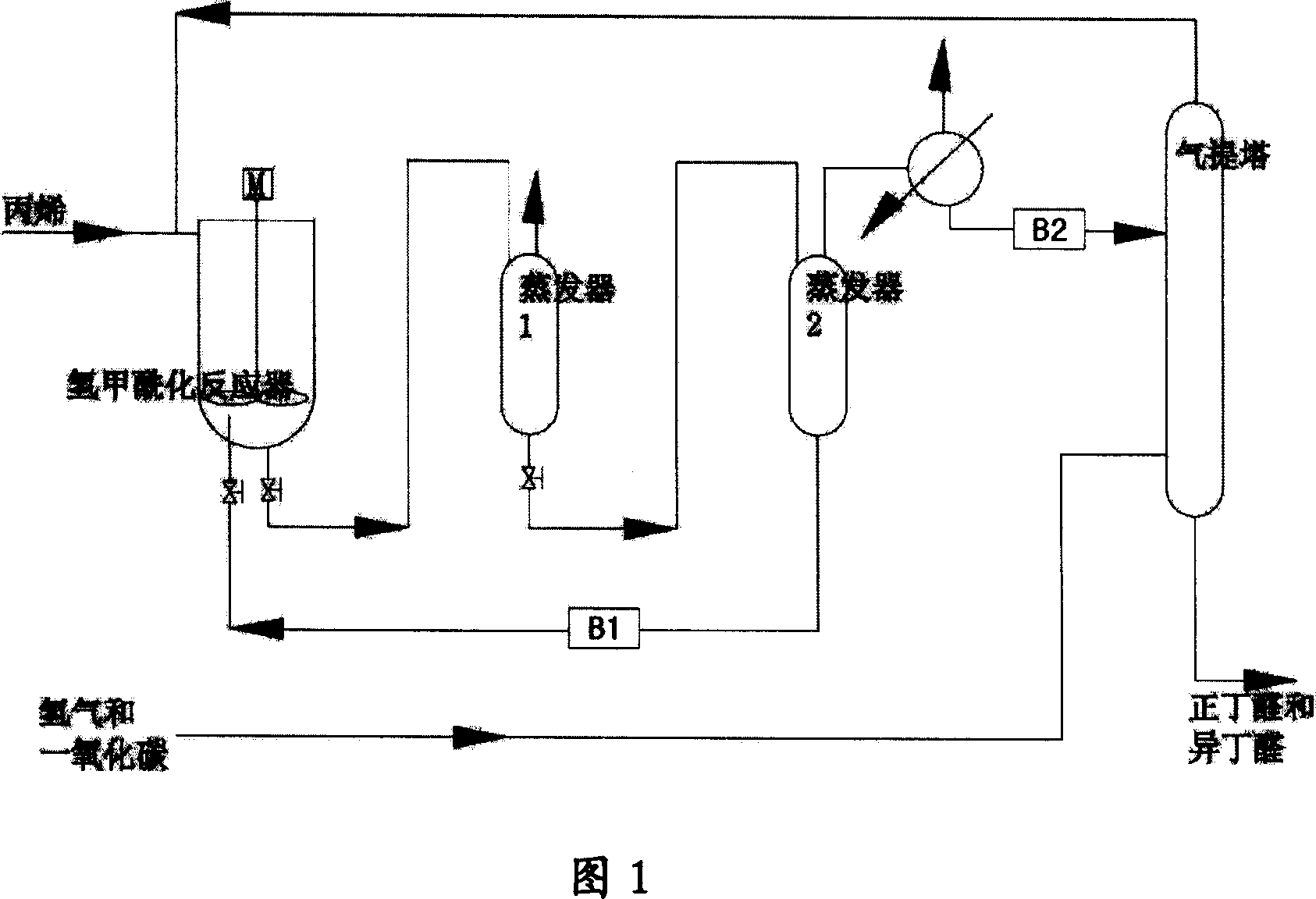

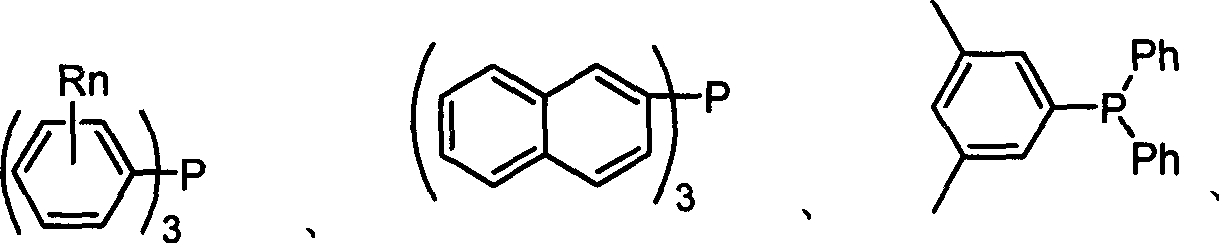

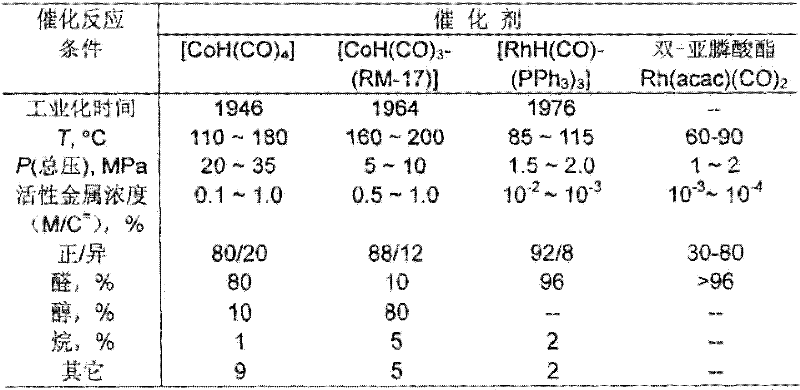

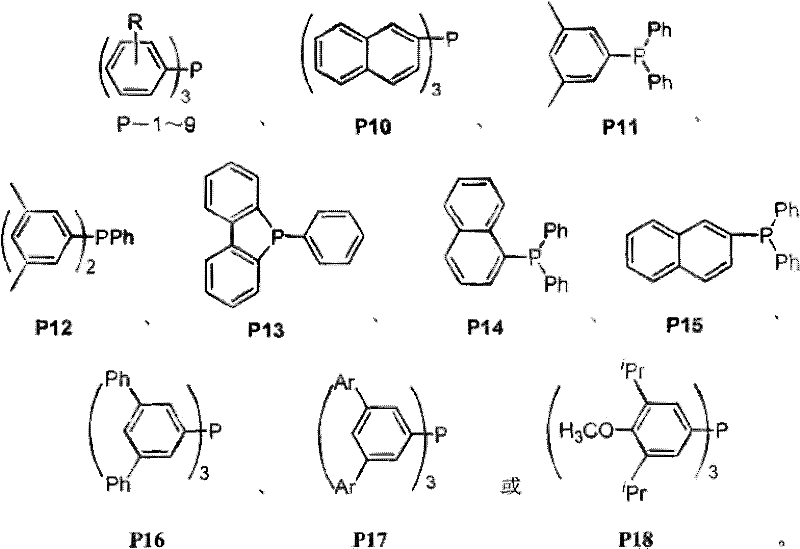

Catalyst system and catalyzing method of propylene hydrogenation and formylation

ActiveCN1986055AReduce dosageImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionTriphenylphosphine

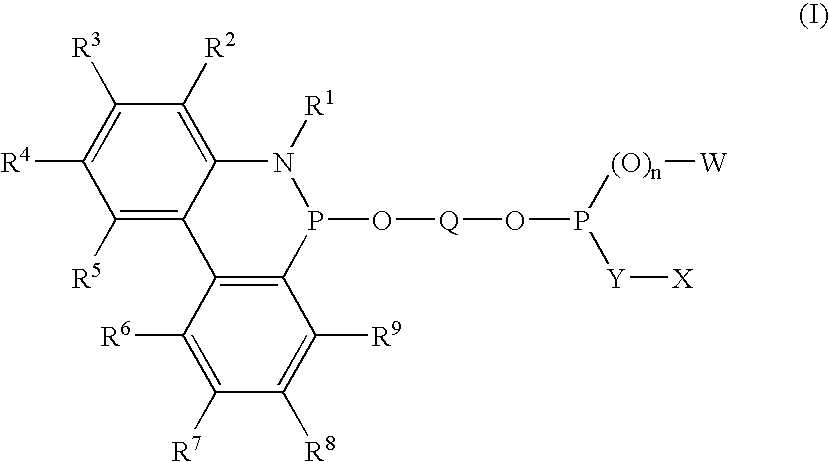

The present invention relates to catalyst system for propylene hydrogenation and formylation and process of catalytically synthesizing butyl aldehyde. The catalyst system is triaryl phosphine-Rh(I) catalyst system with proper additive, such as bisphosphite ester, in proper amount. Compared with similar available catalyst, the catalyst system has obviously higher catalytic acitivity, higher selectivity, higher stability and raised n-butyl aldehyde / isobutyl aldehyde ratio in the catalytically synthesized product.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

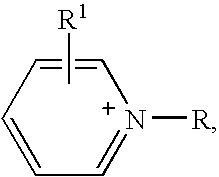

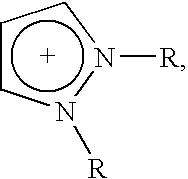

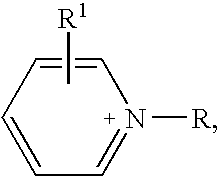

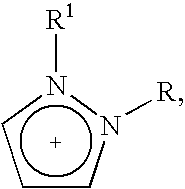

Ionic liquids

InactiveUS7252791B2Stable to hydrolysisImprove the level ofPreparation by carbon monoxide reactionDissolvingHeat carrierChemical reaction

Low melting ionic compounds of the general formula (cation) (R′SO4) in which R′ is a branched or linear, saturated or unsaturated, aliphatic or alicyclic functionalized or non-functionalized hydrocarbon chain with 3-36 carbon atoms are provided. These compounds can serve as ionic liquids, e.g. as solvents or solvent additives in chemical reactions, as extraction agents or as heat carriers. The compounds comprise a cation and anionic sulfate ester.

Owner:MERCK PATENT GMBH

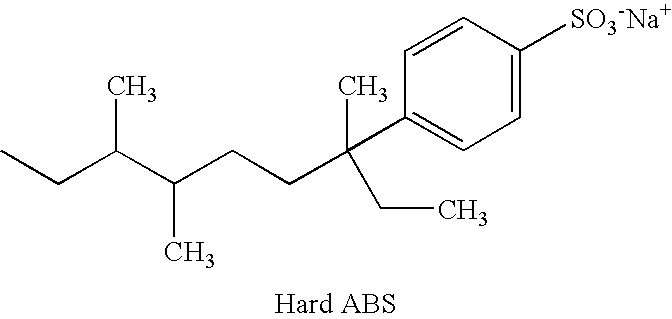

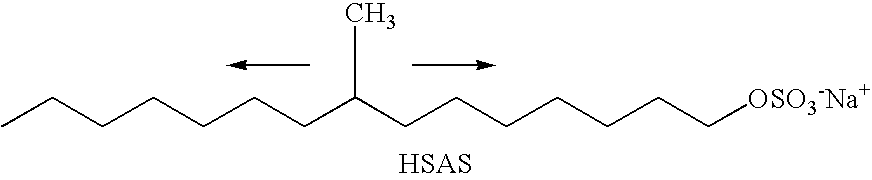

Specific Branched Aldehydes, Alcohols, Surfactants, and Consumer Products Based Thereon

ActiveUS20100137649A1Promote degradationImprove solubilityOxygen-containing compound preparationPreparation by oxo-reaction and reductionHydrogenAlcohol

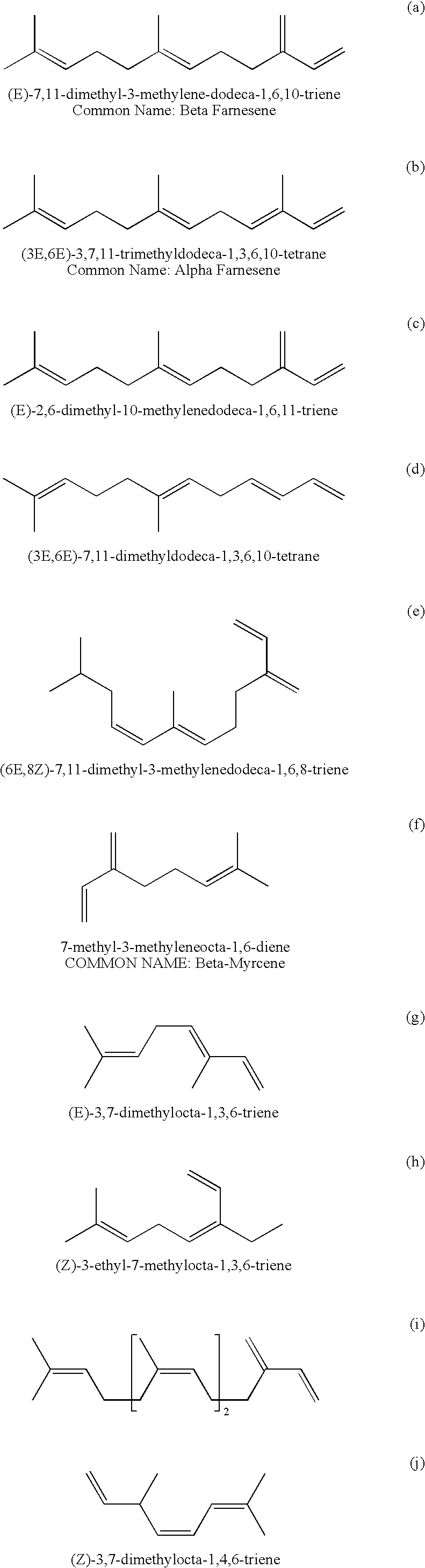

A process for preparing a detergent alcohol mixture comprising the steps of providing one or more poly-branched poly-olefins, wherein the poly-branched poly-olefins must contain one non-branched terminal olefin and one or more additional branched olefins in the molecule; hydroformylating said poly-branched poly-olefins to produce a poly-branched olefin containing aldehyde product with one or more olefins or mixture thereof; reducing the aldehyde product of step (b) in the presence of hydrogen and a hydrogenation catalyst to form a poly-branched detergent alcohol mixture; and removing said poly-branched alcohol mixture from said catalyst and branched aldehydes, alcohols and surfactants produced from the products of this process.

Owner:PROCTER & GAMBLE CO

Process for the synthesis of alpha-substituted acroleins

InactiveUS7141702B2Organic compound preparationPreparation by carbon monoxide reactionSyngasMannich reaction

Owner:COUNCIL OF SCI & IND RES

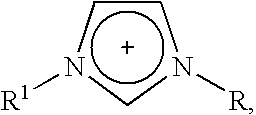

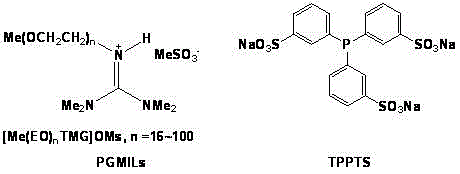

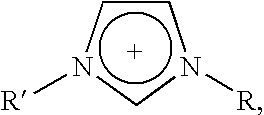

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

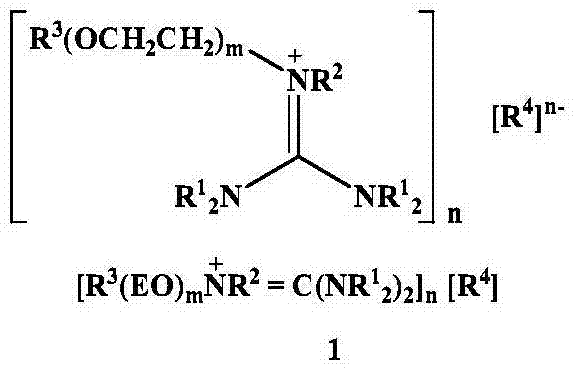

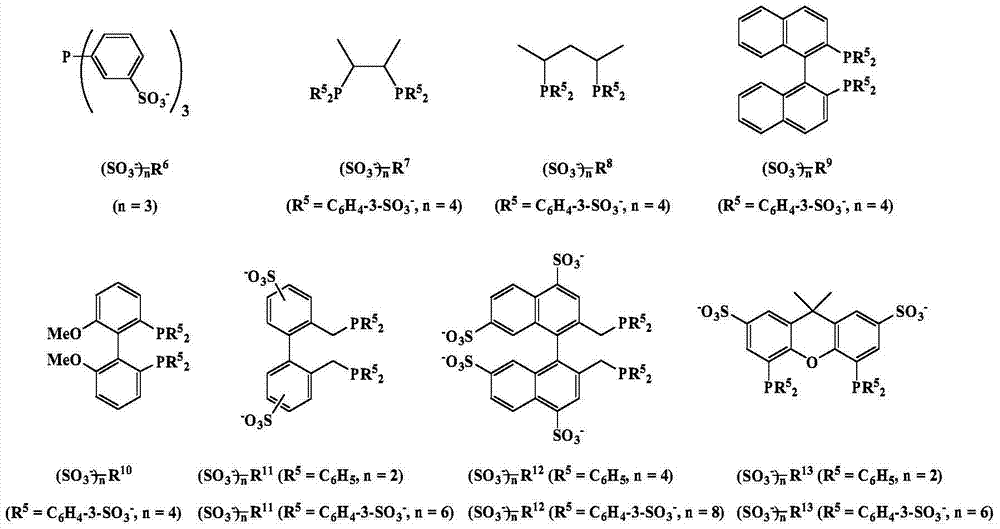

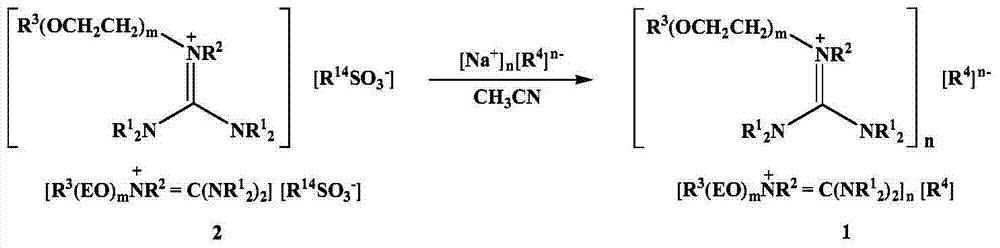

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

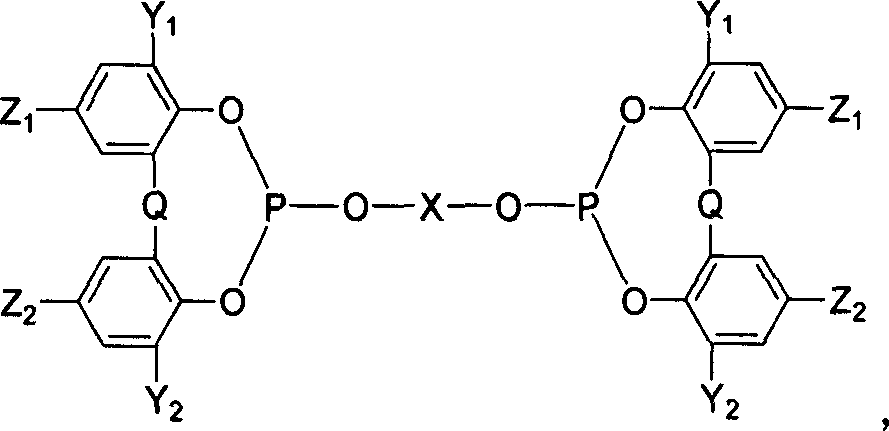

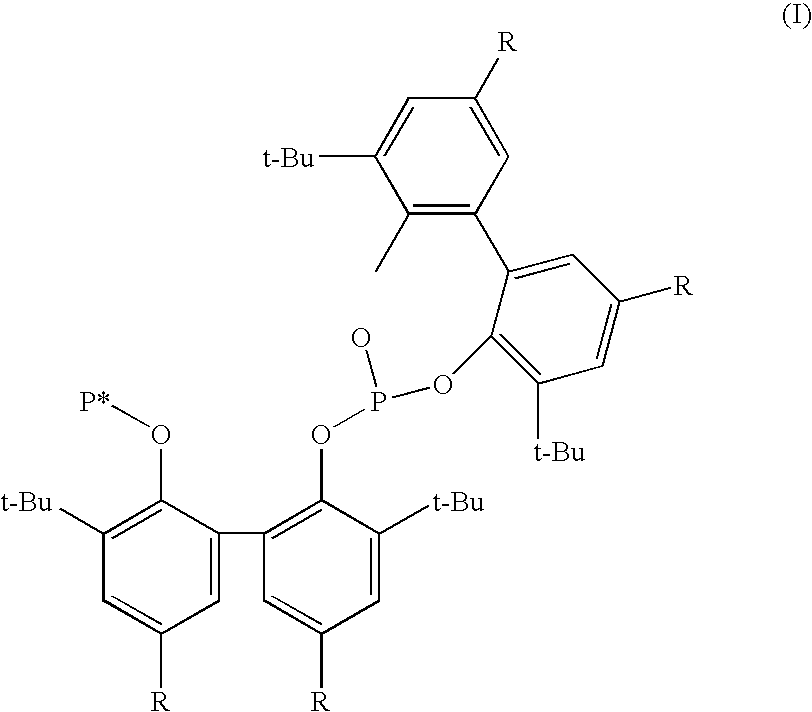

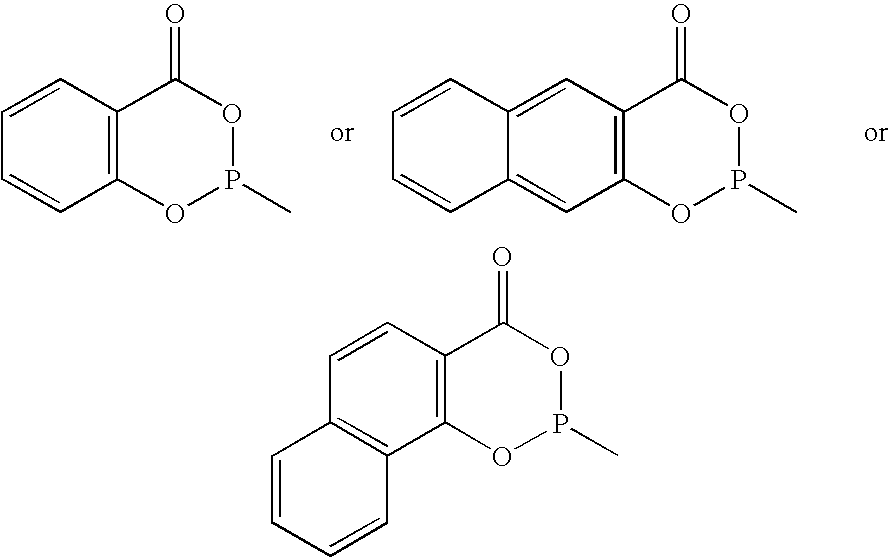

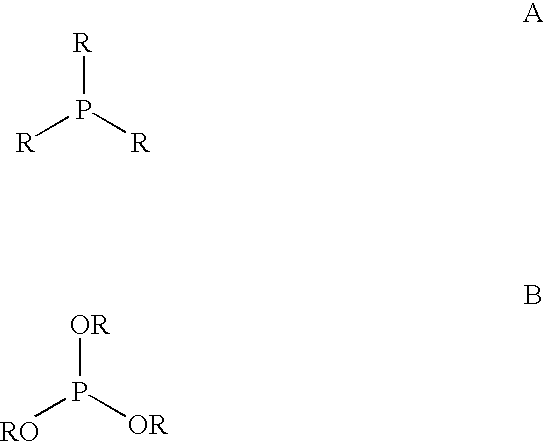

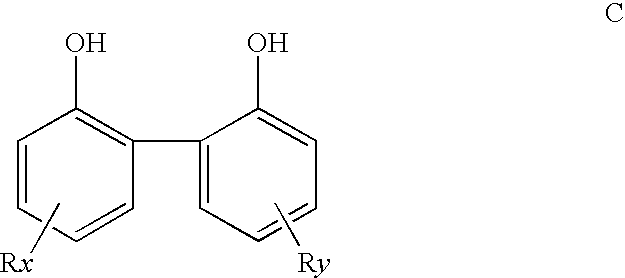

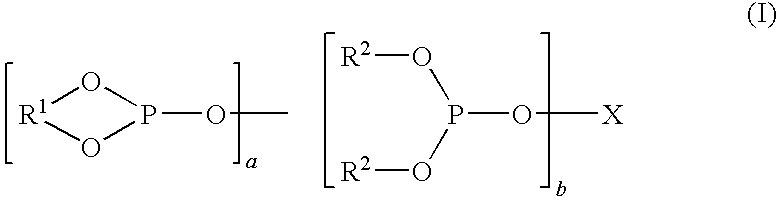

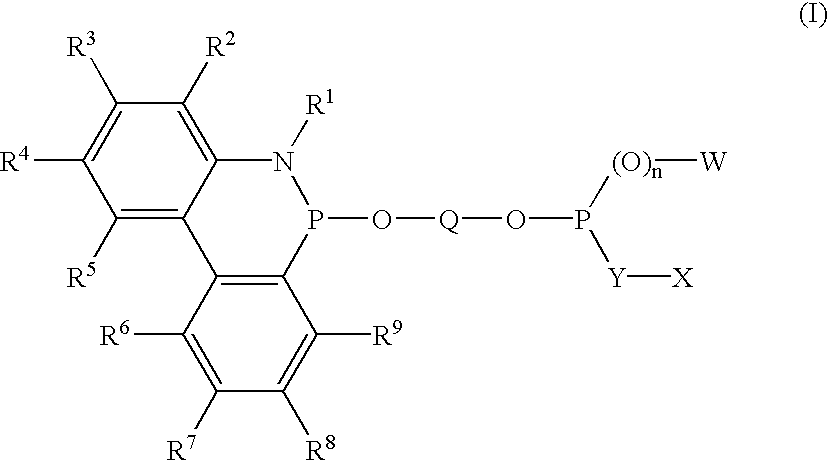

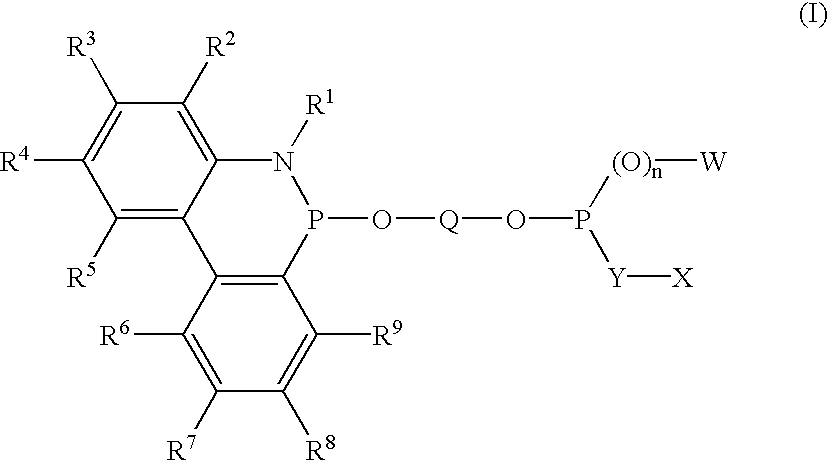

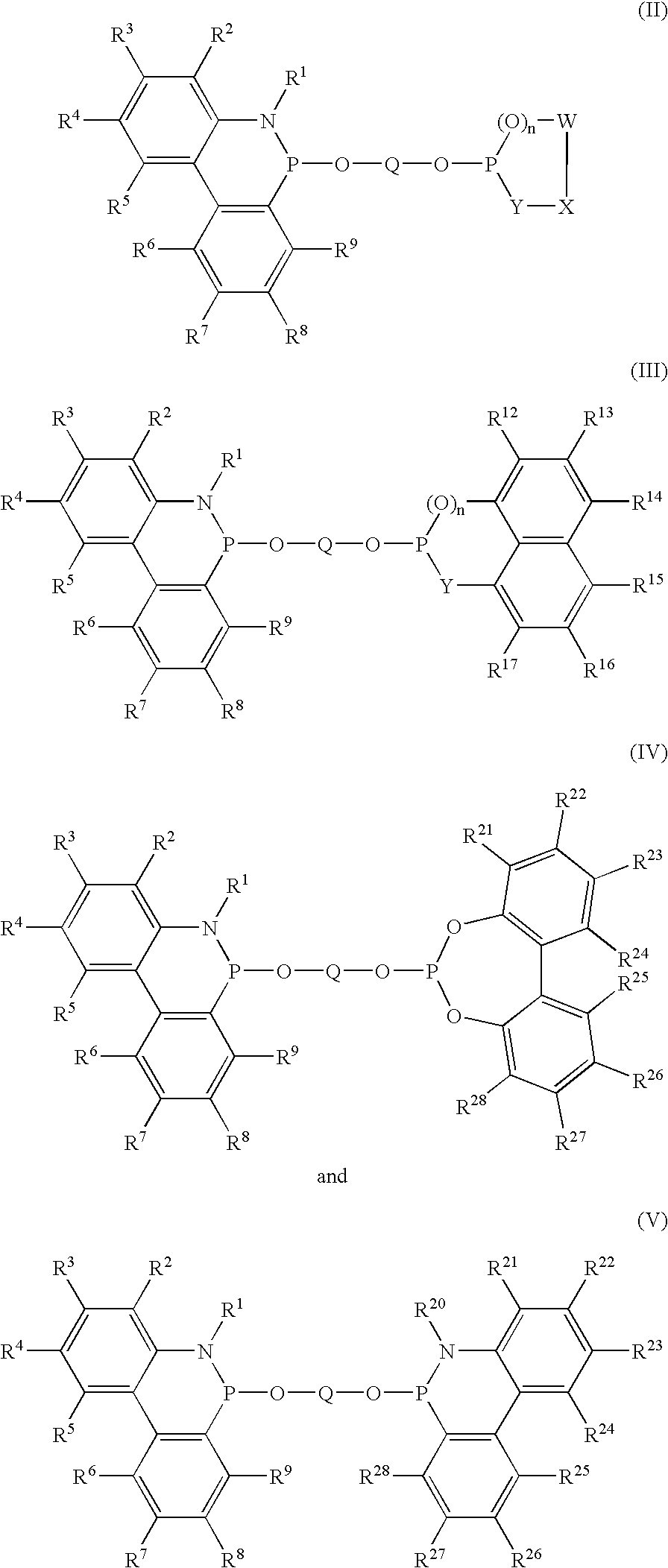

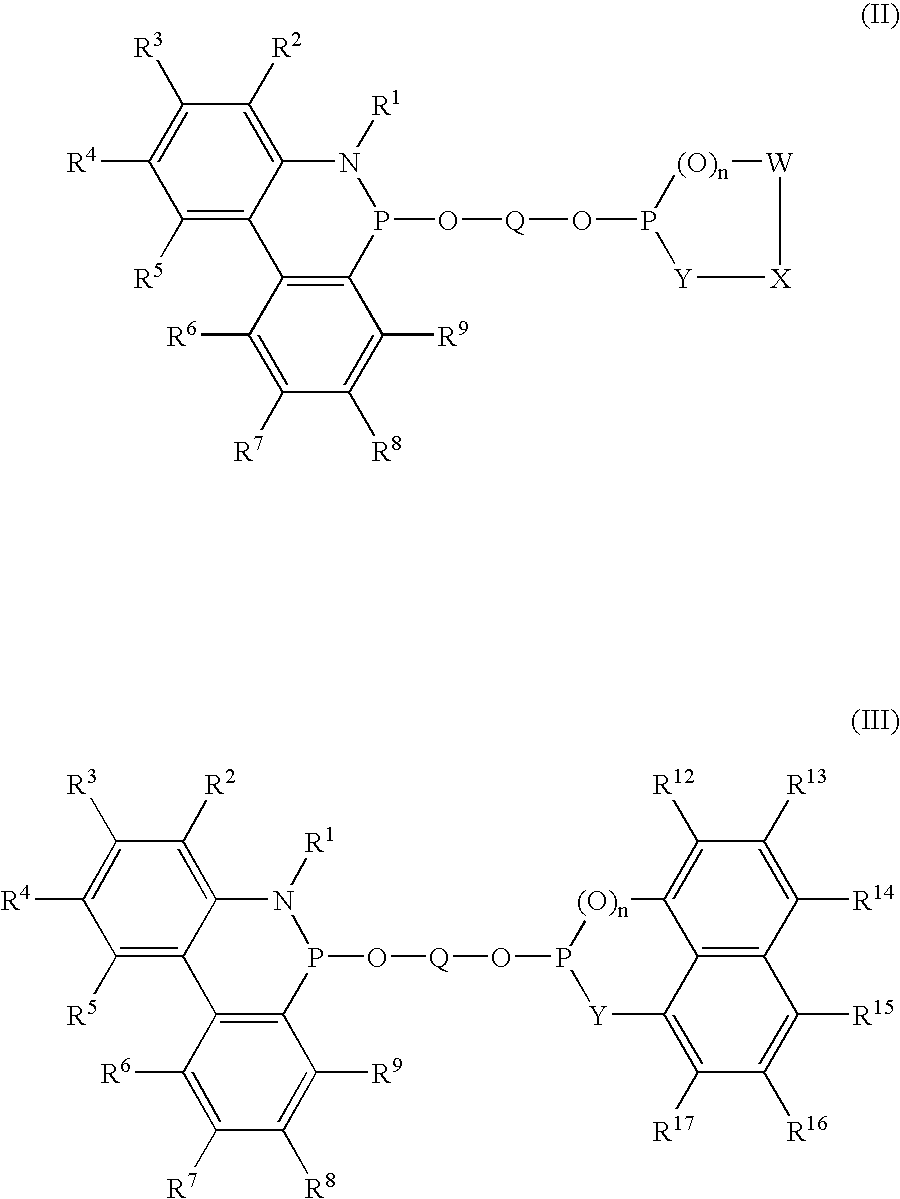

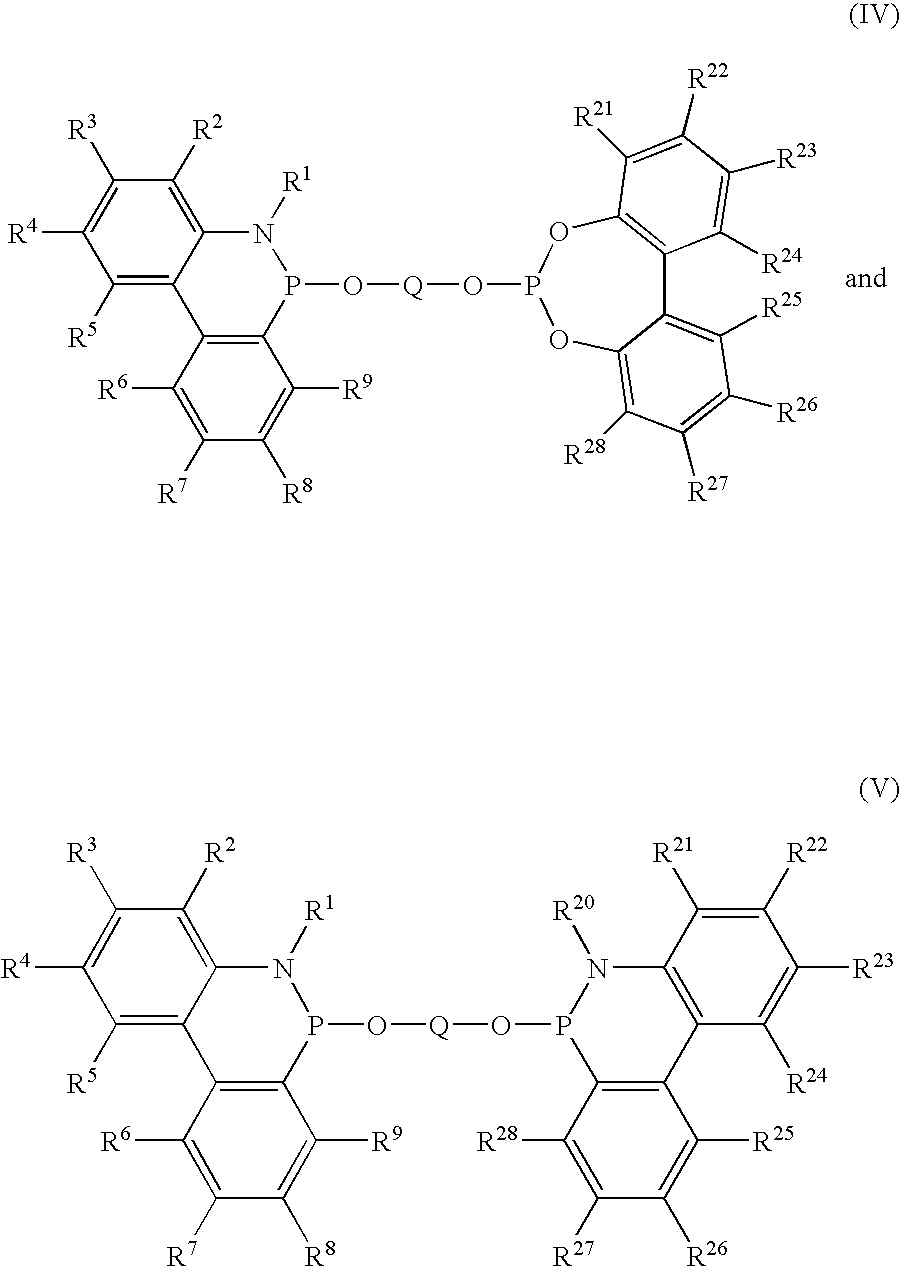

Phosoxophite ligands and use thereof in carbonylation processes

ActiveUS7196230B2High activityHigh selectivitySilicon organic compoundsRhodium organic compoundsCarbonylationProtein carbonyl

A novel organophosphorus composition and synthesis thereof, the composition being characterized by one phosphite moiety, one phosoxophite moiety, and a plurality of sterically bulky substituents. The novel composition finds utility as a ligand in Group VIII transition metal phosoxophite complex catalysts and complex catalyst precursors that are used in carbonylation processes, preferably, hydroformylation processes. Additionally, there is disclosed a novel method of preparing a phosphoromonochloridite composition that finds utility as a precursor to the novel phosoxophite composition.

Owner:DOW TECH INVESTMENTS

Manufacture of alcohols

Owner:EXXONMOBIL CHEM PAT INC

Microchannel with internal fin support for catalyst or sorption medium

InactiveUS7220390B2Fast thermal swingFaster cycle timeCombination devicesMethane captureEngineeringSorption

This invention relates to an apparatus, comprising: at least one process microchannel having a height, width and length, the height being up to about 10 mm, the process microchannel having a base wall extending in one direction along the width of the process microchannel and in another direction along the length of the process microchannel; at least one fin projecting into the process microchannel from the base wall and extending along at least part of the length of the process microchannel; and a catalyst or sorption medium supported by the fin.

Owner:VELOCYS CORPORATION

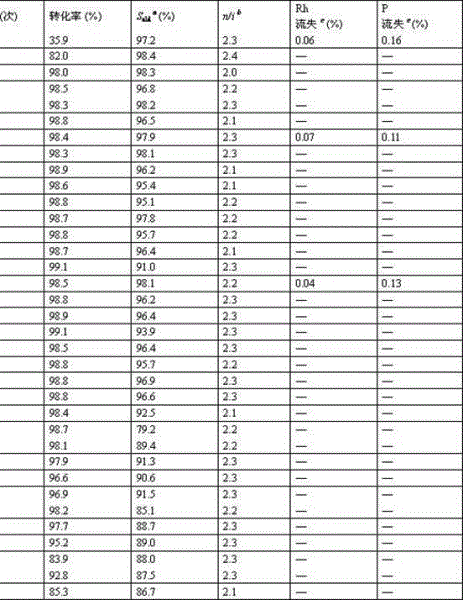

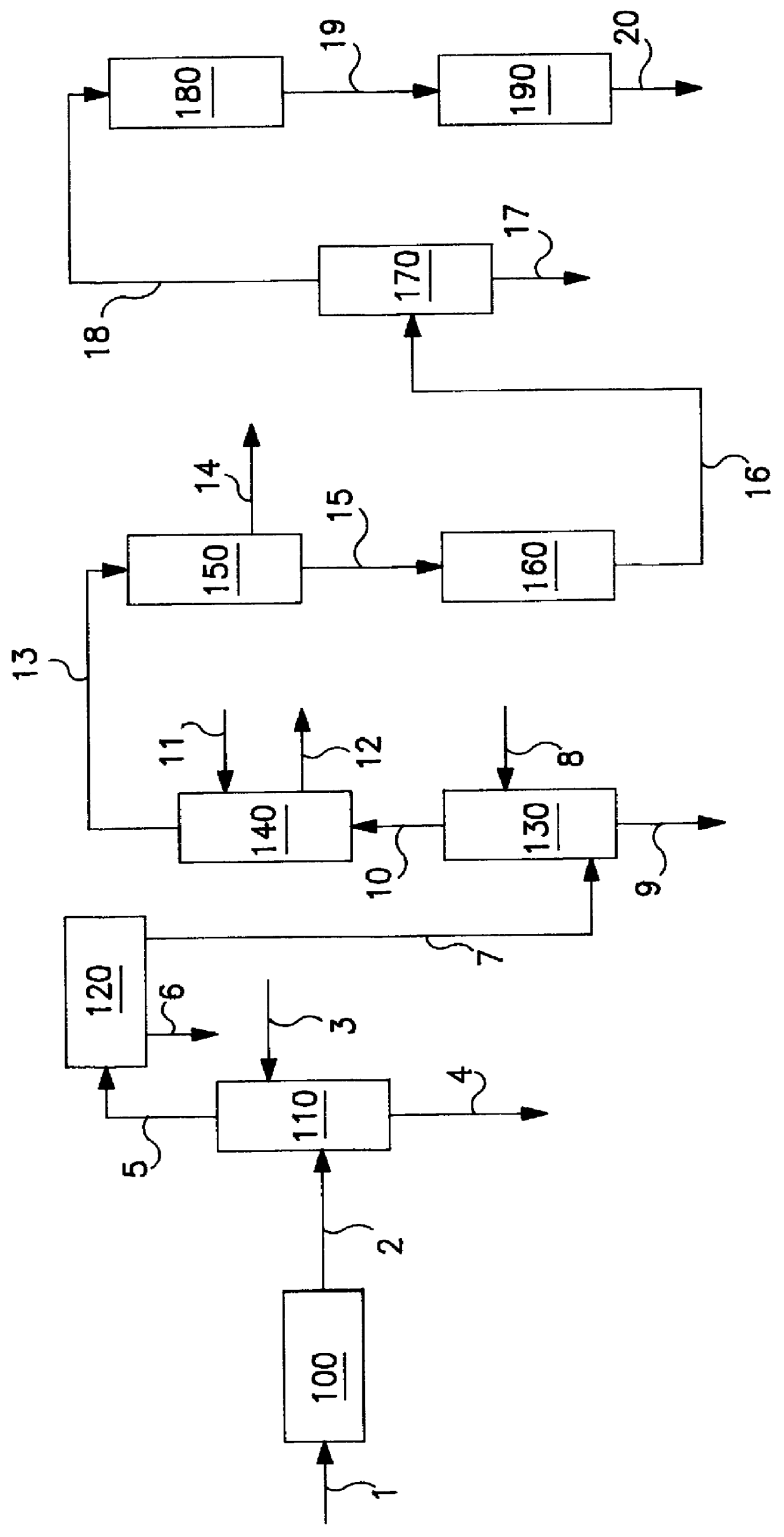

Olefin two-phase hydroformylation method

ActiveCN102617308AEffective fixed loadSeparation and easy handlingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionTPPTSPolymer science

The invention relates to an olefin two-phase hydroformylation method, which consists of three parts: polyether guanidine mesylate ionic liquid (PGMILs) with room temperature solidifiable characteristics, complex catalysts (Rh-TPPTS) formed by RhCl3.3H2O or dicarbonylacetylacetonato rhodium and triphenylphosphine sodium trithionate (TPPTS), and reactants of C6-C14 straight chain 1-olefin, wherein the Rh-TPPTS is dissolved in the PGMILs to form a lower layer catalyst phase, the C6-C14 straight chain 1-olefin or product aldehyde forms an upper layer organic phase, the selectivity of high-carbon aldehyde is 85 to 99 percent, the mol ratio of normal aldehyde to isomerism aldehyde is 2.0 to 2.4, the PGMILs phase containing Rh-TPPTS can be cyclically used for 35 times, the activity and the selectivity are unchanged, the accumulated conversion number (TON) reaches higher than 30000, rhodium flowing to the product phase is 0.04 percent to 0.07 percent, and ultra-long-period catalysis activity and selectivity can be realized.

Owner:山东聚强绿洲生物科技有限公司

Hydroformylation process

InactiveUS6049011AAvoid the needReduce processingPreparation by oxo-reaction and reductionPreparation by hydrogenationEthyleneHydrocarbon

PCT No. PCT / EP96 / 00163 Sec. 371 Date Oct. 15, 1997 Sec. 102(e) Date Oct. 15, 1997 PCT Filed Jan. 17, 1996 PCT Pub. No. WO96 / 22265 PCT Pub. Date Jul. 25, 1996A dilute ethylene stream, e.g., one produced by steam cracking, is oxonated to yield propanal, without the need to separate other lower hydrocarbons.

Owner:EXXON CHEM PAT INC

Supported bis(phosphorus) ligands and their use in the catalysis

InactiveUS6984604B2High selectivityHigh yieldOther chemical processesOrganic compound preparationIsomerizationOrganic compound

Supported bis(phosphorus) ligands are disclosed for use in a variety of catalytic processes, including the isomerization, hydrogenation, hydroformylation, and hydrocyanation of unsaturated organic compounds. Catalysts are formed when the ligands are combined with a catalytically active metal, such as nickel.

Owner:INVISTA NORTH AMERICA R L

Chemical processing microsystems comprising high-temperature parallel flow microreactors

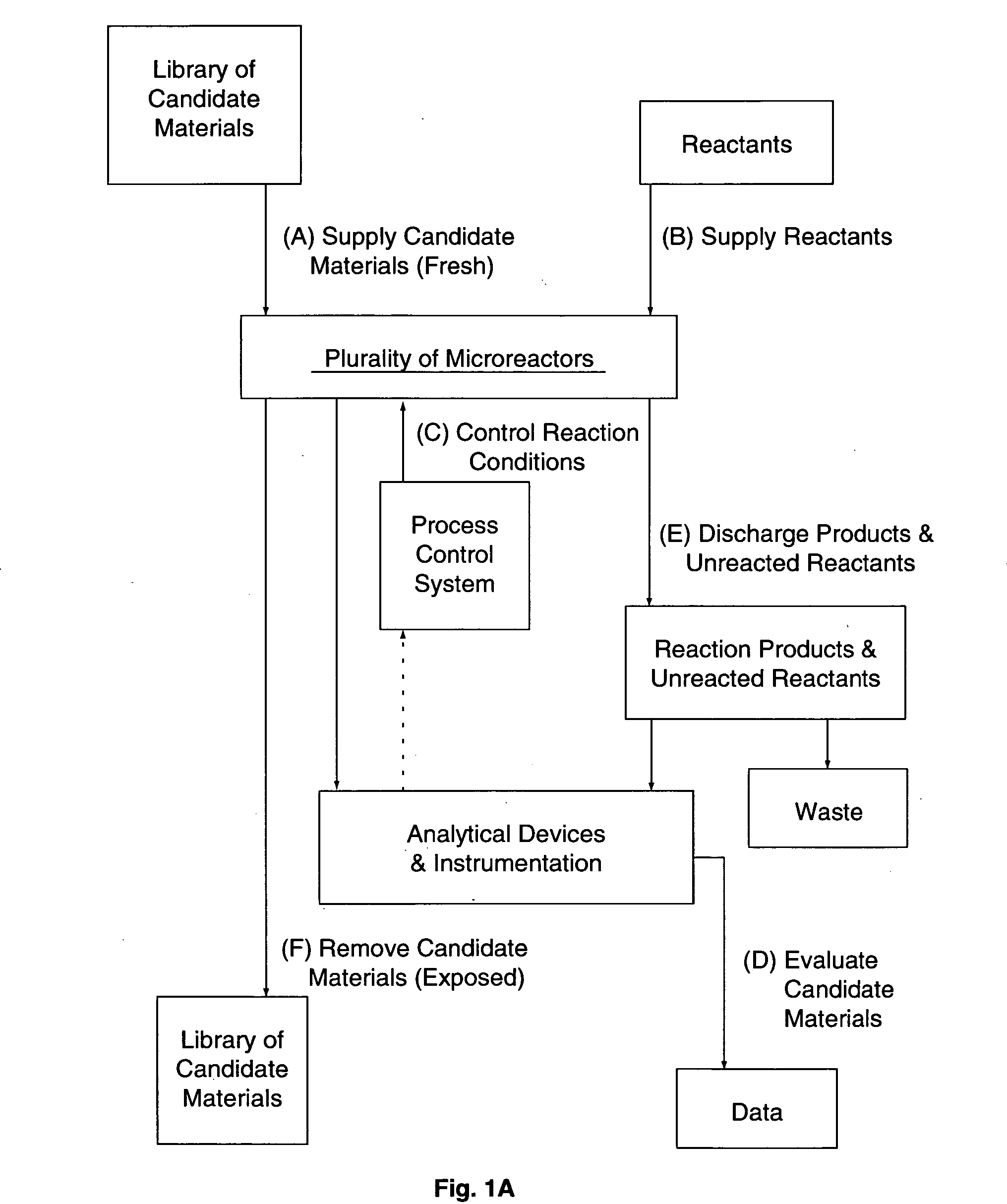

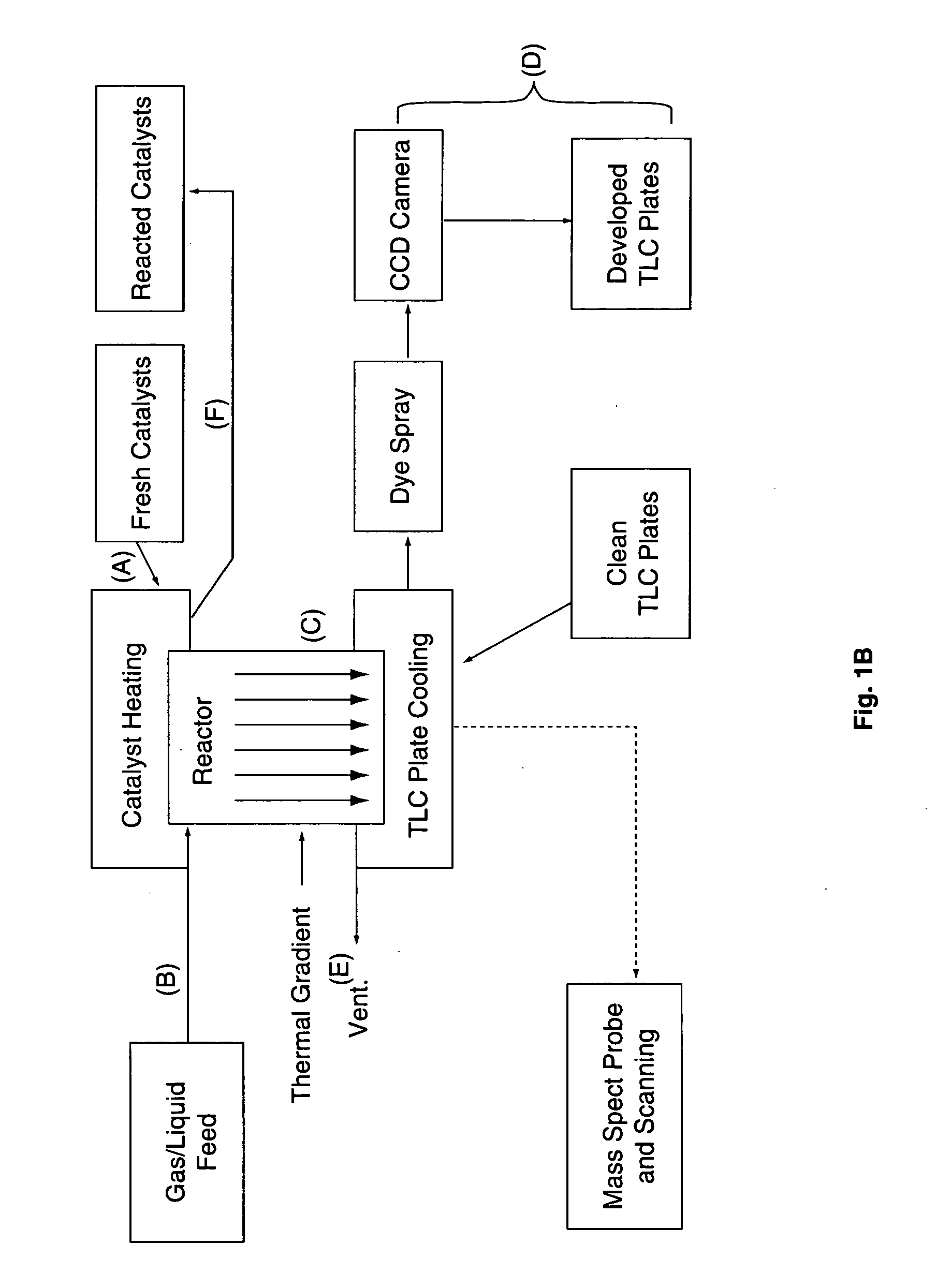

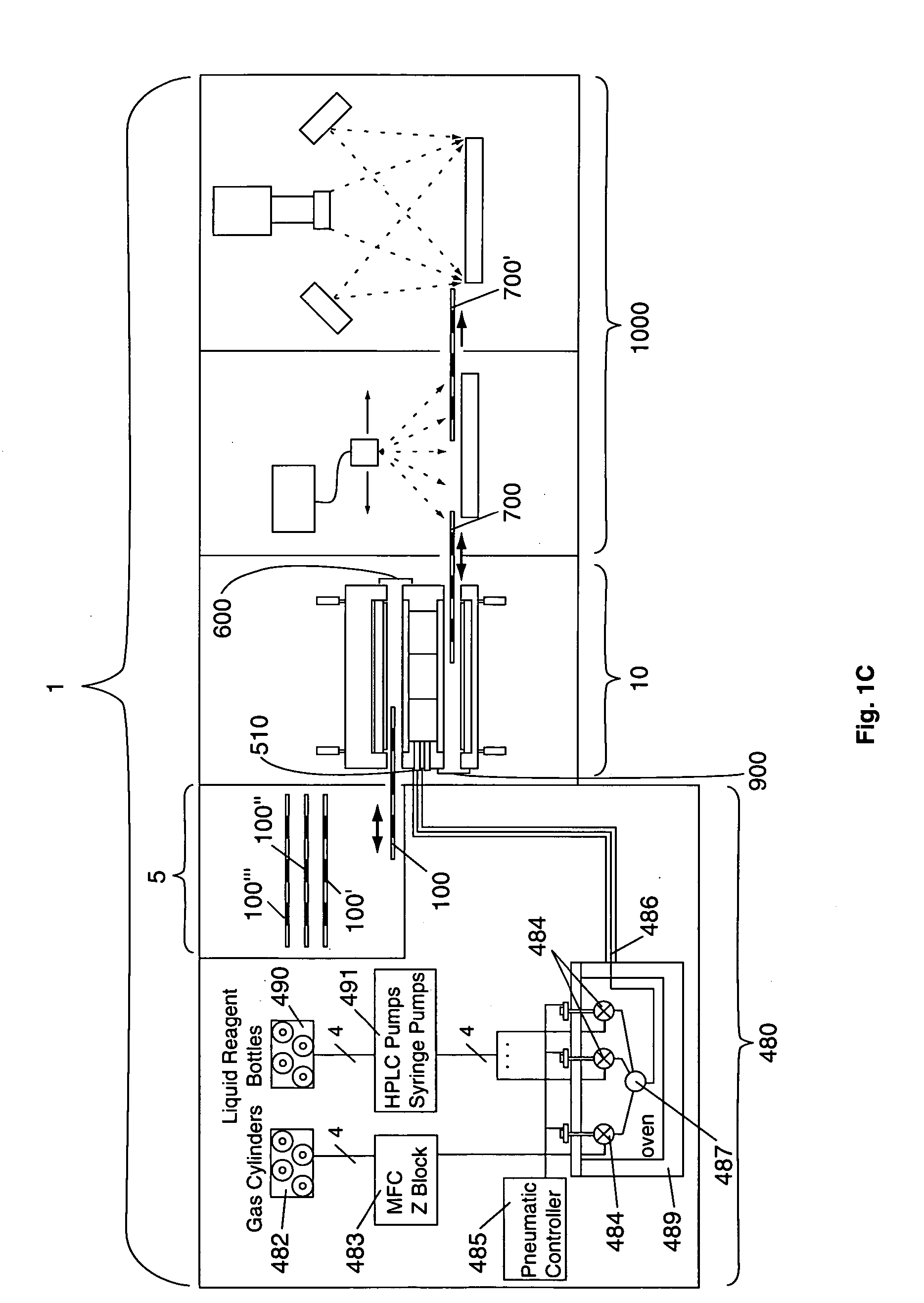

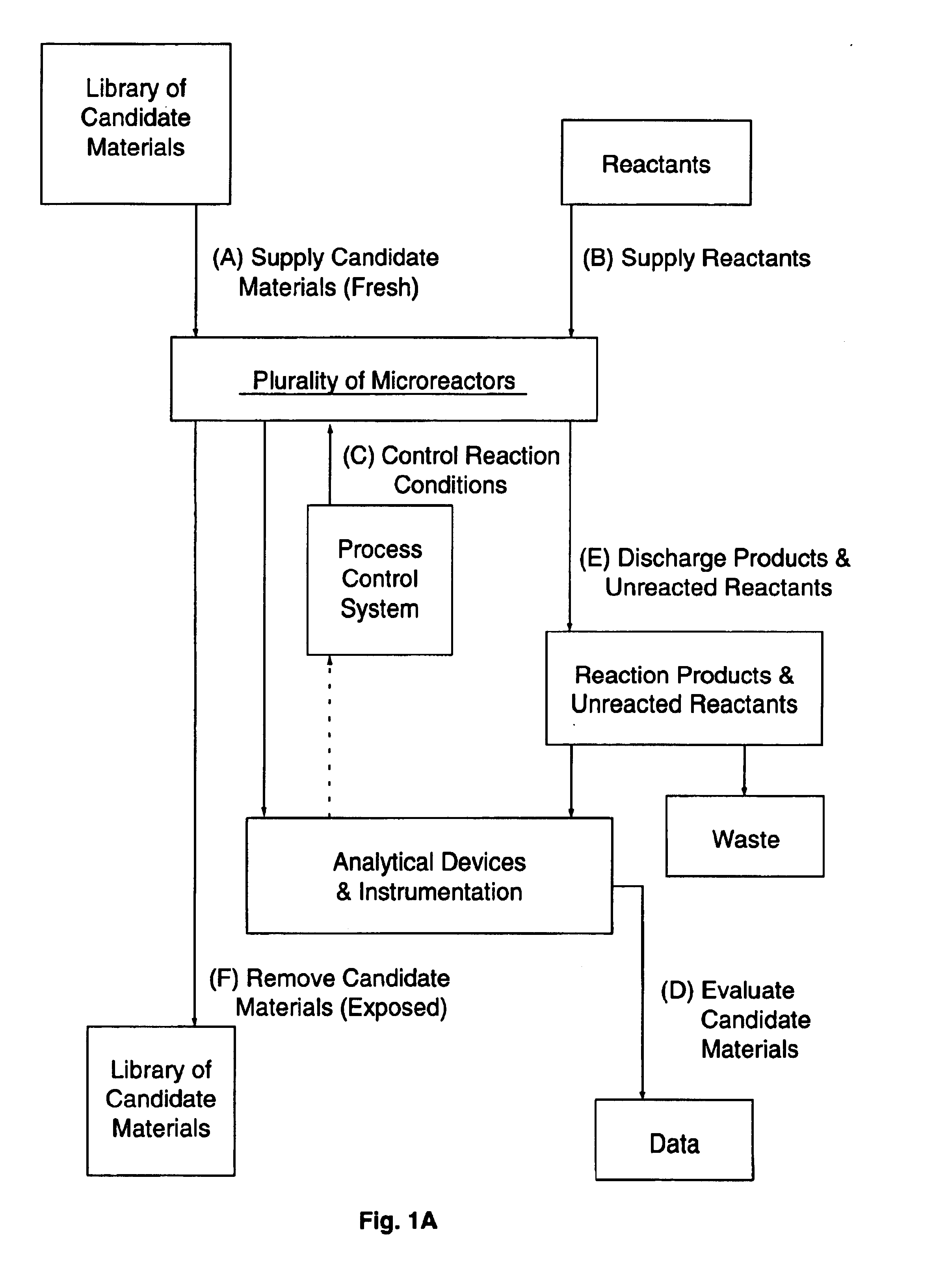

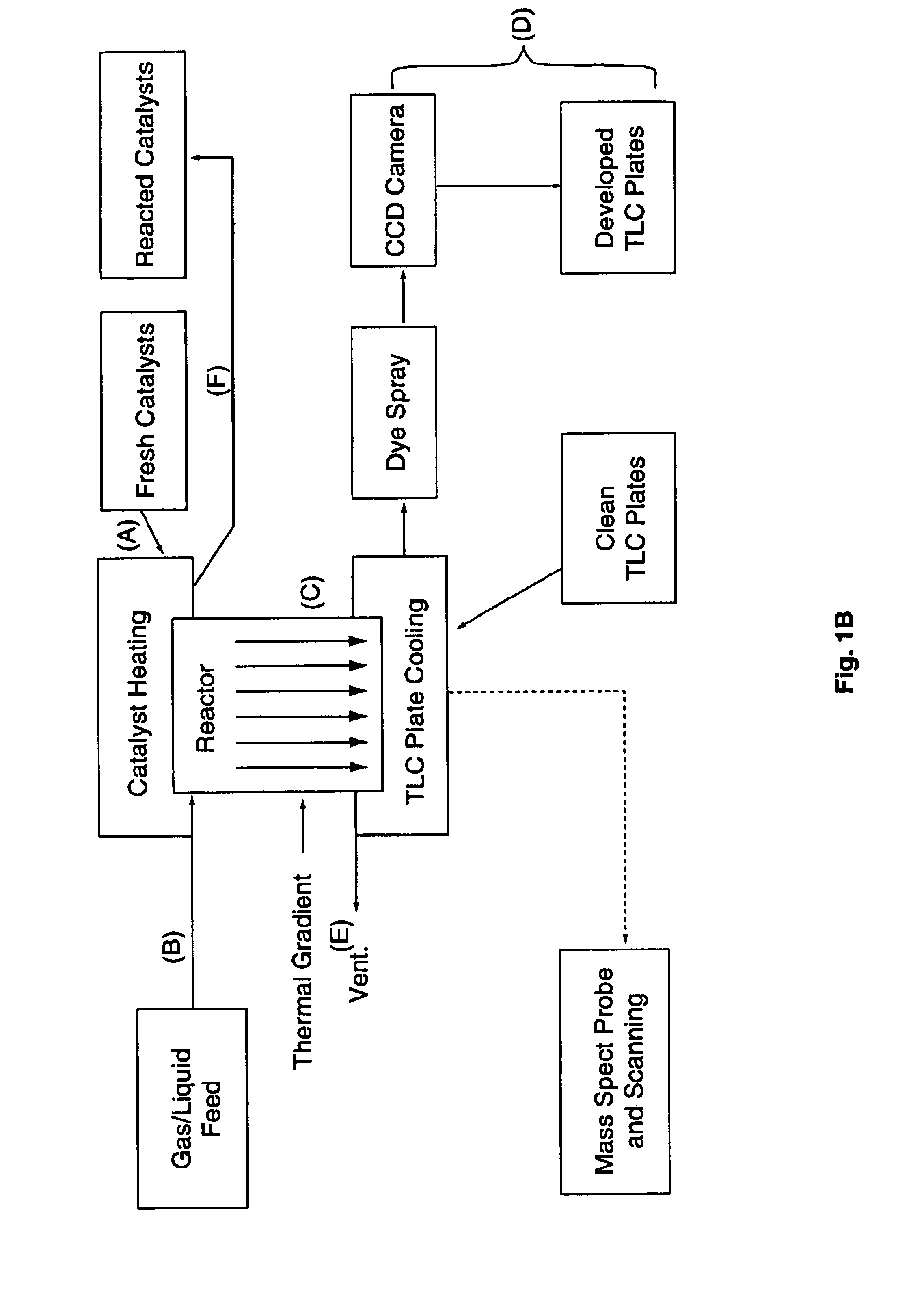

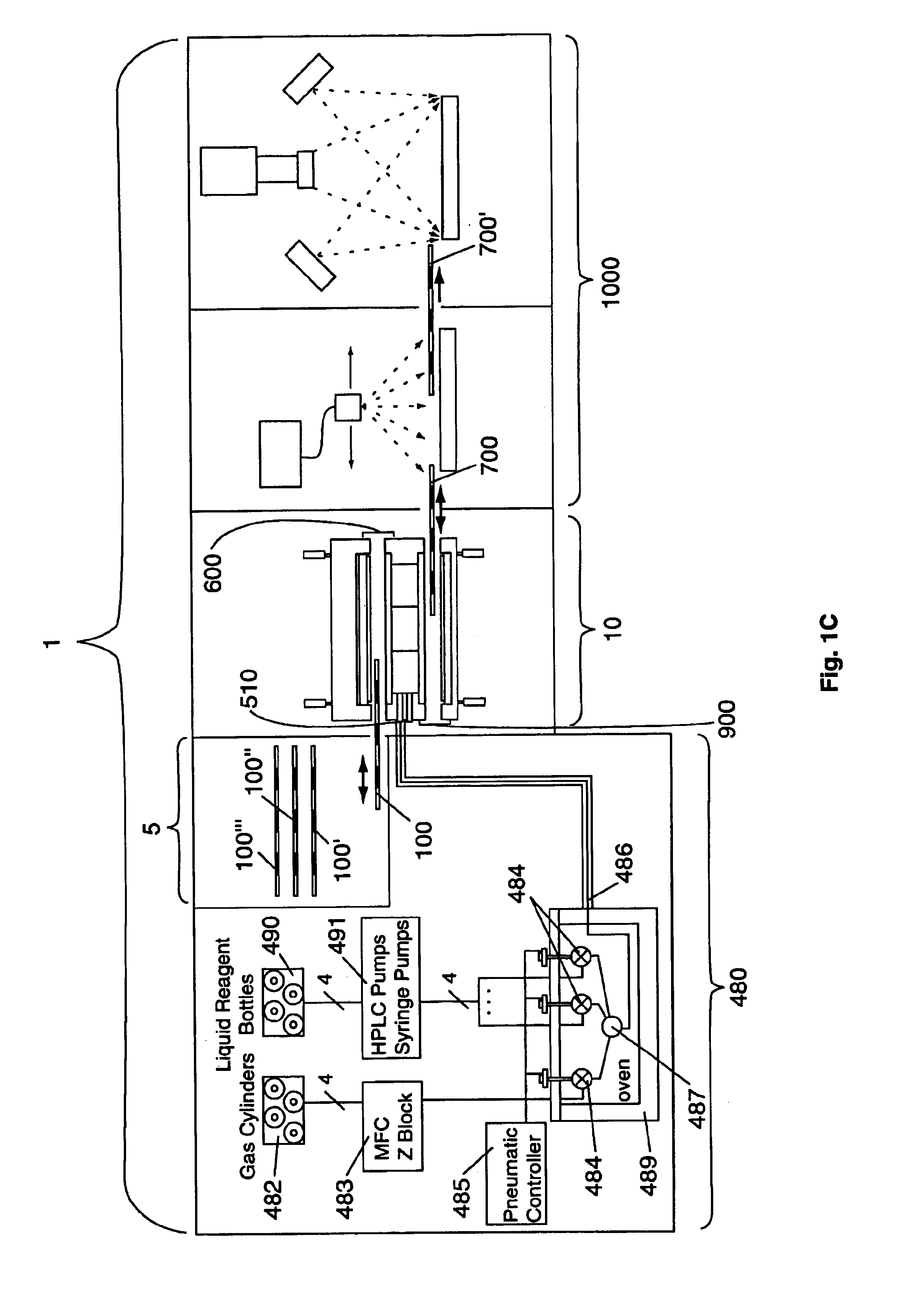

InactiveUS20050009175A1Large degree of analytical flexibilityReduce manufacturing costBioreactor/fermenter combinationsSequential/parallel process reactionsChemical treatmentMicroreactor

A chemical processing microsystem useful for identifying and optimizing materials (e.g., catalysts) that enhance chemical processes or for characterizing and / or optimizing chemical processes is disclosed. The chemical processing microsystem comprises a plurality of microreactors 600 and, in a preferred embodiment, a plurality of microseparators 900 integral with the chemical processing microsystem 10. The microreactors 600 are preferably diffusion-mixed microreactors formed in a plurality of laminae that include a modular, interchangeable candidate-material array 100. The material array 100 comprises a plurality of different candidate materials (e.g., catalysts), preferably arranged at separate, individually addressable portions of a substrate (e.g., wafer). The microseparators 900 are similarly formed in a plurality of laminae that include a modular, interchangeable adsorbent array 700. The adsorbent array 700 comprises one or more adsorbents, preferably arranged at separate, individually addressable portions of a substrate to spatially correspond to the plurality of different candidate materials. Modular microfluidic distribution systems are also disclosed. The chemical processing microsystem can be integrated into a material evaluation system that enables a comprehensive combinatorial material science research program.

Owner:FREESLATE

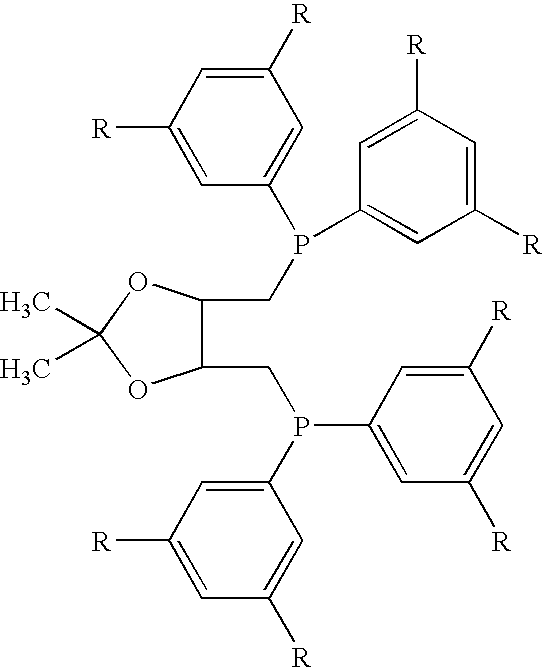

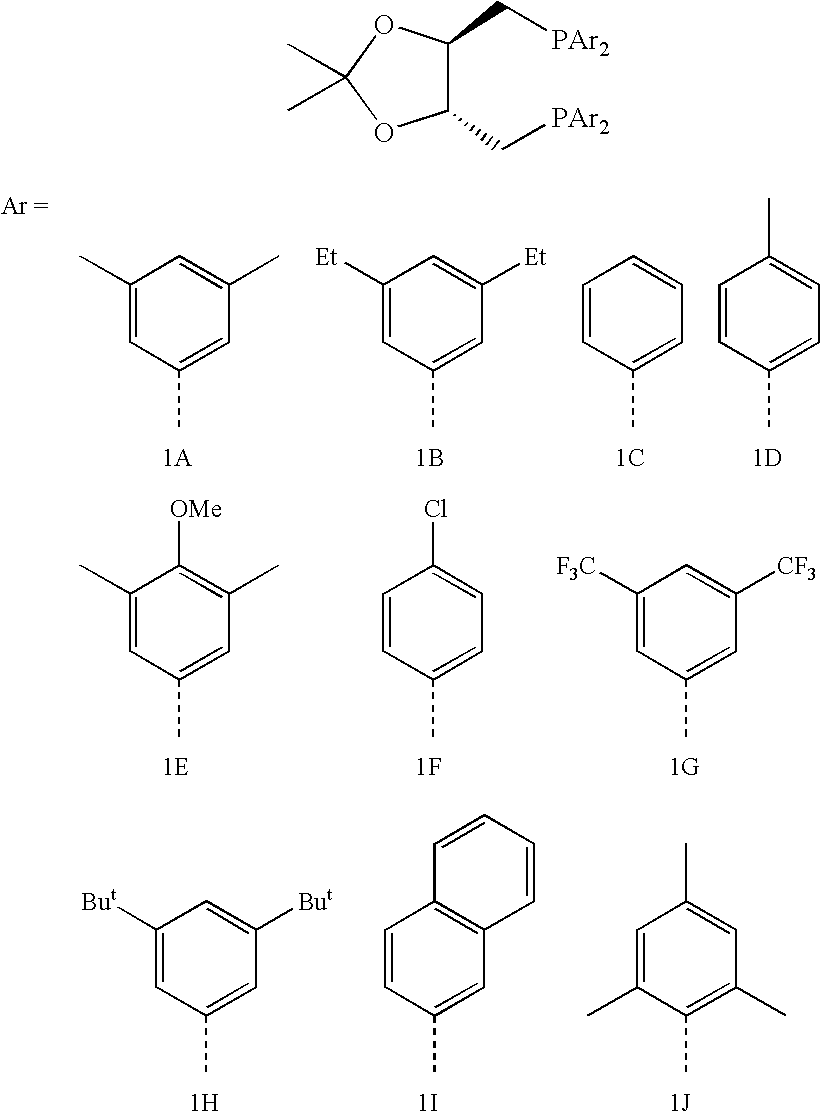

Hydroformylation process

ActiveUS7271295B1Raise the ratioOrganic compound preparationGroup 8/9/10/18 element organic compoundsHydrogenSolvent

A process for the production of 4-hydroxybutyraldehyde is described. The process comprises reacting allyl alcohol with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst system comprising a rhodium complex and a 2,3-O-isopropylidene-2,3-dihydroxy-1,4-bis[bis(3,5-di-n-alkylphenyl)phosphino]butane. The process gives high yield of 4-hydroxybutyraldehyde compared to 3-hydroxy-2-methylpropionaldehyde.

Owner:LYONDELL CHEM TECH LP

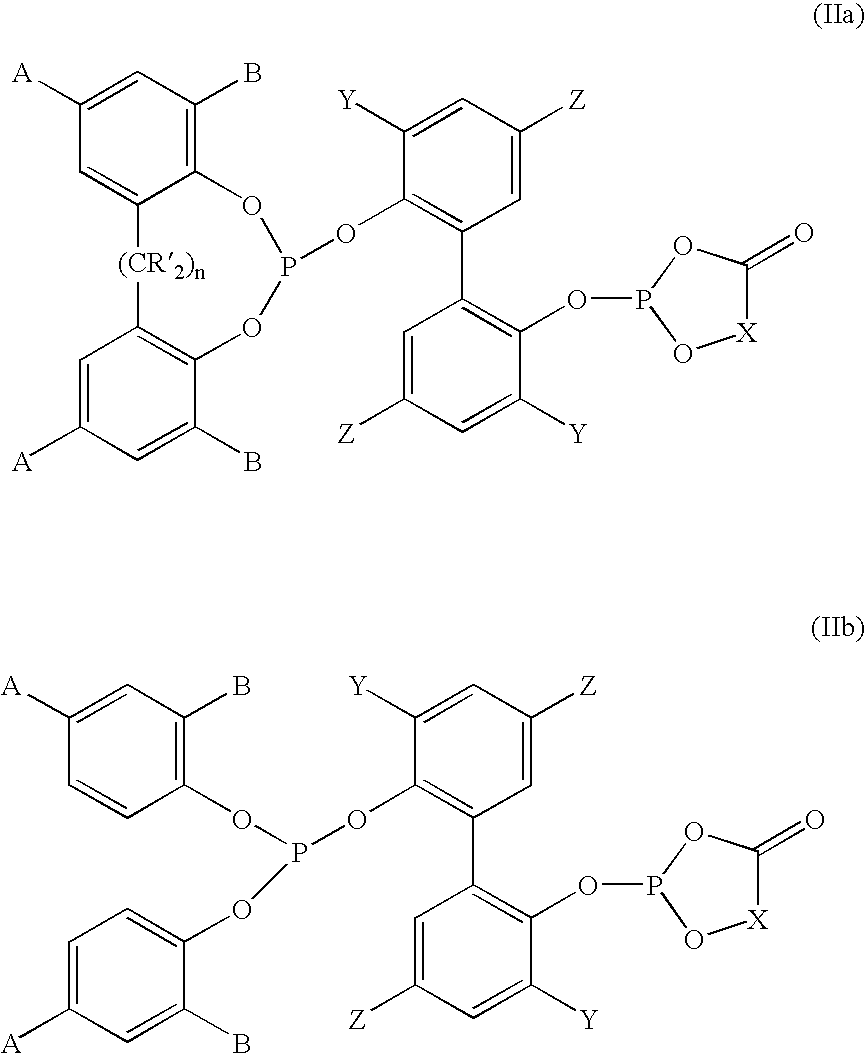

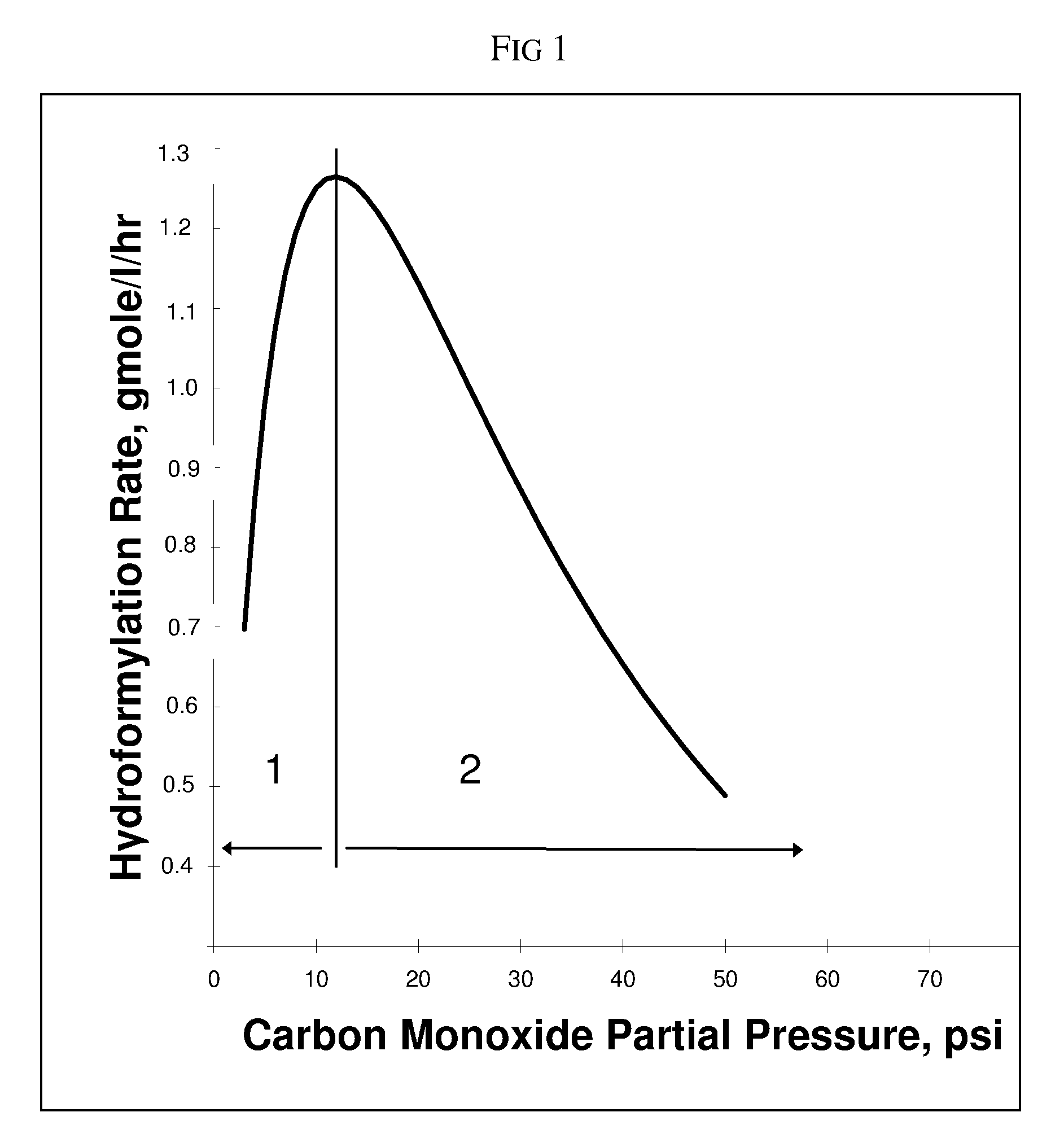

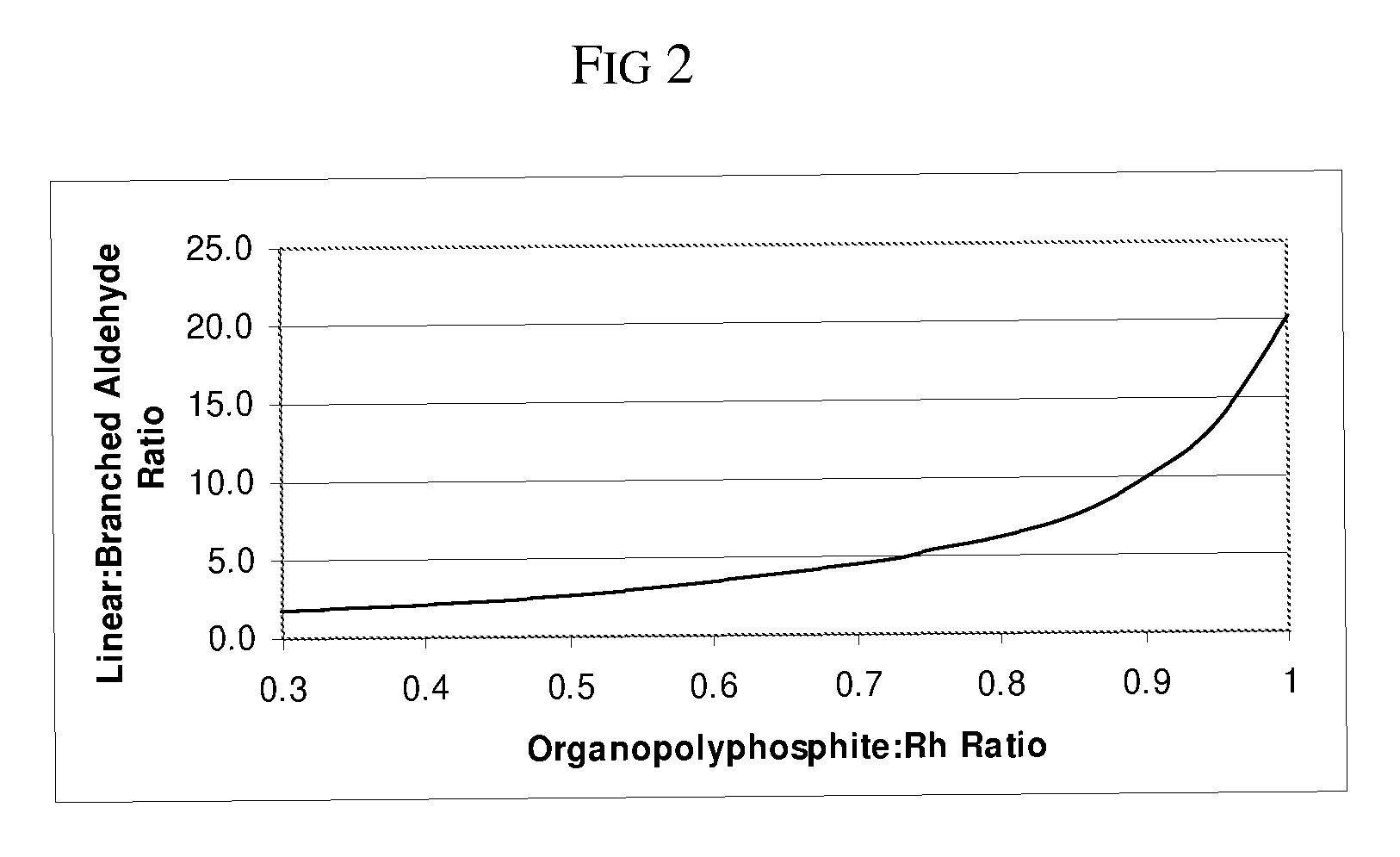

Hydroformylation process with improved control over product isomers

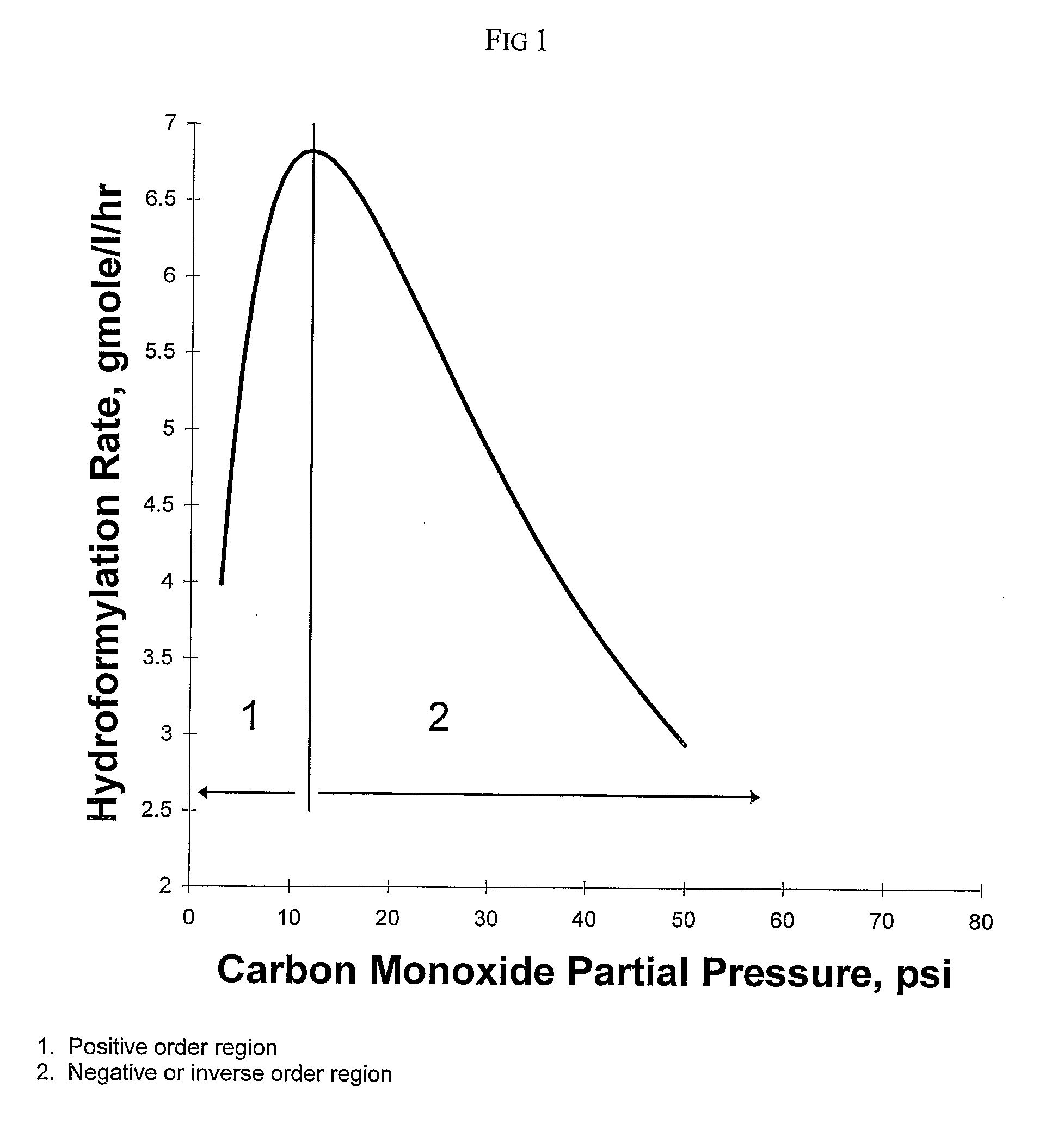

ActiveUS7863487B2Easy to operateReduce concentrationOrganic compound preparationPreparation by carbon monoxide reactionHydrogenRate curve

A continuous hydroformylation process for producing a mixture of aldehydes with improved flexibility and stability of a normal / branched (N / I) isomer ratio of the product aldehydes. The process involves reacting one or more olefinically-unsaturated compounds with carbon monoxide and hydrogen in the presence of an organopolyphosphite ligand and an organomonophosphite ligand, at least one of such ligands being bonded to a transition metal to form a transition metal-ligand complex hydroformylation catalyst; the process being conducted at a sub-stoichiometric molar ratio of organopolyphosphite ligand to transition metal, at a super-stoichiometric (>2 / 1) molar ratio of organomonophosphite ligand to transition metal, and at a carbon monoxide partial pressure in the inverse order region of the hydroformylation rate curve; and controlling and varying the isomer ratio by varying the concentration of organopolyphosphite ligand relative to transition metal.

Owner:DOW TECH INVESTMENTS

Method for preparing load type rhodium catalyst for making high-carbon aldehyde using hydroformylation of higher olefins

InactiveCN101116816AImprove stabilityCatalyst activation/preparationPreparation by carbon monoxide reactionAlkaline earth metalFormylation reaction

A modified activated carbon supported rhodium type catalyst for high carbene hydrocarbon hydrogen formylation reaction is provided. The preparation of the catalyst comprises the techniques such as carrier pretreatment-activity rhodium solid-phase bound reagent combination, and used for gas-liquid-solid three phase catalyst system, which is characterized in that: a certain amount of alkali or alkaline earth metal hydroxide and salt modification activated carbon is used as a carrier, and the supported rhodium catalyst is prepared by using multiple impregnation method. The catalyst of the present invention is high in activity and selectivity. The catalyst is easy to be separated from products after reaction, capable of being used repeatedly, stable in performance, and suitable for the production process of high carbene hydrocarbon or mixed olefin hydrogen formylation made high carbon aldehyde, which has good industrial application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

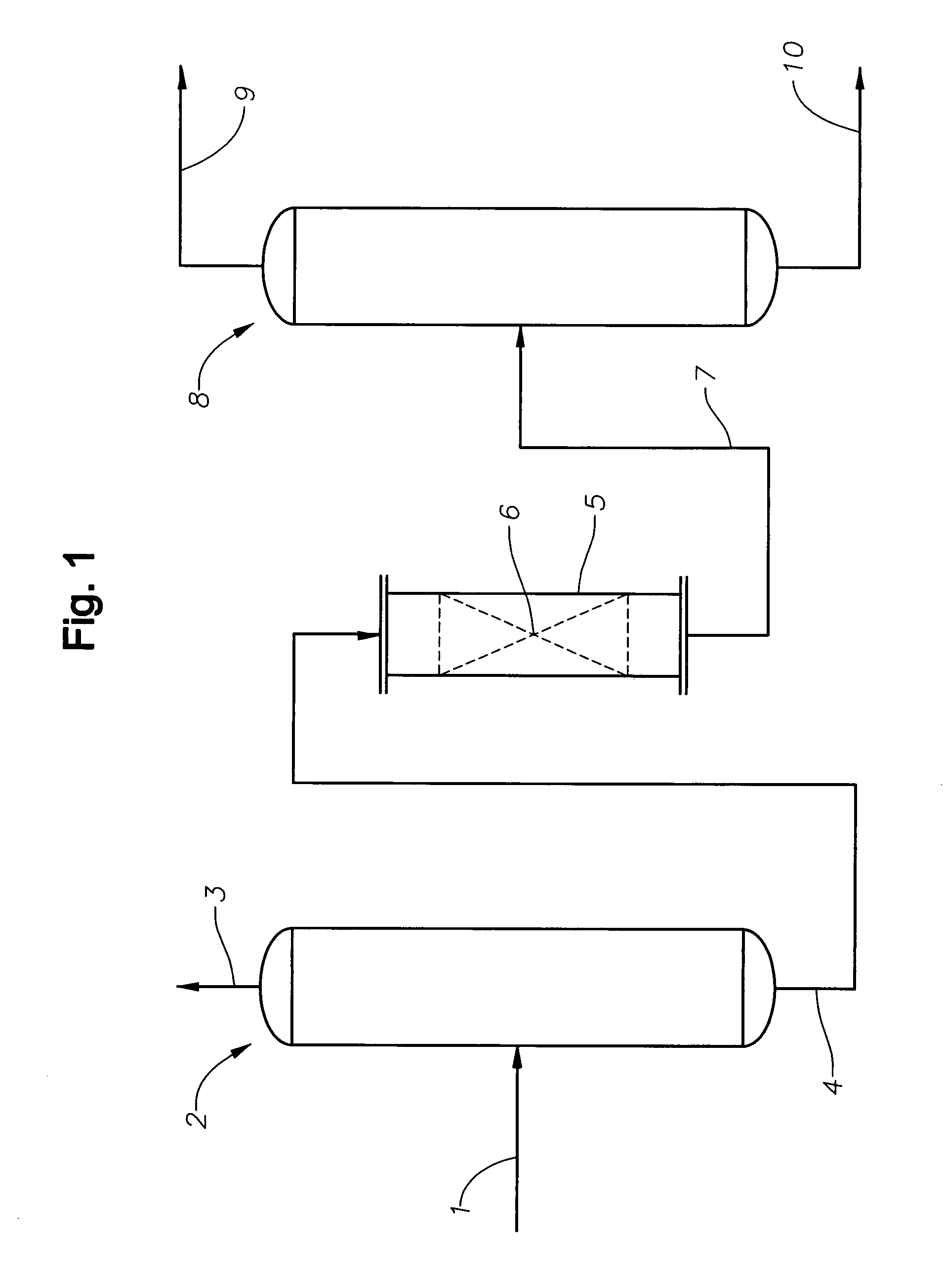

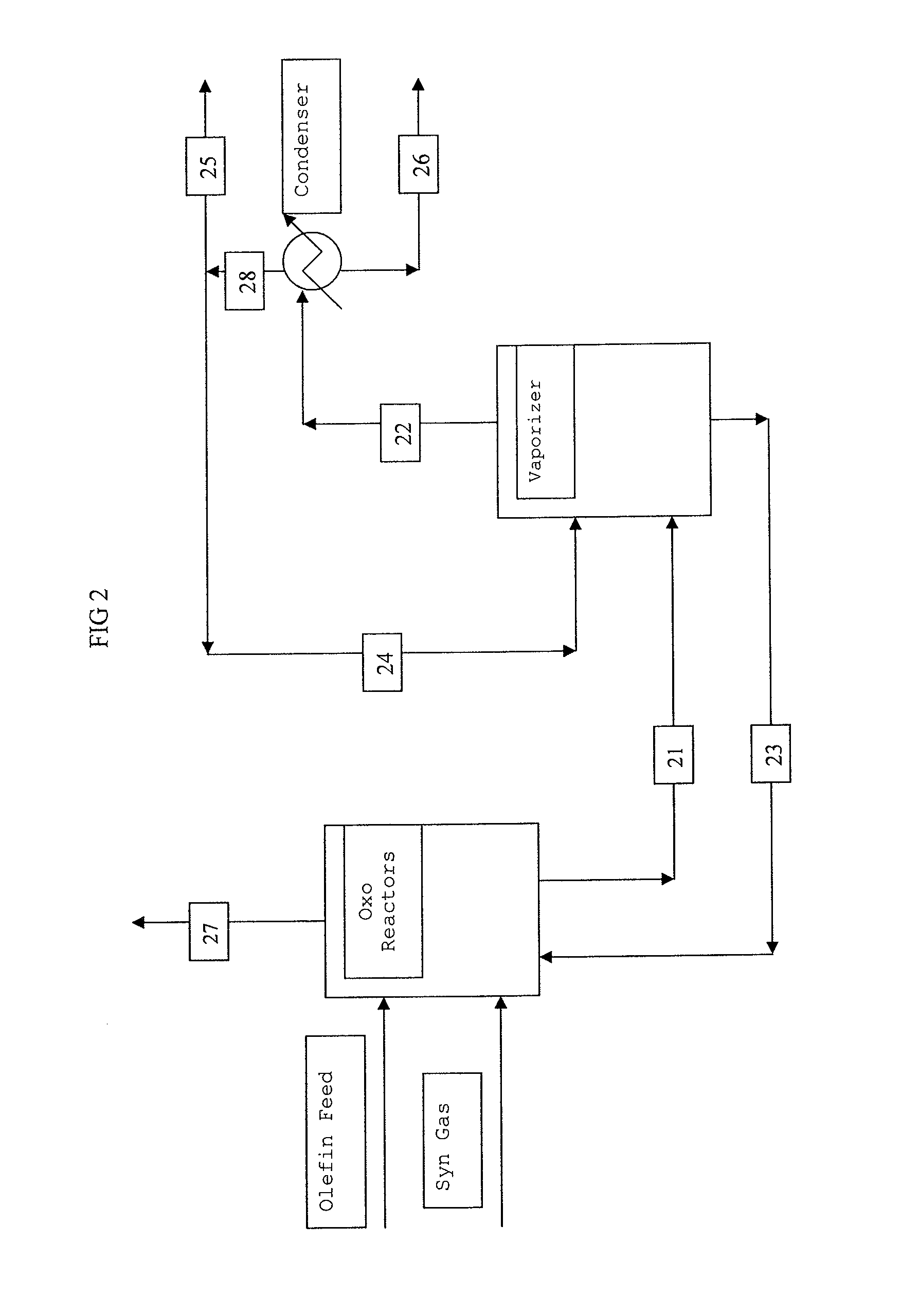

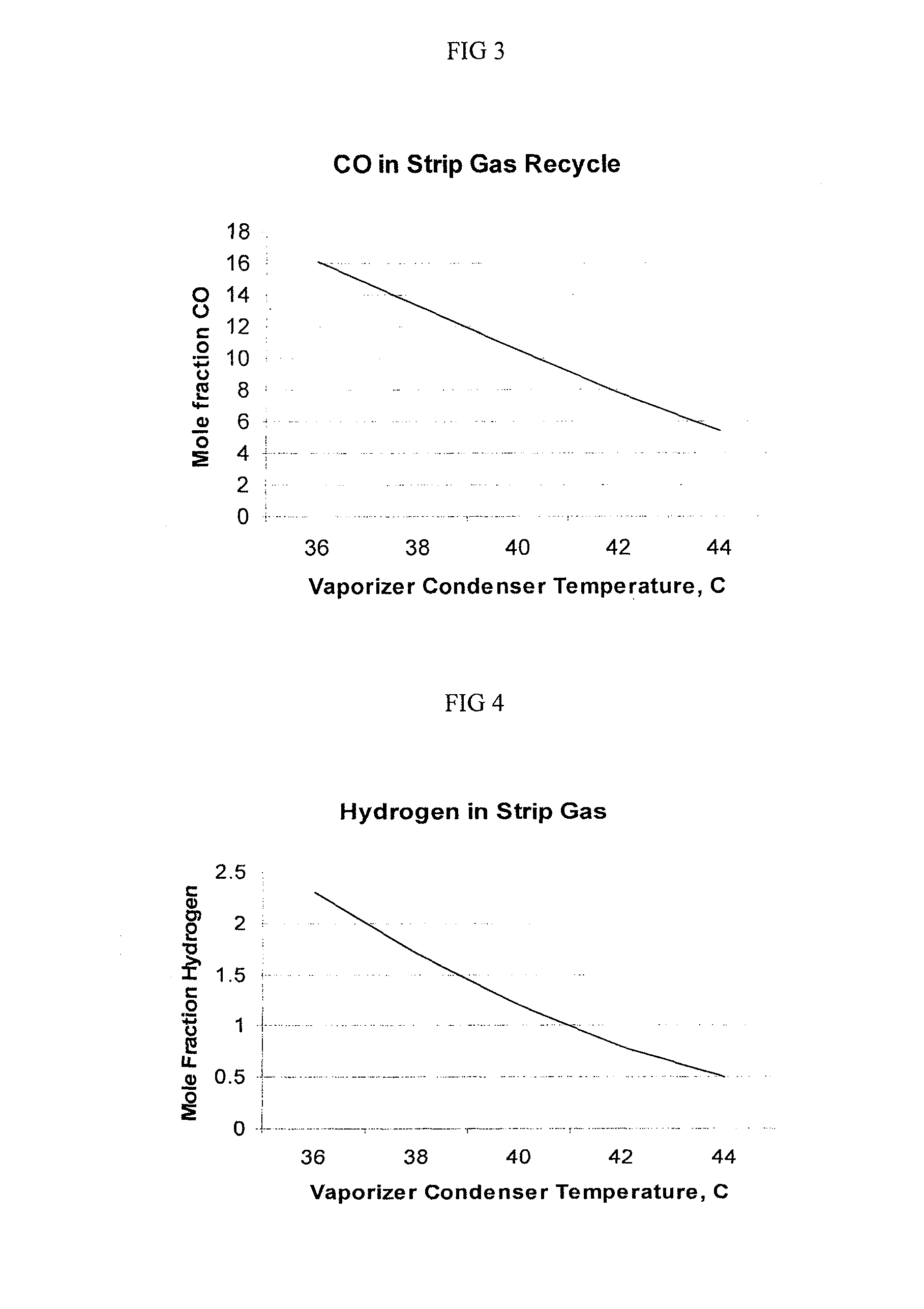

Process of controlling heavies in a recycle catalyst stream

ActiveUS8404903B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistryHydroformylation

A process of controlling heavies in a recycle catalyst stream, particularly, for use in a continuous hydroformylation process of converting an olefin with synthesis gas in the presence of a hydroformylation catalyst to form an aldehyde product stream with subsequent separation of the catalyst for recycle to the hydroformylation step. Heavies are controlled, and preferably reduced, by means of feeding a recycle gas stream, taken as a portion of an over-head stream from a condenser, back to a vaporizer wherein the aldehyde product stream is separated.

Owner:DOW TECH INVESTMENTS +1

Halogen-free ionic liquids

InactiveUS20050070717A1Improve hydrolytic stabilityOrganic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsHeat carrierHalogen

An ionic liquid according to the invention is substantially halogen-free, has a low viscosity and is stable to hydrolytic degradation under test conditions. The ionic liquid is a compound of the formula (cation) (R′—O—SO3), (cation) (R′—SO3), or a mixture of the two compounds. It can be used in processes for the chemical conversion and separation of materials by employing the ionic liquid as a solvent, solvent additive, extraction agent or phase-transfer catalyst. It can also be used in a heat exchange device wherein the ionic liquid serves as a heat carrier or heat carrier additive.

Owner:MERCK PATENT GMBH

Phosphinine compounds and metal complexes thereof

InactiveUS6818770B2Ruthenium organic compoundsOrganic compound preparationPhosphorineCoordination complex

Phosphinines of formula (I) can be combined with metal salts to prepare hydroformylation catalysts. The phosphinine complexes have two phosphorus centers that may be substituted with a variety of hetero atoms or alkyl substituents to modify the ligand characteristics of the phosphinine. Phosphinine metal complexes are employed under normal hydroformylation reaction conditions. The preparatory routes to the phosphinine ligands of formula (I) allow for their convenient synthesis.

Owner:EVONIK OXENO GMBH (DE)

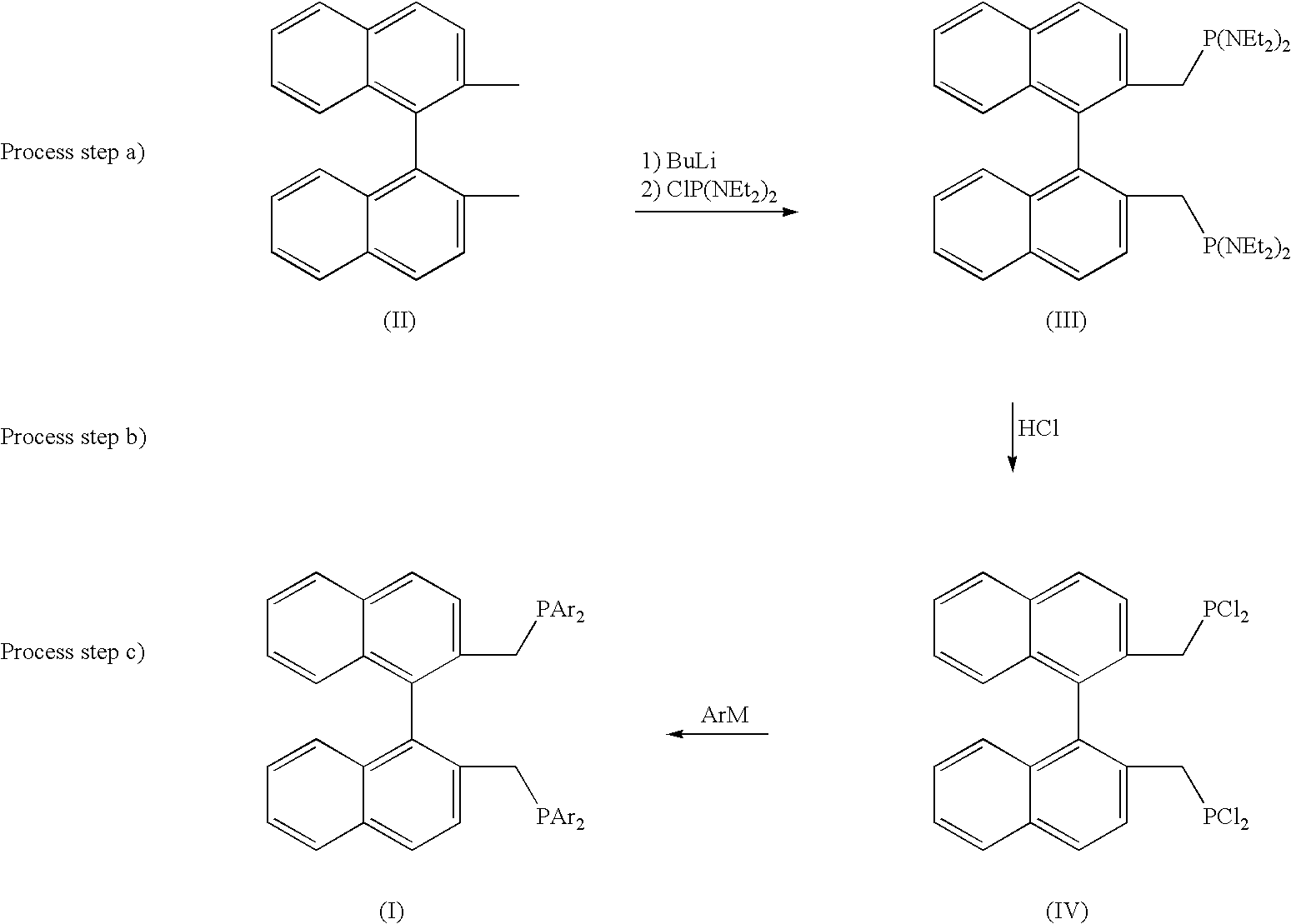

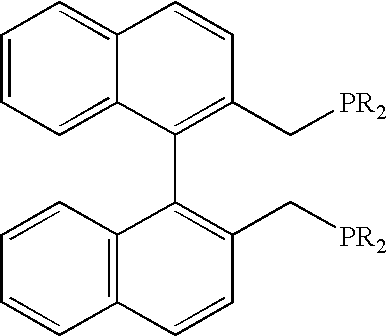

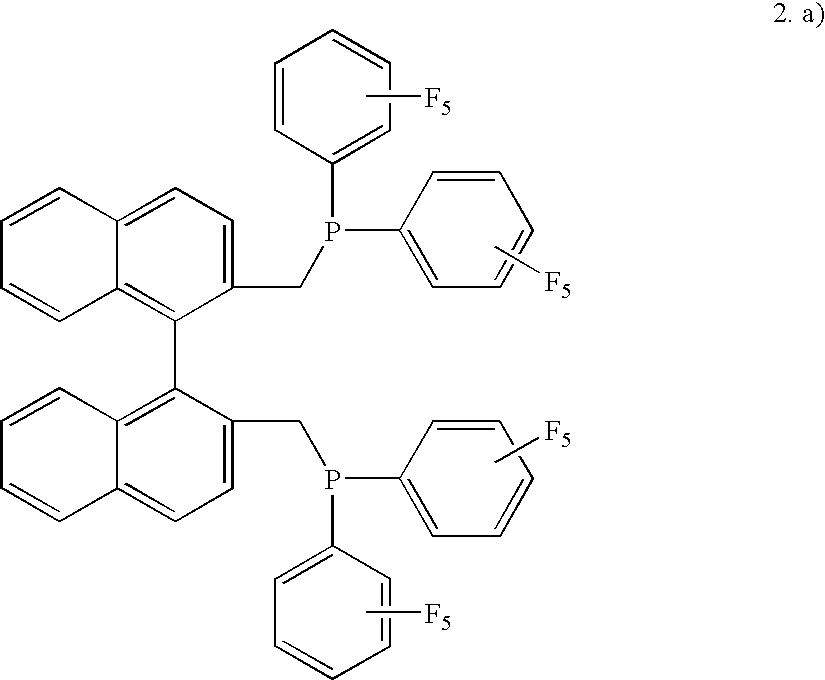

Method for producing diphosphines and the use thereof

InactiveUS6924389B2Carry-out safelyHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAliphatic hydrocarbonDiphosphines

Diphosphine of formula IR1R2P—H2C—Ar—CH2PR1R2 (I)are prepared by a process that comprises a) reacting a dimethyl compound of formula IIH3C—Ar—CH3 (II)with a base and an N-substituted aminophosphorous halide to form bis(aminophosphinomethyl) compound of the formula IIIR3R4P—H2C—Ar—CH2—PR3R4 (III)b) reacting the compound of formula III with HCl to form bis(dichlorophosphinomethyl) compound of formula IVCl2P—H2C—Ar—CH2—PCl2 (IV)and c) reacting the compound of formula IV with an organometallic reagent to give the product compound of formula I, wherein groups R1 and R2 are each, independently of one another, a substituted or unsubstituted aromatic, heteroaromatic or aliphatic hydrocarbon group and may have a covalent bond connecting them and Ar is a substituted or unsubstituted aromatic or heteroaromatic hydrocarbon group an R3 and R4 are each, independently of one another, an N-substituted alkylamino or arylamino group.

Owner:EVONIK DEGUSSA GMBH

Stabilization of a hydroformylation process

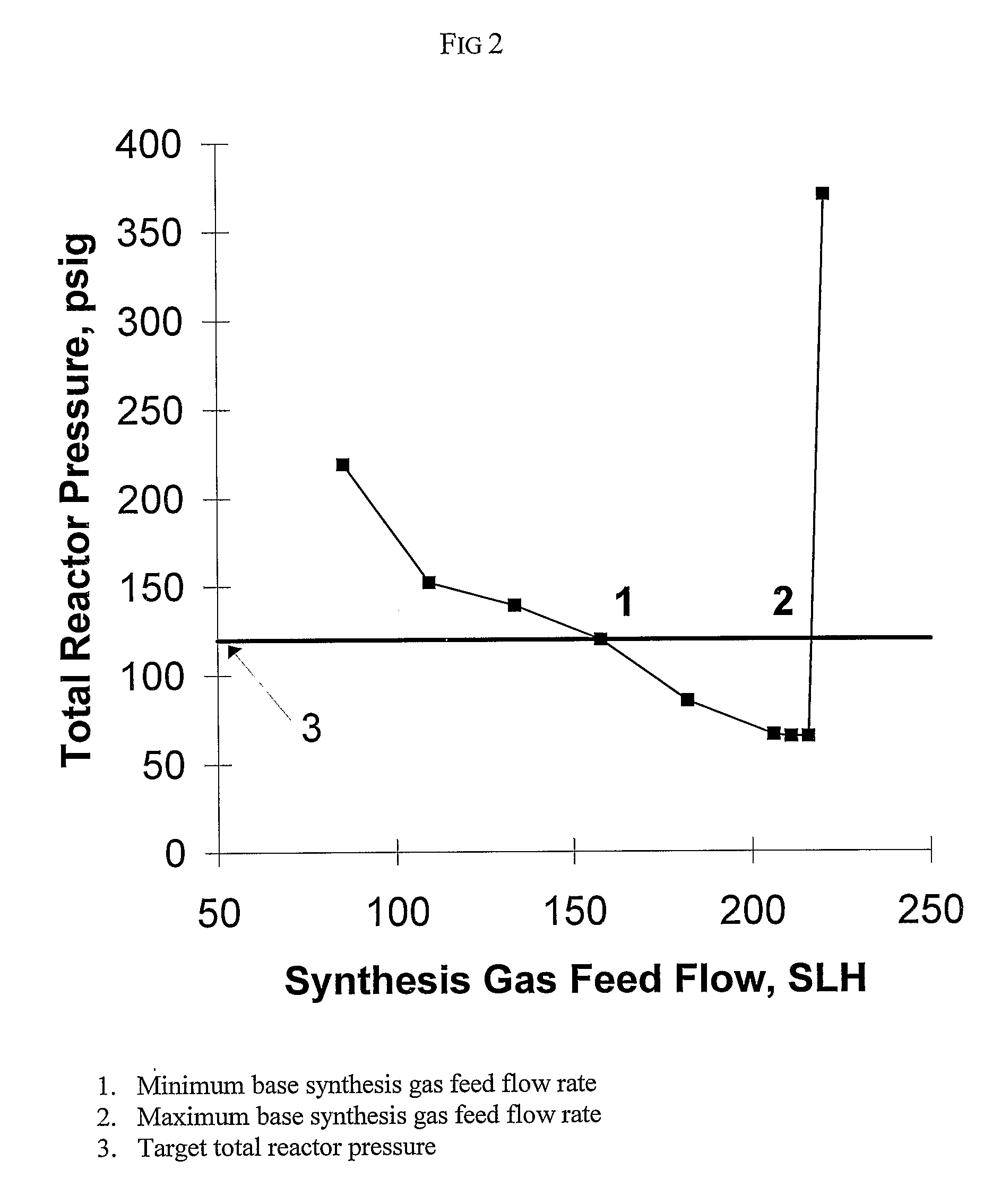

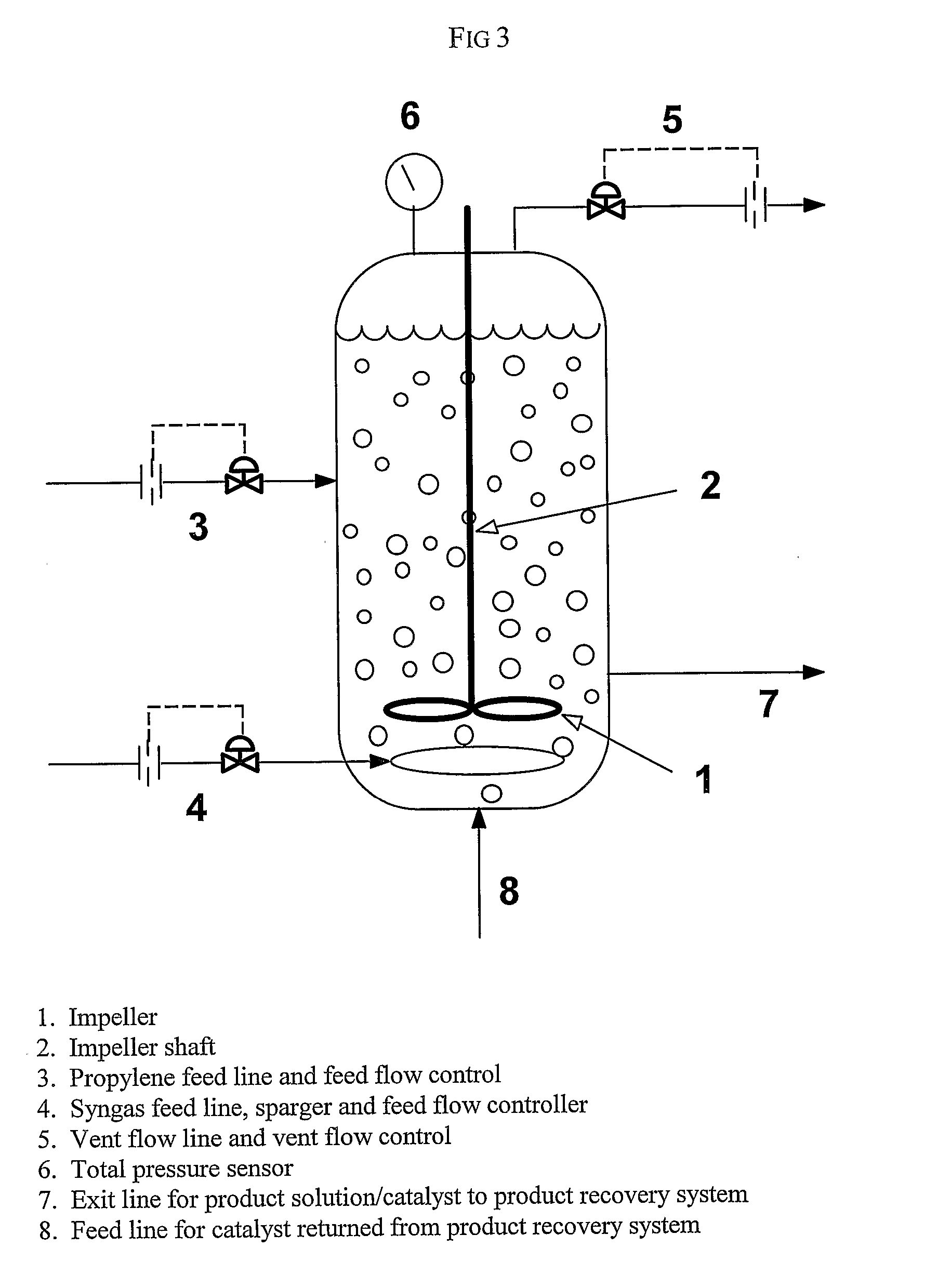

ActiveUS7446231B2Improve efficiencyProcess stabilityLiquid degasificationOrganic compound preparationReaction rateRate curve

An improved hydroformylation process involving reacting one or more reactants, such as an olefin, with carbon monoxide and hydrogen in the presence of a hydroformylation catalyst, to produce a reaction product fluid comprising one or more products, preferably aldehydes; wherein said process is conducted in a region of the hydroformylation rate curve that is negative or inverse order in carbon monoxide, which is sufficient to prevent and / or lessen deactivation of the hydroformylation catalyst; and wherein total pressure is controlled at a predetermined target value and / or vent flow rate is controlled at a predetermined target value, by adjusting a flow of a carbon-monoxide containing inlet gas, so as to prevent and / or lessen cycling of process parameters, e.g., reaction rate, total pressure, vent flow rate, and / or temperature.

Owner:DOW TECH INVESTMENTS

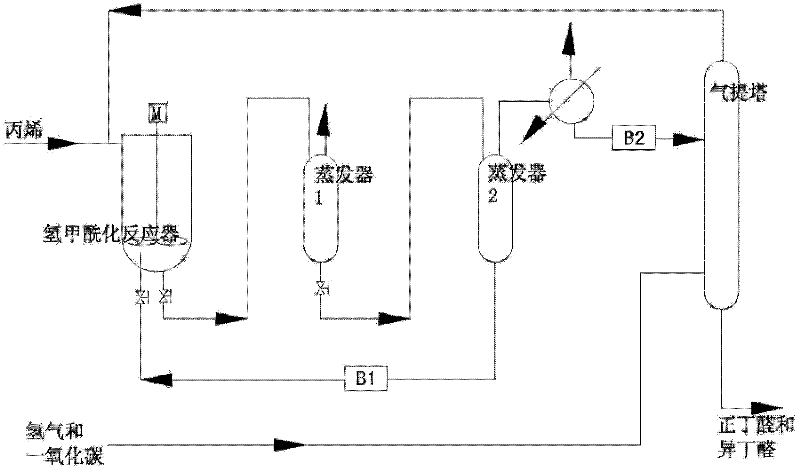

A kind of propylene hydroformylation catalytic system and method

InactiveCN102266796AReduce dosageImprove stabilityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsFormylation reactionTriphenylphosphine

The invention relates to a propylene hydroformylation catalyst system and a method for catalyzing synthesis of butyraldehyde. In the present invention, in the propylene hydroformylation reaction system catalyzed by triarylphosphine-Rh(I), by using appropriate types and quantities of additives, such as bisphosphite, the performance of the Rh(I) / triarylphosphine catalyst can be significantly improved The activity and the positive-iso ratio of butyraldehyde in the product (molar ratio of n-butyraldehyde / isobutyraldehyde>20), and significantly prolong the service life of the bisphosphite ligand, and significantly reduce the amount of triarylphosphine. This type of catalyst system is characterized by higher activity and selectivity than third-generation Rh(I) / triphenylphosphine catalysts and better stability than fourth-generation Rh(I) / bisphosphite catalysts, so The novel catalyst system provided by the present invention can overcome the shortcomings of the third and fourth generation catalysts, reduce the cost of industrialized production of propylene hydroformylation, and provide a new catalyst technology for its industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

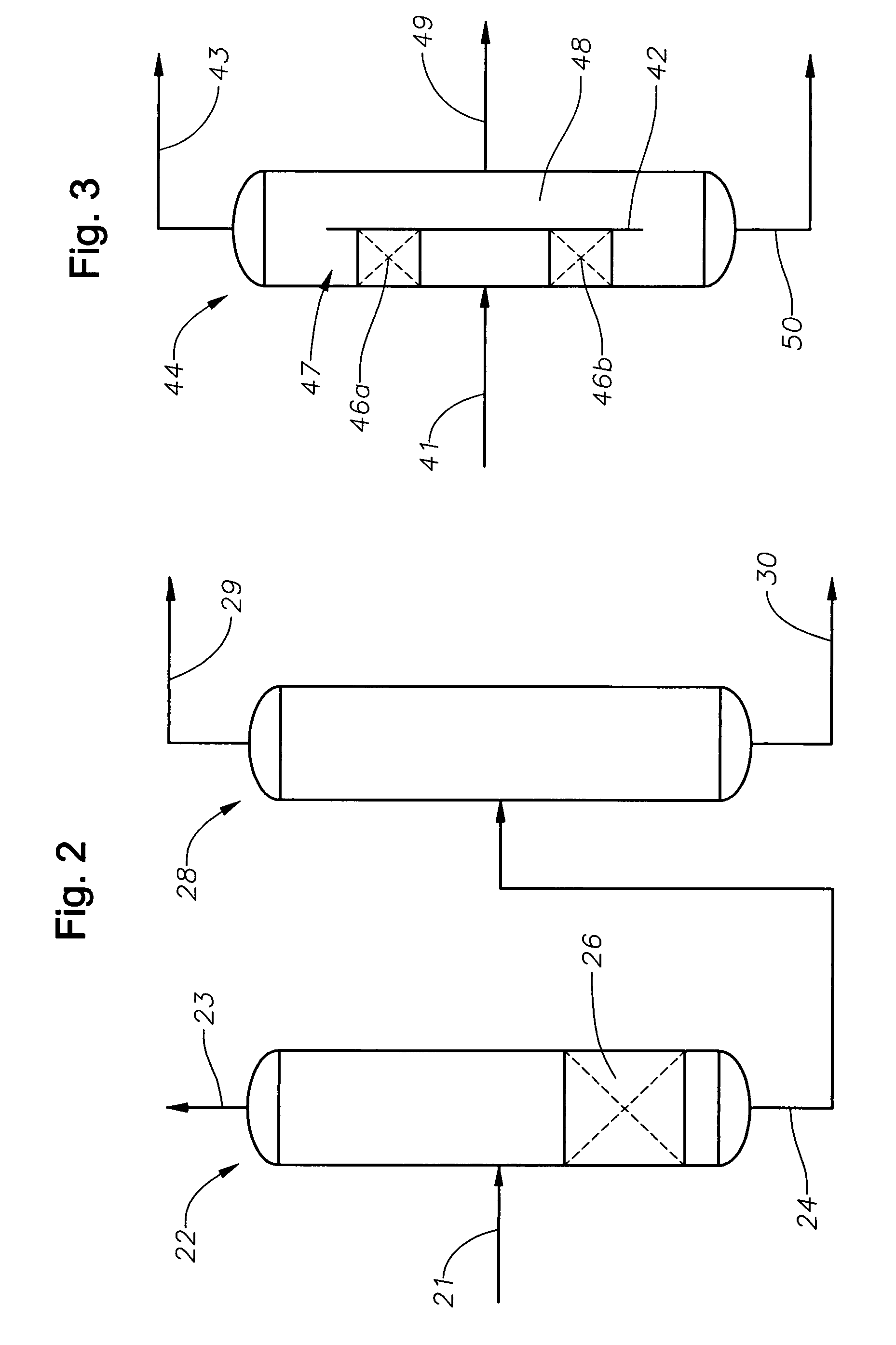

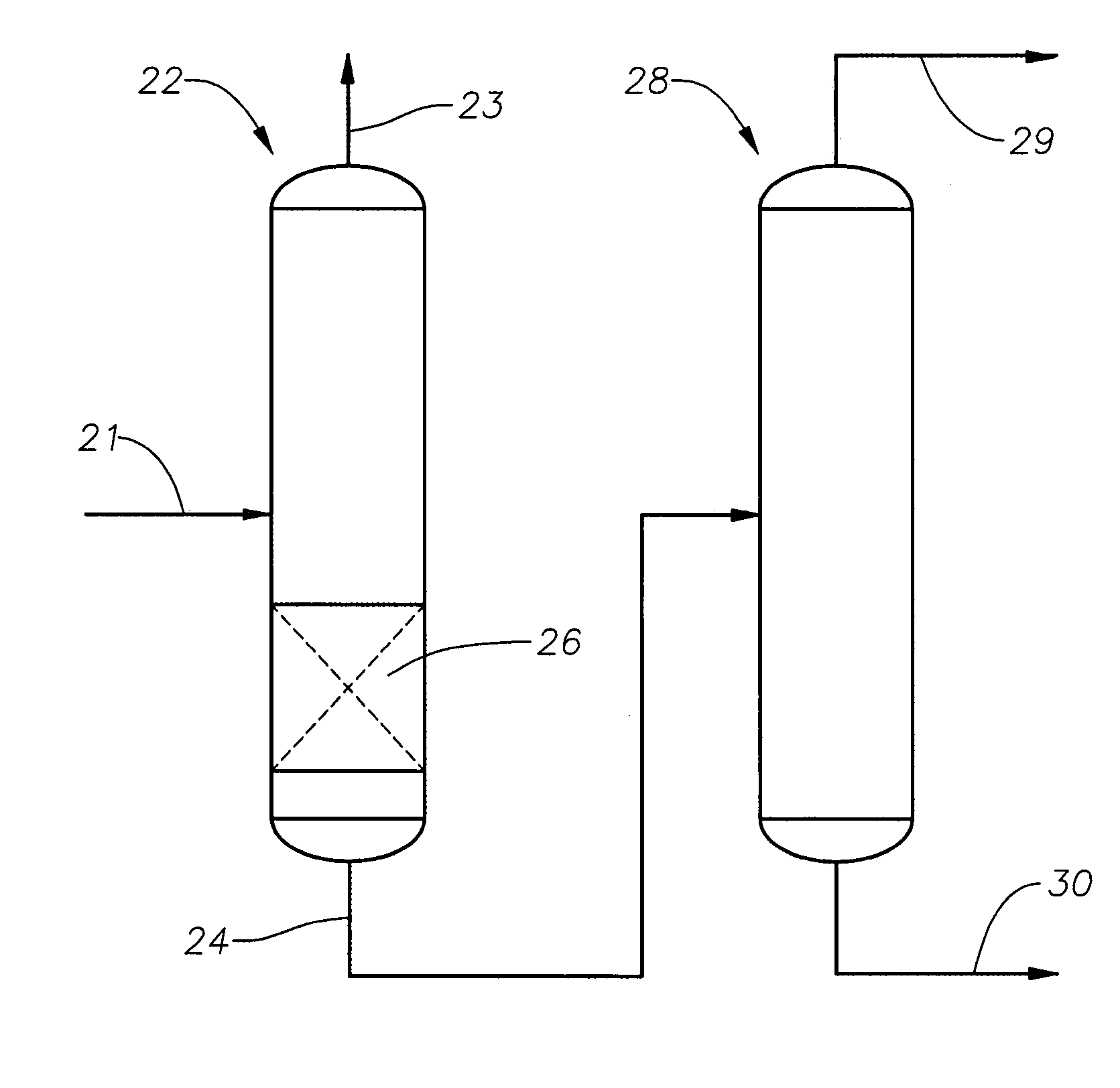

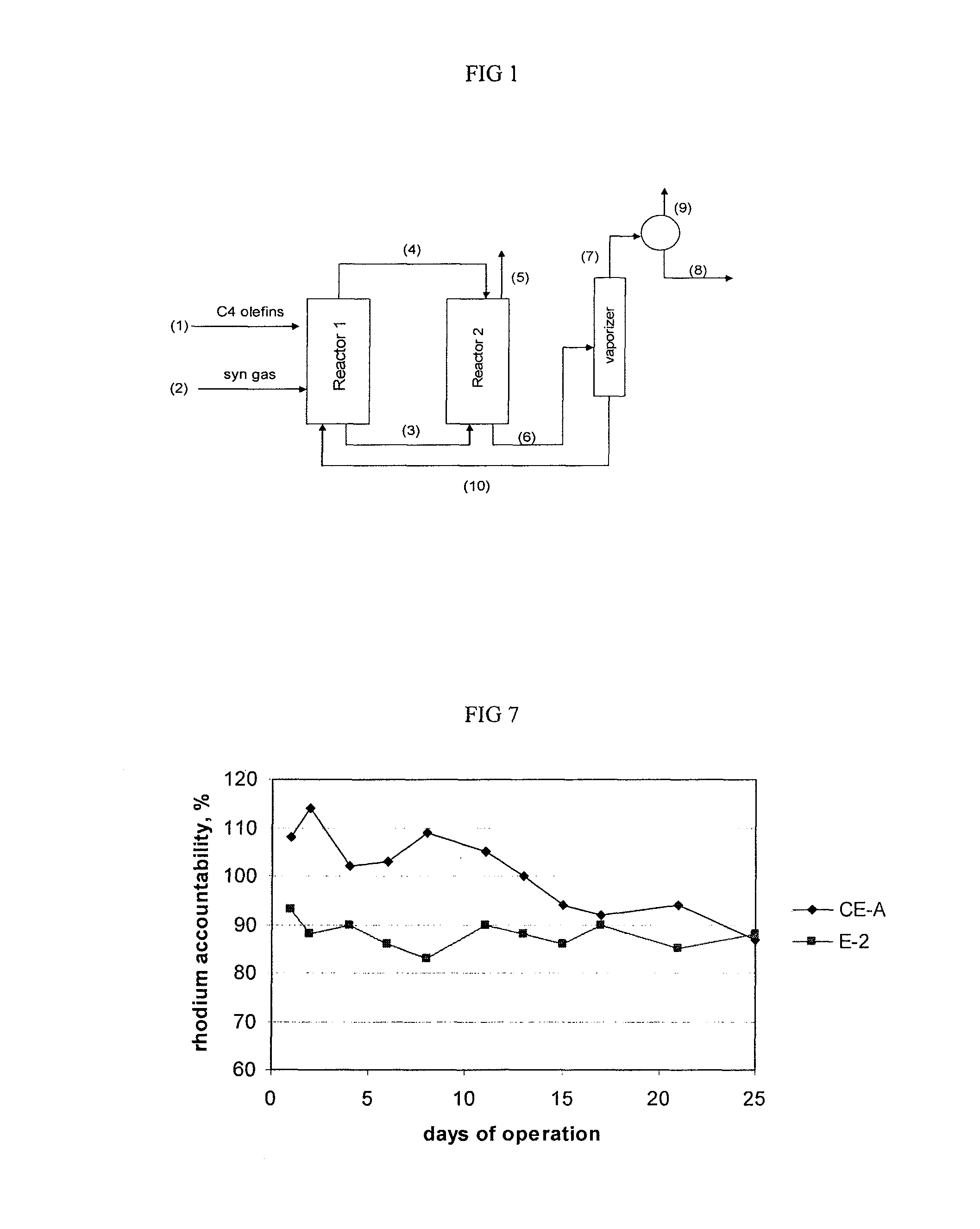

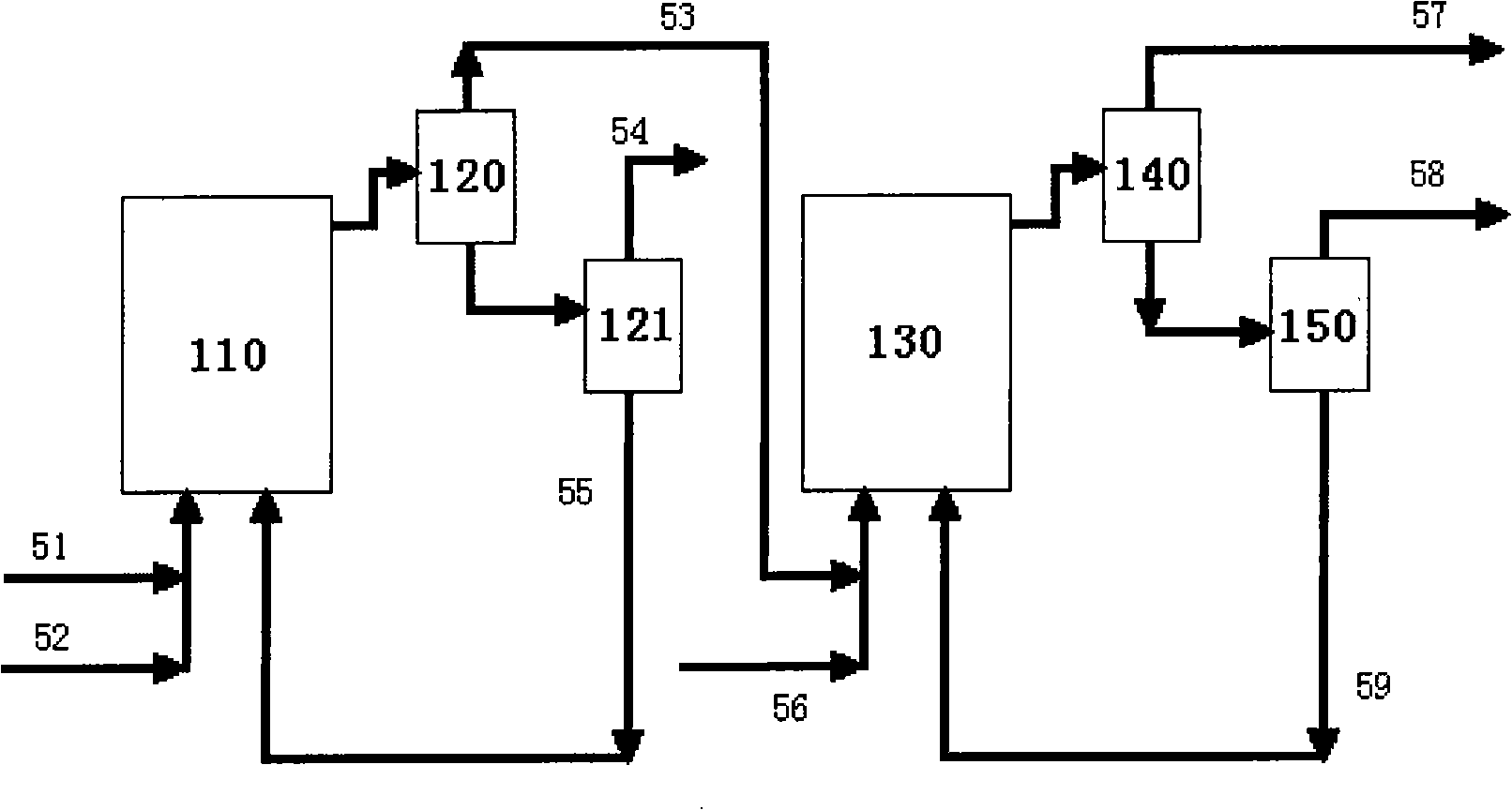

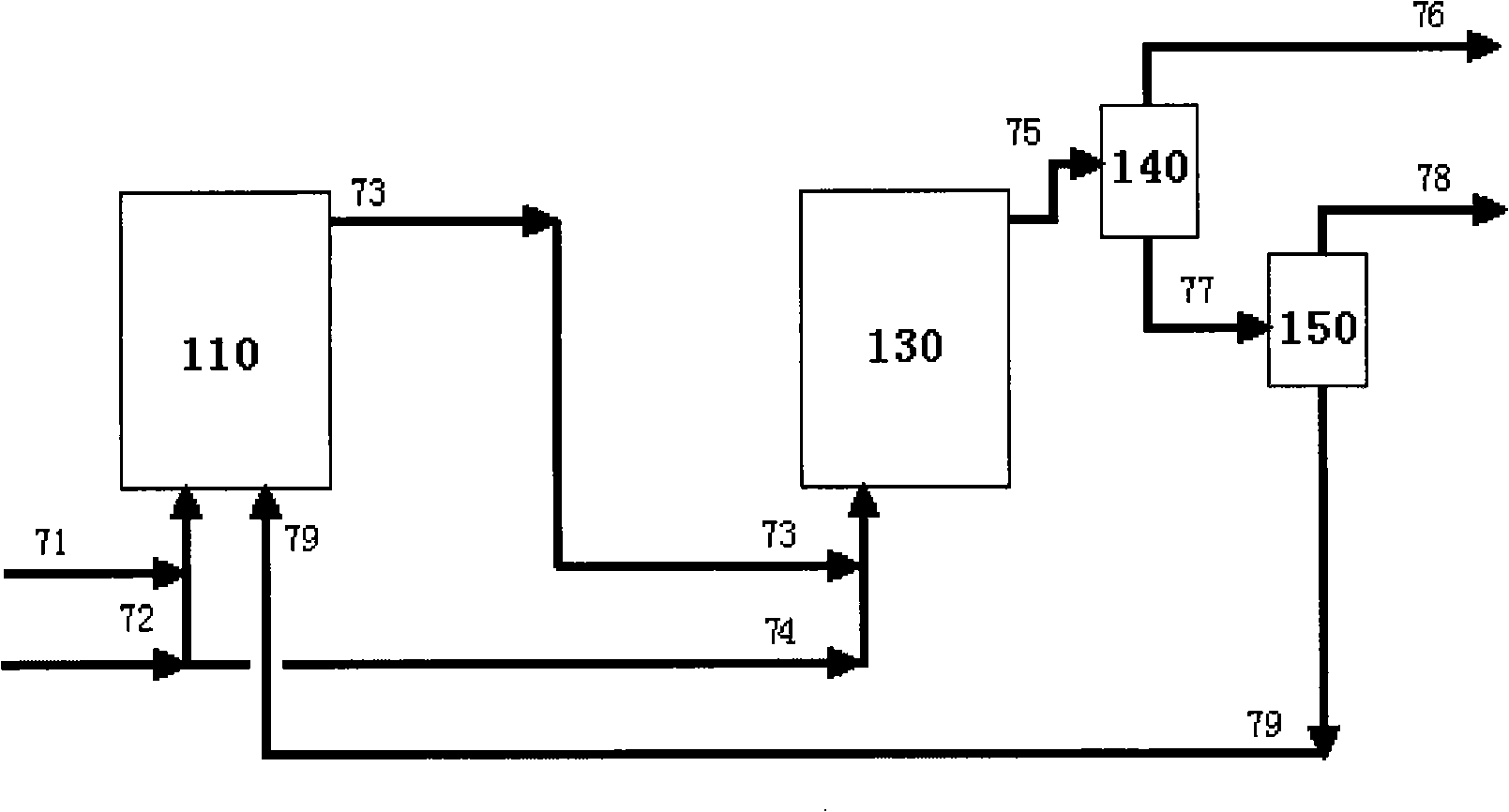

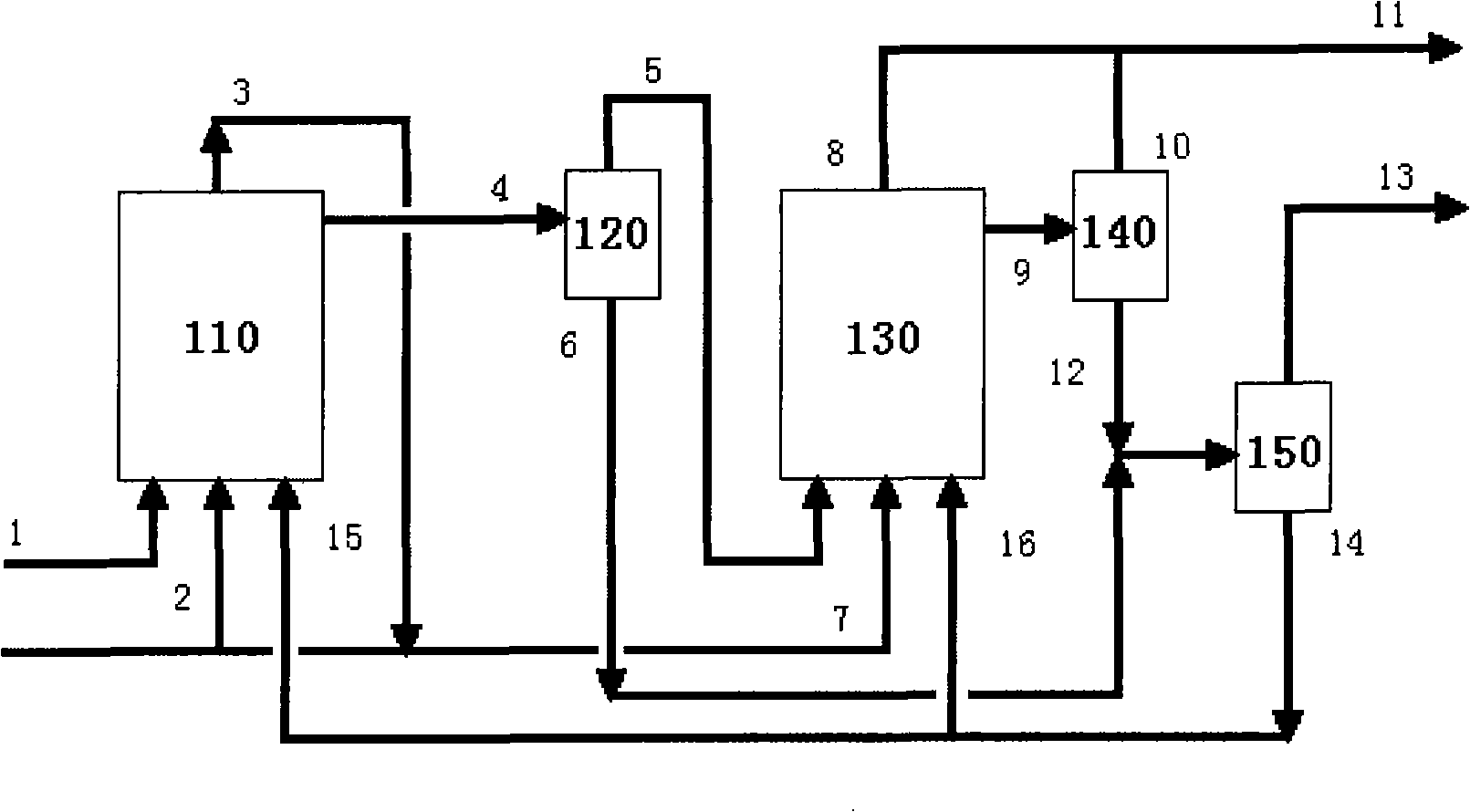

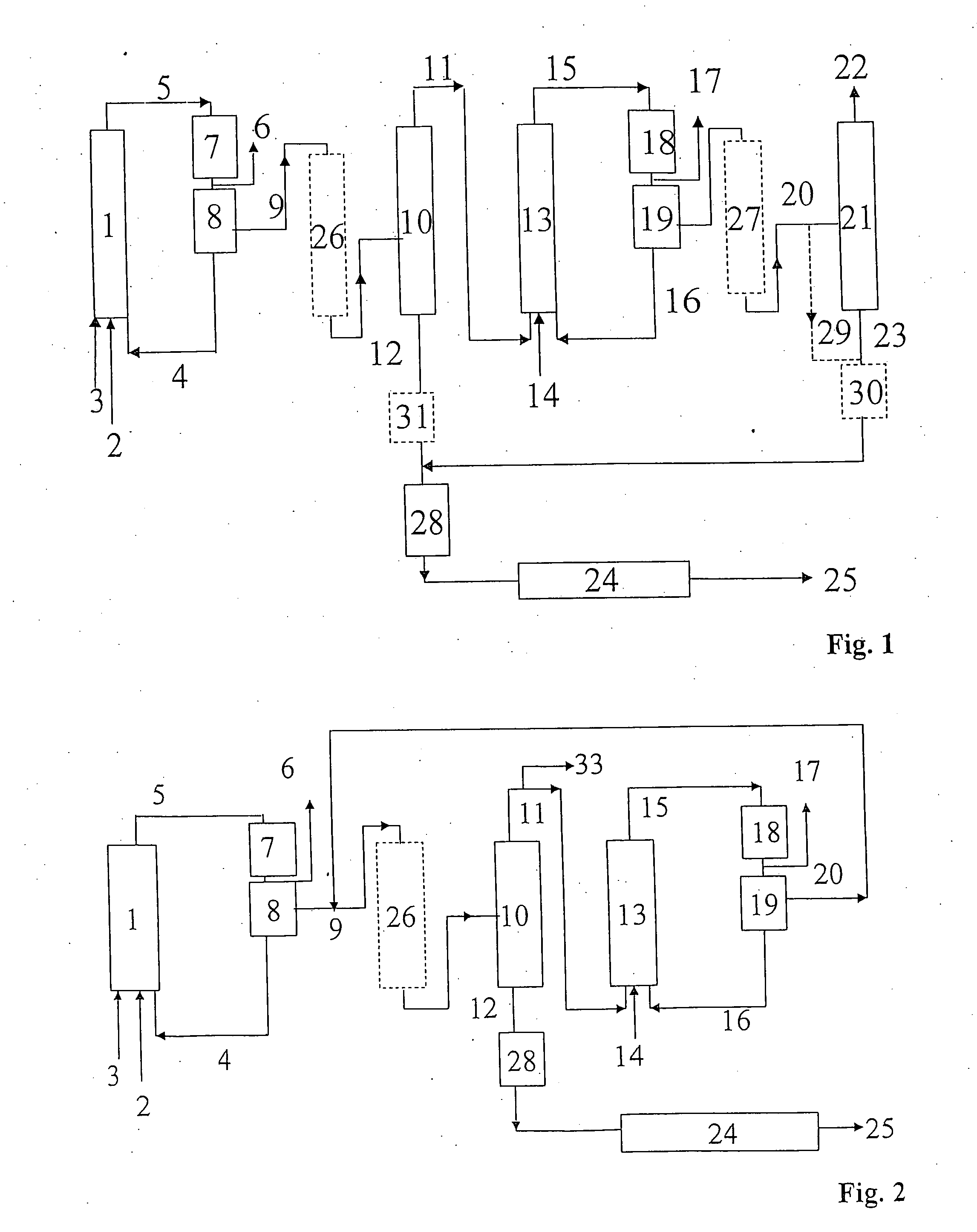

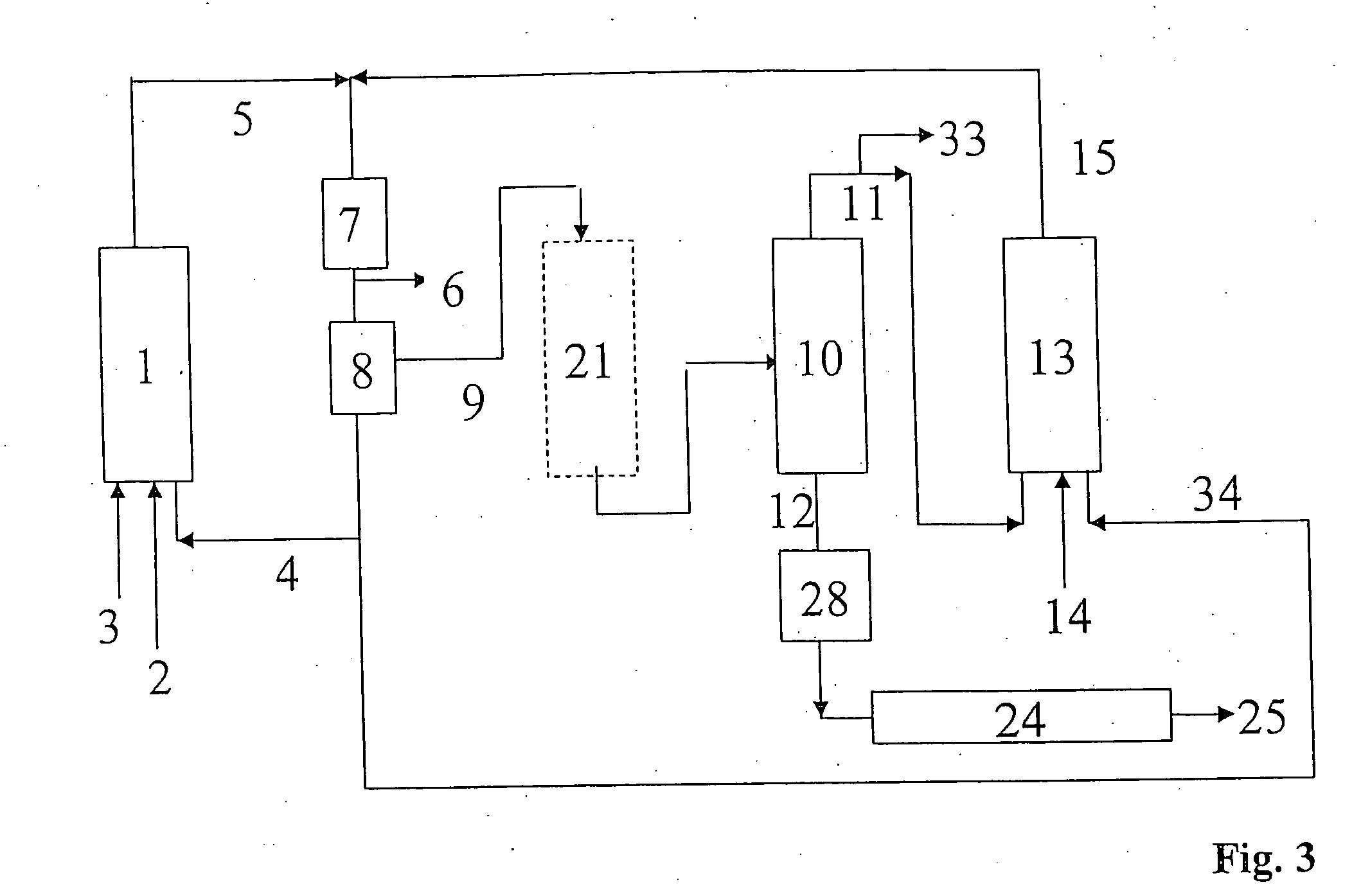

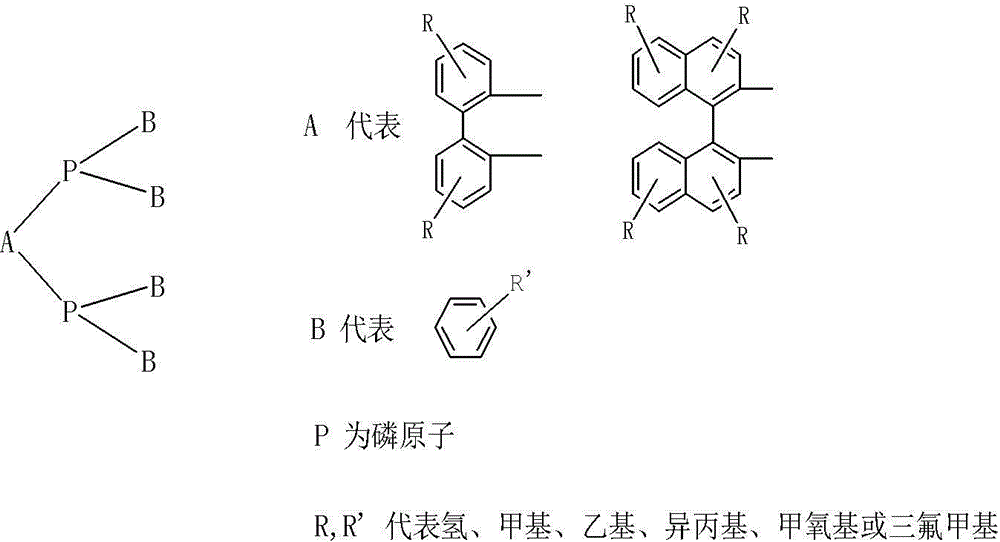

Two-stage reaction method for mixed butylene hydroformylation

The invention relates to an oxo-synthesis reaction method, particularly a method for preparing pentanal from mixed butylenes by a two-stage hydroformylation reaction. The method comprises the steps that after a first-stage hydroformylation is carried out with mixed butylenes containing 1-butylene and 2-butylene as raw materials, the reaction product containing catalyst in the discharged material is separated; the unreacted material is subjected to a second-stage hydroformylation reaction; catalyst in the two-stage products is separated and returned to two reaction vessels according to a certain proportion. The method solves the problem of reaction difference of two olefins, improves olefin utilization efficiency and reduces production cost; and is applied in a petrochemical field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heterogeneous catalysts for alkene hydroformylation reaction and preparation method thereof

ActiveCN103521268AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionMetal catalyst

The invention discloses a supported metal catalyst under double modification of an anchoring ligand and an auxiliary and a preparation method and application thereof. The catalyst comprises an active component, an auxiliary, a carrier and a ligand, wherein the active component is one or more of metals Rh, Ru and Co; the auxiliary is one or more of Al, K, Zn, Cu and Ag; the carrier is a molecular sieve SiO2, Al2O3, MCM-41 or SBA-15; the ligand is an N or P-containing organic ligand capable of acting with silicon hydroxyl. In the catalyst, the metal component and the auxiliary are directly fixed on the carrier, and then the anchoring ligand and the metal generate a coordination action to in-situ generate an active species; due to the double modification of the ligand and the auxiliary, the activity and stability of the catalyst are remarkably improved. The catalyst can be applied to alkene hydroformylation to prepare various organic aldehydes, has relatively high catalytic activity and excellent stability, and is easy to separate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

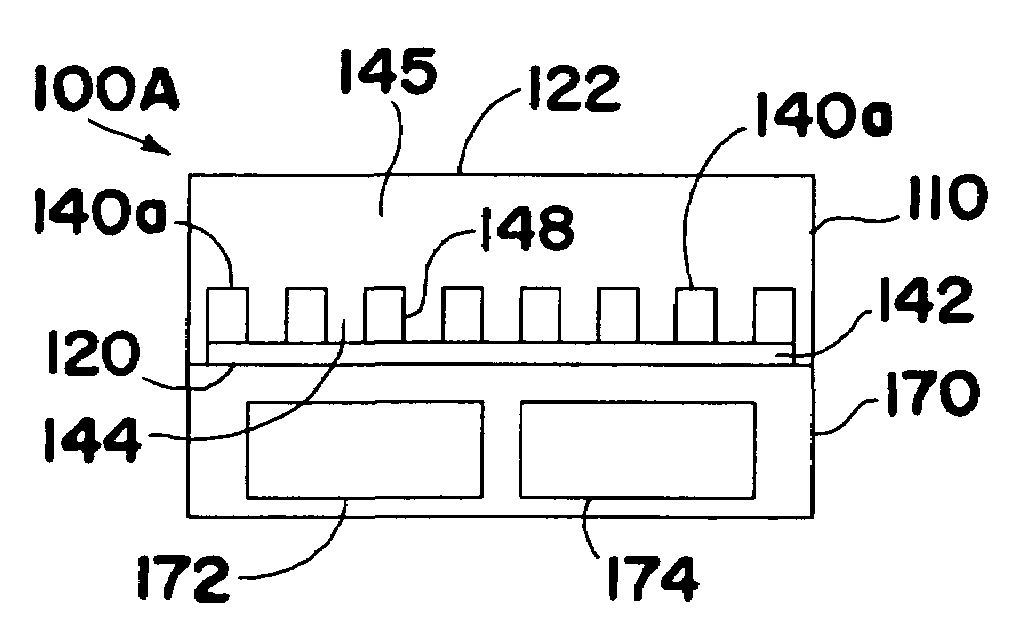

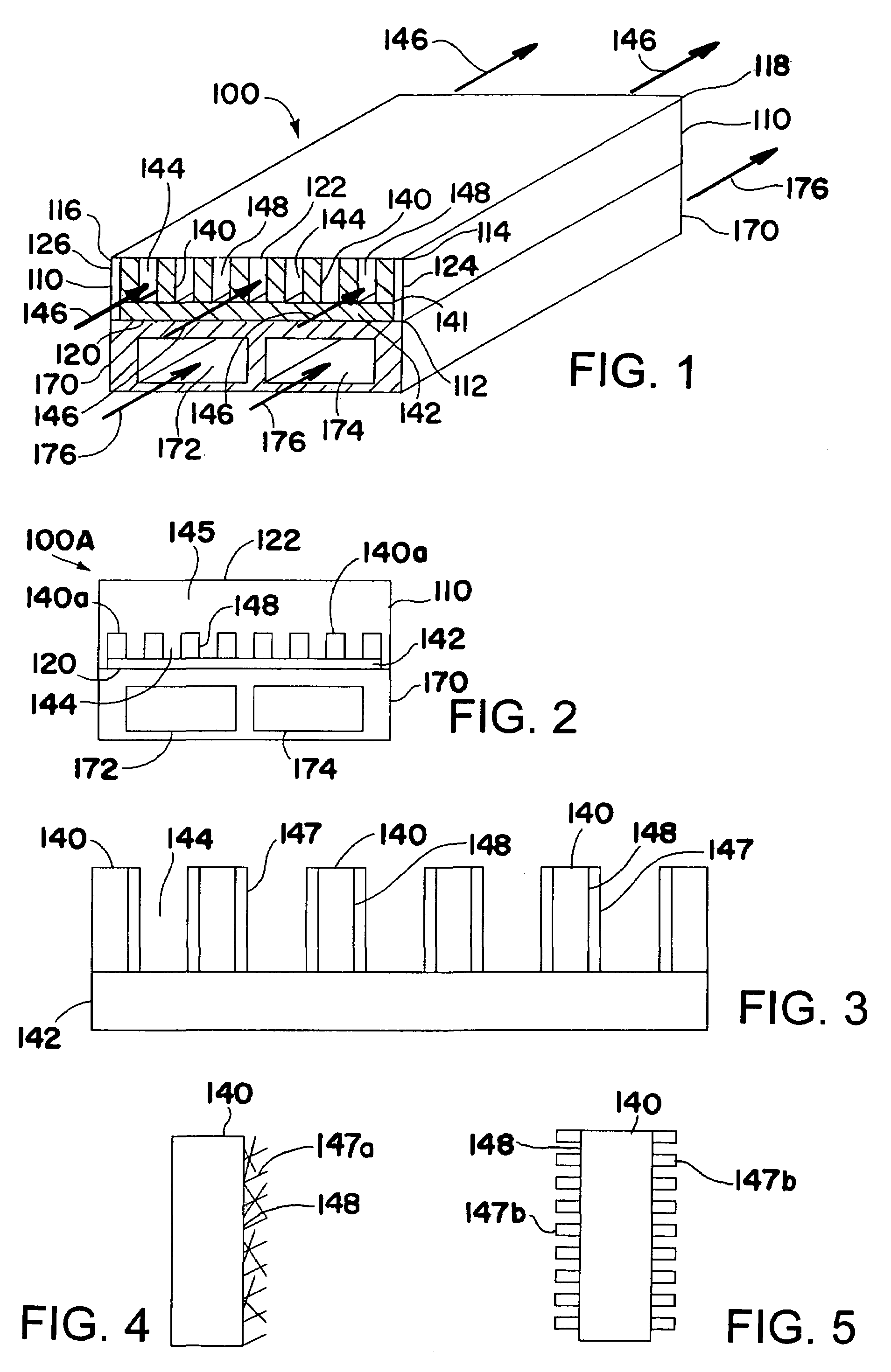

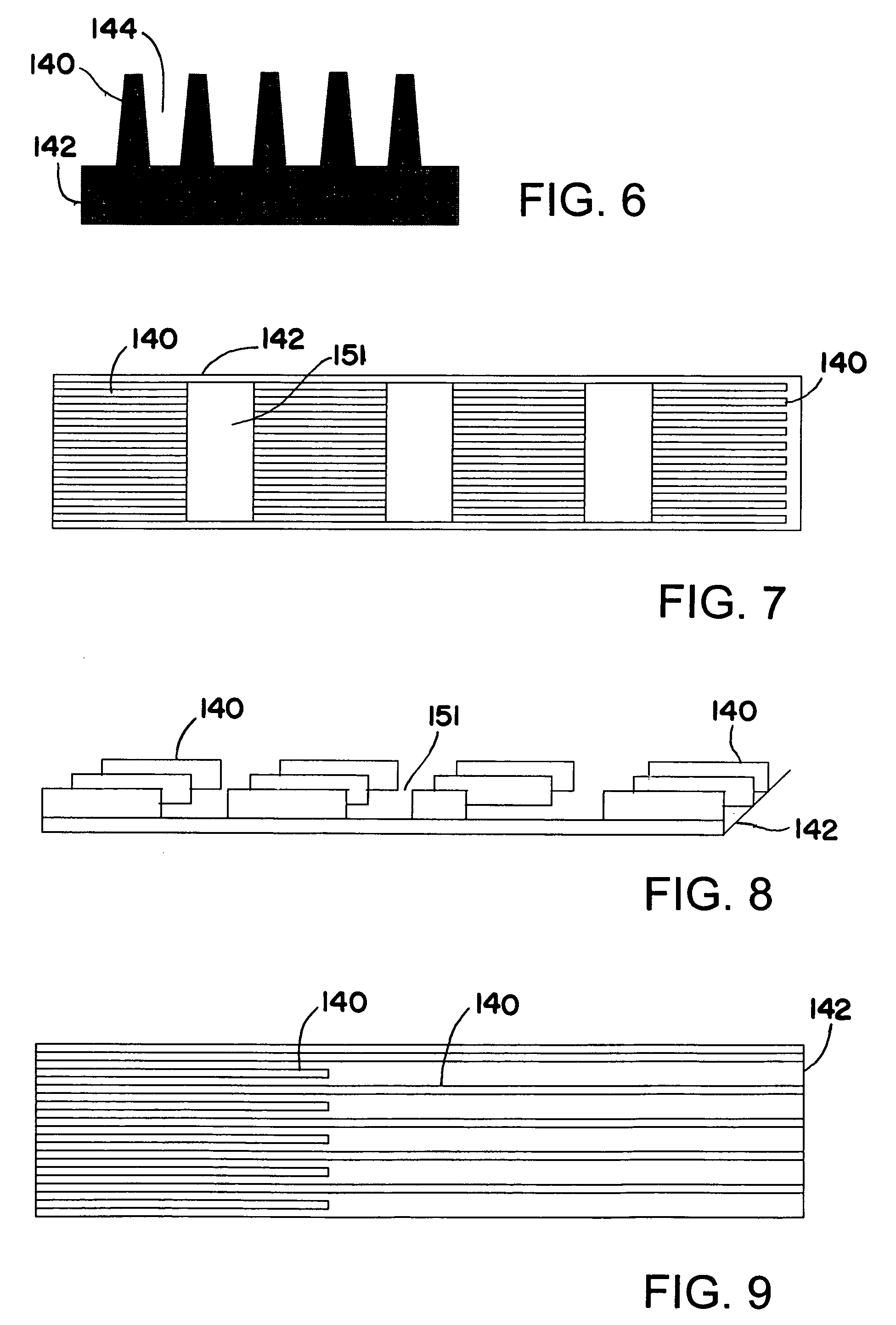

Methods and apparatus for fluid distribution in microfluidic systems

InactiveUS6890493B1Cheap manufacturingEconomical to useSequential/parallel process reactionsFlow mixersChemical treatmentMicroreactor

A chemical processing microsystem useful for identifying and optimizing materials (e.g., catalysts) that enhance chemical processes or for characterizing and / or optimizing chemical processes is disclosed. The chemical processing microsystem comprises a plurality of microreactors 600 and, in a preferred embodiment, a plurality of microseparators 900 integral with the chemical processing microsystem 10. The microreactors 600 are preferably diffusion-mixed microreactors formed in a plurality of laminae that include a modular, interchangeable candidate-material array 100. The material array 100 comprises a plurality of different candidate materials (e.g., catalysts), preferably arranged at separate, individually addressable portions of a substrate (e.g., wafer). The microseparators 900 are similarly formed in a plurality of laminae that include a modular, interchangeable adsorbent array 700. The adsorbent array 700 comprises one or more adsorbents, preferably arranged at separate, individually addressable portions of a substrate to spatially correspond to the plurality of different candidate materials. Modular microfluidic distribution systems are also disclosed. The chemical processing microsystem can be integrated into a material evaluation system that enables a comprehensive combinatorial material science research program.

Owner:FREESLATE

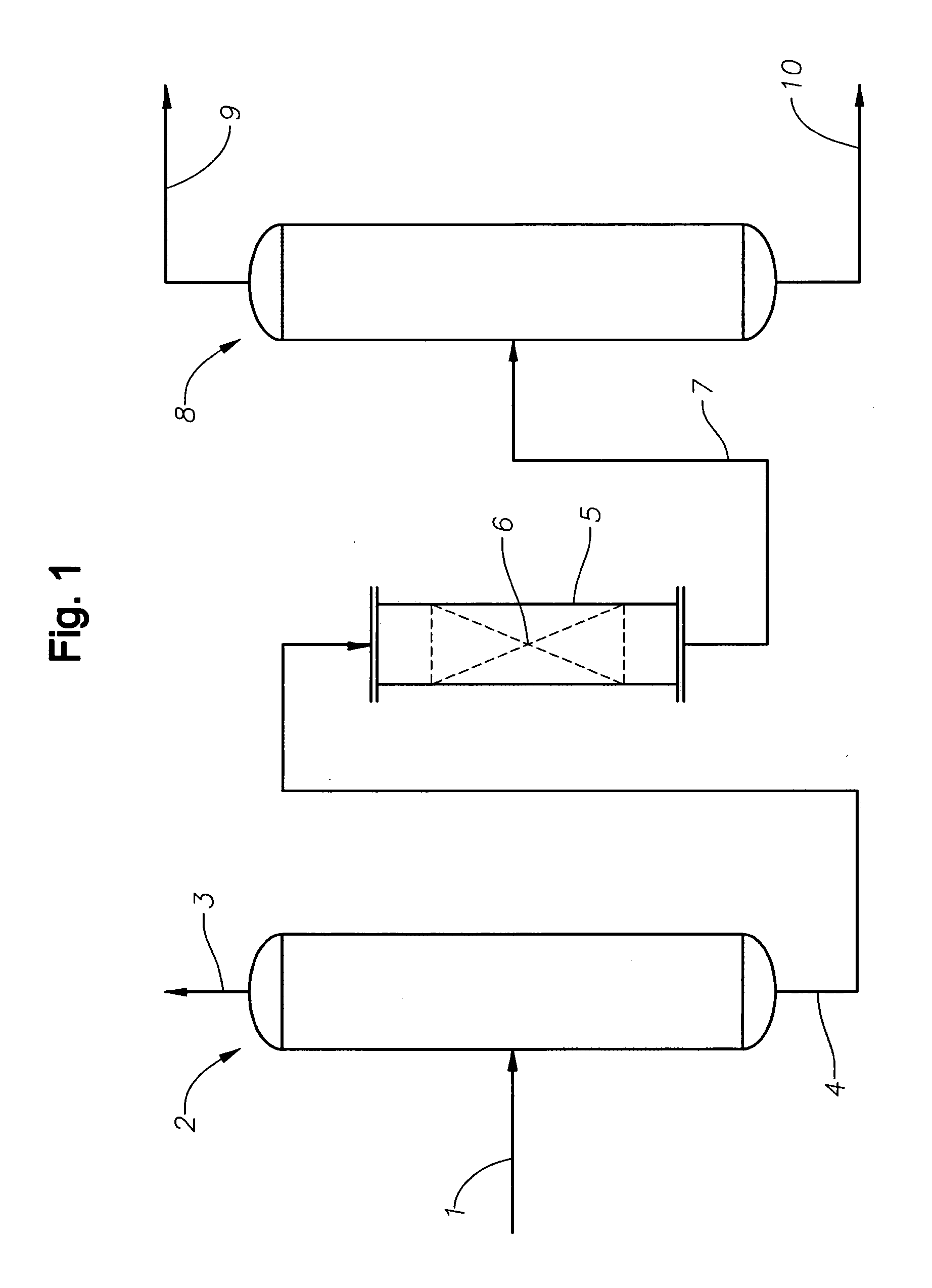

Process for preparing alcohols from olefins by hydroformylation and hydrogenation

InactiveUS20060129004A1Downtime costEasy to preparePreparation by oxo-reaction and reductionOrganic compound preparationCobalt saltOxygen

A process for preparing aliphatic alcohols that includes cobalt-catalyzed hydroformylation of olefins, treatment of a hydroformylation mixture with oxygen-containing gases in the presence of acidic, aqueous cobalt(II) salt solutions, separation of a mixture into an aqueous phase comprising cobalt salts and an organic phase comprising the aliphatic aldehydes, and hydrogenation of an aldehyde-containing organic phase wherein the organic phase and treatment with an adsorbent to separate off cobalt compounds prior to hydrogenation.

Owner:EVONIK DEGUSSA GMBH

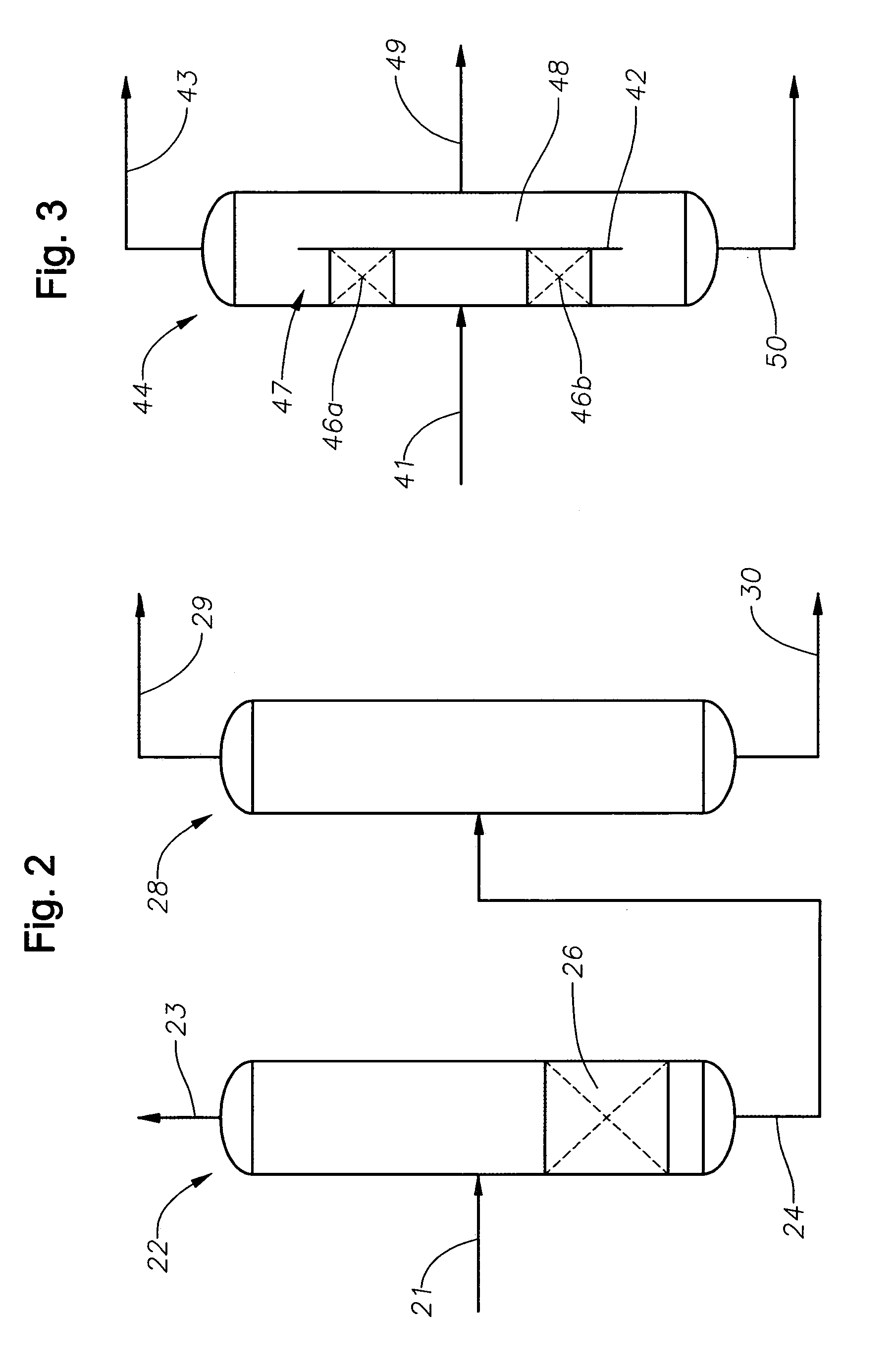

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

Heteroarylic-arylic diphosphines as chiral ligands

InactiveUS6153758ACarboxylic acid esters preparationNickel organic compoundsCarbon–carbon bondDiphosphines

PCT No. PCT / EP97 / 06358 Sec. 371 Date Apr. 18, 1999 Sec. 102(e) Date Apr. 18, 1999 PCT Filed Nov. 14, 1997 PCT Pub. No. WO98 / 22484 PCT Pub. Date May 28, 1998Diphosphines of a mixed heteroarylic-arylic type, wherein the phosphine group carrying backbone is constituted by the interconnection of a five-atom heteroaromatic ring and a carbocyclic aromatic ring, forming an atropoisomeric chiral system with a C1 symmetry. Said chiral diphosphines are advantageously used as ligands for the formation of chiral complexes with transition metals, in particular Ru, Rh, Pd, Ir, Ni. The so-obtained chiral complexes are used as chiral complexes are used as chiral catalysts for stereocontrolled reactions, in particular diastereo and enantioselective reduction reactions, hydroformylation reactions, hydrosilylation reactions, hydrocyanation reactions, double-bond isomerisation reactions, other reactions of carbon-carbon bond formation.

Owner:CHEMI SPA

Novel phosphinine compounds and metal complexes thereof

Phosphinines of formula (I) can be combined with metal salts to prepare hydroformylation catalysts. The phosphinine complexes have two phosphorus centers that may be substituted with a variety of hetero atoms or alkyl substituents to modify the ligand characteristics of the phosphinine. Phosphinine metal complexes are employed under normal hydroformylation reaction conditions. The preparatory routes to the phosphinine ligands of formula (I) allow for their convenient synthesis.

Owner:EVONIK OXENO GMBH (DE)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com