Patents

Literature

546 results about "Mannich reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Mannich reaction is an organic reaction which consists of an amino alkylation of an acidic proton placed next to a carbonyl functional group by formaldehyde and a primary or secondary amine or ammonia. The final product is a β-amino-carbonyl compound also known as a Mannich base. Reactions between aldimines and α-methylene carbonyls are also considered Mannich reactions because these imines form between amines and aldehydes. The reaction is named after chemist Carl Mannich.

Quaternary Ammonium Salt of a Mannich Compound

ActiveUS20080052985A1Organic chemistryTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) Mannich reaction product having a tertiary amino group, said Mannich reaction product being prepared from the reaction of a hydrocarbyl-substituted phenol, an aldehyde, and amine; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

Process for the synthesis of alpha-substituted acroleins

InactiveUS7141702B2Organic compound preparationPreparation by carbon monoxide reactionSyngasMannich reaction

Owner:COUNCIL OF SCI & IND RES

Method of operating internal combustion engine by introducing detergent into combustion chamber

InactiveUS20050215441A1Improve performanceImprove fuel performanceLiquid carbonaceous fuelsAdditivesCombustion chamberMannich reaction

In a method of operating an internal combustion engine, a nitrogen-containing detergent composition is introduced into a combustion chamber of the engine wherein the detergent composition can improve the performance of both a fuel composition and a lubricating oil of the engine. The detergent composition contains (A) a reaction product of a hydrocarbyl-substituted acylating agent and an amine, (B) a hydrocarbyl-substituted amine, (C) a Mannich reaction product, (D) a high molecular weight polyetheramine, or (E) a mixture thereof.

Owner:THE LUBRIZOL CORP

Quaternary ammonium salt of a Mannich compound

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) Mannich reaction product having a tertiary amino group, said Mannich reaction product being prepared from the reaction of a hydrocarbyl-substituted phenol, an aldehyde, and amine; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

Methods and compositions for improving stability of biodiesel and blended biodiesel fuel

Methods and compositions for improving stability of biodiesel fuel. The methods comprise adding to said biodiesel fuel, an effective amount of a combined treatment that includes a (I) hindered phenol and (II) a Mannich reaction product. The compositions comprise I and II dissolved or dispersed in an organic solvent.

Owner:AFTON CHEMICAL

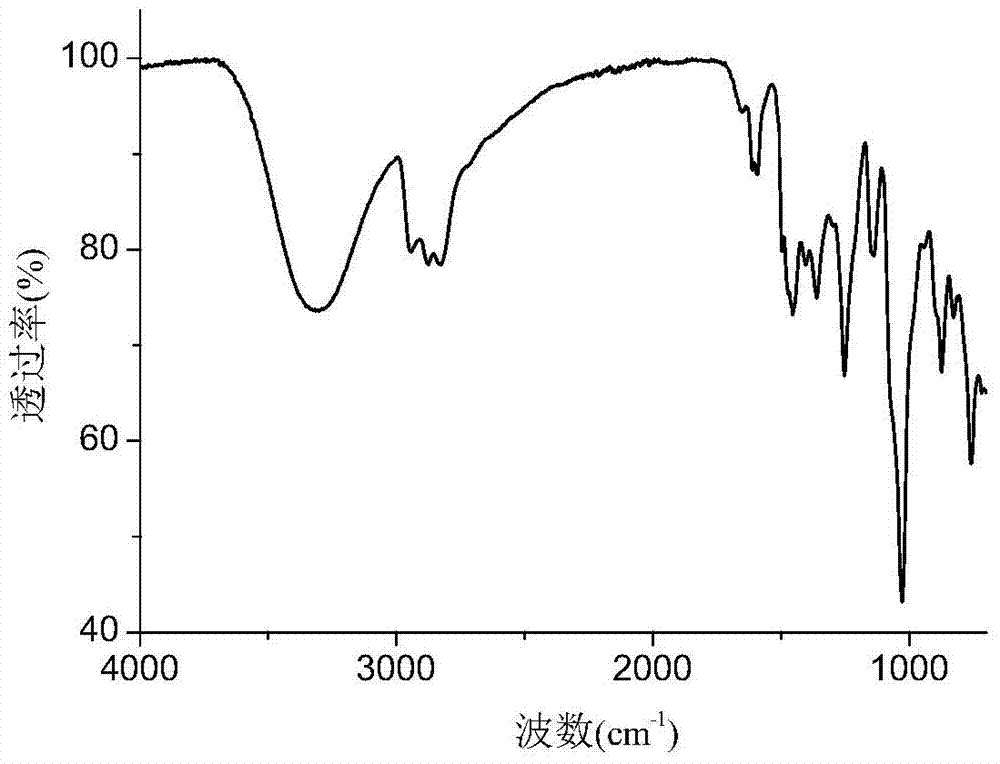

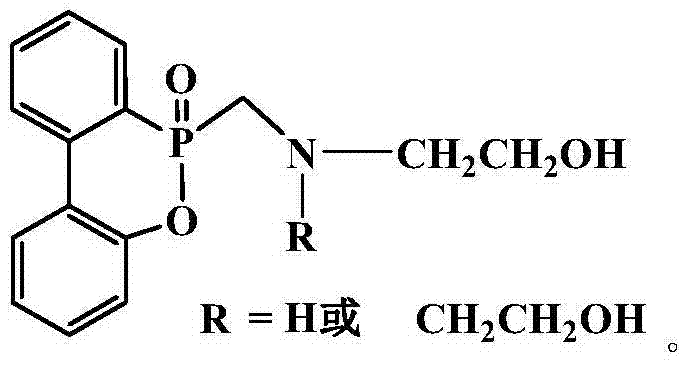

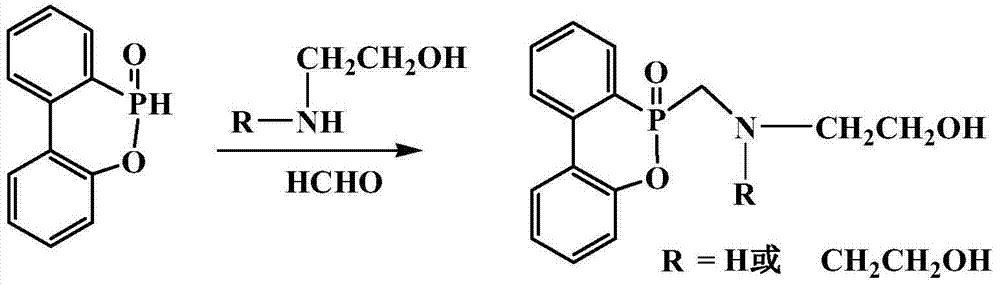

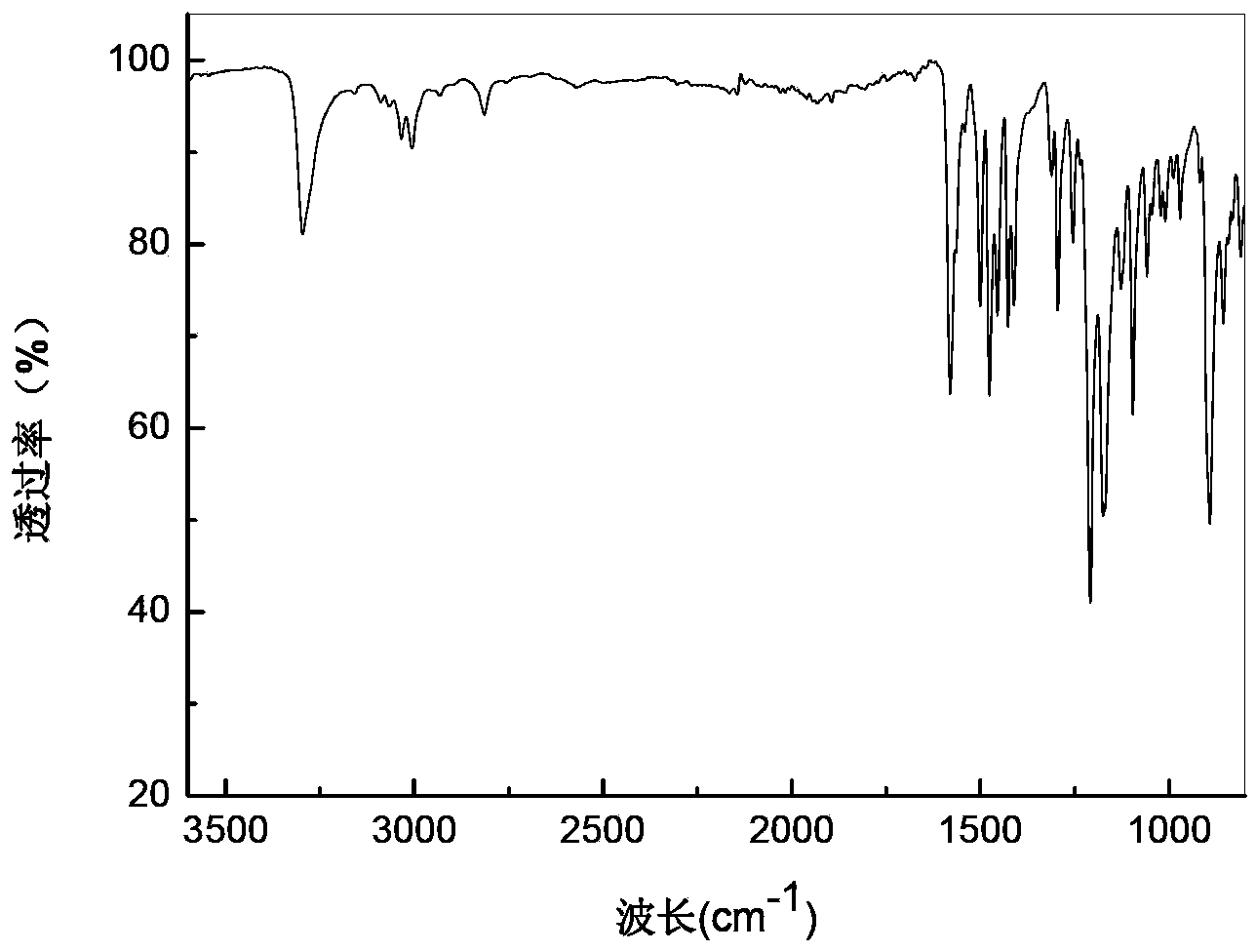

Halogen-free reaction type flame retardant for polyurethane foam as well as preparation method and application thereof

ActiveCN103694434AGood storage stabilityGood compatibilityGroup 5/15 element organic compoundsMannich reactionOxygen

The invention provides a halogen-free reaction type flame retardant for polyurethane foam as well as a preparation method and an application thereof. The halogen-free reaction type flame retardant is prepared through a Mannich reaction of 9,10-dihdro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), alcohol amine and formaldehyde; the structural formula of the halogen-free reaction type flame retardant is as shown in the specification; the alcohol amine and the formaldehyde are introduced to the DOPO flame retardant structure through a DODO reaction; the cost of the flame retardant is reduced; the synthesized halogen-free reaction type flame retardant contains active hydroxyl, flame retardant nitrogen and phosphorus, and primary amine or tertiary amine and has relatively high reaction activity; as rigid benzene rings are applied to the flame retardant type polyurethane foam, the flame retardant type polyurethane foam has relatively high flame retardance, the strength and the flame retardance durability of the flame retardant type polyurethane foam are improved, and the oxygen index can reach 23-28%. The flame retardant type polyurethane foam has wide application prospect in buildings, heat preservation fields and certain special occasions.

Owner:徐州市洛克尔化工科技有限公司

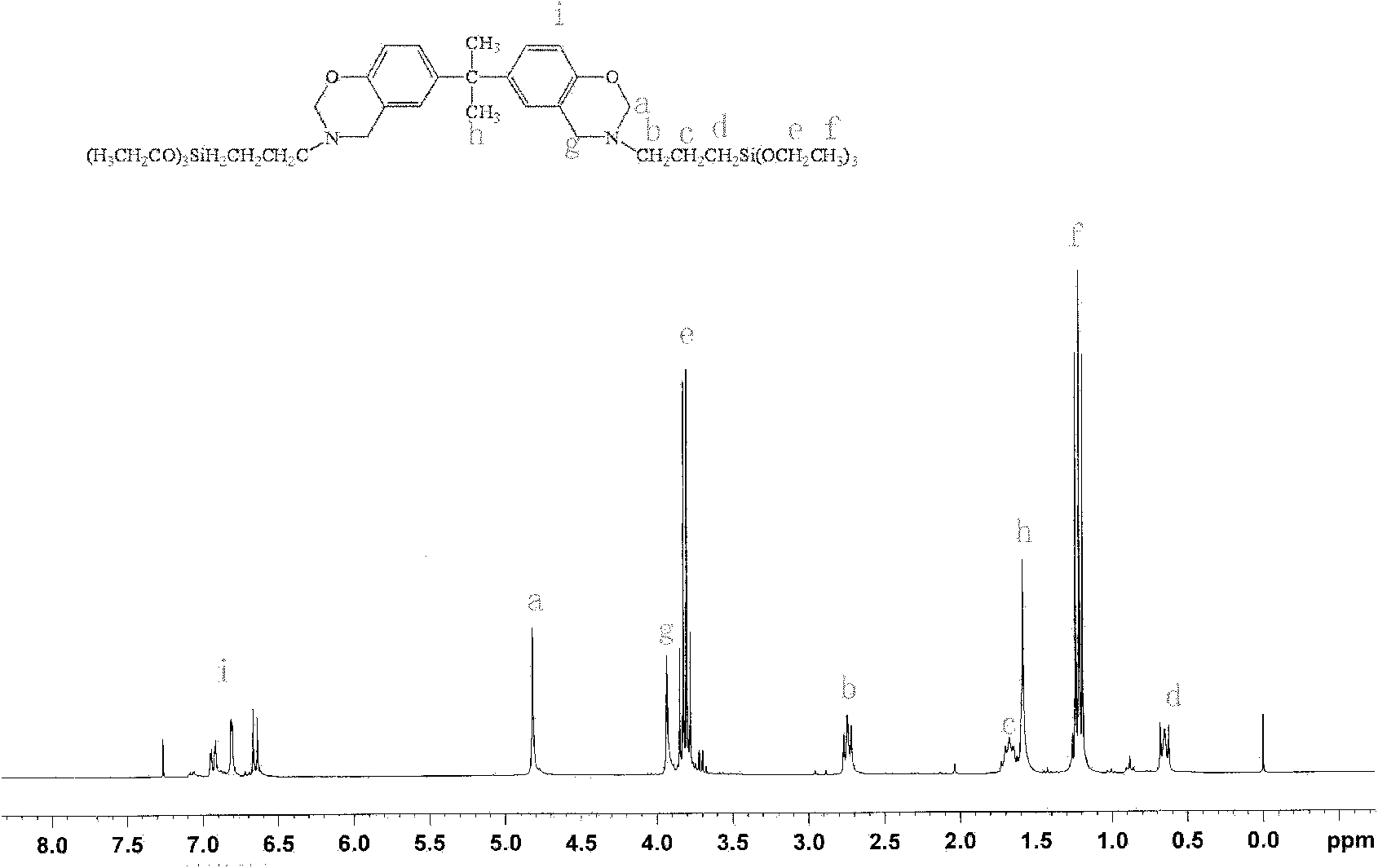

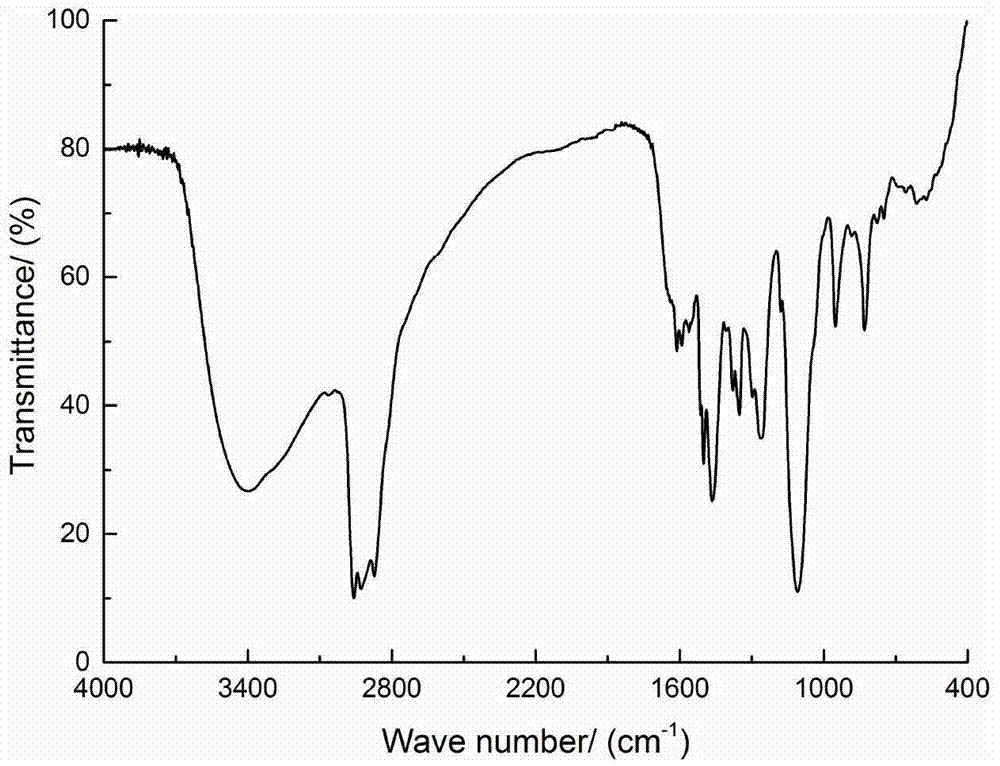

Silicon-containing benzoxazine resin as well as preparation method and application thereof

ActiveCN102134254AHigh carbon residue rateHigh glass transition temperatureGroup 4/14 element organic compoundsCoatingsPolymer scienceSynthesis methods

The invention discloses a silicon-containing benzoxazine resin. A monomer of the silicon-containing benzoxazine resin is synthesized through Mannich reaction according to theoretical mole ratio by taking phenols compounds, formaldehyde and amine compounds as reactive raw materials; and a polymer of the silicon-containing benzoxazine resin is obtained by carrying out hydrolytic condensation and heating ring-opening polymerization reaction on the monomer. Silicon-containing benzoxazine has higher carbon residual rate, glass transition temperature and silicon content and lower surface energy, thereby having potential application prospect in preparing ablation resisting materials, heat resisting material, flame-retardant materials and waterproof materials; and in addition, the invention has the advantages of simplicity, convenience and easy operation of a synthesis method of a benzoxazine monomer and a solidification process of poly-benzoxazine without specific equipment requirements and can carry out industrial production in a general plant.

Owner:SHANDONG UNIV

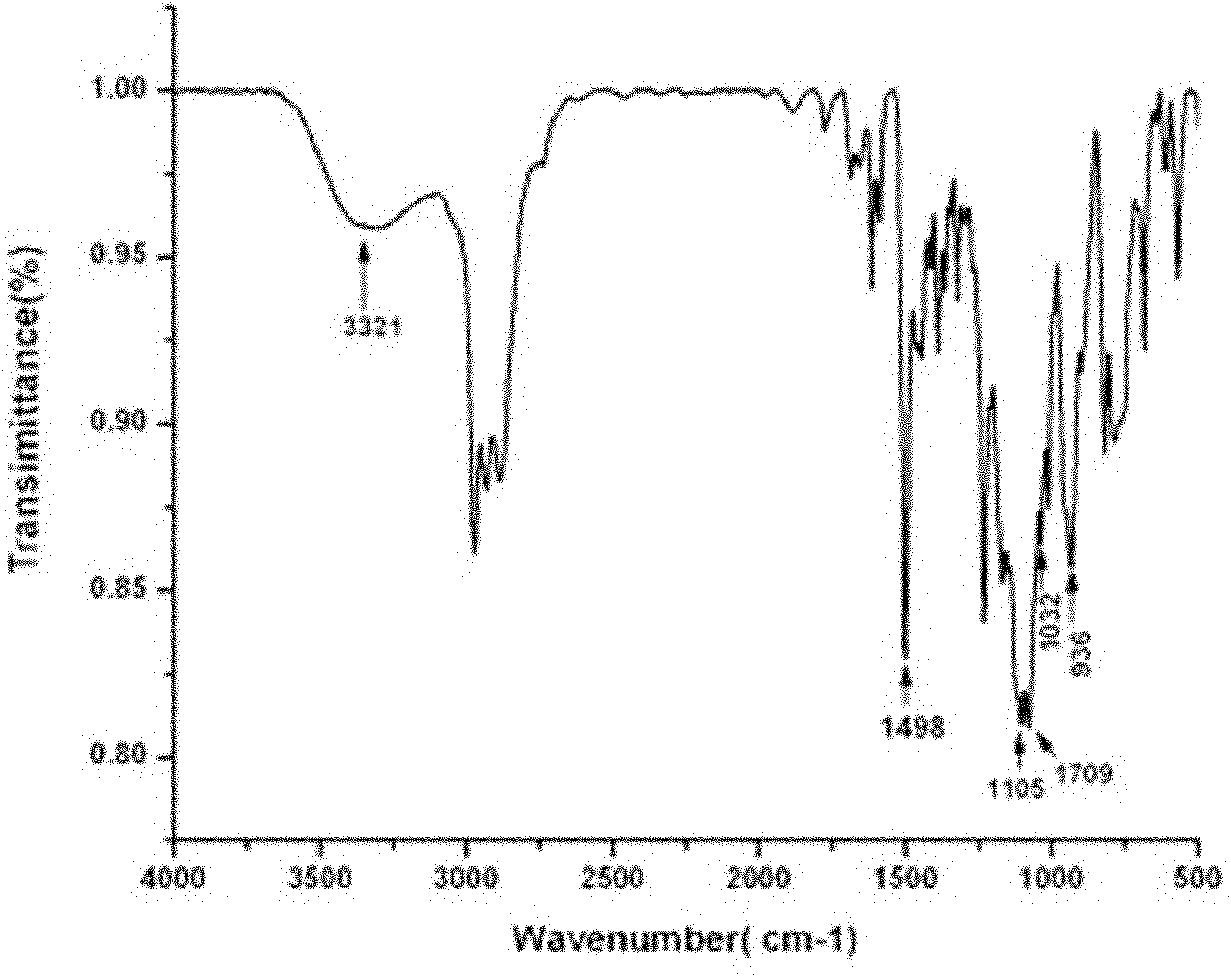

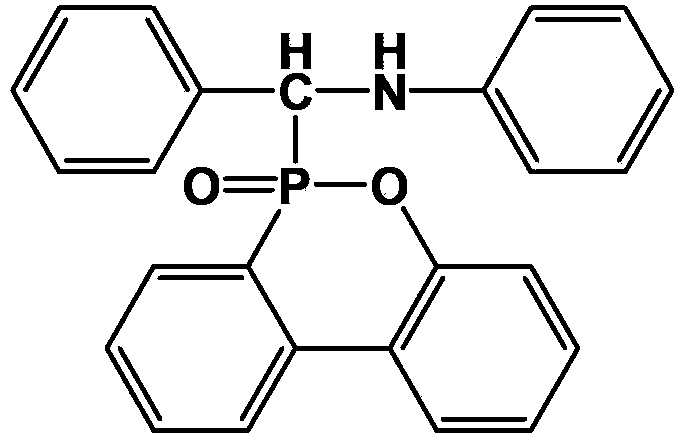

Polyurethane foam fire retardant, and preparation method and applications thereof

InactiveCN103382266AHigh compressibilityImprove durabilityGroup 5/15 element organic compoundsBenzenePolymer science

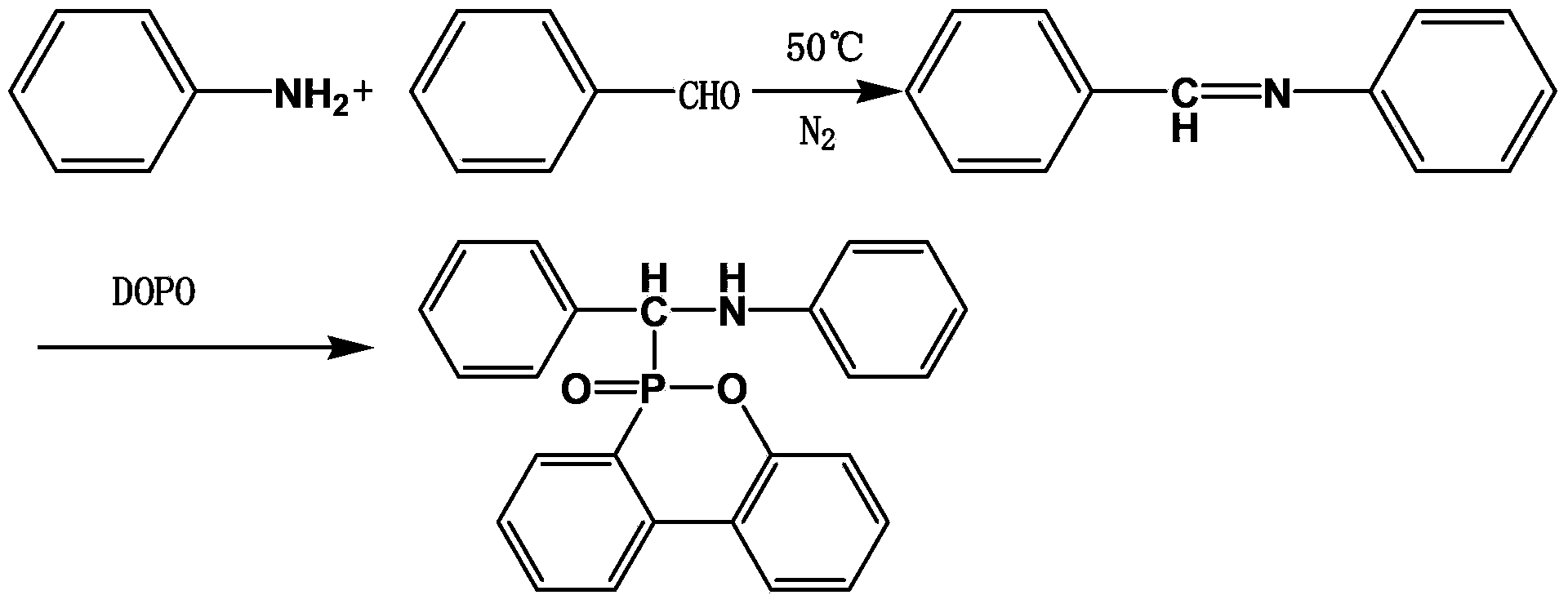

The invention discloses a polyurethane foam fire retardant obtained by reacting 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, aniline and benzaldehyde. The structural formula of the polyurethane foam fire retardant is represented by a formula in the patent specification. According to the preparation method of 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline)methyl]benzene, aniline and benzaldehyde are introduced into the 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) fire retardant structure by Mannich reaction, so that the cost of the fire retardant is reduced; synthesized 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-4-[(aniline)methyl]benzene is used as a fire-retardant rigid polyurethane foam, and possesses relatively high fire retardant; and the oxygen index can reach 24 to 26%. The polyurethane foam fire retardant possesses a promising application prospect in buildings, insulation, and specific occasions.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

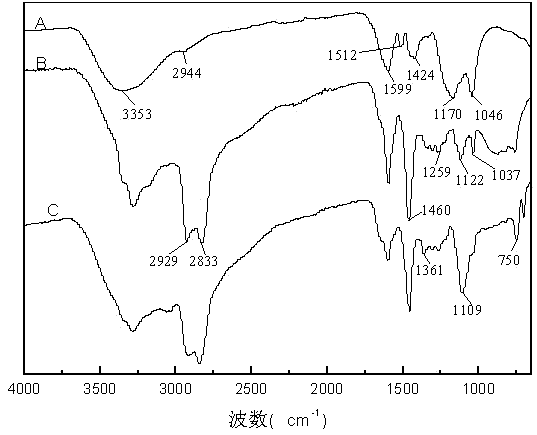

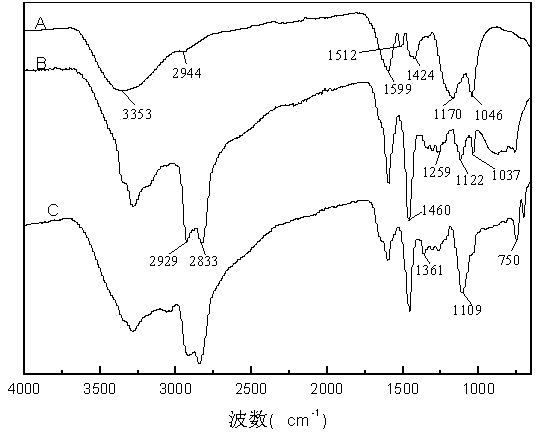

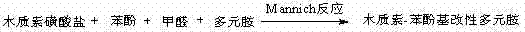

Preparation and application of lignin-phenolic group modified amine waterborne epoxy hardener

The invention discloses preparation and application of a lignin-phenolic group modified amine waterborne epoxy hardener. The method takes lignosulfonate and phenol as raw materials, and comprises the following steps of: performing Mannich reaction on the lignosulfonate, the phenol, polyamine and formaldehyde to prepare lignin-phenolic group modified polyamine, and then terminating the primary amine in the lignin-phenolic group modified polyamine by a single epoxy compound to obtain the lignin-phenolic group modified amine waterborne epoxy hardener. The hydrophilic sulfonic group and the rigid benzene ring structure are introduced into the molecule of the waterborne epoxy hardener product, thus enhancing the hydrophilicity of the hardener and also improving the hardness of a curing system. If matched with liquid epoxy resin, the lignin-phenolic group modified amine waterborne epoxy hardener can be extensively used in cement concrete materials for improving the fracture resistance, tensile property and the like of cement concrete. The preparation method disclosed by the invention is simple and environment-friendly without using toxic solvents in the reaction process, has little energy consumption, fully utilizes rich biomass raw materials of China and is favorable for saving petrochemical resources.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

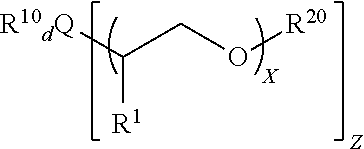

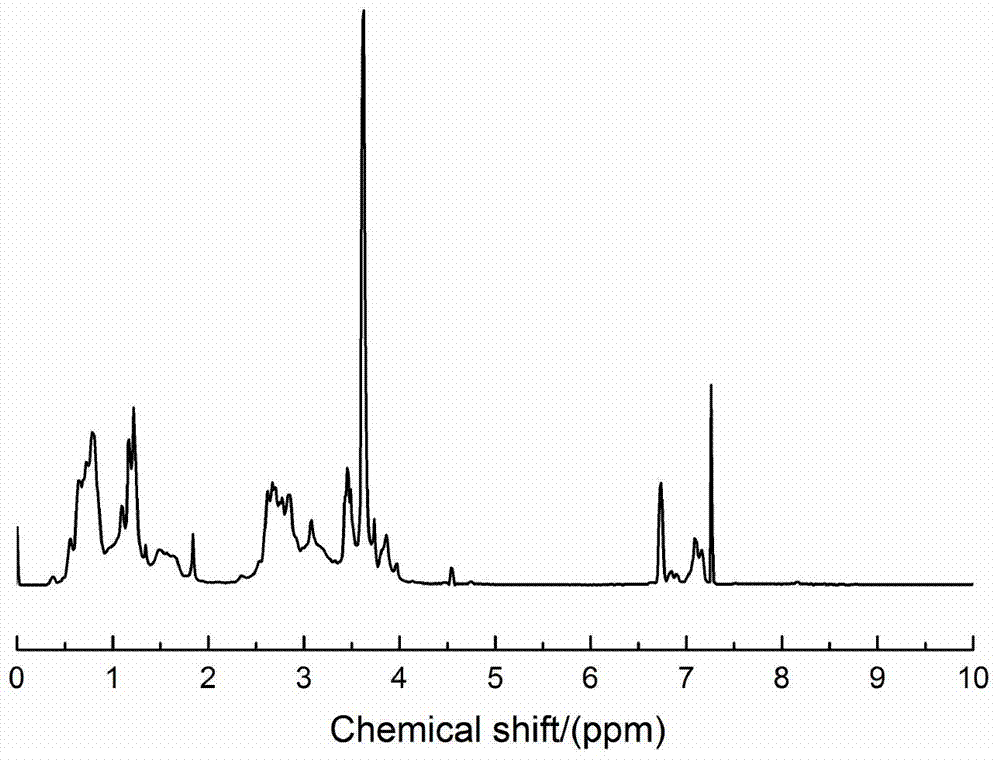

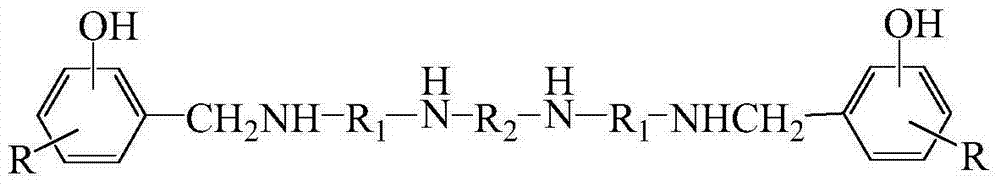

Nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure and preparation method thereof

InactiveCN104262589AThe synthesis process is simpleThe synthesis process is simple and controllableOrganic compound preparationAmino-hyroxy compound preparationWater basedEpoxy

The invention discloses a nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure, of which the molecular general formula is disclosed in the specification. The preparation method comprises the following steps: 1) adding alkyl phenol, polyamine and formalin in a solvent to carry out Mannich reaction, and removing the solvent and byproduct after the reaction finishes, thereby obtaining Mannich amine containing primary amine group; and 2) sufficiently reacting the Mannich amine containing primary amine group with diglycidyl ether, cooling after the reaction finishes, adding water, and sufficiently dispersing to obtain an emulsion, thereby obtaining the product. The synthesis technique is simple and pollution-free; the synthesized curing agent does not need to perform salification reaction to implement self-emulsifying action by using organic acid; the epoxy curing agent has the advantages in the Gemini surfactant and has the characteristics of excellent wettability, excellent emulsibility, excellent stability and the like; and the epoxy curing agent can directly emulsify and cure the liquid epoxy resin, and can also cure an epoxy resin dispersion solution.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

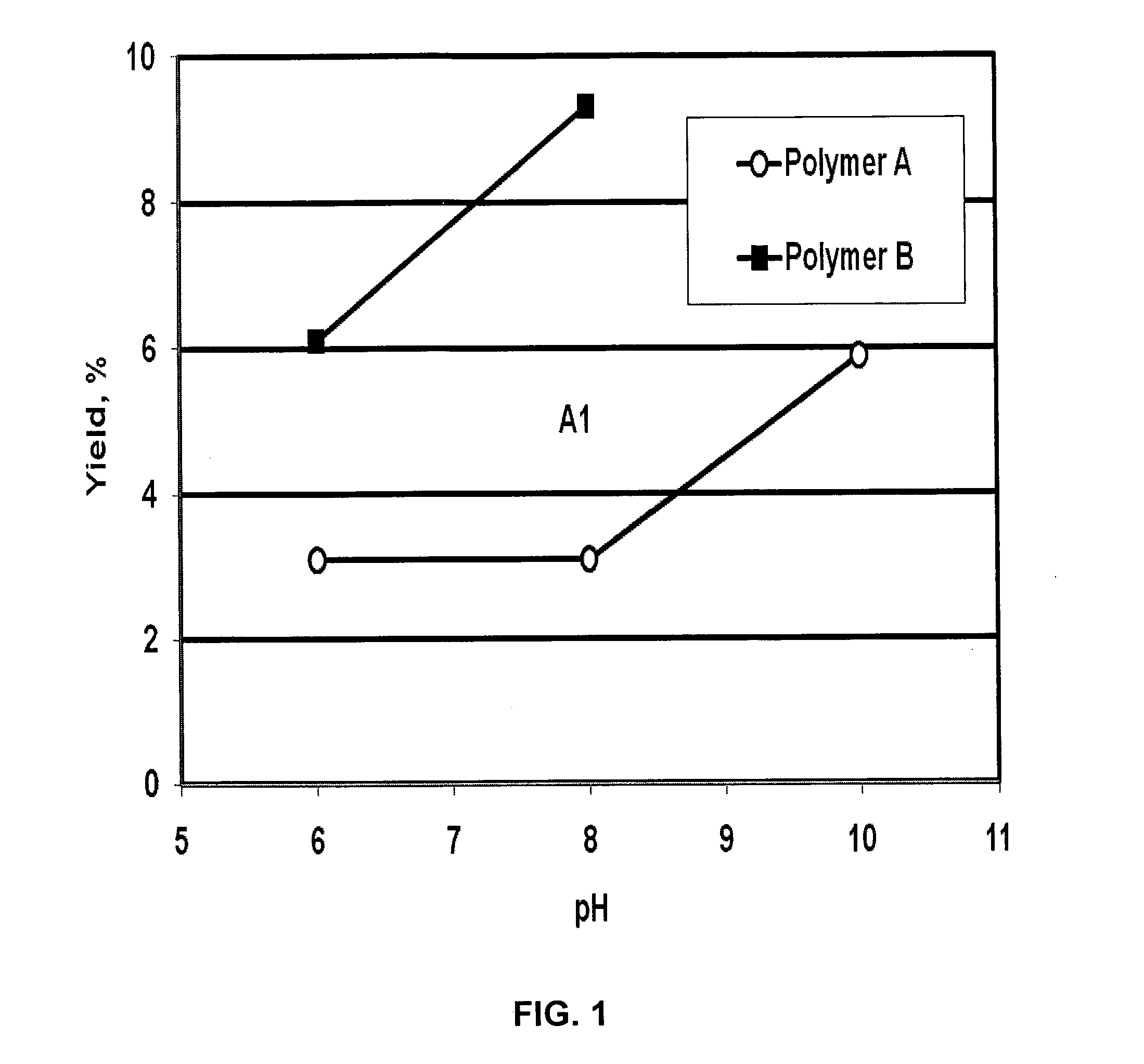

Subterranean Reservoir Treatment Method

A method is given for heterogeneous proppant placement in fracturing by in situ aggregation of fine mesh proppant particulates or other materials such as fibers in a subterranean fracture. A polymer is injected into a subterranean formation and is subsequently subjected to a chemical reaction, for example hydrolysis, under downhole conditions, which leads to formation of either a cationic or an anionic polyelectrolyte. Alternatively, the polyelectrolyte is synthesized downhole by, for example, a Hofmann degradation or a Mannich reaction. The polyelectrolyte acts as a flocculant and provides aggregation of solid particulates such as sand, mica, silica flour, ceramics and the like, which leads to formation of proppant micropillars deep in the fracture. Methods of aggregation of fibers to enhance bridging, and other applications of controlled flocculation are also given.

Owner:SCHLUMBERGER TECH CORP

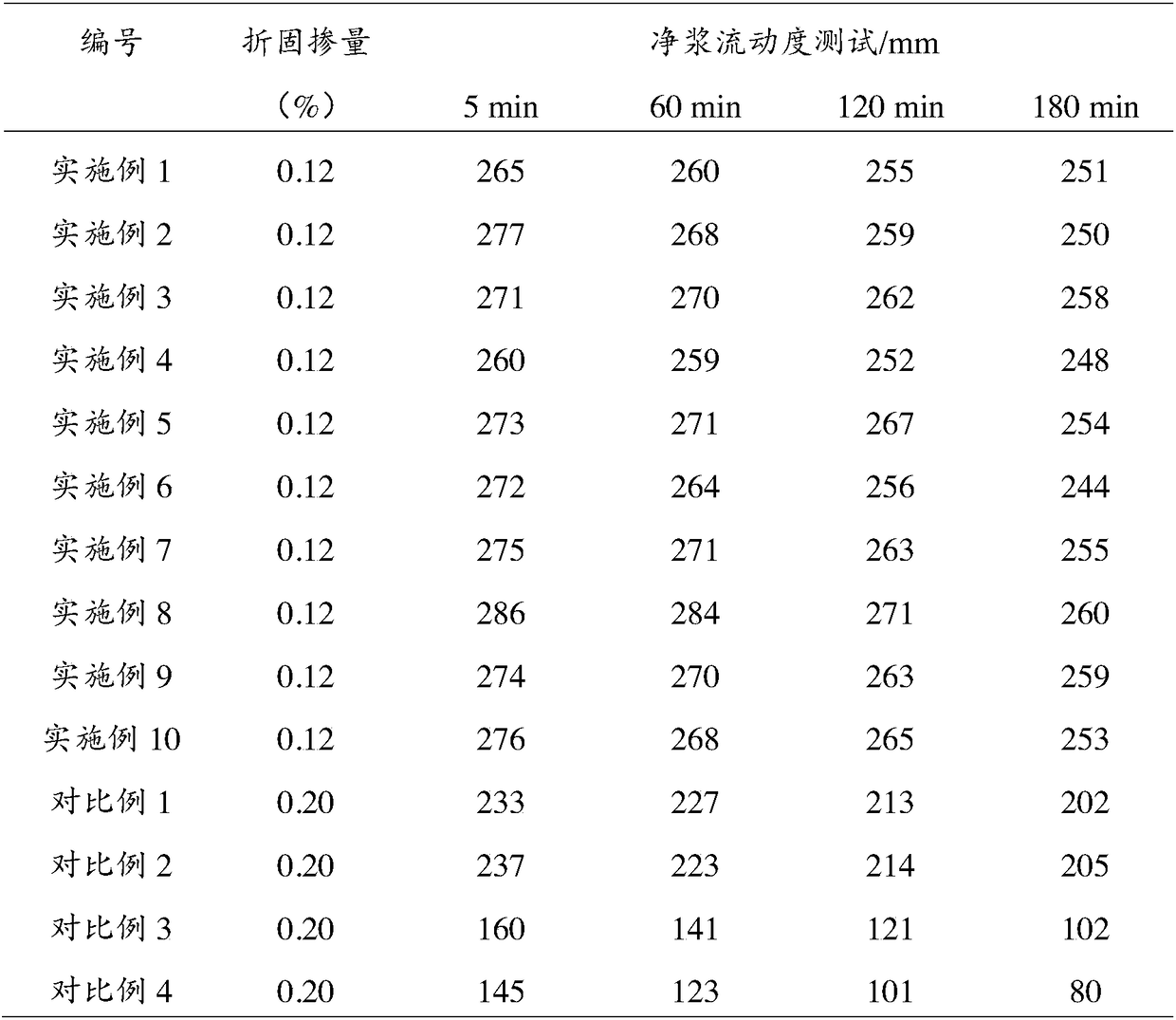

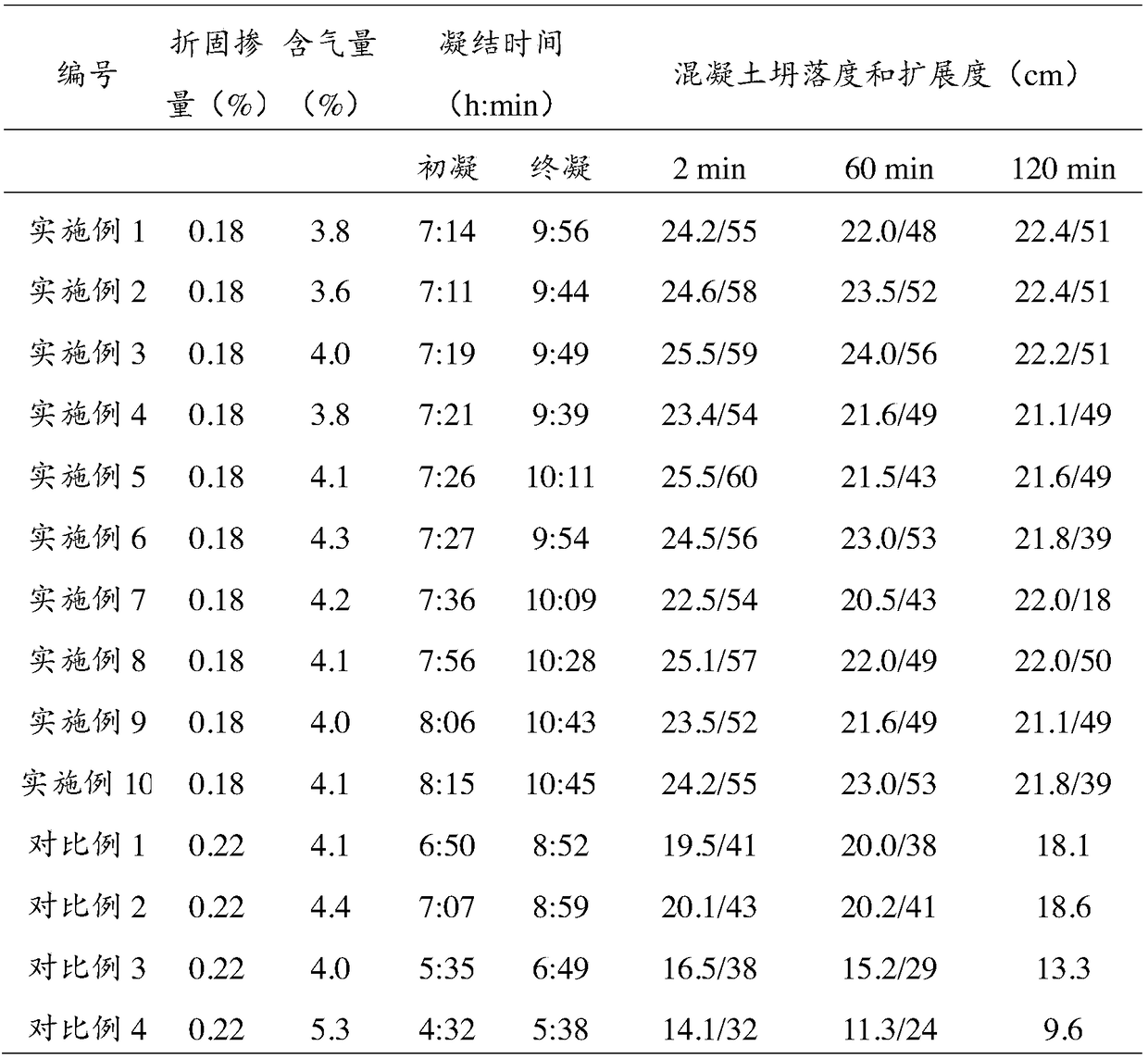

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) copolymerizing three kinds of monomers in certain proportion in water soluble medium to obtain intermediate product PCE; 2) preparing cationic copolymer CNP through Hofmann degradation or Mannich reaction of polyacrylamide or the copolymerization of acrylamide monomer and two other kinds of monomer in water soluble medium; 3) mixing the copolymer PCE and polymer CNP through stirring to obtain amphoteric carboxylic acid grafted copolymer; and 4 ) heating the comb grafted copolymer produced in the last step to 60-100 deg.c and adding crosslinking agent to produce crosslinking reaction producing the amphoteric carboxylic acid comb grafted copolymer. The concrete super-plasticizing agent of the present invention can reduce the water consumption of concrete greatly, and has excellent construction performance.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

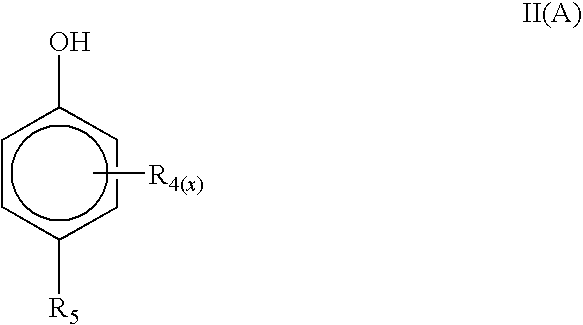

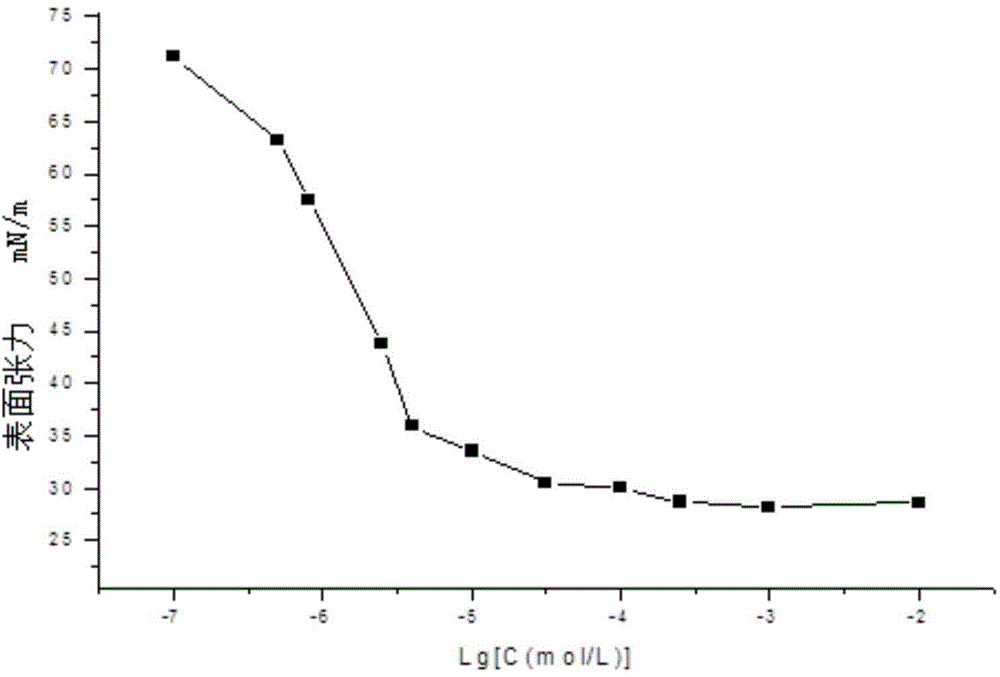

Saturated cardanol betaine surfactant, and preparation method and application thereof

ActiveCN105983370ALow toxicityBiodegradableOrganic compound preparationTransportation and packagingBetaineMannich reaction

The invention discloses a saturated cardanol betaine surfactant. The saturated cardanol betaine surfactant of a specific structure is prepared from saturated cardanol through a Mannich reaction and a quaterisation reaction. The saturated cardanol betaine surfactant has good interfacial performance; an aqueous solution of the saturated cardanol betaine surfactant and alkane or crude oil can form low or ultra-low interfacial tension; so the saturated cardanol betaine surfactant has good application prospects in a plurality of fields like mineral flotation, industrial washing and tertiary oil recovery. The saturated cardanol betaine surfactant has a structure as shown in a formula I which is described in the specification.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

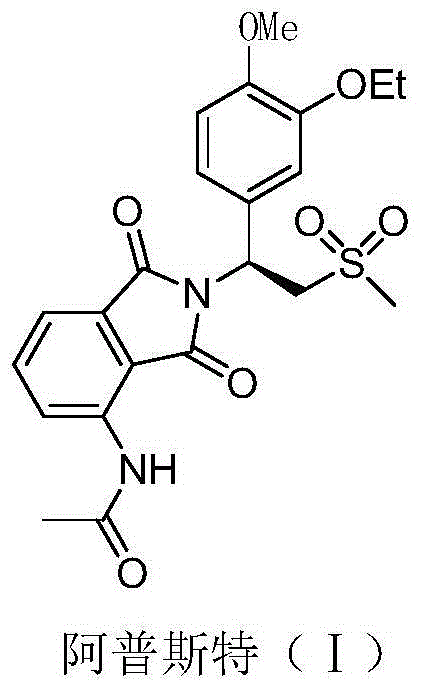

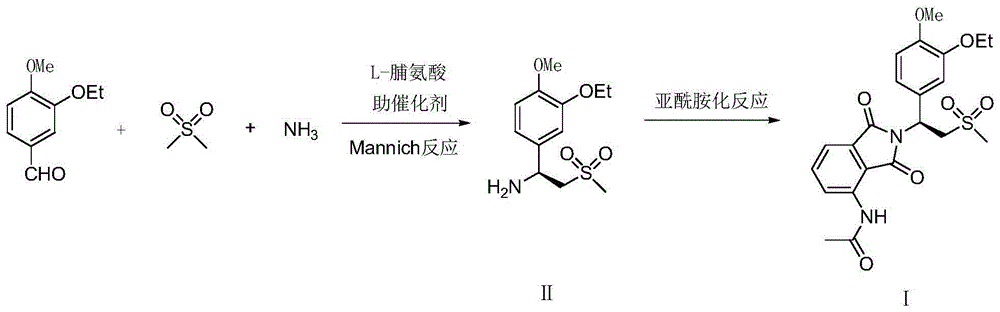

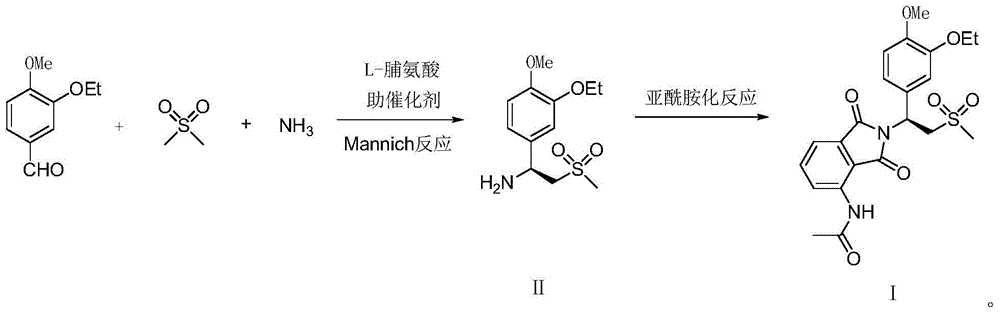

Preparation method for apremilast and intermediate of apremilast

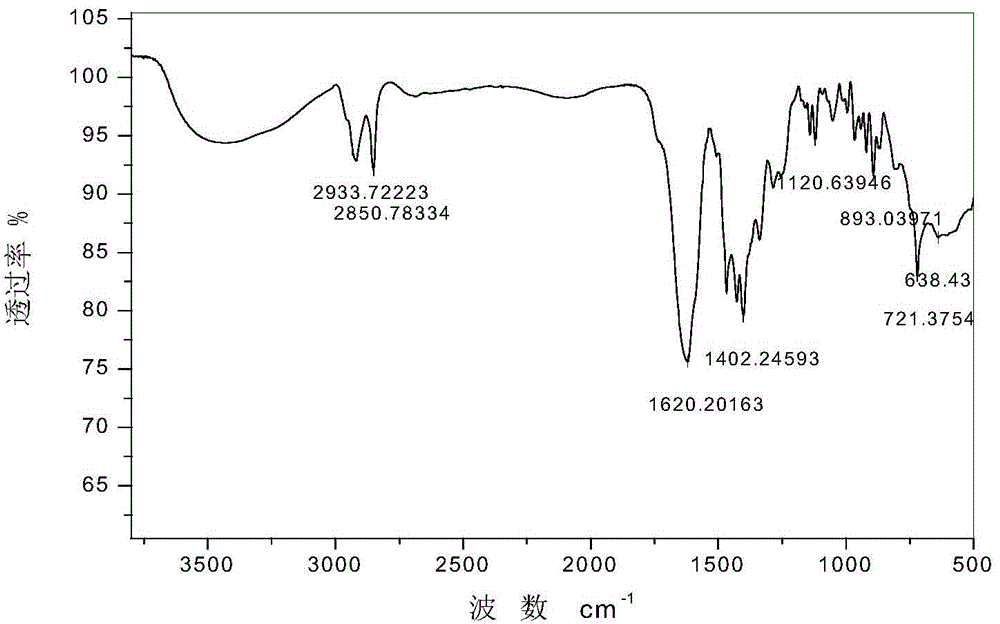

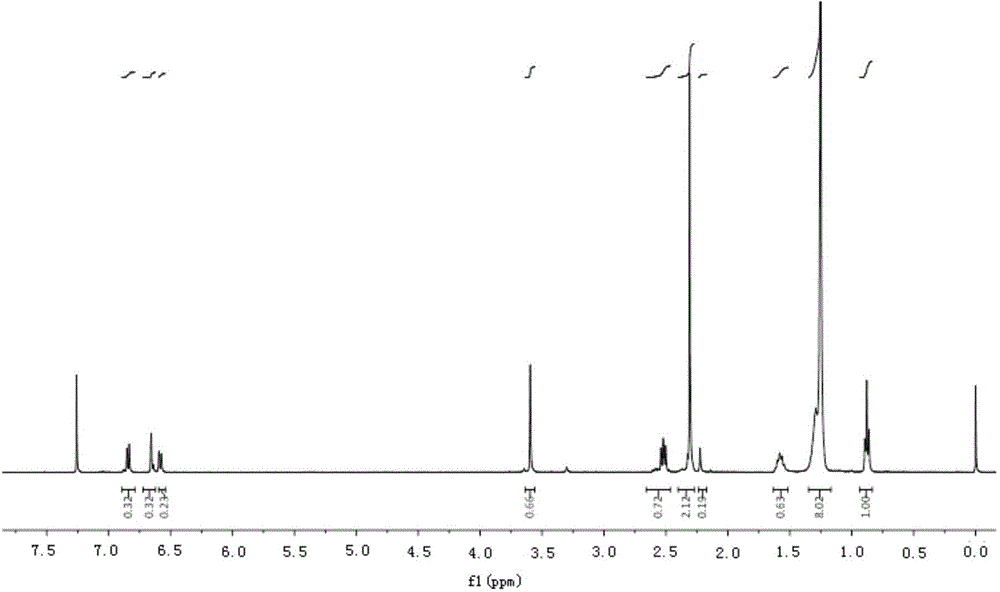

ActiveCN104447443AHigh purityRaw materials are easy to getOrganic chemistryOrganic compound preparationMannich reactionPhthalic anhydride

The invention relates to a preparation method for apremilast and an intermediate of the apremilast. The preparation method comprises the following steps: enabling 4-methoxy-3-ethoxybenzaldehyde to have Mannich reaction with methylsulfonylmethane and ammonia under the action of L-proline and a promoter to obtain an intermediate, (S)-1-(4-methoxy-3-ethyoxyl)phenyl-2-(methylsulfonyl)ethylamine (II), and then amidating the intermediate (II) and 3-acetamido-phthalic anhydride to prepare the apremilast (I). According to the preparation method for the apremilast and the intermediate of the apremilast, the raw materials are easily available, the flow path is short, the process is simple and convenient, the product has high optical purity, and the industrial production is safe and environmentally friendly.

Owner:XINFA PHARMA

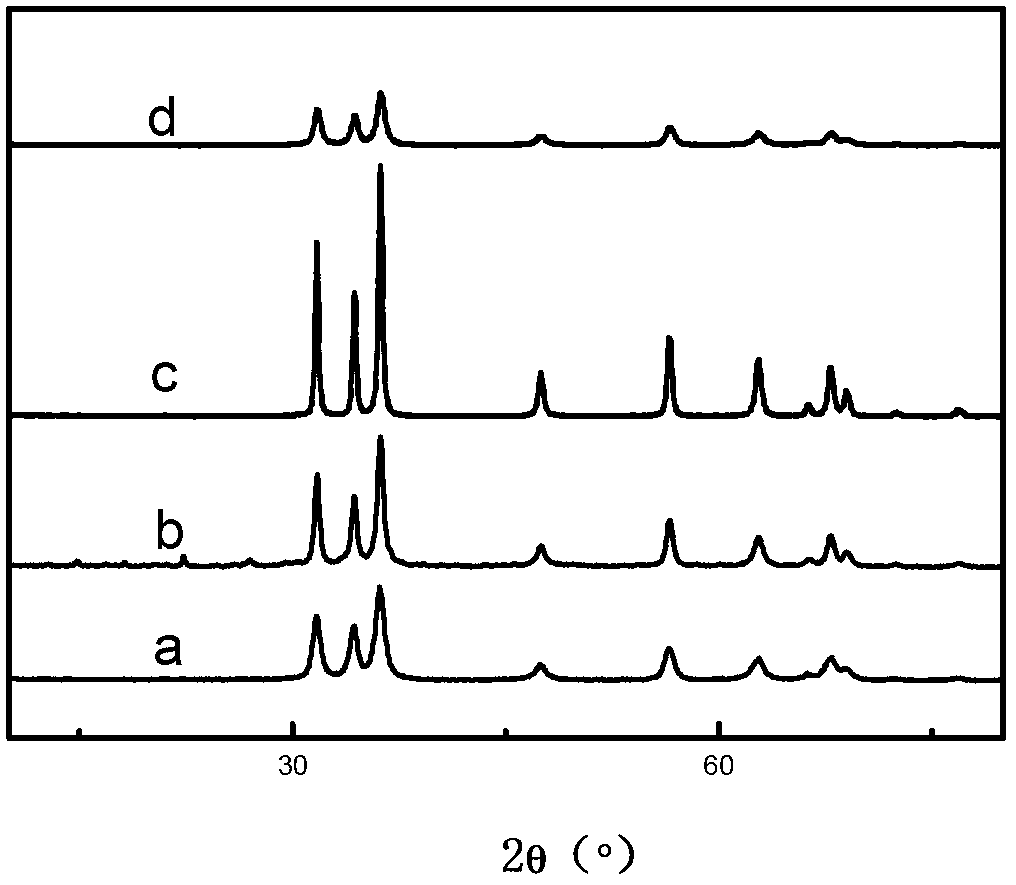

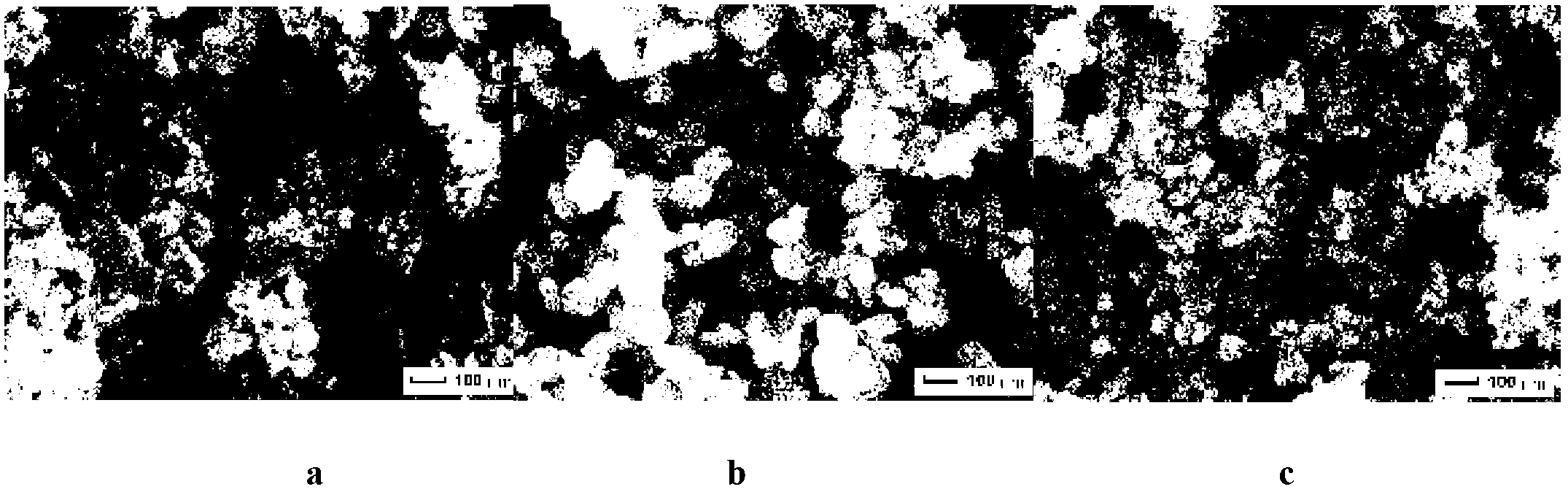

Solid-phase preparation method for nano zinc oxide through template

InactiveCN103183372ALarge specific surface areaHigh yieldMaterial nanotechnologyZinc oxides/hydroxidesMannich reactionNano zinc oxide

The invention discloses a solid-phase preparation method for nano zinc oxide through a template and relates to a solid-phase preparation method for nano zinc oxide. The method comprises the following steps: first, synthesizing lignin into lignin amine; and then, performing solid-phase preparation for nano zinc oxide taking the lignin amine as the template. According to the invention, the reticular lignin amine is prepared from the lignin through Mannick reaction, the advantages of being low in cost, nontoxic, easy to get and the like can be achieved; some base groups of the lignin amine are removed through high-temperature roasting, a pore structure is left, so that the specific surface area of the nano zinc oxide obtained from the lignin amine as a template agent is increased. Therefore, the method provided by the invention has the advantages of simple synthesis process, uniform particle size, controllable dynamics, low cost, easiness in operation, high yield, and low pollution, and reduces the hard aggregation appearance. The product prepared from the method is ice-cream, and adopts the structure of lead zinc ore of hexagonal system, and is suitable for industrialized production.

Owner:JIANGSU UNIV

Preparation method and use of micromolecule water reducer with delayed coagulation and slump retaining properties

ActiveCN108239279AImprove adsorption capacityImprove environmental adaptabilityPhosphorous acidMannich reaction

The invention provides a preparation method and use of a micromolecule water reducer with delayed coagulation and slump retaining properties. The preparation method has the beneficial effects that a preparation method is strong in adjustability and high in cost performance, a preparation process is simple, the prepared micromolecule water reducer has excellent slump retaining property, delayed coagulation property and clay tolerance. The preparation method comprises the following steps: (1) carrying out amination reaction: carrying out C=C double bond Michael addition reaction by virtue of organic amine with a specific structure and unsaturated carboxylate with a specific structure, and purifying, so as to obtain an organic amine intermediate with an amino hydrogen and carboxylic ester group structure; (2) carrying out Mannich reaction by virtue of the organic amine intermediate, formaldehyde and phosphorous acid, and purifying, so as to obtain phosphorylated organic amine intermediate; and (3) carrying out condensation reaction by virtue of carboxyl of the phosphorylated organic amine intermediate and polyether with a specific structure and a terminal OH or a terminal NH2 so as toconvert carboxyl into an ester group or acylamino, and alkalizing for neutralization so as to obtain the micromolecule water reducer with the delayed coagulation and slump retaining properties.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

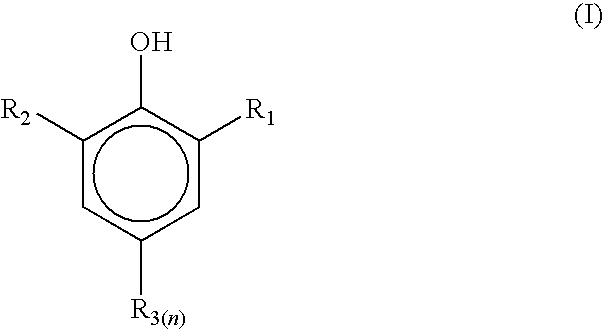

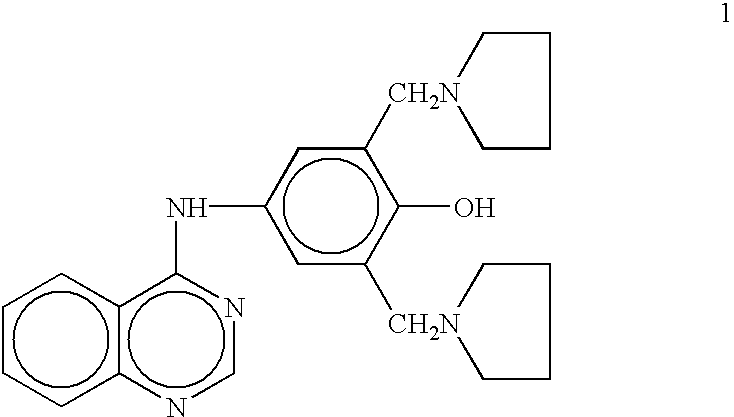

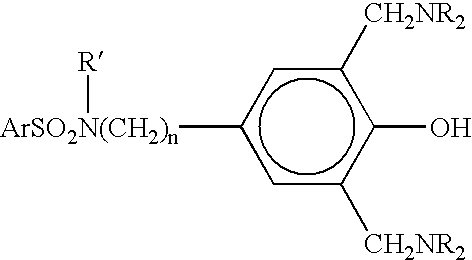

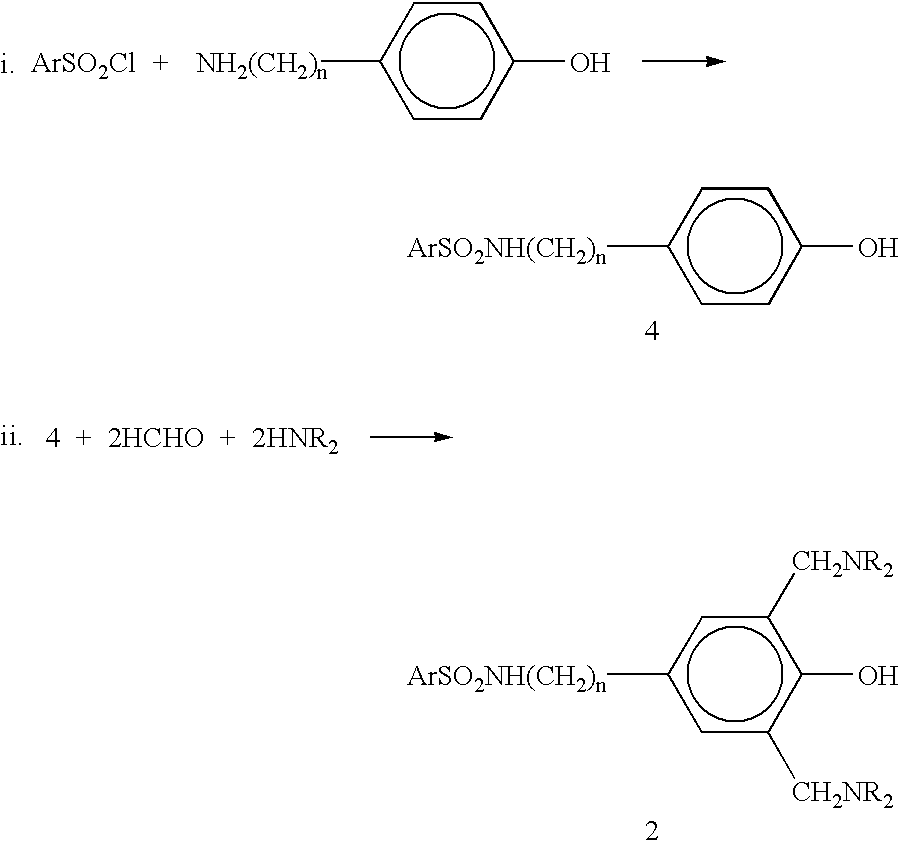

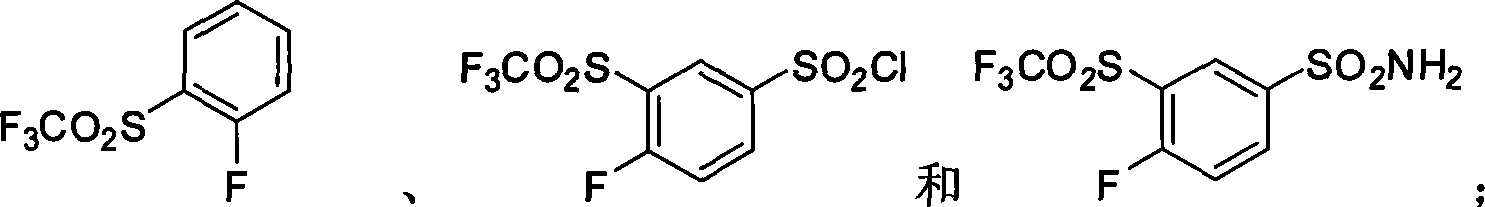

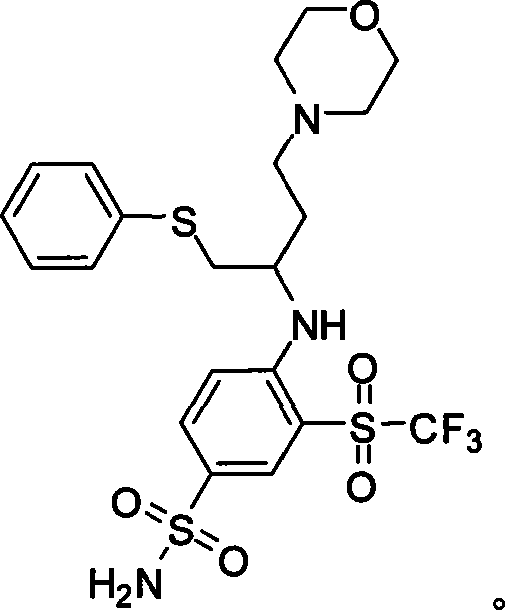

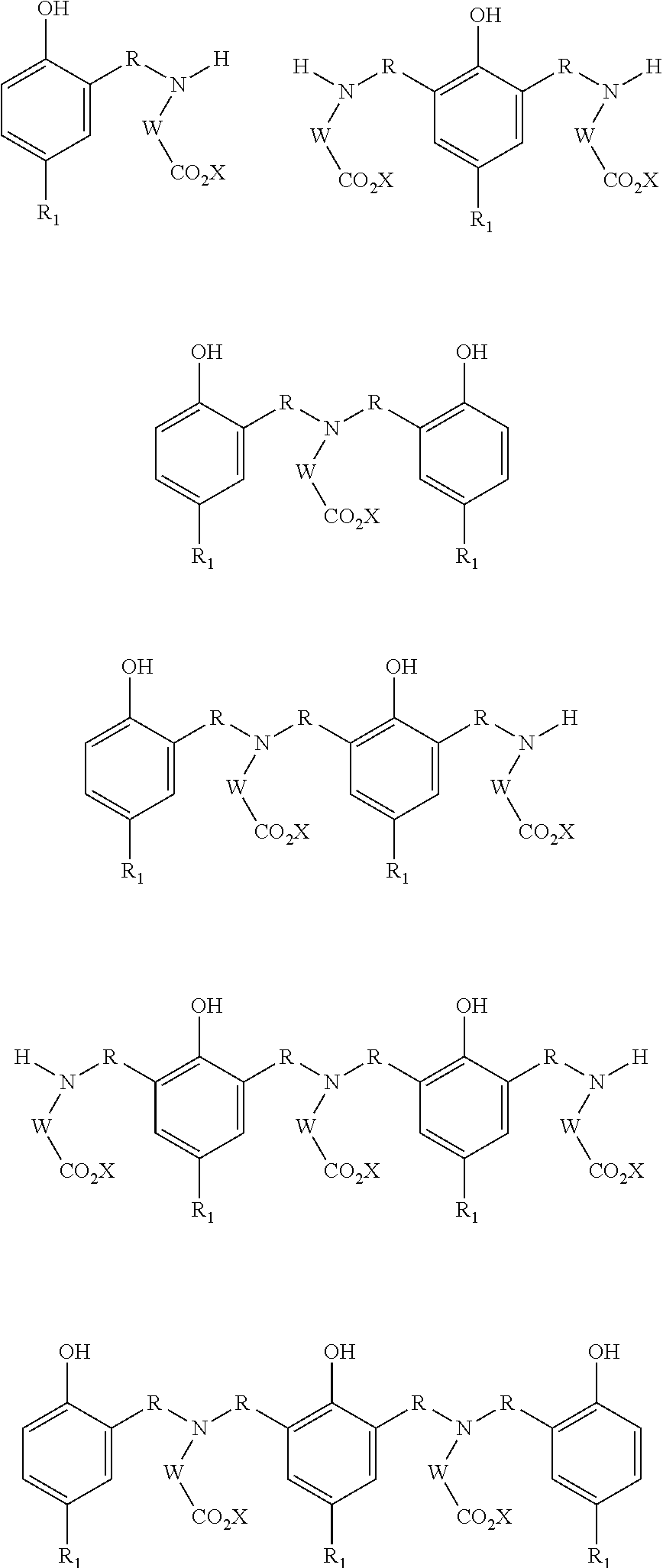

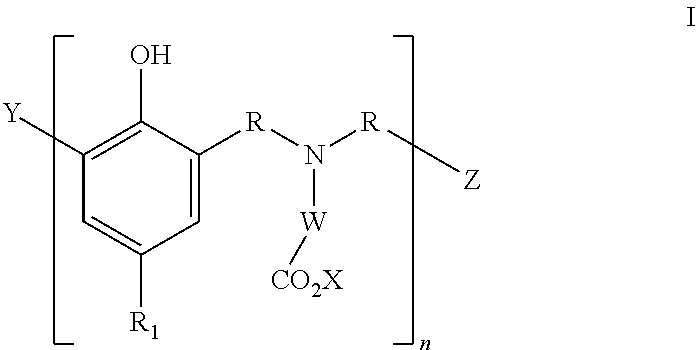

N-substituted benzyl or phenyl aromatic sulfamides compounds and the use thereof

N-(3,5-bis-disubstituted aminomethyl-4-hydroxy)benzyl aromatic sulfonamides and N-(3,5-bis-disubstituted aminomethyl-4-hydroxy)phenyl aromatic sulfonamides compounds in accordance with the animal test, are active in the prevention and the treatment of cardiac arrhythmia. These compounds are prepared as corresponding diamines by the condensation of optionally substituted aromatic sulfochlorides with p-hydroxybenzylamine, p-aminophenol, or the like, which followed by the Mannich reaction of the resulted corresponding aromatic sulfamides with formaldehyde and secondary amines; or directly obtained by the reaction of the aromatic sulfamides with 4-amino-2,6-bis-disubstituted aminomethylphenol. Subsequently, the diamines are reacted with various acids to provide their salts.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

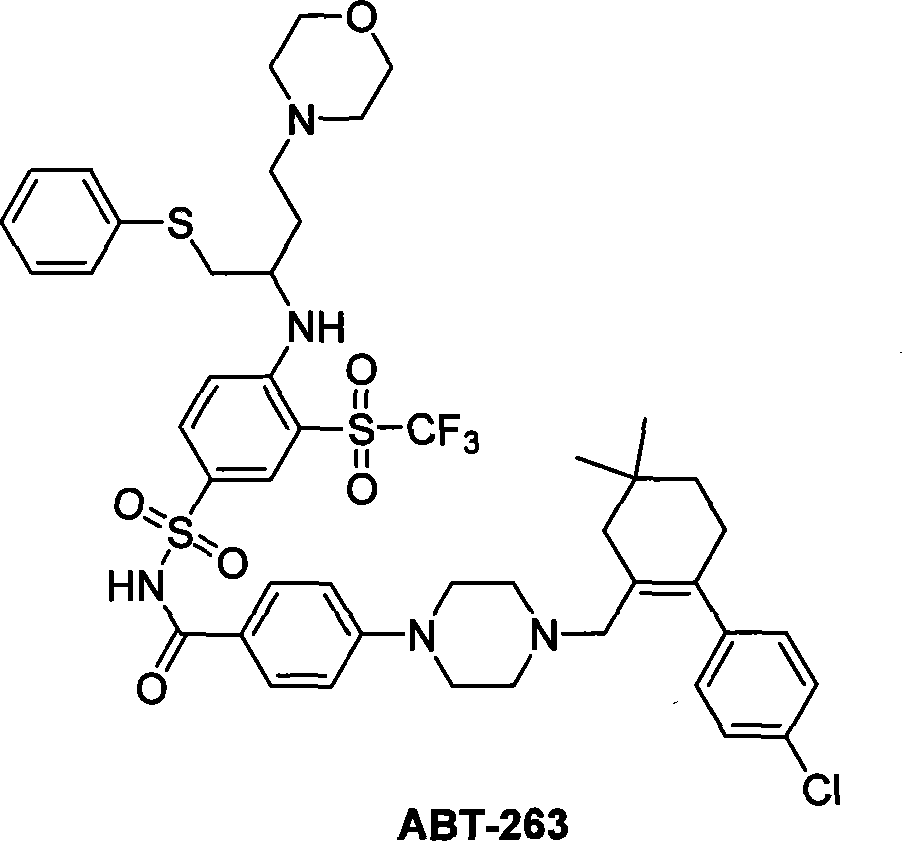

Synthesis of compound ABT-263

ActiveCN101220008AThe synthesis method is simpleMild conditionsOrganic chemistryAntineoplastic agentsChromatographic separationSynthesis methods

The invention discloses a synthetic method for a compound ABT-263, which essentially comprises the following steps: a compound 5 reacts with a compound 9 under a basic condition to derive a compound 13; the compound 13 and a compound 12 are dissolved in dichloromethane to react by adding EDCI and DMAP for 24 hours at a room temperature; the compound ABT-263 is derived via spin drying, watering, acetic ether extraction, drying, condensing, and column chromatographic separation. The invention adopts different starting materials, different synthetic courses, easier available raw materials and methods, and improves the oxidation method of 2-fluoro sulfide phenyl trifluoromethyl; thereby avoiding the pollution of large amount of heavy metal to the environment, as catalytic amount of chromic anhydride is adopted, the yield is improved from 17 percent to 90 percent; in additional, as the adoption of Mannich reaction shortens the reaction steps, the yield is improved.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

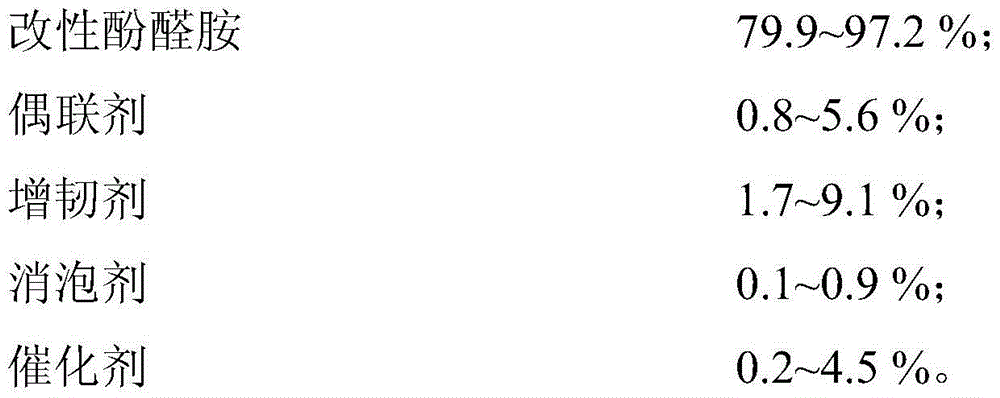

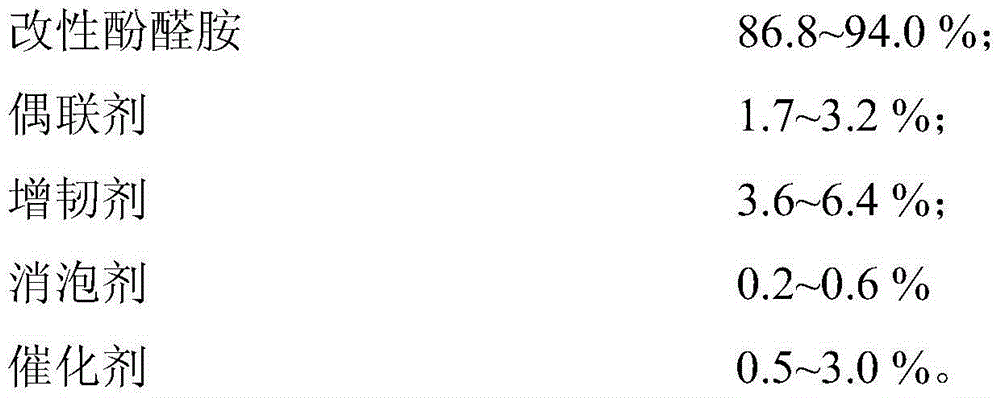

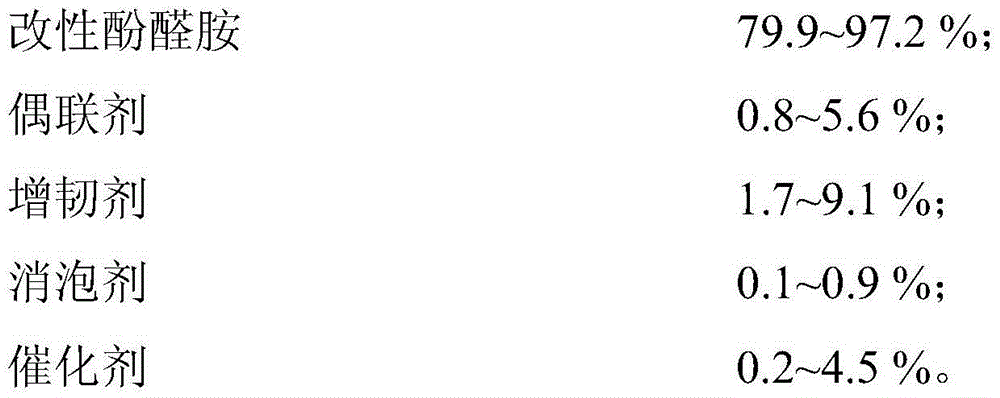

Epoxy resin solvent-free low temperature curing agent, preparation method and application thereof

The invention belongs to the technical field of epoxy resin curing agent preparation technology, and discloses an epoxy resin solvent-free low temperature curing agent, a preparation method and an application. The curing agent can be better used in cement mortar and used for preparing epoxy grouting material under low temperature in water environment. The curing agent comprises the following components by mass percentage: 79.9-97.2% of modified phenolic amine, 0.8-5.6% of coupling agent, 1.7-9.1% of flexibilizer, 0.1-0.9% of antifoaming agent and 0.2-4.5% of catalyst. According to the invention, thiourea group is introduced, thiourea modified amine, polyamine, long chain alkylphenol and paraformaldehyde are performed a Mannich reaction to synthesize novel thioureido-containing Mannich base, so that solidification rate under low temperature environment is increased, disadvantage of poor solidification efficiency under wet surface and water can be overcome, and a silane coupling agent is added for improving surface tension of system contact surface and increasing the solidification efficiency under water environment.

Owner:国科广化(南雄)新材料研究院有限公司

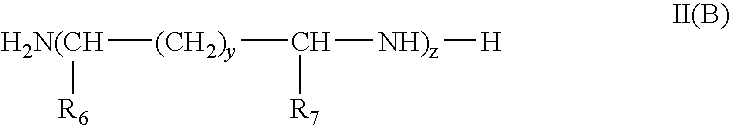

Beta-amino acid esters having optical activity and containing benzothiazole groups and synthetic method and application thereof

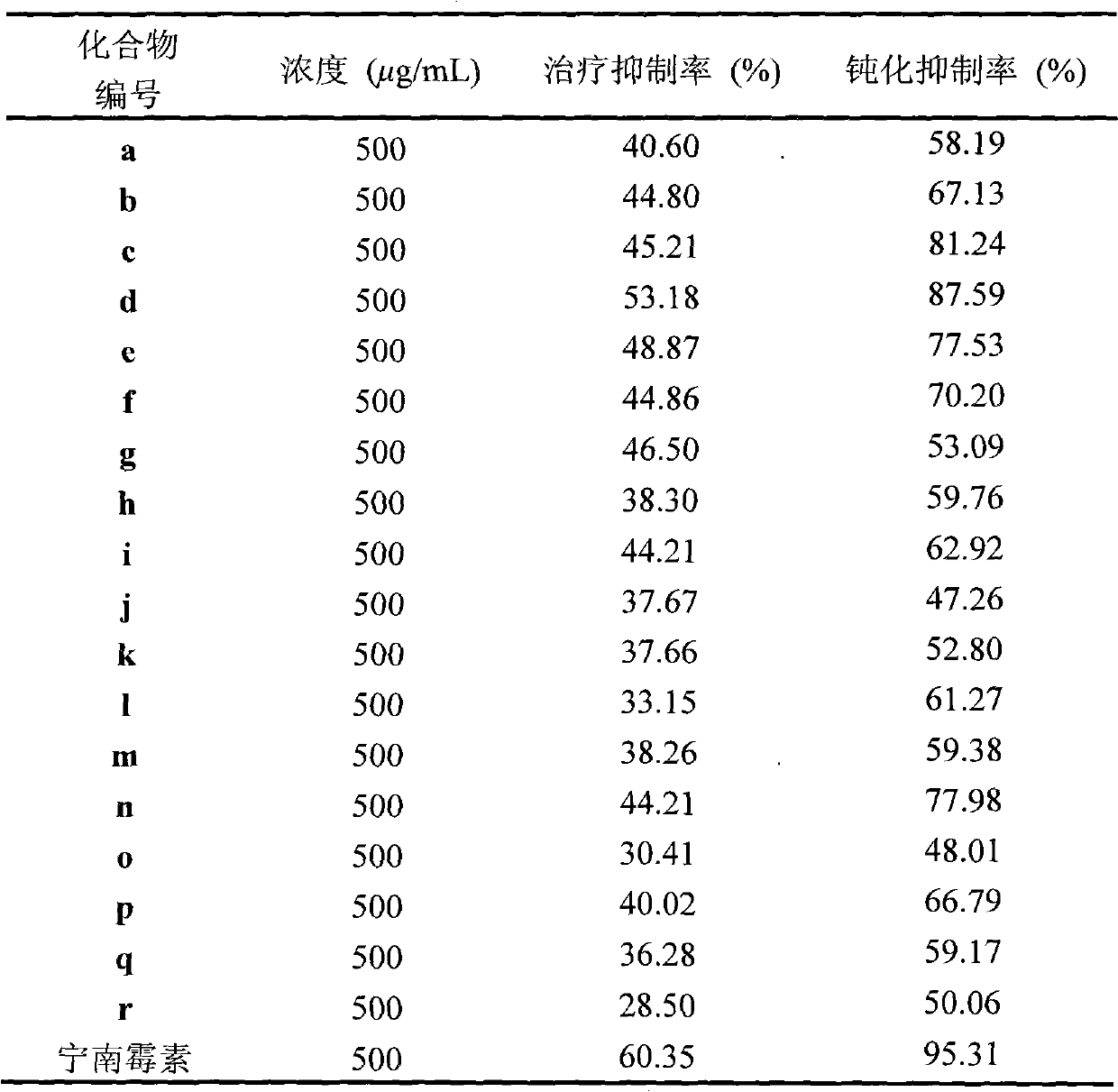

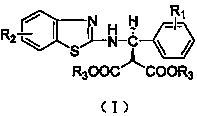

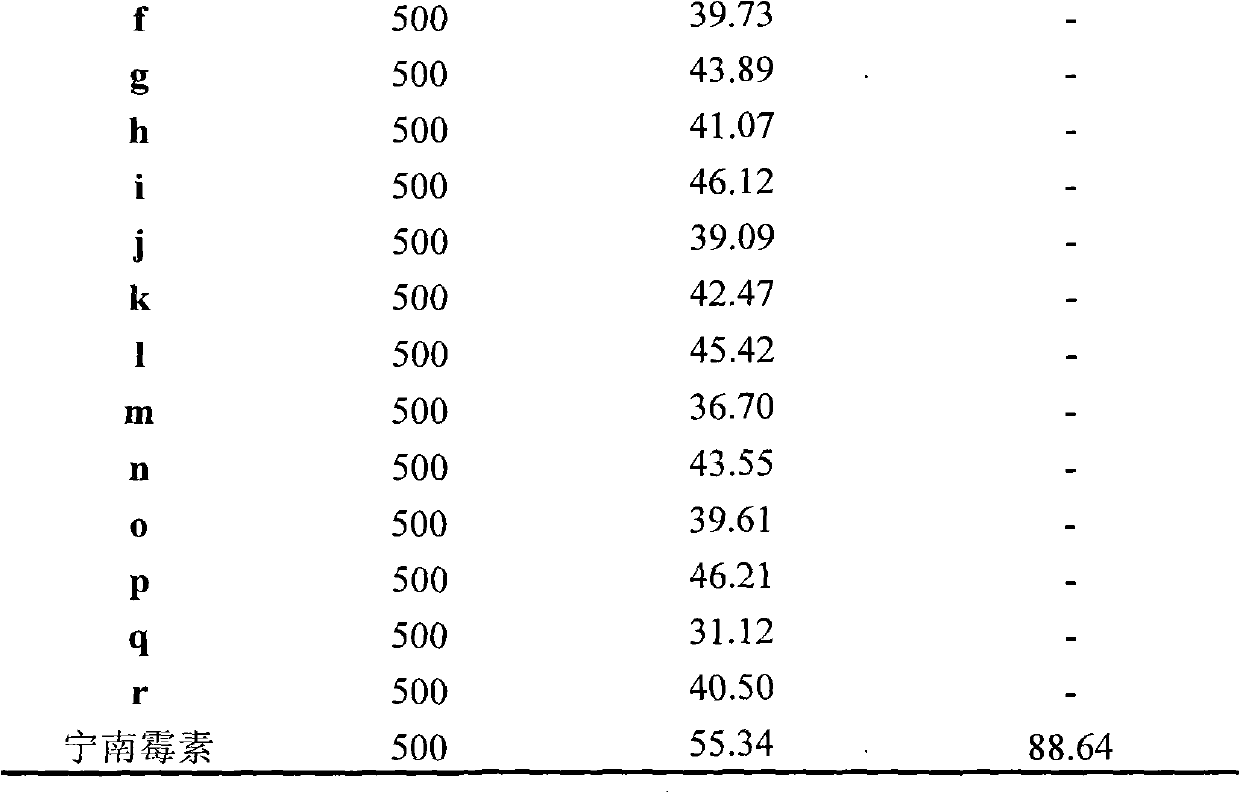

The invention discloses a synthetic method and bioactivity of beta-amino acid esters which have optical activity and contain benzothiazole groups. The beta-amino acid esters which have optical activity and contain the benzothiazole groups have the structure shown in the general formula (I), and in the formula, R1 is a group of hydrogen, p-chloro, o-chloro, p-fluoro, o-fluoro, p-methyl, o-methoxy and the like; R2 is a group of 4-methyl, 6-methoxy and the like; and R3 is a group of methyl, ethyl, propyl, isopropyl and the like. The invention introduces Mannich reaction which uses organic catalyst of cinchona alkaloid thiourea to catalyze benzothiazole imine and malonate, the product is obtained by one-step synthesis, and the reaction yield and the selectivity to enantiomer are both high. Compounds c, d and e in the inveniton have high therapeutic and passivation inhibiting effects towards tobacco mosaic virus (TMV) and cucumber mosaic virus (CMV) and show good anti-plant virus activity.

Owner:GUIZHOU UNIV

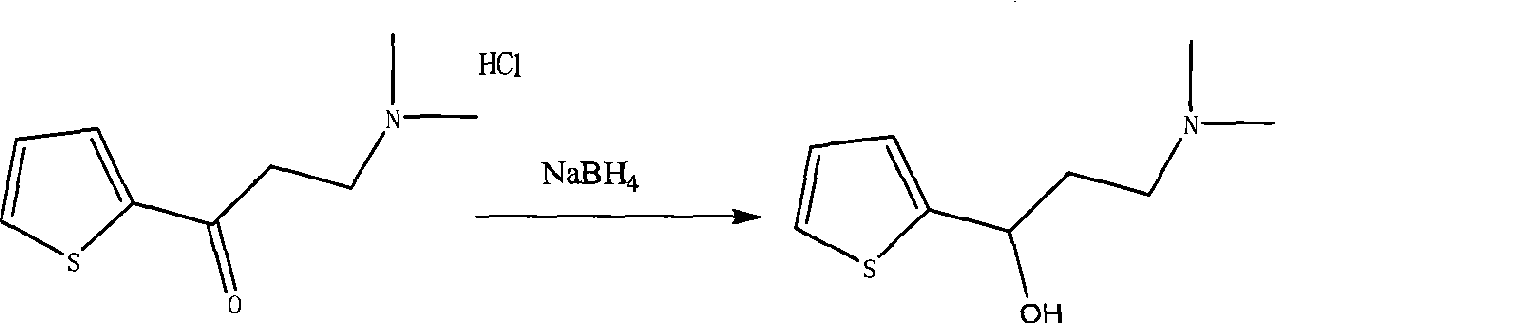

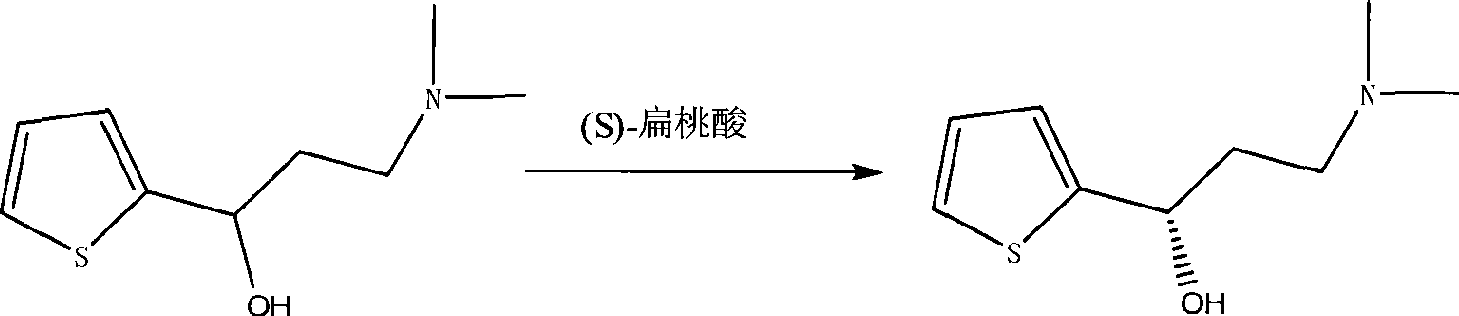

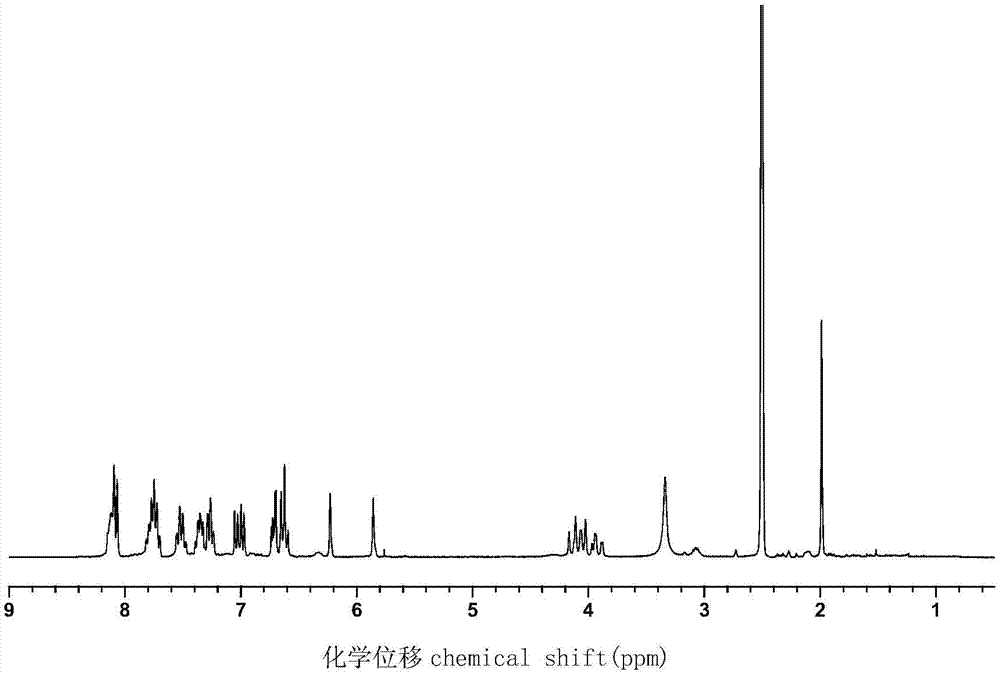

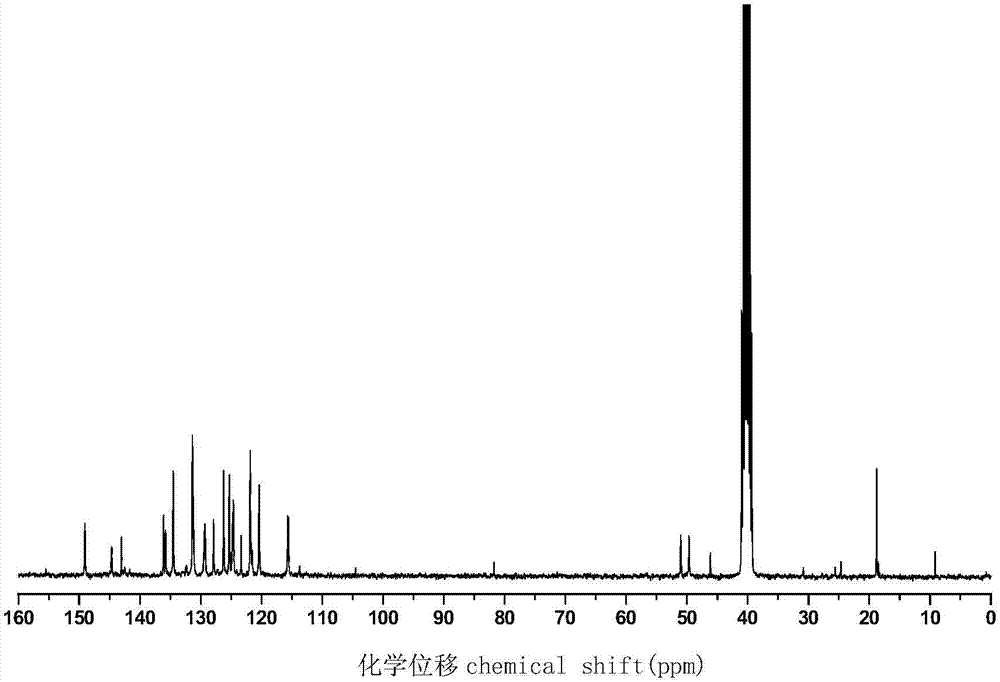

Method for preparing duloxetine

InactiveCN101391991AHigh yieldReduce manufacturing costNervous disorderOrganic chemistryDuloxetineMannich reaction

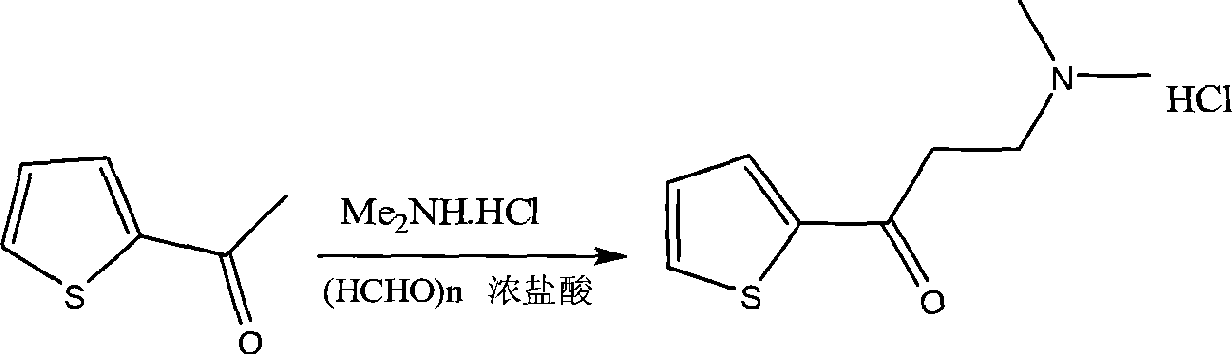

The invention relates to a preparation method of duloxetine, which takes 2-acetyl phenol, paraformaldehyde and dimethylamine hydrochloride as raw materials to obtain the target product by five steps of Mannich reaction, reduction, resolution, etherification and demethylation, and optimizes the reaction conditions of resolution and etherification, wherein, the resolution reaction comprises the steps of one-time resolution, racemization-resolution and secondary racemization-resolution. The invention can improve the yield of the duloxetine and reduce the production cost, and is easy for industrial production.

Owner:SUZHOU LEADER CHEM

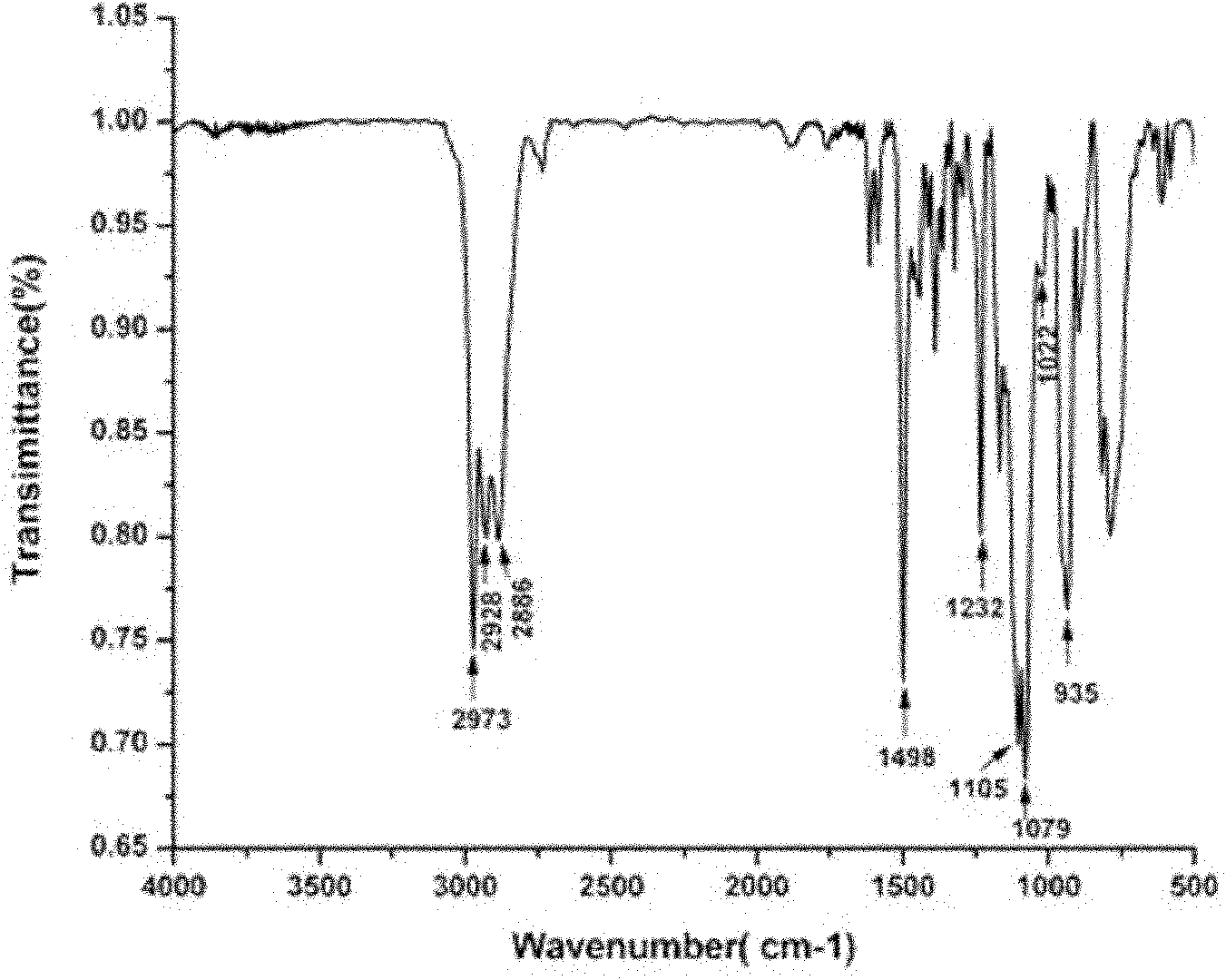

Phosphorus-nitrogen type flame retardant containing active double bond as well as preparation method and application thereof

ActiveCN104262398AImprove flame retardant performanceHigh flame retardant efficiencyGroup 5/15 element organic compoundsMannich reactionP-Aminophenol

The invention discloses a phosphorus-nitrogen type flame retardant containing an active double bond as well as a preparation method and an application thereof. The preparation method comprises the following steps: carrying out Mannich reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, p-aminophenol and paraformaldehyde in the presence of a solvent to obtain a product and washing the product with methanol to obtain a phenolic intermediate compound; reacting the phenolic intermediate compound with methacryloyl chloride in the presence of a solvent and an acid binding agent, filtering to remove acid binding agent salts generated in the reaction to obtain a crude product, purifying the crude product by virtue of washing, carrying out spin evaporation and drying to obtain the phosphorus-nitrogen type flame retardant containing the active double bond. The phosphorus-nitrogen type flame retardant containing the active double bond can be applied in preparation of flame-retardant polymer materials. The raw materials are easily available and the cost is low; the reaction conditions are mild and the yield is high; the purification and separation operations of the product are simple and the phosphorus-nitrogen type flame retardant is easily industrialized and complies with environmental requirements; the flame-retardant effect is good and the application range is wide.

Owner:XIAMEN UNIV

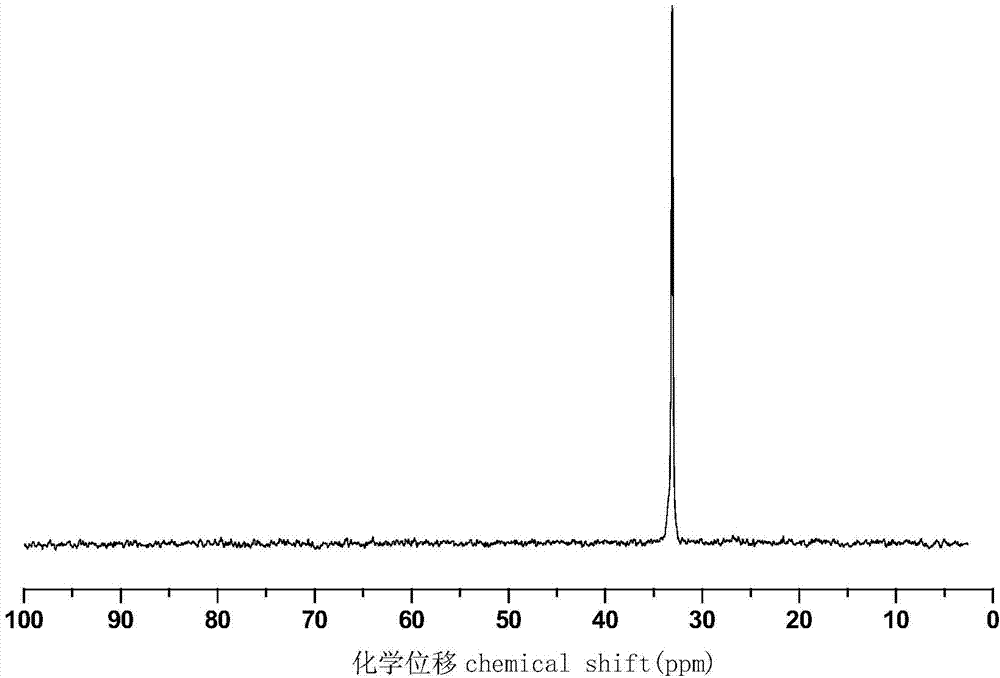

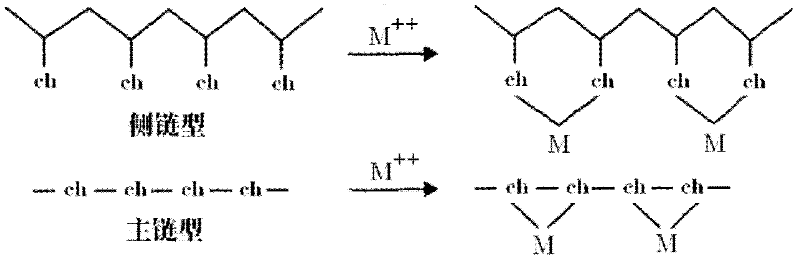

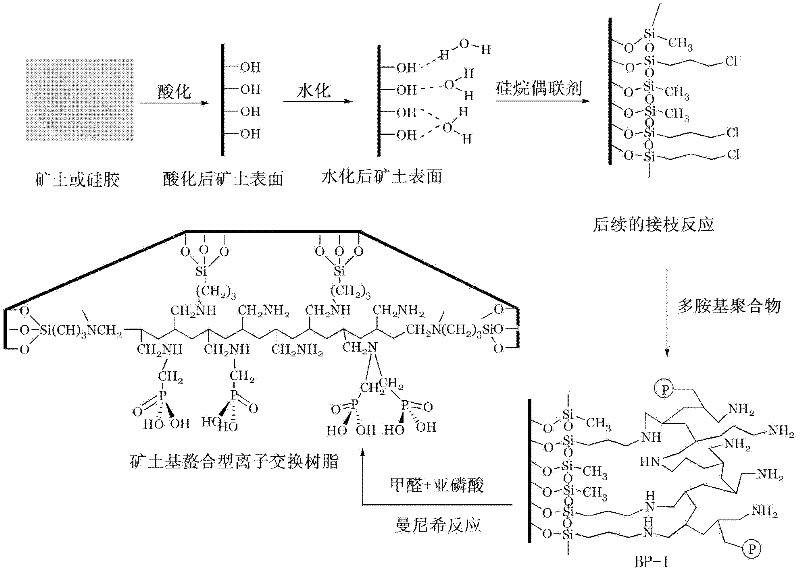

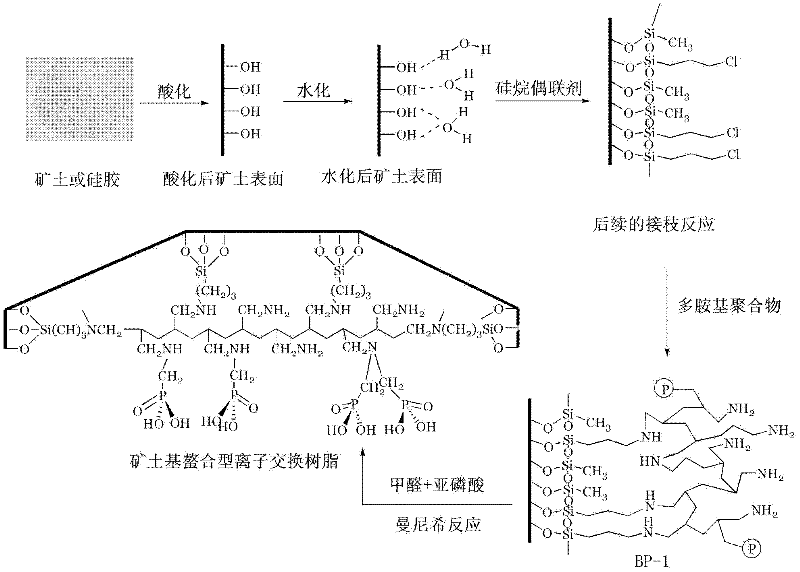

Preparation method for chelating ion exchange resin using inorganic substance as matrix

ActiveCN102391399AImprove performanceIncrease the ion exchange capacityComplex ion-exchangersPhosphorous acidHydration reaction

The invention belongs to the technical field of macromolecular ion exchange resin, and relates to a preparation method for chelating ion exchange resin. The preparation method comprises the following steps of: acidizing a matrix by using acid under the heating condition; washing the matrix by using deionized water until the matrix is neutral; allowing damp air in a sodium bromide or potassium bromide saturated solution reaction kettle to enter the matrix which is treated in the previous steps, so that a water molecule single layer is generated on the surface of the matrix; performing silanization reaction on the hydrated matrix, alkane and a silane coupling agent to obtain a silanized matrix; performing grafting reaction on the silanized matrix and multi-amino polymer to obtain a functional resin material; and performing Mannick reaction on the functional resin material, formaldehyde and phosphorous acid so as to obtain the final chelating ion exchange resin using an inorganic substance as the matrix. The method has the advantages that the operation process is short and the method is convenient to operate. A reagent is not required to be added into an ion exchange column when noble metal ions are adsorbed, so pollution and wastes are avoided.

Owner:GANZHOU RARE EARTH MINERAL IND

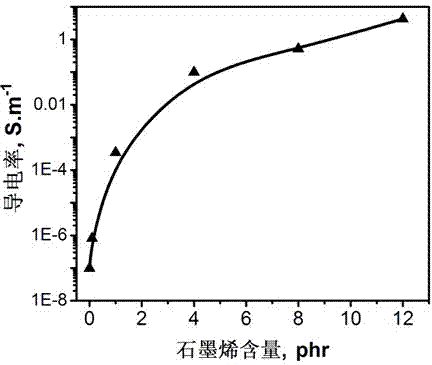

Method for preparing functionalized graphene through Mannich reaction

The invention discloses a method for preparing functionalized graphene through Mannich reaction. The method comprises the following steps of: reducing oxidized graphene by taking plant polyphenols and derivatives of the plant polyphenols as reducing agents to obtain the polyphenol modified graphene; and then preparing the functional graphene with amphipathy through Mannich reaction between polyphenol groups on the surface of the graphene and polyether amine. The method disclosed by the method has the advantages of mild preparation conditions, simple and efficient purification process and no-purification of intermediate products. Simultaneously, raw materials for preparation of the functionalized graphene comprise the reducing agents and a modifier and have the characteristics of rich sources and low cost, and therefore, the functionalized graphene and colloids thereof can be efficiently prepared on a large scale. The functionalized graphene can be used for directly preparing a graphene hybrid material with excellent electric conductivity and toughness, has very good solvent dispersivity and excellent storage stability, and is suitable for compounding with various polymers to prepare a polymer / graphene composite material with high performance.

Owner:SOUTH CHINA UNIV OF TECH

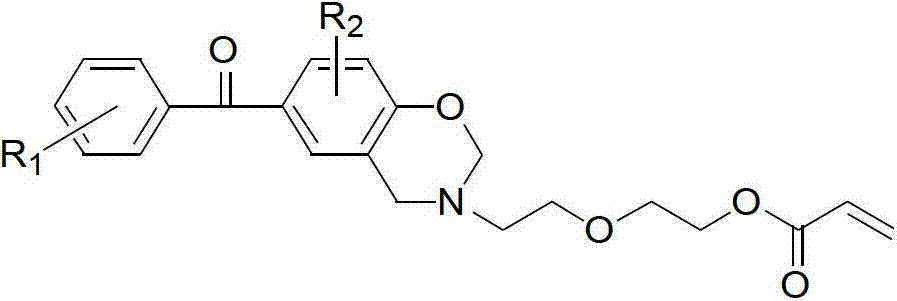

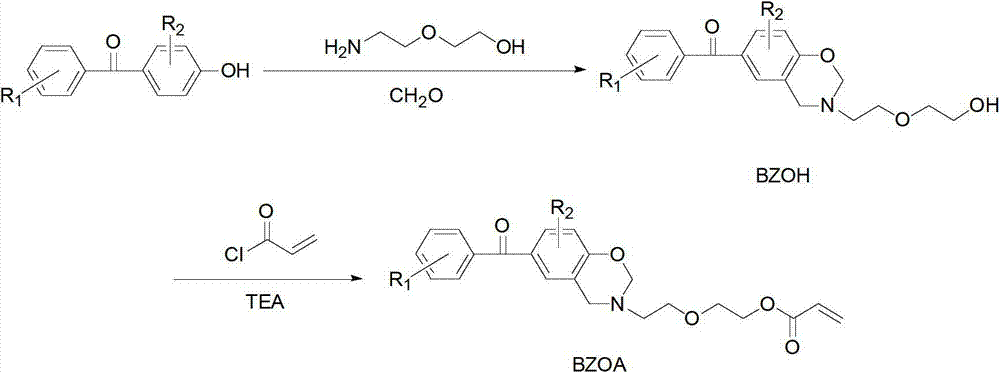

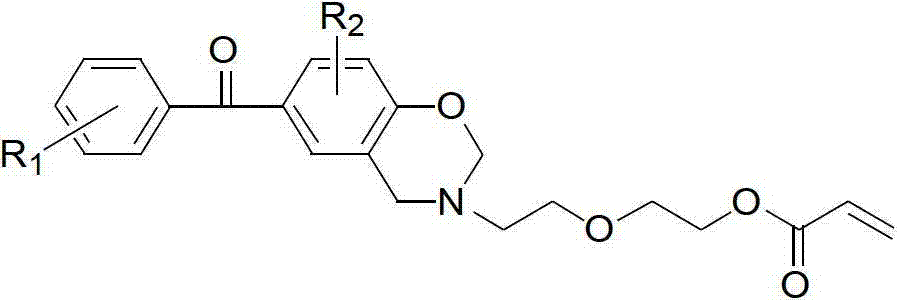

Polymeric photoinitiator and preparation method thereof

InactiveCN103113498AReduce manufacturing costEasy to operateOrganic chemistryMannich reactionDecomposition

The invention relates to a polymeric photoinitiator and a preparation method thereof. The structural formula of the polymeric photoinitiator is shown in the specification. The method comprises the following steps: reacting a hydroxyl-containing benzophenone derivative, paraformaldehyde and diglycolamine which serve as raw materials to synthesize red liquid (BZOH) through a Mannich reaction; and reacting BZOH with acryloyl chloride to generate the polymeric photoinitiator (BZOA). The macromolecule initiator simultaneously contains benzophenone and tertiary amine, and the efficiency of generating reactive species through photosensitive decomposition is improved. Because the initiator contains the benzoxazine structure and unsaturated double bonds, the compatibility with an initiating system is improved, the surface migration of the photoinitiator is reduced, and the photoinitiator can serve as a monomer for synthesizing macromolecules and is widely applied to the fields of ultraviolet light polymerization and the like. R1 and R2 are mutually independent -H, -CH3, -OH or -CH2Cl, wherein at least one substituent group exists at the ortho-position in the hydroxyl-containing benzophenone derivative.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Preparation method of cationized cellulose-based flocculating agent

InactiveCN103788381APromote degradationReduce manufacturing costWater/sewage treatment by flocculation/precipitationCelluloseMannich reaction

The invention discloses a preparation method of a cationized cellulose-based flocculating agent. The preparation method is characterized by comprising the steps: fully dissolving a cellulose material, adding an oxidizing agent, carrying out graft polymerization with polyacrylamide, and cationizing by using a Mannich reaction to prepare the cationized cellulose-based flocculating agent. The preparation method is simple, easy, rapid and efficient, and is especially suitable for preparation of a biodegradable cellulose-based flocculating agent. According to the preparation method, the cellulose material is introduced in the preparation raw material to be used as a molecule basic skeleton to partially replace a synthetic high polymer material, thus the dependency of a conventional synthetic high polymer flocculating agent to petroleum resources is reduced, the biodegradability of the flocculating agent is improved, the grafting ratio of polyacrylamide is increased by using an oxidized grafting reaction; meanwhile, Mannich cationization is performed, and the prepared cationized cellulose-based flocculating agent is suitable for treatment processes such as papermaking, printing and dyeing, municipal wastewater and the like, and has important environment and social benefits.

Owner:ZHEJIANG SCI-TECH UNIV

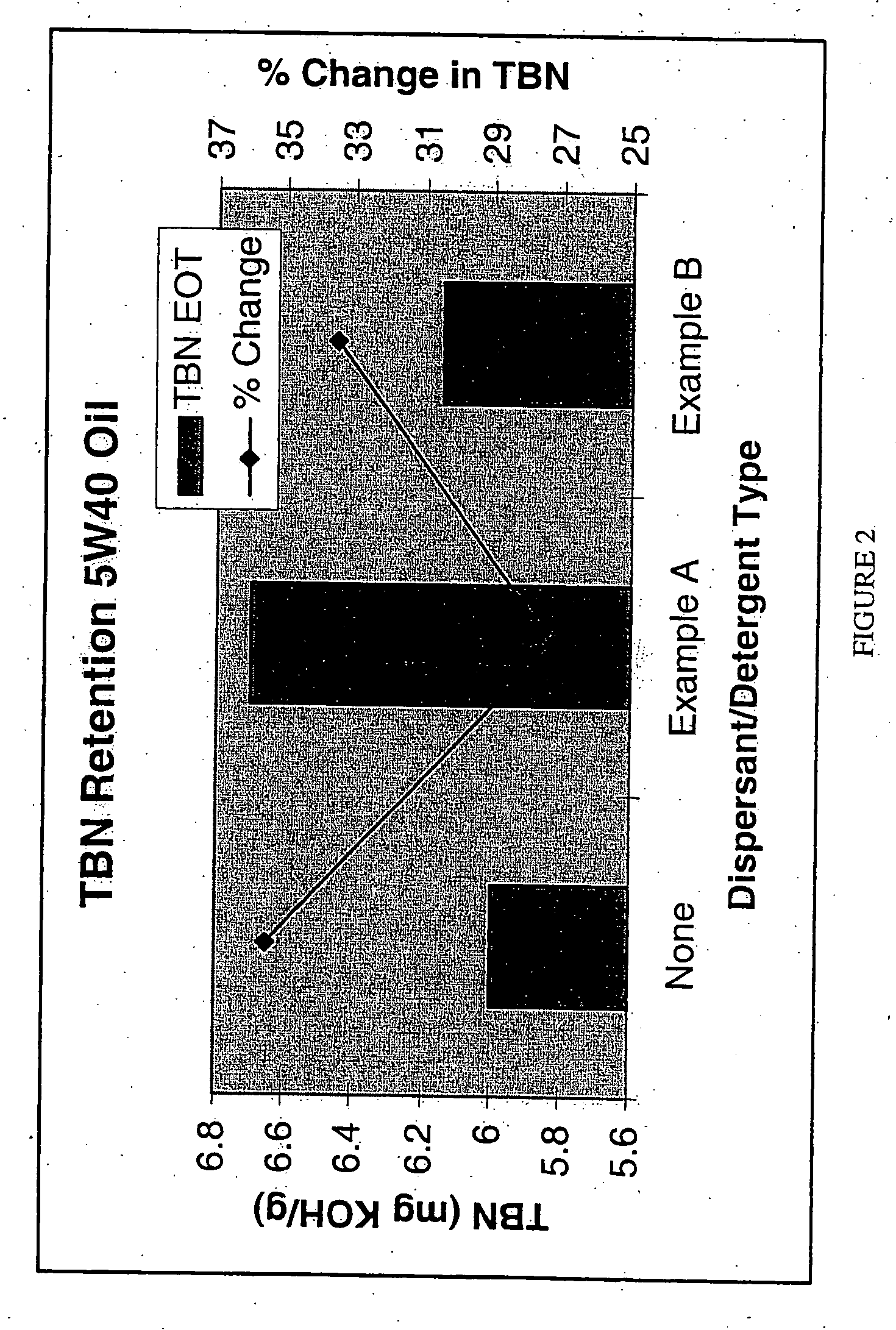

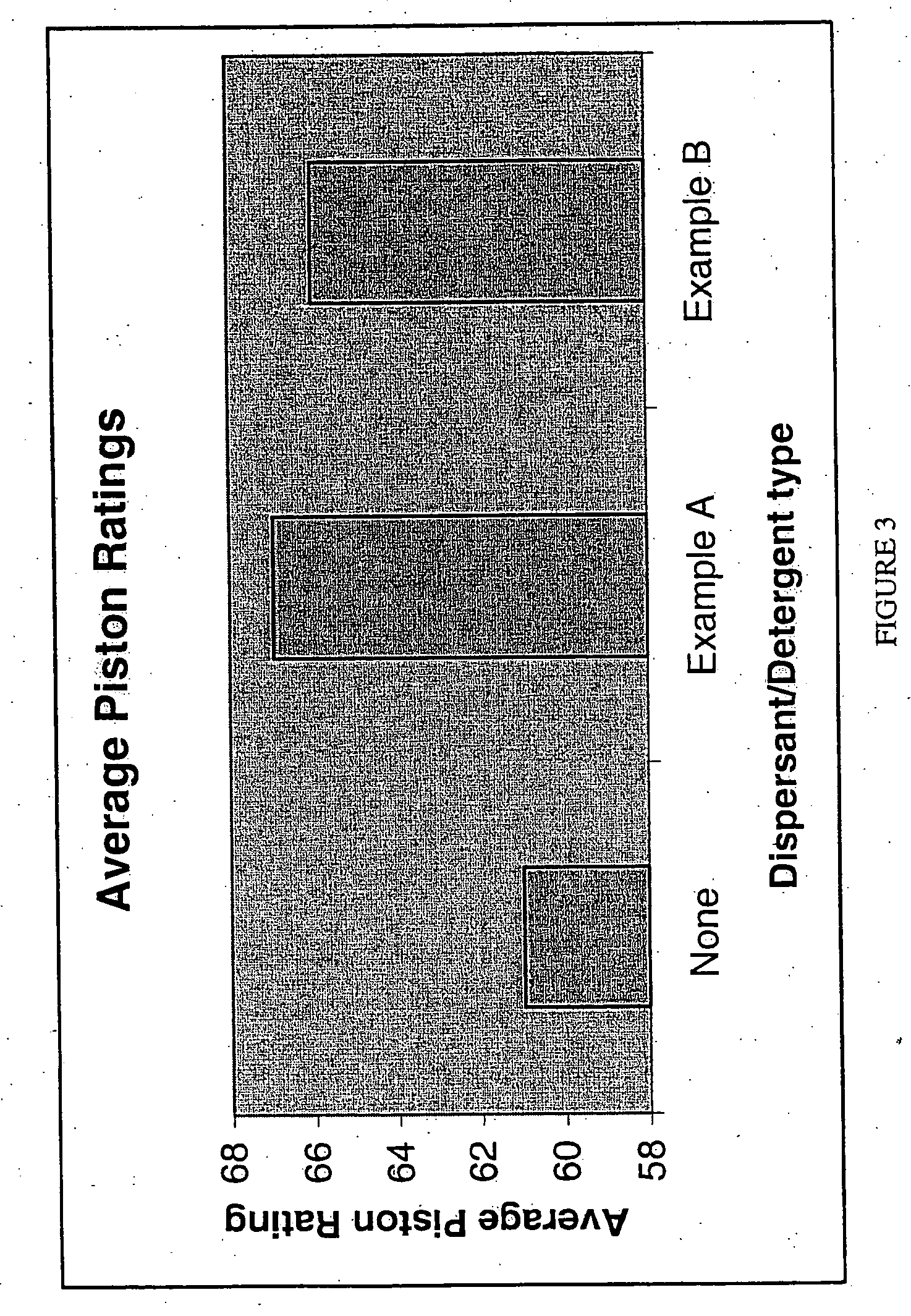

Lubricating oil compositions with enhanced piston cleanliness

ActiveUS9528074B2Promote combustionImprove performanceLubricant compositionChemical compositionMannich reaction

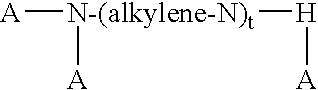

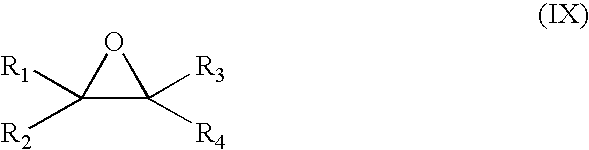

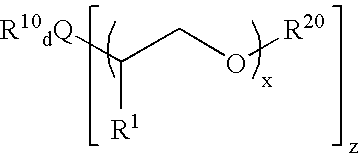

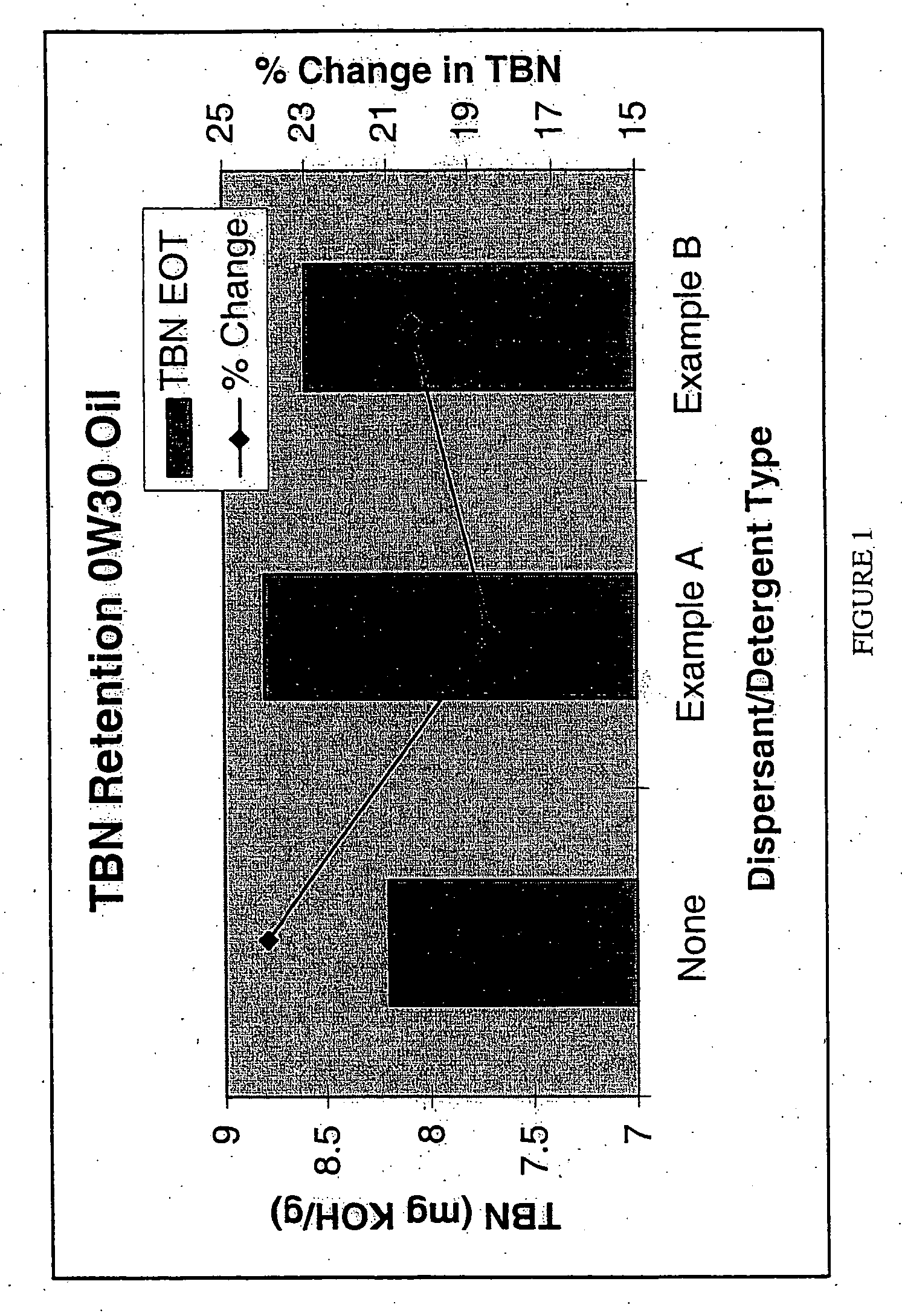

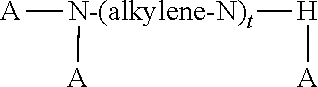

Disclosed herein is lubricating oil composition for providing enhanced piston cleanliness in an internal combustion engine. The lubricating oil composition include (a) from about 50 to about 65 wt. %, based on the total weight of the lubricating oil composition, of a first base oil component having a Kv at 100° C. of about 3.5 to about 4.5 cSt; (b) from about 10 to about 30 wt. %, based on the total weight of the lubricating oil composition, of a second base oil component having a Kv at 100° C. of about 5.5 to about 6.5 cSt; (c) about 1.50 wt. % to about 10 wt. %, based on the total weight of the lubricating oil composition, of at least one Mannich reaction product as disclosed herein; and (d) at least one ashless dispersant other than component (c); wherein the lubricating oil composition has a sulfur content of less than or equal to about 0.30 wt. %, a phosphorus content of less than or equal to about 0.09 wt. %, and a sulfated ash content of less than or equal to about 1.60 wt. % as determined by ASTM D 874, based on the total weight of the lubricating oil composition; and further wherein the lubricating oil composition is a SAE 0W multi-grade lubricating oil composition; with the proviso that when the lubricating oil composition has a sulfated ash content of less than or equal to 0.60 wt. %, based on the total weight the lubricating oil composition, the Mannich reaction product is present in at least about 3.0 wt. %, based on the total weight of the lubricating oil composition.

Owner:CHEVRON ORONITE TECH BV

Mannich base as well as preparation method and uses thereof

The present invention relates to a mannich base which is synthesized by the mannich reaction of dimeric cyclohexanone and formaldehyde with at least one kind of polyamine, wherein, the dimeric cyclohexanone is the dimer of the cyclohexanone, comprising the single or mixed form of 2-(1-cyclohexenyl) cyclohexanone, 2-(1-cyclohexyl) cyclohexanone and 2-(1-cyclohexylidene) cyclohexanone. The concrete preparation method of the product of the present invention is characterized in that by-product containing dimeric cyclohexanone autoclave liquid during the process of the cyclohexanone production is processed for the saponification treatment to collect the dimeric cyclohexanone by distilling (or obtain the dimeric cyclohexanone product directly), the dimeric cyclohexanone and the formaldehyde react with at least one kind of the polyamine for one to ten hours under 10 DEG C to 100 DEG C to be dehydrated to obtain the product. The product of the present invention is mainly used as curing agent to be applied in an epoxy system or a polyurethane system.

Owner:YUEYANG CHANGDE CHEM IND

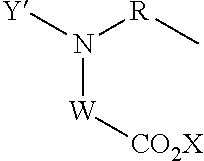

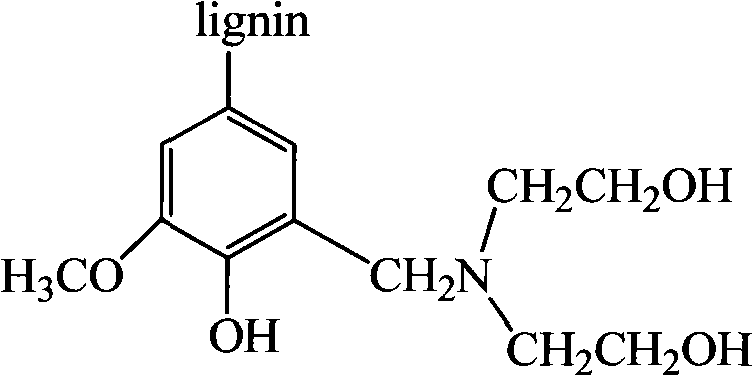

Lignin amido polyol and preparation method thereof

InactiveCN101857678AEasy to operateLow costCatalyst carriersTransportation and packagingMannich reactionStructural formula

The invention discloses a lignin amido polyol and a preparation method thereof. A chemical structural formula is in the specification. The preparation method comprises that: purified lignin serving as a raw material is subjected to Mannich reaction with formaldehyde and diethanol amine to form the lignin amido polyol and the lignin amido polyol is settled and separated by using hydrochloric acid. The preparation method has the advantages of simple process, mild reaction condition and the like. The prepared lignin amido polyol can be used as a catalyst carrier or a surfactant, and also can be reacted with isocyanate to synthesize a polyurethane material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

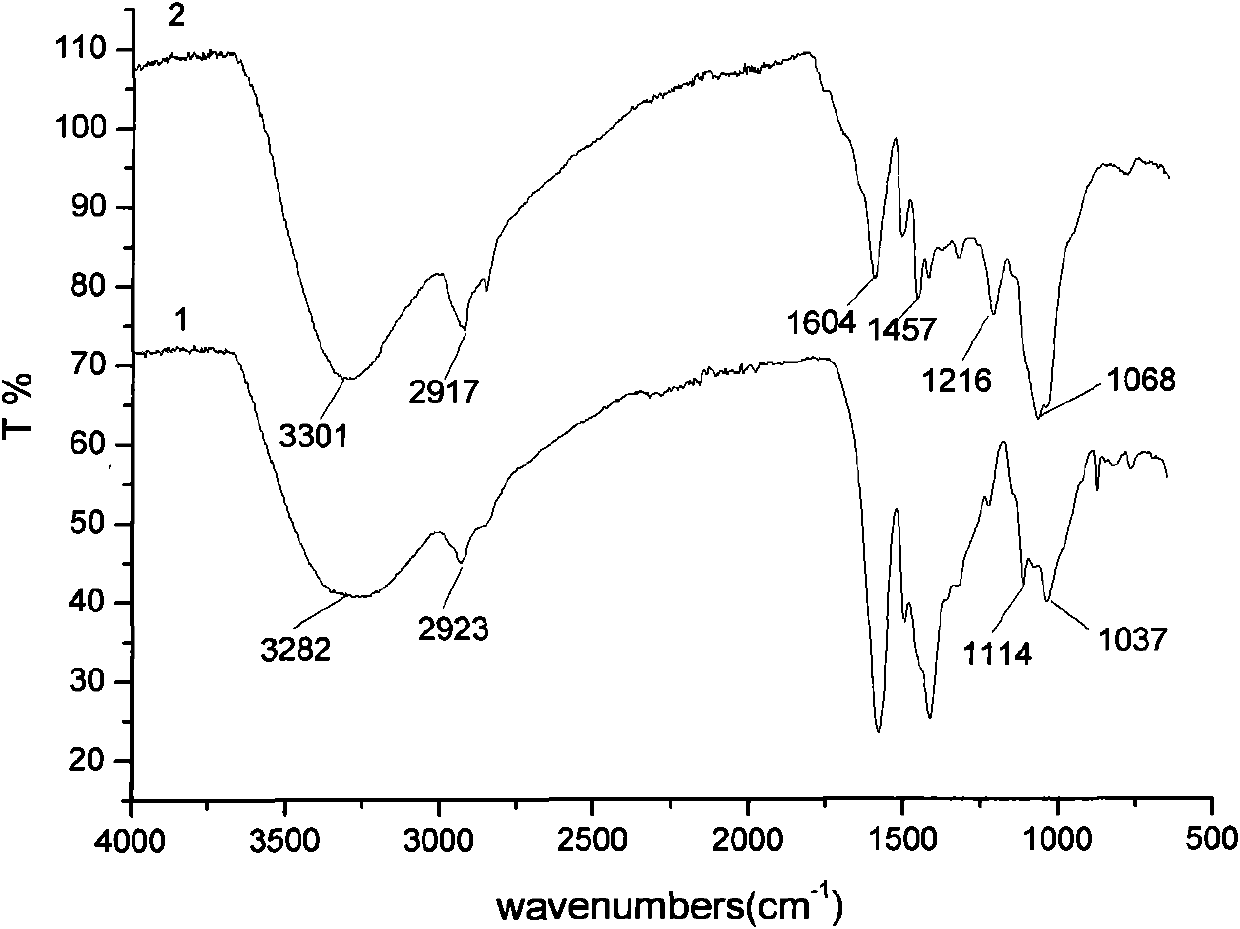

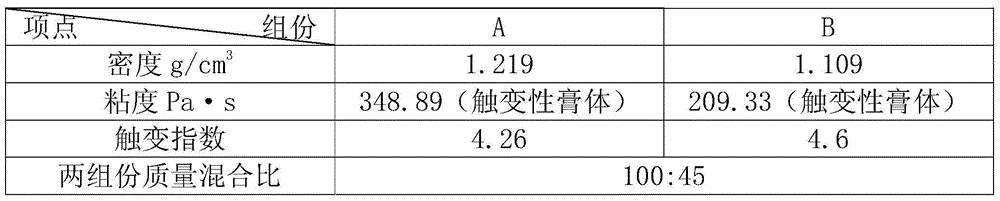

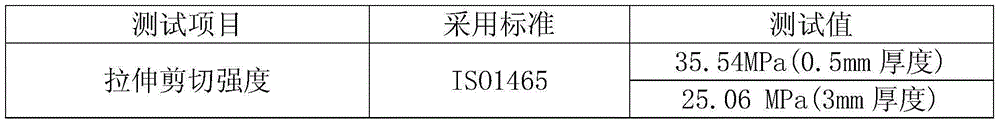

Quick epoxy structure adhesive and preparation method thereof

ActiveCN105018014AHigh strengthGood conditionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyMannich reaction

The invention relates to a quick epoxy structure adhesive and a preparation method thereof. The adhesive adopts a two-component epoxy resin system, and a component A comprises an epoxy resin mixture, a flexibilizer, a thinner, a coupling reagent, a defoaming agent, filler, a thixotropic agent and color paste. A component B comprises polyether amine, aromatic amine, polyamine of a mannich reaction, a coupling reagent, filler, a thixotropic agent and color paste. Gelation time of the adhesive prepared through the technical scheme at the room temperature is 30 min, and the adhesive can be ground after 1 h. When the adhesive is operated at the temperature over 30 DEG C, and gelation time is 25 min. The shearing strength of an adhesive layer which is 0.5 mm thick is 35.54 MPa under room temperature conditions. Tg is 87 DEG C, the thixotropic property is good, the adhesive layer, which is 0.5 mm thick, of a vertical face does not flow when hung, good state maintaining performance is achieved, constructability is excellent, and the adhesive can be widely used in the adhesion field of quick structural components and the repair and patching field of parts.

Owner:NEW UNITED GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com