Preparation and application of lignin-phenolic group modified amine waterborne epoxy hardener

A water-based epoxy and phenol-based technology, used in the field of epoxy resin curing agents, can solve the problems of being discarded in rivers and lakes, polluting water quality and the environment, and achieving the effects of reducing consumption, saving energy, and increasing the content of phenolic hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: In a 500ml four-neck flask equipped with a heating mantle, a stirring device, a condenser, and a thermometer, add 20g of sodium lignosulfonate and 20g of water, stir for 5 minutes, then add 90g of diethylenetriamine and 30g of phenol and stir After uniformity, when the dropwise addition is completed and the temperature is slowly raised to about 85°C, slowly add 69.6 g of formaldehyde dropwise to the flask, and after the dropwise addition is completed, keep warm for 5 hours and then extract the solvent and unreacted polyamine under reduced pressure to obtain lignin -Phenol-based modified polyamines, the primary amine content of the product is 8.2%

[0039] Step 2: Dilute 100 g of the lignin-phenol-based modified polyamine prepared in the first step with water, stir evenly, and slowly add 67.24 g of benzyl glycidyl ether to it, that is, benzyl glycidyl ether and lignin- The ratio of the amount of primary amine contained in the phenol-based modified polyamine is 0.8:...

Embodiment 2

[0042] The molecular structure of lignosulfonate is complex, and elemental analysis to determine the change of nitrogen content in the reaction product is one of the most commonly used methods to identify the effect of Mannich reaction modified lignosulfonate. Elemental analysis was performed on sodium lignosulfonate and the lignin-phenol-based modified polyamine prepared in Example 1, and the results are shown in Table 1. It can be seen from Table 1 that after sodium lignosulfonate is modified by Mannich reaction, the average content of N element in the product increases from 0.34% to 22.14%. The results of elemental analysis showed that diethylenetriamine groups were introduced into the molecular structure of lignin after reacting with diethylenetriamine and formaldehyde.

[0043] Table 1 Elemental analysis results

[0044]

Embodiment 3

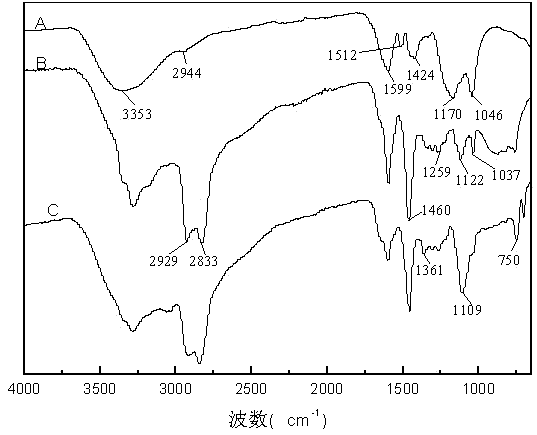

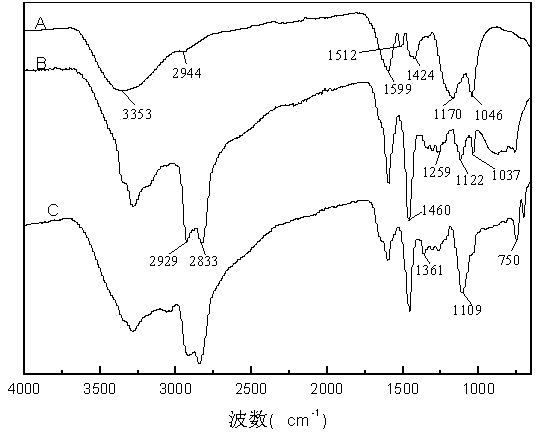

[0046] attached figure 1 Among them, (A) figure is the infrared spectrum figure of sodium lignosulfonate, (B) figure is the infrared spectrum figure of the lignin-phenol group modified polyamine prepared in embodiment 1, (C) figure embodiment 1 prepares Infrared spectrum of lignin-phenol modified amine waterborne epoxy curing agent. attached by figure 1 (A) It can be seen that sodium lignosulfonate is at 3425 cm -1 Nearby is the hydroxyl stretching vibration peak of phenolic hydroxyl and alcoholic hydroxyl connected by hydrogen bond; 1610~1600cm -1 and 1520~1500 cm -1 Vibrates for the aromatic ring skeleton; 1046 cm -1 It is the characteristic absorption peak of sulfate. Comparison between (B) and (A) shows that the height is 1464cm -1 The absorption peak representing the deformation vibration of methylene is obviously enhanced; 1122cm -1 The C-N stretching vibration absorption peak of aliphatic amines appears at , and the aliphatic aldehyde group in the reactant molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com