Saturated cardanol betaine surfactant, and preparation method and application thereof

A technology of surfactant and cardanol, applied in the field of saturated cardanol betaine surfactant and preparation, can solve problems such as not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of saturated cardanol dimethyl ammonium carboxylate betaine surfactant:

[0054] The first step: in the 150mL three-necked bottle that electromagnetic stirring, thermometer, constant pressure dropping funnel are housed, add 50mL molar concentration and be the saturated cardanol dehydrated alcohol solution of 0.50mol / L and 3.38g dimethylamine, control temperature At 30°C, 6.08 g of formaldehyde solution with a mass concentration of 37% was added dropwise, stirring was continued for 2 hours after the dropwise addition, and then heated to reflux for 4 hours. After the reaction was completed, ethanol, water, unreacted formaldehyde and dimethylamine were distilled off under reduced pressure to obtain the crude product of saturated cardanol dimethylamine. Separation and purification with silica gel chromatography column, sequentially using petroleum ether and acetone as eluent to carry out gradient elution on the silica gel column to obtain saturated cardanol dime...

Embodiment 2

[0059] Preparation of saturated cardanol diethylammonium sulfobetaine surfactant:

[0060] Step 1: Add 60 mL of saturated cardanol isopropanol solution and 5.48 g of diethylamine with a molar concentration of 0.42 mol / L in a 150 mL three-necked flask equipped with electromagnetic stirring, a thermometer, and a constant pressure dropping funnel, and control the temperature At 40° C., 6.48 g of formaldehyde aqueous solution with a mass concentration of 37% was added dropwise, stirring was continued for 2 h after the dropwise addition, and then heated to reflux for 16 hours. After the reaction was completed, isopropanol, water, unreacted formaldehyde and diethylamine were distilled off under reduced pressure to obtain the crude product of saturated cardanol diethylamine. Separation and purification with silica gel chromatography column, followed by gradient elution with petroleum ether and acetone as eluent on the silica gel column to obtain saturated cardanol dibutylamine with a...

Embodiment 3

[0064] Preparation of Saturated Cardanol Dibutylammonium Carboxylate Betaine Surfactant

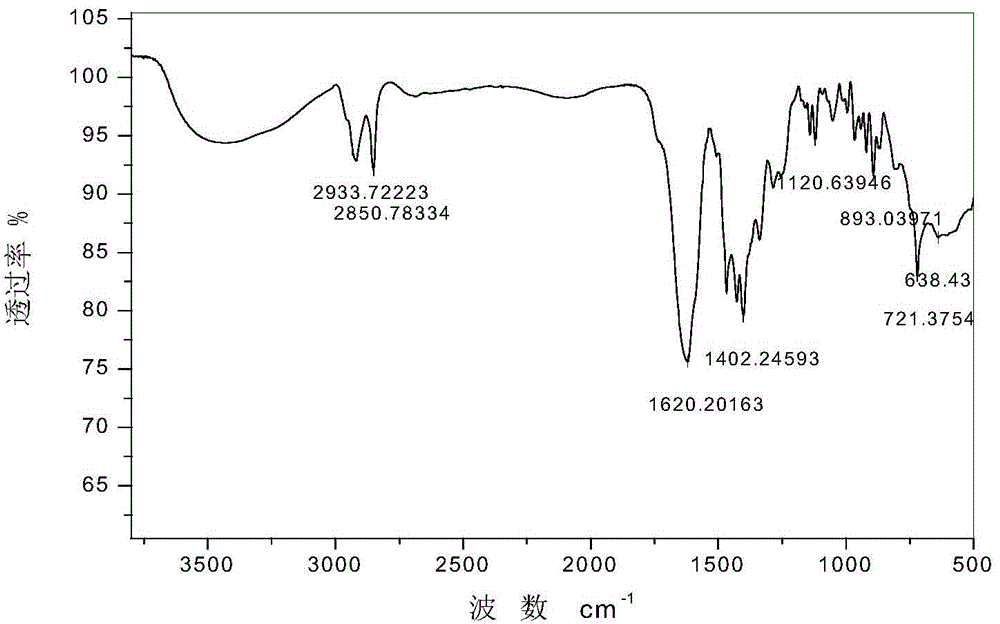

[0065] The technical scheme is basically the same as in Example 1, except that in the first step, dibutylamine is used to replace dimethylamine, and in the second step, saturated cardanol dibutylamine is used to participate in the reaction. Other conditions and operating methods are the same as in Example 1 to obtain The product is saturated cardanol dibutylammonium carboxylate betaine surfactant, and its IR spectrum is as follows Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com