Halogen-free reaction type flame retardant for polyurethane foam as well as preparation method and application thereof

A reactive flame retardant, polyurethane foam technology, applied in the field of halogen-free phosphorus flame retardants, can solve the problems of high cost of DOPO, restrict the application of DOPO flame retardants, etc., to improve storage stability, improve mechanical properties and thermal properties. The effect of stability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

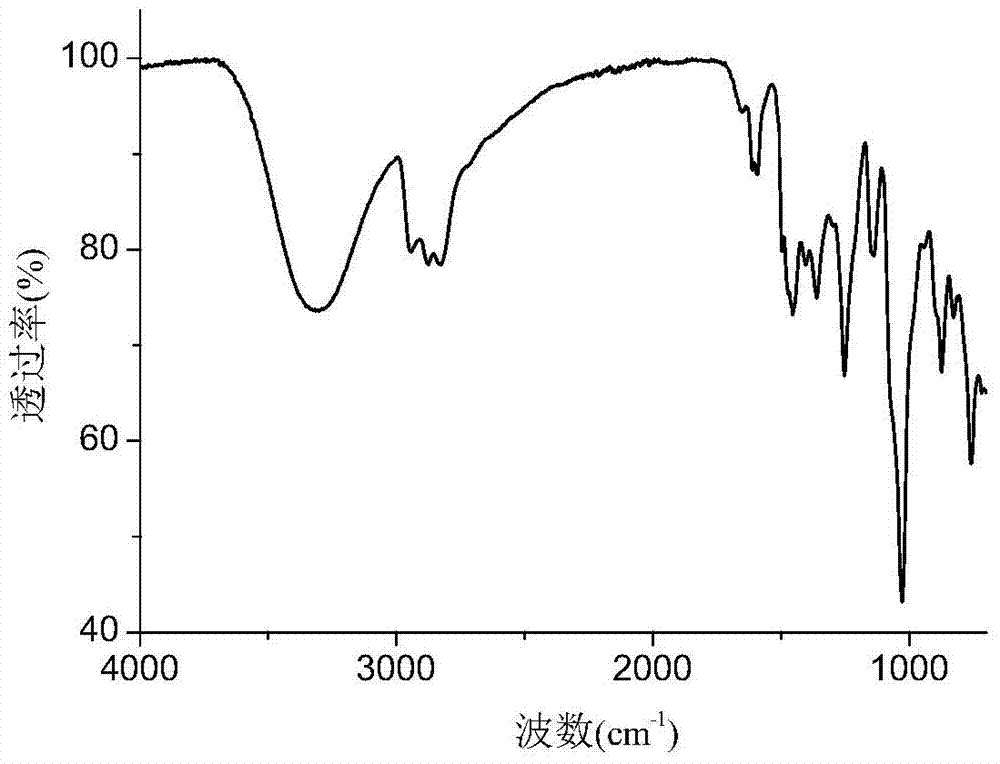

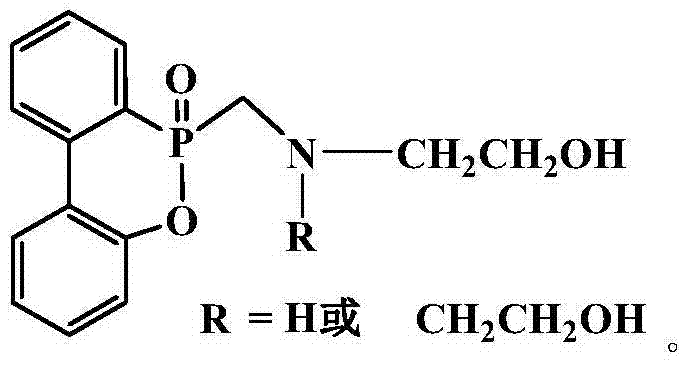

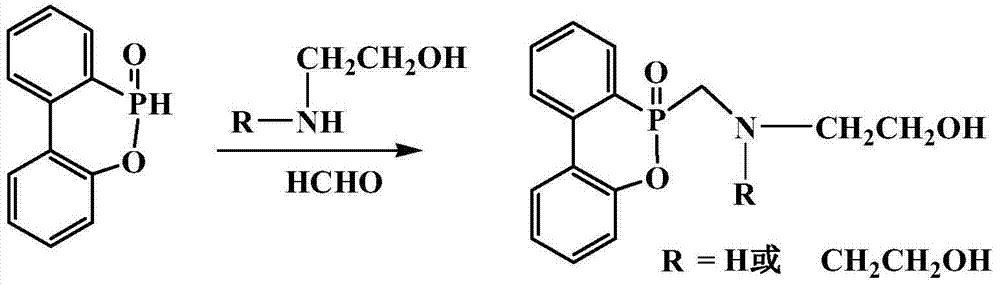

Method used

Image

Examples

Embodiment 1

[0041] Weigh 110 parts by mass of DOPO, 30 parts by mass of ethanolamine, and 15 parts by mass of paraformaldehyde, mix them evenly, heat up to a temperature of 90°C in a nitrogen atmosphere, and react for 4 hours. After the reaction is completed, remove the water in the solution to obtain a halogen-free reaction type flame retardant. Then according to the formula in Table 1, first mix the combined polyol, DOPO derivative halogen-free reactive flame retardant and additives evenly under high-speed stirring conditions, and then stir with isocyanate under high-speed stirring conditions for 10-20s at a speed of 2000 ~3000r / min, pour into the mold, and mature for 48h.

Embodiment 2

[0043] Weigh 100 parts by mass of DOPO, 35 parts by mass of monoethanolamine, and 35 parts by mass (37%wt) of formaldehyde solution and mix evenly, heat up to a temperature of 80°C in a nitrogen atmosphere, react for 5 hours, and remove the water in the solution after the reaction is complete The halogen-free reactive flame retardant can be obtained. Then according to the formula in Table 1, first mix the combined polyol, DOPO derivative halogen-free reactive flame retardant and additives evenly under high-speed stirring conditions, and then stir with isocyanate under high-speed stirring conditions for 10-20s at a speed of 2000 ~3000r / min, pour into the mold, and mature for 48h.

Embodiment 3

[0045] Weigh 105 parts by mass of DOPO, 45 parts by mass of diethanolamine, and 15 parts by mass of paraformaldehyde, mix them uniformly, heat up to a temperature of 90°C in a nitrogen atmosphere, and react for 5 hours. After the reaction is completed, remove the water in the solution to obtain Halogen reactive flame retardant. Then according to the formula in Table 1, first mix the combined polyol, DOPO derivative halogen-free reactive flame retardant and additives evenly under high-speed stirring conditions, and then stir with isocyanate under high-speed stirring conditions for 10-20s at a speed of 2000 ~3000r / min, pour into the mold, and mature for 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com