Solid-phase preparation method for nano zinc oxide through template

A nano-zinc oxide, solid-phase preparation technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The solid-phase preparation of nano-zinc oxide photocatalyst by lignin amine template method, the specific steps are as follows:

[0031] 1. Take 4g of alkali lignin at room temperature and place it in a 250mL round bottom flask, add 95mL of deionized water and 5.5 mL of 0.4 mol. L -1 NaOH solution, stirred for 10 min, added 1.5 mL of formaldehyde, stirred for 10 min, then added 4.8 g of hexamethylenediamine, stirred for 10 min, heated to reflux at 65°C for 3 h, cooled to room temperature, filtered, and added 10% ferricyanide to the filtrate potassium ferricyanide solution to completely precipitate the prepared ligninamine, filter under reduced pressure, wash repeatedly to remove excess potassium ferricyanide, and put the filter cake in a constant temperature drying oven at 60°C for 10 hours;

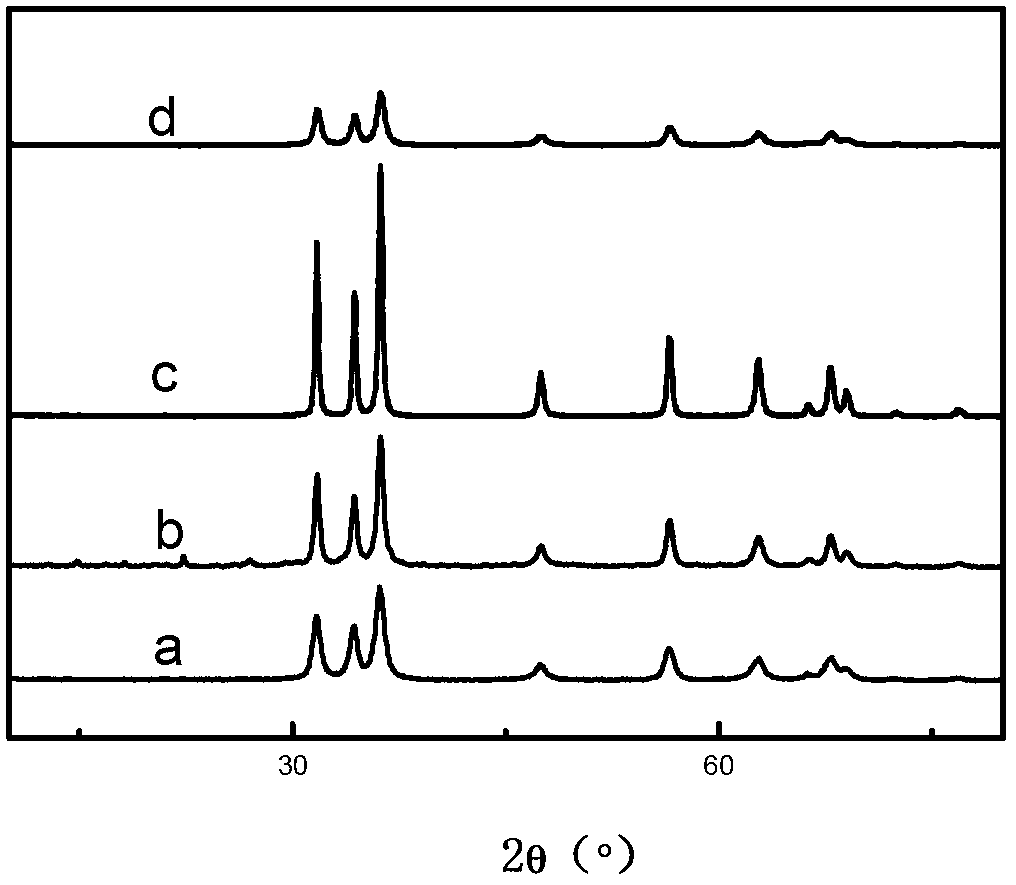

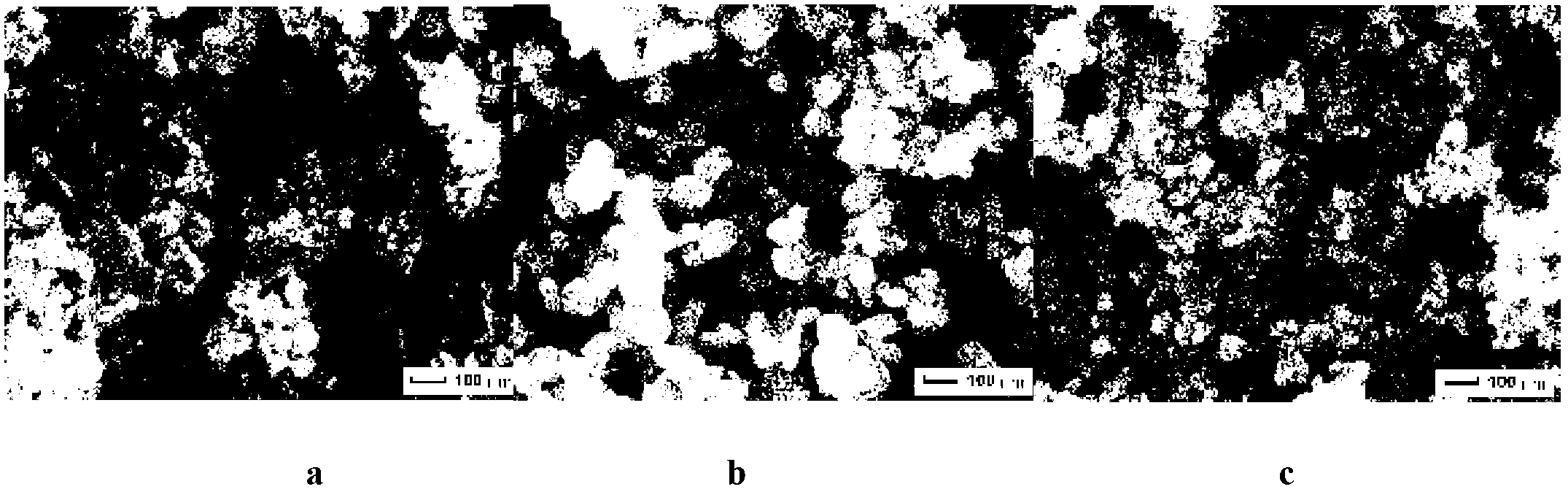

[0032] 2. Add 0.05mol Zn(NO 3 ) 2 6H2O and 0.05molNa 2 CO 3 Grind them in different mortars for 15 minutes, then transfer them to the same mortar, add 1.0 g of the ligninami...

Embodiment 2

[0034] The solid-phase preparation of nano-zinc oxide by lignin amine template method is the same as that of Example 1. The difference is that the formaldehyde added in the first step is 2.5mL, and the amine used is 3.2g of tetraethylenepentamine. In the second step, the final The sample was calcined at 400°C for 2 hours to obtain white nano-zinc oxide. Sample XRD as figure 1 b, SEM such as figure 2 b.

Embodiment 3

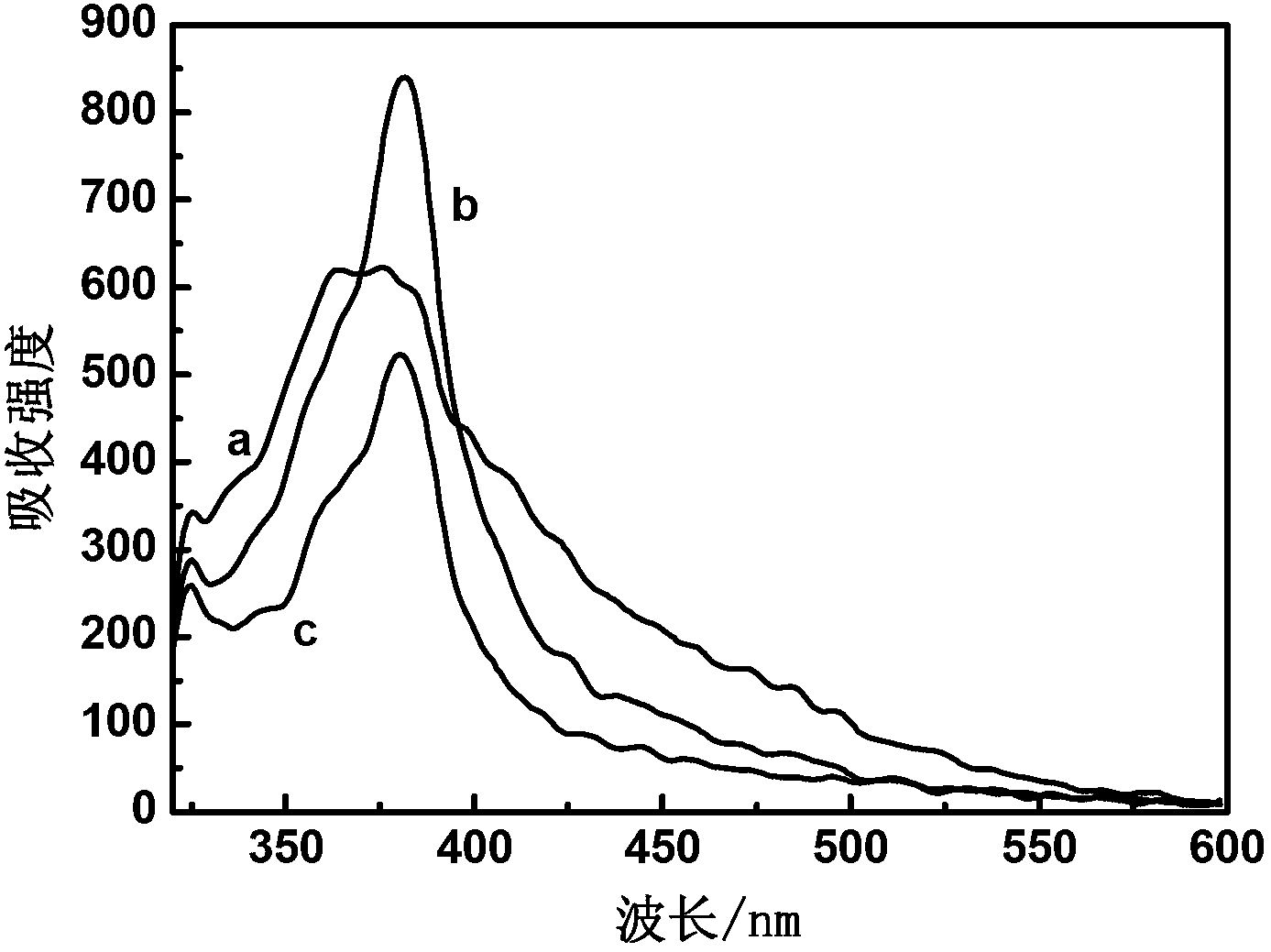

[0036] The solid-phase preparation of nano-zinc oxide by ligninamine template method is the same as that of Example 1, except that in the second step, the sample is finally roasted at 600°C for 2 hours to obtain white nano-zinc oxide. Sample XRD as figure 1 c, SEM such as figure 2 c, PL such as image 3 b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com