Quick epoxy structure adhesive and preparation method thereof

A technology of structural adhesives and adhesives, applied in the field of repair and repair, can solve the problems of inability to apply fast bonding positioning, operator resistance, and inability to meet the special requirements of blade glue, and achieve excellent constructability , short operating time, shortening the production process cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

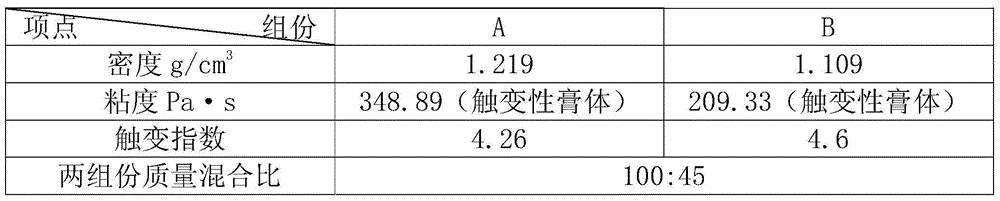

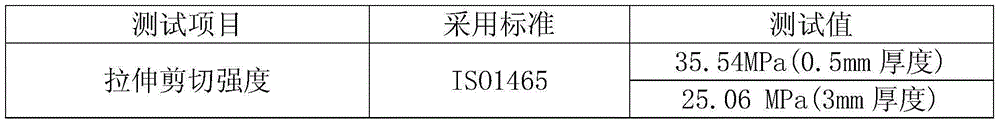

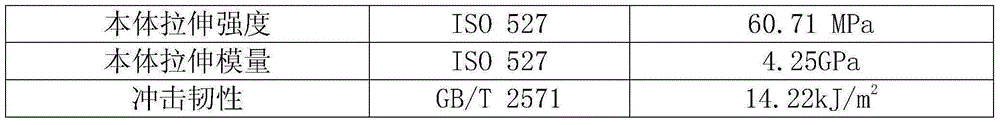

Embodiment 1

[0025] A kind of preparation method of fast epoxy structure adhesive, this preparation method comprises the steps:

[0026] (1) Formulation preparation

[0027] In terms of parts by mass, prepare the formula for component A: 75 parts of epoxy resin mixture E51, 15 parts of NPEF-170; 5 parts of toughening agent M20; 5 parts of reactive diluent AGE500; 2 parts of first coupling agent KH560; 1 part of defoamer A530; 8 parts of filler nano-calcium carbonate, 6 parts of fiber powder (glass fiber and boron fiber are mixed according to the mass ratio of 1:1); 2 parts of thixotropic agent bentonite, 8 parts of white carbon black, BYK605 0.8 parts; color paste: 0.1 parts;

[0028] The formula of component B: polyether amine T-403 7 parts; modified fatty amine T-28 8 parts, 615 5 parts; tertiary amine accelerator DMP-20 3 parts; Mannich reaction series polyamine T31 20 2 parts; 2 parts of the second coupling agent KH550; filler: 4 parts of gypsum powder, 4 parts of fiber powder (glass...

Embodiment 2

[0035] A kind of preparation method of fast epoxy structure adhesive, this preparation method comprises the steps:

[0036] (1) Formulation preparation

[0037] In terms of parts by mass, prepare the formula for component A: 80 parts of epoxy resin mixture E54, 10 parts of NPEF-170; 6 parts of toughening agent SL-3402; 8 parts of reactive diluent BGE501; 1.5 parts of first coupling agent KH560 0.8 parts of defoamer 066N; 7 parts of filler zinc oxide, 4 parts of fiber powder (glass fiber and boron fiber are mixed according to the mass ratio of 1:1), 2 parts of calcium sulfate whiskers; 2.5 parts of thixotropic agent bentonite, 7 parts of white carbon black, 1 part of BYK-E410; color paste: 0.1 part;

[0038] The formula of component B: polyether amine T-5000 8 parts; modified fatty amine T-30 7 parts, 615LC 13 parts; tertiary amine accelerator DMP-30 2 parts; Mannich reaction series polyamine TZ500 21 1.5 parts of the second coupling agent KH550; 4.5 parts of filler alumina, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com