Patents

Literature

237results about How to "High carbon residue rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

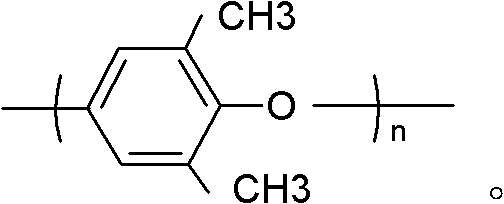

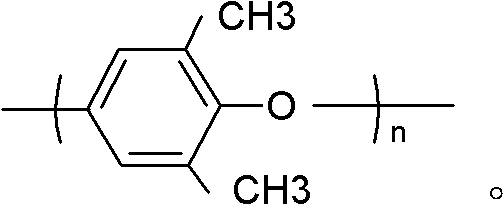

Epoxy resin composition as well as prepreg and laminated board made of same

InactiveCN102051022AGood heat resistanceLow water absorptionSynthetic resin layered productsCircuit susbtrate materialsDielectric lossChemistry

The invention relates to an epoxy resin composition as well as a prepreg and a laminated board made of the same. The epoxy resin composition comprises the following components in parts by weight: 1-50 parts of modified polyphenylene oxide resin, 30-80 parts of epoxy resin, 20-60 parts of active ester curing agent, 0-50 parts of filler and 1-20 parts of assistant. The prepreg made of the epoxy resin composition comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The laminated board made of the epoxy resin composition comprises a plurality of laminated prepregs, wherein each prepreg comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The invention has the advantages of high heat resistance, high fire retardancy, low dielectric constant, low dielectric loss, excellent high-frequency dielectric properties and the like, and is suitable to be used as a high frequency circuit substrate material.

Owner:GUANGDONG SHENGYI SCI TECH

Phenolic cyanate resin and its synthesis method and phenolic cyanate ablative material composite

The present invention discloses a phenol-formaldehyde cyanate resin. It provides its chemical formula and synthesis method, and ablative composite material formed from the the above-mentioned phenol-formaldehyde cyanate resin.

Owner:北京玻钢院复合材料有限公司

Preparation method of natural flake graphite-based negative electrode material

The invention discloses a preparation method of a natural flake graphite-based negative electrode material. The method specifically comprises the following steps of: (1) crushing and processing natural flake graphite, carrying out purifying and drying, then infiltrating the product with a phenolic resin solution, finally evaporating the used solvent, and carrying out pre-carbonization on the obtained graphite under nitrogen protection of 550-750 DEG C; (2) adding the pre-carbonized graphite obtained in the step (1) to pitch coke micro powder for mixing, carrying out shaping and crushing until the tap density is 0.95-1.00g / cm<3>, adding the crushed graphite to dimethicone for mixing, carrying out pre-carbonization under nitrogen protection of 550-750 DEG C and carrying out sieving and magnetic deironing; and (3) carrying out carbonization treatment on the pre-carbonized graphite obtained in the step (2) under nitrogen protection of 950-1250 DEG C to obtain the natural flake graphite-based negative electrode material. The negative electrode material is high in yield, good in material liquid absorption and holdup properties and good in electrochemical properties.

Owner:内蒙古丰辉新材料科技有限公司

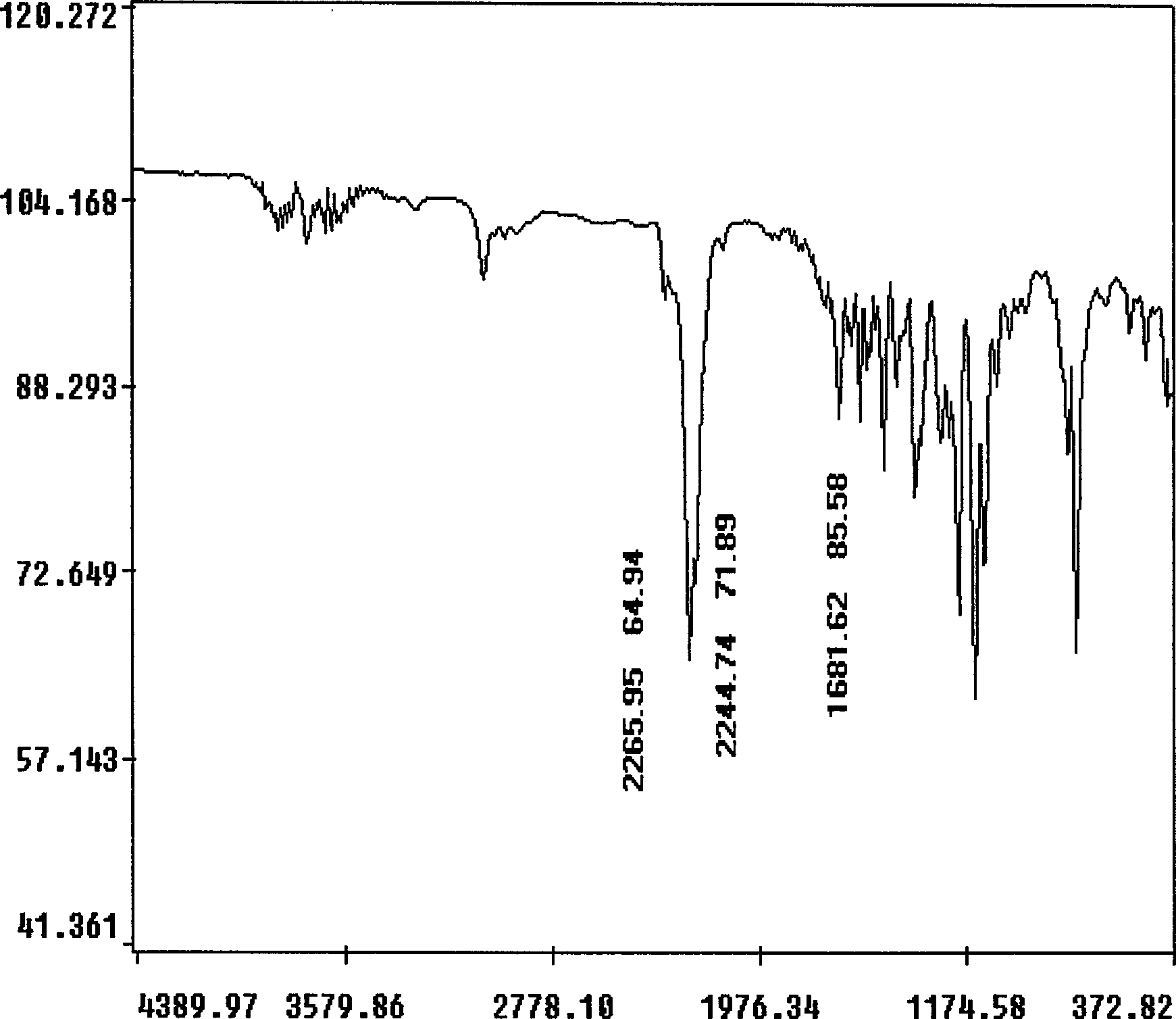

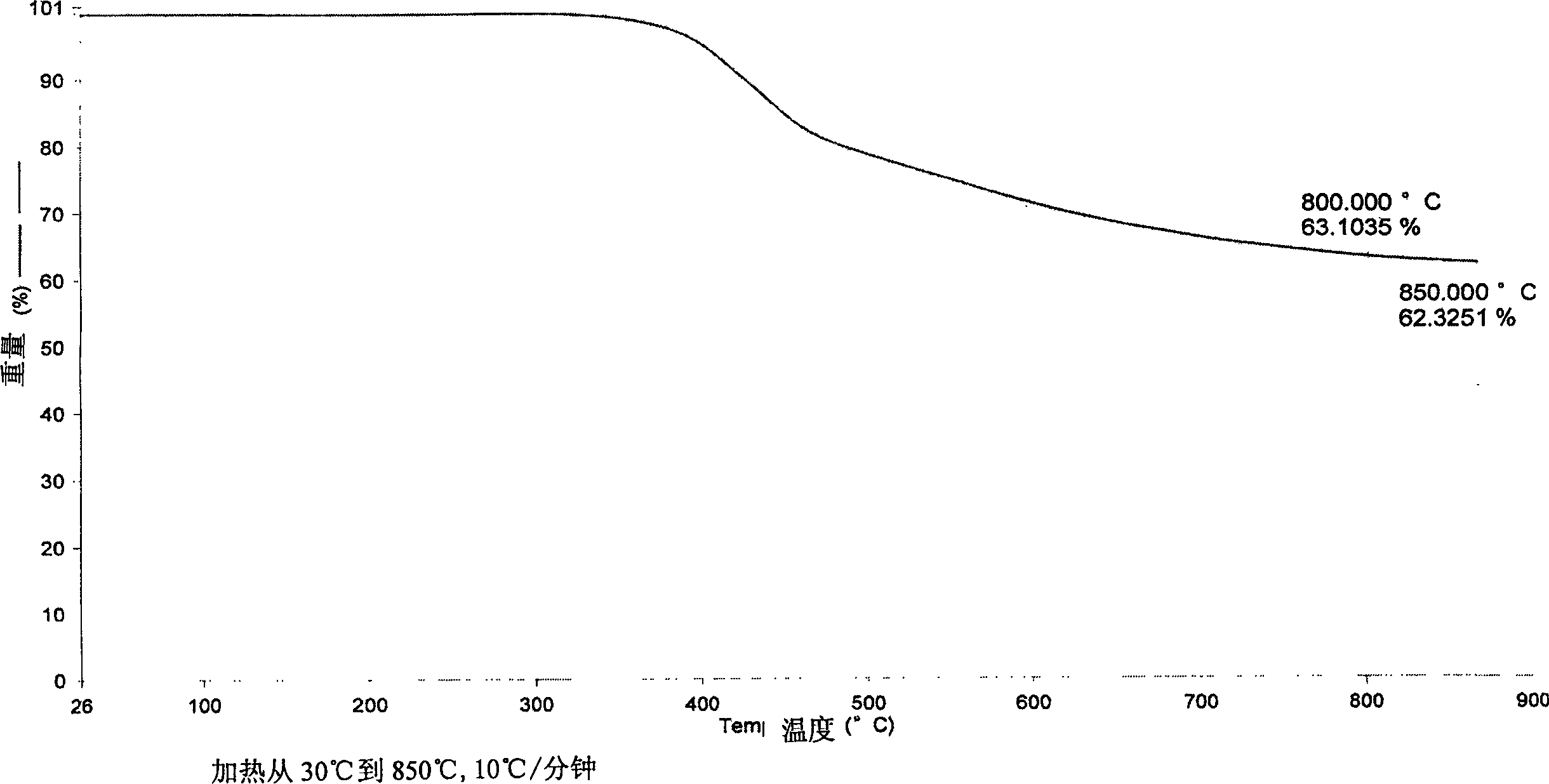

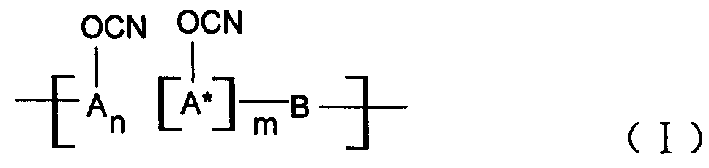

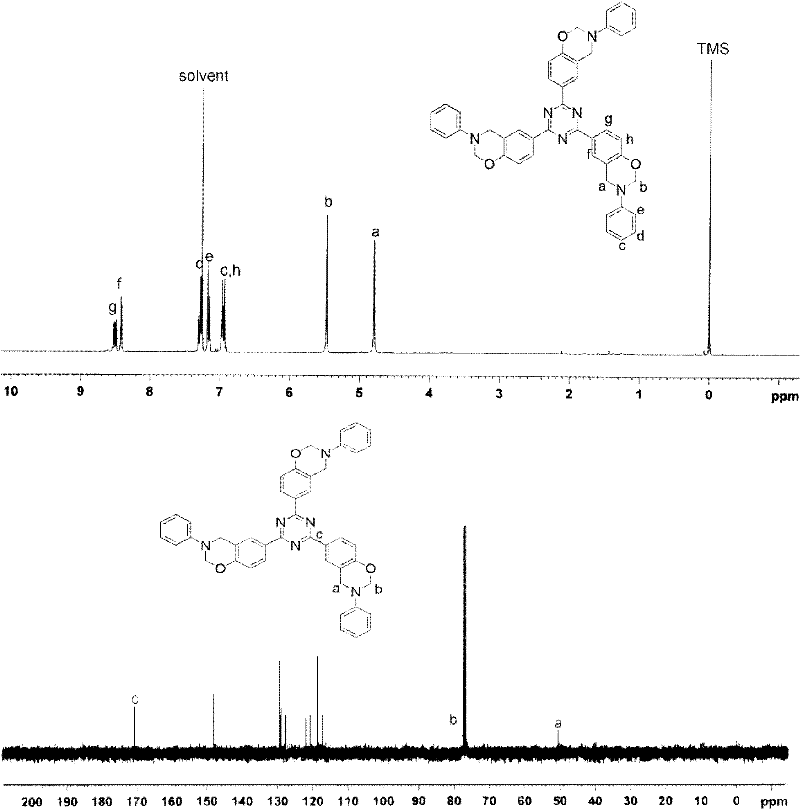

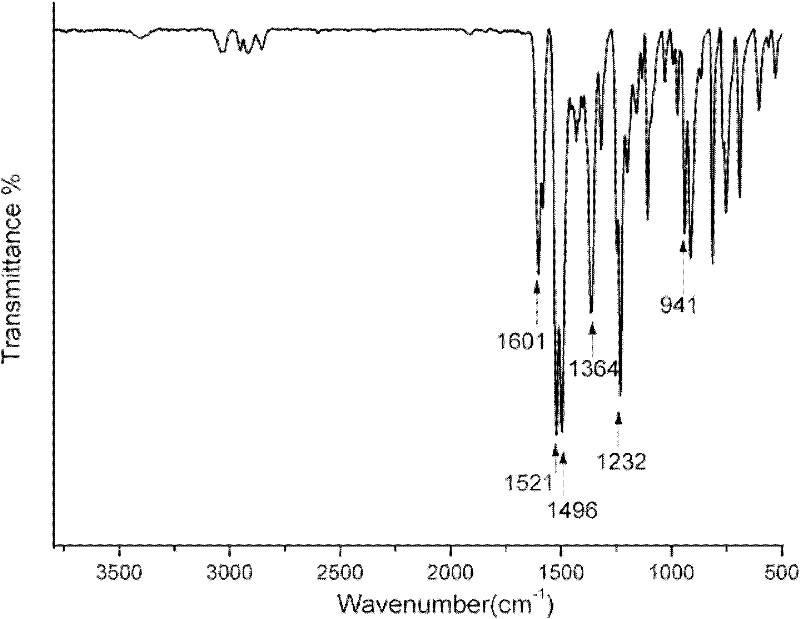

Triazine-containing benzoxazine, triazine-containing benzoxazine polymer, and preparation method thereof

ActiveCN102219785AIncrease contentImprove heat resistanceOrganic chemistryTriflic acidStructural formula

The invention relates to triazine-containing benzoxazine, a triazine-containing benzoxazine polymer, and a preparation method thereof. The preparation method is characterized by: adopting cyanophenol as a raw material; adopting trifluoromethanesulfonic acid or trifluoroacetic acid as a catalyst; synthesizing triazine-containing trihydric phenol (TP for short) in dichloromethane or chloroform or acetone at a common temperature; adopting the synthesized TP, formaldehyde and aminated compounds as reaction raw materials; adopting a alkali as the catalyst, and carrying out a reaction in a alcohol solvent or a ether solvent to synthesize a series of triazine-containing polycyclic benzoxazine monomers (BZ for short) which have not been reported; heating the BZ to carry out a ring-opening polymerization to form polybenzoxazine (PBZ for short). A structural formula of the monomer BZ is shown as follow, substituents R are shown in the specification. The synthesized novel monomer provided by the present invention contains a triazine ring structure, such that the triazine content in the PBZ resin can be substantially raised so as to notably improve heat resistance, residual carbon rate, fire resistance property and wave transmission property of the PBZ.

Owner:SHANDONG UNIV

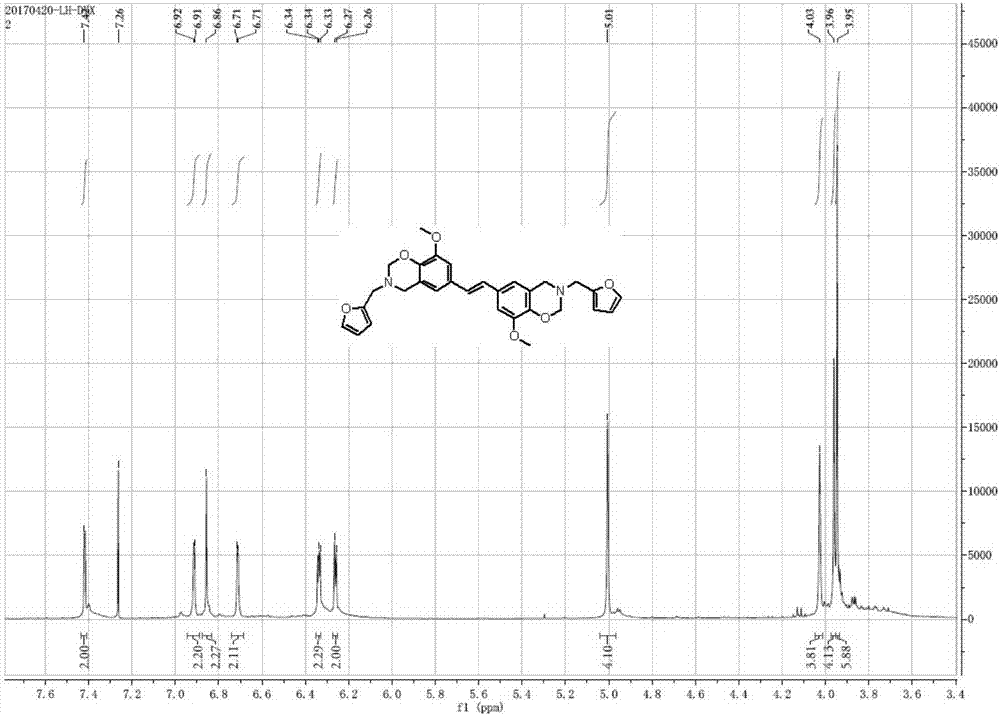

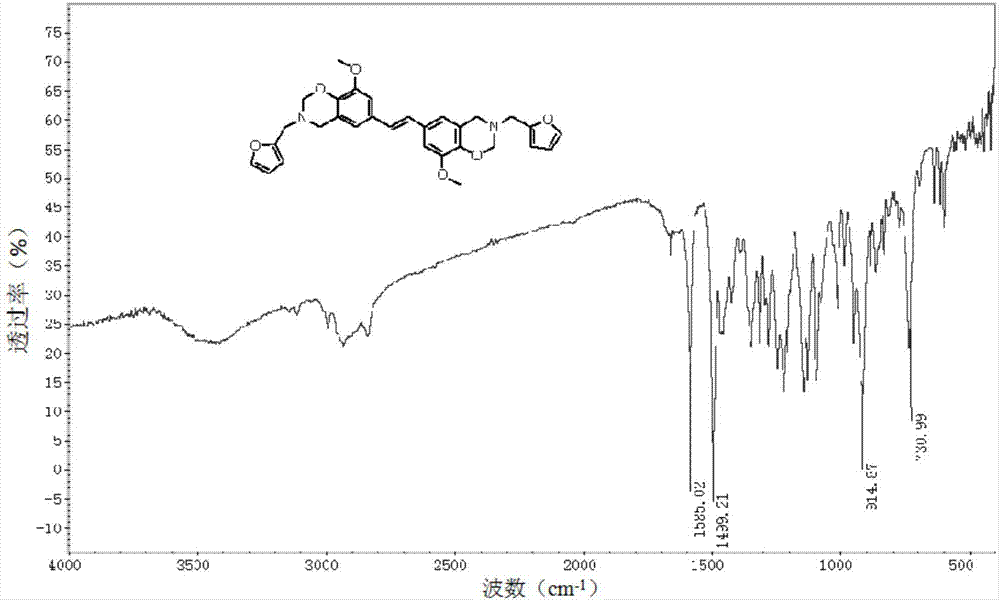

Biology base benzoxazine containing double bond active functional groups and preparation method thereof

InactiveCN107459512AHigh carbon residue rateIncreased curing crosslink densityOrganic chemistryDouble bondSolvent

The invention discloses biology base benzoxazine containing double bond active functional groups. Bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene, primary amine compounds and formaldehyde compounds react to generate the benzoxazine. Bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene is obtained by causing reproducible vanillin to undergo Mcmurry coupling reaction. The method for preparing benzoxazine comprises the steps of adding bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene, the primary amine compounds and the formaldehyde compounds into a round-bottom flask containing solvent benzene or toluene, performing heating reflux water diversion reaction, performing extraction and drying, and performing column chromatography isolation to obtain the product. The benzoxazine has high thermal stability and high residual carbon rate, can be used alone as a monomer or mixed with other benzoxazine monomers or phenolic resin or epoxy resin for use, and an obtained cured product is good in heat resistance and can be used for the fields of high-performance structural materials, ablation-resistant materials and electronic packaging materials.

Owner:SOUTHWEST PETROLEUM UNIV

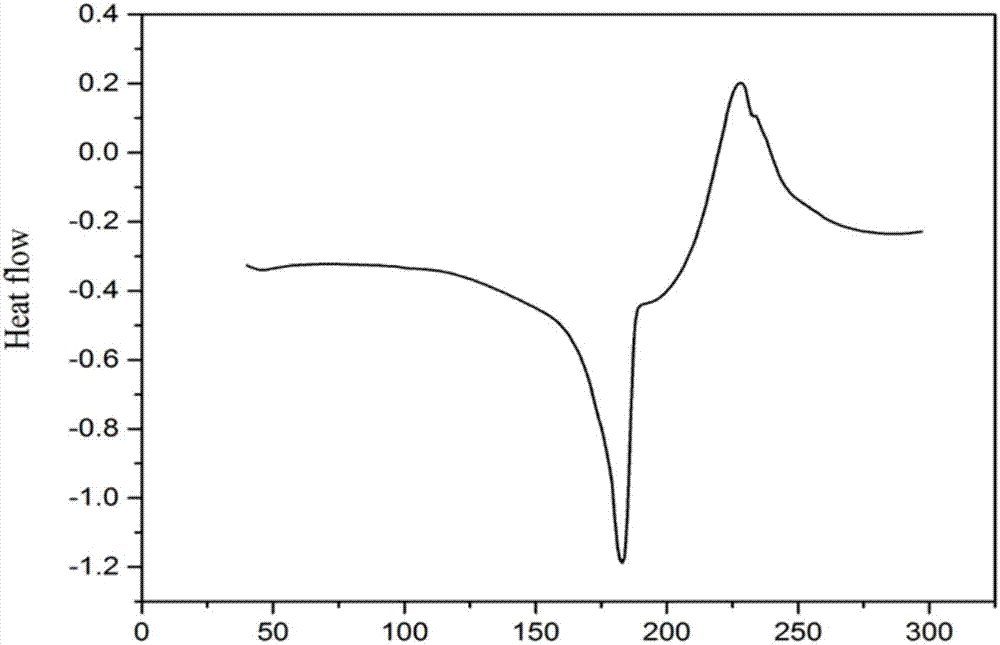

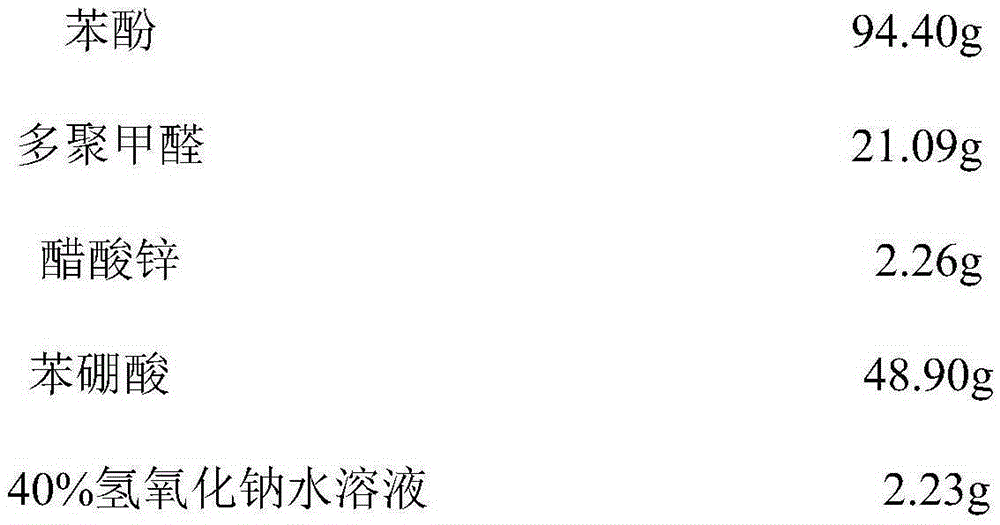

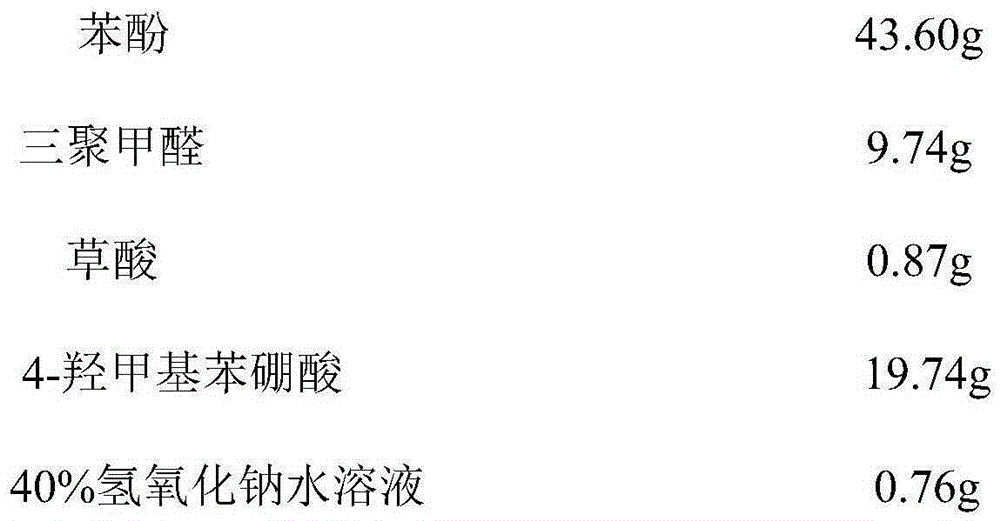

Preparing method for ablation-resisting boron-modified thermoplastic phenolic resin

The invention relates to a preparing method for ablation-resisting boron-modified thermoplastic phenolic resin. For solving the problems that at present, boron-modified phenolic resin is complex in production process and pollutes environment, and an obtained composite material product is high in porosity, solvent is not used in the synthetic process, an effective catalyst is adopted to make a boron-containing compound react fully, a resin structure is connected in a copolymerization mode, the suitable reaction temperature and the suitable time are controlled, and the boron-containing thermoplastic phenolic resin which is high in molecular weight, low in volatile content and low in curing volume shrinkage rate is synthesized, wherein the composite material of the resin is high in ablation performance and mechanical property. While the good heat resistance and ablation resistance of the boron-containing compound are brought into full play, the manufacturability and the mechanical property of the boron-containing phenolic resin are improved, and it is the research core to meet the requirement of aerospace development with the thermoplastic phenolic resin having a high carbon yield, a suitable softening point and good manufacturability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

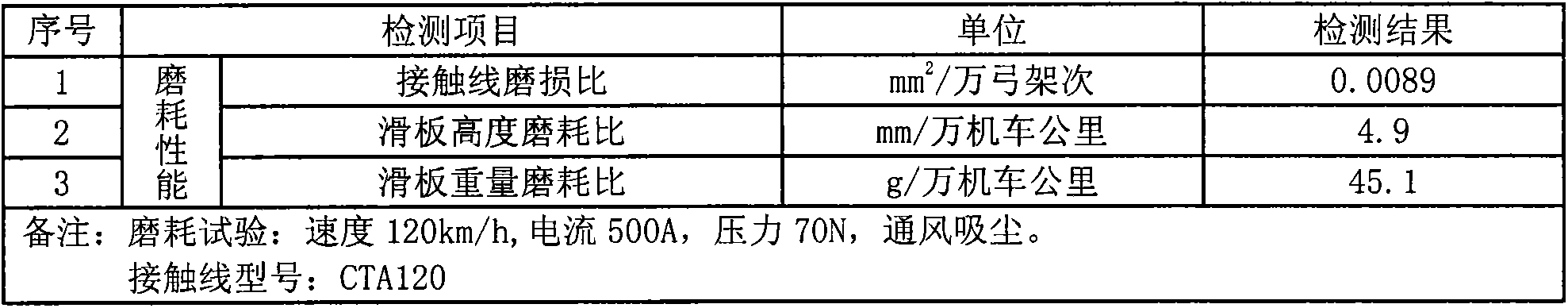

Pantograph slide plate material for locomotive and preparation method thereof

The invention relates to a pantograph slide plate material for a locomotive and a preparation method thereof and belongs to the technical field of materials. The preparation method of the pantograph slide plate material comprises the following steps: selecting pitch coke with high crushing resistance as aggregate, selecting graphite powder with good lubricating property, good electricity-conducting property and good heat-conducting property, then adding hard additive carbon black in a certain ratio, stirring, mixing, moulding, roasting, dipping and processing under the action of a high-strength and high-residue binder, so that the pantograph slide plate material with excellent performances is obtained, and an economic and practicable novel material with low specific resistance, good anti-attrition self-lubricating property and high strength is realized.

Owner:安徽锦美碳材科技发展有限公司

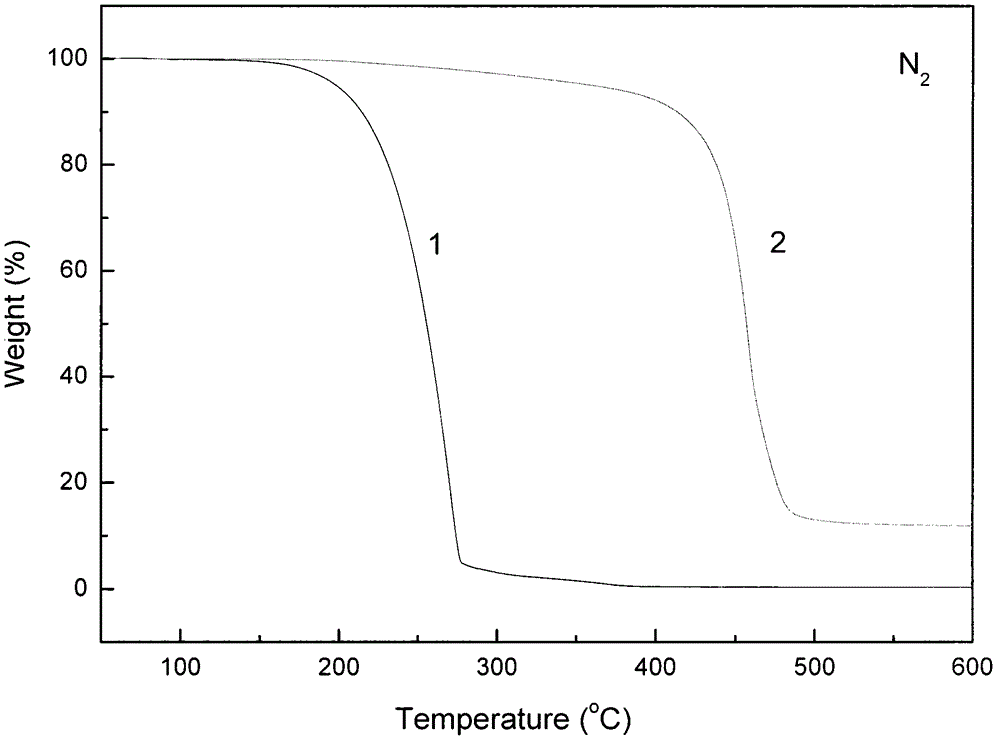

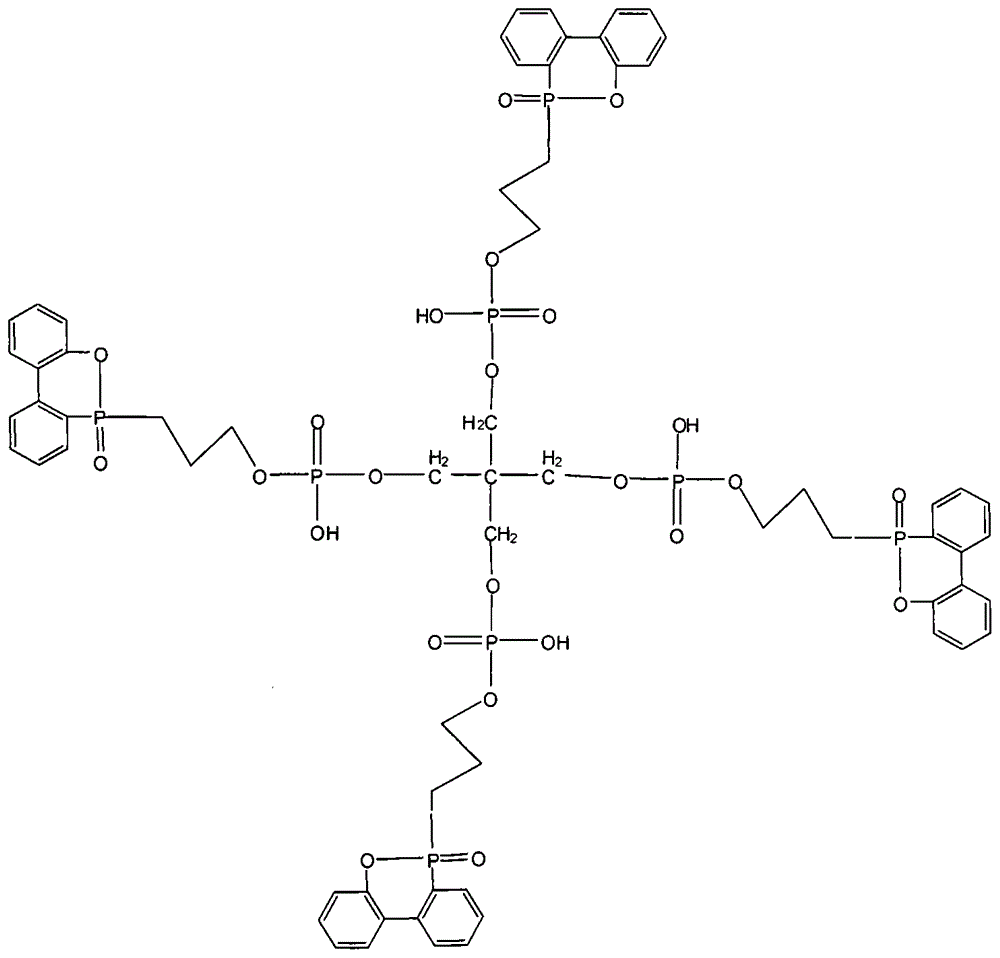

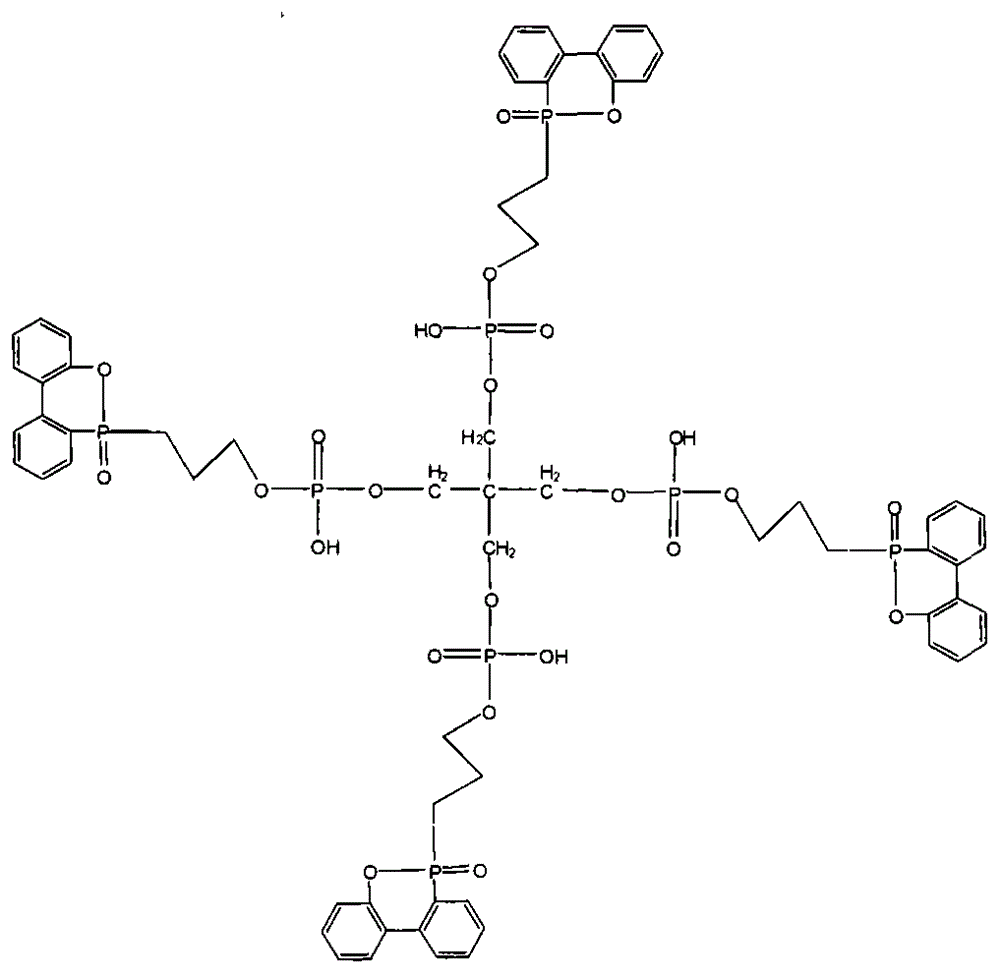

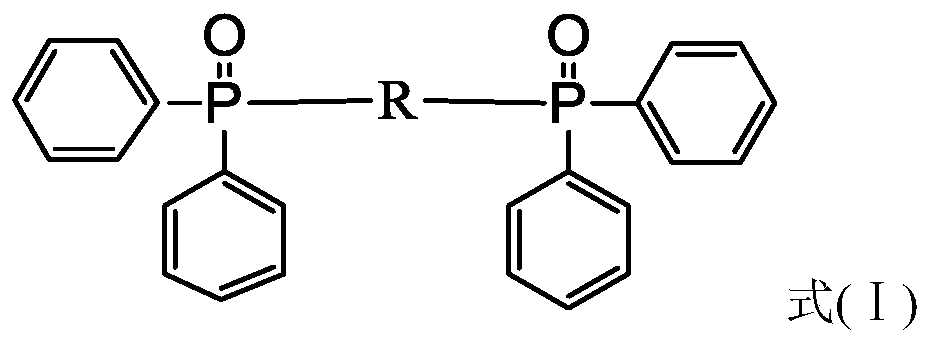

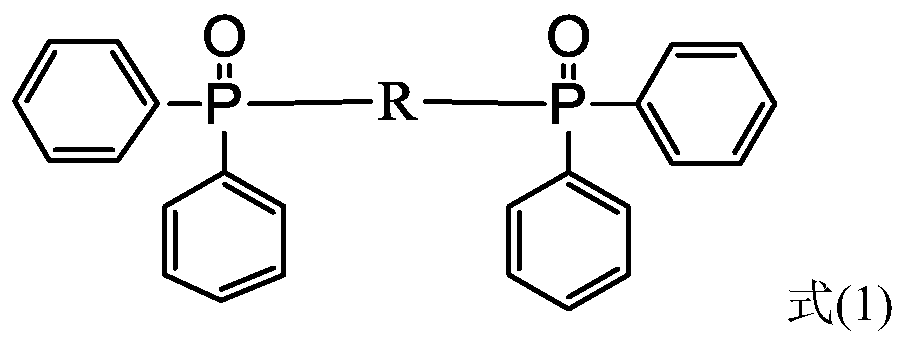

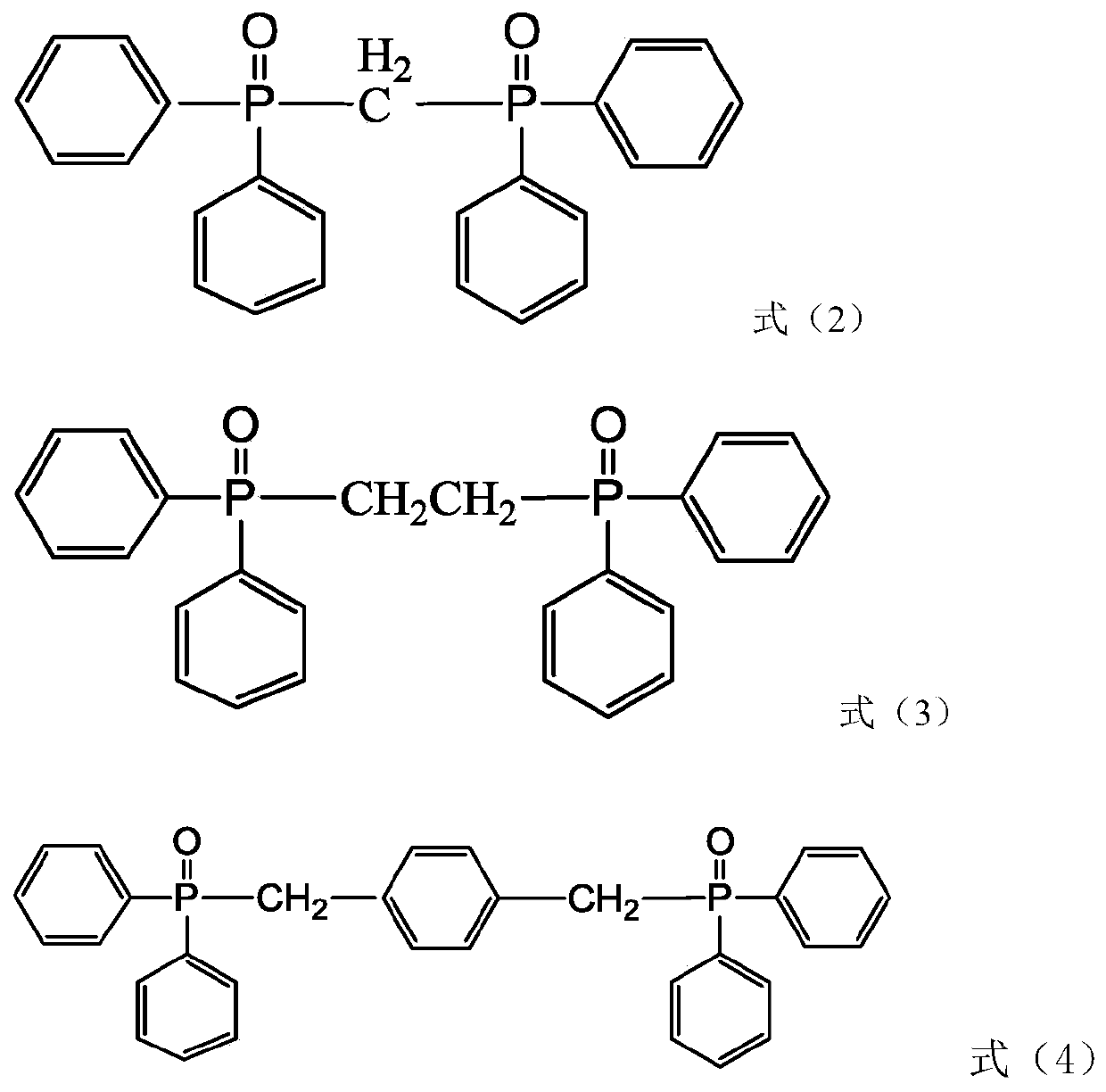

Flame retardant containing DOPO groups and preparation method of flame retardant

InactiveCN104629086AHigh molecular weightImprove thermal stabilityGroup 5/15 element organic compoundsPolymer scienceGas phase

The invention relates to a flame retardant which contains DOPO groups and has gas phase and solid phase flame retardation effects and a preparation method of the flame retardant. The flame retardant is a novel flame retardant, can be added into a polymer material as an improved auxiliary agent, and belongs to the technical field of processing auxiliary agents. The flame retardant disclosed by the invention has high molecular weight and good thermal stability, is high in carbon residue rate after degradation, is stable in flame retardant efficiency, can be used for improving the flame retardant properties of the material by virtue of a gas phase and a solid phase, and can be used for improving the flame retardant properties of high molecular materials after the flame retardant is added into the high molecular materials; and the method disclosed by the invention is simple, adopts a one-pot process, and is high in efficiency.

Owner:国建工材(北京)科技有限公司

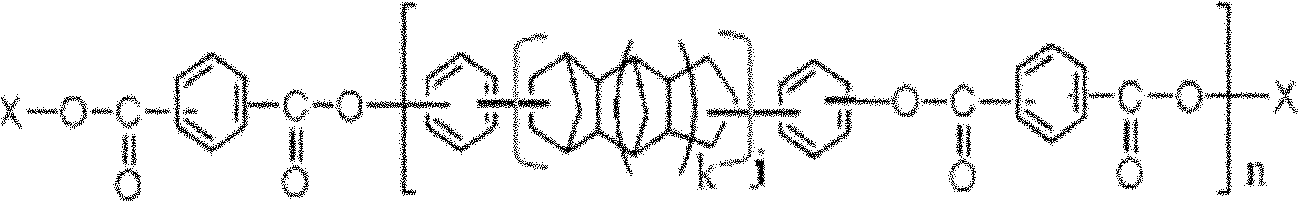

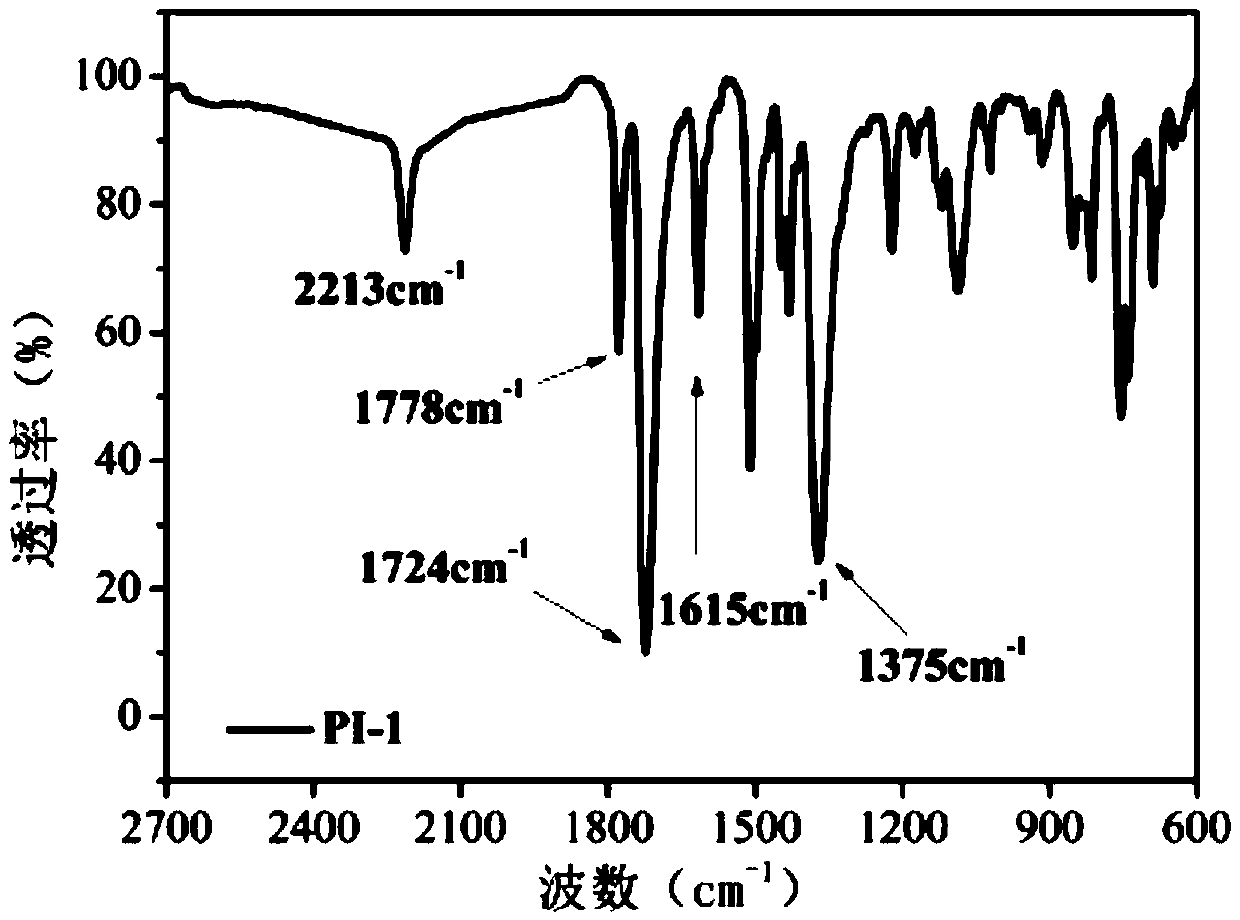

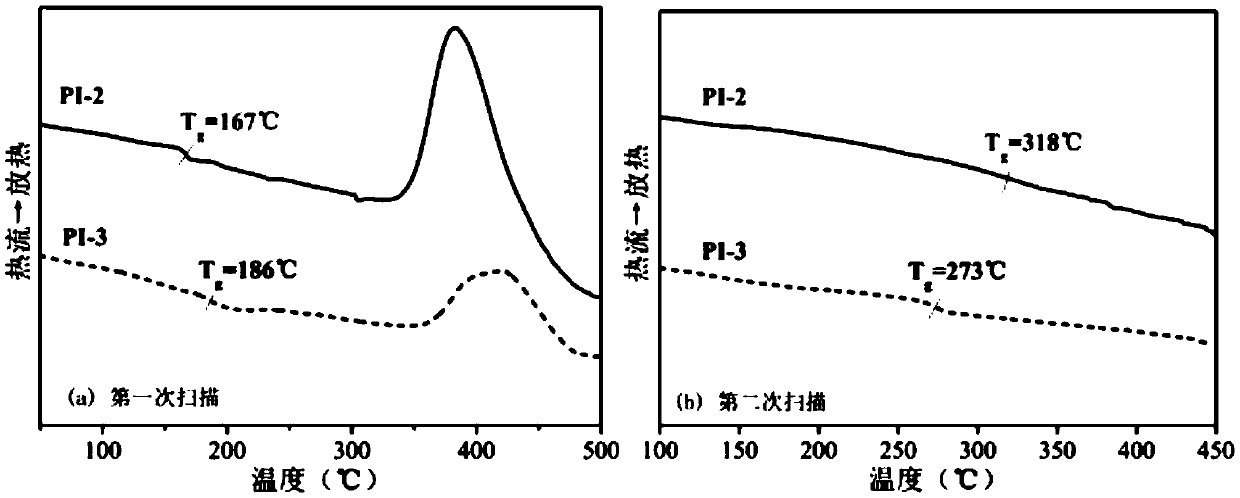

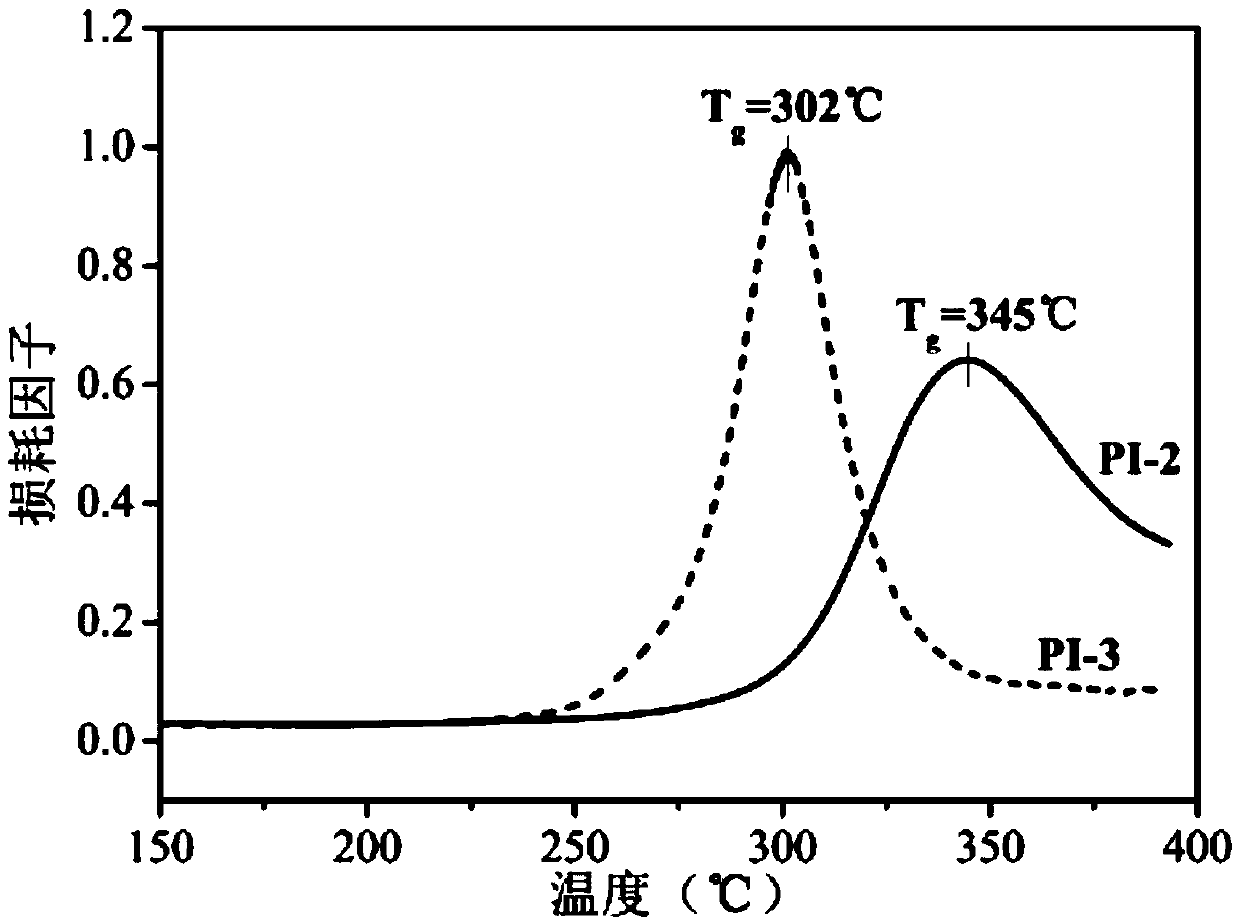

Fluorenyl Cardo type polymide diluting agent and preparing method and application thereof

InactiveCN105504282ALower glass transition temperatureWidening processing wide mouthOrganic chemistryAdhesivesPrepolymerNitrogen atmosphere

The invention relates to a fluorenyl Cardo type polymide diluting agent and a preparing method and application thereof. The structural formula of the diluting agent is shown in the specification. The preparing method comprises the steps that under mechanical stirring and inert gas shielding, BAFL and an end-capping reagent PEPA are dissolved in an organic solvent for a reaction at the room temperature for 2-16 hours, and a polymide acid solution is obtained; then, a dehydrating agent and a dehydrating catalyst are dripped for a reaction at 20-80 DEG C for 3-12 hours, cleaning, filtering, drying and grinding are carried out, and the diluting agent is obtained. The diluting agent is applied to preparation of modified phenylacetylene phthalic terminated polymide resin. By means of the blending modification of the active diluting agent, under the situation that the softening point of a prepolymer is not increased, the glass-transition temperature of the cured polymide resin is increased by 43 DEG C, and the carbon yield in the nitrogen atmosphere at 800 DEG C is increased by 5%; the diluting agent has potential application value in the fields of preparing high-performance advanced composites, high-temperature resistance adhesives and the like as an additive.

Owner:DONGHUA UNIV

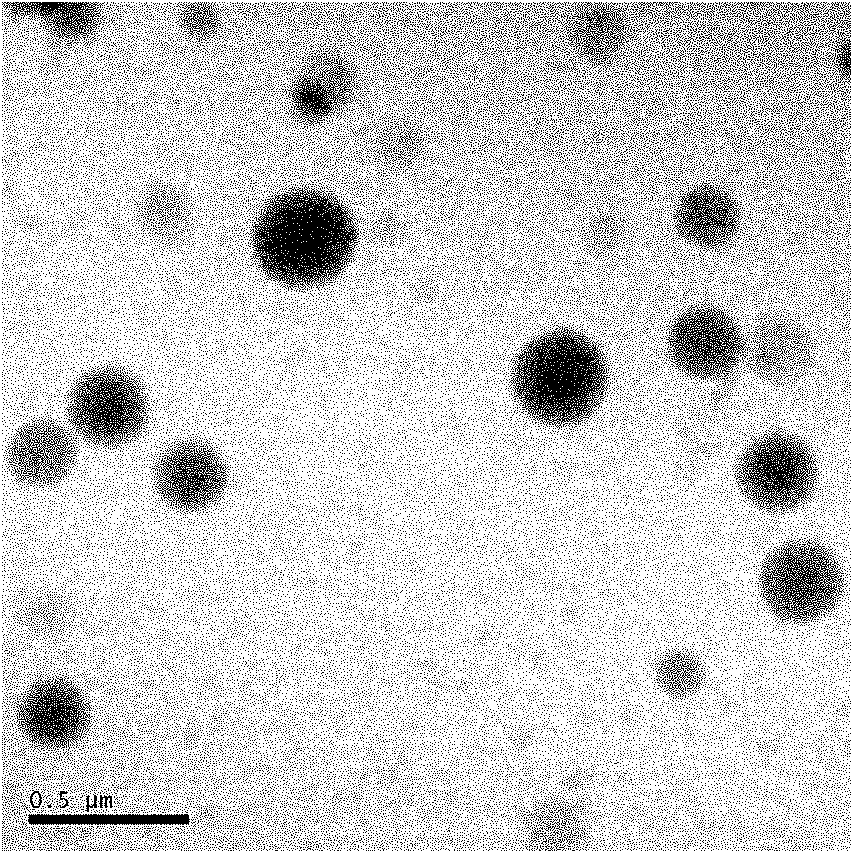

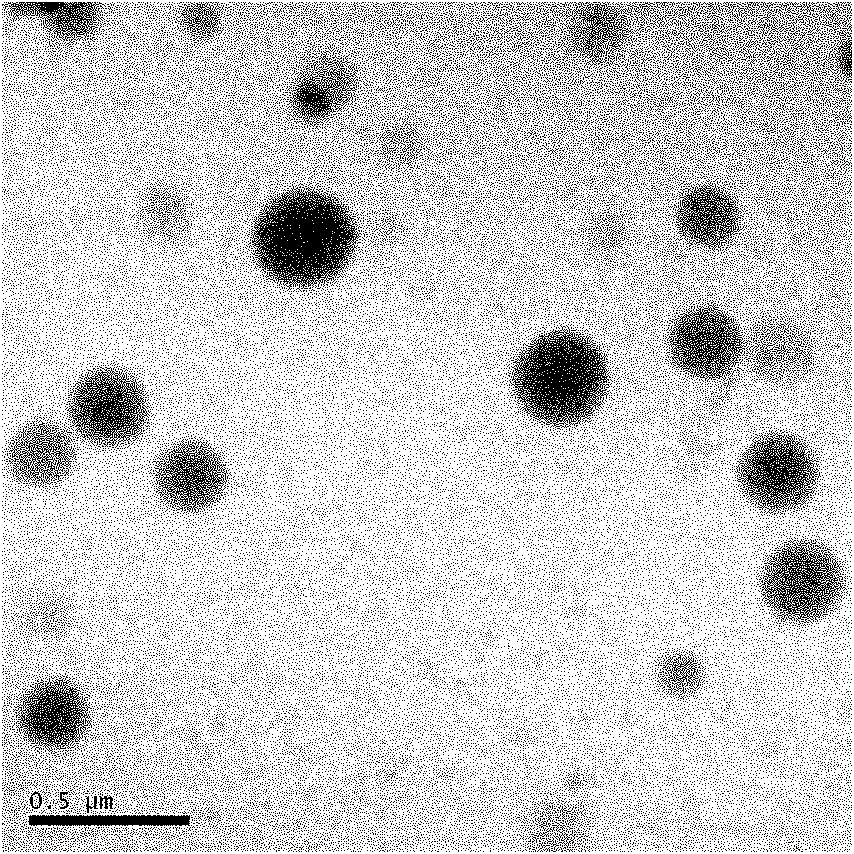

Interphase carbon microball base tube type charcoal film and its preparation method

InactiveCN101147847AWell-developed pore structureEasy to separateSemi-permeable membranesEmulsionMicrometer

The present invention belongs to the field of preparation technology of separation material, and relates to an intermediate phase carbon microsphere basal tube type carbon membrane and its preparation method. Said method includes the following steps: (1), firstly, adopting copolycondensation method, catalytic condensation method or emulsion method to prepare intermediate phase carbon micropheres whose grain size is 5-40 micrometer, then screening according to requirement of subsequent procedure so as to obtain intermediate phase carbon microspheres with different grain size distribution; (2), under the condition of normal temperature placing the intermediate phase carbon microspheres with a certain grain size distribution and binding agent into a mixing device together, and uniformly mixing them, then placing the mixed material into a continuous extrusion forming machine, regulating pressure to obtain tubular raw membrane; and (3), naturally drying said raw membrane by airing, under the condition of inert gas protection or air isolation carbonizing said raw membrane in carbonizing oven so as to obtain the invented product whose average pore size is 0.1-0.3 micrometer.

Owner:天津佰腾生产力促进中心有限公司

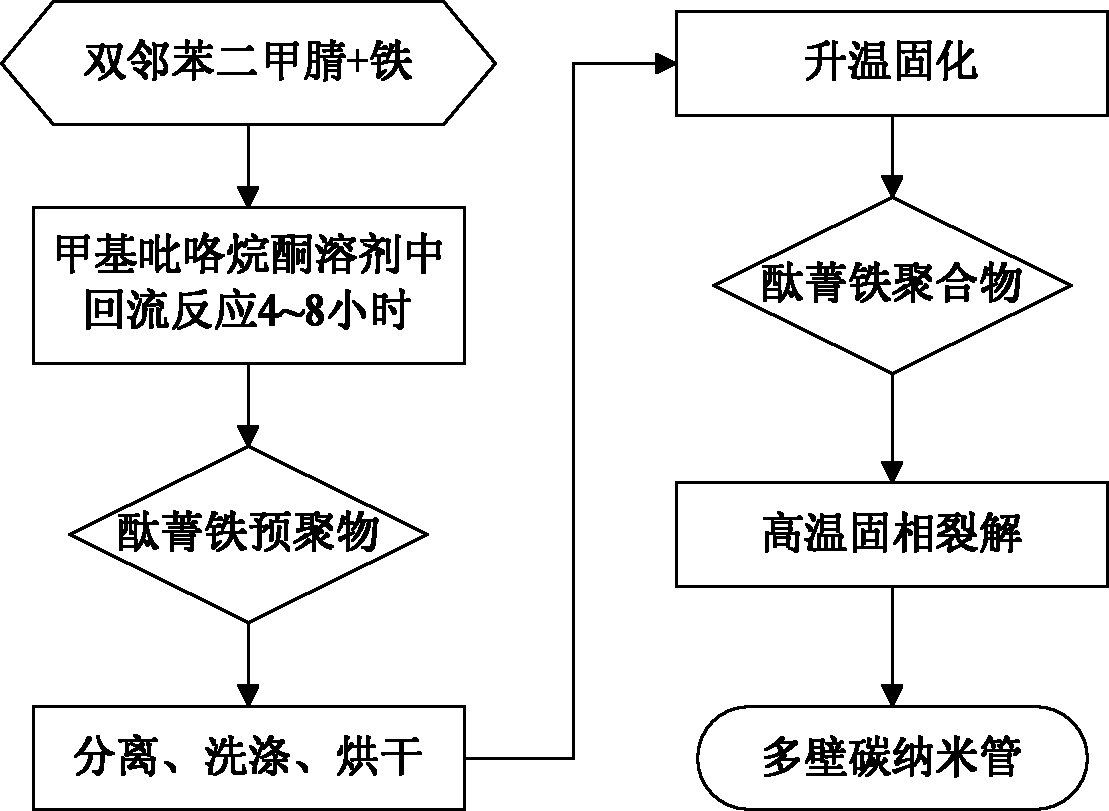

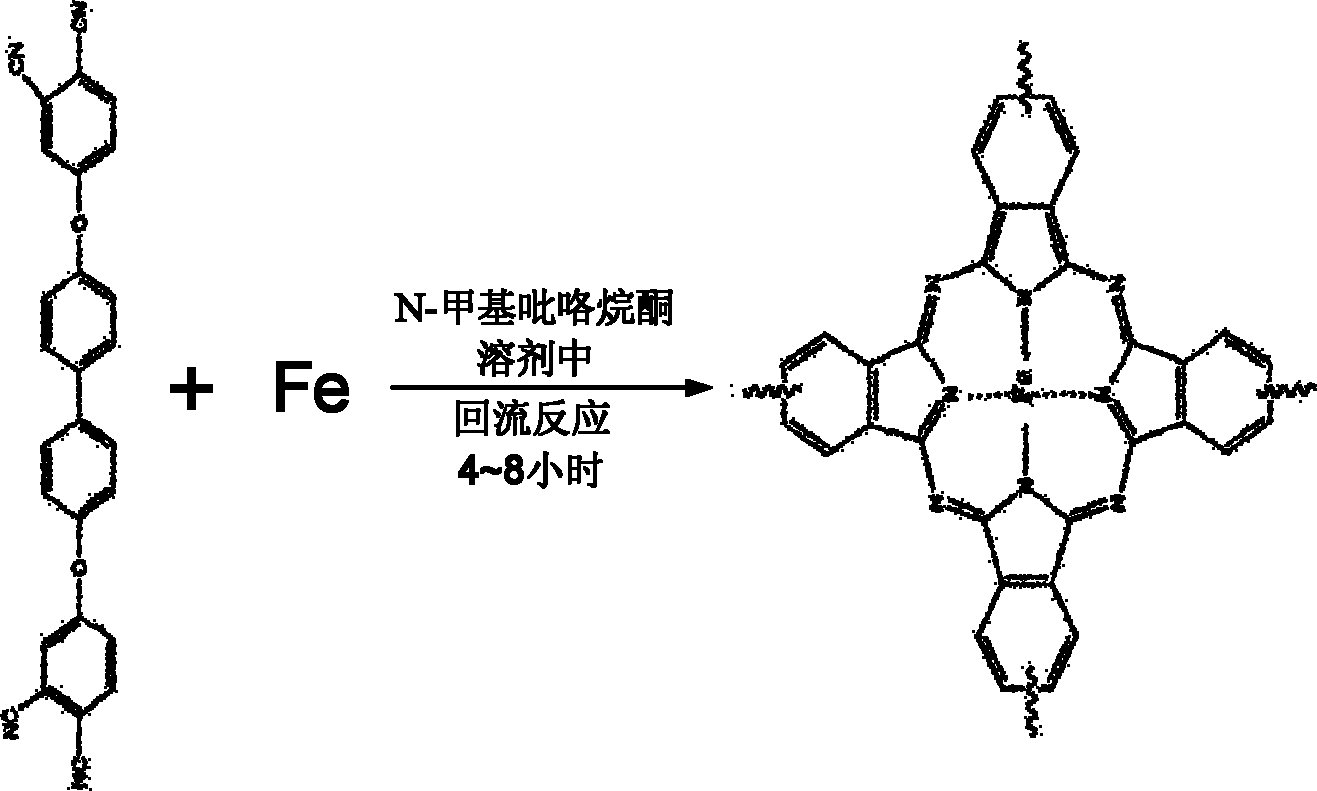

Method for preparing multi-walled carbon nanotubes from phthalocyanine iron polymer by high temperature solid-phase cracking

The invention discloses a method for preparing multi-walled carbon nanotubes from phthalocyanine iron polymer by high temperature solid-phase cracking, belongs to the technical field of nanomaterials, and provides a simple, high-efficiency and low-cost method for preparing the multi-walled carbon nanotubes. The method comprises the following steps of: performing reflux reaction on bisphthalonitrile and an iron-based catalyst in N-methylpyrrolidone solvent to generate a phthalocyanine iron oligomer; heating and curing the phthalocyanine iron oligomer to obtain the phthalocyanine iron polymer; and finally performing the high temperature solid-phase cracking on the phthalocyanine iron polymer under the protection of an inert gas to obtain the multi-walled carbon nanotubes. By using the two iron-based catalysts of carbonyl iron powder and iron nanopowder, the hollow carbon nanotubes and the carbon nanotubes of which the cores are filled with iron nanopowder can be obtained respectively. The multi-walled carbon nanotubes prepared by the method has high purity, uniform tube diameter and length and can be widely applied to the high-technology fields such as various composite materials, microelectronics and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Halogen-free flame-retardant epoxy resin composition and application thereof

The invention relates to the field of high molecular materials, in particular to a halogen-free flame-retardant epoxy resin composition and application thereof. The composition comprises 100 parts ofepoxy resin, a halogen-free composite flame retardant provided with diphenylphosphine oxide flame-retardant groups, 5-15 parts of a main flame retardant, 0-10 parts of an auxiliary flame retardant, 2-30 parts of a curing agent and 0-1 part of a curing accelerating crosslinking agent. The composition further comprises a mixture of at least two of reinforced fibers, a flexibilizer, a filler, a silane coupling agent and a solvent. The composite flame retardant containing the diphenylphosphine oxide groups is high in flame-retarding efficiency and small in adding amount and has excellent compatibility and dispersity with the epoxy resin; and in the curing process, intermolecular dispersion with the epoxy resin can be realized, and the original transparent state of the epoxy resin is maintained. The finally cured flame-retardant resin composition has the advantages of low cost, high transparency, low water absorption rate, high glass conversion temperature, high thermal stability, low dielectric constant and dielectric loss, high flame retarding and the like.

Owner:SHANDONG UNIV OF SCI & TECH

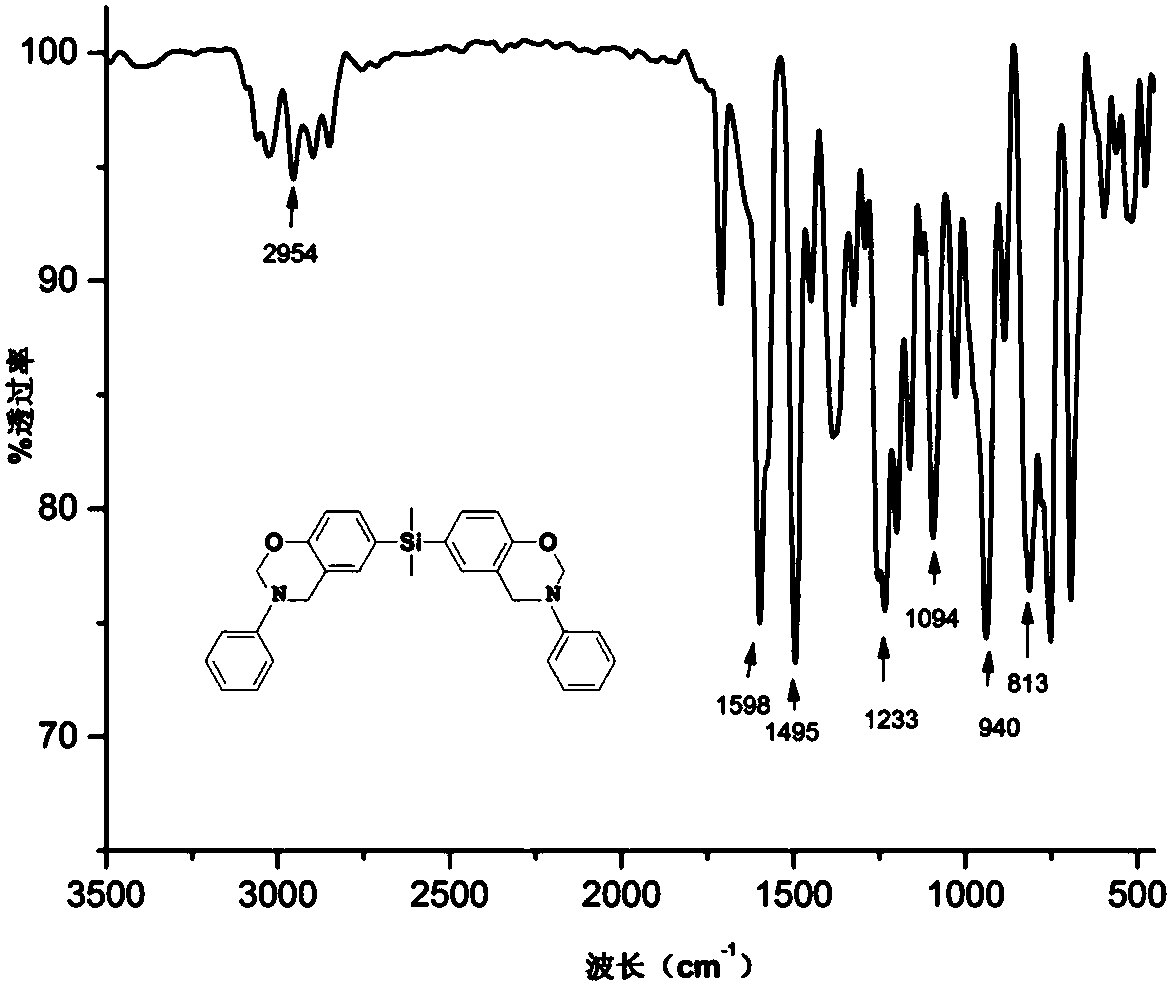

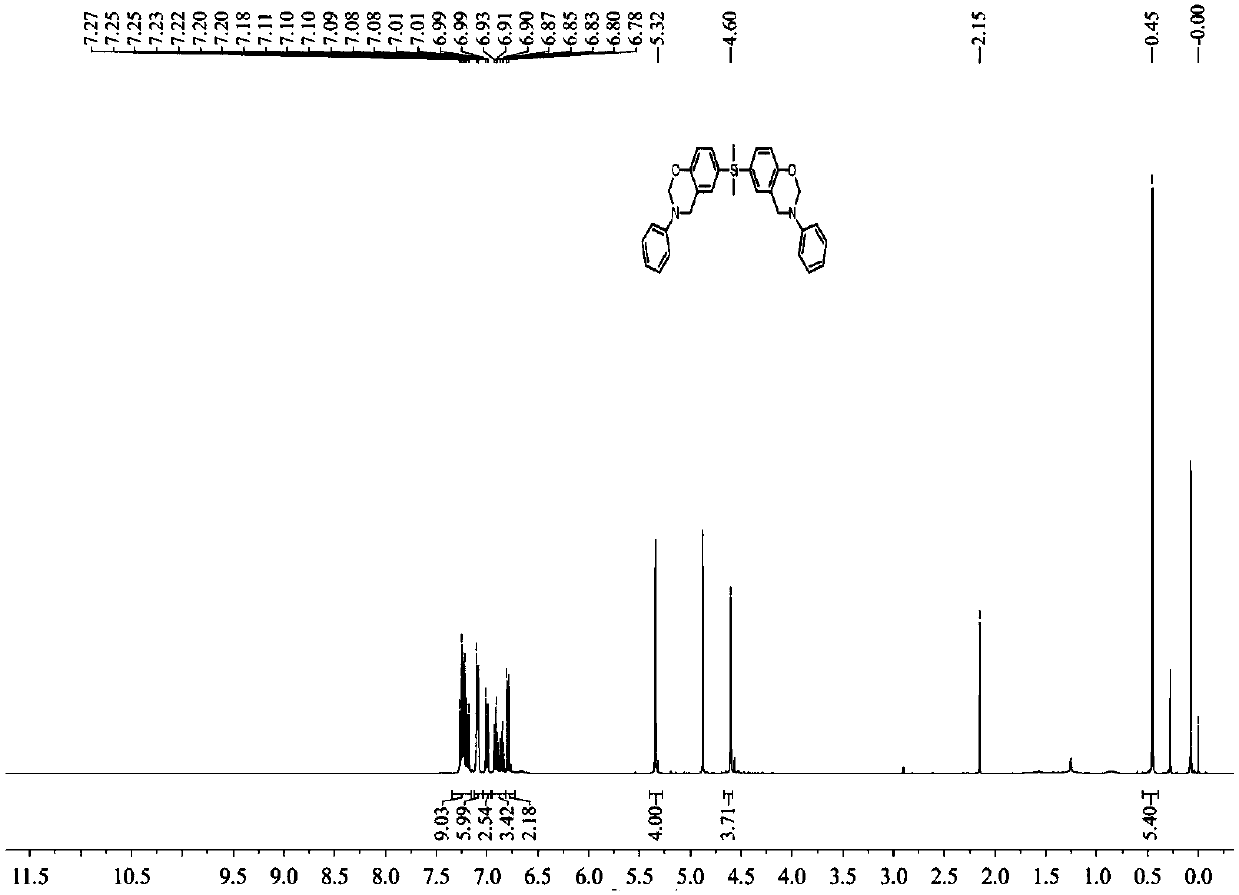

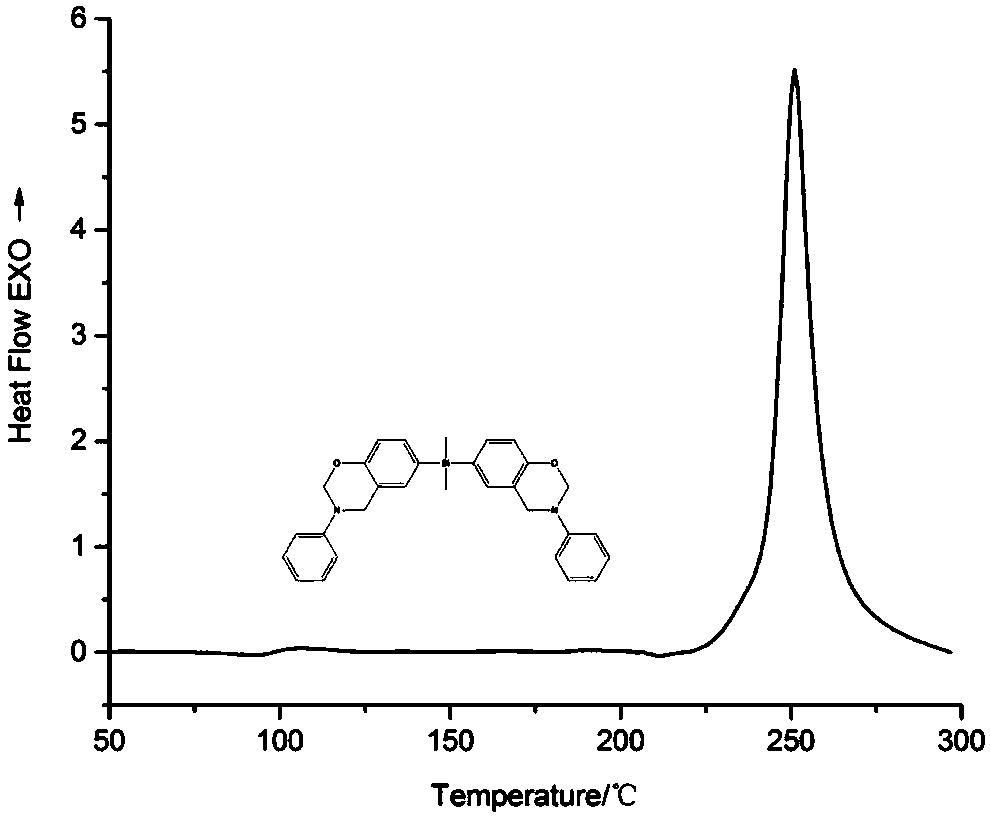

Novel silicon-containing benzoxazine and preparation method thereof

ActiveCN107629082AExcellent dielectric propertiesImprove flame retardant performanceSilicon organic compoundsSolventPhenol

The invention discloses a novel silicon-containing benzoxazine monomer and a preparation method thereof. The silicon-containing benzoxazine monomer is synthesized through reaction of silicon-containing diphenol, an amine compound and paraformaldehyde under a solvent reflux condition; and silicon-containing diphenol is prepared through reaction of phenol halide and chlorosilane. The preparation method of the silicon-containing benzoxazine monomer comprises the steps of adding silicon-containing diphenol, the amine compound and paraformaldehyde into a round-bottom flask containing benzene, methylbenzene or chloroform, carrying out heating reflux, and after the reaction is complete, separating, so as to obtain the silicon-containing benzoxazine monomer. The silicon-containing benzoxazine monomer is put into a round aluminum mold, the round aluminum mold is put into an electric-heating constant-temperature drying tank and is cured at different temperatures in different stages in the electric-heating constant-temperature drying tank, and then ring-opening polymerized polybenzoxazine is obtained. The silicon-containing benzoxazine has high heat stability and carbon residue rate, excellent flame retardance, dielectric property and corrosion resistance and can be applied to the fields of ablation-resistant materials, flame-retardant materials, anti-corrosion materials, electronic packaging and the like.

Owner:SOUTHWEST PETROLEUM UNIV

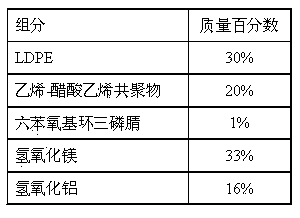

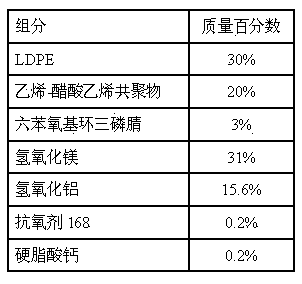

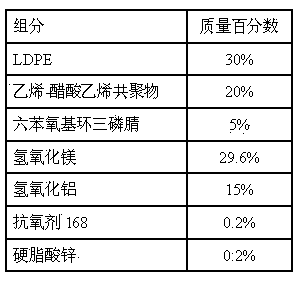

Hexaphenoxy cyclotriphosphazene-containing composite flame-retardant cable material and preparation method thereof

InactiveCN103804748AIncrease the residual rateImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesEngineeringToxic material

The invention relates to a hexaphenoxy cyclotriphosphazene-containing composite flame-retardant cable material and a preparation method thereof. The cable material adopts exaphenoxy cyclotriphosphazene, magnesium hydroxide and aluminum hydroxide as fire retardants to improve the residual rate at a high temperature and improve the thermal stability and the flame retardant property of the cable material; the cable material has the characteristic of low smoke quantity, does not contain toxic substances such as lead, antimony and the like, and is green and environment-friendly; the exaphenoxy cyclotriphosphazene can reduce the filling amount of the magnesium hydroxide and the aluminum hydroxide, improve the flame retardant property of the material and increase the mechanical property of the materials; and the lubricating agent can improve the processability of the material; and therefore, the cable material is a novel high-efficiency flame-retardant cable material.

Owner:SHANGHAI UNIV +1

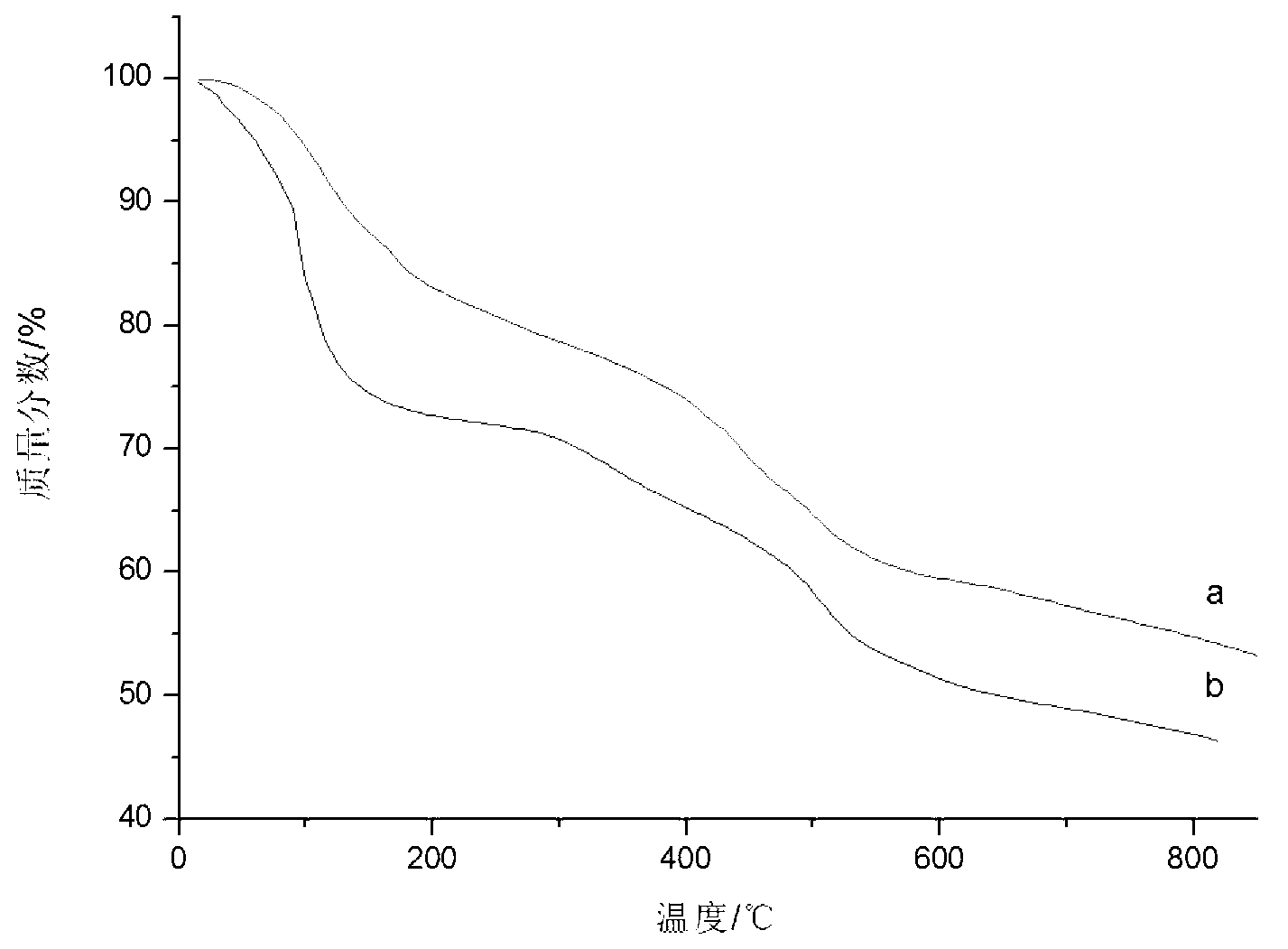

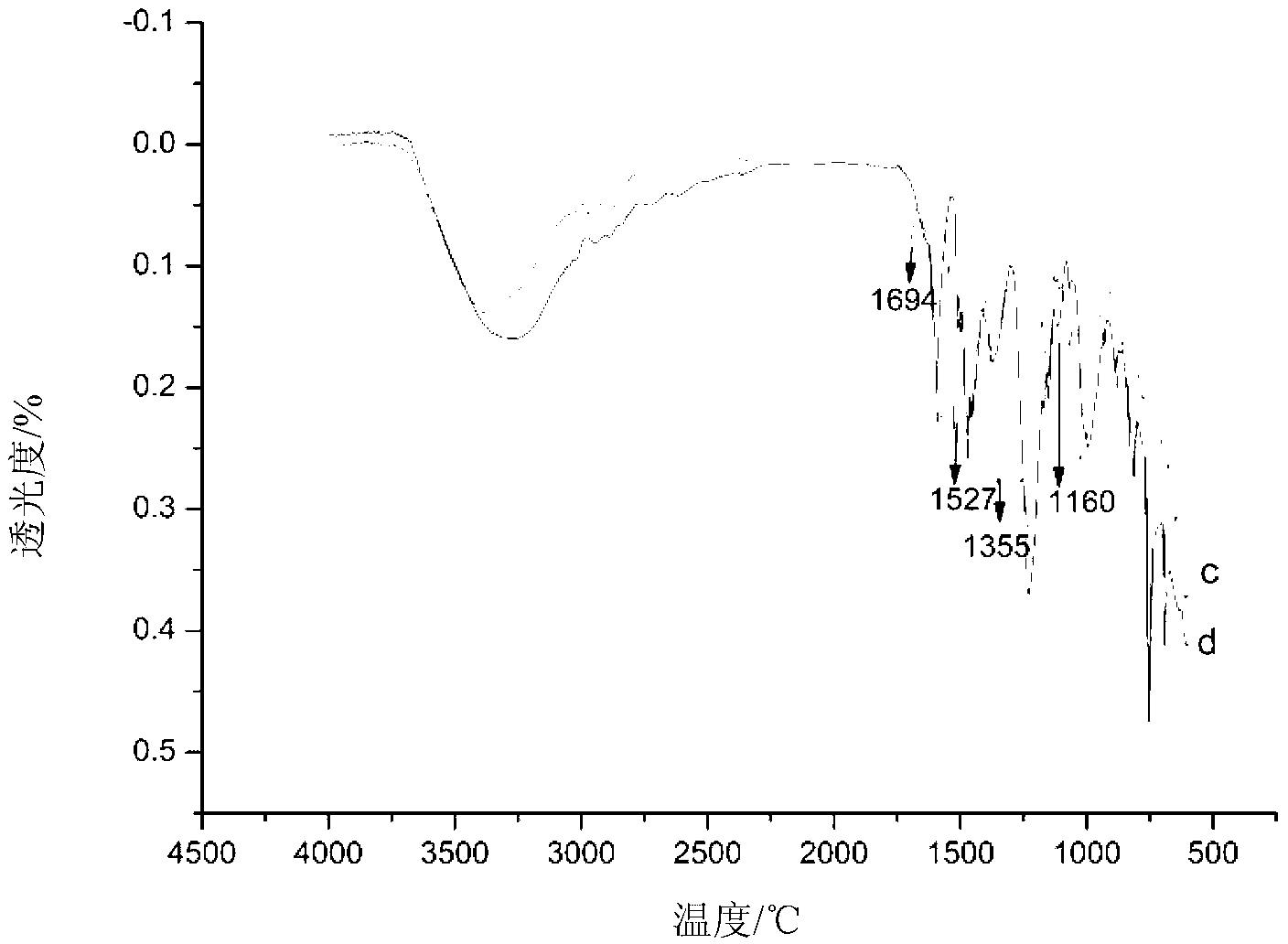

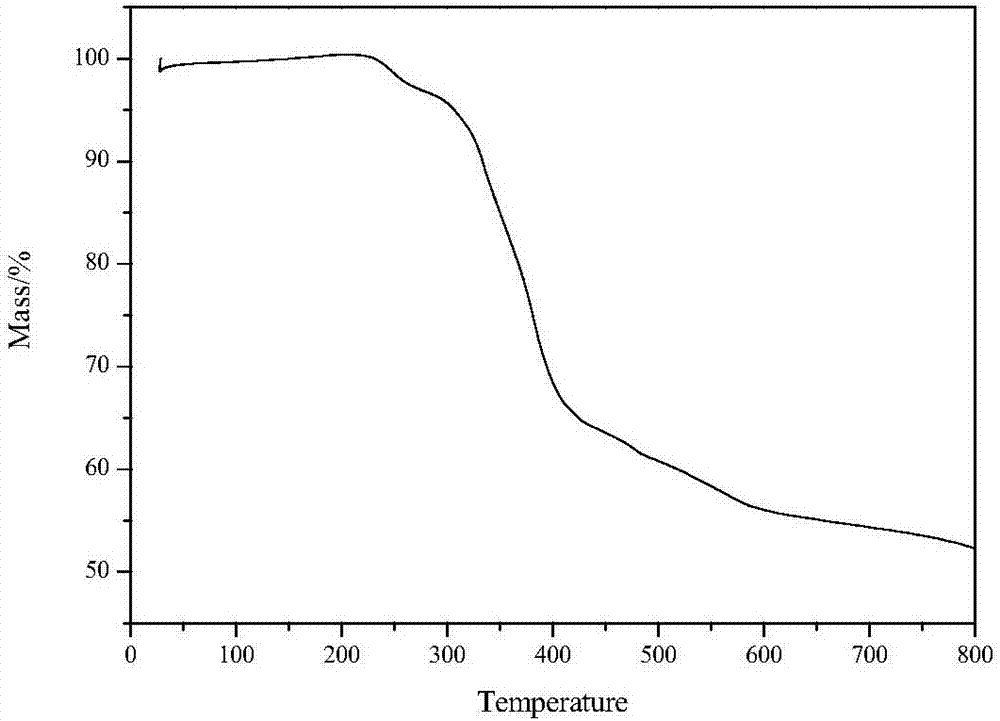

Calixarene [4] modified thermosetting phenolic resin and preparation method thereof

InactiveCN1927905AHigh synthetic preparation production efficiencyHigh carbon residue ratePolymer scienceCalixarene

The present invention discloses one kind of calicene modified thermosetting phenolic resin and its preparation process. The calicene modified thermosetting phenolic resin is prepared with phenolic resin and resorcinol base calicene, p-tert-butyl calicene or resorcinol base calicene containing oxazine cycle. Introducing calicene into thermosetting phenolic resin can raise the high temperature carbon residue greatly and result in high heat resistance. The calicene modified thermosetting phenolic resin has carbon residue at 700 deg.c over 60 wt% and is suitable for preparing ablation resisting composite material.

Owner:SICHUAN UNIV

Composite bonding agent for sliding plate refractory material and preparation method thereof

InactiveCN101942286ALow priceImprove antioxidant capacityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesBreaking strengthAlcohol

The invention relates to a composite bonding agent for a sliding plate refractory material and a preparation method thereof. The technical scheme of the preparation method comprises the following steps of: adding absolute ethyl alcohol into phenolic resin to prepare 30 to 60 weight percent of solution of phenolic resin and absolute ethyl alcohol; adding modified white carbon black into the solution of phenolic resin and absolute ethyl alcohol, wherein the adding amount of the modified white carbon black is 1 to 15 weight percent of the phenolic resin; stirring for 3 to 6 hours at the temperature of 30 to 50 DEG C to obtain mixed liquid of white carbon black and modified phenolic resin; and decompressing and distilling the mixed liquid to remove ethanol so as to obtain the composite bonding agent for the sliding plate refractory material. The preparation method has the advantages of simple process, low production cost and contribution to industrial production. The modified white carbonblack is spherical, so that the white carbon black can be uniformly and well dispersed in a phenolic resin substrate with good dispersion effect. The prepared composite bonding agent has the advantages of high residual carbon rate and high oxidization resistance in a middle temperature area. The sliding plate refractory material prepared from the composite bonding agent has the advantages of relatively high breaking strength and compression strength, relatively low volume density and relatively high hydrability resistance.

Owner:WUHAN UNIV OF SCI & TECH

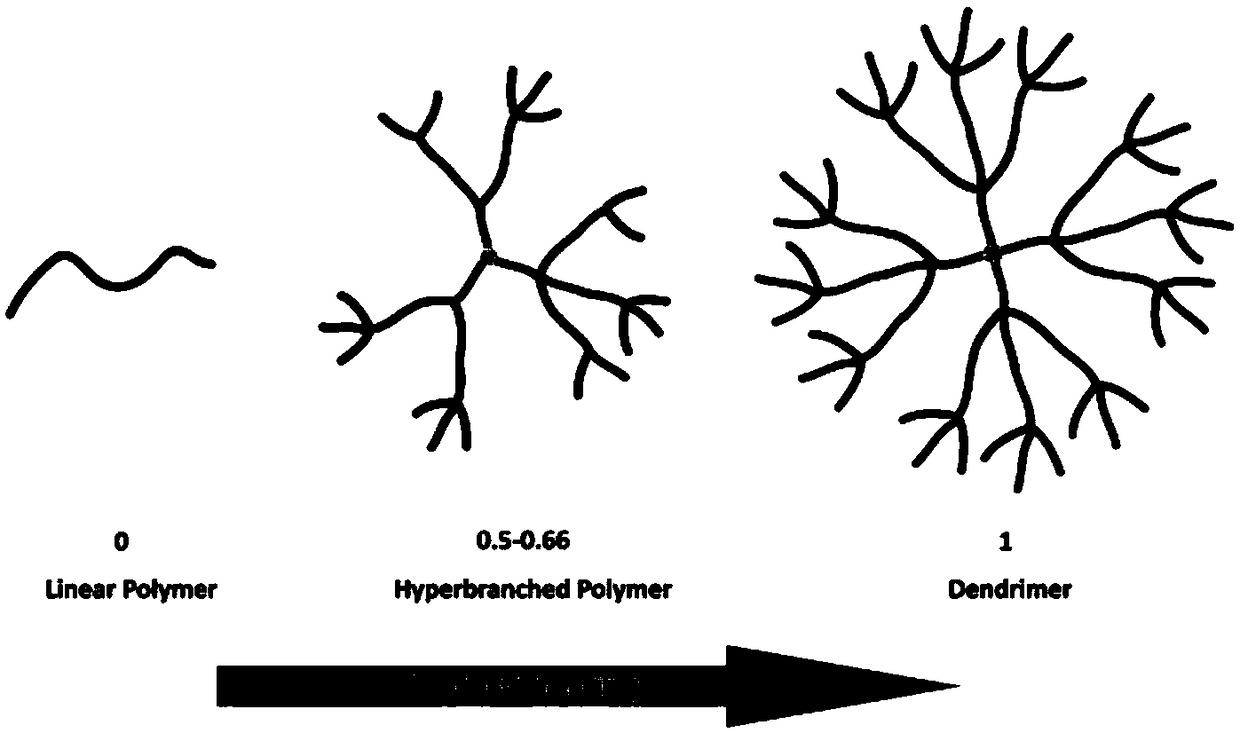

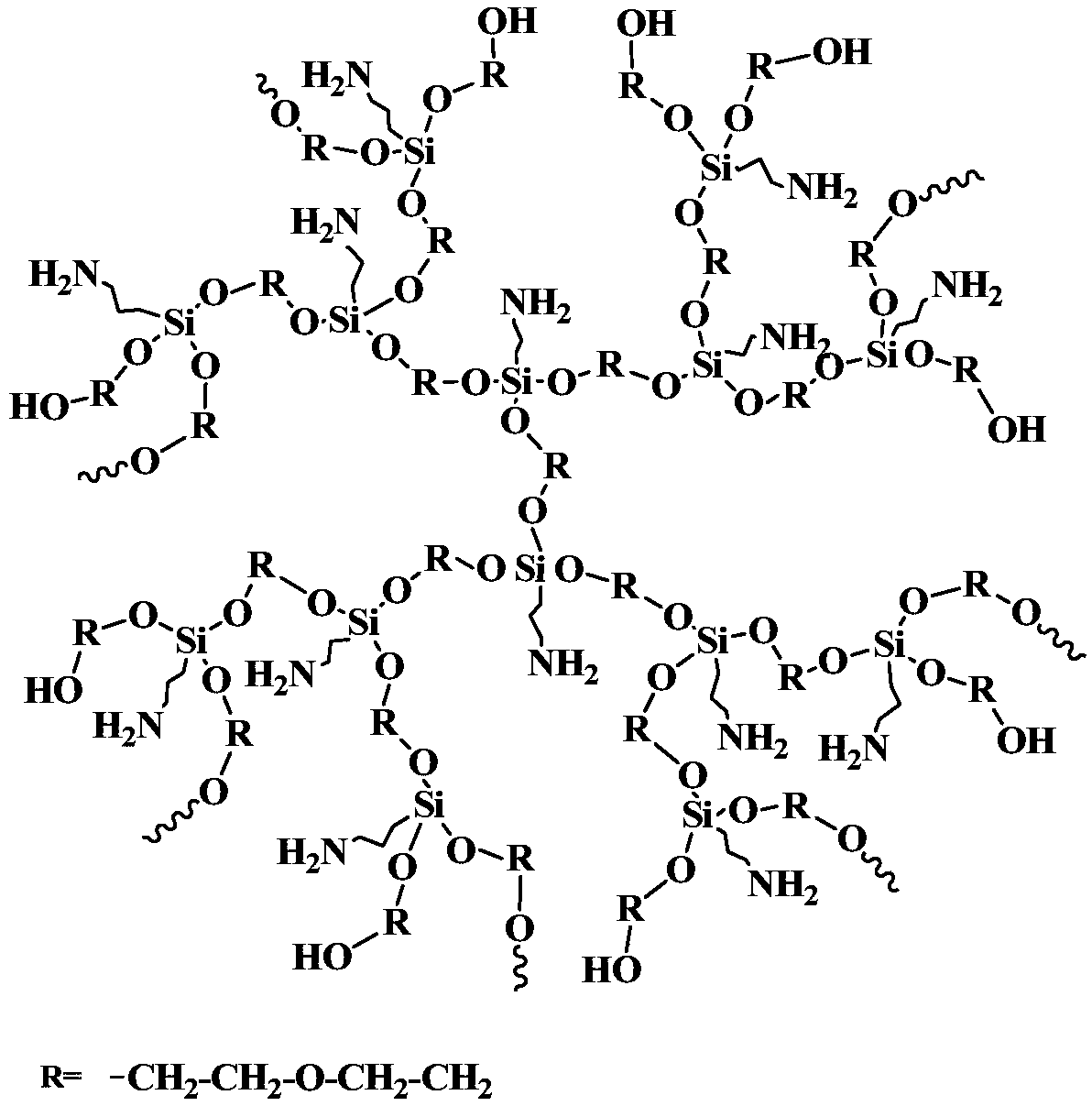

Synthetic method of hyperbranched polymer and application of hyperbranched polymer in modified thermosetting resin

InactiveCN108752592AAvoid corrosionSimple equipment installationHyperbranched polymersMacromolecule synthesis

The invention belongs to the technical field of polymer synthesis and relates to a synthetic method of a hyperbranched polymer and application of the hyperbranched polymer in modified thermosetting resin. Particularly, the hyperbranched polymer is synthesized by adopting a 'one-pot method', and the synthetic method is simple, environment-friendly and efficient. The surface of the hyperbranched polymer contains a plurality of functional groups and can be modified according to actual needs; and by using the hyperbranched polymer as a modifying agent of the thermosetting resin, obvious viscosityreducing and toughening effects can be achieved. Compared with the existing synthetic method, the synthetic method provided by the invention has the advantages of wider application prospects, higher economic benefits, more environment protection and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

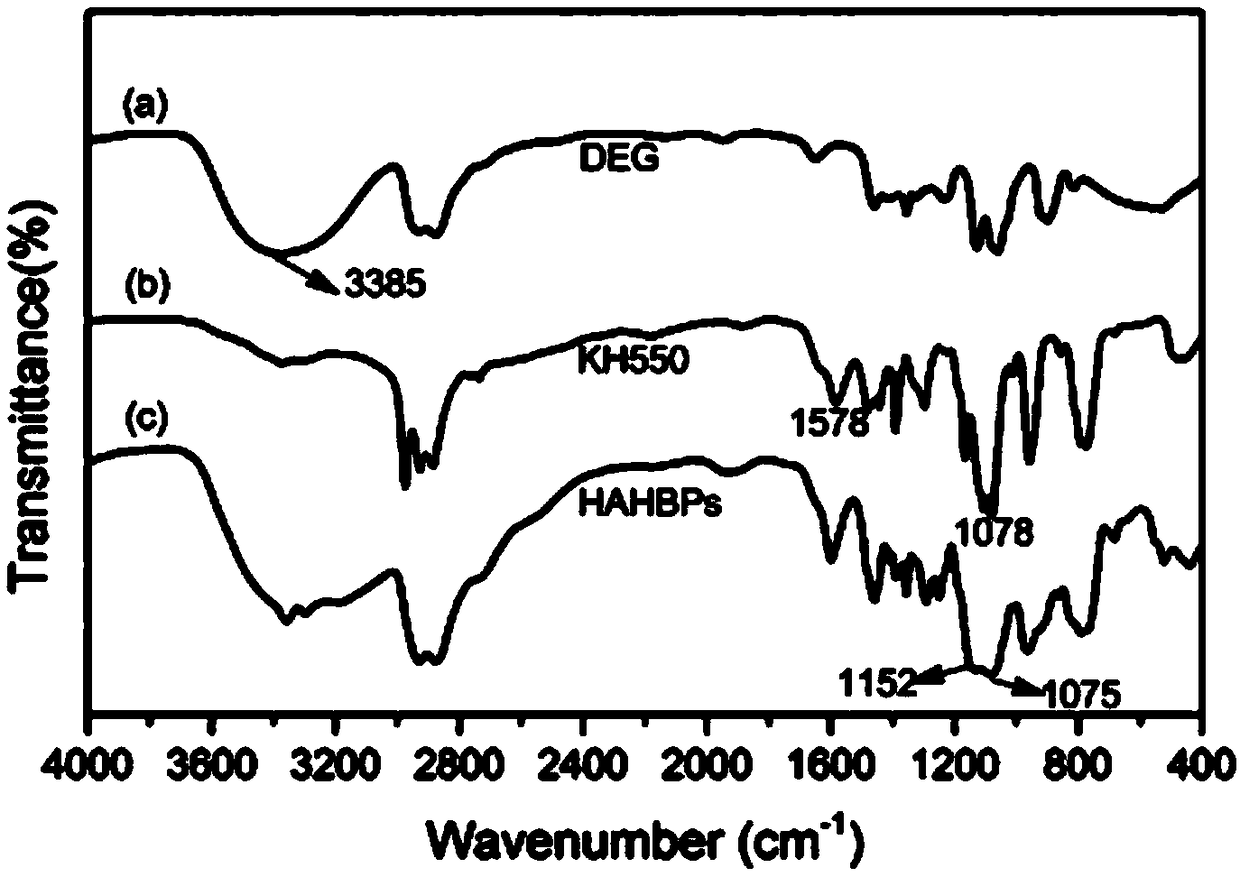

Preparation method of amino POSS graft modified ablation-resistant phenolic resin and phenolic resin thereof

The invention provides a preparation method of amino POSS (polyhedral oligomeric silsesquioxane) graft modified ablation-resistant phenolic resin, which comprises the following steps: preparing phenoland aldehyde according to the molar ratio of 1:(1.0-1.5), adding a catalyst, and carrying out a reaction to generate a hydroxymethyl-containing phenolic resin polymer; preparing amino POSS, wherein the mass ratio of the amino POSS to the phenol in the step (1) is (1-10):100, and dissolving the amino POSS and the phenol in the step (1) in a solvent to form an amino POSS solution; and adding the amino POSS solution into the polymer containing hydroxymethyl phenolic resin, and carrying out a reaction until the amino POSS graft modified ablation-resistant phenolic resin is generated. The invention also provides the phenolic resin prepared by the preparation method of the amino POSS graft modified ablation-resistant phenolic resin. The preparation method is high in modification efficiency, andthe obtained modified phenolic resin is excellent in ablation resistance.

Owner:北京玻钢院复合材料有限公司

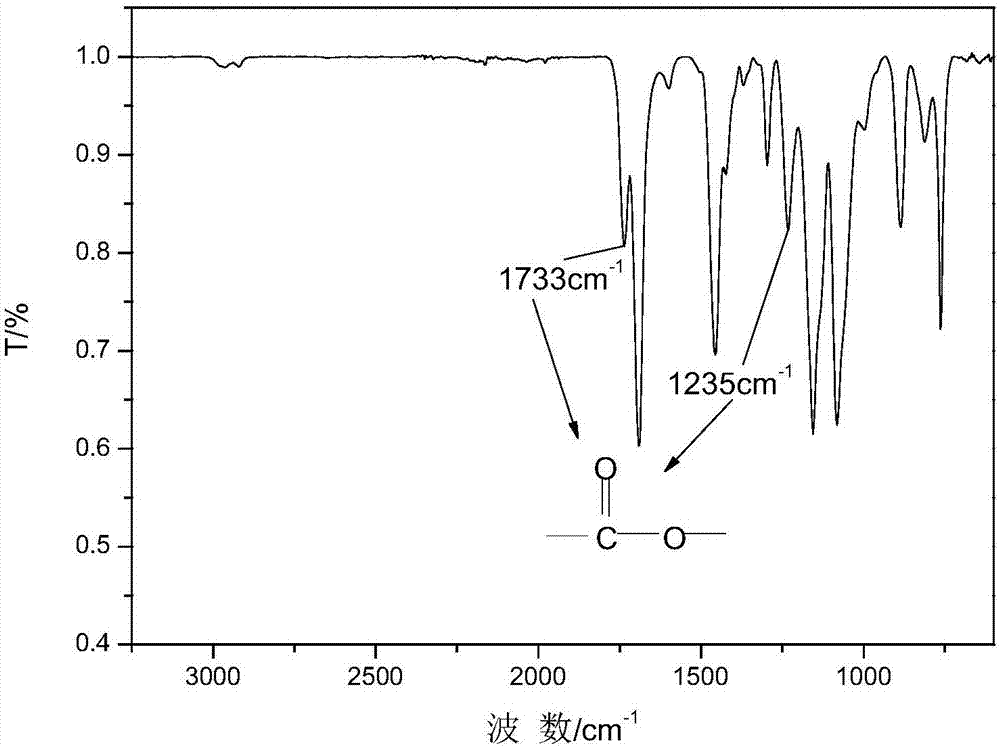

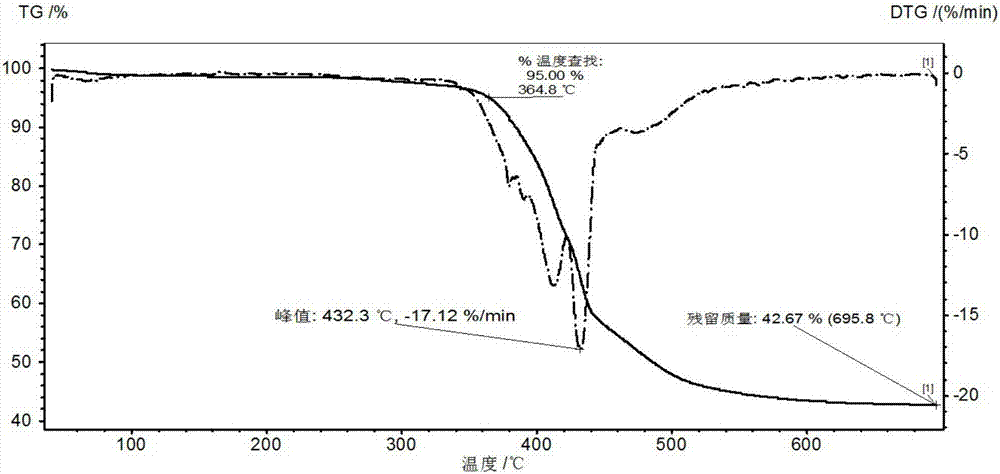

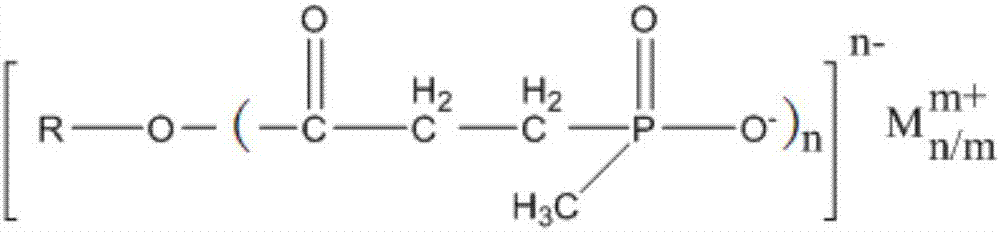

Single molecular expansion type alkyl phosphinate flame retardant and preparation method thereof

ActiveCN106967116AImprove flame retardant performanceHigh carbon residue rateGroup 5/15 element organic compoundsAmidogenMechanical property

The invention discloses a single molecular expansion type alkyl phosphinate flame retardant. A structural general formula is shown in the description, a molecular structure is starlike, R-O- is a hydroxyl dehydrogenized structure after a nitrogen-containing polyhydroxy compound is subjected to esterification reaction, the formula (shown in the description) is a hydroxyl removed structure provided with molecular hydroxyl and obtained after organic phosphonic acid esterification reaction, n corresponds to the number of hydroxy and amidogen of the nitrogen-containing polyhydroxy compound, and M is a metal or semi-metal having the valence m. The invention further discloses a preparation method the flame retardant. The three-source proportion of the flame retardant can be regulated and controlled by selecting different nitrogen-containing polyhydroxy compounds. The molecular structure contains P-C keys and has excellent heat stability and good chemical properties. A specific carboxylic ester structure has good mixing compatibility with a polymer, and the original mechanical properties of the polymer can be retained to the greater degree. Metal ions in molecules can prevent the flame retardant from migrating from the polymer and meanwhile have a catalytic charing effect.

Owner:HONGHU YITAI TECH CO LTD

Zirconium-modified phenolic resin and preparation method thereof

ActiveCN103172811AThe content is easy to controlHigh carbon residue rateHigh carbonZirconium oxychloride

The invention relates to a zirconium-modified phenolic resin and a preparation method thereof. The zirconium-modified phenolic resin is technically characterized by being prepared from the following raw materials in parts by weight: 20-50 parts of phenol, 9-20 parts of formaldehyde, 2-10 parts of sodium hydroxide, 20-40 parts of ethanol, 10-20 parts of acetylacetone, 5-20 parts of zirconium oxychloride, and 0.5-2 parts of hydrogen peroxide. The preparation method comprises the following steps of: charging raw materials, refluxing, stirring, dropwise adding zirconium oxychloride ethanol solution, adjusting the pH value, discharging, and removing the solvent to obtain the zirconium-modified phenolic resin. The preparation method is simple, the cost is low, the content of zirconium is controllable, the prepared zirconium-modified phenolic resin has higher carbon yield, as well as good heat resistance, ablation resistance and mechanical property, is wide in application range, and has obvious economic and social benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

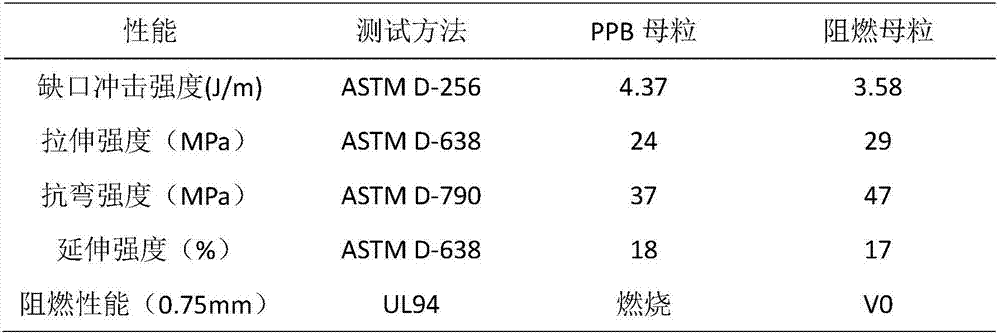

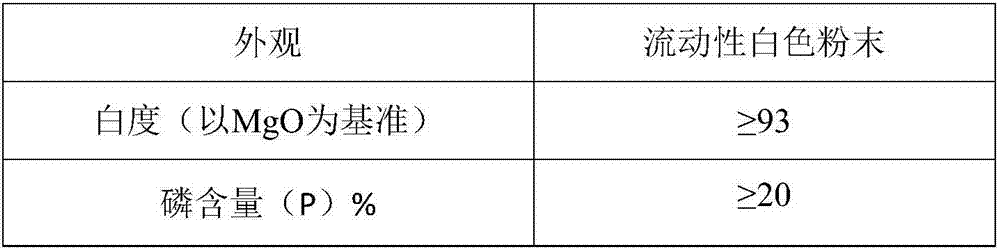

Halogen-free nitrogen-phosphorus complex intumescent flame retardant and preparation method thereof

InactiveCN106939088AImprove flame retardant performanceGood flame retardantDecompositionResidual carbon

The invention discloses a halogen-free nitrogen-phosphorus complex intumescent flame retardant and a preparation method thereof. The complex flame retardant contains nitrogen and phosphorus as main components. Through the specific formula and production processes, the flame retardant has outstanding flame retardant effects, is white (crystalline or amorphous) powder, is a mixture, produces good flame retardant effects on PP through P-N synergistic effects, has good fire resistance, high thermal stability, a decomposition temperature greater than 280 DEG C, high residual carbon content, small hygroscopicity, excellent dispersibility and good chemical stability, can be mixed with other substances and does not easily a chemical change.

Owner:HEFEI UNIV OF TECH

Nanometer silicon dioxide modified epoxy resin coating

InactiveCN109705696AImprove surface propertiesImprove high temperature resistanceRubber derivative coatingsAnti-corrosive paintsFiberEpoxy

The invention discloses a nanometer silicon dioxide modified epoxy resin coating. The nanometer silicon dioxide modified epoxy resin coating comprises the following raw materials by weight: 55 to 70 parts of epoxy resin, 8 to 15 parts of chlorinated rubber, 5 to 18 parts of silicone resin, 9 to 15 parts of alkyd resin, 1 to 3 parts of graphene oxide, 3 to 8 parts of nanometer silicon dioxide, 2 to8 parts of charcoal powder, 1 to 3 parts of silicon carbide, 0.3 to 1.8 parts of nanometer titanium black, 2 to 6 parts of precipitated barium sulfate, 0.7 to 3 parts of bamboo fiber, 3 to 9 parts ofbasalt flakes, 2 to 8 parts of nanometer aluminium oxide, 9 to 25 parts of a curing agent, 0.1 to 1 part of 1-pyrenebutyric acid, 20 to 30 parts of a solvent and 0.2 to 1.5 parts of an auxiliary agent, wherein the curing agent is a mixture of n-butyl trimellitate anhydride, 2-ethyl-4-methyl imidazole, zinc acrylate and a boron-amine curing agent 594. The nanometer silicon dioxide modified epoxy resin coating provided by the invention has high strength, good heat resistance and wear resistance and excellent corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

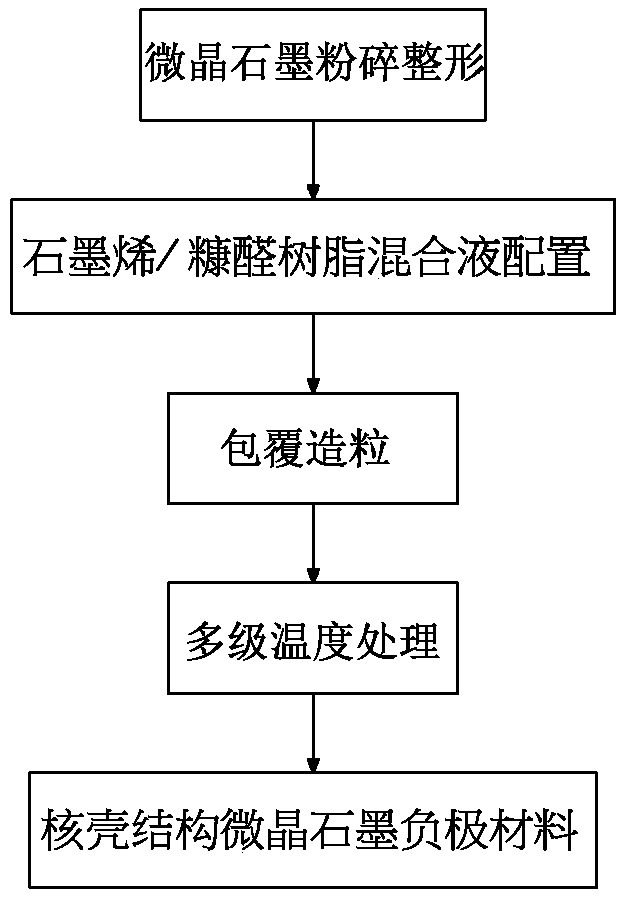

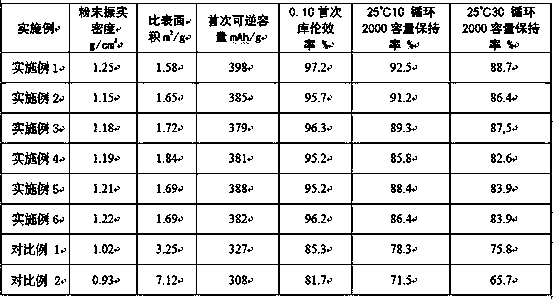

High-performance amorphous graphite negative electrode material and low-cost preparation method thereof

ActiveCN109824047AHigh carbon residue rateHigh densityCarbon compoundsCell electrodesHigh carbonPliability

The invention discloses a high-performance amorphous graphite negative electrode material and a low-cost preparation method thereof. The method includes the steps: (1) crushing and shaping; (2) graphene / furfural resin mixed liquid preparation; (3) coating and granulating; (4) treatment at multistage temperatures. An asphalt / furfural resin composite coating material has high carbon yield, densityand graphitization degree, graphene is doped into the material, and the material is used for enhancing high conductivity and toughness of electrons / ions and improving structure stability. By the aid of a multistage temperature treatment mode, carbonization, graphitization and amorphous graphite purification are combined and implemented, complicated purification of high-purity amorphous graphite isavoided, the method is green and environmentally friendly, processes are simplified, and cost is reduced.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

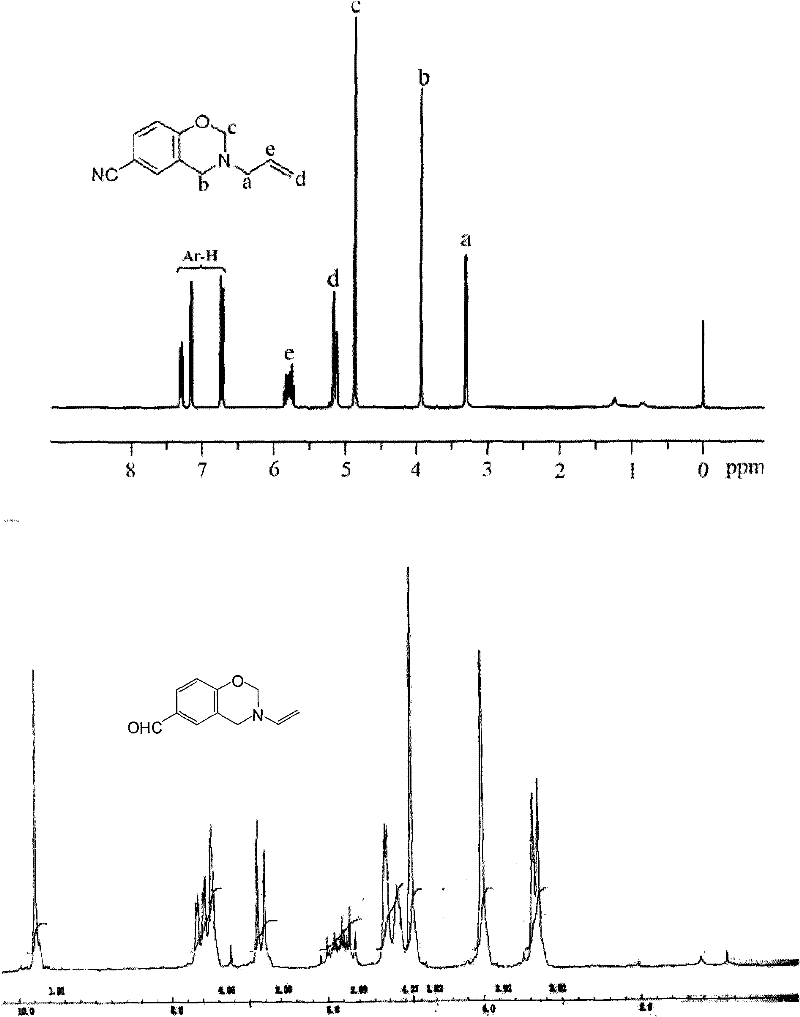

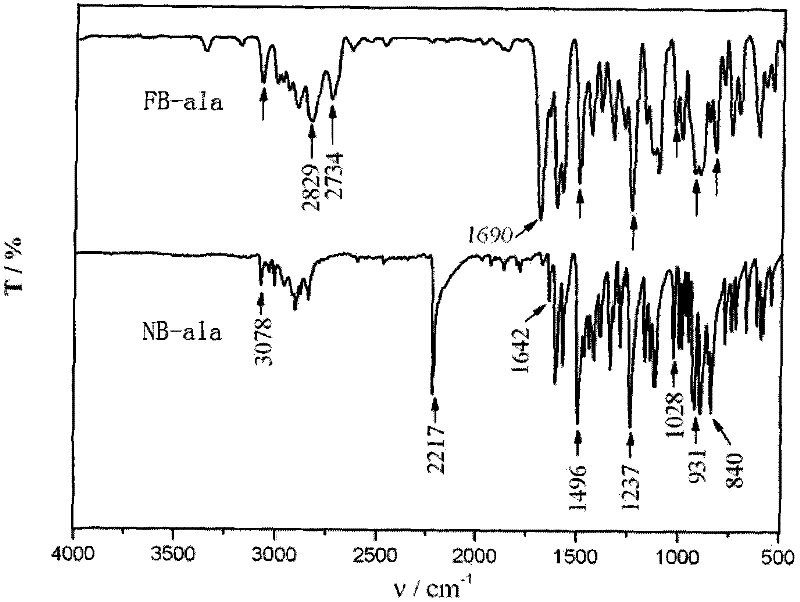

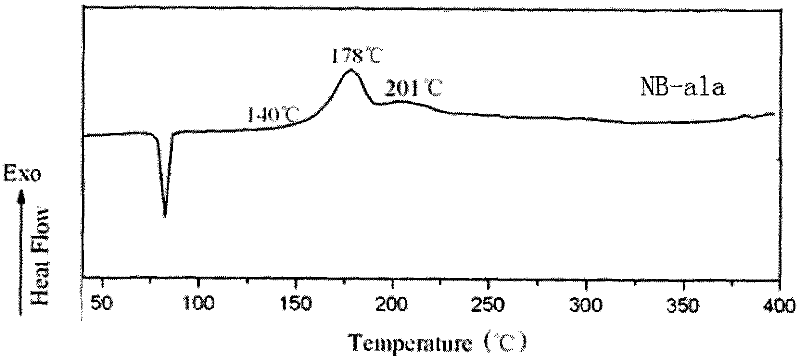

Monocyclic benzoxazine intermediate with low viscosity and a plurality of functional groups and synthesis method thereof

InactiveCN101747288ALow viscosityThe temperature of the ring-opening polymerization is loweredOrganic chemistryVitrificationCross-link

The invention discloses a monocyclic benzoxazine intermediate with low viscosity and a plurality of functional groups, a preparation method thereof and application thereof in the preparation of high-temperature resistant resin. The process method is simple, practicable, and suitable for industrial production in most of factories; a cross-linked polymer prepared by the benzoxazine intermediate has very high vitrification conversion temperature (Tg is larger than 250 DEG C), is available to high-temperature resistant materials used in the temperature more than 250 DEG C, and has higher carbon residue rate (800 DEG C, N2, PNB-ala: 57%; 800 DEG C, N2, FB-ala: 61%) and a certain application prospect in terms of the preparation of carbon materials and ablation resistant materials.

Owner:SHANDONG UNIV

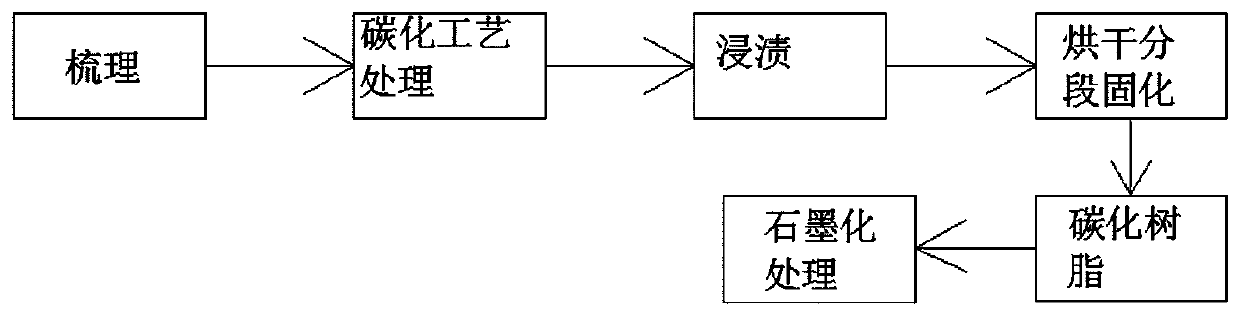

Method of preparing hard carbon felt

InactiveCN110565266AHigh carbon residue rateCarbon fibresHeating/cooling textile fabricsFiberHigh carbon

The invention discloses a method of preparing hard carbon felt. The method includes the following steps that S1, a mesh blank prepared from short-cut pre-oxidized fiber by carding and air-laying is adopted; S2, phenolic resin with a high carbon residue rate is adopted as a precursor; S3, anhydrous ethanol is adopted as a solvent; S4, a PAN pre-oxidized fiber mesh blank is subjected to lamination and relay needle punching on a needle punching machine to the required thickness according to the process design. According to the method of preparing the hard carbon felt, the pre-oxidized fiber is adopted as a raw material, overall pre-oxidized fiber felt is obtained after relay needle punching and severs as a preform, and overall hard thermal-insulating carbon fiber felt is prepared through carbonization, impregnation, curing, graphitization and other processes; because the density of a material has large impact on the mechanical and thermal properties of the material, the density of the overall hard carbon fiber felt prepared by the method is only 0.16 g / cm<3>, the thermal conductivity of the overall hard carbon fiber felt at 1500 DEG C is 0.25 w / (m.k.), and both of the density and thethermal conductivity of the overall hard carbon fiber felt are lower than that of traditional solidified felt formed by bonding soft carbon felt and an interlayer, it is indicated that the main properties of the overall hard carbon fiber felt are better than those of the traditional carbon felt.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

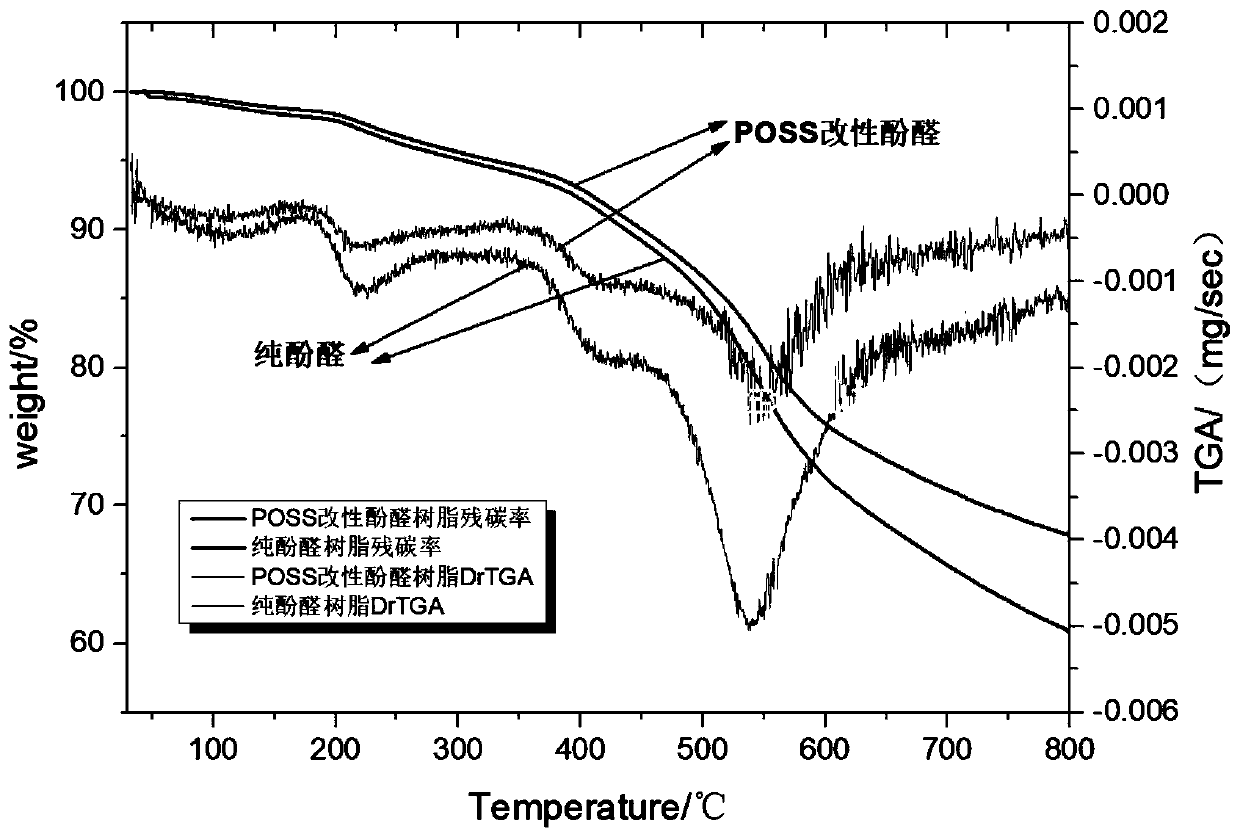

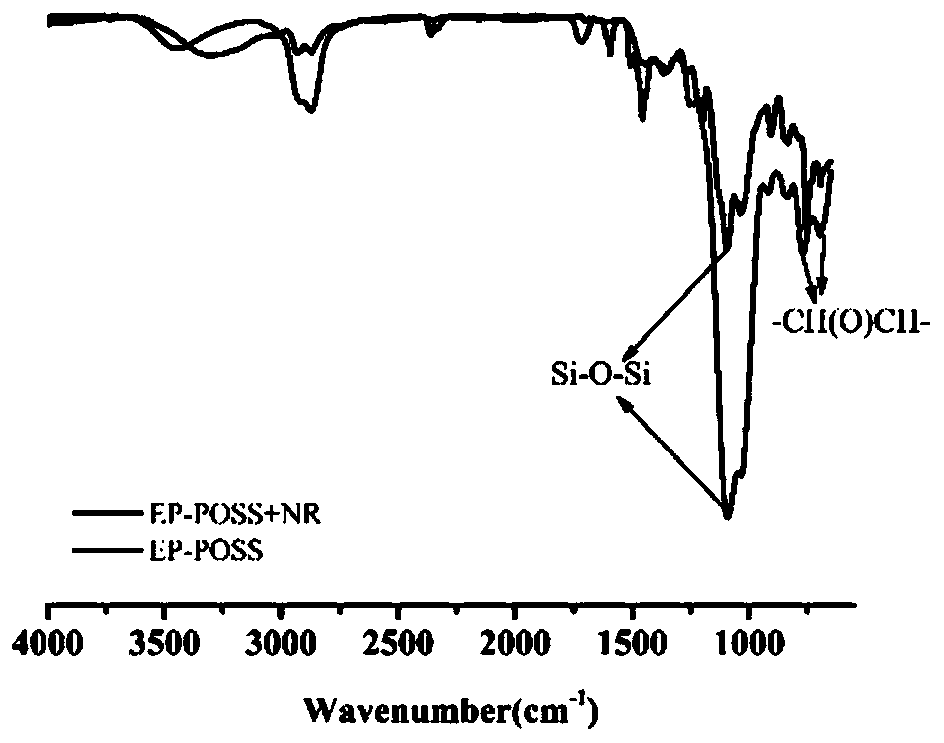

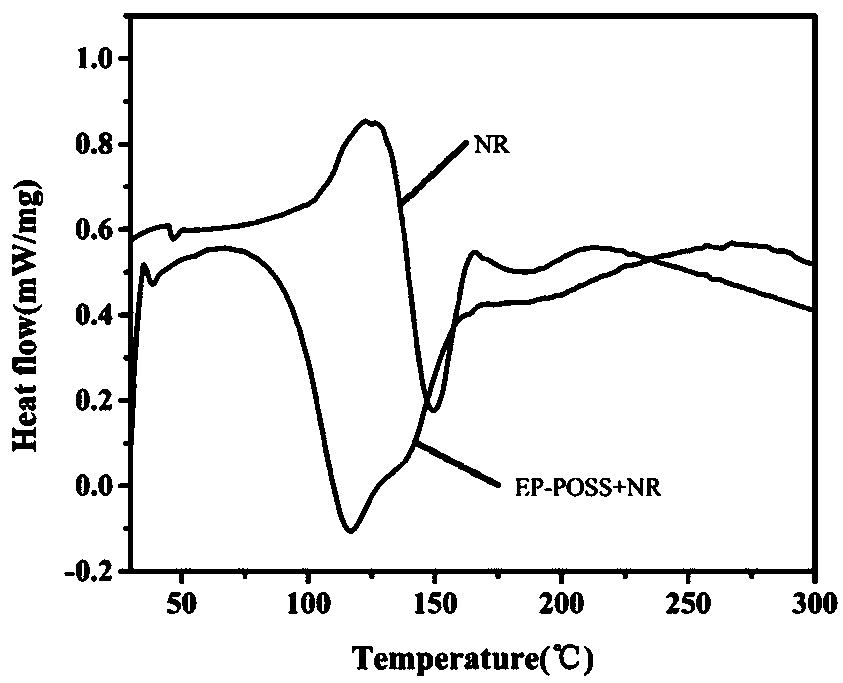

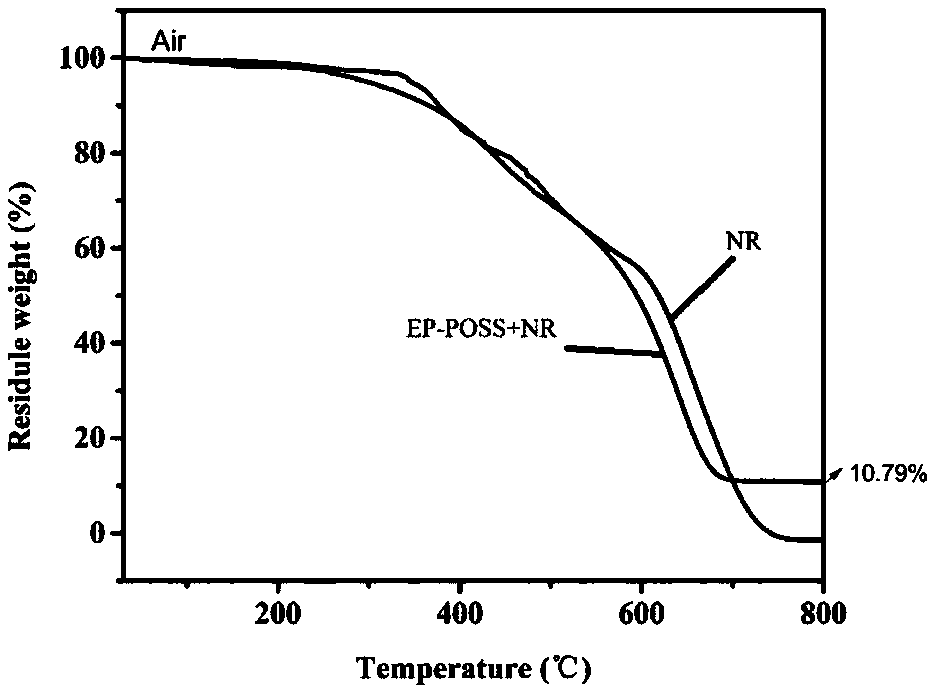

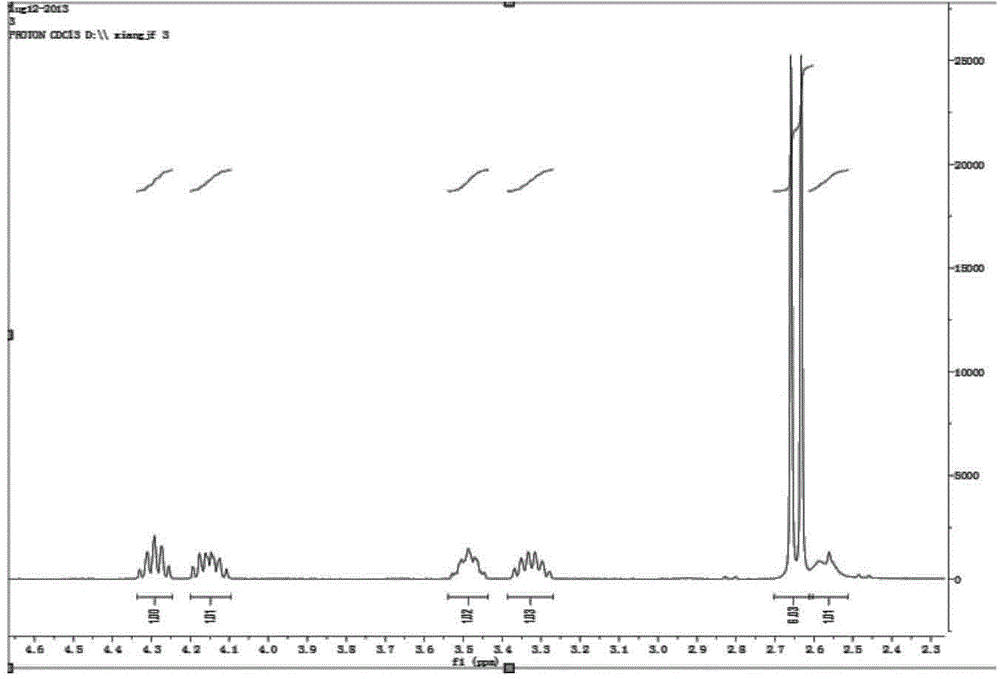

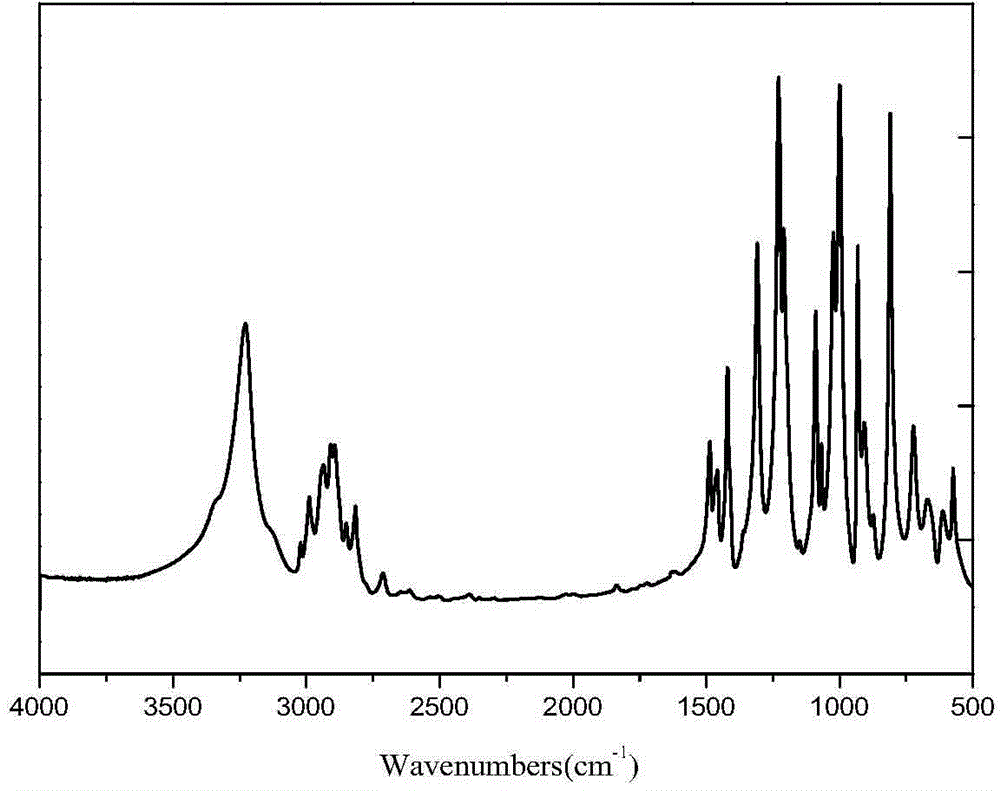

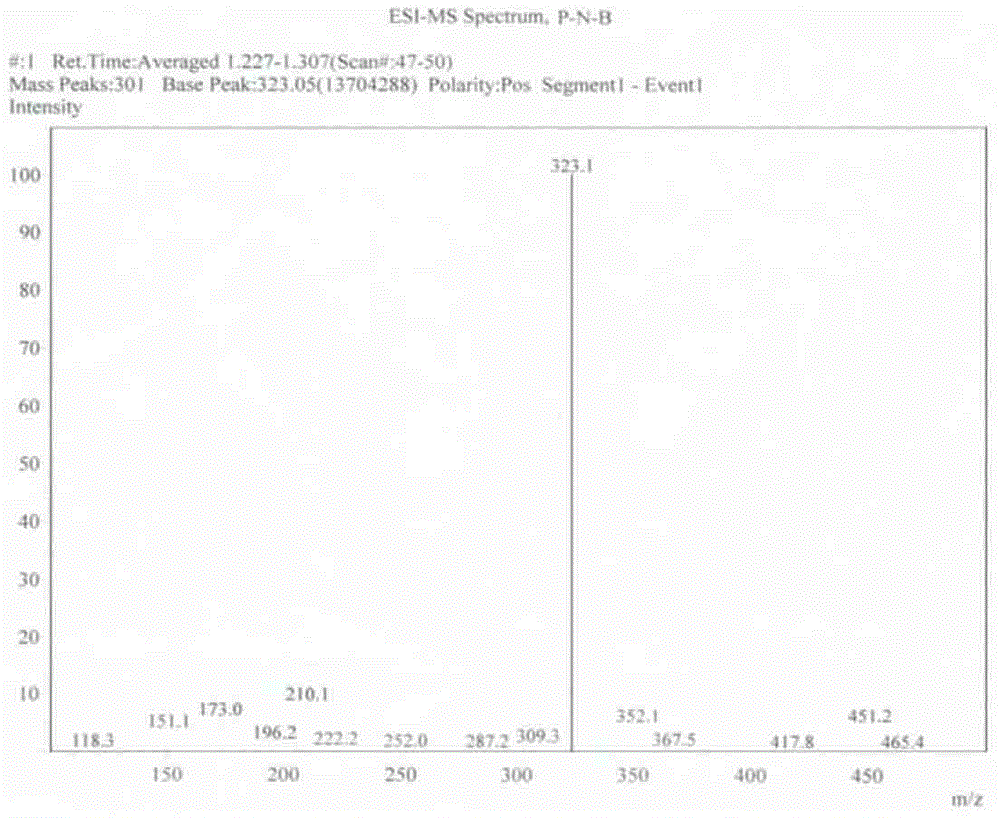

Epoxy polyhedral oligomeric silsesquioxane modified phenolic resin and preparation method thereof

InactiveCN108892760AImprove thermal performanceImprove mechanical propertiesEpoxyNitrogen atmosphere

The invention discloses an epoxy polyhedral oligomeric silsesquioxane modified phenolic resin and a preparation method thereof. The preparation method comprises the following steps: 1) weighing a thermoplastic phenolic resin, epoxy polyhedral oligomeric silsesquioxane and a catalyst, putting a solvent into the thermoplastic phenolic resin to dissolve the thermoplastic phenolic resin, further adding the epoxy polyhedral oligomeric silsesquioxane and the catalyst, and stirring so as to obtain a uniformly dispersed solution; and 2) carrying out a constant-temperature backflow stirring reaction onthe uniformly dispersed solution obtained in the step 1) in a nitrogen atmosphere, and removing the solvent after the reaction is completed, thereby obtaining the epoxy polyhedral oligomeric silsesquioxane modified phenolic resin. The modified phenolic resin has excellent thermal properties and mechanical properties, and in addition is simple in preparation method.

Owner:XI AN JIAOTONG UNIV

Applications of cyclic phosphorus-nitrogen synergic halogen-free flame retardant

The invention relates to applications of cyclic phosphorus-nitrogen synergic halogen-free flame retardant, and particularly relates to applications of 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid, belonging to the field of synthesizing a novel halogen-free high polymer material. As a hard segment chain extender, 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid is applied to halogen-free flame-retardant modification of water-based polyurethane emulsion. Cyclic phosphamide flame retardant 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid as the hard segment chain extender is embedded into a water-based polyurethane macromolecular chain; the research shows that due to the addition of the flame retardant, the limit oxygen index of a polyurethane membrane can be improved to a greater extent, the thermal stability of the polyurethane membrane is enhanced, the carbon residue rate of the material after which is decomposed at high temperature is increased, and the usage amount of the flame retardant is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

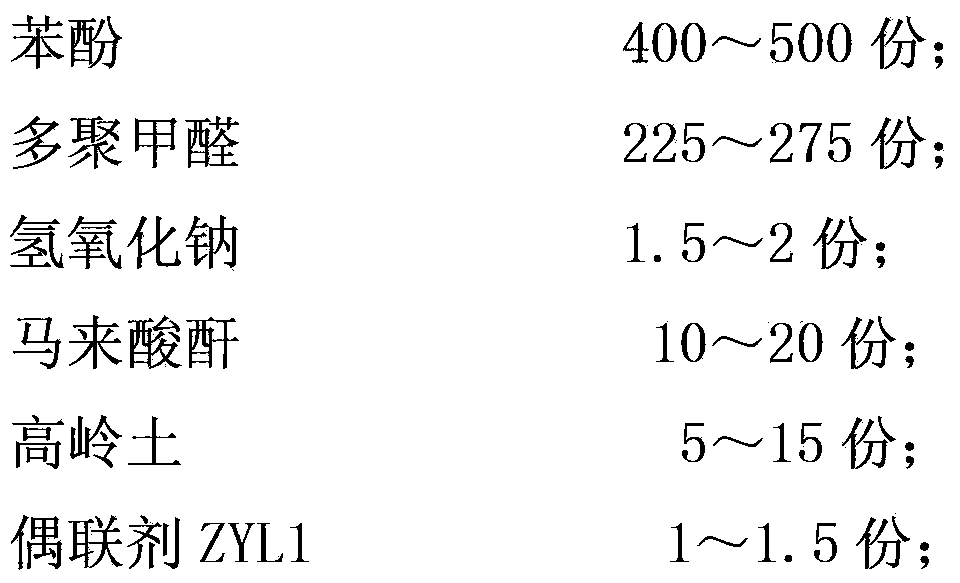

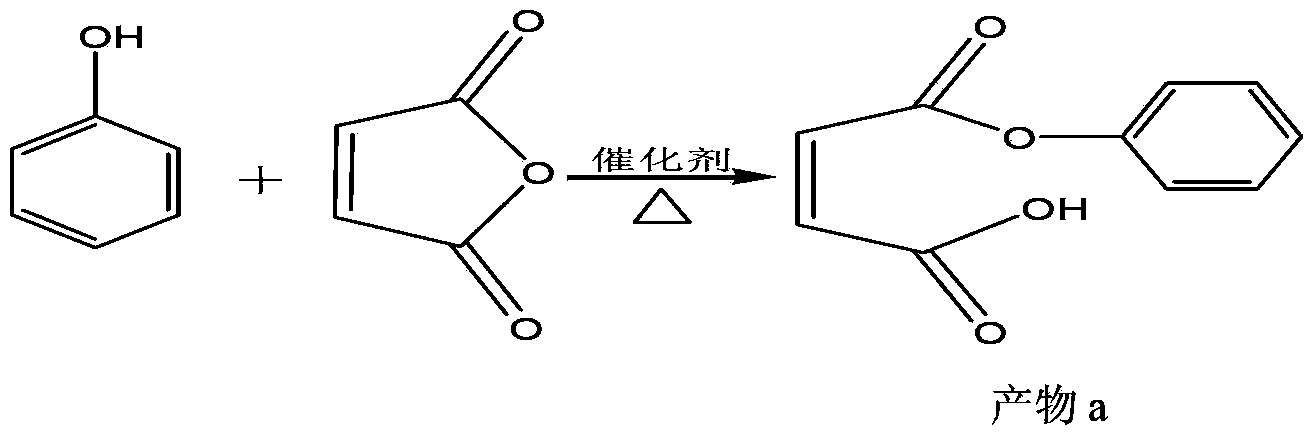

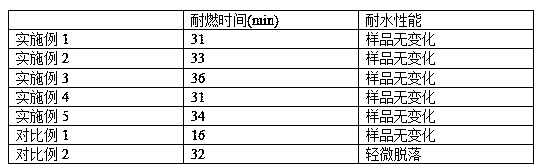

Production method of inorganic soil graft modified phenolic resin foam

ActiveCN103351575AImprove insulation effectImprove fire performanceP-Toluenesulfonic acidFire resistance

The invention discloses a production method of inorganic soil graft modified phenolic resin foam, which comprises the following steps that (1) the following raw materials: phenol, paraformaldehyde, sodium hydroxide, maleic anhydride, kaolin, a coupling agent ZYL1 and water are prepared; (2), phenol, sodium hydroxide and the water are taken, mixed and stirred; (3), paraformaldehyde is taken and put into a reaction kettle; (4), the kaolin and the coupling agent ZYL1 are added, mixed and stirred; (5), dehydration is performed; and (6), kaolin graft modified phenolic resin, BD3088 polyether modified organic polysiloxane, n-pentane and p-toluenesulfonic acid are taken, dissolved in the water and then injected into a die to be foamed to form the inorganic soil graft modified phenolic resin foam. With the adoption of the method, the phenolic resin foam having high flame retardancy, high carbon residue rate, high toughness and high close area percentage can be obtained. The heat preservation performance and the fire resistance of the phenolic resin foam are improved successfully.

Owner:长沙中野机电设备安装有限公司

Intumescent fireproof paint and preparation method thereof

InactiveCN109929345AHigh strengthImprove fire performanceFireproof paintsDiphenyl phosphateCarbon layer

The invention provides an intumescent fireproof paint, which at least comprises the following components by weight: 20-50 parts of water, 5-30 parts of an emulsion, 3-20 parts of a pigment, 3-10 partsof isodecyl diphenyl phosphate, 20-60 parts of a composite intumescent flame retardant, 0.1-1 part of a dispersant, 0.1-1 part of a defoamer, 0.1-1 part of a thickener, 0.1-0.4 part of a pH regulator, 0-0.5 part of a bactericide, and 0-2 parts of a film-forming assistant. Through the synergistic effect of all the components, the obtained intumescent fireproof paint has the performance of environmental protection, decorativeness, color adjustability, dense and high density carbon layer, good adhesion and storage stability.

Owner:上海中南建筑材料有限公司

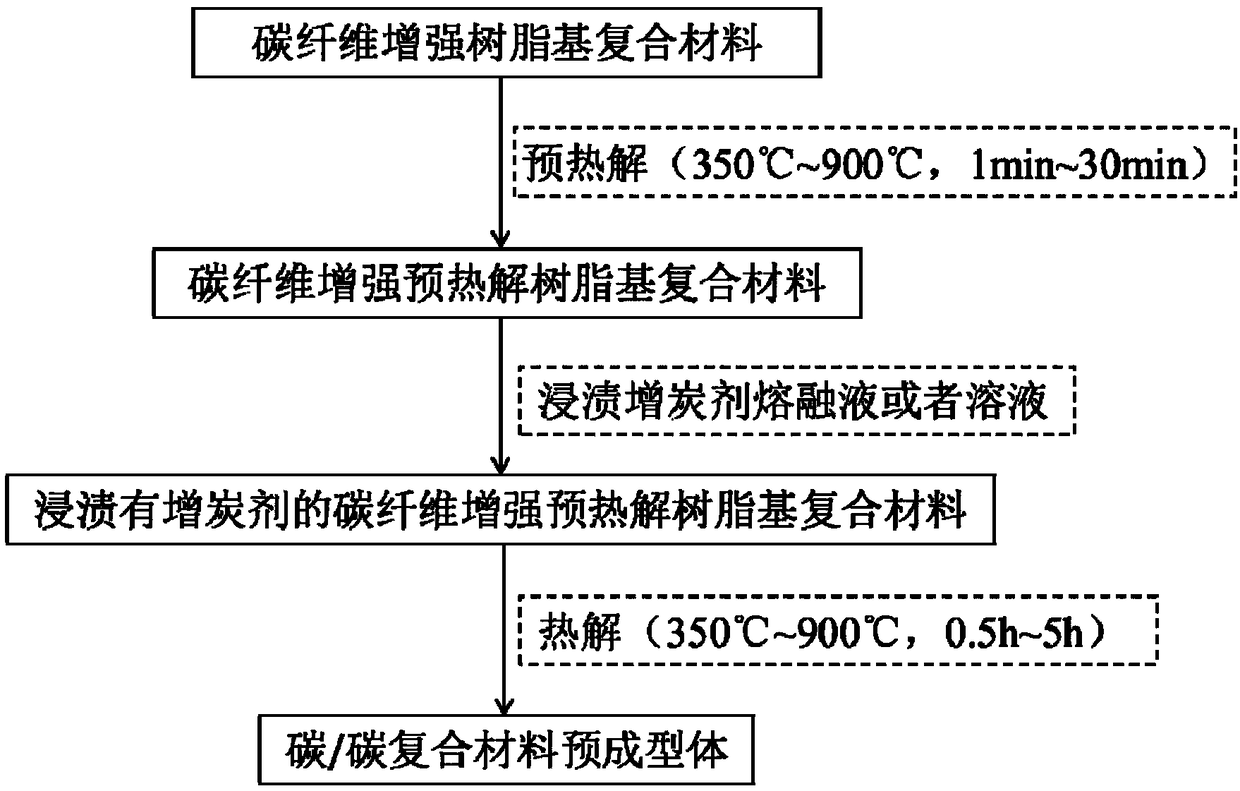

Method for recovering and preparing carbon/carbon preform from carbon fiber reinforced resin matrix composite material

The invention discloses a method for recovering and preparing a carbon / carbon preform from a carbon fiber reinforced resin matrix composite material, and the method comprises the following steps: (1)pre-pyrolyzing the carbon fiber reinforced resin matrix composite material under an inert atmosphere to produce holes on the carbon fiber reinforced resin matrix composite material to obtain a pre-pyrolyzed product; (2) fully immersing a carburant melt or a carburant-containing solution in the holes of the pre-pyrolyzed product, taking the pre-pyrolyzed product out and drying; (3) pyrolyzing the dried carburant-containing pre-pyrolyzed product under the inert atmosphere to sufficiently convert a resin matrix into deposited carbon to obtain the carbon / carbon preform. The method not only fully recovers the resin matrix by the carburant, but also converts the resin matrix into the deposited carbon, the recovered carbon fiber is regular, and the mechanical properties of the recovered carbon fiber are not degraded, and the prepared carbon / carbon perform d can be used for preparing high value-added carbon / carbon composite materials and carbon / ceramic composite materials, and forward development of high-value reuse of the carbon fiber reinforced resin matrix composite material can be realized.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Calixarene [4] modified thermosetting phenolic resin and preparation method thereof Calixarene [4] modified thermosetting phenolic resin and preparation method thereof](https://images-eureka.patsnap.com/patent_img/a9e8b617-899d-4dd9-9467-7208704fb8ac/A20061002196000051.PNG)

![Calixarene [4] modified thermosetting phenolic resin and preparation method thereof Calixarene [4] modified thermosetting phenolic resin and preparation method thereof](https://images-eureka.patsnap.com/patent_img/a9e8b617-899d-4dd9-9467-7208704fb8ac/A20061002196000061.PNG)

![Calixarene [4] modified thermosetting phenolic resin and preparation method thereof Calixarene [4] modified thermosetting phenolic resin and preparation method thereof](https://images-eureka.patsnap.com/patent_img/a9e8b617-899d-4dd9-9467-7208704fb8ac/A20061002196000071.PNG)