Novel silicon-containing benzoxazine and preparation method thereof

A new type of benzoxazine technology, applied in the field of new benzoxazine monomers and their polymers, can solve the problems of insufficient flame retardancy and dielectric properties, poor mechanical properties, poor thermal stability, etc., and achieve excellent Effects of thermal stability and mechanical properties, good thermal stability, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

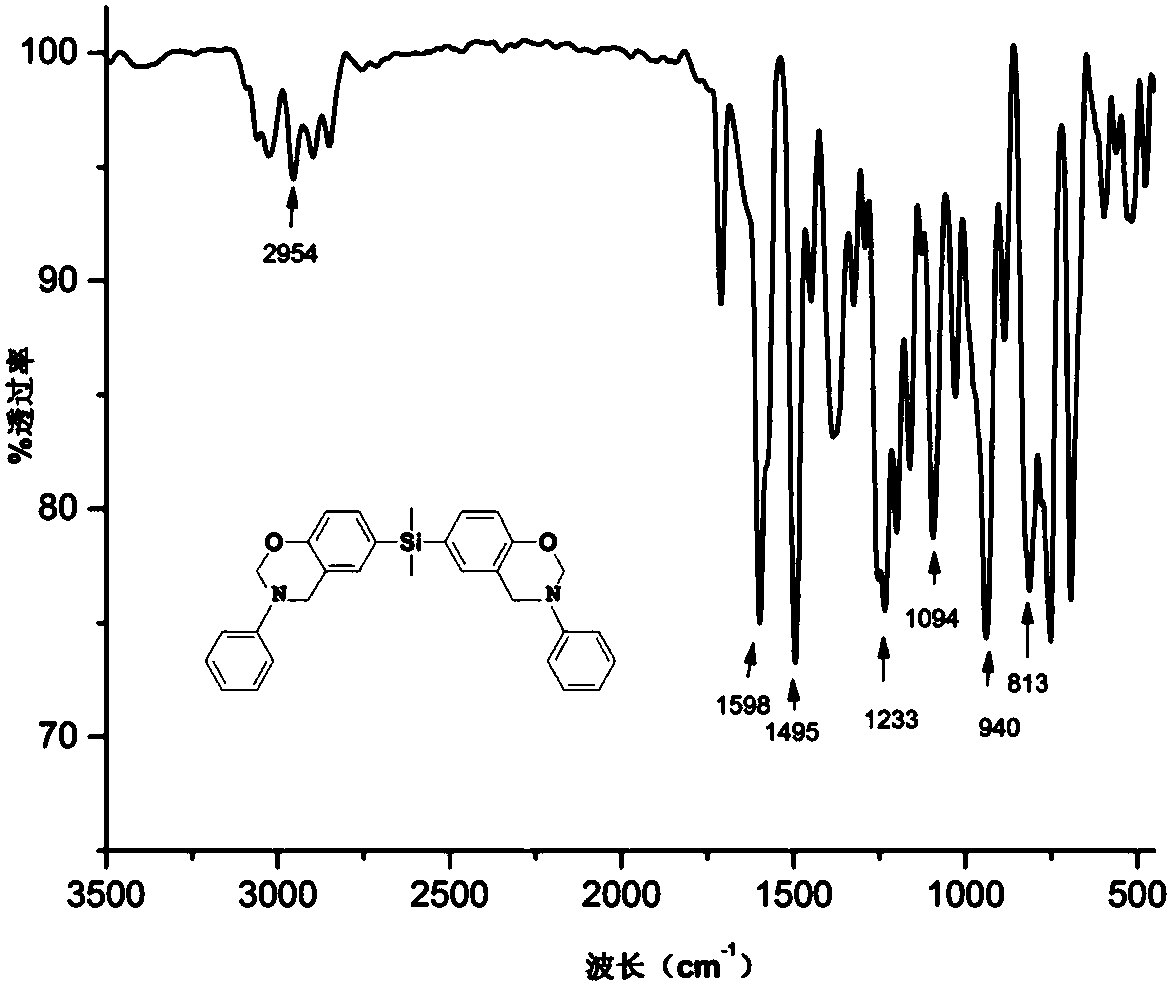

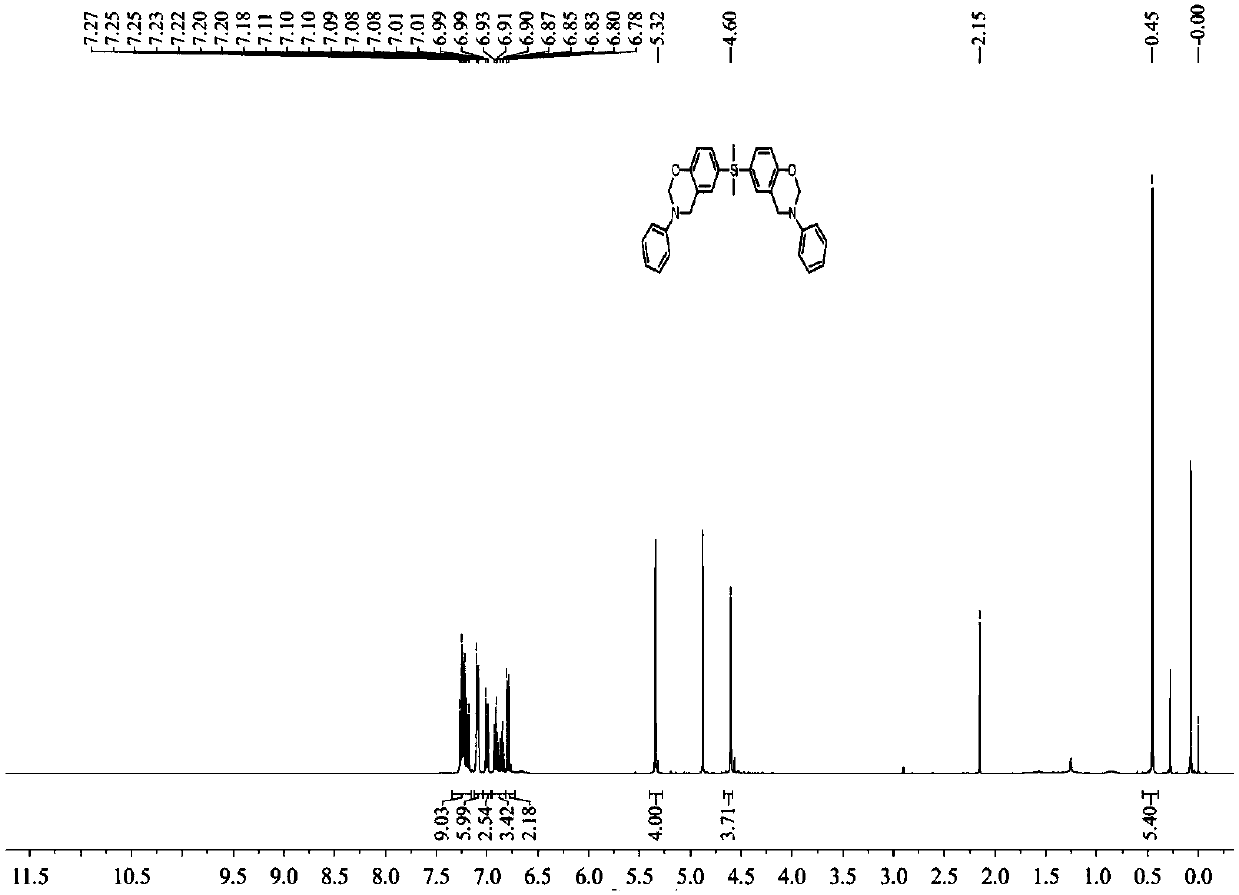

[0039] At room temperature, add 2.44g of bis(hydroxyphenyl)dimethylsilicon, 1.86ml of aniline and 1.23g of paraformaldehyde into a round bottom flask containing 30ml of chloroform. The molar ratio of aniline and paraformaldehyde is 1:2:4.1, and the reaction is heated under reflux for 1 day. After the reaction is complete, the chloroform is evaporated to dryness with a rotary evaporator, and the silicon-containing benzoxazine monomer is obtained by column chromatography. The reaction principle is:

[0040]

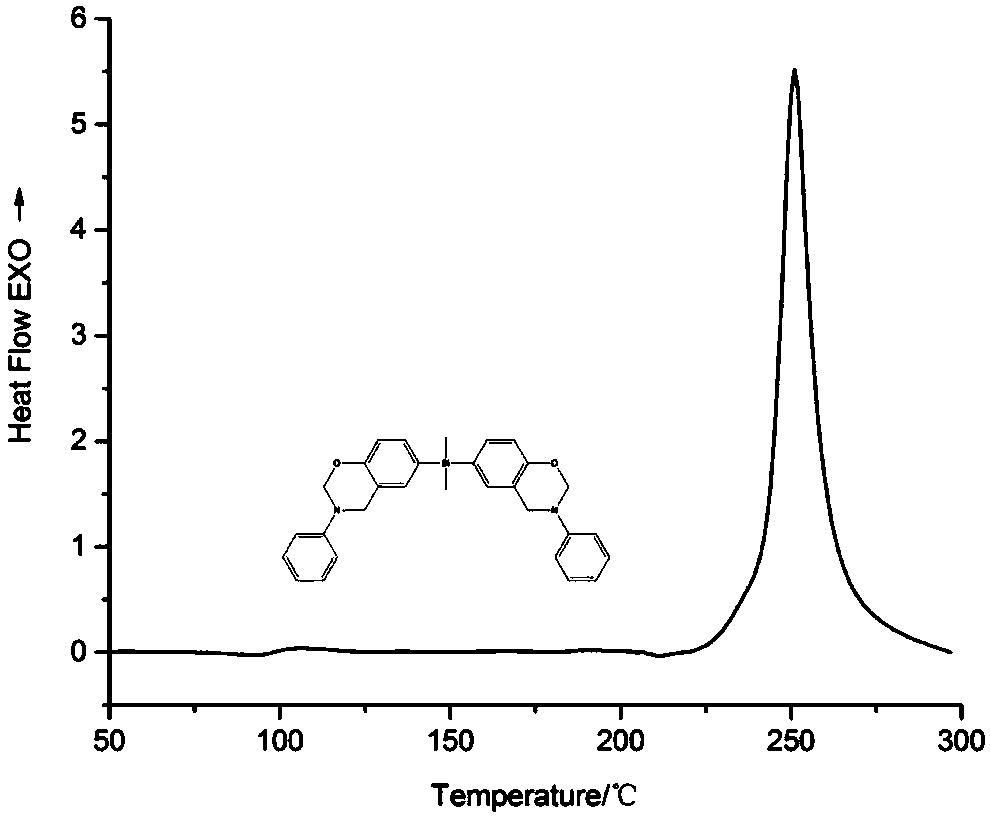

[0041] Pour 2g of the above-prepared silicon-containing benzoxazine monomer into a circular aluminum mold, place it in an electric thermostatic drying oven, and solidify in stages at different temperatures to obtain ring-opening polymerized polybenzoxazine. The temperature rise curing process The steps are as follows: first heat up to 200°C for thermal curing for 3 hours, then heat up to 220°C for 3 hours, and finally heat to 240°C for thermal curing for 3 hours.

Embodiment 2

[0043] At room temperature, add 2.44g of bis(hydroxyphenyl)dimethylsilicon, 1.86ml of aniline and 1.26g of paraformaldehyde into a round bottom flask containing 30ml of toluene, bis(hydroxyphenyl)dimethylsilicon, The molar ratio of aniline and paraformaldehyde is 1:2:4.2, and the reaction is heated and refluxed for 1 day. After the reaction is completed, the toluene is evaporated to dryness with a rotary evaporator, and the silicon-containing benzoxazine monomer is obtained by column chromatography. The reaction principle is:

[0044]

[0045] Pour 2g of the above-prepared silicon-containing benzoxazine monomer into a circular aluminum mold, place it in an electric thermostatic drying oven, and solidify in stages at different temperatures to obtain ring-opening polymerized polybenzoxazine. The temperature rise curing process It is: first heat up to 200°C for thermal curing for 3 hours, then heat up to 220°C for thermal curing for 3 hours, and finally heat to 240°C for thermal cur...

Embodiment 3

[0047] At room temperature, add 2.44g of bis(hydroxyphenyl)dimethylsilicon, 1.86ml of aniline and 1.29g of paraformaldehyde into a round-bottomed flask containing 30ml of benzene, bis(hydroxyphenyl)dimethylsilicon, The molar ratio of aniline and paraformaldehyde is 1:2:4.3, and the reaction is heated and refluxed for 1 day. After the reaction is completed, the benzene is evaporated to dryness with a rotary evaporator, and the silicon-containing benzoxazine monomer is separated by column chromatography. The reaction principle is:

[0048]

[0049] Pour 2g of the above-prepared silicon-containing benzoxazine monomer into a circular aluminum mold, place it in an electric thermostatic drying oven, and solidify in stages at different temperatures to obtain ring-opening polymerized polybenzoxazine. The temperature rise curing process It is: first heat up to 200°C for thermal curing for 3 hours, then heat up to 220°C for thermal curing for 3 hours, and finally heat to 240°C for thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com