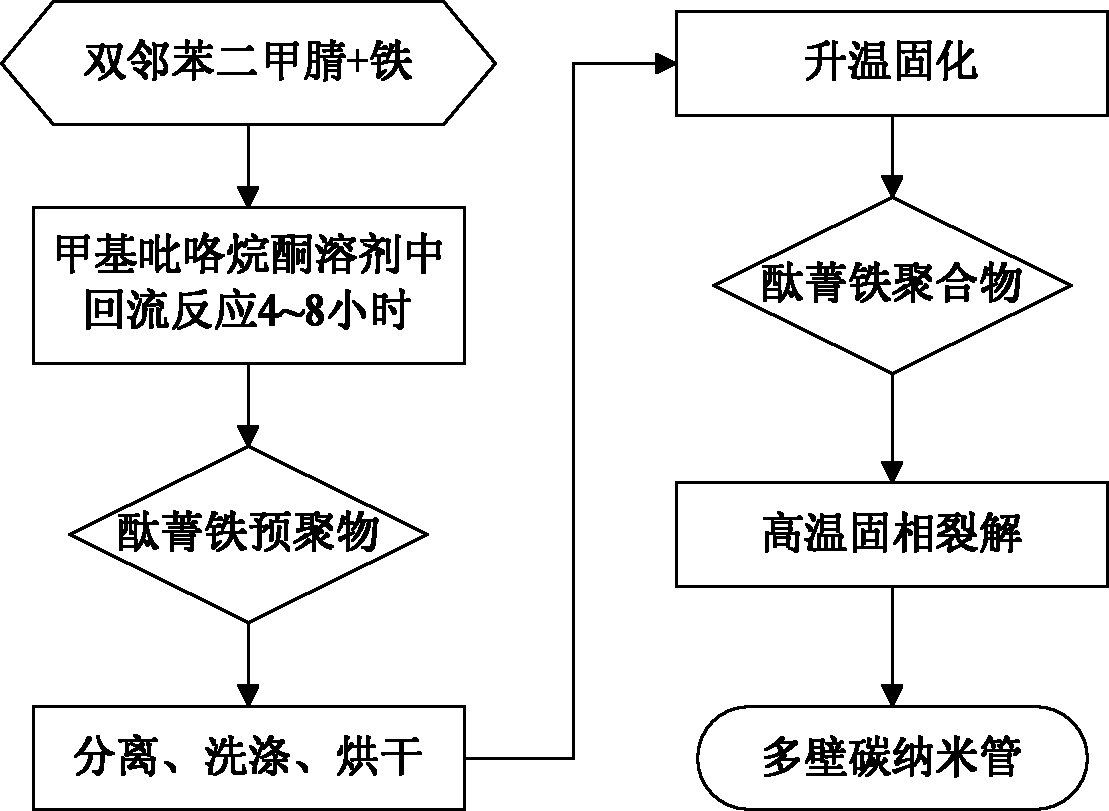

Method for preparing multi-walled carbon nanotubes from phthalocyanine iron polymer by high temperature solid-phase cracking

A technology of multi-wall carbon nanotubes and high-temperature solid phase, applied in the field of nanomaterials, can solve the problems of high yield, unguaranteed, low carbon residue rate, etc., and achieve the effect of simple preparation method, high production rate, and high carbon residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

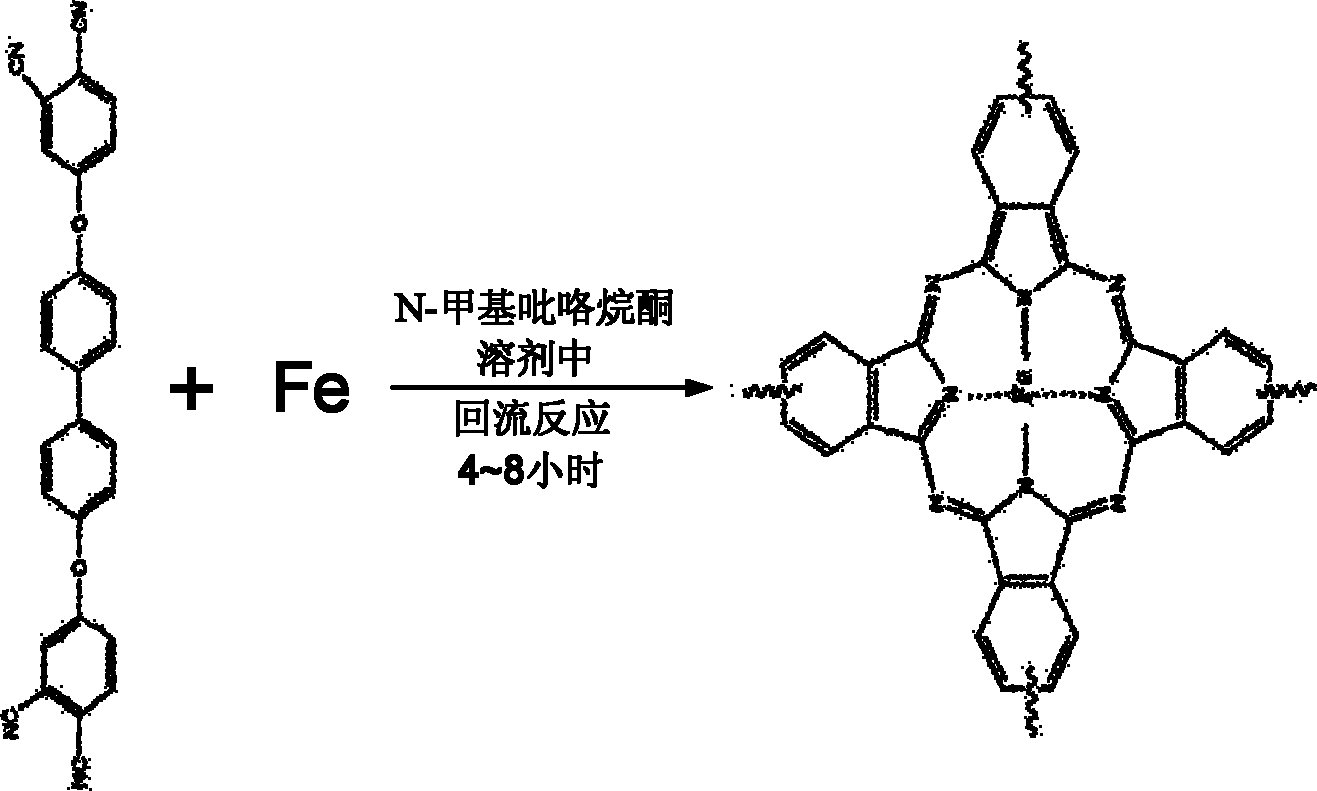

[0032] Example 1 Using bis-phthalonitrile as the initial carbon source and carbonyl iron powder as the catalyst, carbon nanotubes were prepared by a solid-phase cracking method.

[0033] 1. Weigh 10 grams of bisphthalonitrile monomer and 0.6 grams of carbonyl iron powder, put them into a three-necked bottle, pour 15ml of N-methylpyrrolidone as a solvent; heat up to 200°C, and reflux for 4 hours.

[0034] 2. Pour the solution into water, filter, wash the filtered solid with deionized water 2 to 3 times, dry and collect.

[0035] 3. The samples collected in step 2 were cured according to the following procedure at 50°C for 4 hours, at 280°C for 4 hours, and at 300°C for 50 hours.

[0036] 4. Introduce nitrogen, then step 3, the initial temperature is 300°C, and rise to 350°C at a heating rate of 5°C / min (constant temperature for 1 hour); 5°C / min to 400°C (constant temperature for 1 hour); 3°C / min to 500°C (constant temperature for 4 hours); 2°C / min to 800°C (constant temperatu...

Embodiment 2

[0039] Example 2 Using bis-phthalonitrile as the initial carbon source and nano-iron powder as the catalyst, carbon nanotubes were prepared by a solid-phase cracking method.

[0040] 1. Weigh 10 grams of bisphthalonitrile monomer and 0.2 grams of nano-iron powder, put them into a three-necked bottle, and pour 15ml of N-methylpyrrolidone as a solvent. Raise the temperature to 200°C and reflux for 4 hours.

[0041] 2. Pour the solution into water, filter, wash the filtered solid with deionized water 2 to 3 times, dry and collect.

[0042] 3. The samples collected in step 2 were cured according to the following procedure at 50°C for 4 hours, at 280°C for 4 hours, and at 300°C for 50 hours.

[0043] 4. Introduce nitrogen, then step 3, the initial temperature is 300°C, and rise to 350°C at a heating rate of 5°C / min (constant temperature for 1 hour); 5°C / min to 400°C (constant temperature for 1 hour); 3°C / min to 500°C (constant temperature for 4 hours); 2°C / min to 800°C (constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com