Patents

Literature

46results about How to "Increase the residual rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

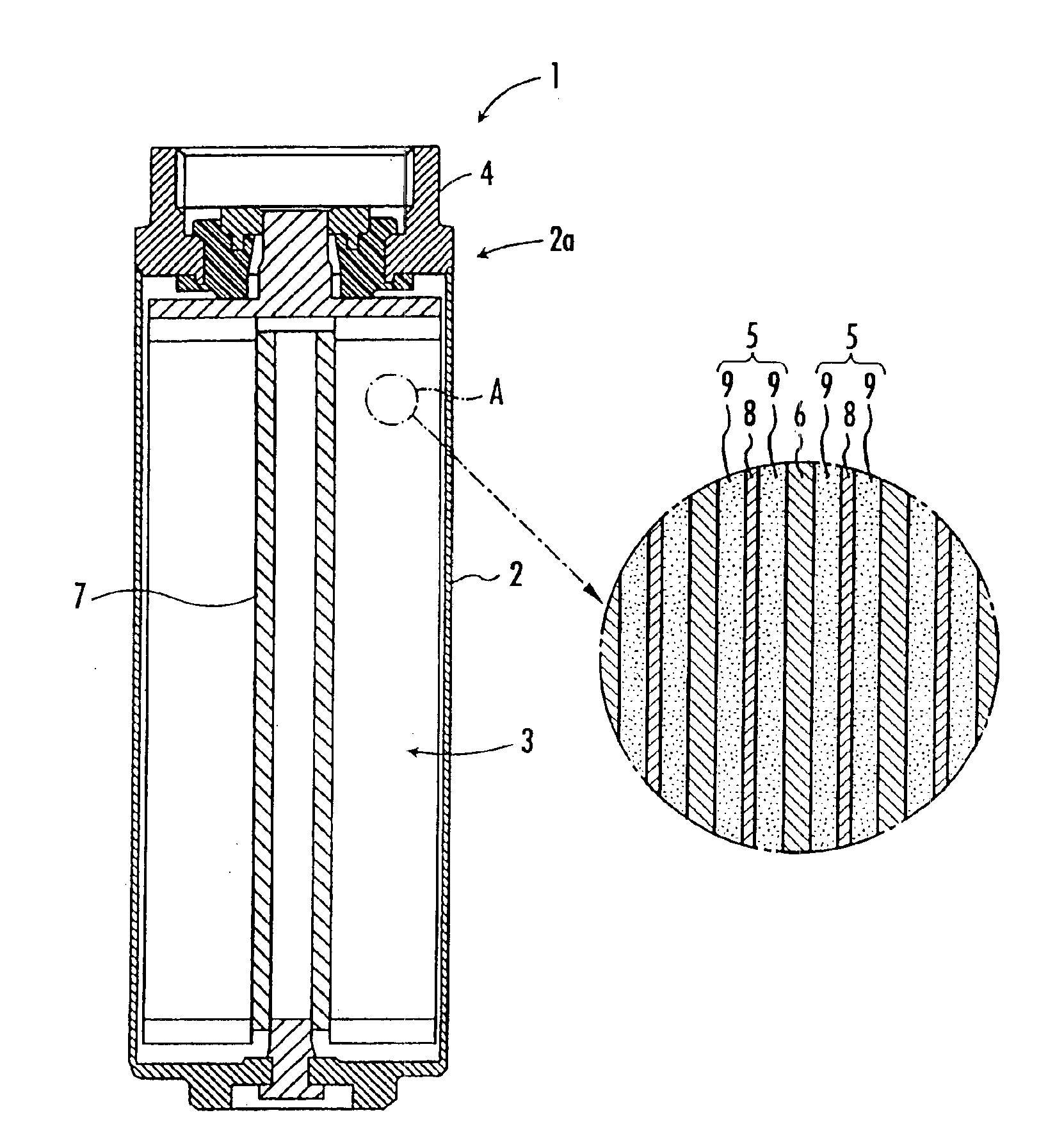

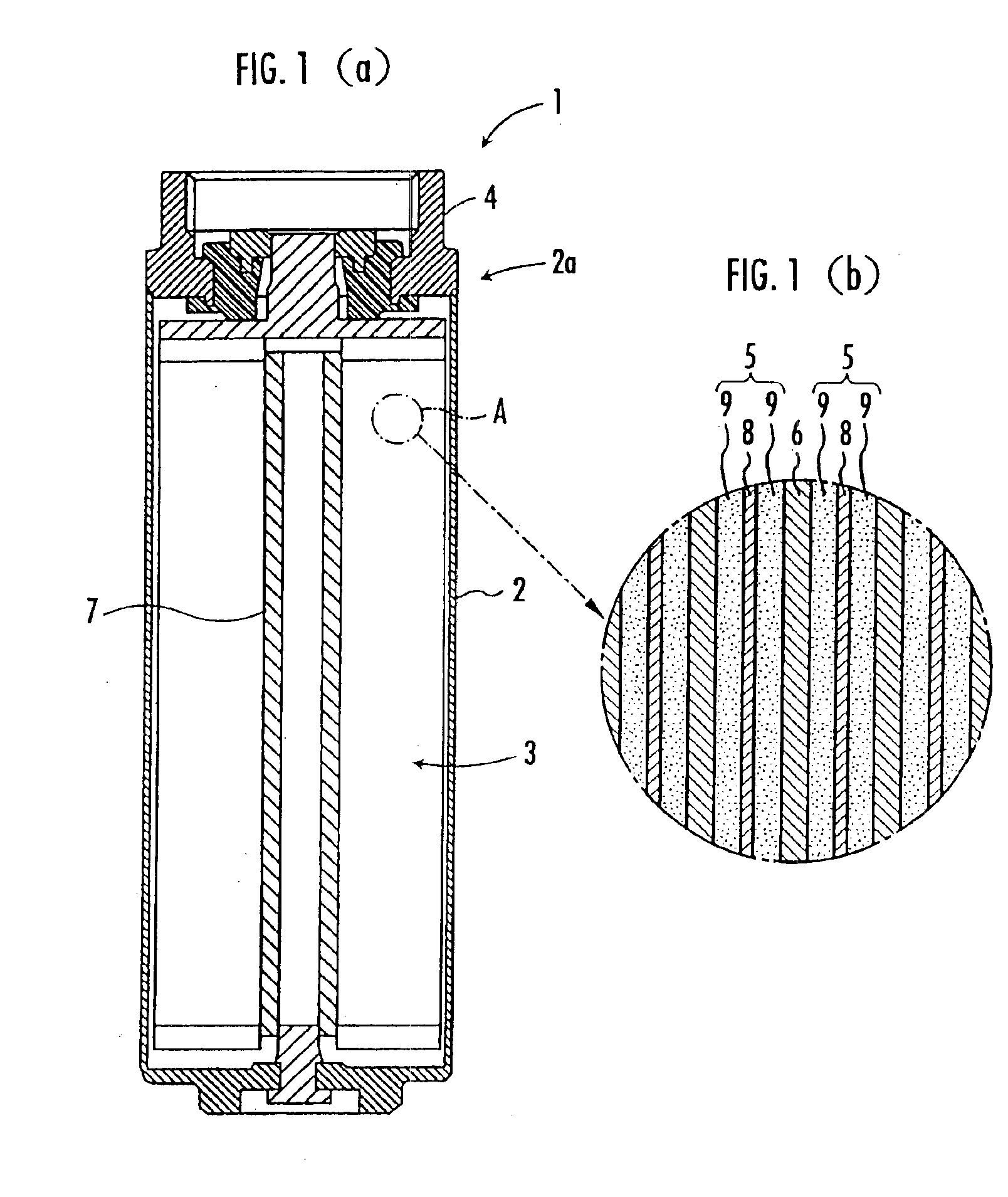

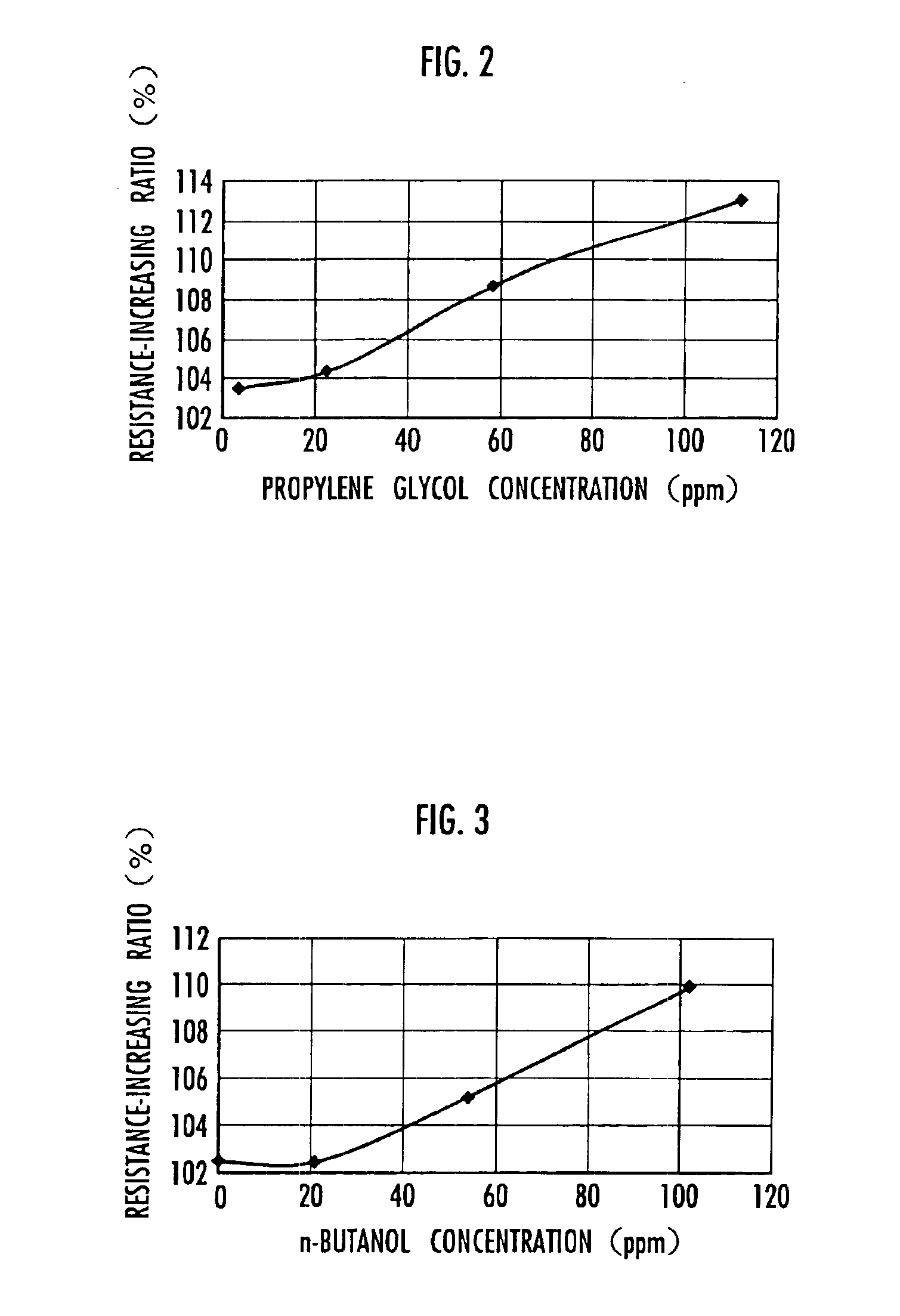

Electrical double-layer capacitor

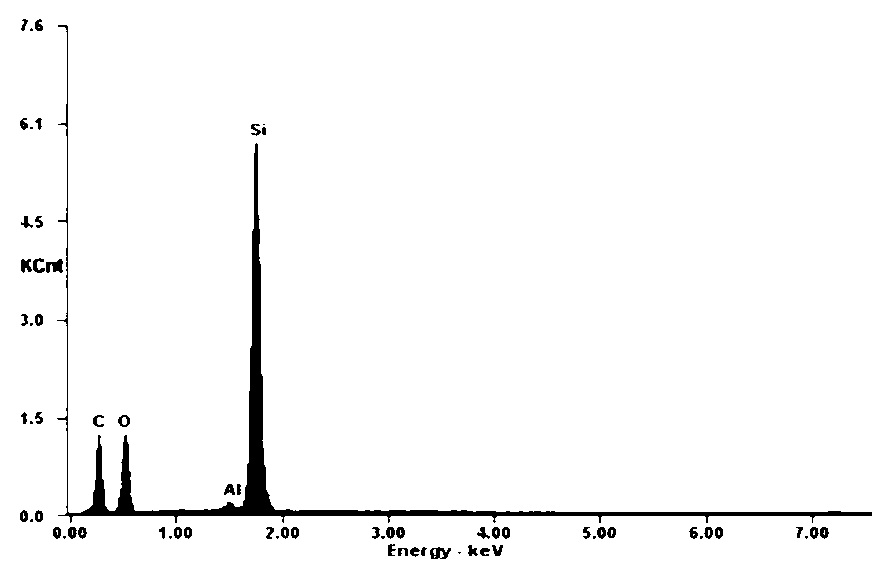

ActiveUS6914768B2Small increase in resistanceIncrease the residual rateHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorQuaternary ammonium cationTetrafluoroborate

An electrical double-layer capacitor showing a sleight increase of resistance when used under continuous application of high voltage and maintaining high energy residual ratio after standing for a long time includes an electrode element including a pair of electrodes disposed opposite to each other with a separator interposed therebetween, and is impregnated with a nonaqueous electrolyte solution prepared by dissolving quaternary ammonium salts into cyclic carbonates and containing impurities of 30 ppm or less of glycols, 30 ppm or less of primary alcohols and less than 20 ppm of tertiary amines. The water content may be 50 ppm or less. The quaternary ammonium salt may be triethylmethylammonium tetrafluoroborate. The cyclic carbonate may be propylene carbonate. The nonaqueous electrolyte solution may have a concentration of 0.1 to 2.5 mol / liter. The electrode may be a polarizable electrode composed of activated carbon.

Owner:MU IONIC SOLUTIONS CORP +1

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

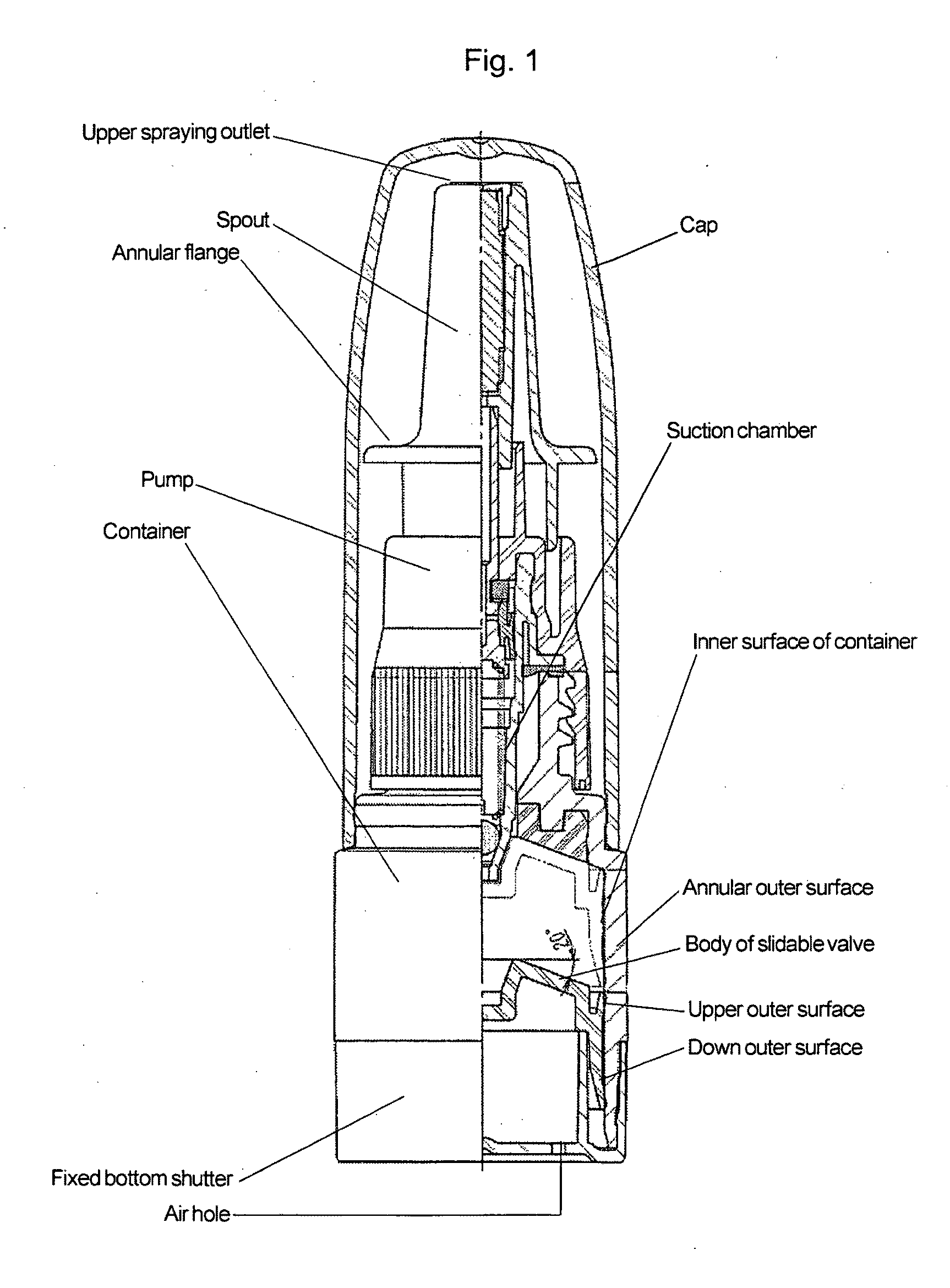

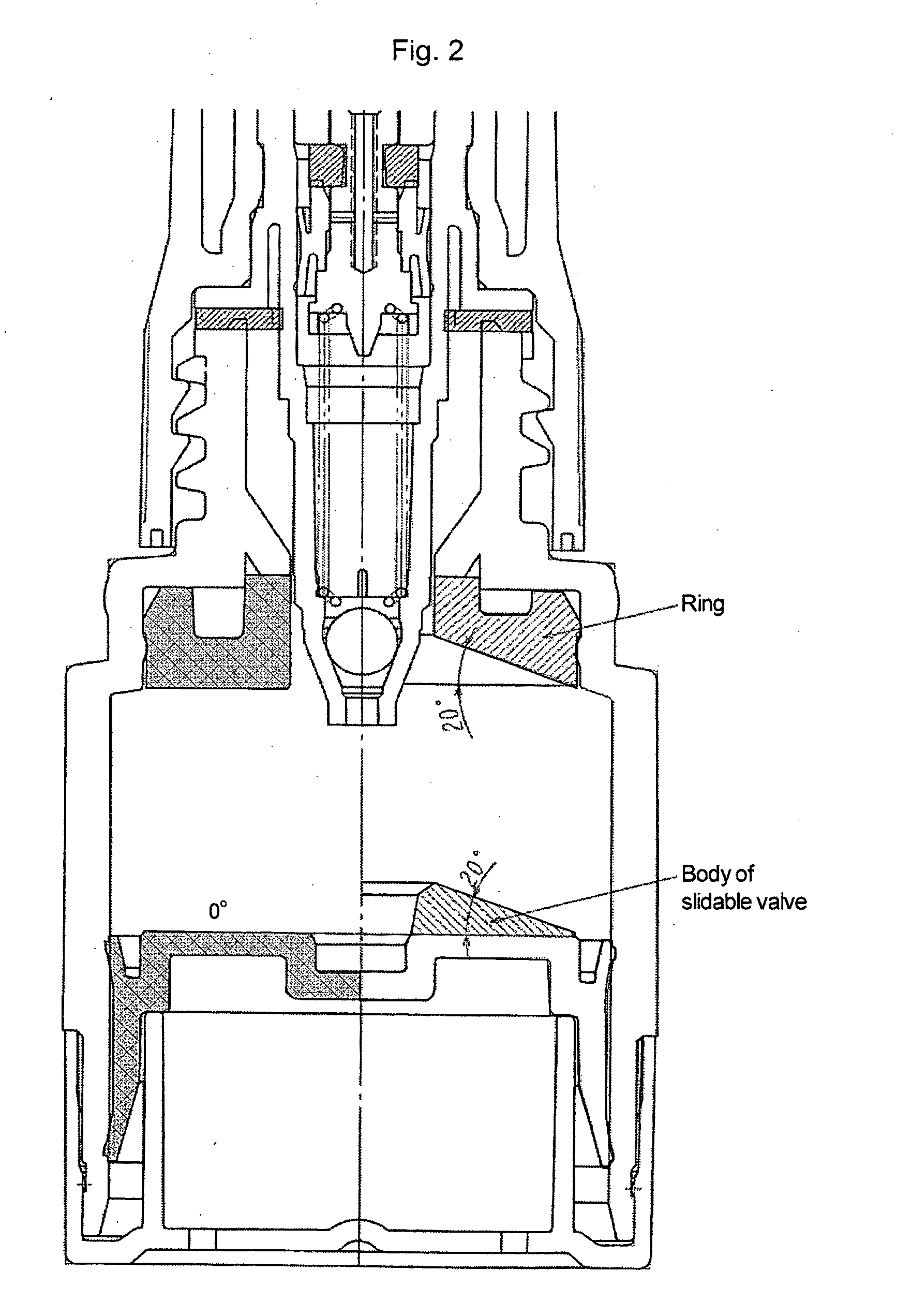

Sprayable Gel-Type Skin/Mucosa-Adhesive Preparation and Administration System Using the Preparation

ActiveUS20090275668A1Avoid stickinessHigh viscosityBiocideAerosol deliveryGel basedAdditive ingredient

Owner:TOKO YAKUHIN IND CO LTD

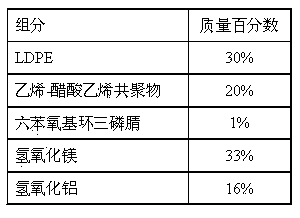

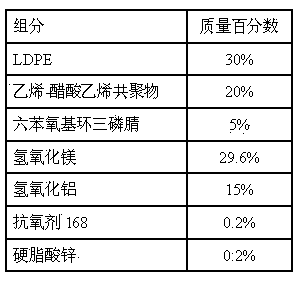

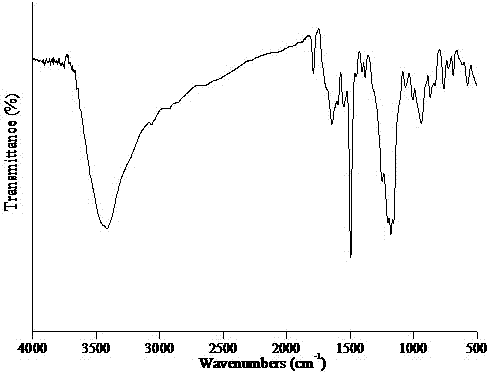

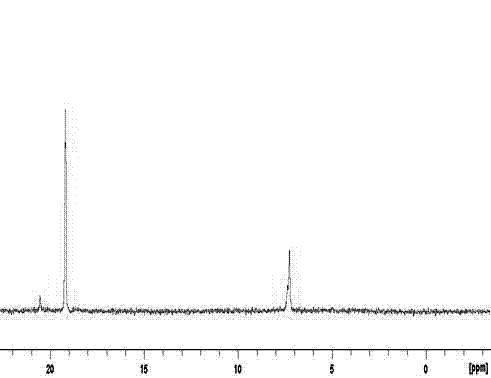

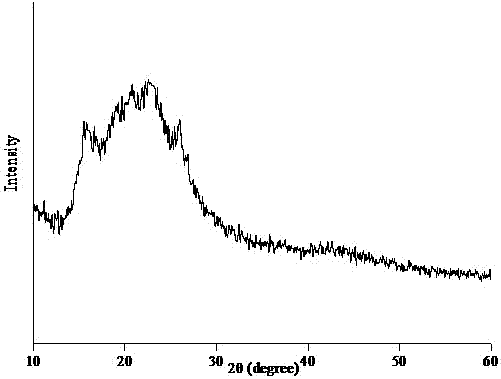

Hexaphenoxy cyclotriphosphazene-containing composite flame-retardant cable material and preparation method thereof

InactiveCN103804748AIncrease the residual rateImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesEngineeringToxic material

The invention relates to a hexaphenoxy cyclotriphosphazene-containing composite flame-retardant cable material and a preparation method thereof. The cable material adopts exaphenoxy cyclotriphosphazene, magnesium hydroxide and aluminum hydroxide as fire retardants to improve the residual rate at a high temperature and improve the thermal stability and the flame retardant property of the cable material; the cable material has the characteristic of low smoke quantity, does not contain toxic substances such as lead, antimony and the like, and is green and environment-friendly; the exaphenoxy cyclotriphosphazene can reduce the filling amount of the magnesium hydroxide and the aluminum hydroxide, improve the flame retardant property of the material and increase the mechanical property of the materials; and the lubricating agent can improve the processability of the material; and therefore, the cable material is a novel high-efficiency flame-retardant cable material.

Owner:SHANGHAI UNIV +1

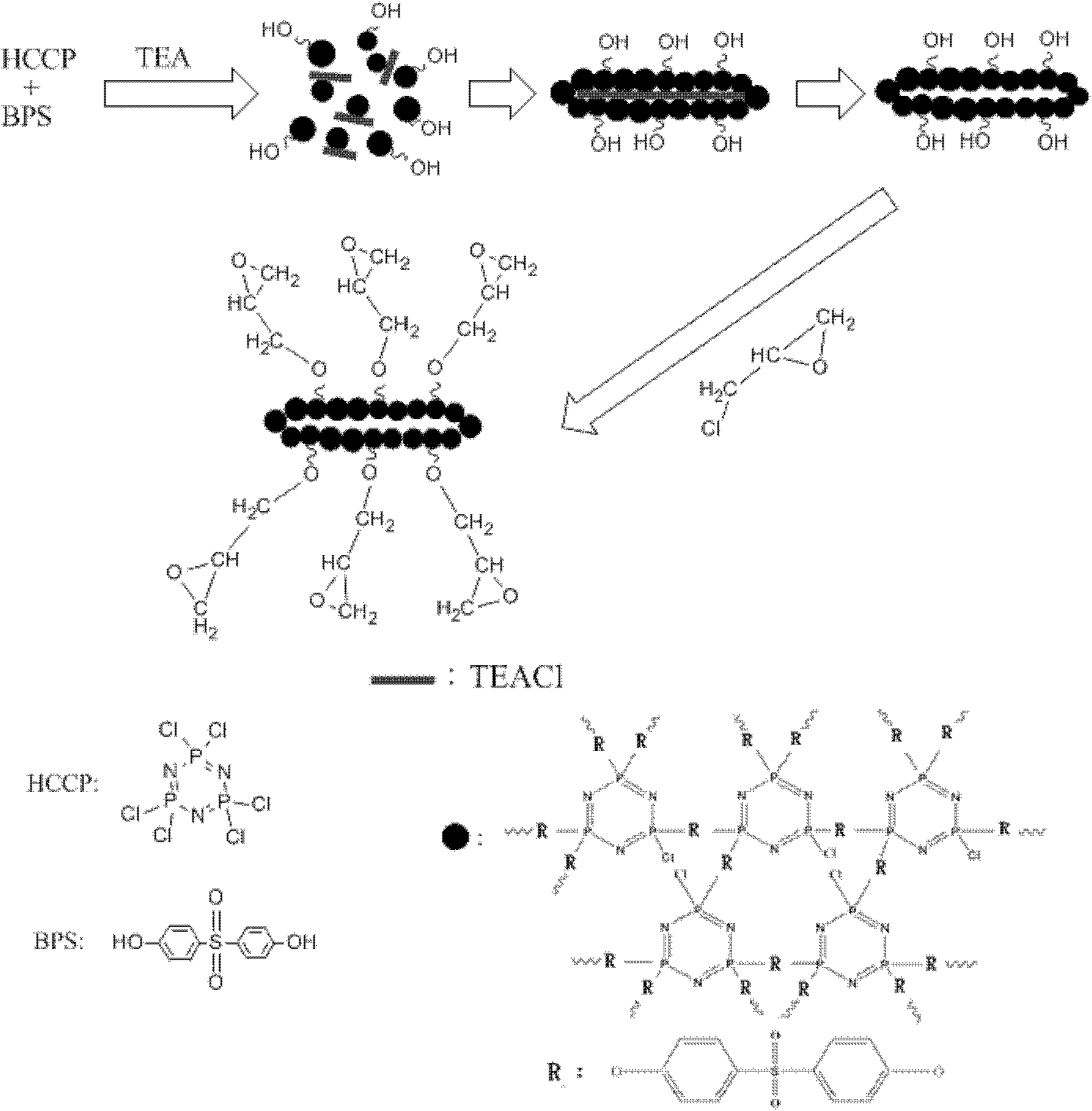

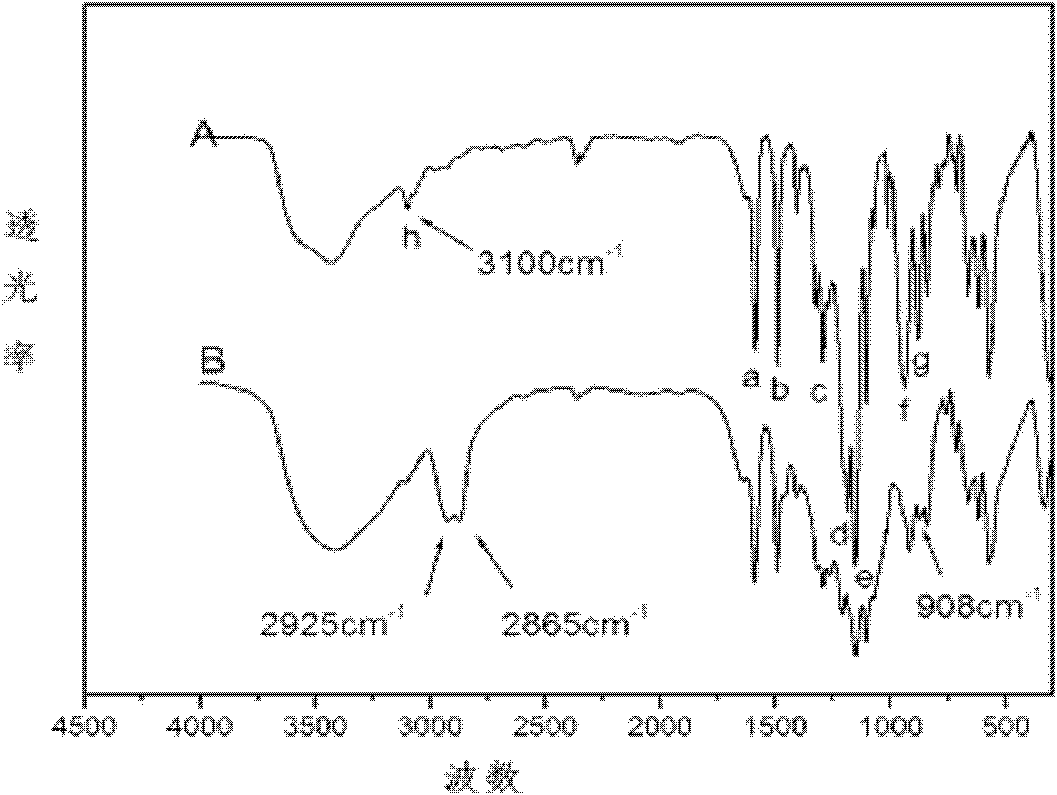

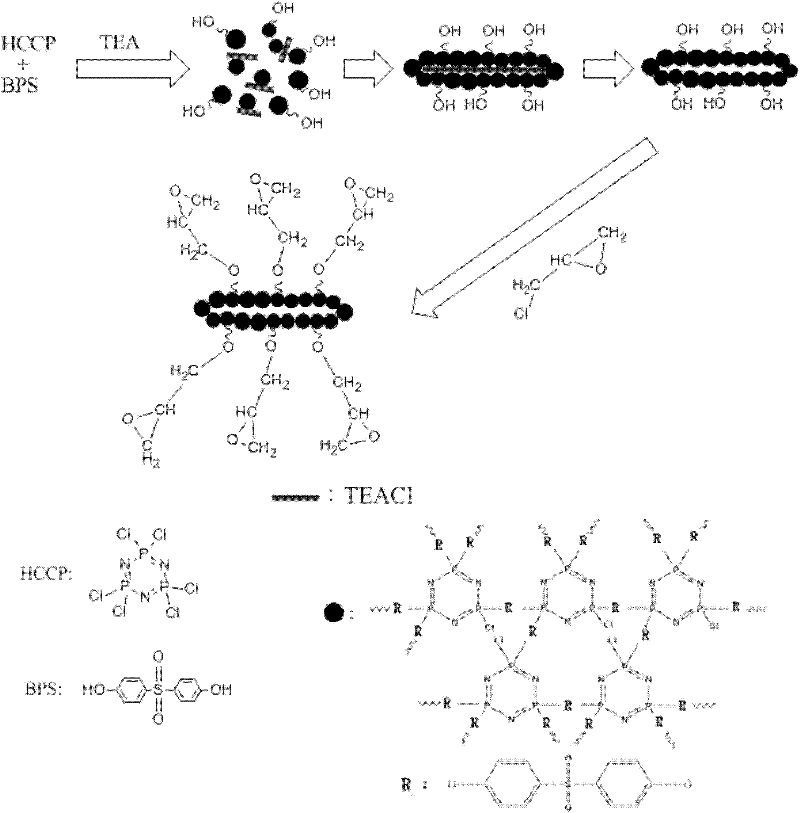

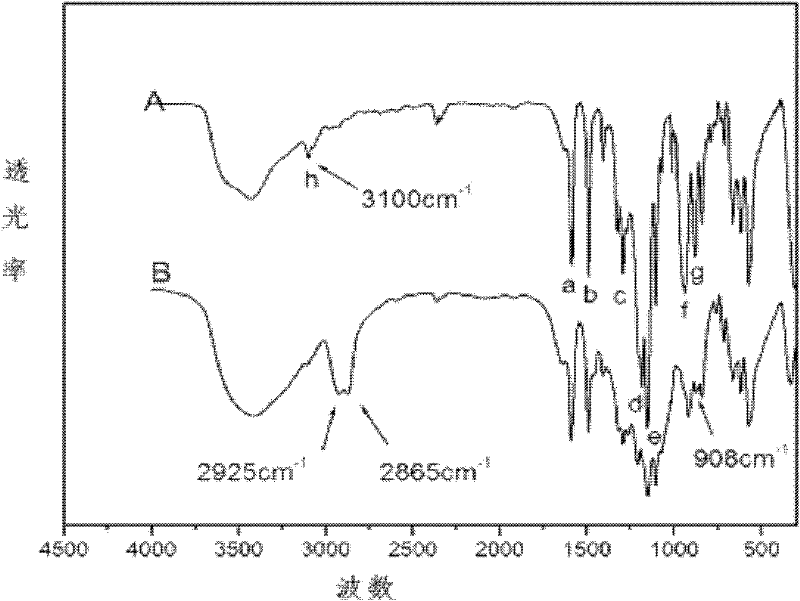

Polycyclotriphosphazene-sulphone phenyl ester and preparation method thereof

ActiveCN103570929AGood solubility in polar solutionsGood flame retardant performanceGroup 5/15 element organic compoundsPhosphazeneChemistry

The invention relates to polycyclotriphosphazene-sulphone phenyl ester and a preparation method thereof. The structural formula of the polycyclotriphosphazene-sulphone phenyl ester is as shown in the specification, wherein R in the structural formula is as shown in the descriptions, and m is equal to 1-60. The polycyclotriphosphazene-sulphone phenyl ester has good polarity solution dissolving property, good flame retardant property, relatively good thermal stability, high thermal decomposition temperature, high residual rate of high-temperature solids and other excellent properties similar to those of POB polybenzoate, is mainly applied to automotive engine components, mechanical components and aeronautical facility components and provides a new choice for high-temperature solid lubrication materials for mechanical components and parts.

Owner:IND RES INST ZHIJIANG COLLEGE OF ZHEJIANG UNIV OF TECH

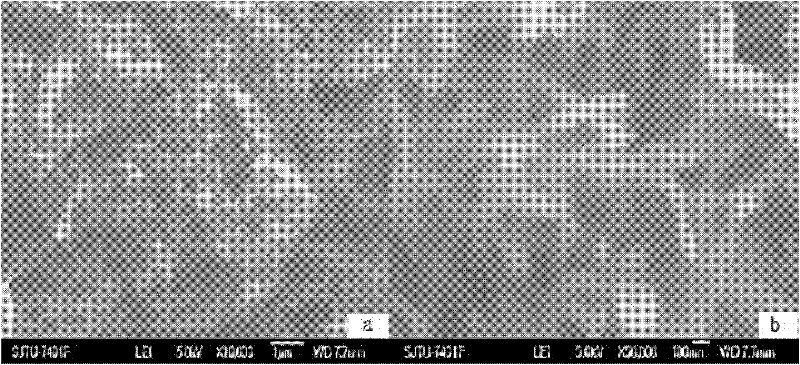

Preparation method of composite material based on epoxy resin and phosphazene nanotubes

The invention relates to a preparation method of a composite material based on epoxy resin and phosphazene nanotubes, which belongs to the technical field of nano materials. The preparation method comprises the following steps: under ultrasonic conditions, adding acid binding agent into tetrahydrofuran; adding 4,4'-dihydroxy-diphenyl sulfone and hexachlorocyclotriphosphazene to carry out condensation reaction; adding epoxy chloropropane; dropwise adding sodium hydroxide water solution; heating to carry out water bath reaction, thereby obtaining epoxide group modified phosphazene nanotubes; adding the epoxide group modified phosphazene nanotubes into the acetone dissolved epoxy resin, adding epoxy resin curing agent, carrying out ultrasonic dispersion, removing acetone in a vacuum drying oven at low temperature, and pouring the mixture into a die; and curing at high temperature to obtain the composite material based on epoxy resin and phosphazene nanotubes. The epoxy resin composite material has the advantages of high shock resistance, tensile property and thermal stability.

Owner:SHANGHAI JIAO TONG UNIV

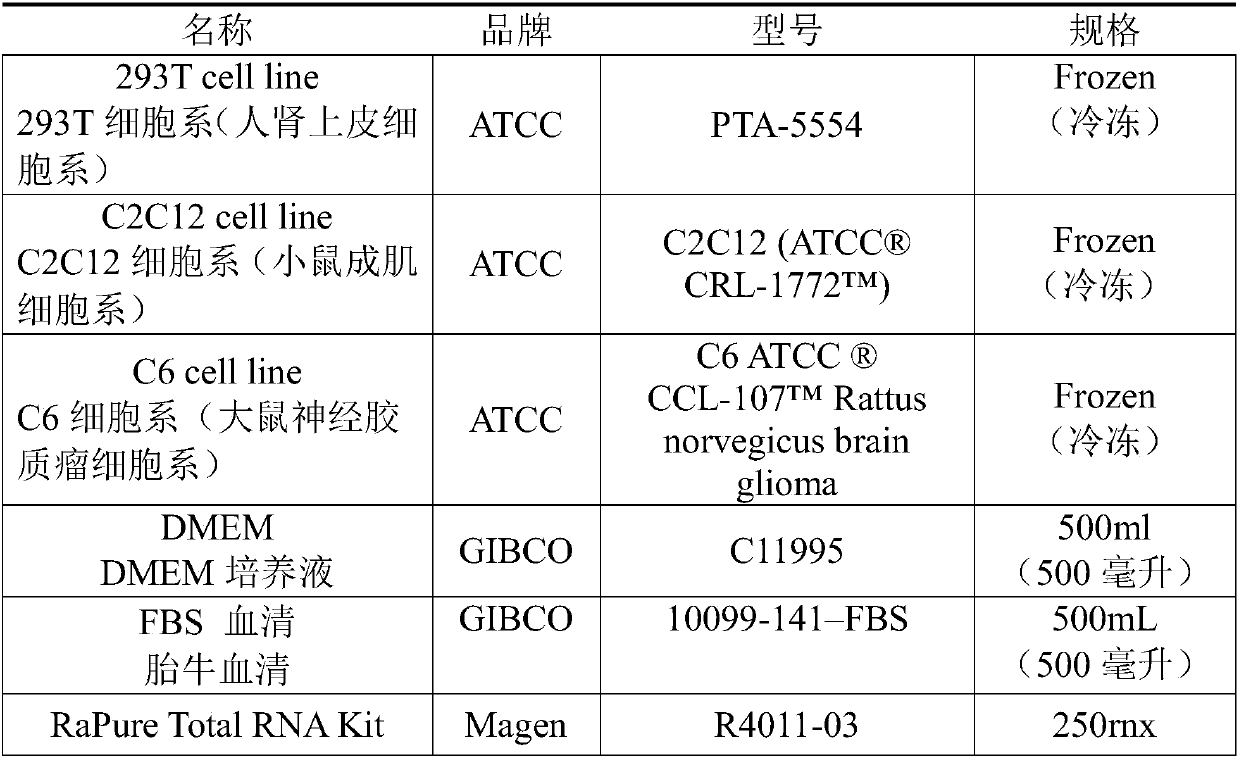

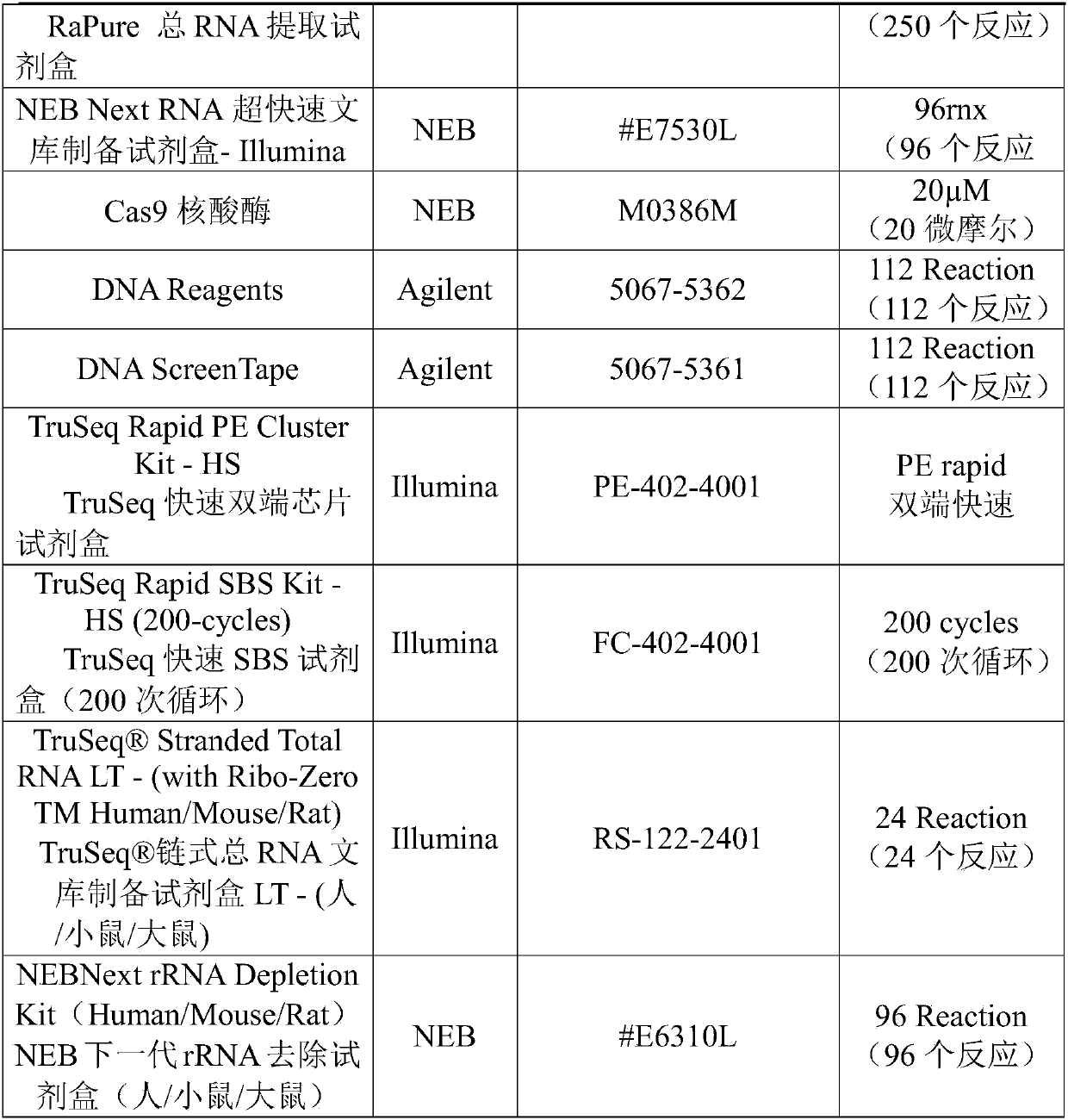

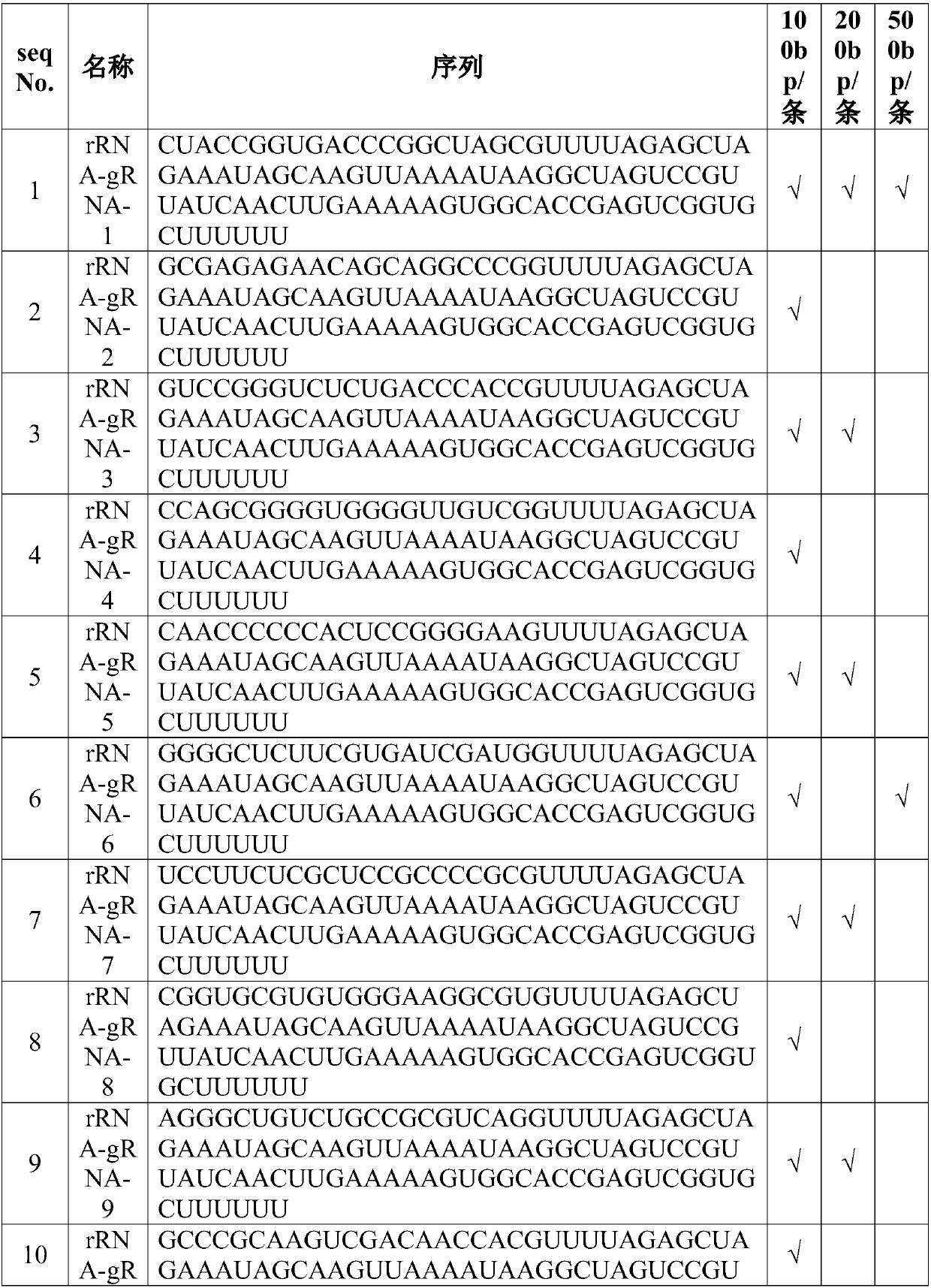

Method and kit capable of removing ribosomal RNA with high efficiency for construction of transcriptome sequencing library

ActiveCN107893260AImprove data qualityImprove effectivenessLibrary creationDNA preparationRibosomal RNAA-DNA

The invention discloses a method for construction of a transcriptome sequencing library. The method comprises the following steps: providing a DNA molecule containing to-be-removed rRNA; carrying outdesigning on account of a DNA sequence of the to-be-removed rRNA so as to obtain a Crispr RNA pool; and allowing a DNA sample to contact with the Crispr RNA pool and Crispr protein so as to obtain a sample compiled by a Crispr system and obtain the transcriptome sequencing library and a kit used for construction of the transcriptome sequencing library. The method and the kit provided by the invention can remove a large number of redundant RNA like rRNA with high efficiency, enrich other molecules in the sample, improve the data quality and the effective data ratio of initial transcriptome sequencing, and reduce the cost of sequencing.

Owner:GUANGZHOU RIBOBIO

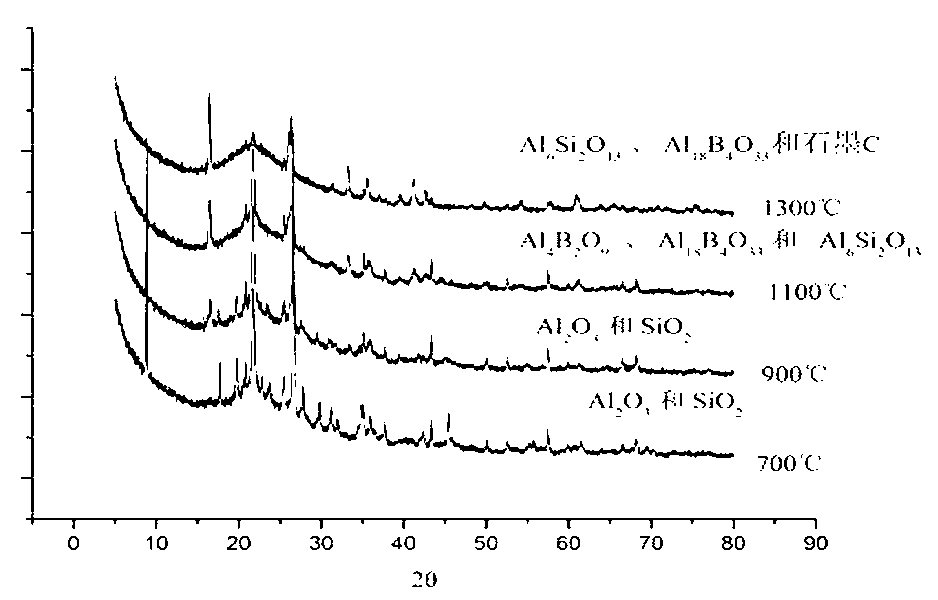

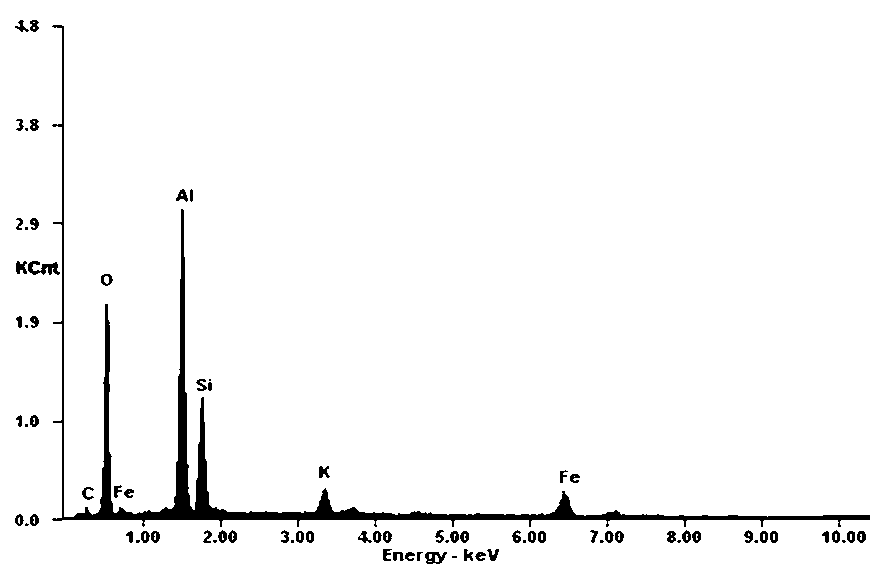

Ceramic high carbon polymer matrix composite and preparation method thereof

ActiveCN103058632ALow porcelain temperatureGood heat protectionClaywaresLamellar structureThermal protection

The invention relates to a ceramic high carbon polymer matrix composite and a preparation method thereof. The composite comprises the following components according to parts by weight: 15-50 parts of high thermoset carbon resin, 5-10 parts of eutecticevaporate mixture, 20-50 parts of clay stratified structure mineral powder, and 0.1-1.5 parts of molding additives. The preparation method comprises the following steps of hot melting and mixing the components according to the proportion, heating and fusing the mixture for vacuum defoamation, casting in a die, and thermocuring for molding at the temperature, so as to obtain the ceramic high carbon polymer matrix composite. The ceramic component of the polymer is characterized in that the ceramic component can be converted into ceramic material containing carbon in high temperature aerobic environment, the temperature for ceramic conversion is controllable, the ceramic conversion rate is high in high temperature aerobic environment, and the ceramic bovine component can be used in the field of antiflaming and fireproofing and thermal protection.

Owner:WUHAN UNIV OF TECH

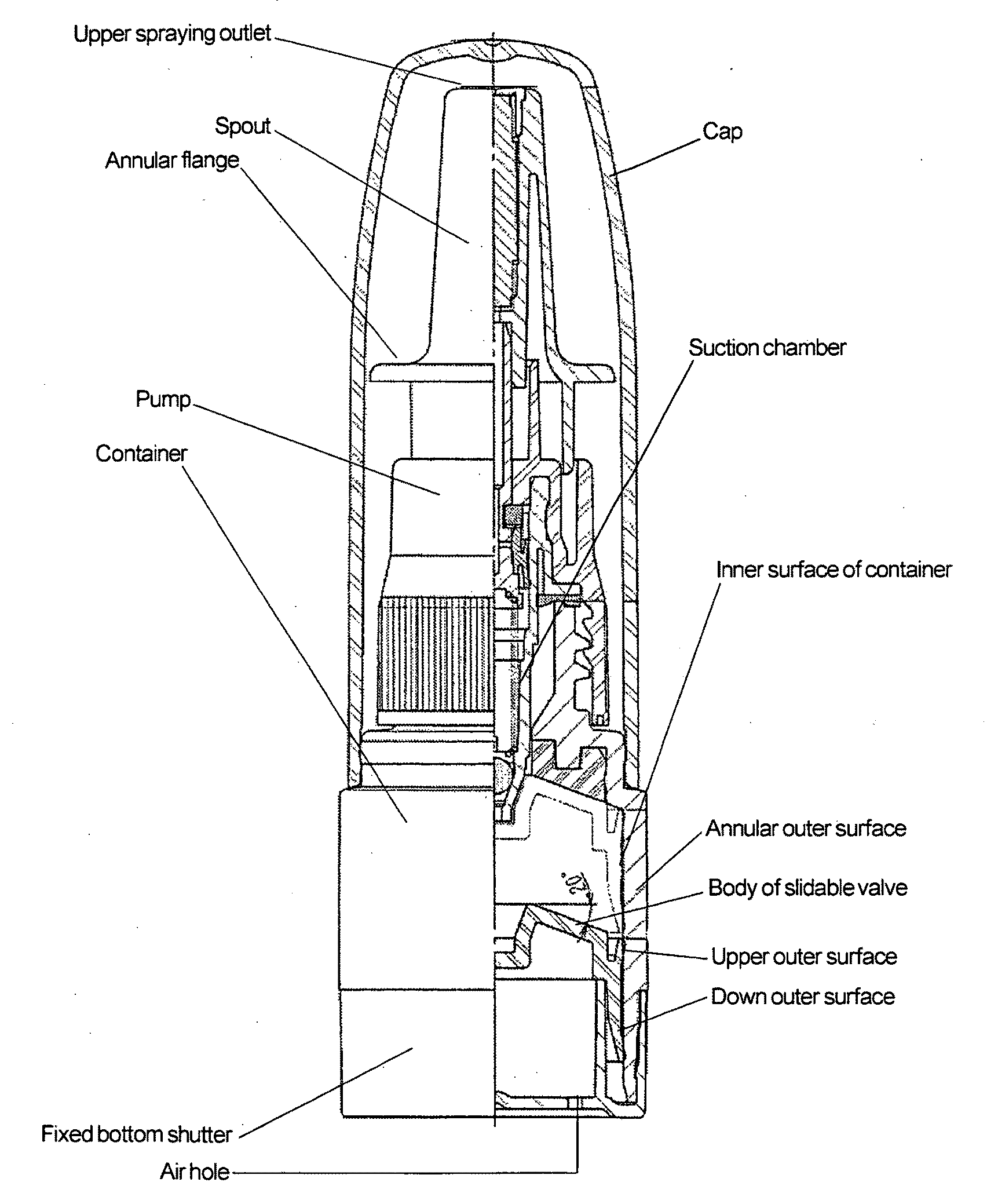

Liquid raw material supply unit for vaporizer

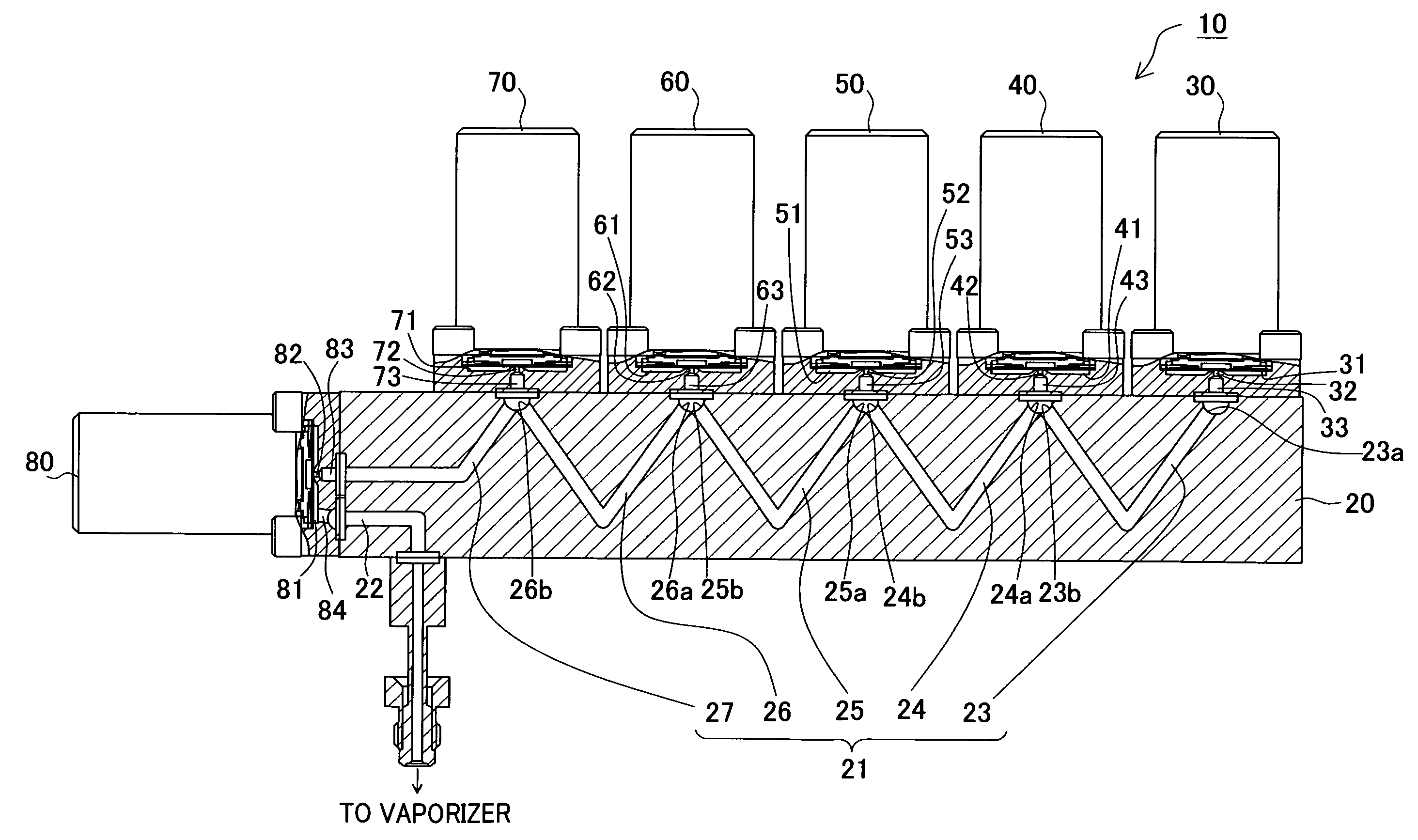

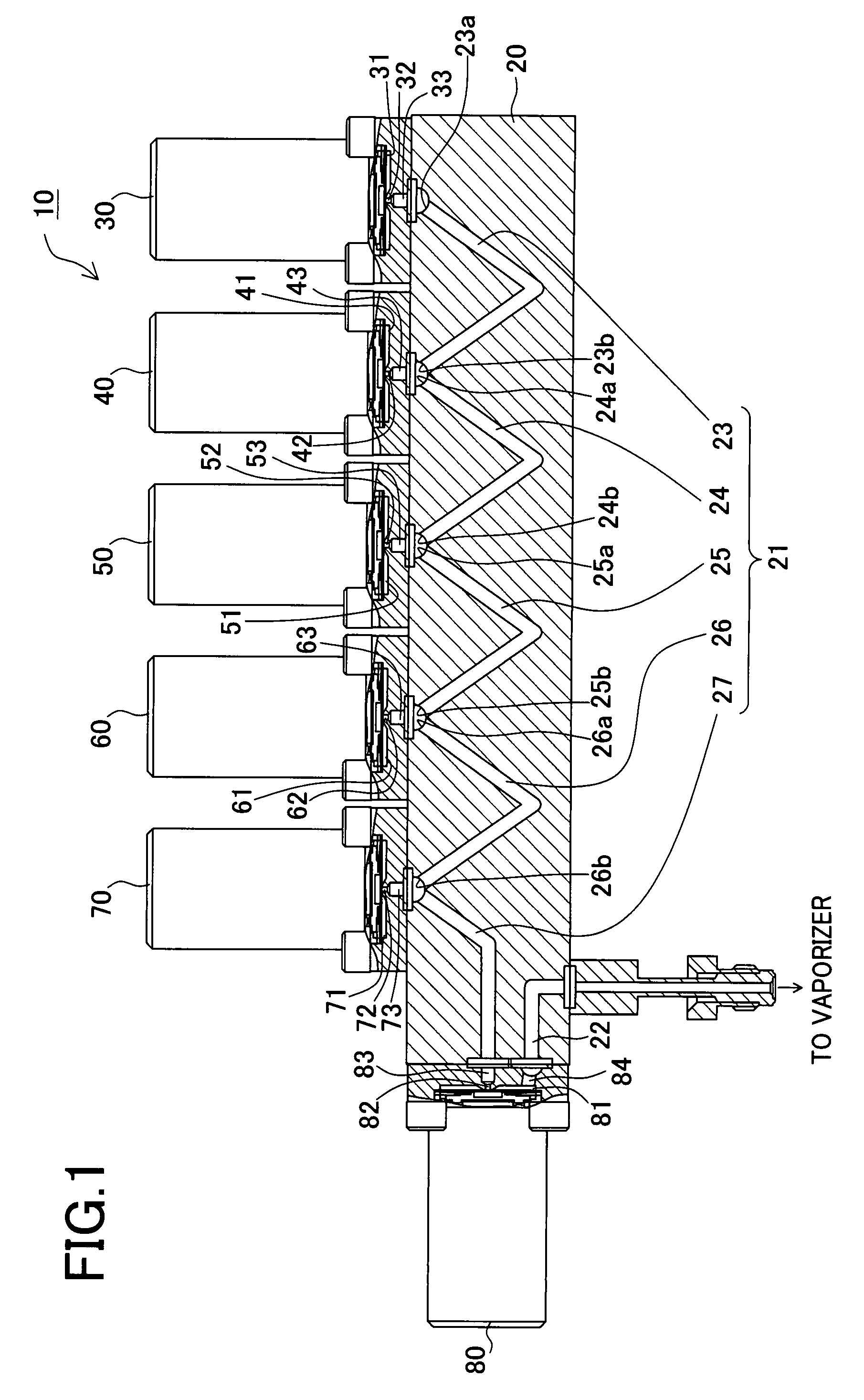

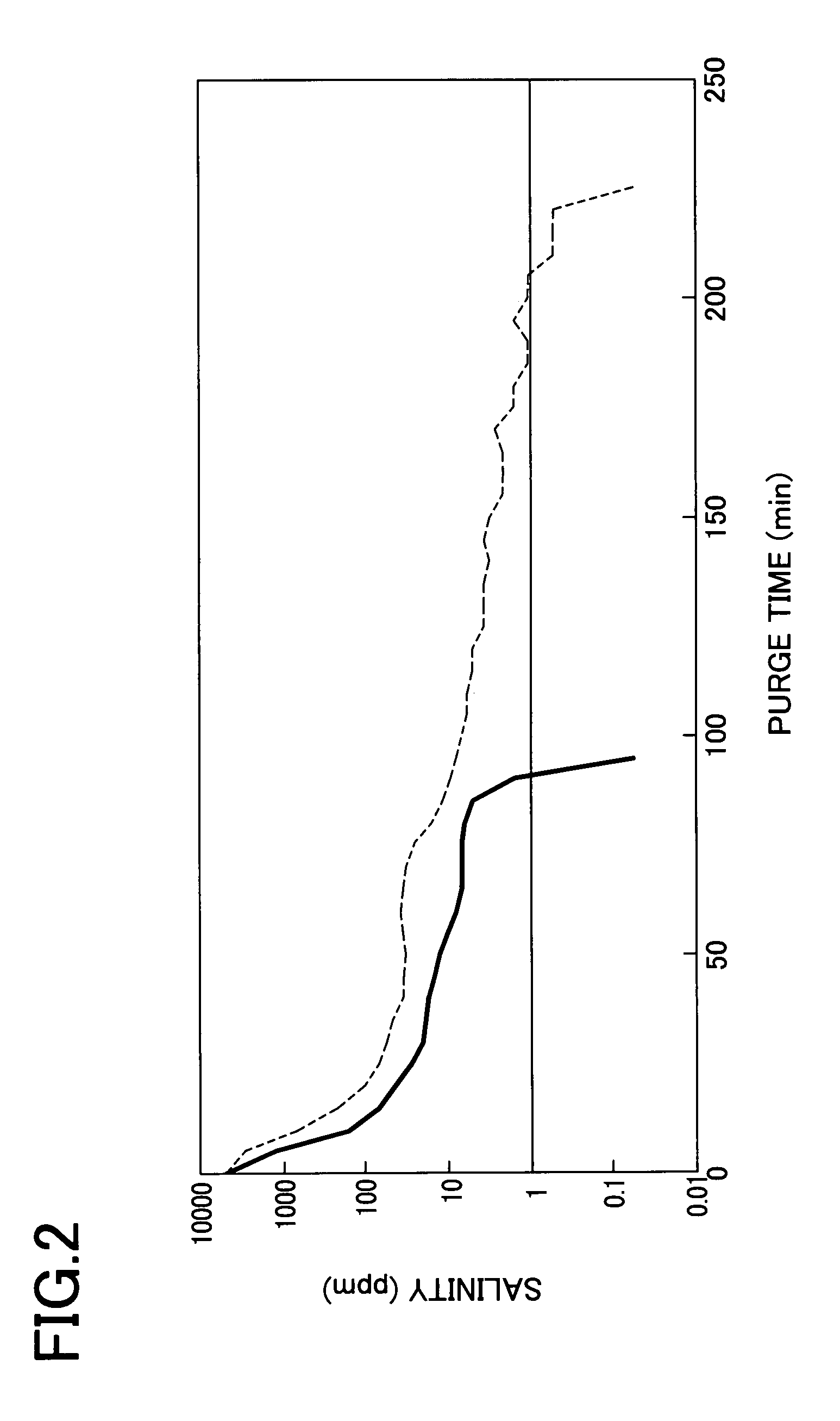

ActiveUS7343926B2Reducing liquid remaining and staying zoneIncrease the residual ratePlug valvesDiaphragm valvesFluid controlProduct gas

A liquid raw material supply unit for a vaporizer is adapted to supply a liquid raw material to the vaporizer that vaporizes the liquid raw material. The unit comprises: a manifold internally formed with a flow passage; and a plurality of fluid control valves mounted on the manifold, wherein the plurality of fluid control valves includes: a liquid raw material control valve for controlling supply of the liquid raw material to the flow passage; a cleaning solution control valve for controlling supply of a cleaning solution to the flow passage; a purge gas control valve for controlling supply of a purge gas to the flow passage; and a first introducing control valve connectable to the vaporizer for controlling supply of a fluid from the flow passage to the vaporizer, the purge gas control valve, the cleaning solution control valve, the liquid raw material control valve, and the first introducing control valve being mounted on the manifold in this order from an upstream side of the manifold, wherein the flow passage is connected to valve ports of the plurality of control valves respectively, the valve ports communicating with valve openings of the respective control valves, and the flow passage is configured to allow the purge gas supplied from the purge gas control valve to directly flow in the valve ports of the cleaning solution control valve and the liquid raw material control valve placed downstream from the purge gas control valve.

Owner:CKD +1

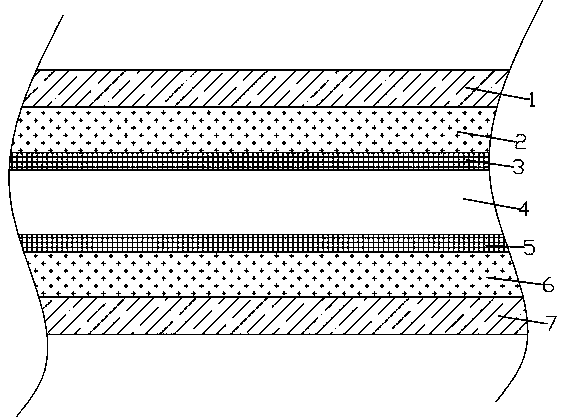

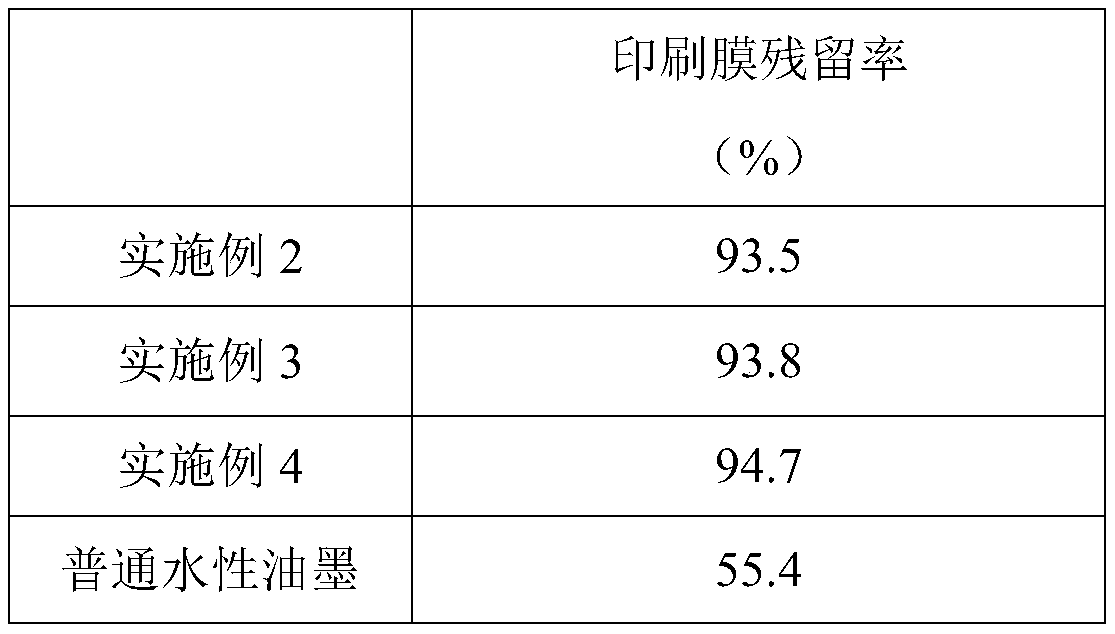

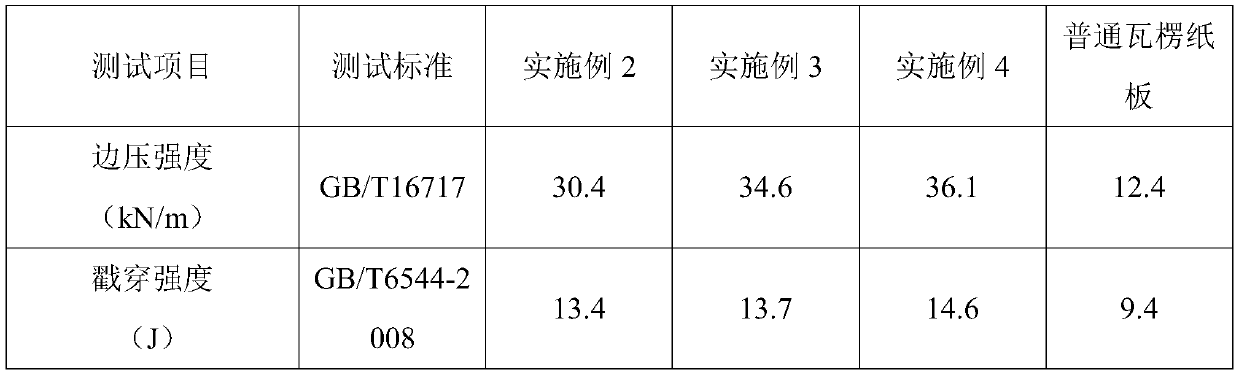

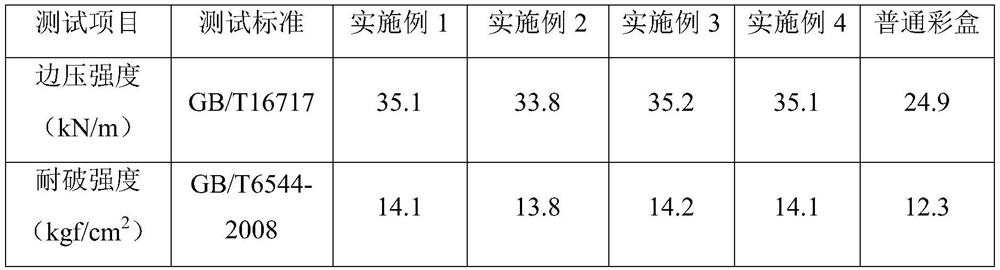

Environment-friendly water-based ink, environment-friendly high-strength damping corrugated paper box and manufacturing method of corrugated paper box

ActiveCN110343423AImprove adhesionImprove water resistanceSynthetic resin layered productsLaminationWater basedEnvironmental resistance

The invention discloses environment-friendly water-based ink, an environment-friendly high-strength damping corrugated paper box and a manufacturing method of the corrugated paper box. The environment-friendly water-based ink is prepared from the following raw materials in parts by weight: 60-70 parts of water-soluble acrylic resin, 20-25 parts of water-based polyurethane resin, 7-10 parts of pigment, 12-15 parts of color paste, 0.75-0.85 part of a defoaming agent, 0.4-0.55 part of a flatting agent, 3-5 parts of a thickening agent, 0.7-0.9 part of a coalescing agent and 3-6 parts of tea polyphenol. According to the environment-friendly water-based ink disclosed by the invention, the raw materials are carefully selected, and the content of each raw material is optimized, so that the residual rate of the prepared environment-friendly water-based ink on a printed film is much larger than the residual rate of conventional water-based ink, adhesive force is higher, and water resistance is better. Patterns and / or characters on the surface of the corrugated paper box are not blurred or fallen off easily in a using process, and attractiveness and use experience can be ensured.

Owner:聚隆(福建)包装有限公司

Syringe needle

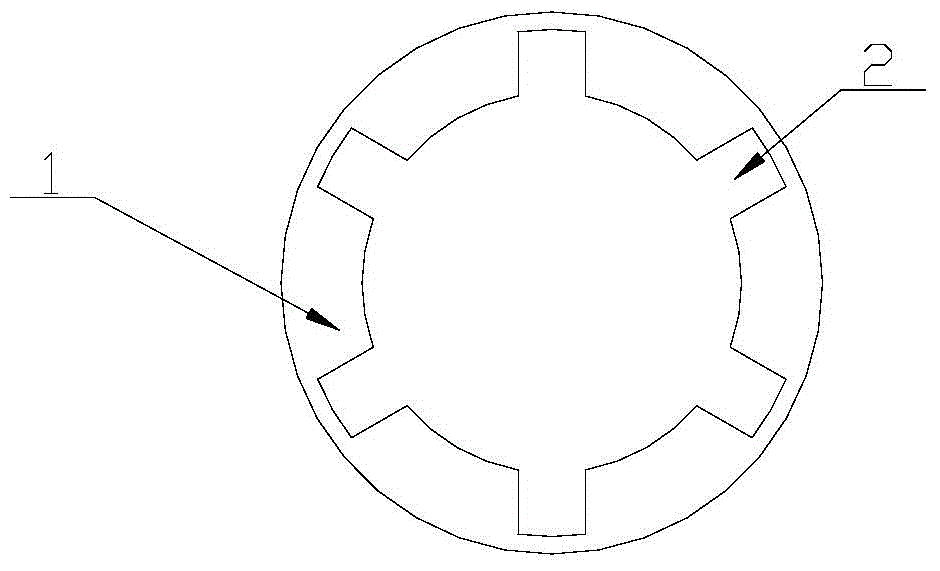

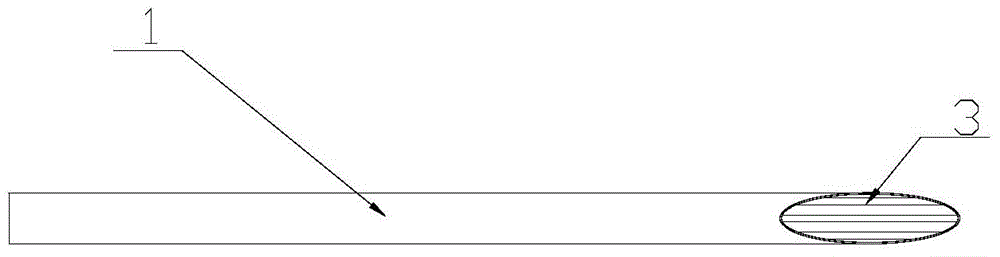

InactiveCN105615928AIncrease the residual rateImprove extraction success rateSurgical needlesApparatus instrumentsSyringe needle

The invention relates to the technical field of medical apparatus and instruments, and in particular relates to a syringe needle which is characterized in that the inner wall of the syringe needle is of a concave-convex rough surface structure. The syringe needle has the beneficial effects that the structure of the inner wall of the syringe needle is changed, under B-ultrasonic localization, a needle part of a puncture needle enters the lump part, and the concave-convex rough surface structure of the inner wall of the needle part enables the needle part to have lateral shear force in the rotation process through multi-direction lifting and inserting; in the withdrawing of the needle, the residual rate of the sucked cells on the inner wall of the needle part can be improved, so that enough lesion cells can be sucked, and even more the lesion cells are divided from the root and completely sucked; an operator does not need to pull a needle pintle by hand continuously, and the negative pressure inside a needle tube can be effectively controlled under the coordinated positioning of a baffle and a gap, so that the sucking success rate can be improved, a satisfactory smear is prepared, and the lesion nature is judged.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

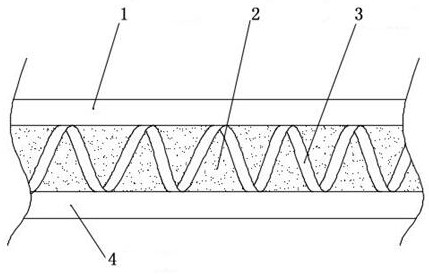

Environment-friendly water-based ink, and environment-friendly high-strength compression-resistant color box and manufacturing method thereof

The invention discloses environment-friendly water-based ink, and an an environment-friendly high-strength compression-resistant color box and a manufacturing method thereof. The environment-friendlywater-based ink is prepared from the following raw materials in parts by weight: 25-35 parts of epoxy acrylic resin, 10-15 parts of fluorosilicone modified acrylate emulsion, 5-8 parts of hydroxy cellulose, 10-30 parts of colorant, 5-20 parts of nano calcium carbonate, 1-3 parts of cerium dioxide, 0-11 parts of butyl cellosolve, 5-10 parts of triethanolamine, 0.5-0.8 part of defoamer, 0.5-1.0 partof sodium hexametaphosphate, 0.5-1.1 parts of trimethoprim, 0.5-1.5 parts of an auxiliary agent, 15-25 parts of deionized water and 3-5 parts of isopropanol. According to the invention, the corrugated paper of the middle layer of the color box is folded into a corrugated structure, so that the stability of the structure of the middle layer is improved, and the situation that the corrugated paperis impacted and deformed, and consequently the corrugated structure in the corrugated paper is damaged is reduced.

Owner:晋江市顺力纸箱有限公司

Preparation method of soft-film type degradable dust suppressant

ActiveCN106010451ANo cracking phenomenonImprove wetting abilityOther chemical processesInorganic saltsLiquorices

The invention relates to a preparation method of a soft-film type degradable dust suppressant and belongs to the field of preparation of dust suppressants. According to the method, firstly, glycyrrhizin containing rich carboxyl is extracted from liquorice roots to serve as a modifier, corn straw is extruded, made into pulp and mixed with glycyrrhizin, the mixture is subjected to biological modification through a compound enzyme preparation and then discharged, and the emulsive soft-film type degradable dust suppressant is obtained. After the prepared dust suppressant is applied, a soft film is formed on the surface of a material, and the dust suppressant has extremely high wettability and adsorbability, does not contain corrosive moisture-absorbing inorganic salt, solves the problem that a traditional hard shell type dust suppressant is easy to break and the dust suppression effect is influenced, is prepared from pure biomass which is easy to degrade, overcomes the defects that the traditional hard shell adhesion type dust suppressant is not easy to degrade, has high residual rate and can cause secondary pollution easily and has broad application prospect.

Owner:宁波绿拾光新材料有限公司

Soft flame retardant cable material and preparation method thereof

The invention discloses a soft flame retardant cable material. The soft flame retardant cable material comprises the following raw materials by weight: 30-40 parts of polyolefin resin, 15-28 parts ofrecycled polyethylene, 13-25 parts of high impact resistant polypropylene, 8-15 parts of vinisol, 5-10 parts of hollow glass microsphere, 4-9 parts of coated nanometer fly ash, 2-3 parts of plasticizer, 5-10 parts of nanometer calcium carbonate, 1-3 parts of zinc stearate, 2-4 parts of trioctyl trimellitate, 1-2 parts of dioctyl sebacate, 2-4 parts of barium stearate, 3-6 parts of triethyl citrate, 1-2 parts of antioxidant, and 5-10 parts of aluminum hydroxide. The soft flame retardant cable material is relatively low in cost, the performance meets the standard request, and the problems that alarge quantity of toxic smoke and corrosive gases produced in the combustion of the existing flame retardant cable in the fire disaster greatly damage survivors and rescue workers and pollute the environment are solved.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Preparation method of composite material based on epoxy resin and phosphazene nanotubes

The invention relates to a preparation method of a composite material based on epoxy resin and phosphazene nanotubes, which belongs to the technical field of nano materials. The preparation method comprises the following steps: under ultrasonic conditions, adding acid binding agent into tetrahydrofuran; adding 4,4'-dihydroxy-diphenyl sulfone and hexachlorocyclotriphosphazene to carry out condensation reaction; adding epoxy chloropropane; dropwise adding sodium hydroxide water solution; heating to carry out water bath reaction, thereby obtaining epoxide group modified phosphazene nanotubes; adding the epoxide group modified phosphazene nanotubes into the acetone dissolved epoxy resin, adding epoxy resin curing agent, carrying out ultrasonic dispersion, removing acetone in a vacuum drying oven at low temperature, and pouring the mixture into a die; and curing at high temperature to obtain the composite material based on epoxy resin and phosphazene nanotubes. The epoxy resin composite material has the advantages of high shock resistance, tensile property and thermal stability.

Owner:SHANGHAI JIAOTONG UNIV

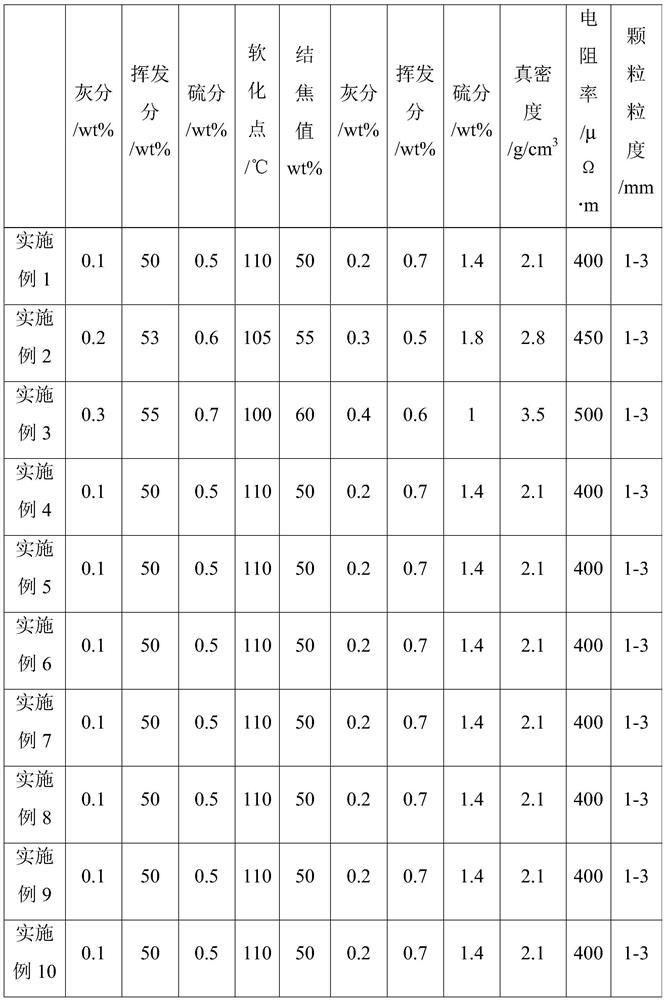

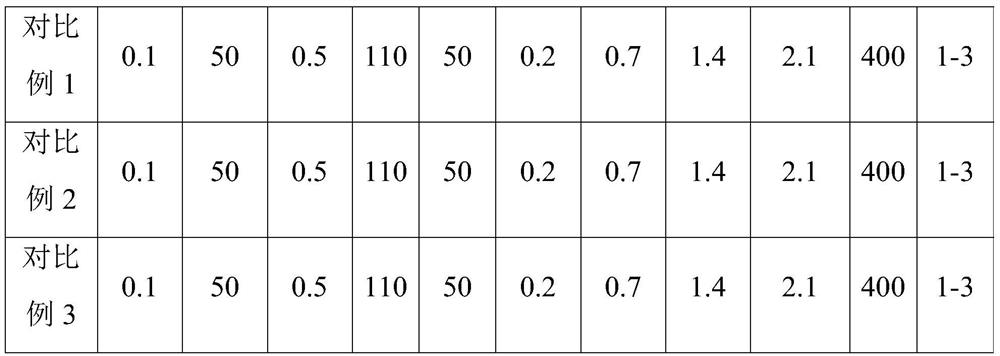

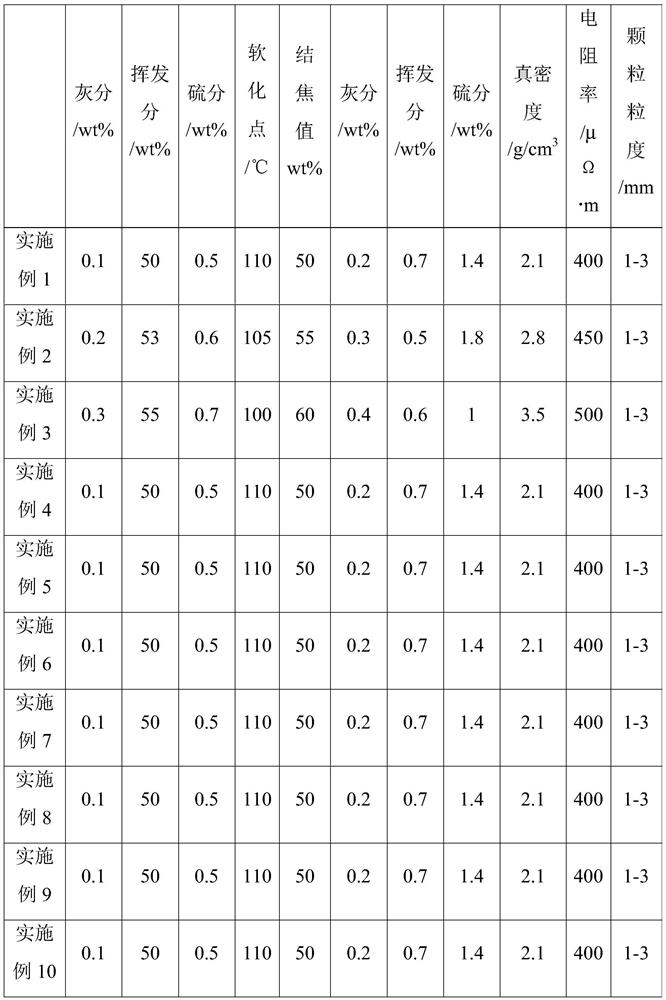

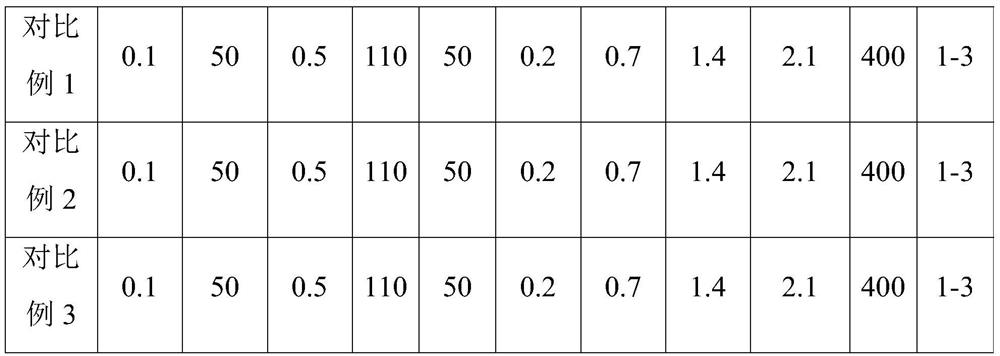

Prebaked anode and preparation method and application thereof

The invention relates to the field of electrolysis, and discloses a prebaked anode and a preparation method and application thereof. The method comprises the steps that modified asphalt and petroleum coke are mixed and kneaded, and an obtained product is roasted to obtain the prebaked anode, wherein the quinoline insoluble substance value of the modified asphalt is 15-19, and the weight ratio of the modified asphalt to the petroleum coke is 1: (8-12). The prebaked anode prepared by the method can achieve the optimal balance between improving the anode scrap rate (namely the anode scrap rate is greater than or equal to 85wt%) and not reducing other parameters, and the other parameters are not lower than those in the prior art, so that the prebaked anode is wide in adaptability.

Owner:山西沁新能源集团股份有限公司

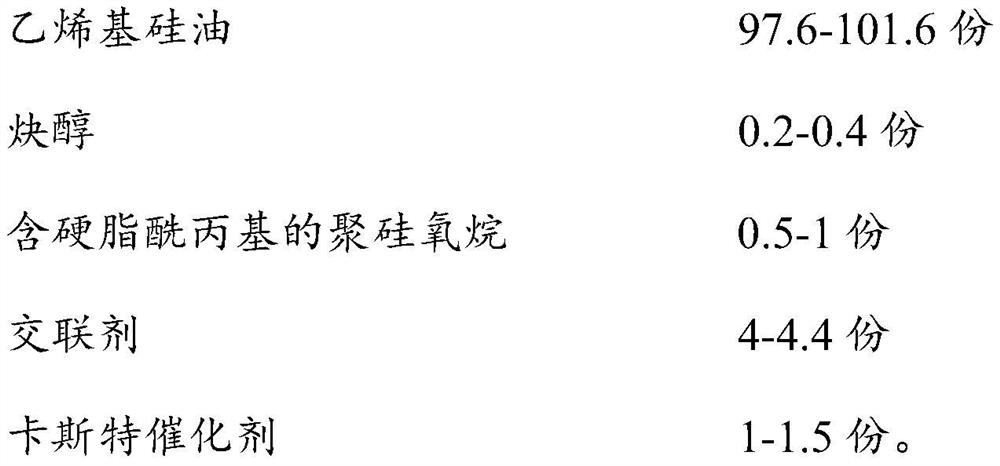

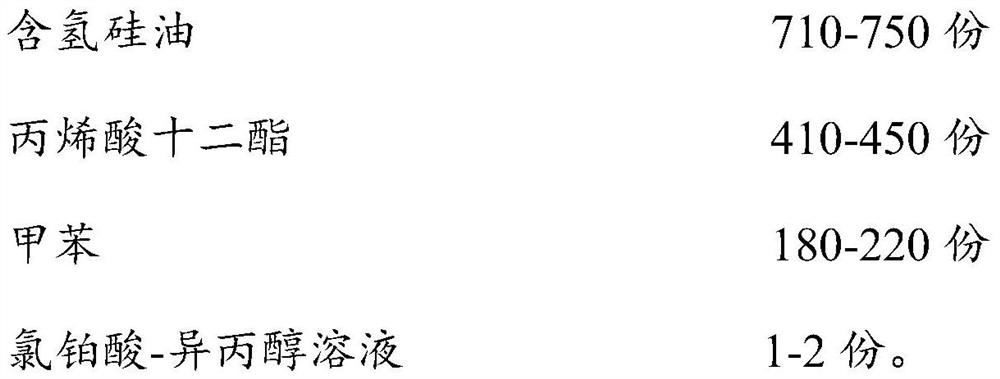

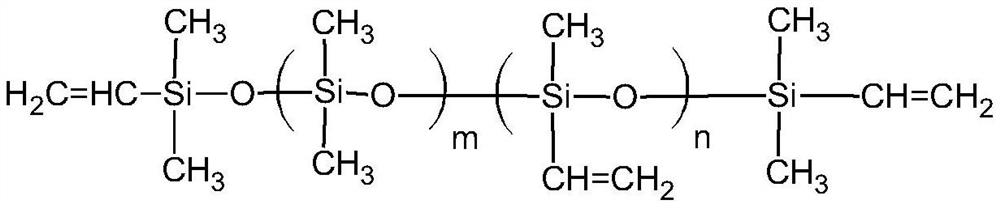

Solvent-free release silicone oil with medium and heavy release force and preparation method of solvent-free release silicone oil

The invention relates to a release silicone oil product, in particular to solvent-free release silicone oil with medium and heavy release force and a preparation method thereof, and the solvent-free release silicone oil with medium and heavy release force comprises the following components: vinyl silicone oil, alkynol, polysiloxane containing stearoyl propyl, a cross-linking agent and a Karst catalyst. The solvent-free release silicone oil product prepared by the invention is wide in application range to a base material, relatively high in cost performance, good in stability and low in stripping noise, an obvious weight increasing effect can be achieved only by using a very small addition amount, and in addition, the solvent-free release silicone oil product is small in release force attenuation amplitude and high in residual rate after being coated with silicon.

Owner:惠州市永卓科技有限公司

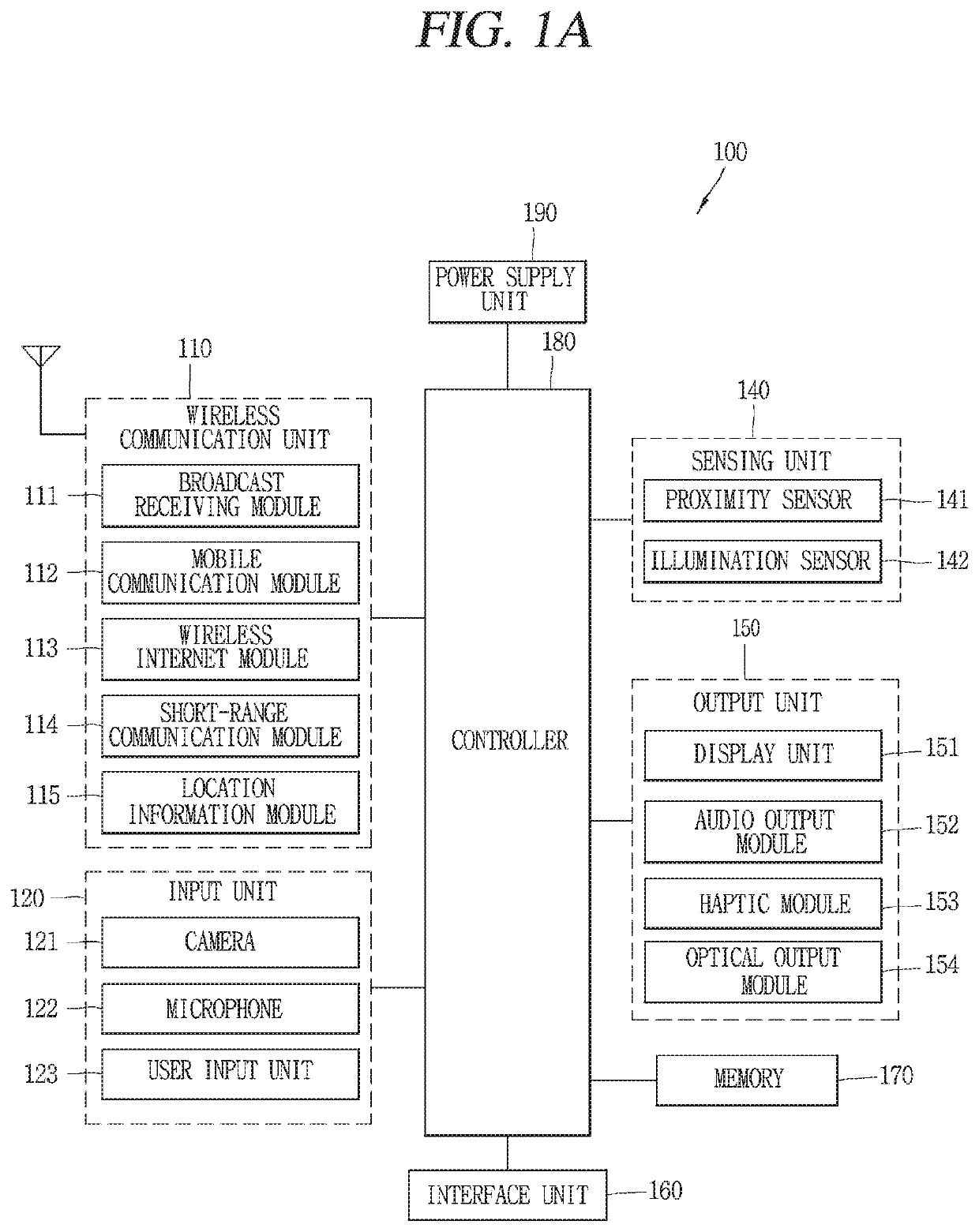

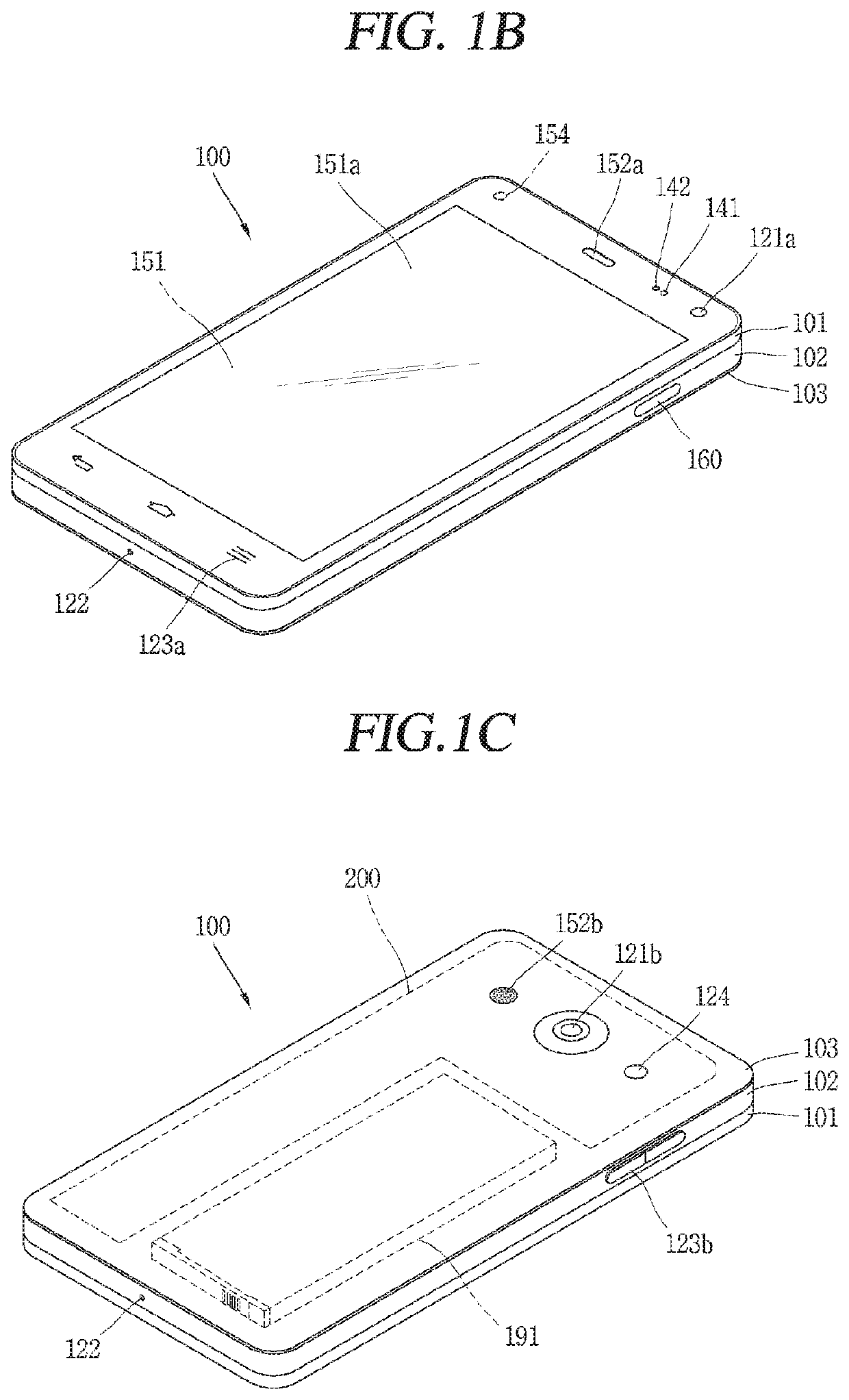

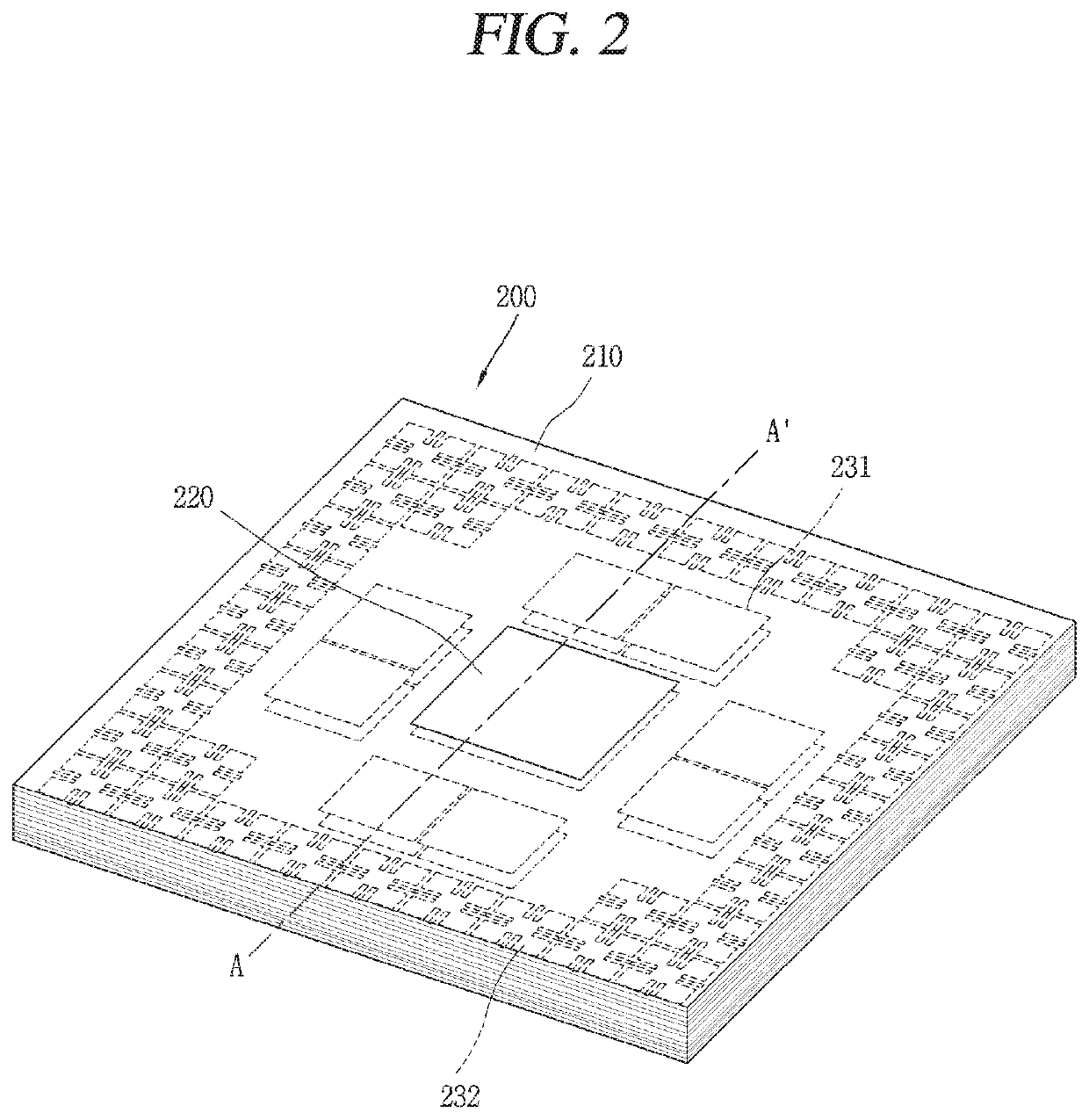

Electronic device

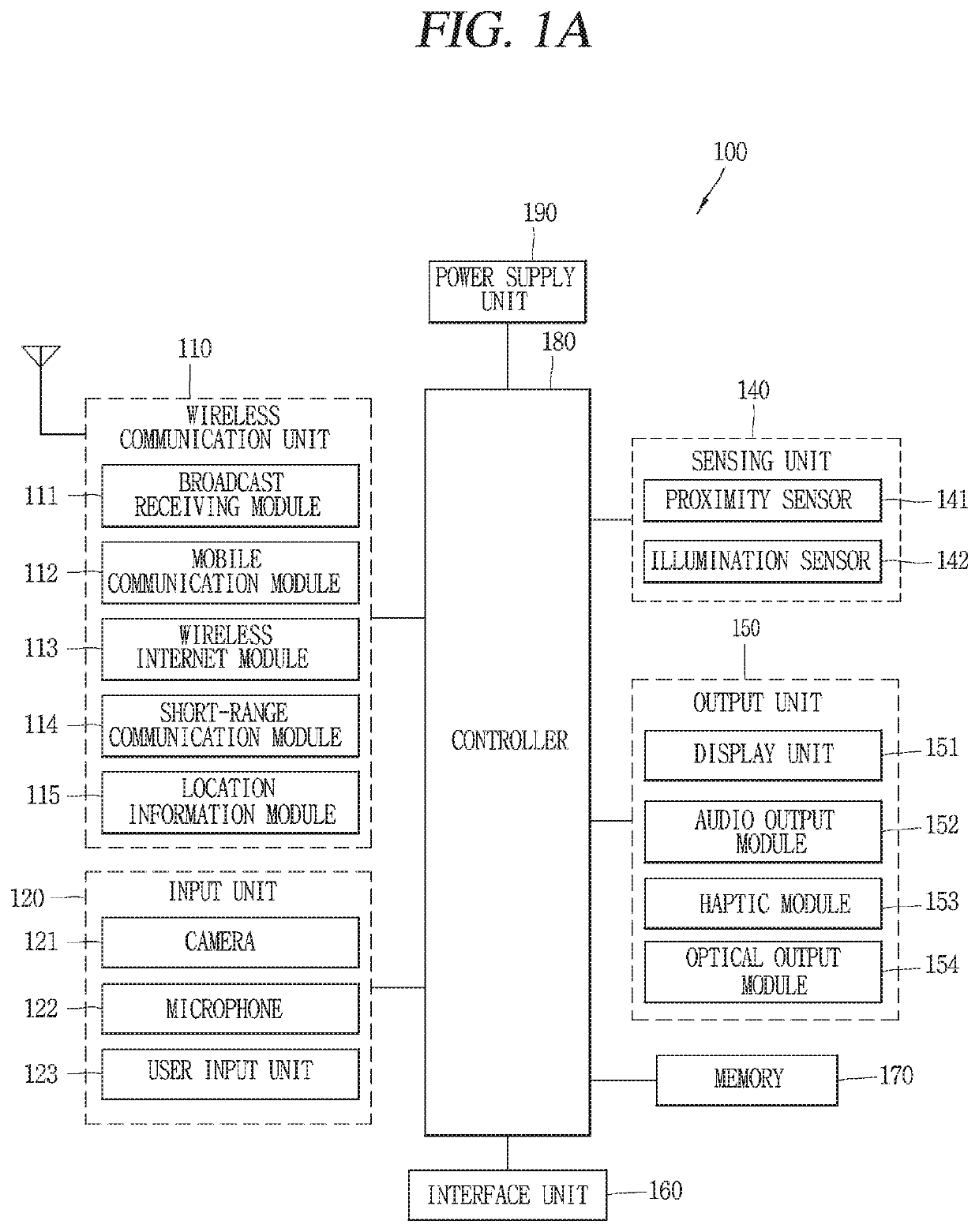

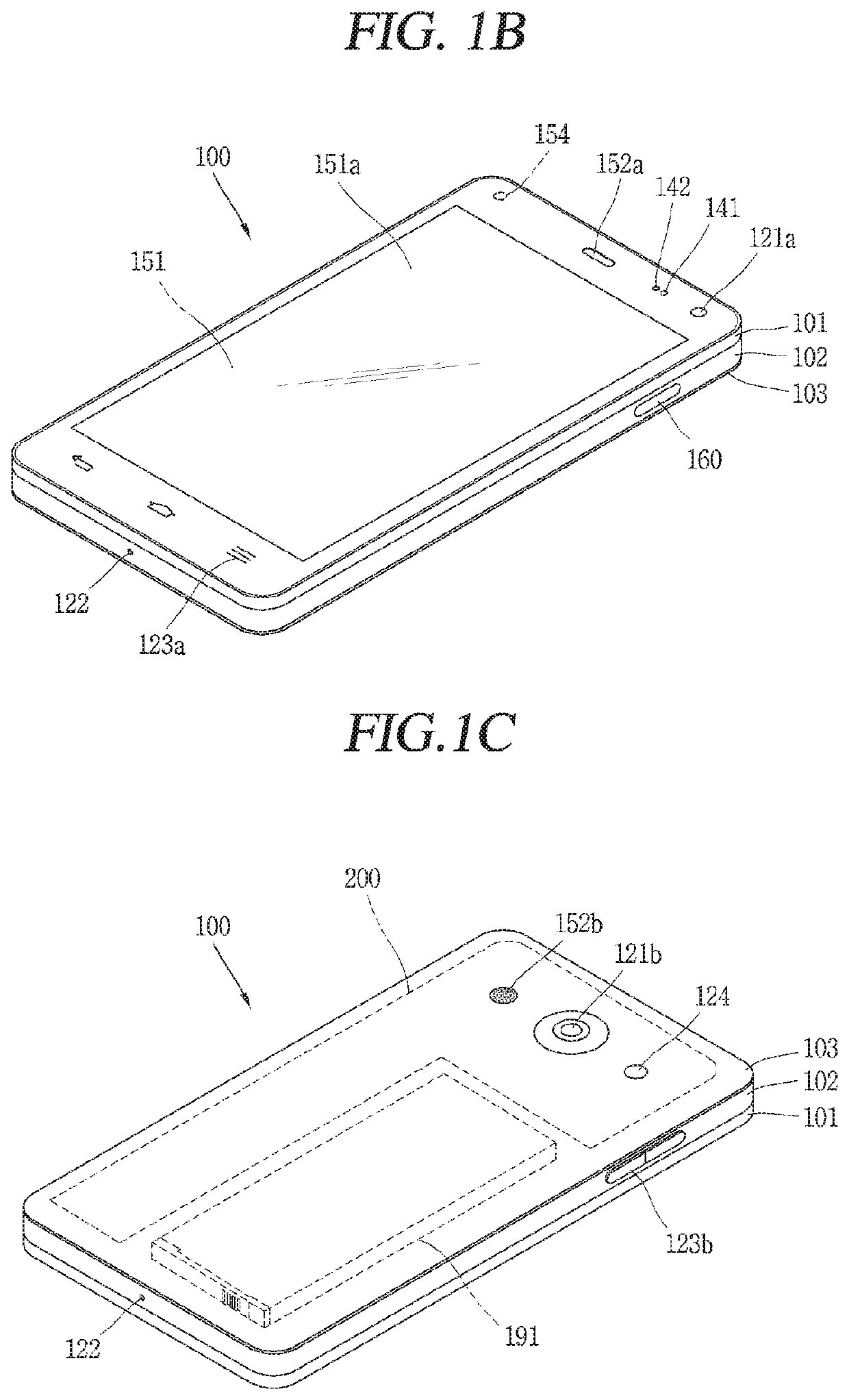

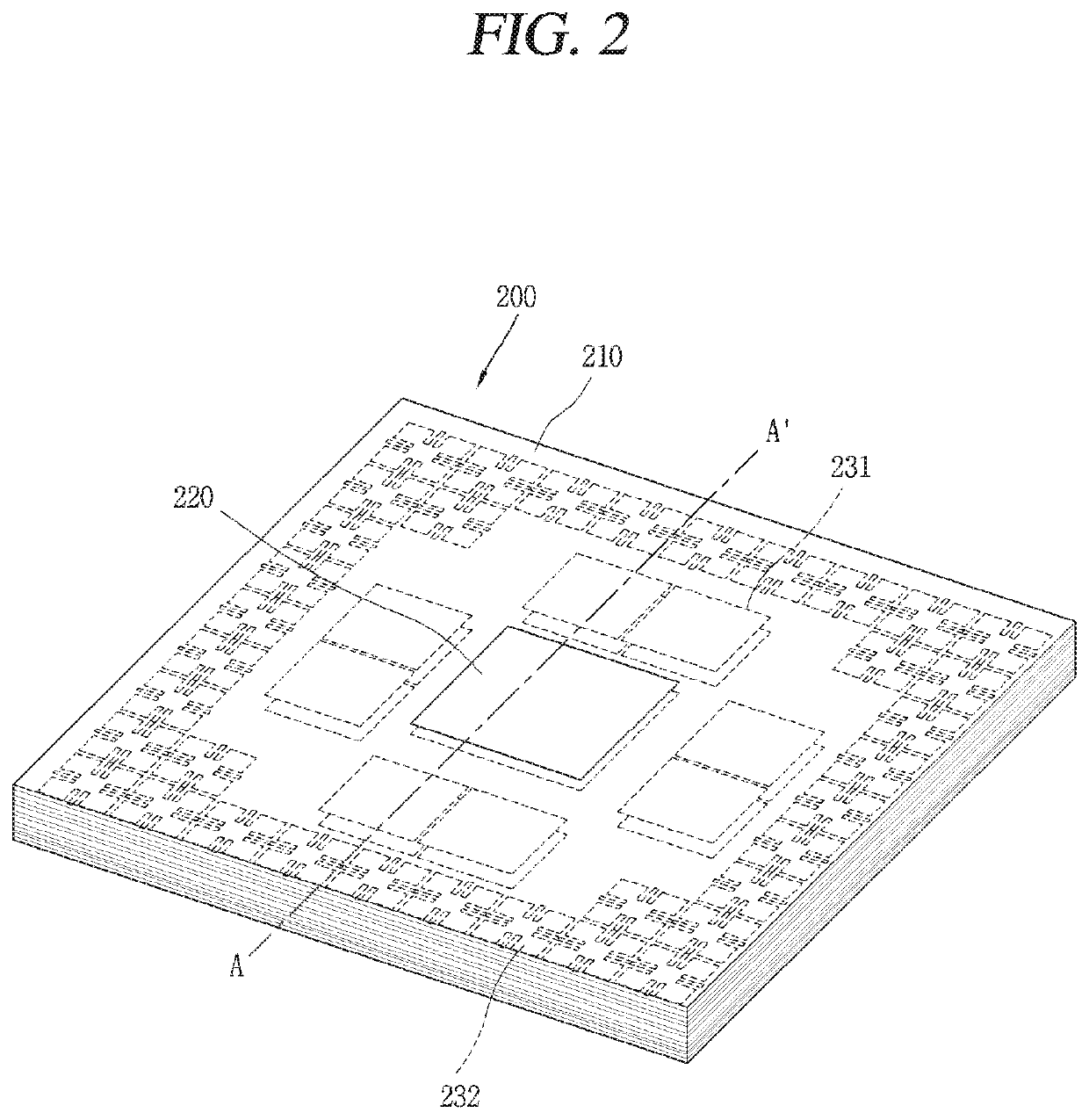

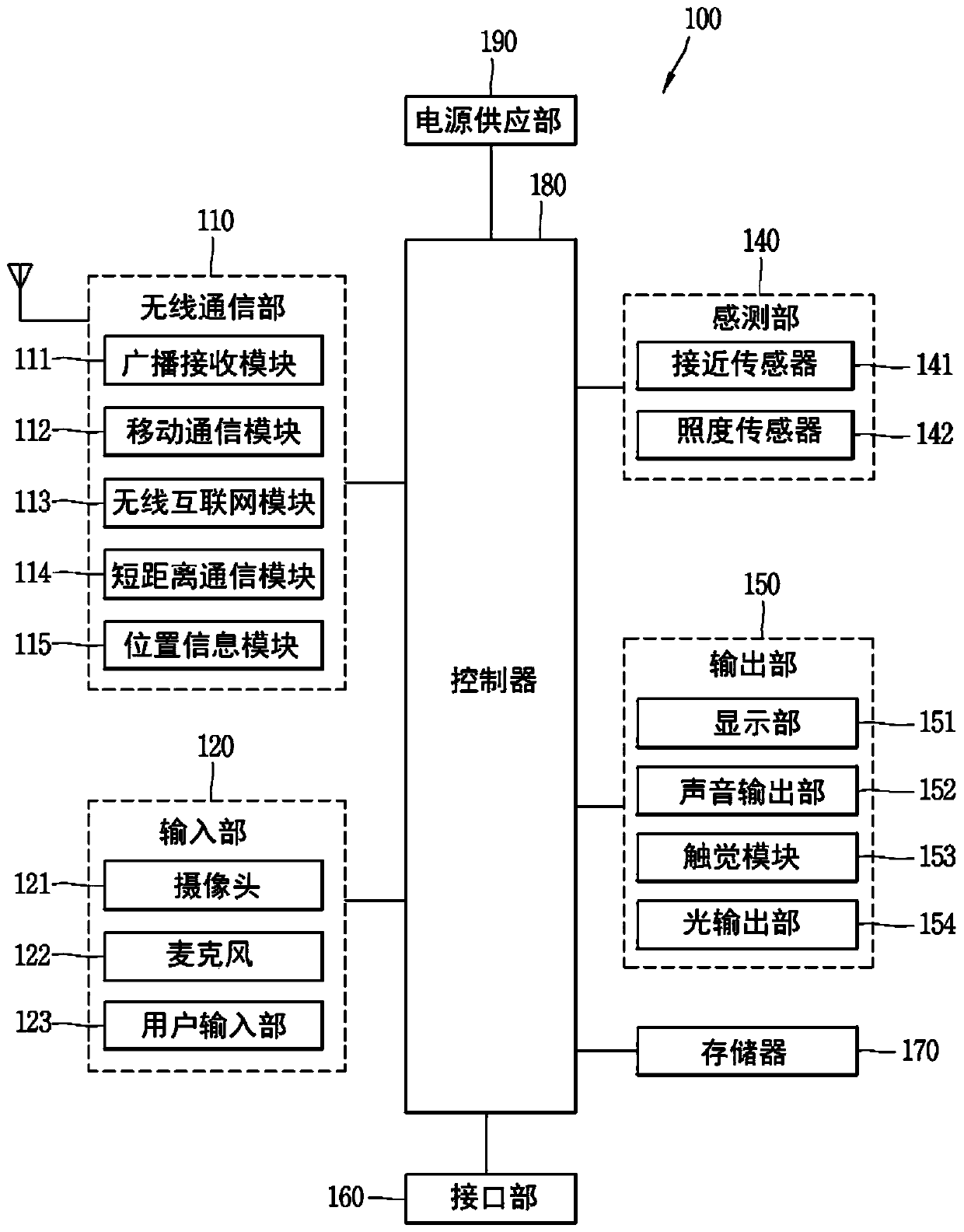

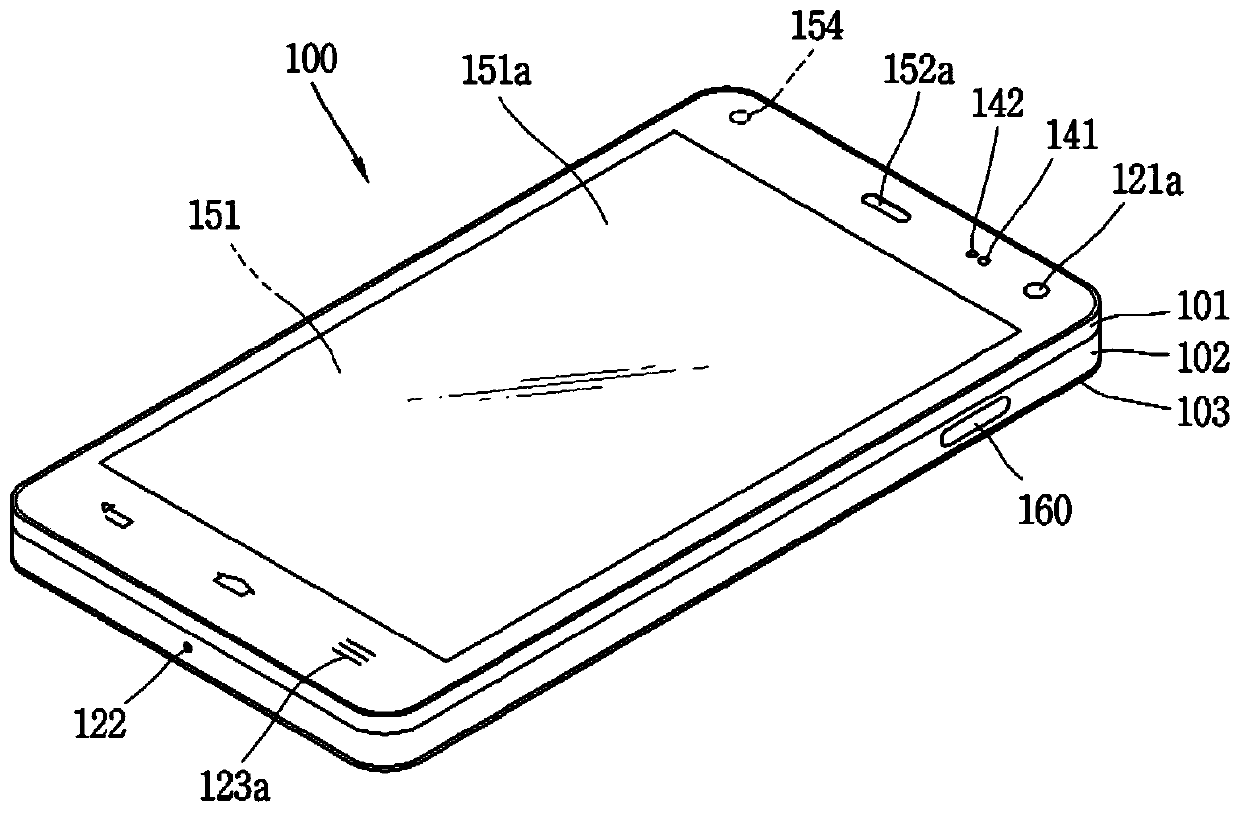

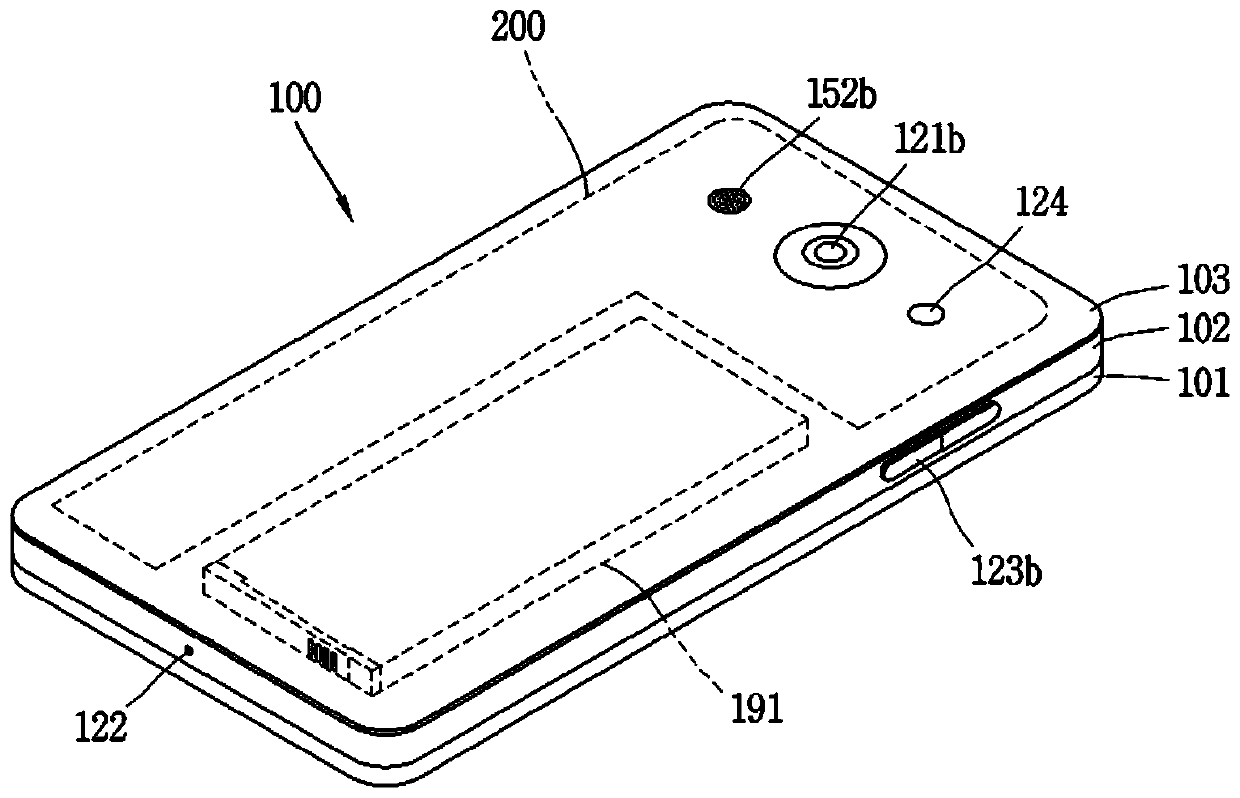

ActiveUS10660198B2Sufficient antenna performance at operating frequencyInhibit deteriorationCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringConductive materials

The present disclosure relates to an electronic device, and the electronic device may include a circuit board provided within a main body of the electronic device, on which a conductive layer made of a conductive material and a dielectric layer made of an insulating material are alternately laminated; at least one or more patch antennas disposed on the circuit board; a core layer located at a central portion inside the circuit board, and configured with any one of the dielectric layers; a ground layer disposed below the core layer; and an EBG structure located inside the circuit board in a symmetrical shape at the top and bottom with respect to the core layer, and the EBG structure restricts operating frequency signals radiated from the respective patch antennas from being interfered with each other.

Owner:LG ELECTRONICS INC

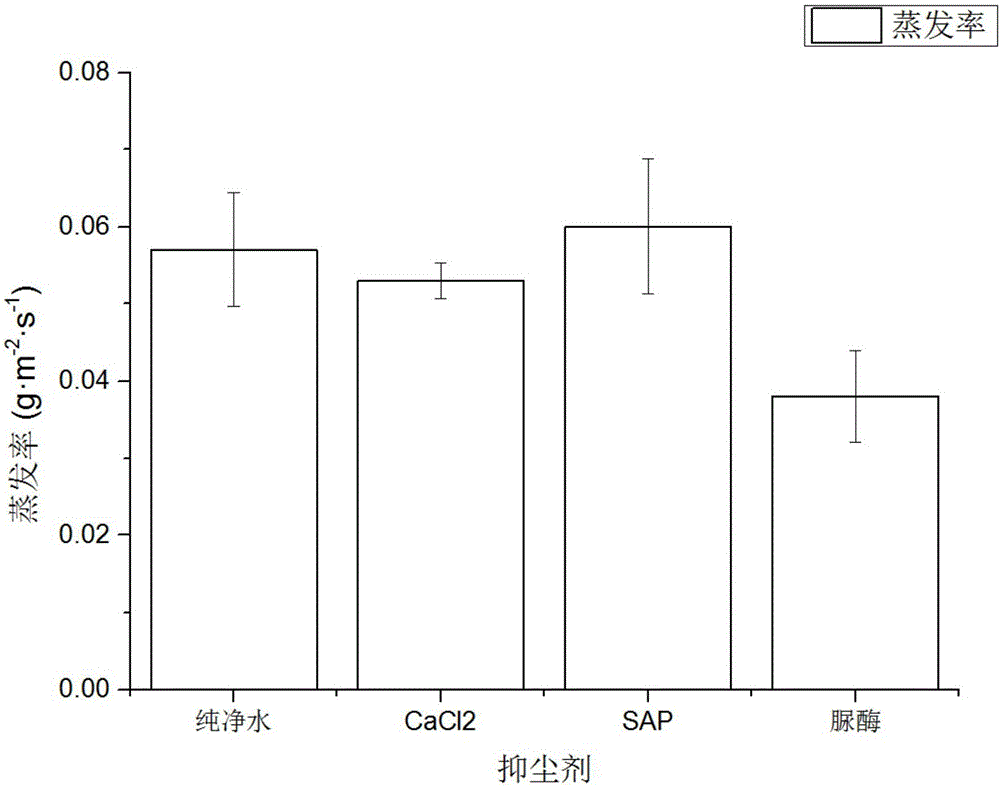

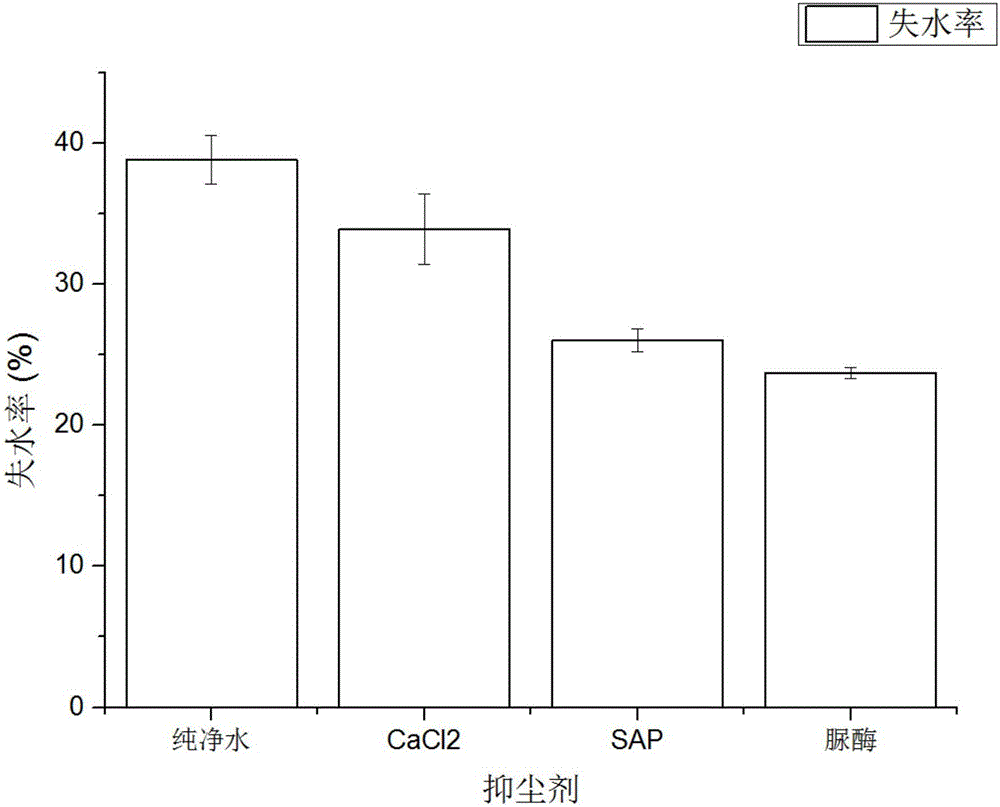

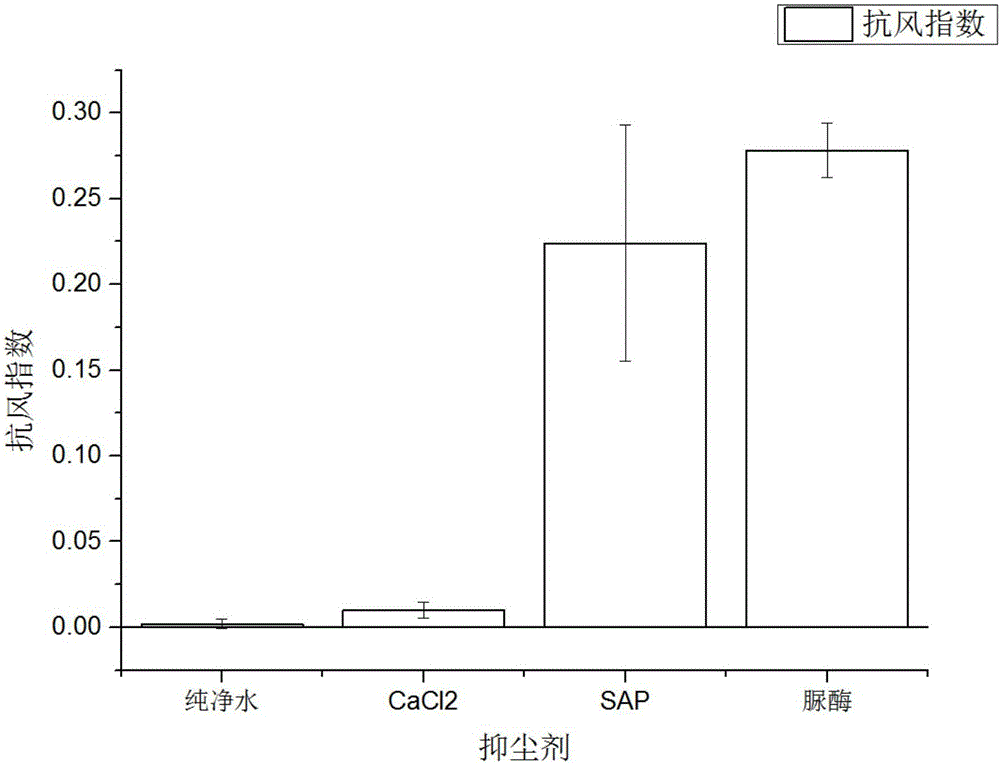

Multifunctional compounded flying dust suppressant prepared on basis of active enzyme

ActiveCN106753248AEnhanced inhibitory effectLong duration of actionOther chemical processesActive enzymeMoisture absorption

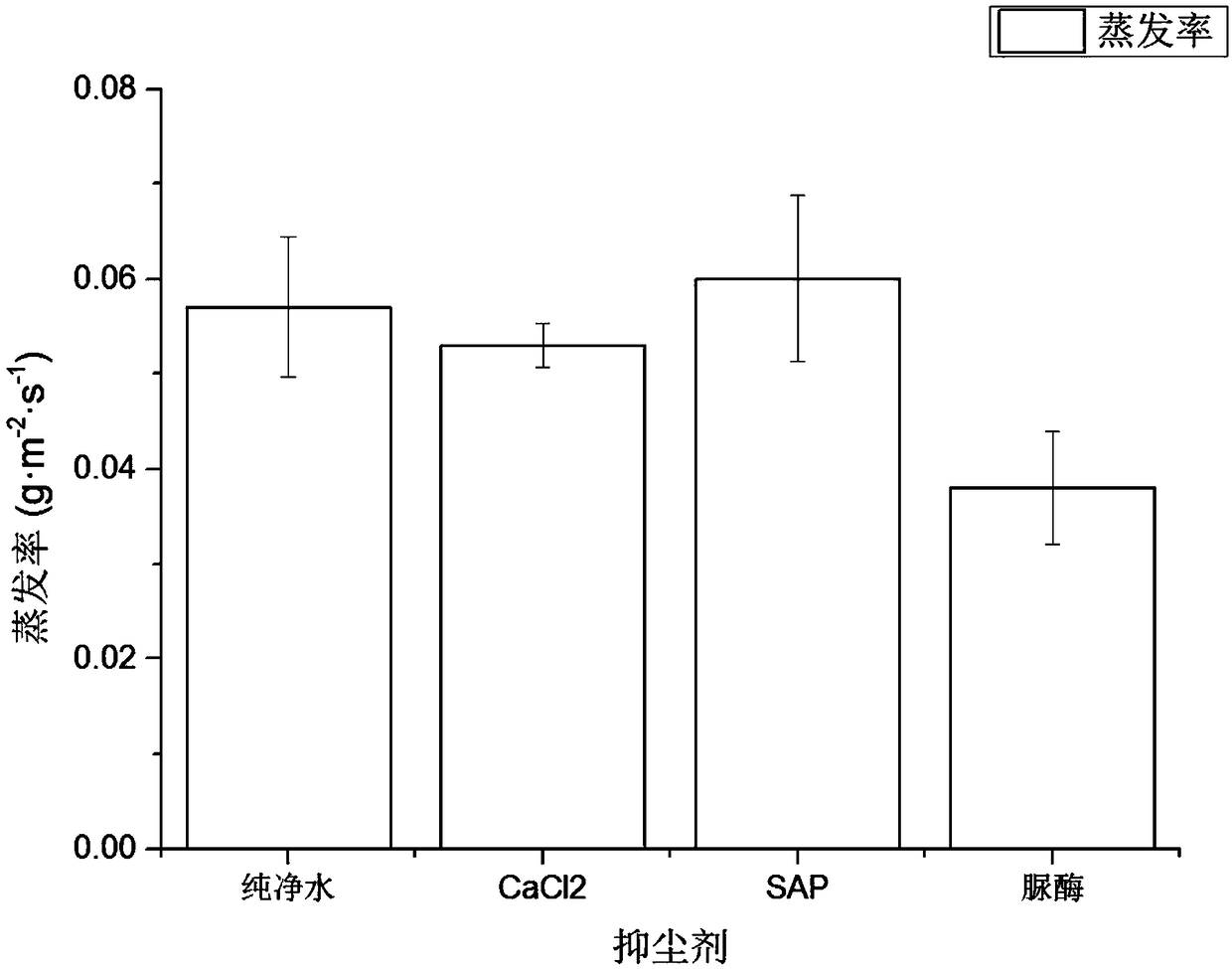

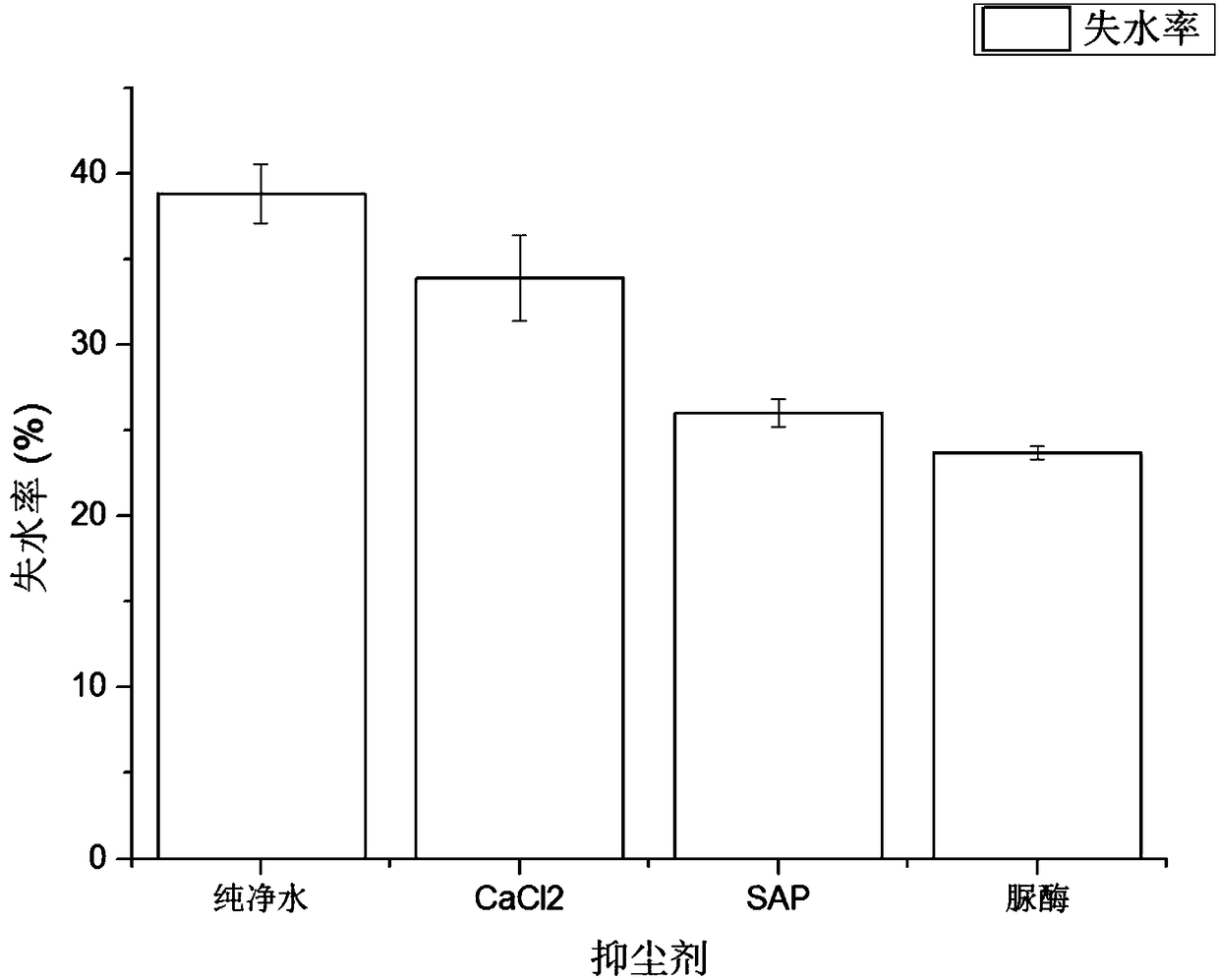

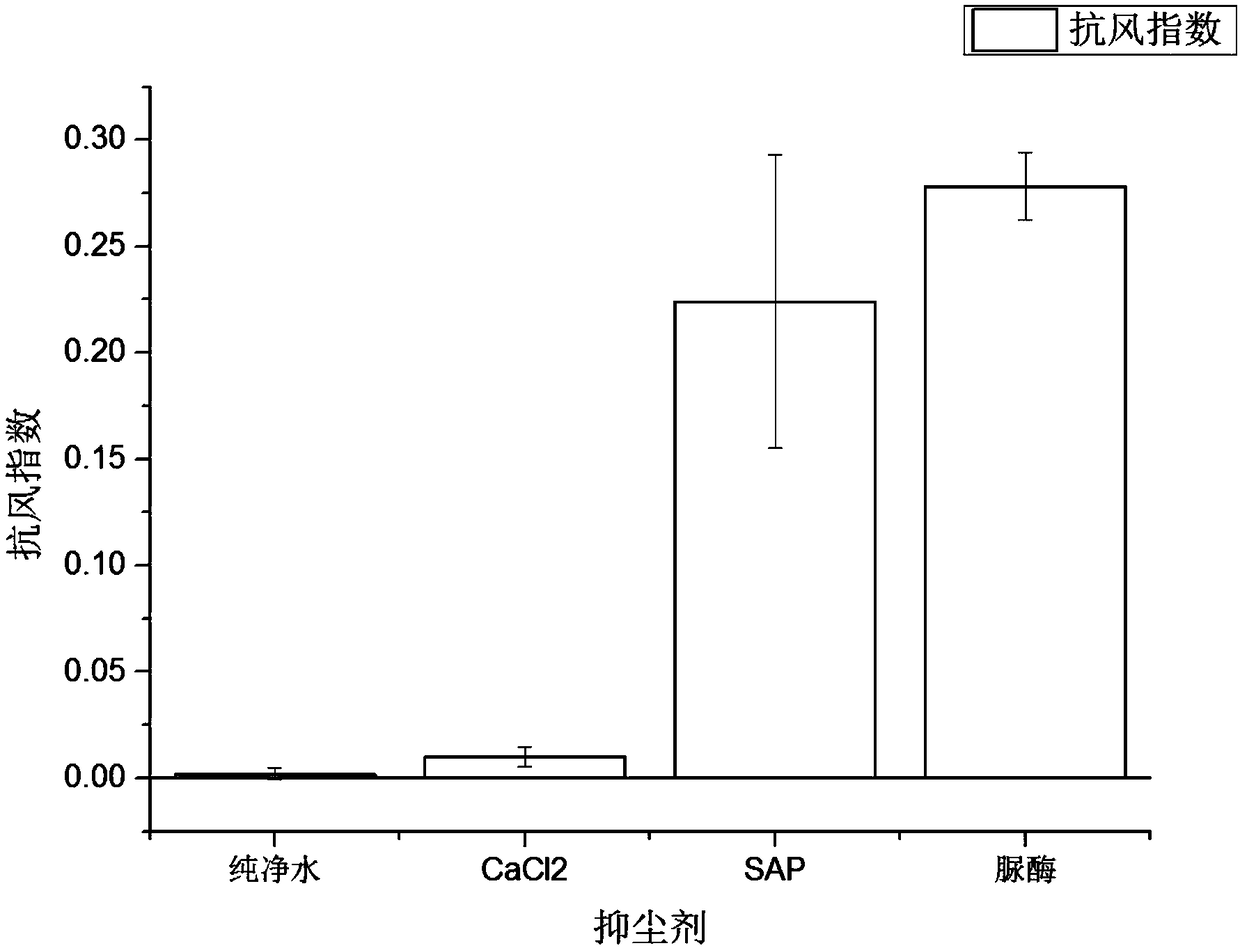

The invention discloses a multifunctional compounded flying dust suppressant prepared on the basis of an active enzyme. The multifunctional compounded flying dust suppressant is prepared from the following raw materials in percentage by weight: 0.28-0.32% of bioactive enzyme, 0.07-0.12% of high-polymer water-absorbing resin, 4.50-5.00% of CO(NH2)2, 4.40-4.50% of CaCl2, 2.20-2.30% of CaO and the balance of water. The bioactive enzyme is urease which is an artificially extracted plant enzyme. The application method of the dust suppressant comprises the following steps: dissolving powder materials in water according to the percentage by weight, uniformly mixing, spraying the mixture on the road surface and stockpile surface, wherein the amount of the mixture is 1-3L for every 1m<2> of the municipal road, and the amount of the mixture is 3-6L for every 1m<2> of the stockpile. By utilizing the principles of moisture absorption, moisture retention, bonding, biodegradation and biological calcification, the dust suppressant effectively enhances the flying dust suppression effect, and has the advantages of long acting duration time, lower secondary flying dust, high reaction speed, high temperature resistance and environment friendliness.

Owner:SOUTHEAST UNIV

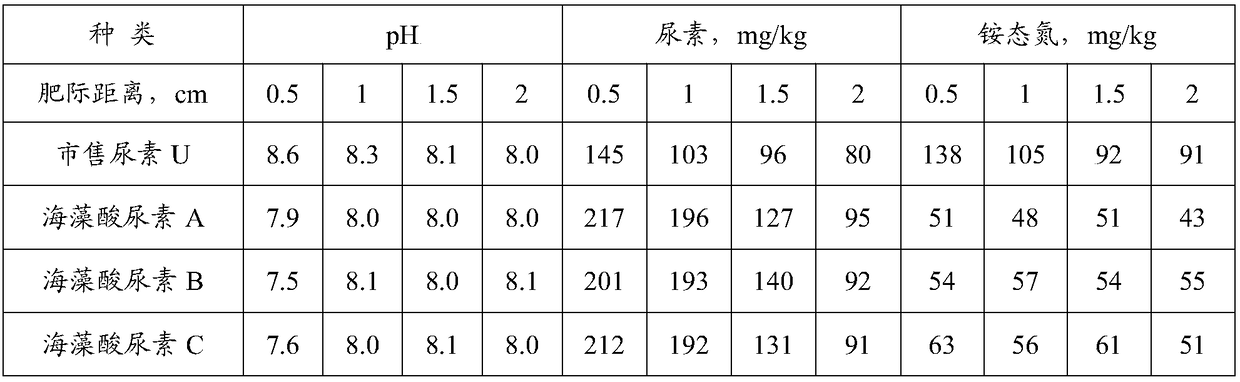

Method for preparing alginic acid synergistic carrier with urea transformation slowing function

InactiveCN109438139ASlow down decompositionReduce conversionUrea compound fertilisersFertilizer mixturesDecompositionAlginic acid

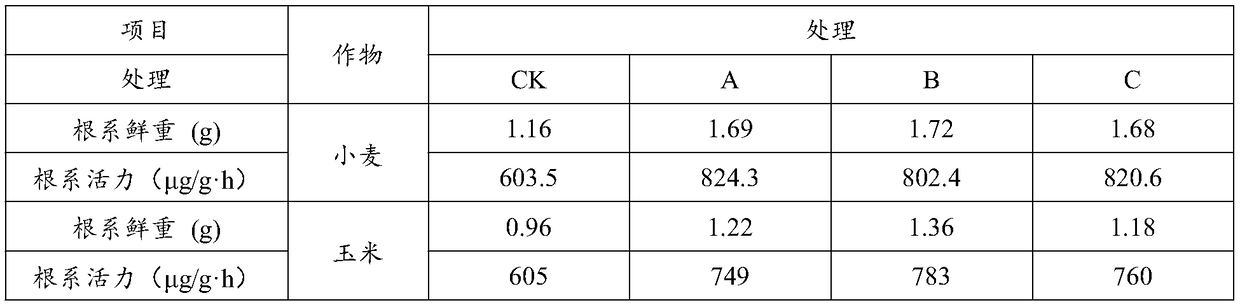

The invention relates to a method for preparing an alginic acid synergistic carrier with a urea transformation slowing function. The method for preparing the alginic acid synergistic carrier with theurea transformation slowing function comprises the steps of alginic acid organic extracting agent preparation, alginic acid extracting liquor preparation, extracting synergistic carrier preparation and the like. Through combination of the alginic acid synergistic carrier and urea, the decomposition, releasing and transformation speed of the urea can be obviously reduced; compared with the urea residual rate of the commercial urea, the urea residual rate of the alginic acid synergistic carrier is increased by 90%; and moreover, the sustained release performance of the urea can be enhanced by affecting fertilizer sphere process, such as pH value of urea transformation; and compared with the commercial urea, the alginic acid synergistic carrier has the advantage that the soil pH value withinthe fertilizer sphere of 1 cm is reduced by 0.3-1.1 units. Compared with the fresh weight and vitality of a contrast, the fresh weight and vitality of a wheat root system treated by the alginic acid synergistic carrier are correspondingly increased by 54.9% and 36.3% on average; and the fresh weight and vitality of a corn root system are correspondingly increased by 38.5% and 26.7%.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

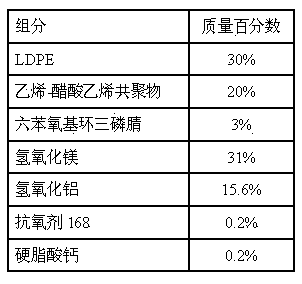

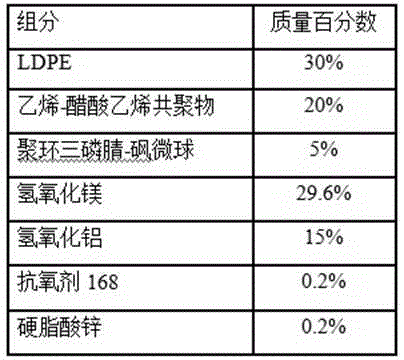

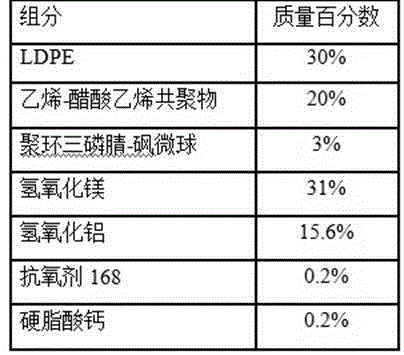

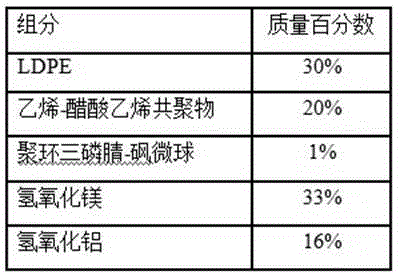

Composite flame retardant cable material containing polycyclotriphosphazene-sulfone microspheres and preparation method thereof

InactiveCN103333382BIncrease the residual rateImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolyphosphazeneMicrosphere

The present invention relates to a polycyclotriphosphazene-sulfone microsphere-containing composite fire retardation cable material and a preparation method thereof. According to the cable material, high cross-linking degree polycyclotriphosphazene-sulfone microspheres, magnesium hydroxide and aluminum hydroxide are adopted as fire retardation agents, such that a residual rate of the cable material at a high temperature can be increased, and thermal stability and fire retardation of the cable material can be increased. The cable material has a characteristic of low smoking, and does not contain lead, antimony and other toxic substances, such that the cable material is a green environmental protection type material. With polyphosphazene microsphere addition, filling amounts of magnesium hydroxide and aluminum hydroxide can be reduced, and mechanical property of the material can be increased while fire retardation of the material is improved. With lubricant addition, a processing performance of the material can be increased. In addition, the cable material is a novel efficient fire retardation cable material.

Owner:SHANGHAI UNIV +1

Electronic device

ActiveUS20200245452A1Sufficient antenna performance at operating frequencyInhibit deteriorationCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringConductive materials

The present disclosure relates to an electronic device, and the electronic device may include a circuit board provided within a main body of the electronic device, on which a conductive layer made of a conductive material and a dielectric layer made of an insulating material are alternately laminated; at least one or more patch antennas disposed on the circuit board; a core layer located at a central portion inside the circuit board, and configured with any one of the dielectric layers; a ground layer disposed below the core layer; and an EBG structure located inside the circuit board in a symmetrical shape at the top and bottom with respect to the core layer, and the EBG structure restricts operating frequency signals radiated from the respective patch antennas from being interfered with each other.

Owner:LG ELECTRONICS INC

Electronic device

ActiveCN111149342AIncrease the residual rateImprove rigidityAntenna arraysCross-talk/noise/interference reductionElectrically conductiveGround plane

The present invention relates to an electronic device comprising: a circuit board installed inside the body of the electronic device and formed by alternately laminating conductive layers made of a conductive material and dielectric layers made of an insulative material; at least one patch antenna arranged on the circuit board; a core layer positioned at the center portion inside the circuit boardand made of one of the dielectric layers; a ground layer arranged on the lower portion of the core layer; and an EGB structure positioned inside the circuit board and shaped such that the upper and lower portions thereof are symmetric with each other with reference to the core layer, wherein the EGB structure can limit interference between operating frequency signals emitted from respective patchantennas.

Owner:LG ELECTRONICS INC

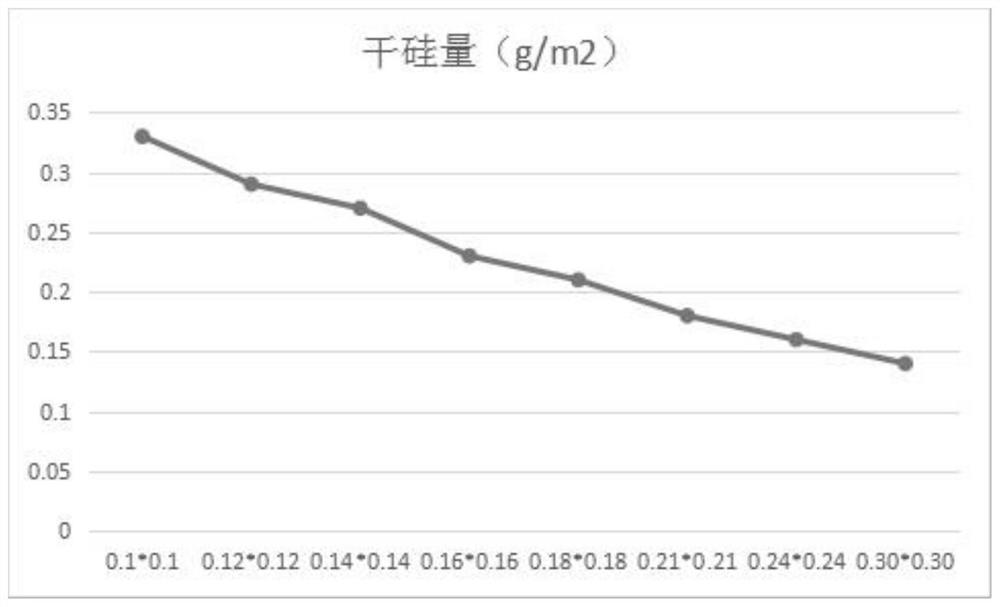

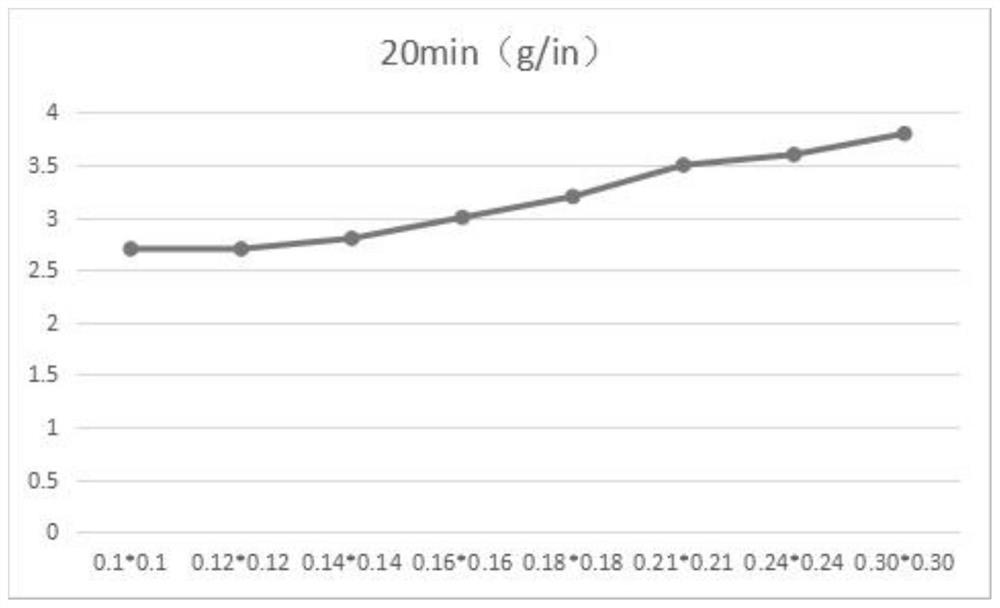

High-permeability grid release film and production process thereof

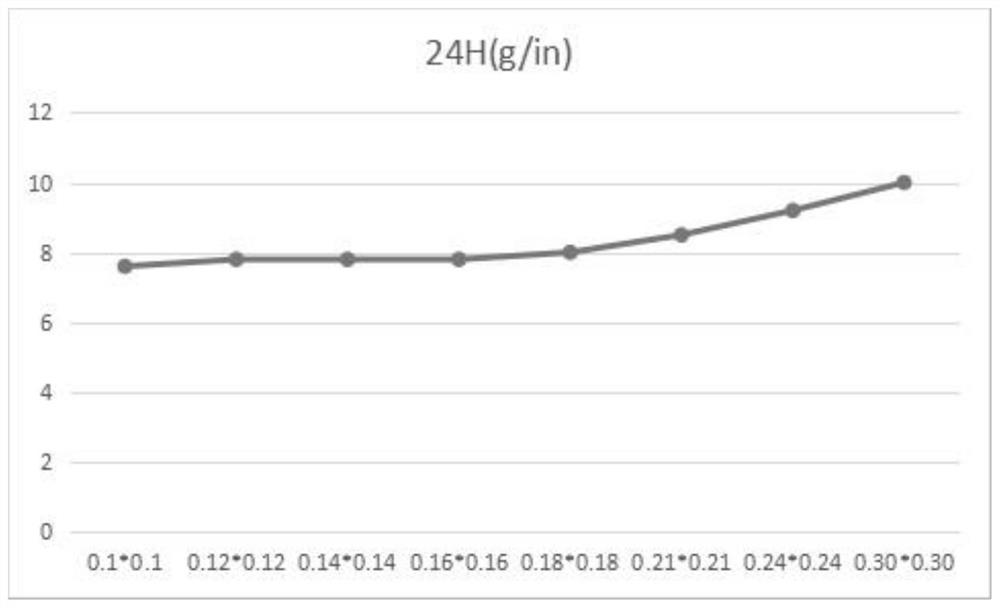

The invention discloses a production process of a high-permeability grid release film. The production process comprises the following steps: 1) coating preparation: mixing 120 #, toluene, butanone and isopropanol as a solvent; (2) treating an original film: adopting a transparent PET grid film with the grid size of 0.16 mm * 0.16 mm as the original film, and pre-coating a layer of antistatic liquid on the surface of the original film; (3) precise coating: the coating mode is slit coating; 4) drying and curing; and (5) receiving and rolling. According to the high-breathability grid release film, the 20 min release force is 2-5 g / in, the 24 H release force is 6-10 g / in, the aging force is 10-15 g / in, the residue is larger than or equal to 80%, and the resistance value is 10<9>-10<11>; under a magnifying lens for one hundred times, the grid release film is free of visible particles or foreign matters, free of scratches on the surface, free of obvious rainbow lines, free of coating leakage and free of coating spots, is low in release, high in breathability, high in residue, low in aging and high in breathability, and is suitable for high-end electronic products.

Owner:江阴华美光电科技有限公司

A multifunctional compound fugitive dust inhibitor based on active enzyme preparation

ActiveCN106753248BCorrosiveIncrease the residual rateOther chemical processesActive enzymeMoisture absorption

The invention discloses a multifunctional compounded flying dust suppressant prepared on the basis of an active enzyme. The multifunctional compounded flying dust suppressant is prepared from the following raw materials in percentage by weight: 0.28-0.32% of bioactive enzyme, 0.07-0.12% of high-polymer water-absorbing resin, 4.50-5.00% of CO(NH2)2, 4.40-4.50% of CaCl2, 2.20-2.30% of CaO and the balance of water. The bioactive enzyme is urease which is an artificially extracted plant enzyme. The application method of the dust suppressant comprises the following steps: dissolving powder materials in water according to the percentage by weight, uniformly mixing, spraying the mixture on the road surface and stockpile surface, wherein the amount of the mixture is 1-3L for every 1m<2> of the municipal road, and the amount of the mixture is 3-6L for every 1m<2> of the stockpile. By utilizing the principles of moisture absorption, moisture retention, bonding, biodegradation and biological calcification, the dust suppressant effectively enhances the flying dust suppression effect, and has the advantages of long acting duration time, lower secondary flying dust, high reaction speed, high temperature resistance and environment friendliness.

Owner:SOUTHEAST UNIV

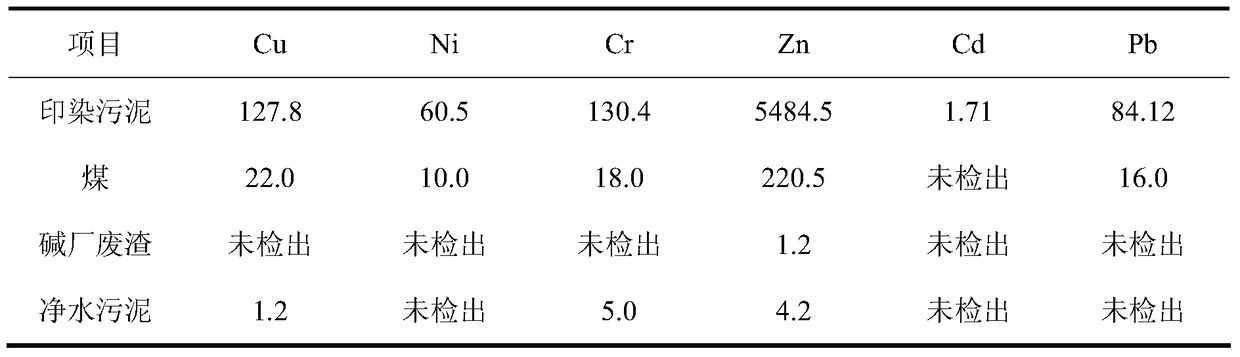

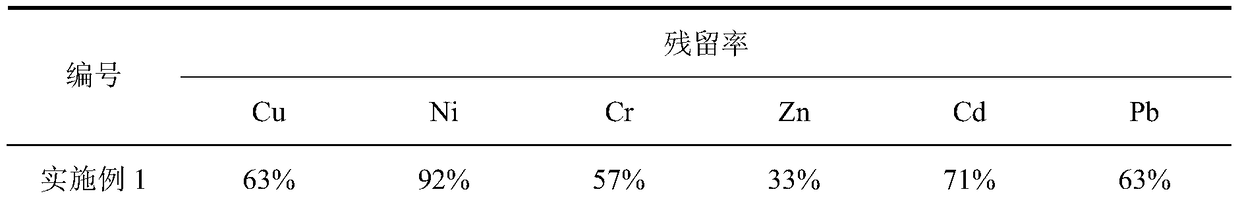

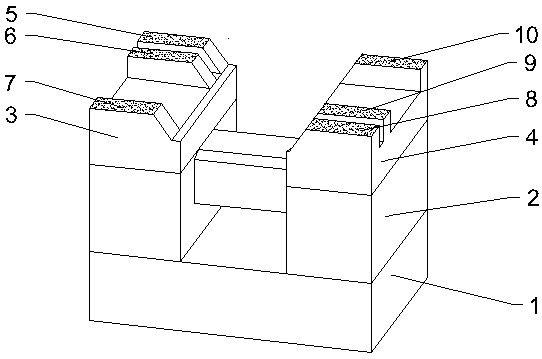

A quenching and tempering treatment method for controlling heavy metal pollution in printing and dyeing sludge co-firing project

InactiveCN105384318BIncrease the residual rateReduce secondary pollutionSludge treatmentSolid fuelsSlagCoal

The invention discloses a quenching and tempering treatment method for controlling heavy metal pollution in a printing and dyeing sludge mixed burning project. In terms of mass fraction, 1-3% of alkali plant waste residue, 1-3% of water purification sludge, 5-15% of printing and dyeing sludge and 81-92% of coal, the alkali plant waste residue, water purification sludge, printing and dyeing sludge and The coal is mixed evenly according to the above content, and then put into the boiler as fuel for incineration. The present invention utilizes the characteristics of high calcium content in alkali plant waste residue and high aluminum content in water purification sludge, as well as its adsorption and capture characteristics for heavy metals in the incineration process, and uses the two types of waste as the incineration process of printing and dyeing sludge mixed with coal. The conditioning agent can significantly increase the residual rate of heavy metals on the slag during the incineration process, thereby reducing the secondary pollution of heavy metals in the tail gas and fly ash during the incineration process. The method of the invention simultaneously realizes the reuse of two kinds of wastes.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

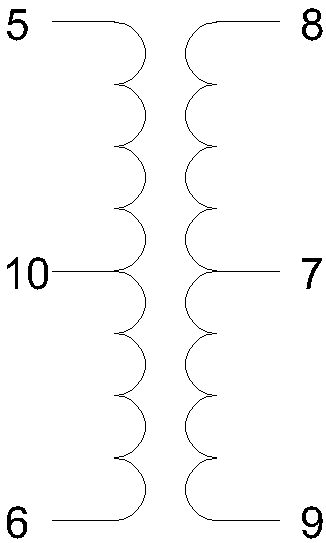

Double-wire winding transformer and preparation method thereof

PendingCN110428956AGood tin attachmentNo WeldTransformers/inductances coils/windings/connectionsTransformerTemperature resistance

The invention provides a double-wire winding transformer. The transformer comprises a transformer main body and a coil wound on the transformer main body, wherein the transformer main body consists ofa first body, a second body, a third body and a fourth body; the surface of the second body is coated with an organic material or an inorganic material, the surface of the first body and the bottom of the second body are subjected to mirror surface treatment, and the second body is bonded and fixed at the top of the first body; the third body and the fourth body are bonded and fixed to two ends of the top of the second body, and electrodes are compounded on the surfaces of the third body and the fourth body through vacuum electroplating or traditional electroplating modes. After the scheme isadopted, the residual rate of a substrate is high, tin soldering high-temperature resistance is achieved, tin attachment property is good, and pseudo soldering is avoided; remote signal transmissionis realized.

Owner:CYGE ELECTRONIC TECH (HUNAN) CO LTD

A kind of preparation method of soft film type degradable dust suppressant

ActiveCN106010451BNo cracking phenomenonImprove wetting abilityOther chemical processesInorganic saltsLiquorices

The invention relates to a preparation method of a soft-film type degradable dust suppressant and belongs to the field of preparation of dust suppressants. According to the method, firstly, glycyrrhizin containing rich carboxyl is extracted from liquorice roots to serve as a modifier, corn straw is extruded, made into pulp and mixed with glycyrrhizin, the mixture is subjected to biological modification through a compound enzyme preparation and then discharged, and the emulsive soft-film type degradable dust suppressant is obtained. After the prepared dust suppressant is applied, a soft film is formed on the surface of a material, and the dust suppressant has extremely high wettability and adsorbability, does not contain corrosive moisture-absorbing inorganic salt, solves the problem that a traditional hard shell type dust suppressant is easy to break and the dust suppression effect is influenced, is prepared from pure biomass which is easy to degrade, overcomes the defects that the traditional hard shell adhesion type dust suppressant is not easy to degrade, has high residual rate and can cause secondary pollution easily and has broad application prospect.

Owner:宁波绿拾光新材料有限公司

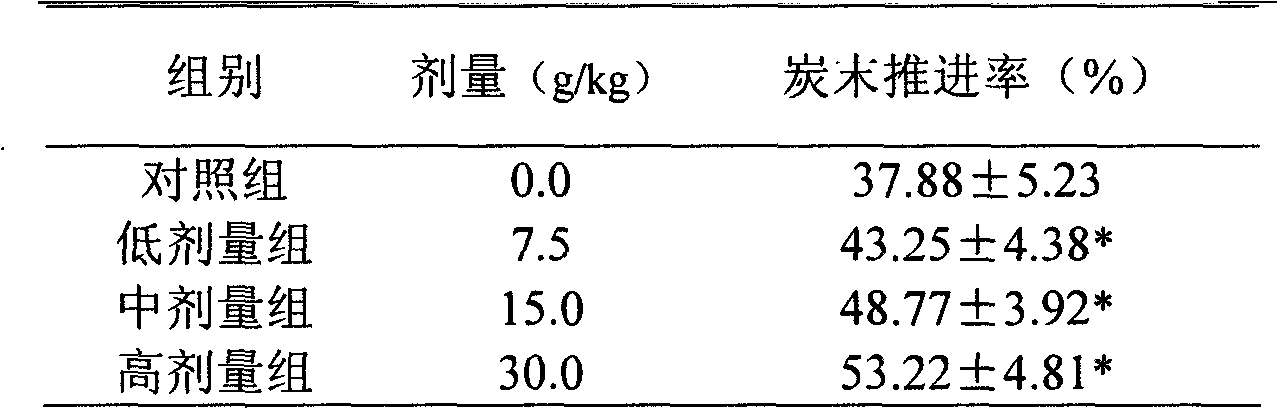

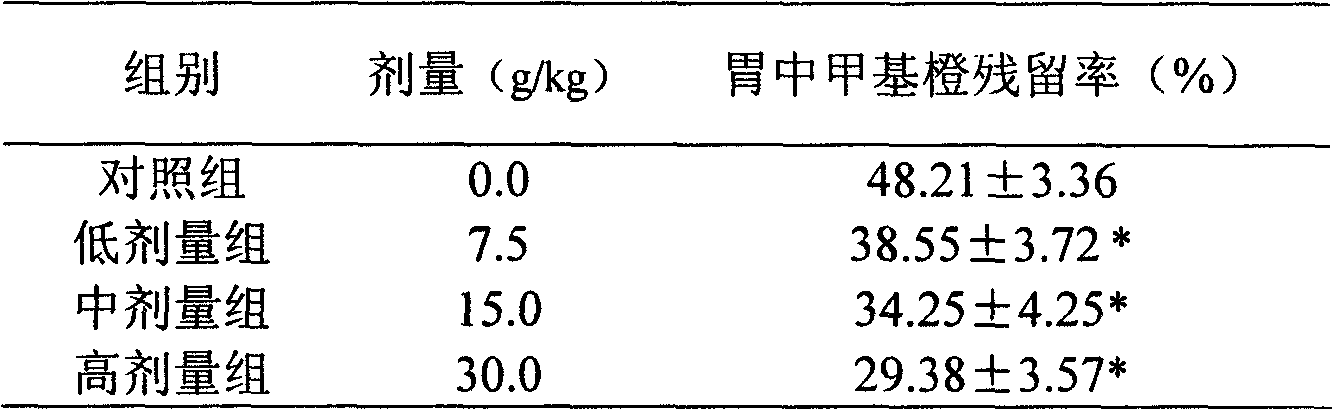

Chinese medicine composition with improving gastrointestinal function and preparation method thereof

InactiveCN102727602BIncrease exerciseEasy to pushDigestive systemPlant ingredientsAdjuvantBULK ACTIVE INGREDIENT

Owner:GUANGZHOU JIAYUAN PHARMA TECH

Prebaked anode and its preparation method and application

The invention relates to the field of electrolysis, and discloses a prebaked anode and a preparation method and application thereof. The method includes: kneading modified pitch and petroleum coke, and roasting the obtained product to obtain a prebaked anode; wherein, the modified The quinoline insoluble value of the asphalt is 15-19; the weight ratio of the modified asphalt to the petroleum coke is 1:8-12. The prebaked anode prepared by the method can achieve the best balance between increasing the residual electrode rate (that is, the residual electrode rate ≥ 85wt%) and not reducing other parameters, and the other parameters are not lower than the prior art, and the adaptability is wide.

Owner:山西沁新能源集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com