High-permeability grid release film and production process thereof

A production process and air permeability technology, which is applied in the field of high air permeability mesh release film and its production process, can solve the problems of high residual and low aging, and achieve the effect of increasing residual rate and reducing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A highly air-permeable grid release film, comprising the following components in parts by mass: 120 # 1 part of mineral spirits, 1 part of toluene, 14 parts of butanone, 1 part of isopropanol, and Methicone 3 SiO(Me 2 SiO) n SiMe 3 1 part, heavy stripping additive Dow Corning 72100.08 parts, crosslinking agent methyl hydrogen silicone oil 0.15 parts, anchoring agent vinyltriacetoxysilane 0.004 parts, glycidyl etheroxypropyl trimethoxysilane 0.005 parts, catalyst 1,3- 0.02 parts of divinyl-1,1,3,3-tetramethyldisiloxane platinum complex.

[0027] The above-mentioned highly air-permeable grid release film comprises the following steps:

[0028] 1), paint configuration: 120 #A mixture of mineral spirits, toluene, methyl ethyl ketone and isopropanol is used as a solvent; simethicone Me 3 SiO(Me 2 SiO) n SiMe 3 As the main agent, add heavy peeling additive Dow Corning 7210, crosslinking agent methyl hydrogen silicone oil, anchoring agent vinyl triacetoxysilane, glyci...

Embodiment 2

[0040] A highly air-permeable grid release film, comprising the following components in parts by mass: 120 # 1 part of mineral spirits, 1 part of toluene, 14 parts of butanone, 1 part of isopropanol, and Methicone 3 SiO(Me 2 SiO) n SiMe 3 1 part, heavy stripping additive Dow Corning 72100.12 parts, crosslinking agent methyl hydrogen silicone oil 0.018 parts, anchoring agent vinyltriacetoxysilane 0.005 parts, glycidyl etheroxypropyl trimethoxysilane 0.003 parts, catalyst 1,3- 0.03 parts of divinyl-1,1,3,3-tetramethyldisiloxane platinum complex.

[0041] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0043] A highly air-permeable grid release film, comprising the following components in parts by mass: 120 # 1 part of mineral spirits, 1 part of toluene, 14 parts of butanone, 1 part of isopropanol, and Methicone 3 SiO(Me 2 SiO) n SiMe 3 1 part, heavy stripping additive Dow Corning 72100.1 part, crosslinking agent methyl hydrogen silicone oil 0.008 part, anchoring agent vinyltriacetoxysilane 0.003 part, glycidyl etheroxypropyl trimethoxysilane 0.005 part, catalyst 1,3- 0.04 parts of divinyl-1,1,3,3-tetramethyldisiloxane platinum complex.

[0044] The preparation method of this embodiment is the same as that of Example 1.

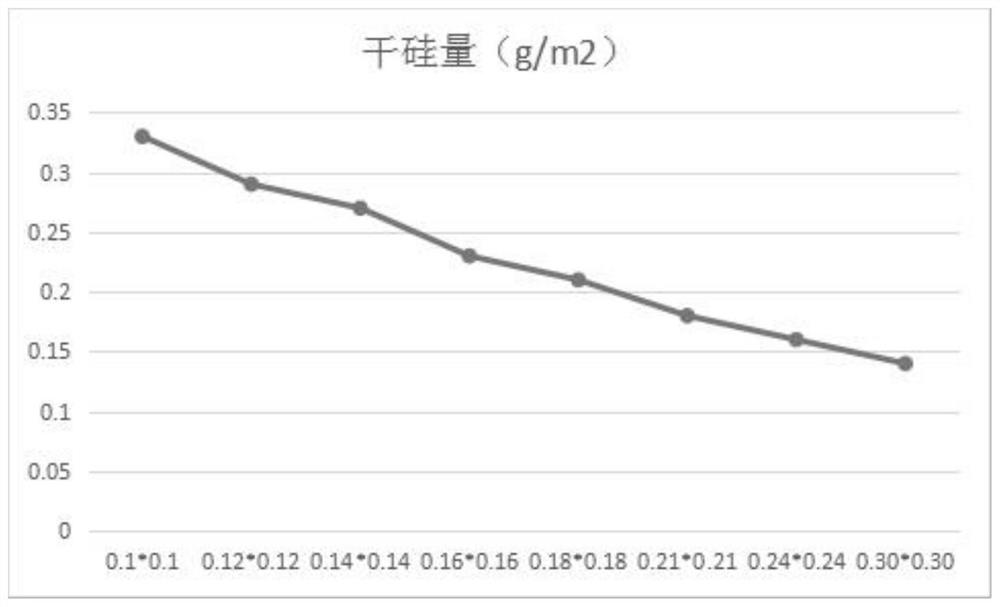

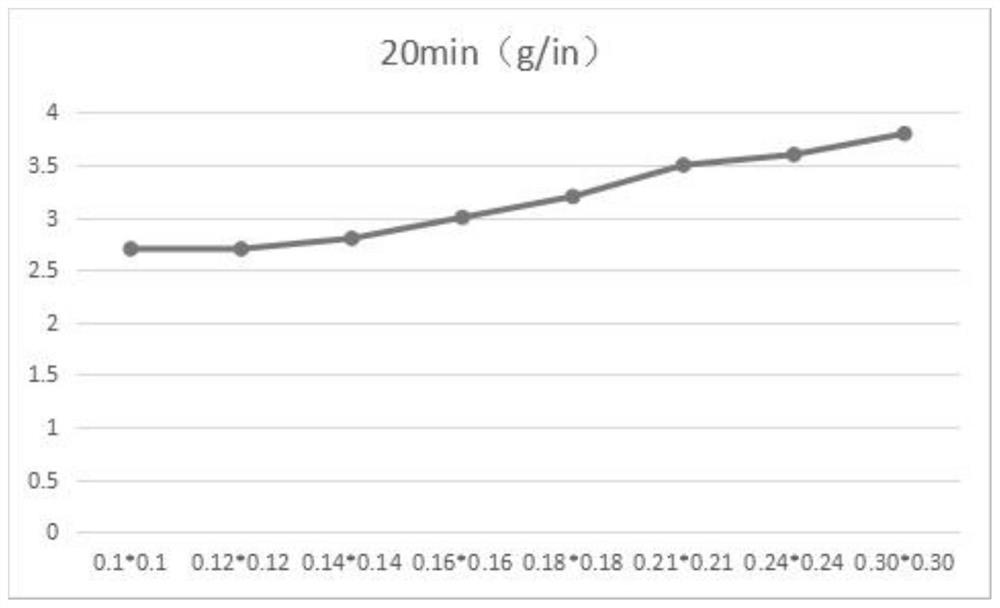

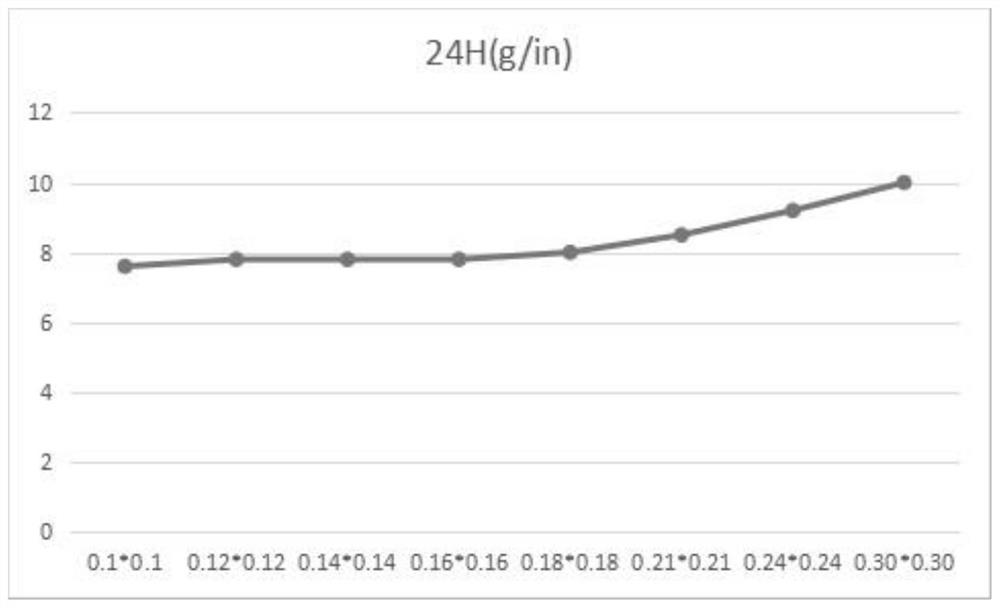

[0045] Table 2 The highly air-permeable grid release film made by Example 1-3

[0046]

[0047] As can be seen from Table 2, the highly air-permeable grid release film of the present invention produced in Example 1-3 has a 20min release force of 2-5g / in, 24H: 6-10g / in, aging: 10-15g / in in, residual ≥ 80%, resistance value 10 9 -10 11 ; Under a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com