Patents

Literature

150results about How to "No aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arrangement for reflection of heat radiation, process of making same and uses of same

ActiveUS20090320824A1No agingReduce the temperatureSelf-cleaning stoves/rangesMirrorsThermal radiationOxide

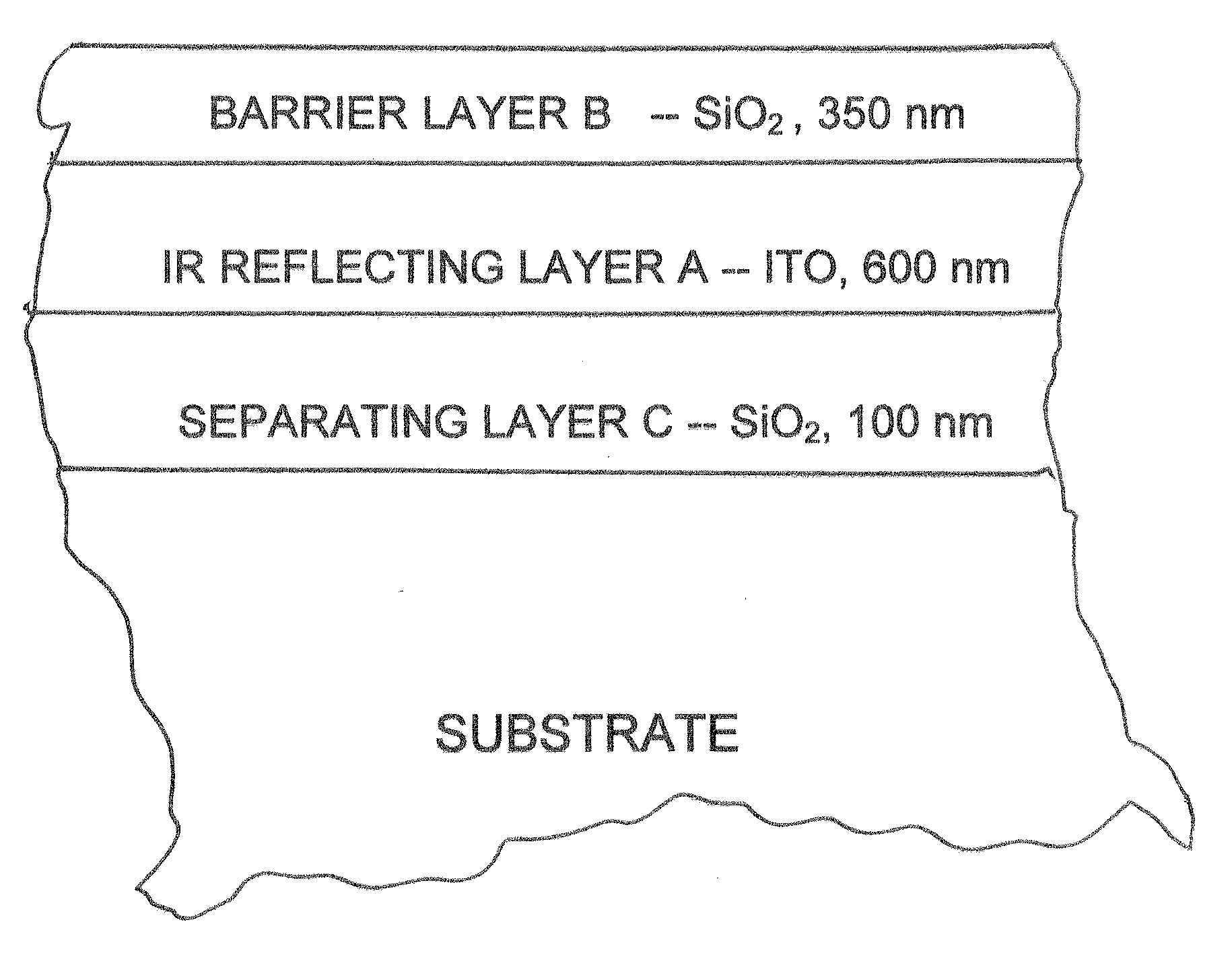

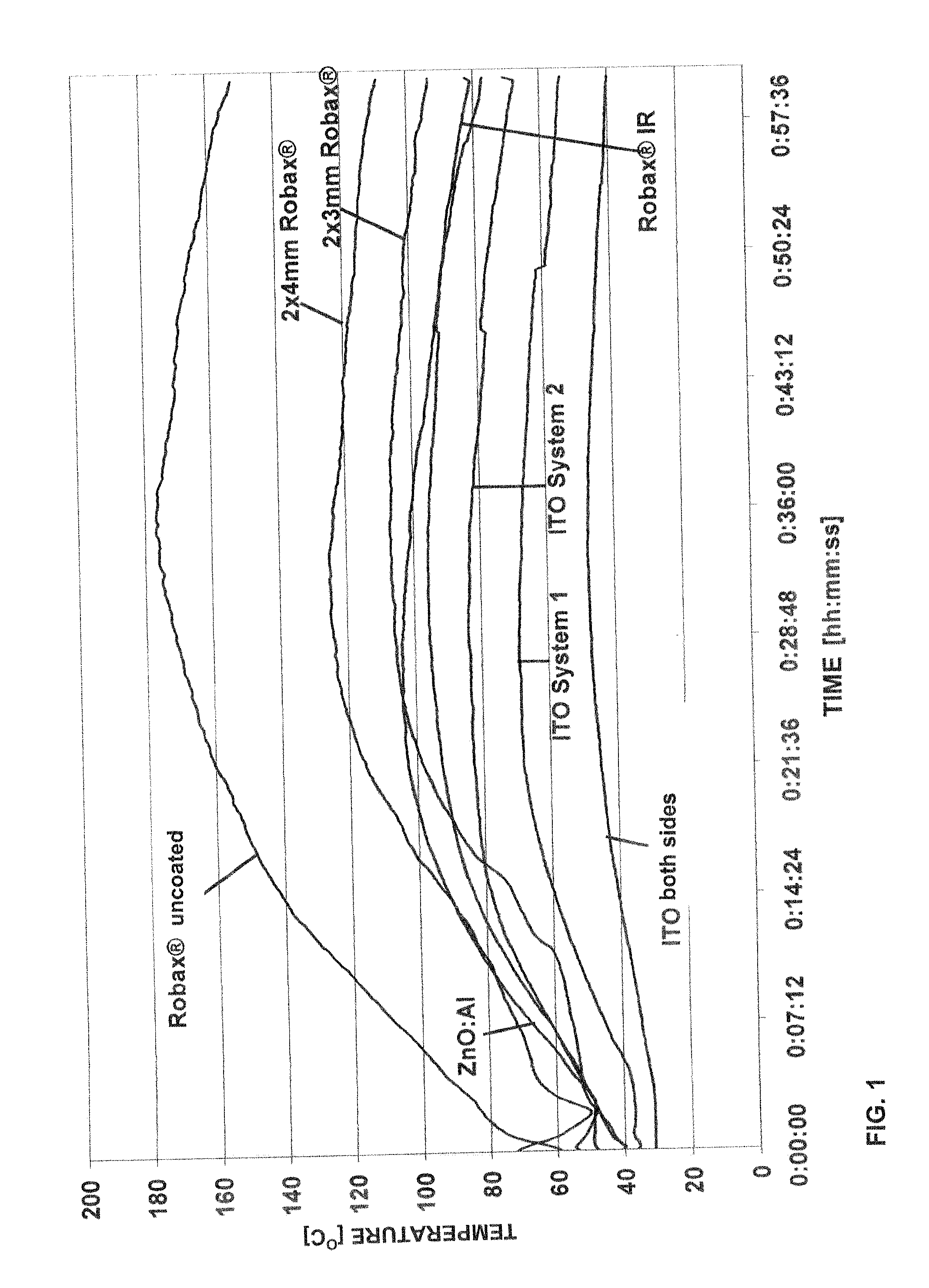

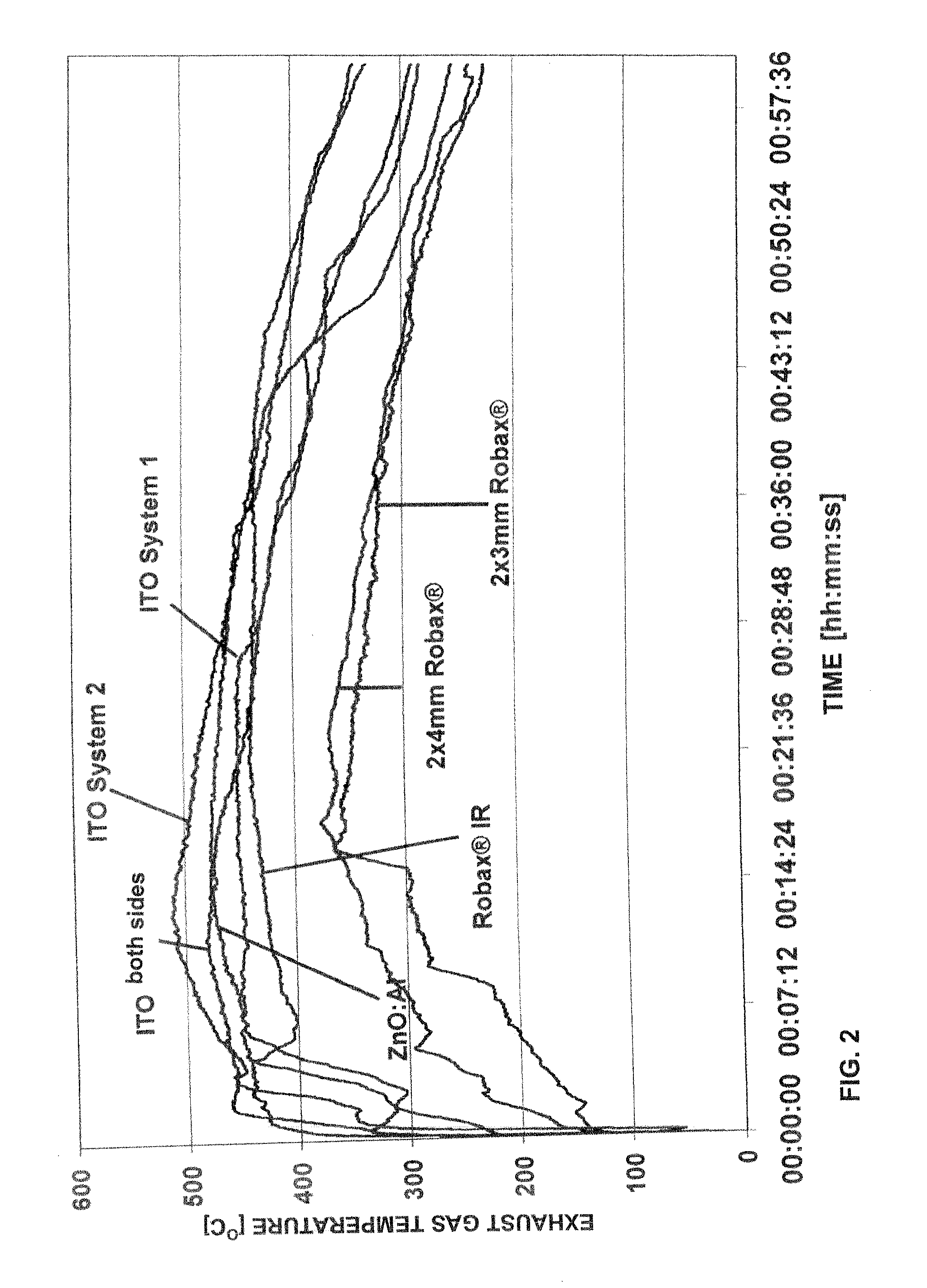

The heat reflecting arrangement with an improved high heat resistance, e.g. 100 hours at 500° C., includes a substrate, a heat reflecting layer (A) on at least one side of the substrate, which contains indium tin oxide (ITO), and a barrier layer (B) that covers the heat reflecting layer (A), which contains a metal oxide and / or a metal nitride. A fireplace or baking oven with a viewing window having this layer system with the heat reflecting layer is also described. In addition a process for providing the heat reflecting arrangement is described.

Owner:SCHOTT AG +1

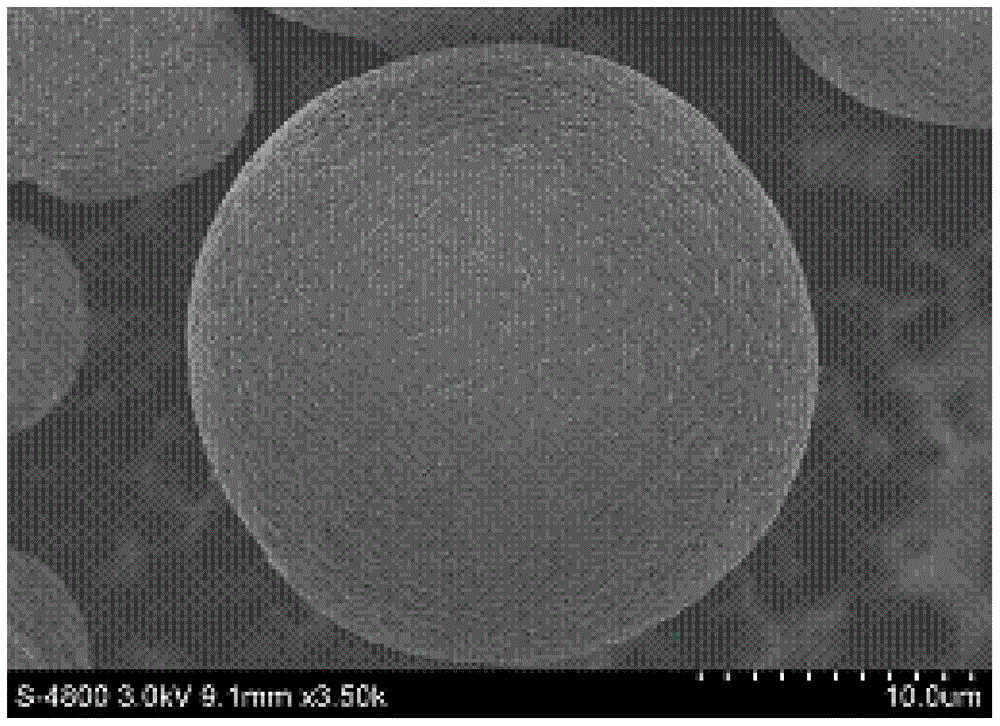

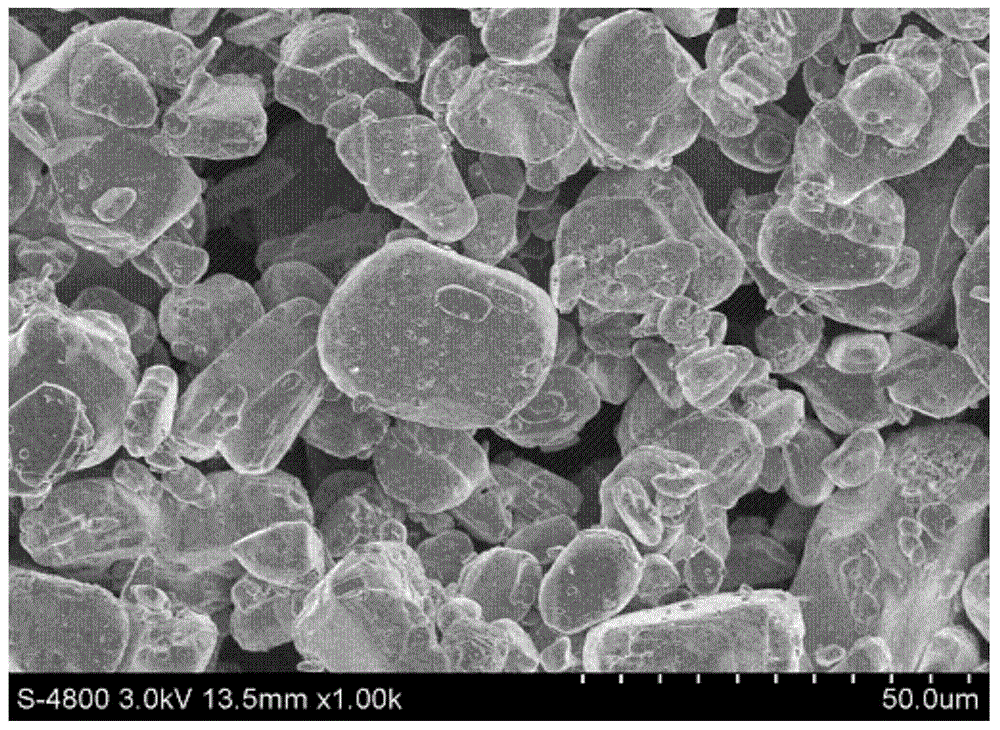

Method for continuously producing large-particle spherical cobalt carbonate

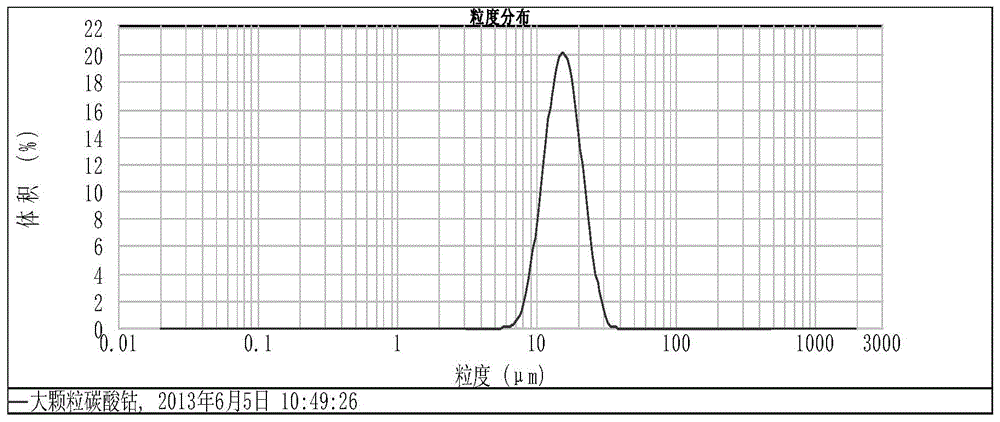

The invention relates to a method for continuously producing large-particle spherical cobalt carbonate. The method comprises the following steps: manufacturing a turbid liquid containing small-particle-size cobalt carbonate seed crystal and manufacturing a turbid liquid containing large-particle spherical cobalt carbonate, stirring the turbid liquid containing the small-particle-size cobalt carbonate seed crystal and the turbid liquid containing large-particle-size cobalt carbonate to form a mixed liquid, carrying out solid-liquid separation, washing and filter pressing to obtain a filter cake as a large-particle cobalt carbonate filter cake, drying the filter cake, and repeatedly operating to obtain the large-particle cobalt carbonate powder. According to the method disclosed by the invention, the small-particle-size cobalt carbonate seed crystal is adopted to control the particle size of the large-particle cobalt carbonate in reaction mother liquor, so that the degree of sphericity of cobalt carbonate produced by continuous production can be ensured to be high, the particle size can be stably controlled within the range of 15+ / -0.5 microns, and the consistency and the stability of the particle size of the large-particle spherical cobalt carbonate through large-scale continuous production can be realized; the method is simple in process, easy to operate and low in cost, and can provide the high-quality raw material for producing high-end lithium cobalt oxide; the carbonate is used as a precipitant, so that the environment can be optimized; the production efficiency can be improved, and the wide application prospect can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

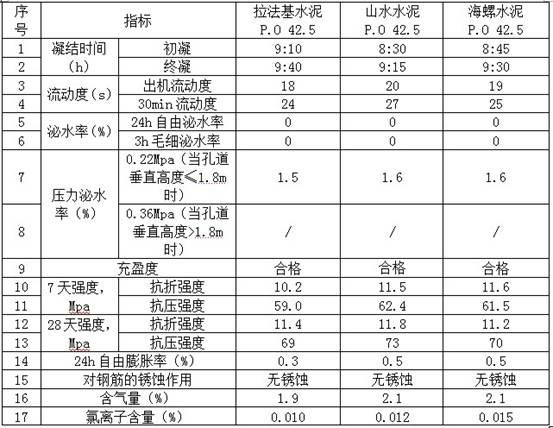

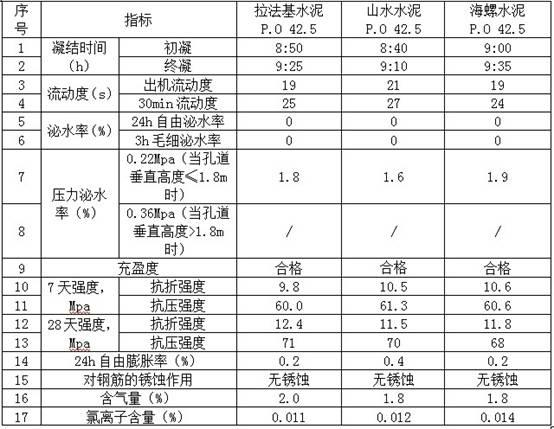

Concrete pipeline mud-jacking agent and preparation method

The invention belongs to the field of building materials, and particularly relates to a concrete pipeline mud-jacking agent and a preparation method thereof. The invention adopts the technical scheme that the concrete pipeline mud-jacking agent comprises the following components in percentage by weight: 0.5 to 2 percent of efficient water reducing agent, 0.1 to 0.5 percent of stabilizer, 1 to 5 percent of early expansion agent, 35 to 55 percent of medium and later expansion agent, 0.1 to 1 percent of retarder, 0.2 to 1 percent of rust inhibitor, 0.05 to 0.1 percent of air entraining agent and 50 to 60 percent of mineral admixture. The concrete pipeline mud-jacking agent has the advantages of wide raw material source, good mobility, high strength, no bleeding or layering, good durability, ageing resistance, low chlorine ion content, no corrosion to steel bars, firmness, high filling property, one-time mud-jacking construction, capability of making slurry in a pipeline compact and pore-free, no shrinkage, no rust corrosion of prestressed steel bars, and firm adhesion with concrete.

Owner:济南鲁新新型建材股份有限公司

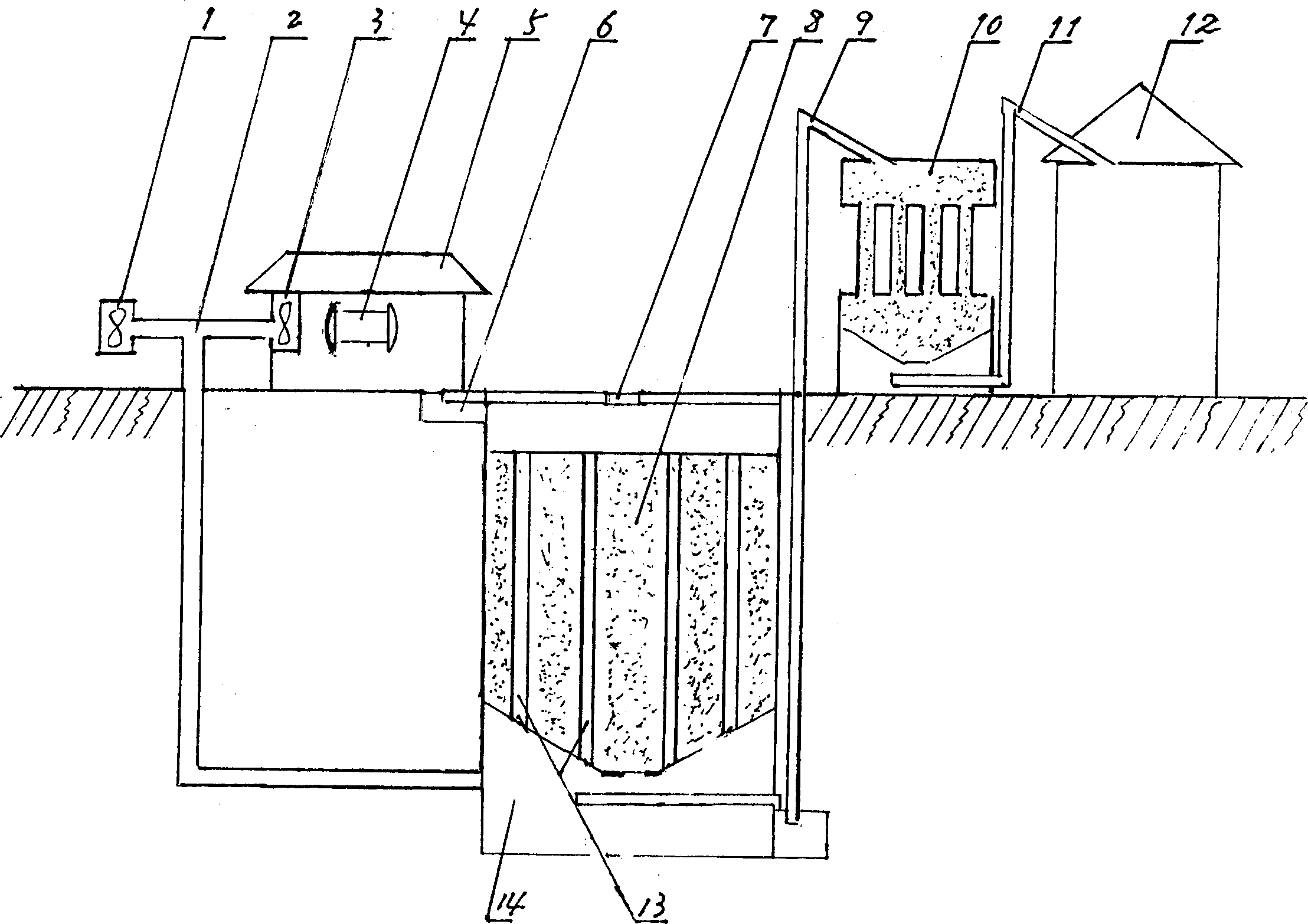

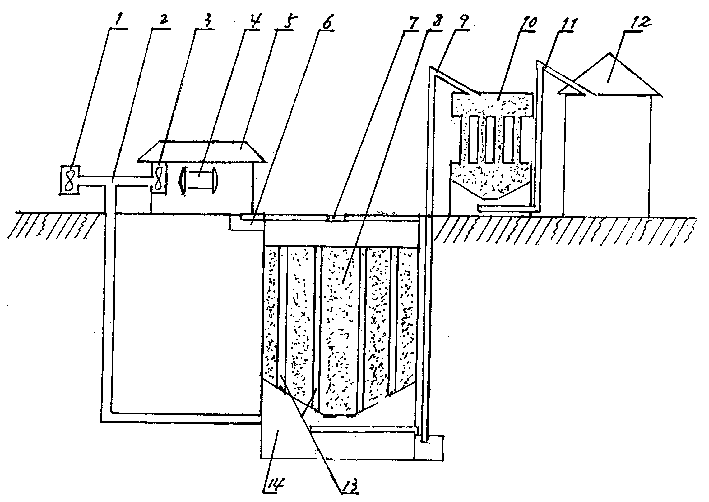

Cold-storing grain depot

InactiveCN1390757ANo agingGood fresh-keeping effectLarge containersTank wagonsUnderground spaceReturn channel

A grain deposit for cold storage of grains features that it is an underground building, and is a composed of blower, wind channel, cold-air blower, refrigerator, refrigerating chamber, air return channel, grains inlet, cold storage, upper and lower conveyers, transition storage, grain deposit and underground space. Its advantages are not ageing grains, high antistaling effect, not mildewing, and high effect on preventing pests and mouse.

Owner:延基权

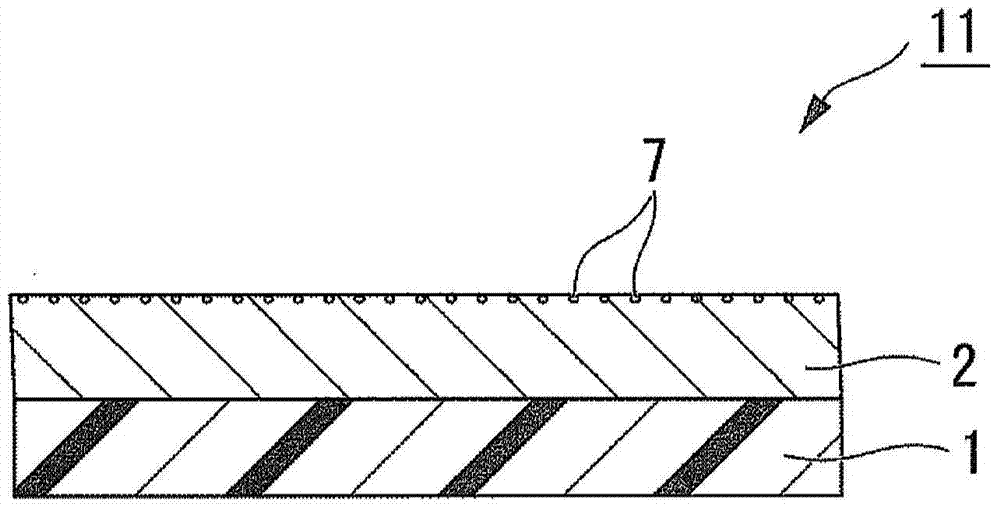

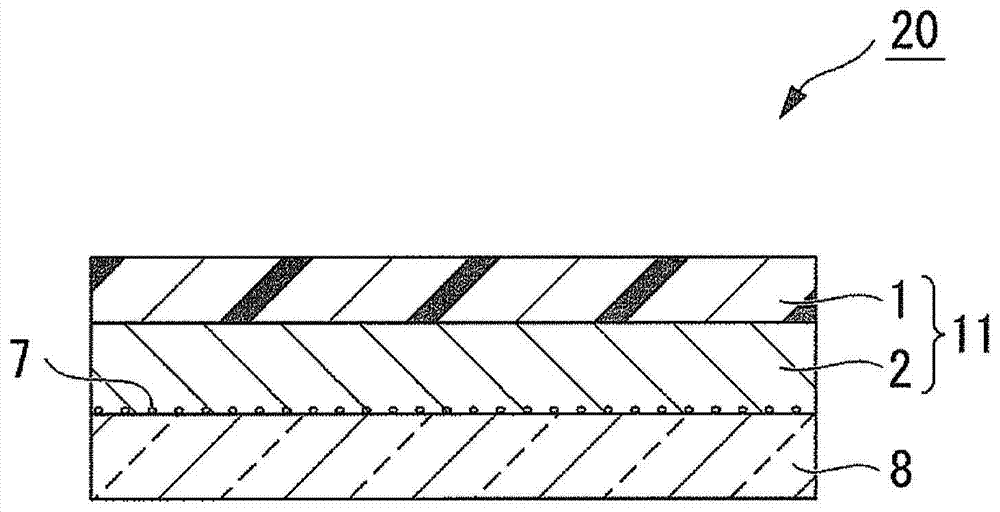

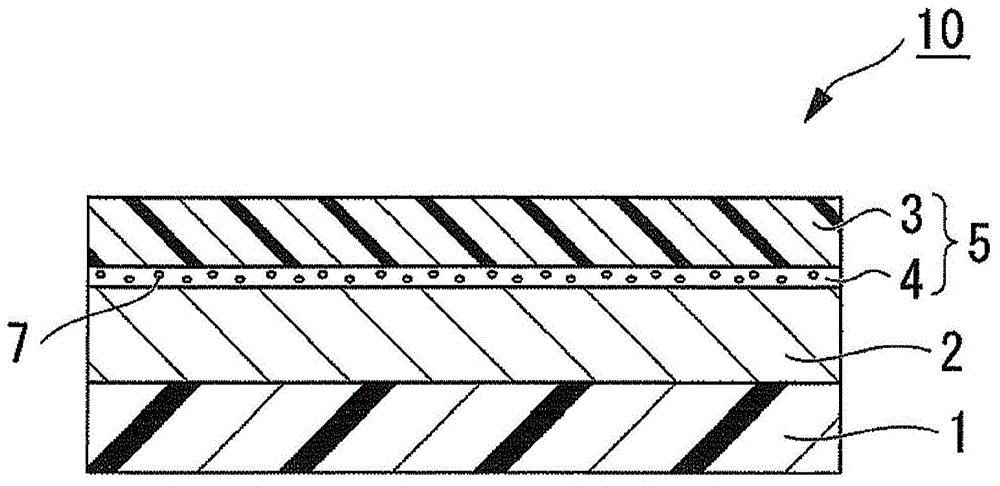

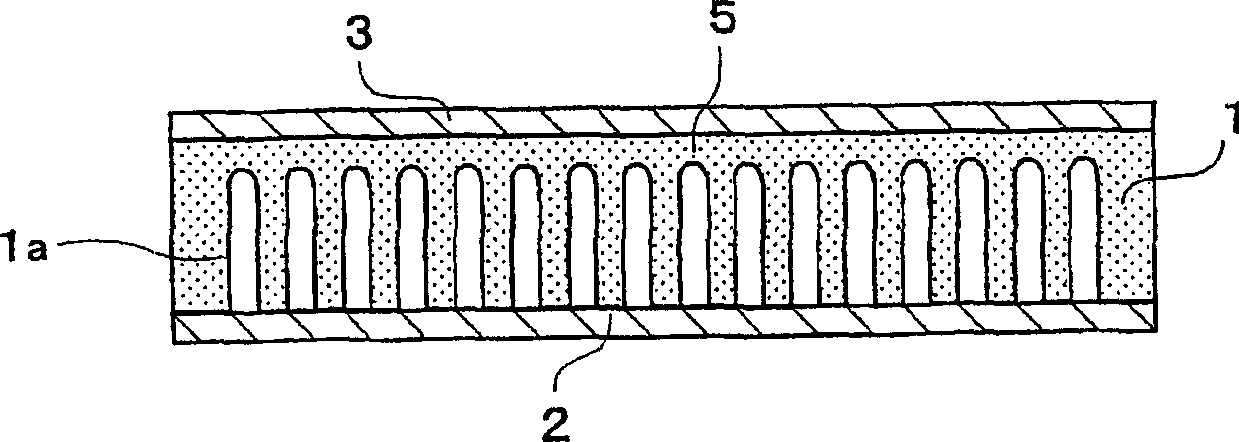

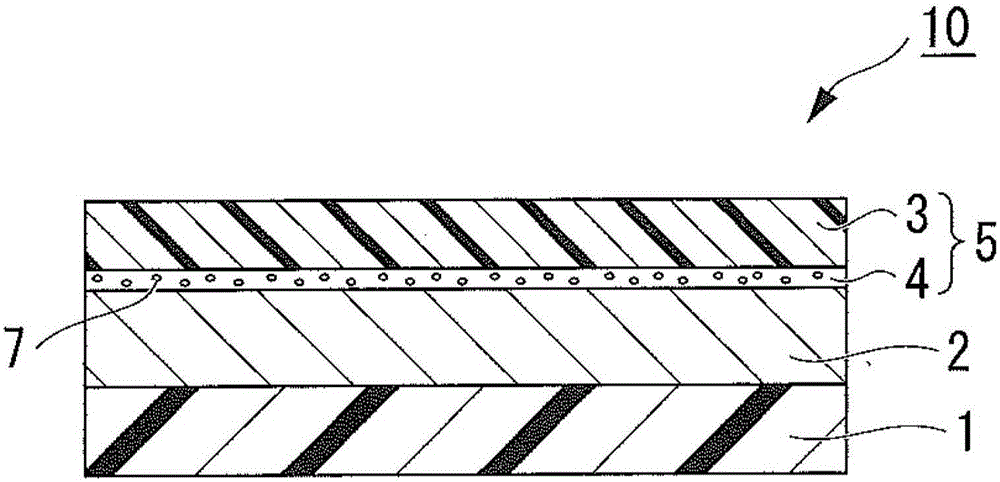

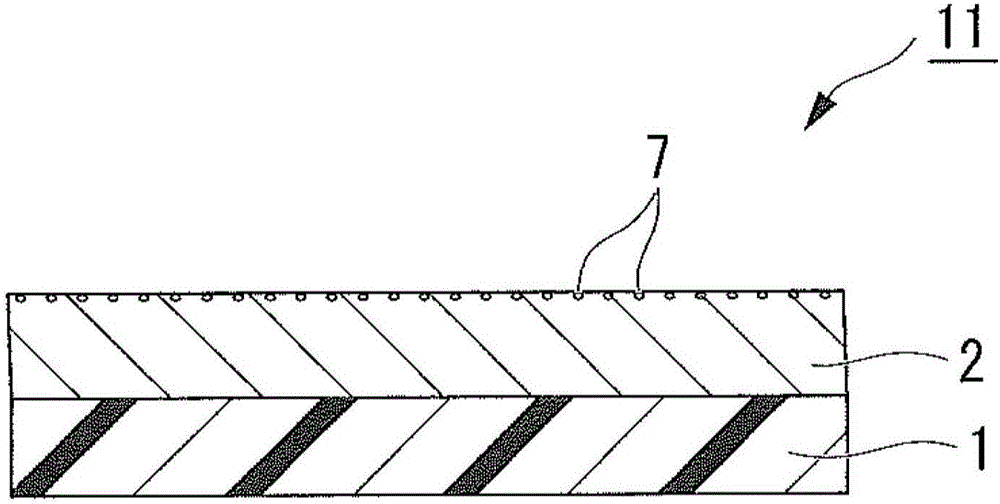

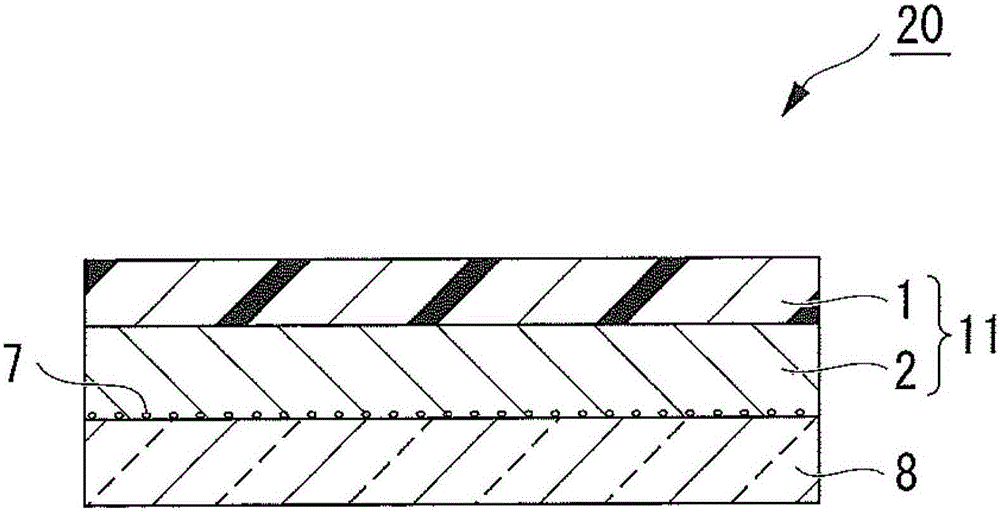

Antistatic surface protection film

ActiveCN104774569ASuppresses peeling static voltageLow agingLamination ancillary operationsNon-macromolecular adhesive additivesAntistatic agentKetone

The invention provides an antistatic surface protection film, the pollution to a pasted body is light, and the antistatic surface protection film is provided with excellent anti-stripping electrostatic properties without time dependent degradation. The antistatic surface protection film is formed in a way that a binder layer (2) composed of a binder composition is formed on one side of a base film (1) formed by a transparent resin, the binder composition comprises an acrylate-based polymer containing copolymers, (F) an isocyanate compound containing more than two functional groups, (G) a crosslinking accelerator and (H) a ketone-enol tautomer compound, a stripping agent layer (4) containing an antistatic agent is laminated on one side of a resin film (3) to form a stripping film (5), and the stripping film (5) is attached to the surface of the binder layer (2) through the stripping agent layer (4). The stripping agent layer (4) is formed by a resin composition, and the resin composition comprises a stripping agent taking dimethyl polysiloxane as the key component, a polysiloxane compound which is liquid under 20 DEG C and an antistatic agent, and the stripping electrostatic pressure of the binder layer (2) is lower than + / -0.6kV.

Owner:FUJIMORI KOGYO CO LTD

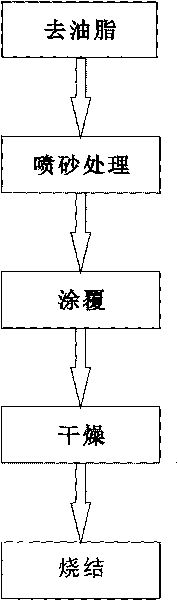

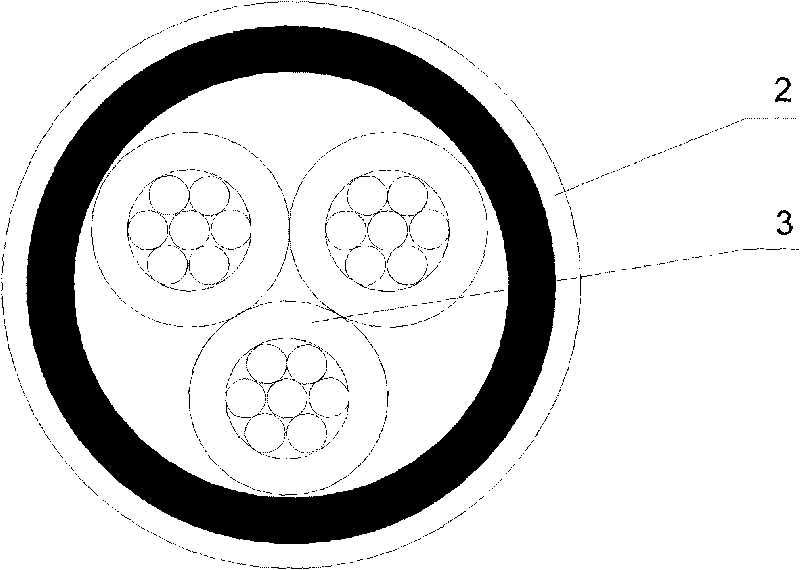

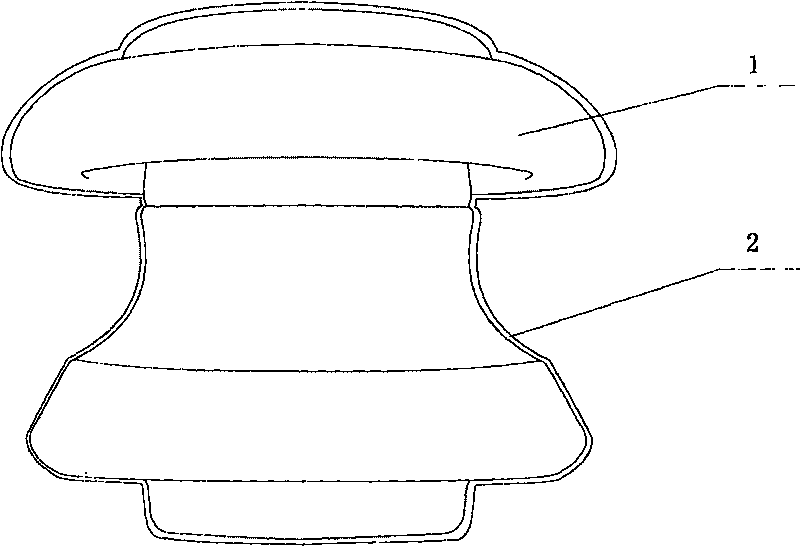

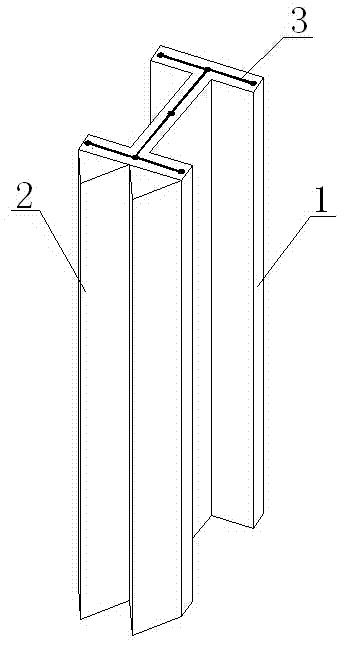

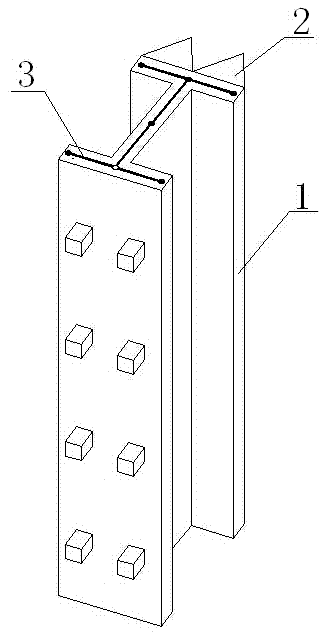

Coating method for wire or electrical insulator with teflon coating

InactiveCN101707103AExcellent heat and low temperature resistanceReduce permeabilityInsulatorsInsulating conductors/cablesTemperature resistanceTransmission line

The invention relates to a coating method for a wire or an electrical insulator with a teflon coating, which relates to the technical field of transmission lines. The coating method for the electrical insulator (3) comprises the steps of degreasing, sand-blasting treatment, coating, drying and sintering. The coating method for the wire (1) comprises the steps of degreasing, coating adhesives and spraying the coatings. As the teflon has inadhesion property and moisture resistance, the aim of preventing serious icing can be fulfilled by spraying the teflon on the outsides of the wire and the electrical insulator, and the aim of preventing the pollution flashover can be fulfilled by spraying the teflon on the outside of the electrical insulator. As the teflon coating film has excellent heat resistance and low temperature resistance, the wire or electrical insulator sprayed with the teflon can work normally in a high-temperature environment in summer or a low-temperature environment in winter.

Owner:河南省电力公司洛阳供电公司输电公司

Pig small intestine epithelial cell line and construction method thereof

InactiveCN101955907ALow nutritional requirementsLow costMicroorganism based processesVertebrate cellsAgricultural scienceSmall intestine

The invention discloses a pig small intestine epithelial cell line (ZYM-SIEC02), which was preserved in China Center for Type Culture Collection on January 13th, 2010 with a collection number of CCTCC-C201001. The invention also discloses the construction method of the cell line. The cell line has the advantages of low nutrient condition requirements, quick cell growth, easy cultivation and convenient promotion and application.

Owner:NORTHWEST A & F UNIV

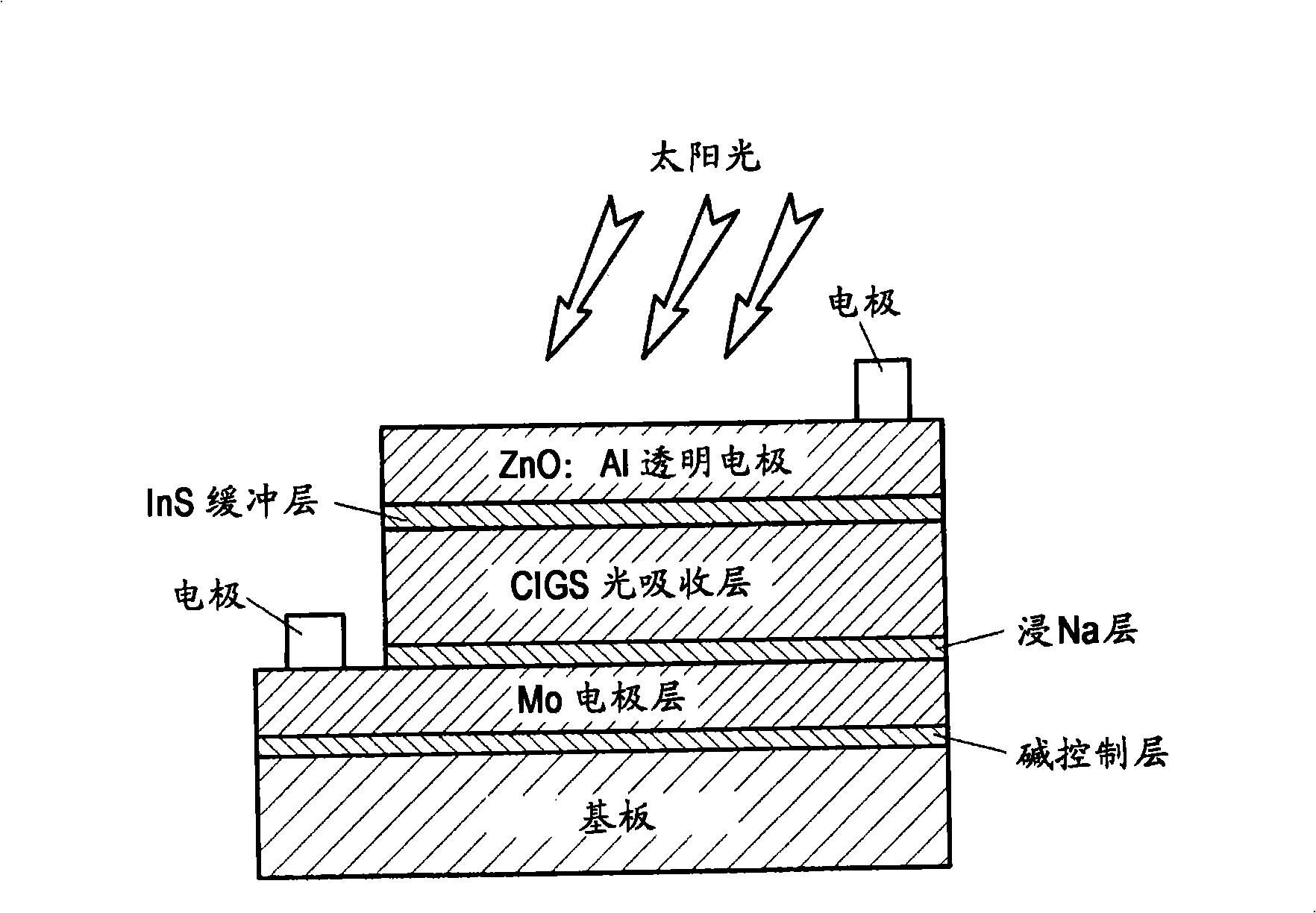

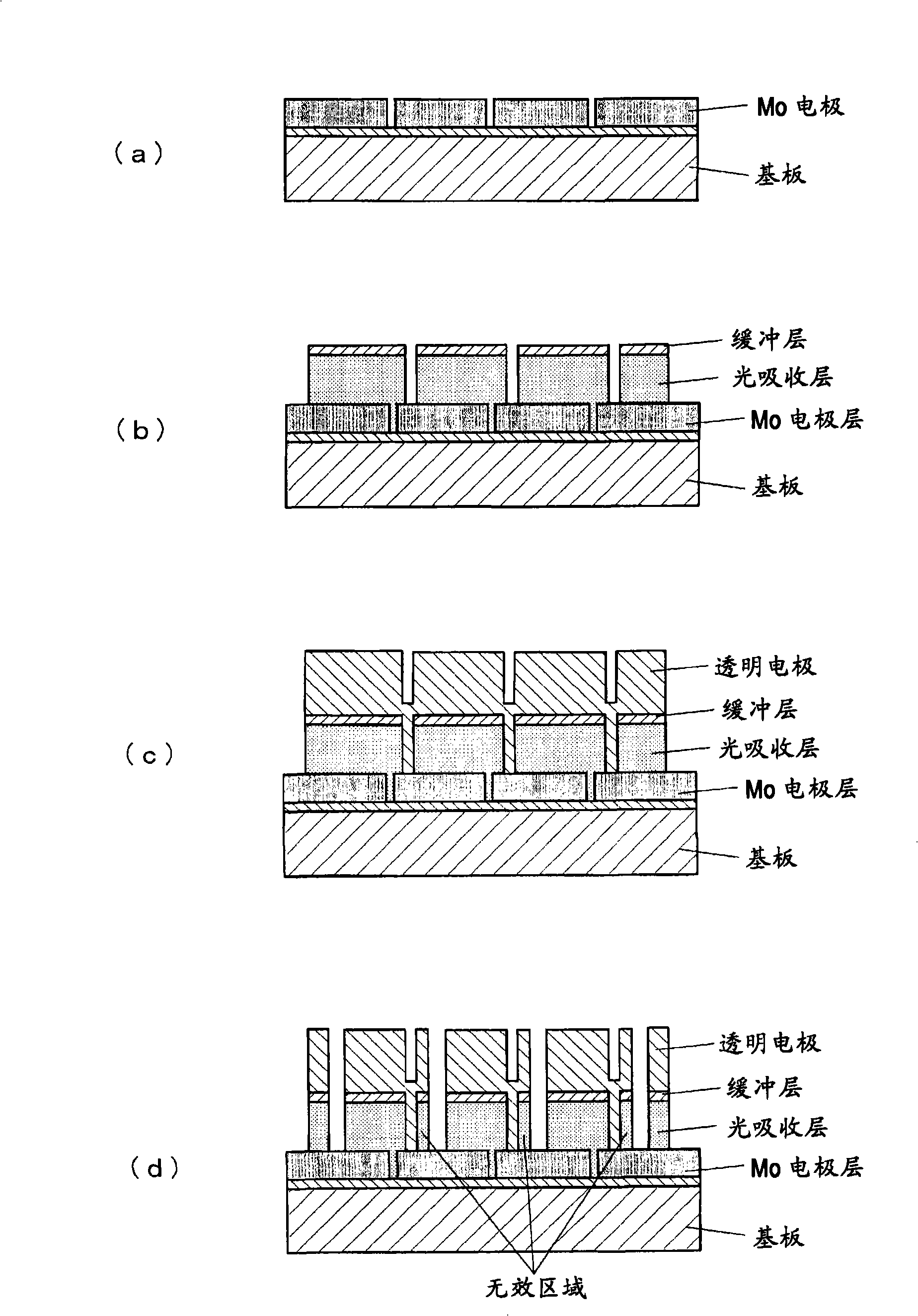

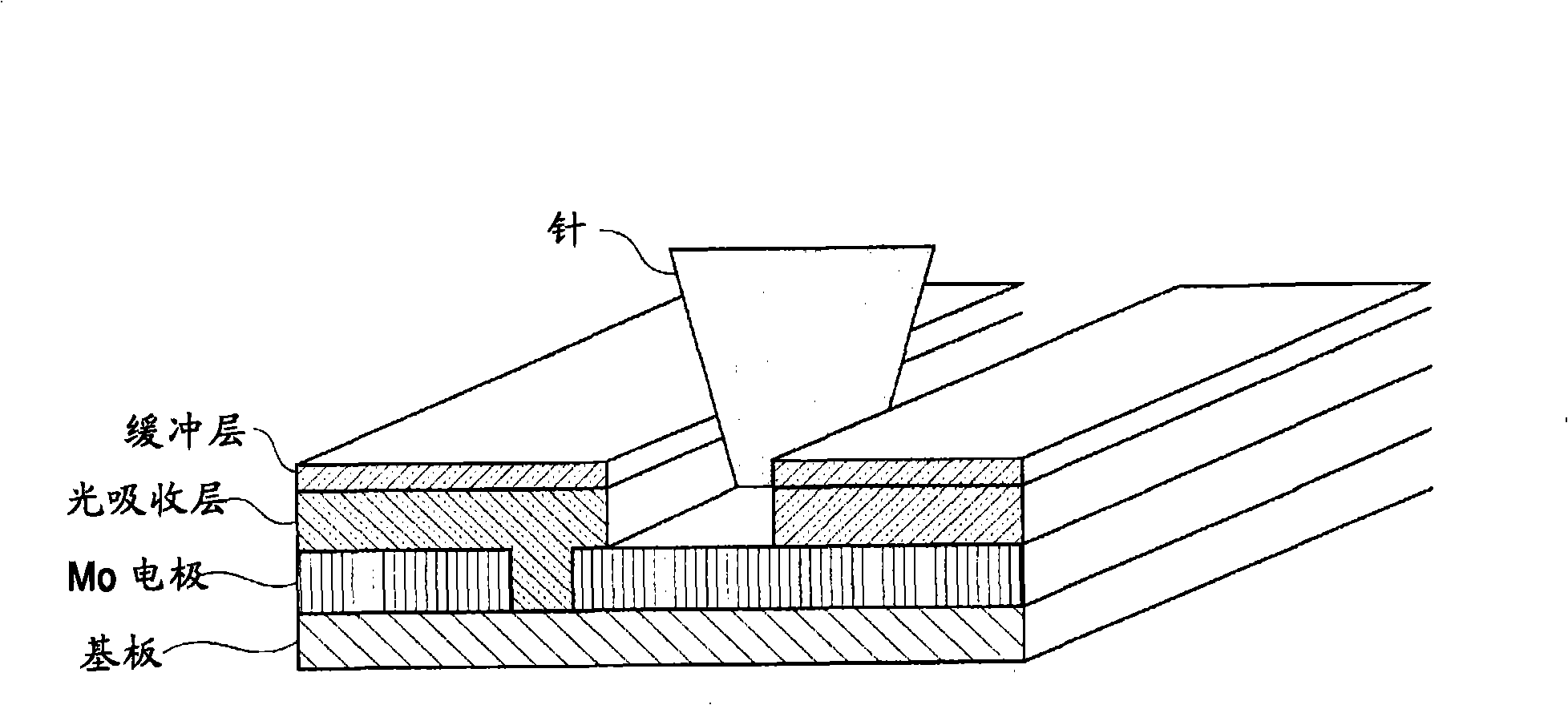

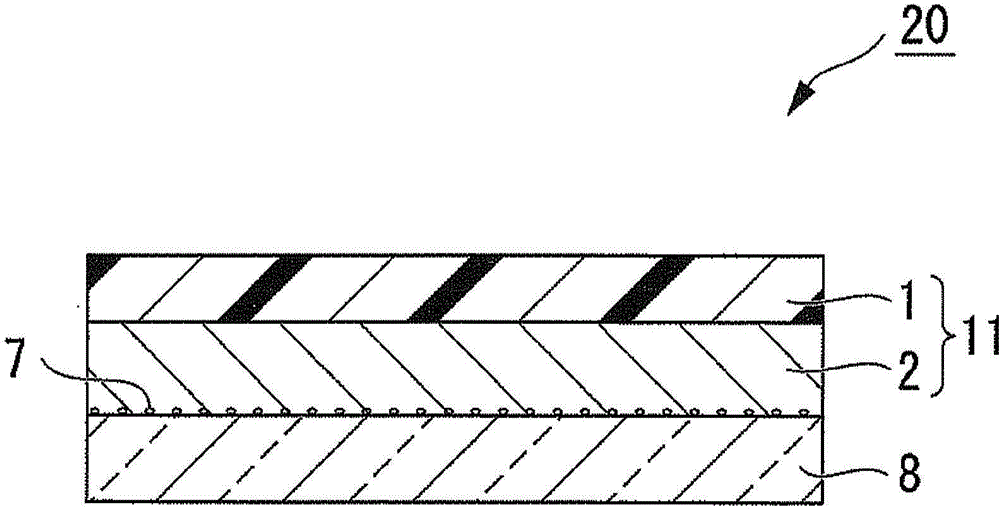

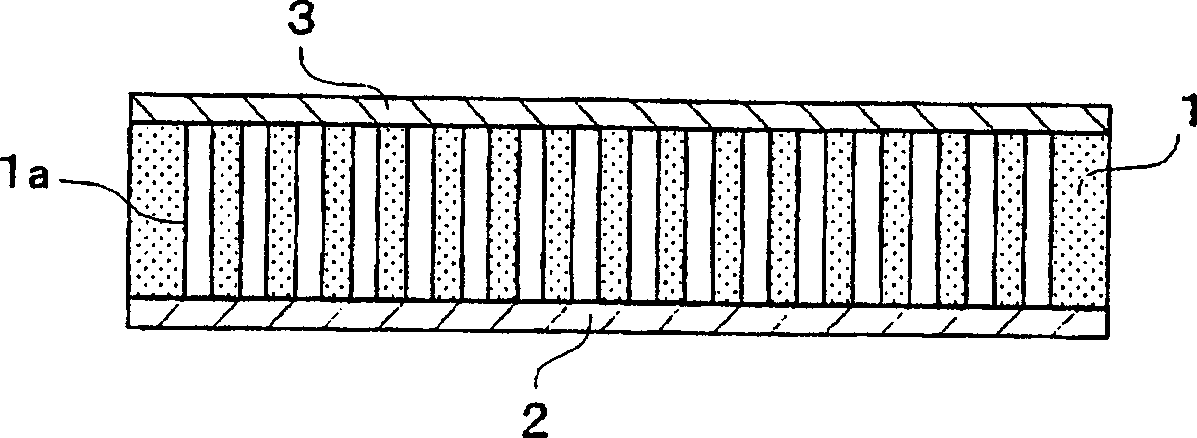

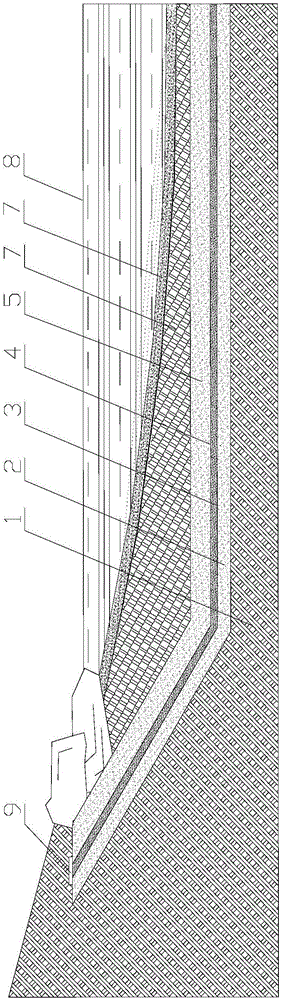

Solar battery

InactiveCN101326645AAvoid breakingImprove photoelectric conversion efficiencyFinal product manufactureSolid-state devicesHigh resistanceIndium

The invention provides a flexible solar battery having a high photoelectric conversion efficiency and no aging. A cell (10) (unit cell) comprises a lower electrode layer (2) (Mo electrode layer) formed on a flexible reconstituted mica substrate (1), a light absorption layer (3) (CIGS light absorption layer) containing copper, indium, gallium, and selenium, a buffer layer thin film (4) having a high resistance and formed of, for example, InS, ZnS, or CdS on the light absorption layer (3), and an upper electrode layer (5) (TCO) formed of, for example, ZnOAl. In order to connect a plurality of the unit cells (10) in series, a contact electrode portion (6) for connecting the upper electrode layer (5) and the lower electrode layer (2) is also formed. The contact electrode portion (6) has a larger Cu / In ratio than that of the light absorption layer (3). In other words, the contact electrode portion (6) is formed with a smaller amount of In and has a p+ type or conductor property with respect to the light absorption layer (3) that is a p-type semiconductor.

Owner:HONDA MOTOR CO LTD

A production method of an aluminum profile frame for a high-speed rail sound barrier

InactiveCN102275064AGuaranteed service lifeNo agingExtrusion profiling toolsCorrosion resistantWeather resistance

The invention relates to a production method of an aluminum section frame for a high-speed rail sound barrier. With aluminum bars as a main material, the novel aluminum alloy section frame is produced by the steps of mold designing, burdening, smelting, extruding, discharging, manual aging, powder spraying as well as assembling and forming. According to the invention, the aluminum alloy frame adopts a 45-degree design and is waterproof; and the aluminum alloy frame the surface of which is subjected to electrostatic powder spray treatment has no changes, such as aging, falloff, color fading and the like in terms of hydrochloric acid resistance, corrosion resistance, weather resistance, and the like after being subjected to experiments for 1000h; and the service life of an assembly is ensured.

Owner:JIANGSU KAILUN ALUMINUM

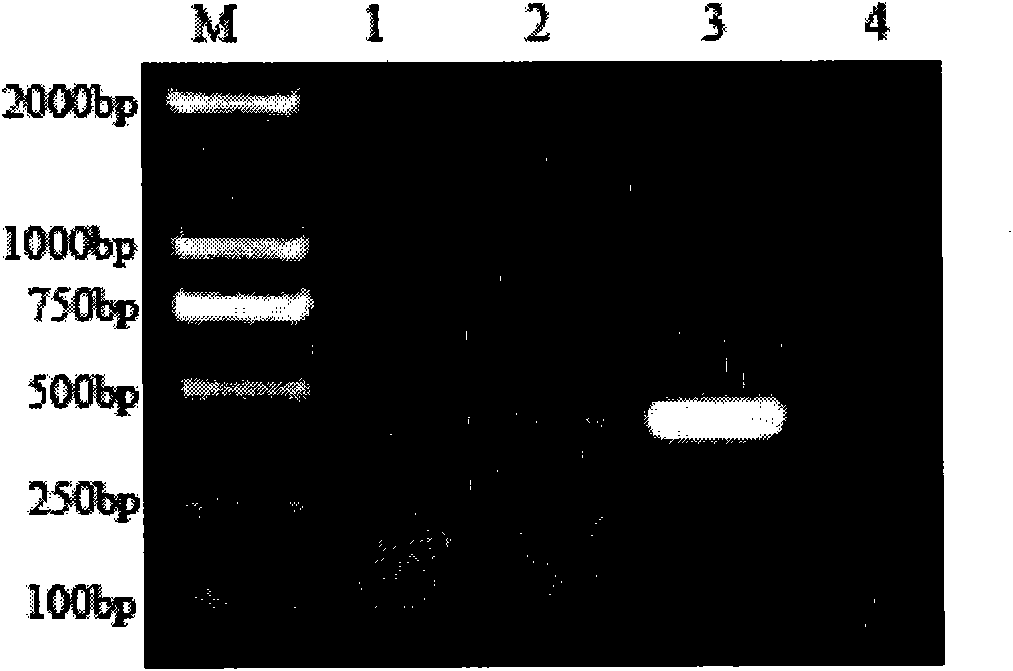

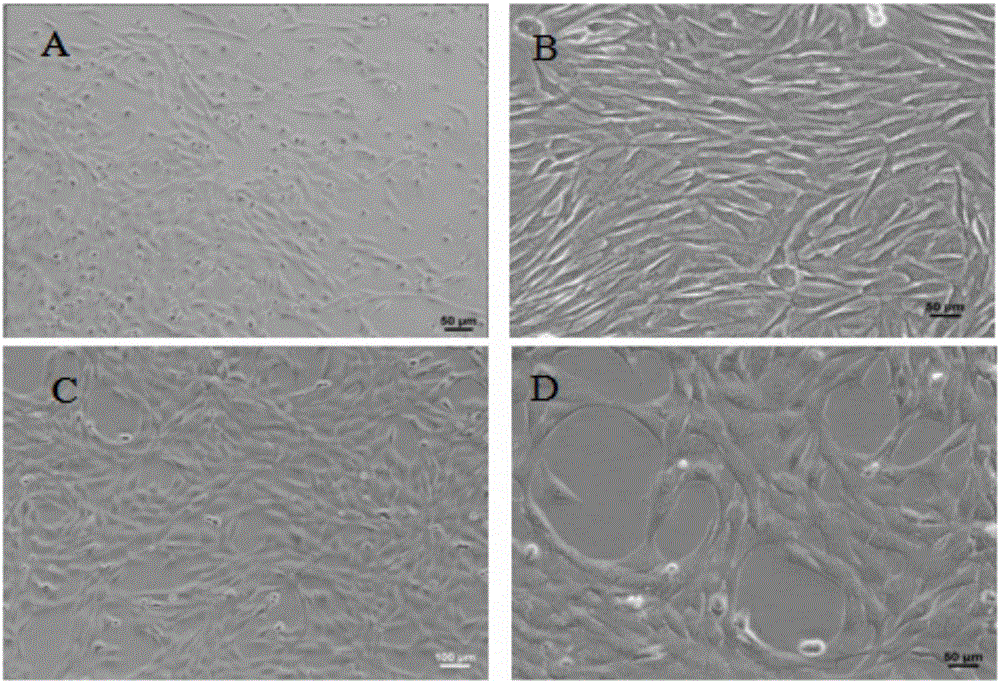

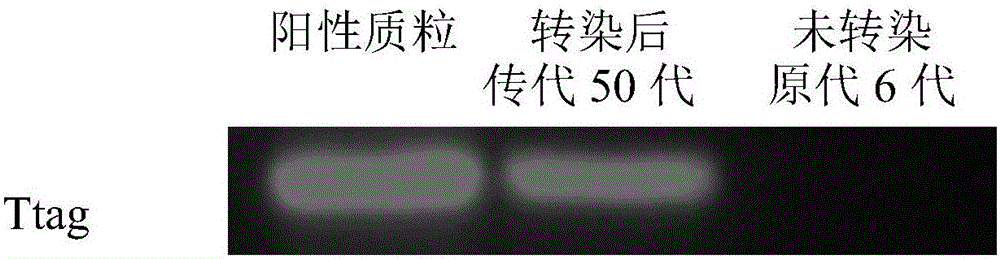

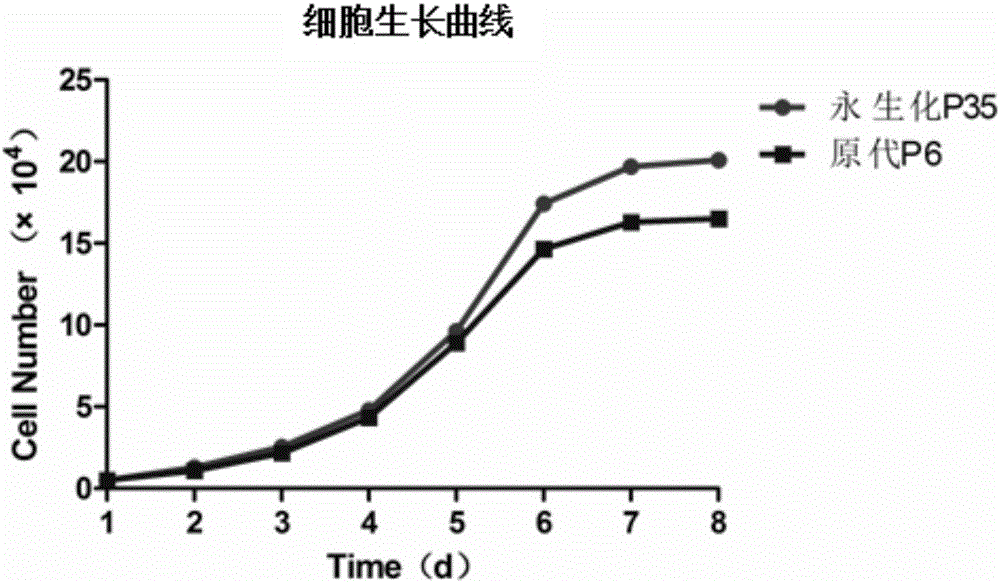

Immortalized canine adipic mesenchymal stem cell line and constructing method thereof

InactiveCN105779395APromote growthMultidirectional differentiation potential performanceMicroorganism based processesSkeletal/connective tissue cellsStem cell lineMesenchymal stem cell

The invention discloses an immortalized canine adipic mesenchymal stem cell line and a constructing method thereof. The immortalized canine adipic mesenchymal stem cell line capable of expressing SV40 large T antigen genes and having multidirectional differentiation is obtained by: transfecting a lentiviral vector carrying SV40 large T antigen (Ttag) by using canine adipic mesenchymal stem cells as host cells, integrating the Tag genes into an adipic mesenchymal stem cell genome and carrying out continuous passage and screening. This cell line is still active in case of 50 in-vitro passages, is high in differentiation and proliferation performance, never ages or dies, can also save medium cost and is an immortalized cell line.

Owner:NORTHWEST A & F UNIV

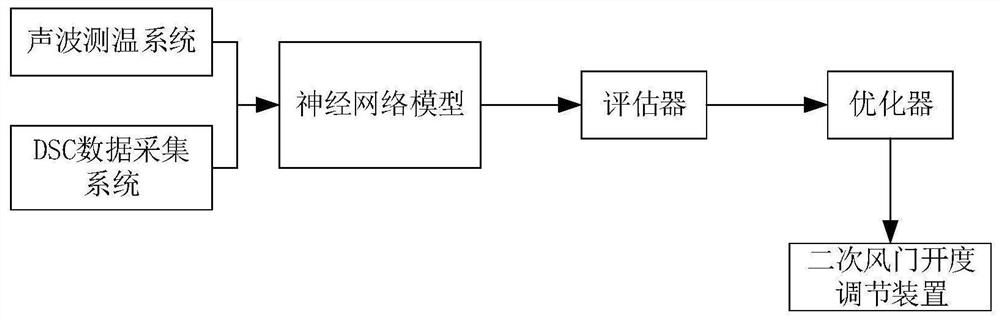

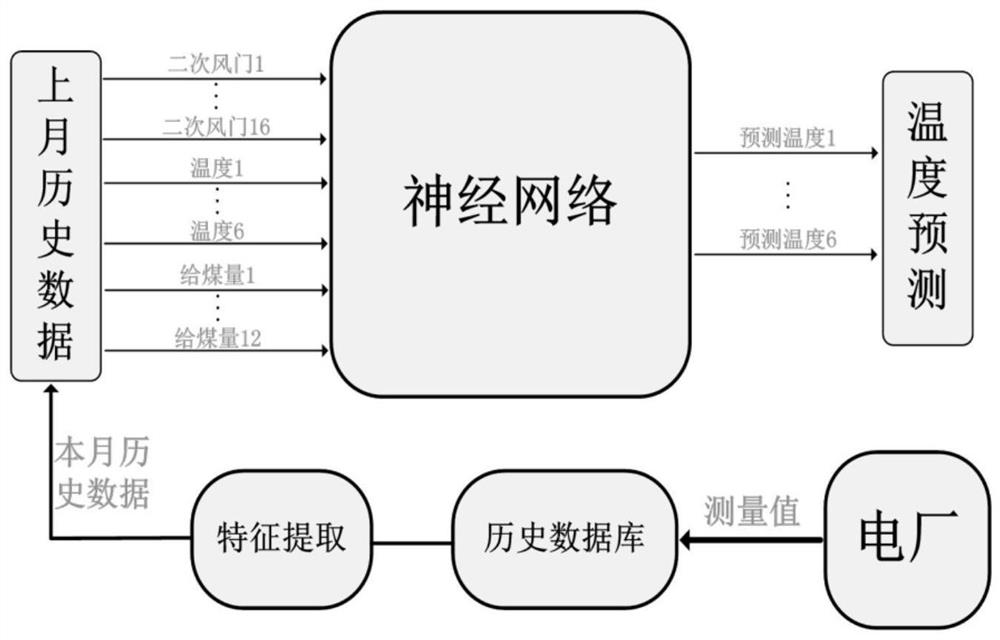

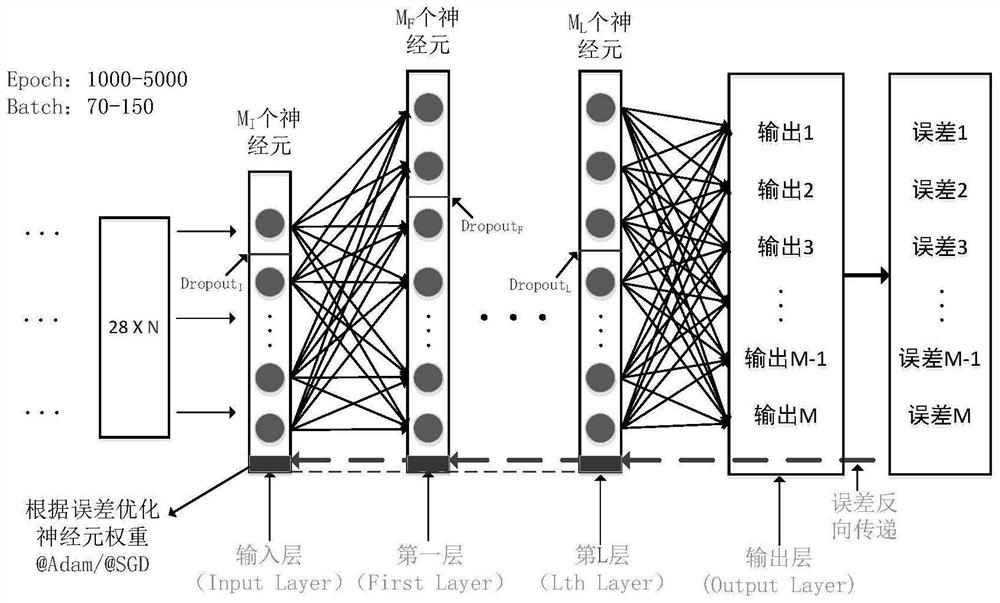

Combustion control system and control method for power plant

ActiveCN111829003AImprove generalization abilityReduce mistakesAir supply regulationTotal factory controlData acquisitionNetwork model

The invention discloses a combustion control system for a power plant. The combustion control system comprises a data acquisition part, a control part and an execution part. The data acquisition partcomprises a sound wave temperature measurement system and a DCS data acquisition system. The control part comprises a neural network model module, an evaluator and an optimizer. The execution part comprises a secondary air door opening degree adjusting device. The invention further discloses a combustion control method for the power plant. According to the system and the method, a neural network is adopted to construct a model, and extremely high universality and transportability are achieved. According to the system and the method, stable, long-term and manual intervention-free combustion canbe achieved for the power plant, and the purposes of reducing coal consumption and NOx and CO emissions as much as possible, reducing the combustion temperature of a hearth, uniform combusting and reducing the smoke temperature under the condition of a given load can be achieved.

Owner:嘉兴汇智诚电子科技有限公司

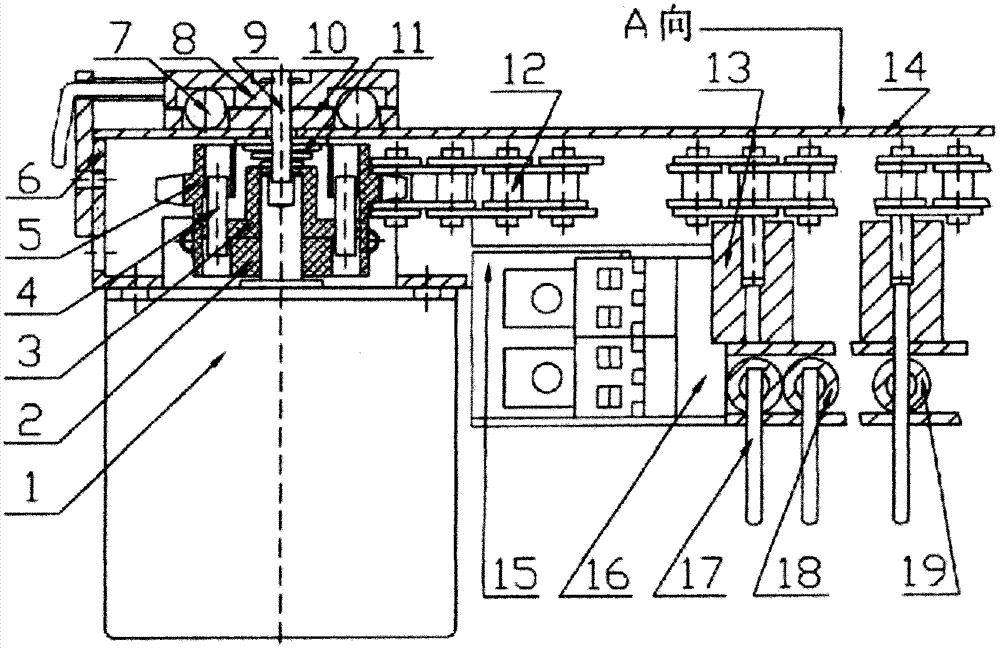

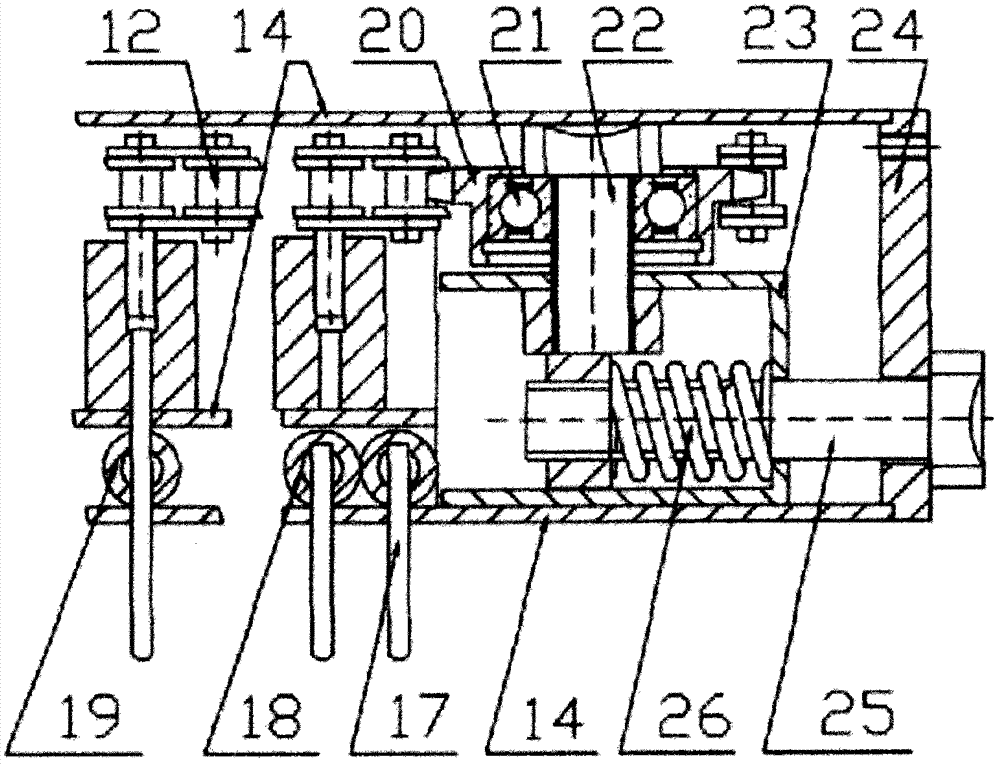

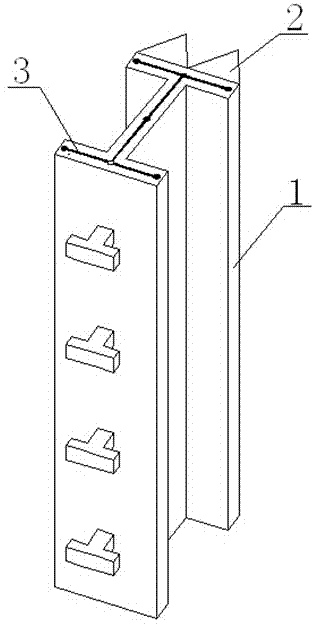

Motor-transmission device double-rail electric curtain machine capable of opening and closing two curtains in single direction or double directions

InactiveCN103494499AKeep private spaceNeat appearanceCurtain accessoriesDrive wheelReciprocating motion

The invention relates to an electric curtain machine. The electric curtain machine comprises a motor, a transmission device and a double-rail aluminum alloy machine box with the -shaped cross section and is controlled manually with one button, capable of performing limiting automatically, provided with a built-in minitype clutch device and capable of driving one curtain (a window shade or a gauze shade) or simultaneously driving two curtains (window shades or gauze shades). The electric curtain machine overcomes the defects existing in the situation that a motor and a transmission device cannot simultaneously drive double rails and two curtains. A minitype alternating current gear motor, a clutch driving device with a major functional piece arranged in a hollow wheel hub of a driving wheel, a driven wheel device with the tension capable of being adjusted, a nickel-plated chain, nylon travel idler wheels, nylon idler wheels, nylon pulleys, a travel limiting switch and stainless hooks are integrated inside and outside the double-rail aluminum alloy machine box. According to the electric curtain machine capable of being operated by hand after power failure, the chain is made to make horizontal reciprocating motor in the machine box through frontward and backward rotation of the motor so that the one or two curtains below the double rails can be driven to be opened or closed and stopped in a single direction or in double directions and can make the two curtains be opened or closed simultaneously.

Owner:王晓东

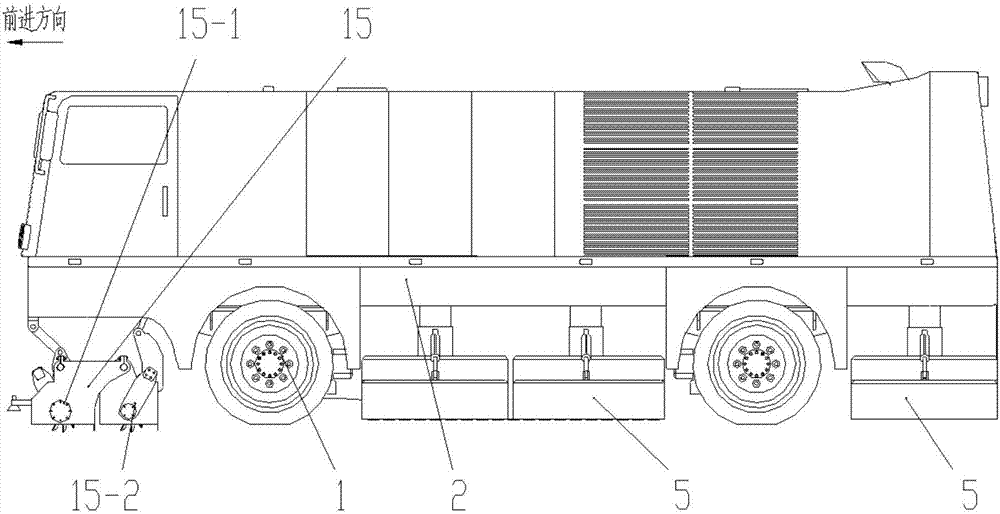

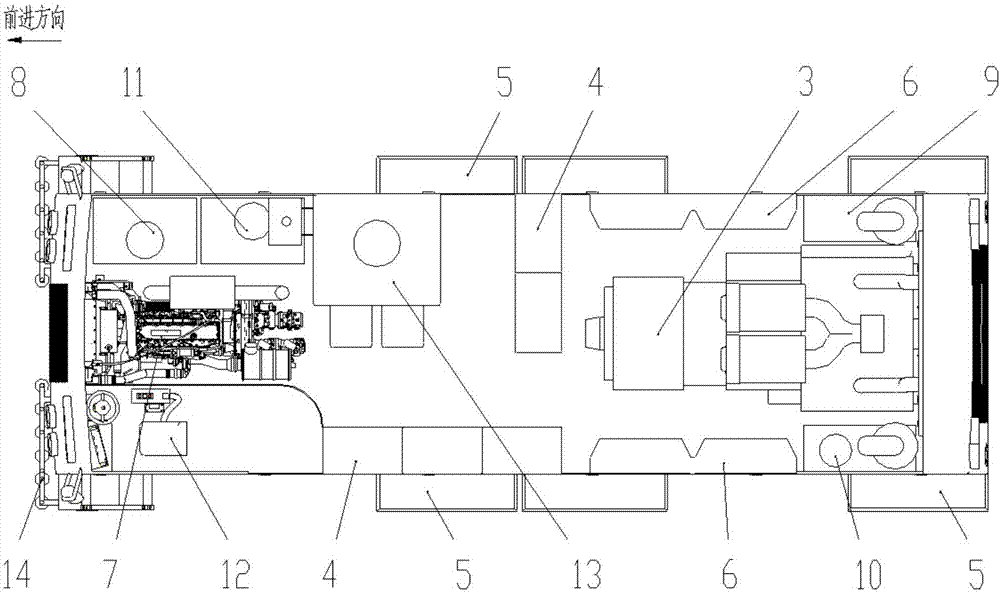

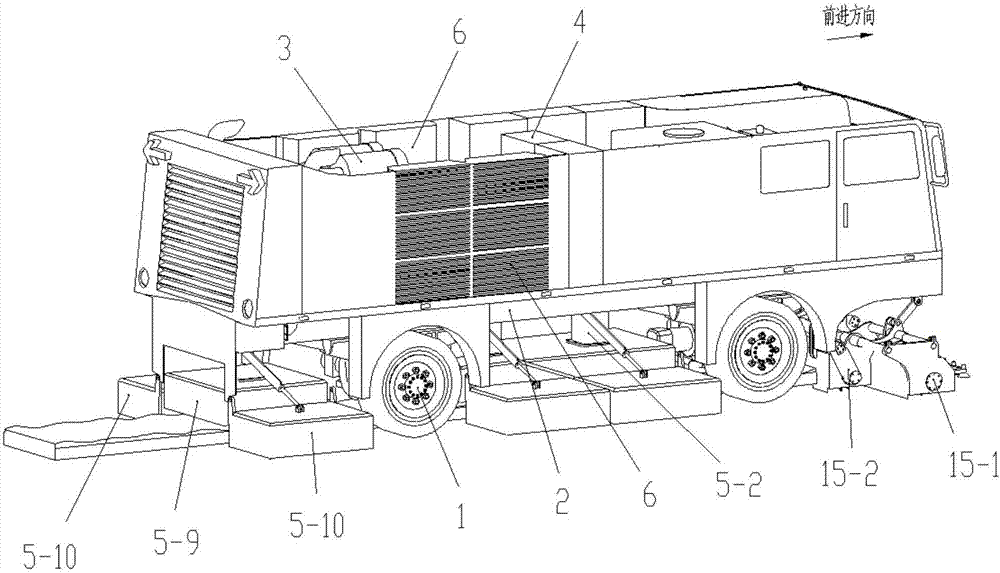

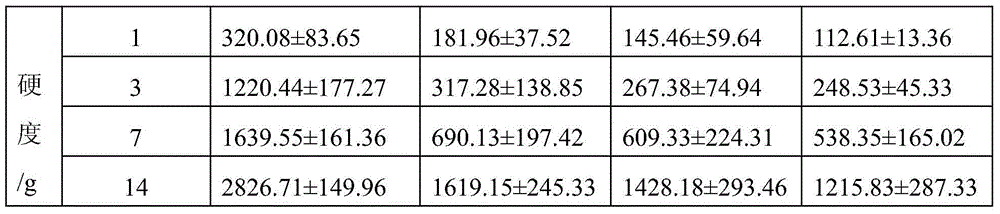

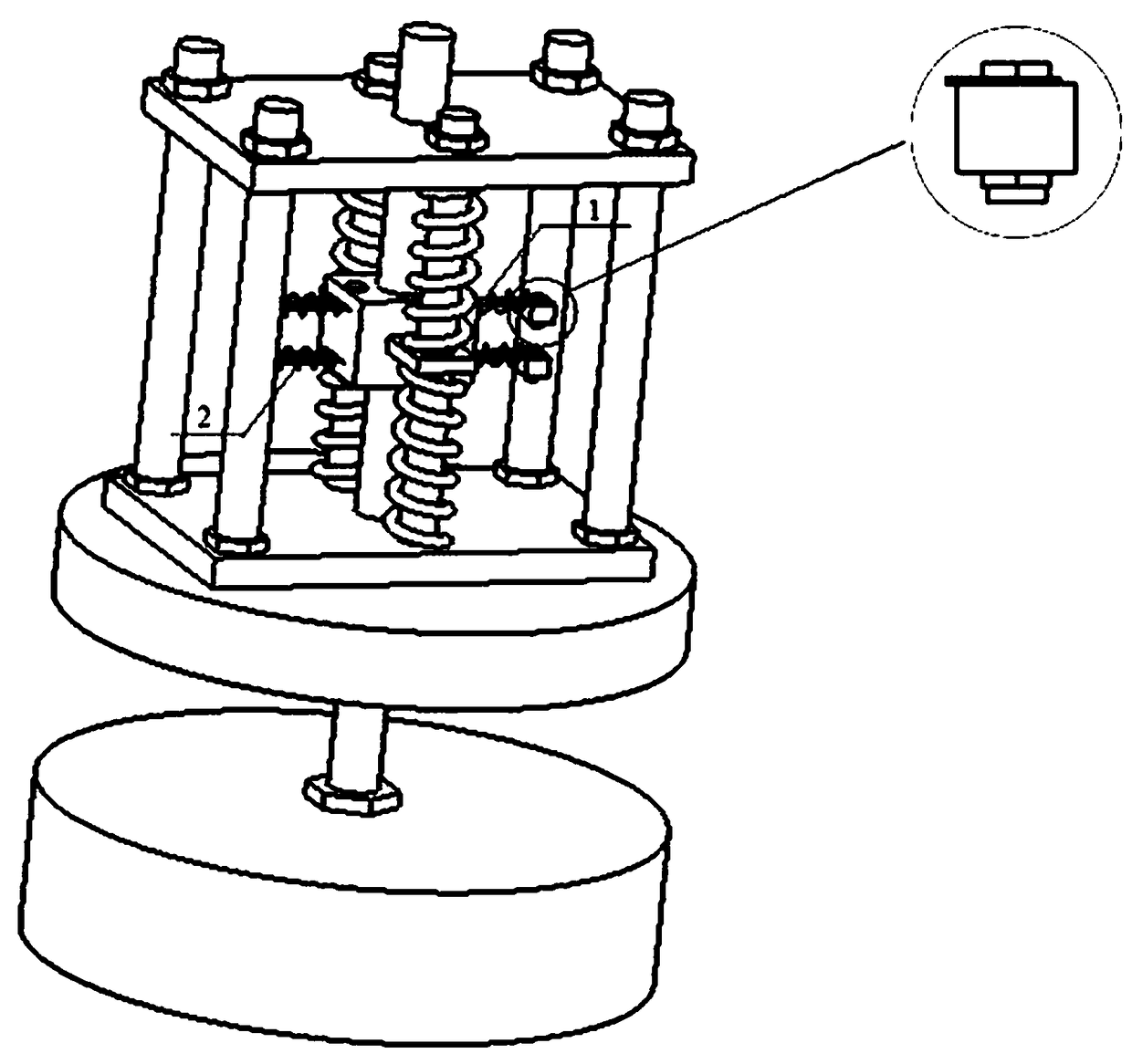

Microwave heating raking machine and microwave heating wall

The invention discloses a microwave heating wall for a microwave heating raking machine. The microwave heating wall consists of a main microwave heating wall and auxiliary microwave heating walls hinged to two sides of the main microwave heating wall, the main microwave heating wall and the auxiliary microwave heating walls have identical structure, several rows of microwave heating components are evenly arranged inside a microwave heating frame, each microwave heating component comprises a microwave generation magnetron, a waveguide antenna is connected below a microwave radiation port of the microwave generation magnetron, and a wave transparent protection board is horizontally arranged below the waveguide antenna. The microwave generation magnetrons in the main microwave heating wall generate microwave energy with frequency of 2.45GHz, and the microwave generation magnetrons in the auxiliary microwave heating walls generate microwave energy with frequency of 5.8GHz. According to the invention, a 2.45GHz and 5.8GHz frequency combined microwave heating technology is employed to realize reheating and temperature raising of asphalt pile gathered after harrowing and thermal caking heating of asphalt pavement after harrowing, the asphalt material is free of aging and coking, and is efficient and environment-friendly.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

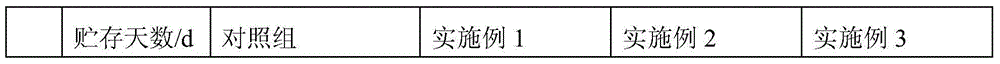

Anti-retrogradation germinated brown rice cake and production method thereof

InactiveCN104686935AExtended shelf lifeReduce the degree of regenerationFood preparationAmylaseNutritive values

The invention provides anti-retrogradation germinated brown rice cake and a production method thereof. The raw materials comprise glutinous rice flour and germinated brown rice flour, and the glutinous rice flour and the germinated brown rice flour are collectively referred to be as total rice flour; the weight of the germinated brown rice flour accounts for 30-50% of the weight of the total rice flour; the following additives are added in the total rice flour: 3-5% of vegetable oil, 5-8% of white granulated sugar, 2-3% of oxidized hydroxypropyl starch, 2-3% of wheat gluten powder, 0.3-0.5% of monoglyceride, 0.005-0.008% of beta-amylase and 60-65% of water. The germinated brown rice flour containing an anti-retrogradation component is added in the glutinous rice flour to serve as a main raw material for preparing rice cake, so that the nutritive value of the rice cake can be reinforced, the taste and flavor of the rice cake can be improved, and the retrogradation degree of the rice cake can also be greatly reduced.

Owner:JIANGNAN UNIV

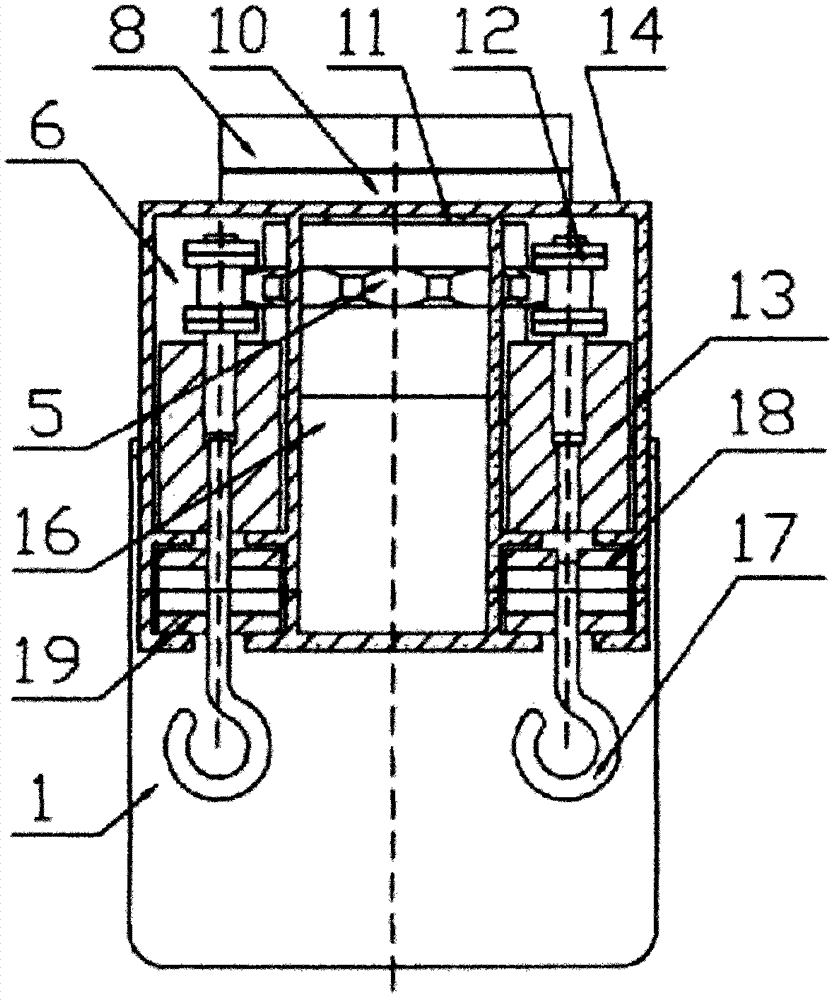

Float-type wave vibration generating device for magnetostriction slice

InactiveCN109026508AImprove energy conversion efficiencyNo fatiguePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesInterference fitDrive shaft

The invention relates to a float-type wave vibration generating device for a magnetostriction slice. The overall structure of the float-type wave vibration generating device is a symmetrical structure. The float-type wave vibration generating device comprises a fixing block. A transmission shaft sequentially penetrates through a floating body, a supporting plate, a lower end plate, the fixing block and an upper end plate from bottom to top. The fixing block is fixed to the transmission shaft in an interference-fit mode, and the upper end plate and the lower end plate are connected through a centrosymmetric supporting shaft. Two guide rods penetrate through through holes in the two ends of the fixing block correspondingly. An upper spring and a lower spring are vertically arranged on the guide rods in a sleeving mode. One end of the super-magnetostriction slice is fixed into a rectangular groove in the side face of the fixing block, and the other end of the super-magnetostriction sliceis provided with a mass block. A pick-up coil is wound on the super-magnetostriction slice. The transmission shaft drives the fixing block to swing vertically to provide vibration for the super-magnetostriction slice, electric energy generated in the generating process is picked up through the pick-up coil, and the energy collecting process for converting vibration energy generated in the wave fluctuation motion process into the electric energy to be output is achieved.

Owner:SHENYANG POLYTECHNIC UNIV

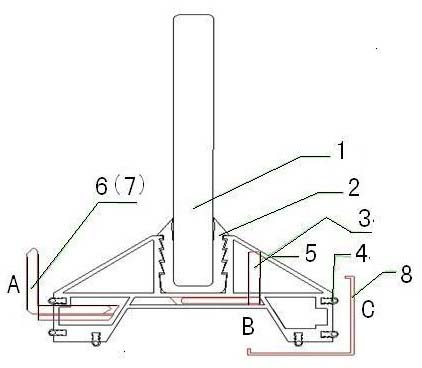

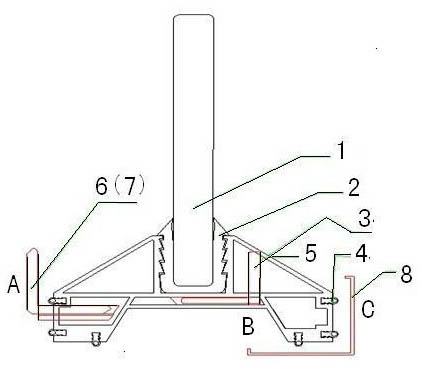

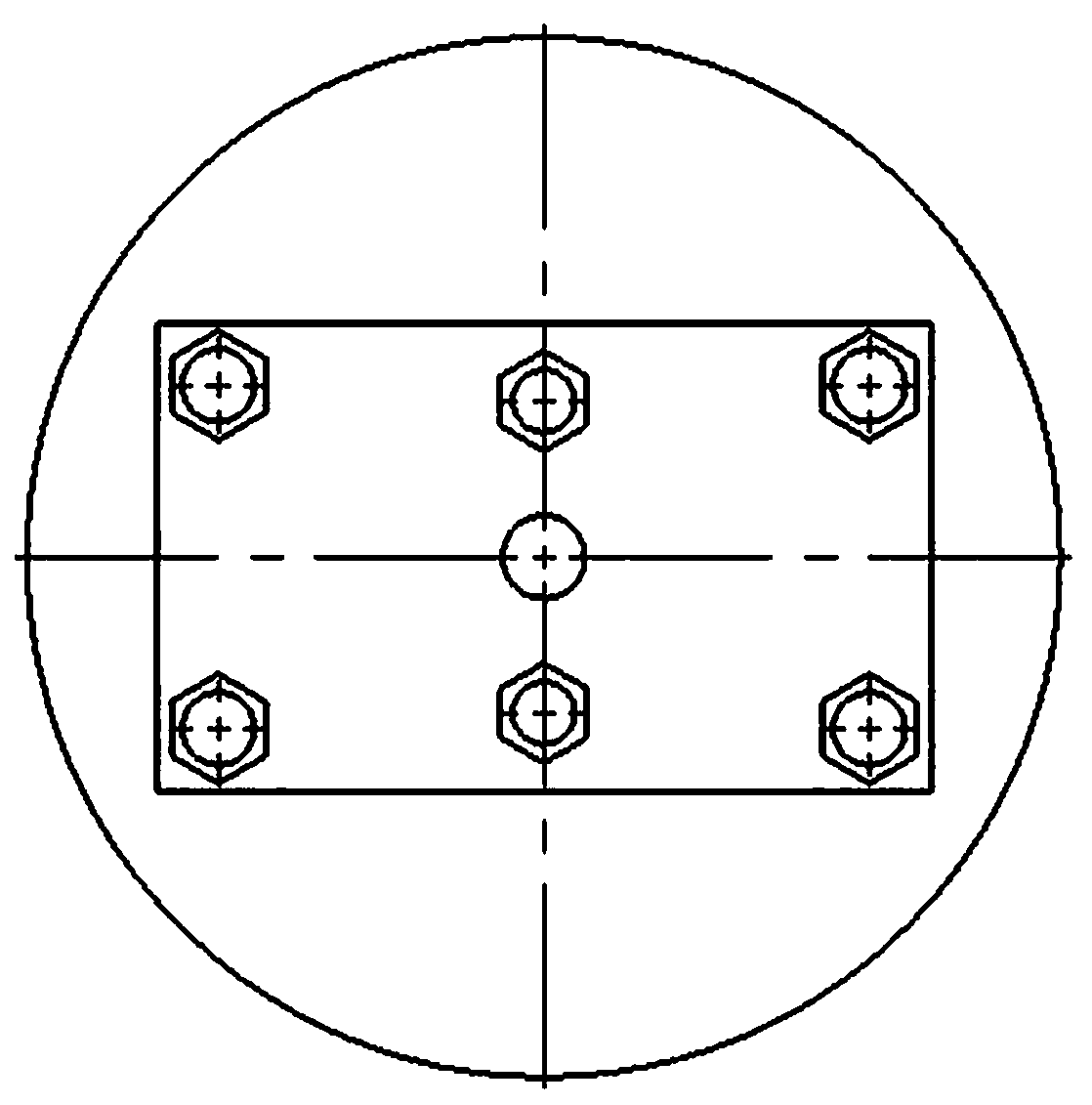

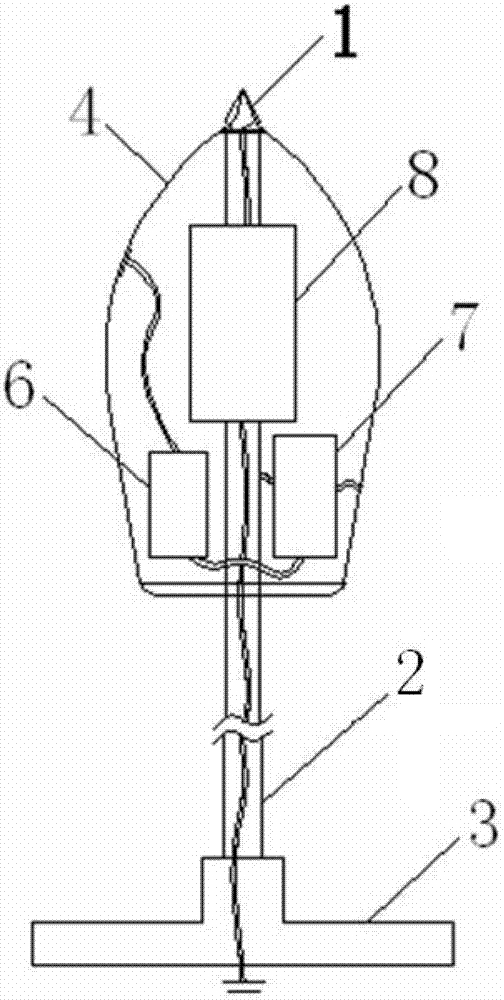

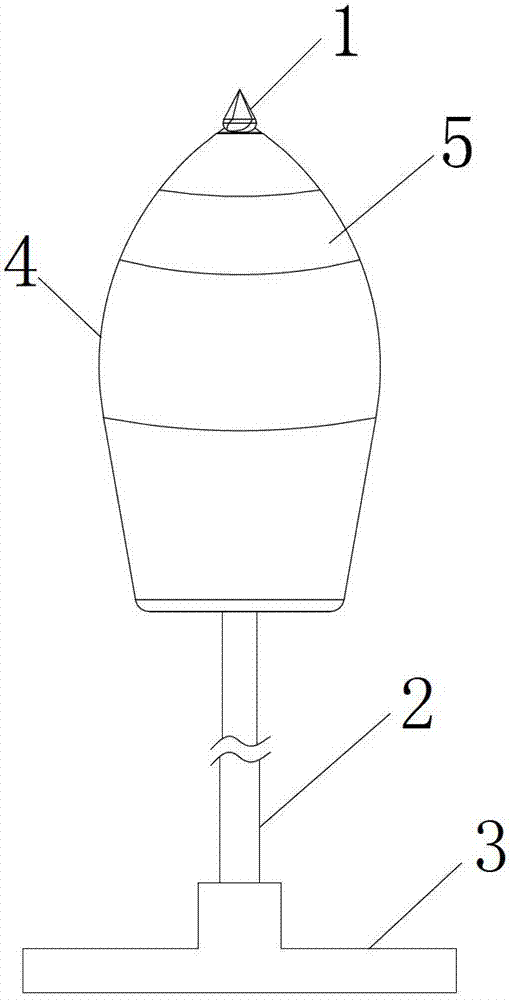

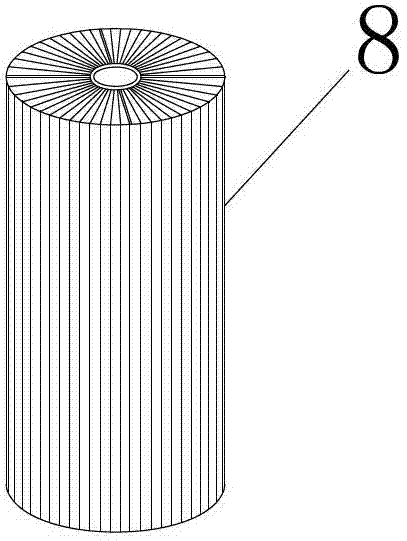

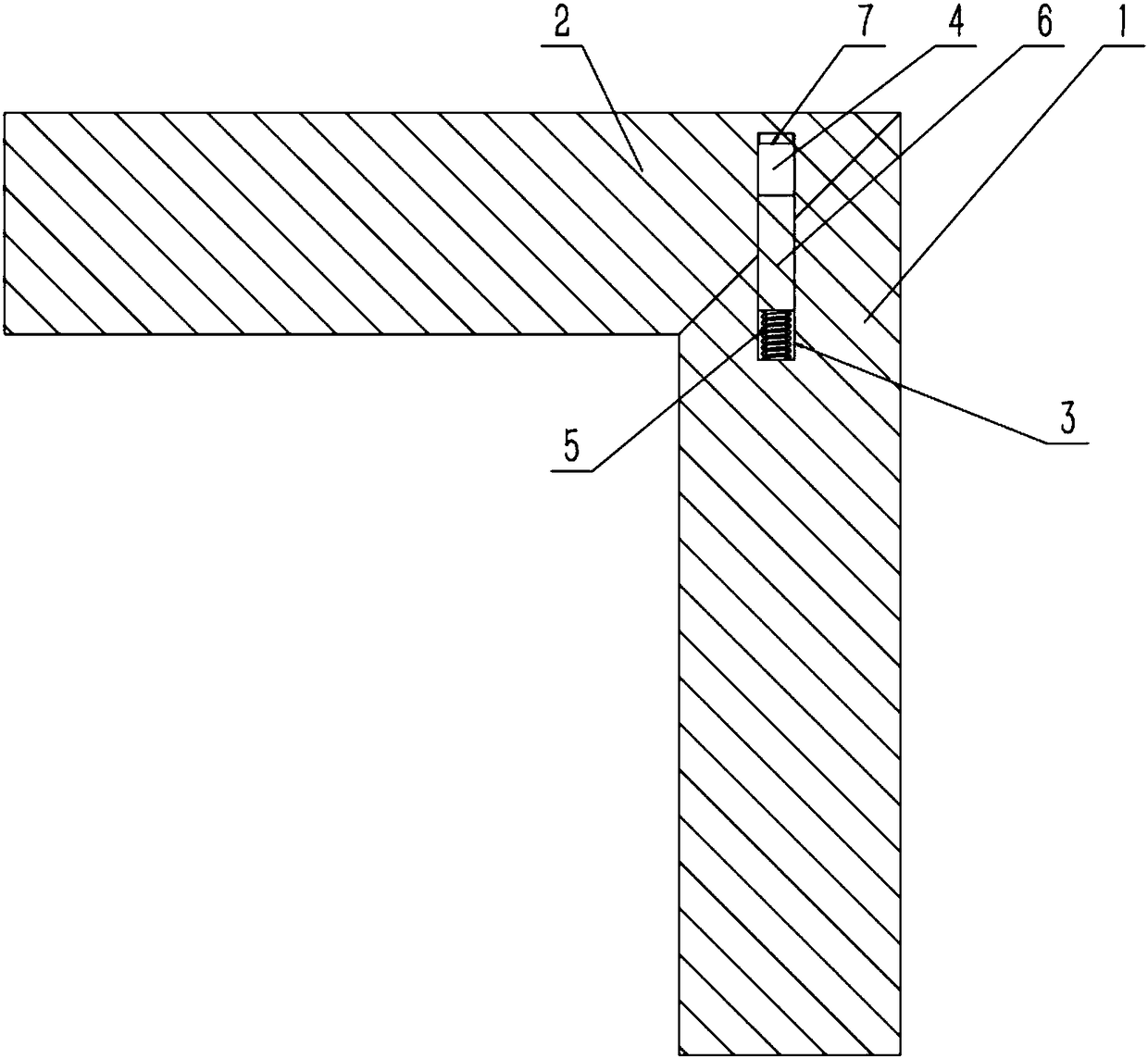

Predischarge lightning conductor

InactiveCN102769254AImprove protectionFast response discharge sensing timeBatteries circuit arrangementsElectric powerLightning rodEngineering

The invention relates to the technical field of lightning protection equipment, in particular to a predischarge lightning conductor. The predischarge lightning conductor comprises an air-terminal body (1), a downlead, a supporting rod (2) and a substrate (3), wherein the air-terminal body (1) is fixedly connected with one end of the downlead; the other end of the downlead is connected with the substrate (3); the substrate (3) is grounded; the downlead is arranged in the supporting rod (2); a lightning conductor cover (4) is arranged at the upper part of the supporting rod (2); a solar absorption board (5) is mounted on the outer surface of the lightning conductor cover (4); a storage battery (6) and a predischarge induction device (7) are internally arranged in the lightning conductor cover (4); and the predischarge induction device (7) is connected with the conductor cover (4) and the downlead in a circuit mannner. Compared with the prior art, the predischarge lightning conductor is novel and simple in structure; a predischarge function is achieved; protection radius is larger; lightning current pulse intensity in each air terminating is reduced; and a secondary effect caused by lightning induction is reduced.

Owner:上海库革电气设备制造有限公司

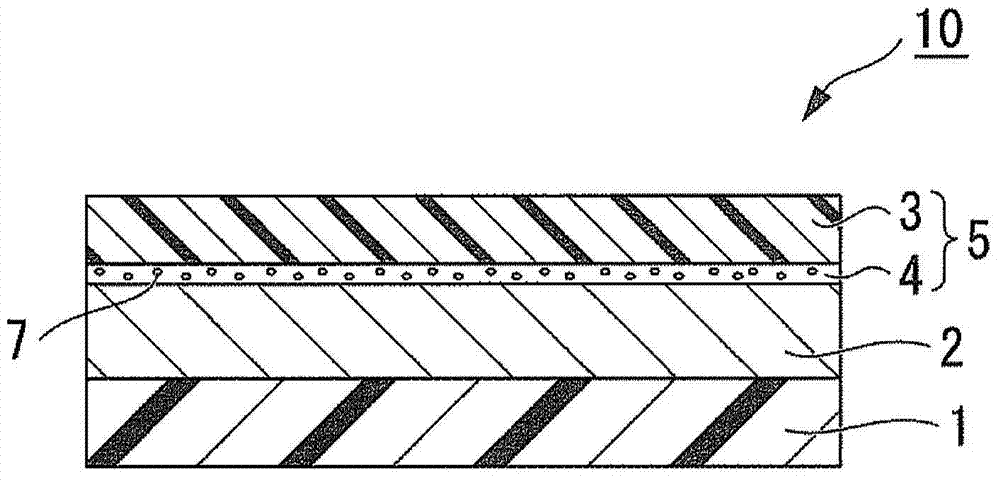

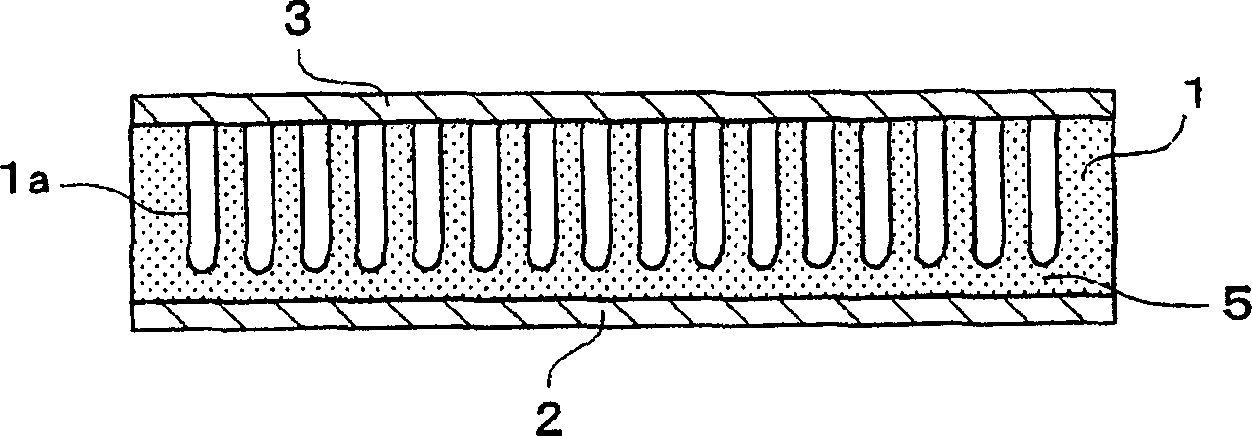

Surface protection film and optical component attached with the film

ActiveCN104342044AReduce pollutionSuppresses peeling static voltageOther chemical processesFilm/foil adhesivesTectorial membraneStatic performance

The invention provides a surface protection film having little pollution to an adhered object, low pollution unchanged along with the time, and good anti-stripping static performance without degradation, and an optical component attached with the surface protection film. The surface protection film (10) is provided with an adhesive layer (2) on a single surface of a substrate film (1) formed by transparent resin, and a stripping film (5) adhered with a stripping agent layer (4) is adhered to the adhesive layer (2), wherein the stripping film (5) is formed by forming the stripping agent layer (4) on the single surface of a resin film (3). The stripping agent layer (4) comprises the stripping agent adopting dimethyl polysiloxane as the main component, a polysiloxane compound that is liquid below 20 DEG C and a resin composition of an ionic compound having a melting point of 30-80 DEG C. The adhesive layer (2) is an acrylic acid type adhesive layer.

Owner:FUJIMORI KOGYO CO LTD

High-ductility cement-based material and preparation method thereof

The invention relates to the technical field of a cement-based material, in particular to a high-ductility cement-based material. The high-ductility cement-based material is prepared from silicate cement, coal ash, quartz sand, water, water reducing agent, thickening agent, PVA fibers and concrete expanding agent, and the weight percent of each component in the material to the silicate cement is as follows: 1.0 to 2.5 percent of coal ash, 0.8 to 1.2 percent of quartz sand, 0.8 to 0.85 percent of water, 0.005 to 0.05 percent of water reducing agent, 0.001 to 0.003 percent of thickening agent, 0.08 to 0.12 percent of concrete expanding agent, and the total volume ratio of the PVA fibers is 0.005 to 0.025 percent. The high-ductility cement-based material has good mobility, can basically reacha self-flatting agent, and is excellent in mechanical properties, good in anti-freeze performance, good after being circulated for 300 times in a thawing manner, and applicable to a cold district; the material is good in waterproofness, the seepage resistance grade of the material is 12, and the 28-day carbonization test depth is 12 mm; impact resistance and shock resistance are good; and the high-ductility cement-based material is resistant to the radiation of ultraviolet rays, and free from aging and failure at a low temperature.

Owner:东莞市润阳联合智造有限公司

Antimicrobial sheet material capable of generating negative ion far-infrared

InactiveCN101195235AUnique formulaImprove ventilation functionMixing operation control apparatusCeramic shaping plantsIonBlood circulation

The invention provides an antibacterial plank capable of producing negative ion and far infrared ray for a long time. The invention is made by mixing, stirring, and blank forming with the following components according to weight percentage, then placing the blank in rail kiln for baking under constant temperature, wherein tourmaline concentrate is 20-40%, nano-scale tourmaline powder is 5-10%, nano-scale titanium dioxide powder is 5-10%, and artificial marble material is 40-70%. Floors made of the antibacterial plank are capable of producing negative ion and far infrared ray for a long time, killing bacterium and hazardous substance in the air, improving blood circulation of human being, activating human histiocyte and increasing human immunity.

Owner:汪滔

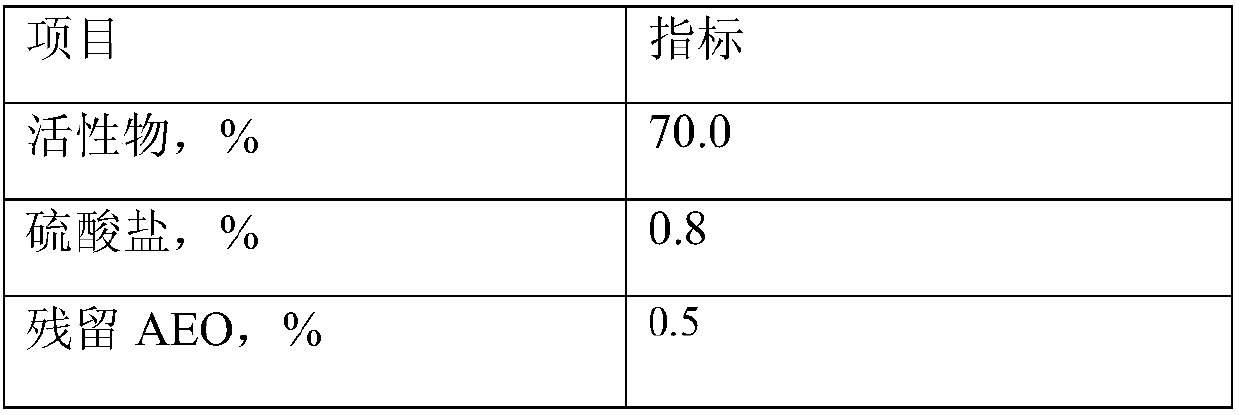

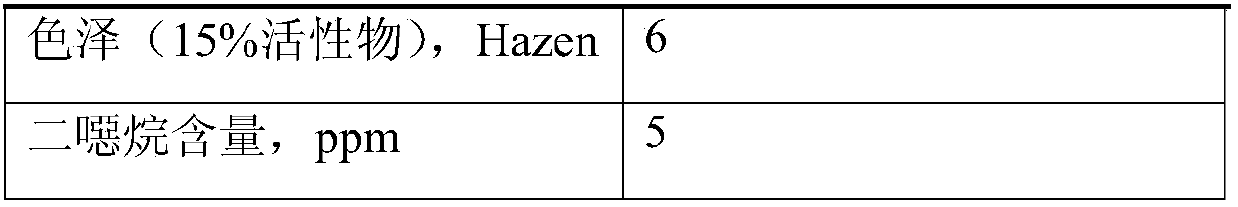

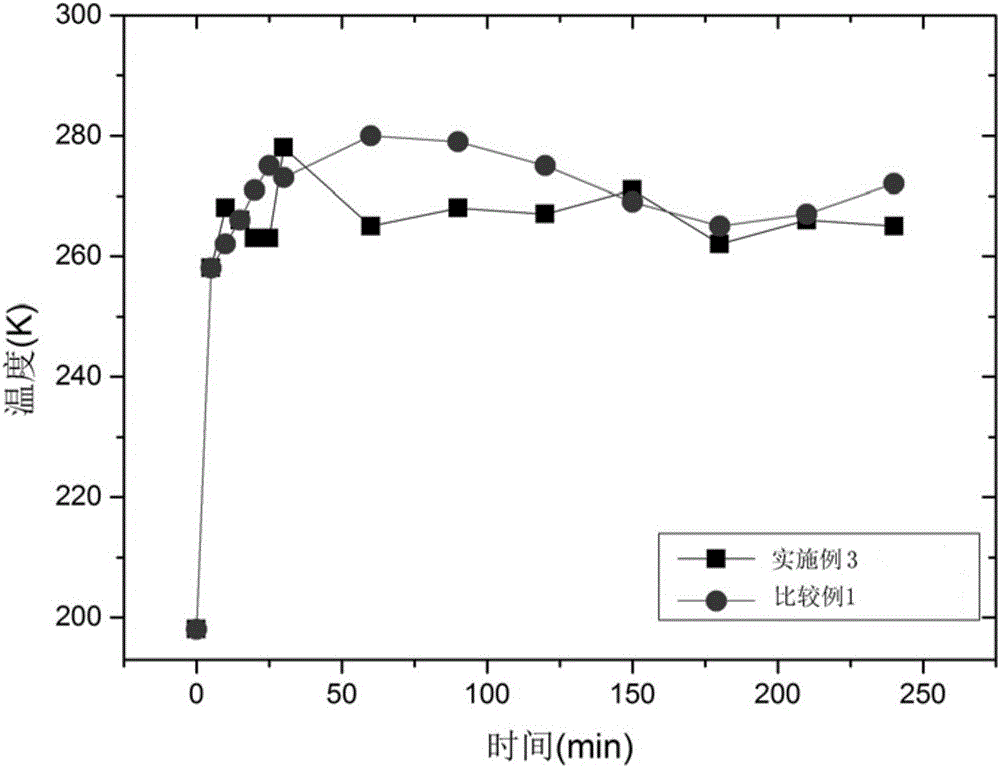

Production process of high-quality fatty alcohol polyoxyethylene ether sulfate

ActiveCN107915837ANo agingStabilize the sulfonation processSulfuric acid esters preparationChemistryVapor phase

The invention belongs to the technical field of fine chemicals. The invention aims at providing a production process of a high-quality fatty alcohol polyoxyethylene ether sulfate with high content ofactive matters, light color and low dioxane residues; and simultaneously, the process flow is simple and can be conveniently realized on an existing production device of the fatty alcohol polyoxyethylene ether sulfate without changing sulfonation equipment. The technical scheme is as follows: the production process of the high-quality fatty alcohol polyoxyethylene ether sulfate comprises the following steps: 1) pre-dissolving an appropriate amount of sulfonation stabilizer in fatty alcohol polyoxyethylene ether; 2) sulfonating the fatty alcohol polyoxyethylene ether pre-dissolved with the sulfonation stabilizer on an existing vapor phase SO3 film type sulfonation device according to an existing sulfonation production process of the fatty alcohol polyoxyethylene ether sulfate; and 3) enabling an sulfonated acid ester to directly enter a neutralization system without aging and producing the fatty alcohol polyoxyethylene ether sulfate according to an existing neutralization process.

Owner:河南赞宇科技有限公司

PTC inorganic composite material and preparation method and application thereof

ActiveCN106467412AConductiveRealize the effect of internal insulationHeating element materialsNon-adjustable resistorsGraphite carbonEconomic benefits

The invention provides a PTC inorganic composite material, which is mainly prepared from the following raw materials (by weight): 75-95% of a nano-ceramic material, 1-20% of a graphite carbon material coating agent and 0.5-5% of a dispersant. A preparation method of the composite material comprises the following steps: mixing the nano-ceramic material and the graphite carbon material coating agent, adding the dispersant and a proper amount of ethanol and uniformly mixing to obtain a uniform solution, and carrying out heat treatment under the protection of inert gas at the temperature of no more than 200 DEG C. According to the PTC inorganic composite material of the embodiment, an inorganic material, namely the nano-ceramic material, is compounded with the graphite carbon material coating agent, and the carbon material is used for coating particles of the inorganic material so as to realize conductivity and internal insulation effects of the carbon material. The material can be applied to electrical heating materials, such as carbon crystal heating panels. Properties are more stable, and problems such as aging, bloating, etc. will be avoided. Properties of the carbon crystal panels are subversively enhanced, service life is greatly prolonged, and considerable economic benefit is also generated.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Sound barrier upright post and preparation method of sound barrier upright post

ActiveCN104775369AImprove sound absorption performanceNon-corrosiveNoise reduction constructionCeramic shaping apparatusFiberSound barrier

The invention discloses a sound barrier upright post, comprising an upright post body and sound absorption materials; the upright post body is made of reactive powder concrete; the sound absorption materials are composited on wing edges, facing one side of a sound source, of the upright post; the cross section of the upright post body is of an H shape; the reactive powder concrete comprises the components of cement, mineral powder, rice hull ash, natural sand, quartz powder, polycarboxylate superplasticizer, steel fiber and water at the mass ratio of 1: (0.15-0.25): (0.23-0.28): (1.15-1.25): (0.35-0.40): (0.02-0.025): (2.5-3.0): (0.22-0.25). The sound barrier upright post is made of the non-metal materials, so the phenomena such as corrosion, aging and bolt looseness are avoided; the service life of the upright post is equal to or even longer than a main body structure, no maintenance is needed when the upright post is used and the long-term economic benefit is obvious; the upright post has extremely high safety and reliability.

Owner:JIANGSU XINGUANG ENVIRONMENTAL PROTECTION ENG

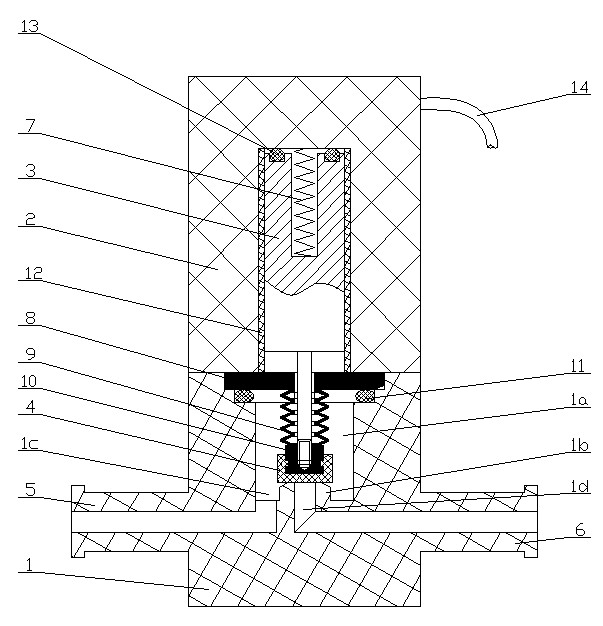

Electromagnetic valve for blood purification

ActiveCN102091381AGood biological propertiesStainlessDialysis systemsMedical devicesDisinfectantEngineering

The invention discloses an electromagnetic valve for blood purification. The bottom of the inner cavity of a valve body is provided with an annular boss; a seal gasket for sealing the central hole of the annular boss is positioned in the inner cavity of the valve body; the inner cavity of the valve body is provided with an elastic isolating piece, the upper end of the isolating piece is compressed tightly and fixed by a coil body, and the lower end of the isolating piece is fixedly connected with the seal gasket; the lower end of a slide iron core extends into an isolating body and is fixedly connected with the isolating body; and the inner hole at the upper end of the slide iron core is internally provided with a spring, and the upper end of the spring is connected with the coil body in a propping manner. The electromagnetic valve for blood purification provided by the invention has the advantages of good biology performance and high corrosion resistance, and can not rust, can not cause medium pollution, and can not be aged even if liquids with high corrosivity such as a disinfectant, acid liquor and the like are used; and the actions of the slide iron core are flexible and reliable, and the noise of the electromagnetic valve is lower during starting and closing.

Owner:SWS HEMODIALYSIS CARE CO LTD

Electron source device and display

InactiveCN1714420AStrong launching abilityAvoid direct contactNanoinformaticsImage/pattern display tubesElectron sourcePorous layer

An electron source device comprising a porous layer (for example, a porous alumina layer) composed of an insulator and having a plurality of micropores arranged in a direction perpendicular to a main surface; and first and second electrodes arranged on both sides of the porous layer. 2 conductive layers, the current density I / S when the second conductive layer is used as an anode and a DC voltage is applied between the first conductive layer and the first conductive layer is 1 μA / cm2 or more. In the formula, S represents the area of the overlapping portion of the first conductive layer, the second conductive layer, and the porous layer. Since an electron source device with high electron emission capability, low cost, and long life even at a low degree of vacuum can be obtained, a display device with high luminous efficiency and high reliability can be realized.

Owner:KK TOSHIBA +1

Damping rubber material

InactiveCN105440464AImprove mechanical propertiesImprove shock absorptionRubber materialParaffin wax

The invention discloses a damping rubber material. Raw materials of the damping rubber material comprise, by weight, 50-70 parts of butyl rubber, 30-50 parts of butadiene-acrylonitrile rubber, 50-70 parts of a composite filler, 15-25 parts of micro-encapsulation red phosphorus, 10-15 parts of melamine phosphate, 5-8 parts of tributyl phosphate, 10-15 parts of epoxidized soybean oil, 15-25 parts of tributyl citrate, 0.5-0.8 part of sulphur, 0.1-0.2 part of stearic acid, 0.1-0.15 part of zinc oxide, 0.2-0.4 part of a promoter DM, 2-4 parts of a Ca / Zn compound stabilizer, 2-4 parts of dibutyltin dilaurate, 0.1-0.3 part of an anti-aging agent RD, 0.1-0.2 part of an anti-aging agent 445, 0.2-0.4 part of an anti-fatigue agent PL and 3-5 parts of paraffin. Raw materials of the composite filler contain modified nano-white carbon black and beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic octadecanol. The damping rubber material of the invention has good damping performance.

Owner:宁国市开源橡塑汽车零部件有限公司

Environment-friendly furniture wood connecting structure

The invention discloses an environment-friendly furniture wood connecting structure. The structure comprises a first wood piece and a second wood piece, wherein corner cutting surfaces of the first wood piece and the second wood piece are attached to each other, and a first rectangular hole and a second rectangular hole which are vertically arranged and communicate with each other are formed in the corner cutting surfaces of the first wood piece and the second wood piece correspondingly; and an elastic body is fixed at the bottom of the first rectangular hole. The environment-friendly furniture wood connecting structure has the beneficial effects that through the first rectangular hole and the second rectangular hole arranged oppositely to each other in the corner cutting surfaces of the first wood piece and the second wood piece correspondingly, a bolt is attracted by a strong magnet, so that the bolt is positioned between the first wood piece and the second wood piece, and the freedom degree of the first wood piece and the second wood piece is limited, so that the purpose of fixing the first wood piece and the second wood piece is achieved; and the structure does not need to useglue, and harmful substances harmful to the body and the environment cannot be generated, aging is avoided, and the service life of the furniture is greatly prolonged.

Owner:金福生

Special porelike grouting agent for bridge concrete

The invention discloses a special porelike grouting agent for bridge concrete, which is characterized by being prepared from the following additives in proportion: 81.5-90.8 percent of dispersing agent, 4-8 percent of water reducing agent, 0.2-0.5 percent of plastic expanding agent, 1-3 percent of enhancer and 4-7 percent of adjustable solidification agent. Compared with the prior art, the special porelike grouting agent has the following remarkable advantages: the flowability is excellent, the mud jacking has the characteristics of fullness, early strength, minimum inflation and the like, the product has higher fullness, one-time mud jacking construction can be realized, slurry inside a pipe is compact and clearance-free, prestressed reinforcement is not corroded and firmly sticked with concrete, a plurality kinds of materials are not needed on the spot, out-of-date products are eliminated, energy consumption is reduced, and the special porelike grouting agent can be used immediately when water and cement are added and uniformly stirred on the spot, the operation is simple and convenient, the durability of bridges is improved, and the service life of bridges are prolonged.

Owner:URUMQI JIANBAO TIANHUA NEW MATERIAL TECH CO LTD

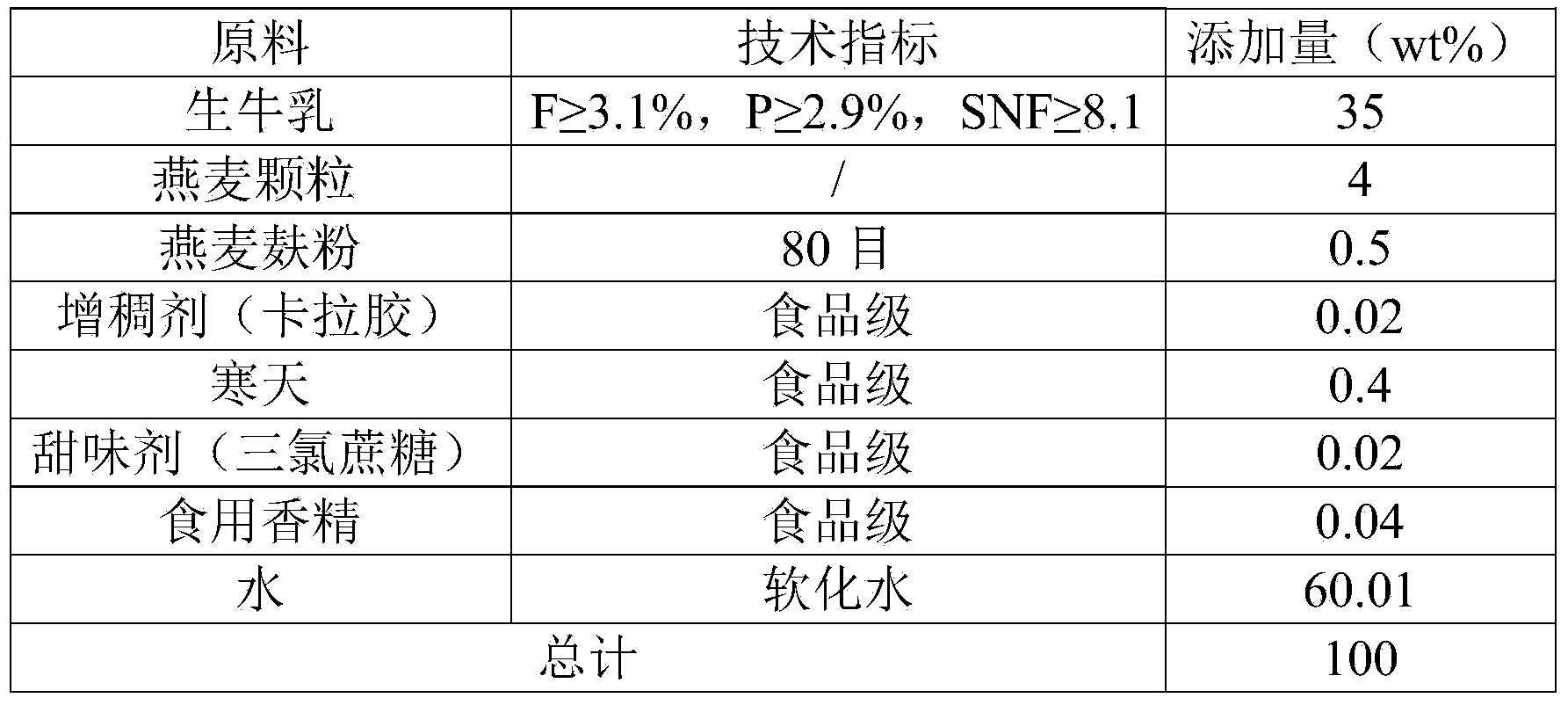

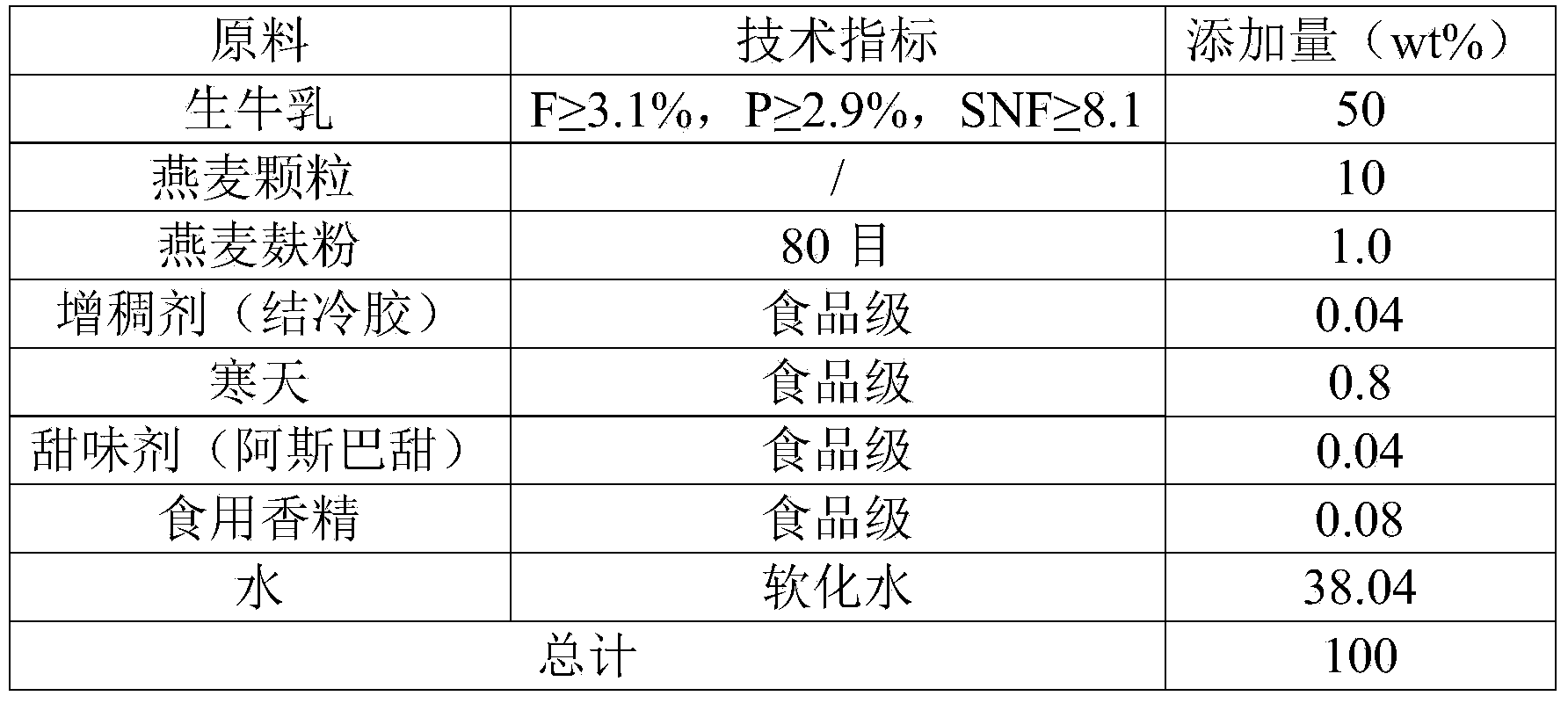

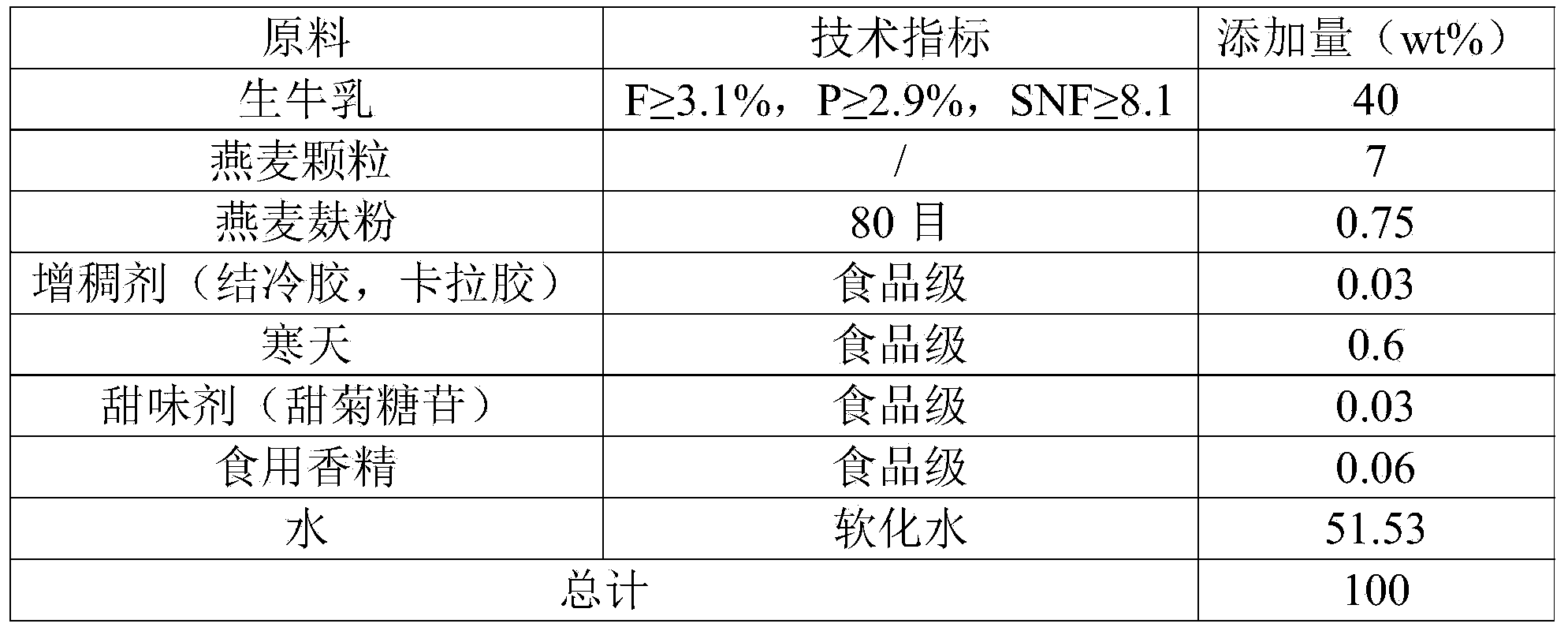

Oat dairy product and preparation method thereof

The invention discloses an oat dairy product and a preparation method thereof. The oat dairy product comprises the following components in percentage by mass: 35% to 50% of raw milk, 4% to 10% of oat particles, 0.5% to 1% of oat bran powder, 0.4% to 0.8% of agar, 0.02% to 0.04% of thickening agent, 0.02% to 0.04% of sweetening agent and water, wherein the thickening agent is carrageenan and / or gellan gum. The preparation method comprises the following steps: preparing feed liquid A and feed liquid B, wherein the feed liquid A is prepared by boiling the oat particles in boiling water for 20 to 30 minutes, then adding the oat bran powder, and agitating for 5 to 10 minutes in a heat preservation manner, and the feed liquid B is prepared by uniformly mixing the raw milk, the agar, the thickening agent, the sweetening agent and water; uniformly mixing the feed liquid A and the feed liquid B; performing immersive ultra-high-temperature instant sterilization; filling in a hot state; and then cooling to obtain the oat dairy product. The oat dairy product tastes great, brings elastic mouthfeel of large oat particles, and is high in stability.

Owner:BRIGHT DAIRY & FOOD

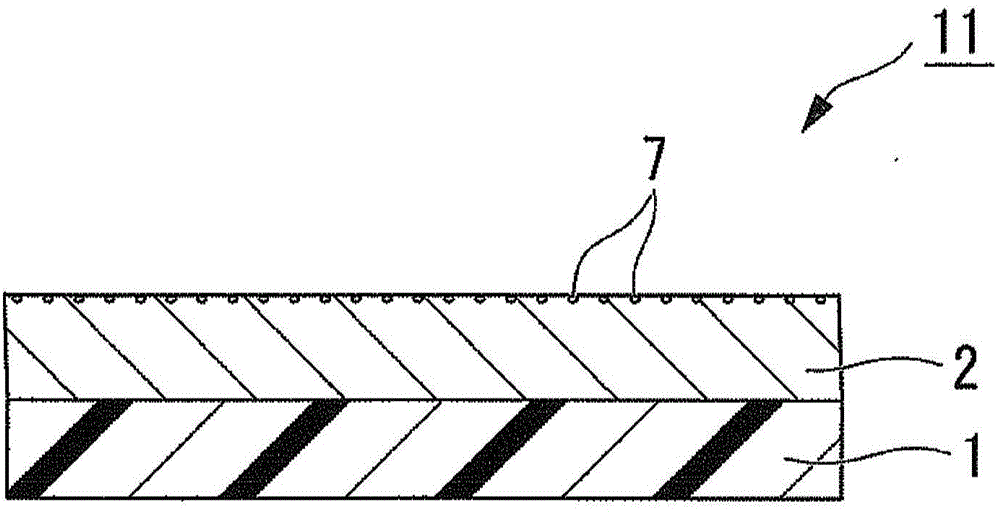

Antistatic surface-protective film

ActiveCN106189895ASuppresses peeling static voltageLow agingFilm/foil adhesivesOrganic non-macromolecular adhesiveCross-linkMeth-

The present invention provides an antistatic surface-protective film that has little contamination of an adherend and that has excellent peeling antistatic performance which does not deteriorate over time. In accordance with the present invention, on one surface of a base film 1 including a transparent resin, is formed an adhesive layer 2 including an adhesive composition, which includes an acrylic-based polymer of a copolymer including (A) a least one (meth)acrylic acid ester monomer having a C4 to C18 alkyl group and (B) at least one hydroxyl group-containing copolymerizable monomer, but not including a carboxyl group-containing copolymerizable monomer, and which further contains (C) a bifunctional or higher isocyanate compound, (D) a cross-linking promoting agent, and (E) a keto-enol tautomer compound; and a peeling film 5, which has a release agent layer 4 laminated, is attached on a surface thereof, wherein the release agent layer 4 includes a release agent having dimethylpolysiloxane as the main component and an antistatic agent.

Owner:FUJIMORI KOGYO CO LTD

Waterproof structure for ecological artificial lake

The invention discloses a waterproof structure for an ecological artificial lake, relates to a waterproof technology for underground construction, and specifically relates to a waterproof technology for the bottom of an ecological artificial lake. The waterproof structure for the ecological artificial lake comprises a rammed-earth layer, a silty clay-rolled cushion layer, a silty clay-rolled protection layer and a medium sand water purification layer. The waterproof structure for the ecological artificial lake is characterized in that the constructed layers of the waterproof structure are located at the bottom of the waterproof structure, and sequentially are the rammed-earth layer, the silty clay-rolled cushion layer, a bentonite waterproof layer, a non-woven fabric, the silty clay-rolled protection layer, a silty clay-rolled counter-weight and the medium sand water purification layer from bottom up; the edge of the waterproof structure is more than 200mm higher than the horizontal plane; and a concrete protection belt is laid on the upper part of the edge of the waterproof structure, and the concrete protection belt is located on the upper part of the edge of the bentonite waterproof layer for preventing the bentonite waterproof layer from leakage. The waterproof structure for the ecological artificial lake, which is disclosed by the invention, has the characteristics of being novel in structure, simple and convenient to construct, capable of reducing construction cost, high in waterproofness, capable of achieving a service life of over thousand years, and the like; therefore, a novel waterproof structure for an ecological artificial lake, which integrates economical efficiency with practicability, is achieved.

Owner:何发林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com