Sound barrier upright post and preparation method of sound barrier upright post

A sound barrier and column technology, applied in the field of sound insulation materials, can solve the problems of increasing the safety maintenance cost of the sound barrier, hidden dangers of driving safety, and instability of the sound barrier, and achieve significant long-term economic benefits, high safety and reliability, and enhanced absorption. The effect of sound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

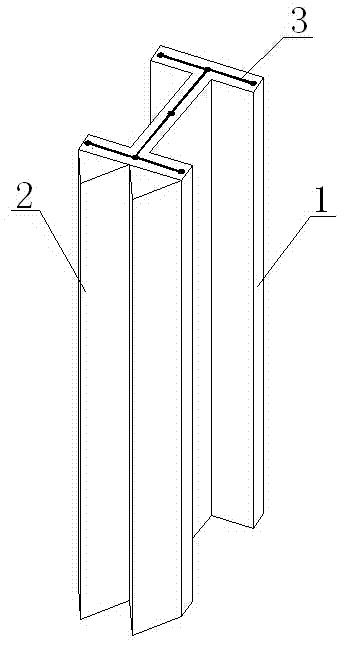

[0026] Such as Figure 1 to Figure 2 as shown,

[0027] A sound barrier column, including a column body 1 and a sound-absorbing material 2 compounded on the side flange of the column facing the sound source, the cross section of the column body is H-shaped and made of active powder active concrete, and the active powder Active concrete includes cement, mineral powder, rice husk ash, natural sand, quartz powder, polycarboxylate superplasticizer, steel fiber and water. The weight ratio of each component is cement: mineral powder: rice husk ash: natural sand: Quartz powder: polycarboxylate superplasticizer: steel fiber: water=1: 0.15:0.23:1.15: 0.35:0.02:2.5:0.22.

[0028] The cement is ordinary portland cement of grade 52.5.

[0029] The rice husk ash is obtained by incinerating acid-treated rice husk at a constant temperature of 500°C for 2 hours and grinding for 20 minutes.

[0030] The natural sand is fine sand, and its gradation is in Zone III.

[0031] The column body 1...

Embodiment 2

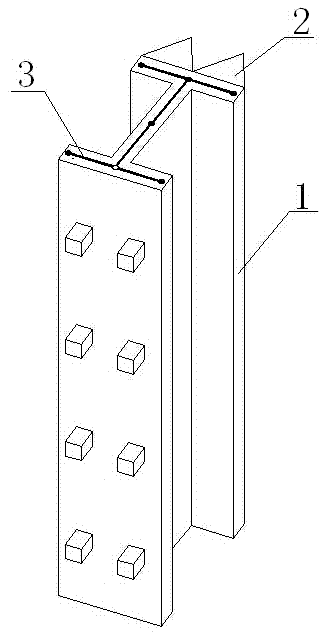

[0039] Basically the same as Example 1, the difference is that the weight ratio of each component is cement: mineral powder: rice husk ash: natural sand: quartz powder: polycarboxylate superplasticizer: steel fiber: water=1:0.25: 0.28: 1.25: 0.40: 0.025: 3.0: 0.25; the cement is Portland cement of grade 52.5; the rice husk ash is obtained by incinerating acid-treated rice husk at 600°C for 2 hours and grinding for 20 minutes ; The reinforcing rib is a carbon fiber rib; the sound-absorbing material is a ceramsite sound-absorbing material; image 3 As shown, the planar flange on the side of the column body facing away from the sound source is provided with an embedded component insert and is cast and connected together with the bridge to form a whole. The preparation method is basically the same as that of Example 1, except that the non-metallic sound-absorbing material and the gelling material are mixed and then poured into a mold and pressurized at a pressure of 1.5KN. The ce...

Embodiment 3

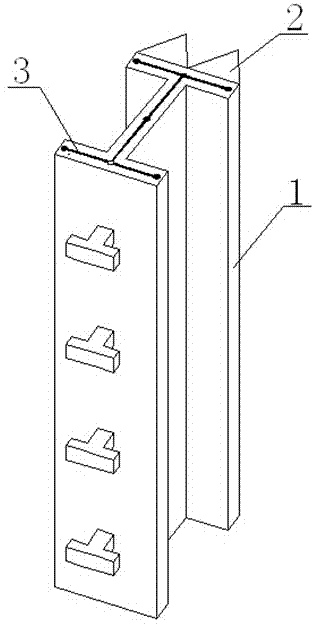

[0041] It is basically the same as Example 1, except that the weight ratio of each component is cement: mineral powder: rice husk ash: natural sand: quartz powder: polycarboxylate superplasticizer: steel fiber: water=1:0.2: 0.25:1.2:0.38:0.022:2.75:0.23; the cement is ordinary portland cement of 52.5R grade; the rice husk ash is acid-treated rice husk incinerated at 700°C for 2 hours and ground for 20 minutes Obtained afterwards; Described reinforcing bar is basalt fiber bar; Described sound-absorbing material is sawdust sound-absorbing material; As Figure 4 As shown, the planar flange on the side of the column body facing away from the sound source is provided with an embedded part socket and connected with the bridge as a whole. The preparation method is basically the same as that of Example 1, except that the non-metallic sound-absorbing material and the gelling material are mixed well, then poured into a mold and pressurized at a pressure of 1.2KN. The cementitious mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com