Sound-insulation noise-reduction water-based wood primer

A water-based, wood-based technology, used in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor low-frequency sound absorption, narrow sound absorption frequency band, inconvenient use, etc., and achieve good sound absorption and fire resistance. , blocking and absorbing sound waves, the effect of superior comprehensive performance

Inactive Publication Date: 2015-03-11

广州益景春环保材料科技有限公司

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, materials such as slag bricks have poor sound absorption performance, and are bulky and inconvenient to use. Although inorganic fibers (such as glass wool) have good sound absorption performance, flame retardancy, and corrosion resistance, they have problems such as polluting the environment and endangering health.

As a result, fiberless sound-absorbing materials represented by resonant sound-absorbing materials (structures) appeared, but their sound-absorbing frequency bands are narrow, and they are generally only suitable for medium and low-frequency single-frequency sounds, and they have not been able to repla

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

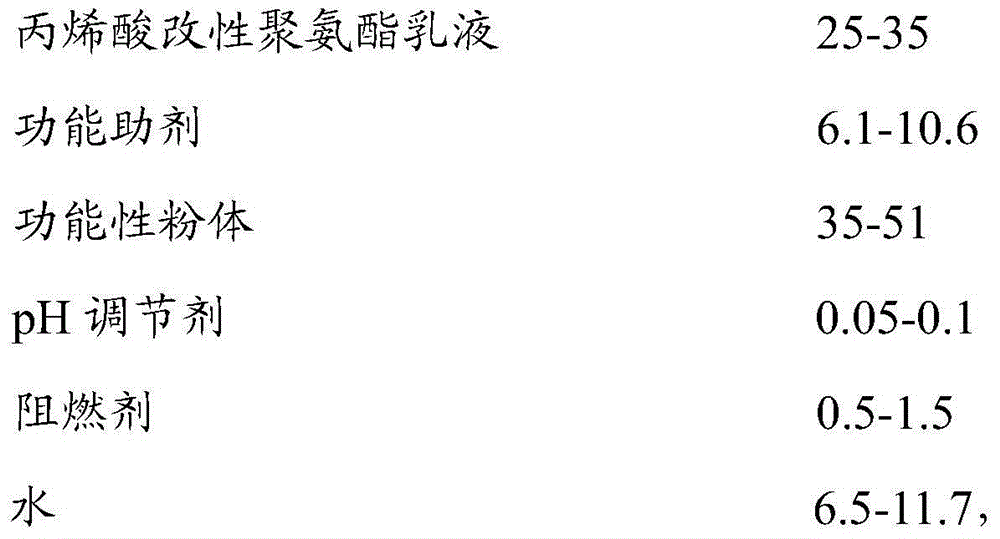

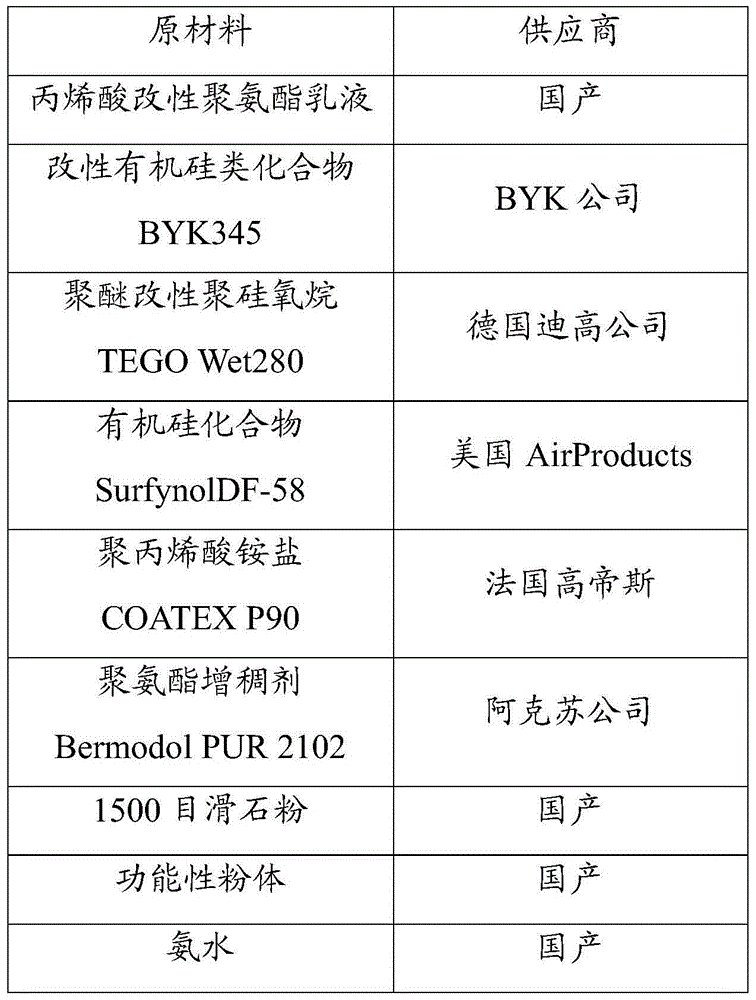

The invention discloses a sound-insulation noise-reduction water-based wood primer. The sound-insulation noise-reduction water-based wood primer is prepared from the following materials in parts by weight: 25-35 parts of acrylic acid modified polyurethane emulsion, 6.1-10.6 parts of functional additives, 35-51 parts of functional powder, 0.05-0.1 part of a pH regulator, 0.5-1.5 parts of fire retardants and 6.5-11.7 parts of water, wherein the functional powder is sericite powder, expanded graphite and silicon and aluminum based hollow microspheres; the fire retardants are aluminum hydroxide. The sound-insulation noise-reduction water-based wood primer has excellent fire resistance, sound insulation and noise reduction effects, filling capability, brushing property and combination property, and also has the characteristics of high hardness, crack resistance, corrosion resistance and the like.

Description

technical field [0001] The invention relates to the field of coatings, in particular to a sound-insulating and noise-reducing water-based wood primer. Background technique [0002] With the development of science and technology and modern industry, noise pollution has become a worldwide problem. Together with water pollution and air pollution, it is listed as the world's three major pollutions, seriously threatening human health. At present, there are two measures for the prevention and control of noise: one is to control the sound source, that is, to improve the quality of processing and assembly through equipment improvement, so as to reduce the radiation energy of the sound source, but the practical application of this measure is limited; the other is to use sound absorption materials, which is currently the most effective noise control solution. When the sound wave conducts through the sound-absorbing material, the sound intensity is weakened due to factors such as visc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/14C09D5/18C09D7/12

CPCC08L2201/02C08L2205/02C08L2205/035C09D5/18C09D7/61C09D7/63C09D175/14C08L83/04C08L83/12C08L33/02C08L75/04C08K13/04C08K2003/2227C08K7/18C08K3/34C08K3/04C08K5/46

Inventor 刘勇邓建华

Owner 广州益景春环保材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com