Patents

Literature

804 results about "Sound barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sound barrier or sonic barrier is the sudden increase in aerodynamic drag and other undesirable effects experienced by an aircraft or other object when it approaches the speed of sound. When aircraft first began to be able to reach close to the speed of sound, these effects were seen as constituting a barrier making faster speeds very difficult or impossible. The term sound barrier is still sometimes used today to refer to aircraft reaching supersonic flight.

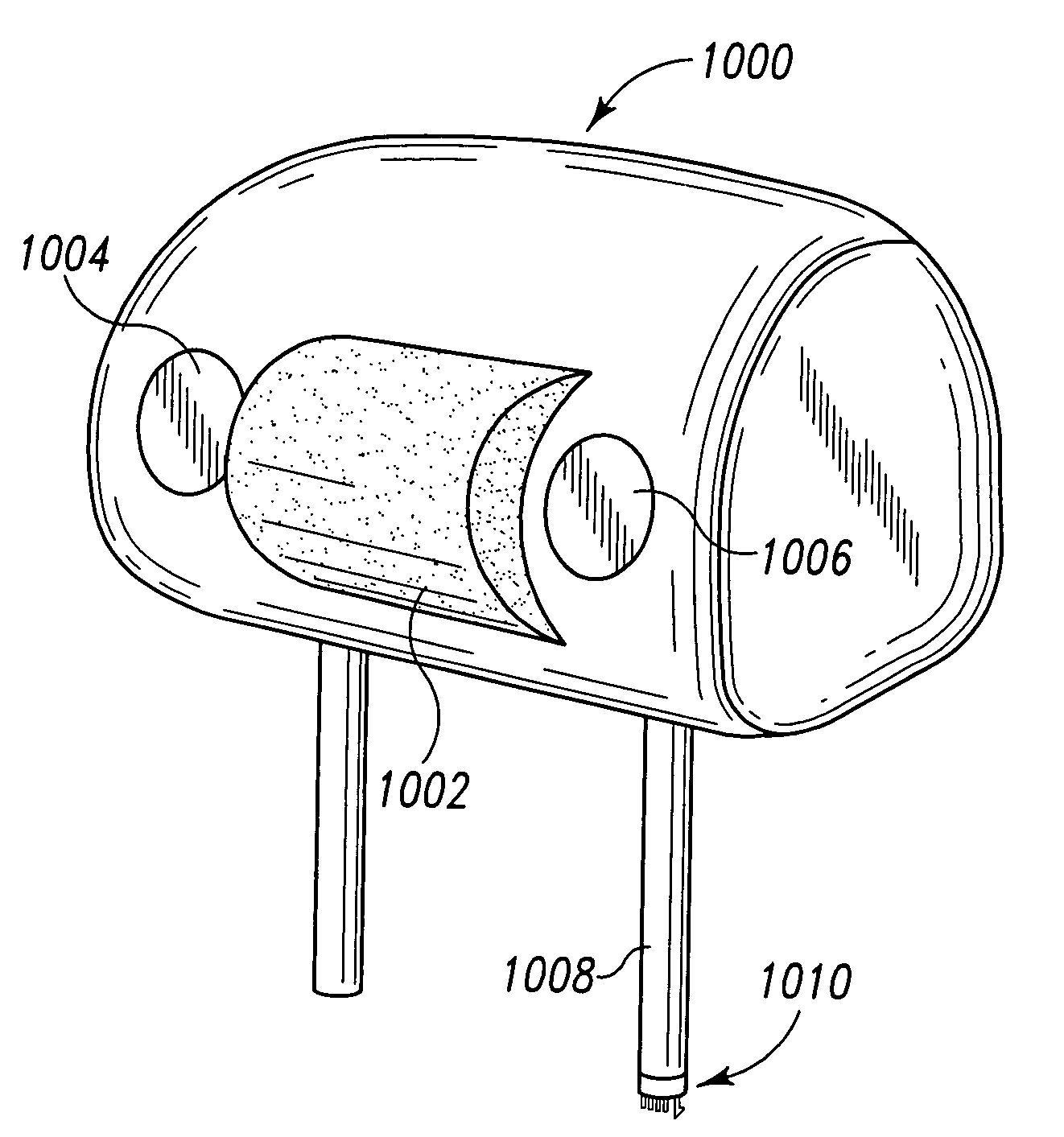

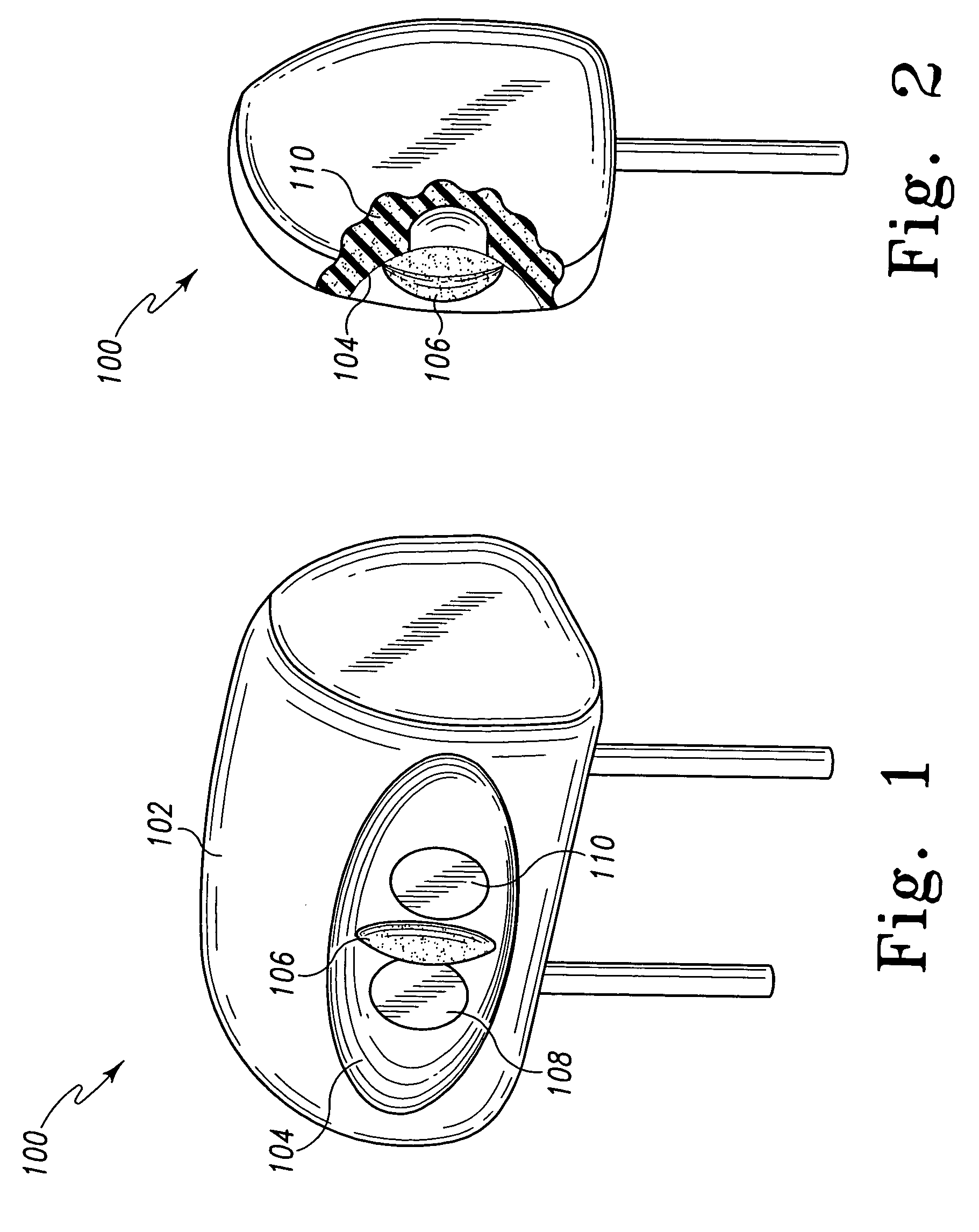

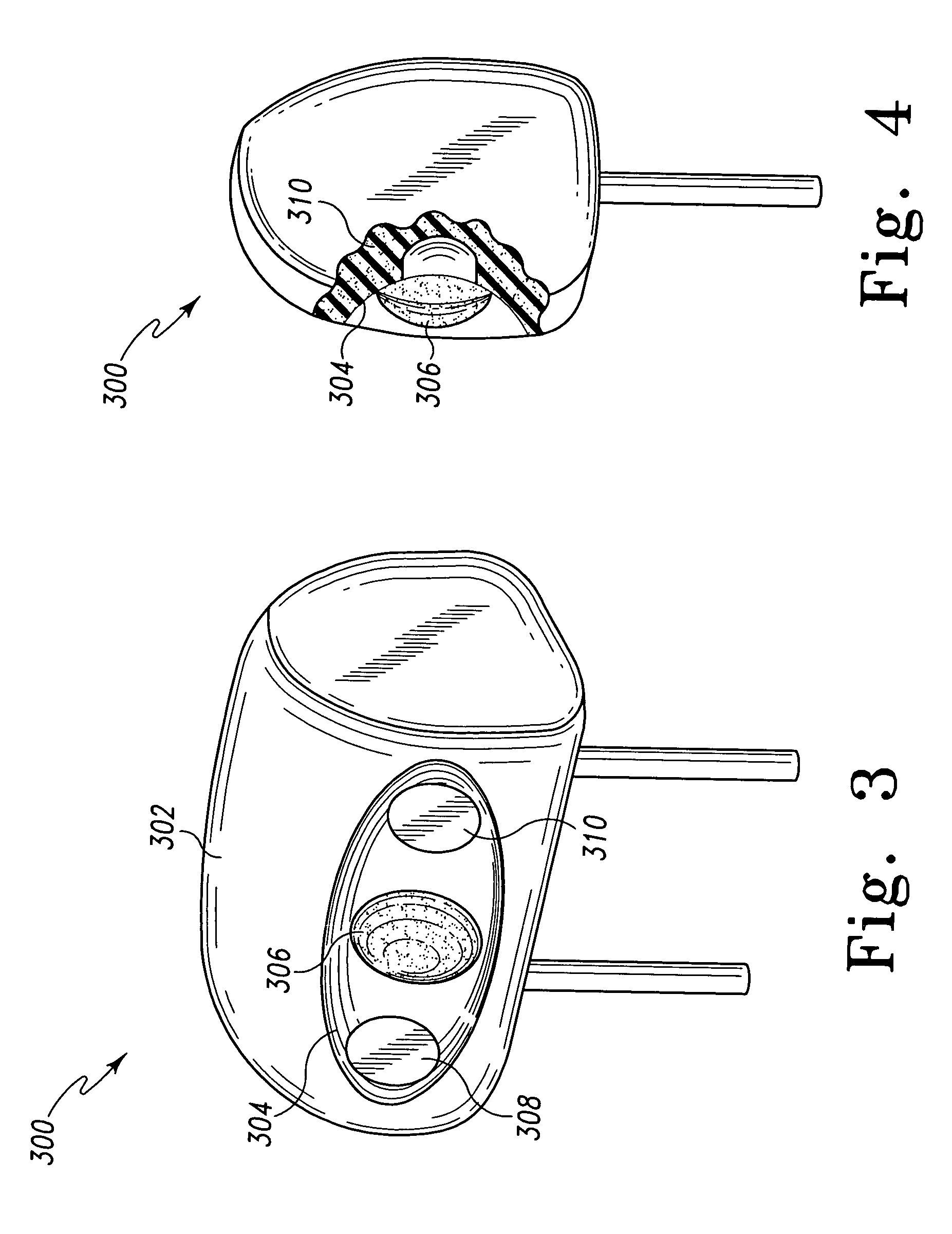

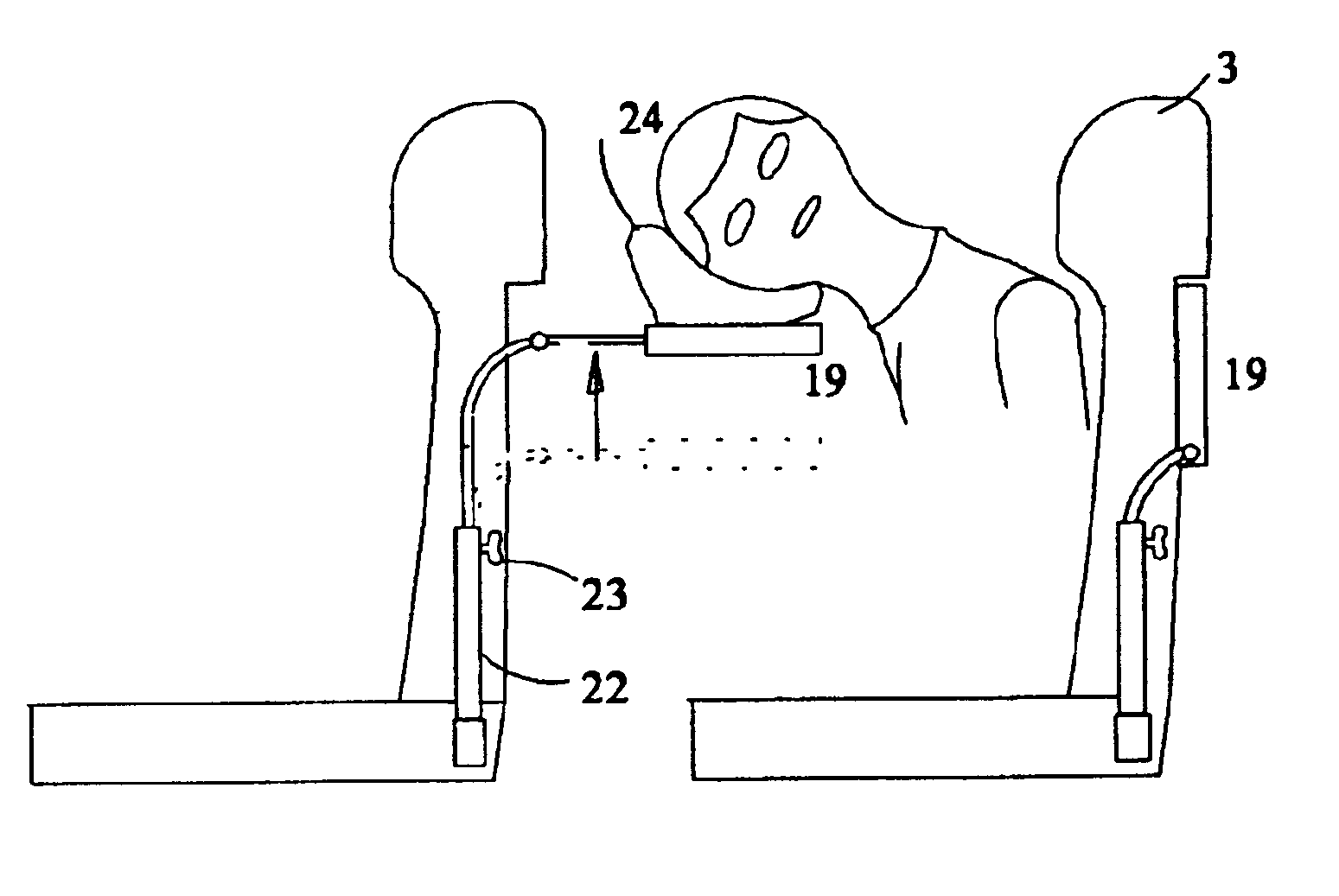

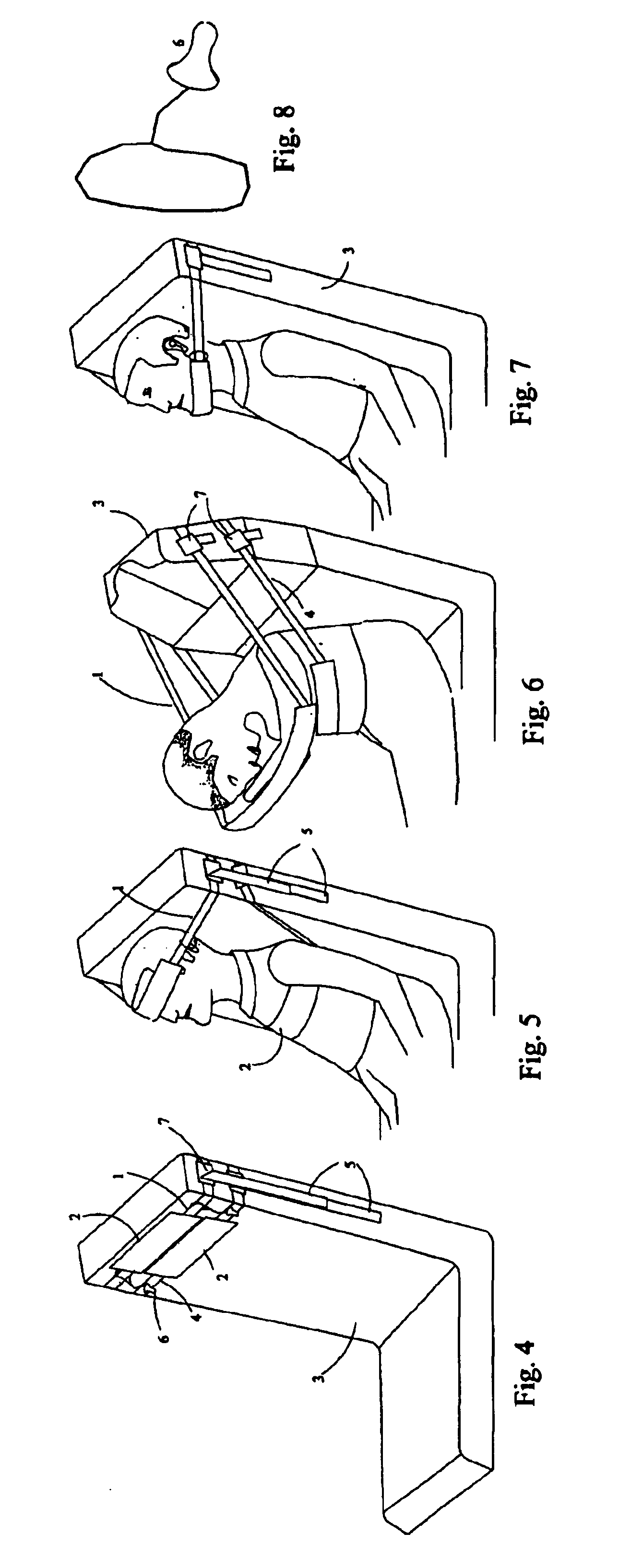

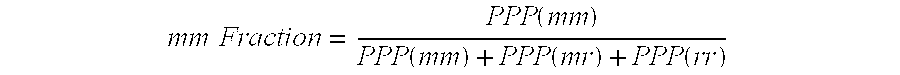

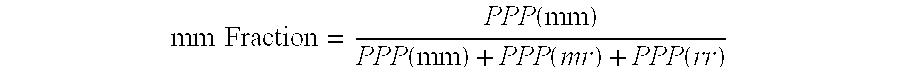

Seatback audio system

A seatback audio system having one or more speakers mounted in a surface of a seatback or a headrest. The speakers may be separated by a sound barrier to reduce cross-talk between the speakers. The surface may have a concave area where the speakers and the sound barrier are mounted. Alternatively, the surface may have two concave areas, and one speaker may be mounted in each concave area. The system may include a manual or an automated positioning system for one or both of the speakers. The system may also include a soft-cell waveguide having a plurality of tubes to direct the sound from one or both of the speakers. The seatback may include a backrest and a removable headrest, each including an electrical connector, where the one or more speakers are mounted to the headrest and the electrical connectors form a circuit when the headrest is mounted to the backrest.

Owner:HARMAN INT IND INC

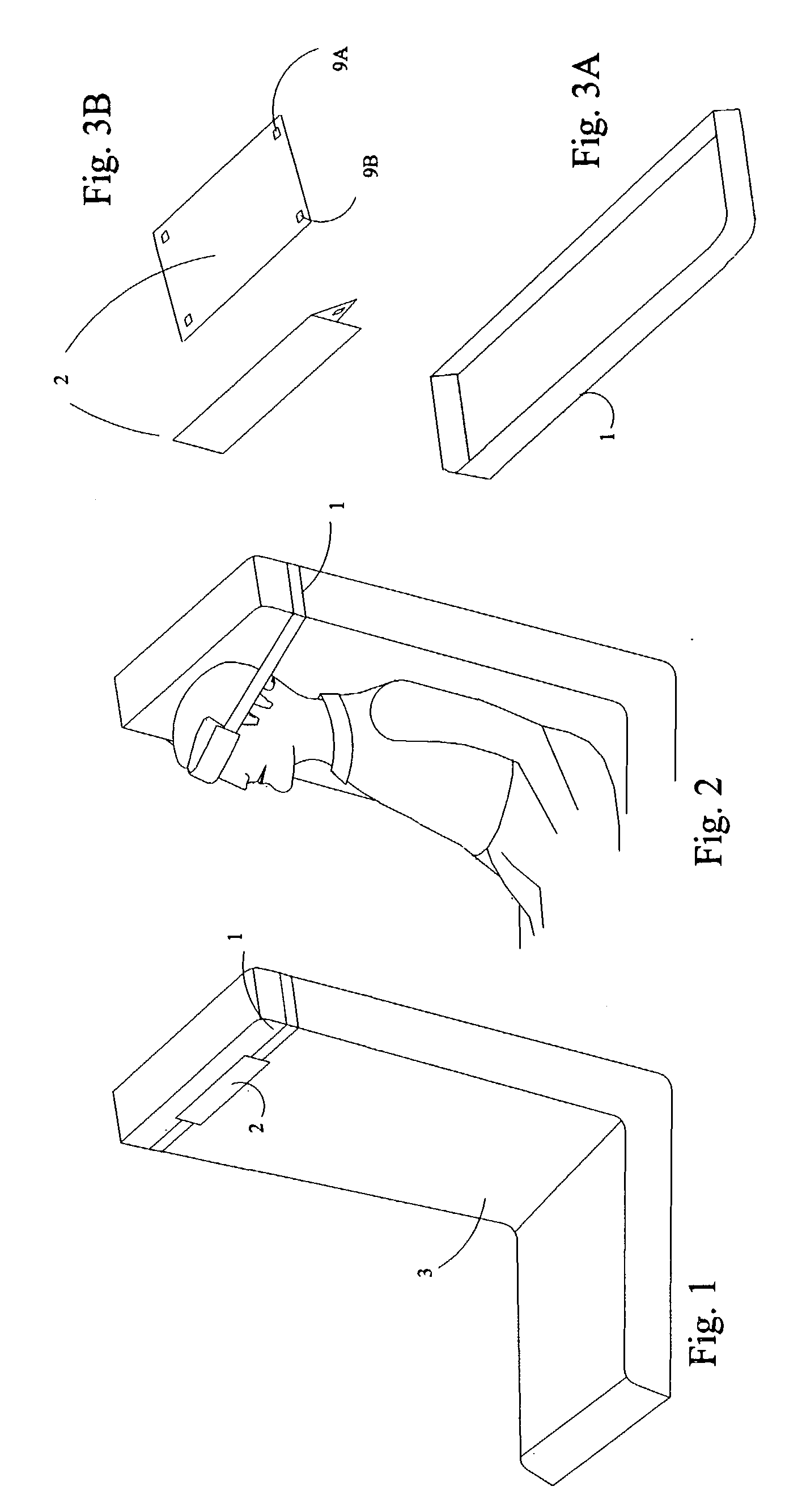

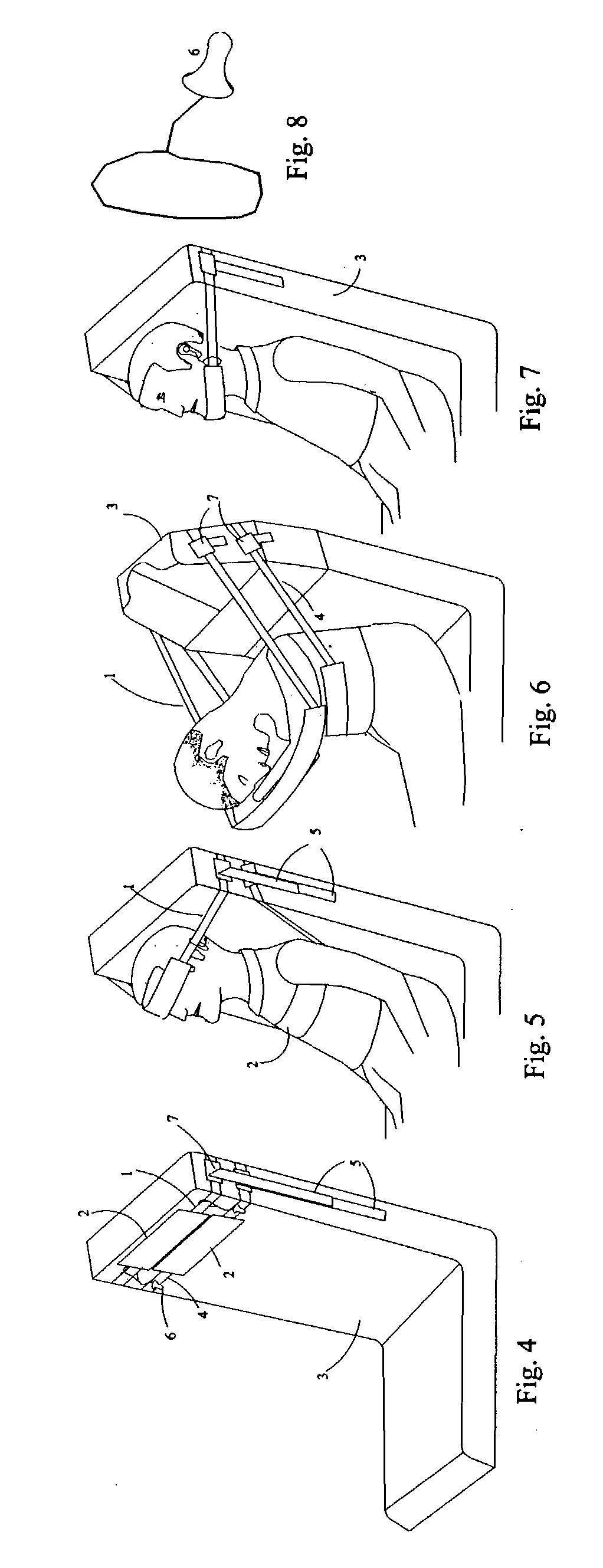

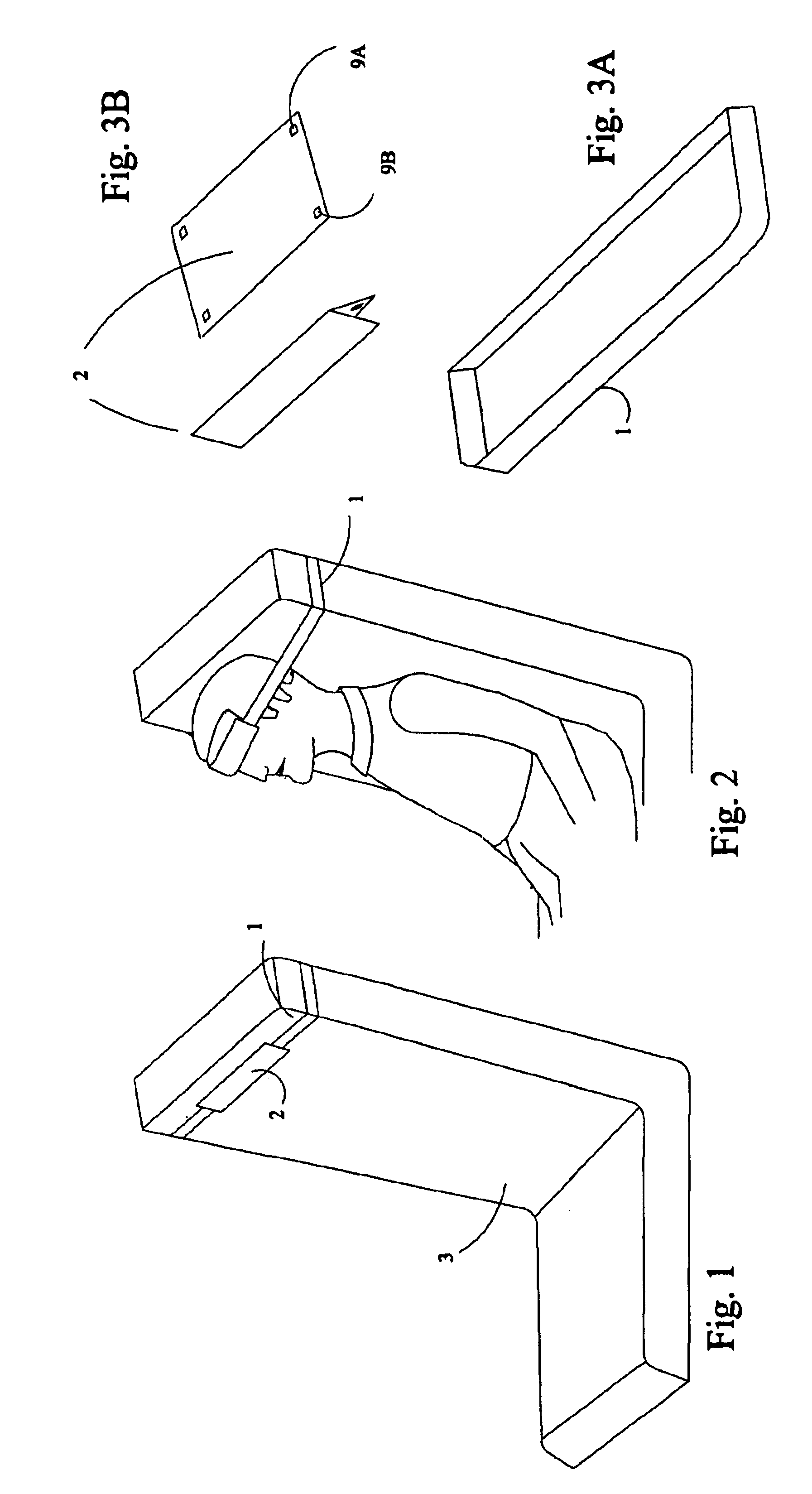

Facilitate sleeping of a person in sitting position by supporting the head and/or body

InactiveUS20040124685A1Reduce swingFlexibility of distanceVehicle seatsOperating chairsSound barrierBack rests

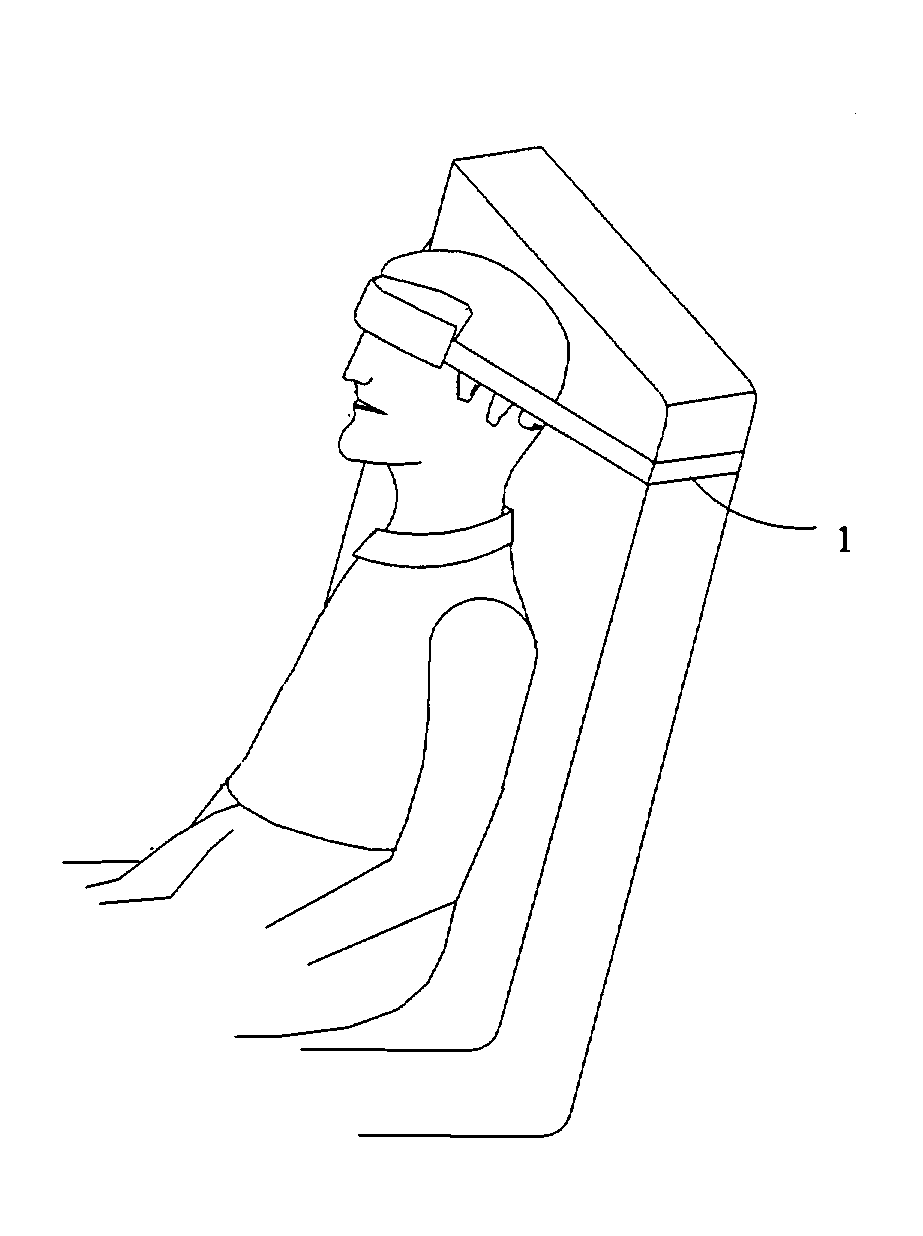

The invention facilitates Sleeping in sitting position by supporting and / or the body (torso) of a person in various positions. This invention combines one or more of: straps, sound barrier, light barrier, Headrest and backrest to improve the Sleeping.

Owner:BUCH PRADIP CHANDRAKANT

Facilitate sleeping of a person in sitting position by supporting the head and/or body

The invention facilitates Sleeping in sitting position by supporting and / or the body (torso) of a person in various positions. This invention combines one or more of: straps, sound barrier, light barrier, Headrest and backrest to improve the Sleeping.

Owner:BUCH PRADIP CHANDRAKANT

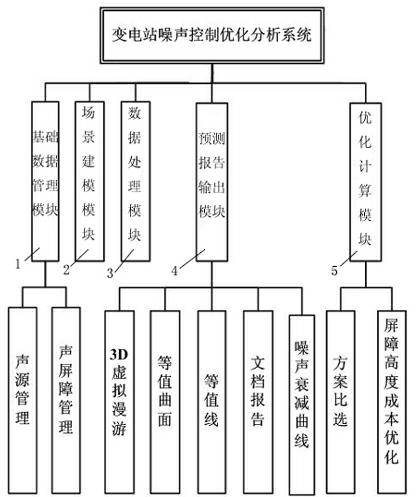

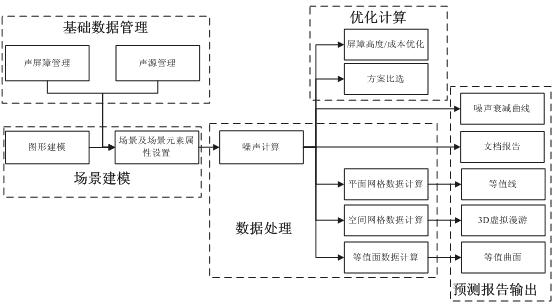

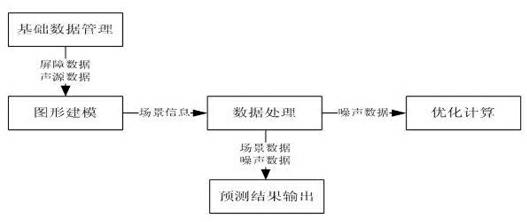

Optimized analytical method and system for noise control in transformer station

ActiveCN102194027ALow costQuick and effective design referenceSpecial data processing applicationsEnvironmental resistanceNoise control

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

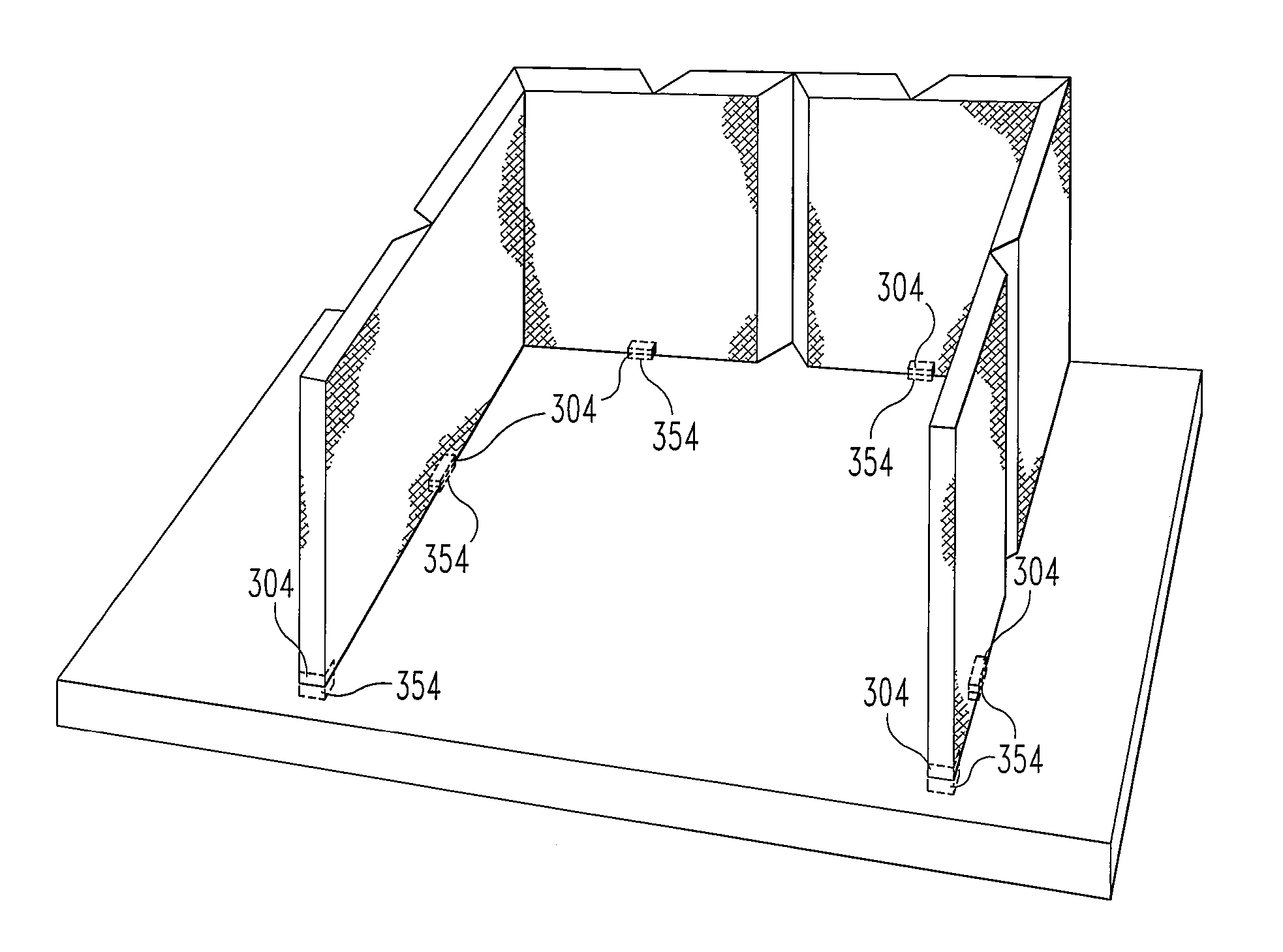

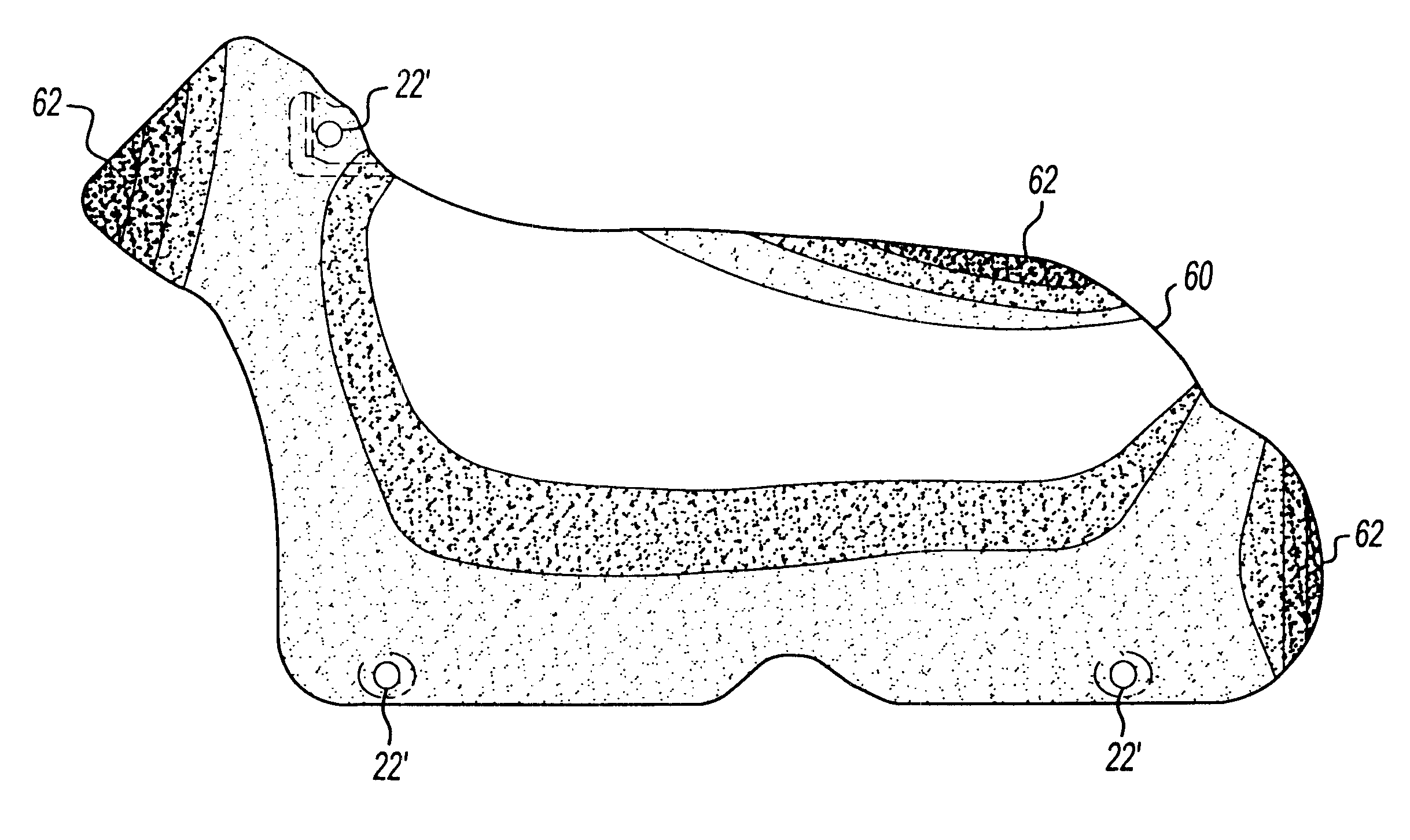

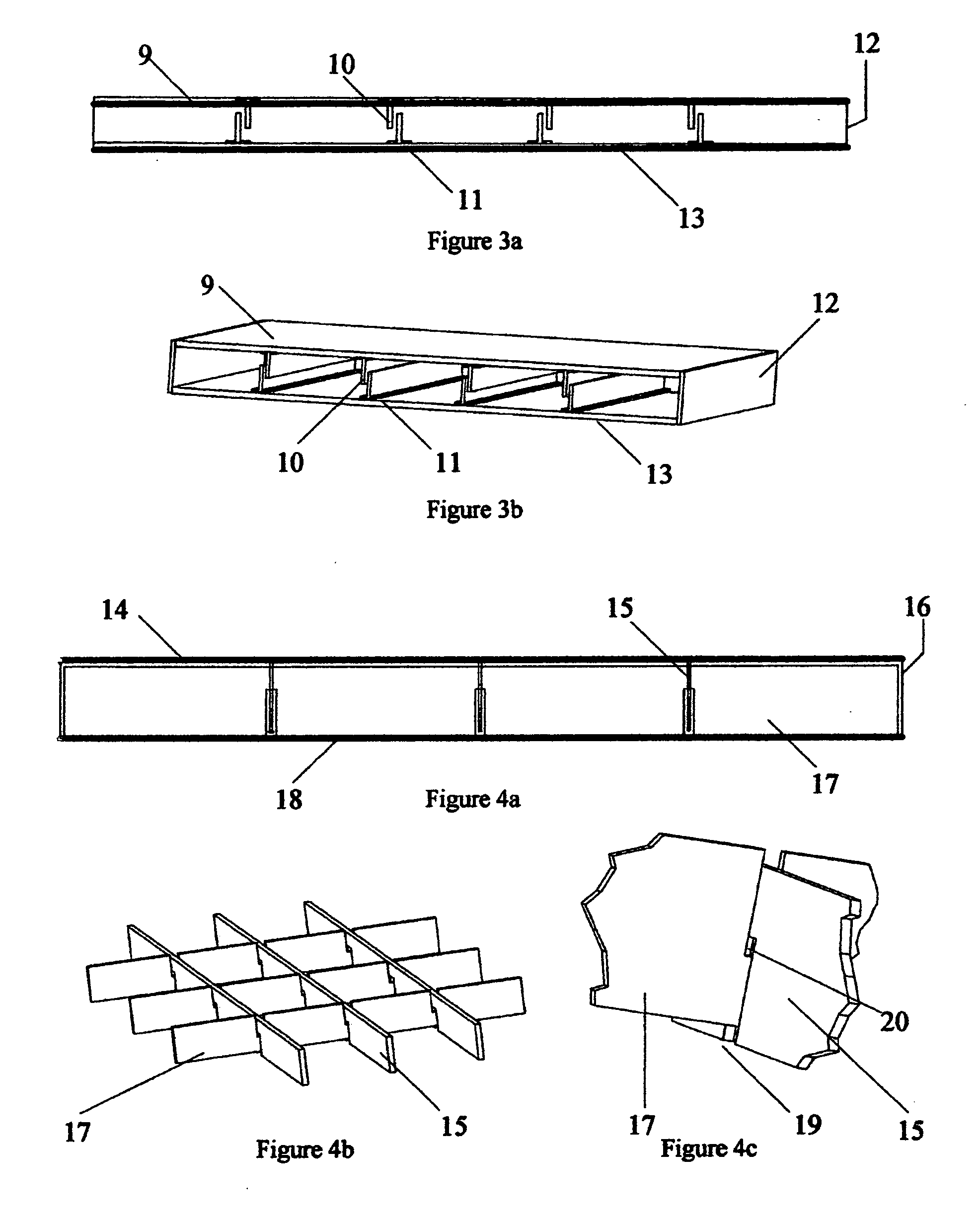

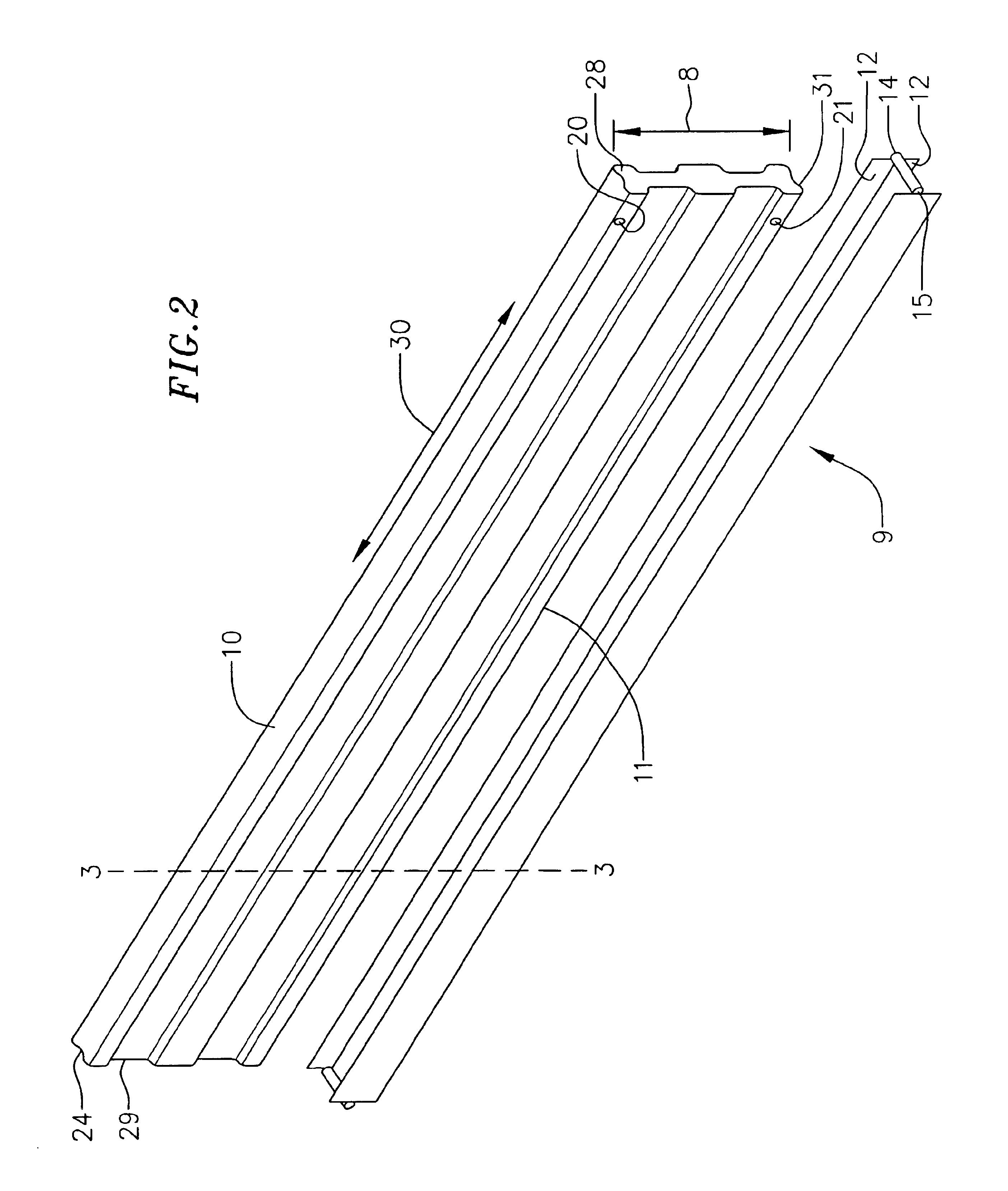

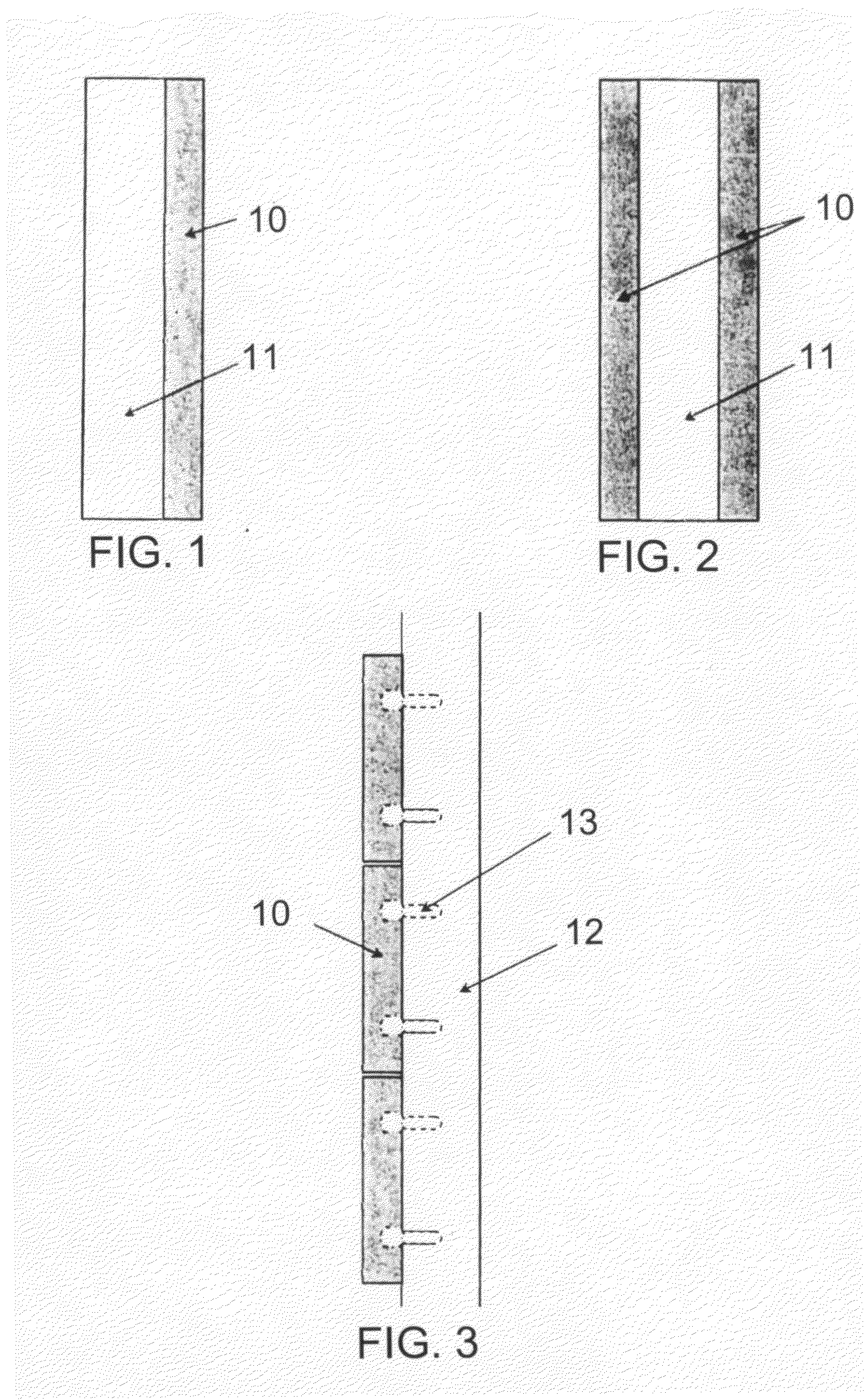

Sight and sound barrier

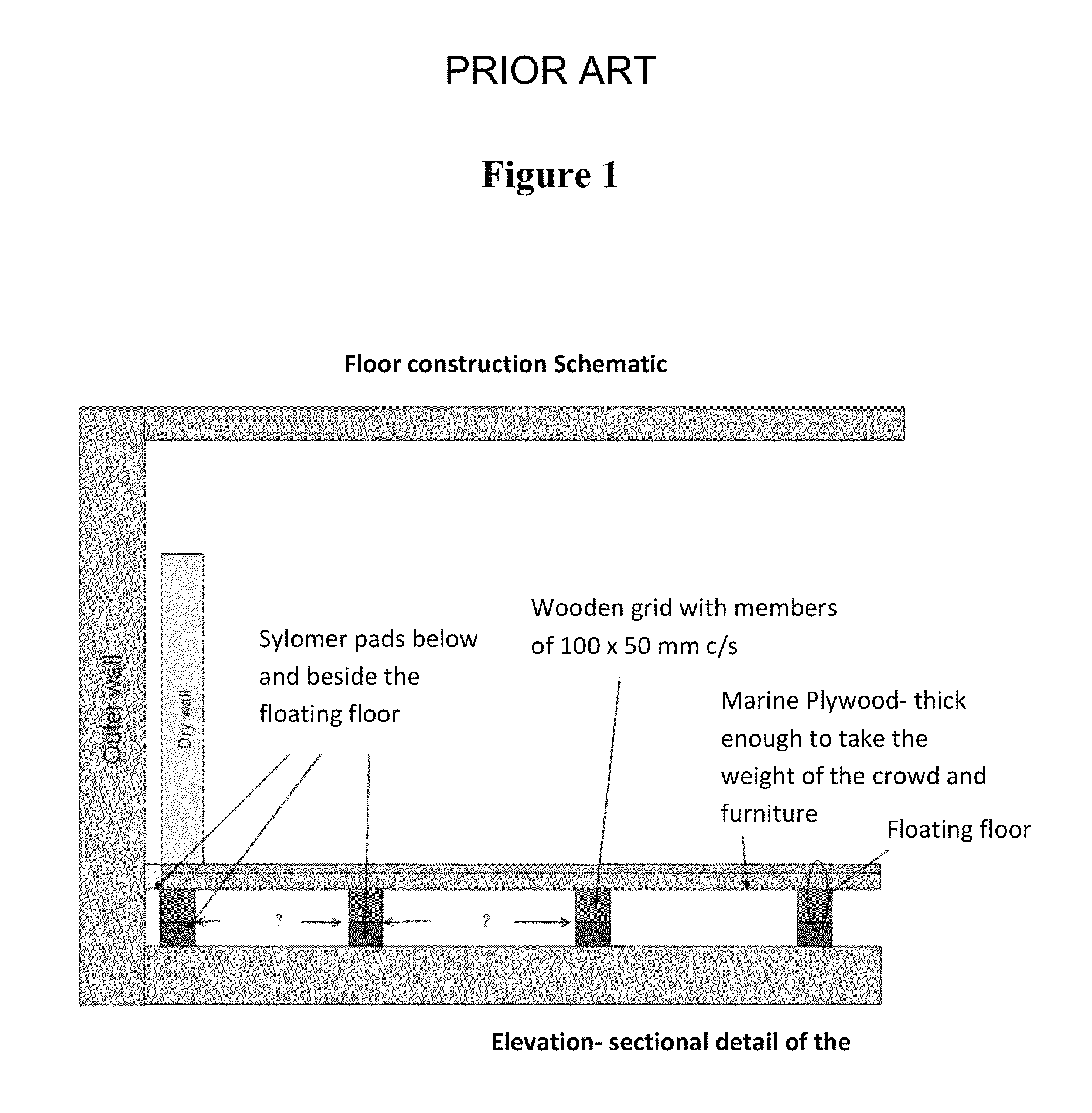

ActiveUS7690158B2Room for improvementImprove acoustic propertiesBuilding roofsWallsSound barrierPolystyrene

Owner:CHILDRENS FACTORY LLC

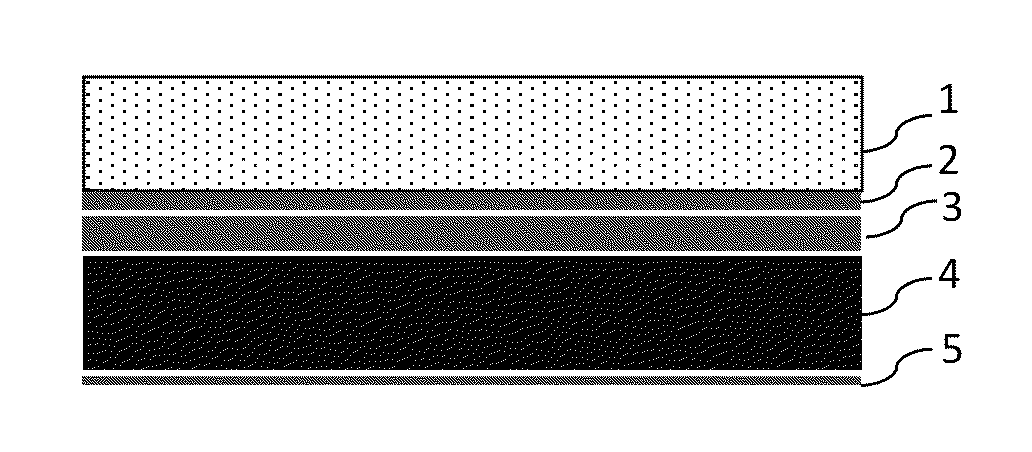

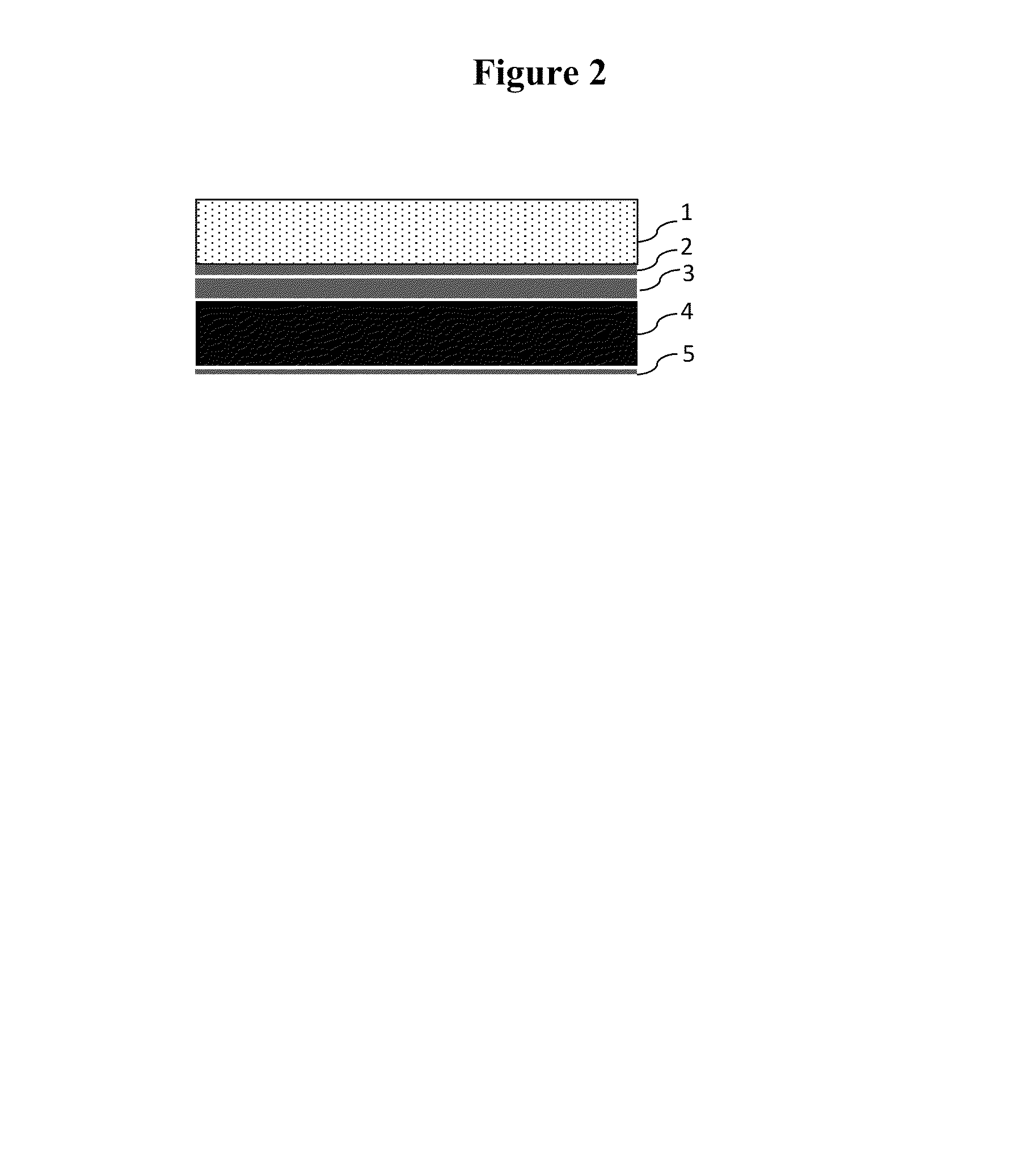

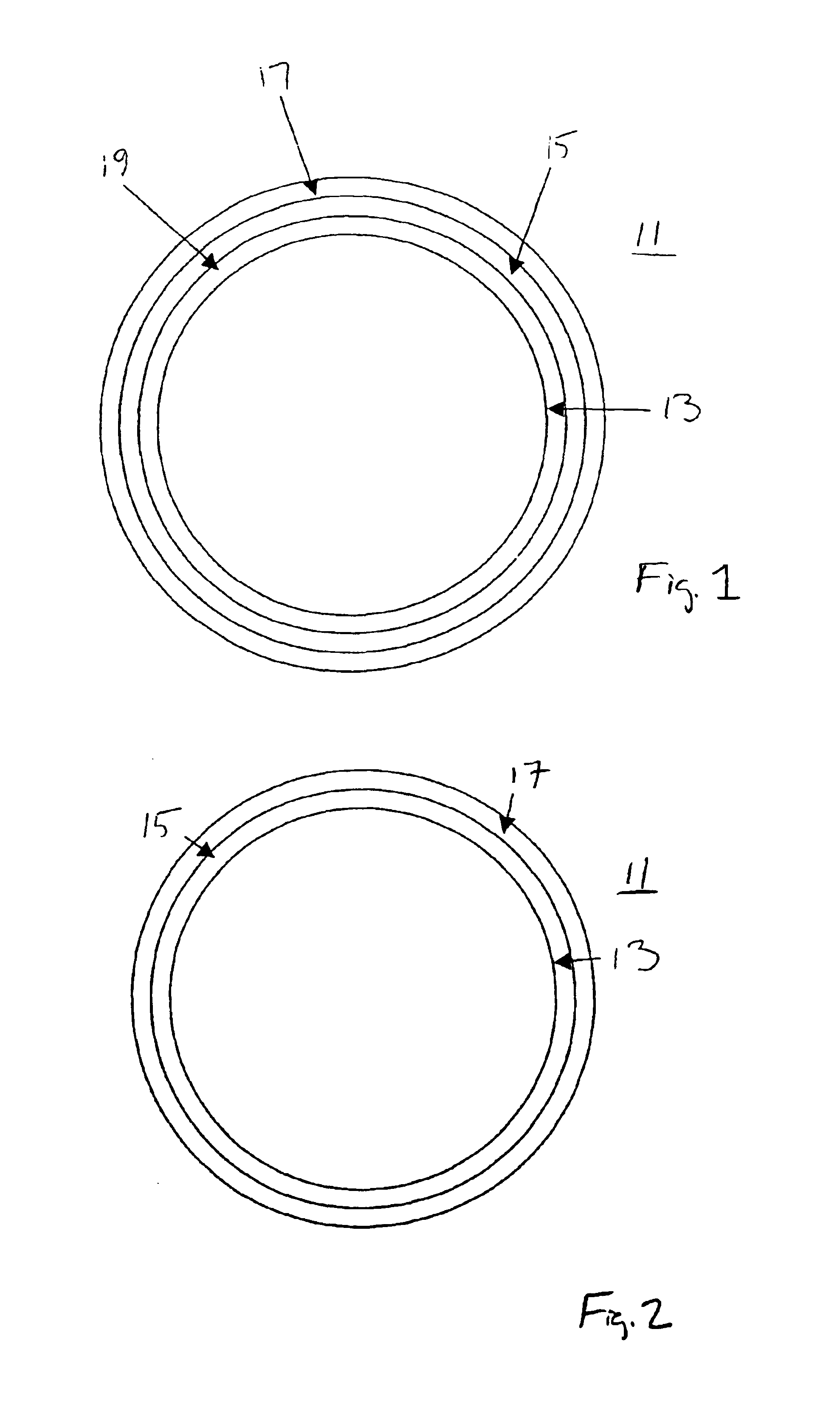

Sound proof membrane

ActiveUS8590670B1Reduce transmissionDissipating sound vibrational energySound proofingAdhesive processes involving weldingSound barrierVapor barrier

A sound barrier membrane comprises of a decoupling layer, a barrier layer and a dampening layer. The membrane also provides crack isolation, and acts as a vapor barrier. Numerous materials are disclosed which can be used to create these layers. Methods for assembly of the sound barrier membrane are also disclosed.

Owner:POLYGLASS

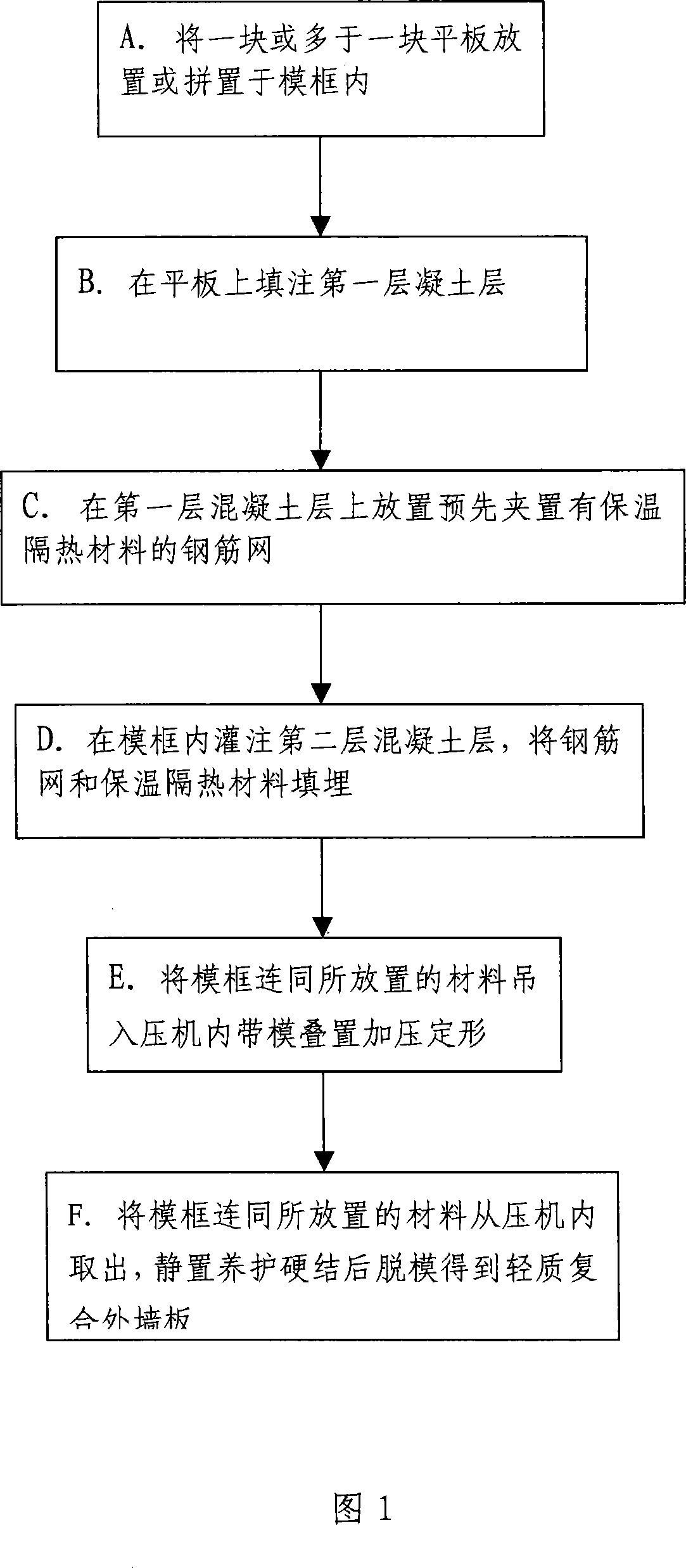

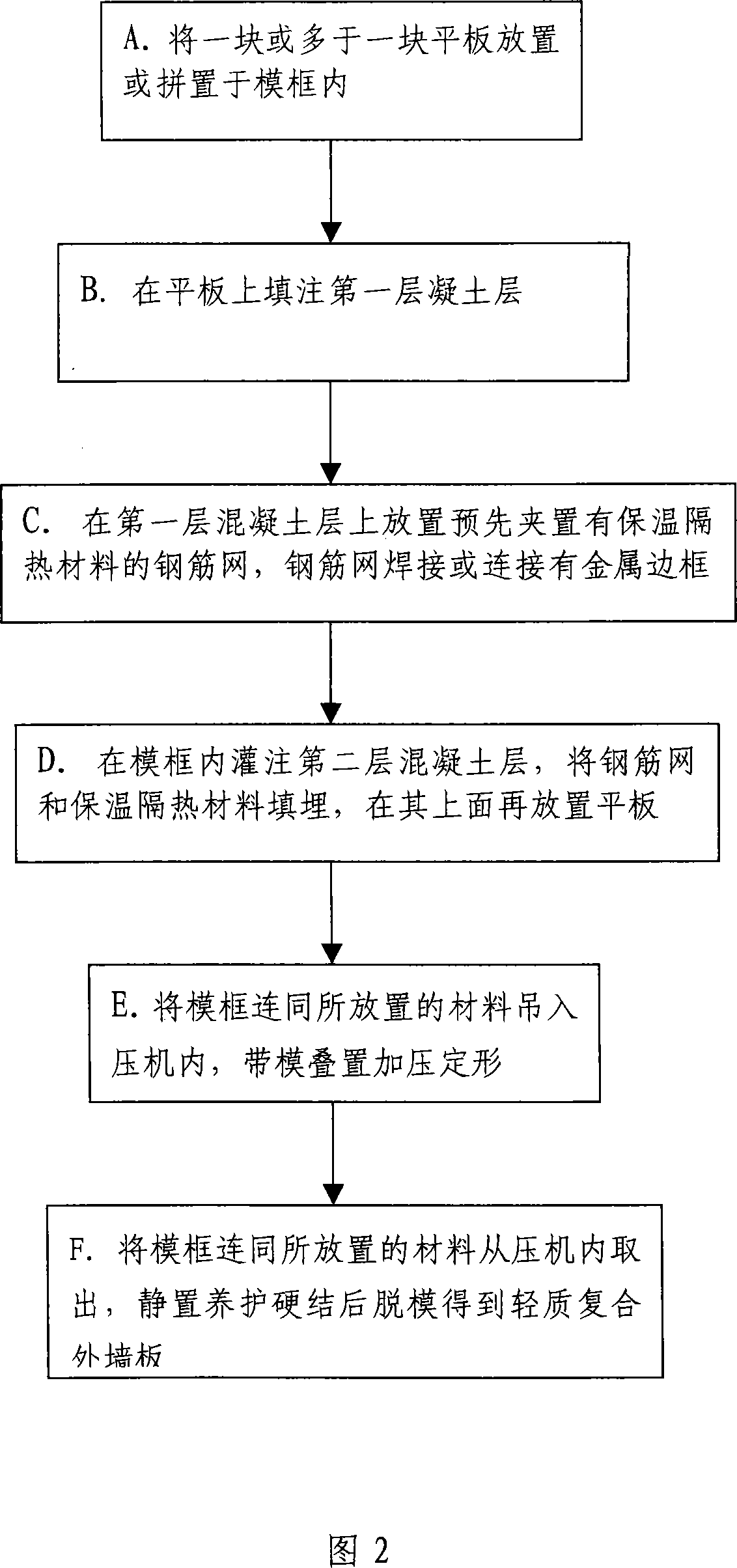

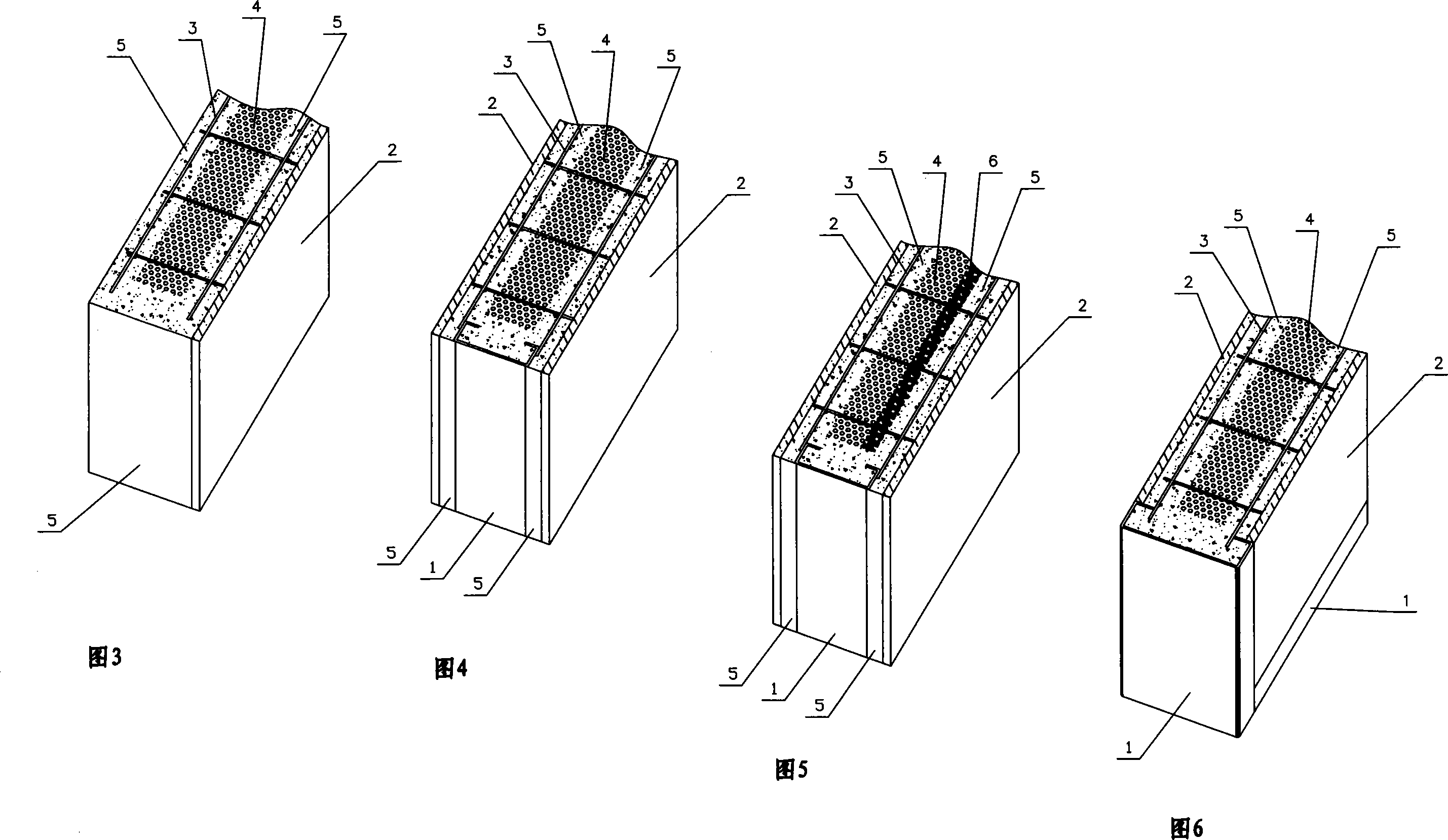

Method for manufacturing light concrete composite wall plate, building plate and road sound barrier plate

ActiveCN101100887AHighlight substantiveSignificant progressBuilding componentsSound barrierFloor slab

A construction method for light weight concrete wall, floor plate and sound screen on road follows the steps as: A. put plate into a module frame; B. fill in a premier layer of concrete on the plate; C. on the premier concrete layer put a steel web pre-inserted with heat preservation material and connected to the frame; D. grout a secondary layer of concrete filling into the steel web or put plate on it; E. modeling press. F. standing and harden.

Owner:广州益群板业有限公司

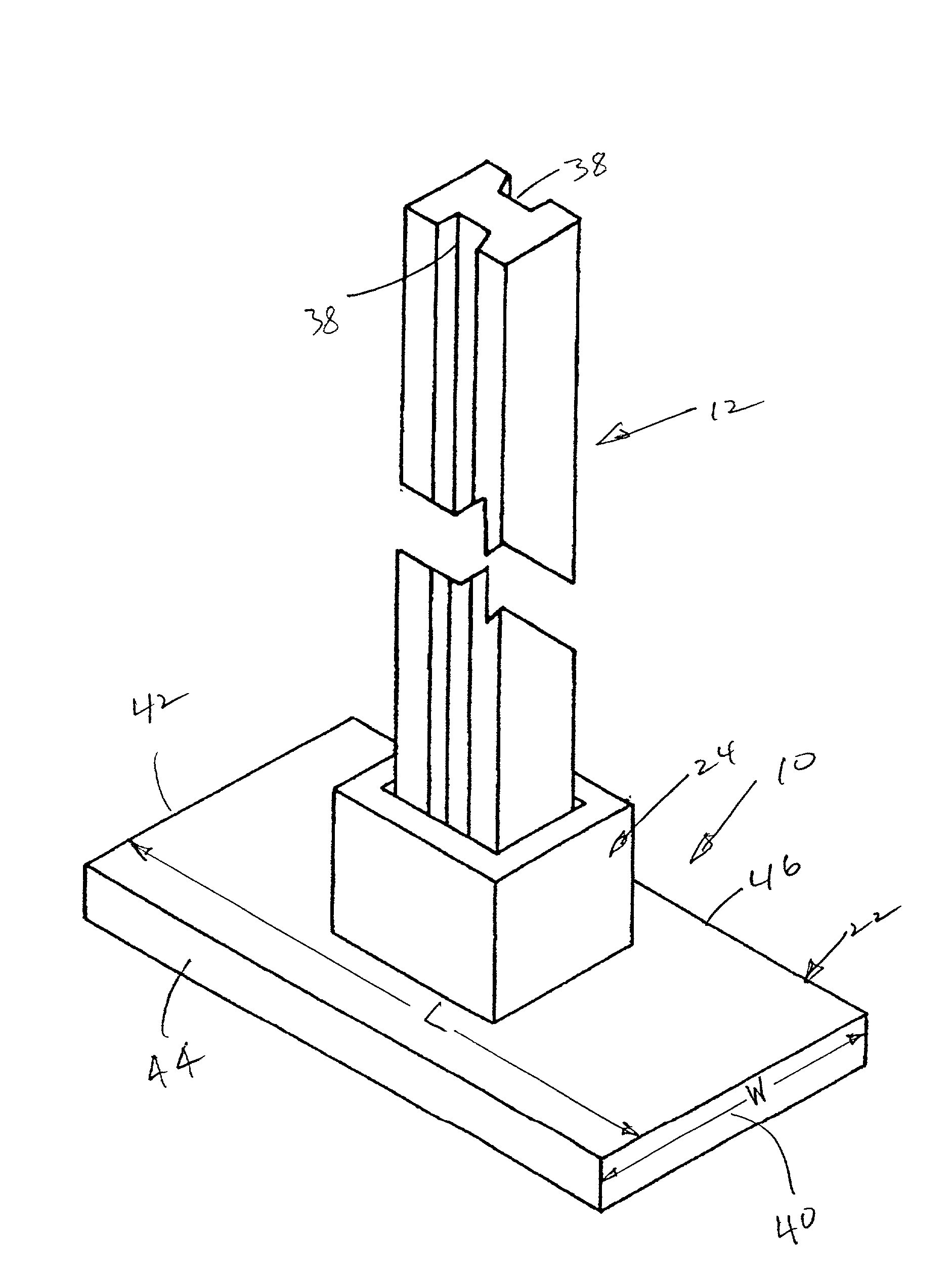

Footing for sound-barrier walls

InactiveUS20020166302A1Improve efficiencyEffective installationNoise reduction constructionFoundation engineeringSound barrierPre stress

Owner:CONCRETE PRECAST SYST

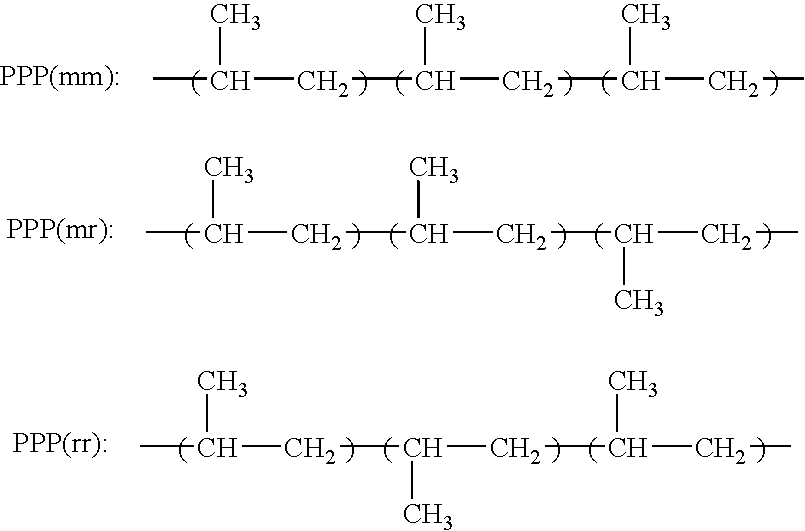

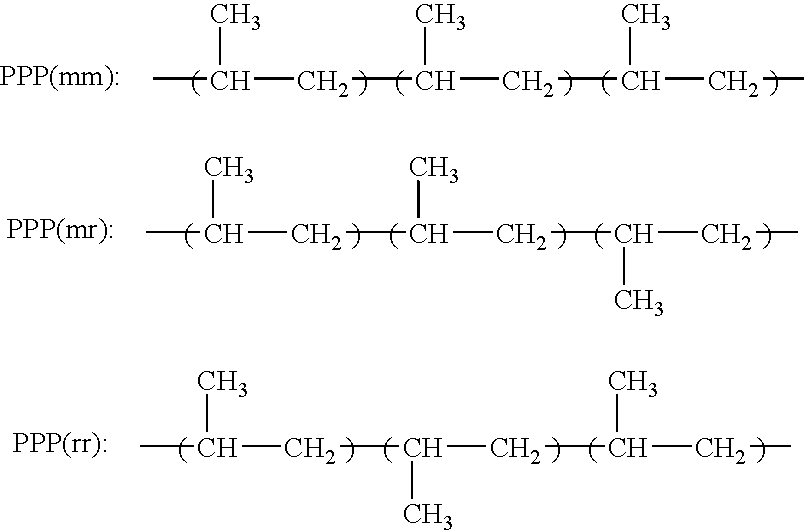

Polyolefin composition with high filler loading capacity

Disclosed are highly filled thermoplastic olefin compositions and, in particular, thermoplastic olefin compositions that comprise propylene / alpha-olefin copolymers and a high level of organic or inorganic filler. Specifically, the description addresses a filled polymer composition comprising: (a) a first polymer component comprising propylene copolymer having a heat of fusion<about 75 J / g and a triad tacticity of from about 50% to about 99%, the first polymer component having a melt flow rate at 230° C.≦about 800 g / 10 min.; and (b) at least about 15% by weight of a filler, based on the total weight of the filled composition. Such compositions are useful as sound barriers, flame retardant compositions, roofing membranes, and the like.

Owner:EXXONMOBIL CHEM PAT INC

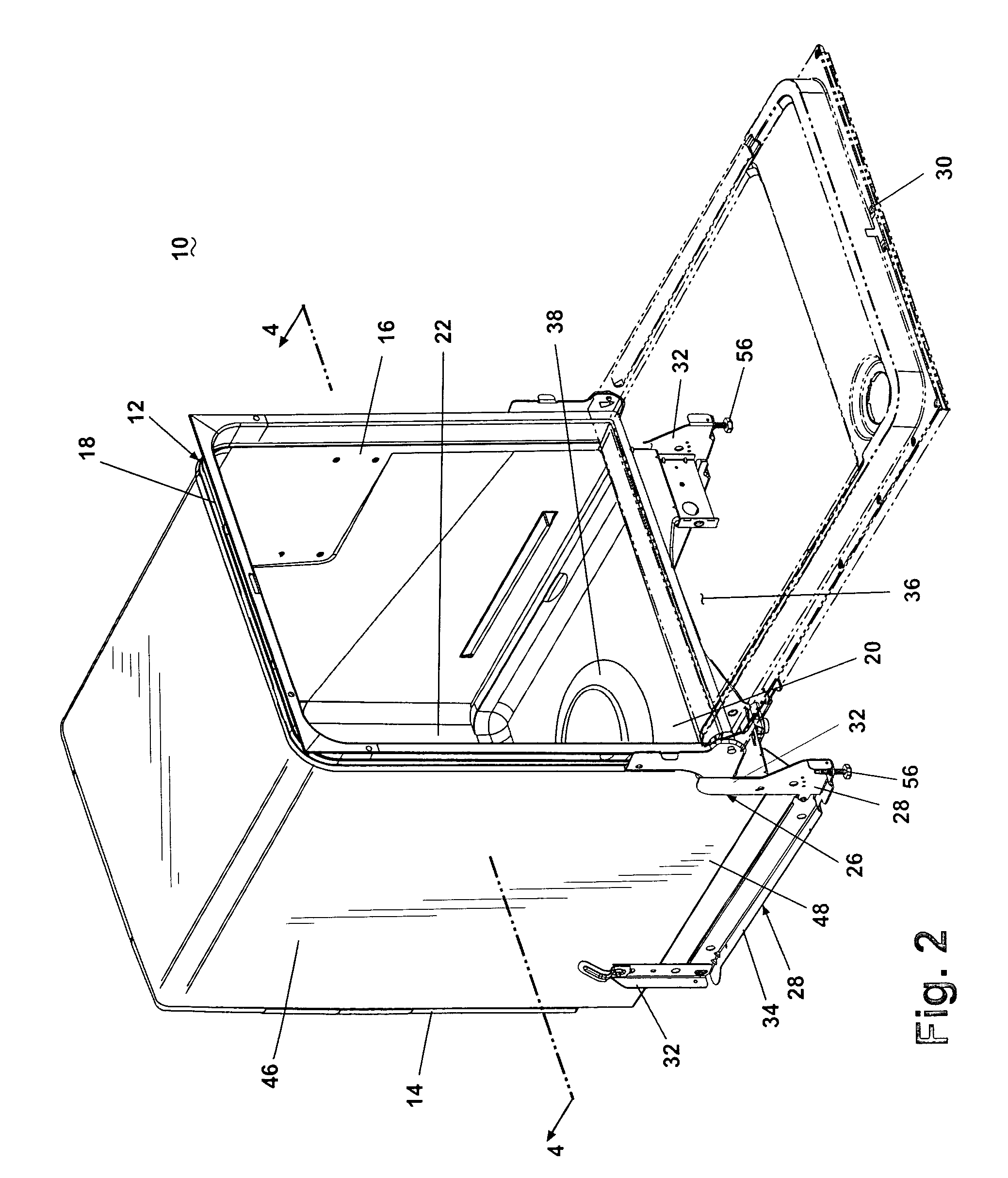

Dishwasher and motor cavity sound attenuator

ActiveUS7409959B2Tableware washing/rinsing machine detailsElectrostatic cleaningSound barrierSound Absorber

A dishwasher with a sound attenuator for attenuating the sound emanating from a motor cavity of the dishwasher. The sound attenuator comprising a sound absorber and a sound barrier. The sound absorber absorbing sound in the motor cavity with the sound barrier blocking the unabsorbed sound from escaping.

Owner:WHIRLPOOL CORP

Polyolefin composition with high filler loading capacity

Disclosed are highly filled thermoplastic olefin compositions and, in particular, thermoplastic olefin compositions that comprise propylene / alpha-olefin copolymers and a high level of organic or inorganic filler. Specifically, the description addresses a filled polymer composition comprising: (a) a first polymer component comprising propylene copolymer having a heat of fusion < about 75 J / g and a triad tacticity of from about 50% to about 99%, the first polymer component having a melt flow rate at 230° C. ≦ about 800 g / 10 min.; and (b) at least about 15% by weight of a filler, based on the total weight of the filled composition. Such compositions are useful as sound barriers, flame retardant compositions, roofing membranes, and the like.

Owner:EXXONMOBIL CHEM PAT INC

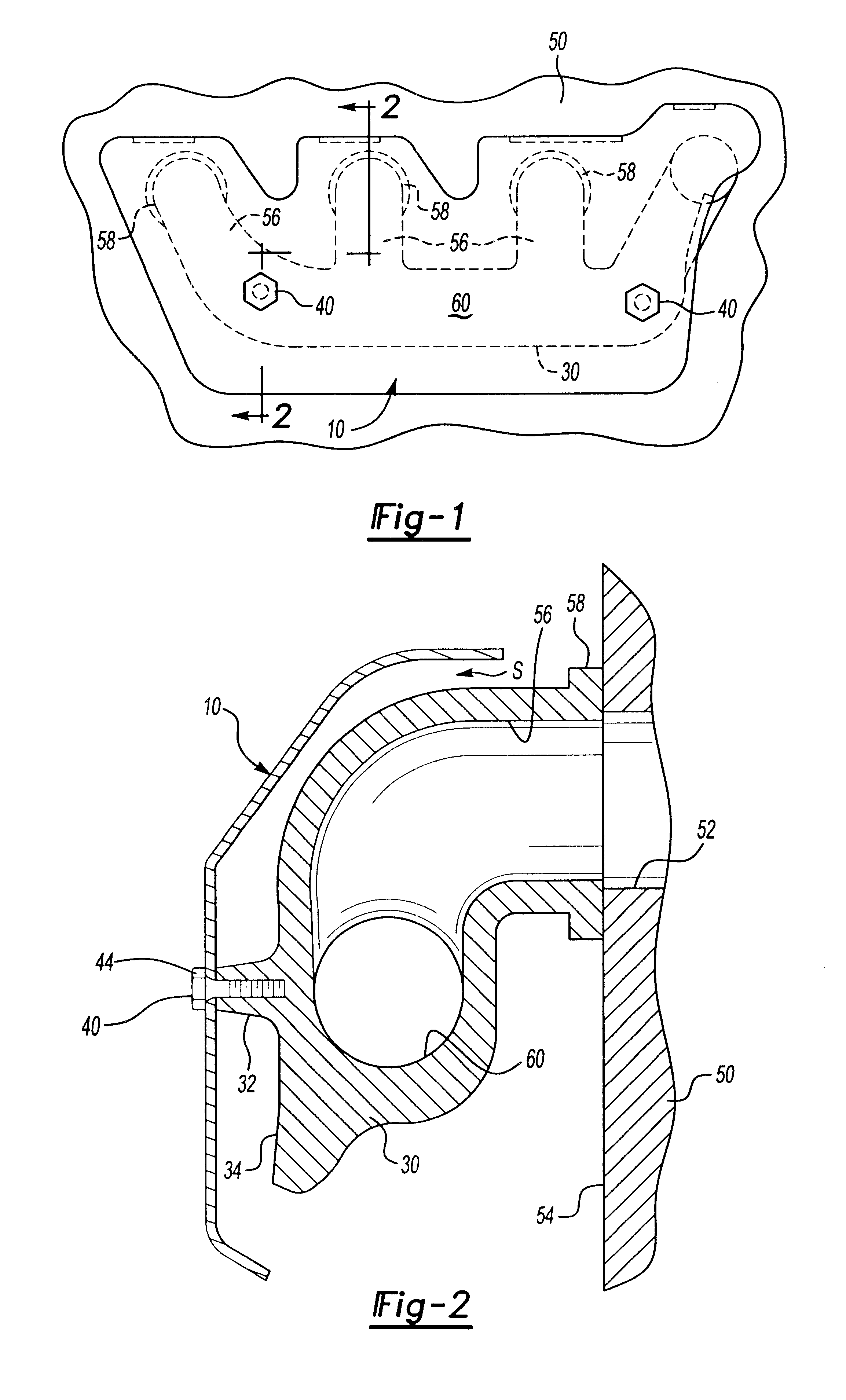

Sound barrier layer for insulated heat shield

InactiveUS6681890B1Low densityReduce noiseVibration measurement in solidsVibration measurement in fluidGlass fiberSound barrier

An improved heat shield provides thermal insulation and reduced noise transmission of vehicular engine components, including exhaust manifolds. The structure has three layers; an outer structural metal layer, a center insulation layer to isolate heat and dampen noise, and an inner metal layer directly adjacent the shielded component for reflecting heat back to the shielded component. The heat shield is attached by bolts to the shielded component. In the described embodiment, the volume of the insulation layer is expanded by approximately 15 to 20 percent over conventional shields to produce a softer, thicker material having a lower density but unchanged mass. The invention provides a technique to achieve desired thickness and density in insulation layers via modal finite element analysis. The relatively thicker heat shield more effectively absorbs vibration and attenuates noise without increase in mass. In the described embodiment, the layer contains cellulose, diatomaceous earth, talc, and fiberglass.

Owner:DANA AUTOMOTIVE SYST GRP LLC

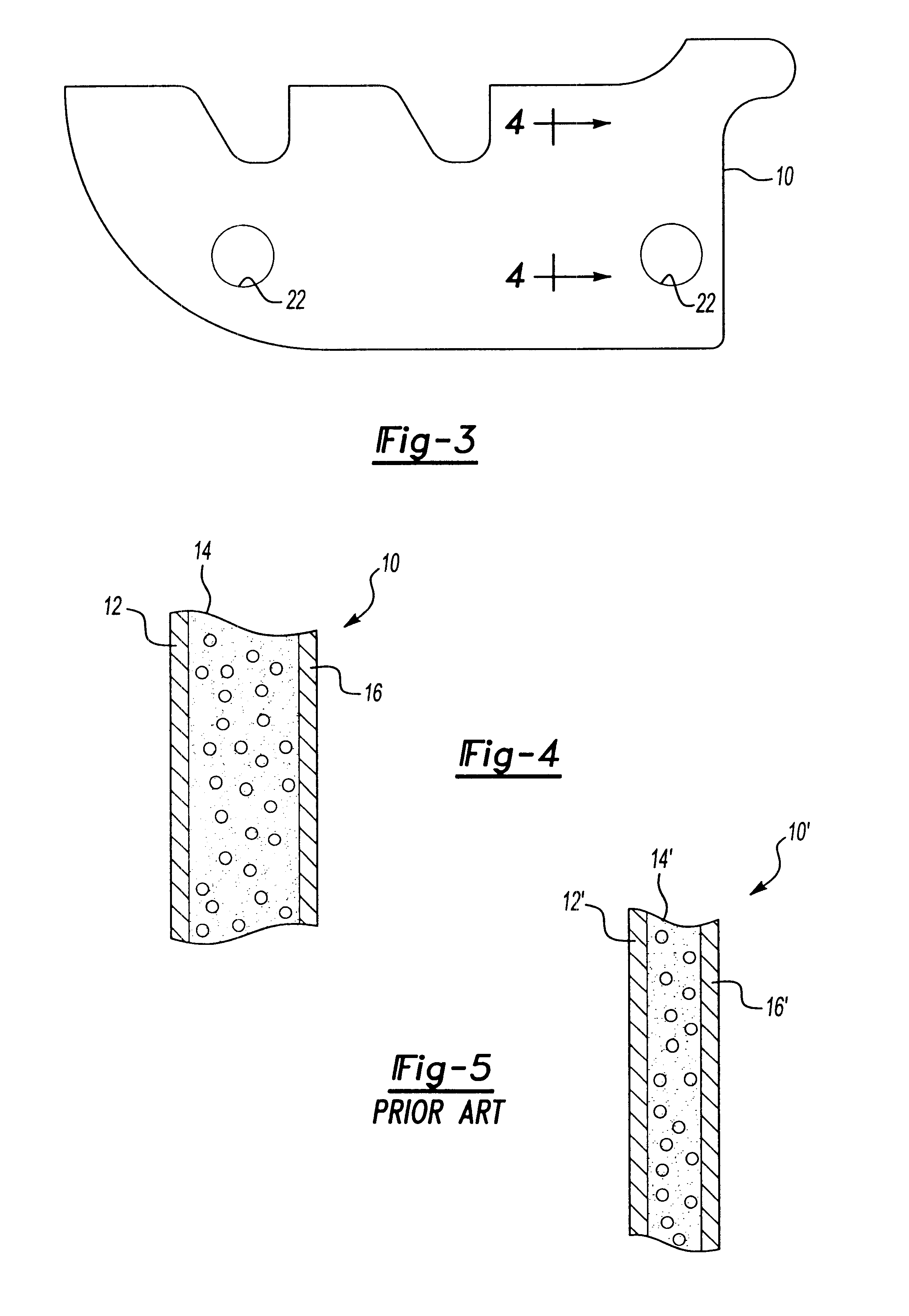

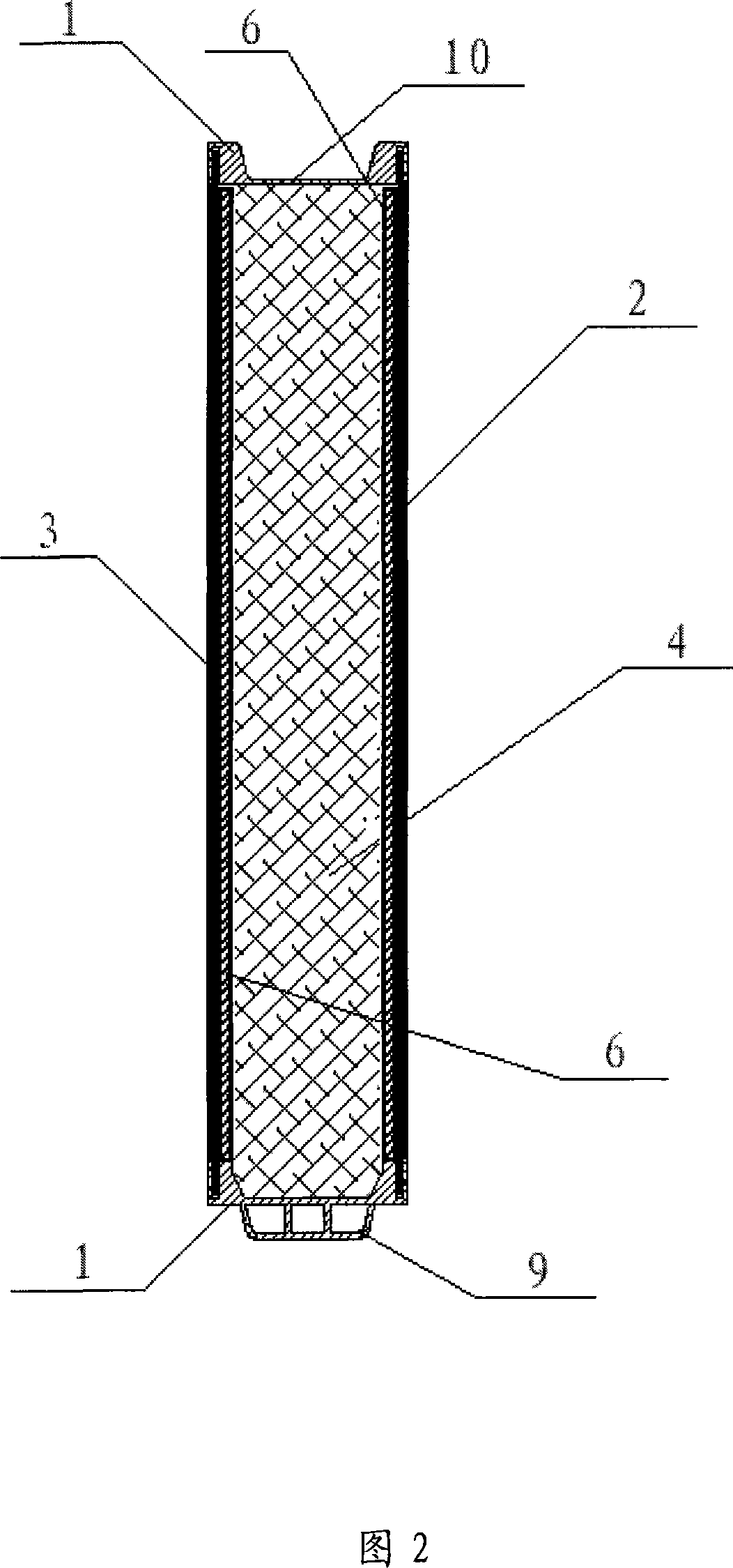

Braced sound barrier vacuum panel

InactiveUS20080289898A1Inward flexing of the upper and lower sheets is largely preventedInexpensive materialsClimate change adaptationInsulation improvementSound barrierEngineering

A vacuum panel using internal or external bracing strips to provide a substantially flat sound barrier capable of very high sound rejection independent of frequency.

Owner:RICKARDS MICHAEL JOHN

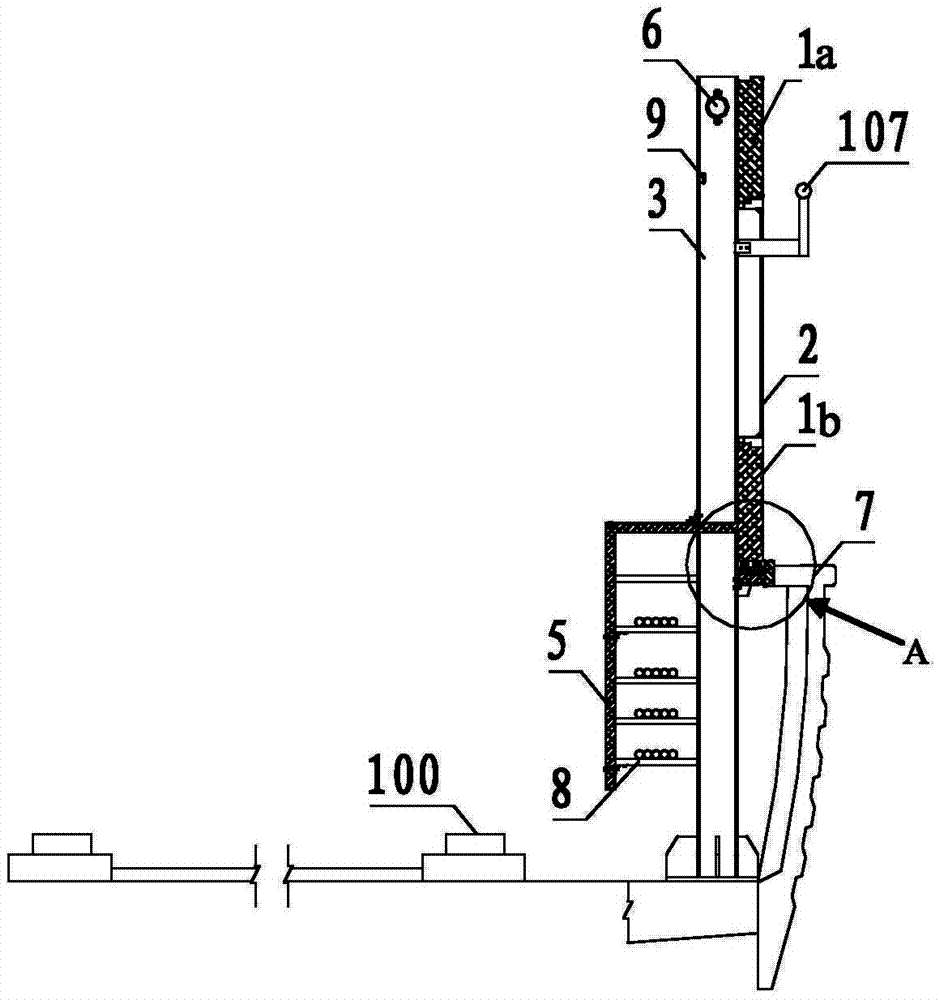

External-hanging sound barrier for rail transit

ActiveCN103485290AStable structureImprove performanceNoise reduction constructionSound barrierEngineering

The invention discloses an external-hanging sound barrier for rail transit. The sound barrier comprises a plurality of vertical steel columns located on one side of a rail. Every two adjacent vertical steel columns are fixedly connected through a support crossbeam. A guardrail board is disposed on one side, away from the rail, of each vertical steel column, and a sound absorbing and shielding body is located above the guardrail board. Each vertical steel column is provided with a through hole allowing a steel wire rope to penetrate. The sound barrier further comprises a noise sensor which is disposed on one side, away from the rail, of each sound absorbing and shielding body, and the noise sensor is connected with a control circuit which is connected with a storage battery. The sound barrier has the advantages that the sound barrier is durable in structure, stable in performance, convenient to mount, and good in appearance streamline, main body construction of the rail transit is unaffected, various cables are prevented from being exposed under sunlight, noise on the outer side of the sound barrier can be monitored in real time, and the noise reduction and sound shielding amount of the sound barrier is 10-15dB(A).

Owner:JIANGSU YUANXING ENVIRONMENTAL PROTECTION GROUP

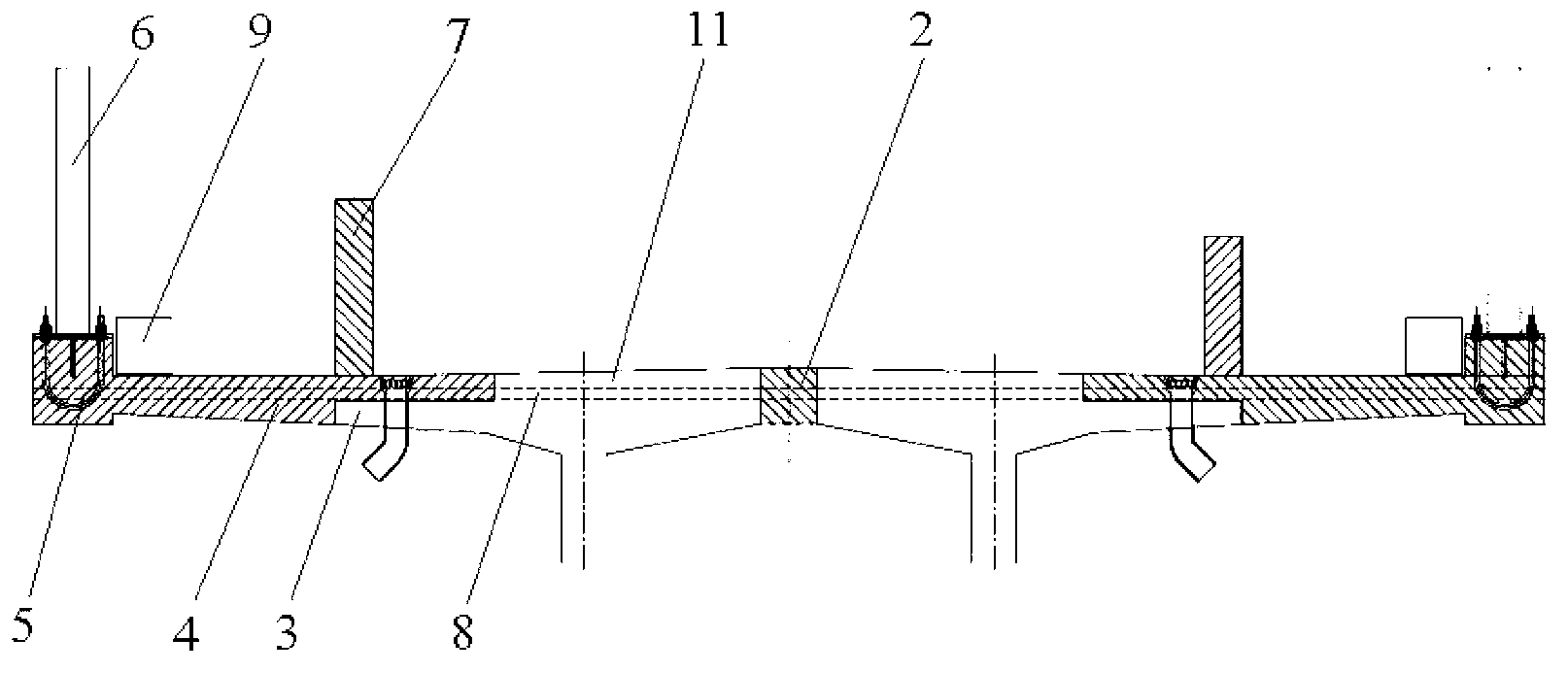

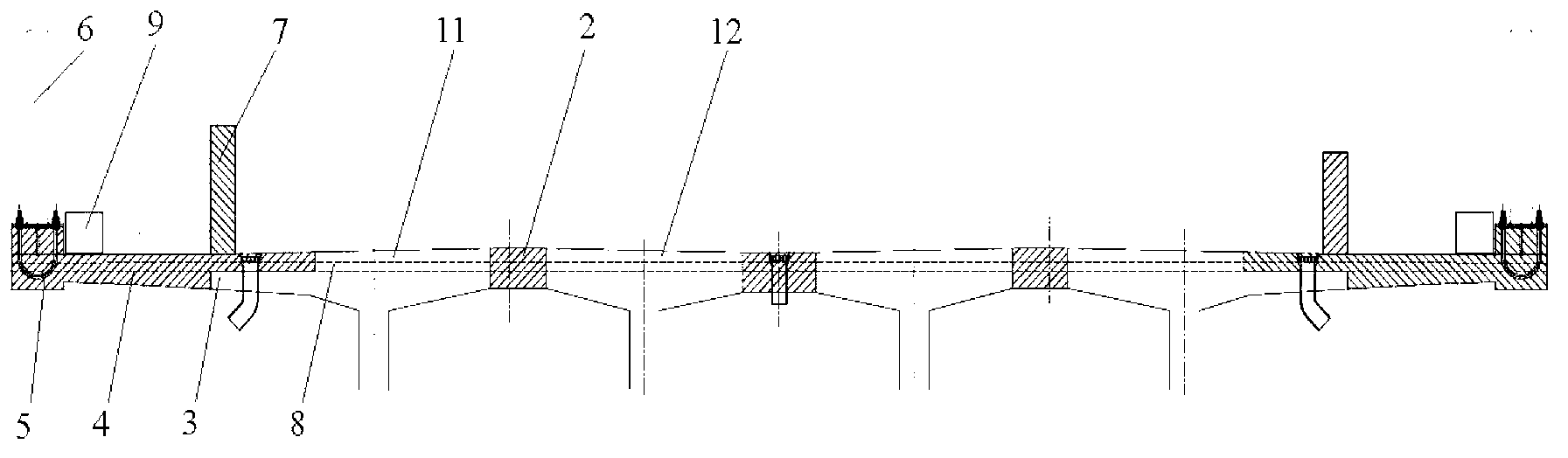

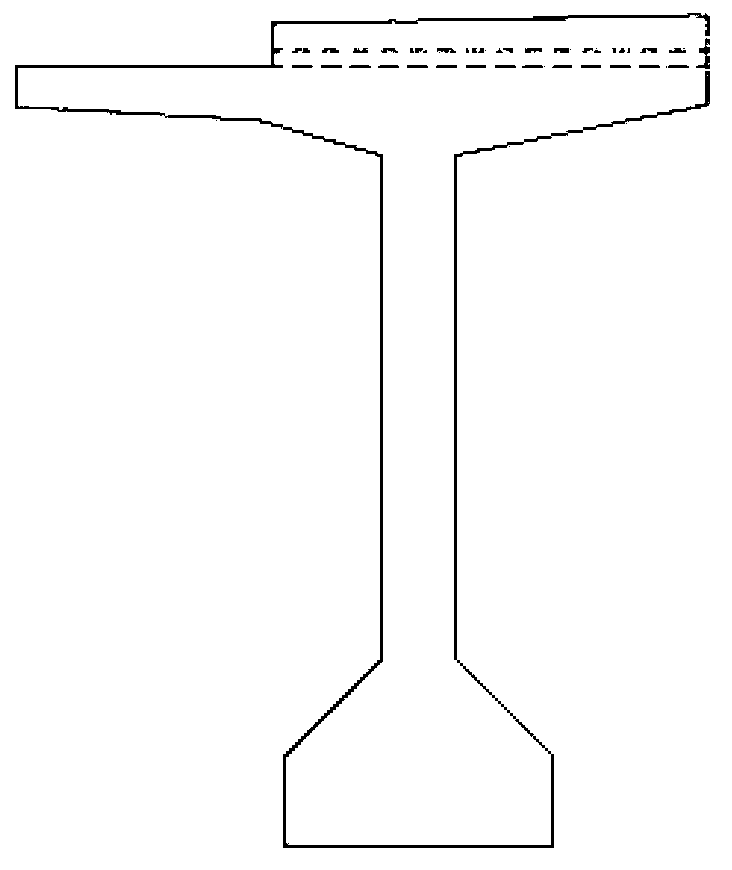

Sound-barrier simply-supported T-beam bridge

ActiveCN103061242AImprove integrityReduce workloadNoise reduction constructionBridge structural detailsSound barrierT-beam

The invention relates to the technical field of railway bridges and particularly discloses a sound-barrier simply-supported T-beam bridge which comprises a plurality of simply supported T-beams. Each simply supported T-beam is formed by connecting a plurality of simply supported T-beam units end to end. The simply supported T-beams are transversely connected through transverse partitions, wet joints and concrete. Concrete cast-in-place decks are arranged outside the simply supported T-beams on two sides. The upper surfaces of the simply supported T-beams, the upper surfaces of concrete connections and the upper surfaces of the concrete cast-in-place decks form an integral bridge deck. The whole integral bridge deck is provided with transverse prestressed bars. Sound-barrier column foundations are arranged outside the concrete cast-in-place decks, and sound-barrier columns are arranged at the sound-barrier column foundations. A sound barrier is arranged between each two adjacent columns. The performance of the railway bridge is improved, the railway bridge meets the requirement of providing the sound barrier by the aid of the integral bridge deck, sound barrier absorbs or isolates noise generated in running process of trains and the influence of the trains upon lives of nearby residents is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

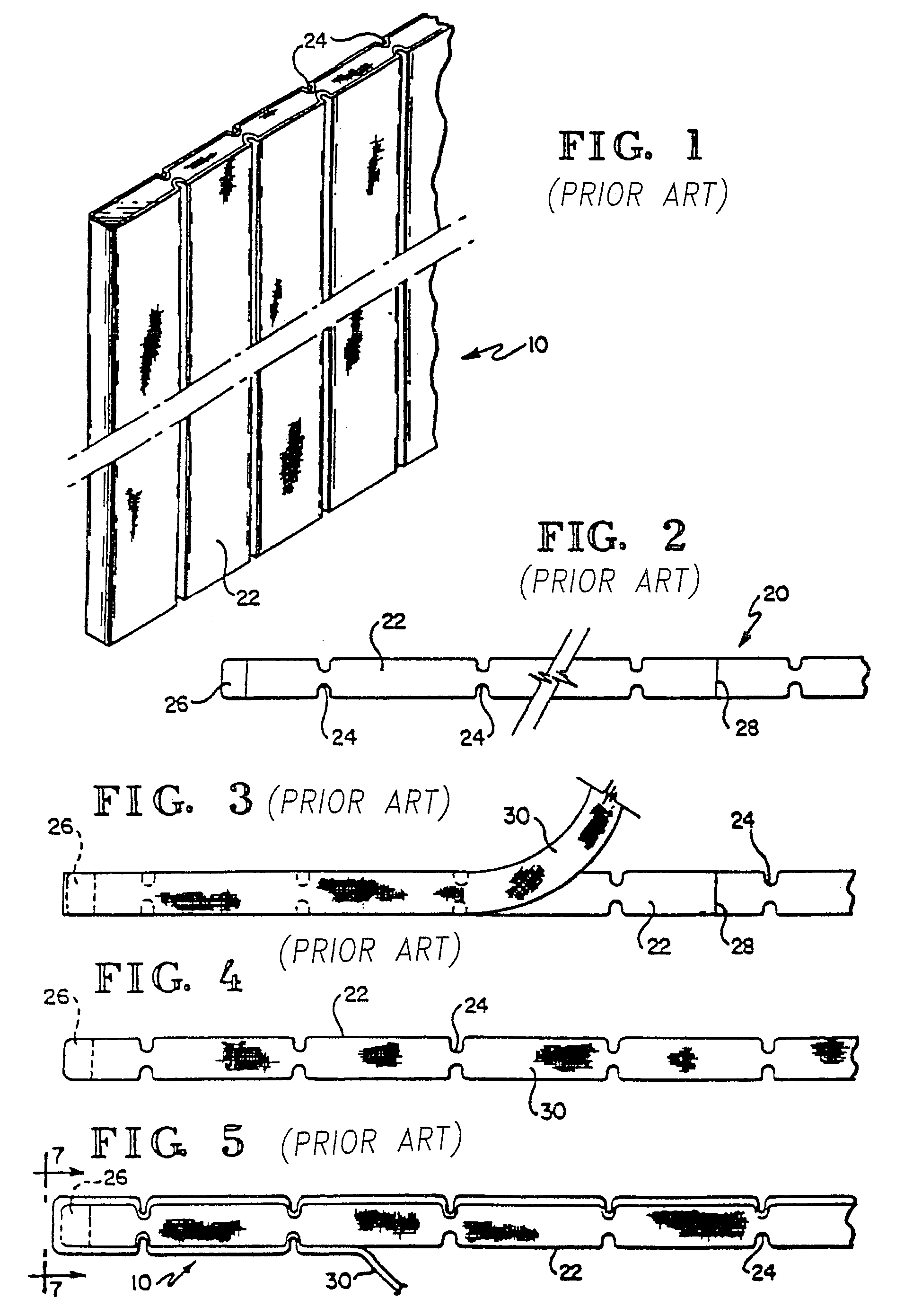

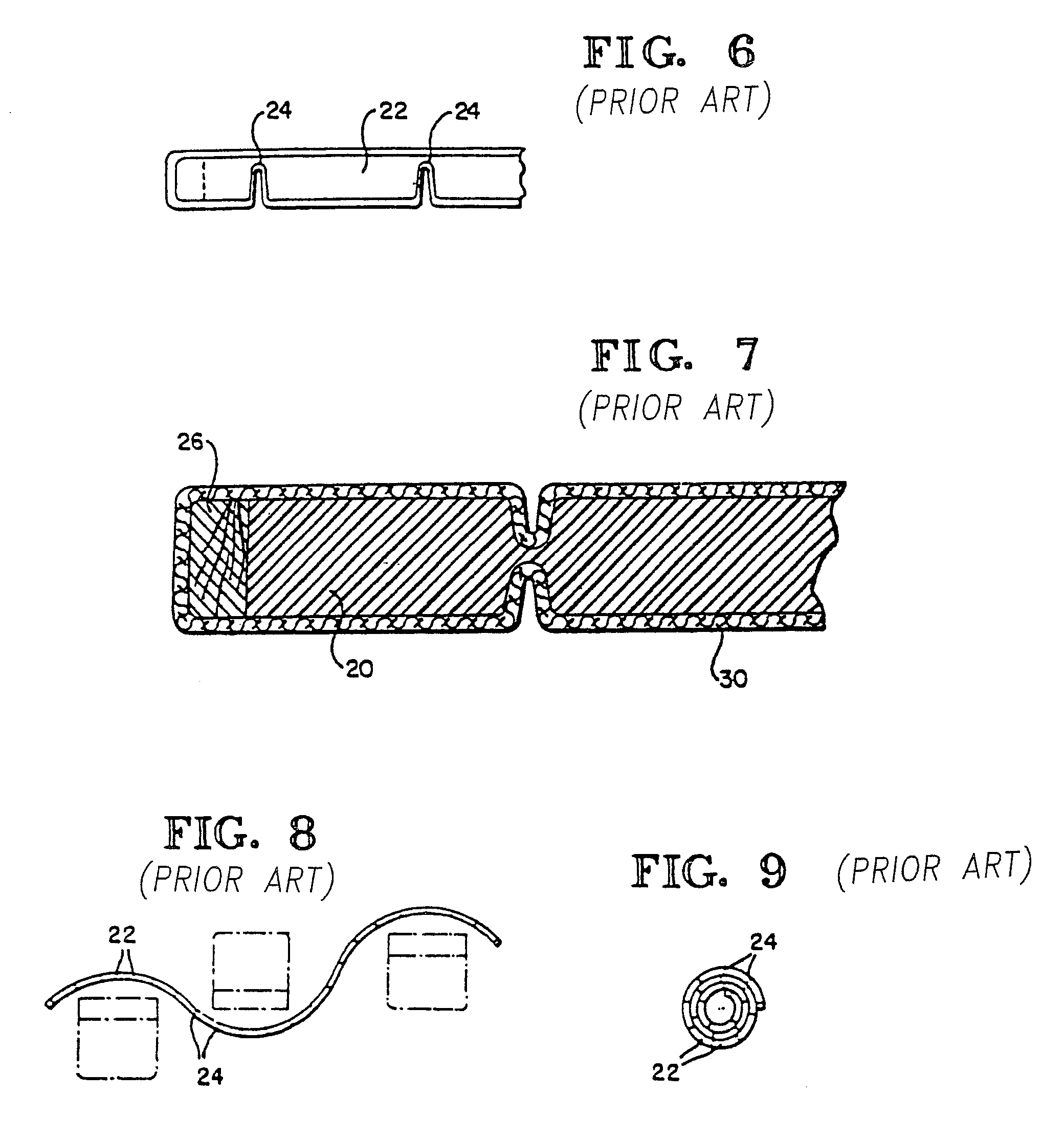

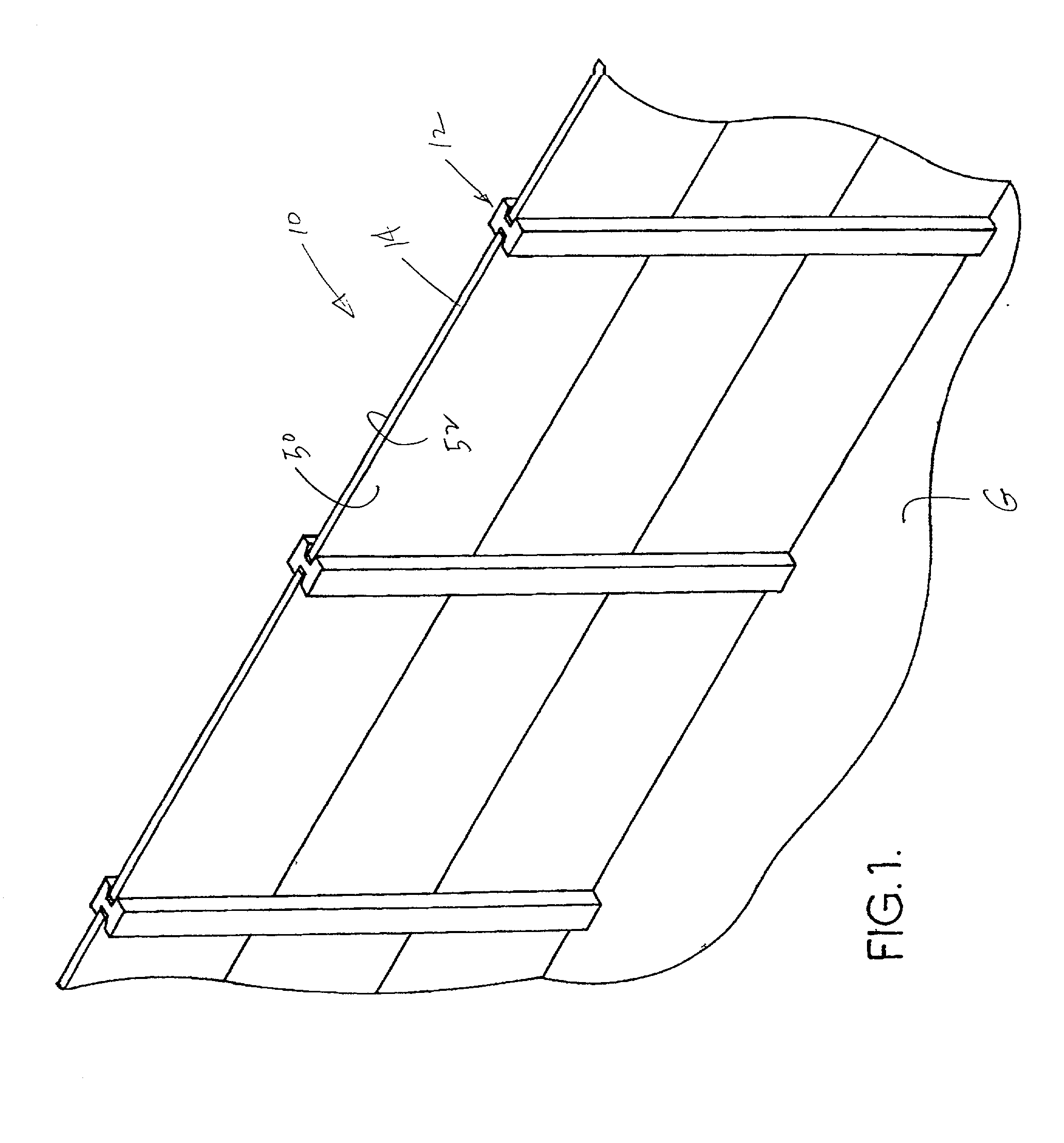

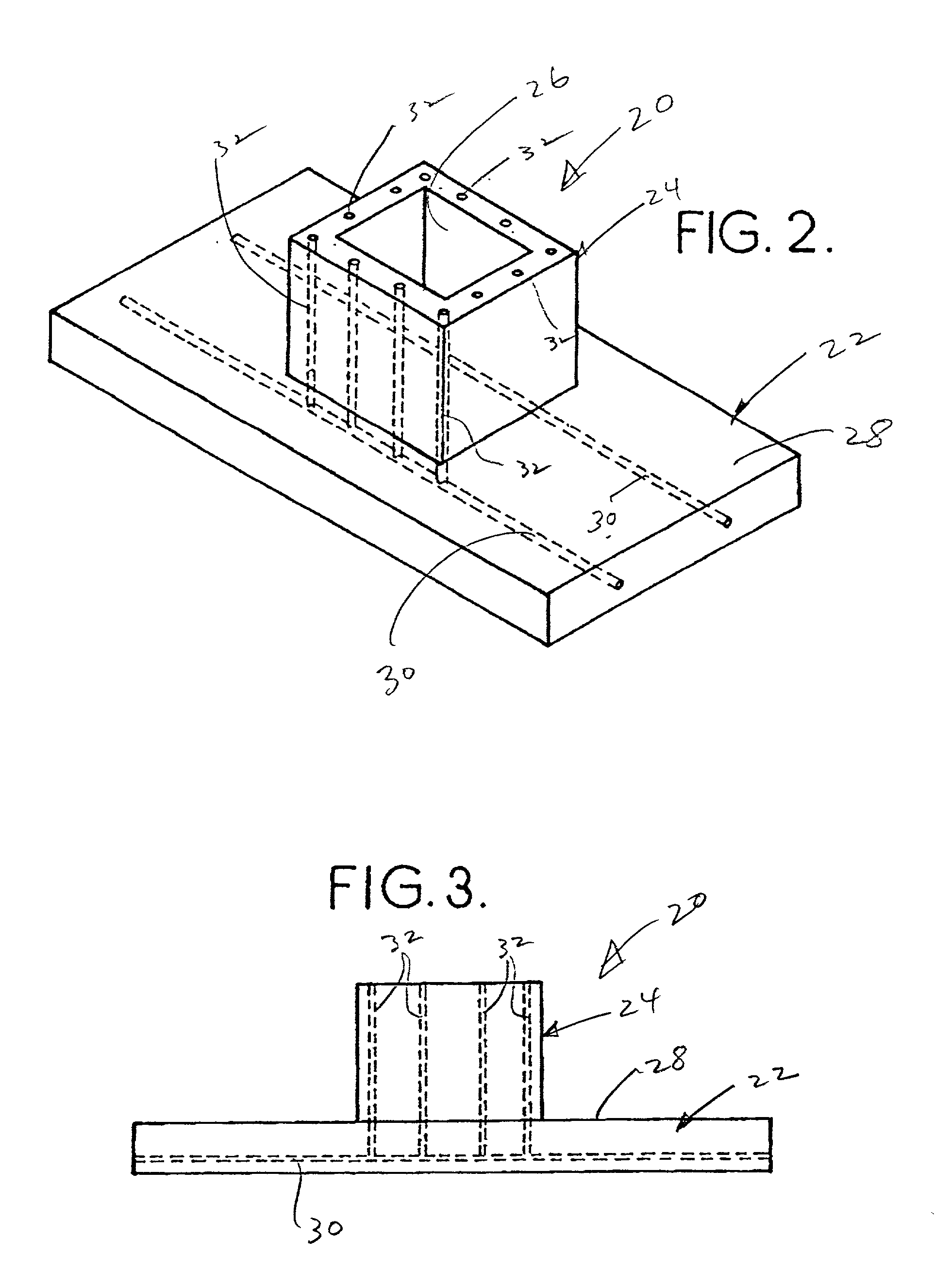

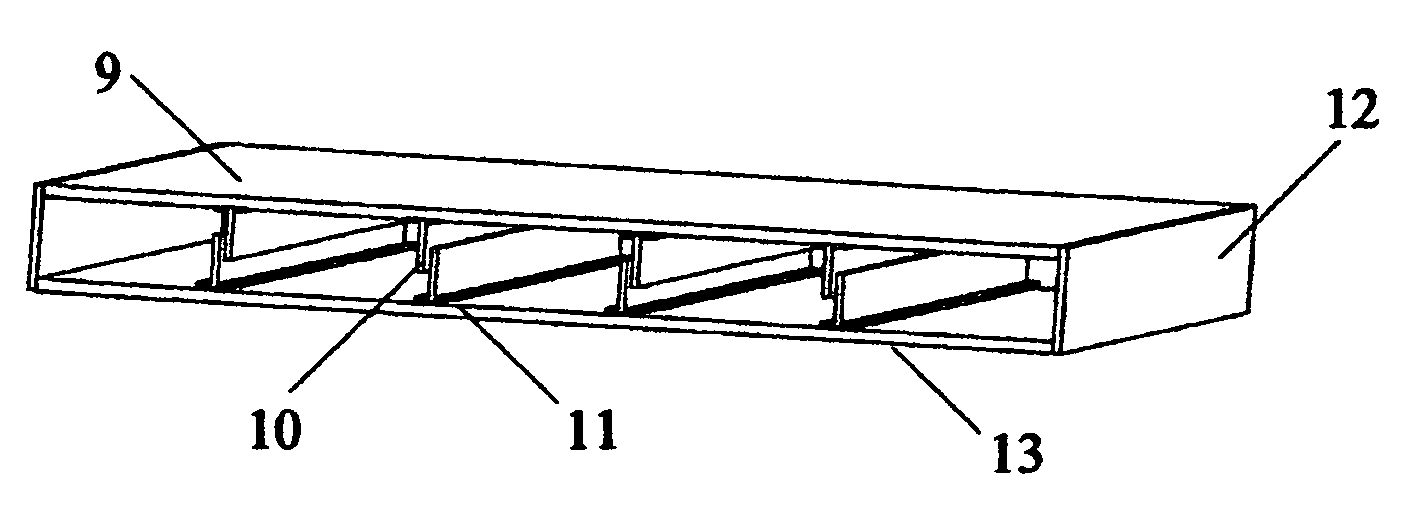

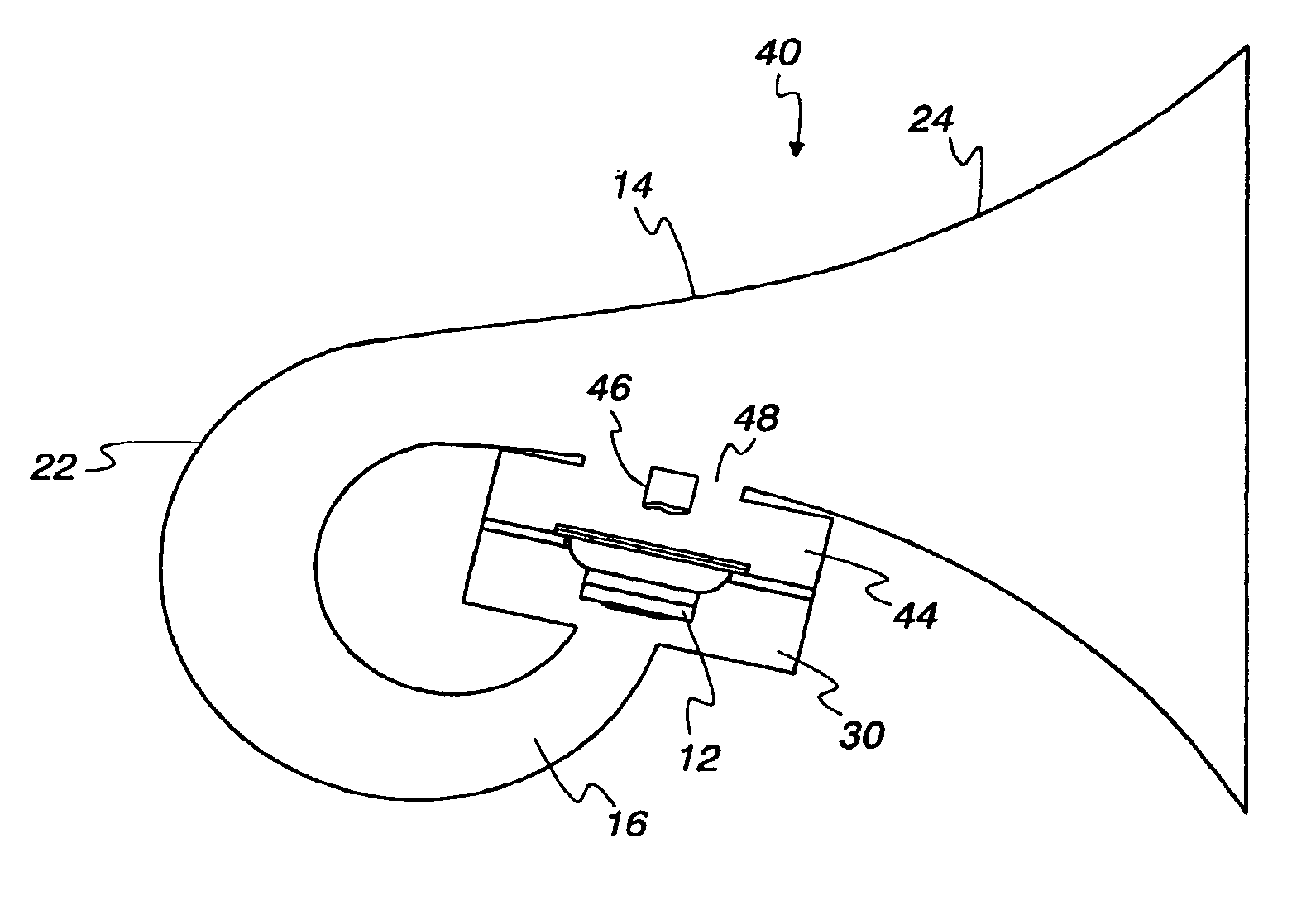

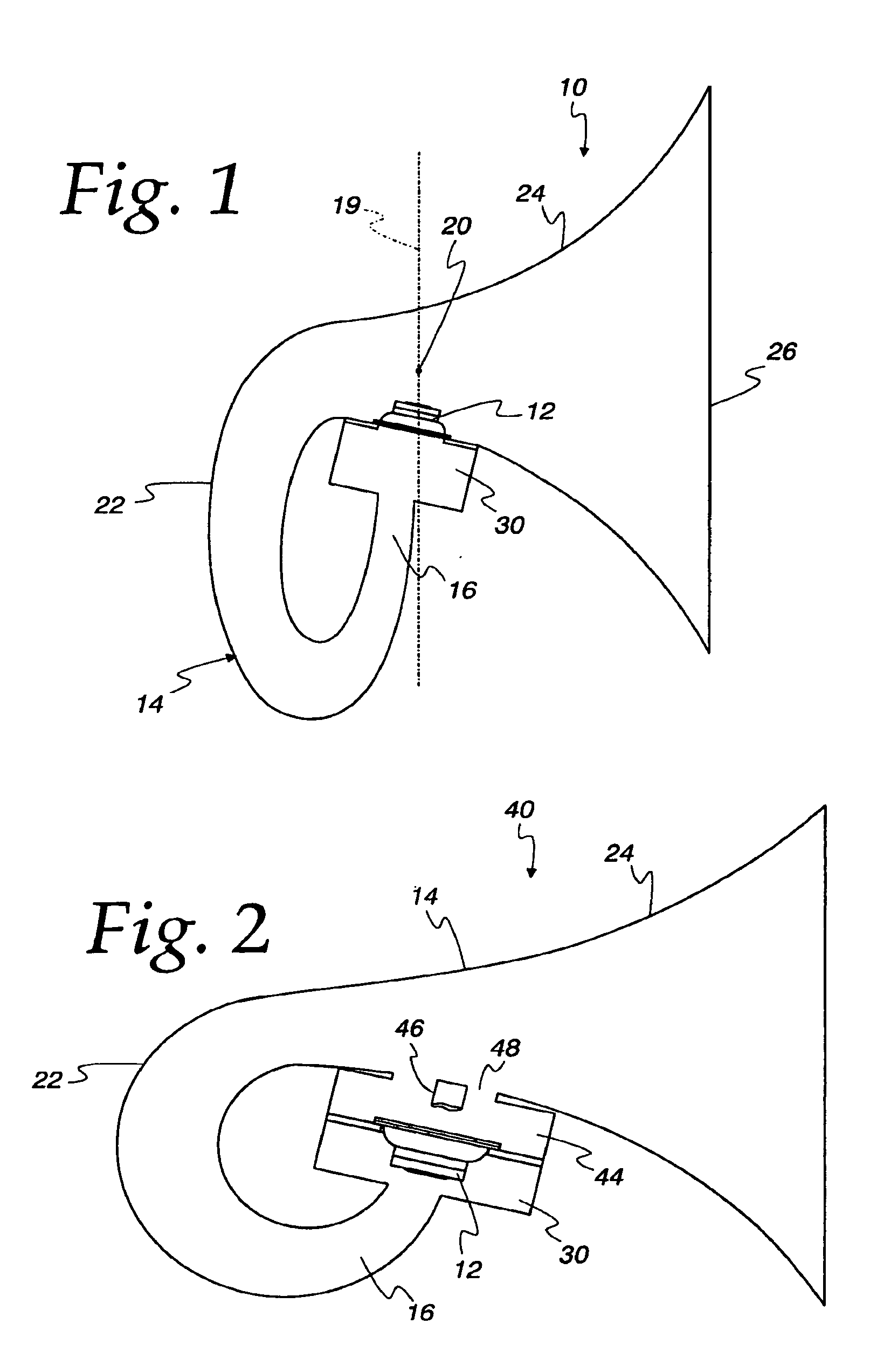

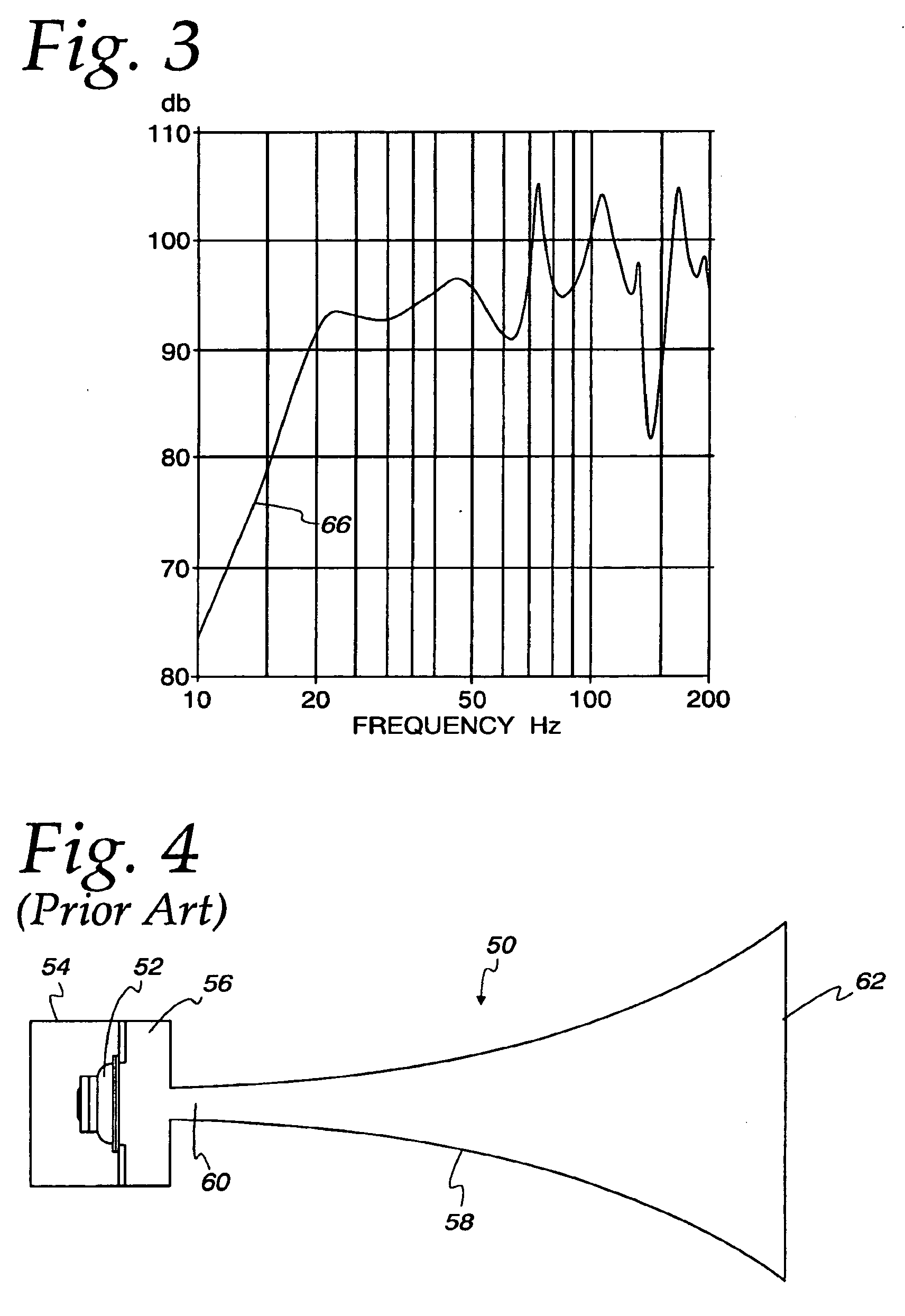

Sound Reproduction With Improved Low Frequency Characteristics

ActiveUS20090087008A1Wind musical instrumentsFrequency/directions obtaining arrangementsSound barrierEngineering

A sound reproduction system (10) is disclosed in which a sound barrier (14) defines a horn passageway having an upstream (22) and a downstream section (24). A driver (12) is mounted at the throat (16) of the upstream section (22) so that its rearward directed output communicates with the downstream section (24). Output from the upstream section and the rearward directed output of the driver are merged at a tap point located at the beginning of the downstream section. By altering the respective areas and lengths of the upstream and downstream sections a variety of different frequency dependent responses are obtained. In one example, low-frequency response systems of heretofore unobtainable compact size are realized.

Owner:DANLEY THOMAS J

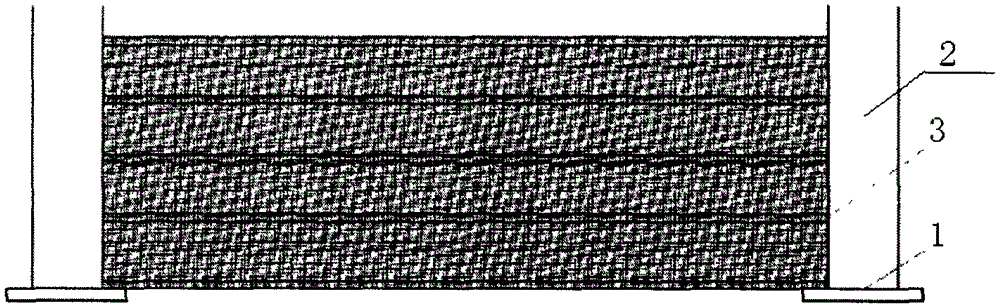

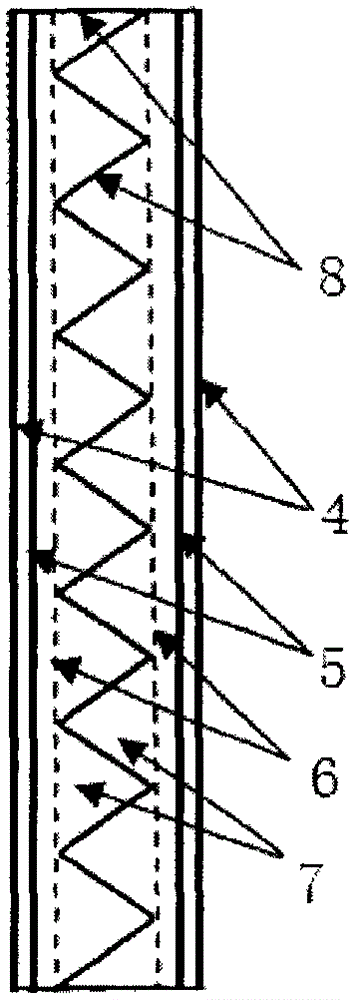

Noise prevention and sound insulation barrier for building structure

InactiveCN105297646AHigh strengthNo deformationNoise reduction constructionCeramicwareFiberSound barrier

The invention relates to a noise prevention and sound insulation barrier for a building structure. The noise prevention and sound insulation barrier comprises a foundation. A plurality of stand columns are fixed to the foundation. A plurality of sound barrier unit boards are fixed between the adjacent stand columns. Each sound barrier unit board comprises two layers of aluminum fiber sheets, two layers of concrete sound absorption boards, two layers of foamed ceramic boards, a cavity, a foldable noise absorption board and a peripheral framework, wherein the aluminum fiber sheets are arranged on the outer surfaces of the two sides of the sound barrier unit board respectively, the two layers of concrete sound absorption boards are arranged in the two layers of aluminum fiber sheets, the two layers of foamed ceramic boards are arranged in the two layers of concrete sound absorption boards, the cavity is formed between the two layers of foamed ceramic boards, the foldable noise absorption board is made of glass wool and arranged in the cavity in a vertically and continuously folded and connected mode, and the two layers of aluminum fiber sheets, the two layers of concrete sound absorption boards and the two layers of foamed ceramic boards are sequentially fixed in the peripheral framework from outside to inside. Serving as a part of the building structure, the noise prevention and sound insulation barrier is simple in structure and low in manufacturing cost and achieves a very good sound absorption and insulation effect.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

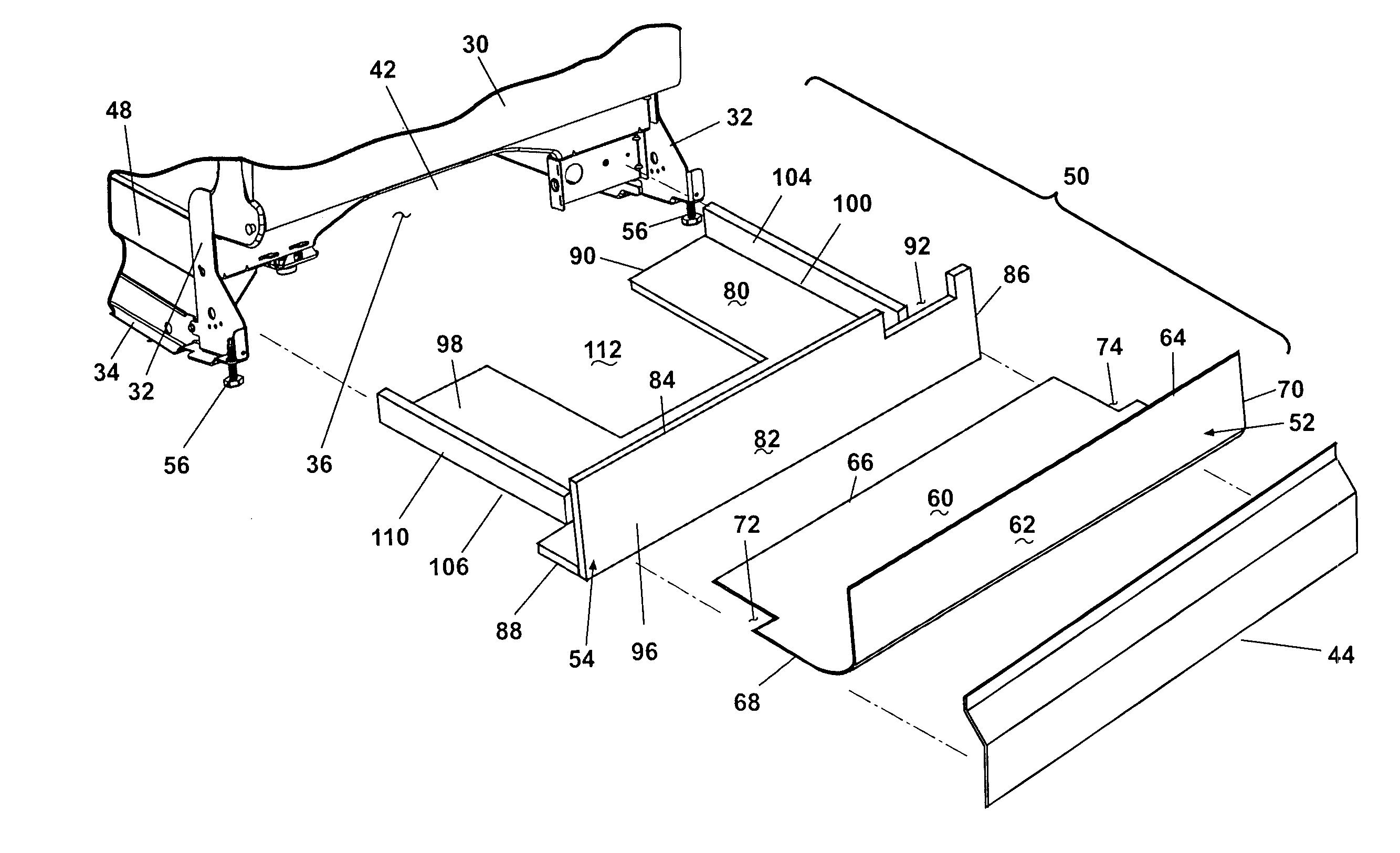

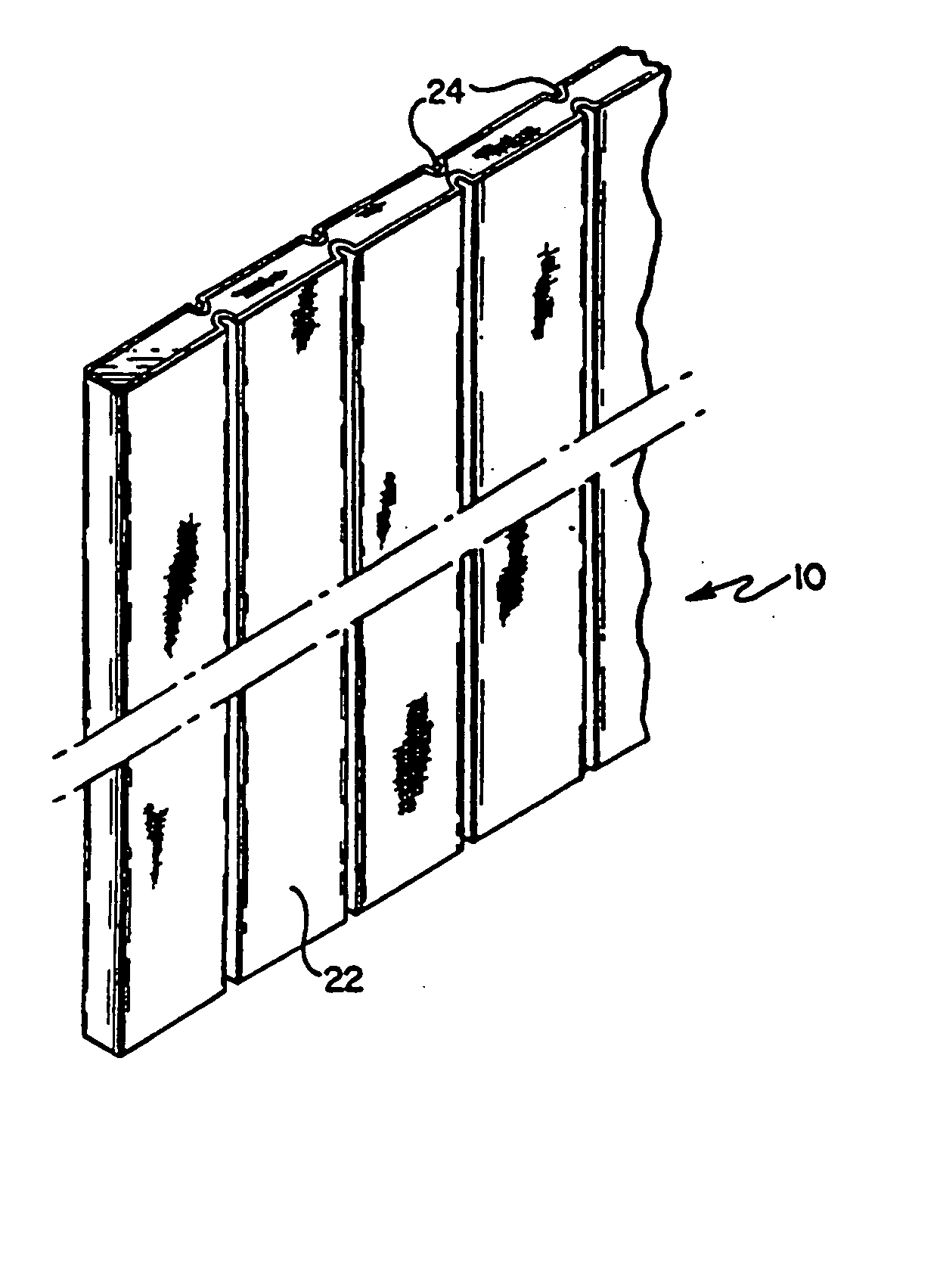

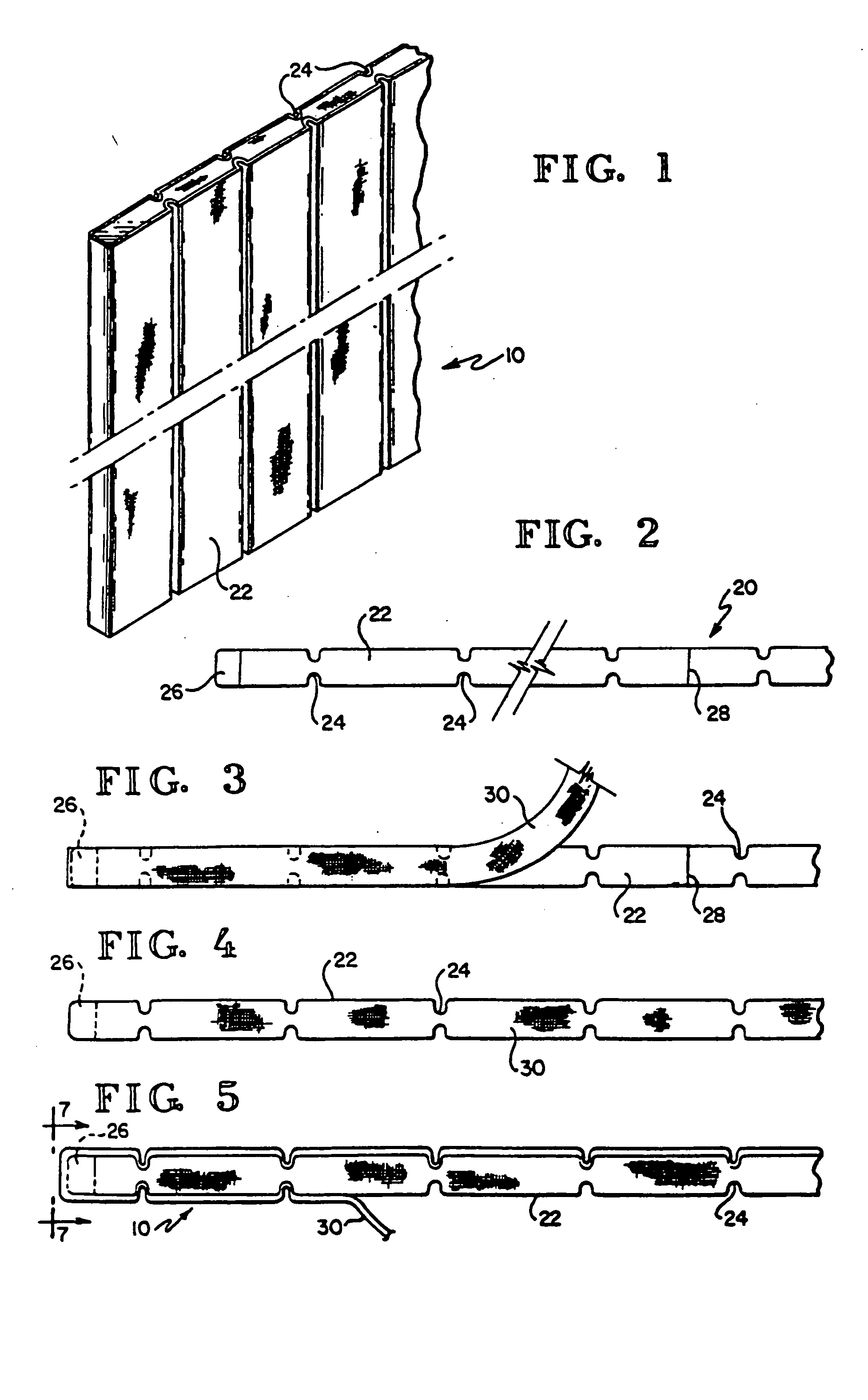

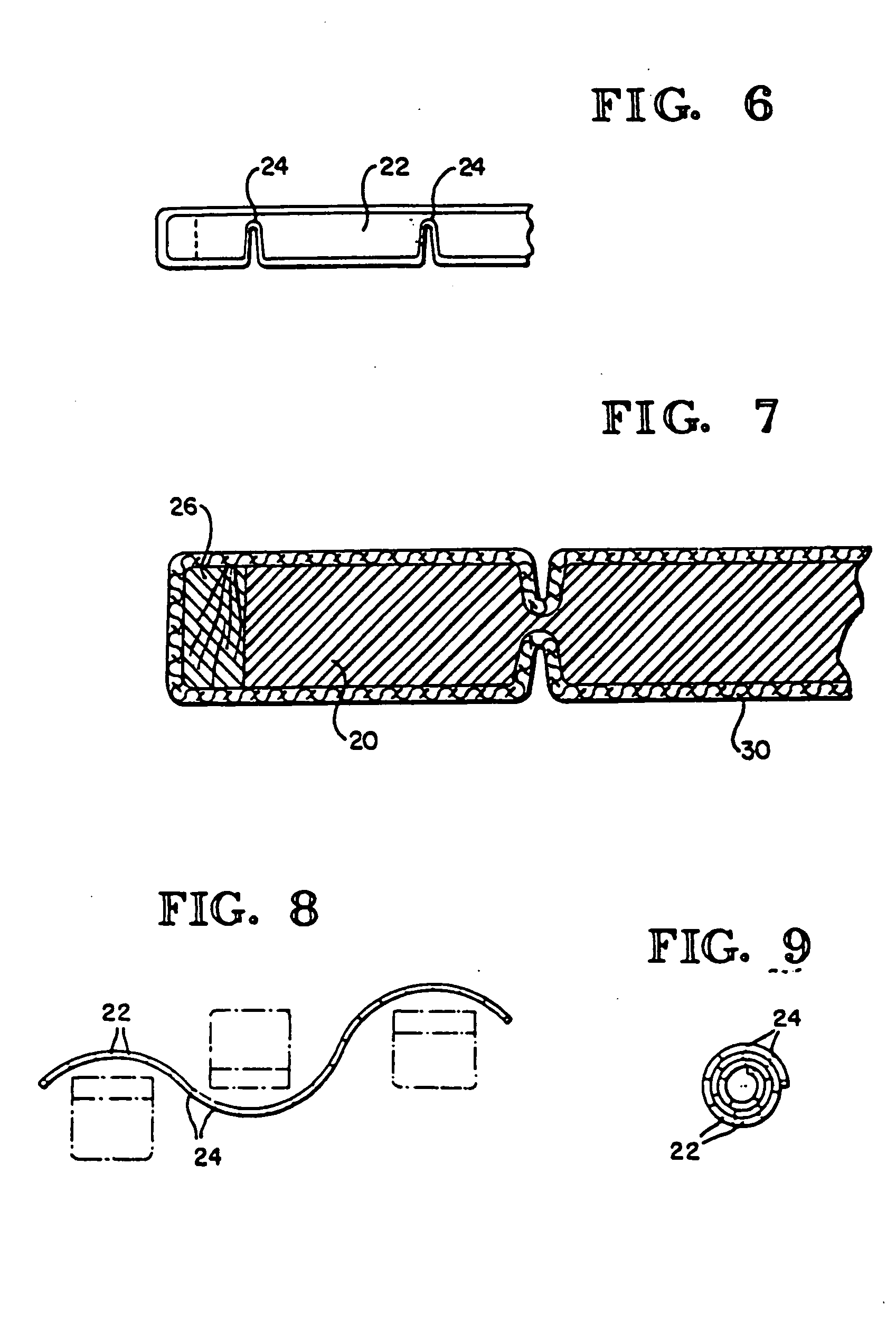

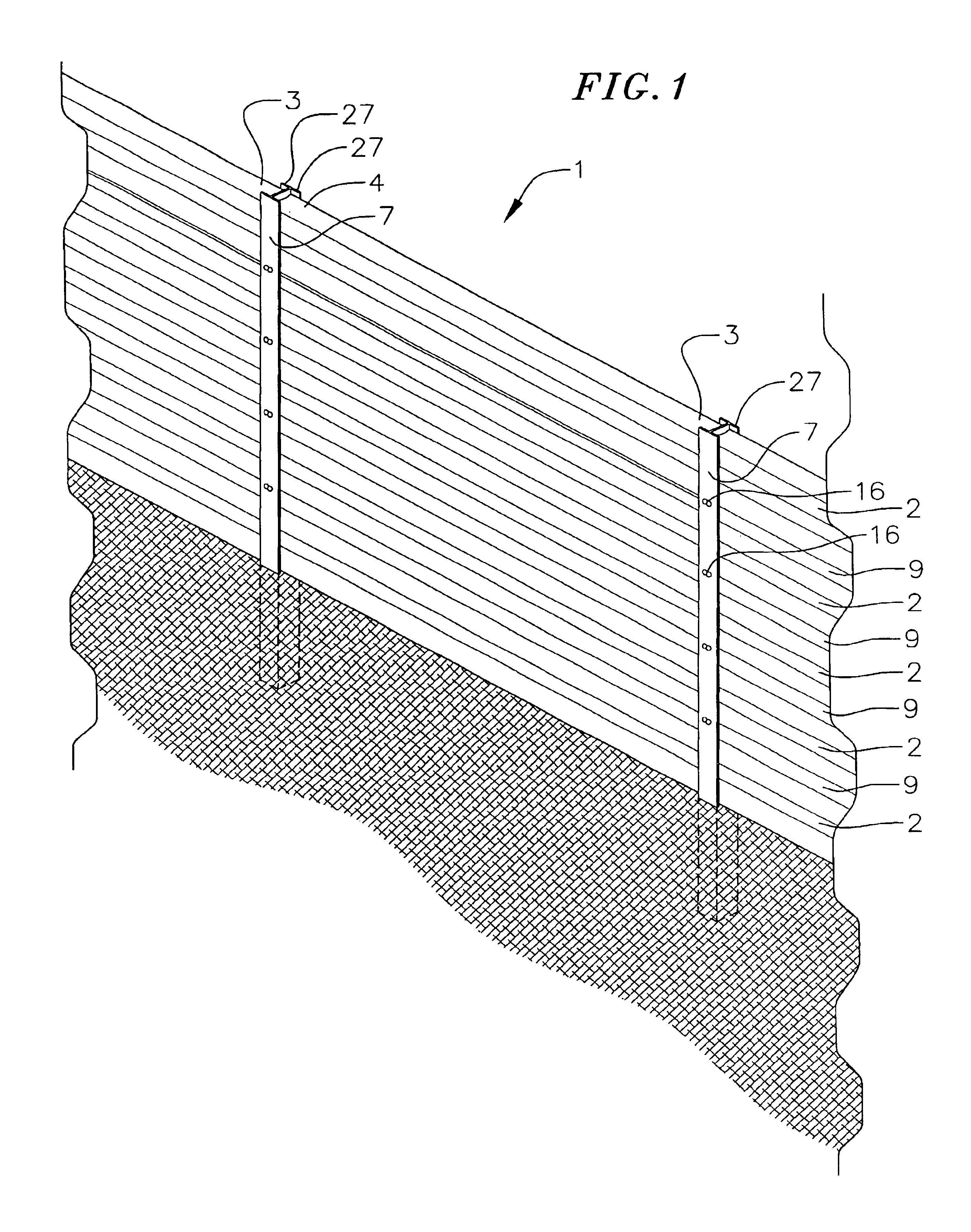

Sight and sound barrier

ActiveUS20050076585A1Room for improvementImprove acoustic propertiesBuilding roofsWallsSound barrierPolystyrene

In one embodiment, the sight and sound barriers of this invention have a flexible sheet of lightweight, resilient foam as a core. This core is covered by a fabric or other suitable covering to further enhance the acoustic properties and to make the walls attractive. In this embodiment the core of polyethylene, polystyrene, urethane, or a mosaic thereof, for example, is made flexible with alternating wall and hinge portions. In an alternate preferred embodiment, the barriers or panels are formed with mitered grooves to allow the panel to be bent into larger degree corners, such as 90 degrees in one direction or 180 degrees in the opposite direction. Preferably the grooves have a depth extending substantially through the thickness of the core. In one embodiment, the covering material on one side of the panel is laid into the groove so that the covering material of a wall portion approaches, or preferably touches, the covering material on the opposite side. In an optional feature, grooves can be placed on alternating sides of the panel or barrier. In an optional feature, groove inserts may be sized and shaped to be placed in the grooves. The groove inserts may include a face which is flush with, recessed or protrudes from the adjacent wall portions. The groove inserts and mitered grooves may use various connectors such as Velcro® hook and loop fasteners or magnets.

Owner:CHILDRENS FACTORY LLC

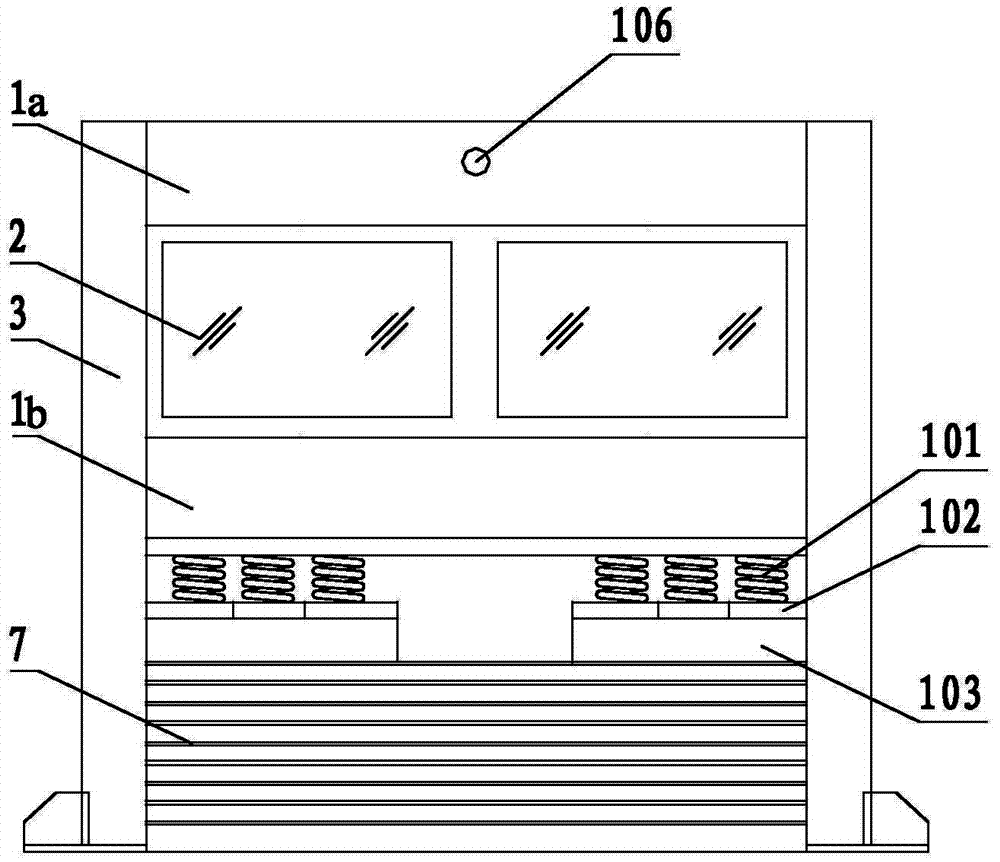

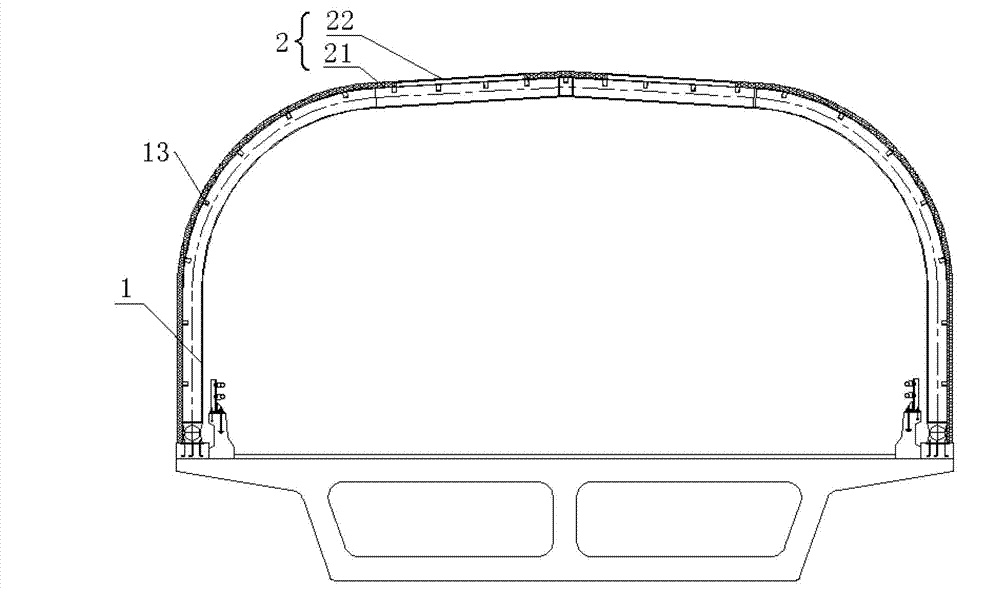

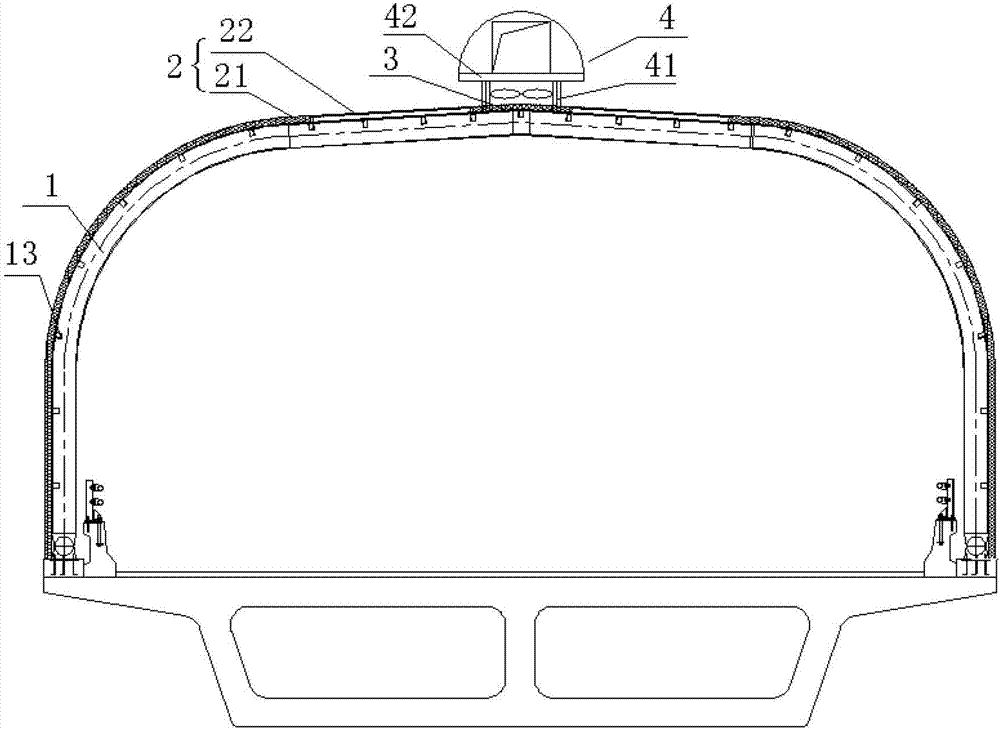

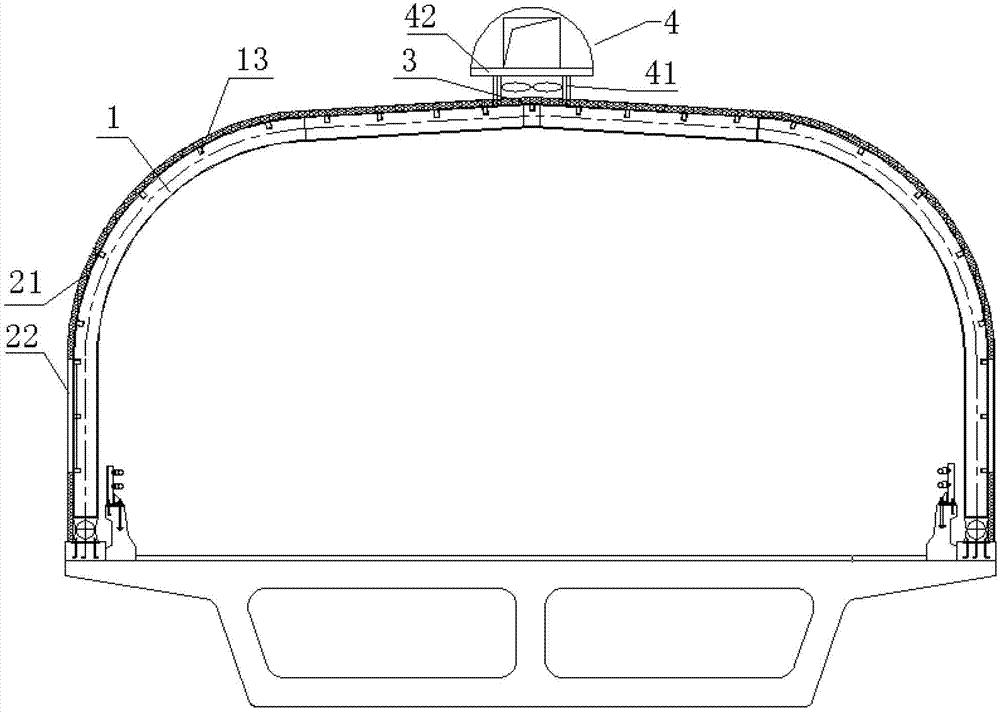

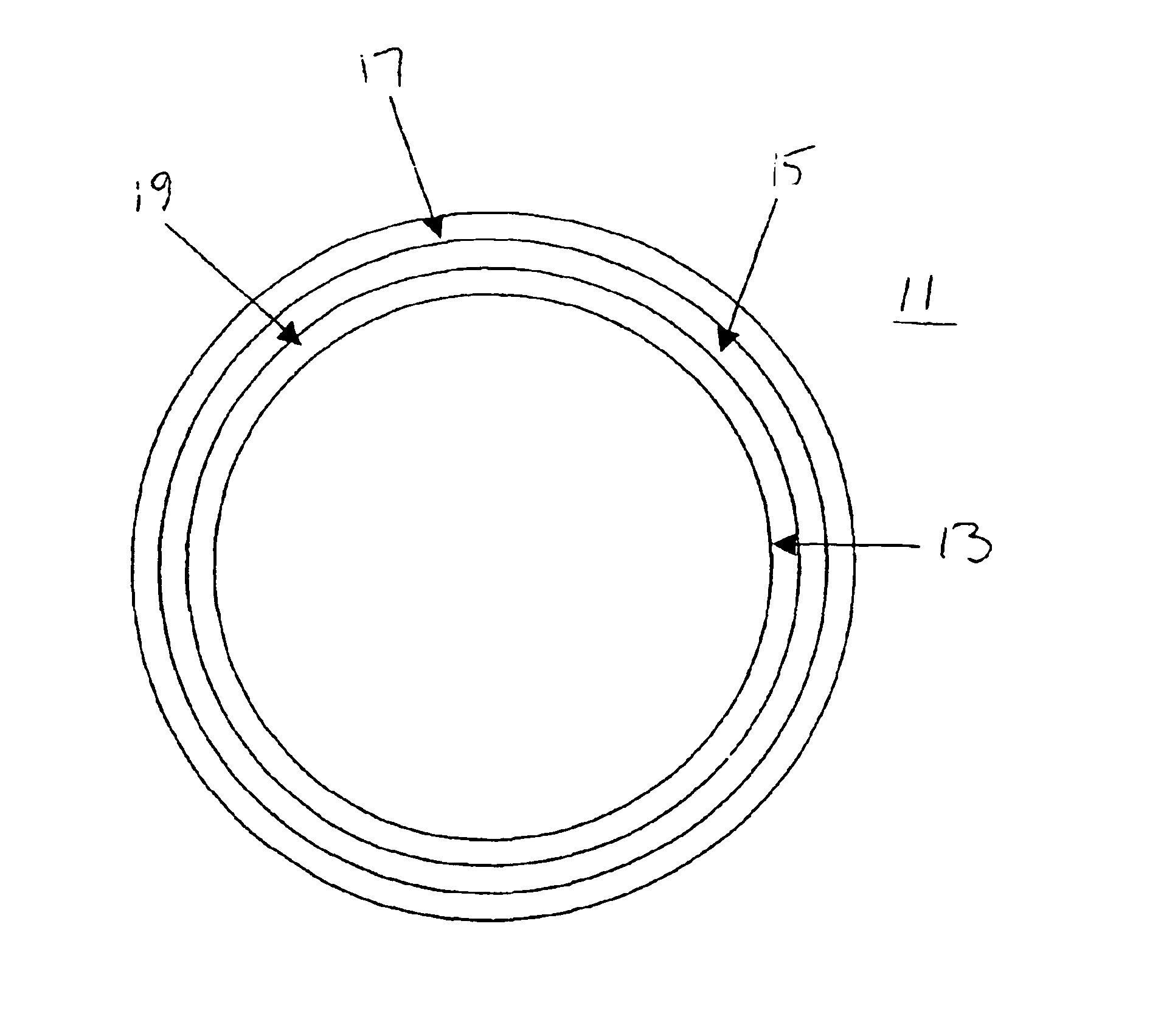

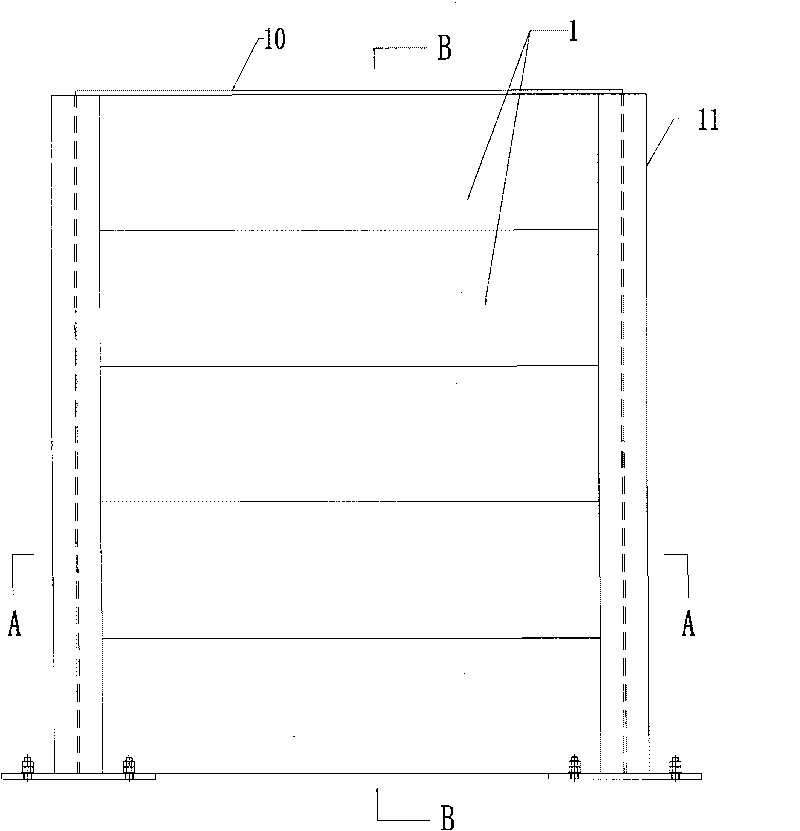

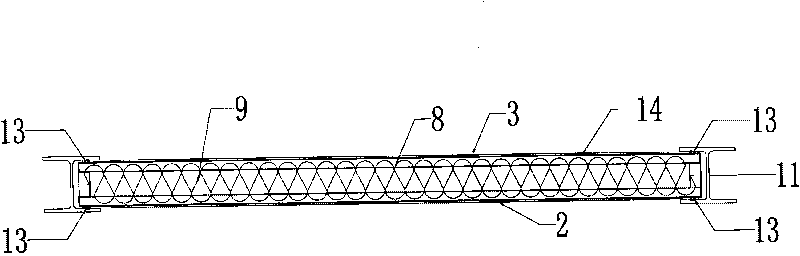

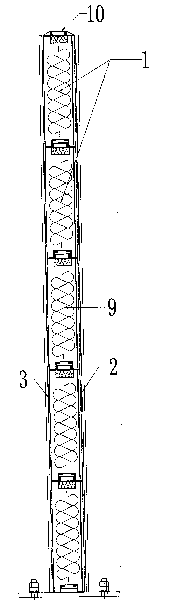

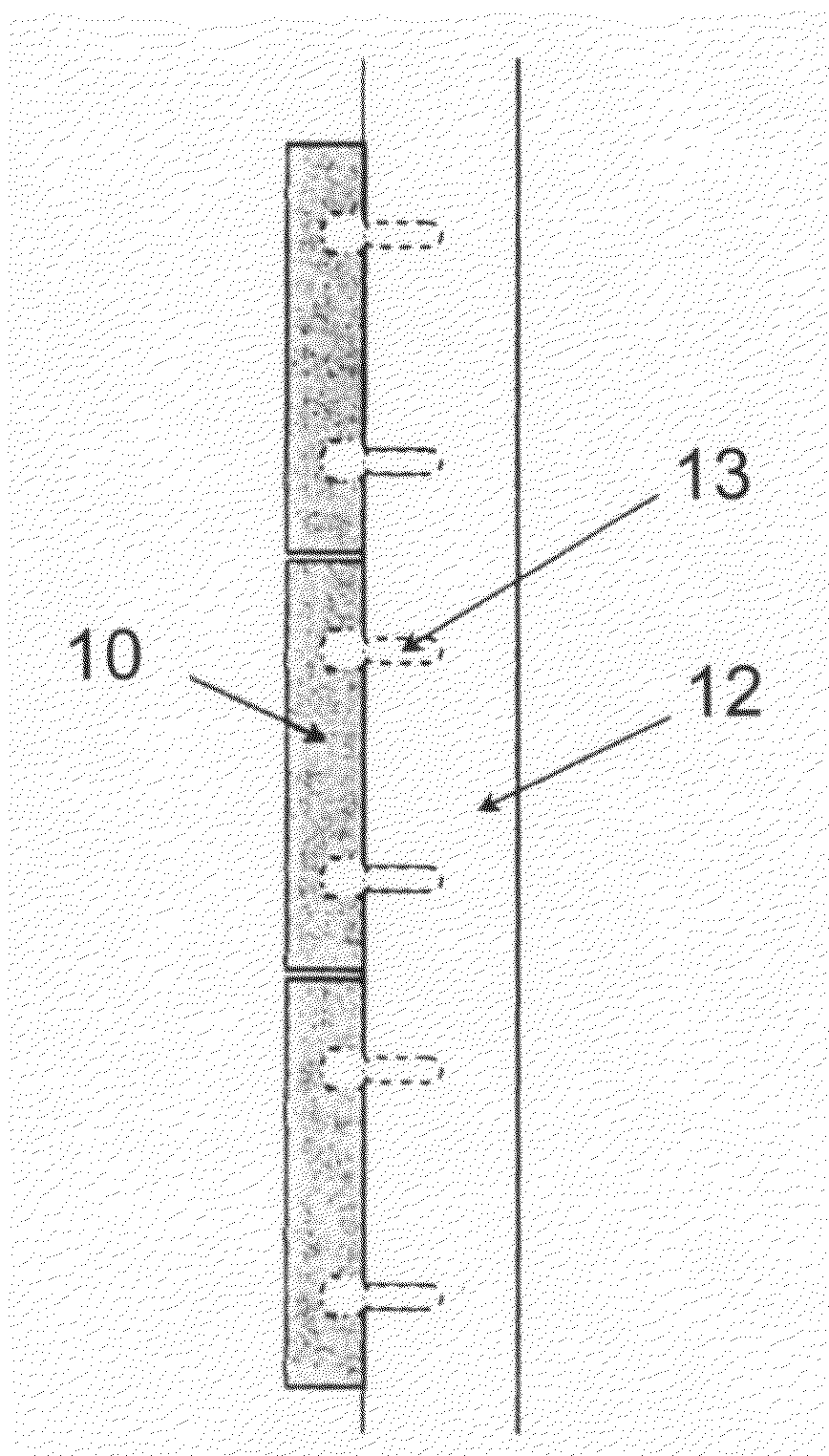

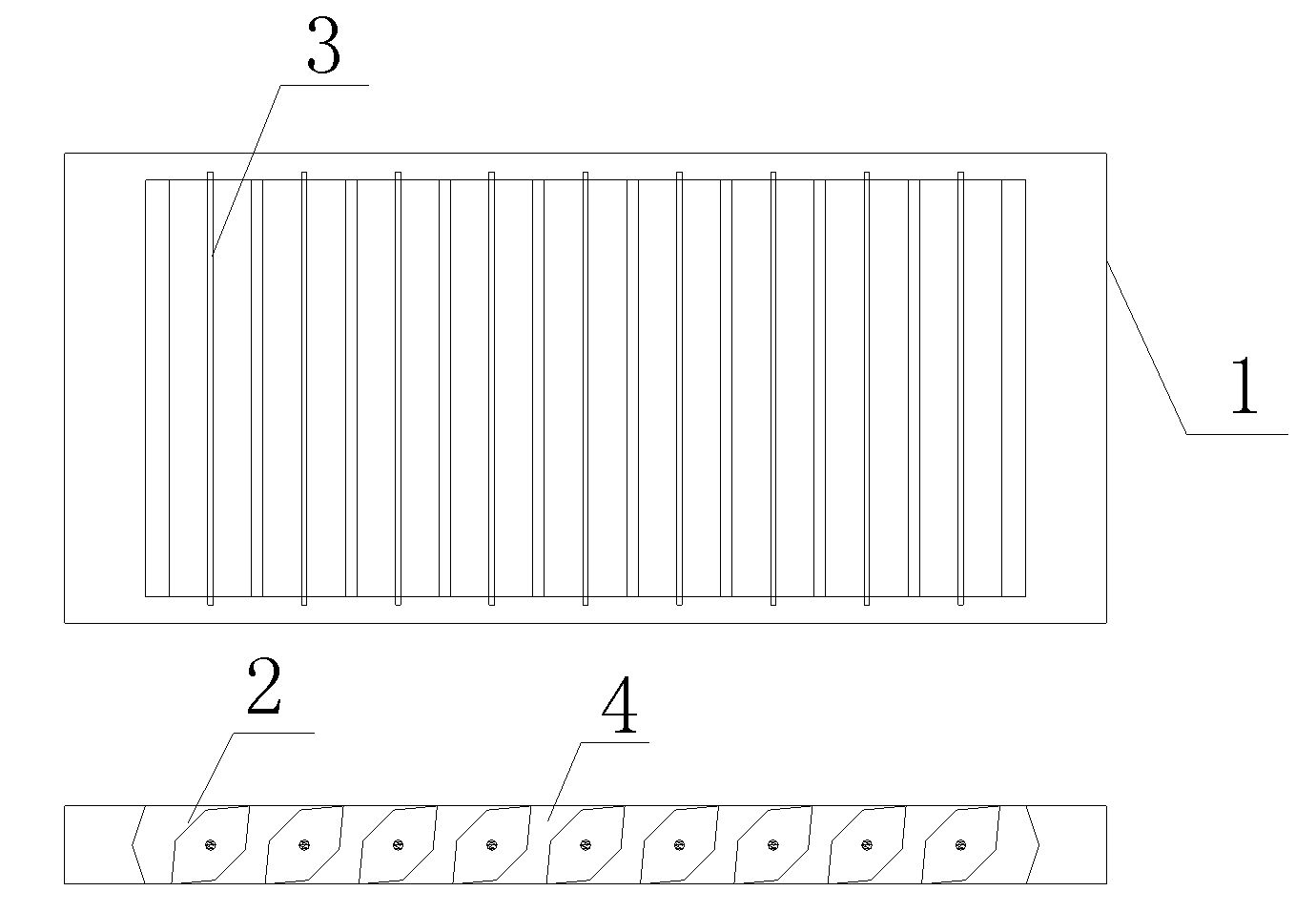

Totally closed sound barrier

ActiveCN103046490AReduced sound insulationAchieve full coverageNoise reduction constructionNoise controlSound barrier

The invention discloses a totally closed sound barrier, and belongs to the field of environmental protection and the field of noise control facilities. The totally closed sound barrier comprises a gate-type steel frame (1) and sound barrier plates (2) laid on the gate-type steel frame (1). The sound barrier plates (2) include sound insulation and absorption barrier plates (21) and transparent sound barrier plates (22), and the sound insulation and absorption barrier plates (21) and the transparent sound barrier plates (22) are mounted on the outer side of the gate-type steel frame (1) together. The transparent sound barrier plates realize lighting effects for the inside of the sound barrier, so that the sound barrier has excellent sound insulation capacity while natural lighting is realized, an external sound insulation effect of the integral sound barrier is guaranteed, matching of sound insulation factors of the transparent sound barrier plates and the sound insulation and absorption barrier plates is guaranteed, the totally closed sound barrier is excellent in impact resistance performance and wind load resistance performance, and high safety of the structure of the sound barrier is guaranteed.

Owner:CENT INT GROUP

Sound jacket for noise reduction in refrigeration apparatus

An insulating jacket for refrigeration system component comprising a closed cell insulation layer comprising an inner and outer surface, an open cell foam layer comprising an inner and outer surface, the inner surface in contact with the outer surface of the closed cell insulation layer, and a sound barrier layer comprising an inner surface in contact with the outer surface of the open cell foam layer.

Owner:CARRIER CORP

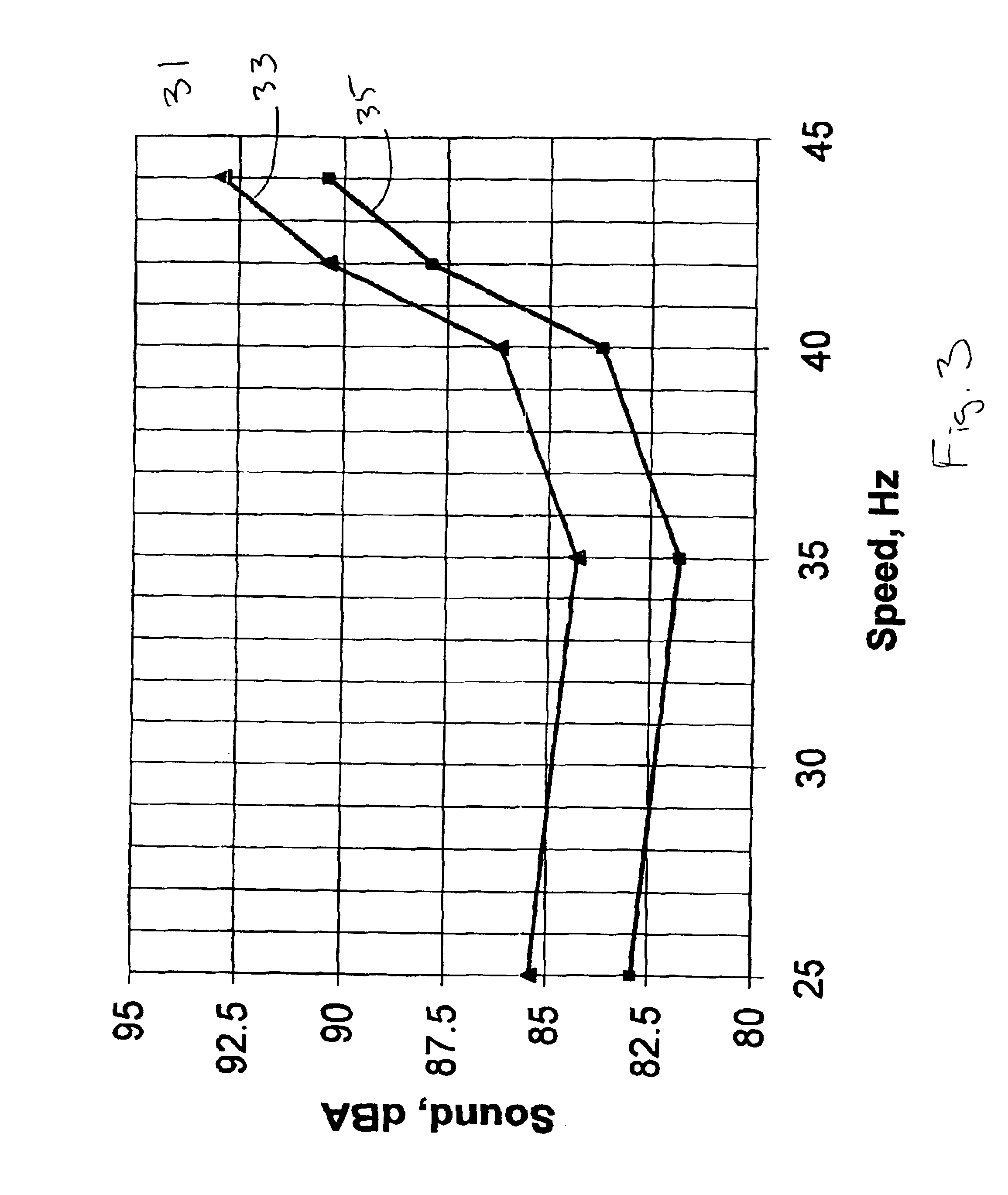

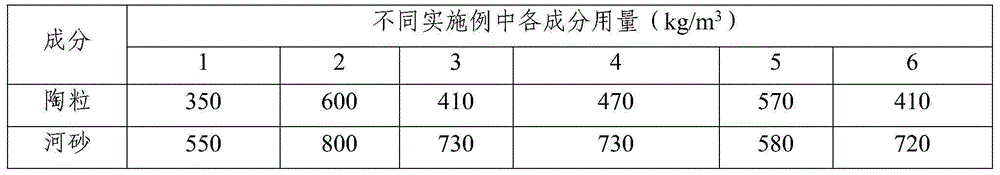

Composite fiber macromolecular reinforced concrete sound barrier and manufacturing method thereof

The invention discloses a composite fiber macromolecular reinforced concrete sound barrier and a manufacturing method thereof. Concrete raw materials comprise ceramsite, sand, gel materials, reinforcing fibers, a water reducing agent, polymer emulsion and water. The gel materials comprise cement, coal ash, silicon ash and mineral powder. The reinforcing fibers are steel fibers and / or polypropylene fibers. The polymer emulsion is acrylate copolymer emulsion or butenolide copolymer emulsion. According to the manufacturing method, the ceramsite is pre-soaked, and after the other raw materials are added in sequence and stirred, pouring, grout collecting, plastering and hardening are performed. Through the combination of lightweight aggregate, sound absorption materials, organic fibers, inorganic fibers, macromolecular reinforcing agents and other materials in the formula, the composite fiber macromolecular reinforced concrete sound barrier is light in weight, good in mechanical property, good in sound absorption and insulation effect, low in cost, good in durability and environmentally friendly.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Noise reducing device

InactiveUS20050157890A1Improve noise reductionReduce noiseEar treatmentNoise reduction constructionSound barrierWavefront

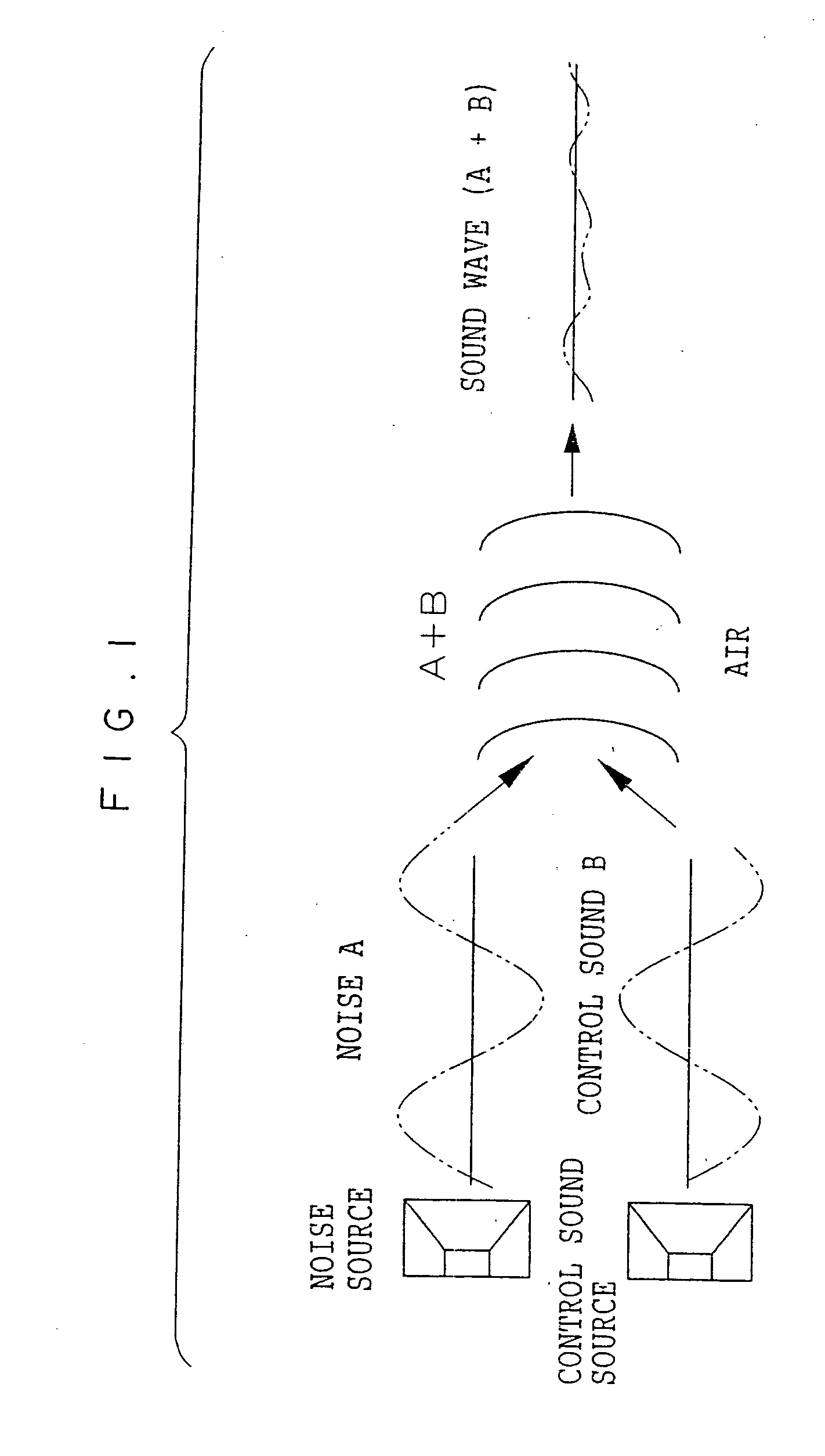

The present invention provides an active control type noise reducing device that is disposed at a sound barrier and with which can be obtained an excellent noise reduction effect with respect to moving sound sources. Linear array of flat loudspeakers are arranged in ascending order from an incoming side of automobiles towards an outgoing side. Delay times of 0, τ, 2τ, . . . , 8τ are respectively given in the arrangement order to the linear array of flat loudspeakers. By delaying signals in correspondence to the arrangement order, the wavefront of a control sound can be slanted in a diagonal direction. Namely, “line sound sources”, where sound sources are linearly arranged, arc pseudo-realized.

Owner:TAKENAKA KOMUTEN CO LTD

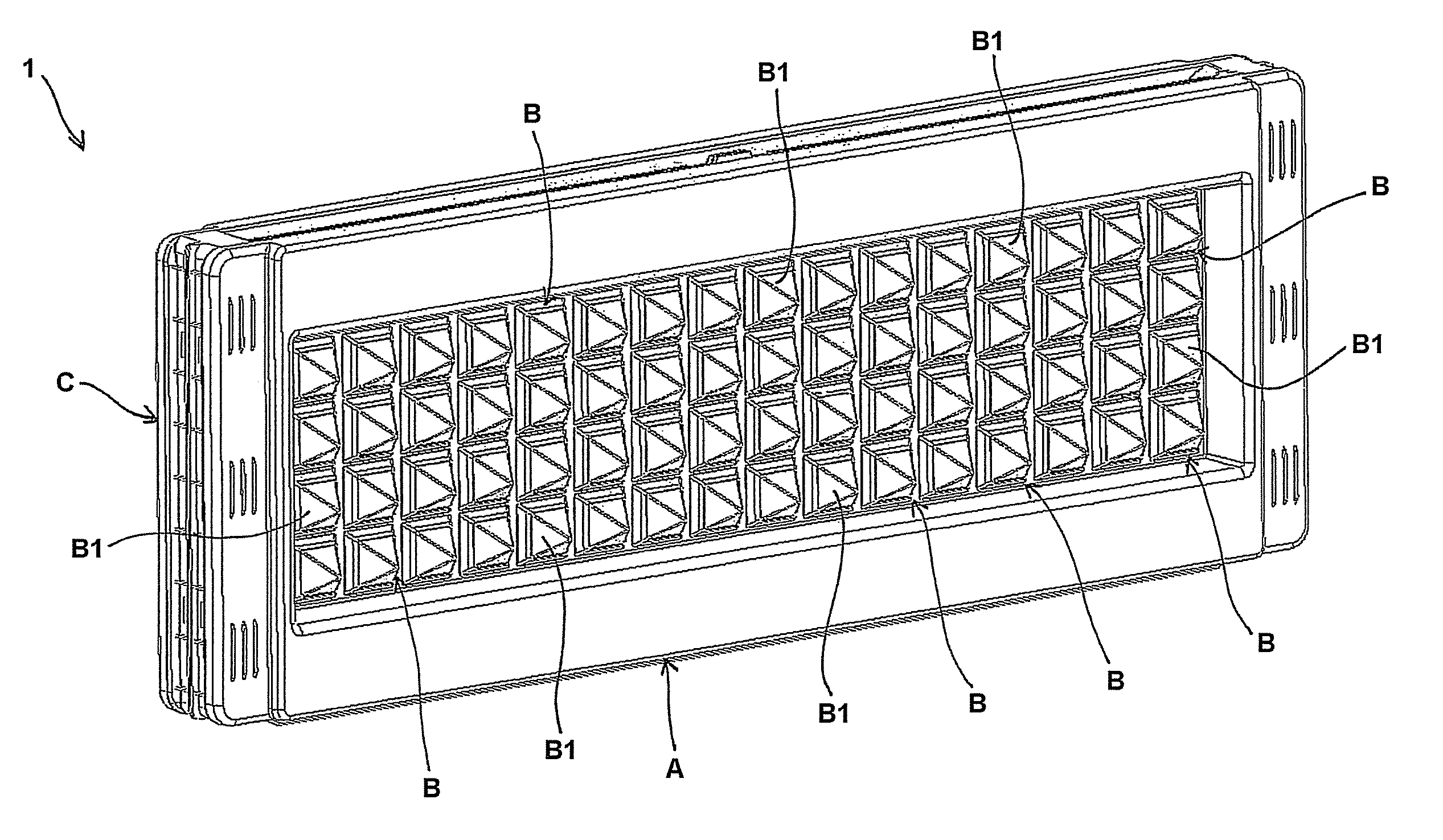

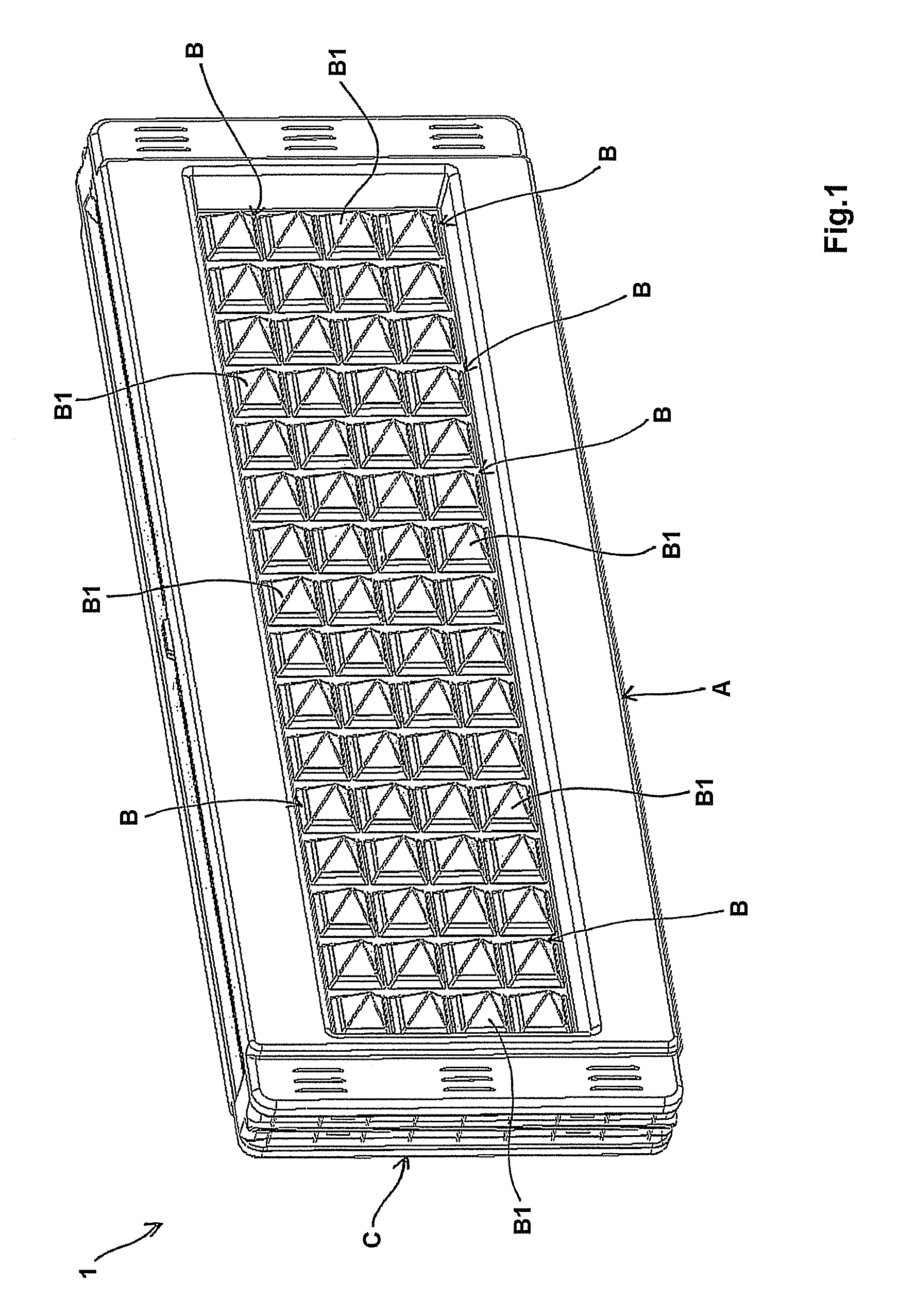

Anti-noise panel

It is disclosed an anti-noise panel comprising a front shell and a rear shell that are coupled together within which rubber elements of specifically designed shape and size are incorporated. Said panel can be advantageously obtained by using also recycled, injected thermoplastic material, that allows the resulting panel to be conveniently used when the wind causes strong impact, for example, along railway lines where the compression waves generated by trains traveling at high speed over time tend to disassemble the riveted aluminum / steel sound barriers currently in use.

Owner:ANGELICO MICHELE

Hard polyvinyl chloride sound insulation barrier and manufacturing technique

InactiveCN101240098AImprove noise reductionImprove sound insulationDomestic articlesMetal working apparatusSound barrierPolyvinyl chloride

A rigid polyvinyl chloride sound barrier comprises raw materials of 70-90 parts of polyvinyl chloride, 2-12 parts of anti-impact modifier, 4-14 parts of filler, 6-7 parts of composite stabilizer, 0.5-1 parts of ultraviolet inhibitor, 0.5-2 parts of lubricant and 0.01-2 parts of colorant. The preparation includes adding polychloroethylene into heating blend agitator with low rotate speed, increasing rotate speed, adding anti-impact modifier, filler, composite stabilizer, ultraviolet inhibitor, lubricant, and colorant, mixing, heating to the temperature of 100-140 DEG C., discharging the material to cold blend agitator, decreasing temperature to 50 DEG C., discharging, filtering, delivering to extrusion group, cooling and pressing by plate die to produce special plate for sound barrier, which includes back board, front board and connecting board, punching sound absorption holes on front board with a opening ratio ranging 8-30%, a diameter ranging 1-4 millimeters, assembling to form the sound barrier. The sound barrier is light in weight, easy to process, good in corrosion resistance, low in price, easy to install, great heat durability, reusable, with long life and small workload of maintenance.

Owner:杨益琴

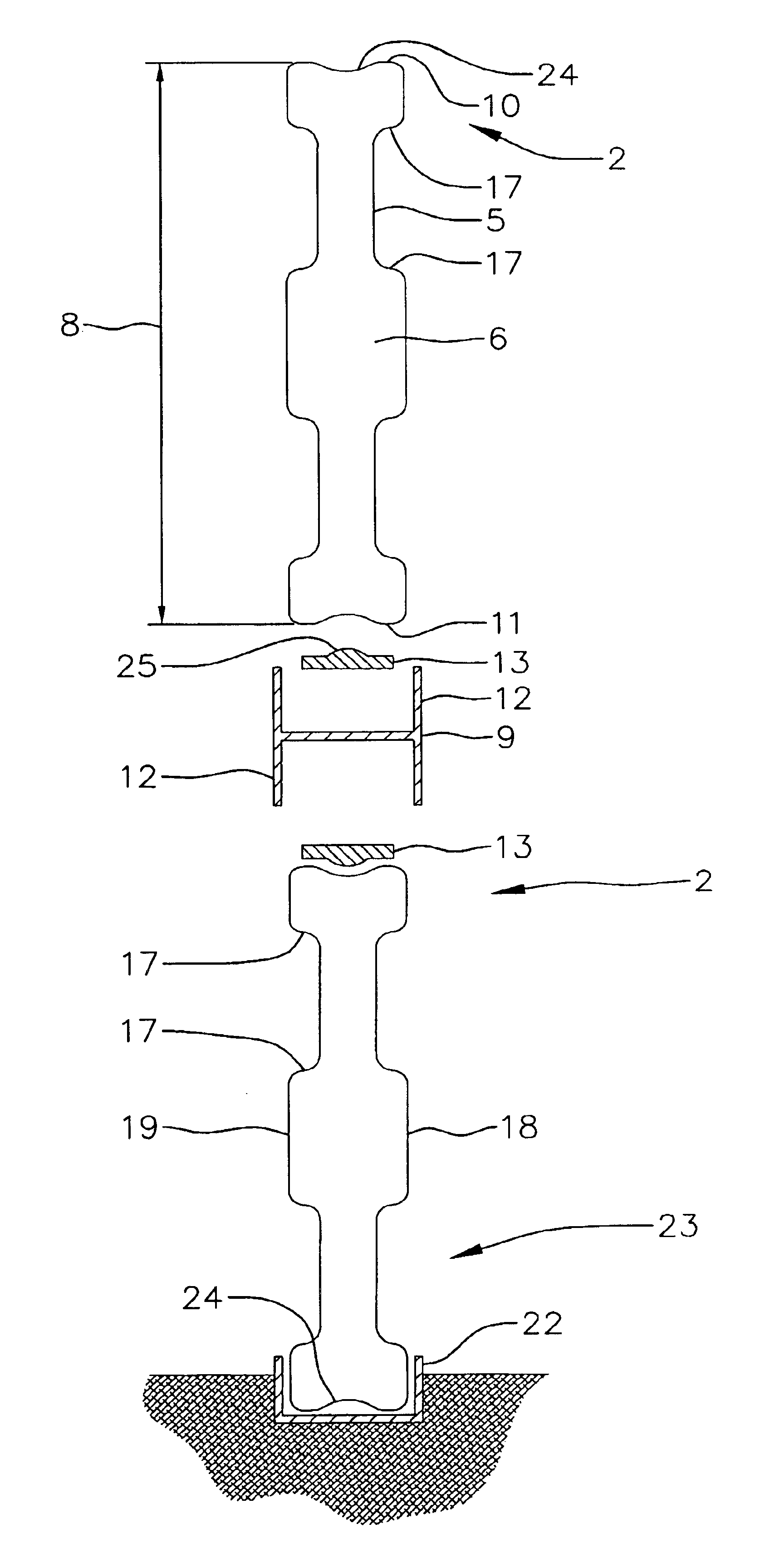

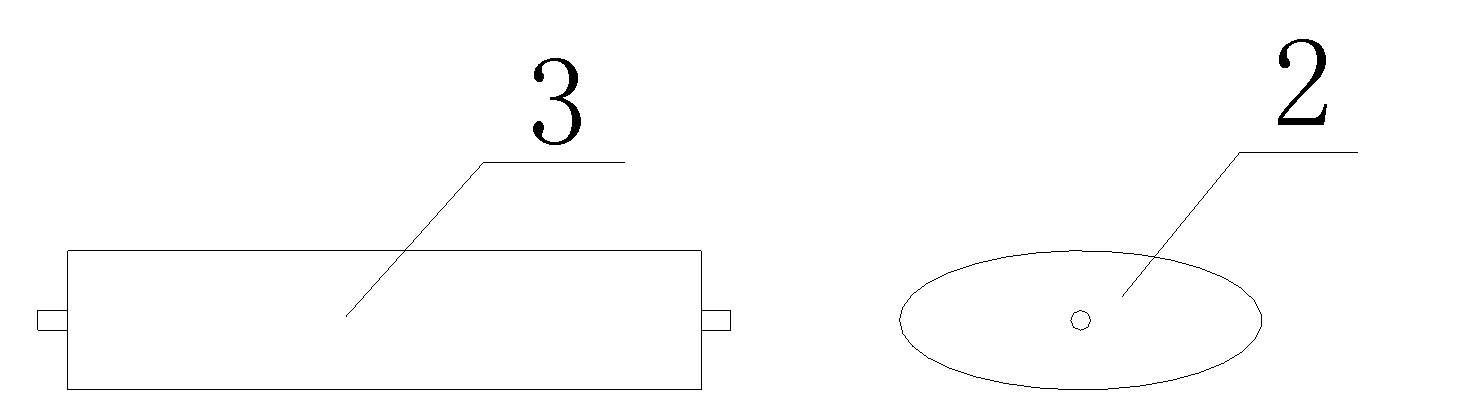

Sound barrier

The present invention provides a sound barrier 1 including a plurality of elongate panels 2 having first and second ends 3 and 4, each panel 2 being formed from a shell 5 defining an inner chamber 6 adapted to contain sound attenuating liquid, said plurality of panels 2 being supportable in a planar configuration by a first support means 7 adapted to engage said first and second ends 3 and 4 respectively.Preferably the shell 5 is constructed from plastic and / or fiberglass and the sound attenuating liquid is water which may optionally include other materials such as sand, slurry, concrete rubble, mud, etc.Some embodiments include second support means 9 which are attachable to the post 7 so as to engage the panels 2 and thereby transfer a, substantial portion, or all of, the weight of each panel 2 to the post 7.

Owner:ROBERTS JOHN KENNETH +1

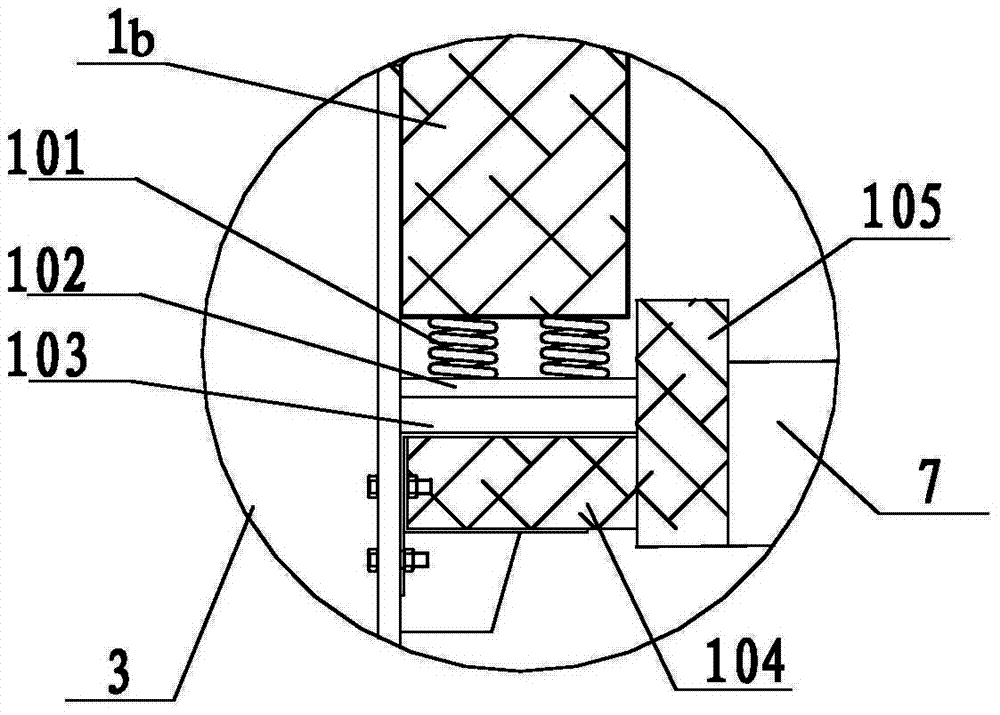

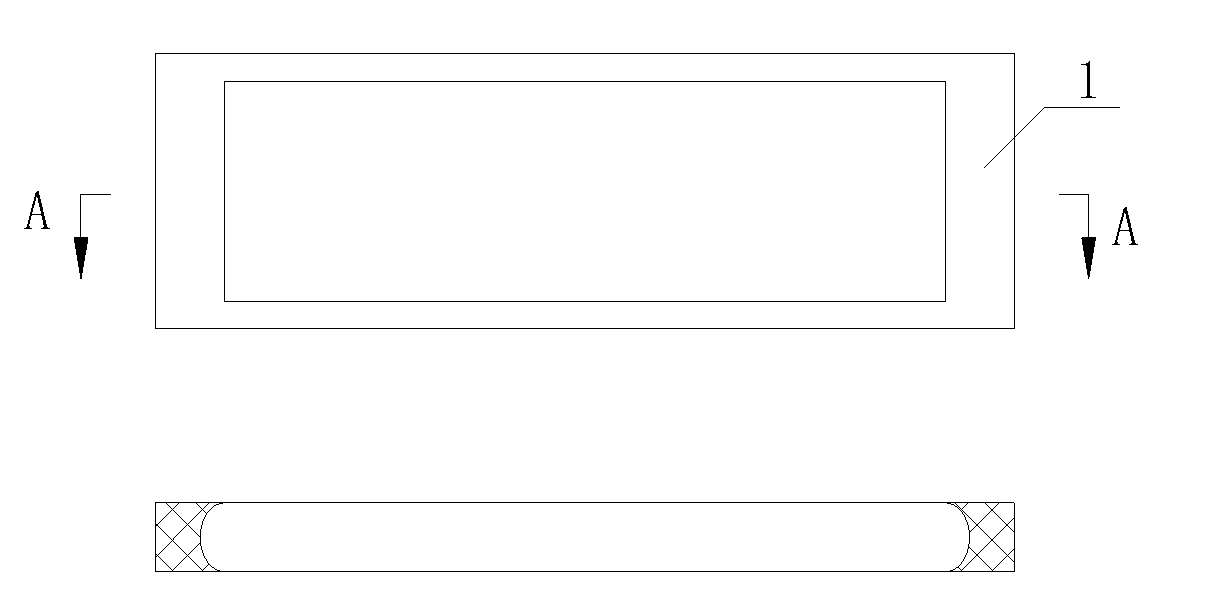

Sound barrier structure for high speed railways

InactiveCN101713171ALighten the loadIncrease stiffnessNoise reduction constructionSound barrierShock resistance

The invention relates to a sound barrier structure for high speed railways. The sound barrier structure comprises a steel upright post and a plurality of sound barrier absorption / sound insulation unit plates which are transversely inserted in the steel upright post; elastic rubber is filled in a gap between a flange plate of the steel upright post and the sound barrier absorption / sound insulation unit plate; the sound barrier absorption / sound insulation unit plate comprises a front side plate, a rear side plate, locking buckles, a central framework and a sound absorption material, wherein the front side plate and the rear side plate are locked to a first locking plate and a second locking plate and the upper side and lower side of the central framework through the locking buckles; and the sound absorption material is filled in the gaps inside the locked front and rear side plates. Based on the conventional sound barriers, the sound barrier structure has good economic performance and durability by improving and expanding the types of the conventional sound barriers, and particularly the mechanical strength is greatly improved; and because the technology of bolt-free connection is adopted, the rigidity, shock resistance, fatigue resistance and safety performance of the sound barrier structure are greatly improved.

Owner:ATEC ENERGY&ENVIRONMENT CO LTD

Acoustical sound barrier material

The present composition is a mixture of pozzolanic binder, recycled raw cellulosic materials (mineralized softwood chips and / or particles, hardwood chips and / or particles or a combination of the two and wood based construction waste), sand, ash and / or ground slag that when cured, forms a sound absorptive product and suitable for use in all climates and weather conditions. The primary use for the present composition is for highway sound barrier walls but the product can also be used in any application where a durable sound absorptive material is required, including rail, industrial, tunnel, residential, and existing wall retro-fit applications. The present composition can be used as an absorptive panel or cast monolithically with reinforced concrete which forms a structural and absorptive precast concrete panel.

Owner:MCNEAL JR JERRY J

Ventilation pressure leakage sound barrier module

ActiveCN101858061AImprove noise reductionChange directivityNoise reduction constructionSound barrierFree rotation

The invention discloses a ventilation pressure leakage sound barrier module, belonging to the noise reduction field. The module comprises a ring-shaped rigidity frame, a plurality of regulation screws and noise elimination vanes which correspond to the regulation screws and can freely rotate around the regulation screws; the noise elimination vanes are arranged in the ring-shaped frame regularly to form a shutter structure which can freely rotate. The module of the invention adopts the rotatable design of the noise elimination vanes, can reach more excellent ventilation noise elimination effect by regulating the wind facing angle of the module, realize free selection of different noise elimination ranges and ventilation amount, and simultaneously also changes the direction of noise radiation; in addition, the rotatable design of the noise elimination vanes can lead the module to automatically regulate the ventilation angle of the noise elimination vanes according to different travelling directions of vehicles, thus achieving the best noise elimination and pressure leakage effects.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

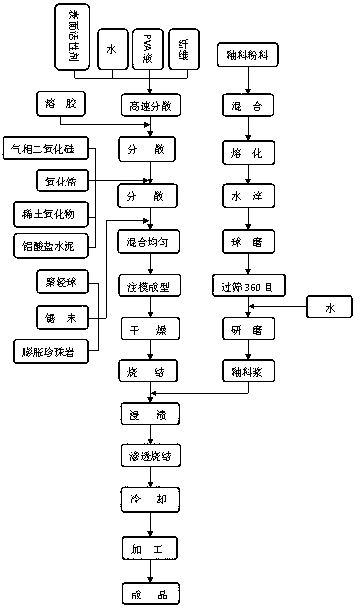

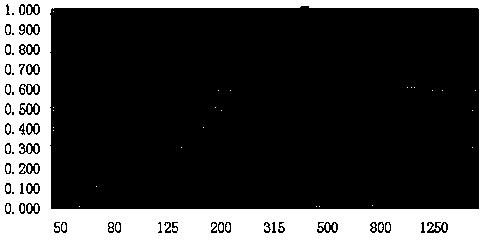

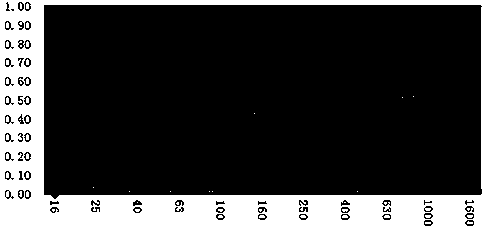

Ultra-microporous ceramic sound-absorbing material and preparation method thereof

ActiveCN103539482AExcellent acoustic absorption performanceHigh strengthCeramicwareFiberSound barrier

The invention discloses an ultra-microporous ceramic sound-absorbing material and a preparation method thereof. The ultra-microporous ceramic sound-absorbing material comprises water, polyvinyl acetate (PVA), composite sol, inorganic fiber, rare earth oxide or zirconium oxide, a microporous material, a pore-forming material and a surfactant, and ceramic glaze which is soaked in a matrix prepared from the above materials. The preparation method comprises the preparation steps of preparing slurry, performing injection molding, sintering, glazing the matrix, sintering and the like. The ultra-microporous ceramic sound-absorbing material disclosed by the invention has excellent sound-absorbing performance; zirconium oxide or / and rare earth oxide is added into the material, so that the whole material has high strength while maintaining excellent sound-absorbing performance; according to detection, the ultra-microporous ceramic sound-absorbing material disclosed by the invention has higher sound-absorbing coefficient compared with the conventional sound-absorbing material, and wide distributed frequency band, in particular, has high sound-absorbing coefficient in low-frequency band, so the material is particularly suitable for serving as the sound-absorbing material of a sound barrier of a high-speed rail.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND +1

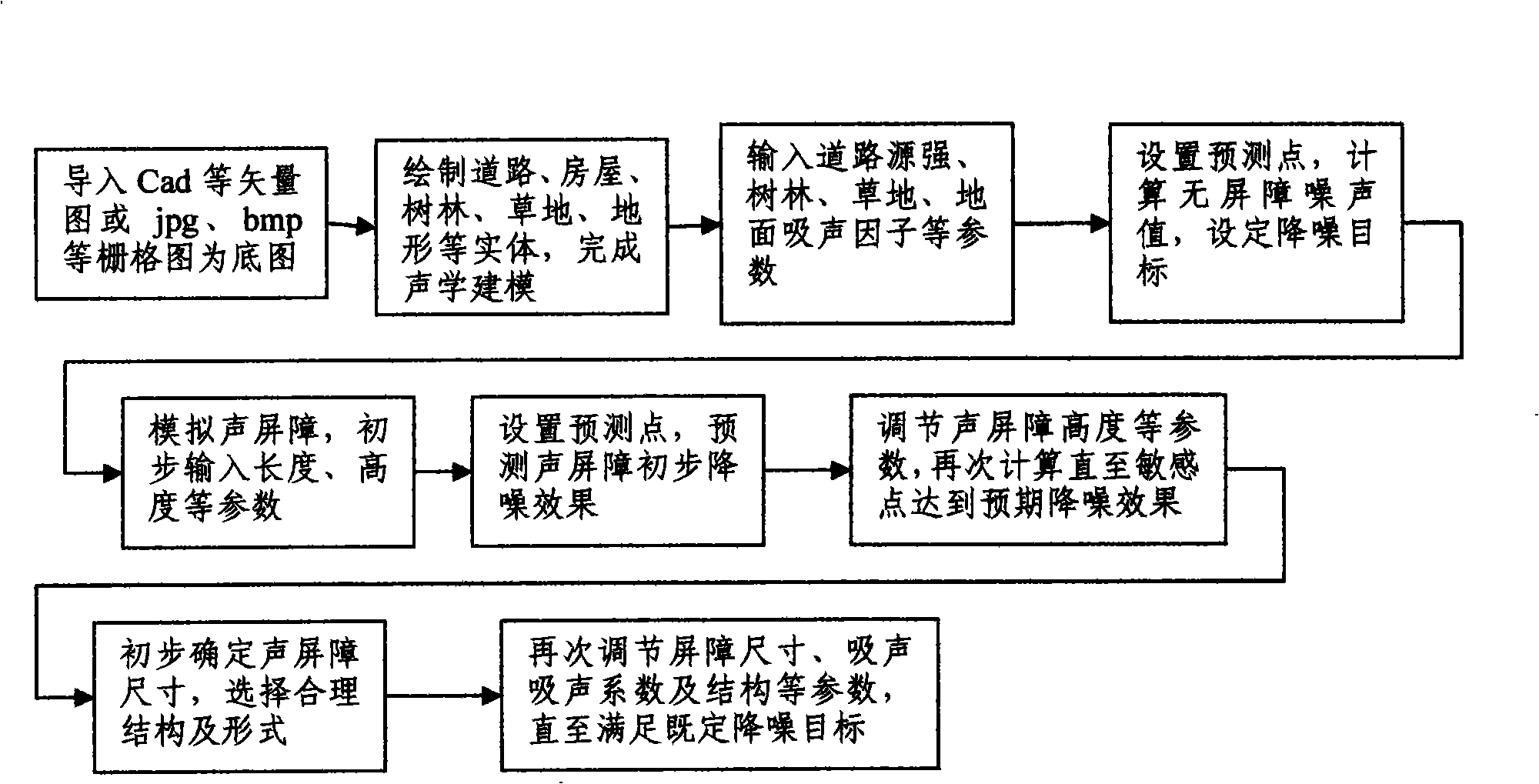

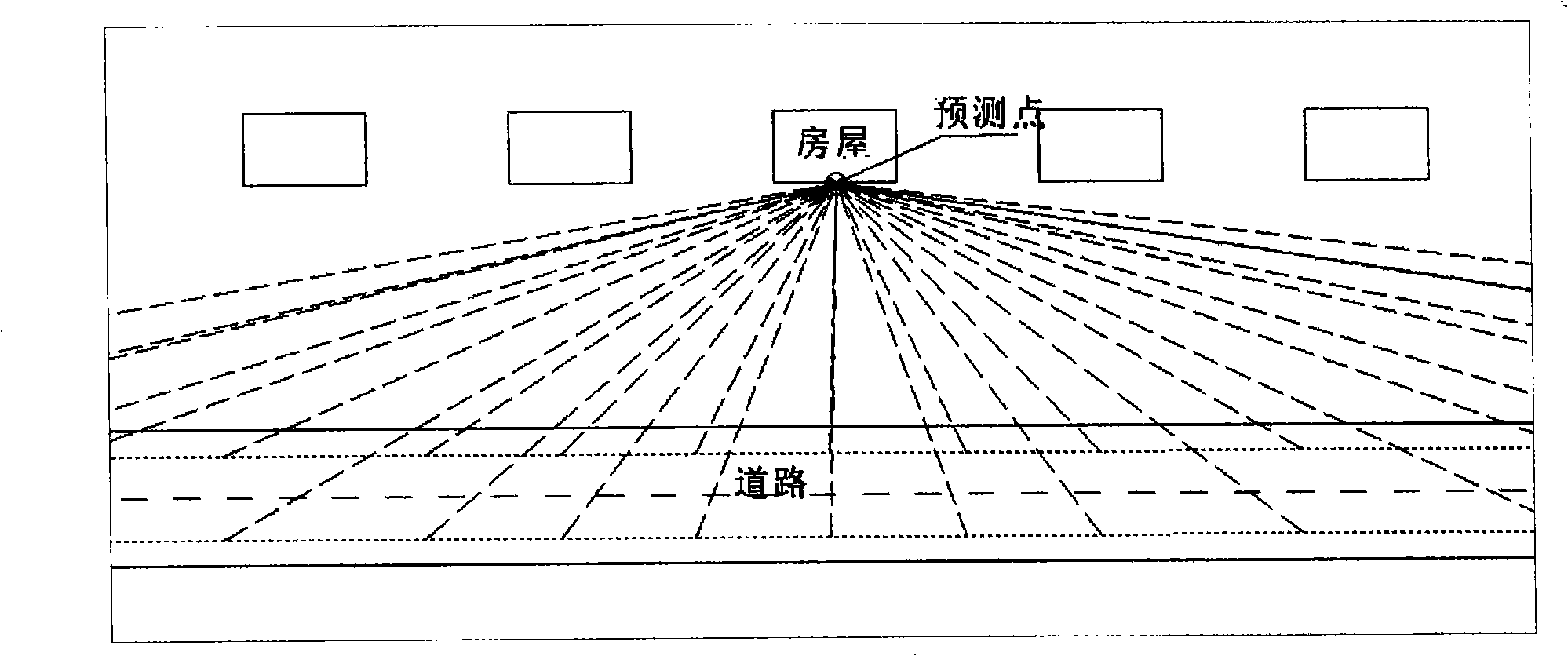

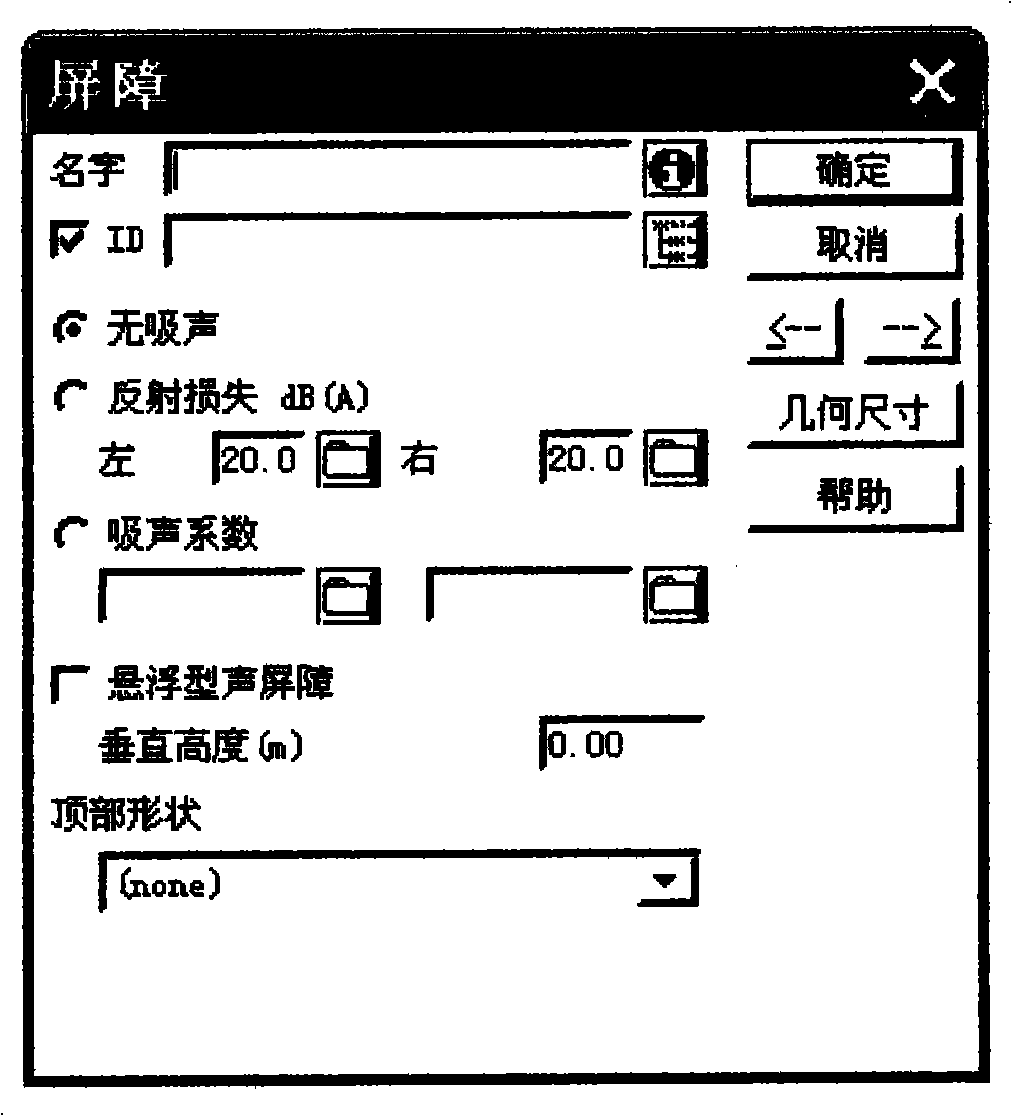

Acoustic design method for road noise barrier

The invention discloses an acoustic design method for road noise barrier, which comprises the steps of: 1) importing a vector diagram with a Cad format for characterizing the terrains of noise barrier or grid maps with formats such as jpg, bmp, tif, and the like; 2) calibrating the imported graph to achieve the consistence of graphic proportion and actual proportion; 3) combining the actual situation to draw entities such as roads, terrains, houses, forests, grasslands, and the like based on the importing of the graph, and adopting a batch conversion function to finishing the basic work of acoustic modeling by adopting a batch conversion function if the graph is a Cad graph; 4) setting a noise prediction point at a protected sensitive point, calculating a noise value when no barrier exists, and determining an noise-reducing index of the barrier; 5) simulating the noise barrier, adjusting the height and the length of the barrier, and preliminarily calculating a geometrical dimension of the barrier which meets the requirement; and 6) re-calculating the noise-reducing effect of the barrier by combining the geometrical dimension of the sound barrier and simulating the barriers with different structures and sound absorption coefficients until the combination of the geometrical dimension, the structure and the sound absorption coefficient of the sound barrier which meets the requirement is calculated.

Owner:SHANGHAI SHIP & SHIPPING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com