Ventilation pressure leakage sound barrier module

A sound barrier and pressure relief technology, which is applied in construction, noise absorption devices, etc., can solve the problems of regenerative noise, pressure loss increase of the pressure relief module, area length limitation, etc., to achieve lower structural requirements, lower length limitation, Requirement reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

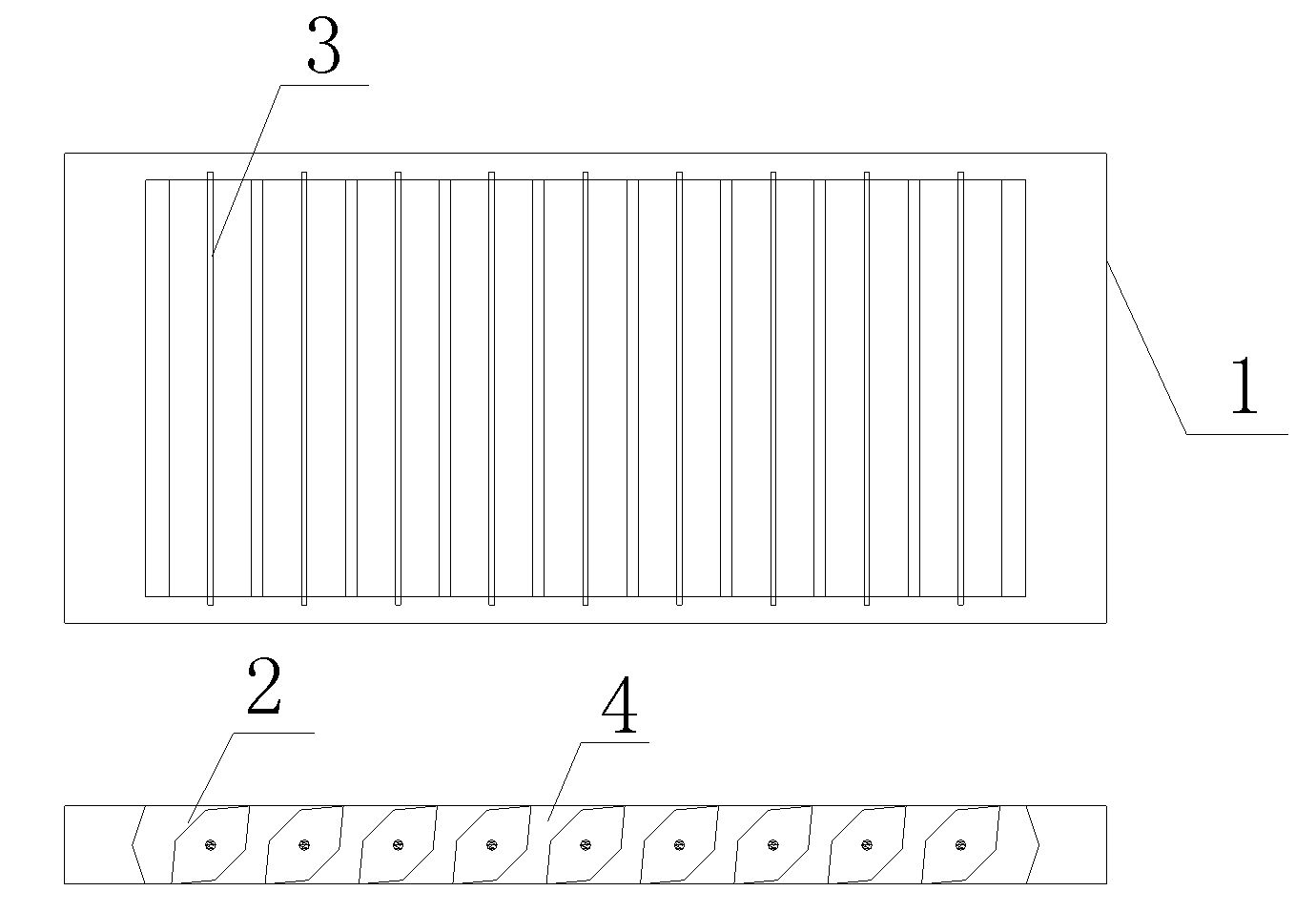

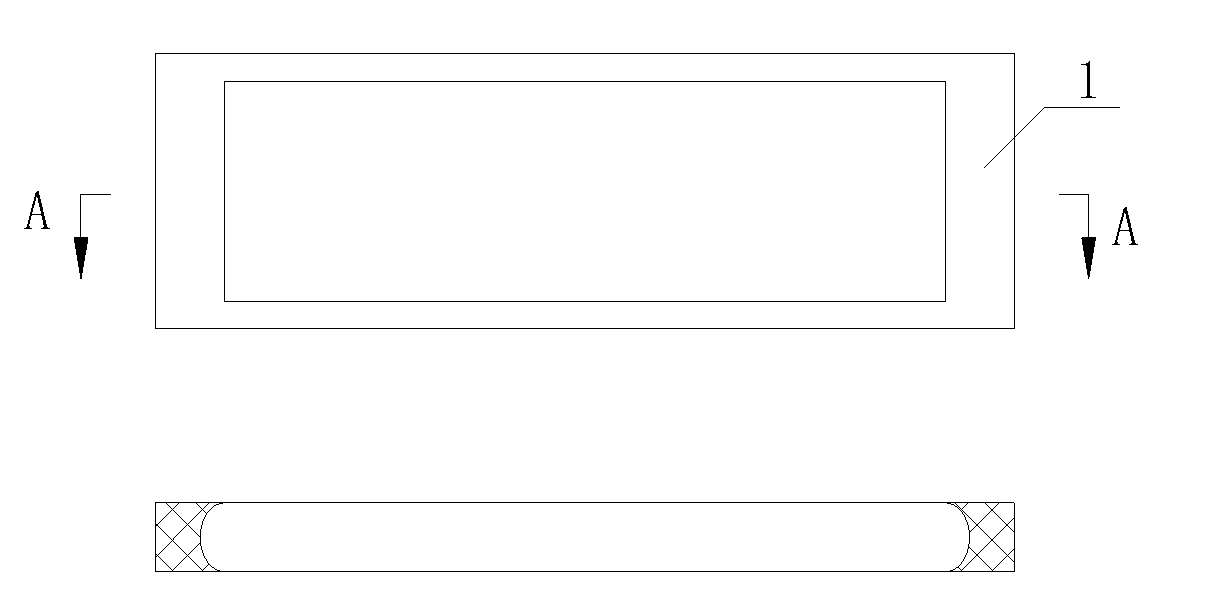

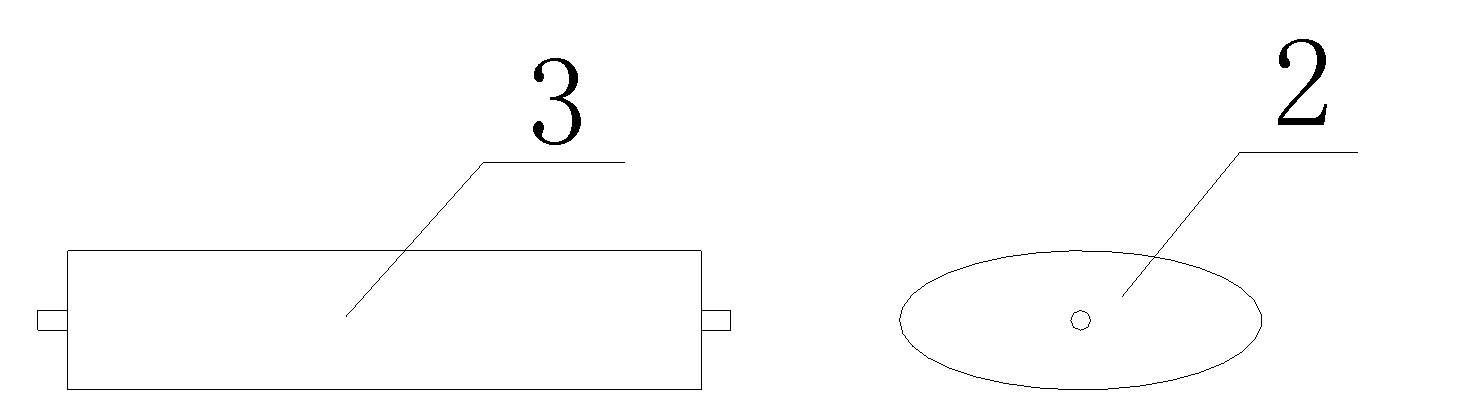

[0029] Such as Figures 1 to 3 As shown, the ventilation and pressure relief sound barrier module of this embodiment is composed of a rigid frame 1, several silencing blades 2 and adjusting screws 3, the silencing blades 2 are in one-to-one correspondence with the adjusting screws 3, and the adjusting screws 3 pass through the silencing Acoustic vane 2, so that muffler vane 2 can freely rotate around adjusting screw rod 3, thereby forming air channel 4 whose channel size can be automatically adjusted. Rigid frame 1 is a rectangular ring structure made of aluminum, filled with sound-absorbing material wrapped in non-woven fabrics between the rectangular rings, the inner circumference of the rigid frame 1 and the side facing the track during use are perforated plate structures, the perforation rate ≥ 23%; the peripheral surface of the outer ring of the rigid frame 1 and the side facing away from the track during use are blind plate structures. In order to be able to replace exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com