Patents

Literature

135results about How to "Reduced sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial stone with irregular pore and preparation method thereof

The invention provides an artificial stone with irregular pores and a preparation method thereof. The artificial stone composed of a cementitious material, a pore forming agent and a thickener is prepared by the following method: preparing a slurry; casting the prepared slurry in a mould; and vibrating for molding in a vibration table. Compared with the natural stone, the artificial stone with irregular pores provided by the invention has the advantages of low cost, multiple effect changes, environment-friendliness, no radiation, low density, excellent thermal insulation, sound insulation and refractory properties, and good mechanical property; and the artificial stone with irregular pores has strong durability and color stability in all kinds of weather conditions, and is an ideal decorative material.

Owner:SHANGHAI APE STONE

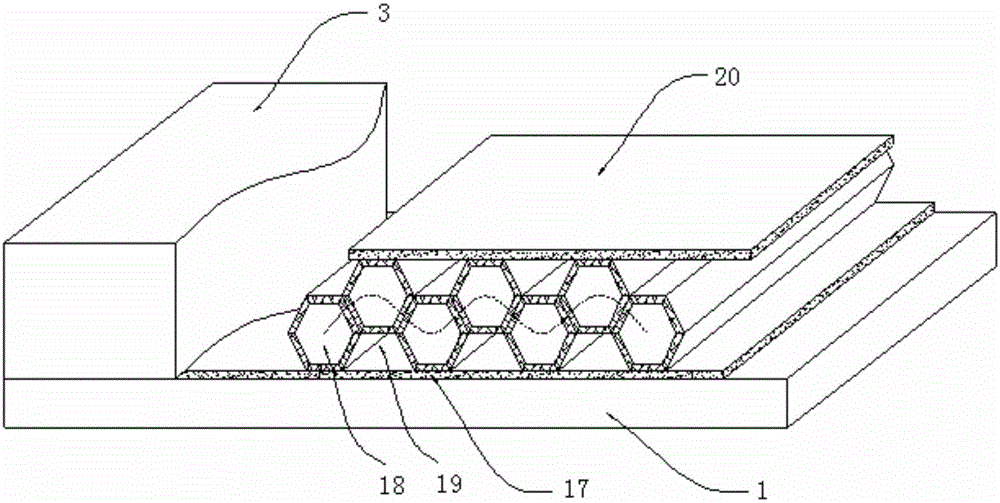

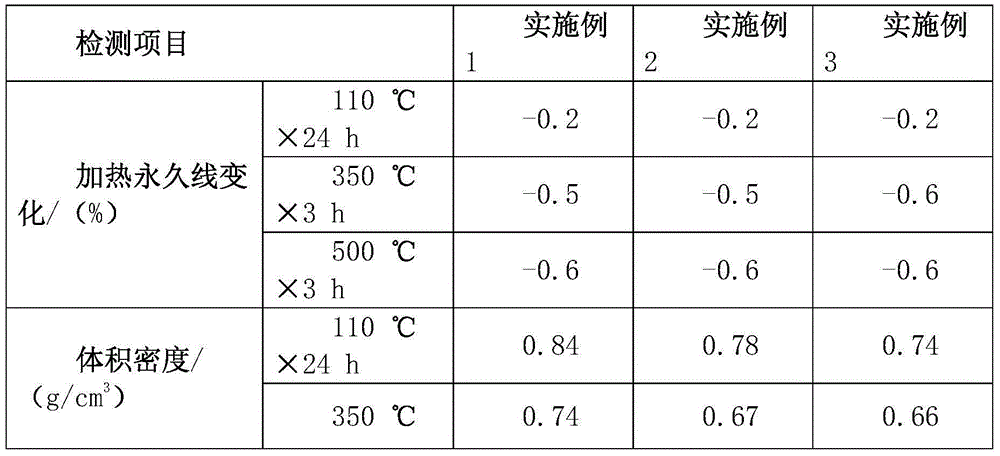

Aerogel composite board and preparation method thereof

InactiveCN103568379AEasy to useReduce wind pressureLayered productsBuilding componentsComposite plateSilicon dioxide

The invention relates to an aerogel composite board and a preparation method thereof. The composite board comprises a panel, a bottom board, and skeletons which are positioned between the panel and the bottom board and are crossed to form a plurality of cavities. The preparation method comprises the steps of coating a binding agent at one side of the bottom board so as to bind the skeletons with the bottom board; filling the cavities of the skeletons with silica aerogel; coating a binding agent at one side of the panel and binding with the skeletons filled with the silica aerogel. The aerogel composite board and the preparation method thereof have the advantage that the mechanical strengths of the panel, the bottom board and the whole composite board are improved by adopting a structure of enabling the skeletons as a center and compounding boards up and down; the coefficient of thermal conductivity of is reduced to 0.010-0.020 (W / m.k) through the aerogel evenly distributed in the cavities of the skeletons, so that the composite board is superior to various heat-insulating materials, and is next only to a vacuum insulating board; The application range of the composite board application scope is widespread, such as industry, the external walls of buildings, interior decoration, traffic transportation vehicles and ships.

Owner:江苏龙睿建设工程有限公司

Method for producing energy-saving bricks by comprehensive utilization of paper making sludge and fly ash

InactiveCN101337793AEmission reductionImprove performanceSolid waste managementBrickThermal insulation

The invention relates to a method for producing energy-saving baked bricks by comprehensively using papermaking sludge and pulverized fuel ash or furnace bottom slag. The method for producing energy-saving baked bricks is characterized in that 5 to 30 parts of biological sludge, 5 to 30 parts of deinked sludge, 1 to 5 parts of white mud from alkali recovery, 5 to 25 parts of pulverized fuel ash or furnace bottom slag, and 50 to 70 parts of shale are mixed by weight; the mixture is extruded and molded before the mixture is cut into adobe; the adobe is put in a ring kiln; after the adobe is dried, the dried adobe is burnt for four to eight hours at the temperature of 900 to 1050 DEG C, thus getting the finished product. The method for producing energy-saving baked bricks has the advantages that all of the solid wastes produced by papermaking plants such as papermaking sludge, pulverized fuel ash or furnace bottom slag are effectively used for producing energy-saving baked bricks having excellent performance; the bricks have the characteristics of light weight, sound insulation, heat insulation, thermal insulation and radioactivity indices lower than national standard, and applicability for building energy-saving buildings. In addition, the method for producing energy-saving backed bricks have the advantages of short production cycle, low manufacturing cost, simple process, energy conservation, soil conservation, and small exhaust emission of SO2, and clean production.

Owner:蒋伟

Light hollow block with polystyrene particle and production thereof

InactiveCN1746127AUniform textureSmall water absorptionSolid waste managementCeramic shaping apparatusPolymer scienceSlag

A light hollow block with polystyrene granule and its production are disclosed. The block consists of polystyrene granule, bluestone powder, fly ash, cement, slag, sand, waterproofing agent and binder. The process is carried out by adding water into the batching, mixing, adding hollow block into primary shaper, vibrating, pressurizing in block mould, forming and drying. Its advantages include high strength, low density, good thermal-insulating and sound-absorbing performances.

Owner:郭家良

Comprehensive foamed concrete property-modifying additive, preparation method thereof and concrete

The invention discloses a comprehensive foamed concrete property-modifying additive, a preparation method thereof and concrete. The property-modifying additive comprises the following components in parts by weight: 1.8 parts of calcium stearate, 1.2 parts of dispersing agent NNO, 0.8 part of FDN superplasticizer, 1.2 parts of light calcium carbonate, 0.2 part of hydroxypropyl methylcellulose, 0.7 part of redispersible powder, 0.4 part of rosinate soap foaming powder (vegetable protein), 0.5 part of aluminum sulfate, 1.5 parts of sodium silicate, 0.2 part of sodium dodecyl benzene sulfonate and 0.5 part of sodium hexametaphosphate. A foamed cement (concrete) product prepared by using the comprehensive foamed concrete property-modifying additive disclosed by the invention has an excellent heat insulation property and is light in weight, low in flexible damping property and excellent in sound insulation property and water resistance.

Owner:FOSHAN SENKE NEW ENERGY DEV

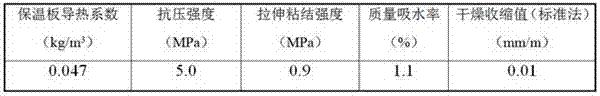

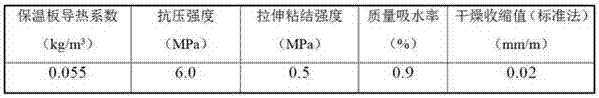

Thermal-insulation and fire-proof plate made of aerogel foamed concrete and provided with decorative surface and preparation method of thermal-insulation and fire-proof plate

ActiveCN107266115ALow densityLow thermal conductivityClimate change adaptationInsulation improvementFoam concreteThermal insulation

The invention provides a thermal-insulation and fire-proof plate made of aerogel foamed concrete and provided with a decorative surface and a preparation method of the thermal-insulation and fire-proof plate. The thermal-insulation and fire-proof plate is prepared from the aerogel foamed concrete, a transition layer and a facing layer, wherein the aerogel foamed concrete is prepared from aerogel powder and foamed concrete, the aerogel powder comprises an inner hydrophobic layer and a surface hydrophilic layer, and the thickness of the surface hydrophilic layer is 0.1-100 mu m. The preparation method of the thermal-insulation and fire-proof plate main comprises steps as follows: aerogel powder modification, dry blending-wet blending, foaming, molding, curing, transition layer coating and facing layer preparation. The thermal-insulation and fire-proof plate made of the aerogel foamed concrete and provided with the decorative surface has excellent properties such as low density, low heat conductivity coefficient, low water absorption, sound insulation, integration of thermal insulation, decoration and fireproofing and the like, construction processes are reduced, construction cost is reduced, the problem that construction quality is difficult to control is solved, and the application prospect is broad.

Owner:NANJING WEICAI NEW ENERGY TECH

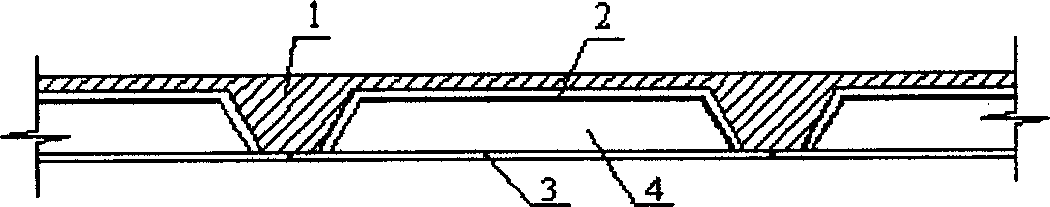

Reinforced concrete ribbed grid-like large floorslab and preparation method thereof

The invention relates to a steel bar concrete dense-rib well-shape building roof cover and relative construction method. It directly uses molded assemble phosphor plasterboard as the undetachable mold plate of on-site irrigation steel bar concrete dense-rib well-shape building roof cover, and uses the bottom plate of assemble phosphor plasterboard as the plaster suspending roof. Compared to present technique, it has lower height, light weight, undetachable phosphor plaster mold plate, easy construction, and sound, heat and fire insulation with lower cost.

Owner:GUIZHOU UNIV

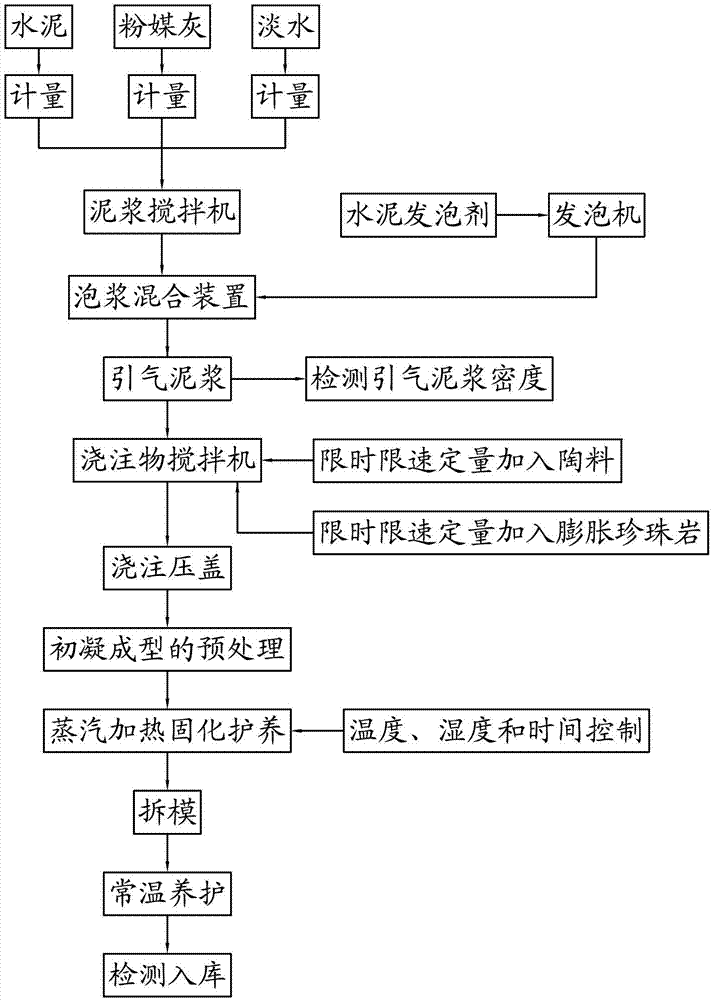

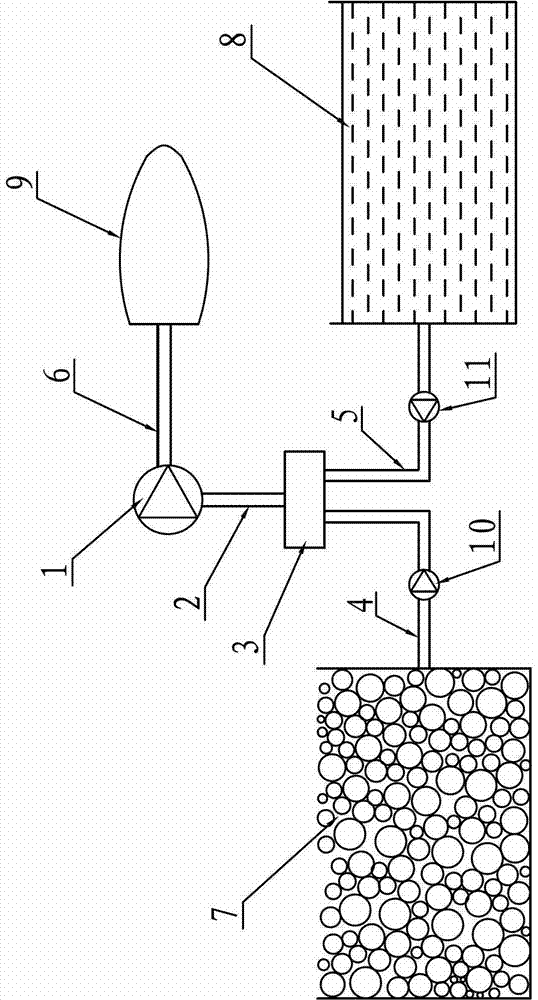

Heat-insulation sound-insulation light-weight high-strength aerated concrete building block and producing method thereof

The invention discloses a heat-insulation sound-insulation light-weight high-strength aerated concrete building block and a producing method thereof. The building block is made from special concrete materials by molding, pouring and curing; the the special concrete materials include the following components in percentage by weight: 25-30 parts of cement, 26-31 parts of coal ash, 15-25 parts of ceramsite, 5-8 parts of expanded perlite, 18-25 parts of fresh water and 2-3 parts of cement foaming agent; and the green body of the aerated concrete building block is prepared by the steps of preparation of slurry, preparation of aerated concrete pouring material, pre-solidification molding of a pouring gland, pretreatment after pre-solidification molding, steam heating solidification and maintenance and removal of the die. A foam-slurry mixing device is used for mixing foams with primary slurry to form entraining slurry, the density of the entraining slurry is controlled by adjusting the input quantity of foams, and ceramisite and expanded perlite are added regularly and quantitatively to obtain the pouring material; furthermore, pouring is completed in the stirring state, therefore, the strength of the produced product is equivalent to that of the existing products, but the sound-insulation, heat-insulation and density performance indexes are prior to those of the existing products, and the dispersion is small.

Owner:CHANGZHOU MICROTEK SELF THERMAL INSULATION WALL MATERIAL

Lightweight high-strength composite block and production method thereof

The invention discloses a lightweight high-strength composite block and a production method thereof. The block comprises the following raw materials, by weight, 10-80 parts of building gesso, 10-30 parts of Portland cement, 10-40 parts of coal ash, and 0.1-1.5 parts of borax. The production method of the block comprises the following steps: 1, preparing the raw materials according to above weightparts; 2, using the raw materials according to a case that 500-1100kg of the raw materials are used in 1m<3> of a container, and adding water under fully stirring to obtain a slip until the weight of1m<3> of the slip reaches 1.6-1.65t; and 3, casting the slip into a mold, curing, demolding, and maintaining for 10-12h at 50-95DEG C. The block of the invention has the advantages of good sound and thermal insulation performance, good processability after molding, high strength, good water resistance, good freeze resistance and good permeability resistance.

Owner:CHANGSHA XIHUA THERMAL INSULATION MATERIALS +1

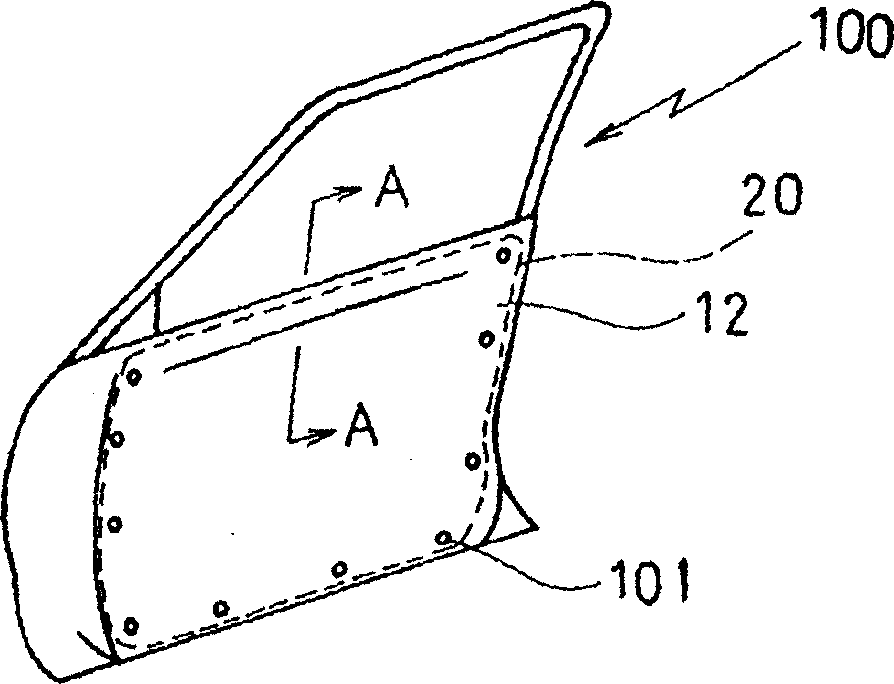

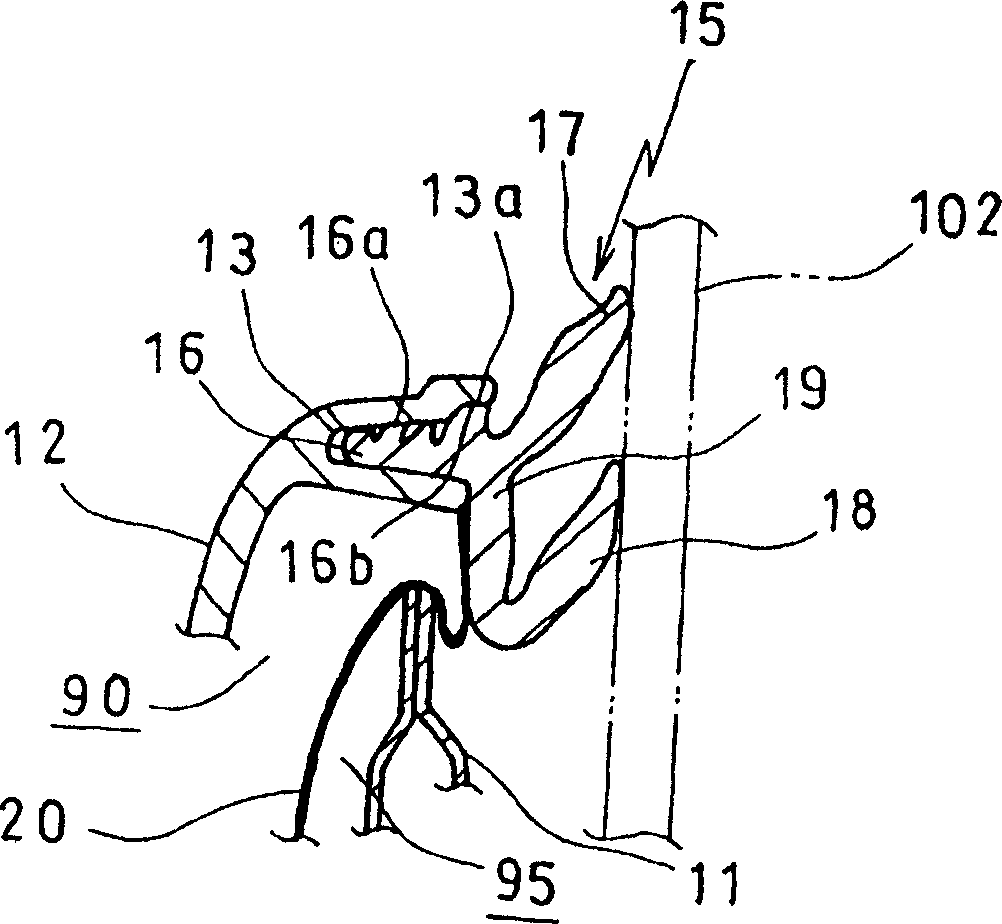

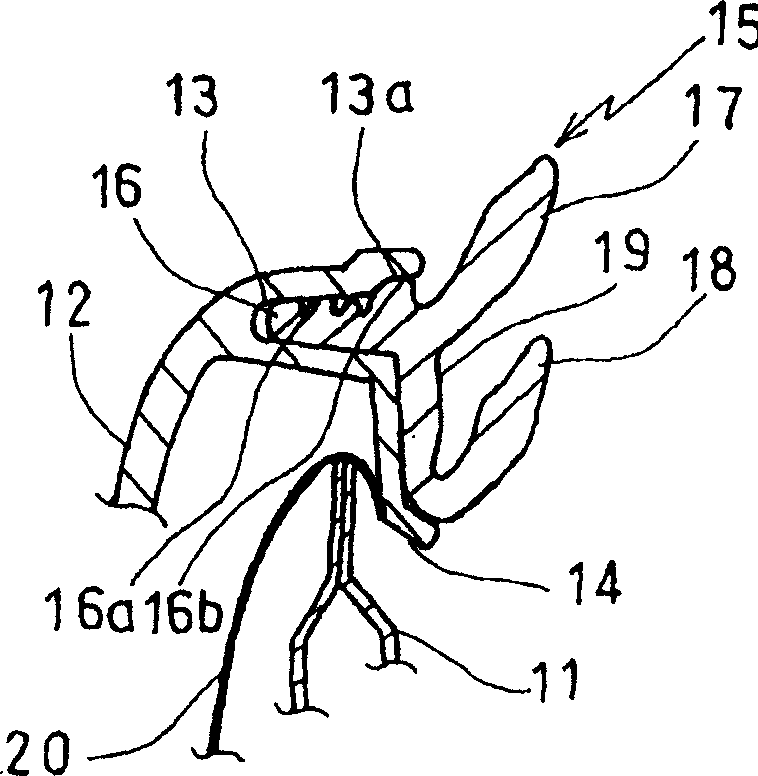

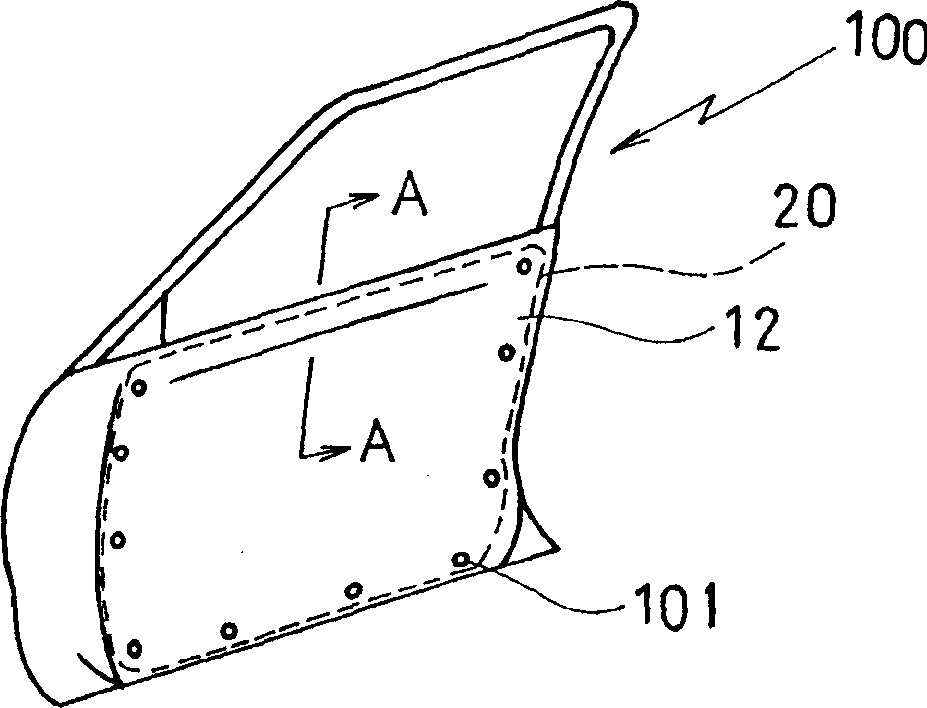

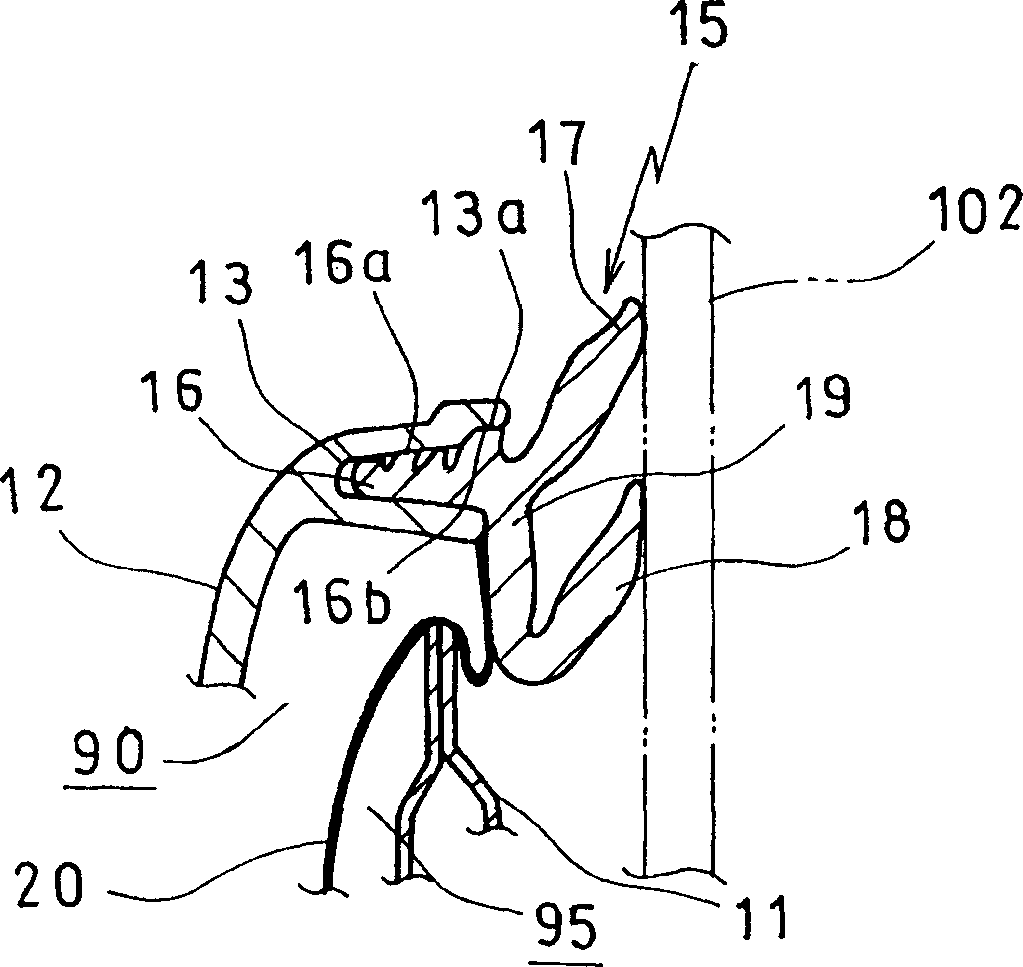

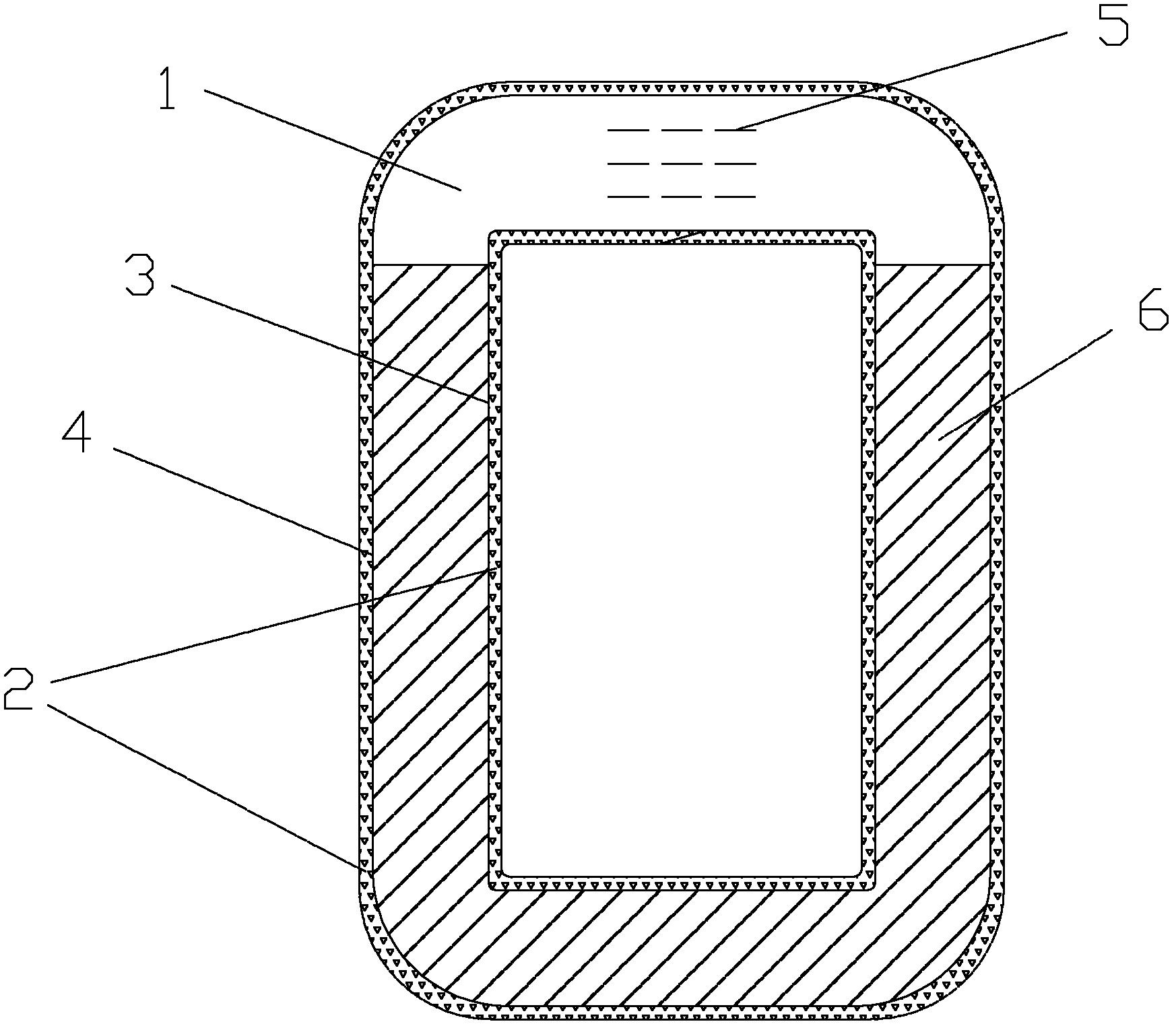

Car door structure and noise insulation sheet

InactiveCN1721649AImprove sound insulationReduce noiseDoor/window applicationsSealing arrangementsAcoustic boardElectrical and Electronics engineering

A car door structure comprises a door inner panel 11, an interior door trim 12 and a noise insulation sheet 20. The interior door trim 12 is installed in the interior side of the door inner panel 11. The noise insulation sheet 20 is provided between the door inner panel 11 and the door trim 12, where it is hung down from the upper side to the lower side of the door inner panel like a curtain. The noise insulation sheet 20 is fixed to either the door inner panel 11 or the door trim 12. The noise insulation sheet 20 is provided at about an upper half or a lower half of the door inner panel 11, or it is provided at a central part of the door inner panel 11 while dividing approximately into three sections in a vertical direction or a horizontal direction.

Owner:NISHIKAWA RUBBER

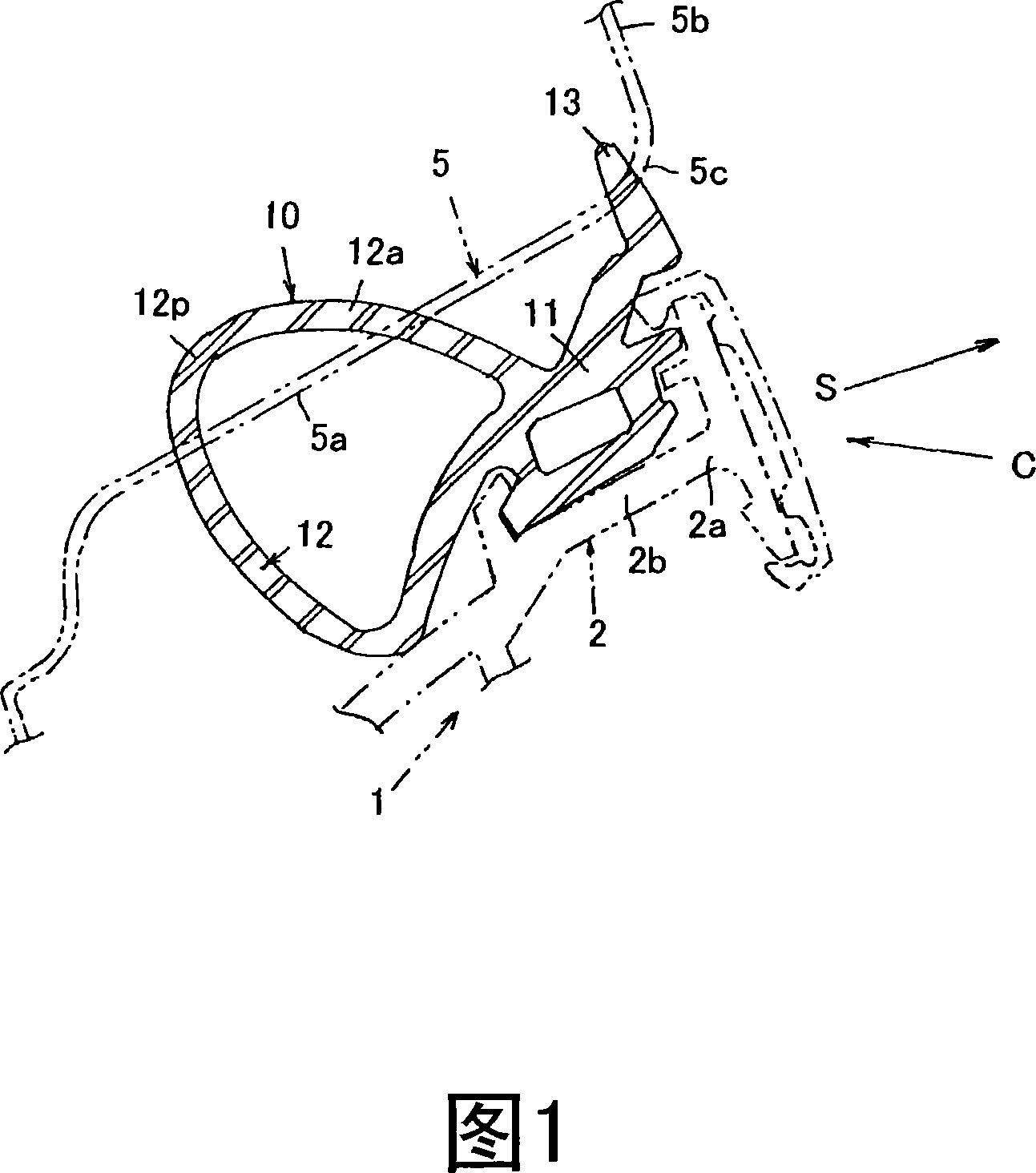

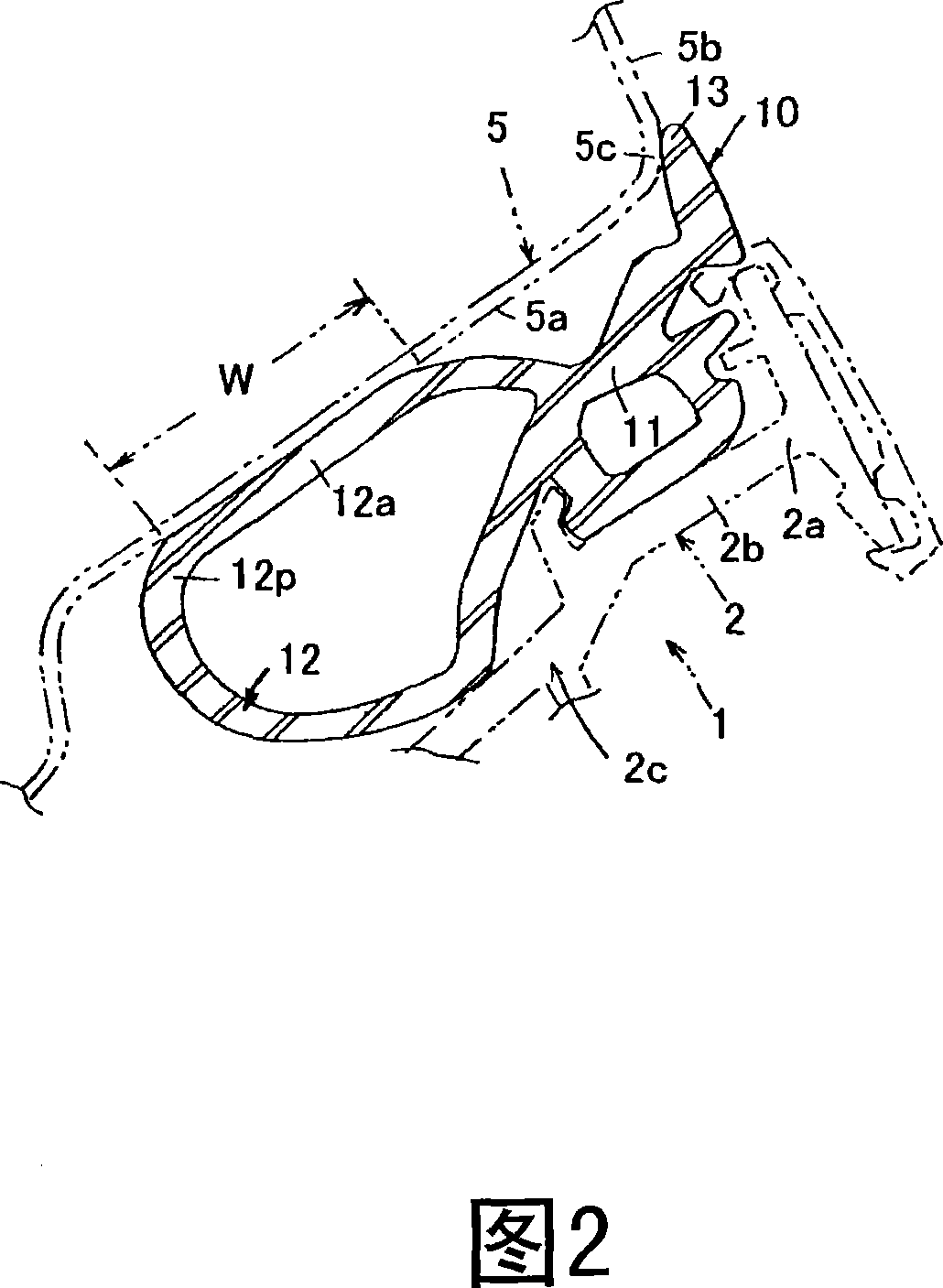

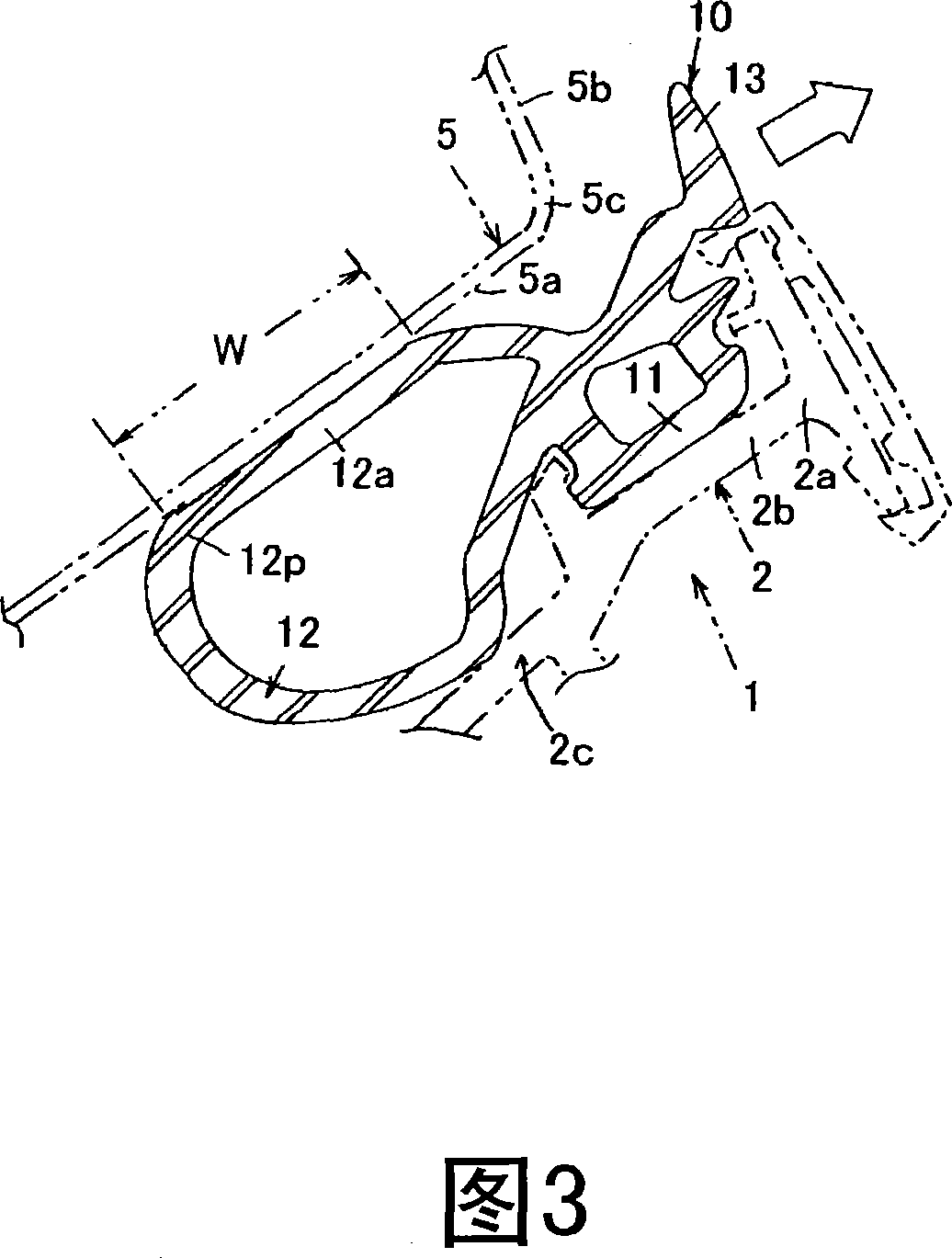

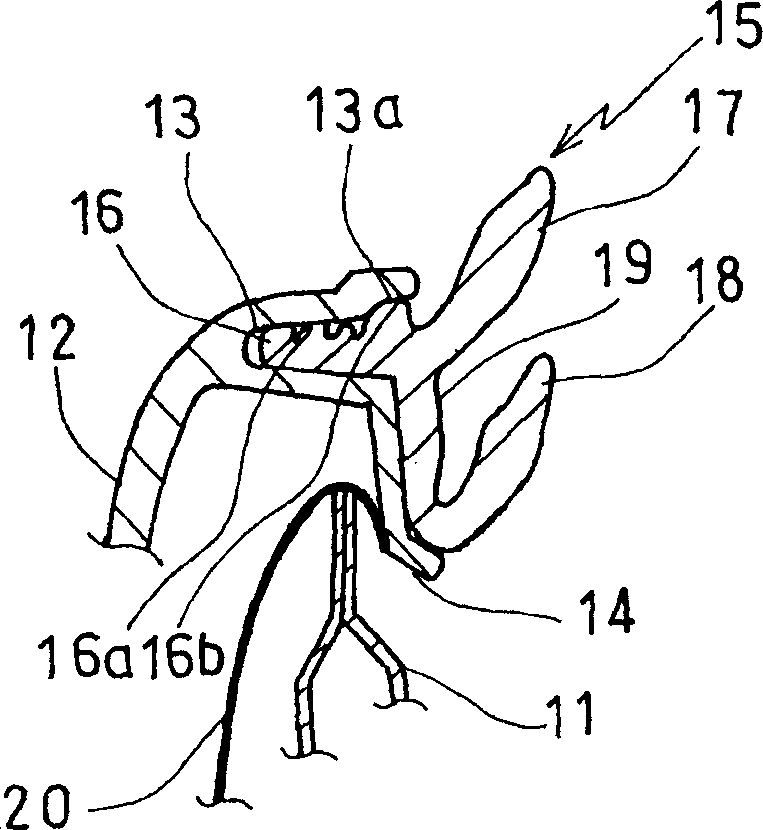

Attachment structure of door weather strip for vehicle

InactiveCN101062653AImprove sealingClosed retentionEngine sealsVehicle sealing arrangementsTravel modeEngineering

The invention provides a car door weather strip mounting structure capable of maintaining the high sealability even when a door is sucked outside a car when the car is traveling while maintaining the good door closability. The door weather strip 10 has a mounting base part 11 mounted on a retainer part 2a of a door sash 2, and a hollow seal part 12 which is integrated with the mounting base part 11 and elastically brought into contact with a body panel 5 when the door is closed. A part of the body panel 5 with the hollow seal part 12 elastically brought into contact therewith forms a flat parallel seal face 5a which is formed parallel or substantially parallel to the sucking direction S of a door 1 in a traveling mode.

Owner:NISHIKAWA RUBBER +1

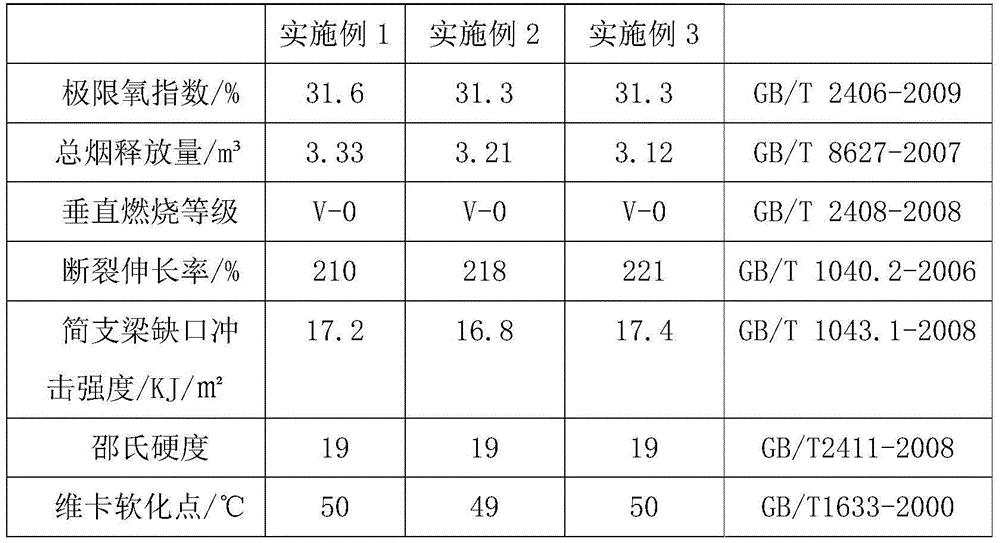

Antimony oxide compound flame-retardant PVC soft composite material and preparation method thereof

The present invention discloses an antimony oxide compound flame-retardant PVC soft composite material and a preparation method thereof. The composite material includes the following materials: PVC (SG-3), a plasticizer, antimony trioxide, ammonium molybdate, montmorillonite, a calcium zinc stabilizer, EVA, epoxy soybean oil, a coupling agent and a dispersing agent. The preparation process of the product is as below: modifying antimony trioxide; mixing the modified antimony trioxide with ammonium molybdate, montmorillonite and EVA; screening the mixture by a vibrating centrifugal screening machine; and drying the screened powder and conducting waterproof packaging. The product of the invention has efficient flame retardant and smoke suppression performance, limiting oxygen index up to 31.6%, elongation at break of 210% and Shore hardness as low as 17, can be used as a direct added raw material for PVC product, or be added as a modification additive, and can also be used as soft fireproof materials, such as PVC leather and protective decoration materials.

Owner:广西华锑科技有限公司

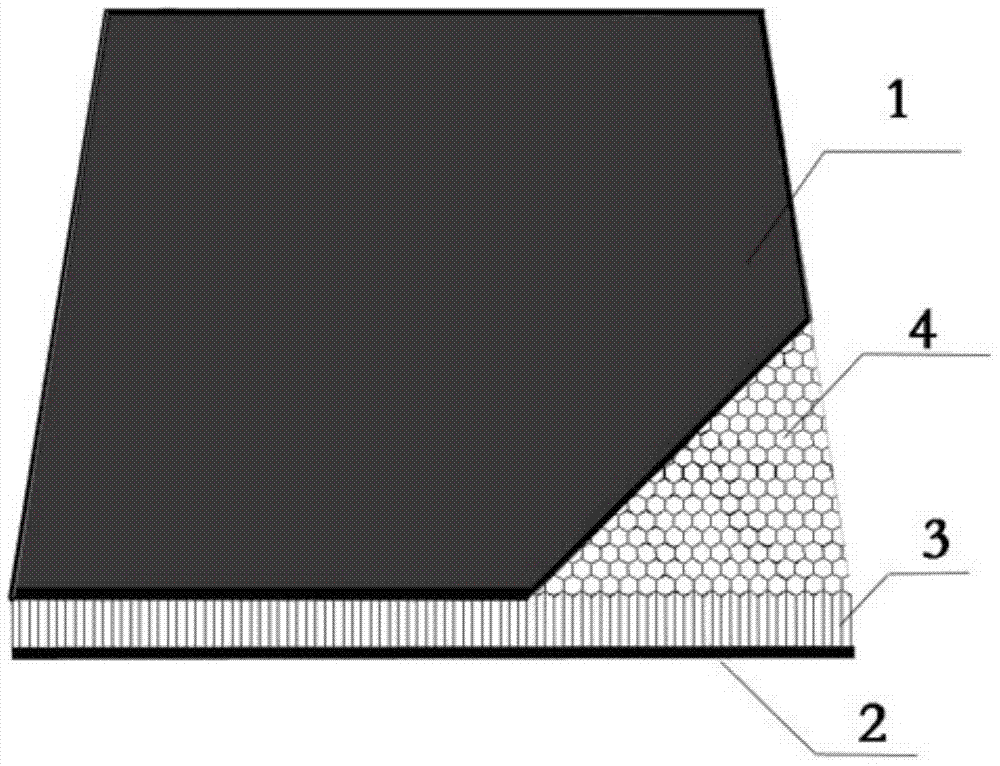

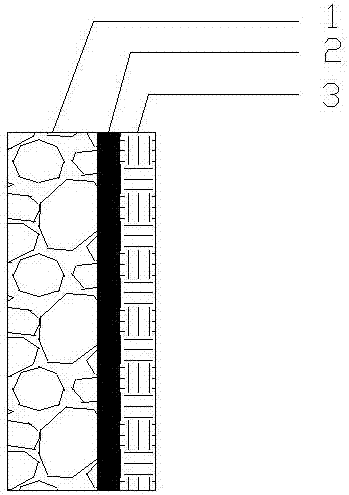

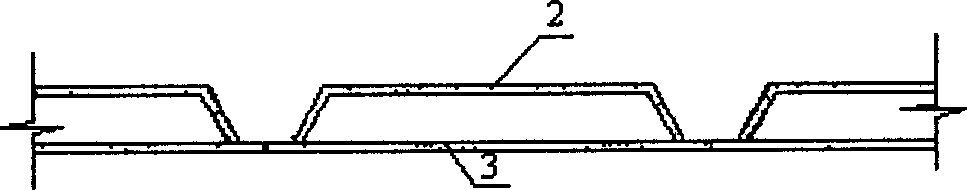

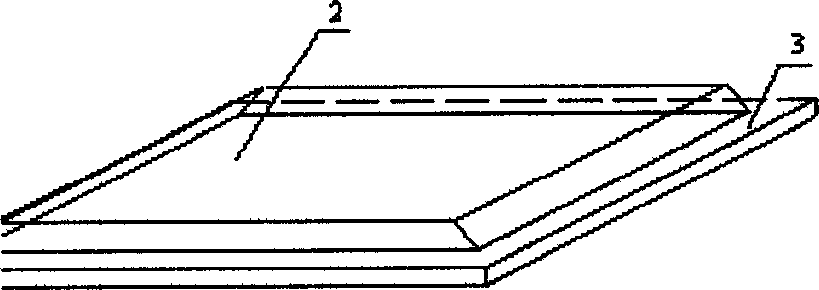

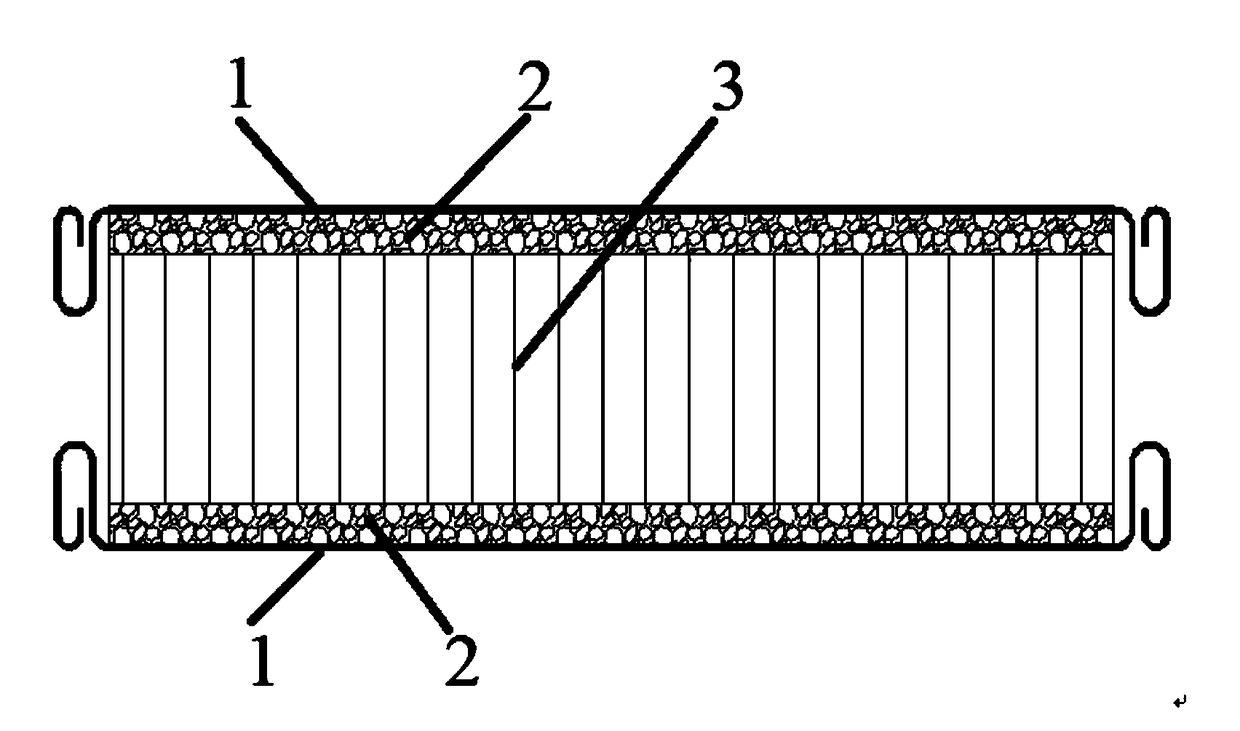

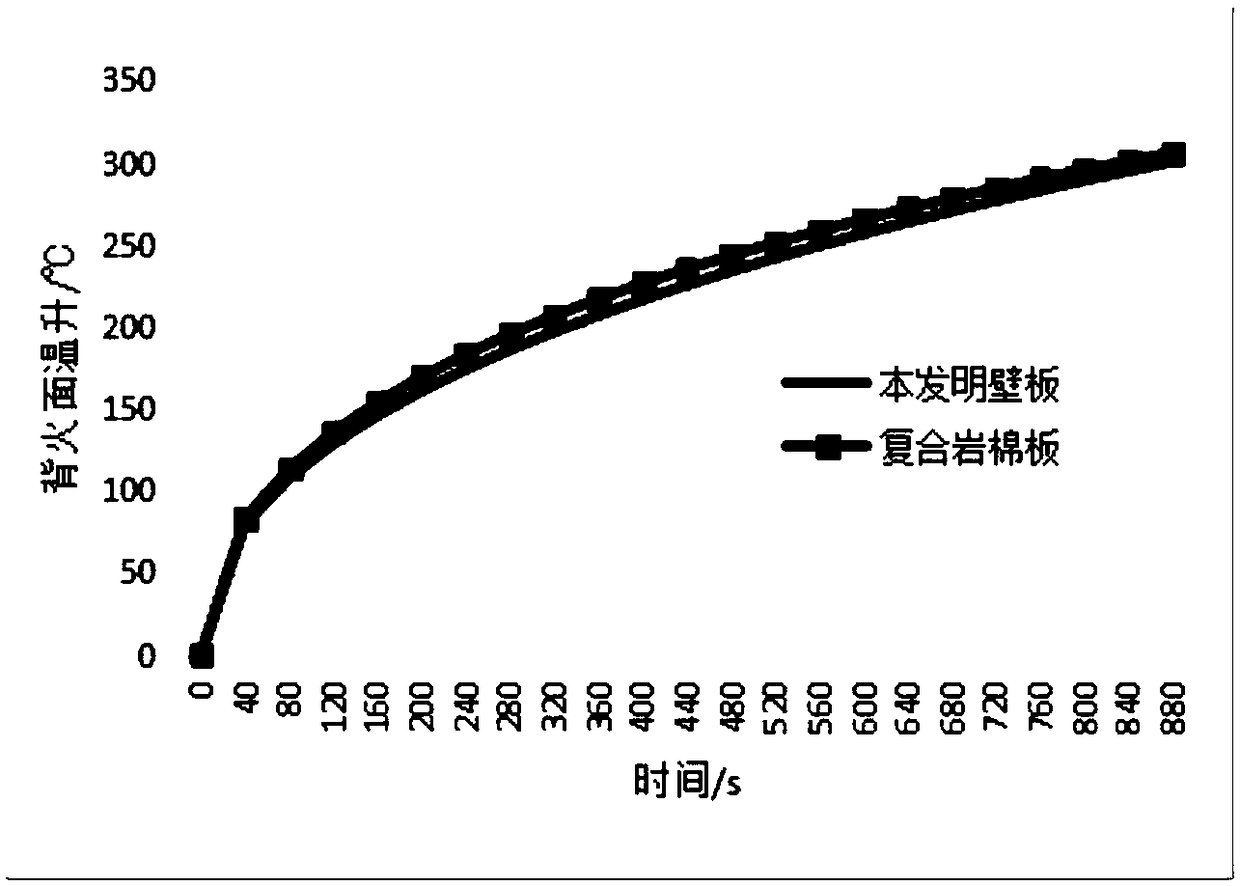

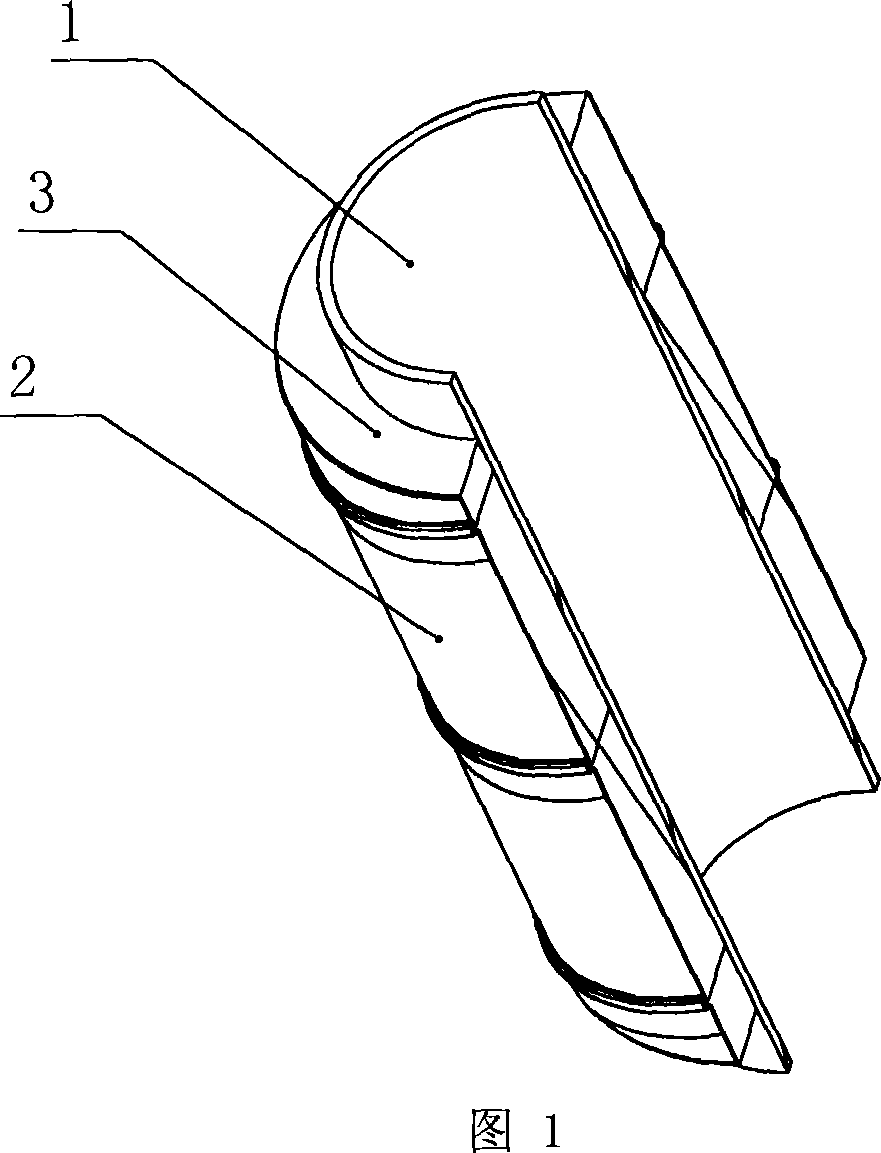

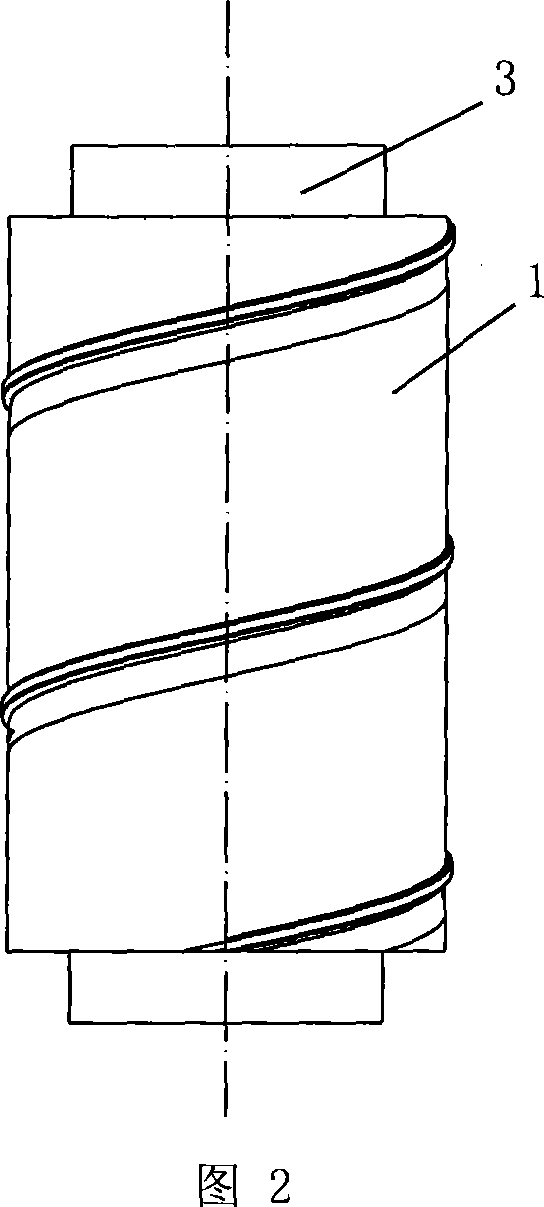

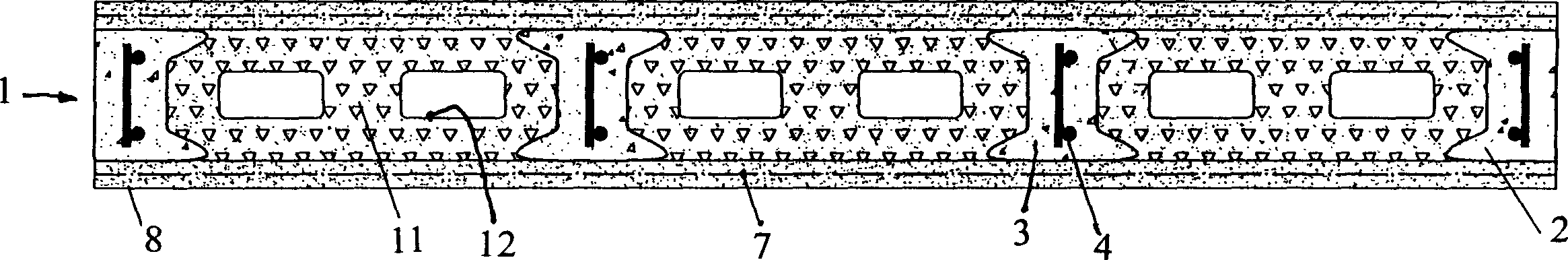

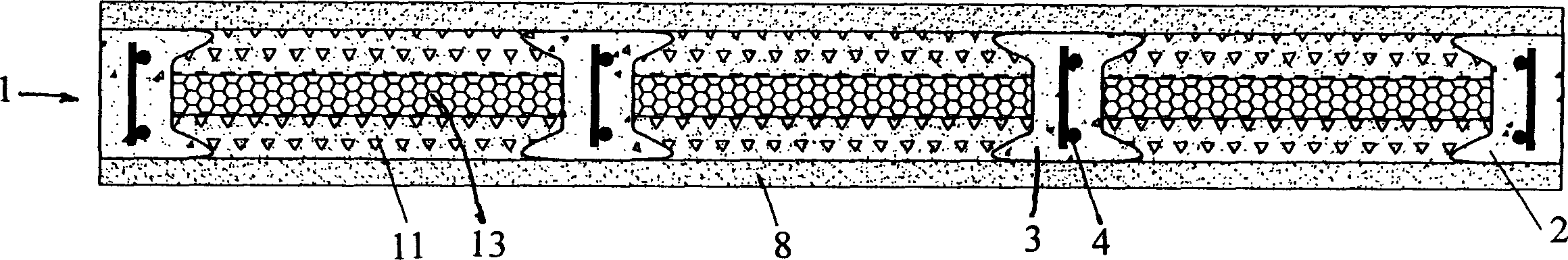

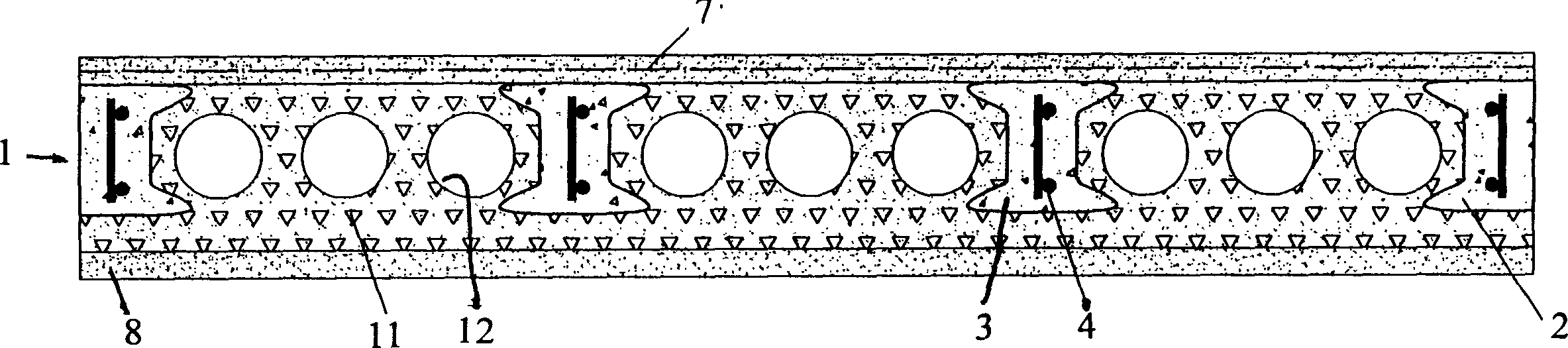

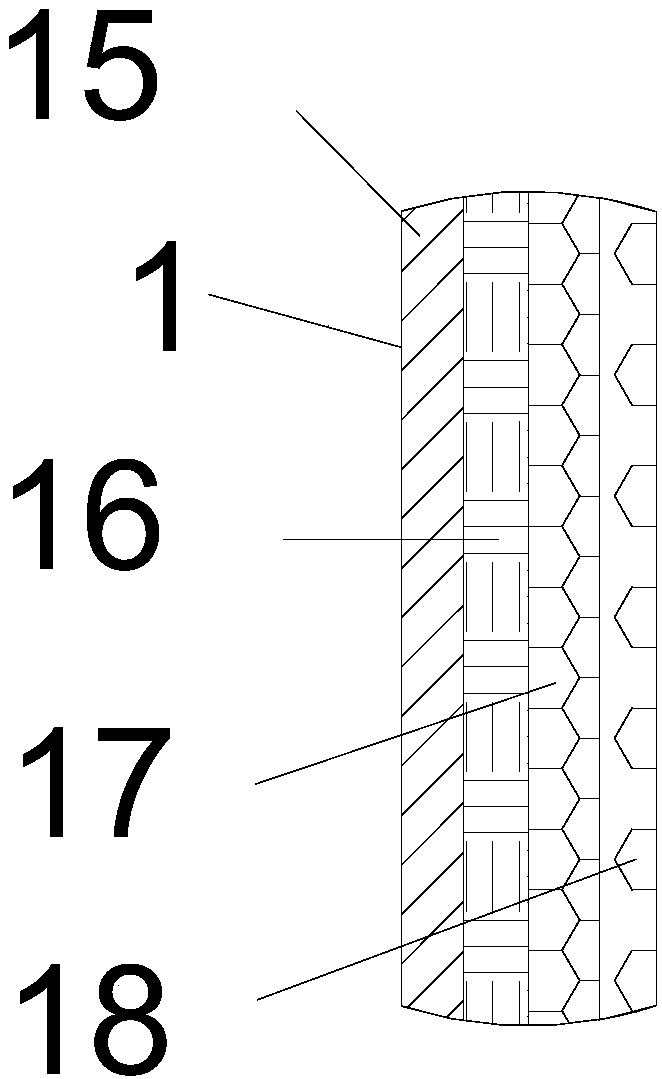

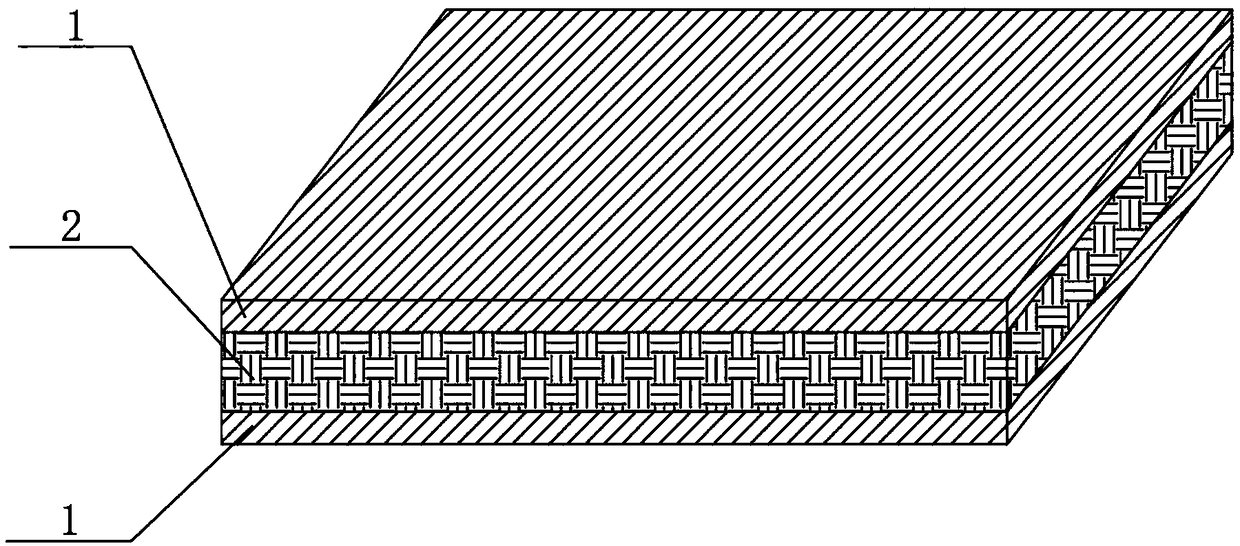

Lightweight acoustic insulation and fire resistant ship compartment wallboard and production method thereof

InactiveCN108819381AMeet the mechanical performance requirementsReduce weightLayered product treatmentSynthetic resin layered productsMarine engineeringThermal insulation

The invention discloses a lightweight acoustic insulation and fire resistant ship compartment wallboard and a production method thereof. A connecting structure is arranged on the side of the ship compartment wallboard; the ship compartment wallboard comprises a five-layer structure, namely a panel (1), an interlayer thermal insulation material layer (2), a supporting core material layer (3), another interlayer thermal insulation material layer (2) and another panel (1) in sequence; thermal insulation materials of the interlayer thermal insulation material layers (2) are aerogel. Compared witha composite rockwool panel, the ship compartment wallboard disclosed by the invention has light weight; compared with an aluminum honeycomb panel, the ship compartment wallboard has the advantages that fire-resisting separating performance and acoustic insulation performance are greatly improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

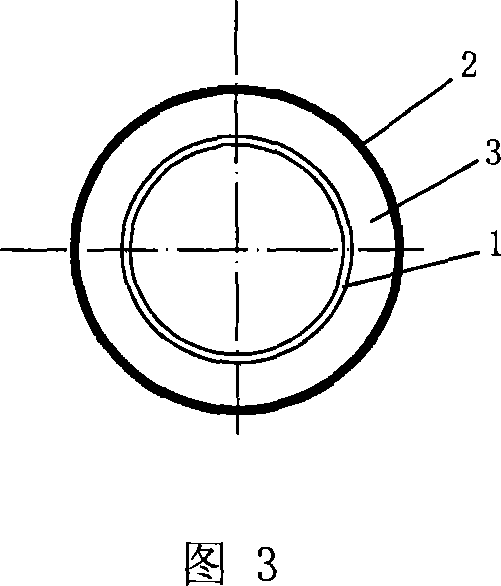

Prefabricated spiral phenolic aldehyde insulation tube and its production method

InactiveCN101055049AImprove insulation effectImprove insulation performanceLayered productsRigid pipesIsolation effectThermal insulation

A prefabricated spiral pnenolic aldehyde thermal insulation pipe and a manufacturing method thereof, a thermal insulation pipe is related. A prefabricated spiral pnenolic aldehyde thermal insulation pipe which has good heat preservation, insulation and sound isolation effect, is difficult in burning, no smoke in open flame, nontoxic, difficult in water absorption, not constringency, not deformation, good in machinery intensity, low in heat conductivity coefficient, no harm for human body, and broad in application and a method which is simple in technics, forming in one time, low in cost and can continuously or intermittently produce the prefabricated spiral pnenolic aldehyde thermal insulation pipe are provided. The thermal insulation pipe is a three layer composite pipe and is disposed with an inner pipe, an outer pipe and an intermediate pipe. The step is that: mixing formaldehyde-phenol resin, combustion inhibitor, modifying agent, and surfactants with proportion as A material; mixing firming agent and aerating powder as B material, opening a drying tunnel and heating it to predetermined temperature, starting a tube machine and a high-pressure foam maker, pouring A material and B material into the spiral pipe after mixing them with high pressure, pouring the material while making pipe, the pipe after being poured with foaming materials will be heated in the drying tunnel to foam, the one time form can be achieved, cutting after the foam body solidified and piling code by an automatic code putting machine.

Owner:厦门高特高新材料有限公司

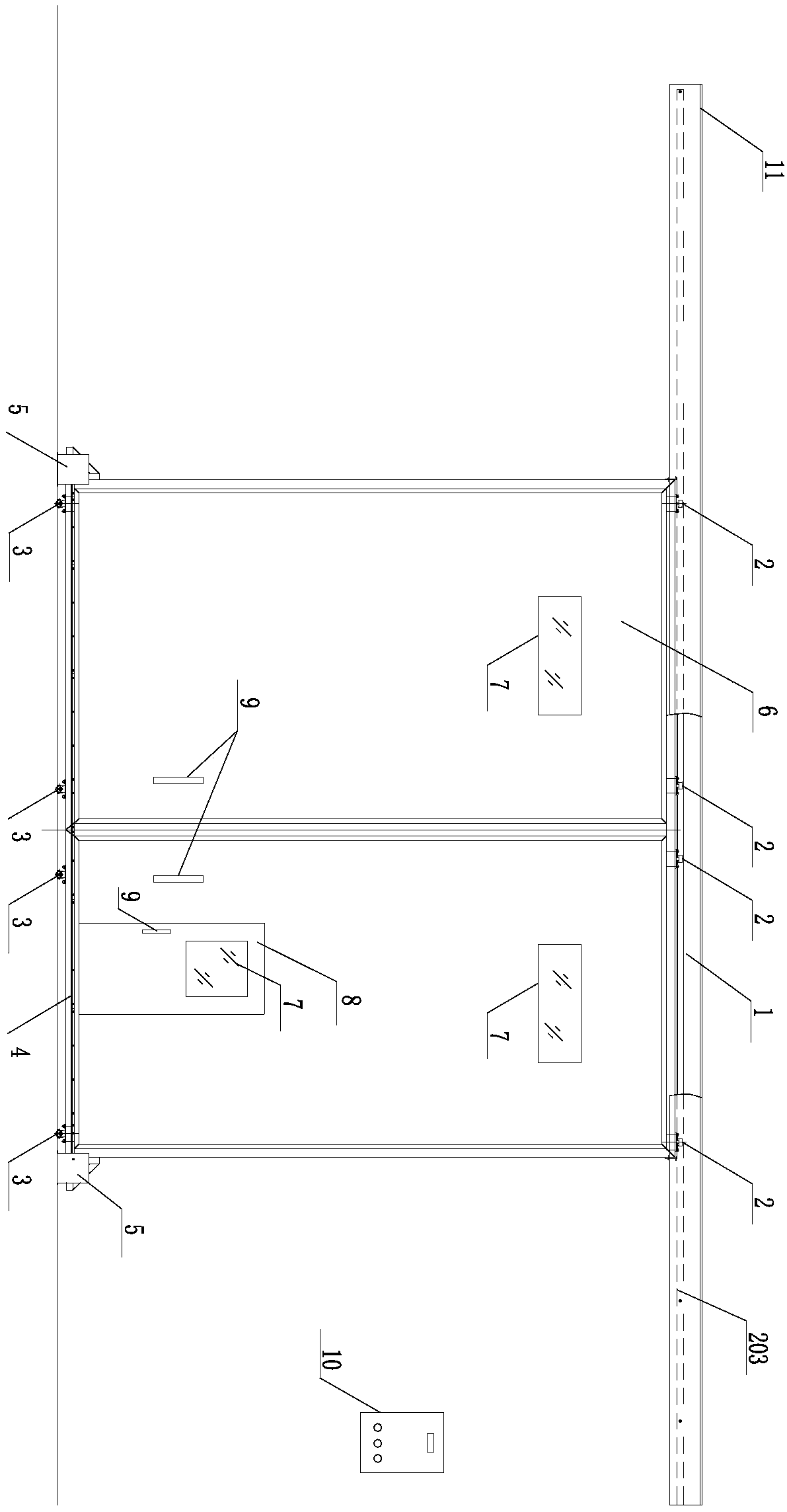

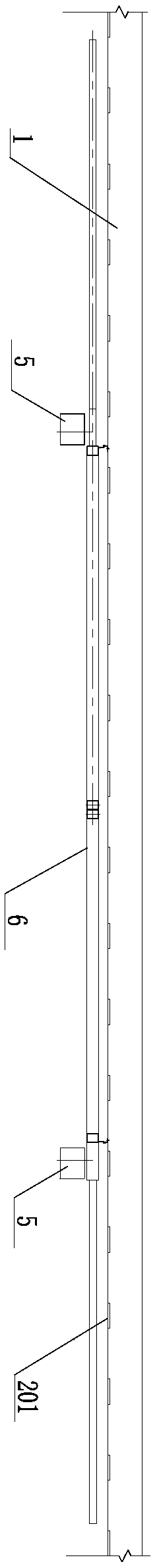

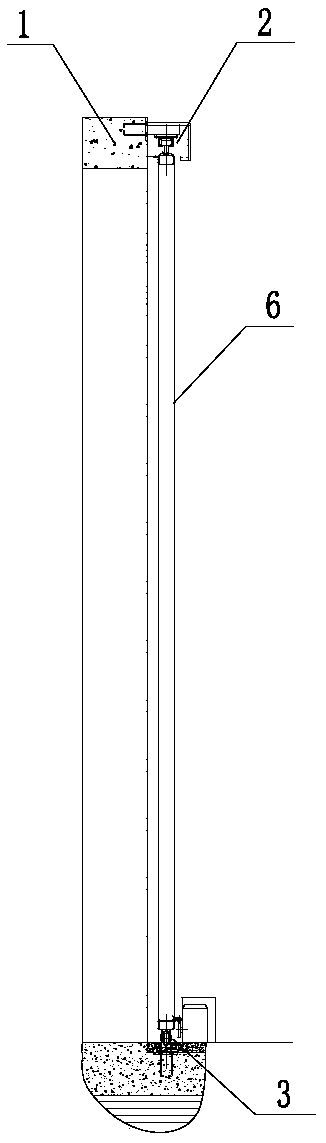

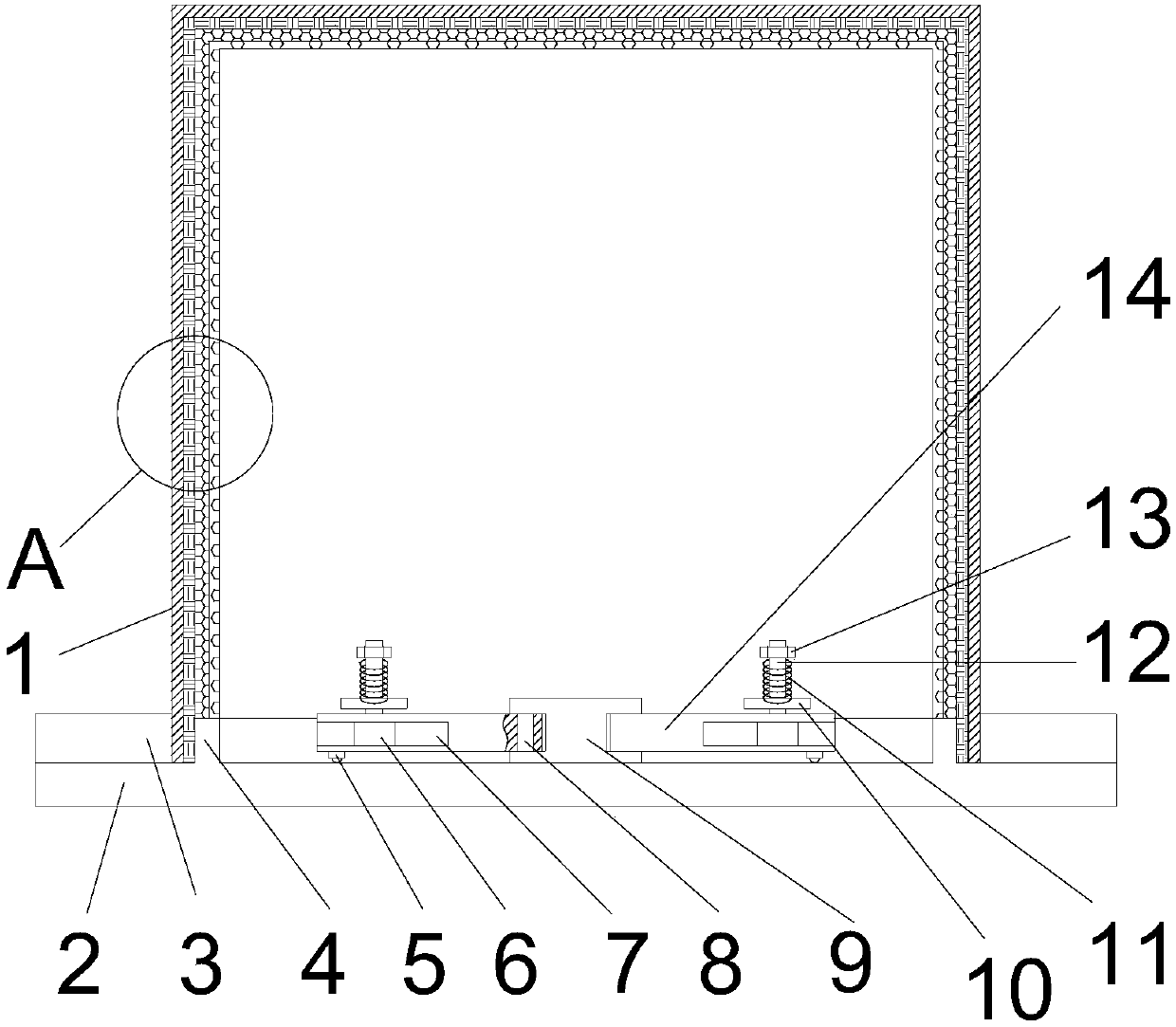

Heavy-duty sound insulation electric sliding door

PendingCN109356487AEnsure safetyPlay the role of noise isolationNoise insulation doors/windowsPower-operated mechanismOccupancy rateCurrent noise

The invention discloses a heavy-duty sound insulation electric sliding door. The heavy-duty sound insulation electric sliding door comprises sound insulation door panels and upper guiding systems installed at the tops of the sound insulation door panels, bottom walking wheel assemblies at the bottom and an electric control driving system. The upper guiding systems each comprise an upper guiding pre-embedded part, a guide rail bracket, a guide rail, a sound insulation encloser, a guide wheel and a door panel sealing system. The bottom walking wheel assemblies each include a lower sealing system, a bottom light rail pre-embedded part, a walking wheel, a light rail and a steel structure bracket. The sound insulation door panels are steel structure frameworks, and the sound insulation door panels can be filled with sound insulation materials aiming at corresponding sound insulation factors of different noise sources to isolate noise. The heavy-duty sound insulation electric sliding door realizes a good sound insulation effect indoors and outdoors, meanwhile, free movement or rotation motion of the heavy-duty sound insulation door is realized by driving the upper guiding systems and thebottom walking wheel assemblies at the bottom by the electric control driving system, and the problem that a current noise reduction gate has a high space occupancy rate, a low degree of electrical automation and a poor noise insulation effect is solved.

Owner:中国人民解放军92578部队 +1

Fire-proof sound insulation composite plate

InactiveCN1587563AHigh strengthImprove sound insulationHeat proofingSound proofingFoam concreteFloor slab

The composite fireproof sound isolating plate includes concrete frame with one or several connected ribs; light material boards of light concrete, concrete with polyethylene foam grains or foamed concrete filled between the frame and the rib; and steel rib net to connect the frame and ribs. The composite fireproof sound isolating plate may be used as wall plate and floor slab, and has high strength, light weight, and outstanding fireproof, heat insulating and sound isolating effects.

Owner:张英保

Preparation method and application of vacuum glass

ActiveCN106746755AProne to frost and condensationAvoid internal condensationClimate change adaptationWindows/door improvementInfraredLaser etching

The invention discloses a preparation method of vacuum glass. The method comprises the steps of (1) placing two pieces of plain glass with same size into a tempering furnace for tempering or placing into a bending and tempering furnace for bending and tempering so as to obtain plain or curved tempered glass; (2) adopting a chemical corrosion way or a laser etching way for setting support objects arranged in a dot matrix way on the surface of one piece of tempered glass; (3) placing the other piece of tempered glass on the support objects, and aligning the tempered glass at the tempered glass provided with the support objects in the step (2); (4) filling an edging material around a gap between the two pieces of tempered glass, quickly heating and curing the edging material and accomplishing sealing side parts of the two pieces of tempered glass; (5) pumping air between the two pieces of tempered glass through an air pumping hole so as to form a vacuum chamber between the two pieces of tempered glass, and quickly sealing the air pumping hole through an infrared heating or laser radiation way so as to accomplish the preparation of the vacuum glass. The movement of the support objects during a subsequent processing process is avoided, the requirement on temperature resistance of the material is reduced, and the noise is reduced.

Owner:青岛同心邦科技有限公司

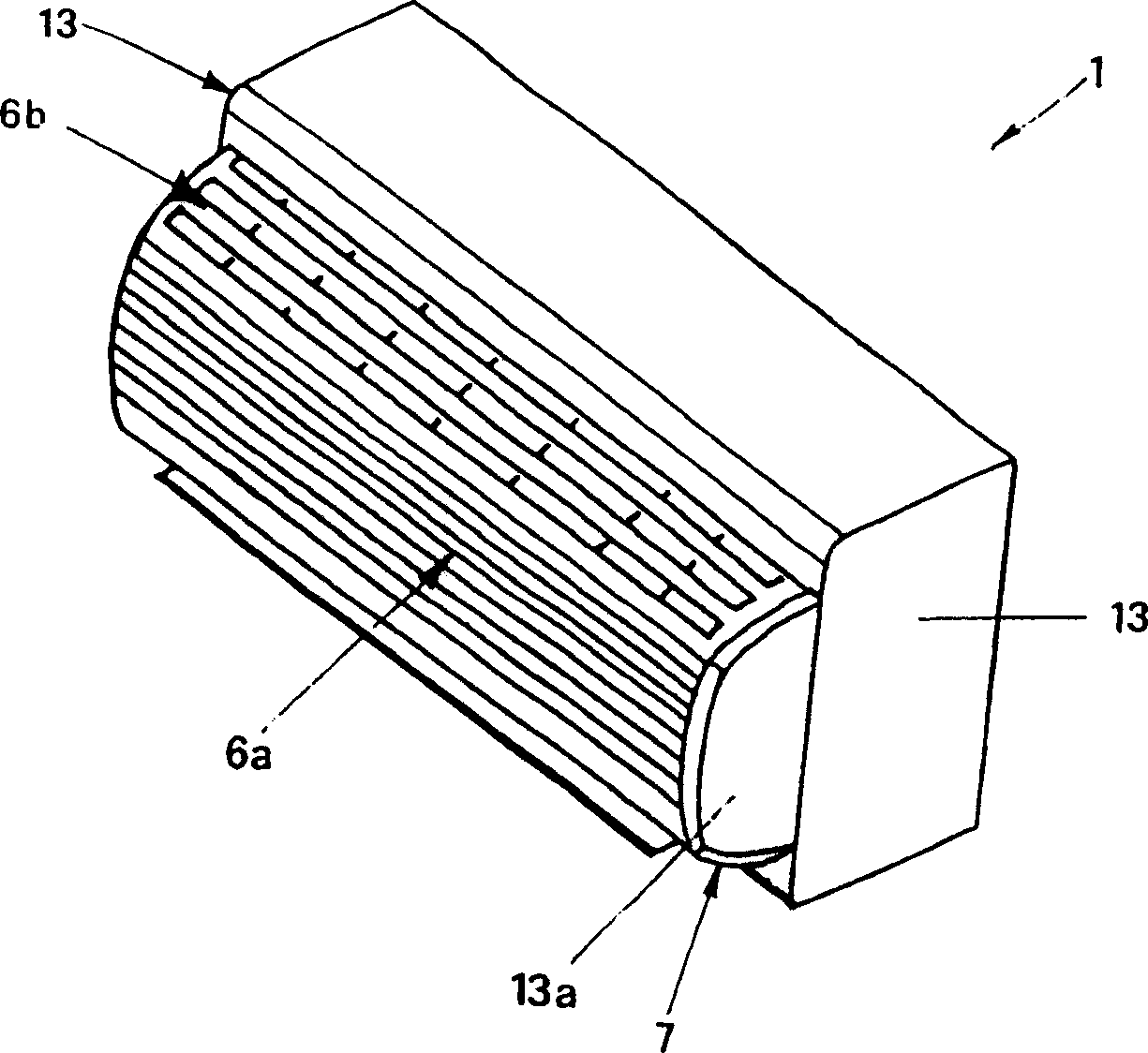

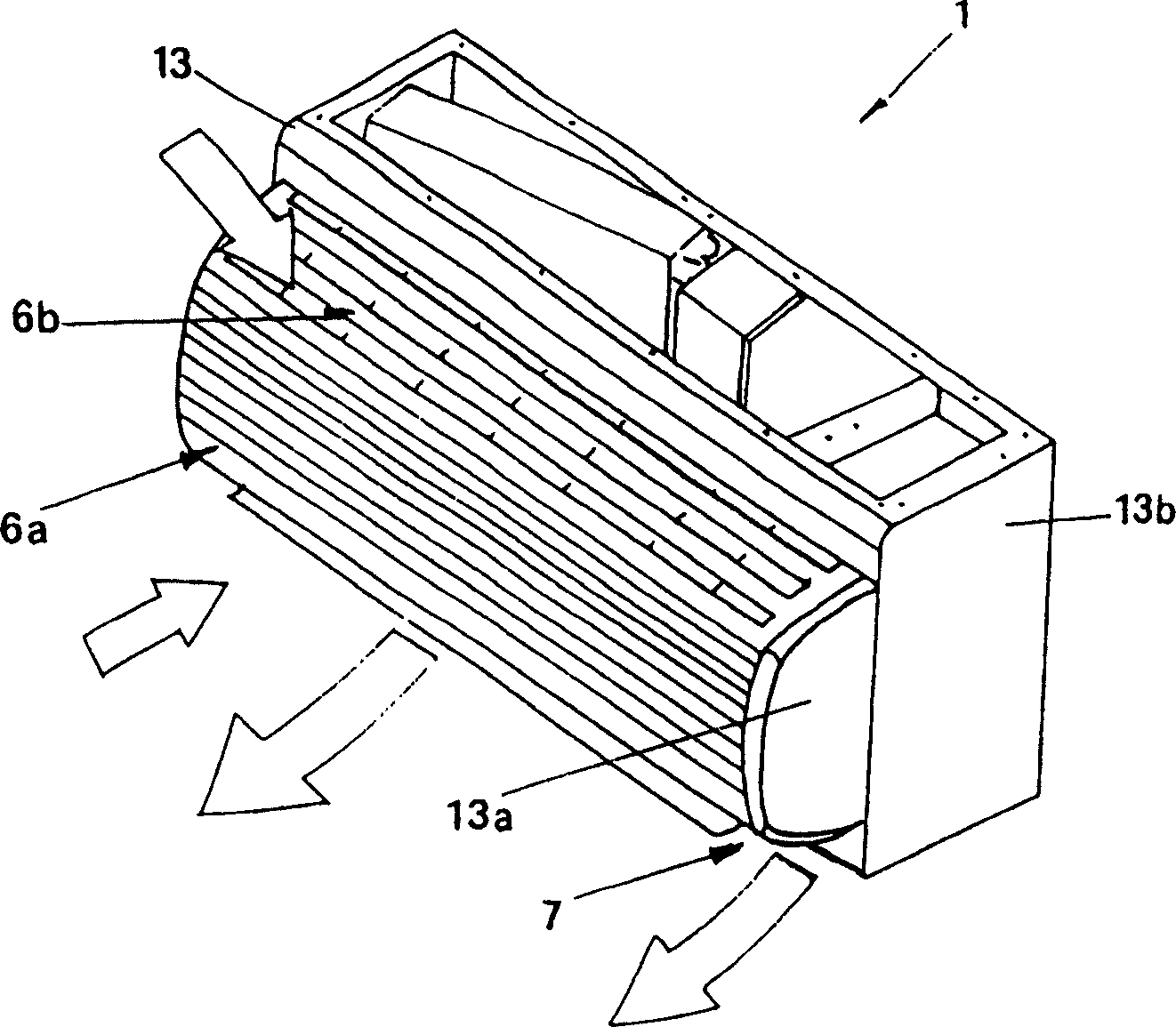

Enbloc air conditioner

InactiveCN1668878ASmall sizeImprove aestheticsLighting and heating apparatusAir conditioning systemsEngineeringEvaporator

Owner:XIANG

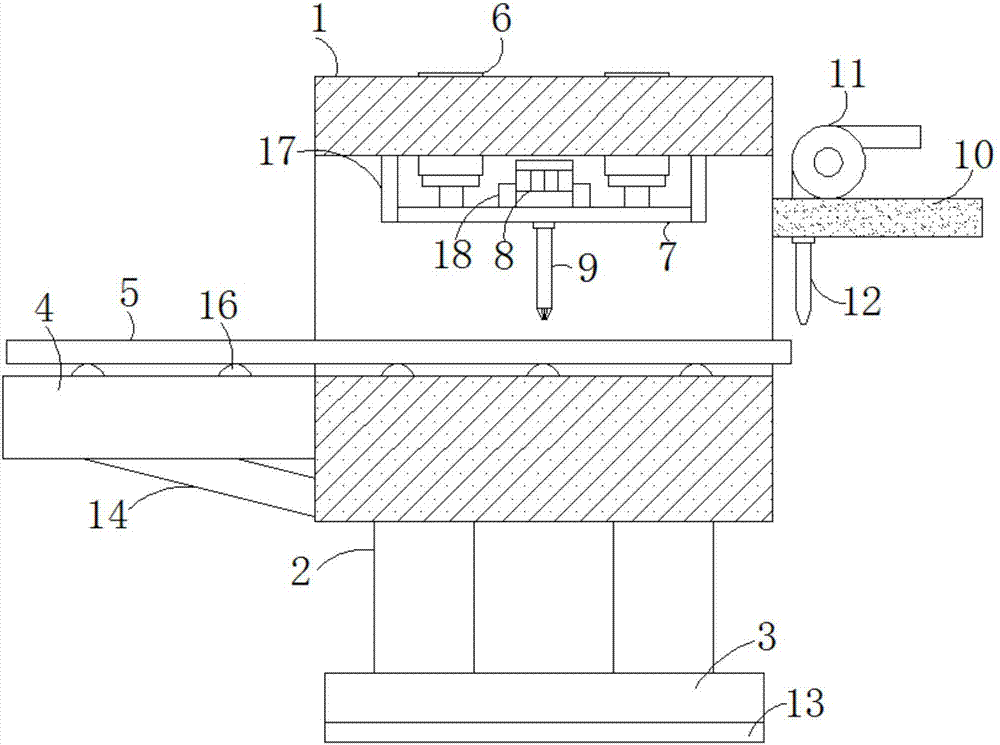

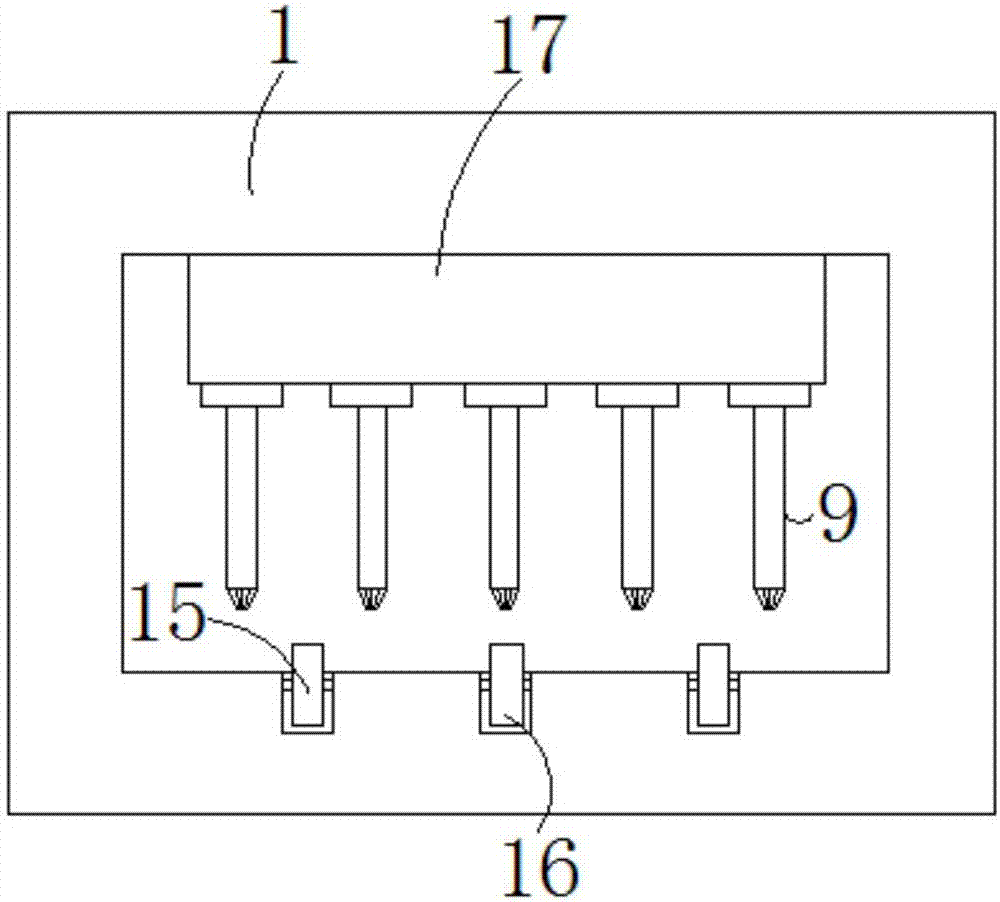

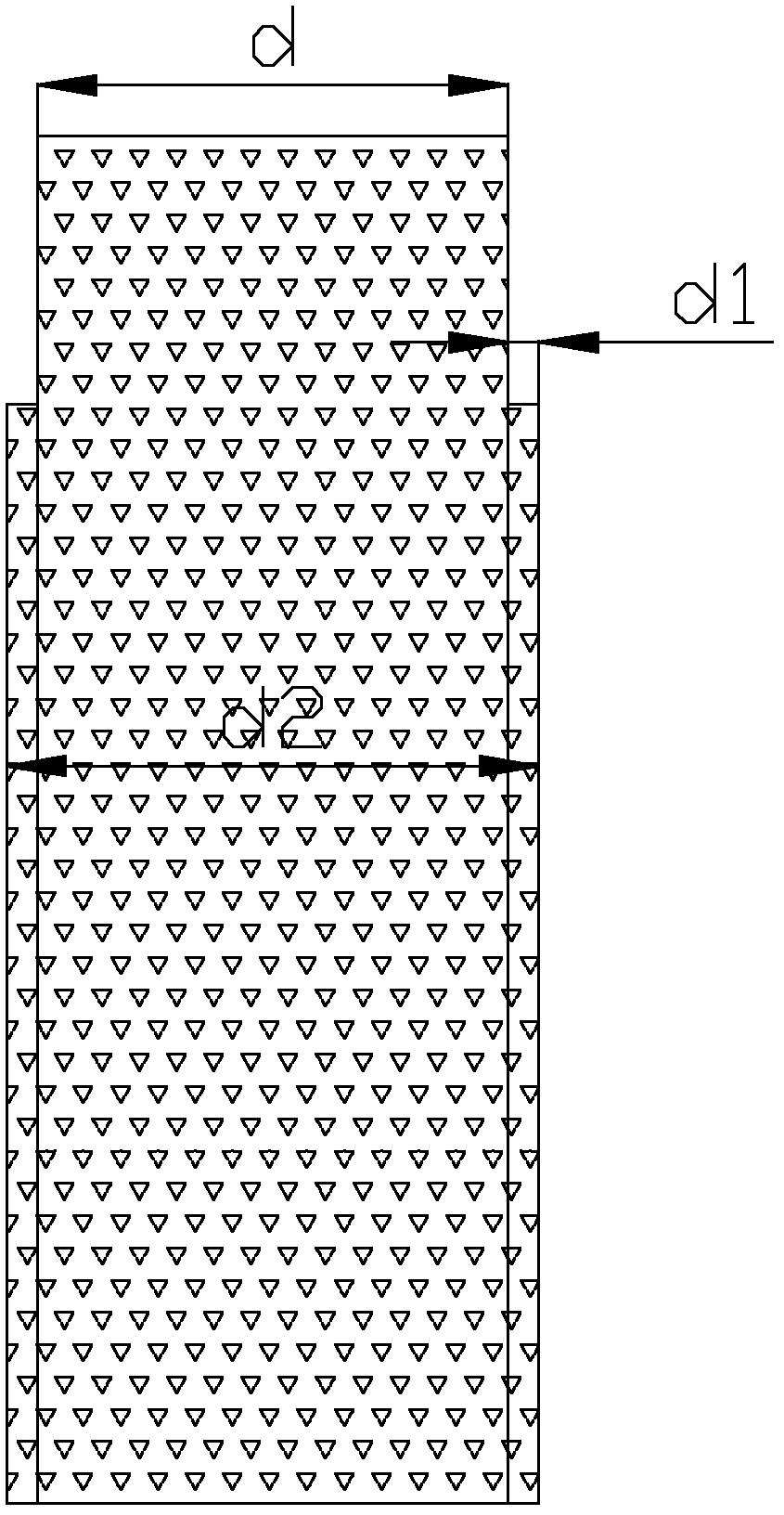

Fast processing device for sound-insulation holes of sound-insulation plate

InactiveCN107282968AImprove processing efficiencyImproved quality and sound insulationMetal working apparatusBoring/drilling machinesGeotechnical engineeringEconomic benefits

The invention discloses a rapid processing device for sound-insulating holes of a sound-insulating board, which comprises a drilling frame. Both sides of the bottom of the drilling frame are fixedly connected with supporting legs, and the bottom of the supporting legs is fixedly connected with a base. The drilling The bottom of the left side of the frame is fixedly connected with the first support plate, and the top of the first support plate is fixedly connected with the sound insulation board body, and the right end of the sound insulation board body passes through the inner cavity of the drilling frame and extends to the right side of the drilling frame. The present invention can utilize a plurality of drilling rods to pair the sound insulation board body Drilling treatment can be carried out, and the temperature of the punched part can be cooled in time, and the impurities of the plate can be removed in time, which greatly improves the processing efficiency of the sound insulation board body, improves the quality of the sound insulation hole and the sound insulation effect, and then gives the sound insulation board processing Enterprises bring huge economic benefits.

Owner:长兴天象声学技术有限公司

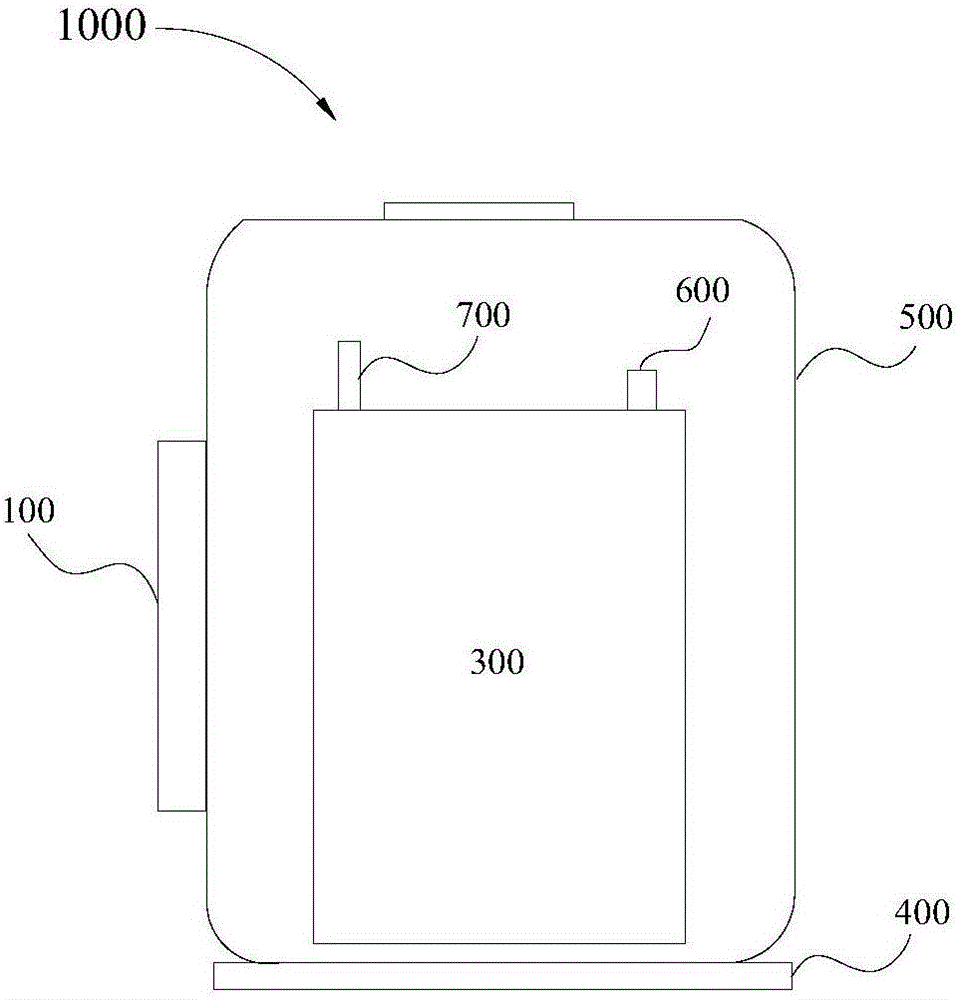

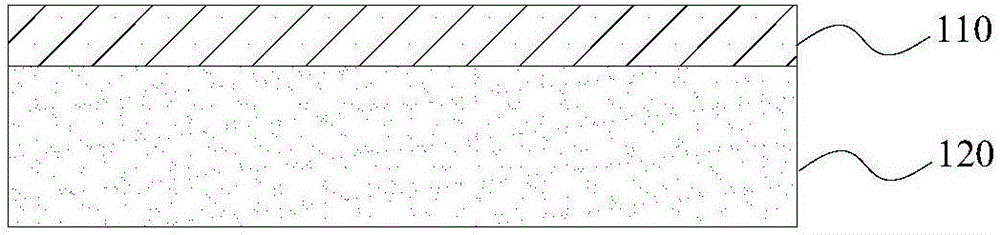

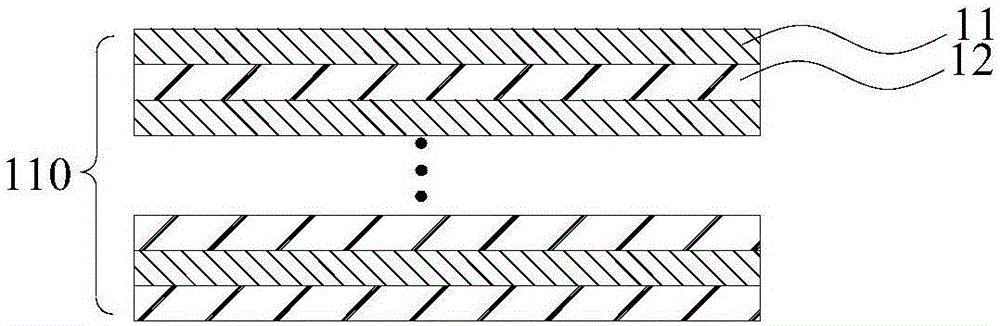

Compressor

InactiveCN106837743ALow densityMaterial texture is softPositive displacement pump componentsPositive-displacement liquid enginesEngineering

The invention provides a compressor comprising a base, a compressor shell body, a compression assembly and a sound insulation assembly. The sound insulation assembly is arranged on the base and at least one surface of the compressor shell body and comprises laminating layers and sound absorbing layers, wherein each laminating layer comprises foaming sub-layers and non foaming sub layers, and the sound absorbing layers are arranged on the lower surfaces of the laminating layers. The compressor has a good sound insulation effect.

Owner:MIDEA GRP CO LTD

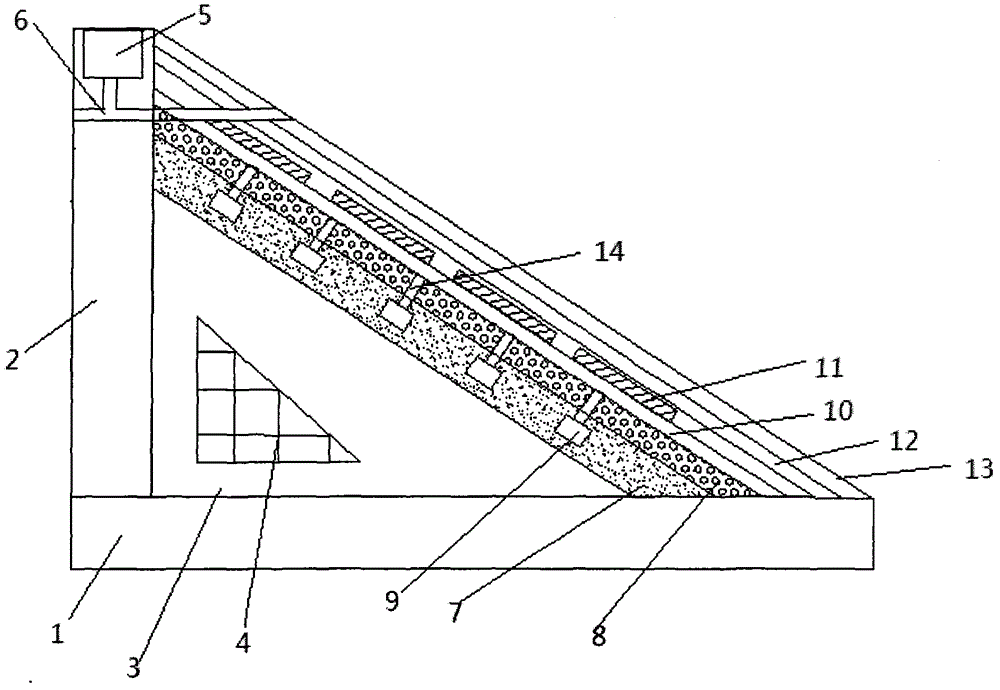

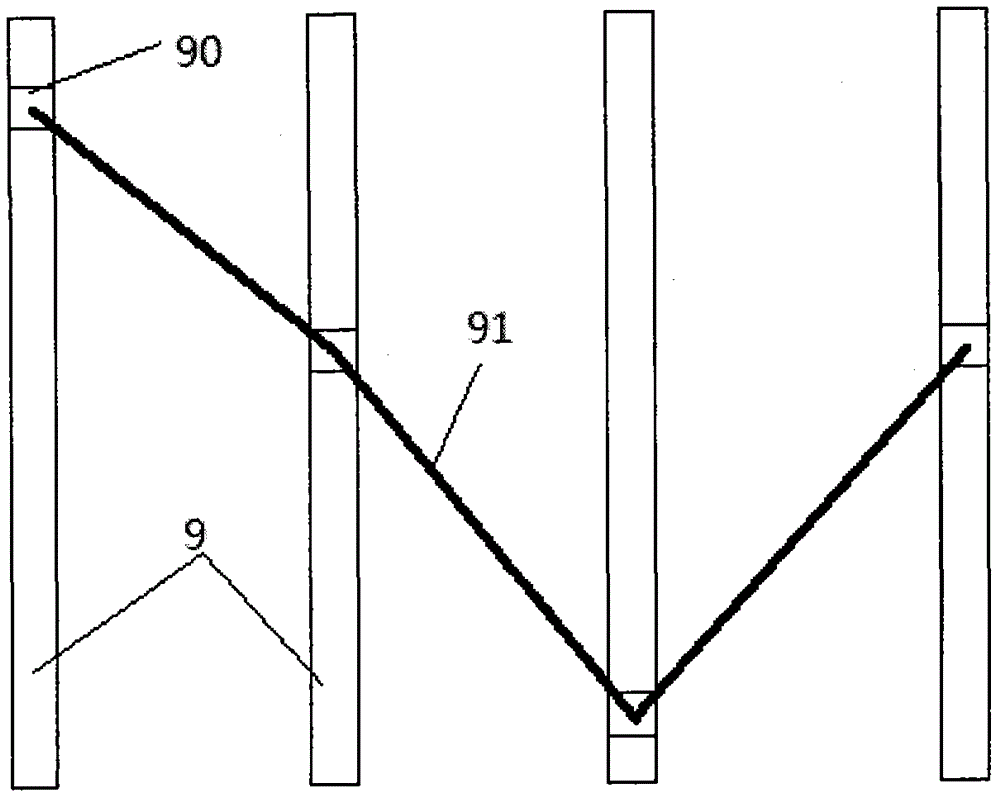

Water conservancy retaining wall project

InactiveCN104532875AFirmly connectedImprove bearing capacityArtificial islandsCoastlines protectionCarrying capacityKeel

The invention discloses a water conservancy retaining wall project; the strength of a concrete wall is reinforced by a basalt braiding layer, the connection area of a keel and a concrete pouring layer is increased by arranging fixed racks on the keel, and a reinforcing rib arranged between the fixed racks can form a triangular support structure with the keel, thus reinforcing the whole solidness of a building curtain wall. Foaming cement is used as a buffering layer, which can reinforce firmness of the connection between an outer all board and the keel. As a lot of bubbles exist in the foaming cement, the buffering layer also has the effects on relieving the whole quality of the wall and insulating sound besides plays a role in buffering; through the design of using a concrete reinforced body as a foundation main body and supported and fixed by piles and support posts, the good carrying capacity of the foundation is ensured. The whole foundation is designed to be with a big end up, thus improving the gravity position of the foundation. The water conservancy retaining wall project is high in structural intensity, good in impact resistance, elegant in appearance and convenient to build.

Owner:CHANGCHUN INST OF TECH

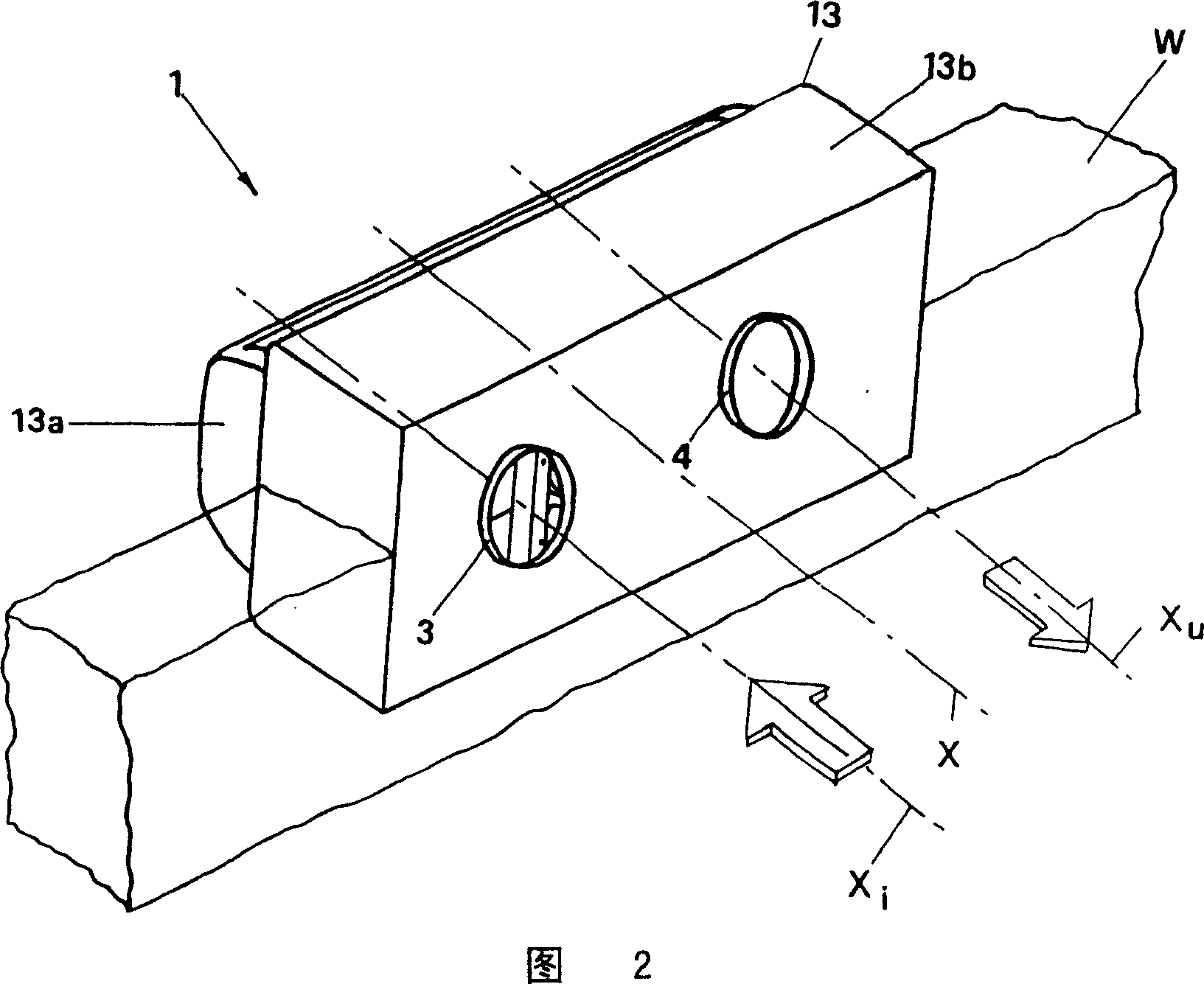

Bus door structure and sound insulating plate

InactiveCN1442326AImprove sound insulationReduce noiseEngine sealsVehicle sealing arrangementsEngineeringAcoustic board

A car door structure, which includes a door inner protection panel 11 , an inner door lining 12 and a sound insulation board 20 . The inner door liner 12 is installed inside the door inner panel 11 . The sound insulation panel 20 is provided between the door inner panel 11 and the door liner 12 , wherein the sound insulation panel hangs like a door curtain from the upper side of the door inner panel to the lower side thereof. The sound insulation panel 20 is fixed to both the door inner panel 11 and the door liner 12 . The sound insulation panel 20 is arranged on the upper half or the lower half of the door inner panel 11, or when the door inner panel 11 is divided into three parts in the vertical or horizontal direction, it is arranged on the door inner panel Middle part of 11.

Owner:NISHIKAWA RUBBER

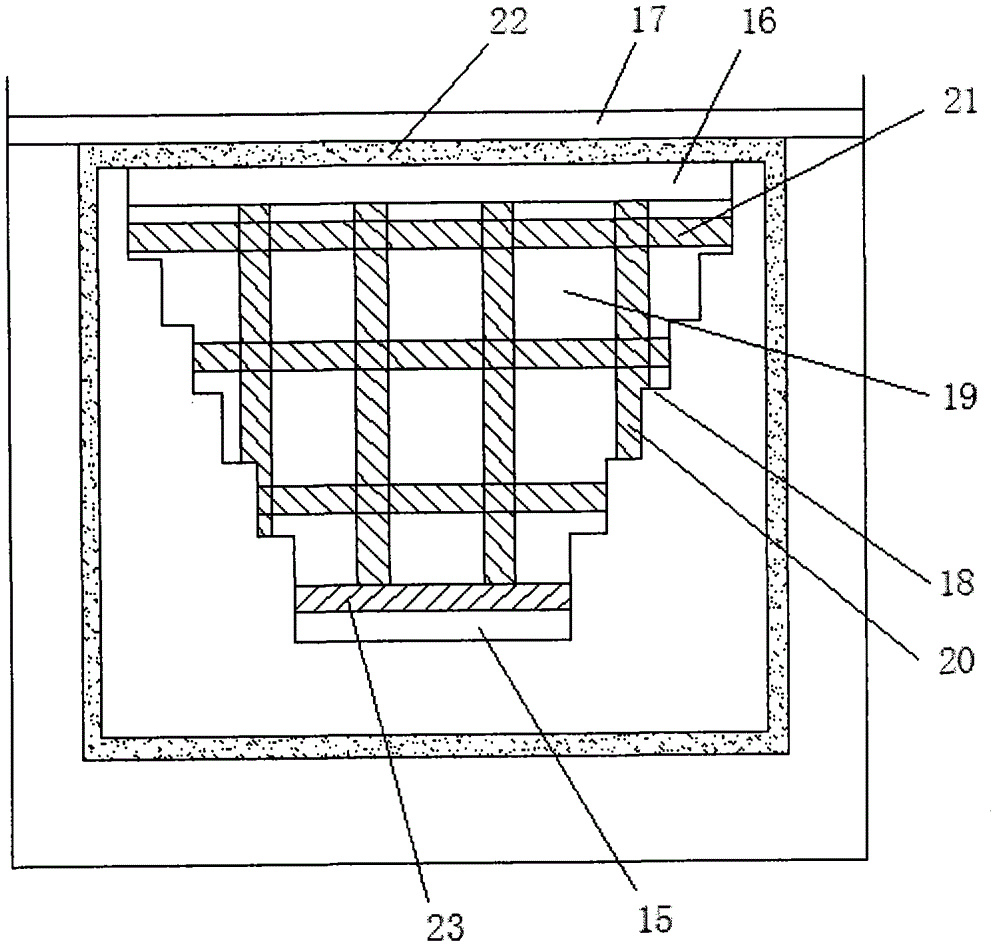

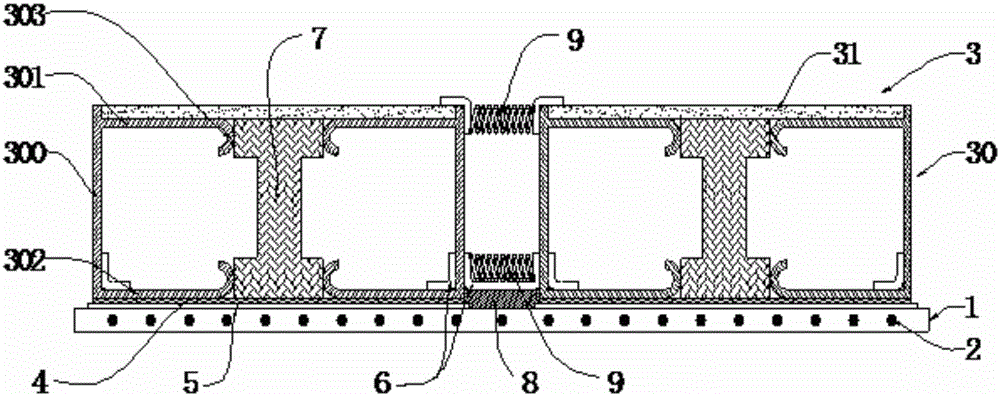

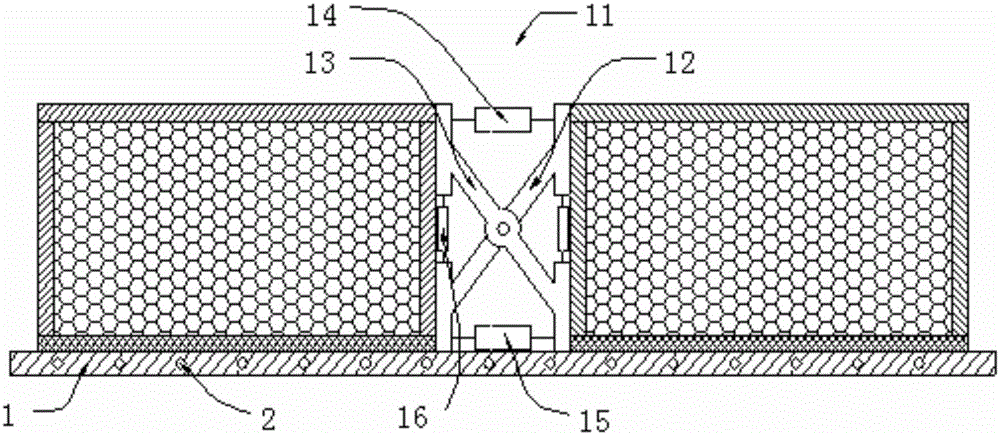

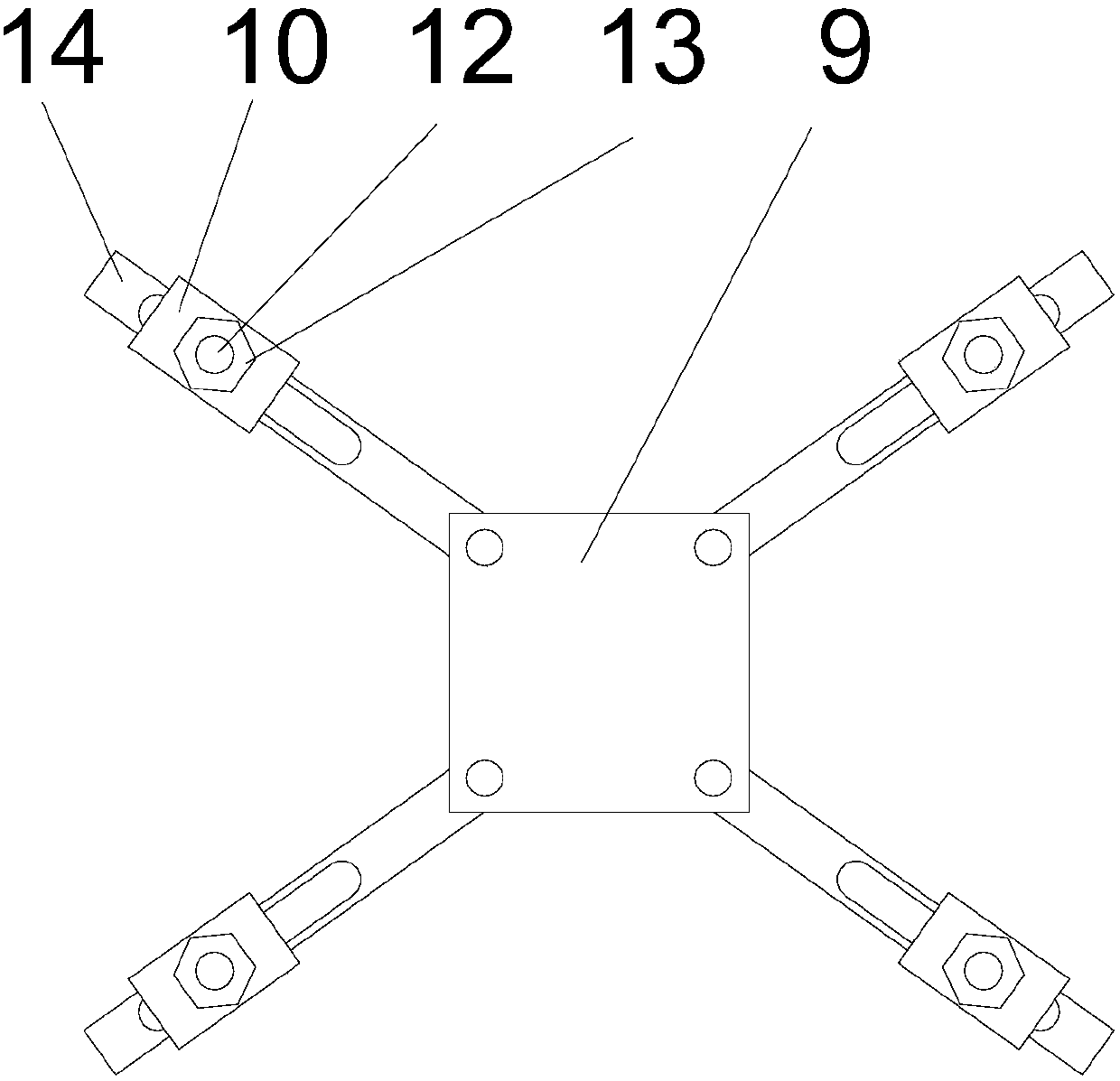

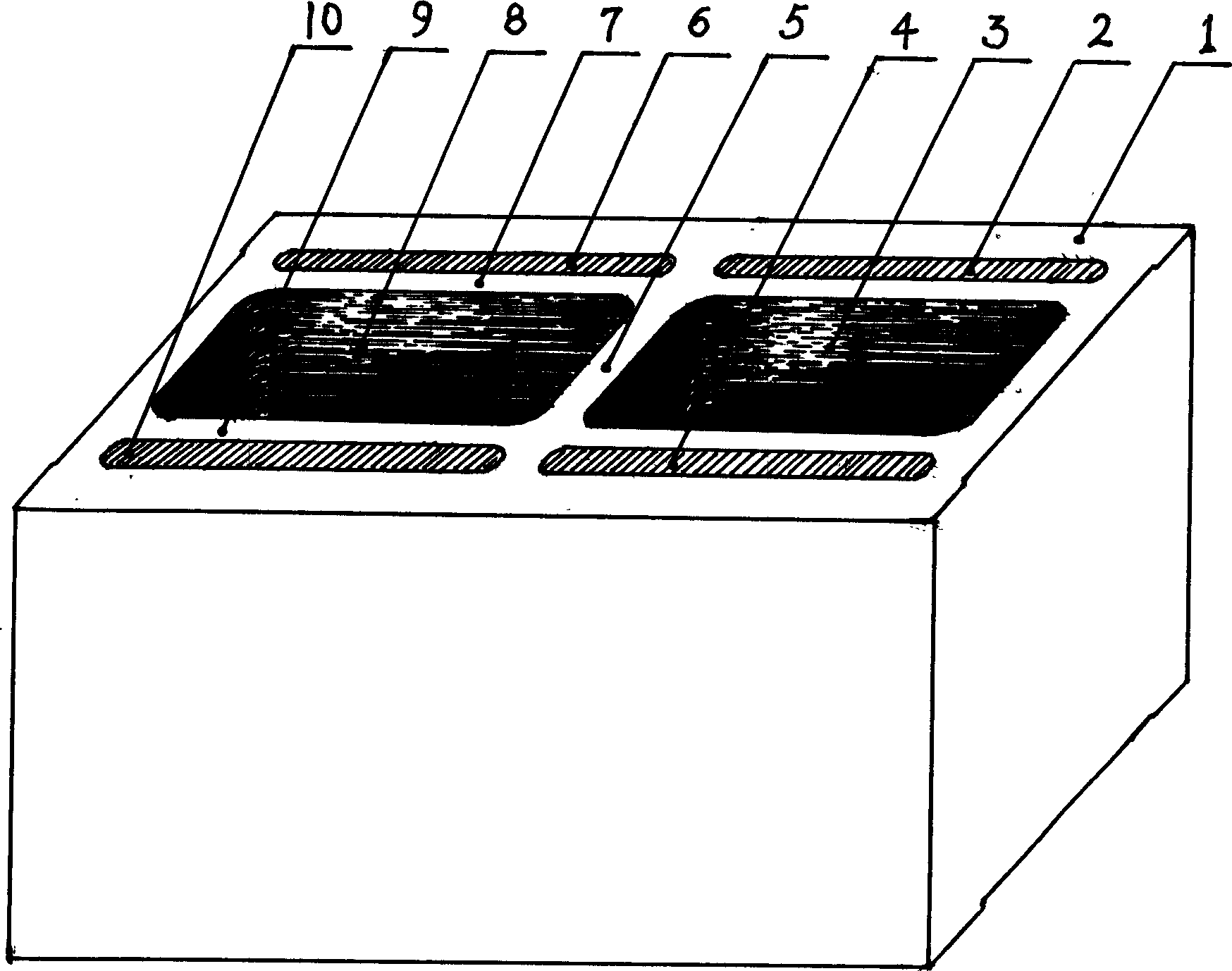

Anti-seismic soundproof floor system for building

InactiveCN105155750AHigh strengthIncrease stiffnessFloorsSound proofingEngineeringStructural engineering

The invention provides an anti-seismic soundproof floor system for a building. A plurality of cavity modules which are independent mutually are arranged on a baseplate, each cavity module comprises side formworks which are in left-right symmetry and opposite arrangement, an auxiliary wing face facing a turned edge in the direction of a ventral face of the corresponding formwork is arranged at the free end of each of an upper wing face and a lower wing face of each side formwork, a polytef plate and a stainless steel plate are arranged between each lower wing face and the baseplate, a supporting column with an H-shaped longitudinal section between opposite side formworks, a transverse damping structure is arranged between each two adjacent cavity modules, a plurality of soundproof columns which are connected mutually are arranged in each cavity module, a hollow inside of each hollow cavity is filled with a filling body, the soundproof columns are parallelly connected sequentially along the length direction or the width direction of the floor system, and a connecting line of central points of cross sections of each two adjacent soundproof columns is wavy. Anti-seismic performance of the floor system in an earthquake environment is improved, and impact sound from upstairs can be lowered by 80%.

Owner:范峰杰 +1

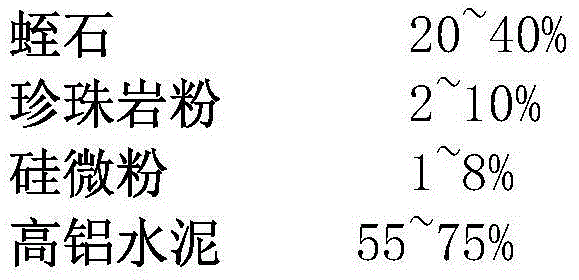

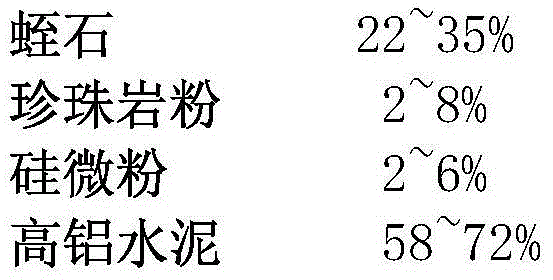

Lightweight, heat-insulation and fire-proof castable composition, and application and preparation method thereof

The invention discloses a lightweight, heat-insulation and fire-proof castable composition, and an application thereof in a nitrogen purification device and a preparation method thereof; the castable composition includes vermiculite, a perlite powder, a silica micro-powder and high-alumina cement. The castable composition has the characteristics of low thermal conductivity, low volume density, good thermal shock resistance, high use temperature and the like; at the same time, the castable composition also has good fluidity and easy and convenient construction; after being applied to the nitrogen purification device, the castable composition can effectively reduce heat loss of the nitrogen purification device, improves the thermal efficiency, reduces energy consumption, saves energy and reduces emissions. In addition, raw materials adopted by a lightweight, heat-insulation and fire-proof castable are non-toxic and non-corrosive, so the lightweight, heat-insulation and fire-proof castable has the characteristics of energy saving and environmental protection, and plays an important role in improving and protecting the environment. At the same time, all kinds of used raw materials can be purchased from markets, and the production costs of the lightweight heat-insulation and fire-proof castable are reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Compressor anti-knock noise reduction box convenient to mount

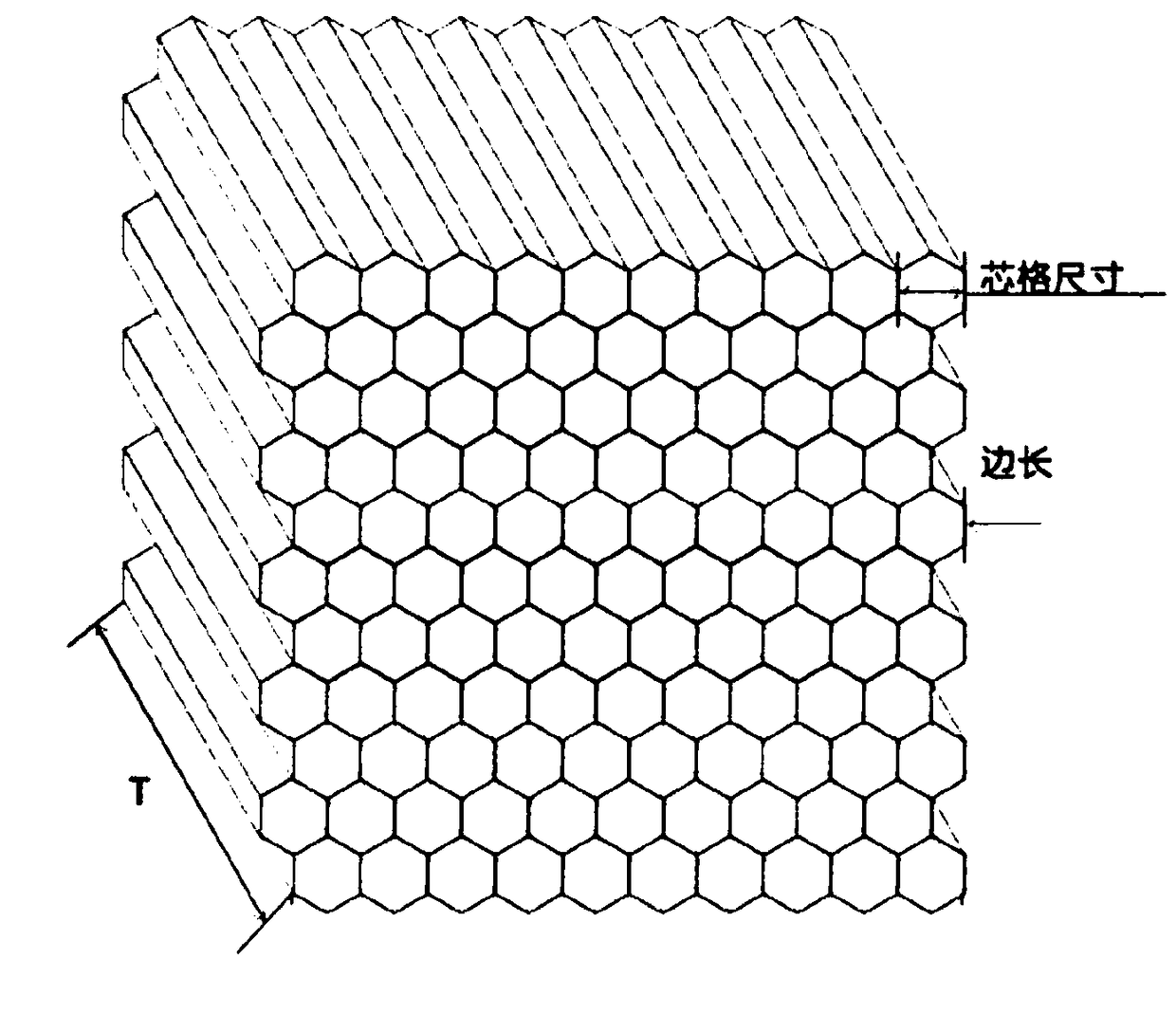

ActiveCN107939642AEasy to installImprove shock absorptionPositive displacement pump componentsPositive-displacement liquid enginesHoneycombEngineering

The invention discloses a compressor anti-knock noise reduction box convenient to mount. The box comprises a base and a sound-proof box. The upper end of the base is connected with the sound-proof boxthrough a flange, the lower portion of the sound-proof box is provided with a mounting block, the mounting block is connected with the base, a fixing block is arranged in the middle of the upper endof the base, the side face of the fixing block is connected with a fixing rod through a pin shaft, in the use process of the compressor anti-knock noise reduction box convenient to mount, the fixing rod can rotate around the pin shaft, an assembling rod is arranged and moves in a sliding groove in the fixing rod through a sliding block, through the adjusting structure, a compressor can be conveniently mounted, the assembling efficiency is improved, production time is saved, a ball base and balls are arranged, the fixing rod can more portably rotate, time and labor are saved, the sound-proof box formed through bonding of a sound-proof plate, an asbestos fiber layer, a sound absorbing cotton layer and a honeycomb sound absorbing core layer has the good sound insulation effect, and can reducethe noise, and a damping spring is arranged to have the good damping effect on the compressor.

Owner:BENGBU GAOKE ENERGY EQUIP

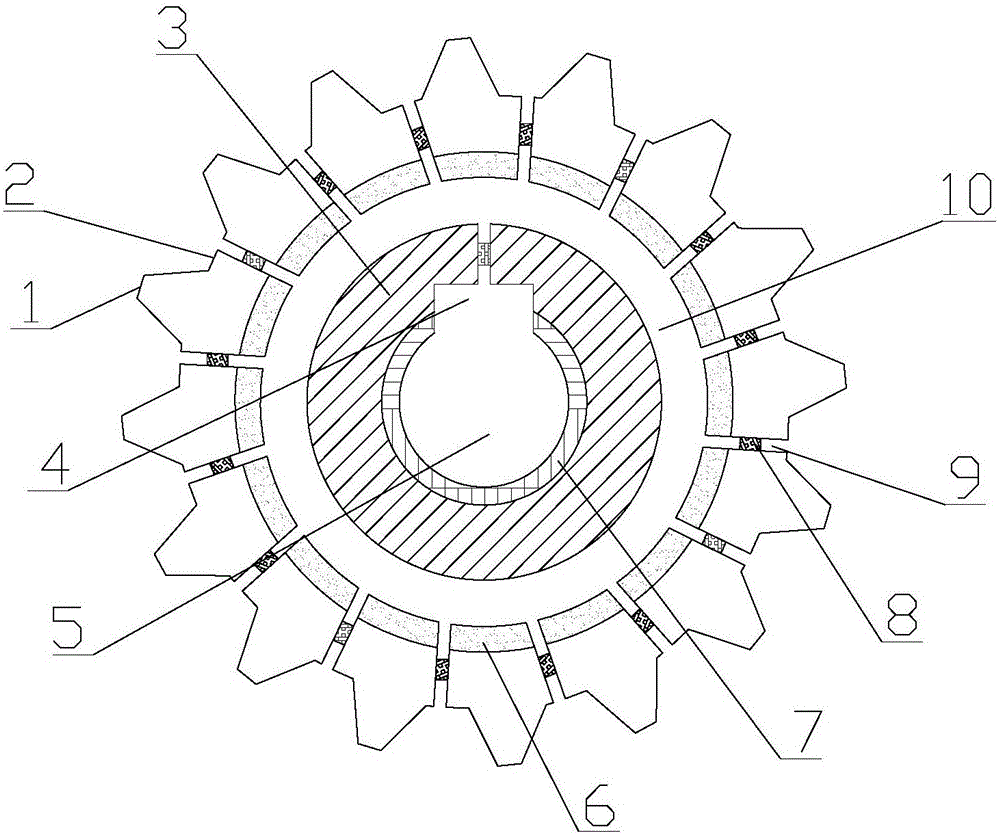

Noise elimination vibration reduction gear

InactiveCN105805273AReduced sound insulationExtended service lifeGear lubrication/coolingPortable liftingEngineeringCavity wall

The invention discloses a noise elimination vibration reduction gear which comprises a gear body, and further comprises an oil storage cavity, an elastic pressing piece and a foamed aluminium noise elimination layer, wherein teeth are arranged on the outer contour of the gear body; tooth grooves are formed between the adjacent teeth; a shaft hole is formed in the central position of the gear body; a keyway is formed in the inner wall of the shaft hole in the radial direction of the gear body; the oil storage cavity is formed inside the gear body; oil ducts are formed in the inner cavity wall of the oil storage cavity; the oil ducts are distributed on all the tooth grooves, and communicate with the upper surfaces of the tooth grooves; oil suction devices are arranged in the middle parts of the oil ducts; the elastic pressing piece is mounted around the inner wall of the shaft hole; and the foamed aluminium noise elimination layer is arranged on the inner wall of the oil storage cavity. According to the noise elimination vibration reduction gear, through the arranged elastic pressing piece, the oil ducts and the foamed aluminium noise elimination layer, when the gear runs, the elastic pressing piece reduces the friction of the shaft hole and a bearing, the oil ducts prevent the teeth from having dry friction, and the foamed aluminium noise elimination layer has a sound insulation effect.

Owner:蒙泽喜

Low-noise amorphous alloy transformer iron core

InactiveCN102938297AIsolation of noise transmission pathsReduced sound insulationTransformers/inductances noise dampingTransformers/inductances magnetic coresLow noiseAlloy

The invention discloses a low-noise amorphous alloy transformer iron core which comprises an inner side wrapping sheet, an outer side wrapping sheet, an amorphous alloy core and deadening felts. The amorphous alloy core is arranged between the inner side wrapping sheet and the outer side wrapping sheet, and the deadening felts are arranged on non-touch surfaces of the inner side wrapping sheet, the outer side wrapping sheet and the amorphous alloy core. The deadening felts are arranged on the inner side surface and the outer side surface of the amorphous alloy transformer iron core, so that noise transmission routes of the amorphous alloy iron core can be effectively isolated, and the low-noise amorphous alloy transformer iron core is simple in process, convenient to operate, low in cost and remarkable in noise reduction effect.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

Method for producing vacuum glass by using 3D (three dimensional) printing technology and use of vacuum glass

InactiveCN106673461AProne to frost and condensationAvoid internal condensationAdditive manufacturing apparatusInfraredFlat glass

The invention discloses a method for producing vacuum glass by using a 3D (three dimensional) printing technology. The method comprises the following steps: placing two pieces of flat glass with a same size into a toughening furnace to be toughened or placing into a bending toughening furnace to be bent and toughened, and obtaining flat or curved toughened glass; (2) arranging supports in a dot matrix arrayed manner on the surface of one piece of the toughened glass by using the 3D printing technology; (3) placing the other piece of the toughened glass onto the supports and aligning the toughened glass with the toughened glass with the supports in step (2); (4) pouring an edge-sealing material to the periphery of a gap between the two pieces of toughened glass, rapidly heating and curing the edge-sealing material, and encapsulating edge portions of the two pieces of toughened glass; and (5) extracting air between the two pieces of toughened glass by virtue of extractor vents to form a vacuum cavity between the two pieces of toughened glass, rapidly sealing the extractor vents by virtue of infrared heating or laser radiation, and completing the preparation of the vacuum glass. The displacement of the supports in a subsequent processing process is avoided; the requirement on the temperature resistant performance of the material is reduced; and the noise is reduced.

Owner:QINGDAO HENGDA GLASS TECH

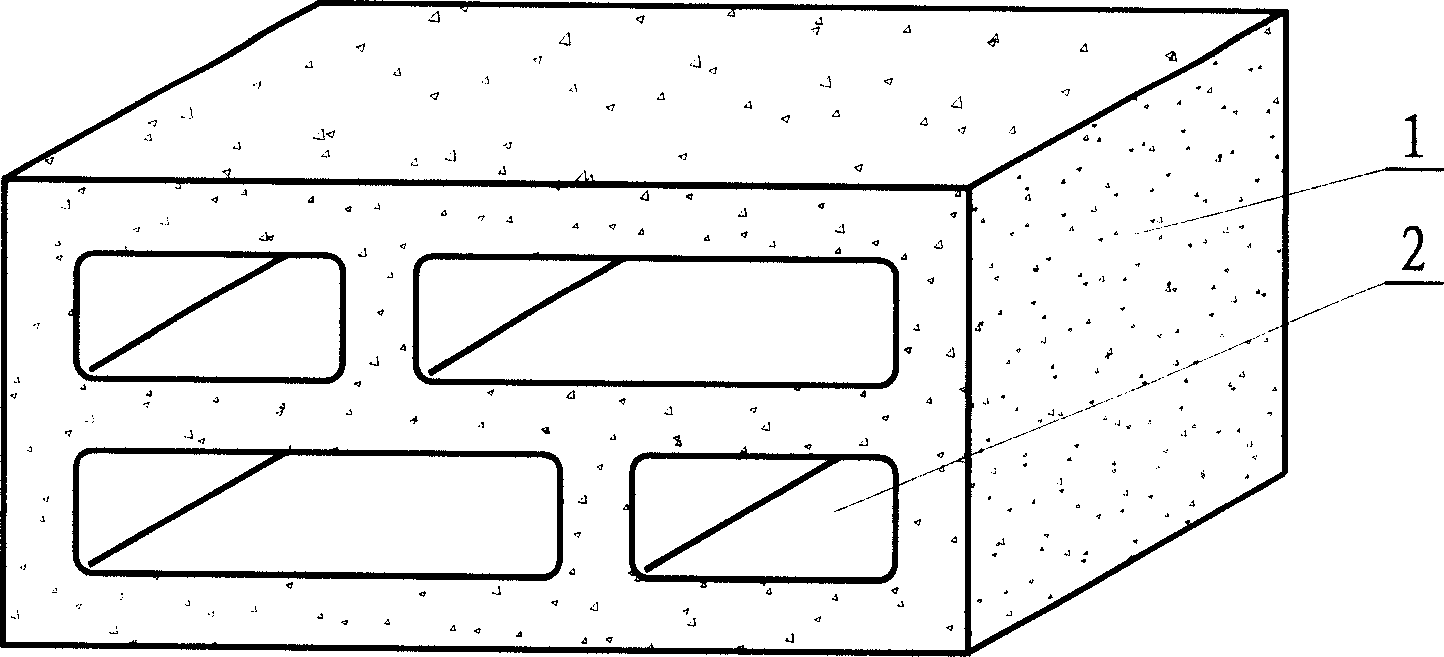

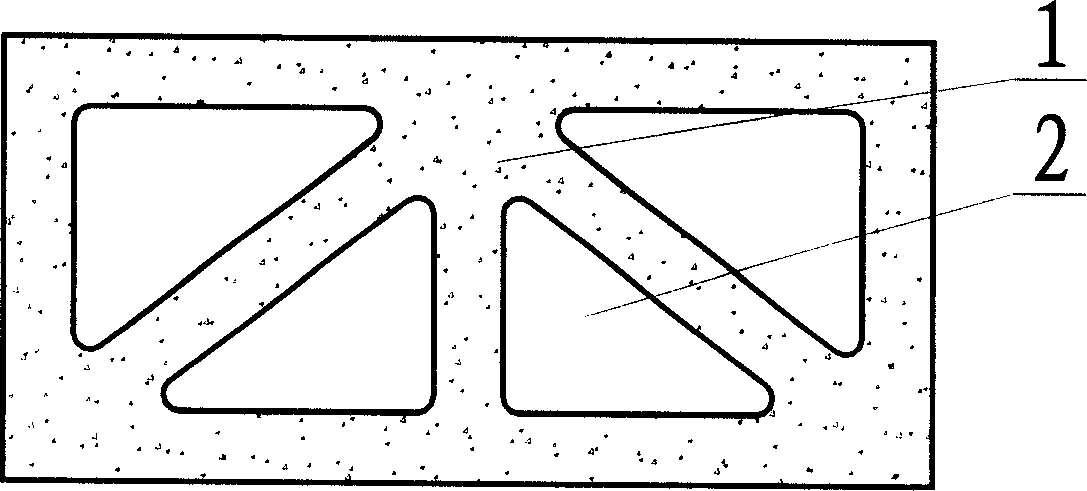

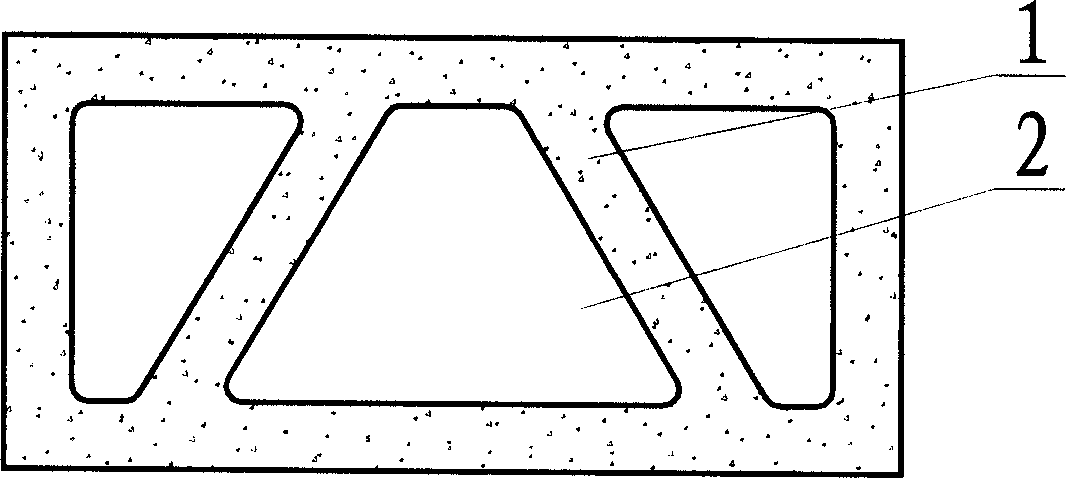

Light aggregate concrete sandwich thermal insulated block, and its production method

InactiveCN1851192ARealize energy savingAchieve noiseConstruction materialCeramic shaping apparatusPolystyreneMaterials science

The invention relates to a light aggregate concrete sandwich heat- insulation block and the producing method thereof, providing a novel heat-insulation wall building material, and it is made by four procedures of modifying mould, batching and blending, prefabricating hollow block, and filling in polystyrene foam material, and the making method is simple, and low-cost, and the product quality is stable. And it is used to replace traditional concrete hollow block and has effects of heat insulation and sound isolation and environmental protection, making a building wall have heat-insulation, energy-saving, and noise-reducing effects, and it is lightweight and more convenient and quick to construct.

Owner:姚建国

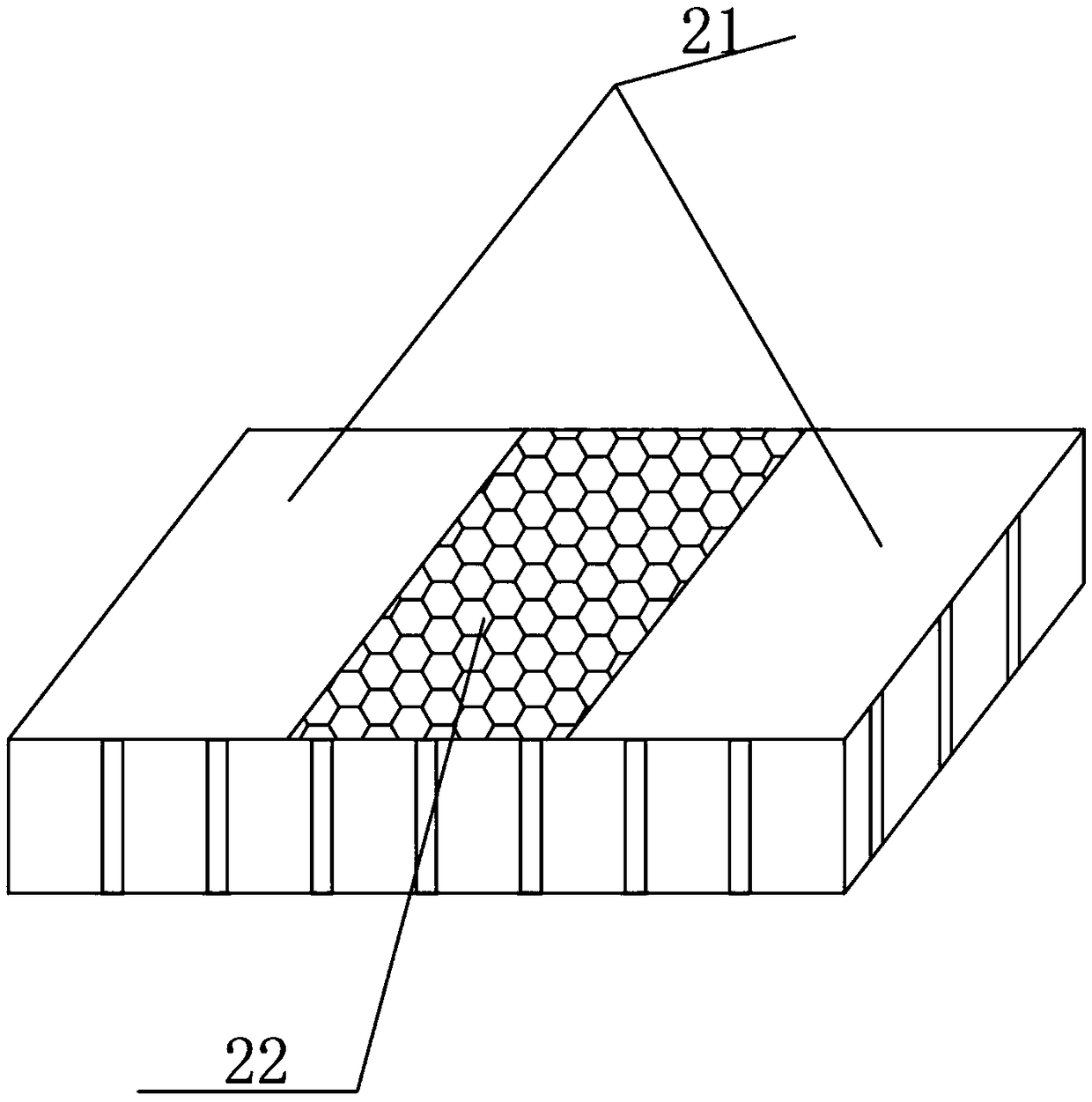

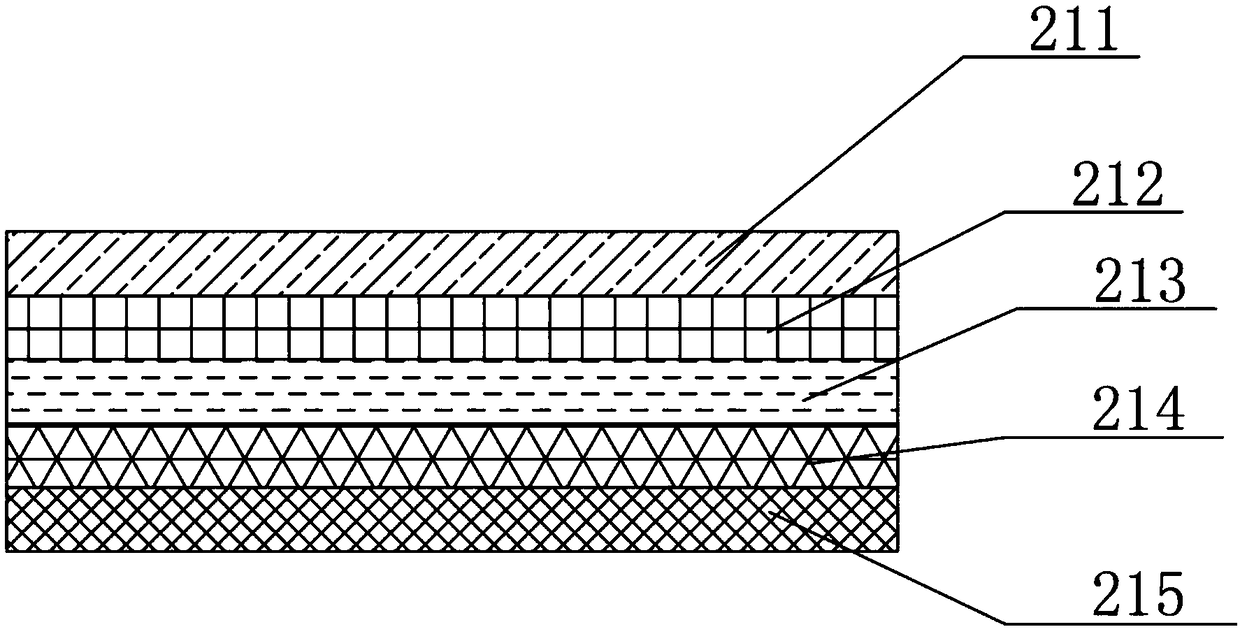

Composite material for high-speed railway top board

ActiveCN109016732AImprove safety and comfortImprove impact resistanceRailway roofsSynthetic resin layered productsHoneycombUltimate tensile strength

The invention discloses a composite material for a high-speed railway top board. The composite material comprises an outer aluminum plate, a reinforced composite material and an inner aluminum plate,wherein the reinforced composite material is arranged between the outer aluminum plate and the inner aluminum plate, the reinforced composite material includes a surface reinforcing material and a core material, the surface reinforcing material includes a sound-insulating flame-retardant layer, a prepreg layer, an impact-resistant layer, a strength layer, and a rigid structural layer, and the corematerial is a honeycomb core material. The structural design of the material is reasonable, and the selected novel reinforced composite material not only reduces the weight of a vehicle body, reducesenergy consumption, increases the impact resistance and sound insulation and flame retardant performance of the high-speed railway top board, and enhances the safety and comfort performance of a high-speed railway.

Owner:山东甲子湖畔新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com