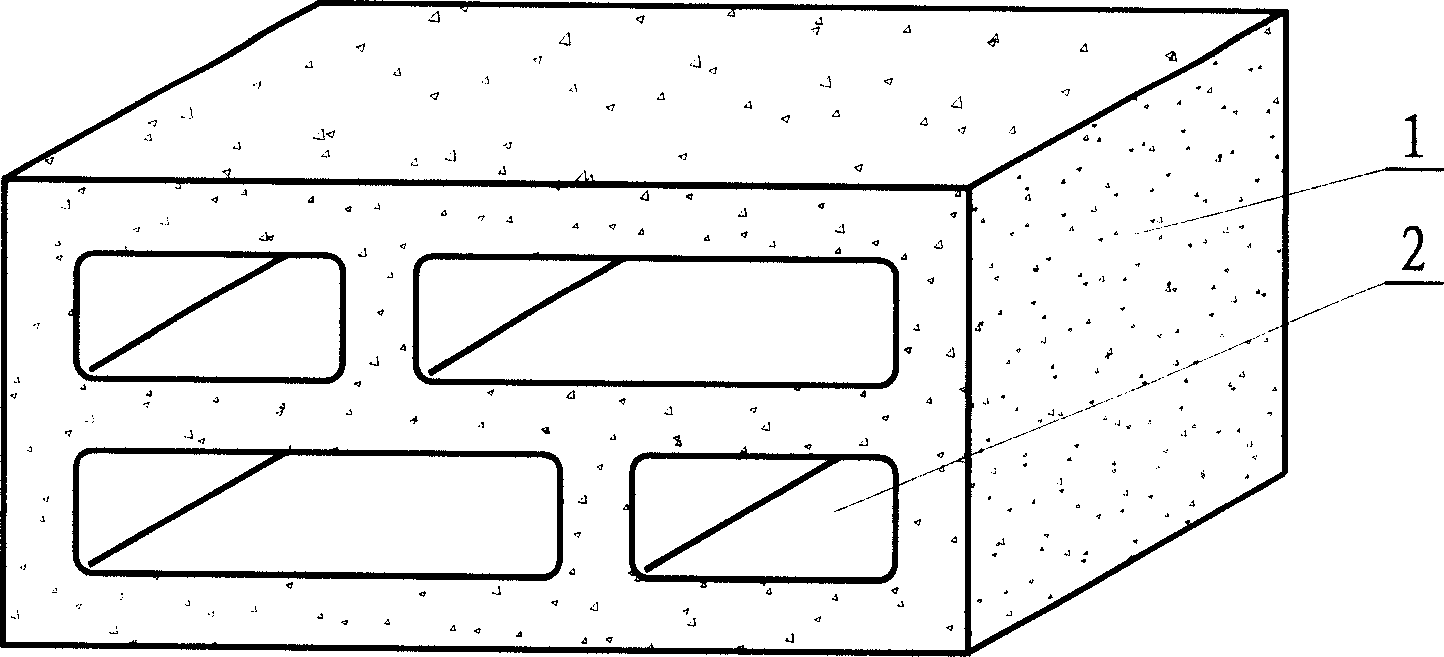

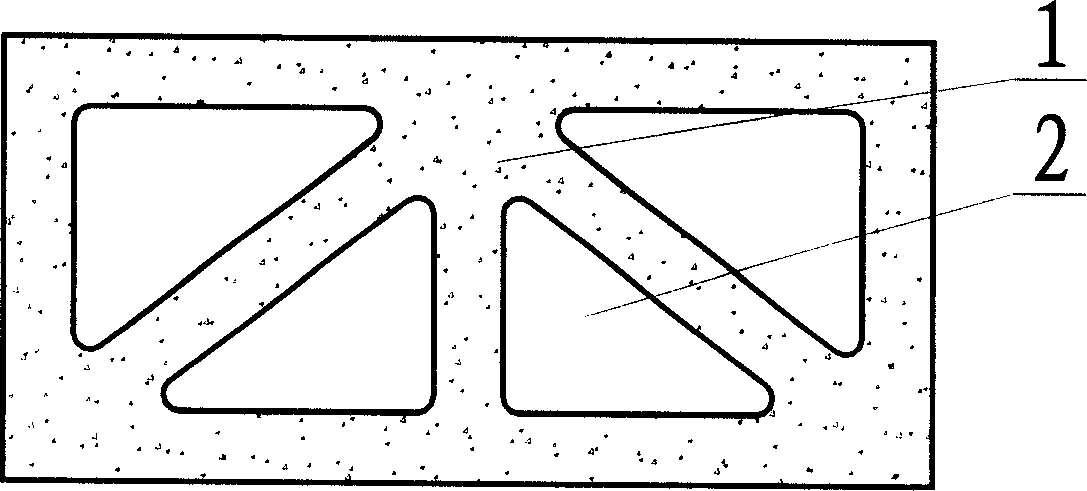

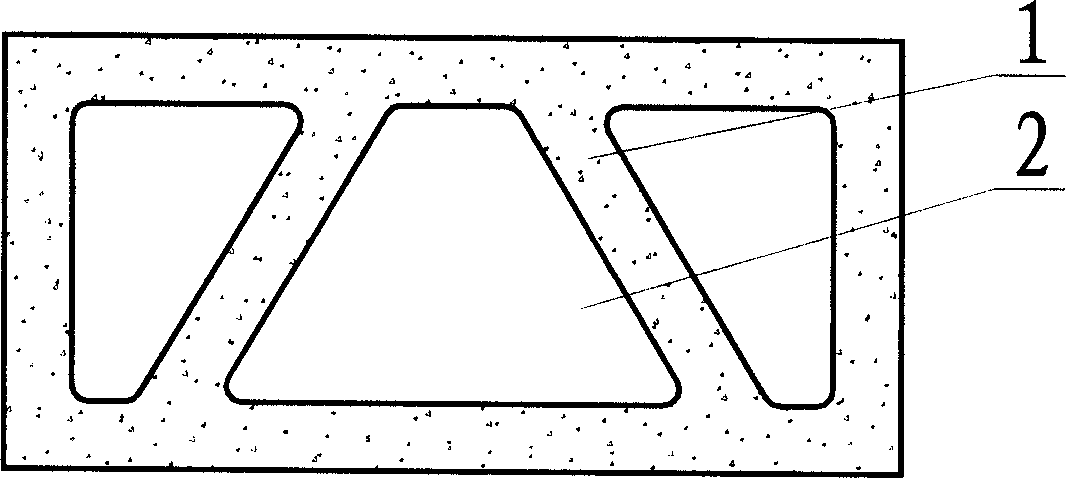

Light hollow block with polystyrene particle and production thereof

A technology of polystyrene particles and hollow blocks, which is used in the manufacture of tools, ceramic products, other household appliances, etc., can solve the problems of complex composition and structure, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the polystyrene particle lightweight hollow block of the present invention is combined with Example 1 in Table 1. The preparation method is:

[0042] Step A: Add 200Kg of bluestone powder (about 40%), 250Kg (about 50%) of fly ash and 50Kg (about 10%) of cement into the mixer, add 10Kg of water to mix ingredients and start mixing. Then, 0.7 Kg (about 0.14%) of polystyrene particles were added. Continue to stir evenly;

[0043] Step B: The uniformly mixed materials are added to the hollow block primary forming machine, and the block mold is pressurized to form after being uniformed by vibration;

[0044] Step C: The formed lightweight hollow block of polystyrene particles is sent to the drying site, and after two days, it is naturally dried to make a finished product.

[0045] If steel slag and / or sand are to be added to the ingredients, the particle diameter of the steel slag or sand should be between 4 and 5 mm. If the particle size requirements ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com