Patents

Literature

845 results about "Light rail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

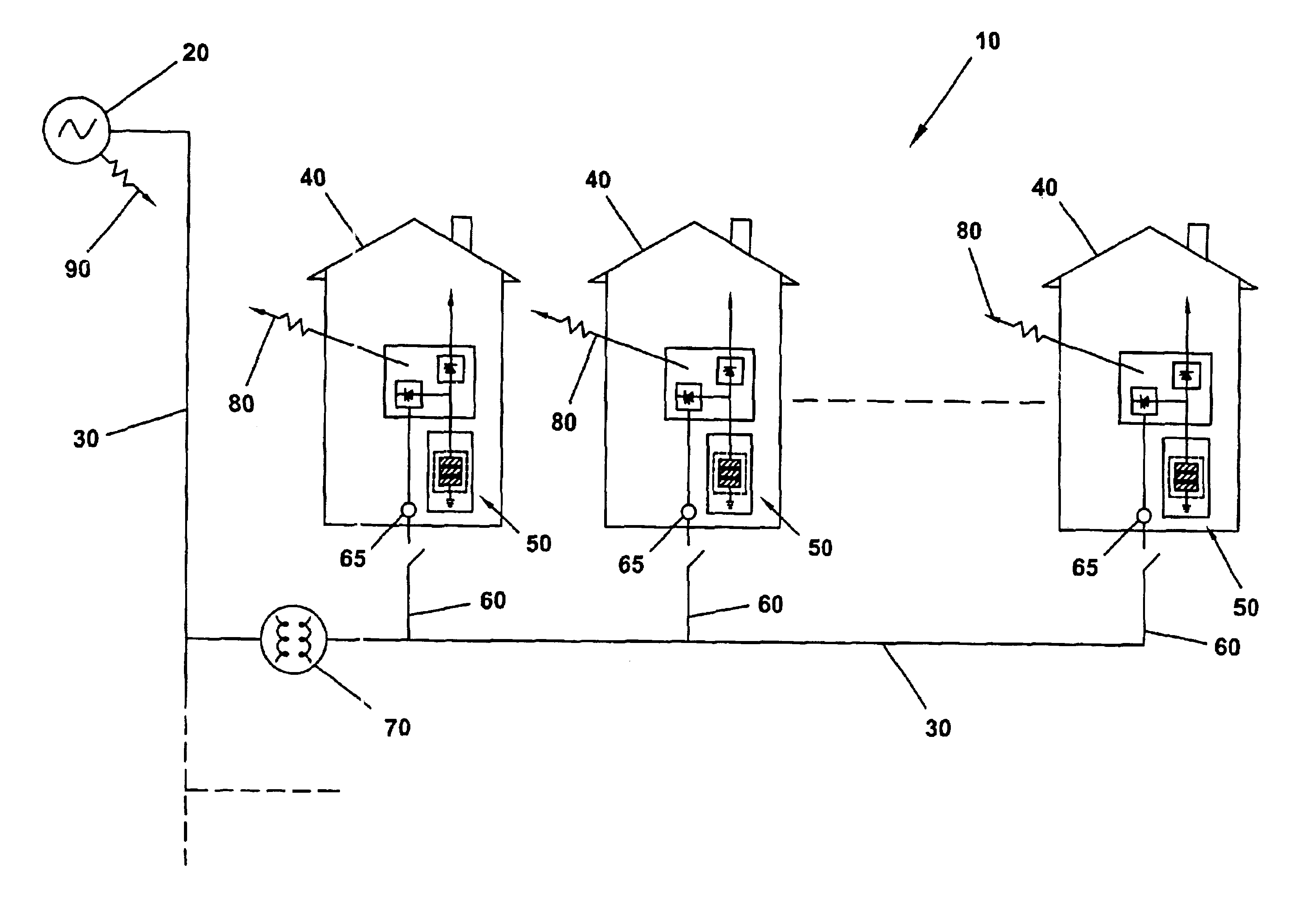

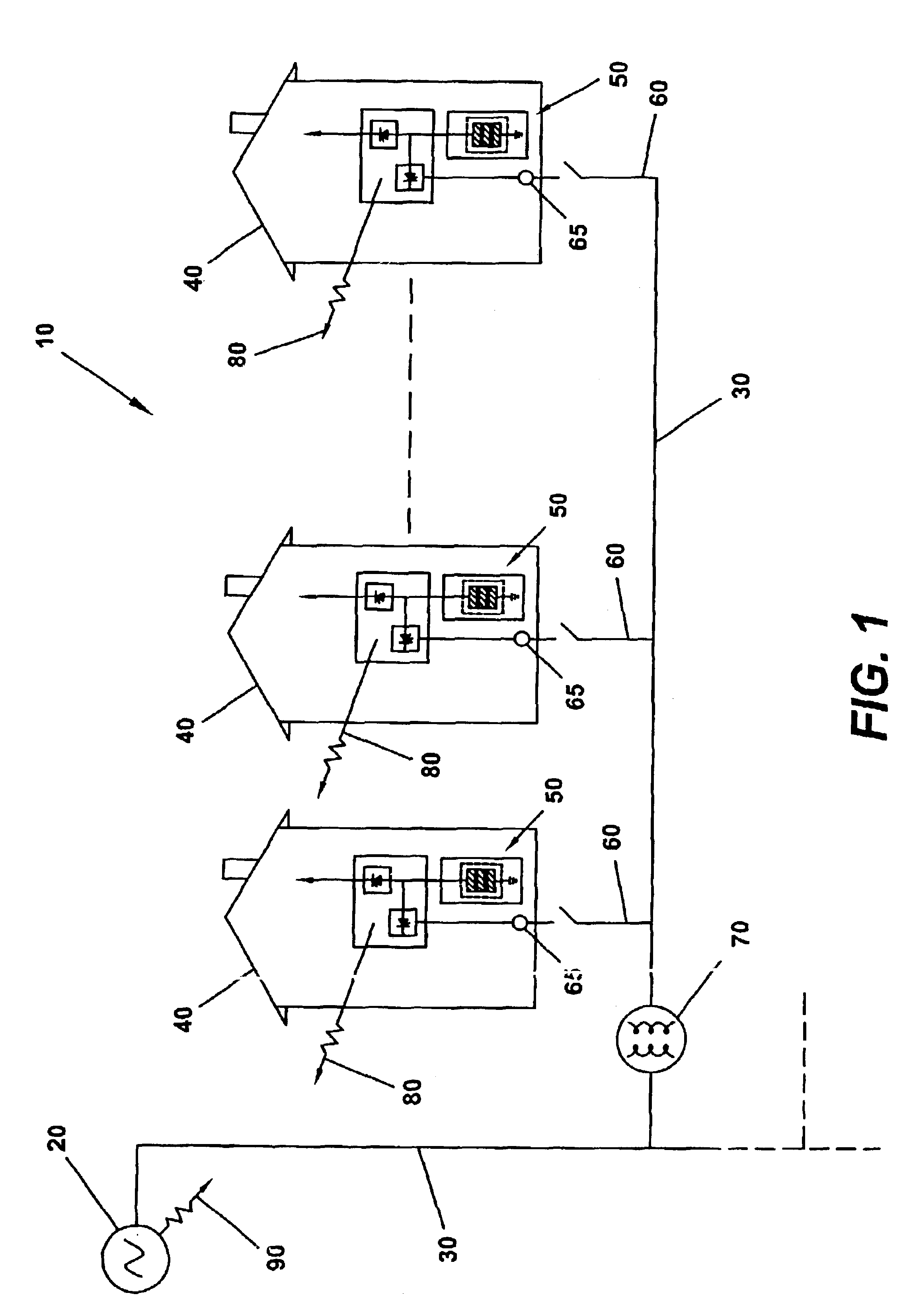

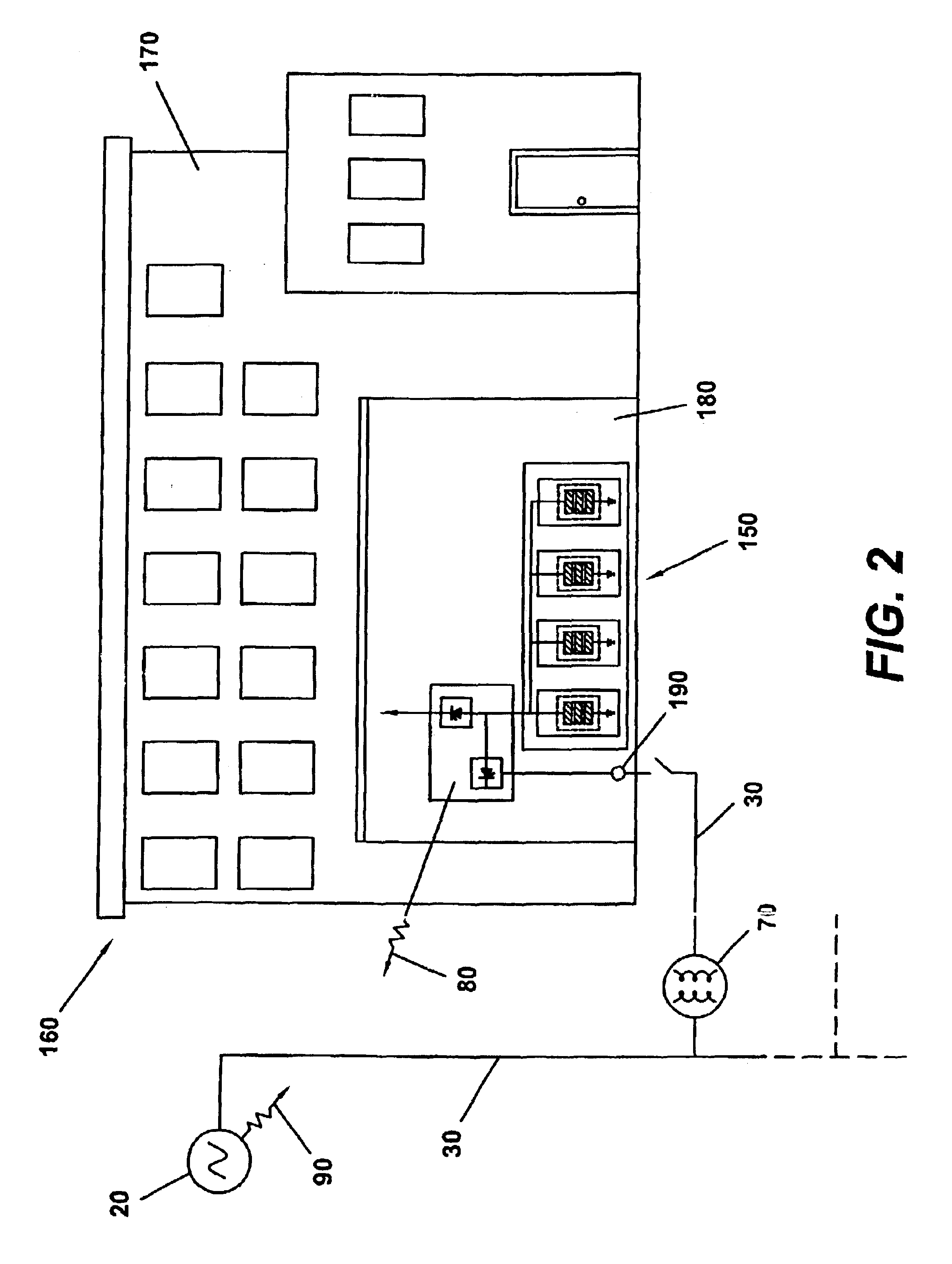

Power load-leveling system and packet electrical storage

InactiveUS6900556B2Reduce and even eliminate anomalyLong-term powerBatteries circuit arrangementsElectric devicesLow demandThermal energy storage

A large-scale, capacitor-based electrical energy storage and distribution system capable of effectuating load-leveling during periods of peak demand on a utility, and of effectuating a cost savings associated with the purchase of electrical energy. A capacitor or multitude of capacitors may be charged with electrical energy produced by the utility, such as during periods of low demand or low cost, and discharged during periods of high electrical energy consumption or high electrical energy cost. One or more capacitors may be located at a consumer's residence or business. Alternatively, a farm of capacitors may be provided at or near a utility, or at or near a location experiencing high demand. In another embodiment, one or more capacitors may be located in or on a vehicle, such as an automobile, a truck, or a train of a light rail system.

Owner:AMERICAN ELECTRIC POWER CO INC

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

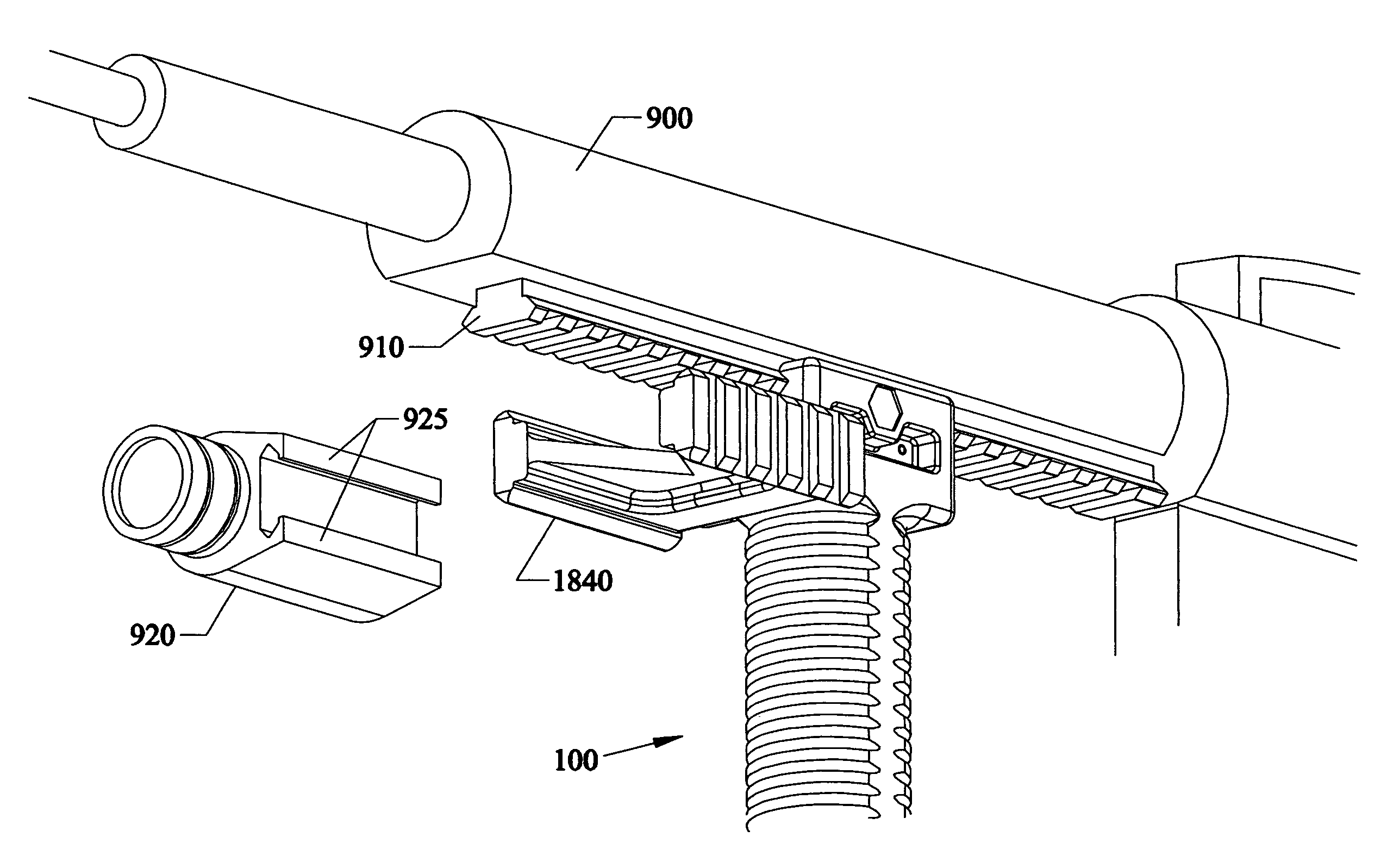

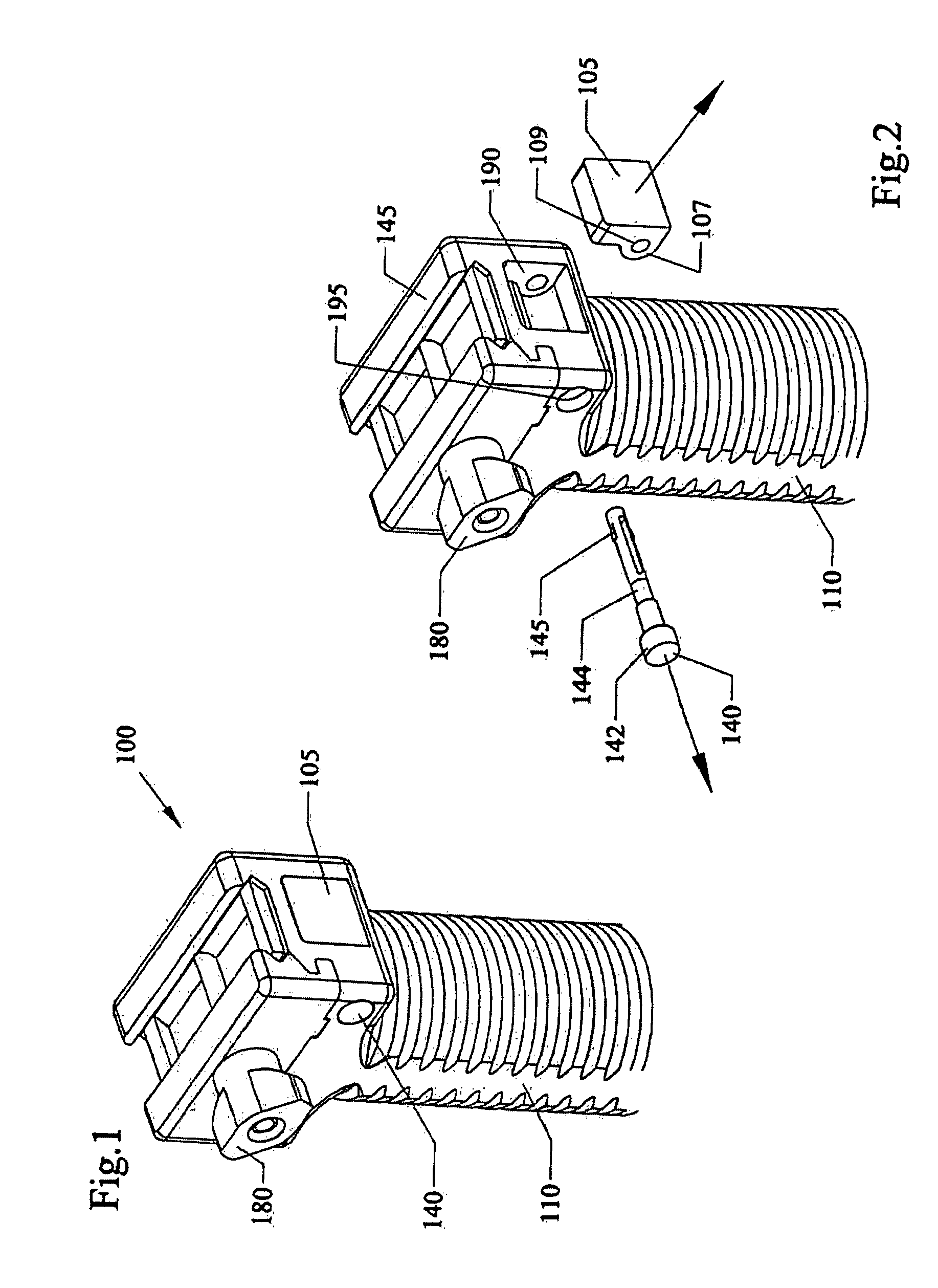

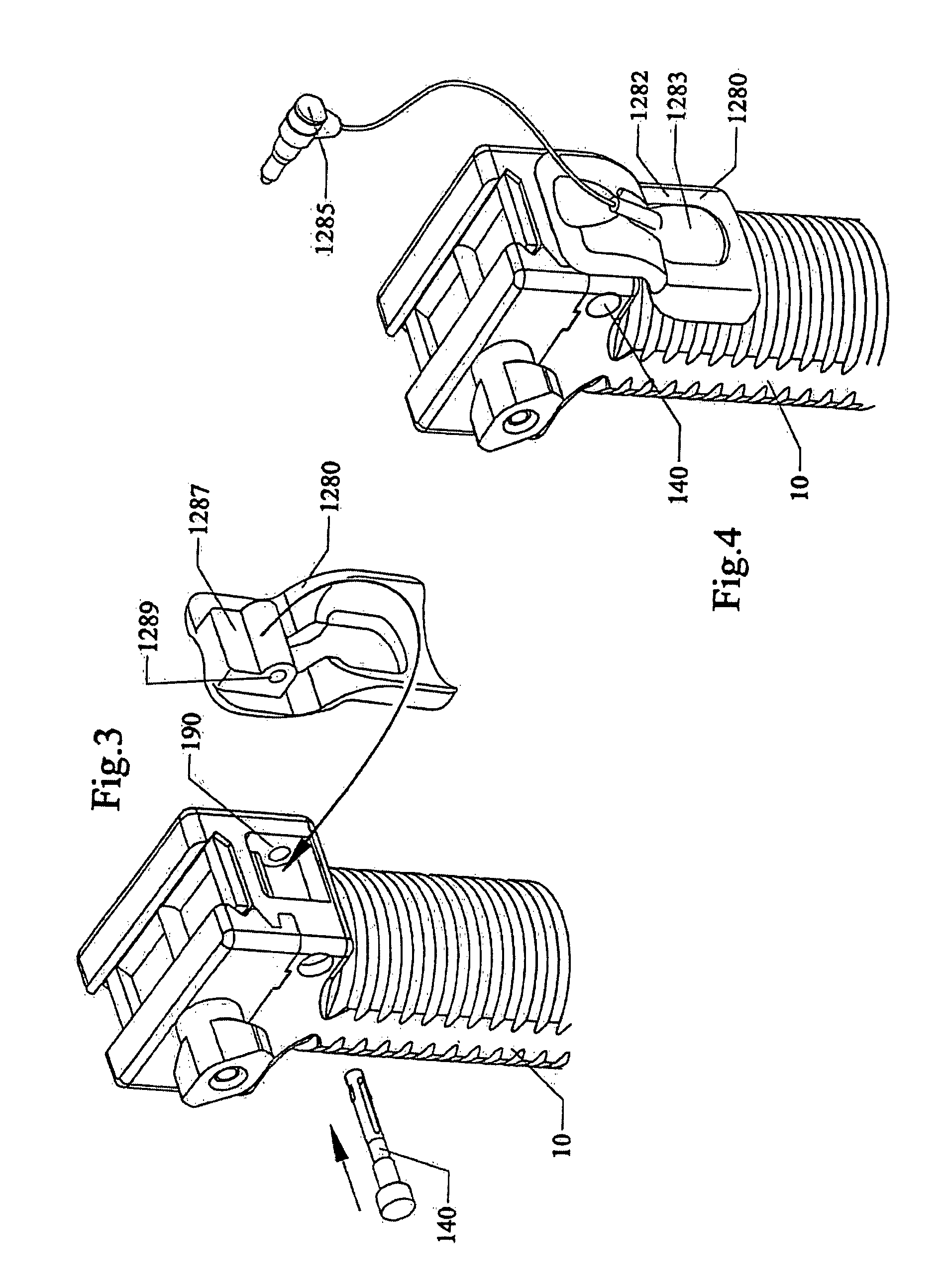

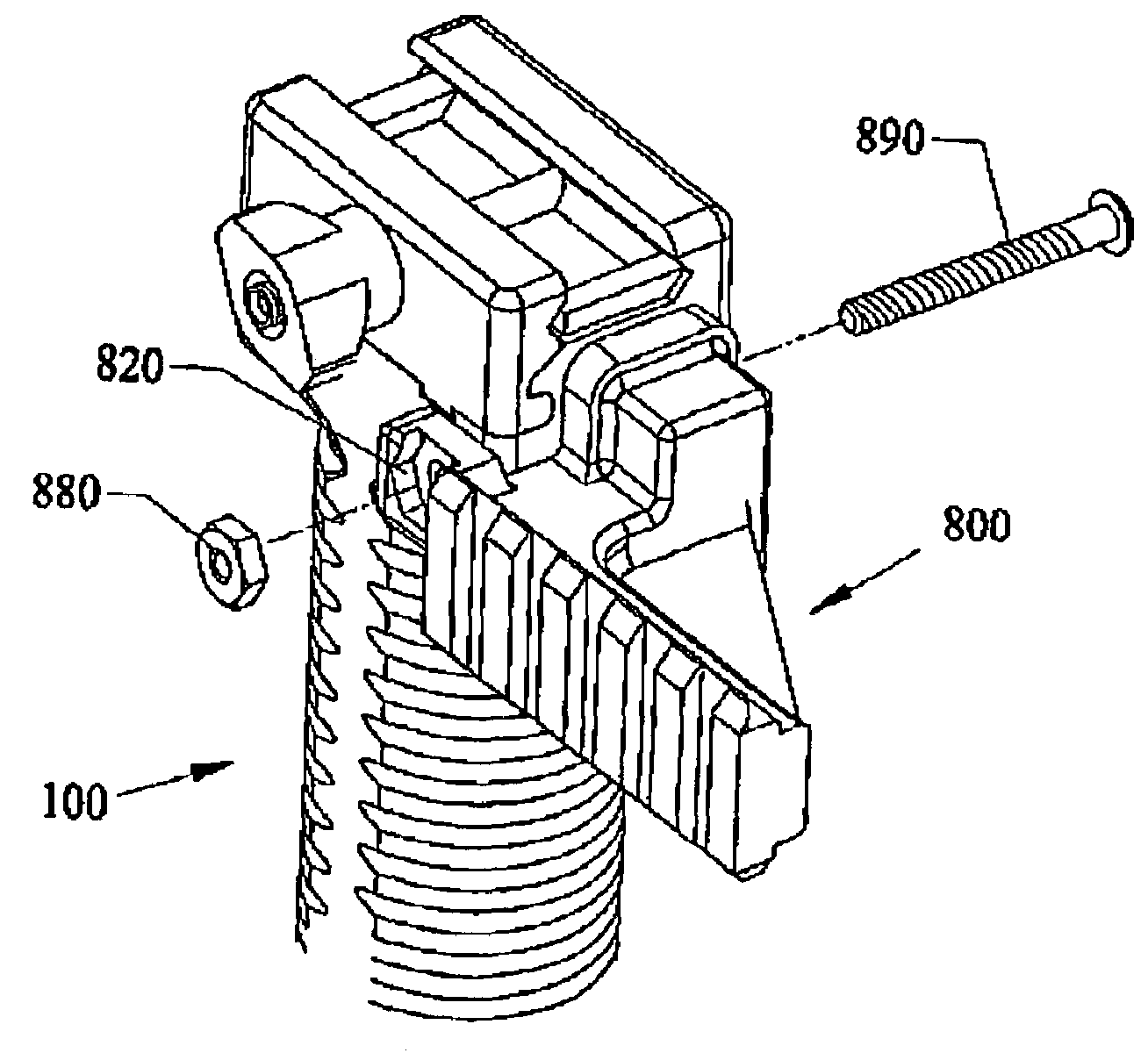

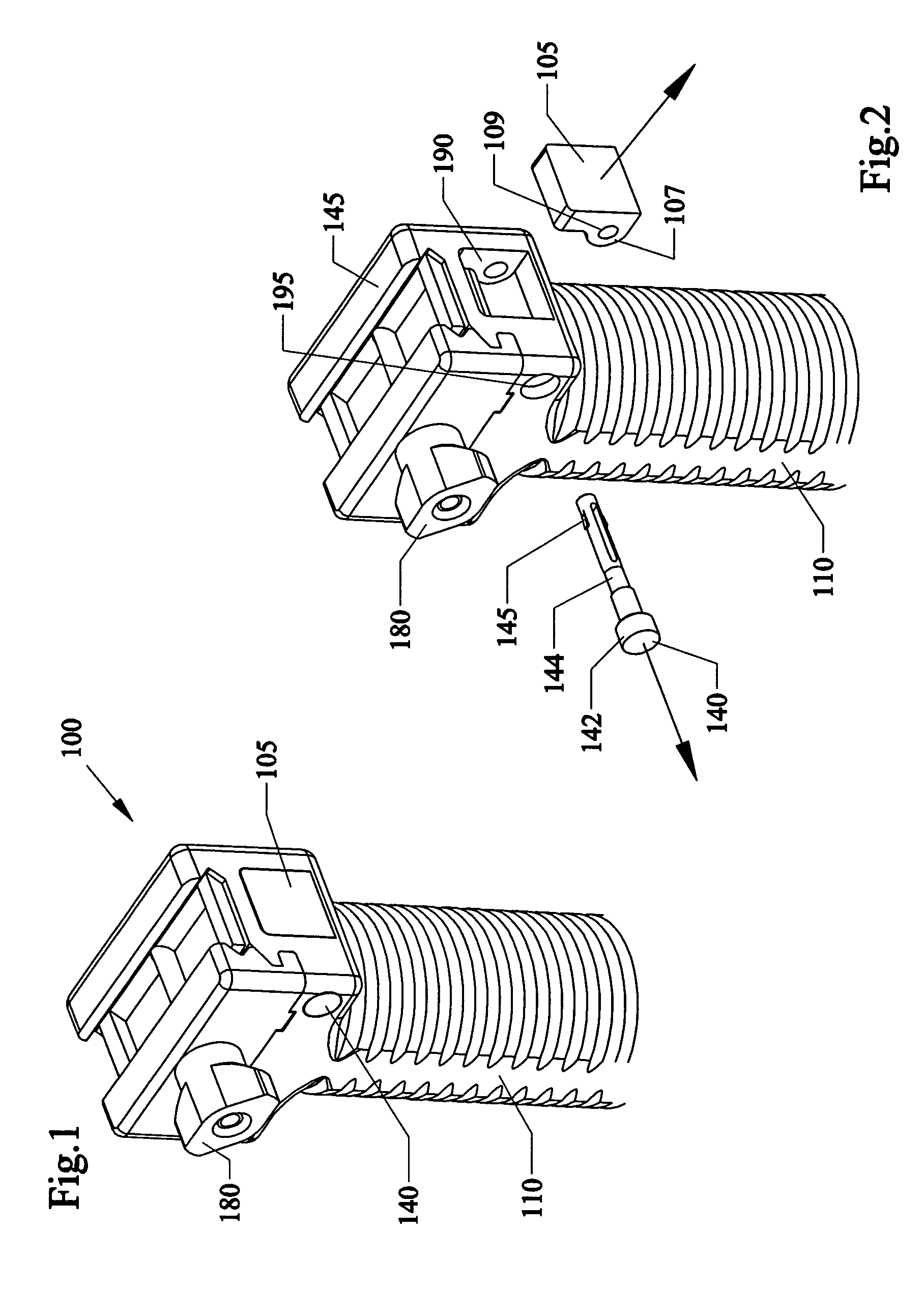

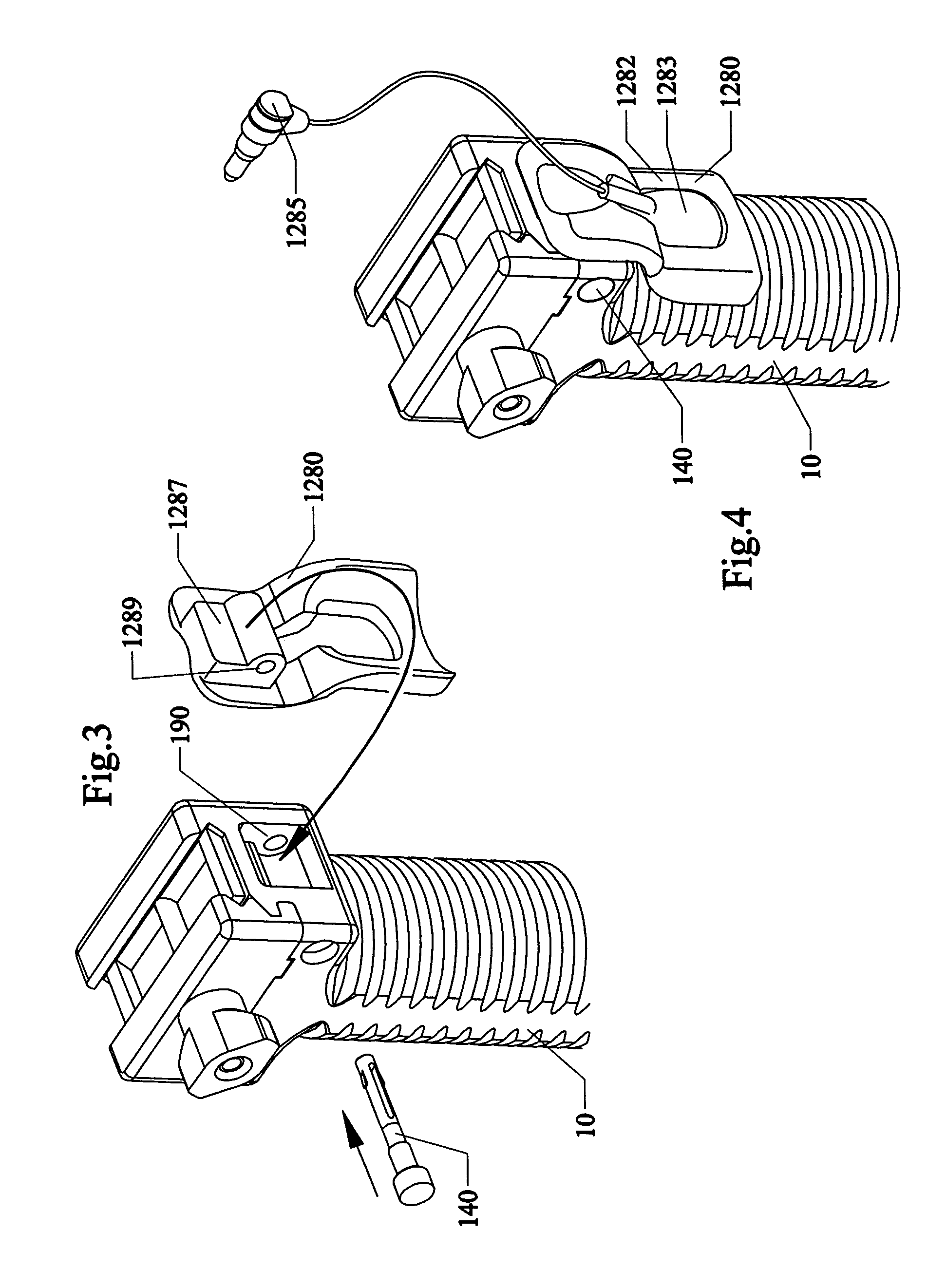

Dual light rails and accessory rail mounts for vertical foregrips

InactiveUS7559167B1Simple bolt attachmentSelf containedSighting devicesAmmunition loadingLight railEngineering

Devices, and methods of attaching accessory mounts to vertical fore grip handles on firearms, such as rifles. The accessory mounts can be molded to extend off of the handles. The accessory mounts can attach to the handles by interlocking plugs and slots. The accessory mount can have rails so that an accessory can attach to the rails on the accessory mount. The rails can be located on a left side of the mount for allowing accessories to be mounted to the left of the fore grip handle. The rails can be located on a right side of the mount for allowing accessories to be mounted to a right side of the fore grip handle. The rails can be located on both sides of the mount so that accessories can be mounted on both the right and left sides of the fore grip handle. The accessory can include lights, lasers, bayonets, sights, scopes, and the like. The vertical fore grip can be an elongated handle fixed to the firearm. The vertical fore grip can be an elongated handle that is detachable from beneath rails on the firearm. The vertical fore grip can include expandable bipod legs.

Owner:GRIP POD SYST INT

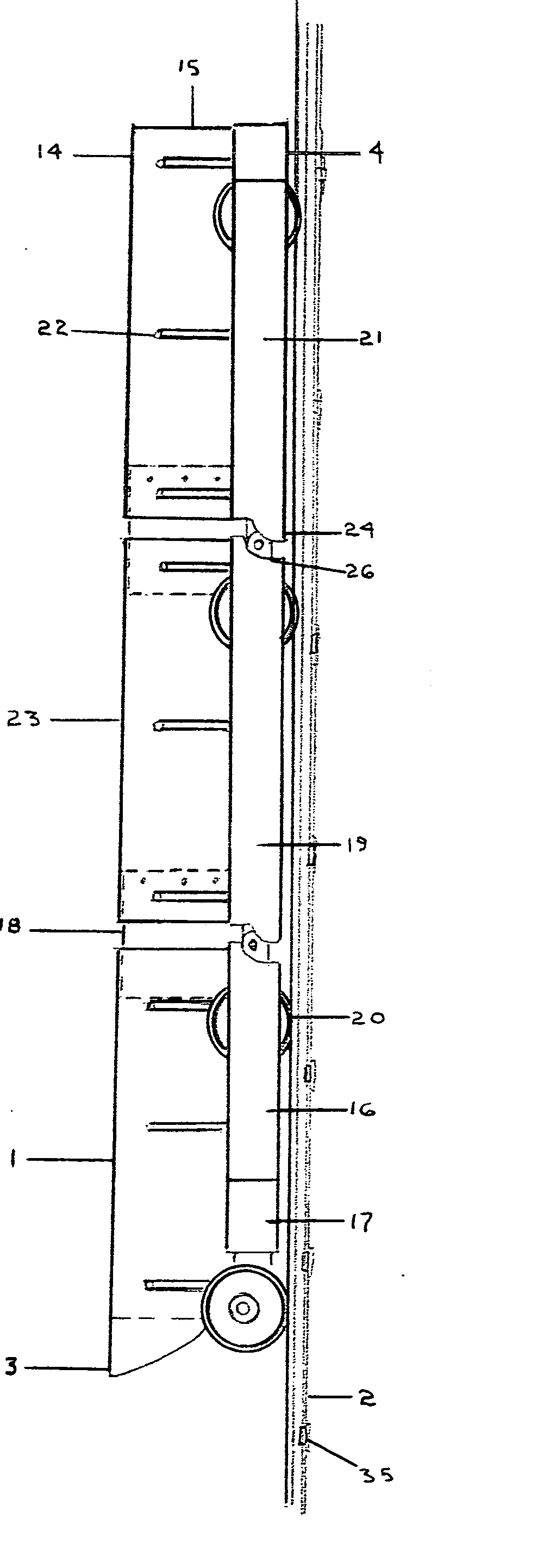

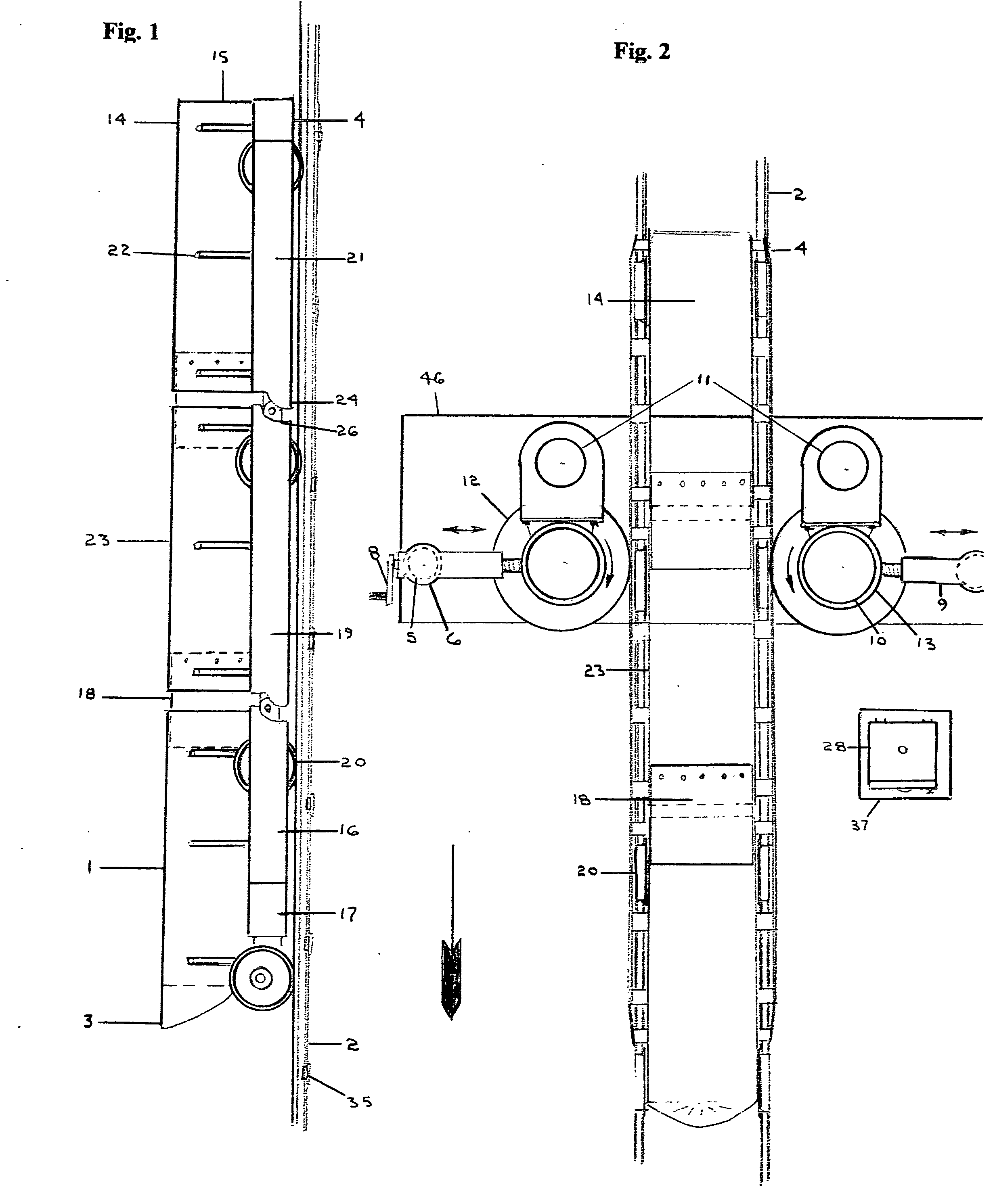

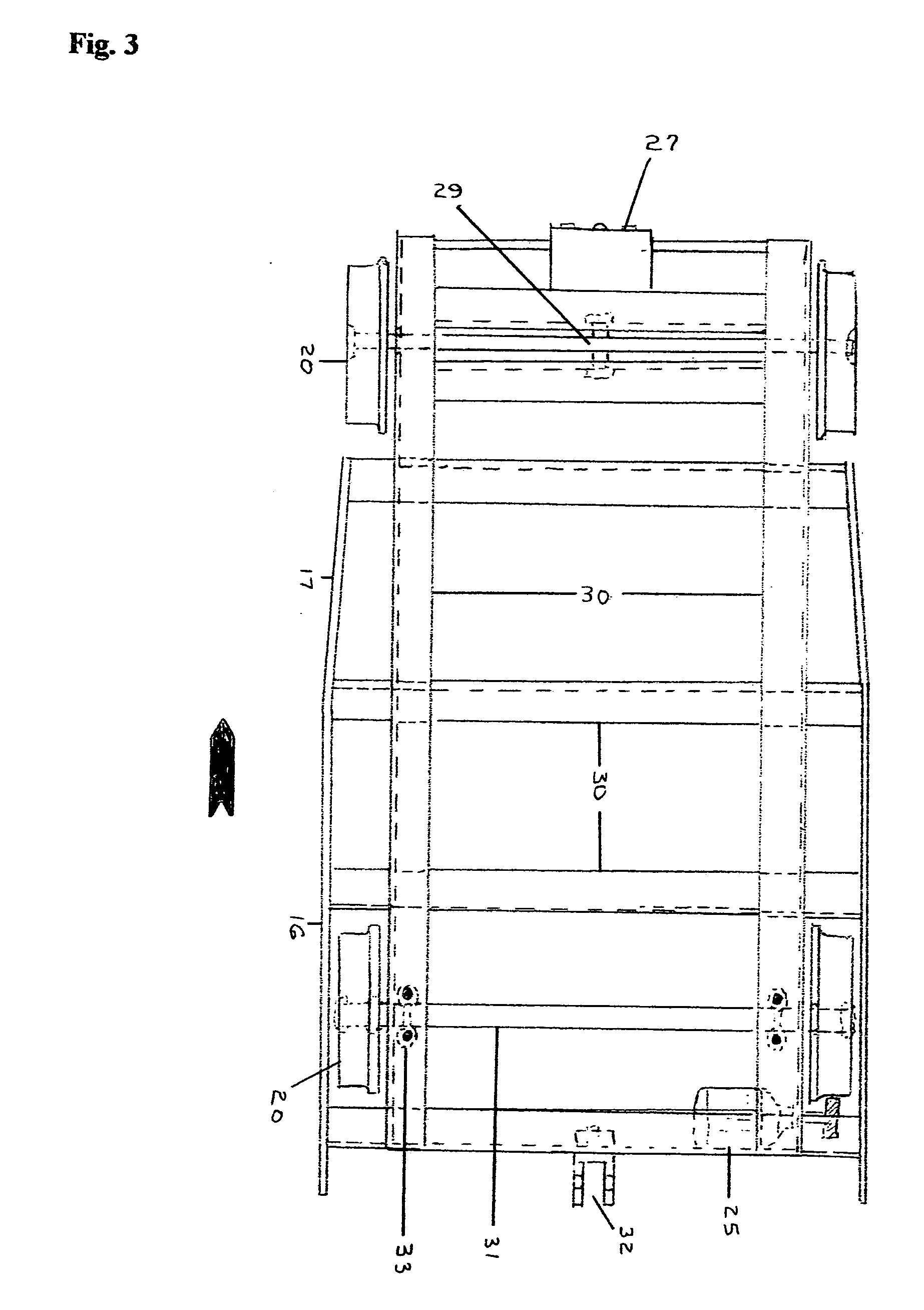

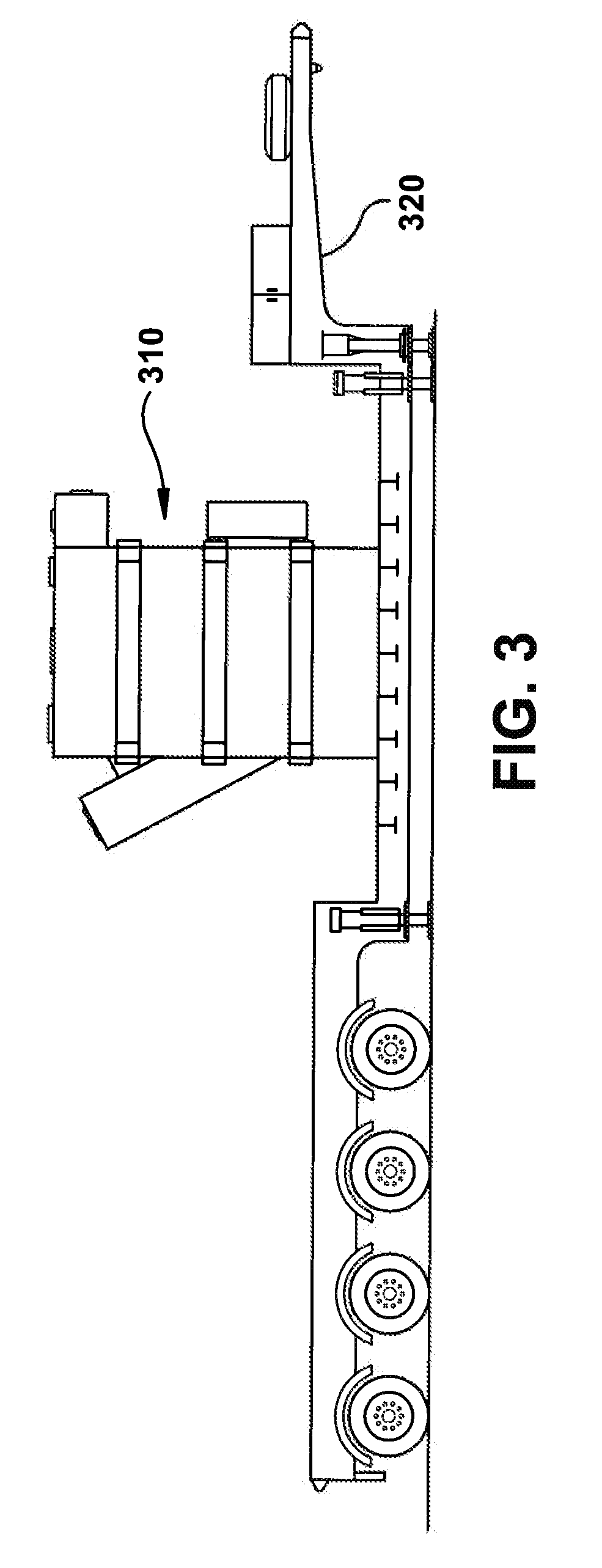

Light rail transport system for bulk materials

InactiveUS20060162608A1Reduce needSmoother rotational transitionRailway tracksRope railwaysTransport systemTransit system

A non-powered, light rail unit train (referred to as Rail-Veyor by the inventor) combination for the transport of bulk materials consisting of a plurality of connected cars open at each end except for the first and last cars, which have end plates. The train forms a long open semi-circular trough and has a flexible flap attached near the front of each car, overlapping the gap between car in front to prevent spillage during operation while allowing articulated movement of the train during transport. The lead car has four flanged wheels and tapered side drive plates at the front of the car for smooth entry into the systems stationary drive stations. The cars that follow each have parallel drive plates on either side of the car that are outside the two flanged wheels that are approximately the same width as the flexible drive tire. Each car has a clevis type hitch at the front and rear with the front clevis hitch connecting to the rear clevis hitch of the car immediately forward. Forward motion is provided by a series of appropriately placed fixed drive stations consisting of drive motors, gear reducers and horizontal flexible drive tires located on either side of the track which can be adjusted to provide sufficient friction on the aforementioned drive plates to transform rotational tire motion to horizontal thrust of the entire train. The motors at each drive station are controlled by use of an A / C inverter and controller whereby said motors are synchronized and both the voltage and frequency can be modified as needed to provide and adjust system operating needs. The flanged wheels are symmetrical to the side drive plates allowing operation in an inverted position which, when four rails are used to encapsulate the wheel outside loop discharge of the bulk material is possible. By using elevated rails, the train can operate in the inverted position as easily as in the convention manner.

Owner:DIBBLE MERTON F

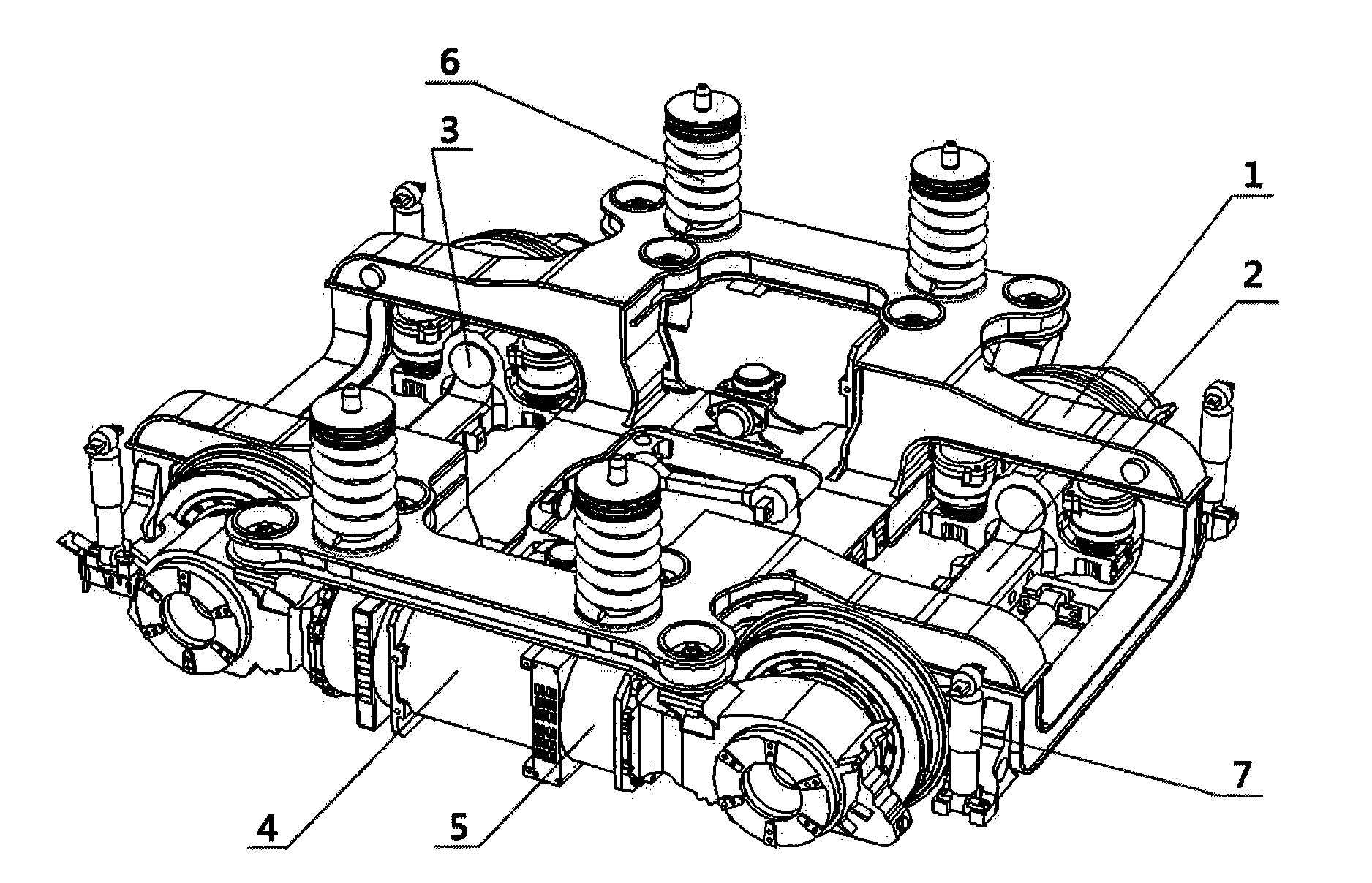

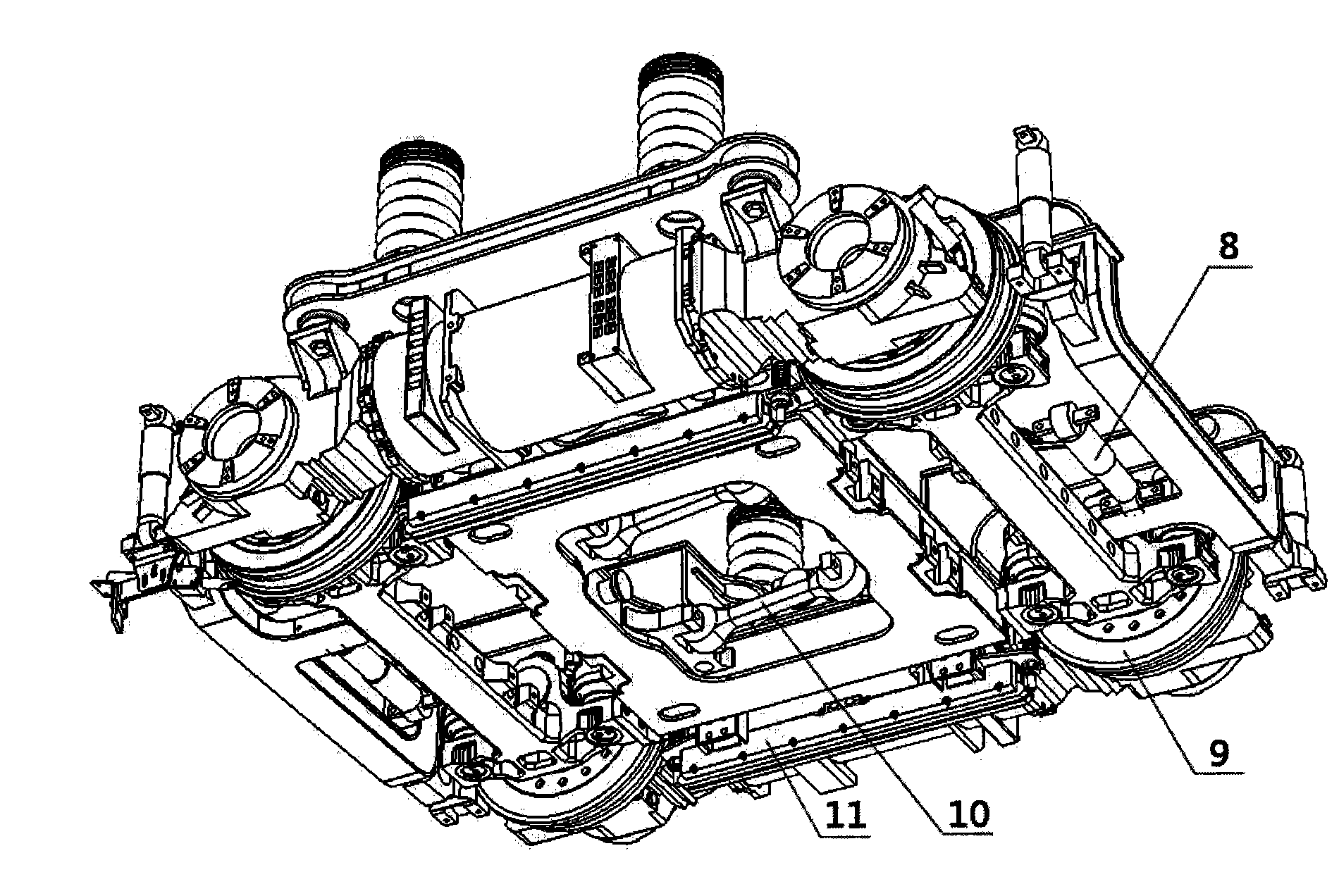

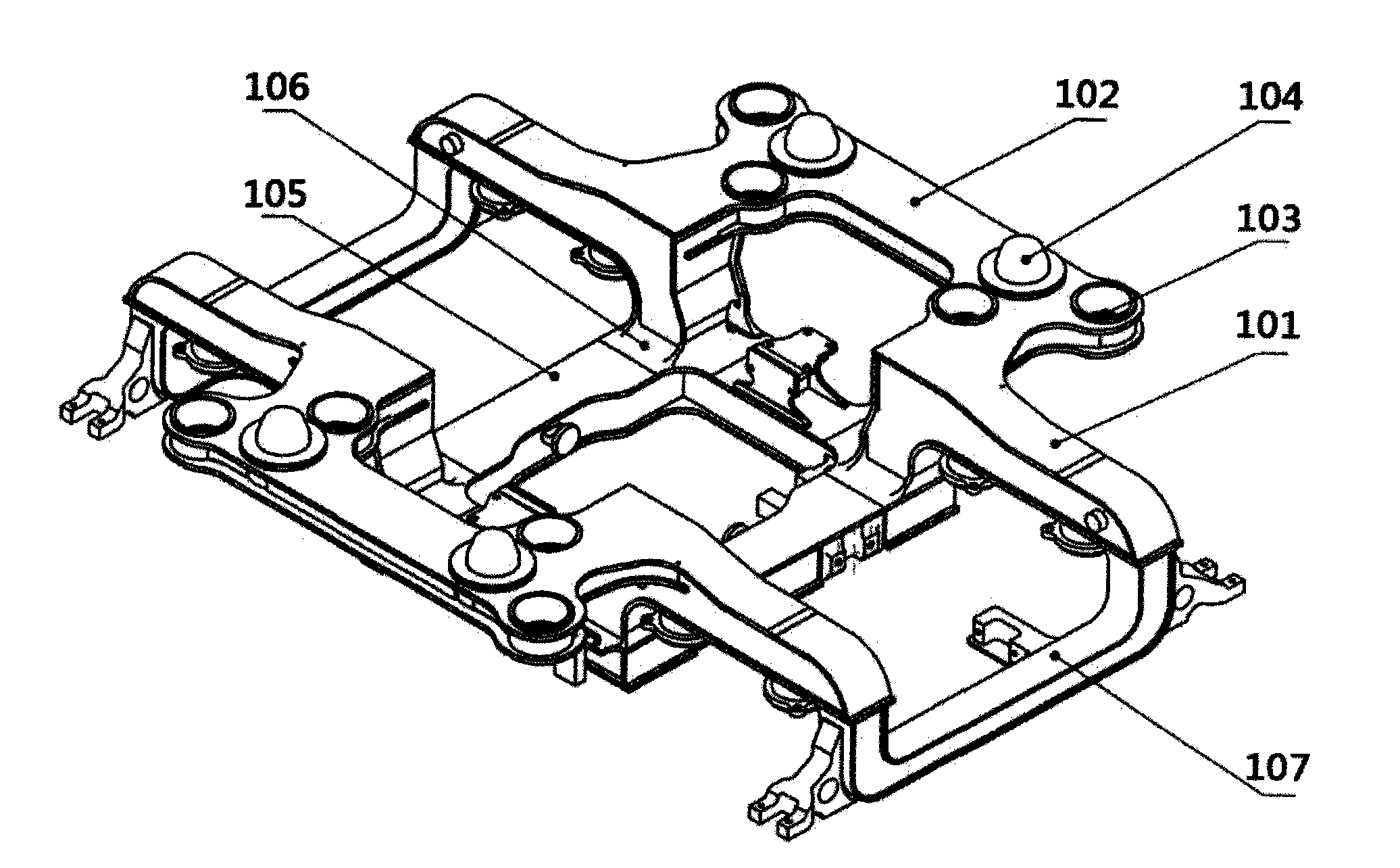

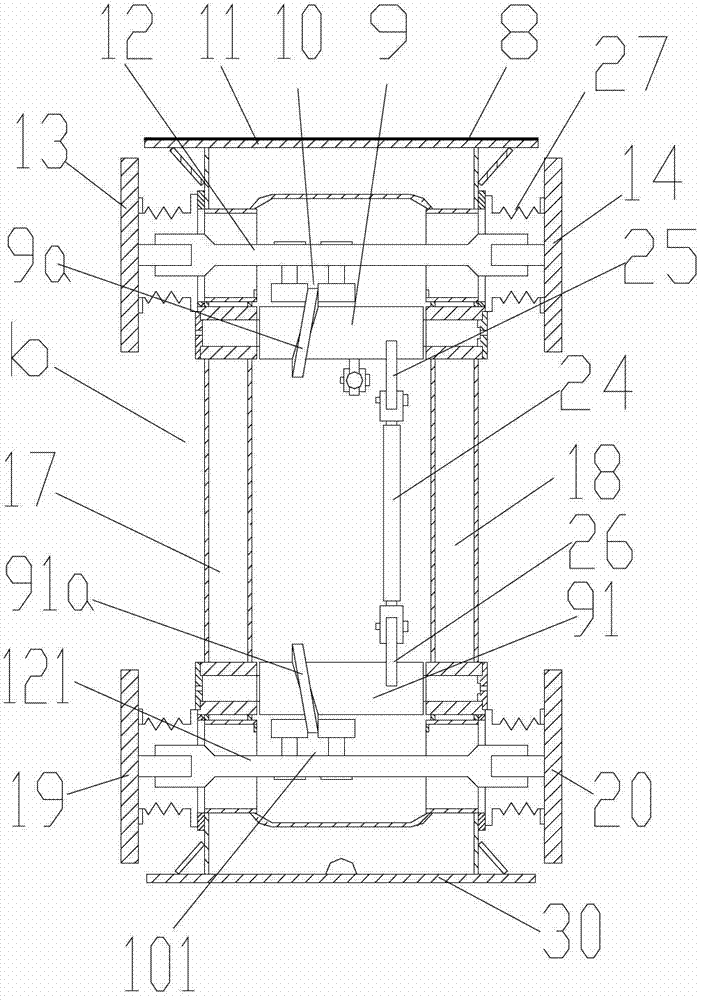

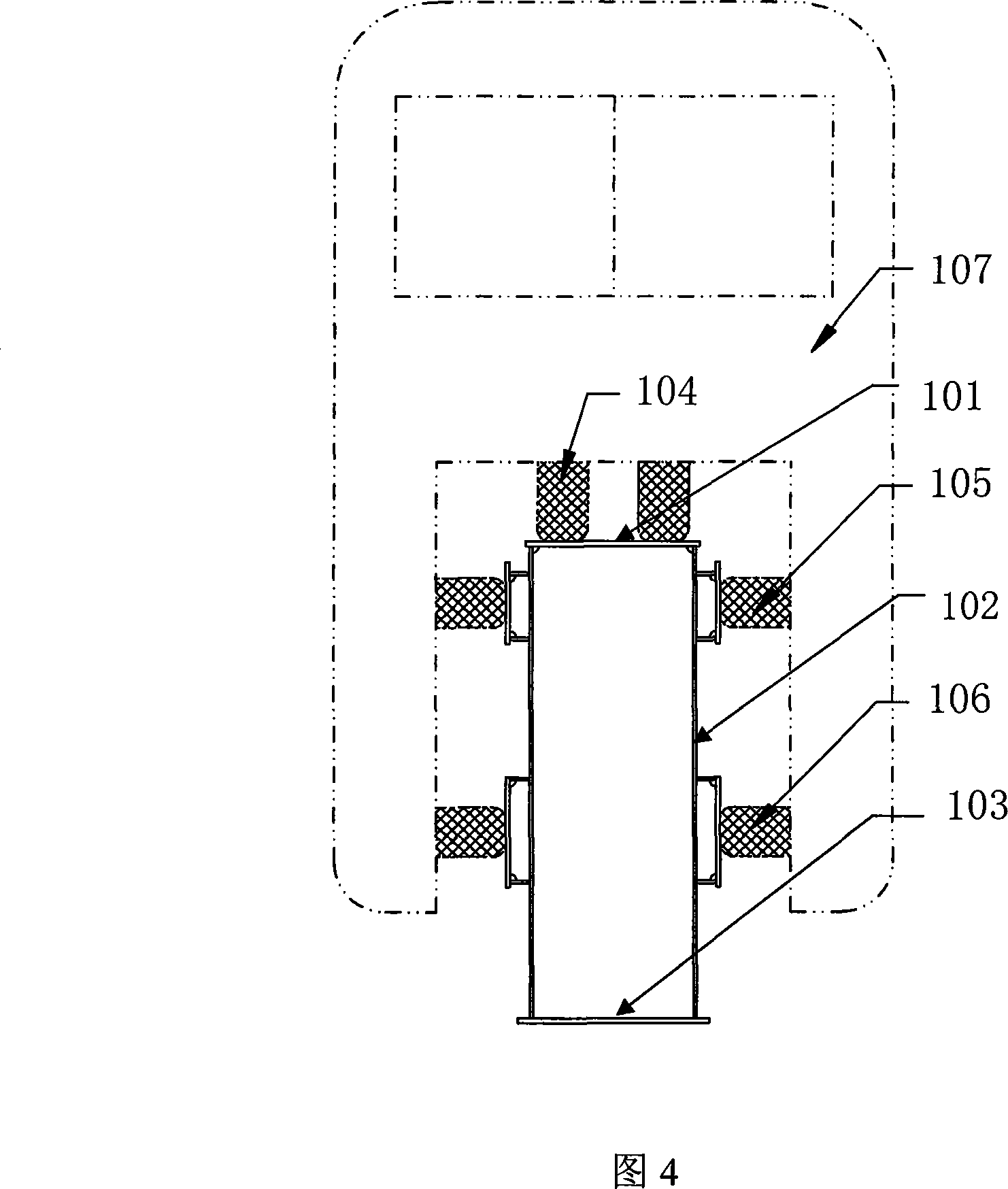

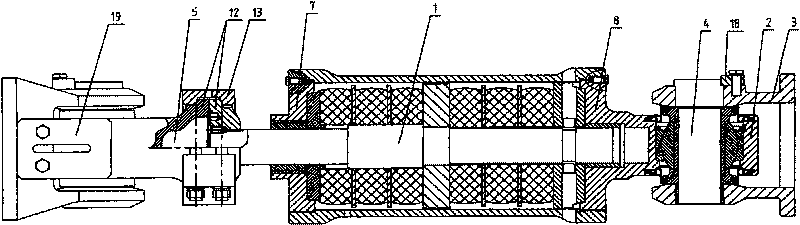

Power bogie with independent wheels for 100 percent low-floor light rail vehicles

The invention discloses a power bogie with independent wheels for 100 percent low-floor light rail vehicles. The power bogie with the independent wheels comprises a framework, an axle mechanism, primary springs, secondary springs, secondary vertical and transverse dampers, a double-pull rod traction mechanism, the longitudinal driving mechanism of an elastically frame-suspended motor and a hydraulic brake unit, wherein the side beams of the framework are cantilevers which protrude outward; two short shafts are supported by bearing units and connected with elastic wheels respectively; an axle consists of the two short shafts; two wheels on the same side of the bogie are fixed on a motor-driven shaft; a motor is coupled with two gear boxes; a brake system is integrated with a traction motor; the four secondary vertical dampers are arranged at the four corners of the framework; the secondary transverse dampers are arranged at the two ends of the framework; and a parallel double-pull rod traction system is arranged on the inner side of the framework. The requirement of 100 percent low floor on vehicle bodies is really realized by the high-strength welded framework, the independent wheel axle mechanism, the primary springs and the secondary springs which are rationally structured, the optimal secondary vertical and transverse dampers, the parallel double-pull rod traction device with internal traction, the longitudinal drive of the elastically frame-suspended motor, and the hydraulic brake unit which is integrated with the traction motor.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Rail transportation system of small vehicle

ActiveCN1526596ASave construction investmentReduce operating costsRailway componentsRailway stationLight railRail transit

The rail transportation system of small vehicles is used to replace available underground railway and light rail system, and has small driverless vehicles running in closed rail. The system consists of vehicles, closed rails and stations, the vehicles are computerized automatic ones, the closed rails is provided with vehicle controlling equipment, and the vehicles are started from stations randomly for express service from station to station. The present invention has the advantages of great traffic amount similar to that of main stem transportation, personalized service, low construction investment and low running expensive. It may be used for both passenger transport and cargo transport, and municipal rail transportation network may be constructed.

Owner:沈涌

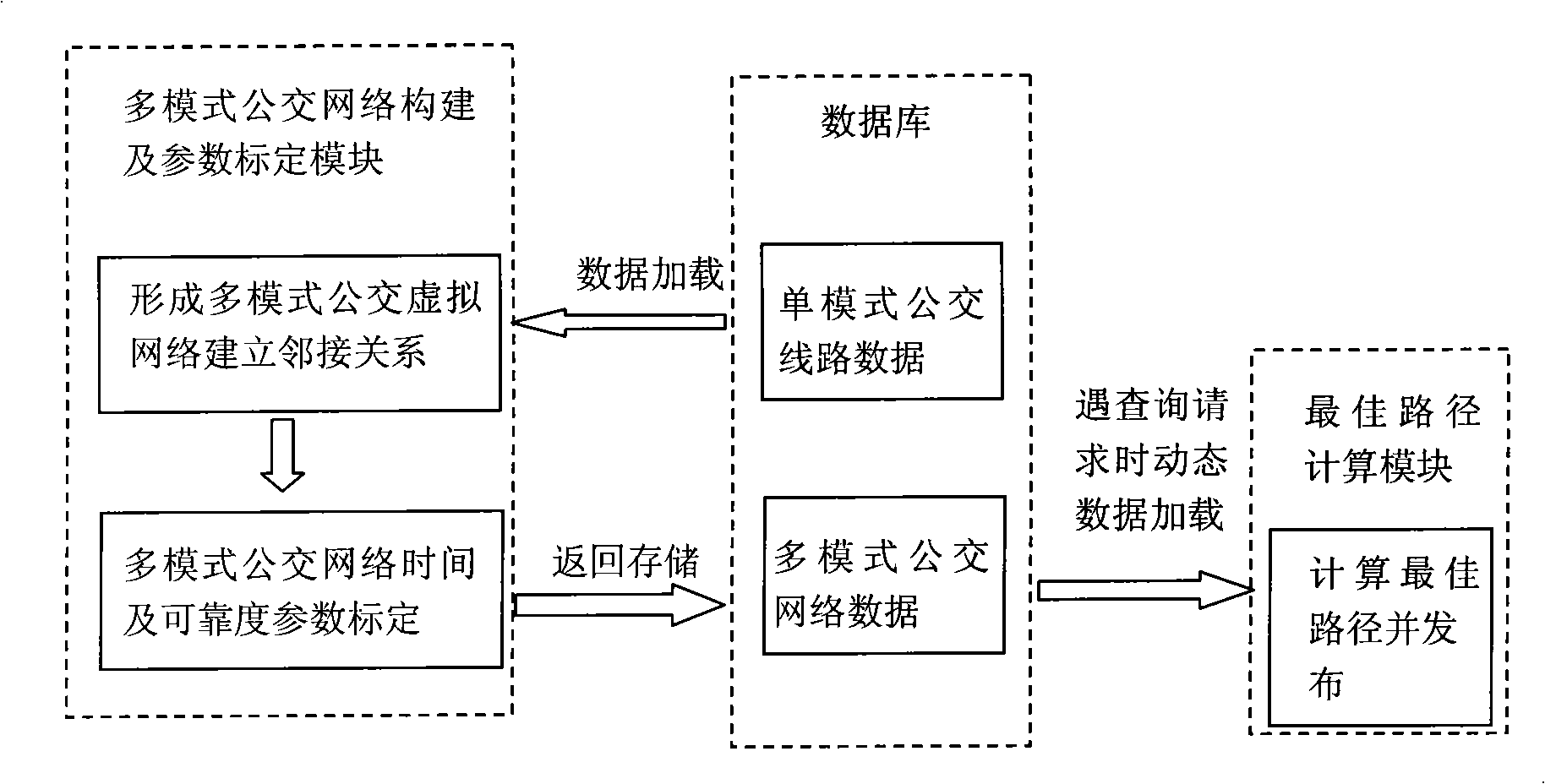

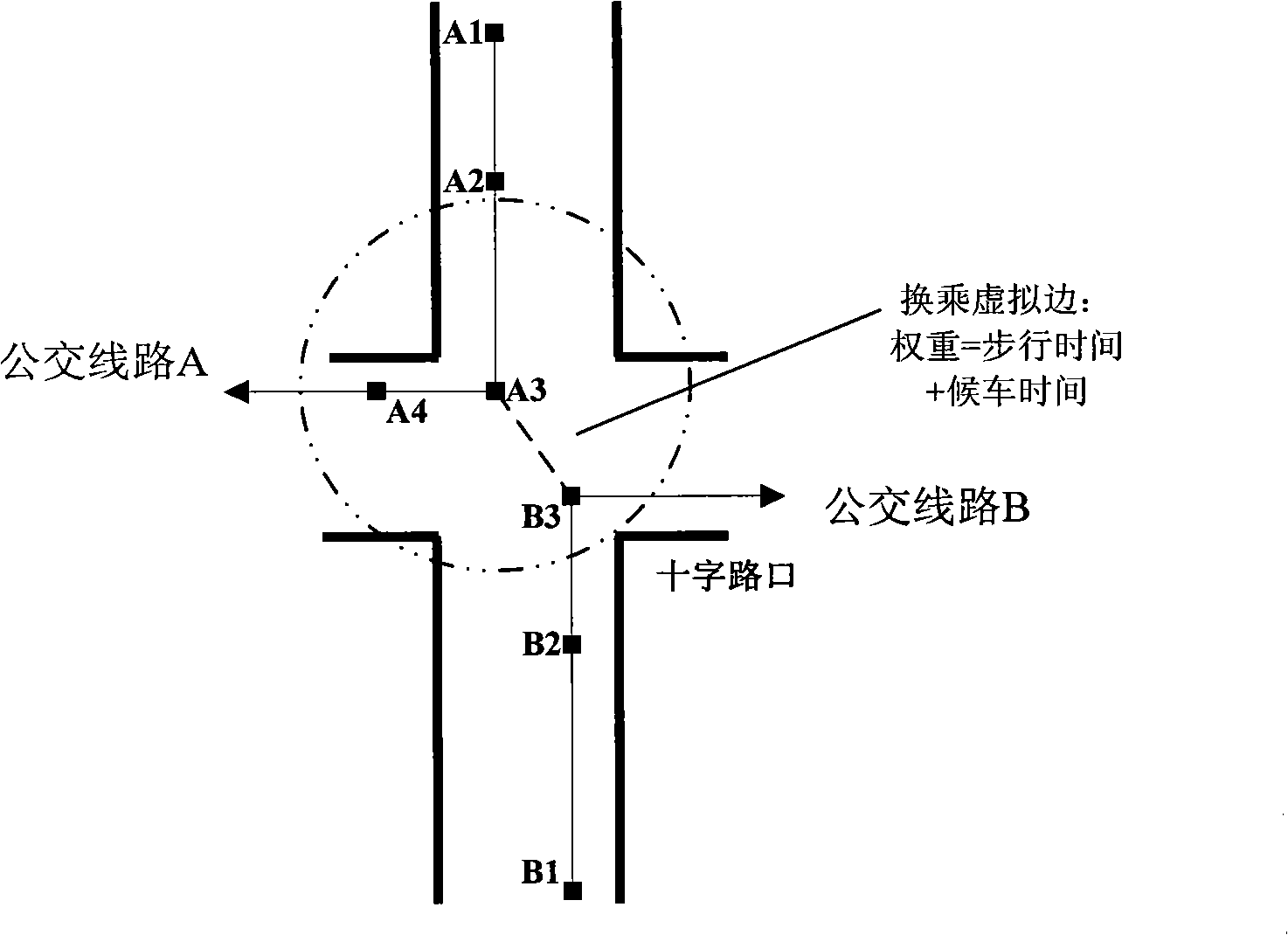

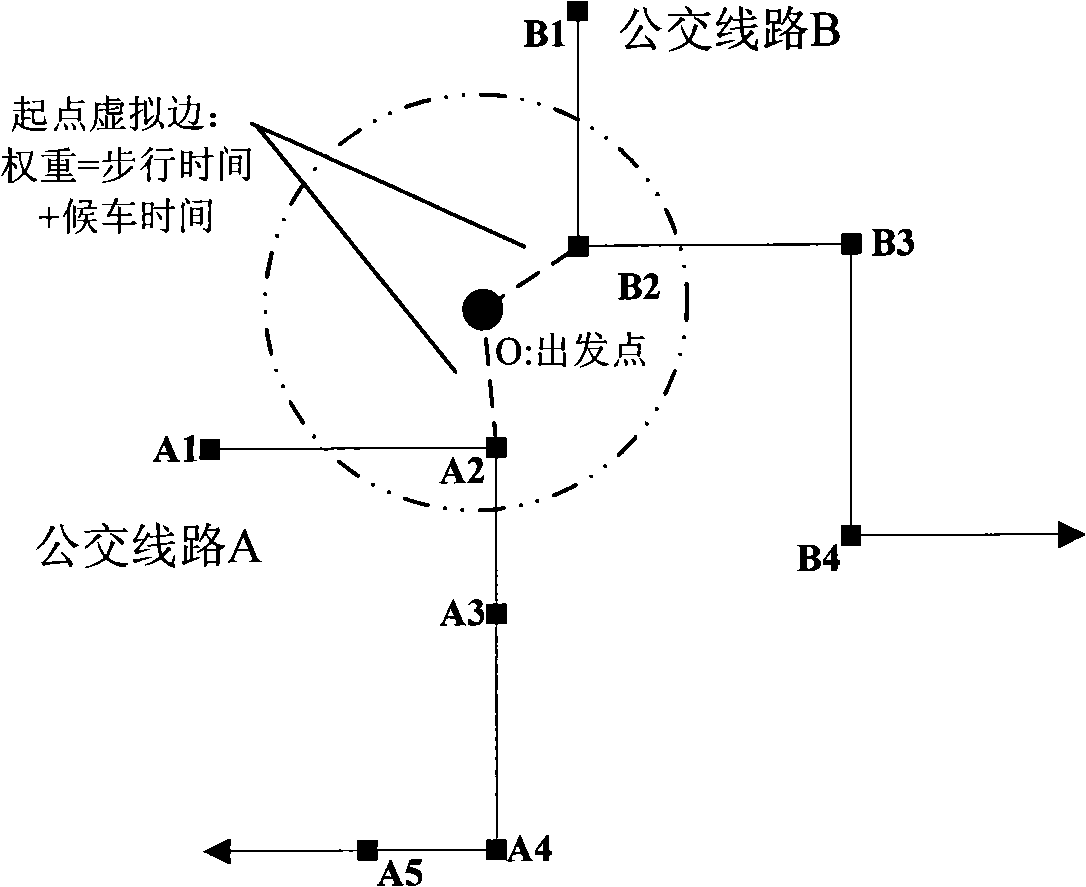

Multi-mode optimal path selection method for public transport

InactiveCN101308555AImprove accuracyRich release contentForecastingSpecial data processing applicationsBus laneTime information

A multi-mode public transport travel route optimization method belongs to the public transport travel information release field and is specifically used for optimum line inquiry in public transport traveling. The invention takes each line of the public transport travel chain as edges to establish a multi-mode public transport line network which allows transfer, through constituting a multi-level network adjacent relationship which comprises different public transport modes, such as metro, light rail, bus lane and ground bus, and enabling double-empowerment of the average travel time and the time reliability to each edge; in the absence of real-time information conditions, the relatively short traffic time and the smaller delay risk are taken as the double targets for route optimization to achieve rapid search of the reliable route which can effectively reduce the delay risk within the range permitted by the traveling time, through the heuristic avoidance from the routes and transfer points prone to delay in the route optimization process. Based on the method, a touch-screen information system or internet is taken as a platform to build a multi-mode public transport route inquiring system and carry out the route and transfer information inquiry and release.

Owner:BEIJING UNIV OF TECH

Light rail and accessory rail mount for vertical fore grip

InactiveUS7568304B1Simple bolt attachmentSelf containedAmmunition loadingWeapon cleaningLight railRifle

Devices, and methods of attaching accessory mounts to vertical fore grip handles on firearms, such as rifles. The accessory mounts can be molded to extend off of the handles. The accessory mounts can attach to the handles by interlocking plugs and slots. The accessory mount can have rails so that an accessory can attach to the rails on the accessory mount. The accessory can include lights, lasers, bayonets, sights, scopes, and the like. The vertical fore grip can be an elongated handle fixed to the firearm. The vertical fore grip can be an elongated handle that is detachable from beneath rails on the firearm. The vertical fore grip can include expandable bipod legs.

Owner:GRIP POD SYST INT

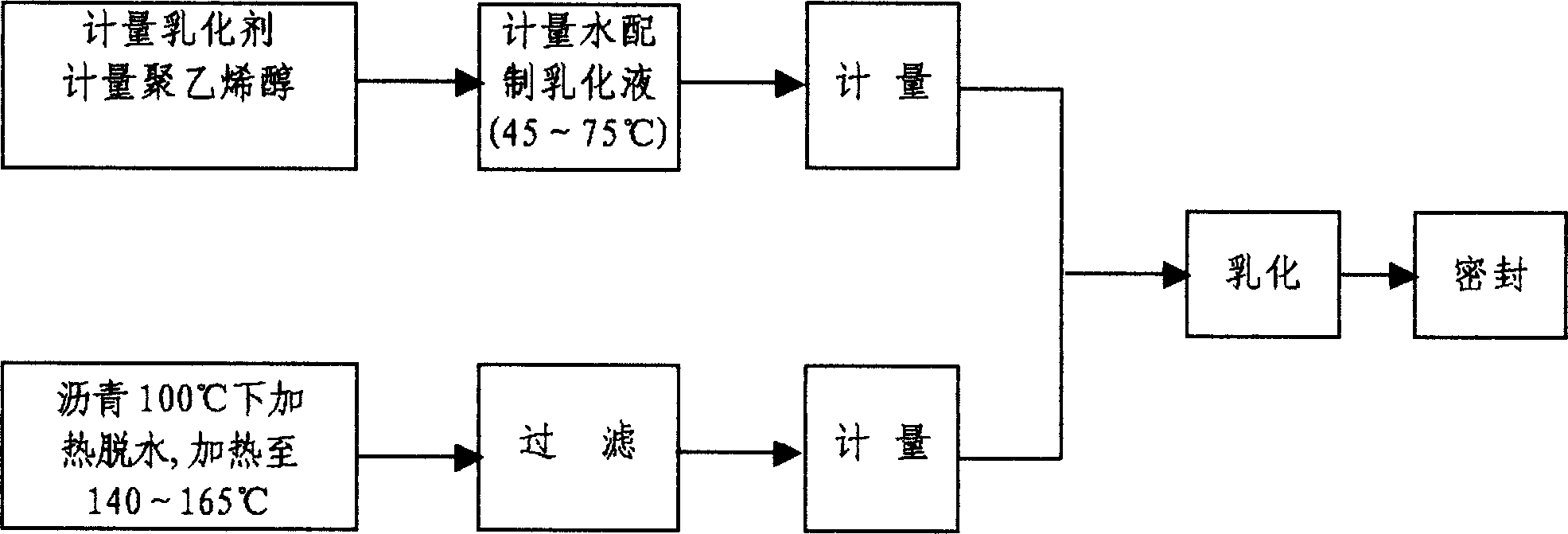

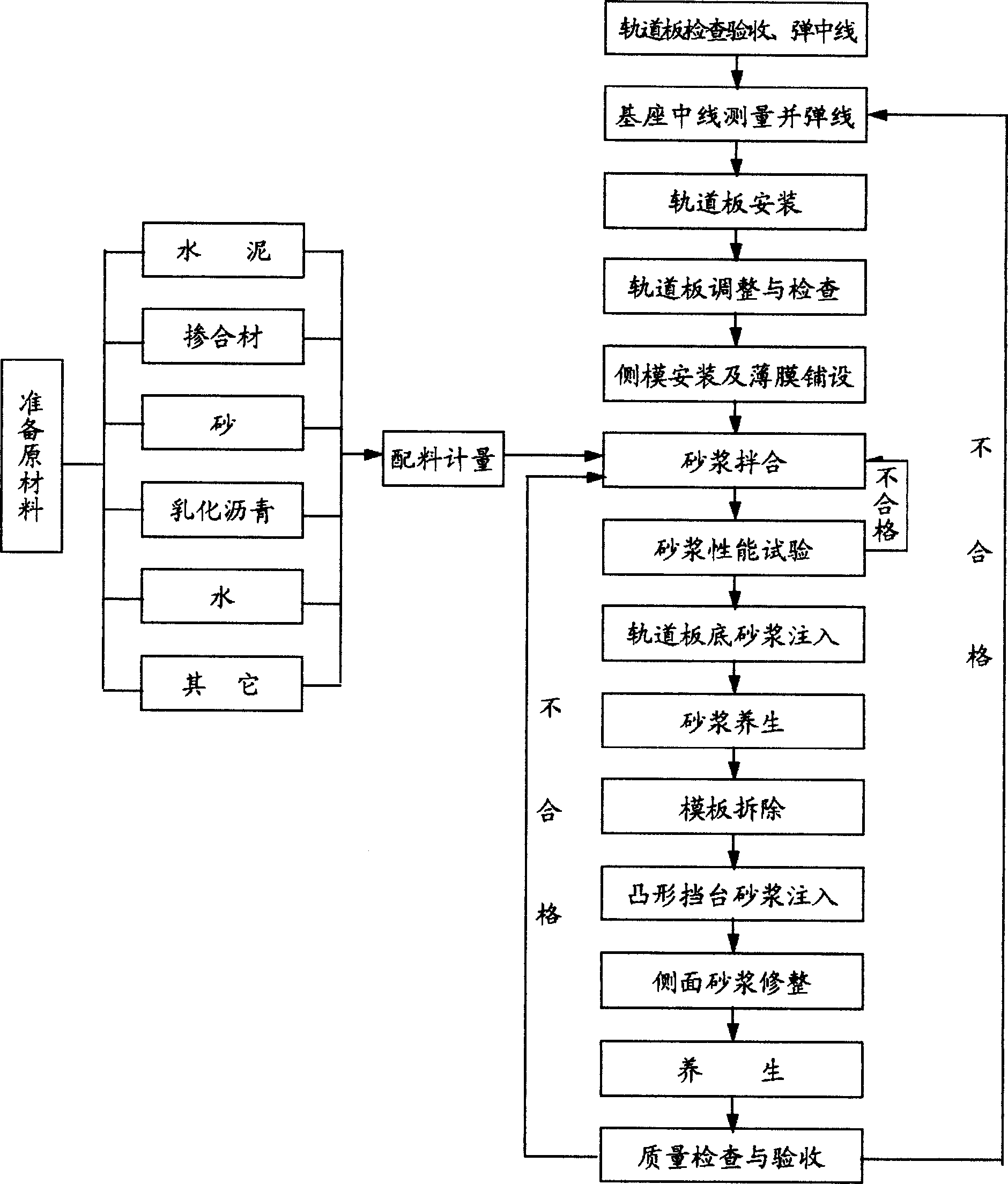

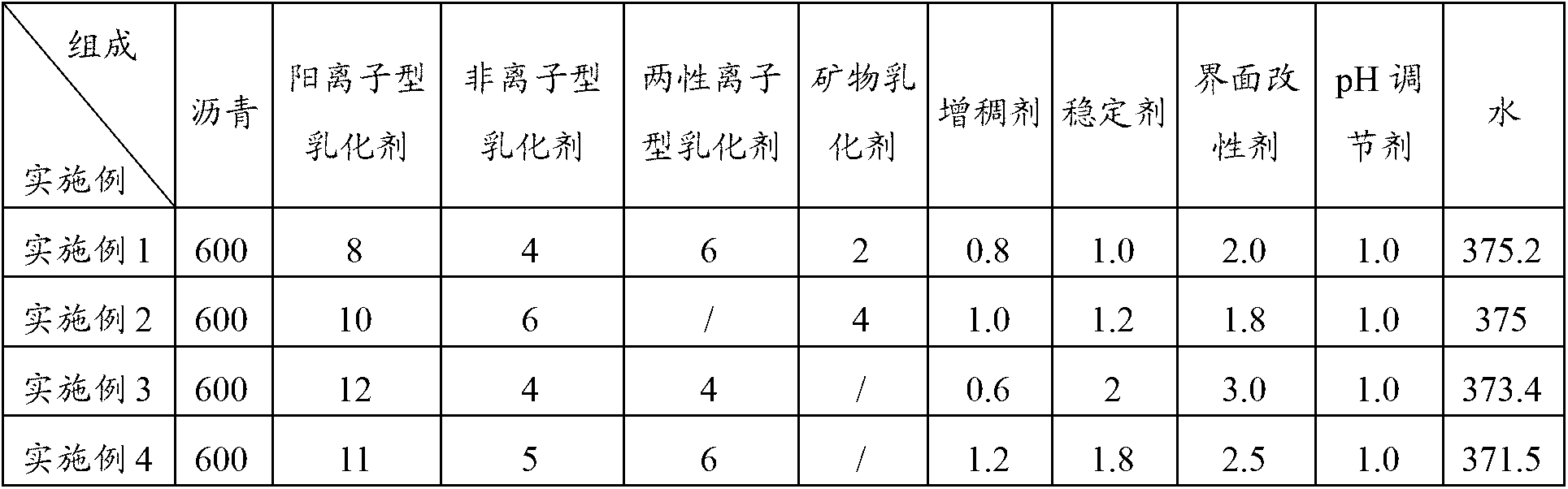

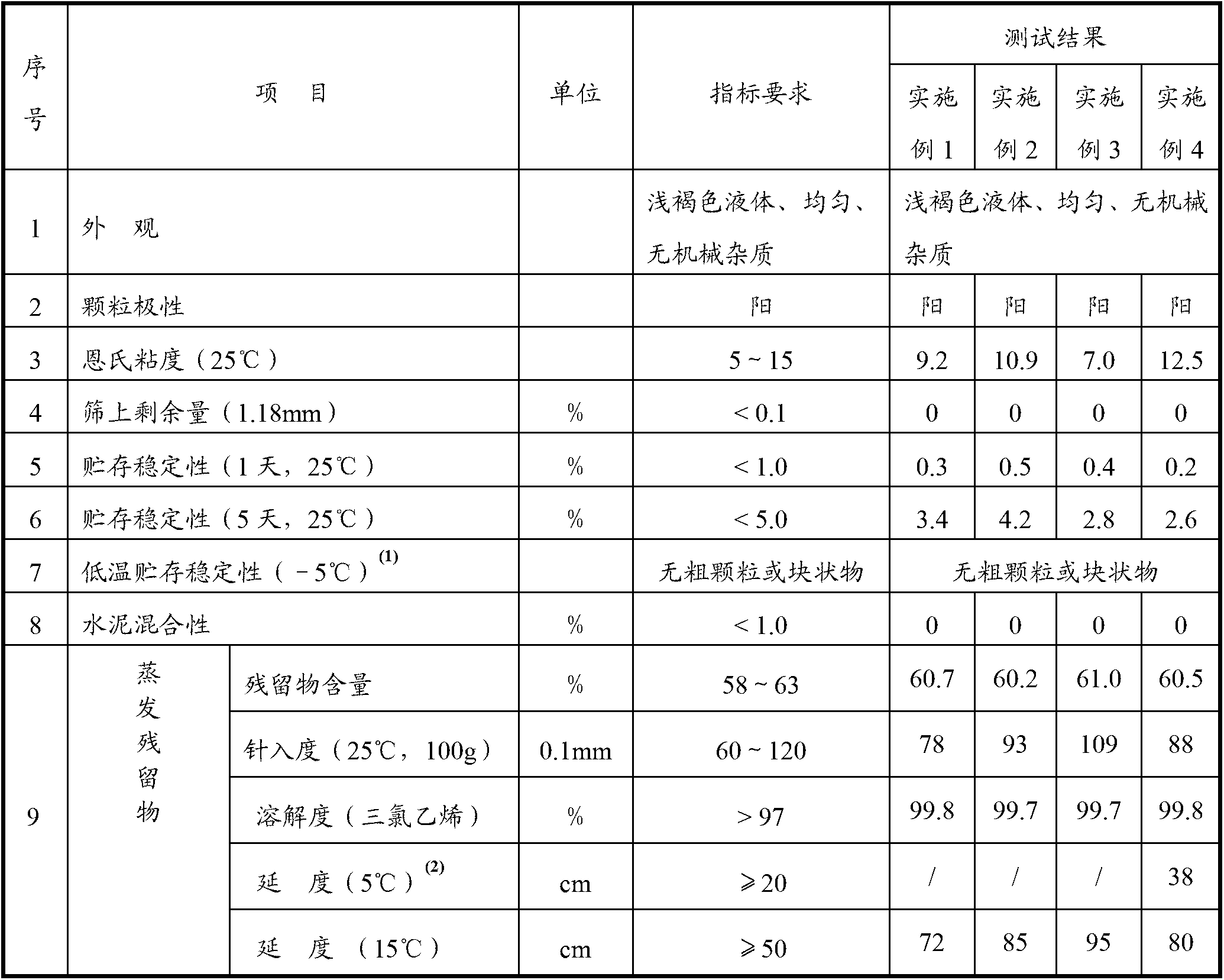

Emulsified asphalt

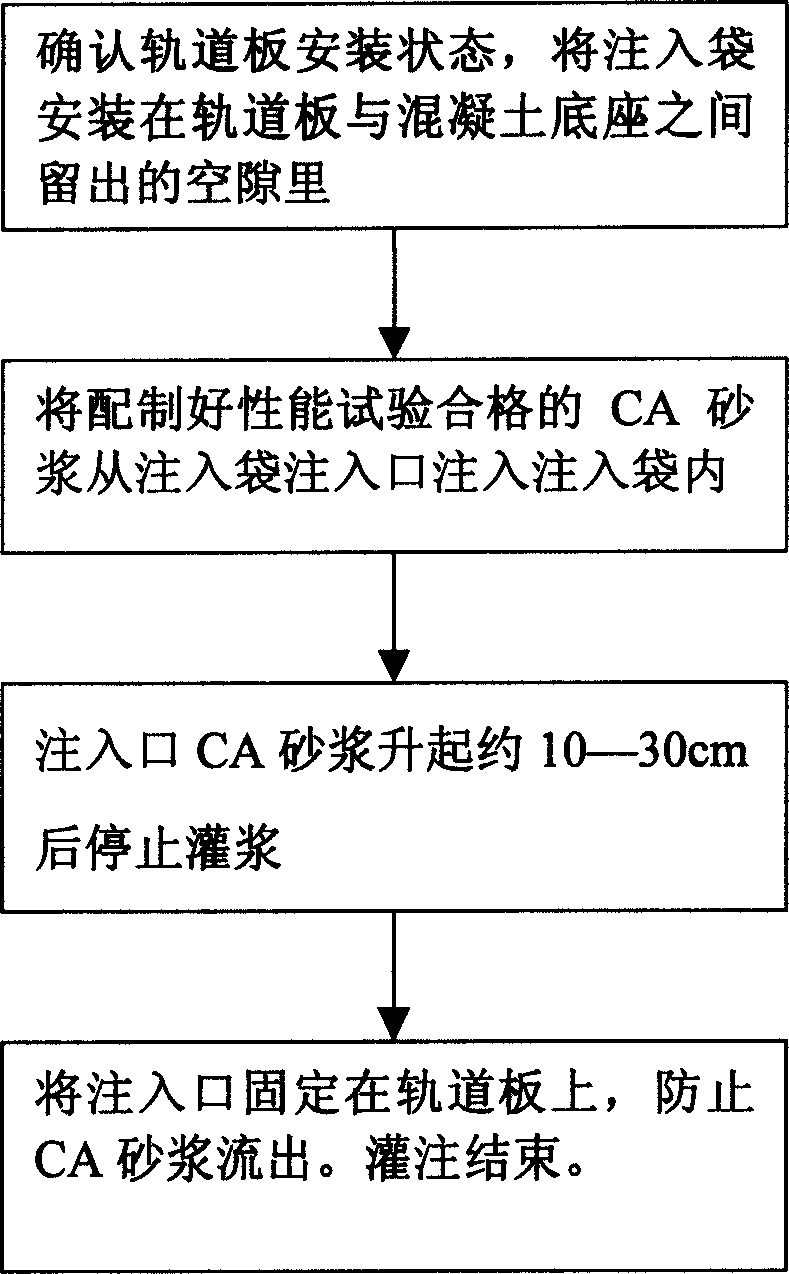

InactiveCN101153118AEasy to control air contentEasy to control fluidityBuilding insulationsLight railCement mortar

The present invention provides emulsified asphalt made of asphalt, surfactant, additive and water. Wherein, the contents of each component are: 38 percent to 58 percent of asphalt, 1 percent to 15 percent of ionic surfactant and 2.5 to 19 percent of non-ionic surfactant of the surfactant, 0.5 to 8 percent of additive; and the left is water; all are calculated according to a weight percentage. The product of the present invention is the emulsified asphalt of good stability and simple production process. In the actual use, the CA mortar can avoid eduction and contraction; thus the CA mortar has appropriate work time and high strength in the early period, which can fully meet the requirements of plate type ballastless track. Therefore, the product of the present invention can be effectively used in emulsified asphalt cement mortar (also known as CA mortar) for plate type ballastless track of high-speed railway or urban light rail.

Owner:张洪武

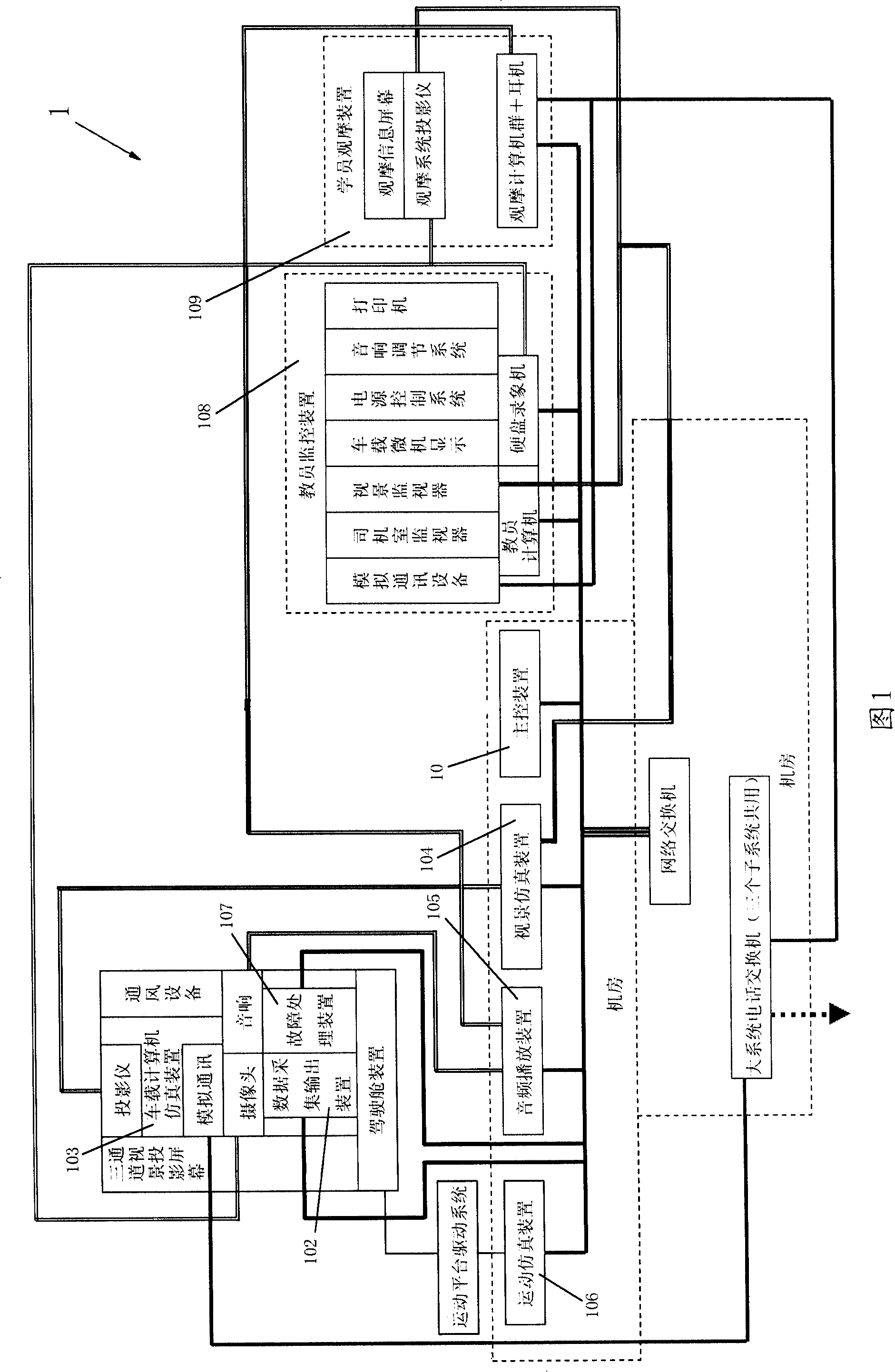

Train simulation drive system

ActiveCN101201983AImprove business levelHigh ability to handle emergenciesCosmonautic condition simulationsSimulatorsDriver/operatorSimulation

The invention relates to a simulation driving system of trains, which comprises a master control device, a data collecting and output device and a vision simulation device, wherein, the collecting and output device receives and transmits the input data of simulation driving to the master control device; the master control device produces simulation data according to the input data of stimulation driving and sends the simulation data to the vision simulation device to set up simulation scenes of trains when running. The simulation driving system of trains can be used for training master operation skills of train drivers and drivers of city light rail or underground during transportation operation process so as to ensure that the workers have relatively high professional levels and relatively high ability for handling emergencies.

Owner:CHINA SHENHUA ENERGY CO LTD +1

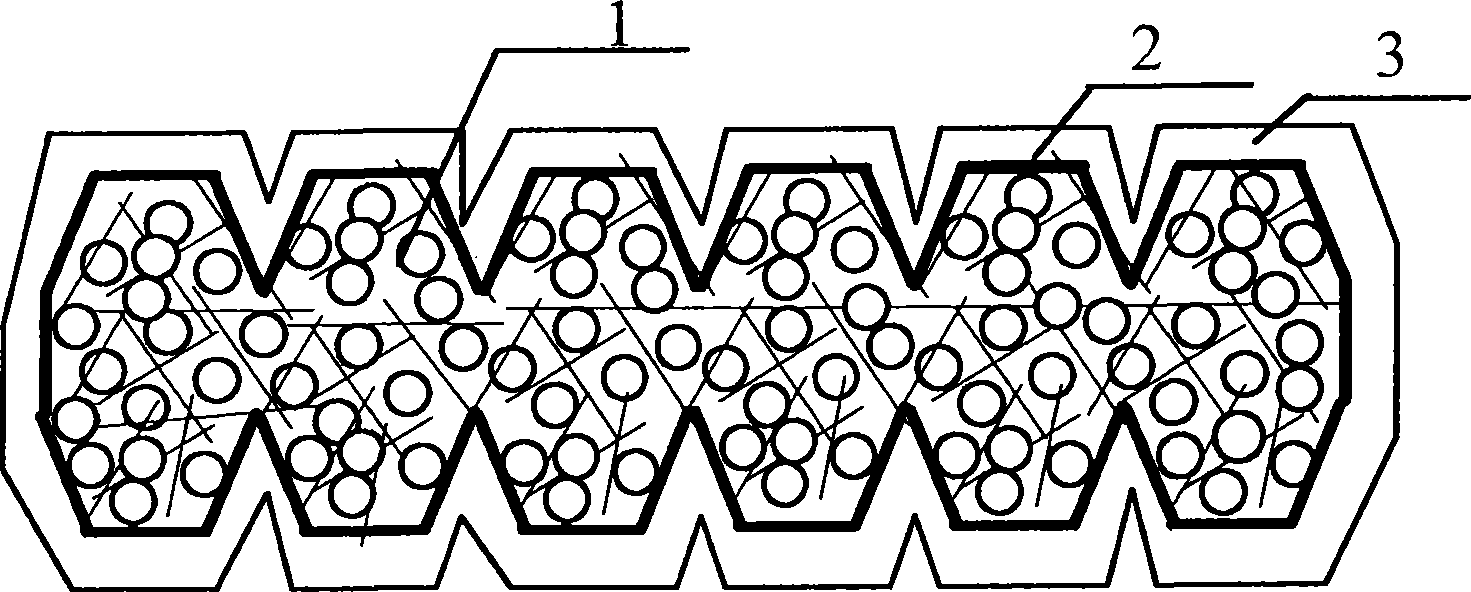

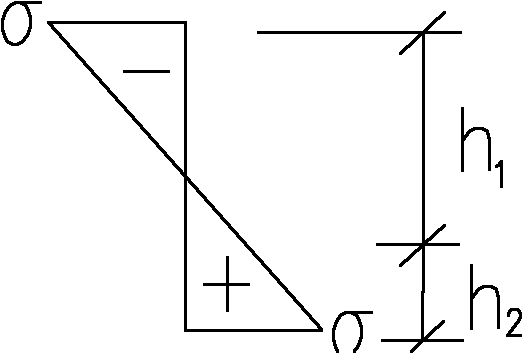

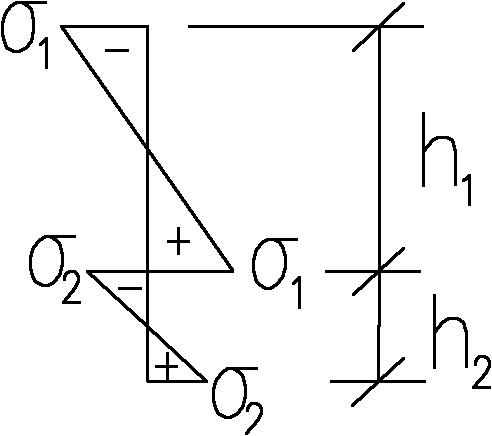

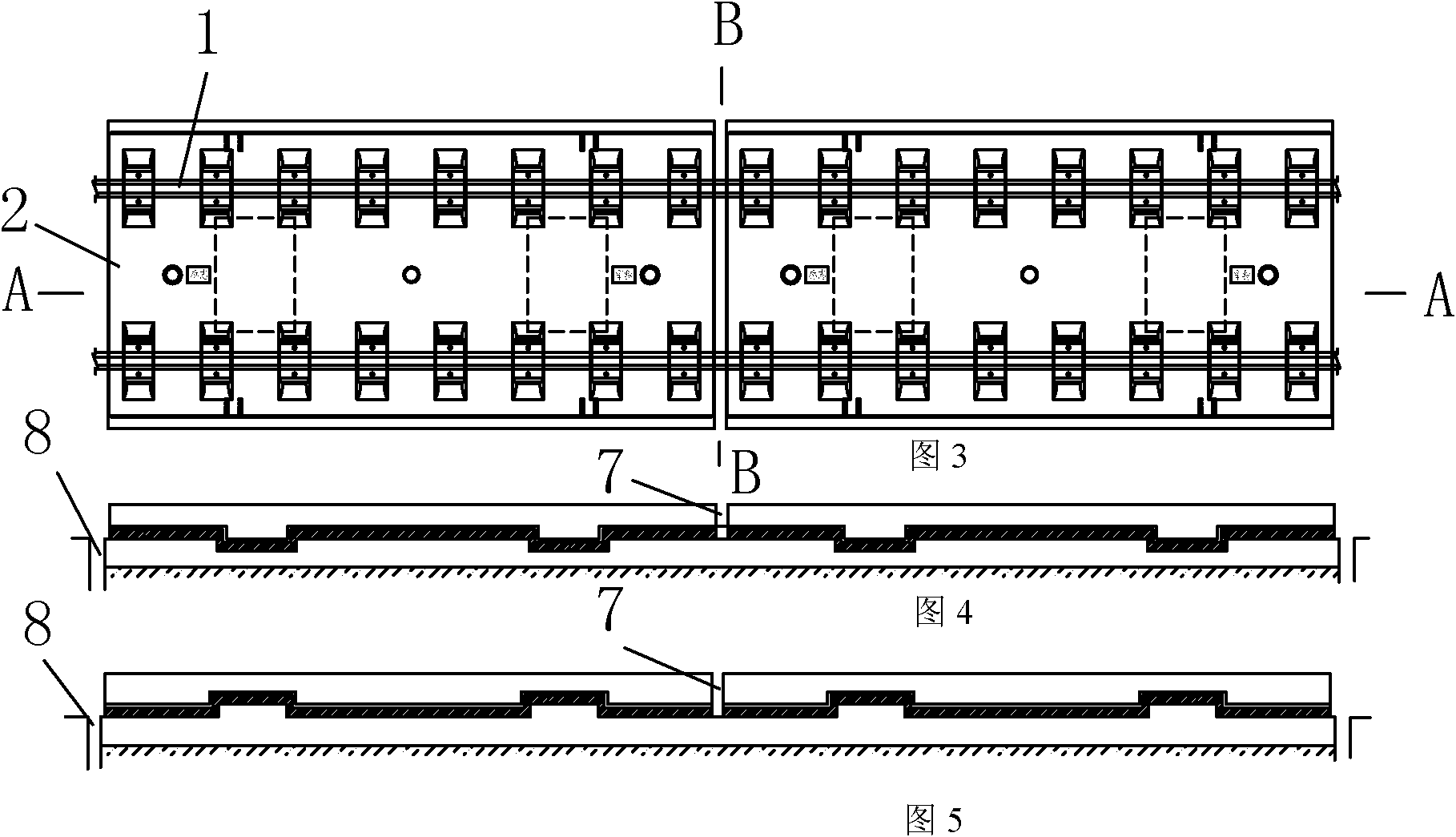

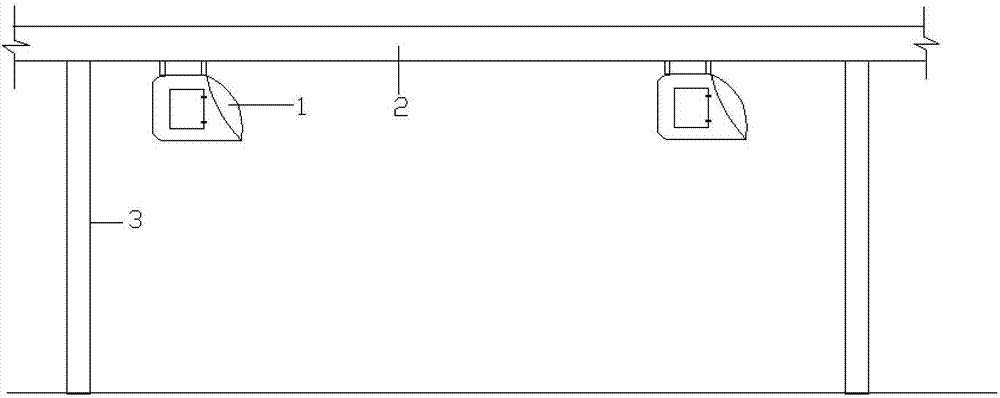

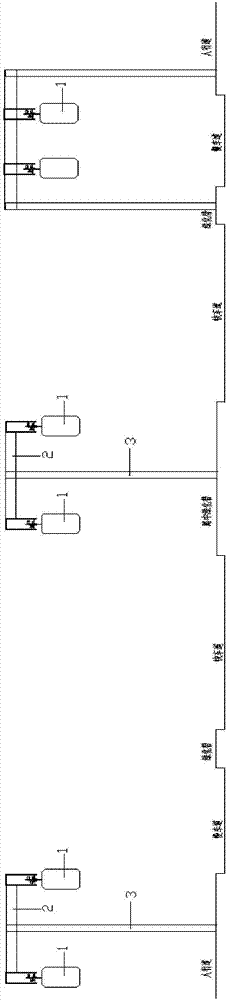

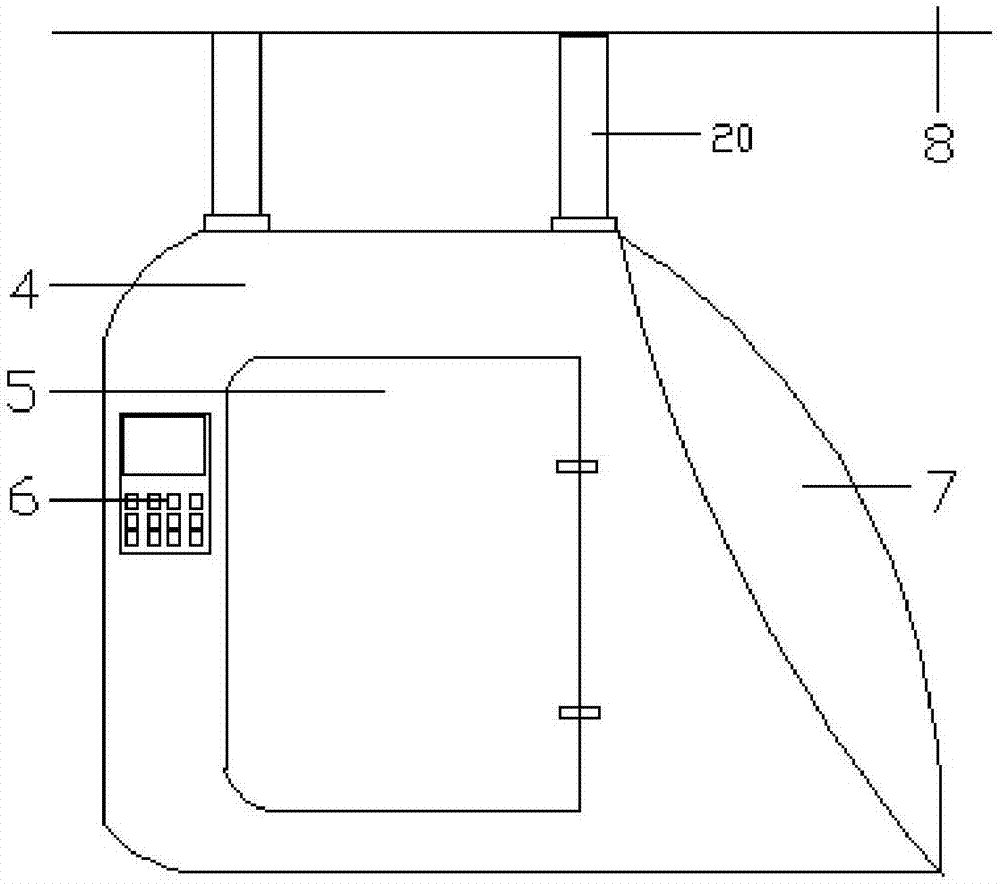

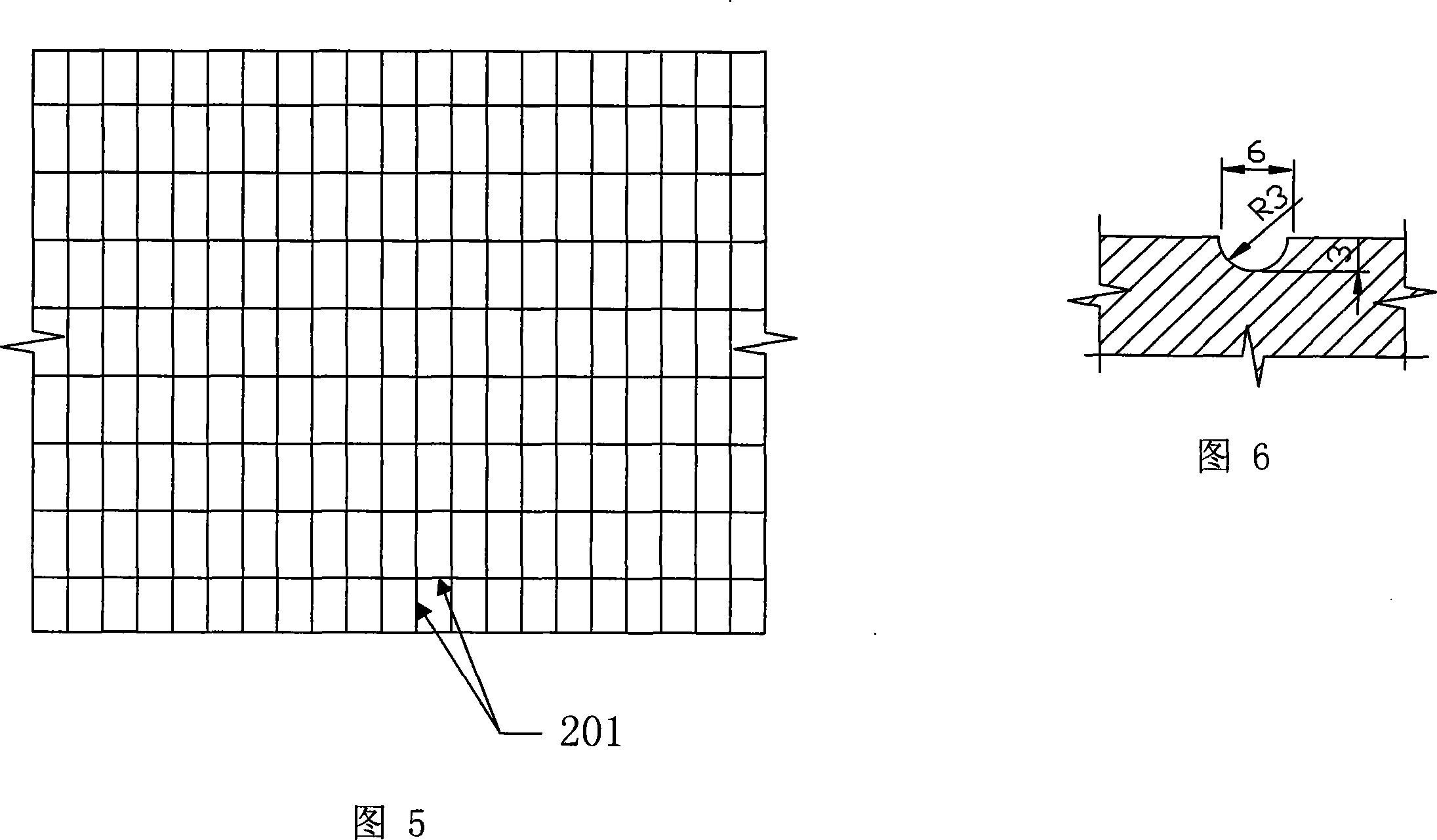

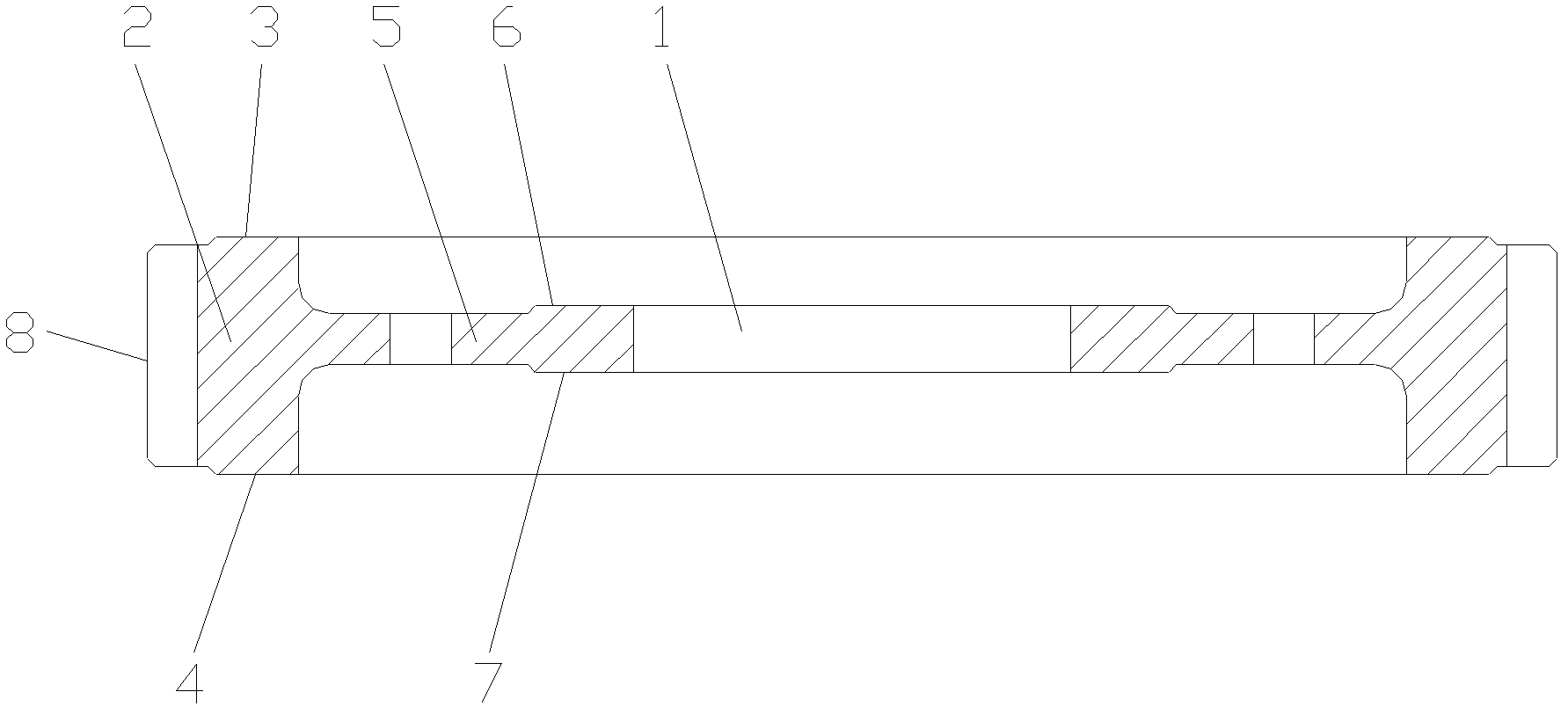

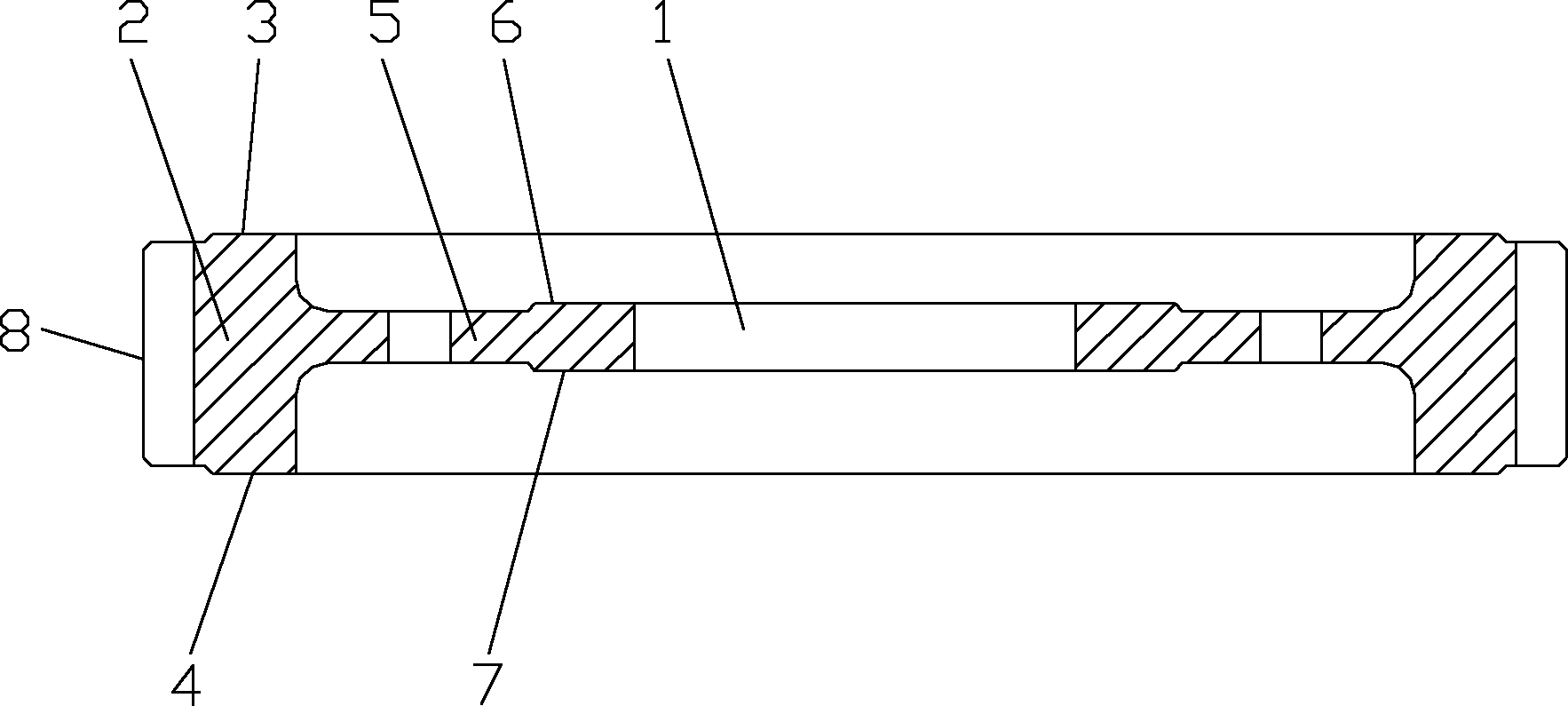

Precast slab type ballastless track structure

InactiveCN102182120ACorrect geometryEfficient deliveryRailway tracksTemperature stressHigh intensity

The invention discloses a precast slab type ballastless track structure. The structure comprises a steel rail (1), fasteners, a precast track slab (2), an adjusting layer (3) and a base (4). The structure is characterized in that: the bottom of the track slab is provided with limiting lug bosses (5) or limiting grooves (6), and the number of the limiting lug bosses (5) or the limiting grooves (6) is single or many. The structure has reasonable stress and good stability and durability, and can fully exert the functions of high strength and high rigidity of the track slab, lighten the longitudinal temperature stress of the track slab and meet the requirements of high smoothness and high stability of rail transit such as railways, light rails, subways and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

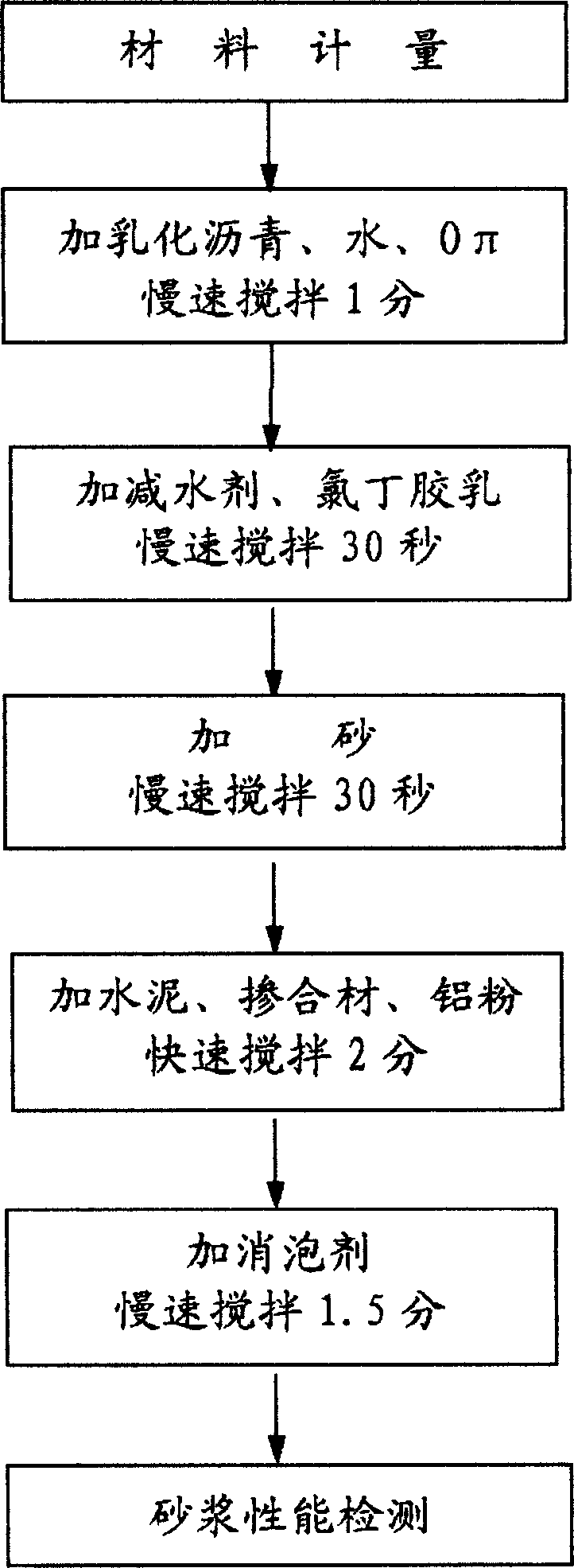

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

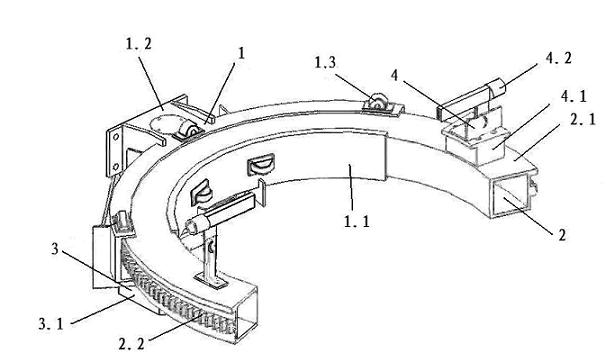

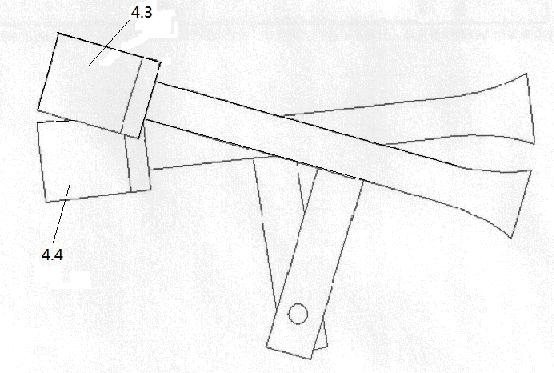

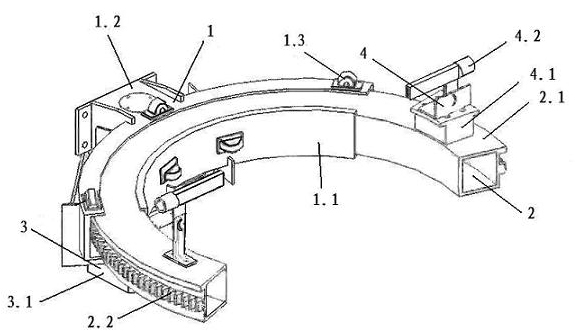

Sprayer device for cleaning brace insulator with dry ice

InactiveCN102205293AVersatileSimple structureSpraying apparatusCleaning processes and apparatusSprayerDry ice

The invention discloses a sprayer device for cleaning a brace insulator with dry ice, which comprises a fixing mechanism, a rotating mechanism, a driving device and a cleaning sprayer, wherein the fixing mechanism comprises a fixing frame and a guide rail; the driving device is mounted on the lower part of the guide rail; the rotating mechanism passes through the interior of the guide rail; a guiding wheel of the rotating mechanism is arranged on the guide rail; the rotating mechanism main body is an arc-shaped light rail; a rack which is engaged with a spindle gear of the driving device is arranged outside of the rack; position limiting switches are arranged at two sides of the rack; cleaning sprayers are arranged at two ends of the rotating mechanism; and the device is mounted on a lifting mechanism of a cleaning device through the fixing frame. The device has the advantages of simple structure, flexibility in operation, high cleaning efficiency, and is easily controlled and is fit for cleaning the brace insulator with dry ice. By adopting a crossed double sprayer, the upper and lower surfaces of an umbrella skirt of the brace insulator can be efficiently cleaned without a dead angle. Aiming at the brace insulators in different voltage levels, sprayer modules in different sizes are designed. The device can be applied according to the actual materials, so as to achieve the best cleaning effect. Besides, the electric on-line cleaning can be realized.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP +1

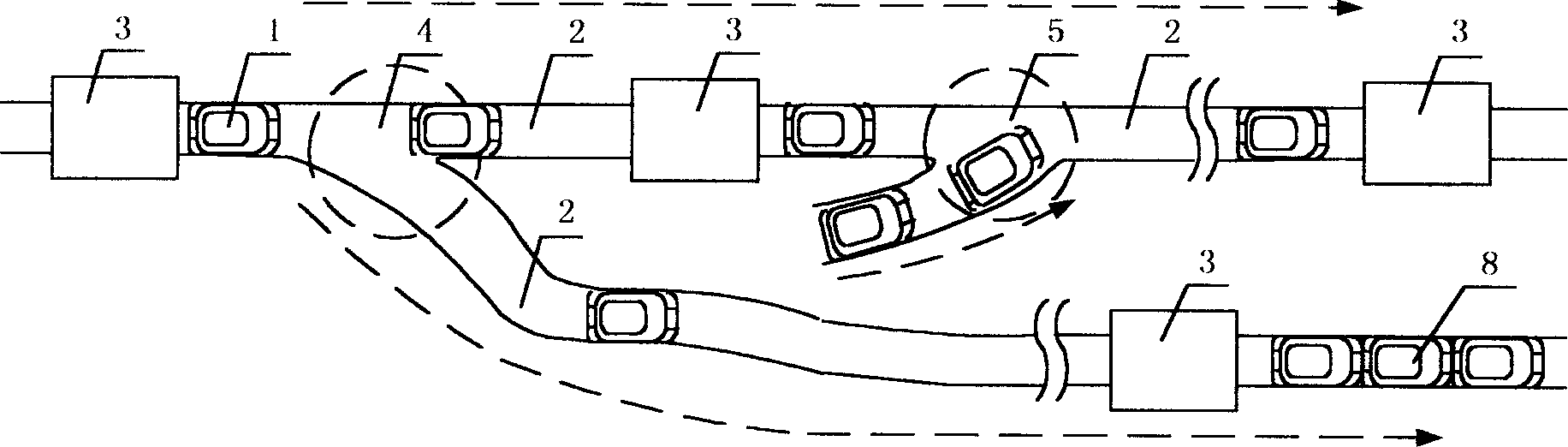

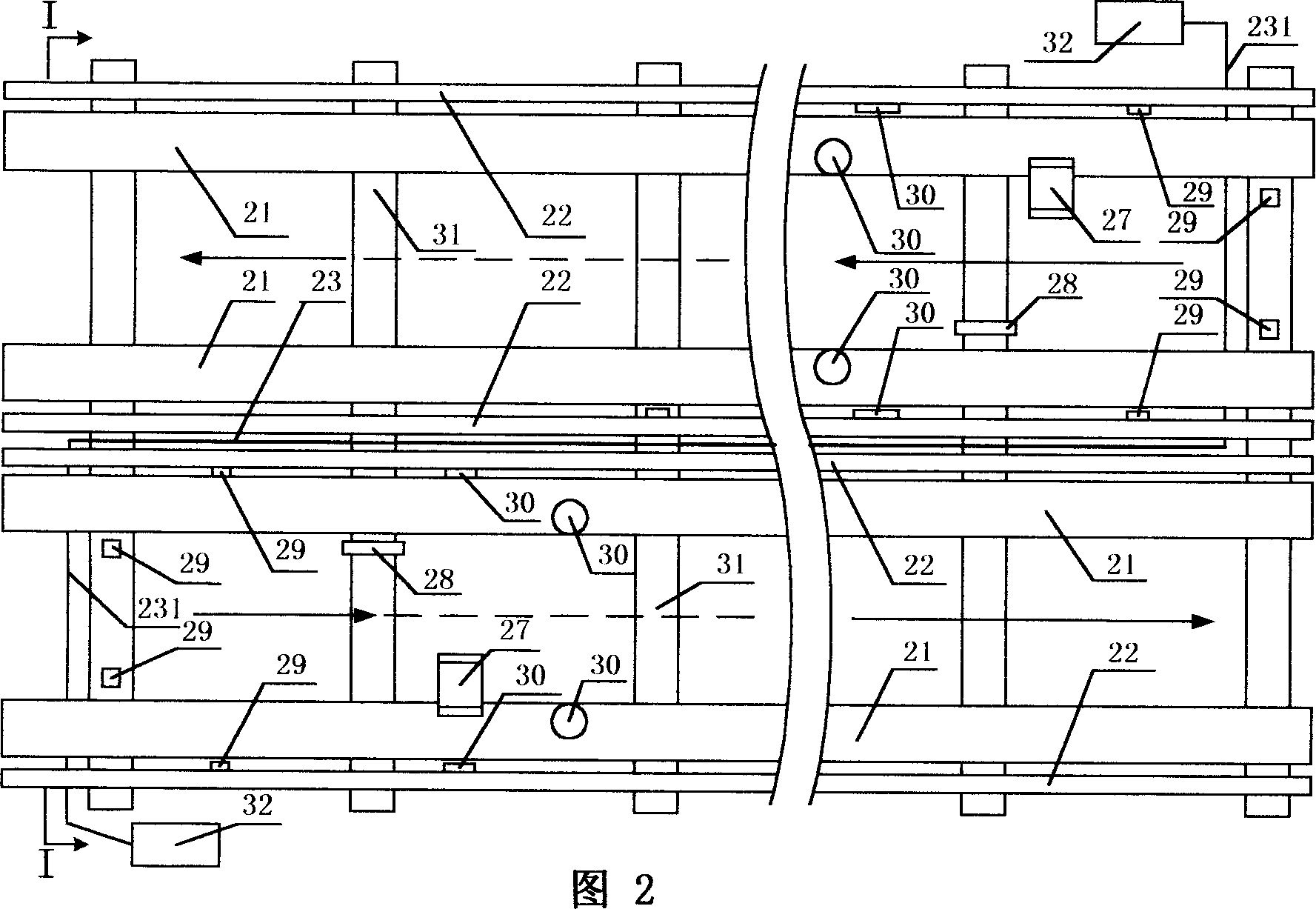

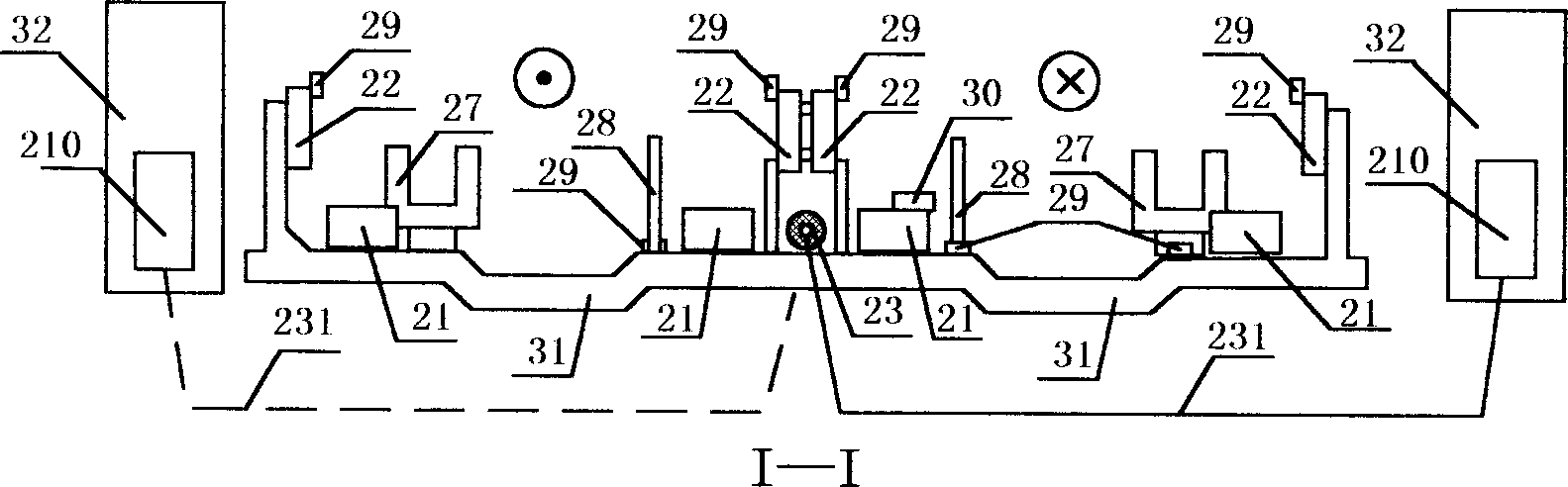

Personal hanging type double-rail and double-power automatic control light rail traffic system

ActiveCN106864464AAchieve steeringMergingAutomatic systemsRailway tracksComputer control systemAutomatic control

The invention discloses an personal hanging type double-rail and double-power automatic control light rail traffic system which comprises a rail system, rail vehicle power systems, a rail vehicle traffic network control system, a rail vehicle compartment system, a rail vehicle power supply system and a rail vehicle stop station system. The rail system of the personal hanging type double-rail and double-power automatic control light rail traffic system is provided with a left side straight rail line and a right side turning rail line which are in parallel but are different in top face level, and the two power systems of a left side straight rail drive device and a right side turning rail drive device are separately arranged above two rails. The relative distance between the turning drive device and the turning rail is changed through a lifting device, and meanwhile, under the effect of a change of the relative level between the straight rail and the turning rail, switching of a rail vehicle between the left side straight rail and the right side turning rail is achieved. According to the personal hanging type double-rail and double-power automatic control light rail traffic system, a central computer control system is used in cooperation, automatic control is achieved, and the rail vehicle autonomously travels, so that a PRT concept is truly converted into an application technology for serving lives of people.

Owner:合肥华举建筑装饰工程有限公司

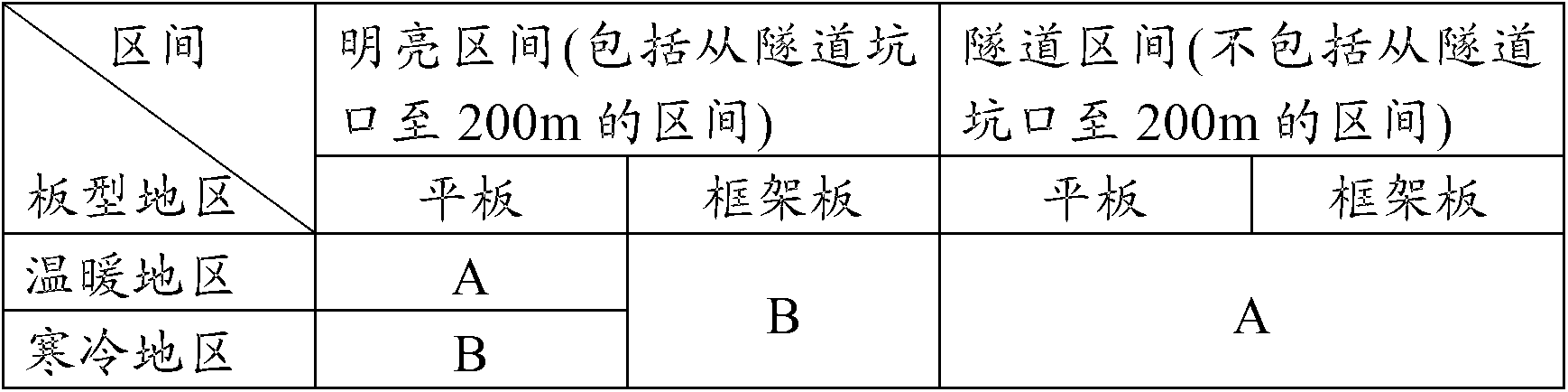

Cement-emulsified asphalt mortar for slab tracks in severe cold areas

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

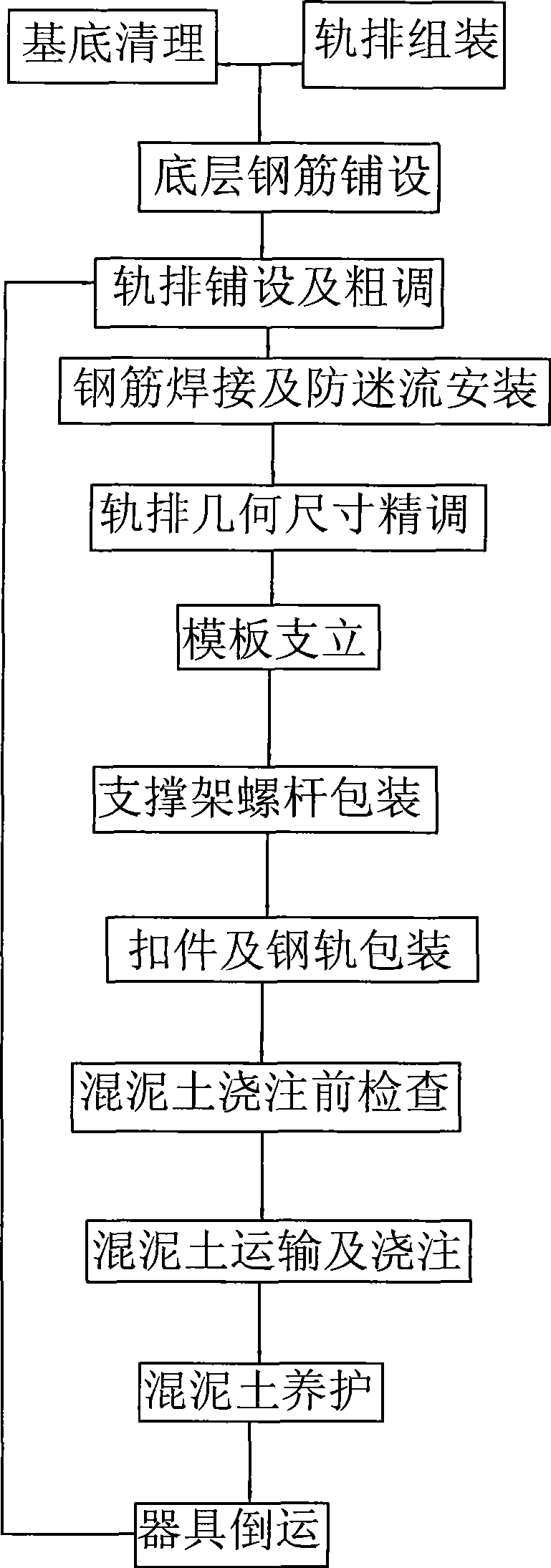

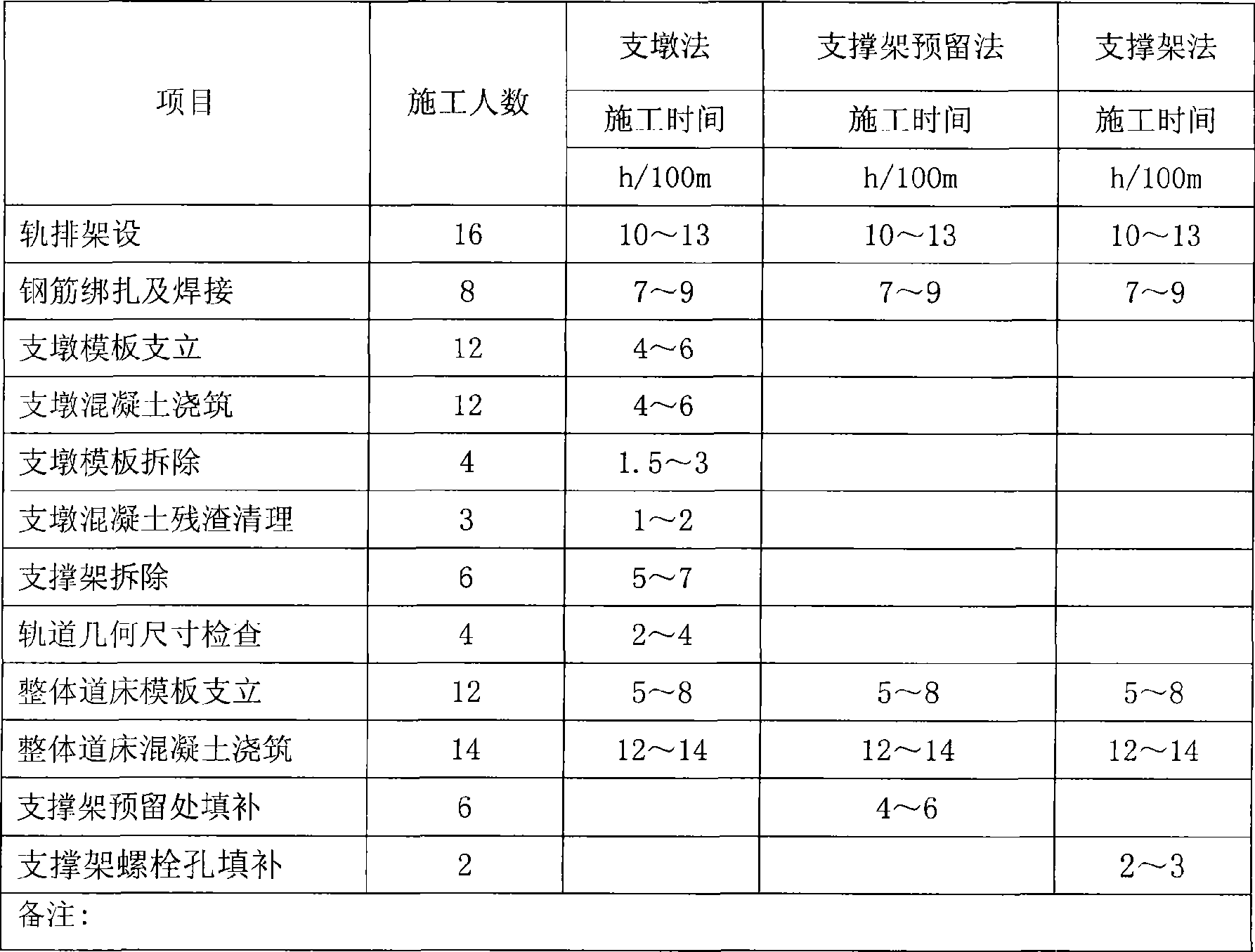

Construction method of monolithic road-bed in rail tunnel

ActiveCN101418535AReduce construction proceduresLow costRailway track constructionEngineeringLight rail

The invention discloses a method for constructing an integrated road bed of a track traffic tunnel, which is a supporting frame method for short. Firstly, a finished track panel assembled on a base is hoisted to the constructed tunnel; and the track panel of sleepers with different forms is born through adopting a supporting frame of a lower bearing type track panel; secondly, the track panel in the construction working face is hoisted to the designed elevation; the supporting frame of the track panel is mounted to support the track panel; a transverse supporting lever is utilized to approximately fix the direction of the track panel; and finally, according to fiducial mark, the elevation of track surface, the direction of the track, level and height are adjusted to the designed positions; after the binding and welding of concrete reinforcing bars and the erection of a template of the road bed are sequentially completed, and the integrated road bed is finally subjected to concrete pouring to obtain the integrated road bed; and the steps are sequentially advanced to complete the whole construction. The method reduces control links and material waste, improves construction schedule, ensures construction quality and is mainly used for the structural construction of undergrounds, light rails, tunnels, bridges, large-scale vehicle fields and other integrated road beds.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

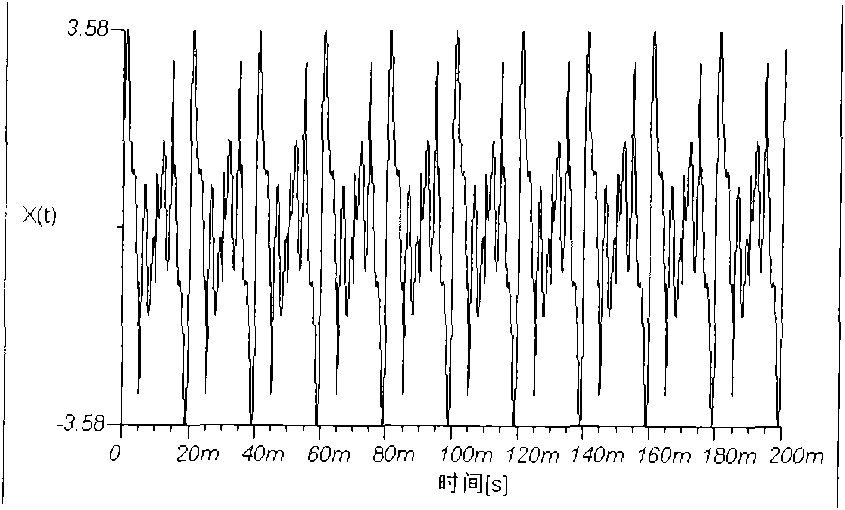

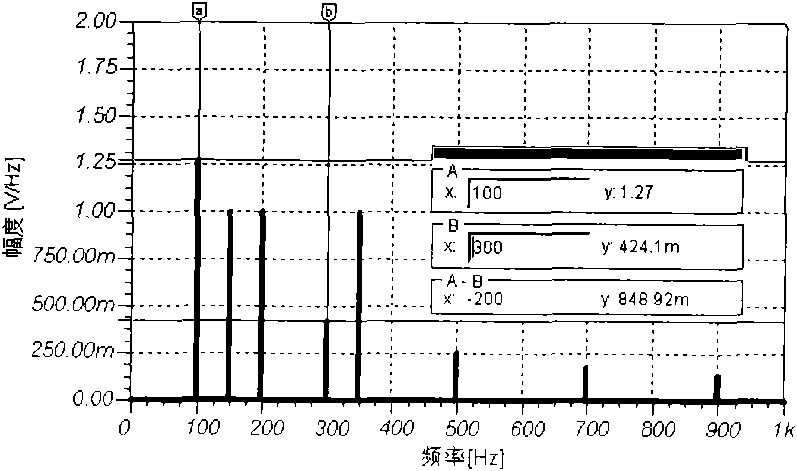

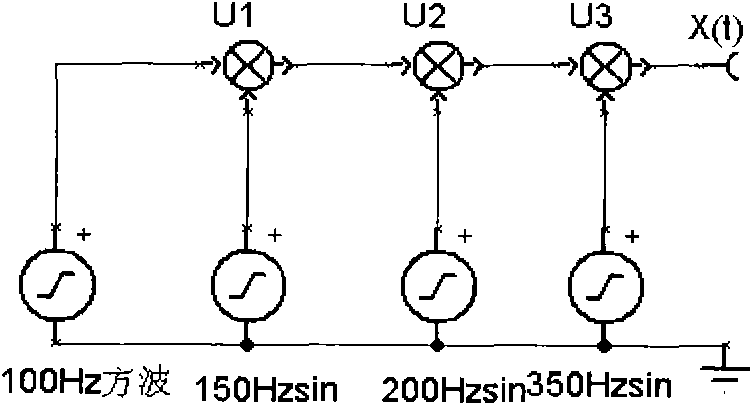

Rotating speed tracking and sampling and spectrum number curing and analyzing method of variable speed mechanical fault diagnosis

ActiveCN101846692ASimplify the tedious processFacilitate automatic diagnosisLinear/angular speed measurementFast Fourier transformFrequency spectrum

The invention relates to a rotating speed tracking and sampling spectrum number solidifying method of variable speed mechanical fault diagnosis, which is characterized by comprising the steps of: sampling mechanical related fault signals by replacing rotating speed pulse signals with frequency of Xfn in a moving machine with astronomical clock recurrent pulse signals; and then carrying out numerical analysis on the signals by applying an FFT (Fast Fourier Transform) technology, reconstructing a classical frequency coordinate system of FFT analysis output information into a spectrum number coordinate system of rotating speed tracking FFT analysis, and establishing a recognition function of spectrum numbers corresponding to information characteristics. The invention can change the classical rotating speed variable state which can not be monitored and diagnosed in a process of sampling a astronomical clock period into a state which can be monitored and diagnosed by rotating speed tracking and sampling, thereby greatly improving the time coverage rate of safety monitoring, preventing a dead zone of a classical technology, and being especially suitable for fault diagnosis in fields of city light rail traffic, subway, city buses, wind power generation and the like. The recognition of the classical technology to spectrogram and frequency spectrum is greatly simplified by applying a curing characteristic spectrum number formula, which is beneficial to manual spectrum recognition and more computer automatic diagnosis.

Owner:北京唐智科技发展有限公司

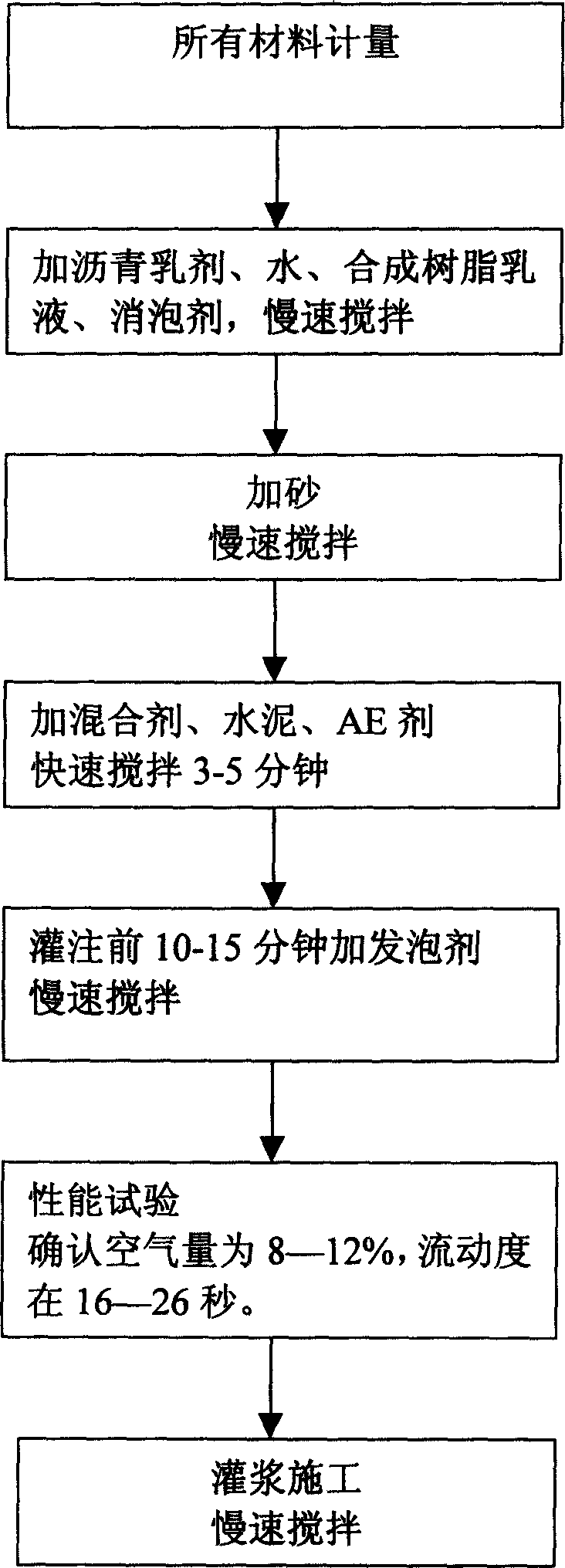

Cement asphalt mortar in use for ballastless track in railroad or city light rail, as well as fabricating method and construction method

Cement, mixing agent, pitch emulsion, sand (1.90-2.10 portion), water, foaming agent, aluminium powder, AE agent and plasthetics emulsion are mixed by equitable selecting material and matching, compound pitch emulsion agent is added in to make sand aggregate not being separated and has elasticity and excellent vibration strength since that small quantity of nonion polymer is mixed in compound pitch emulsion agent.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

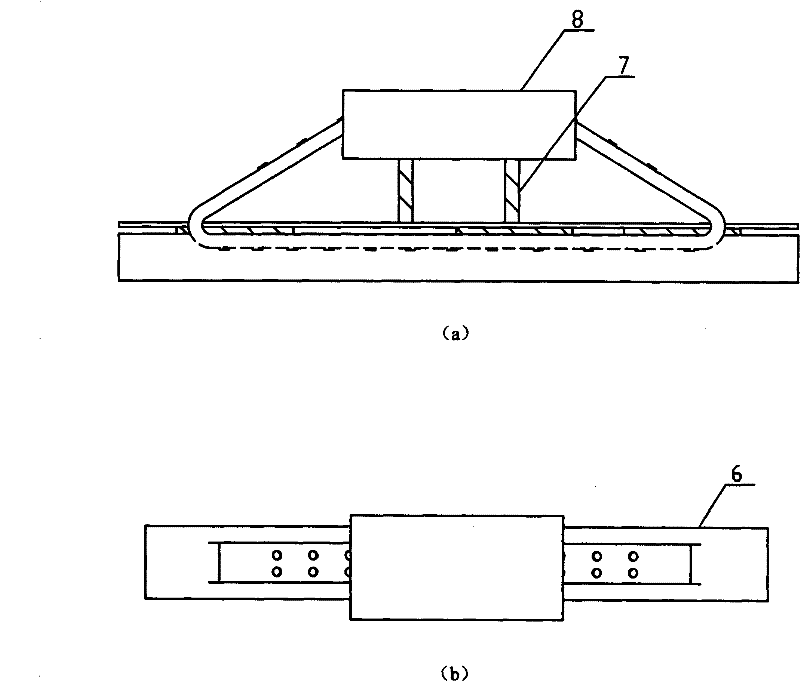

Flexible turnout beam section for saddle type single track traffic track

ActiveCN102817289AEasy accessGuaranteed comfortRailway tracksManufacturing cost reductionStructural engineering

The invention discloses a flexible turnout beam section for a saddle type single track traffic track. The flexible turnout beam section comprises a traveling support and a flexible beam body which deforms in a flexible manner along a horizontal direction. The traveling support comprises a traveling face and a flexible side supporting plate. The structure of the flexible turnout beam section is formed by a flexible turnout beam section which is flexibly deformed forcibly. Flexible deformation driven by external forces occurs when the flexible turnout beam section is jointed with the track which transfers. A guide face and a stable face of the flexible turnout beam section are in smooth transition, fold lines are eliminated, so that a light rail train can pass through. Compared with the conventional turnout beam structure, structure of the flexible turnout beam section for the saddle type single track traffic track is greatly simplified, manufacturing cost is lowered, manufacturing period is shortened, service life is longer, and use and maintenance costs are saved. Traveling comfort and safety of a light rail can be ensured and traveling noise of a vehicle is reduced, so that the flexible turnout beam section for the saddle type single track traffic track has a better environmental performance.

Owner:重庆川东船舶重工有限责任公司

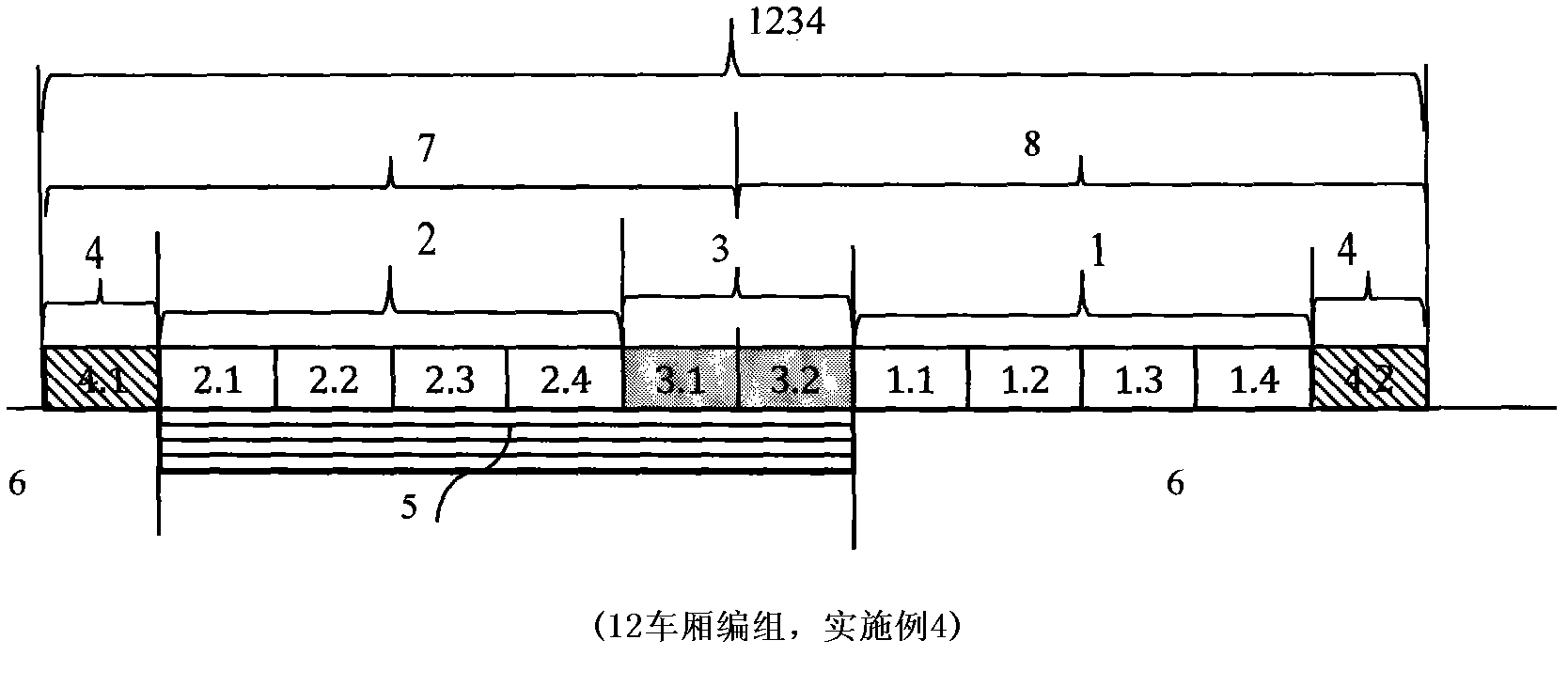

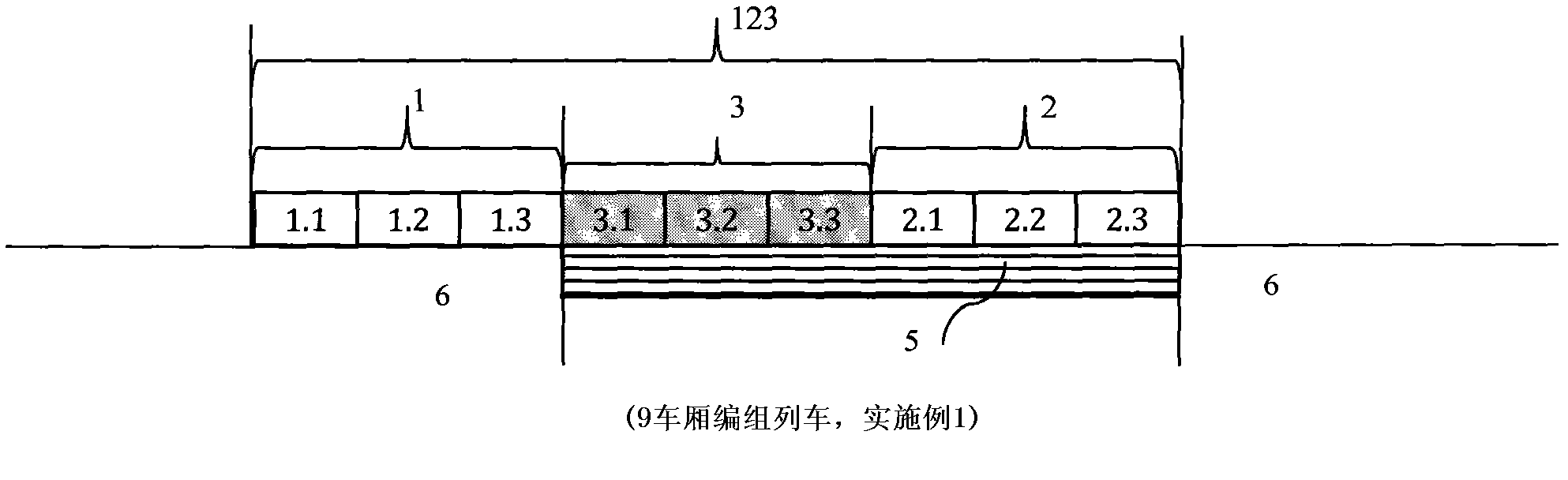

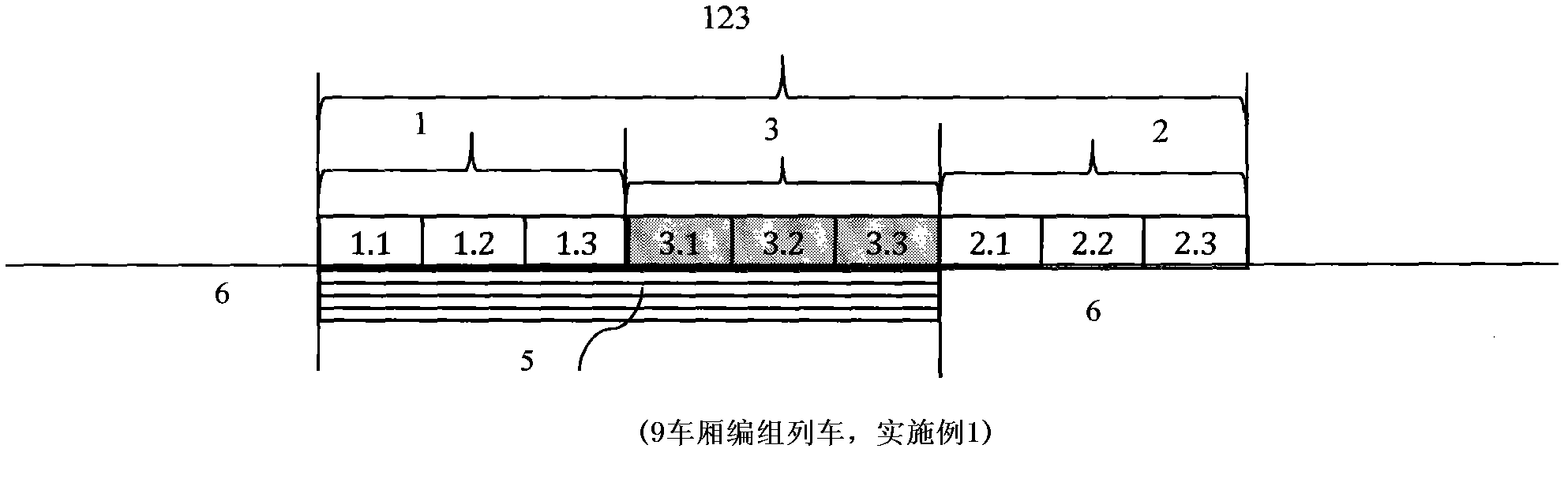

Ultra-long train marshalling operation and platform length determination method for subway or light rail

The invention relates to an operation method for a subway or light rail train, of which the marshalling length is larger than the length of a station platform, and a design method for determining the length of the platform, and by adopting the method, the transport capacity can be greatly improved. According to whether the length of the platform is larger than that of the train, stations in the whole line are divided into conventional stations and unconventional stations; then lines corresponding to the unconventional stations are disintegrated into one or more standard sections, or one or more standard sections and one or more non-standard stop stations; four compartment units, namely an odd number station stop unit, an even number station stop unit, a whole course stop unit and a whole course door-closing unit; in each standard section, the whole train can be disintegrated into the combination of two or more than two units. An embodiment using the method is also provided.

Owner:王哲

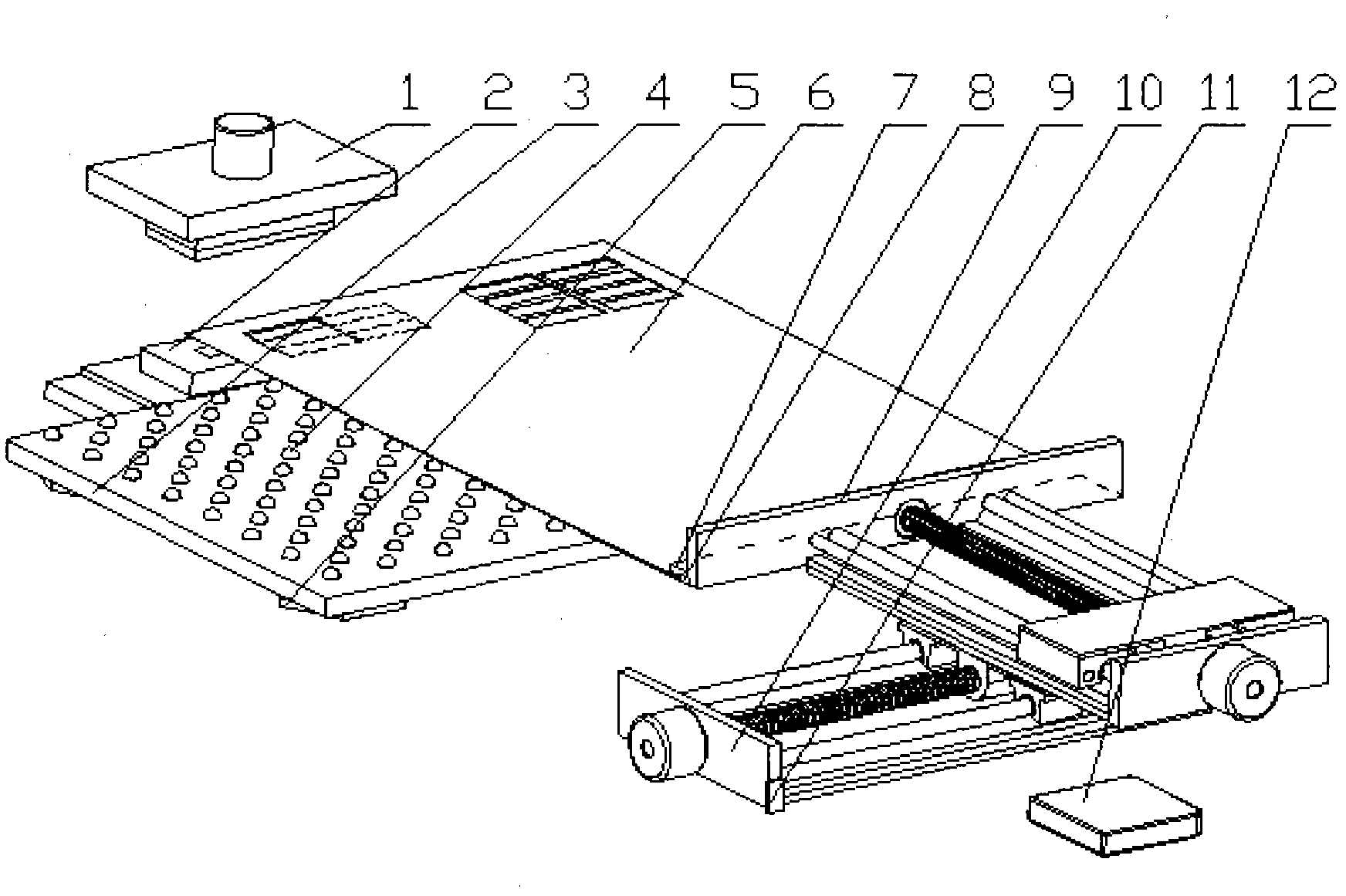

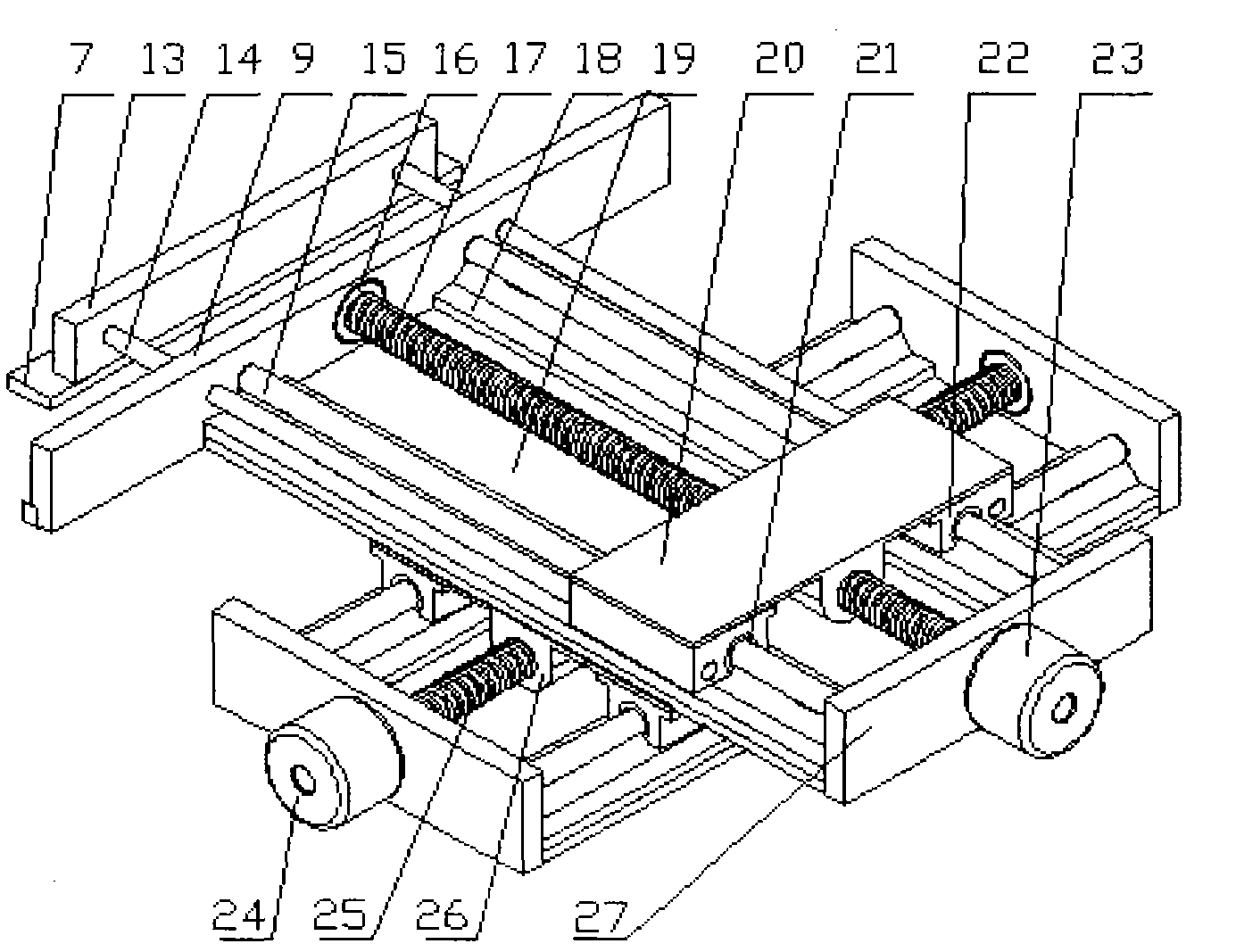

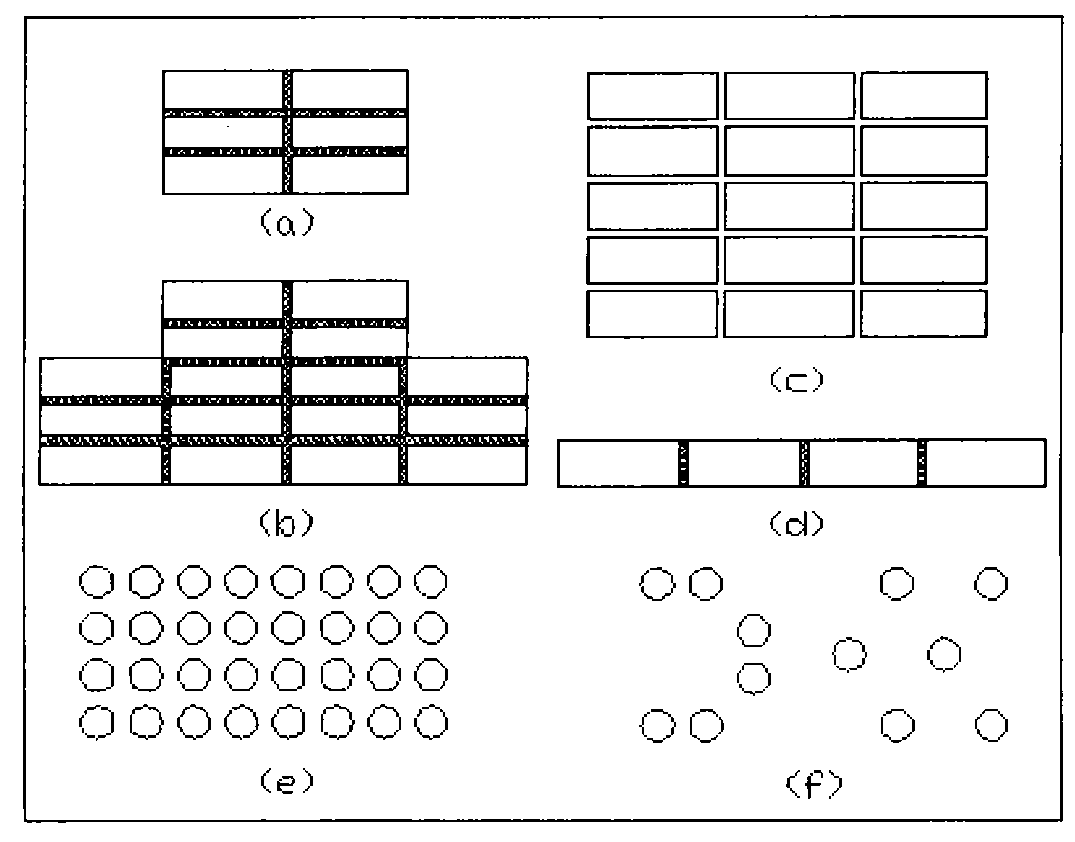

Universal automatic feeding device for punch press

InactiveCN102350463AMeet production needsMetal-working feeding devicesPositioning devicesPunch pressBall bearing

The invention discloses a universal automatic feeding device for a punch press. The universal automatic feeding device comprises a ball backing plate, balls, a regulating nut, a magnetic suction plate, a positioning nail, a metal positioning backer, a computer slot, a push plate, a push rod, a light-rail guide rod, a bearing, ball screw rods, a guide rod support, a light-rail base plate, moving guide plates, a ball bearing bush, a light-rail guide pillar, servo motors, bearing fixing plates and a computer, wherein two special light rails which are connected in a cross manner are arranged on the device in design, the two special light rails are respectively provided with one servo motor which is used for respectively driving the corresponding ball screw rod to rotate, the magnetic suction plate is connected onto the upper-layer light rail and is used for tightly sucking a metal plate to be punched, the servo motors are controlled by the computer so as to realize automatic metal plate feeding in the directions of back and forth as well as left and right. The universal automatic feeding device for the punch press is suitable for various punch presses to complete precise punching on workpieces of various shapes and automatic discharging of various punched pieces.

Owner:王崇庆

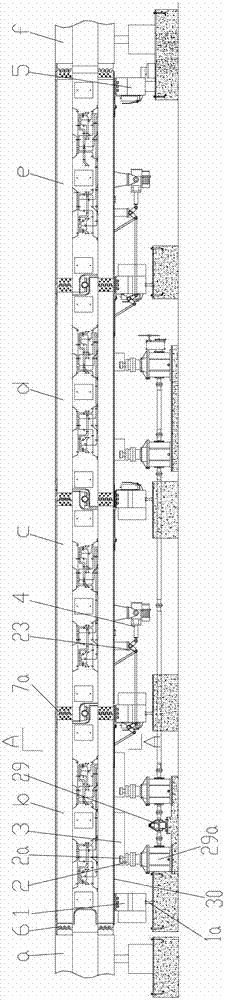

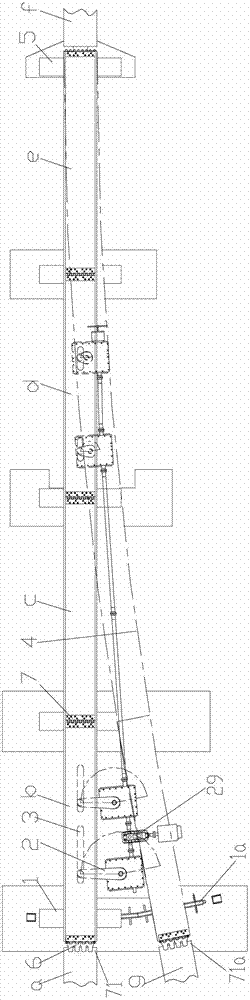

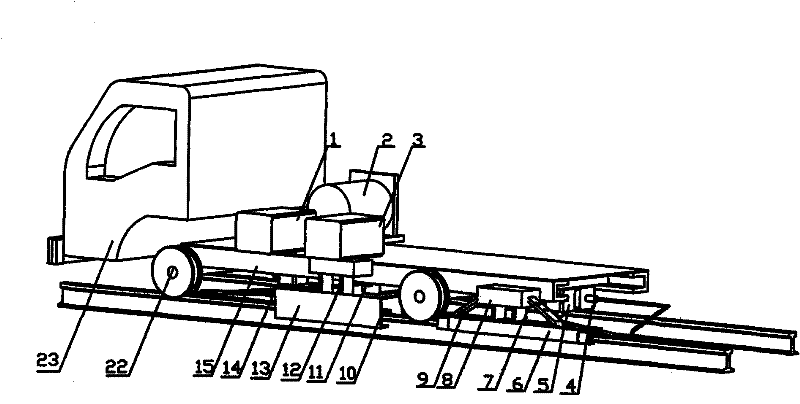

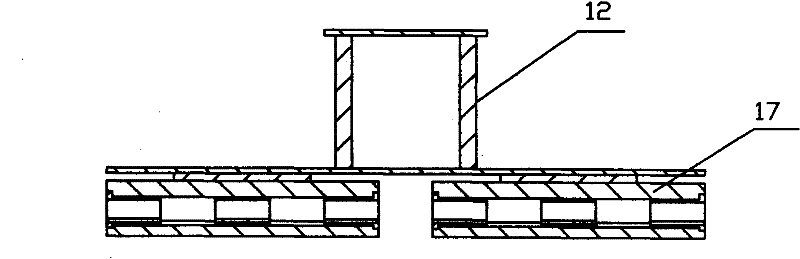

A cleaning maintenance vehicle using in a track

InactiveCN102162221AHigh degree of automationGuaranteed working accuracyRailway cleaningLight railSolvent

The invention discloses a cleaning maintenance vehicle using in a track, comprising a body device, a scraping mechanism, a scrubbing maintenance mechanism and a power energy mechanism. The cleaning maintenance vehicle using in the track is a track cleaning maintenance equipment of higher automation degree, and can realize a pre-treatment before the cleaning on the track working face, a thorough cleaning of the dirt on the track working face, a collecting and a cleaning of the cleaned down dirt, and an oiling maintenance of the cleaned track. The cleaning maintenance vehicle using in the tracktotally overcomes the problems in the prior art that the surface greasy filth and dry scab of the track can not be cleaned out automatically and effectively, the maintenance of the cleaned track is lacked, and the dirt and cleaning solvent can not be collected and cleaned in the process of cleaning. The cleaning maintenance vehicle using in the track of the invention realizes the automation of the cleaning and maintenance of the track, has the characteristics that the dirt is easy to recycle and clean, the cleanliness is high and the track working face is not easy to damage, etc. The cleaningmaintenance vehicle using in the track is not only suitable for cleaning dirt for the special track and similar track surfaces, but also suitable for maintenances of the city subway and city light rail.

Owner:海安磊洪新型建材有限公司 +1

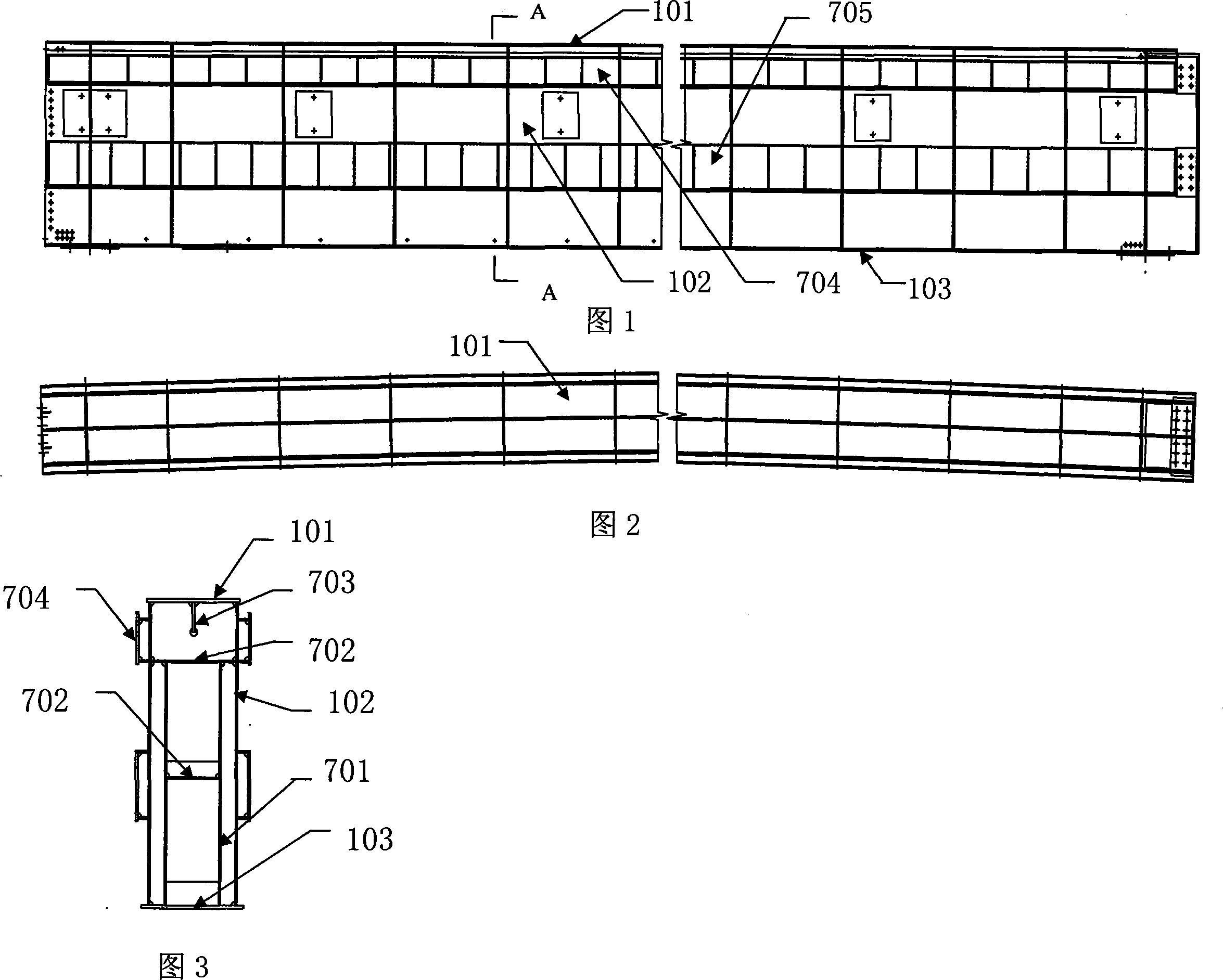

Arcuated steel rail beam and manufacturing method thereof

InactiveCN101220576ASolve welding deformationSolve arc processingRailway tracksBridgesLight railWelding deformation

The invention provides an arc steel track beam and a manufacturing method thereof, and an upper cover, two web plates which erect relatively and a lower cover in the steel track form box structure which is provided with a horizontal rib plate which is parallel to the upper cover, a longitudinal reinforcing rib which is parallel to the web plates, a guide beam and a stabilizing beam which are matched with the a light rail guide wheel and a stabilizing wheel are arranged symmetrically on the external side of the two web plates; a criss-crossed antiskid groove is evenly arranged on the top surface of the upper cover. The manufacturing method of the arc steel track beam comprises that: the upper cover of the steel track beam is processed, the anti-skid groove is processed, the arc prefabrication of the track beam is done and the track beam is assembled and welded. The invention guarantees the welding deformation amount to be controlled in the maximum amount owing to adopting reasonable technique and welding sequence.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Copper alloy conducting bar and end ring for high-power frequency-adjustable speed-adjustable asynchronous traction motor and preparation method thereof

The invention relates to a copper alloy conducting bar and an end ring for a high-power frequency-adjustable speed-adjustable asynchronous traction motor and preparation methods thereof. The conducting bar is prepared by the processes of medium-frequency induction melting, semi-continuous casting, ingot homogenization, hot extrusion, online quenching, cold drawing, aging and machining; and the end ring is prepared by the processes of medium-frequency induction melting, semi-continuous casting, ingot homogenization, forging, solid solution hardening, cold heading, aging and machining. The alloy of the conducting bar for a traction motor of a rapid train comprises the following components in percentage by weight: 9 to 12 percent of Zn, 0.3 to 1 percent of Cr, 0.05 to 0.3 percent of Zr and the balance of copper and inevitable impurities, wherein the resistance Rho at 150 DEG C of the alloy is kept at (5.00+ / -0.05)*10<-6>ohm.cm, and at a test temperature of 350 DEG C, sb is more than or equal to 320MPa, s0.2 is more than or equal to 270 and d5 is more than or equal to 10 percent; the alloy of the conducting bar for the traction motors of subway and light rail trains comprises the following components: 0.5 to 3 percent of Zn, 0.3 to 1 percent of Cr, 0.05 to 0.3 percent of Zr and the balance of copper and inevitable impurities, wherein the resistance Rho at 150 DEG C of the alloy is kept at(3.45+ / -0.05)*10<-6>ohm.cm, and at a test temperature of 350 DEG C, sb is more than or equal to 290MPa, S0.2 is more than or equal to 240MPa, and d5 is more than or equal to 12 percent; the copper alloy of the end ring for the traction motor comprises the following components: 0.3 to 1 percent of Cr, 0.05 to 0.3 percent of Zr and the balance of copper and inevitable impurities, wherein the resistance Rho at 150 DEG C of the copper alloy is kept at (2.70+ / -0.05)*10<-6>ohm.cm, and at a test temperature of 350 DEG C, sb is more than or equal to 260MPa, s0.2 is more than or equal to 220MPa.

Owner:CHANGSHA ZHONGGONG NEW MATERIAL

Light rail output bevel wheel machining process

The invention discloses a light rail output bevel wheel machining process which comprises blank making, normalizing, semifinishing, quenching, finish machining and final inspection. The finish machining process comprises a semi-finish turning I, a semi-finish turning II, a finish turning I, a finish turning II, a grinding gear excircle and a grinding gear. By means of the light rail output bevel wheel machining process, semifinishing and finish machining are carried out twice on an end face after quenching treatment is carried out on a teeth blank, when the teeth blank is clamped on a lathe, alignment is carried out according to pitch circle runout, grinding of the end face is replaced by turning, quality of machined gears is improved, and requirements for light rail high power output are met.

Owner:重庆方禾机电设备有限公司

Special emusified asphalt for railway or light underground plated non-fragment rail and its production

ActiveCN1939977AGive full play to the synergistic effectImprove temperature adaptabilityTemporary pavingsBuilding insulationsIonic strengthEngineering

Special emulsified asphalt for railway or light-rail plated non-fragment rail and its manufacture are disclosed. The process is carried out by emulsifying by mineral, regulating by pH value, building up with other emulsifiers and blending for emulsifier and applier. Its advantages include excellent stability, compatibility, elasticity and endurance and higher ionic strength.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

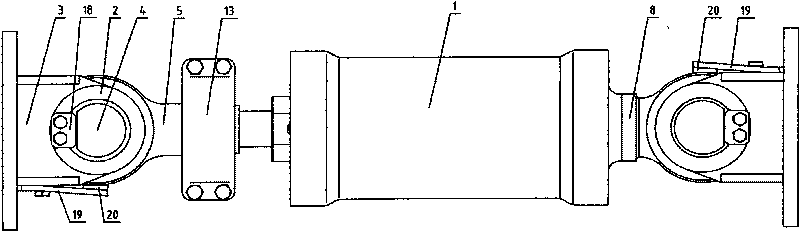

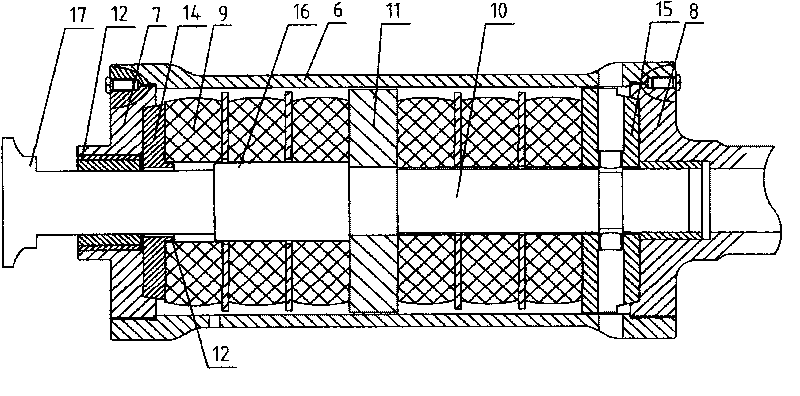

Semi-permanent car coupler for light rail

ActiveCN101698414ADoes not interfere with movement in all directionsEasy loadingDraw-gearLight railEngineering

The invention relates to a semi-permanent car coupler for a light rail, which comprises an end with a buffer and an end without a buffer, wherein the end with the buffer comprises the buffer, a joint bearing connected with the buffer and an installing seat, and the joint bearing is connected with the installing seat through a coupler yoke key; the end without the buffer comprises a left pull ring, a joint bearing connected with the left pull ring and an installing seat, and the joint bearing is connected with the installing seat through a coupler yoke key; the buffer is a double-acting buffer which comprises a shell, a left end cover, a right pull ring, elastomers, a central axis and a middle clapboard, wherein the central axis passes through the center of the left end cover and the right pull ring and is in slide contact with the left end cover and the right pull ring; one end of the central axis extends out of the left end cover; the middle clapboard is fixedly arranged on the central axis and divides the inside of the shell into two elastomer containing cavities, and the elastomers are positioned in the two elastomer containing cavities; and a convex plate is arranged at the other end of the left pull ring, a convex plate is also arranged at one end of the central axis extending out of the left end cover, and the two convex plates are connected through a connecting ring.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

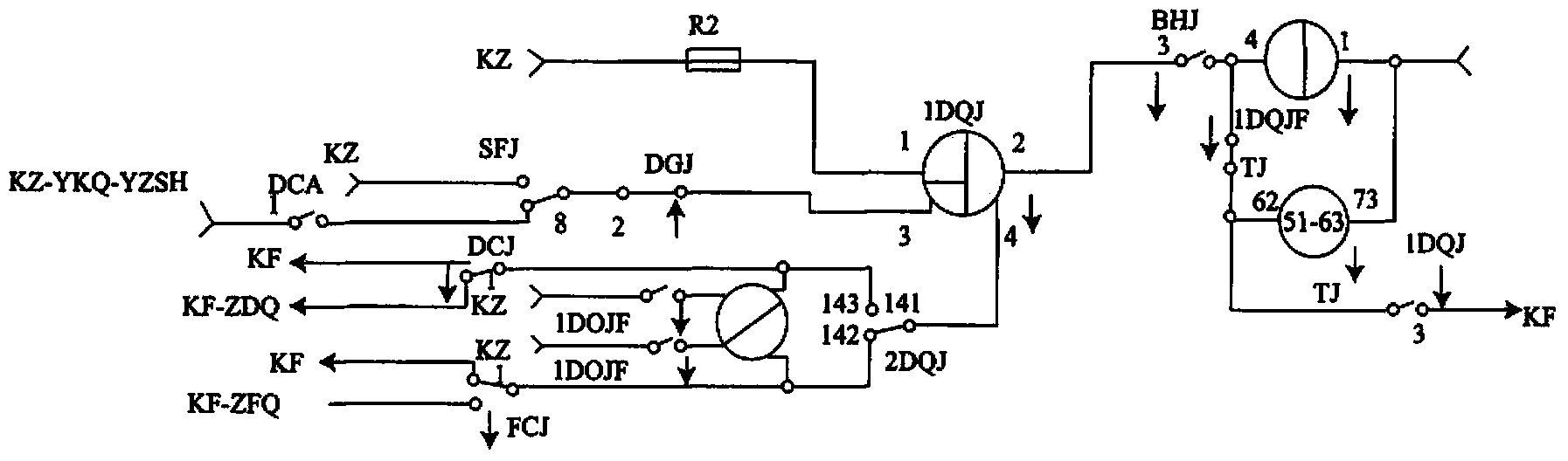

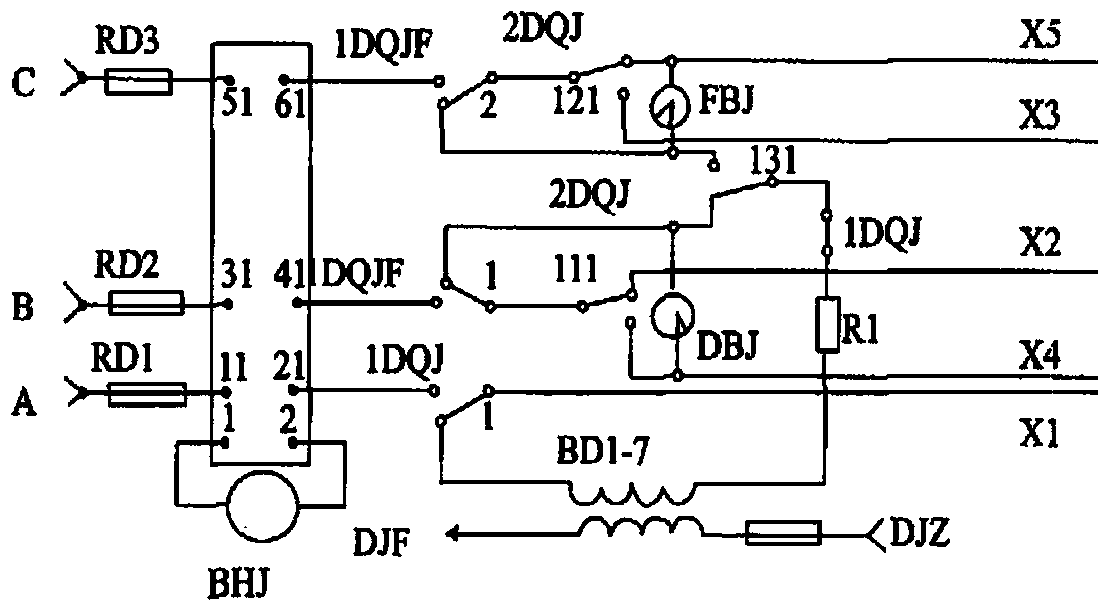

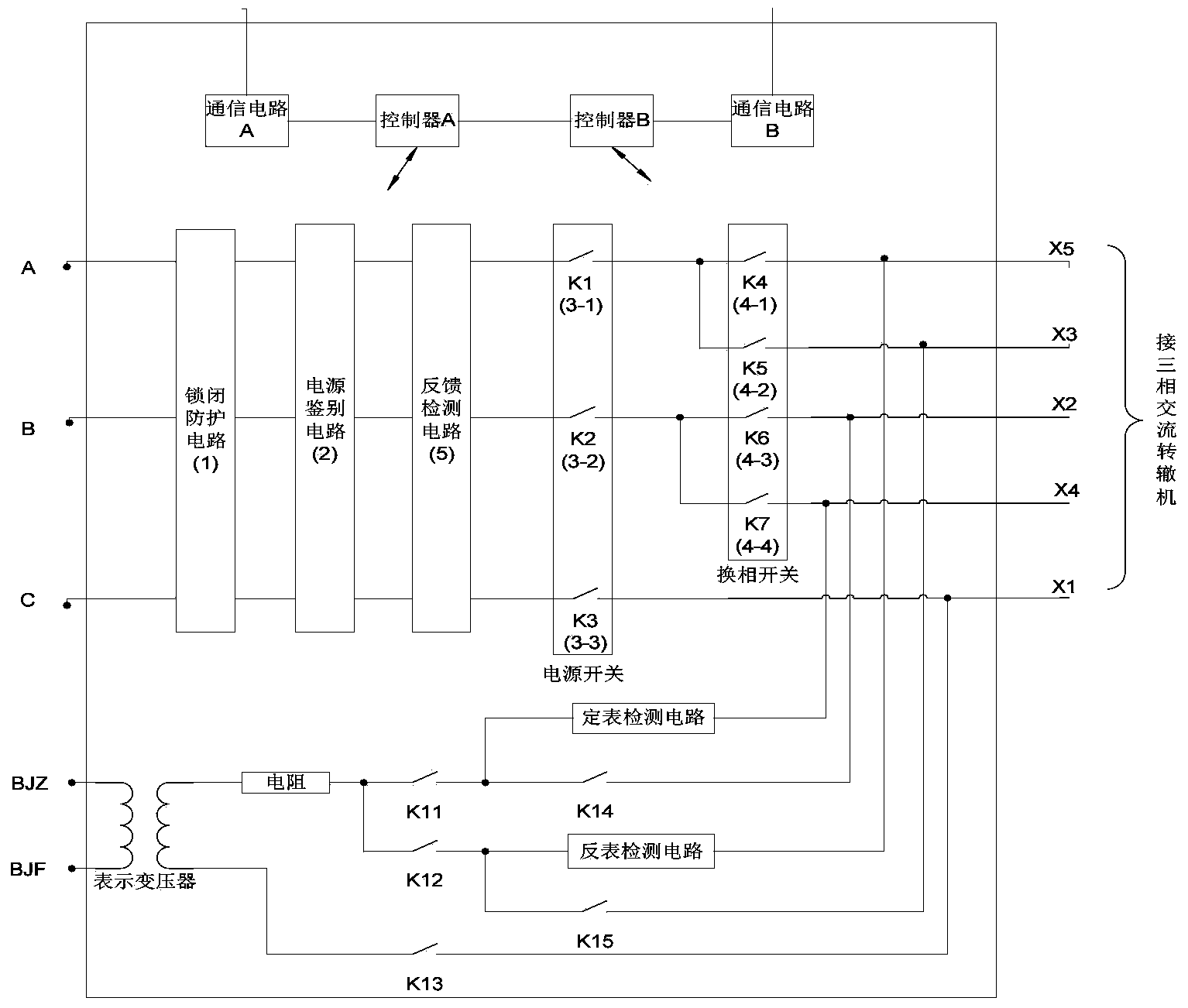

Device and method for railway heavy type turnout multi-point-switch synchronous traction and control

ActiveCN103786750AImprove securityLow costElectric devices for scotch-blocksDiscriminatorMulti machine

The invention relates to a traffic transportation railway signal automatic control system which comprises places such as a railway special line, a bus special line, a subway and a light rail where a signal control device for heavy type turnout multi-machine traction is used. A device for railway heavy type turnout multi-point-switch synchronous traction and control is mainly characterized in that a phase A power line is connected with a power source discriminator circuit and a feedback detection circuit through a locking protection circuit and the output end of the phase A power line is connected with an X5 end of a point switch through a power switch K1 and a change-over switch K4 and connected with an X3 end of a point switch through the power switch K1 and a change-over switch K5; a phase B power line is connected with the power source discriminator circuit and the feedback detection circuit through the locking protection circuit and the output end of the phase B power line is connected with an X2 end of a point switch through a power switch K2 and a change-over switch K6 and connected with an X4 end of a point switch through the power switch K2 and a change-over switch K7; a phase C power line is connected with the power source discriminator circuit and the feedback detection circuit through the locking protection circuit and the output end of the phase C power line is connected with an X1 end of a point switch through a power switch K3. The device has the advantages that a five-wire system turnout switching indication circuit composed of a safety relay is replaced by an electronic circuit, indication of localization and anti-position of a turnout can be detected and analyzed in real time, and safety is further improved.

Owner:LANZHOU JIAOTONG UNIV

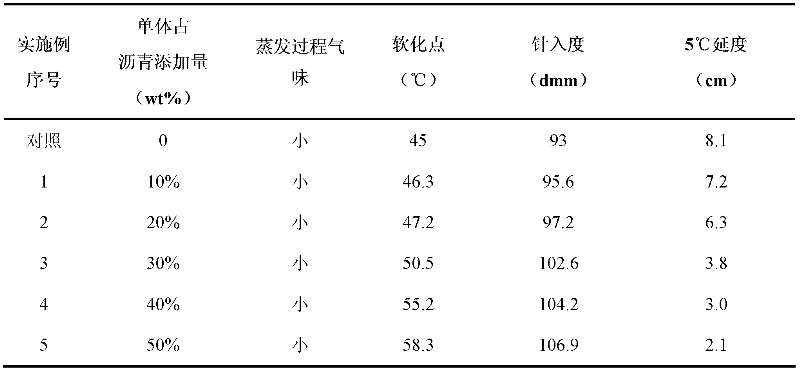

Preparation method for polymer microcapsule modified emulsified bitumen

ActiveCN102352113AImprove stabilityImprove performanceBuilding insulationsPolymer modifiedCrack resistance

The invention discloses a preparation method for polymer microcapsule modified emulsified bitumen, which belongs to the technical field of modification of bitumen. A polymer shell layer is formed through microcapsule in-situ cladding and crosslinking on the surface of bitumen microballoons by using the method of miniemulsion polymerization, and an organic / inorganic composite core-shell structure is formed. After the polymer microcapsule modified emulsified bitumen becomes a film, an interpenetrating polymer network of a polymer and bitumen is formed; the polymer microcapsule modified emulsified bitumen has the characteristics of an organic / inorganic composite, better heat resistance and a high softening point; a mixture fabricated with the polymer microcapsule modified emulsified bitumen has good resistance to permanent deformation, can prevent harmful damage like formation of ruts on a pavement in high temperature seasons and better adapts to needs for pavement construction and maintenance in hot areas. Since the polymer microcapsule modified emulsified bitumen has the characteristic of modification by the polymer, the emulsified bitumen has improved toughness and good crack resistance, and can be extensively used in the fields like emulsified bitumen cement mortar for plate type ballastless tracks of high-speed railways or urban light rails.

Owner:TSINGHUA UNIV

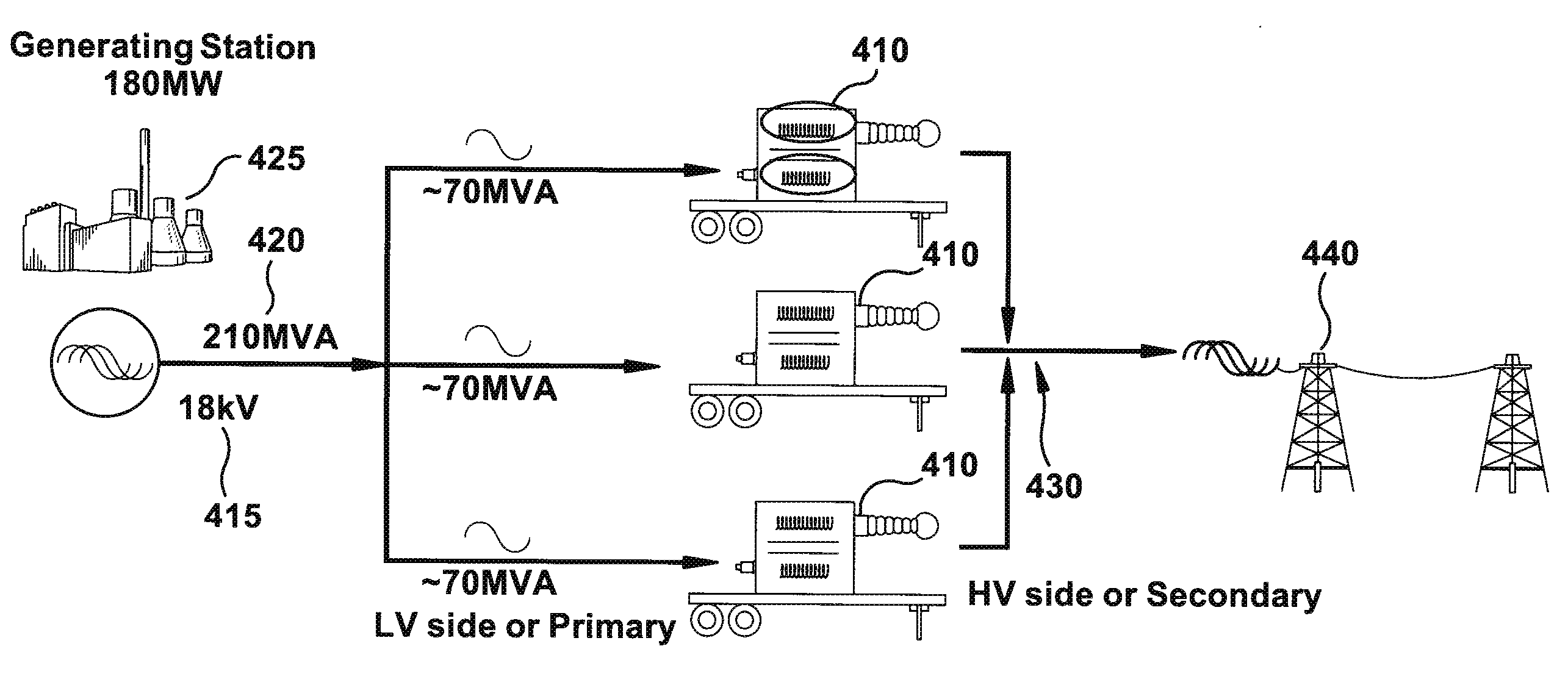

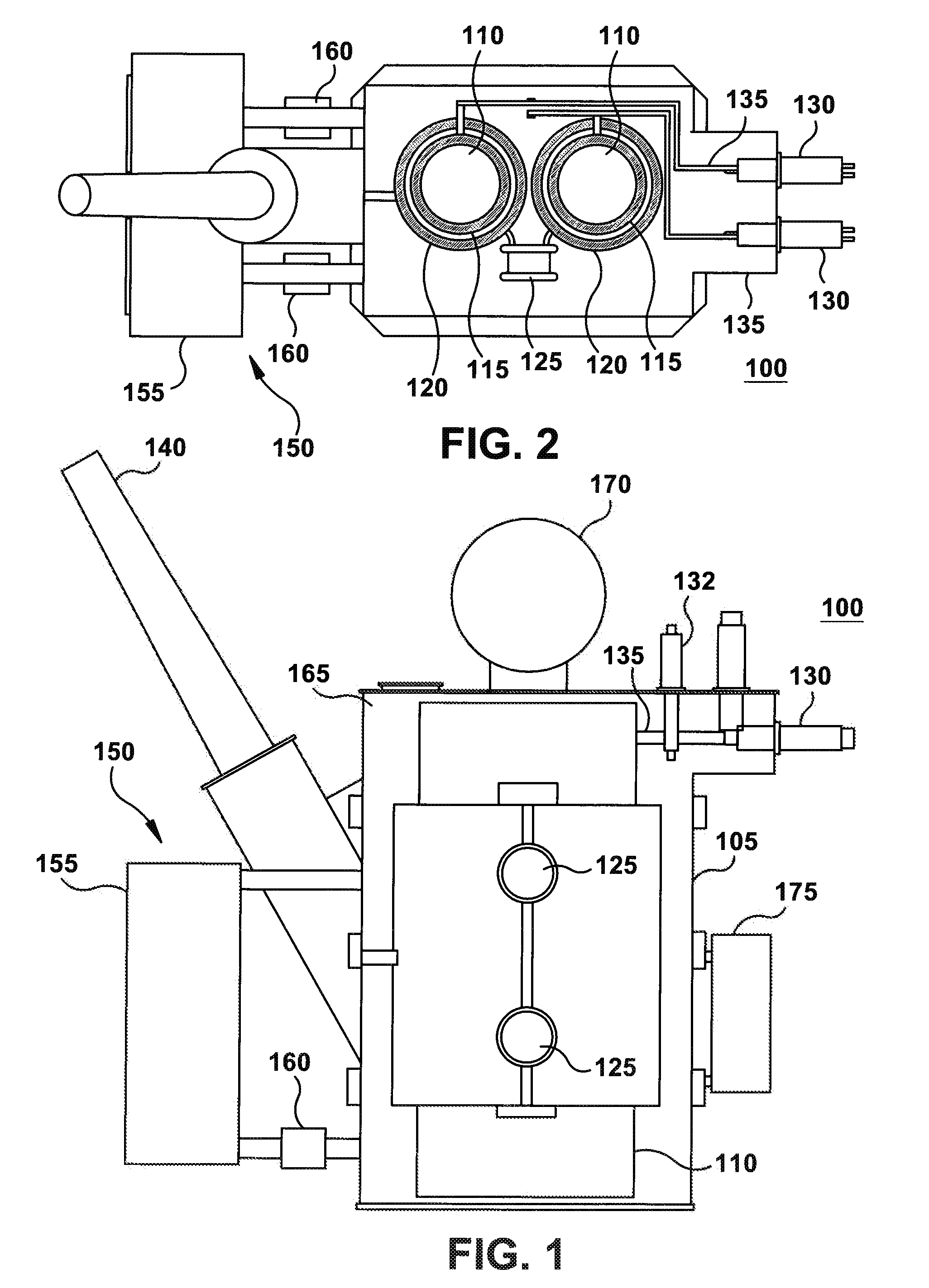

Portable transformer and method for improving reliability of electric power delivery

InactiveUS20100090543A1Easy to transportAlleviate and minimize issueSubstation/switching arrangement detailsSupport structure mountingTransformerElectricity delivery

The present invention relates to an apparatus and method for improving the transportation and installation of portable step-up power transformers for a power generating station due to failure or unavailability of installed step up transformers. A large MVA portable transformer may be used to alleviate or minimize these issues by being purpose built for transportability and commissioning speed. The portable transformer is transportable by road or lighter rail. Its size and weight are arranged to overcome restrictions such was weight limits, bridge constraints, and power line constraints. This device may also provide for rapid commissioning and decommissioning. This transformer may be a set of three single-phase units of sufficient size to be used as a generator step up transformer in three-phase operation.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com