Patents

Literature

80results about How to "Solve welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

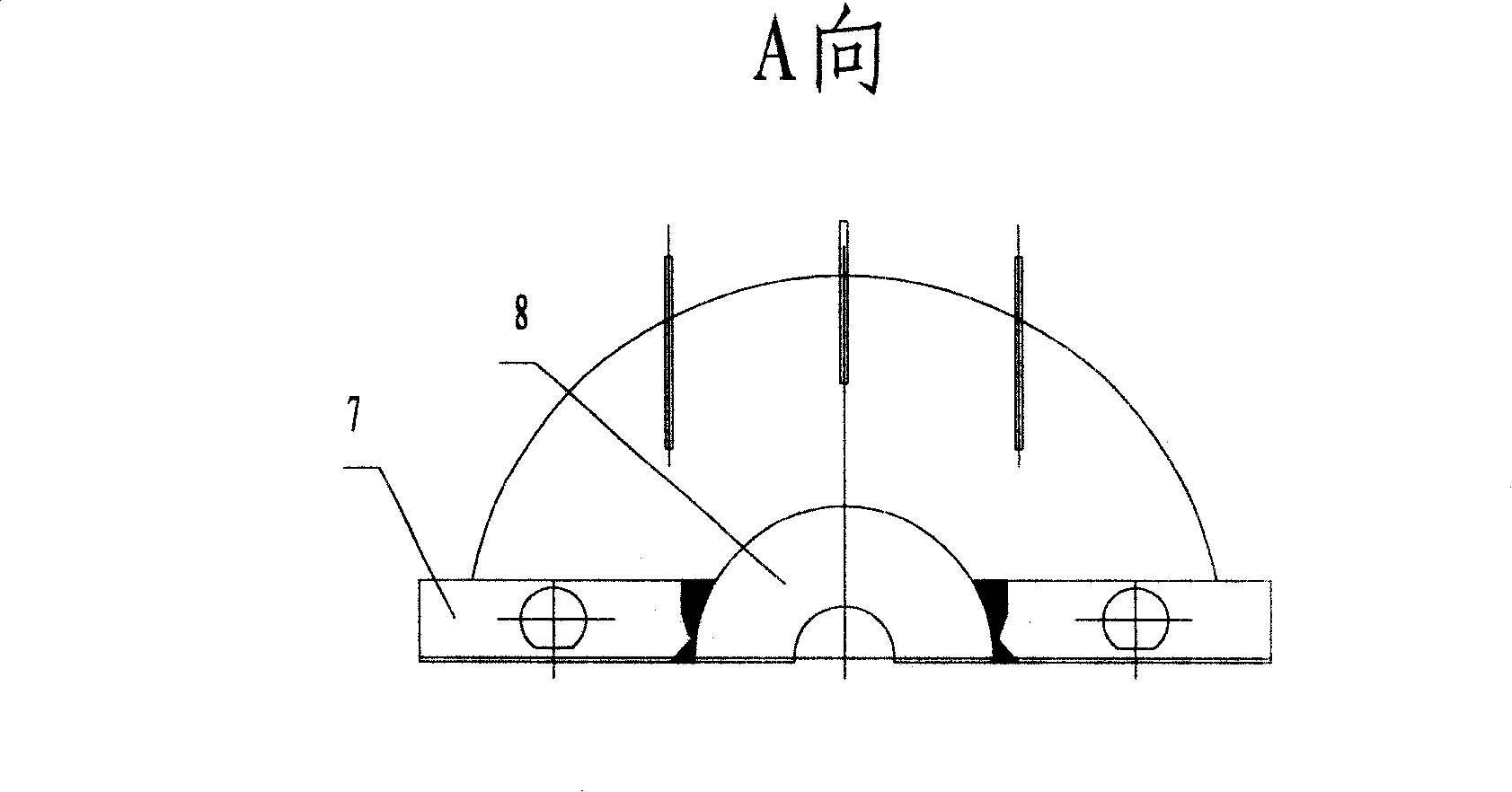

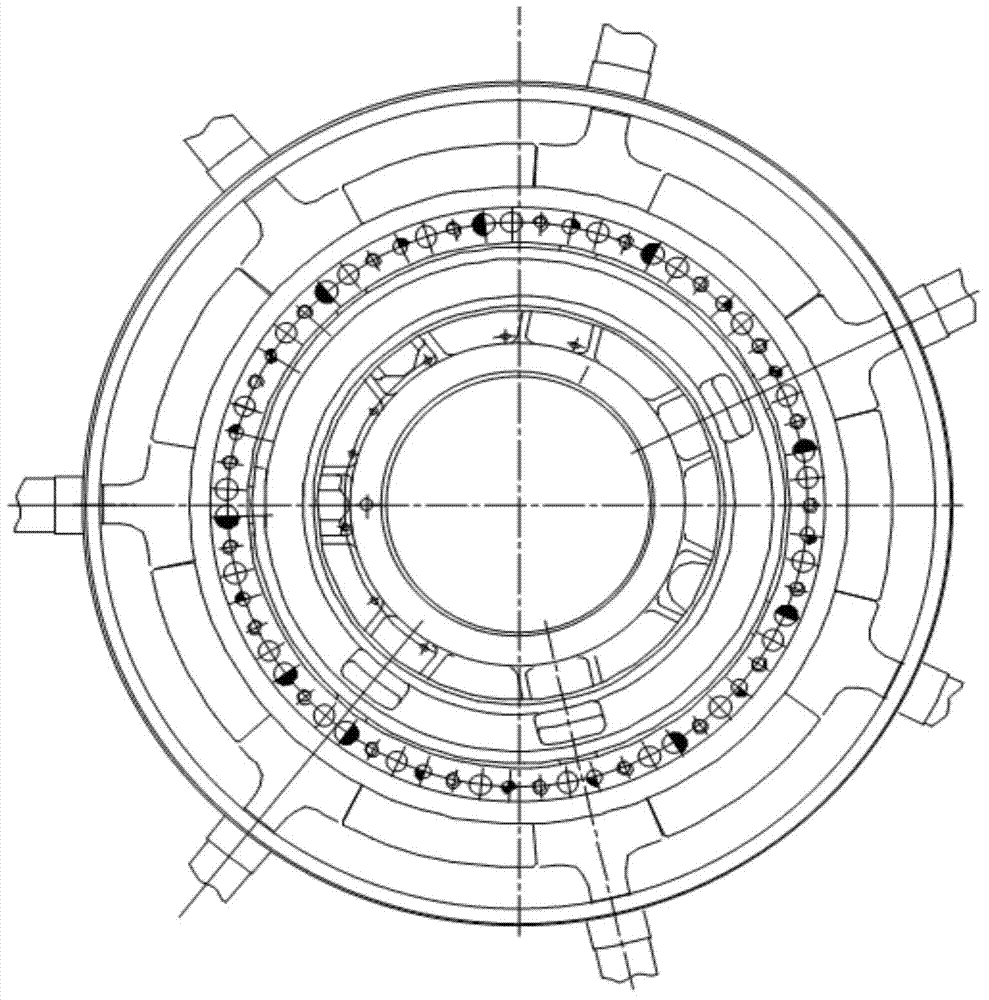

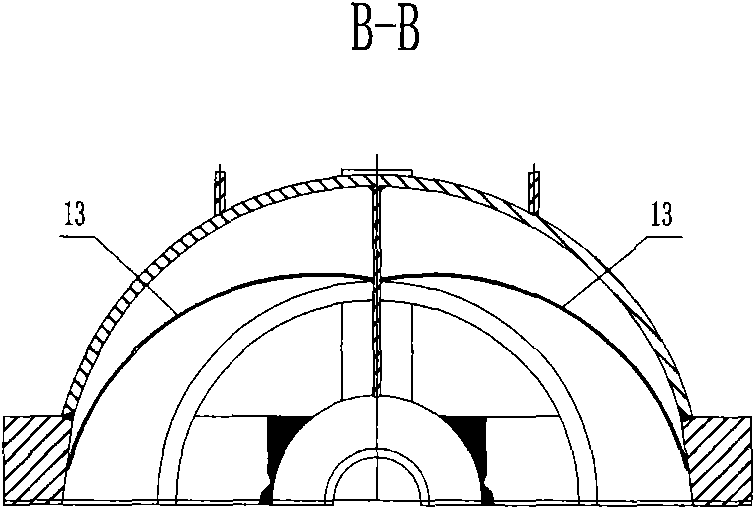

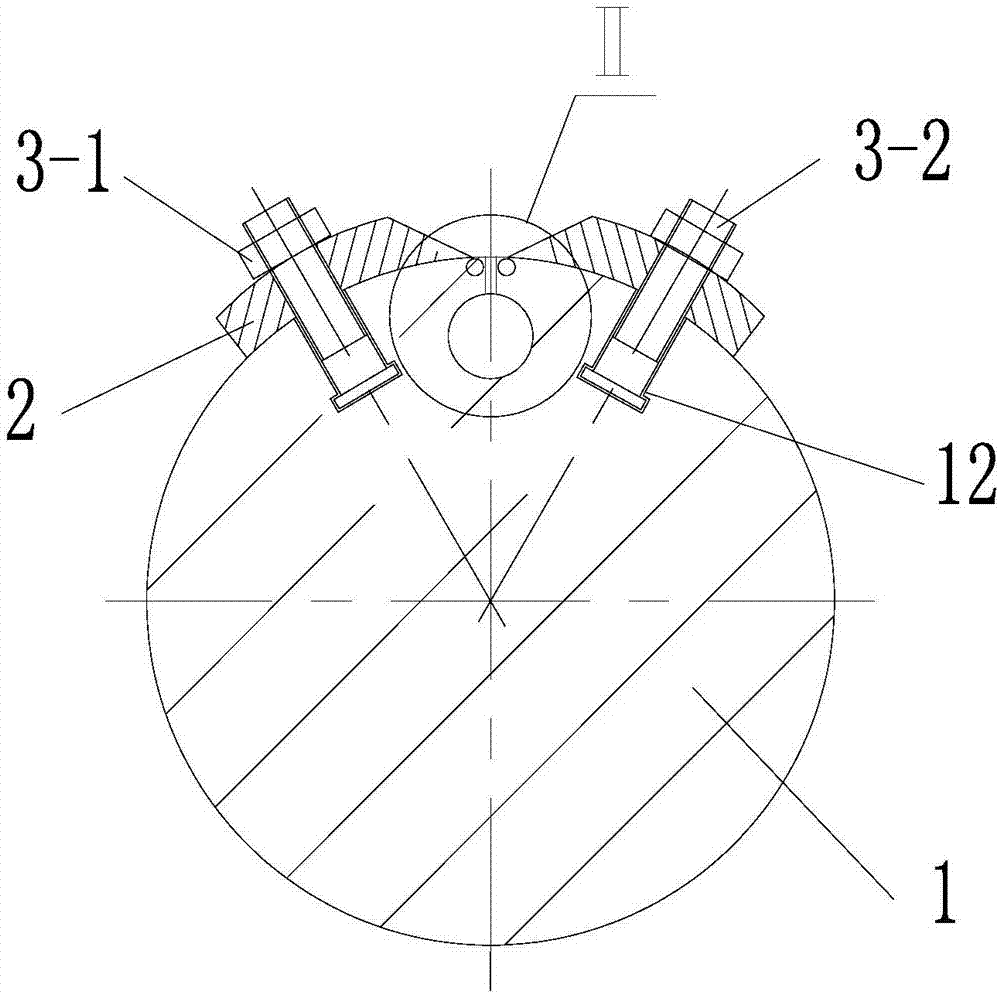

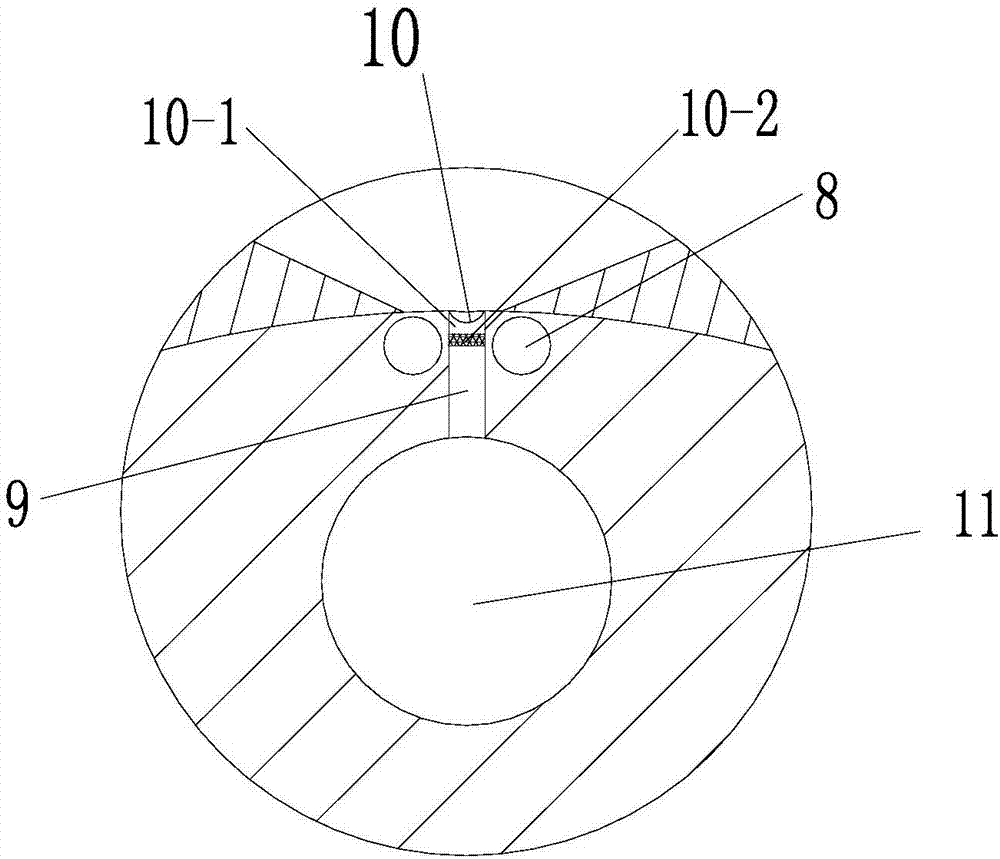

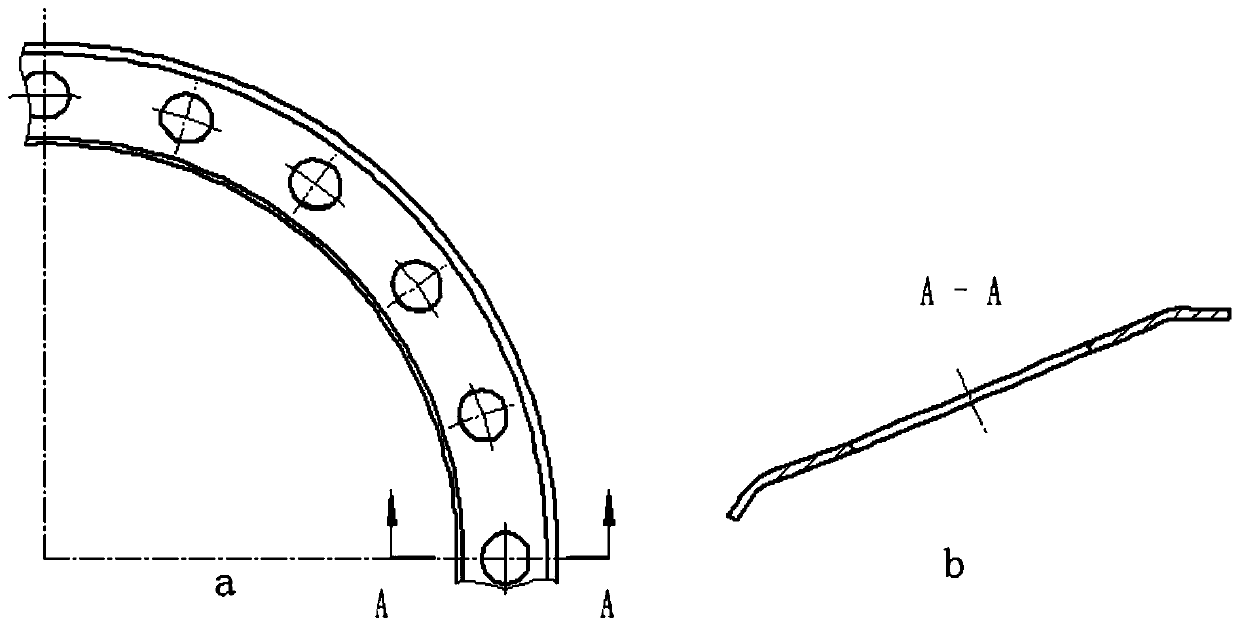

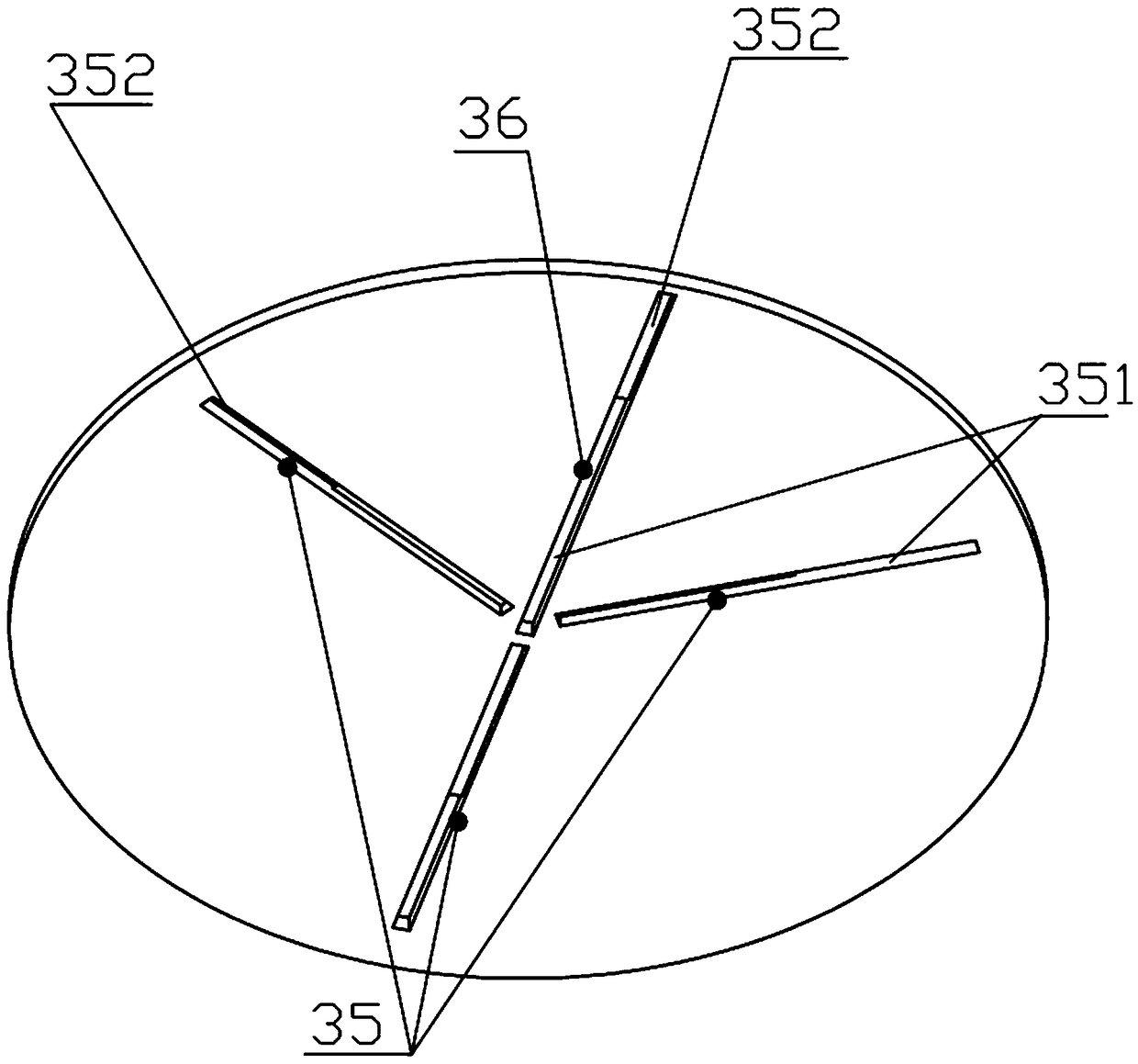

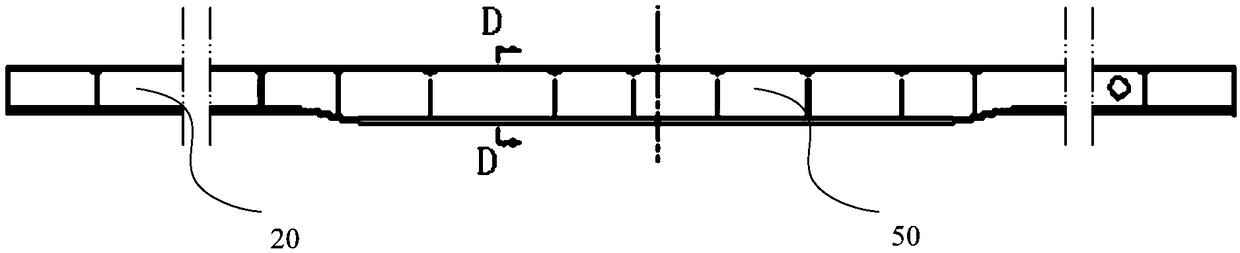

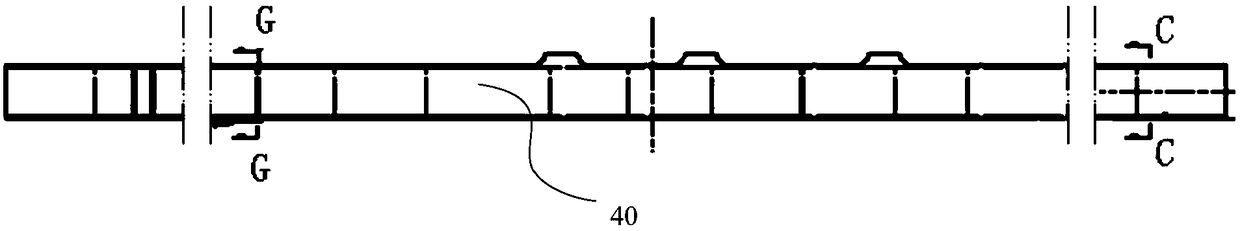

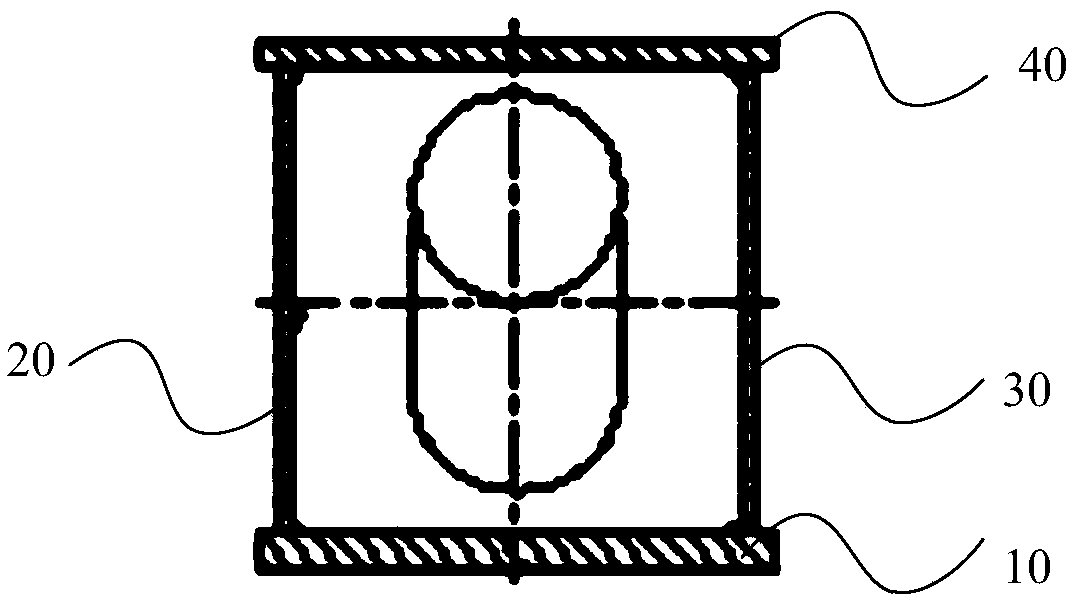

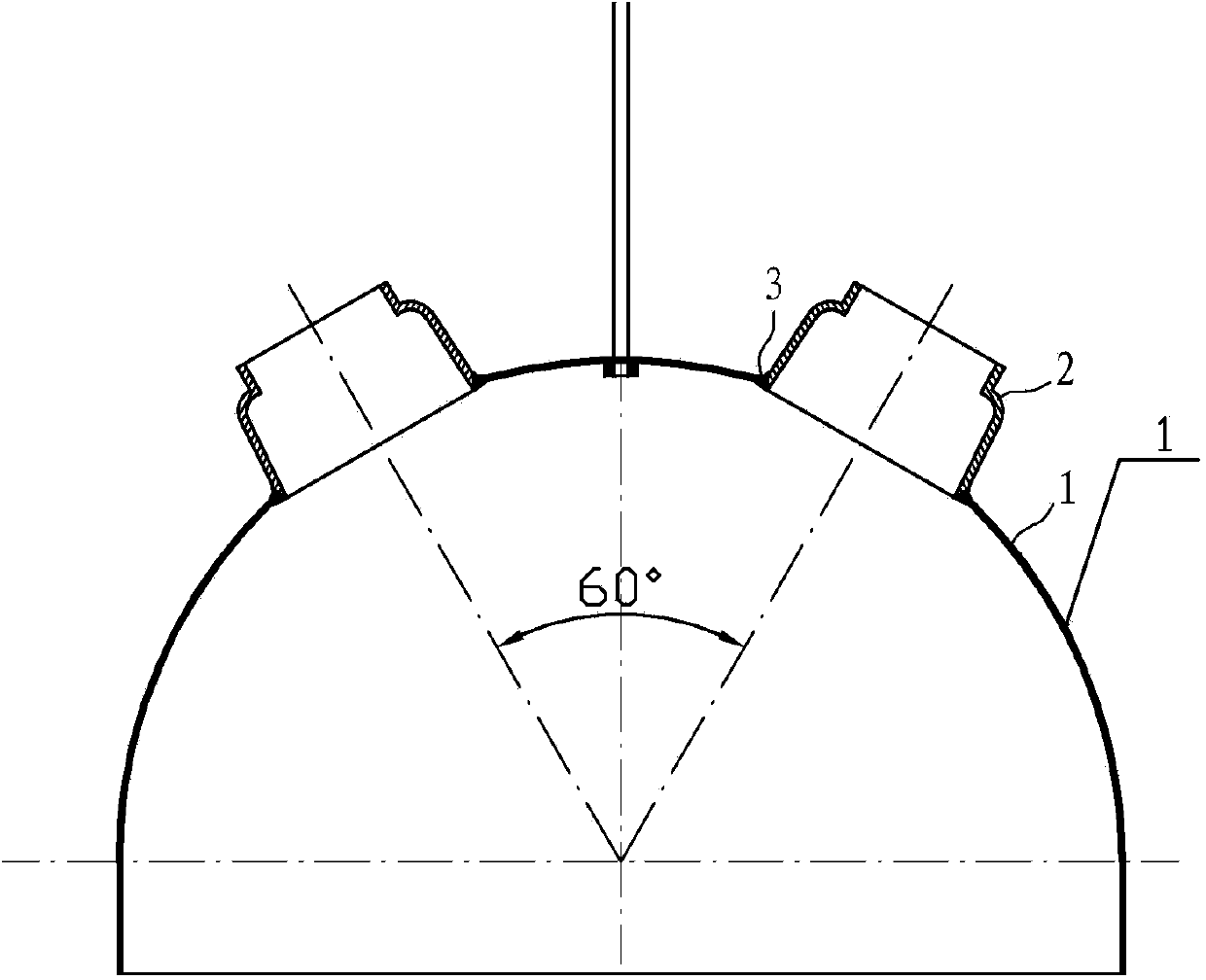

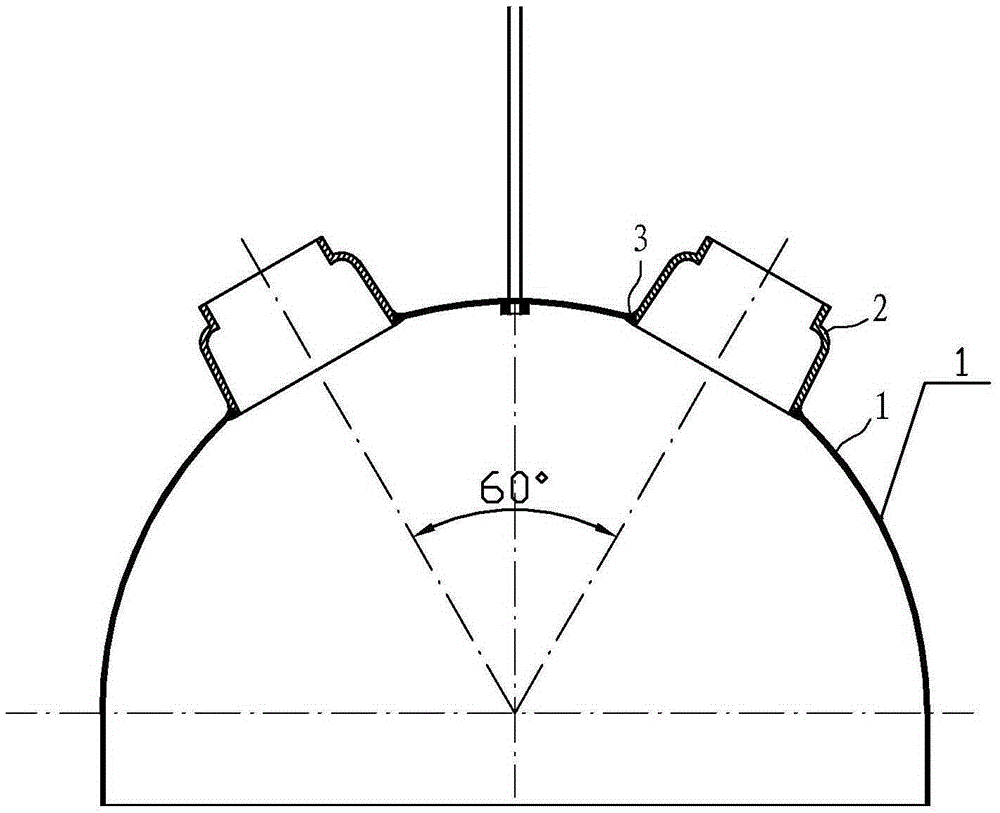

Cantilever and radials type titanium alloy casing deformation control method and device

ActiveCN104493369ASolve welding deformationMeet quality requirementsWelding/cutting auxillary devicesArc welding apparatusDeformation controlTitanium alloy

The invention provides a cantilever and radials type titanium alloy casing deformation control method and device. The welding is performed in sequences from interior to exterior, from the middle to two sides and from the internal layer to the external layer, stress removal heat treatment are performed after welding, and the final stress removal heat treatment is performed before assembly; argon gas protection is adopted in the back welding process, and welding gun protection is adopted in the front welding process. The device comprises a heat treatment clamp and a welding clamp; a base of the heat treatment clamp is connected to a positioning ring integrally in a welded manner, and positioning blocks of the welding clamp are connected through a pin, are in clearance fit and are pressed through press bolts. The method and device has the advantages that the problem of welding deformation of a complex welding structure casing is solve smoothly, the quality requirements of an aircraft engine metal seal ring can be met, and a part of the variety is free of a heavy entire casting structure.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

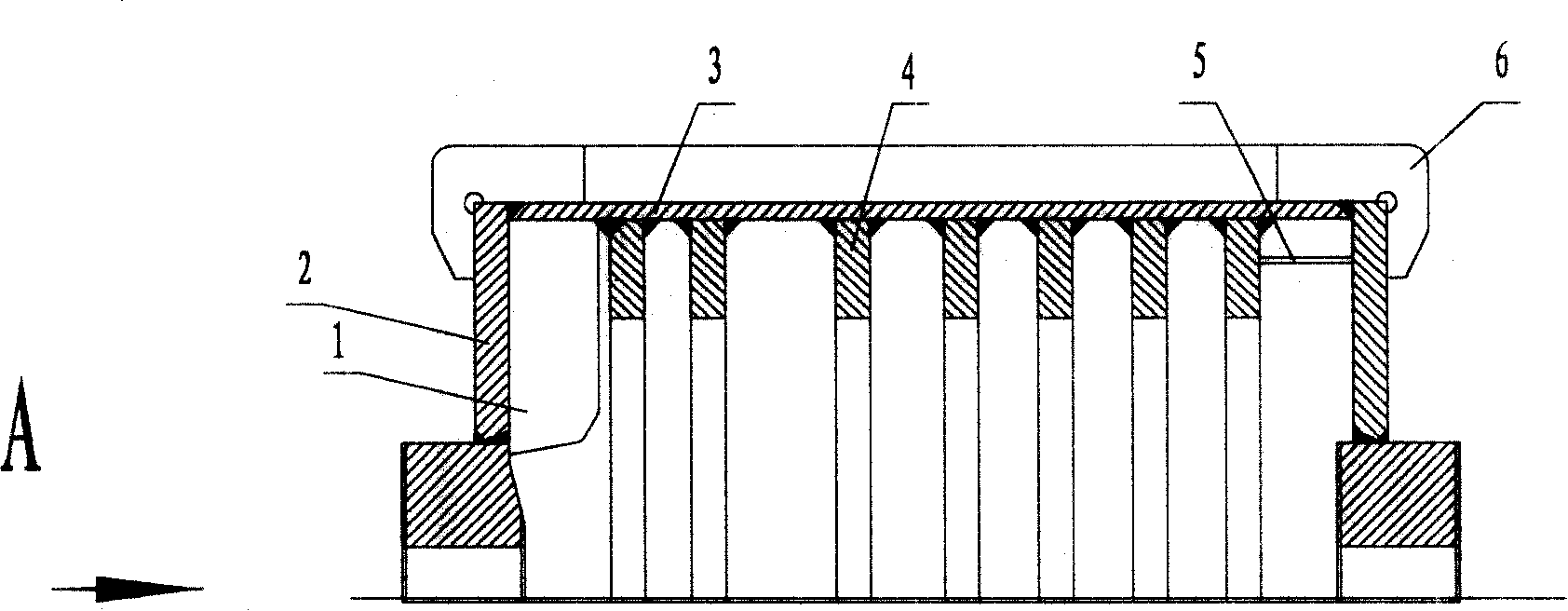

Welding process of megaton ethane compressor casing

ActiveCN101890557AShorten welding cycleQuality assuranceWelding/cutting media/materialsSoldering mediaShielding gasWeld seam

The invention relates to a welding technology in the equipment manufacture industry and relates a special welding technology of an MCL (Mean Control Limit) type horizontally-split centrifugal compressor welder casing, in particular to a welding technology of a megaton ethane centrifugal compressor welder casing with forgeable pieces of 16 Mn and Q345R and ZQ230-450 materials. Gas shielded welding is adopted to weld the welder casing with the forgeable pieces of 16 and the Q345R low alloyed steel, and an electrode in a brand of H08Mn2SiS with a diameter shown in the specification, power supply polarity of DCRP (Direct Current Reverse Polarity) is adopted and comprises fore-welding treatment, welding process and post-welding treatment, wherein the welding process comprises the following process parameters: a welding current is 250-280 A, a welding voltage is 28-32 V, a protective mixed gas comprises 80 percent by volume of Ar and 20 percent by volume of CO2, a welding speed is 280-320 mm / min, the dry extension is 20-25 mm, and the gas flow is 15-20 L / min. The invention can solve the problems of welding deformation, layered tearing, low welding efficiency, and the like and ensure the welding seam strength by selecting an MAG (Metal Active Gas) shielded welding material with similar chemical contents and matched strength with a welder casing material.

Owner:SHENYANG BLOWER WORKS GROUP CORP

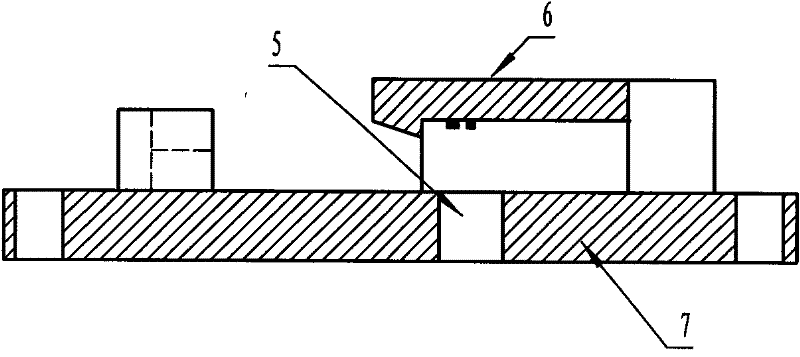

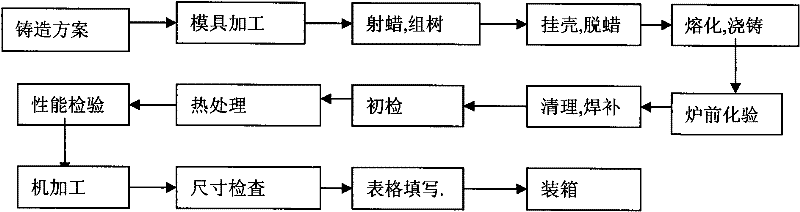

Special alloy steel and method for high-speed rail turnout integral sliding bedplate

InactiveCN102453842ASolve the problem of precision and welding deformationSimple structureRail switchesFoundry mouldsCarbon steelCorrosion resistant

The invention which relates to novel special alloy steel, and concretely relates to special alloy martensite stainless steel and a method for preparing a high-speed rail turnout integral sliding bedplate from the stainless steel belongs to the technical field of novel material preparations and applications thereof. The special alloy steel comprises the following chemical components, by weight, equal to or less than 0.10% of C, equal to or less than 1.5% of Si, equal to or less than 1.5% of Mn, equal to or less than 0.03% of P, equal to or less than 0.03% of S, 12.5-15.5% of Cr, 1-2% of Ni, a certain amount of Nb, 0.05-0.2% of W, 0.0003-0.0005% of B, 0.02-0.04% of N, and the balance Fe, wherein the amount of Nb is 3-5 times the amount of C. The method is carried out with integral casting one-time forming. According to the invention, defects of the processing technology complexity and the short service life caused by the adoption of easily abraded common carbon steel and the welding of three parts in the prior art are offset. The integral sliding bedplate of the invention, which successfully replaces split-welded sliding bedplates, has the characteristics of high strength, good abrasion resistance, corrosion resistance and no rust, no deformation, and short production period. So, the method which can satisfy essential conditions for the streamline production is very suitable for the large batch production.

Owner:张佳秋

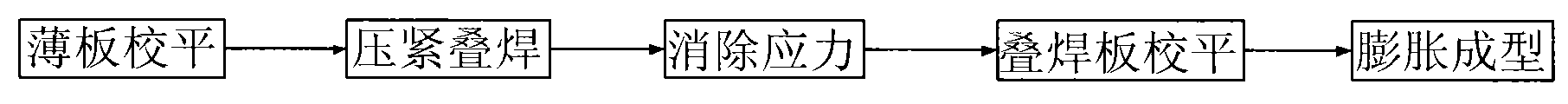

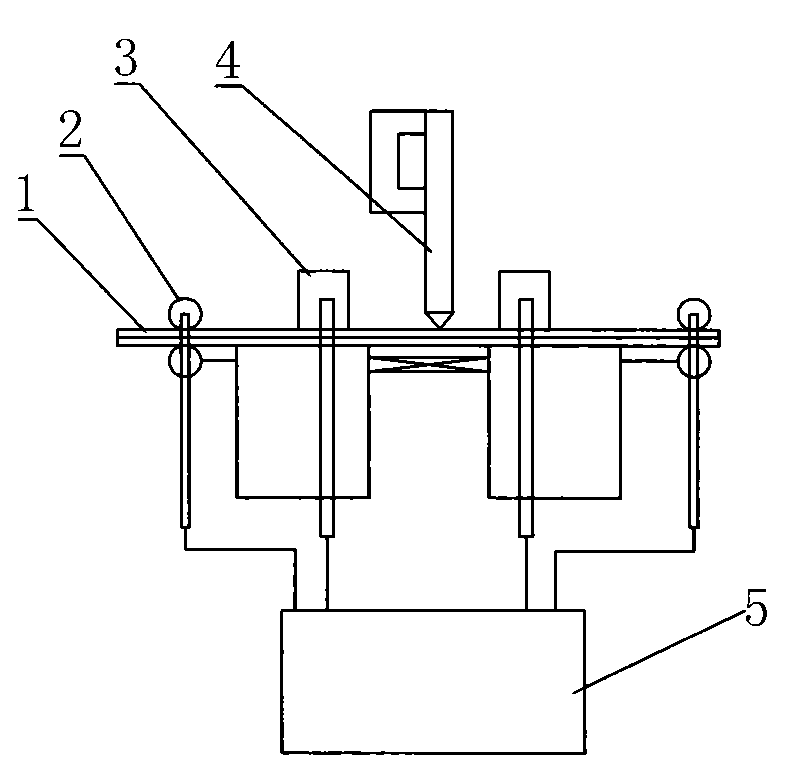

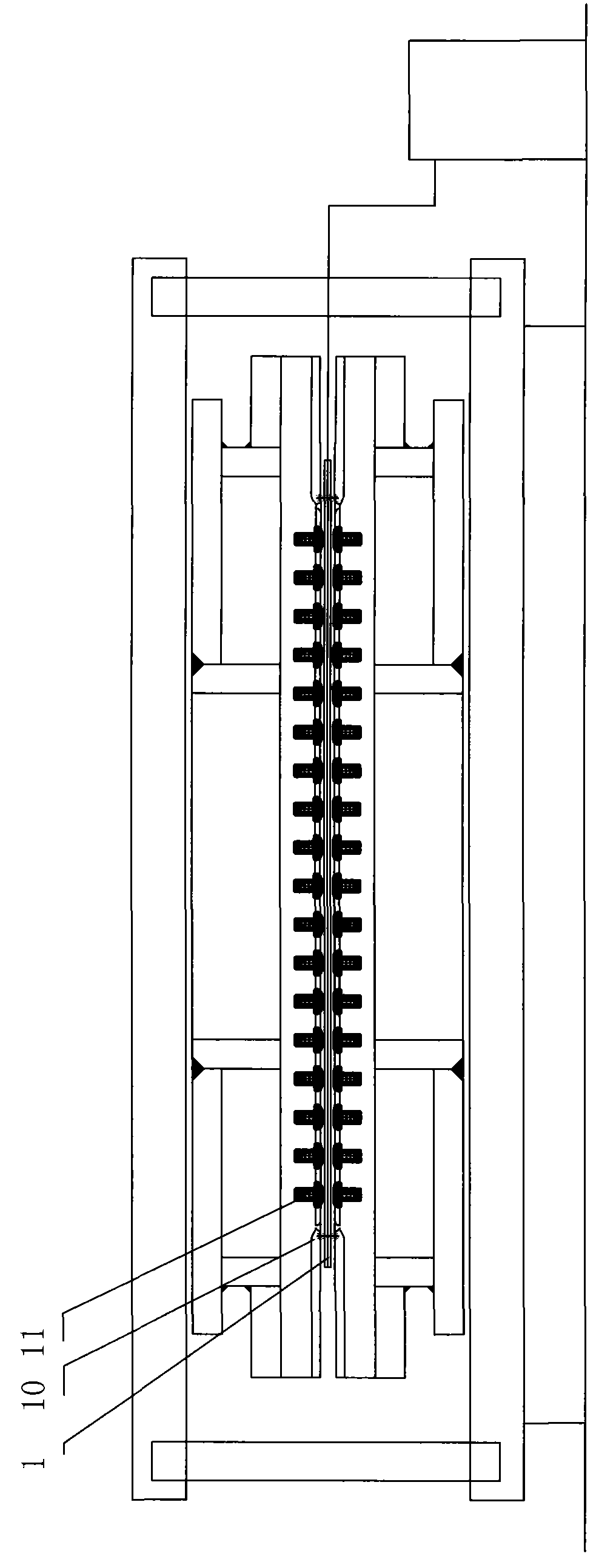

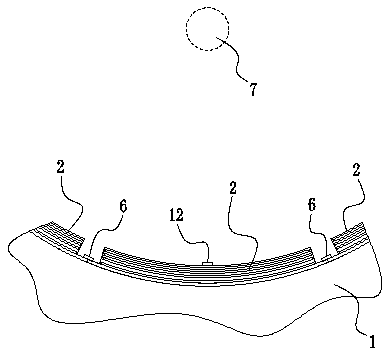

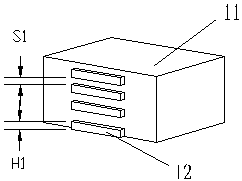

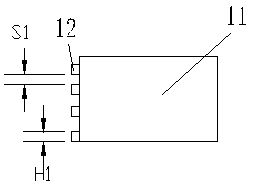

Processing technique of heat exchanger sheet

InactiveCN101927427AKeep shapeSolve welding deformationOther manufacturing equipments/toolsMetal sheetEngineering

The invention discloses a processing technique of a heat exchanger sheet, which comprises the following steps: (1) leveling the metal sheets for making the heat exchanger sheet; (2) overlapping two metal sheets, putting the two metal sheets on a working platform, compacting and flattening the two metal sheets by using a hold-down gear, and stitch-welding the two metal sheets according to the flow channel shape of the heat exchanger by using a laser welder head, wherein the reserved flow channel position is not welded; (3) after welding is completed, carrying out stress relieving on the stitch-welded metal sheets; (4) leveling the stitch-welded metal sheets; and (5) putting the leveled and stitch-welded metal sheets on a die, clamping the welding position or periphery of the welding position by using the die, reserving the gap for expansion on the die in the reserved flow channel position of the metal sheets, and introducing water or oil between the two metal sheets by using a hydraulic press to pressurize and maintain the pressure, so that the flow channel part expands outwards to form. The processing technique is simple and can be used for making a heat exchanger sheet from sheets.

Owner:中机西南能源科技有限公司

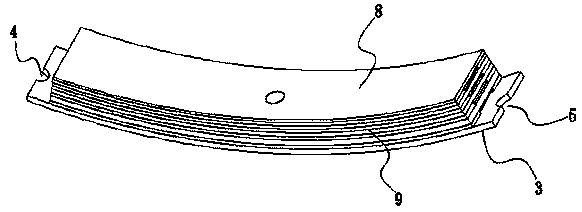

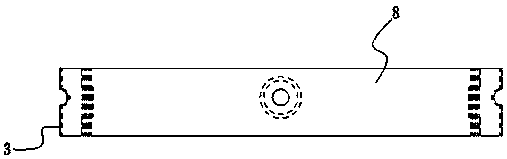

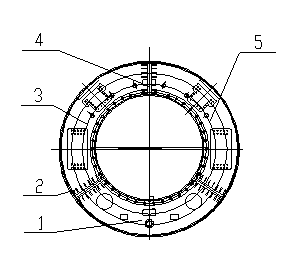

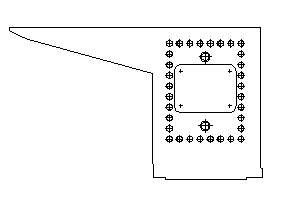

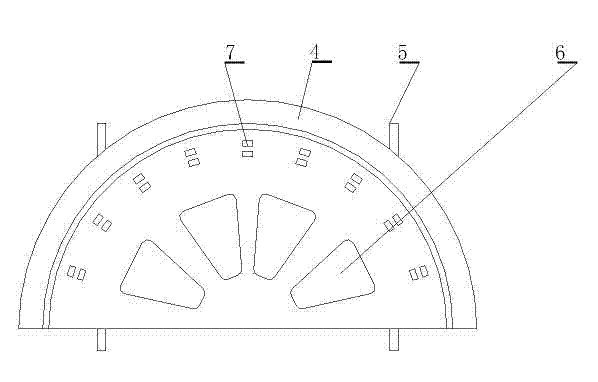

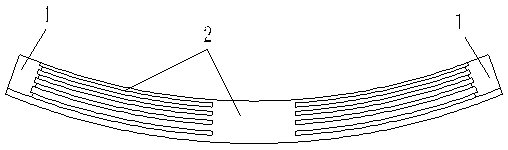

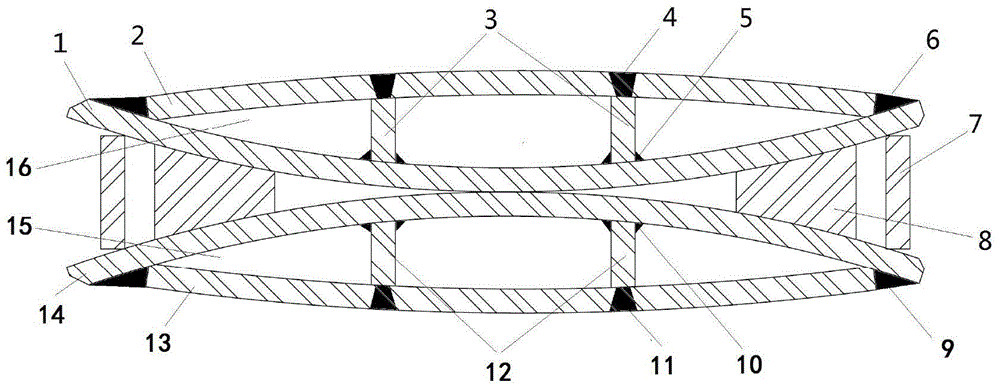

Wheel noise reduction method and multi-layer type wheel noise reduction block

ActiveCN107584966AMeet the structureMeet the material propertiesRail-engaging wheelsSustainable transportationVibration attenuationAgricultural engineering

The invention discloses a wheel noise reduction method and a multi-layer type wheel noise reduction block. According to the wheel noise reduction method, the multi-layer type wheel noise reduction block is arranged on a wheel for vibration attenuation and noise reduction, a mounting board is arranged in the multi-layer type wheel noise reduction block, a first hole and a second hole are formed inthe two ends of the mounting board correspondingly, and two end portion bolts penetrate through the first hole and the second hole to be screwed onto the wheel; a first outer restraint layer is arranged on the side, close to an axle, of the multi-layer type wheel noise reduction block; a suspension type inner restraint layer is arranged between the mounting board and the first outer restraint layer; a hollow spindle penetrates through the suspension type inner restraint layer, one end of the spindle makes contact with the mounting board, and the other end of the spindle makes contact with thefirst outer restraint layer; the suspension type inner restraint layer is vulcanized and stuck between the mounting board and the first outer restraint layer through a first damping layer; and a middle bolt penetrates through the first outer restraint layer, the spindle and the mounting board and then is screwed into the inner side portion of the circumferential direction of the wheel, and accordingly the middle of the multi-layer type wheel noise reduction block is connected to the wheel.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Technique for integrally manufacturing semi-structure of full-face tunneling machine shield

ActiveCN102699639AAvoid defectsIncrease the difficultyWelding apparatusLeft halfStructure of the Earth

The invention discloses a technique for integrally manufacturing a semi-structure of a full-face tunneling machine shield applied to the field of a full-face tunneling machine. A front shield is separated into a left half body, a right half body and a lower half body, wherein three pairs of coupling flanges are arranged; the coupling flanges are firstly processed and then each pair of flanges is closed by a process bolt to be as a combined element to be welded into a whole together with each half body; in order to prevent a flange surface from separating to generate a crack and deformation during overall heat treatment, a dense steel plate tie bar is welded to connect on a seam of inner and outer shell plates; the steel plate tie bar is cut off, polished and repaired after thermal treatment according to the processing situation so as to ensure the shield achieves the shape tolerance requirements. According to the technique, the defects of the conventional technique for manufacturing the shield of the semi-structure can be overcome; the coupling flanges are processed one by one, and two flanges are merged into a whole and welded with the steel plate on the shield by the process bolt, so that the problems that the welding is easy to deform are solved, the excircle geometrical tolerance is difficultly ensured, the processing cost is high, the processing difficulty of the flange is large and each half body is difficultly closed.

Owner:NORTHERN HEAVY IND GRP CO LTD

Method for preventing deformation of large-size thin-wall annular casting during welding process

ActiveCN102528218ANo mouth opening/neck deformationNo distortionWelding accessoriesLarge sizeMaterials science

The invention relates to a method for preventing deformation during a welding process, in particular to a method for preventing the deformation of a large-size thin-wall annular casting during the welding process. The method is characterized in that the method comprises the following steps of: preparation before welding: preparing a shim plate used for supporting at least five points of the casting so as to ensure that the casting is padded flatly and cannot be deformed by external forces during the welding, and an anti-deformation welding tooling, and then fixing the casting on the tooling; pre-heating before welding; selection of parameters of the welding process; and control of the welding process. The method provided by the invention is unique; the quality of the casting can be ensured; the production cycle can be shortened; the working efficiency can be improved; and the production cost can be saved.

Owner:KOCEL STEEL

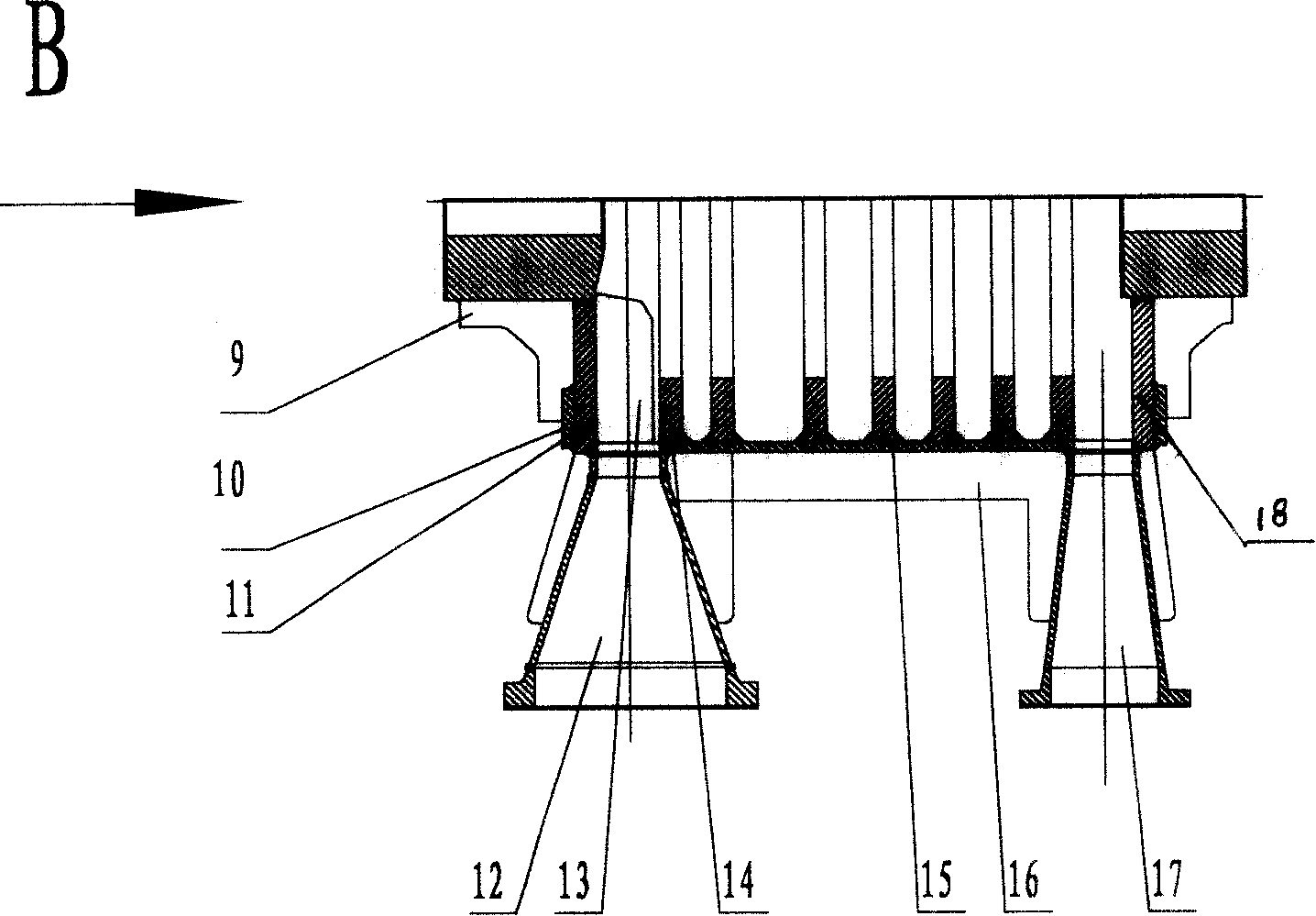

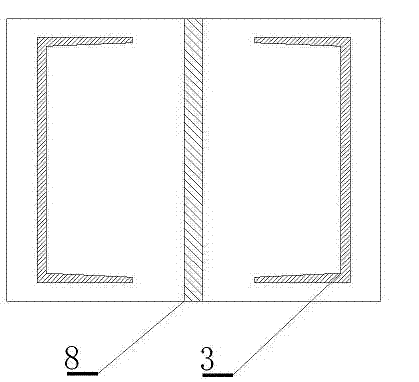

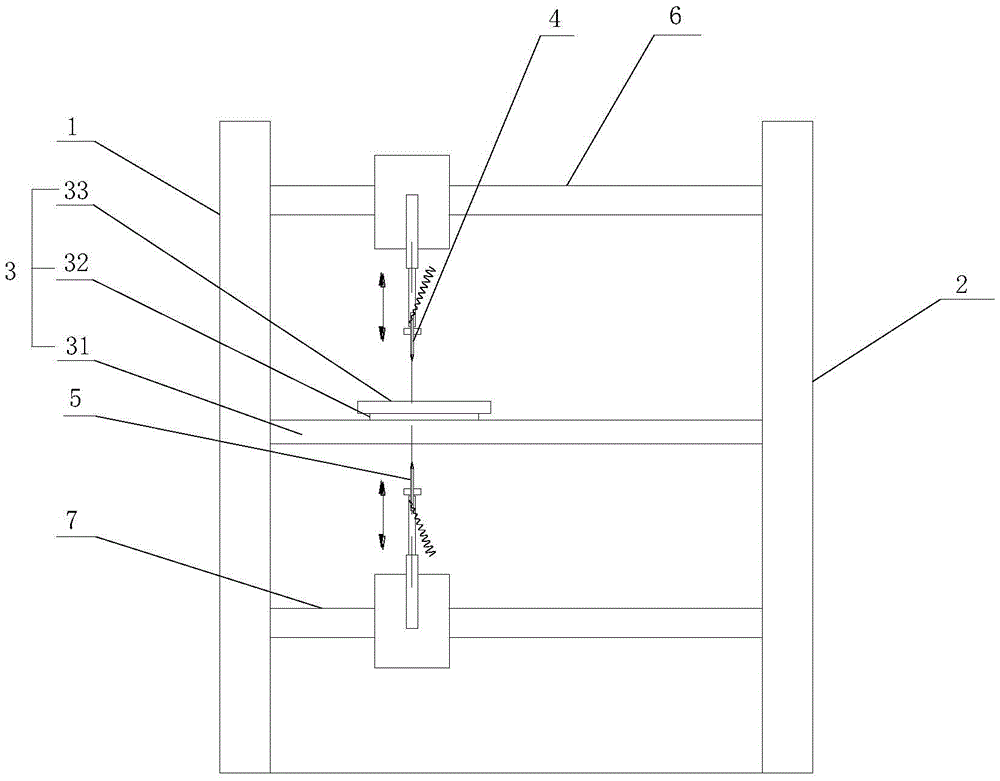

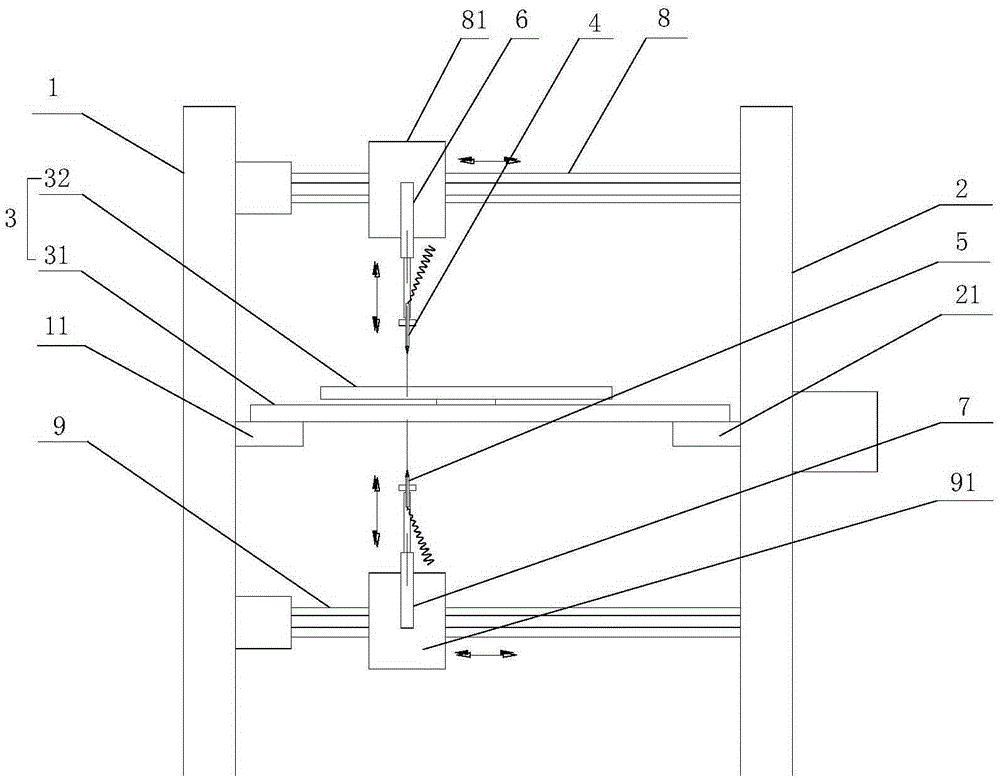

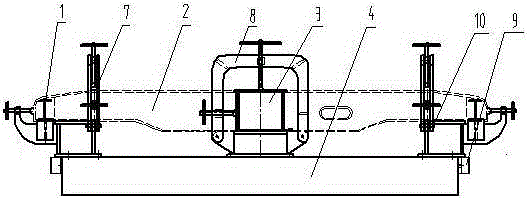

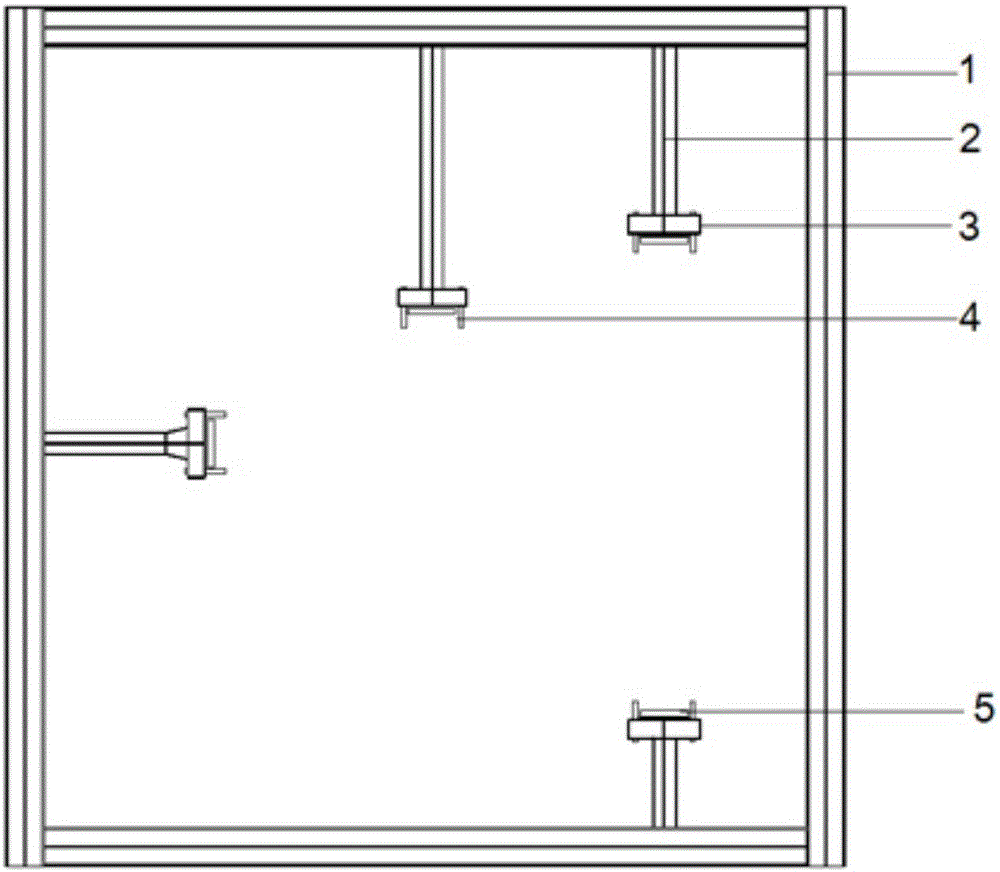

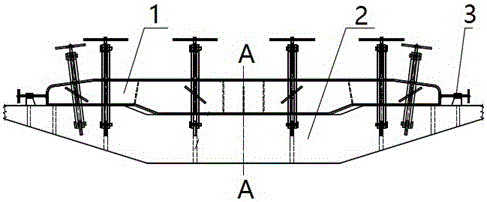

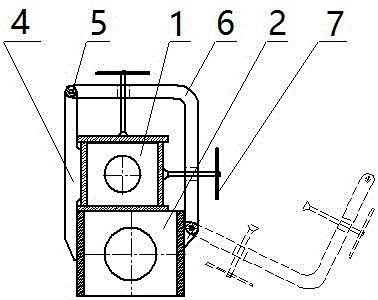

Forklift portal double-face welding device

InactiveCN105458572AImprove welding effectImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesTransverse beamWelding

The invention discloses a forklift portal double-face welding device. The forklift portal double-face welding device comprises a first side support, a second side support, a workpiece fixing support, a first welding mechanism, a second welding mechanism, a first driving mechanism and a second driving mechanism; the workpiece fixing support is located between the first side support and the second side support and connected with the first side support and the second side support; an upper transverse beam and a lower transverse beam are arranged between the first side support and the second side support and located above and below the workpiece fixing support; the first welding mechanism is installed on the upper transverse beam; the first driving mechanism is used for driving the first welding mechanism to do vertical movement; the second welding mechanism is installed on the lower transverse beam; and the second driving mechanism is used for driving the second welding mechanism to do vertical movement. According to the forklift portal double-face welding device, the first side support, the second side support, the workpiece fixing support, the first welding mechanism, the second welding mechanism, the first driving mechanism and the second driving mechanism are matched to achieve double-face synchronization welding on a forklift portal.

Owner:ANHUI HECHA FORKELEVATOR

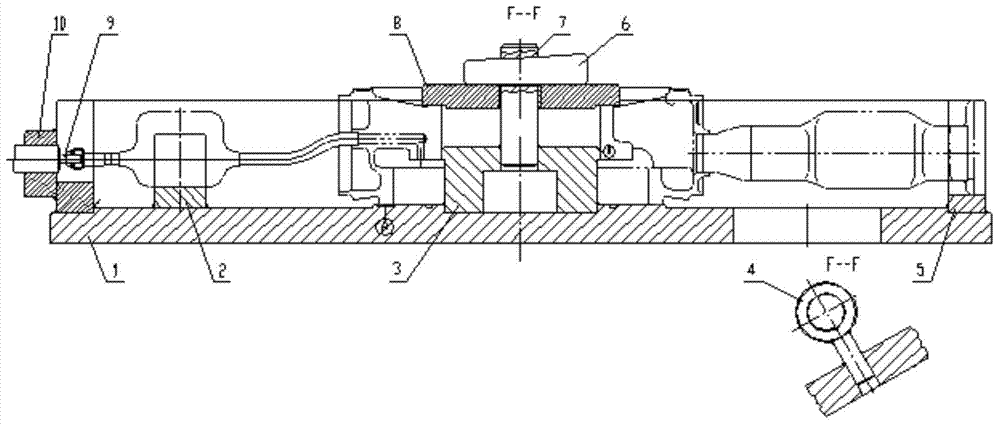

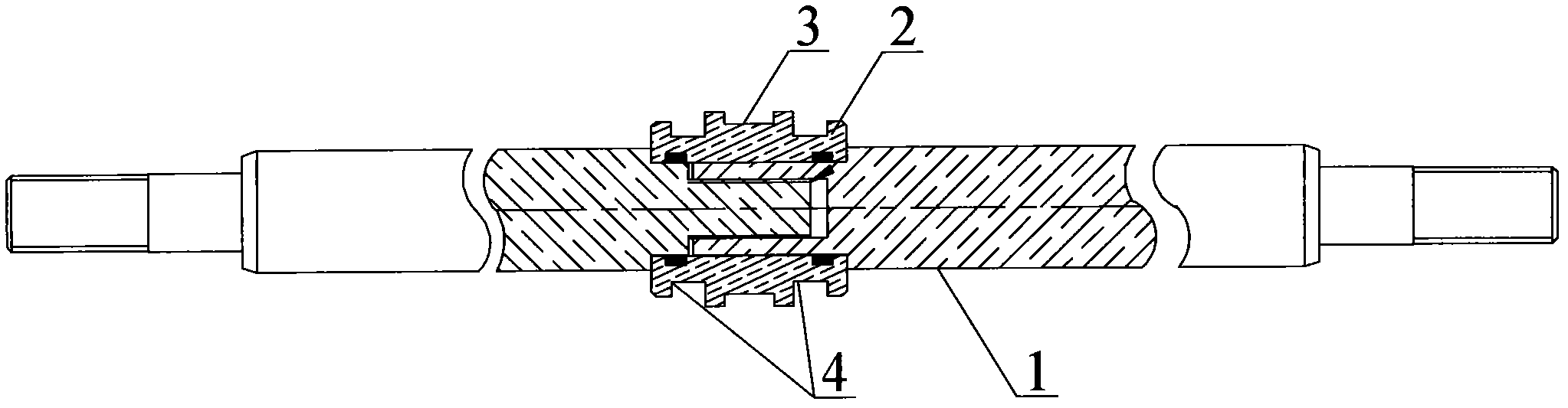

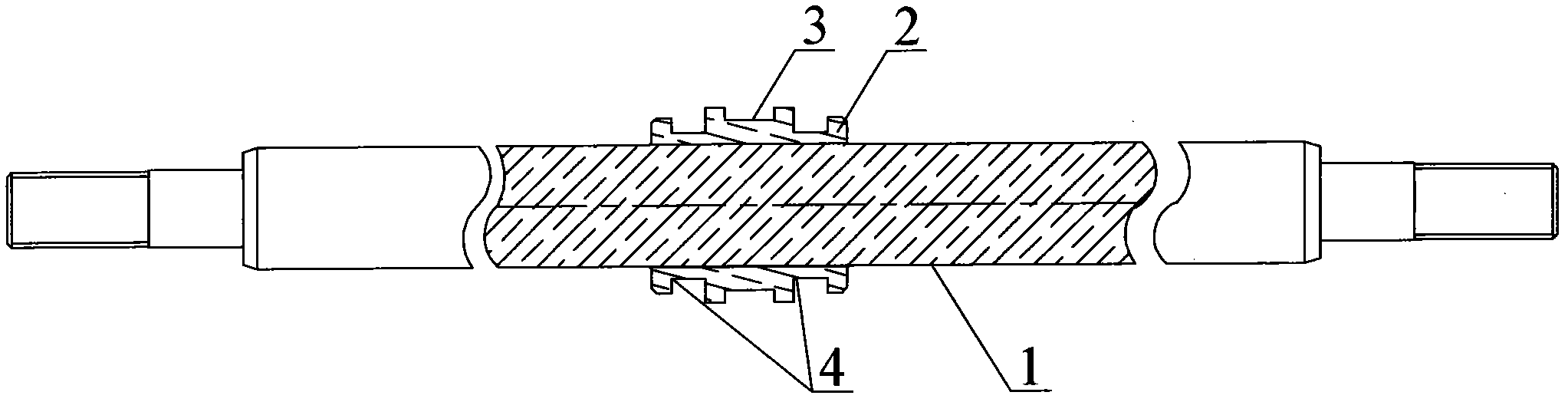

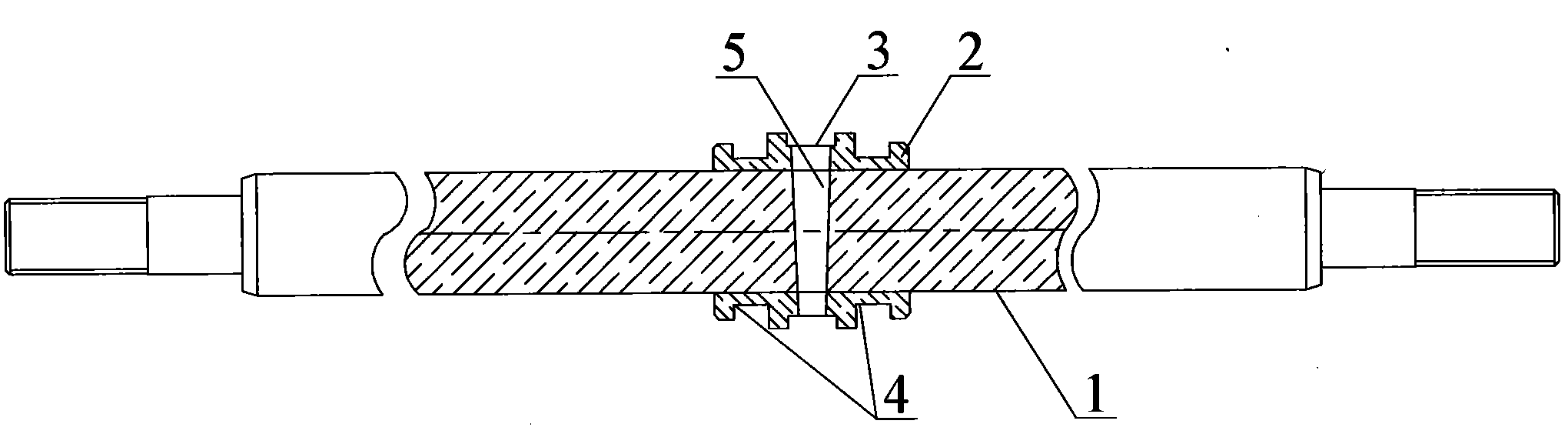

Connecting structure and installation method for piston and piston rod

InactiveCN102128261ATightly sealed stateTightly locked statePiston ringsPlungersInterference fitWear resistant

The invention discloses a connecting structure for a piston and a piston rod. The connecting structure mainly comprises the piston rod and the piston sleeved on the piston rod, wherein the piston is in interference fit with the piston rod; the outer wall of the piston is provided with a wear-resistant pad clamping groove and a sealing ring clamping groove; and the piston is provided with a tapered pin hole which passes through the piston rod from one side to the other side and is positioned in the wear-resistant pad clamping groove. The piston is in interference fit with the piston rod according to an expansion and contraction principle of metal, so that the piston and the piston rod are tightly sealed and locked; the tapered pin hole is drilled in the middle of the piston, so that the locking fixing force of the piston is increased, and the piston does not move or drain oil on the piston rod during work; and production benefit is improved, and production cost is reduced.

Owner:CHENGDU SANHUAN METAL PROD

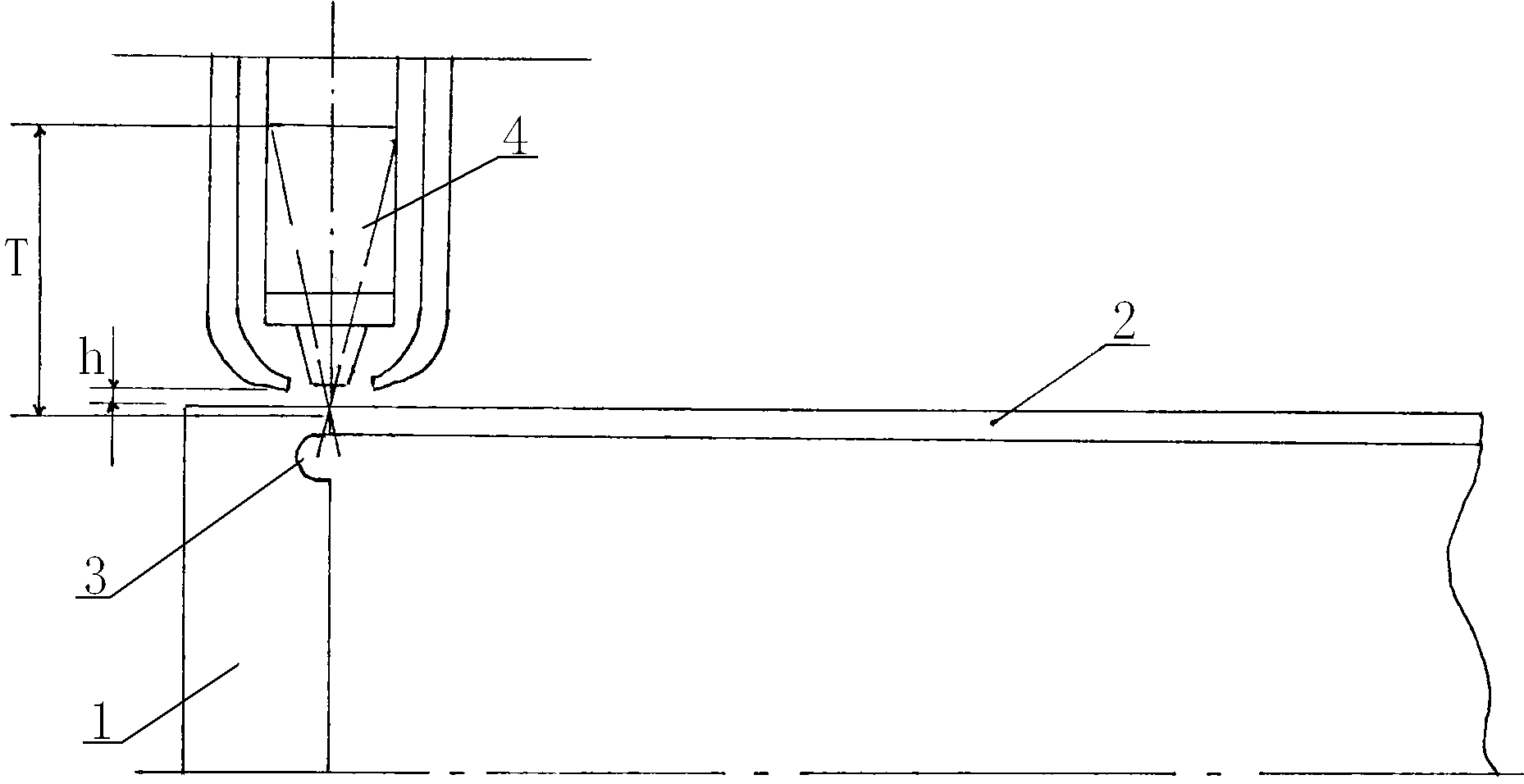

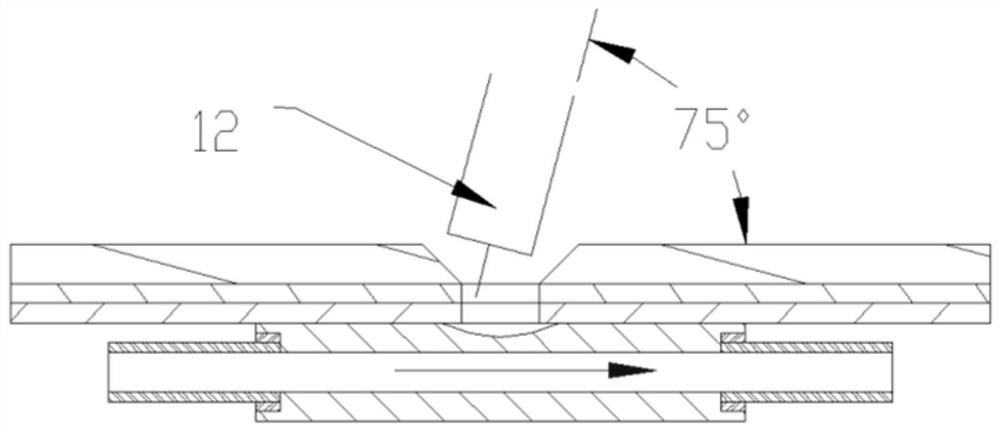

Laser welding method of nuclear fuel storage framework bush square tube and small base plate

ActiveCN103317237AReasonable designSolve welding deformationLaser beam welding apparatusButt jointEngineering

The invention relates to a laser welding method of a nuclear fuel storage framework bush square tube and a small base plate. The method includes: machining a R1.5mm-R2mm arc groove 3-4mm in depth at a position 2mm from the periphery of the small base plate; mounting the arc groove to a clamp tool to allow the arc groove to be in butt joint with the nuclear fuel storage framework bush square tube, adjusting laser welding power to 2500W and a welding focus point T to 98.5-99mm, and welding under protection of helium with high purity; if partial out of tolerance of welding seam gap or welding seam straightness occurs, and adjusting the welding focus point T to 99.5-100mm for secondary welding so as to correct welding seam quality; using a tool for rotation so as to weld welding seams of other faces; wherein R refers to radius, butt joint gap between the arc groove and the nuclear fuel storage framework bush square tube is strictly controlled to be smaller than 0.1mm and welding seam straightness is controlled to be smaller than 0.5mm, when the welding focus point T is adjusted to 99.5-100mm, welding seam width is increased slightly, and all original welding seams can be remelted, and during welding of welding seams of other faces, symmetric welding is adopted to reduce welding stress and deformation.

Owner:JIANGSU GREEN WATER TREATMENT

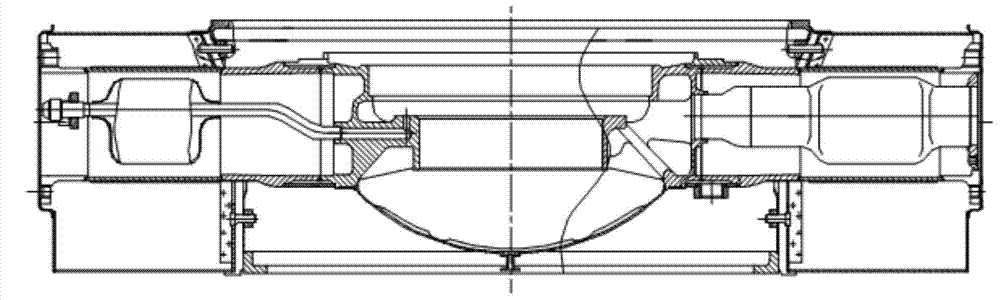

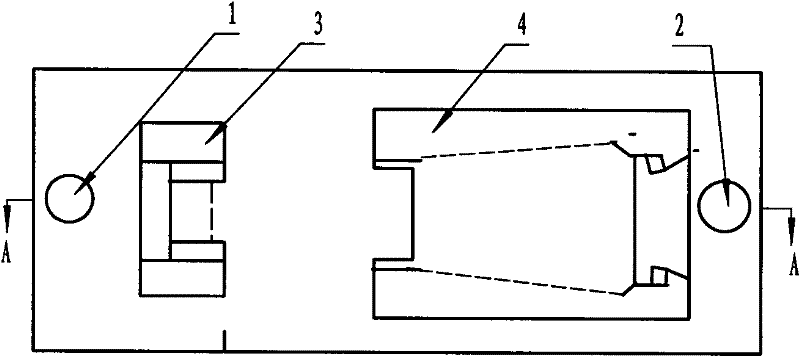

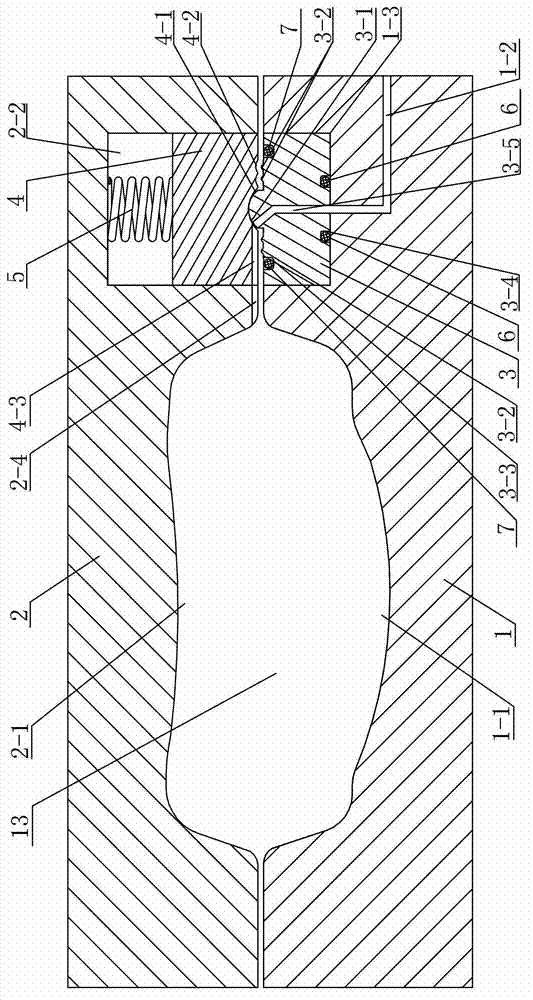

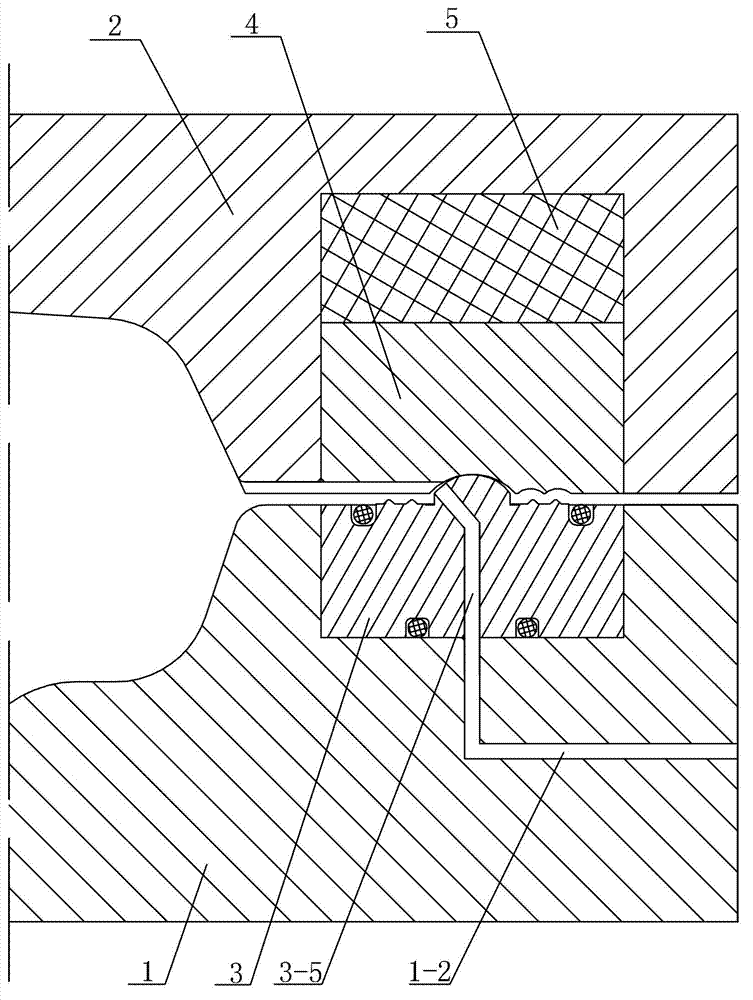

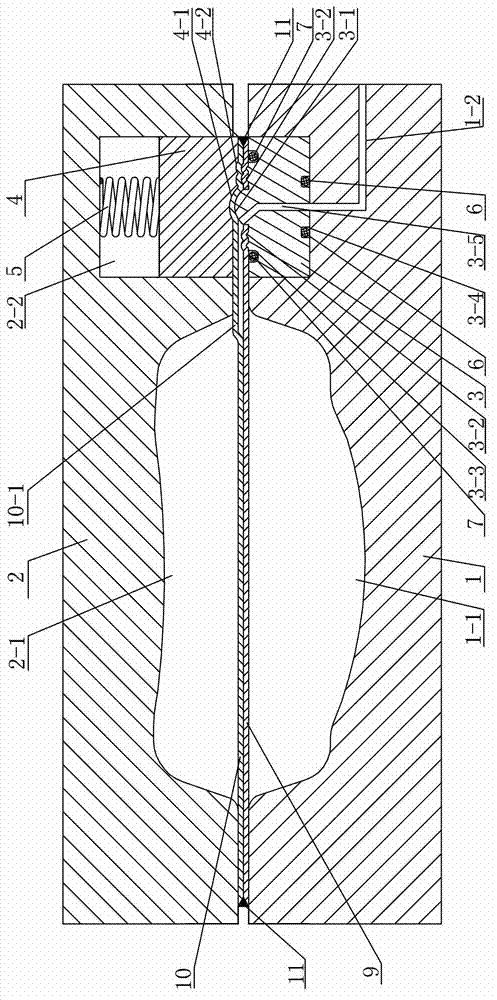

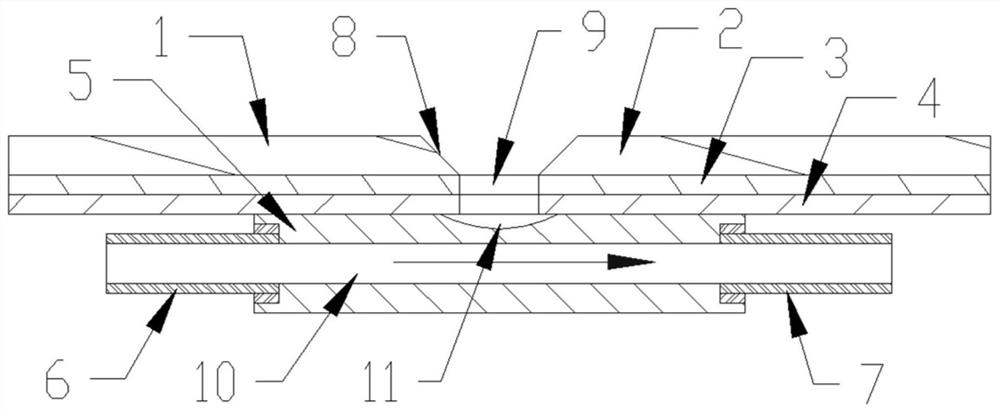

Device and method for hydraulic forming of cavity part with complex curved surface

InactiveCN102806261AReduce wall thicknessSolve welding deformationWelding residual stressDeep drawing

The invention discloses a device and a method for hydraulic forming of a cavity part with a complex curved surface, and relates to a device and a method for forming metal plates. The device and the method solve the problem of large welding deformation and welding residual stress in the prior art for stamping and deep drawing of parts with complex curved surfaces and also solve problems that in the initial forming stage, double plate blanks need to be pressed by high mold clamping force to guarantee sealing of liquid at a liquid charging opening, so that the plate blanks at two ends of a cavity are difficult to flow into the cavity of a mold when a cavity part with a complex curved surface is formed, the wall thickness of the part is reduced due to high expansion deformation, and the part is difficult to form by the existing double-plate hydraulic forming technology. The device comprises an upper mold, a lower mold, a lower liquid charge insert, an upper liquid charge insert, an elastic component, a first sealing ring and a second sealing ring, the elastic component and the upper liquid charge insert are sequentially arranged in an upper groove from top to bottom, the lower liquid charge insert is arranged in a lower groove, and the second sealing ring is mounted in a second sealing groove. The device and the method are used for forming of the cavity part with the complex curved surface.

Owner:HARBIN INST OF TECH

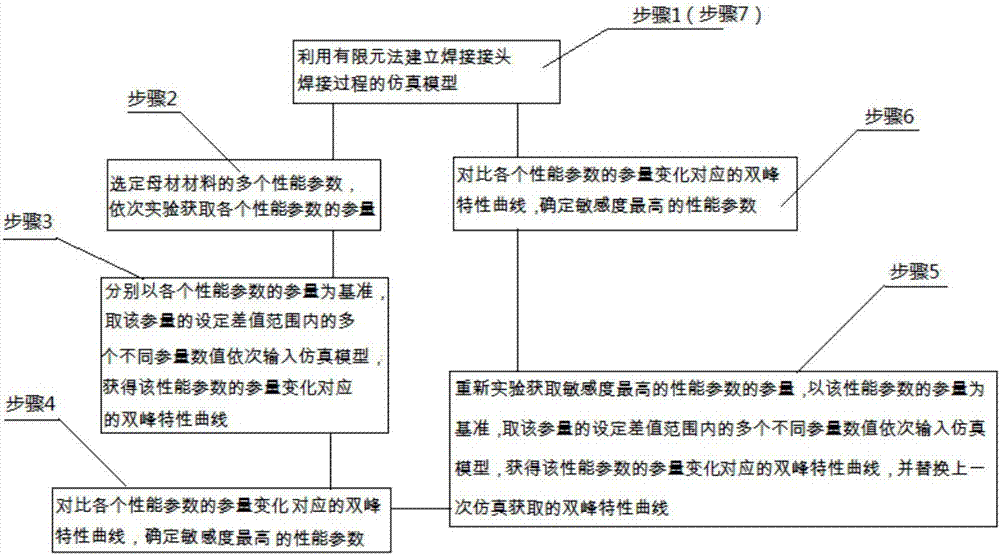

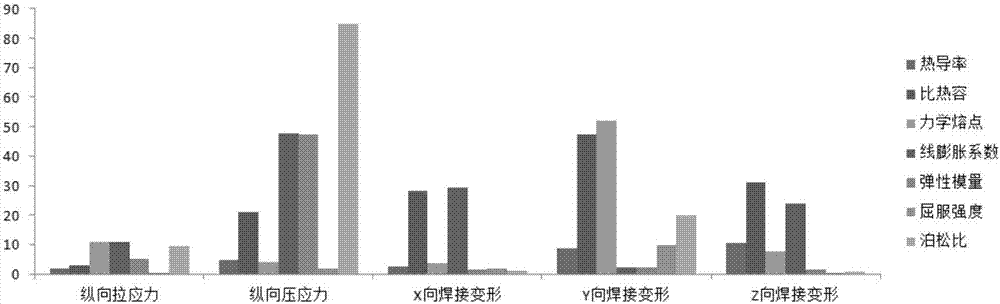

Acquiring method of influence sensitivity of parameters on welding residual stress and deformation

ActiveCN107220410AImprove Welding Simulation ReliabilityReduce testing costsDesign optimisation/simulationSpecial data processing applicationsLoop analysisWelding residual stress

The invention relates to the field of welding, discloses an acquiring method of influence sensitivity of parameters on welding residual stress and deformation, and establishes a simulation model of the welding process of a welded joint. The method comprises the steps of selecting multiple performance arguments of a parent material, conducting experiments sequentially, and acquiring a parameter of each performance argument; adopting the parameter of each performance argument as a standard, and inputting multiple different parameter values within a set difference range of the argument into the simulation model sequentially; conducting the experiments again to acquire the parameter of a performance argument with the highest sensitivity, adopting the parameter of the performance argument with the highest sensitivity as the standard, and inputting multiple different parameter values within the set difference range of the performance argument with the highest sensitivity into the simulation model sequentially; comparing doublet characteristic curves corresponding to parameter changes of each performance argument, determining the performance argument with the highest sensitivity, and forming a close-loop analysis. The acquiring method of influence sensitivity of parameters on welding residual stress and deformation can establish a simulation database of core welding, improves the reliability of welding simulation, and reduces the cost of the testing experiments.

Owner:CRRC QINGDAO SIFANG CO LTD

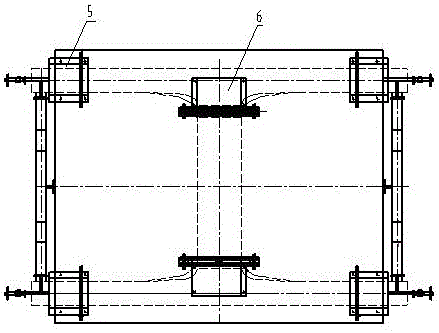

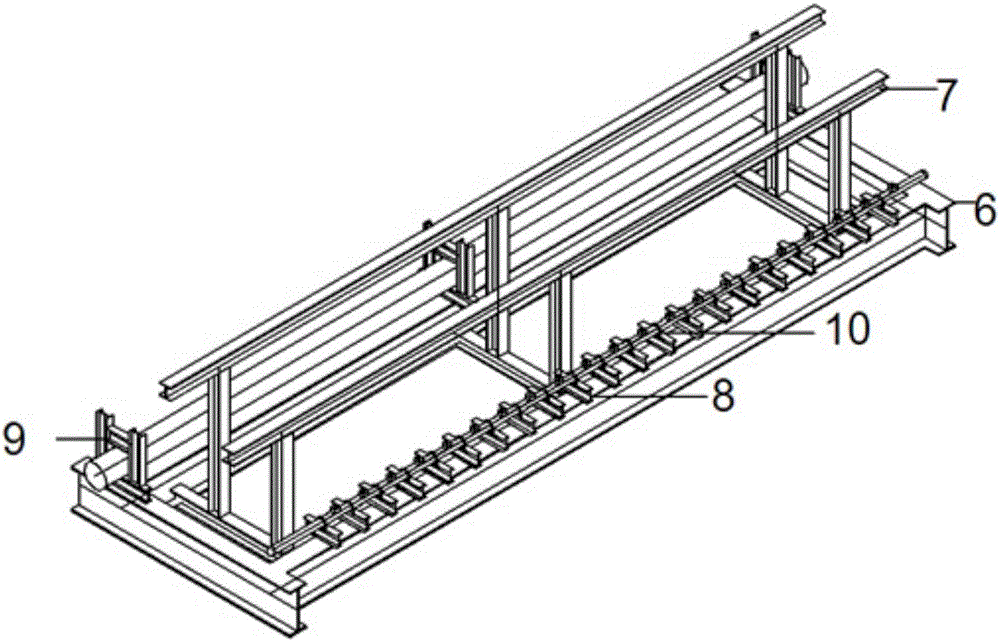

Quick welding device for forklift mast

InactiveCN105397349AQuick resetFully automatedWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention discloses a quick welding device for a forklift mast. The quick welding device comprises a first side frame, a second side frame, a workpiece fixing frame, a first welding gun, a second welding gun, a first telescopic air cylinder, a second telescopic air cylinder, a first driving mechanism, a second driving mechanism and a third driving mechanism. A first crossbeam, a second crossbeam, a first supporting table and a second supporting table are arranged between the first side frame and the second side frame. A first sliding rail and a second sliding rail are arranged on the first supporting table and the second supporting table respectively. The workpiece fixing frame is mounted on the first sliding rail and the second sliding rail and driven by the first driving mechanism. A third sliding rail and a fourth sliding rail are arranged on the first crossbeam and the second crossbeam respectively. A first sliding table and a second sliding table are mounted on the third sliding rail and the fourth sliding rail respectively and are driven by the second driving mechanism and the third driving mechanism respectively. The first telescopic air cylinder and the second telescopic air cylinder are mounted on the first sliding table and the second sliding table respectively. The first welding gun and the second welding gun are connected with the first telescopic air cylinder and the second telescopic air cylinder respectively.

Owner:ANHUI HECHA FORKELEVATOR

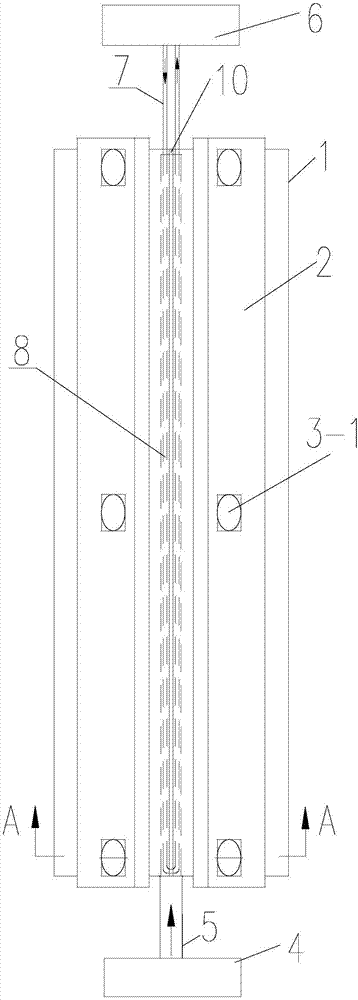

Control system and method for weld-forming of thin-walled pipe

ActiveCN107186342AIncrease stiffnessGuarantee the quality of back weld formationMetal working apparatusLaser beam welding apparatusControl systemPipe fitting

The invention discloses a control system and method for weld-forming of a thin-walled pipe. The control system comprises a welding tool used for weld-forming of the thin-walled pipe and a quality control device used for controlling the quality of longitudinal joints, welded by the welding tool, of the thin-walled pipe. The method comprises the following steps of 1, assembling the welding tool and the to-be-welded thin-walled pipe; 2, debugging the welding tool; 3, initializing the quality control device; 4, starting welding the to-be-welded thin-walled pipe; 5, acquiring real-time welding data of the thin-walled pipe; 6, judging whether the real-time welding data of the thin-walled pipe are abnormal or not; 7, judging whether the thin-walled pipe is defective or not; 8, judging whether the thin-walled pipe is deformed or not; and 9, carrying out stress relaxation on the thin-walled pipe. According to the control system and method for weld-forming the thin-walled pipe, the welding tool provides stable protective gas flow and double cooling measures for the to-be-welded thin-walled pipe, the welding quality of the to-be-welded thin-walled pipe is monitored in real time through the quality control device, so that the residual stress is eliminated, the fatigue life is prolonged, and the stress corrosion resistance is improved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Method for improving manufacturing precision of components at head switching section of annular flame cylinder

ActiveCN110238617AImprove manufacturing precisionIncrease productivityStructural engineeringWelding deformation

The invention discloses a method for improving the manufacturing precision of components at a head switching section of an annular flame cylinder. The method comprises the following steps of first, pre-forming the head switching section to form a primary head switching section with a turbulator mounting hole, meanwhile pre-processing an internal cooling ring and an external cooling ring to form an internal cooling ring coarse structure and an external cooling ring coarse structure, and separately welding the internal cooling ring coarse structure and the external cooling ring coarse structure to the primary head switching section to form primary welding components; and positioning the profile of the formed head switching section and the turbulator mounting hole, and processing and forming the internal cooling ring coarse structure and the external cooling ring coarse structure to form a final internal cooling ring and a final external cooling ring. At first, the head switching section is pre-formed, and the head switching section is finally formed in the component state, so that the influence of welding deformation and heat treatment deformation on the profile tolerance of the head switching section and the location degree of the turbulator mounting hole is avoided, the manufacturing precision of the component is improved, and meanwhile, the method is higher in production efficiency.

Owner:AECC AVIATION POWER CO LTD

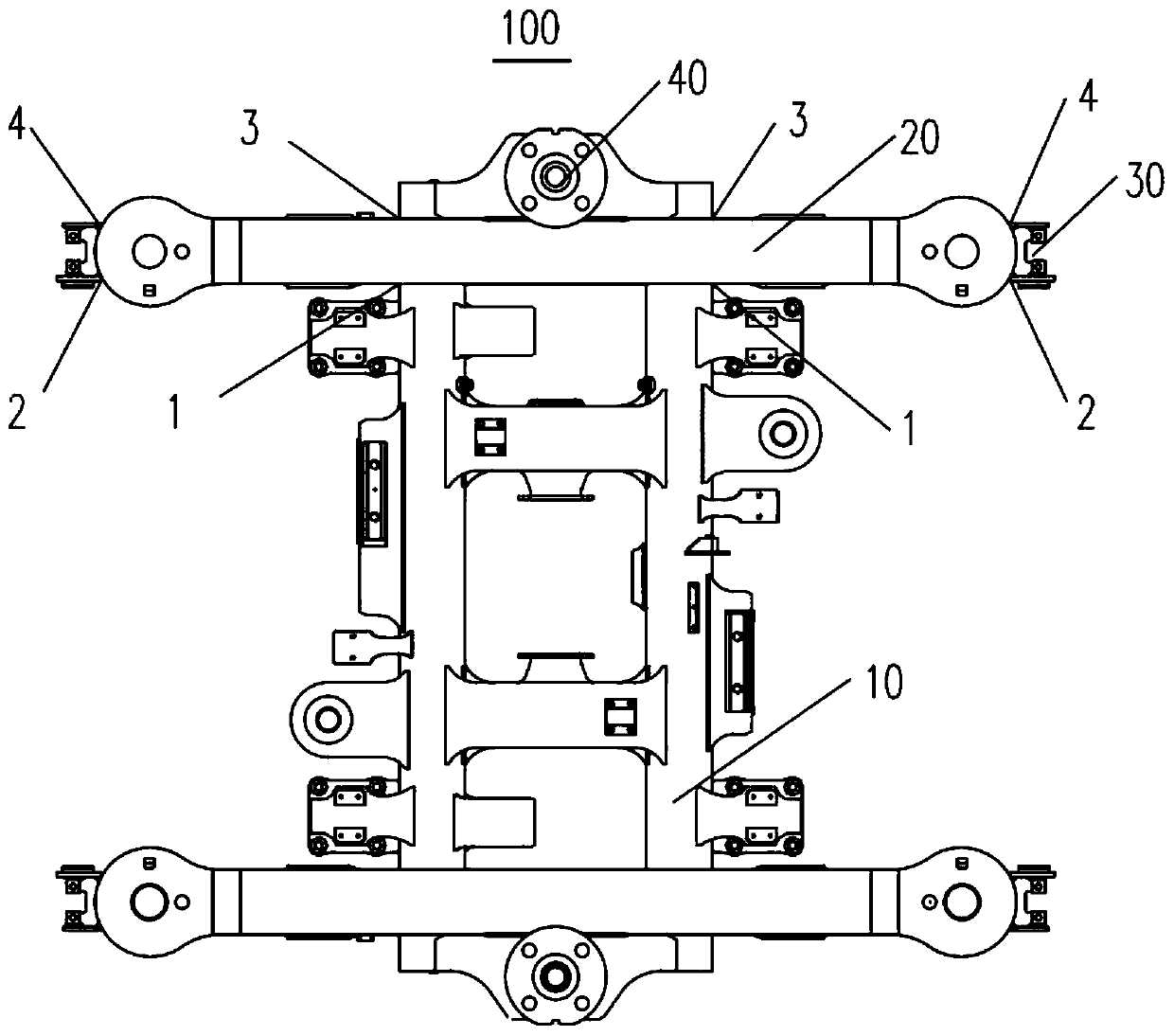

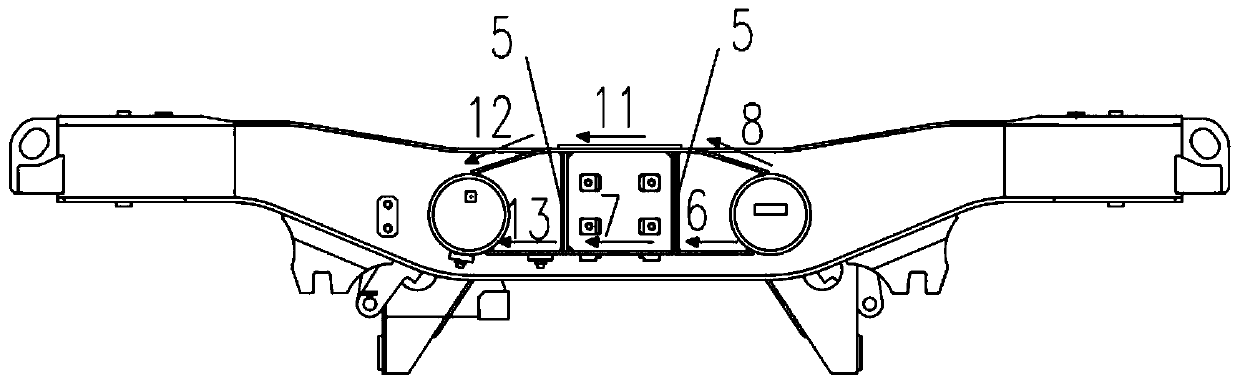

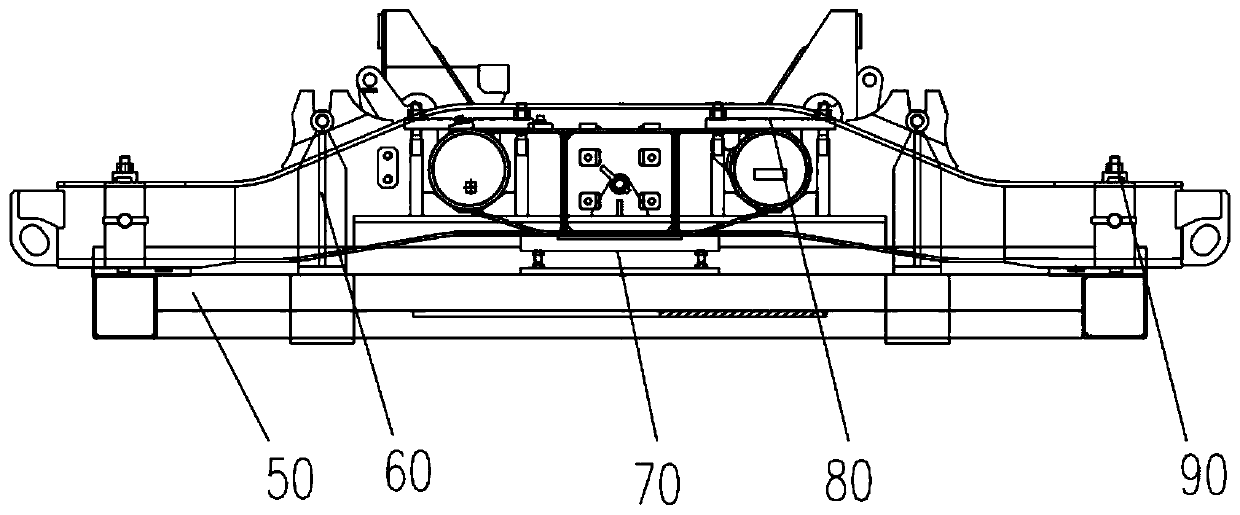

Tool used for rapid assembly of JW4G frame

ActiveCN105081654AGuarantee the quality of pairingQuick pairWelding/cutting auxillary devicesAuxillary welding devicesPortal frameWelding process

The invention discloses a tool used for rapid assembly of a JW4G frame. The tool comprises a main platform, two groups of four-corner height platforms, two middle height platforms, adjusting and pressing devices, four end beam positioning backstops and pin shafts, wherein the four-corner height platforms are arranged at the four corners of the main platform in a pairwise opposite manner; the adjusting and pressing devices comprise portal frames, connecting plates, nuts, vertical screw rods, transverse screw rods and moment arm rods; the two middle height platforms are arranged on the main platform; and the four end beam positioning backstops are respectively arranged on the outer sides of the main platform below the four four-corner height platforms, and are pairwise matched to be used for bearing and positioning two end beams to allow the two end beams to have the verticality. By employing the tool, the positioning of side beams, cross beams and the end beams during the assembly is realized; frame deformation in an assembly welding process is avoided; the effects of the rapid and efficient assembly and time saving are achieved; and the assembly quality is ensured.

Owner:CRRC LUOYANG CO LTD

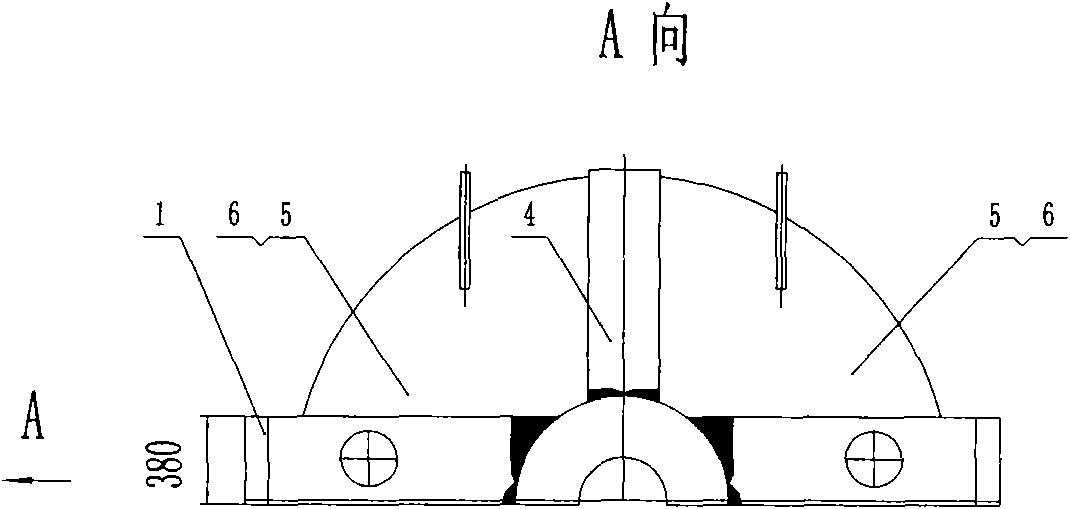

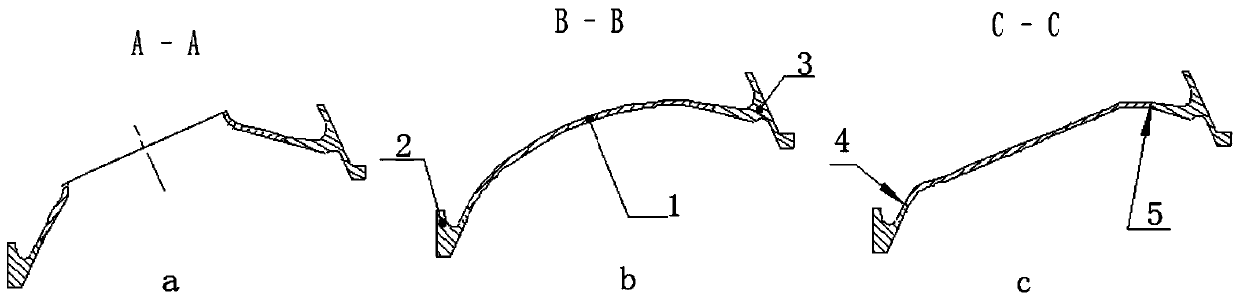

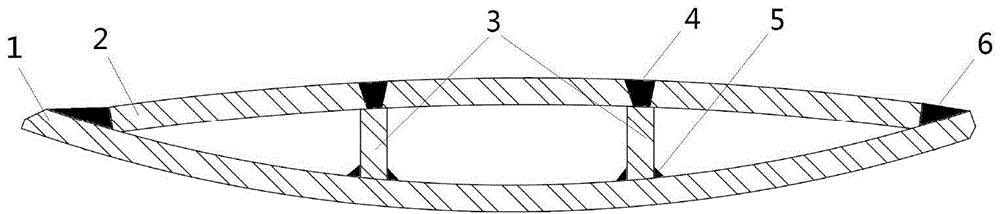

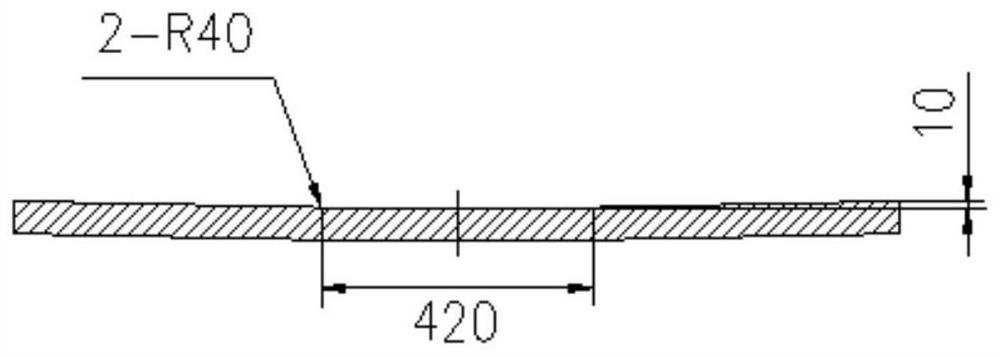

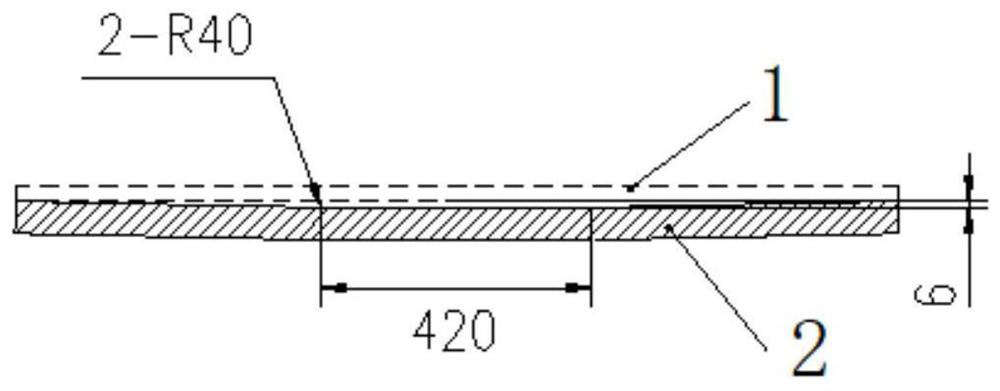

Large length-width ratio hollow-out type fixing guide vane

InactiveCN104533691AReduce weightReduce material costsHydro energy generationReaction enginesFillet weldEngineering

The invention provides a novel large length-width ratio hollow-out type fixing guide vane with the simple and reasonable structure, the good rigidity and the high strength. The large length-width ratio hollow-out type fixing guide vane is characterized in that ribbed plates are arranged between an upper vane body and a lower vane body. The ribbed plates are in welded connection with the lower vane body through fillet welds. The ribbed plates are in welded connection with the upper vane body through plug welds. The upper vane body is in welded connection with the lower vane body through groove welds. According to the large length-width ratio hollow-out type fixing guide vane, raw material is greatly saved, the manufacturing cost is lowered, and meanwhile the needed rigidity and strength for fixing the guide vane is guaranteed. After welding, by means of the polishing, a transition fillet is obtained, the manufacturing period is shortened, the manufacturing cost is lowered, the material is saved and the manufacture is simple.

Owner:HARBIN ELECTRIC MASCH CO LTD

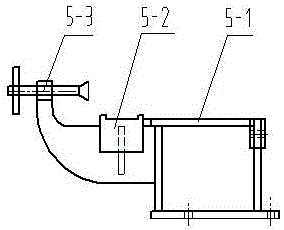

Combined tool for manufacturing manifolds

InactiveCN105729030ASolve welding deformationReduce adverse effectsWelding/cutting auxillary devicesAuxillary welding devicesBraced frameEngineering

A combined tooling made of manifolds, including two parts: prefabricated tooling and assembly tooling used in conjunction with the prefabricated tooling, wherein the prefabricated tooling is provided with: an external support frame and several internal support members fixed on the external support frame , respectively fixed on the internal support, and the limit joints that restrain the branches of the manifold; the assembly tool is equipped with: a basic frame, two branch support beams that are opposite and vertically installed on the basic frame, and are evenly fixed on the Several mother pipe support beams on both sides of the foundation frame, a mother pipe limit frame fixed on one side of the foundation frame, several mother pipe limit devices fixed on the mother pipe support beams, and a Anti-deformation hydraulic controller. The invention not only solves the problem of welding deformation in the process of manifold welding, but minimizes the adverse effects caused by welding deformation in the process of manifold welding; moreover, it also improves the construction accuracy of manifold fabrication and speeds up the fabrication of manifolds construction efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Filling method of damping layers of wheel noise reduction block, positioning structure and wheel noise reduction block

PendingCN107584705AGuaranteed bonding strengthGuaranteed uniformityRail-engaging wheelsVulcanizationEngineering

The invention provides a filling method of damping layers of a wheel noise reduction block. A damping material is filled into gap layers of an interlayer structure of the wheel noise reduction block by using a vulcanizing and bonding manner to form damping layers; positioning blocks are used for positioning constraining layers of the interlayer structure during vulcanizing and bonding so as to prevent the constraining layers from deforming in the vulcanizing process; the positioning blocks are arranged at the edges of the interlayer structure and one part of each positioning block stretches into the gap layers to support and position the constraining layers during vulcanizing, so that the deformation of the interlayer structure in the vulcanizing process is avoided. According to the filling method, a vulcanization molding manner is adopted; the bonding strength between the damping layers and the interlayer structure is ensured; the uniformity degree and the beautiful degree of the damping layers are ensured; the positioning blocks are used for positioning and controlling the constraining layers of the interlayer structure during vulcanizing and filling; the problem of deformation of the constraining layers and mounting plates caused by high freedom degree of the ends in the vulcanizing process can be avoided, so that the non-uniform thickness of the damping layers can be avoided; the production quality and the size deviation of the wheel noise reduction block are ensured; and the effect of reducing vibration and noise can be improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

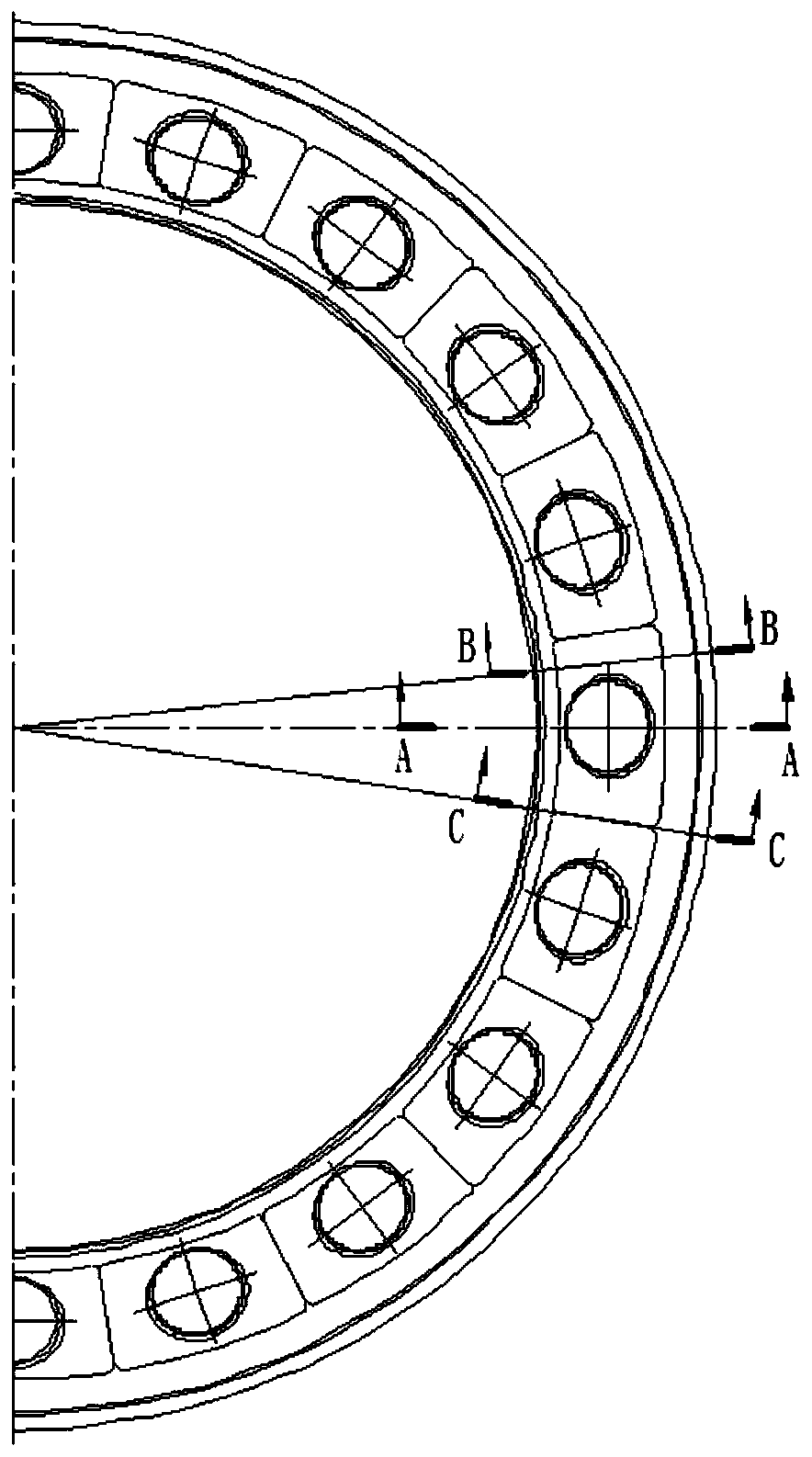

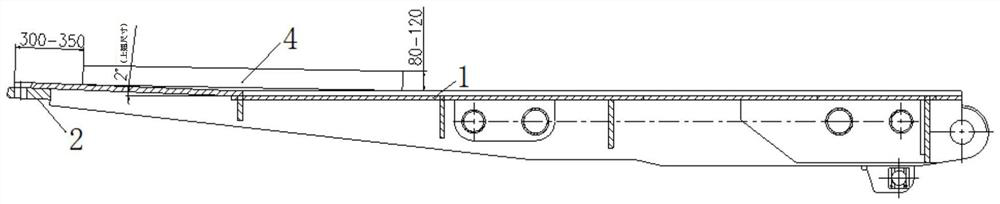

Welding technology method for assembling large length-width ratio hollow type fixed guide vane of large-scale hydroturbine

InactiveCN104625353AReduce manufacturing costReduce weightArc welding apparatusLeg lengthWidth ratio

The invention relates to a welding technology method, in particular to a welding technology method for assembling a large length-width ratio hollow type fixed guide vane of a large-scale hydroturbine. The fixed guide vane is made by welding an upper clack body, a lower clack body and a reinforcing plate, the technology method solves the critical technology problem of the large length-width ratio hollow type fixed guide vane by a technology process of split charging, stack charging, stack welding, annealing and splitting, the technology method for assembling and welding the large length-width ratio hollow type fixed guide vane of the large-scale hydroturbine has the advantages that the production cost is low, the welding technology process is reasonable and simple, the strength of a structure can be improved, the operating space is saved, and the quality of a product is improved.

Owner:HARBIN ELECTRIC MASCH CO LTD

Quick assembling and welding fixture used for side beams of engineering car framework

InactiveCN106736204APrevent side beam deformationEfficient pairingWelding/cutting auxillary devicesAuxillary welding devicesProduction rateEngineering

The invention discloses a quick assembling and welding fixture used for side beams of an engineering car framework. The quick assembling and welding fixture comprises a main frame, positioning baffles, first compression devices, second compression devices and hinge pins. The fixture is used for solving the problems that welding deformation is caused and the size is difficult to control during assembly and welding of the side beams; by structural study and analysis on the side beams, the fixture can achieve positioning of an upper cover, a lower cover and a vertical plate of the side beams during assembling, so that side beam deformation in the welding process is prevented, the purpose of quick and efficient assembly is achieved, the assembly quality of the side beams is ensured while the time is shortened, and the production rate is improved.

Owner:CRRC LUOYANG CO LTD

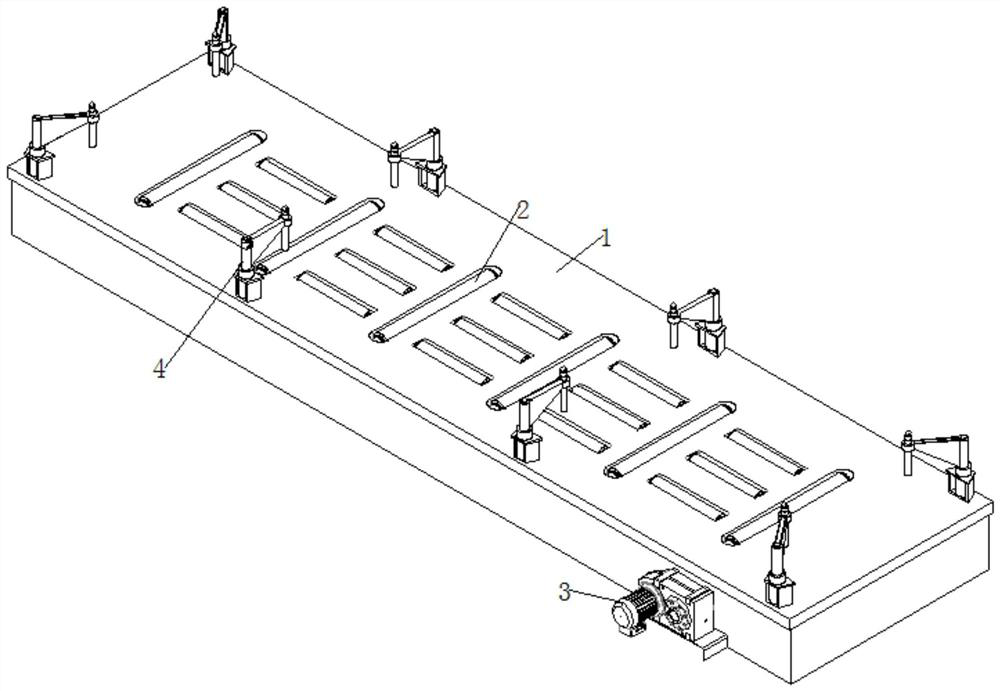

Dumper compartment side plate welding platform and welding method

ActiveCN111843348AControl deformationGuarantee molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention provides a dumper compartment side plate welding platform. The dumper compartment side plate welding platform comprises a workbench, lifting rollers and a driving mechanism for controlling the lifting rollers, the horizontally-distributed lifting rollers and the vertically-distributed lifting rollers are arranged on the workbench in an alternated mode, and a pressing device is arranged on one side of the workbench. The invention further involves a welding method. The welding method comprises the following steps that firstly, a punched dumper compartment side plate is placed on the workbench, and the dumper compartment side plate comprises a bottom plate, a cross beam, vertical beams, stand columns and fences and is fixed through the pressing device; and secondly, the cross beam and the vertical beams form side plate grids, welding is performed on vertical welding seams and oblique welding seams in the z-axis direction in the side plate grids from top to bottom, the side plate grids are taken as cells, and the cells on the bottom plate are operated from left to right and from bottom to top.

Owner:山东聚鑫专用车制造有限公司

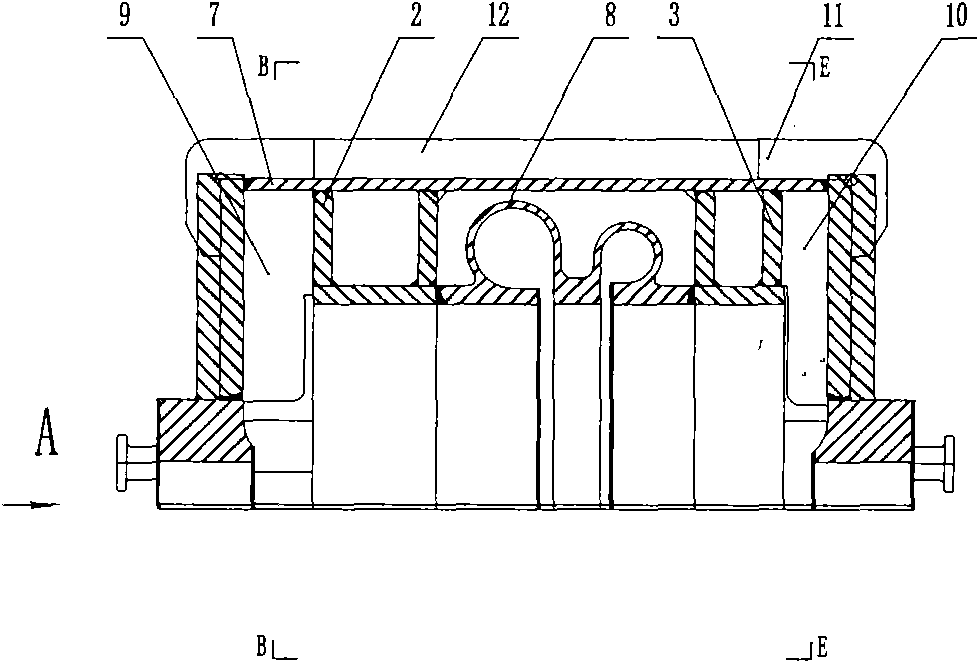

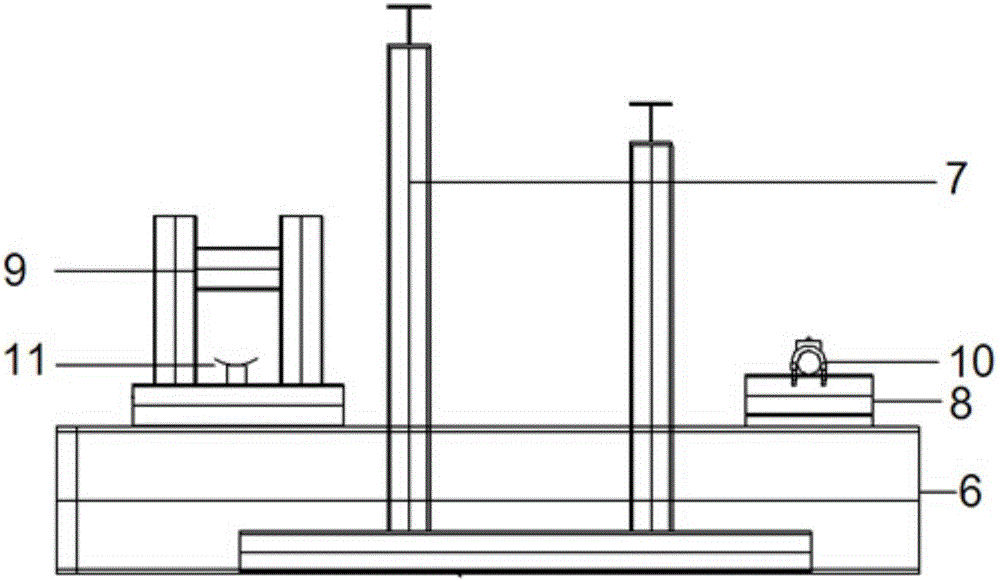

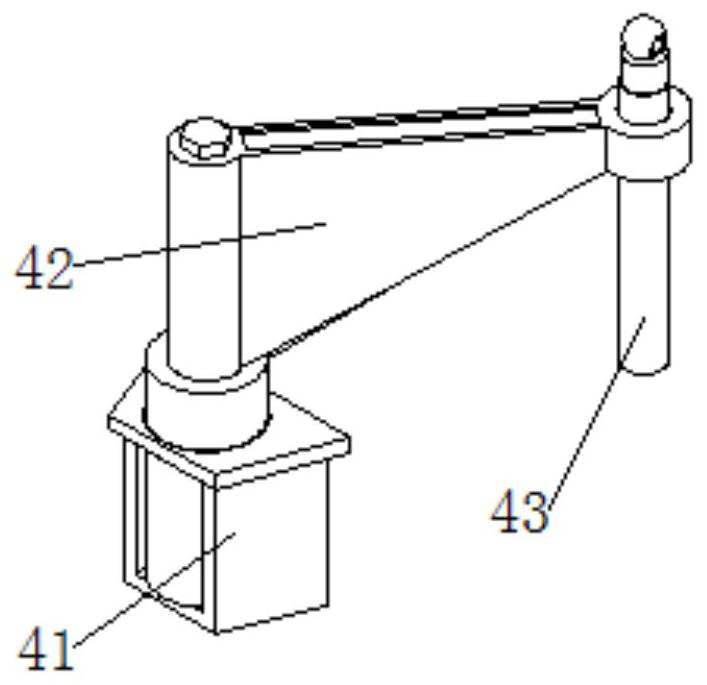

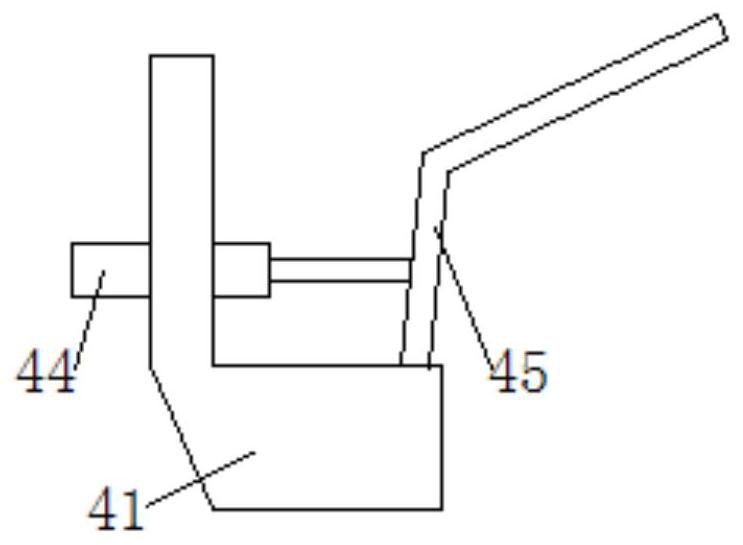

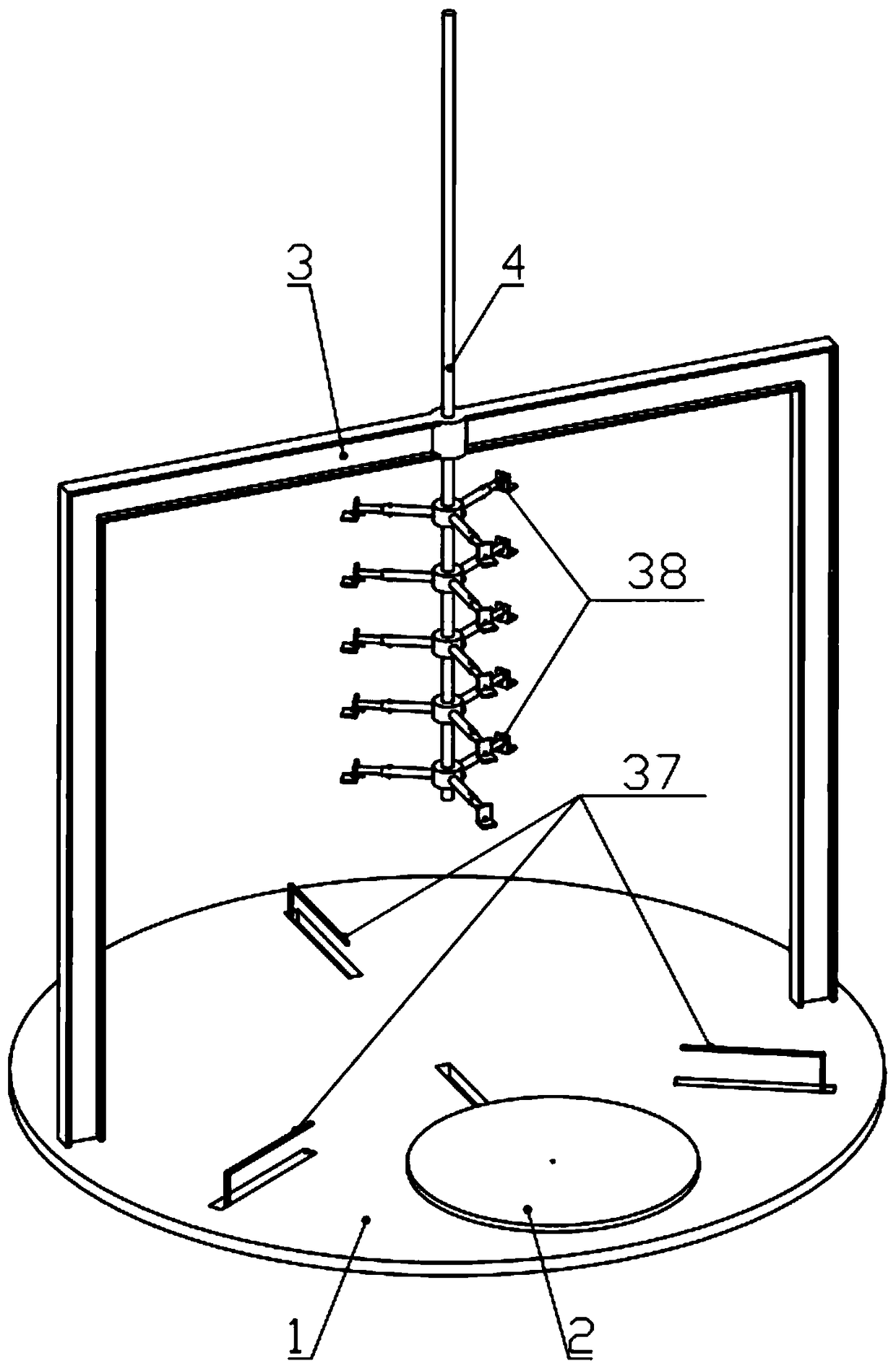

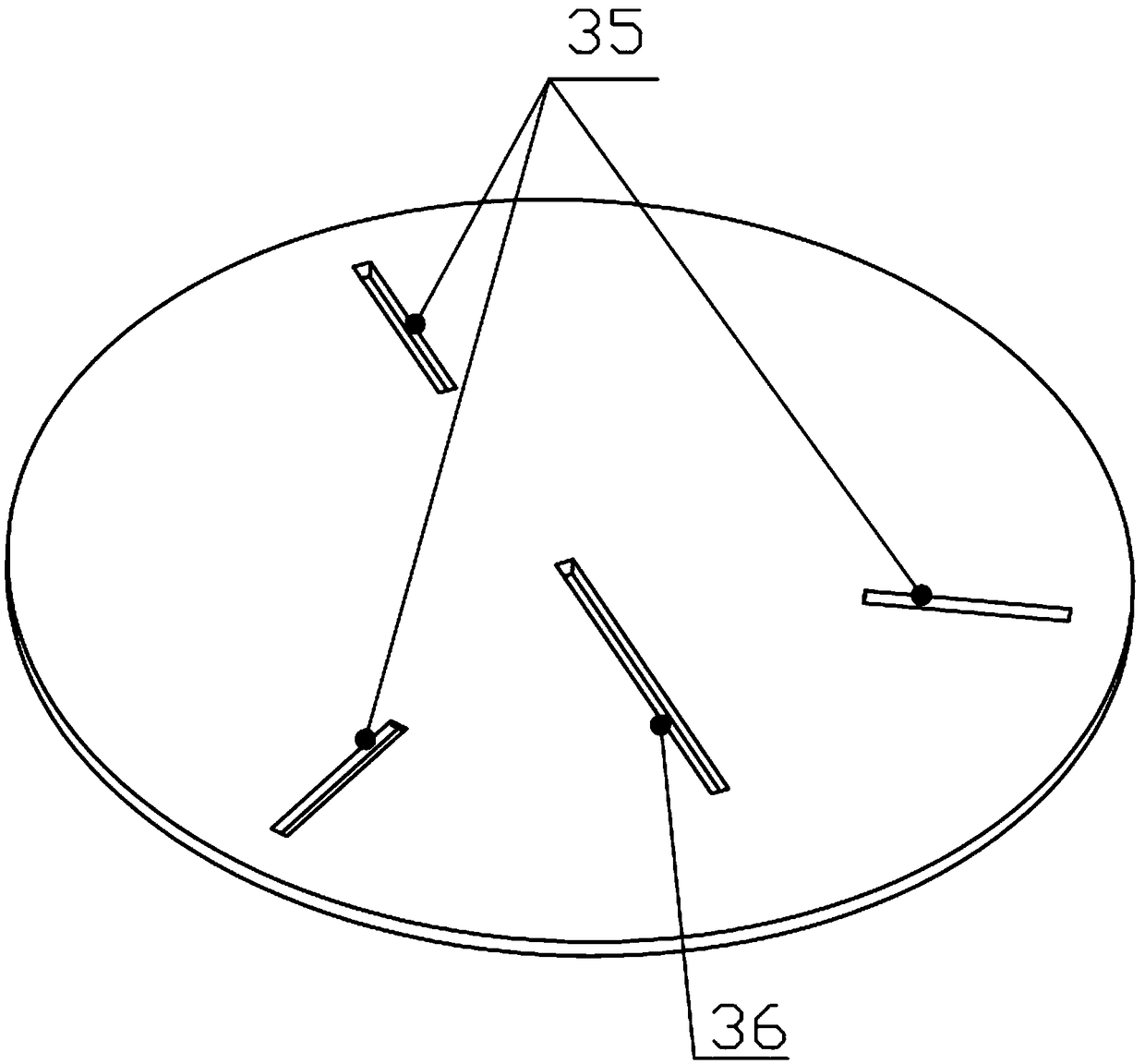

Assembly tool of inner ring rib cylindrical shell pressure resisting structure and assembly method thereof

ActiveCN108907608ASimple structureEasy to useWelding/cutting auxillary devicesAssembly machinesStress ProblemMechanical engineering

The invention relates to an assembly tool of an inner ring rib cylindrical shell pressure resisting structure and an assembly method thereof. The tool comprises a working platform, a flat car for loading cylindrical shells, a frame, a lifting shaft, a positioning mechanism for clamping and positioning the cylindrical shells, a guide mechanism for transferring the cylindrical shells, and rib toolsfor assembling annular ribs; the flat car is movably arranged on the surface of the working platform; the lifting shaft is inserted in the frame; multiple rib tools are mounted at the outer peripheryof the end, towards the working platform and extending out of the frame, of the lifting shaft from top to bottom; the positioning mechanism and the guide mechanism are mounted at the bottom of the working platform through hole structures formed in the working platform; and the guide mechanism is connected with the flat car through a releasing device and a connecting piece. The tool is simple in structure and convenient to use; and after the assembly is finished, no gaps or smaller gaps are formed between the cooled cylindrical shells and the ribs, so that the welding deformation and participation stress problems caused by large assembly gaps are solved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Heating correction method of welded structure

ActiveCN109332427ASolve side bending after weldingResolve distortionShaping toolsWelding/cutting auxillary devicesCorrection methodDistortion

The invention provides a heating correction method of a welded structure. The heating correction method of the welded structure comprises the steps that the part generating bending deformation in thewelded structure is subjected to a first heating correction treatment process, so that the bending deflection of the welded structure is less than or equal to a preset threshold; and after the first heating correction treatment process is completed, the part generating distortion deformation in the welded structure is subjected to a second heating correction treatment process, the second heating correction treatment process refers to heating correction through a gradually-wide flame, and the flame width, corresponding to the side with small distortion deformation in the welded structure, of the gradually-wide flame is less than the flame width, corresponding to the side with large distortion deformation in the welded structure, of the gradually-wide flame. According to the heating correction method of the welded structure, the problems that as for existing repeated heating correction, base materials are prone to overburning, and the correction working time is long are solved.

Owner:CRRC DALIAN CO LTD

Nickel-metal hydride battery shell electron beam welding method

ActiveCN103624392ASmall heat affected zoneReduce welding stressHigh frequency current welding apparatusElectron beam welding apparatusPorosityEngineering

A nickel-metal hydride battery shell electron beam welding method is characterized by including the following steps of firstly, preparation before welding, namely, an upper shell and a pole sleeve are cleaned respectively, oil films, water films and organic impurities on the welding surface are removed, the pole sleeve and the upper shell are assembled after being completely cleaned, and the assembling clearance is smaller than 0.05mm; secondly, the electron beam welding process, namely, in order to improve electron beam penetrating capacity and reduce porosity, vacuum welding is suitable for being adopted, and the welding vacuum degree is larger than 5*10<-4> mbar. By the adoption of vacuum electron beam welding, the welding defects of pores, concave parts and poor formed surfaces in the nickel-base superalloy electron beam welding process are effectively overcome, welding deformation is avoided, the comprehensive mechanical performance of a battery shell welding connector with the pole sleeve is improved, and nickel-base superalloy welding joints which meet the welding technical requirements of external quality, internal quality and the depth of fusion are acquired.

Owner:北方材料科学与工程研究院有限公司 +1

Control structure and method for preventing welding deformation of upwarp type top beam

PendingCN111774759AControl welding deformationSolve welding deformationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringManufacturing engineering

The invention discloses a control structure and method for preventing welding deformation of an upwarp type top beam. The top beam comprises a top plate, a tongue plate welded to the front end of thetop plate and a clamp for assembly, the top plate and the tongue plate are clamped through the clamp before welding, and the tongue plate is provided with a reverse deformation structure which is opposite in the welding deformation direction of the top plate and similar in size. Before welding, two long-strip-shaped fixed plates are longitudinally fixed to the back face of the top plate, sizing blocks are added between the top plate and the fixed plates, and the thickness of the sizing blocks is the deformation amount of the welded top plate. The purpose of controlling welding deformation is achieved by bending a weldment in the direction opposite to the welding deformation in advance through reverse deformation and a clamp fixing method and increasing the rigidity and constraint of a component. The problem of welding deformation of the front end of the upwarp type top beam thin top plate structure is solved.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

Framework welding deformation control method and framework welding tool

ActiveCN111347184ASolve welding deformationReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention relates to the technical field of welding deformation control and discloses a framework welding deformation control method and a framework welding tool. The method comprises the following steps: performing structural simulation analysis on a framework to divide the framework into a plurality of welding compositions according to modules and determining the welding sequence of welded joints among all the welding compositions; and based on the welding sequence, welding the welded joints among all the welding compositions. The framework welding tool comprises a clamp body, and a middle support, a torsion-proof device, a cross beam tight-pressing device and a side beam tight-pressing device which are arranged on the clamp body, so that mounting and fixation of the framework are facilitated. Repairing of the framework can be avoided, the manufacturing period is greatly shortened and efficiency and quality are enhanced.

Owner:CRRC QINGDAO SIFANG CO LTD

Resistance spot welding repairing device and method for stainless steel vehicle body

ActiveCN113333932ASolve welding deformationBeautiful repair tracesOther manufacturing equipments/toolsResistance welding apparatusBulk resistanceStructural engineering

The invention provides a resistance spot welding repairing device and method for a stainless steel vehicle body. The resistance spot welding repairing device comprises a run-on plate and a run-off plate. The run-on plate and the run-off plate are fixedly arranged on the outer side wall, away from a second stainless steel plate, of a first stainless steel plate through clamping pieces, the run-on plate and the run-off plate are symmetrically arranged on the two sides of a to-be-repaired welding spot and are located on the same straight line, grooves are formed in the ends, close to the to-be-repaired welding spot, of the run-on plate and the run-off plate, and the lower edges of the grooves are tangent to the edge of the to-be-repaired welding spot. A base plate is fixedly arranged on the outer side wall, away from the first stainless steel plate, of the second stainless steel plate through a clamping piece, a water inlet and a water outlet are formed in the two ends of the base plate respectively, the water inlet is connected with a water inlet pipe through a water inlet pipe connector, the water outlet is connected with a water outlet pipe through a water outlet pipe connector, and the water outlet pipe is communicated with the water inlet pipe. The resistance spot welding repairing device and method solve the problem of welding deformation of the stainless steel plates of the vehicle body in the repairing process, and the flatness of the surface of the workpiece repaired through the method is not obviously different from that before welding.

Owner:天津中车唐车轨道车辆有限公司 +1

Electron Beam Welding Method for Nickel-Hydrogen Battery Shell

InactiveCN103624392BSmall heat affected zoneReduce welding stressHigh frequency current welding apparatusElectron beam welding apparatusPorosityEngineering

A nickel-metal hydride battery shell electron beam welding method is characterized by including the following steps of firstly, preparation before welding, namely, an upper shell and a pole sleeve are cleaned respectively, oil films, water films and organic impurities on the welding surface are removed, the pole sleeve and the upper shell are assembled after being completely cleaned, and the assembling clearance is smaller than 0.05mm; secondly, the electron beam welding process, namely, in order to improve electron beam penetrating capacity and reduce porosity, vacuum welding is suitable for being adopted, and the welding vacuum degree is larger than 5*10<-4> mbar. By the adoption of vacuum electron beam welding, the welding defects of pores, concave parts and poor formed surfaces in the nickel-base superalloy electron beam welding process are effectively overcome, welding deformation is avoided, the comprehensive mechanical performance of a battery shell welding connector with the pole sleeve is improved, and nickel-base superalloy welding joints which meet the welding technical requirements of external quality, internal quality and the depth of fusion are acquired.

Owner:北方材料科学与工程研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com